Method for comprehensive oil gas recovery

A recovery method, oil and gas technology, applied in the direction of liquid hydrocarbon mixture recovery, separation methods, chemical instruments and methods, etc., can solve the problems of high investment and operating costs of regeneration equipment, high feed temperature, high vacuum degree, etc., and achieve operating costs Low, high absorption efficiency, efficient recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

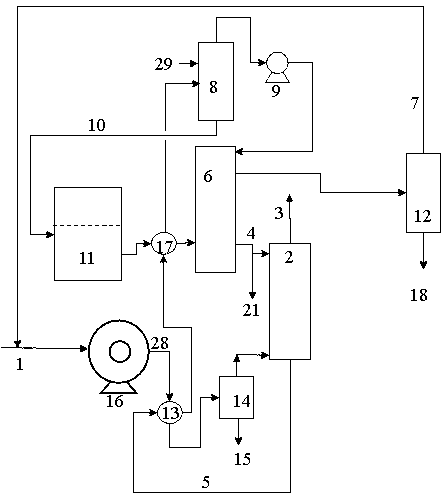

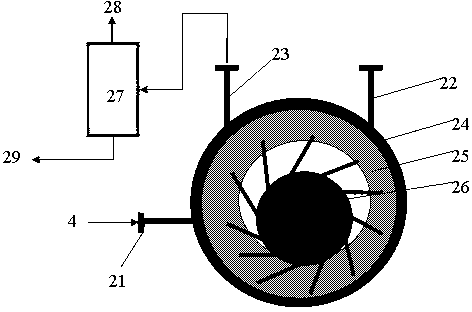

Embodiment 1

[0032] In this example, the source of oil and gas is the oil and gas produced during the loading process of gasoline. The volume content of light hydrocarbons in the oil and gas is 30%. Commercial diesel oil No. 10 is used as the absorbent for absorption treatment. The measured flash point is 69°C. use as figure 1 the process described. The working fluid of the liquid ring compressor is commercial diesel oil at 5°C refrigerated by the refrigeration unit, and the working fluid of the liquid ring compressor is operated in one pass. 40% to 60% (volume) of oil and gas can be recovered in the steps of liquid ring compressor and outlet oil and gas condensation. The commercial diesel absorbent entering the absorption packing tower is cooled to 5°C by the refrigerating unit. The operating condition of the absorption packing tower is that the volume ratio of fresh absorbent diesel to oil and gas is 0.2, and the design value of the volume flow space velocity of oil gas to packing at th...

Embodiment 2

[0036] In this example, the source of oil and gas is the oil and gas produced by volatilization of gasoline storage tanks. The volume content of hydrocarbons in the oil and gas is 25%. Commodity diesel-20 diesel oil is used as the absorbent for absorption treatment. The measured flash point is 63°C. The commercial diesel absorbent entering the absorption packing tower is cooled to -10°C by the refrigerating unit (the working fluid of the liquid ring compressor is also the -10°C commercial diesel oil), and the operating condition of the absorption packing tower is that the volume ratio of fresh absorbent diesel to oil gas 0.04, the design value of the volume flow space velocity of the oil gas at the inlet of the packed tower to the packing is 500h -1 , The operating pressure of the absorption packed tower is 0.2MPa (gauge pressure). After absorption, the exhaust gas oil and gas content is lower than 12g / m 3 .

[0037] After heat exchange and temperature rise of the rich absor...

Embodiment 3

[0040] In this example, the source of oil and gas is the oil and gas produced by the volatilization of gasoline storage tanks. The volume content of hydrocarbons in the oil and gas is 25%, and commercial diesel No. 0 diesel oil is used as the absorbent for absorption treatment. The temperature is 270°C. The commercial diesel absorbent entering the absorption packing tower is cooled to 10°C by the refrigerating unit (the working fluid of the liquid ring compressor is also the 10°C commercial diesel oil). The operating condition of the absorption packing tower is that the volume ratio of fresh absorbent diesel to oil gas is 0.1 The design value of the volume flow space velocity of the oil gas to the filler at the inlet of the packed tower is 600h -1 , The operating pressure of the absorption packed tower is 0.6MPa (gauge pressure). After absorption, the exhaust gas oil and gas content is lower than 10g / m 3 .

[0041] After heat exchange and temperature rise, the rich absorben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com