Stainless steel workpiece cutting device

A cutting device, stainless steel technology, applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of poor lubrication effect, poor cooling effect, easy chip accumulation, etc., to achieve full wetting and wear reduction, Good lubricating effect, guaranteed lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

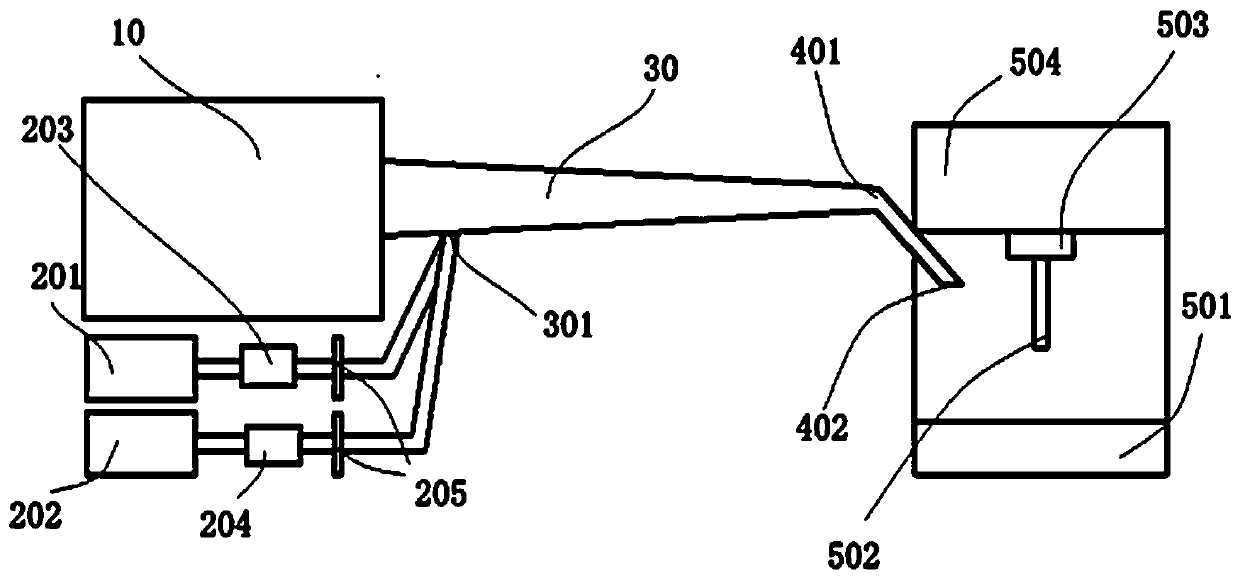

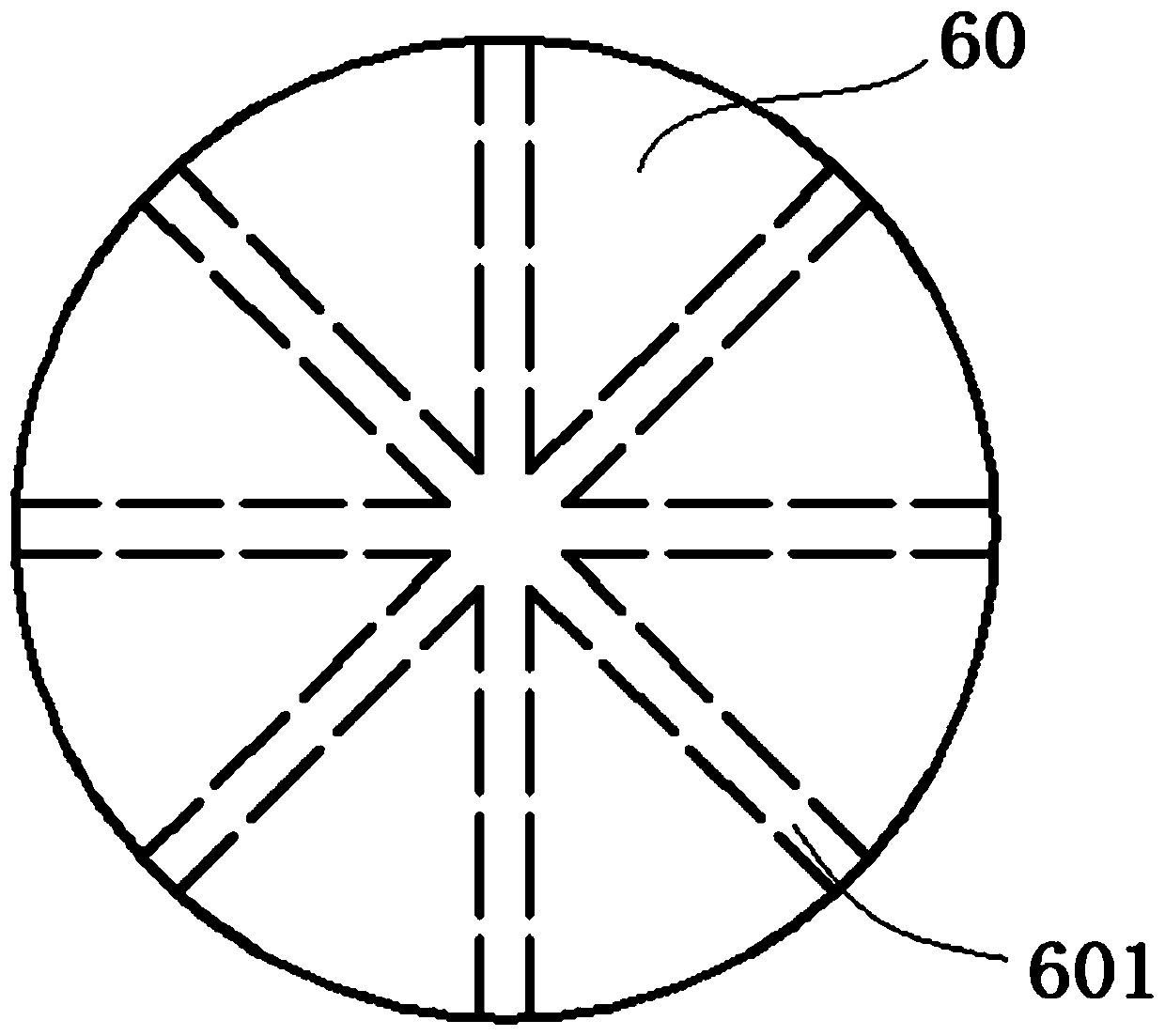

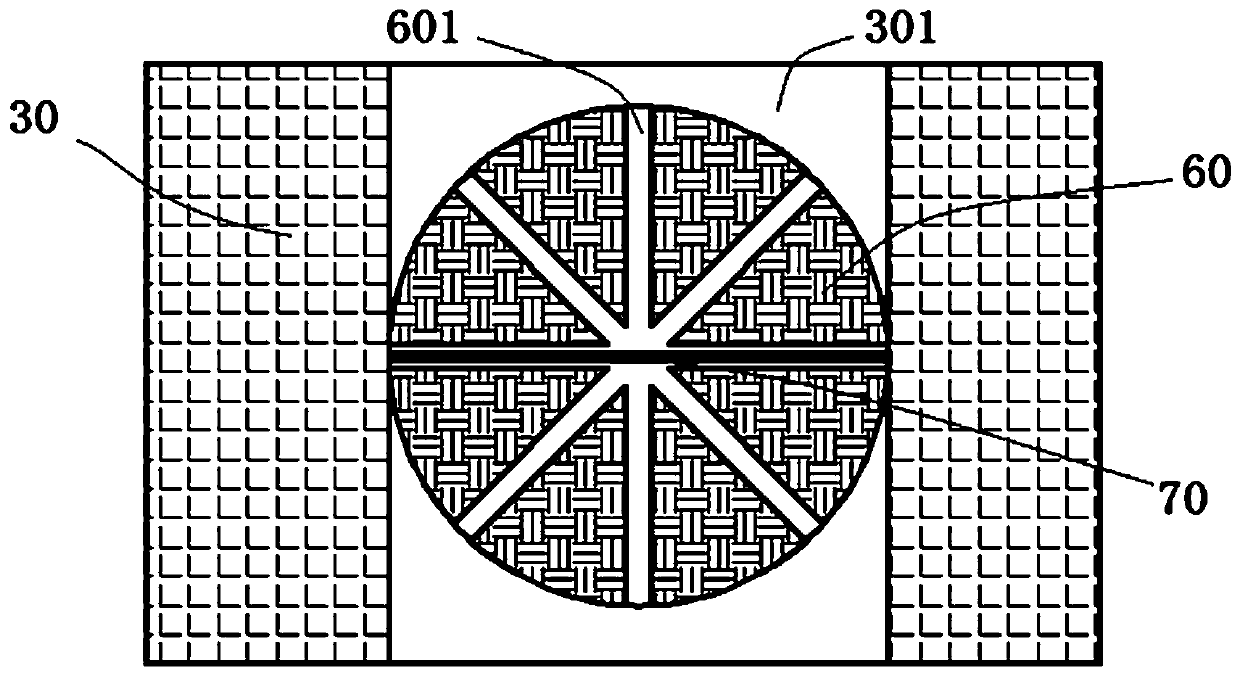

[0037] Such as figure 1 As shown, the present embodiment provides a stainless steel workpiece cutting device, comprising: a water-oil mixing assembly: comprising a water tank 201, an oil tank 202, a water pump 203 and an oil pump 204, the water pump 203 includes a water inlet and a water outlet, and the water tank 201 and the water inlet The water port is connected to the pipeline; the oil pump 204 includes an oil inlet and an oil outlet, and the oil tank 202 is connected to the oil inlet pipeline. The delivery pipe 30: the delivery pipe 30 is a tubular structure with two ends open, and the wall of the delivery pipe 30 is provided with a through hole 301, the water outlet and the oil outlet are connected to the output pipe at the through hole 301; the low-temperature gas generation assembly 10; the low-temperature gas generation assembly 10 is connected to the delivery pipe 30 at one end of the output pipe; the nozzle: includes a liquid inlet 401 and a nozzle 402, the liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com