Method for preparing silicon-based oxynitride fluorescent powder

A technology of nitride phosphors and silicon-based oxygen, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unmentioned multi-component systems and affect optical properties, and achieve reduced energy consumption, reduced degree of agglomeration, and reduced synthesis The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

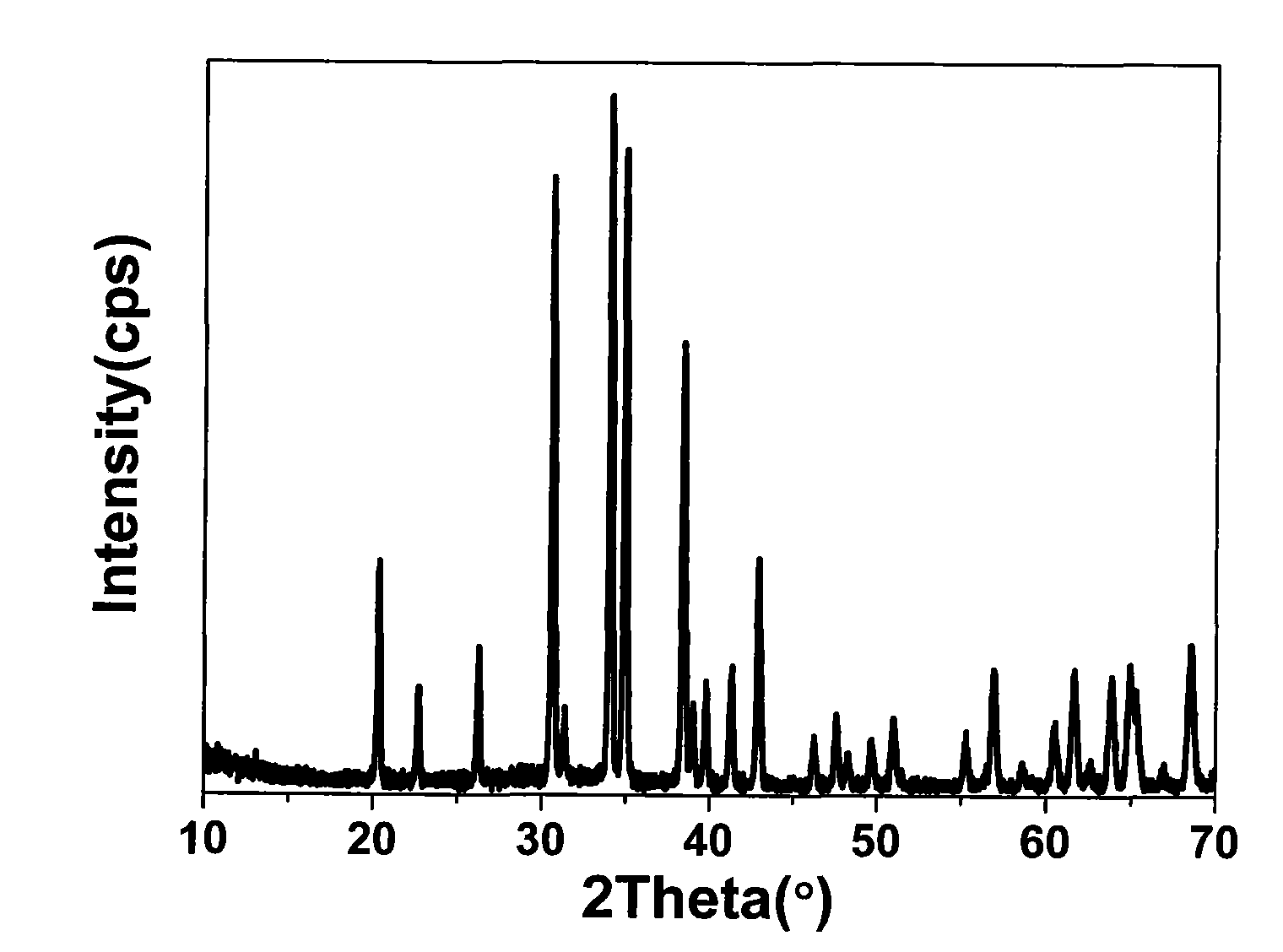

[0043] 1) According to the chemical formula Ca of the target product silicon-based oxynitride phosphor 0.95 Eu 0.05 Si 9 Al 3 ON 15 , Weigh 1.1886g CaCO 3 , 0.1100gEu 2 o 3 , 5.1758gAlF 3 ·3H 2 0, 3.1596g particle size is 400 mesh silicon powders as starting material, puts into 100mL agate ball mill jar jointly, adds 12mL ethanol as medium, ball mills more than 5 hours with the rotating speed of 500 rev / mins, makes various raw materials fully mix, Dry the collection at 80°C.

[0044] 2) Take 3g of the above-mentioned completely mixed raw material powder and put it into a corundum boat, put it into a corundum tube furnace, and perform a vacuum operation on the high temperature furnace so that the vacuum degree in the high temperature furnace is -0.1MPa, and then pass through the reduction The gas is NH with a purity of 99.99% 3 to slightly positive pressure, in flowing NH 3 In the atmosphere, the temperature was raised to 1000°C at a heating rate of 5°C / min, and then...

Embodiment 2

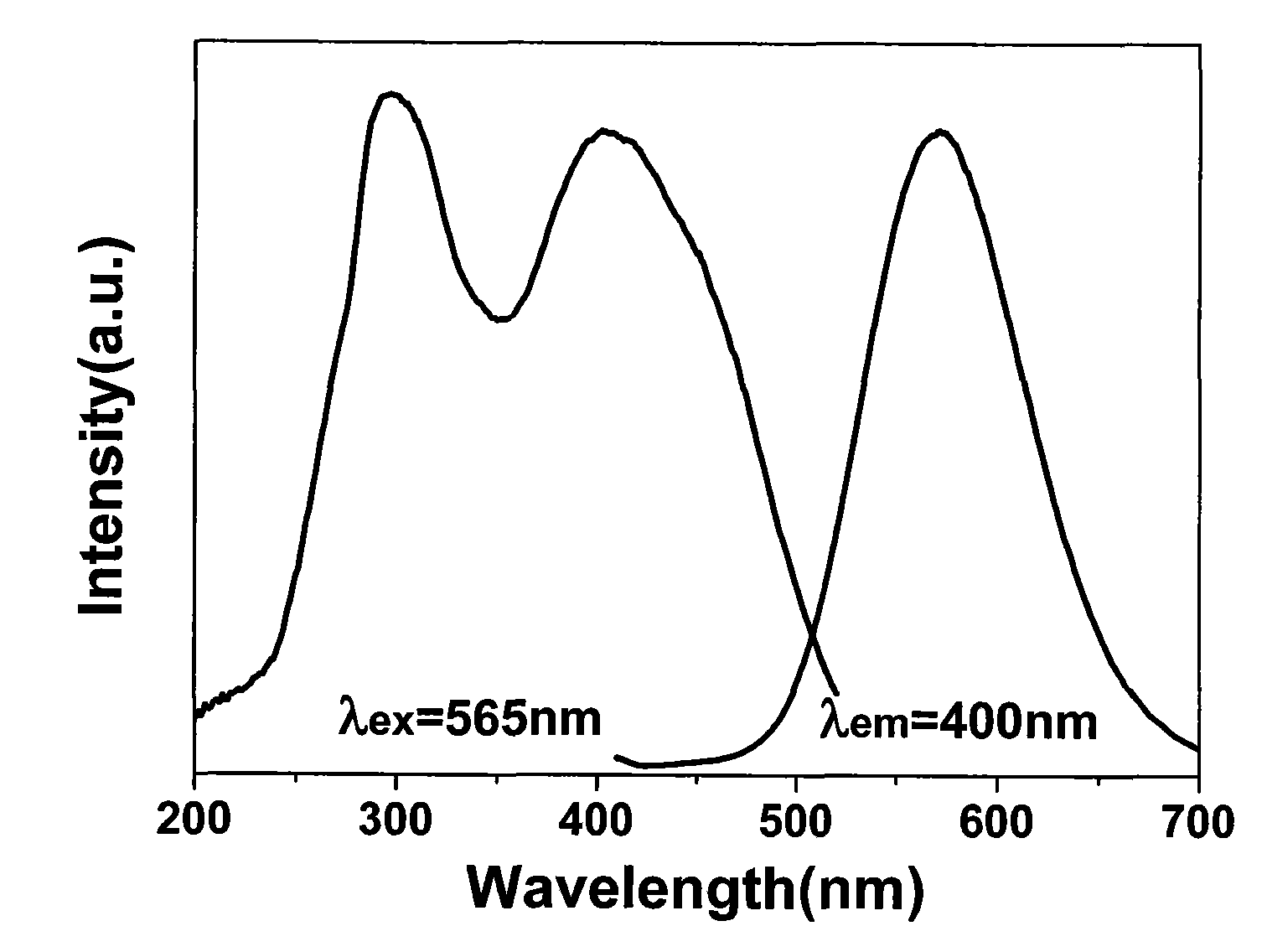

[0047]1) According to the chemical formula Sr of the target product silicon-based oxynitride phosphor 0.98 Eu 0.02 Si 2 o 2 N 2 , weighed 8.2959gSr(NO 3 ) 2 , 0.1408gEu 2 o 3 , 2.2464g of silicon powder with a particle size of 200 mesh as the starting material, put them together into a 100mL agate ball mill jar, add 15mL of ethanol as the medium, and ball mill at a speed of 485 rpm for 10 hours to fully mix the various raw materials. Collect dry.

[0048] 2) Take 3g of the obtained powder and put it into a corundum boat, put it into a corundum tube furnace, and vacuumize the high-temperature furnace so that the vacuum degree in the high-temperature furnace is -0.1MPa, and then feed the reducing gas, that is, the purity is 99.99% N 2 to slightly positive pressure, in flowing N 2 In the atmosphere, the temperature was raised to 1000°C at a heating rate of 5°C / min, and then the gas was adjusted to NH 3 , the flow rate is 0.5L / min, and then the temperature is raised to ...

Embodiment 3

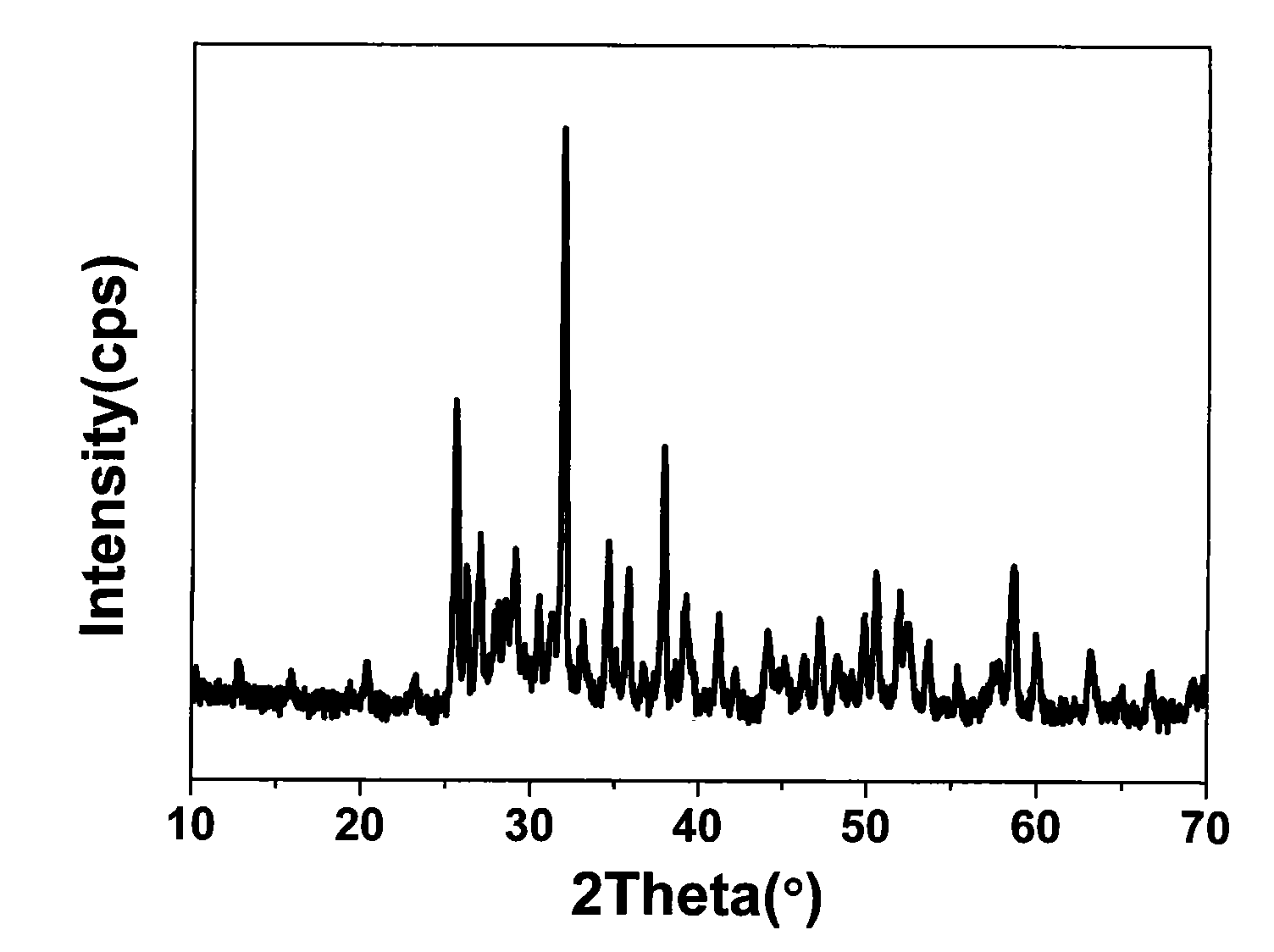

[0051] 1) According to the chemical formula Y of the target product silicon-based oxynitride phosphor powder 3.8 Ce 0.2 Si 2 o 7 N 2 , weighed 2.1452gY 2 o 3 , 0.1721gCeO 2 , 0.150 2 gSiO 2 , 0.2106g of silicon powder with a particle size of 600 mesh as the starting material, put them together in a BN mortar, manually grind for 1 hour, and collect.

[0052] 2) Take 2g of the obtained powder and put it into a corundum boat, put it into a corundum tube furnace, and vacuumize the high-temperature furnace so that the vacuum degree in the high-temperature furnace is -0.1MPa, and then feed the reducing gas, that is, the purity is 99.99% N 2 to slightly positive pressure, in flowing N 2 In the atmosphere, the temperature was raised to 1000°C at a heating rate of 5°C / min, and then the N 2 The flow rate is 0.3L / min, and the flow rate is 50mL / min H 2 , then raise the temperature to 1350°C at a heating rate of 4°C / min, keep the temperature for 2 hours, and turn off the H 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com