Patents

Literature

176results about How to "Fast defoaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of defoaming agent for waterborne system

ActiveCN105148571AActive ingredient reductionReduce manufacturing costCoatingsFoam dispersion/preventionAdjuvantNitrogen gas

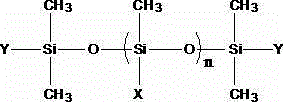

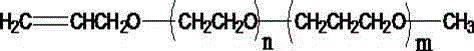

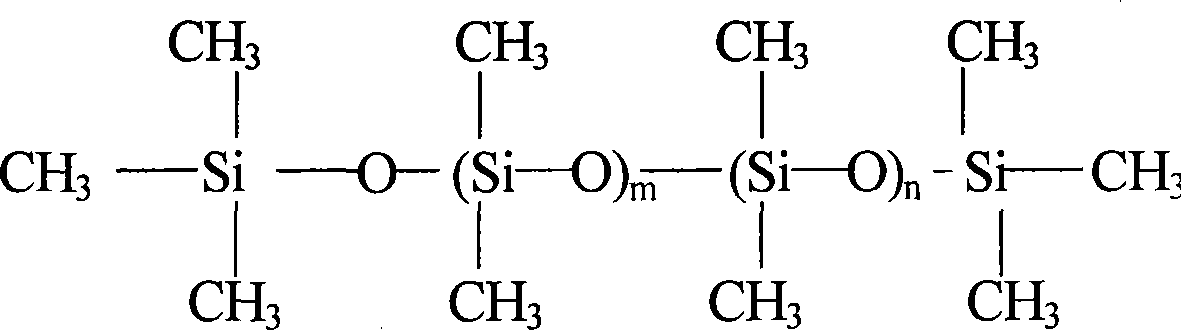

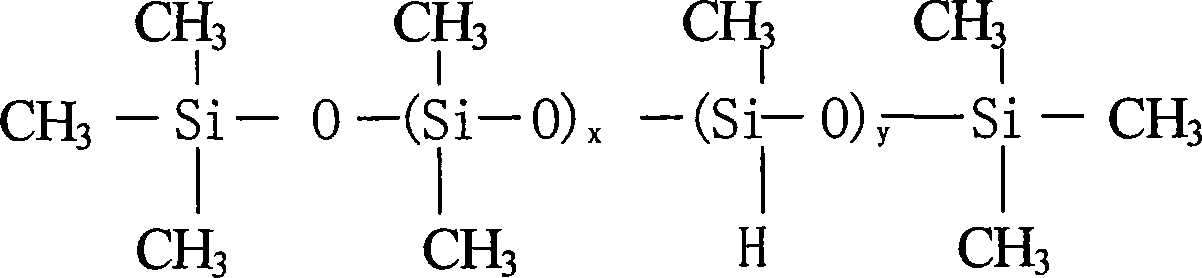

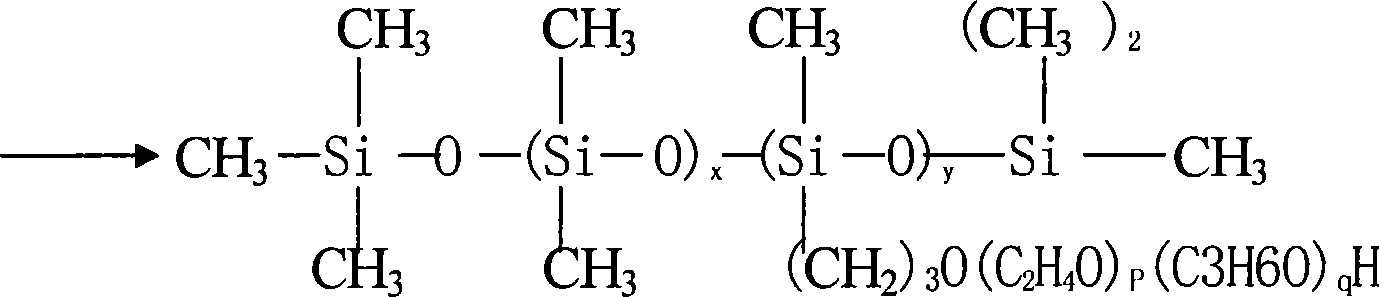

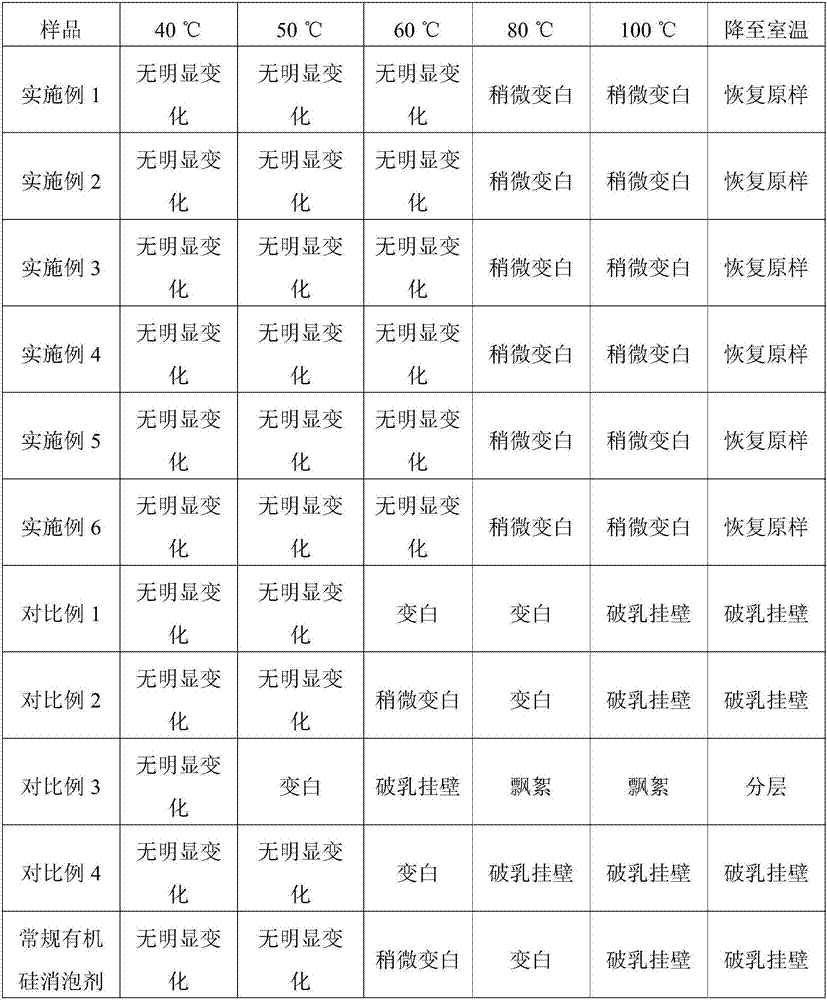

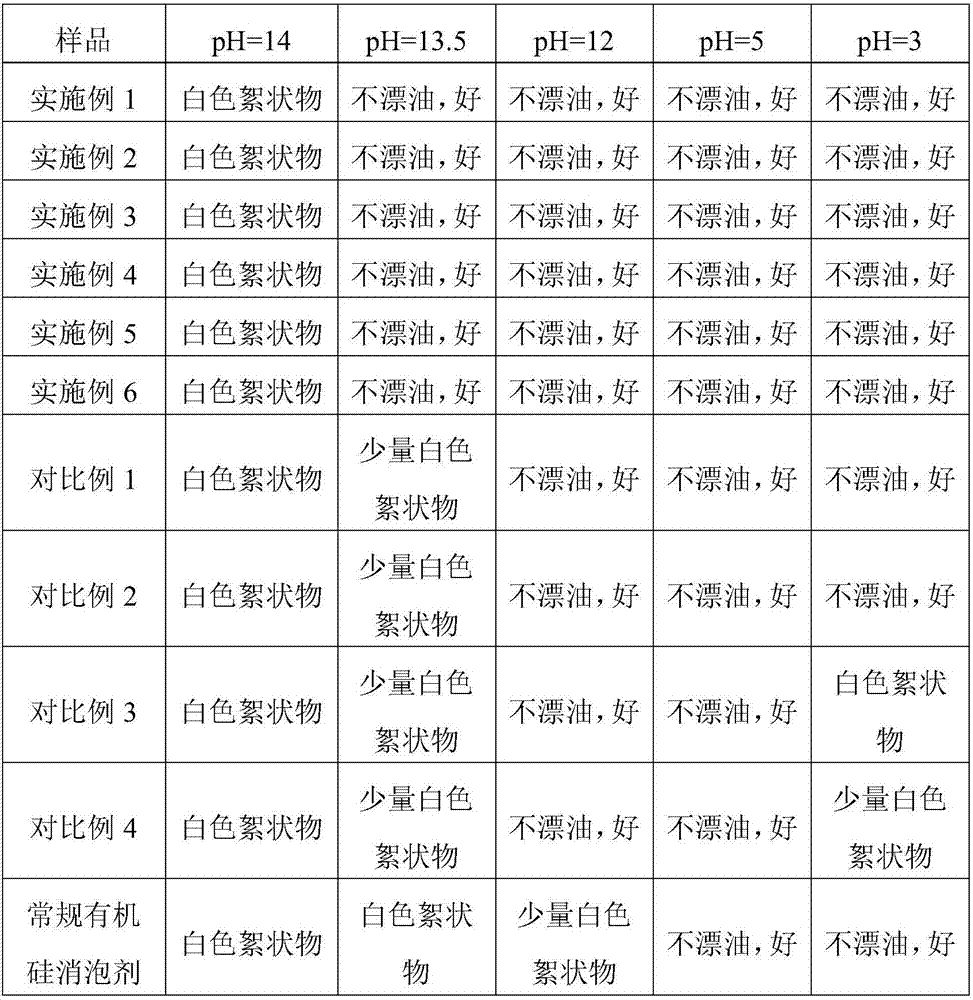

The invention relates to a preparation method of a defoaming agent for a waterborne system. The preparation method of the defoaming agent for the waterborne system comprises the following steps: a) adding silicon oil, gaseous silicon dioxide and catalyst into a reaction container according to proportions, and preparing silicon cream under an agitating condition protected by nitrogen; b) adding hydrogen-containing silicon oil and allyl polyether into the reaction container, agitating under the protection of nitrogen, increasing temperature and adding an initiator for reaction to obtain polyether modified organic silicon; c) jading the silicon cream obtained in step a), the polyether modified organic silicon obtained in step b) and an emulsifier into the reaction container, adding water for emulsification under a high-speed agitating condition, and adding a thickening agent to regulate viscosity to obtain a product. The defoaming agent prepared by adopting the preparation method provided by the invention has the advantages that the active components are low, the manufacturing cost is low and the environmental friendliness is better; the emulsification is stable, the compatibility in the waterborne system is good, the defoaming agent is easy to disperse, the surface tension is low, the defoaming speed is quick, the foam inhibiting time is long, the thermal resistance, shear resistance and acid and alkali resistance thereof are good, and the defoaming agent can adapt to various places; the defoaming agent can be separately used and can also be jointly used with other adjuvants, the stability is good, the phenomenon of oil floating due to demulsification does not occur, no sediment is produced and shrinkage cavities during coating are not caused; and the defoaming agent is also very effective to non-waterborne systems.

Owner:KITO CHEM CO LTD

Polyether modified organic silicon defoamer and preparation method thereof

The invention discloses a polyether modified organic silicon defoamer and a preparation method thereof. The defoamer comprises compounding raw materials in percentage by weight as follows: 5%-40% of polyether modified silicone oil, 10%-40% of dimethyl silicone oil, 5%-30% of white carbon black, 2%-30% of an emulsifying agent, 0.01%-8% of a regulator and 10%-80% of water, and the sum of components is 100%. According to the preparation method of the polyether modified organic silicon defoamer, the polyether modified organic silicon defoamer is prepared by the compounding raw materials in percentage by weight, the technological method is as follows: (a), the polyether modified silicone oil, the white carbon black and the dimethyl silicone oil in different weight ratios are put in a reaction kettle, stirred and heated to the temperature of about 200 DEG C, and a silicon paste is prepared; and (b), the emulsifying agent is added into the silicon paste and heated to the temperature of about 50 DEG C-75 DEG C, the regulator is added, water is dropwise added, the mixture is stirred for 5-10 hours, cooled, discharged and packaged, and the polyether modified organic silicon defoamer is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

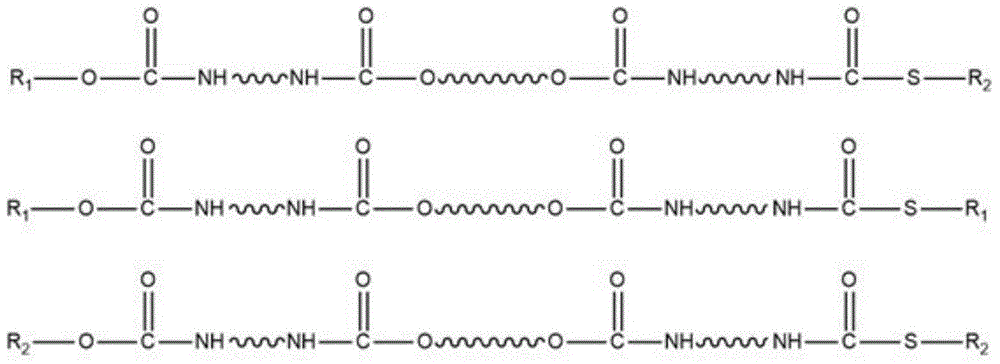

UV curing liquid optical cement and preparation method and application thereof

ActiveCN105985749AThere will be no glue overflow problemModerate bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingOligomer

The invention discloses UV curing liquid optical cement. The UV curing liquid optical cement is prepared from, by weight, 20-70 parts of active oligomer, 10-50 parts of tackifying resin, 10-40 parts of reactive diluent, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The tackifying resin has a unique molecular structural formula. A preparation method of the UV curing liquid optical cement comprises the steps that the active oligomer, the tackifying resin, the reactive diluent, the photoinitiator and the additive are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and a finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and UV curing for cement overflow prevention are solved, a cement film formed by the UV curing liquid optical cement has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after UV curing is carried out again, the surface of the cement film is very smooth, a certain edge shape is kept, and no edge collapse phenomenon occurs; the UV curing liquid optical cement is suitable for automatic equipment coating and especially suitable for full lamination of modules.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Antifoaming agent

InactiveCN103127748AFast defoamingEnhanced inhibitory effectFoam dispersion/preventionPotassium iodinePhenol

The invention discloses an antifoaming agent which comprises, by weight, the following raw materials: 1 part to 3 parts of potassium iodide, 2 parts to 5 parts of boric acid, 1 part to 4 parts of sodium bromide, 2 parts to 4 parts of calcium stearate, 4 parts to 8 parts of nonyl phenol polyoxyethylene ether, 2 parts to 6 parts of tetrabutyl phosphorus bromide, 1 part to 5 parts of benzyl triphenyl phosphorus bromide, 3 parts to 6 parts of isoamylene alcohol, 4 parts to 7 parts of tert-amyl chloride, 1 part to 2 parts of trifluoroacetylacetone and 3 parts to 9 parts of simethicone. The antifoaming agent is rapid in antifoaming and good in inhibition performance, and does not affect basic property of a foaming system. Meanwhile, the antifoaming agent is good in diffusivity and permeability, stable in chemical property, free from corrosion, toxicity and adverse side effect and high in safety.

Owner:NANTONG HAISHUN CHEM

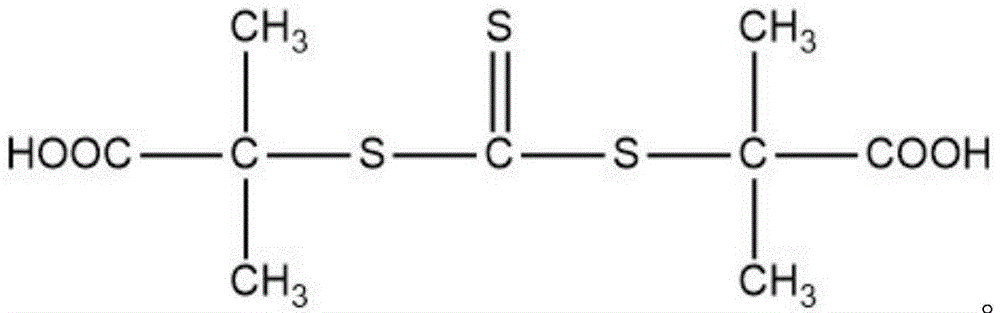

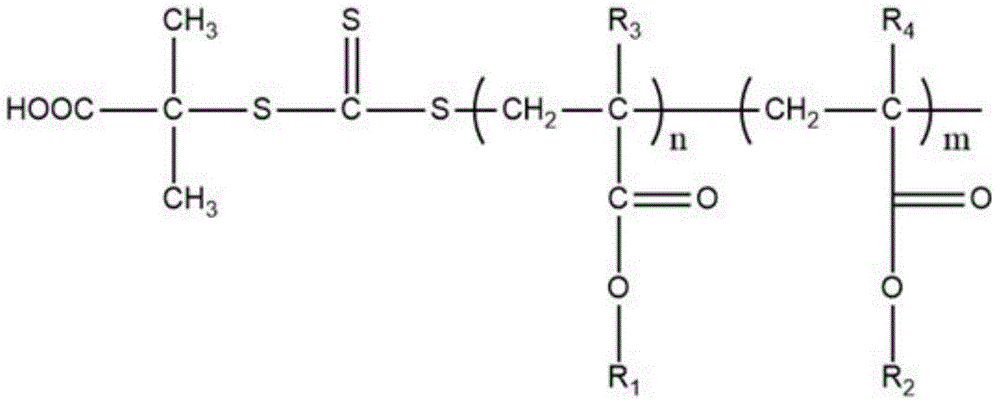

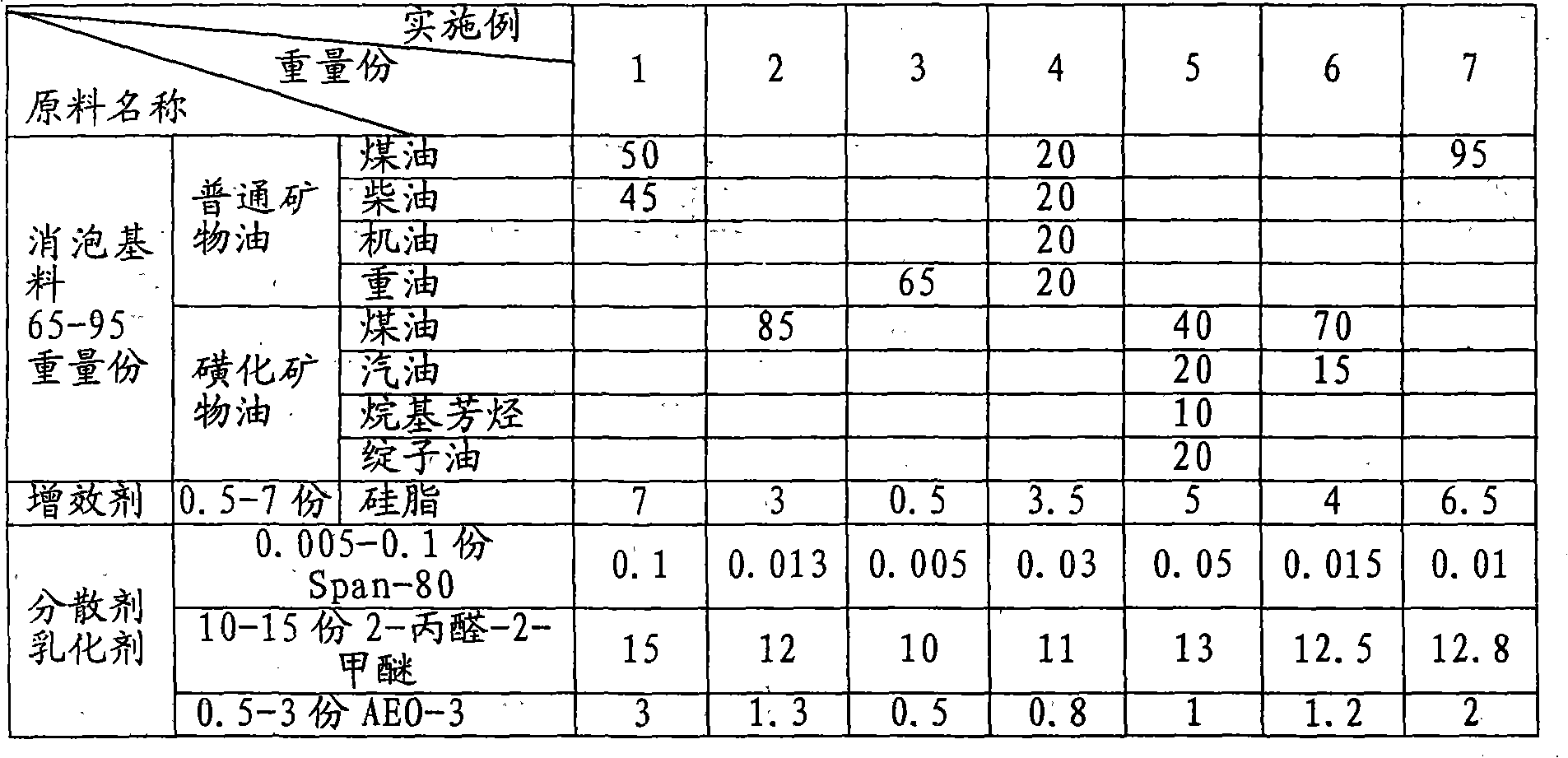

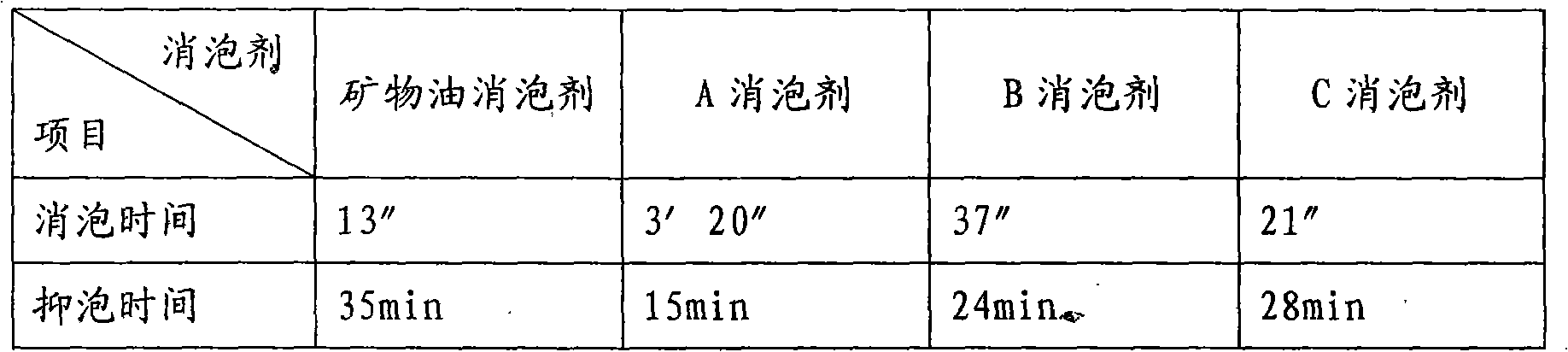

Mineral oil antifoam agent and production method thereof

InactiveCN101310814AGood effectFast defoamingTransportation and packagingMixingOil productionFermentation

The invention relates to a mineral oil defoamer and a production method thereof, the mineral oil deforamer is composed of raw materials with the following parts by weight: 65 to 95 parts by mineral oil, 0.5 to 7 parts of silicon grease, 0.005 to 0.1 part of Span-80, 10 to 15 parts of 2-propanal-2-methyl ether and 0.5 to 3 parts of AEO-3; the mineral oil defoamer is colorless or light yellow or light brown oily liquid, the specific gravity is 0.87 to 0.95g / ml, the pH is equal to 6.5 to 8.0, the lead content is less than or equal to 5ppm, the defoaming rate is more than or equal to 95 percent and the foam suppressing rate is more than or equal to 95 percent; the production process is as follows, the raw materials are weighted for preparing the materials according to the mix ratio, the prepared mineral oil is poured in a reaction kettle, the silicon grease is added, the stirring is carried out, the temperature raises to 60 to 80 DEG C, the temperature is kept for 50 to 70min, and other three raw materials are sequentially added during the full stirring for preparation. The defoamer is applied in oil production, well drilling, oil-gas separation, oil fermentation, oil ink production, waste water treatment and other processes, thus having the advantages of small using amount, stable effect, rapid defoaming, long foam suppressing time and low using cost, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

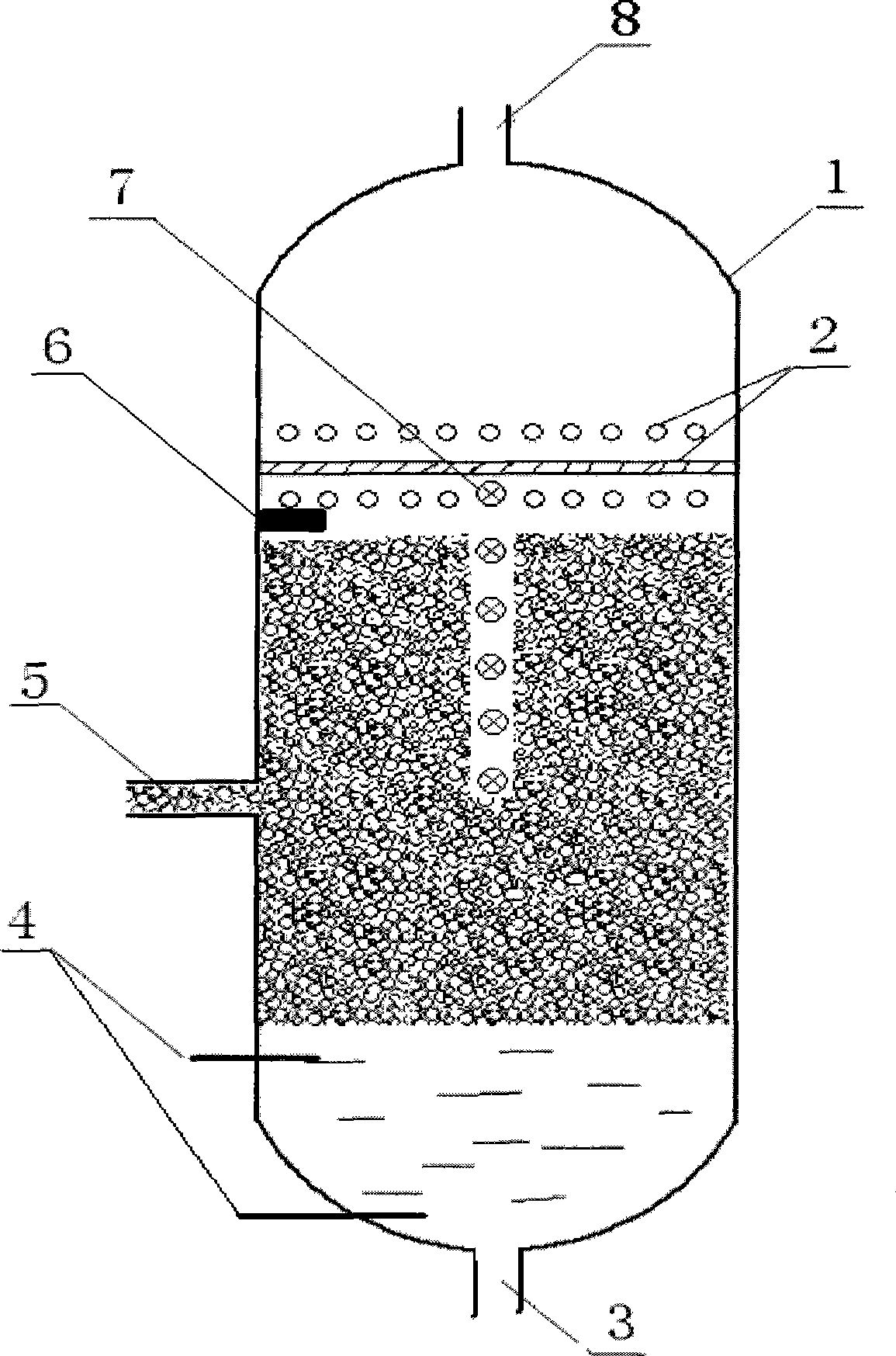

Defoaming method and device for eliminating foam of drilling fluid by thermal radiation

The invention relates to a defoaming method and a deforming device for removing the foam of drilling fluid through thermal radiation, which belong to the technical field of the physical defoaming of the drilling fluid. The defoaming device comprises a cylindrical container. The defoaming device is characterized in that a gas outlet is arranged on the top of the cylindrical container, a fluid and slag outlet is arranged on the bottom of the cylindrical container, a foam inlet is arranged on the side face of the middle lower part of the cylindrical container, a thermal radiation element is arranged on the upper inner wall of the cylindrical container, a temperature sensor is arranged below the thermal radiation element on the cylindrical container, an ultrasonic foam height sensor is also arranged below the thermal radiation element on the cylindrical container, and fluid level sensors are arranged on the middle and lower parts of the inside cylindrical container. The foam flows into the device through the foam inlet, the thermal radiation element on the device gives off thermal radiation to break the foam with low intensity near the device, the separated gas is discharged through the gas outlet, and the foam base fluid and the solid carried by the foam are discharged through the fluid and slag outlet. The defoaming device can quickly remove a great amount of foam discharged from foam drilling and prevent the foam from being accumulated in a mine. In addition, the nature of the foam base fluid is not affected, thereby facilitating the cyclic utilization of the foam base fluid.

Owner:SHANDONG UNIV

UV-moisture dual-curing liquid optical cement and preparation method and application thereof

ActiveCN105985750ARealize the function of dual curingReduce consumptionPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingReactive diluent

The invention discloses UV-moisture dual-curing liquid optical cement. The UV-moisture dual-curing liquid optical cement is prepared from, by weight, 45-80 parts of UV moisture curing matrix resin, 10-50 parts of tackifying resin, 10-35 parts of reactive diluents, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The matrix resin and the tackifying resin have unique molecular structures. The invention further provides a preparation method of the UV-moisture dual-curing liquid optical cement. The preparation method comprises the following steps that the matrix resin and the tackfying resin are prepared; then all the materials are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and the finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and moisture curing for cement overflow prevention are solved, a cement film formed by the UV-moisture dual-curing liquid optical cement after primary UV curing has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after moisture curing, the surface of the cement film is very smooth, a certain edge shape is kept, no edge collapse phenomenon occurs, and the UV-moisture dual-curing liquid optical cement is suitable for automatic equipment coating.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Water-borne plastic paint and preparation method thereof

InactiveCN105885582AGood film formingImprove coalescenceFireproof paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to water-borne plastic paint and a preparation method thereof, and belongs to the technical field of paint processing. The water-borne plastic paint is prepared from the following components in a certain proportion: water-borne acrylic resin, water-borne epoxy resin, a coalescing agent, a water-borne color paste, hydroxyethyl cellulose, talc powder, a defoaming agent, a flatting agent, flame retardant, nano-silicon dioxide, dimethylethanolamine and deionized water. The paint film has strong adhesion, good glossiness and strong strength, has a certain flame retardant effect, and is safe and reliable.

Owner:杭州高思途实业有限公司

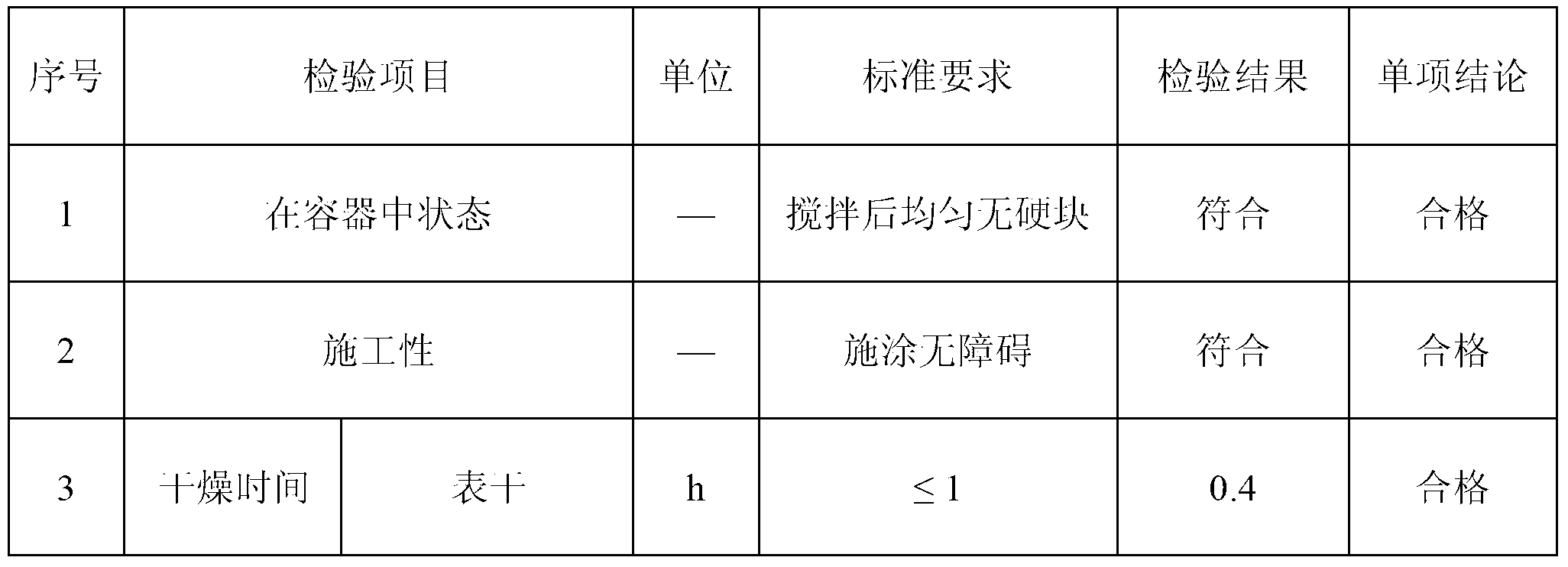

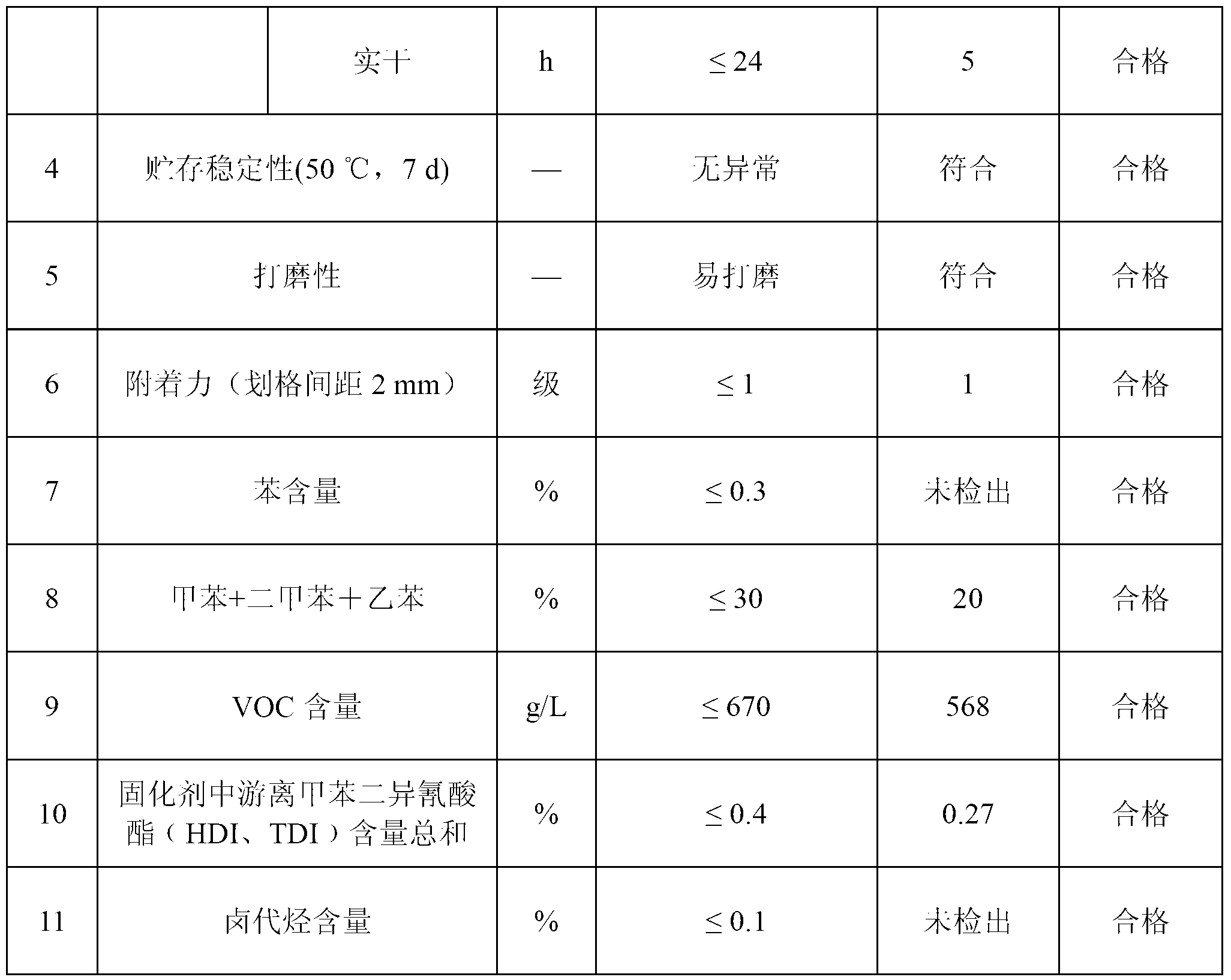

Anti-sinking PU extra-clear primer and preparation method thereof

ActiveCN103305113AGood anti-sag performanceHigh transparencyPolyurea/polyurethane coatingsMethyl carbonateSlurry

The invention provides an anti-sinking PU extra-clear primer which is prepared by mixing an anti-sinking PU polyurethane primer, a PU anti-sinking curing agent and a PU anti-sinking diluent, wherein the anti-sinking PU polyurethane primer is prepared from soybean oil alkyd resin, a dispersant, an antifoaming agent, anti-settling slurry, pigment and filler, nitrocotton liquid, a leveling agent, a dryer and the like in addition with an environment-friendly solvent; the PU anti-sinking curing agent is prepared from n-butyl acetate, isocyanate tripolymer and isocyanate heteropolymer; and the PU anti-sinking diluent is prepared from the solvents such as n-butyl acetate, propylene glycol monomethyl ether acetate, dimethyl carbonate and the like. The anti-sinking PU polyurethane primer, the PU anti-sinking curing agent and the PU anti-sinking diluent are sufficiently and uniformly mixed to prepare the anti-sinking PU extra-clear primer which has excellent anti-sinking property and extra high transparency and is easy to polish; and the shortcomings of slow drying, poor anti-sinking property, common adhesion, low transparency, common polishing property and the like of the commercially available products are overcome.

Owner:广东花王涂料有限公司

Compound defoaming agent

InactiveCN106731034AFast defoamingLong foam suppression timeWater/sewage treatment by degassingFoam dispersion/preventionIsooctyl alcoholGlycol ethers

The invention discloses a compound defoaming agent which comprises the following ingredients: 20-25 parts of polyoxyethylene polyoxypropylene glycol ether, 20-25 parts of dimethicone, 15-20 parts of polyether modified siloxane, 15-20 parts of glycerol tristearate, 5-10 parts of sodium dodecyl sulfate and 5-10 parts of isooctyl alcohol. The compound defoaming agent has the characteristics of quick defoaming, long foam inhibition time, alkali resistance, acid resistance, high-temperature resistance and good compatibility, and can be widely used for removing harmful foam in industrial production.

Owner:新疆水处理工程技术研究中心有限公司

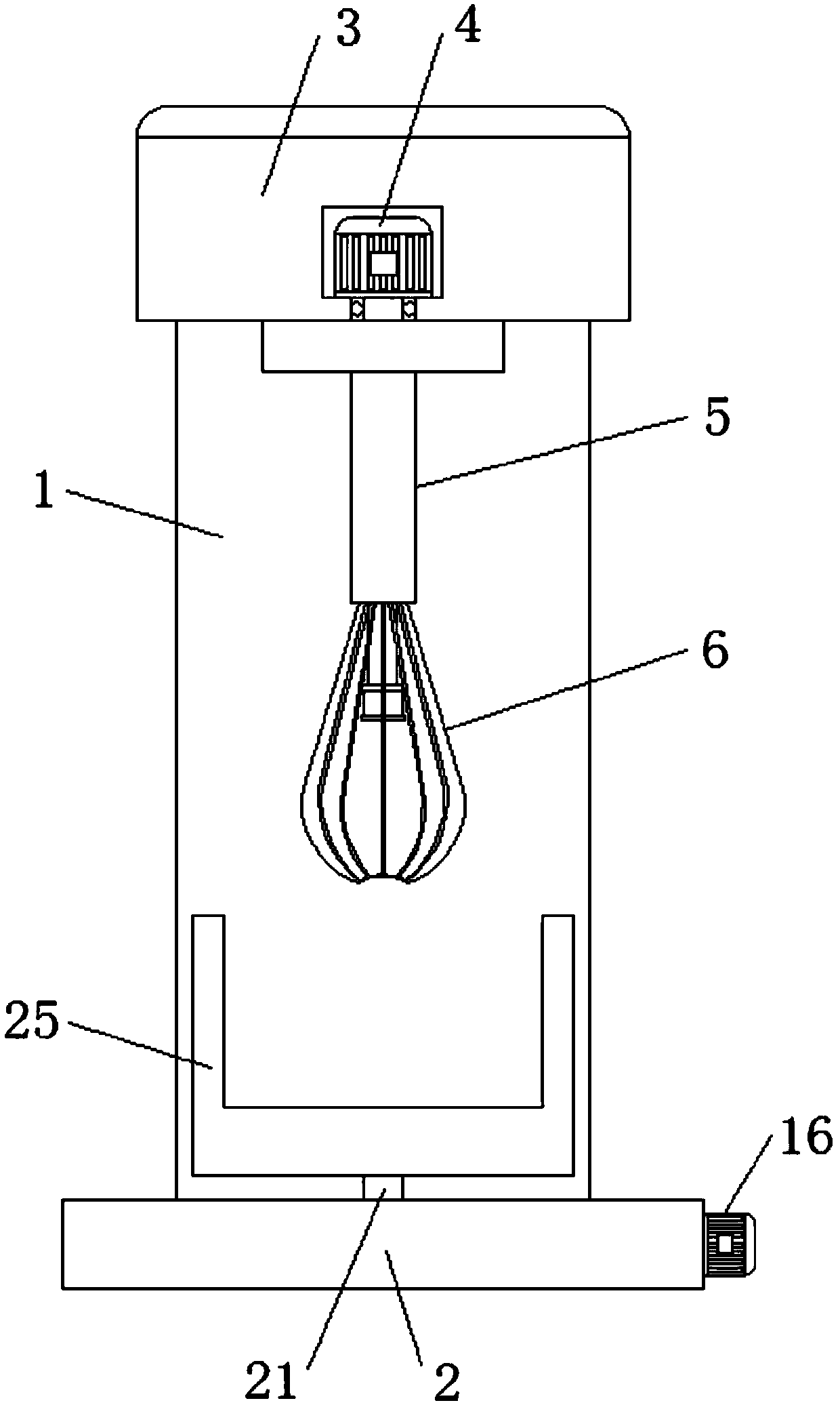

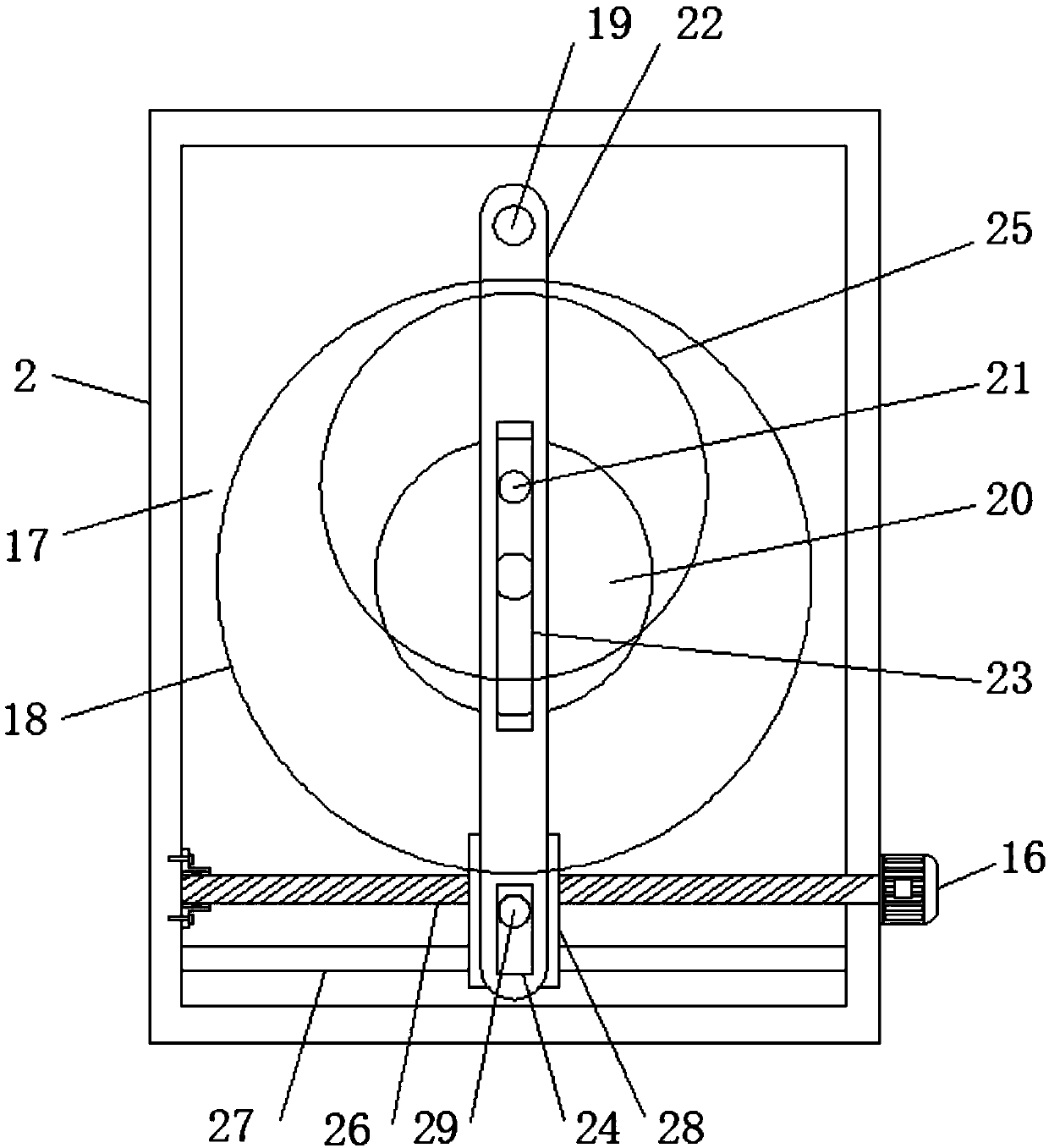

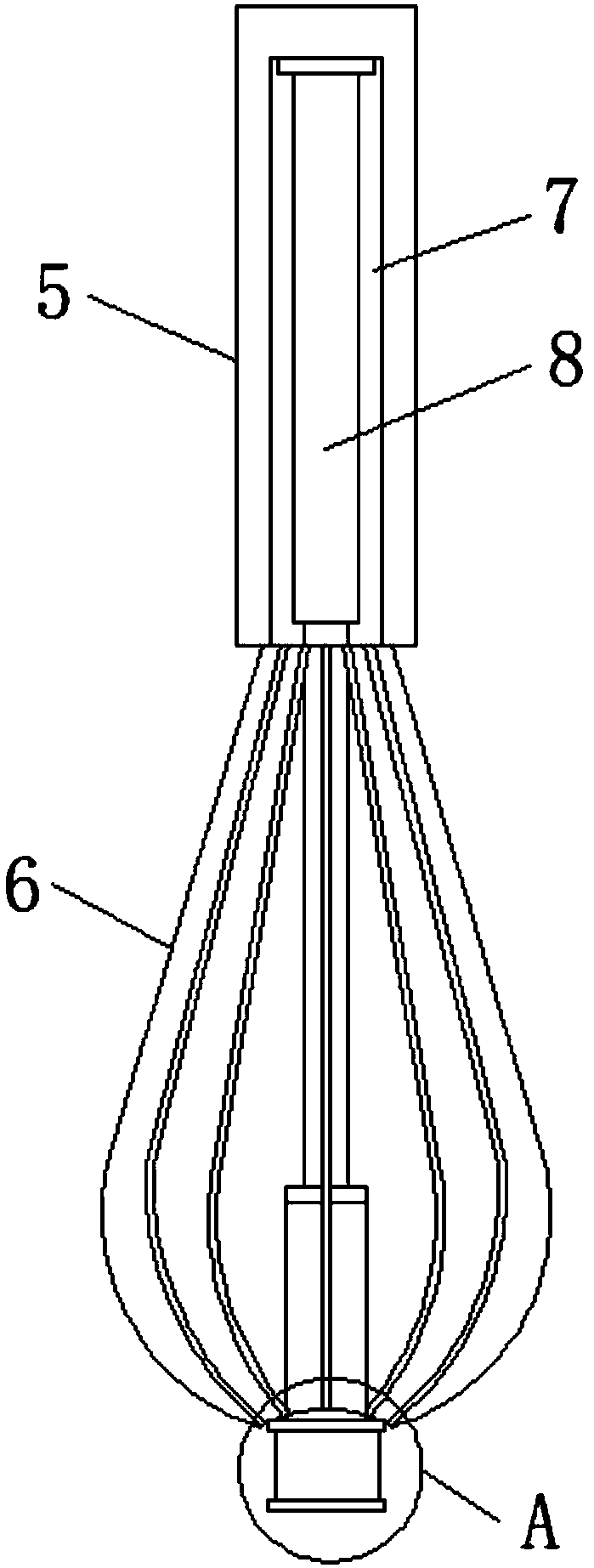

Combined type egg beater with rapid defoaming effect

The invention discloses a combined type egg beater with a rapid defoaming effect. The combined type egg beater with the rapid defoaming effect comprises an egg beater body, a base and an egg beating mechanism, wherein the base is positioned on one side of the bottom of the egg beater body; a control box is mounted on the top of the egg beater body; a first motor is mounted in the control box; theegg beating mechanism is arranged at the bottom of the control box; the egg beating mechanism comprises a fixed rod and a stirring net head; a defoaming plate is movably mounted in the fixed rod; a liquid inlet is formed in the bottom of the defoaming plate; a filter screen is mounted in the liquid inlet; multiple layers of defoaming cavities are formed in the defoaming plate; a plurality of defoaming openings are formed between each two adjacent defoaming cavities; a plurality of stainless steel pricking needles are arranged in each defoaming opening; a liquid outlet is formed in the top of the defoaming plate; an adjusting cavity is formed in the base; and the inner wall of the bottom of the adjusting cavity is rotatably connected with a positioning rod and a rotating plate separately. The combined type egg beater with the rapid defoaming effect is reasonable in design and convenient to use; defoaming can be implemented rapidly; the purpose of shaking while stirring is achieved; andthe egg beating effect and the using effect of the product are improved effectively.

Owner:宁波远大电器有限公司

Defoaming agent

InactiveCN104548678AEnhanced inhibitory effectDoes not affect the basic propertiesFoam dispersion/preventionParaffin oilsStearic acid

The invention discloses a defoaming agent. The defoaming agent comprises the following raw materials in parts by weight: 30-40 parts of dimethyl silicon oil, 3-5 parts of potassium iodide, 5-10 parts of polyether, 3-5 parts of paraffin, 6-10 parts of an emulsifier, 3-5 parts of ethylene glycol, 1-2 parts of stearic acid and 5-10 parts of tributyl phosphate. The defoaming agent disclosed by the invention has the advantages of high defoaming speed, good inhibition performance and no influence on basic nature of a foaming system, as well as good diffusibility and permeability.

Owner:HAIAN YATAI ADDITIVES

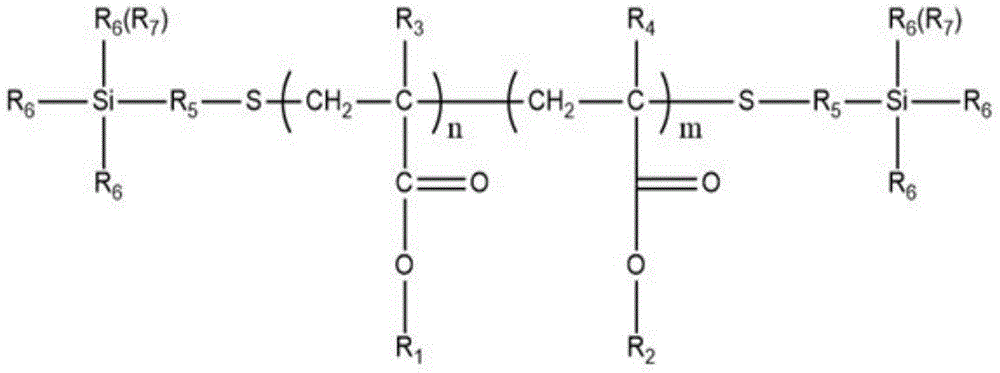

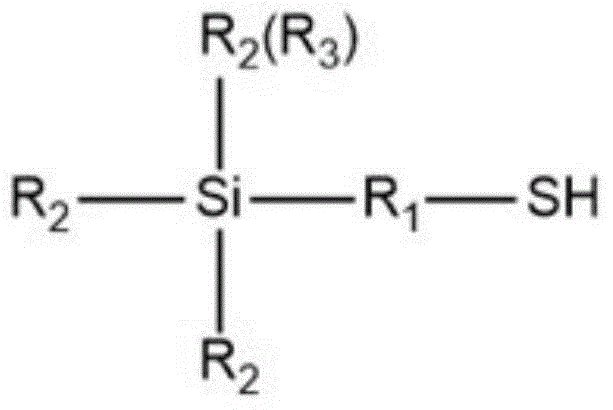

Silyl ether mixed defoaming agent emulsion and preparation method thereof

InactiveCN105031978AEasy to operatePromote fermentationFoam dispersion/preventionEmulsionFermentation

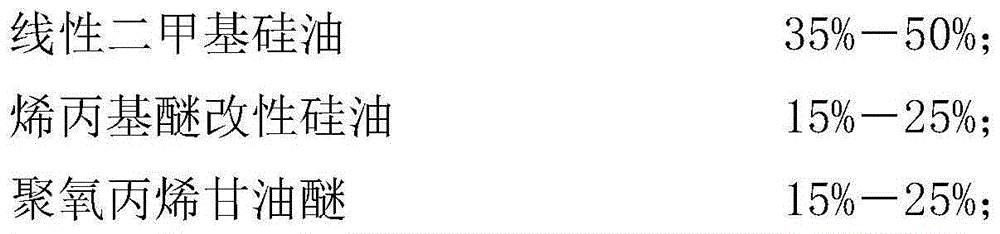

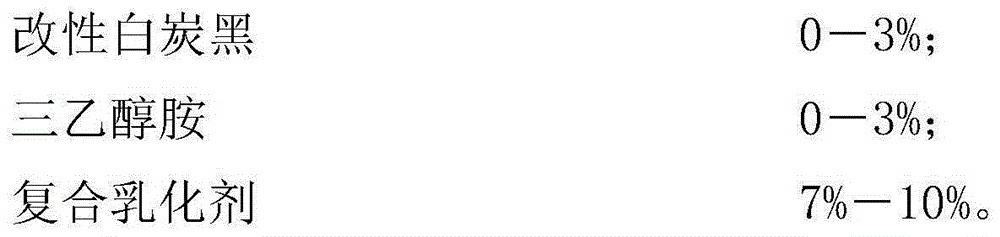

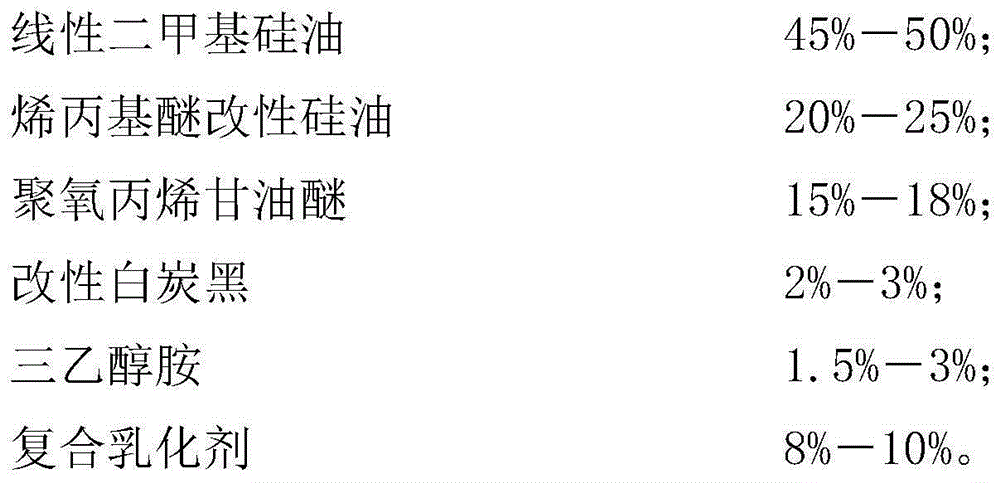

The invention discloses silyl ether mixed defoaming agent emulsion and a preparation method thereof. The silyl ether mixed defoaming agent emulsion is prepared from the following components: linear simethicone, allyl ether modified polysiloxane, polyoxypropylene glyceryl ether, modified white carbon black, triethanolamine and a compound emulsifier. The preparation method comprises the following steps: uniformly mixing the linear simethicone and the modified white carbon black, and heating to obtain a mixture I; adding triethanolamine into the mixture I, stirring and cooling to obtain a mixture II; adding the allyl ether modified polysiloxane and the polyoxypropylene glyceryl ether, and further stirring to obtain a mixture III; adding the compound emulsifier into the mixture III, and stirring at high speed to obtain coarse emulsion; adding thickening water into the coarse emulsion, and preparing raw emulsion; and pouring the raw emulsion into a high-speed homogenizer for stirring to obtain the fine-smooth and stable emulsion. The defoaming agent easily dissolves in water, and is small in specific surface area, high in defoaming speed, lasting in foam inhibition and small in use amount; the preparation method is convenient and easy to operate; the defoaming agent has no toxic effects on microorganisms, has an effect of promoting the growth of mycelia, is beneficial to microbial fermentation and is relatively environmentally friendly.

Owner:杭州彤诚新材料技术有限公司

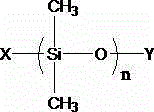

Process for producing polyvinyl chloride polymerization organosilicon inarch polyether antifoam agent

The invention relates to fine chemical products, in particular to a preparation method of a polyvinyl chloride polymerization organic silicon graft polyether defoamer. A defoamer is used for defoaming and foam inhibition in the process of producing polyvinyl chloride in a suspension method. Domestic defomer is classified into two types, wherein, one is pure polyether type with poor defoaming effect and foam inhibition effect, and the other one is oil defoamer which has good effect but contaminates a PVC resin. Foreign high-efficiency defoamer has a better defoaming and inhibition effect, but the price is higher. The preparation method of the invention is that: step 1, the synthesis of hydrogenous midbody, and the raw material and the proportion are as follows: 100 portions of octamethylcy-clotetrasiloxane, 25 to 30 portions of hydrogen-containing silicone oil, 15 to 20 portions of hexamethyl disiloxane, 6 to 8 portions of oil of vitriol and 15 to 18 portions of sodium carbonate. Step 2, the graft of the hydrogenous midbody and polyether with the raw material and the proportion of 100 portions of hydrogenous midbody, 300 to 350 portions of polyether and 0.001 to 0.0015 portions of palladium chloride catalyst.

Owner:河北盛华化工有限公司

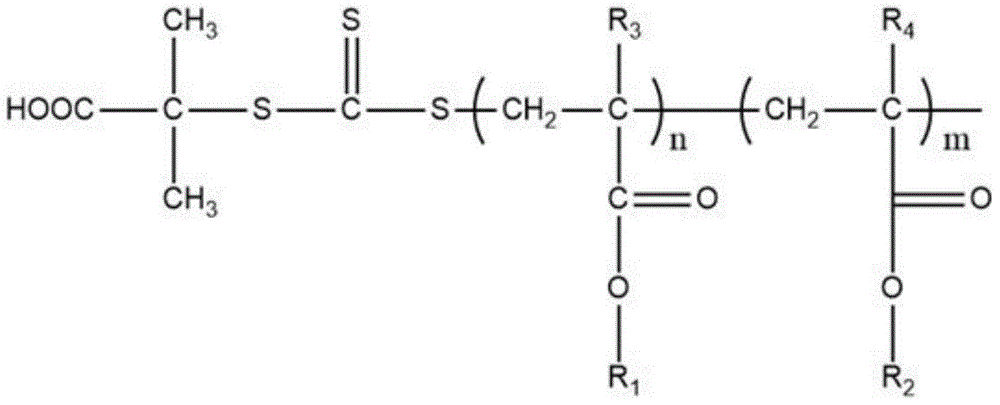

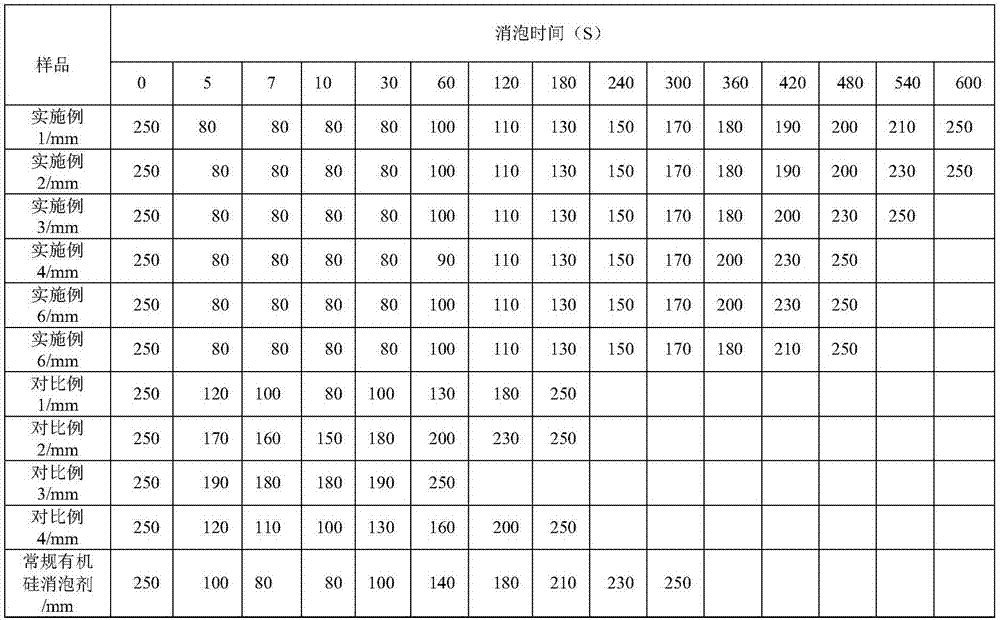

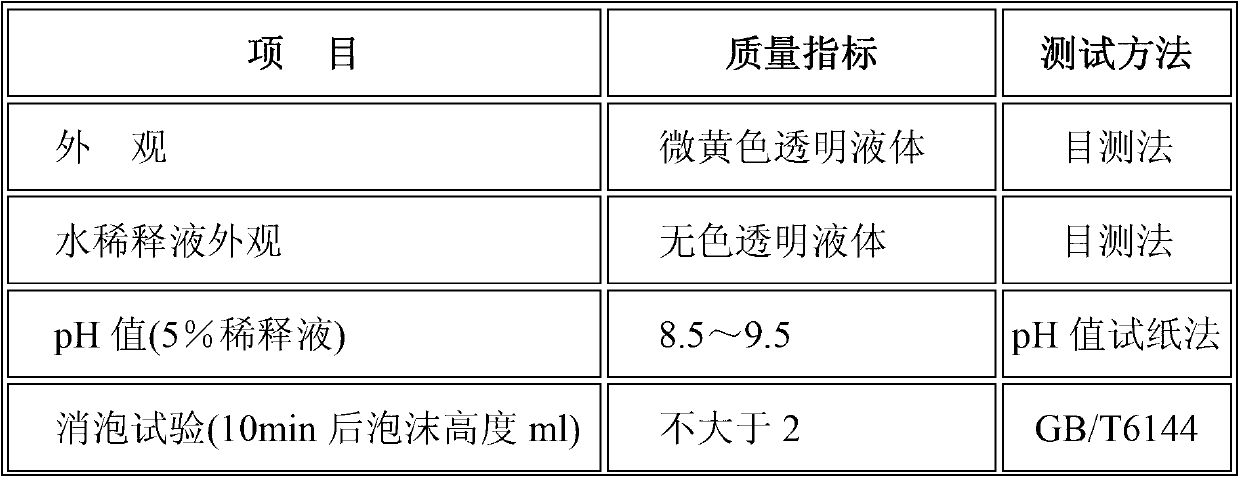

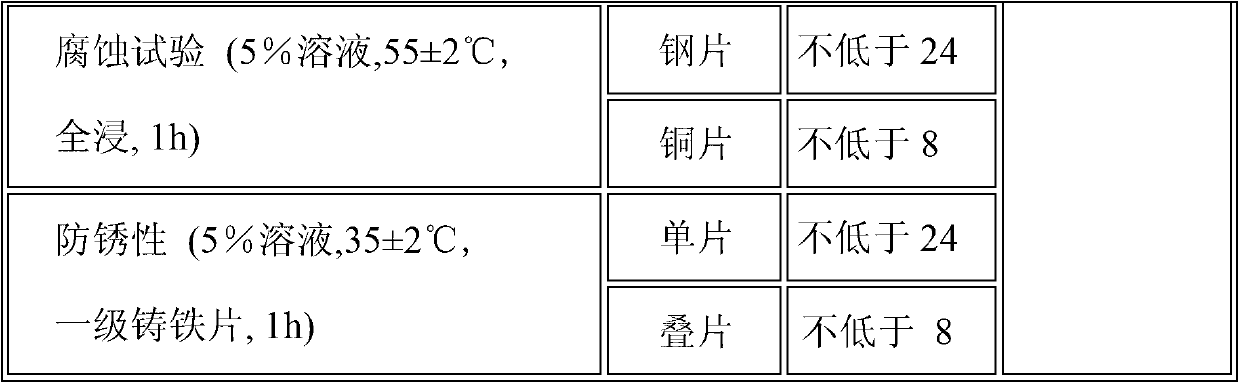

Modified organosilicone defoaming agent, defoaming agent composition and preparation method thereof

ActiveCN107982963AFast defoamingLong-lasting foam suppressionFoam dispersion/preventionTemperature resistanceDefoaming Agents

The invention discloses a modified organosilicone defoaming agent, a defoaming agent composition and a preparation method thereof. The modified organosilicone defoaming agent comprises the following raw materials in parts by weight: 10 to 20 parts of silicon paste, 10 to 15 parts of an EO / PO block copolymer, 2 to 5 parts of a surfactant, 1.5 to 3 parts of a thickening agent and 70 to 85 parts of water. The defoaming agent obtained by the modified organosilicone defoaming agent is rapid in defoaming, durable in foam inhibition, high in cost performance and high in dispersibility; the defoamingagent has high-temperature resistance, acid and alkali resistance, electrolyte resistance and shear resistance, has high compatibility with various kinds of dye, avoids oil floating, does not have silicon spots, is safe and non-toxic, meets the environment-protecting requirement, has stable quality, proper viscosity and proper concentration, and is convenient to use and dilute.

Owner:广州旭太材料科技有限公司

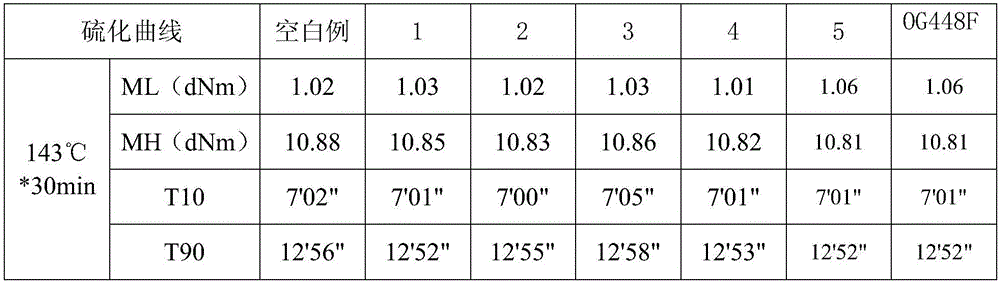

Elliptical machine light cover surface silica gel and preparation method thereof

InactiveCN107130448ASuitable for operational needsSuitable for operationDyeing processVulcanizationPolymer science

The invention discloses elliptical machine light cover surface silica gel and a preparation method thereof. The light cover surface silica gel comprises, by weight, 100 parts of vinyl polysiloxane, 10-15 parts of white carbon black, 0.15-0.2 part of inhibitors, 0.3-0.5 parts of platinum catalysts, 11-12 parts of hydrogen-containing silicone oil and 0.2-0.5 part of fluoroalkyl silicone oil. By the aid of a compound comprising base gel, the hydrogen-containing silicone oil, propargyl alcohol and methyl propargyl alcohol, the content of vinyl in the base gel is 0.13%, the content of hydrogen in the hydrogen-containing silicone oil is 0.2%, the surfaces of silica gel materials are dried in about 5S at the temperature of about 50 DEG C, operating time is longer than 4H, and the silica gel meets elliptical machine operating requirements. The invention further discloses a preparation method of the elliptical machine light cover surface silica gel. The viscosity of the cover surface silica gel prepared by the method is about ten thousands, defoaming and leveling are the silica gel are accelerated, the silica gel cannot be embrittled, is suitable for elliptical machine operation and good in physical performance and has long operation time, high vulcanization, defoaming and leveling speed.

Owner:广东省良展有机硅科技有限公司

Settleability water base grinding fluid and preparation method thereof

ActiveCN103131331AReduce surface tensionReduce pollutionAqueous dispersionsEthylenediamineWater based

The invention provides settleability water base grinding fluid and a preparation method thereof. The settleability water base grinding fluid comprises, by weight, the following ingredients: 5-20% of settling agents, 25-60% of antirust agents, 15-40% of lubricating agents, 1-3% of sterilizing agents and the balance water. The settling agents are selected from one or more mixtures of polyethylene dichloro ethyl ether tetramethyl ethylenediamine, polyglycerol and ethylene glycol butyl ether (EGBE). The settleability composite grinding fluid has the advantages of being good in settleability, rapid in defoaming, good in antirust effect, long in service life and high in comprehensive performance cost ratio.

Owner:广东恒昌科技润滑油有限公司

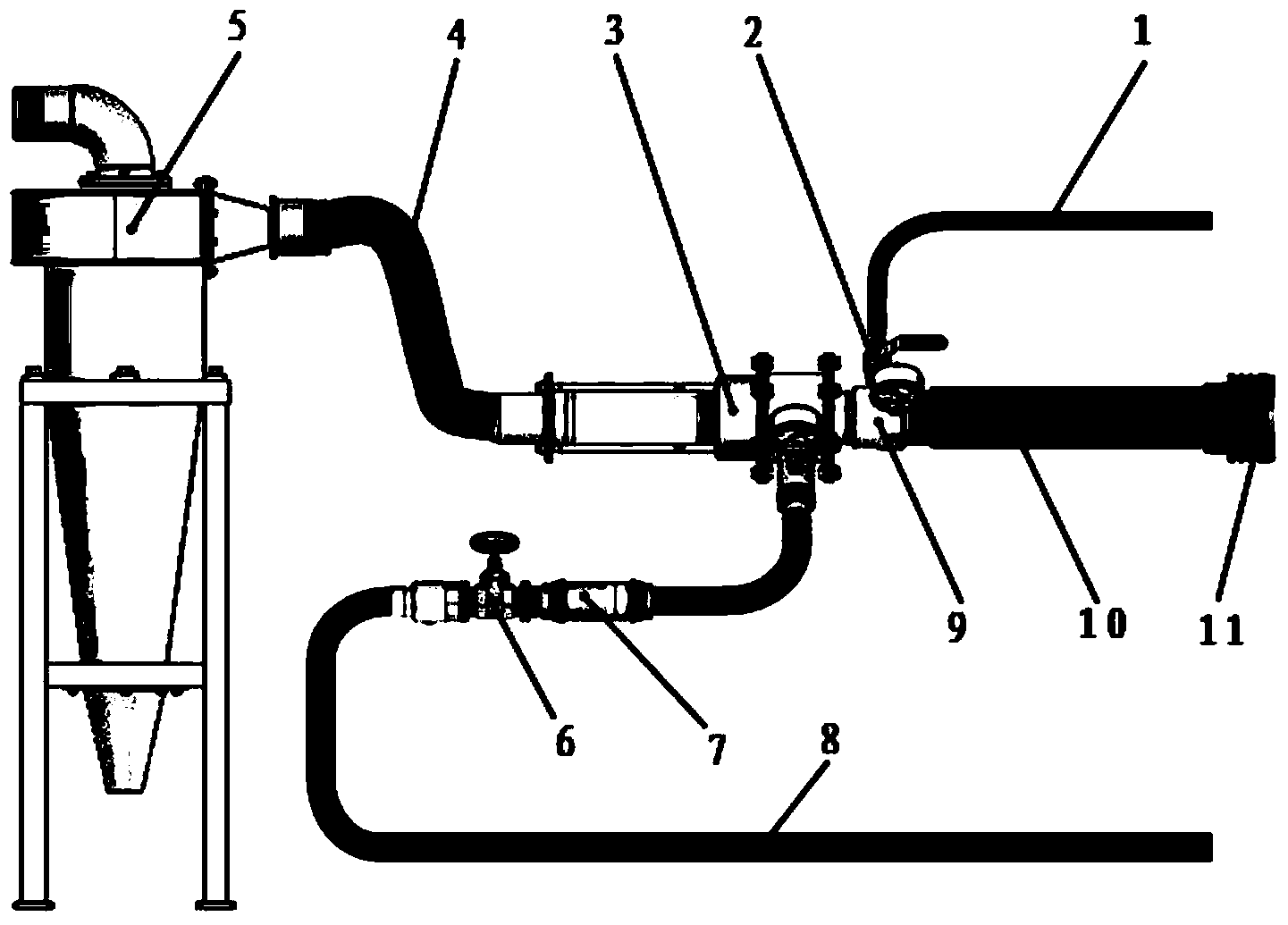

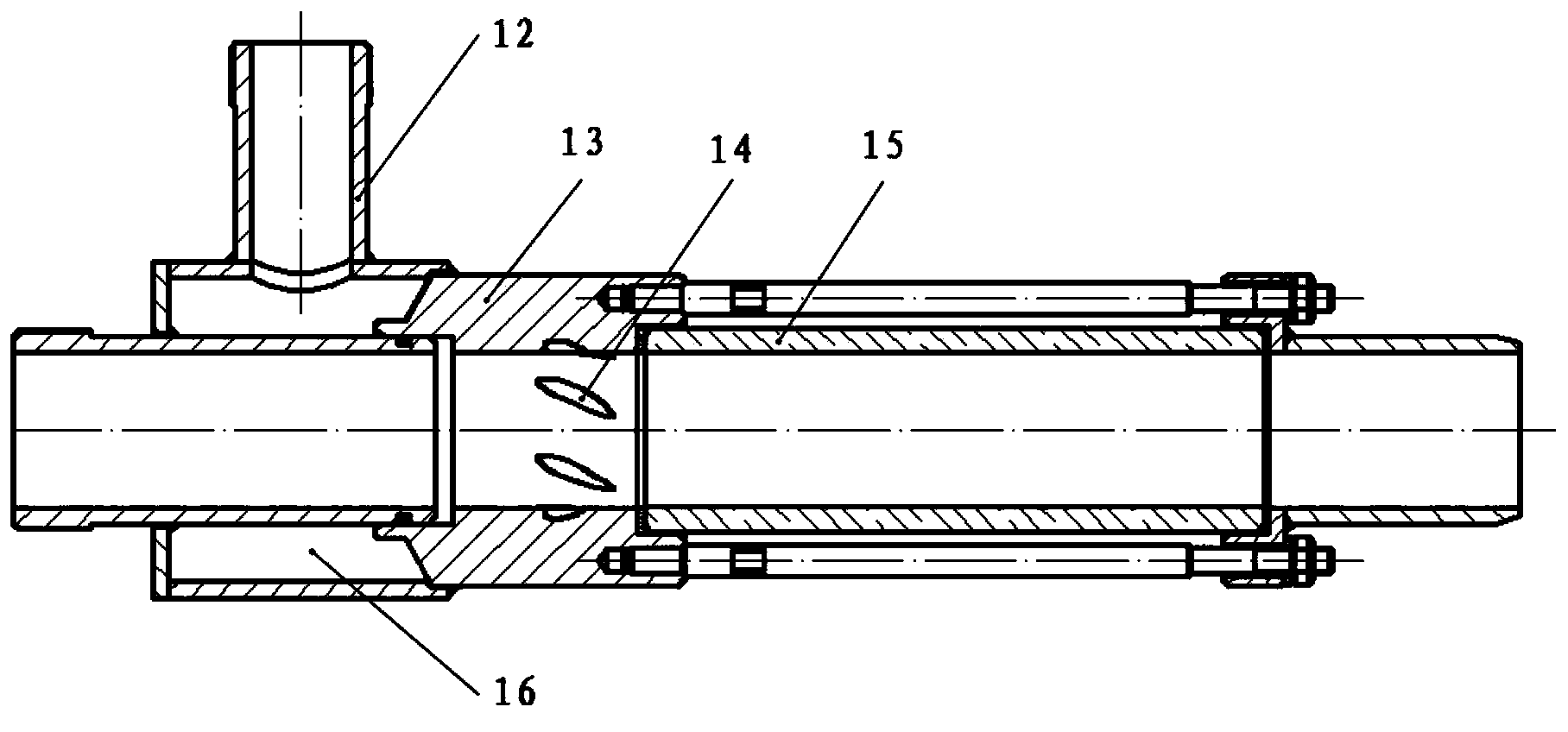

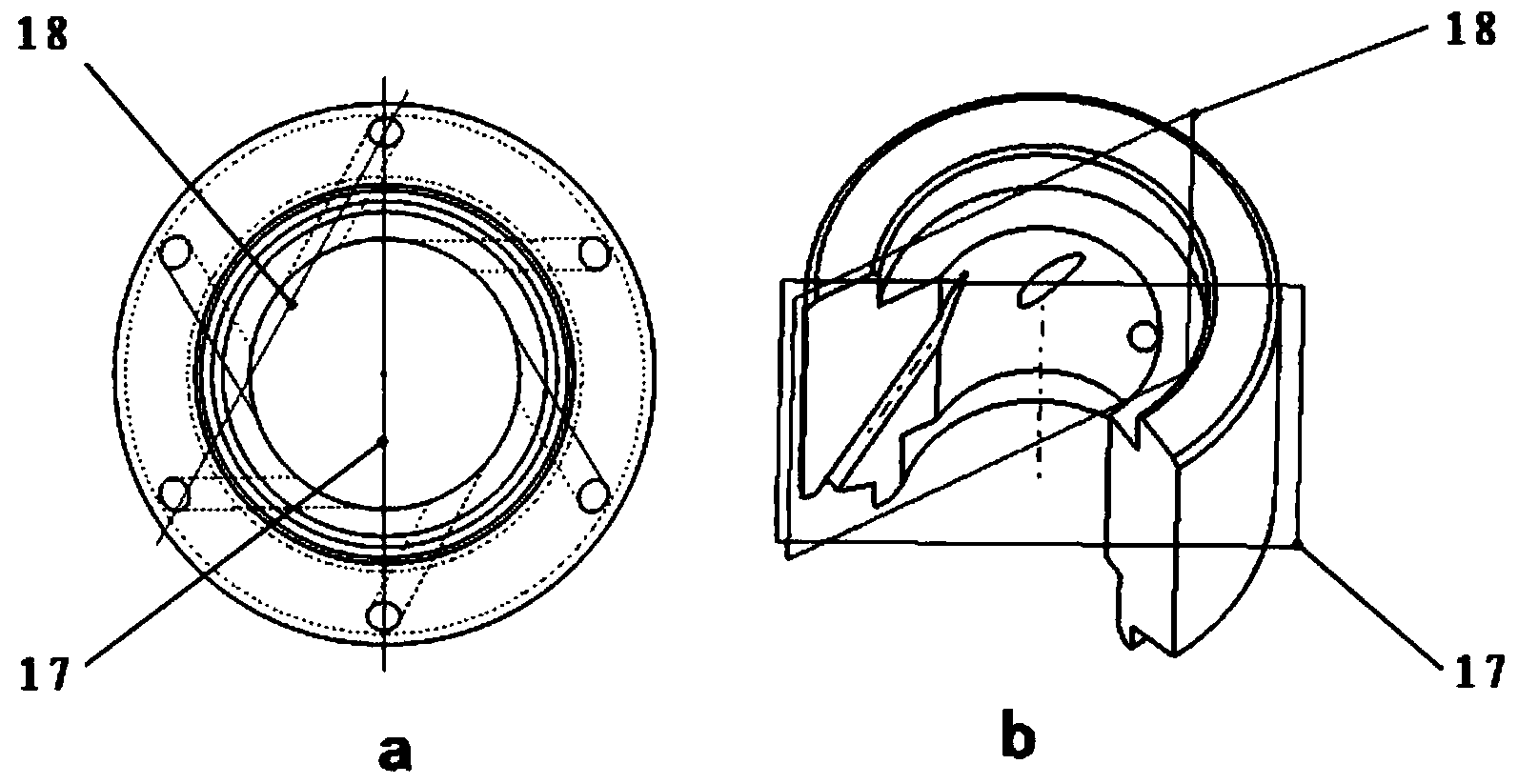

Defoaming device and method for coal-mine foam drilling

The invention discloses a defoaming device and method for coal-mine foam drilling. When a foam drilling process is utilized to perform construction of bedding gas drainage long boreholes among soft coal seams in the coal mine, the problems that waste foam accumulates in the drilling field for a long time and normal drilling construct operations are affected exist. According to the defoaming method, compressed air is adopted as a motive medium, wall-adherent jet is adopted as one single motive source, three technical manners of chemical defoaming, air flow jet defoaming and centrifugal defoaming are integrated, and the defoaming method has the advantages of reliable and rapid defoaming; the matching device is free of movable parts and electrical components, the requirements on explosion-proof performance of equipment in coal-mine construction operating environment can be met, and the defoaming device has the advantages of small size, lightweight performance and low requirements on place conditions.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

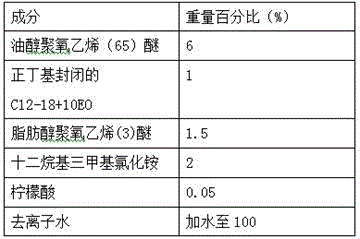

Water-based chain plate lubricating agent for soft beverage packages and preparation method of water-based chain plate lubricating agent

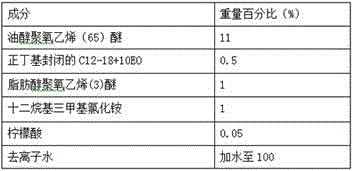

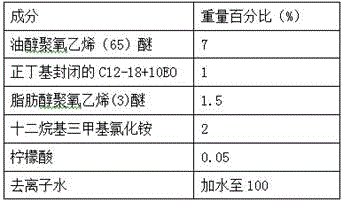

ActiveCN105886094AIncrease surface tensionReduce interface frictionLubricant compositionWater basedAlcohol

The invention relates to a water-based chain plate lubricating agent for soft beverage packages and a preparation method of the water-based chain plate lubricating agent. The water-based chain plate lubricating agent for soft beverage packages consists of the following raw materials in percentages by mass: 5-10% of alkyl alcohol polyoxyethylene ether, 1-3% of short EO chain fatty alcohol-polyoxyethylene ether, 0.5-1% of a foam control agent, 1-3% of a solubilizer, 0-0.2% of a pH regulator, and the balance of water. The water-based chain plate lubricating agent provided by the invention has the feature of good lubricating performance, and has the advantages of small surface tension, low bottle felling rate and low friction coefficient when used for lubricating the soft beverage packages.

Owner:GUANGZHOU TAISHENG BIOTECH

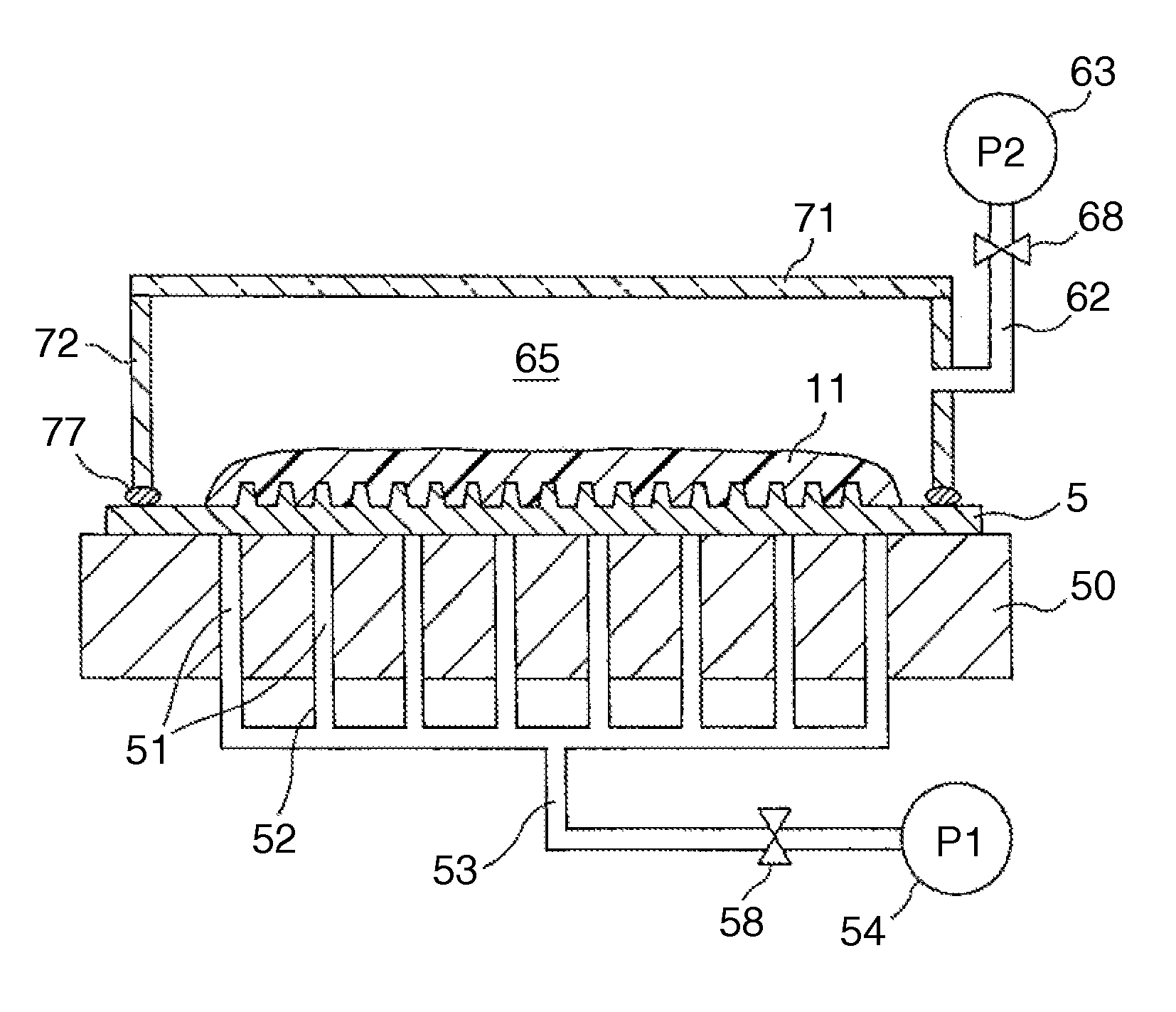

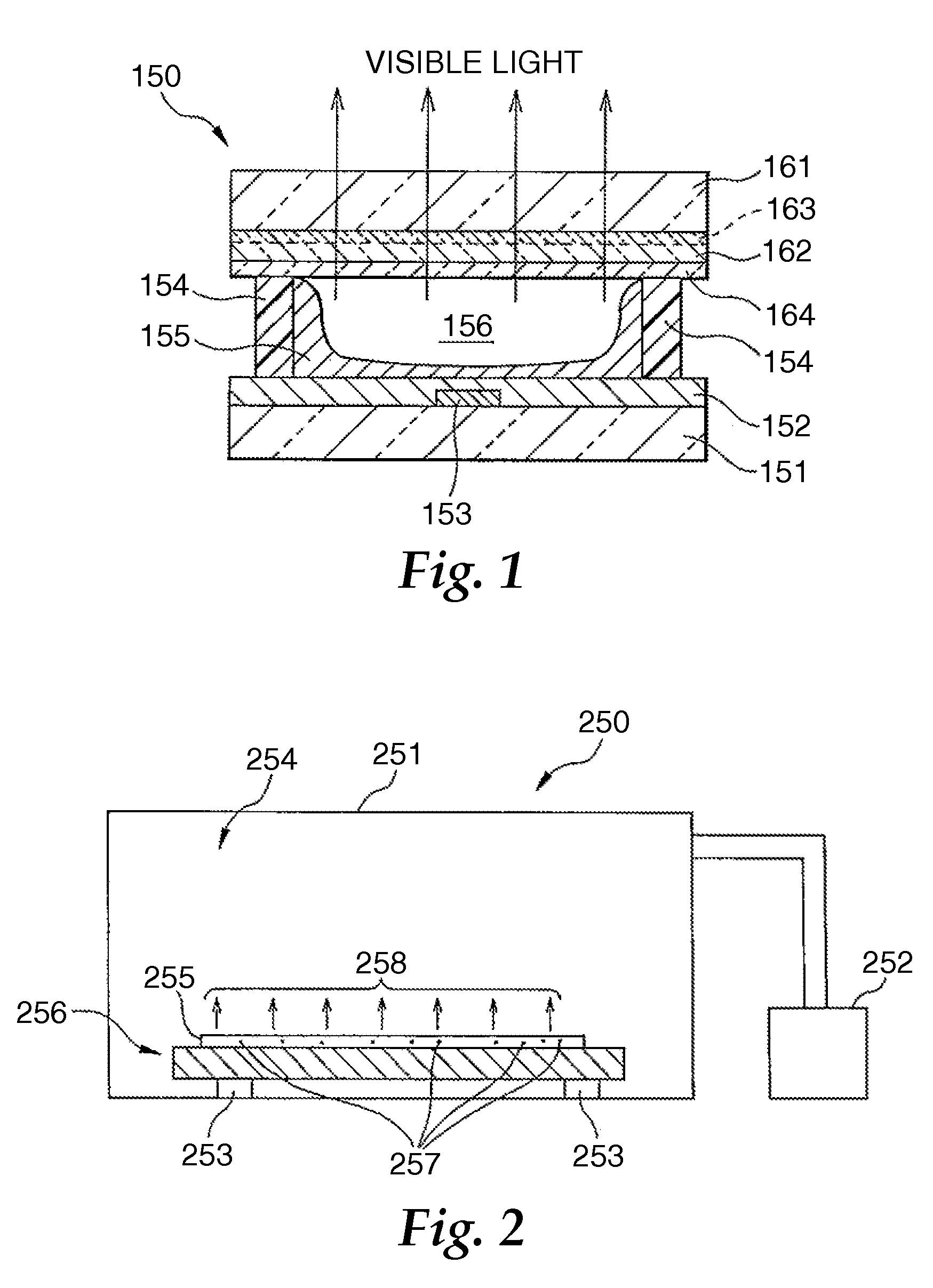

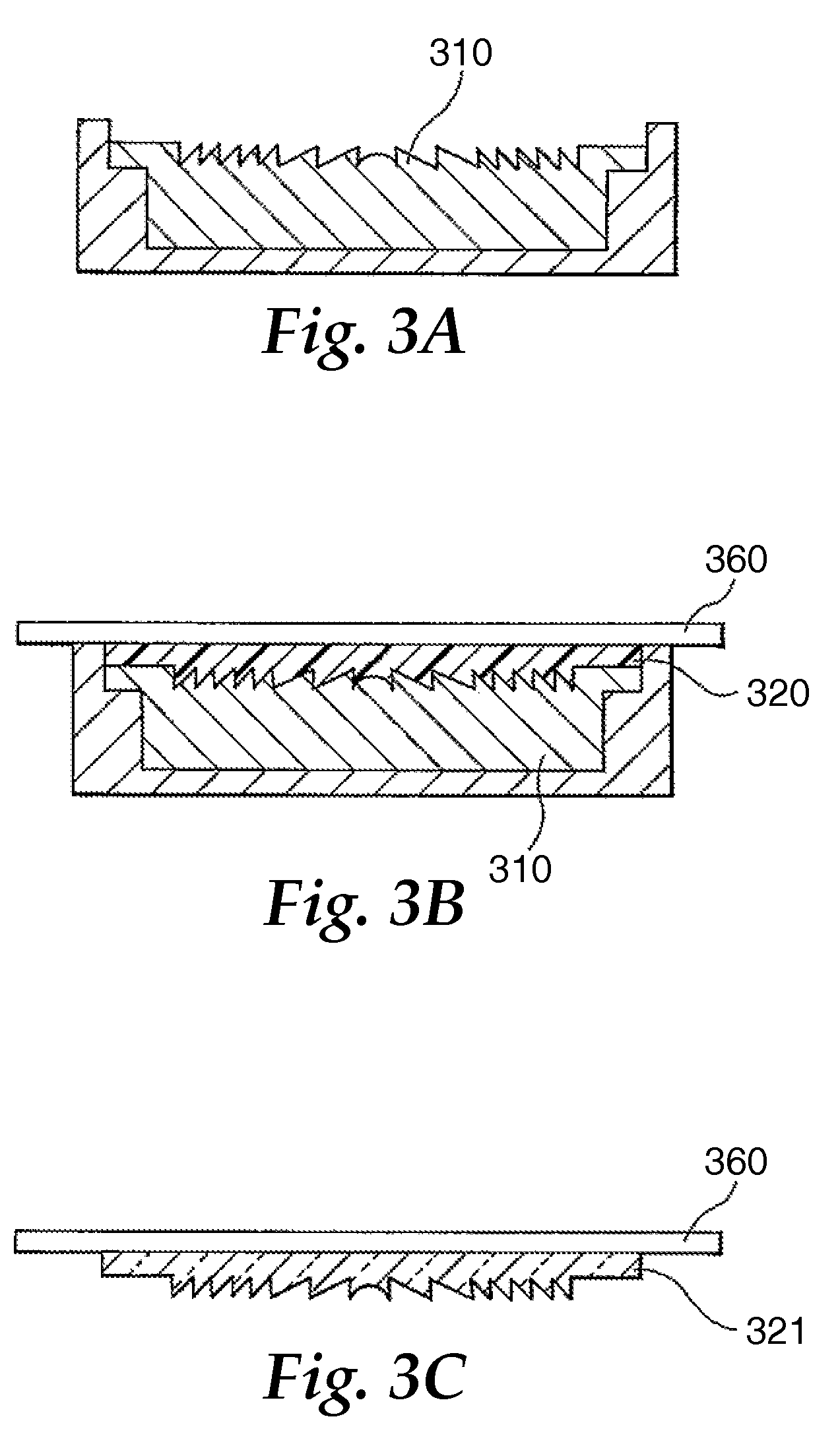

Defoaming method, defoaming device and manufacturing method of transfer mold

InactiveUS7722789B2Improve accuracyHigh yieldLiquid degasificationCeramic shaping apparatusAir bubble

Owner:3M INNOVATIVE PROPERTIES CO

Infant formula milk powder with quick bubble removal effect and production method of infant formula milk powder

The invention provides infant formula milk powder with a quick bubble removal effect and a production method of the infant formula milk powder. The method comprises the steps as follows: dissolving phospholipid in an oil raw material, then, dispersing the oil raw material in a milk powder liquid by homogenization, and introducing compressed gas before spray drying. The invention also provides theinfant formula milk powder with the quick bubble removal effect, produced by the method. The infant formula milk powder produced by the method is dissolved by brewing, can produce a large number of large bubbles after violent shaking and contains few small bubbles. The large bubbles further fuse and break quickly and basically completely disappear within 5-30 s. Under the same condition, bubbles of ordinary infant formula milk powder still exist after being placed for 30 min.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Compound-type de-foaming agent and preparation method thereof

InactiveCN104014165AChange performanceNo poisonFoam dispersion/preventionPolyethylene glycolPapermaking

The invention discloses a compound-type de-foaming agent. The compound-type de-foaming agent comprises the following raw materials in percentage by mass: 1-20 percent of modified silicon polyether, 5-70 percent of polyether modified siloxane, 3-50 percent of an emulsifying agent, 10-20 percent of polyethylene glycol, 1-10 percent of fatty alcohol and 2-15 percent of triglyceride. The compound-type de-foaming agent has the advantages of stable performance, high de-foaming speed and long foam inhibition time, does not poison sewage microorganisms, does not change the COD (chemical oxygen demand) and BOD (biochemical oxygen demand) of sewage, and is applicable to wastewater treatment of enterprises of papermaking, printing-dyeing, sugar refinery, pharmacy and leather.

Owner:吴朝东

Graphene modified organosilicone liquid defoaming agent

InactiveCN107469412AWith high temperature resistanceWith acid and alkali resistanceFoam dispersion/preventionHydrolysateAlkylphenol

Disclosed is a graphene modified organosilicone liquid defoaming agent. The agent is prepared from, by weight, 50-70 parts of organosilicone active matter, 20-30 parts of emulgator, 2-5 parts of graphene, 1-1.5 parts of thickening agent and 1-1.5 parts of coupling agent. The organosilicone active matter is formed by compounding one or more of methyl silicone oil, methyl phenyl silicone oil, ethyl silicone oil, polyether modified silicone oil and dimethyl siloxane hydrolysate; the emulgator is a non-ionic surface active agent and is formed by compounding one or more of alkylphenol polyoxyethylene ether, polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the thickening agent is formed by compounding one or more of hydroxymethyl cellulose, hydroxyethyl cellulose and hydroxypropyl cellulose. The defoaming agent has the performance of high temperature resistance, acid and alkali resistance and hydrophile of oxidized graphene, the defoaming performance of the defoaming agent can be enhanced, and the foam generating performance is inhibited. The invention further provides a preparation method of the defoaming agent.

Owner:徐州中泰能源科技有限公司

Casting epoxy resin composition for part repair

The invention relates to a casting epoxy resin composition for part repair, aims at achieving the technical purpose that the requirements of rapid curing at room temperature and excellent properties can be met simultaneously, and belongs to technical field of high-molecular polymers. The composition is characterized in that a preparation method of the composition comprises the steps that 1, preheated bisphenol A type epoxy resin, toughening type epoxy resin and a diluent are added into a reaction kettle in sequence, the temperature inside a stirring tank is maintained to be 50-70 DEG C, a defoamer is added, stirring and defoaming are conducted simultaneously, and a resin mixture is obtained; 2, aliphatic amine is added into another reaction kettle, stirring is started, the temperature inside a tank is maintained to be about 25-40 DEG C, alicyclic amine and an amine type accelerator are added in sequence, mixing and stirring are conducted continuously for 15-30 min, and a curing agent mixture is obtained; 3, the resin mixture and the curing agent mixture are mixed to be uniform according to the ratio of 100:(15-17), and the epoxy resin composition for part repair is obtained. The comprehensive performance of the product is excellent, and the composition has low viscosity and rapid curing speed and can meet curing requirements in different temperature environments.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

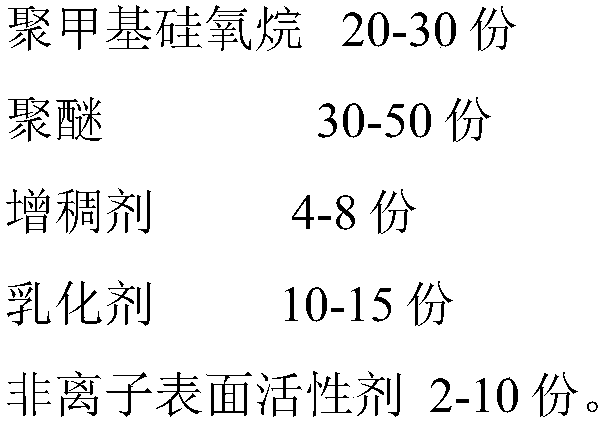

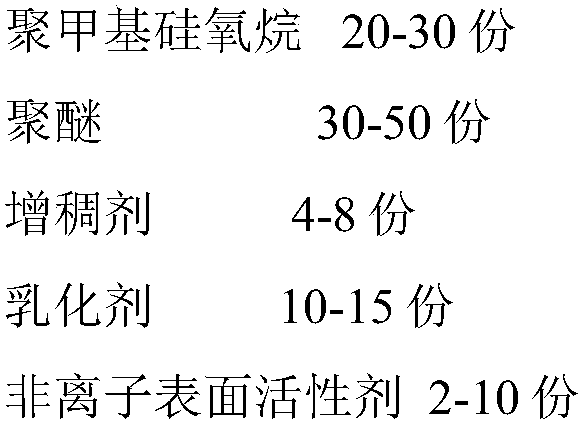

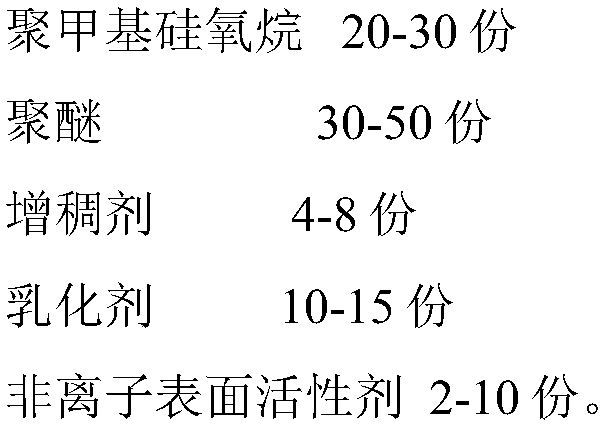

Oil field industry defoaming agent composition and preparing method thereof

InactiveCN107648890ASolve the defoaming problemFast defoamingFoam dispersion/preventionDefoaming AgentsEnvironmentally friendly

The invention provides an oilfield industrial defoamer composition, which is prepared from the following components in parts by mass: 20-30 parts of polymethylsiloxane, 30-50 parts of polyether, and 4-50 parts of thickener 8 parts, 10-15 parts of emulsifier, 2-10 parts of nonionic surfactant, the defoamer composition can efficiently eliminate and suppress foaming, stable performance, less dosage, non-toxic and environmentally friendly.

Owner:SICHUAN KELIXIN NEW MATERIALS CO LTD

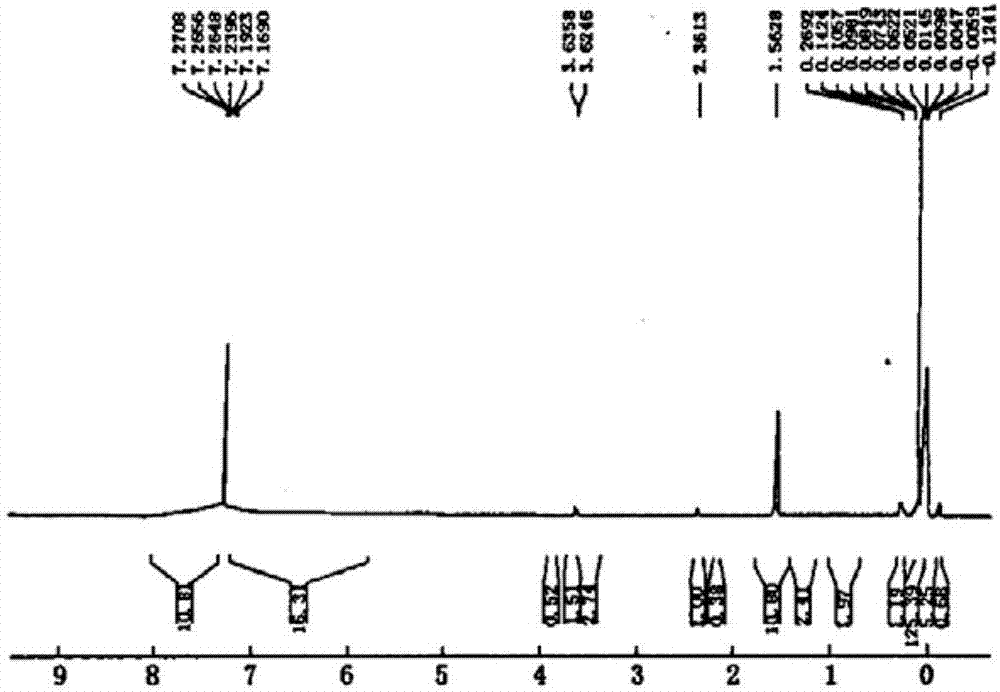

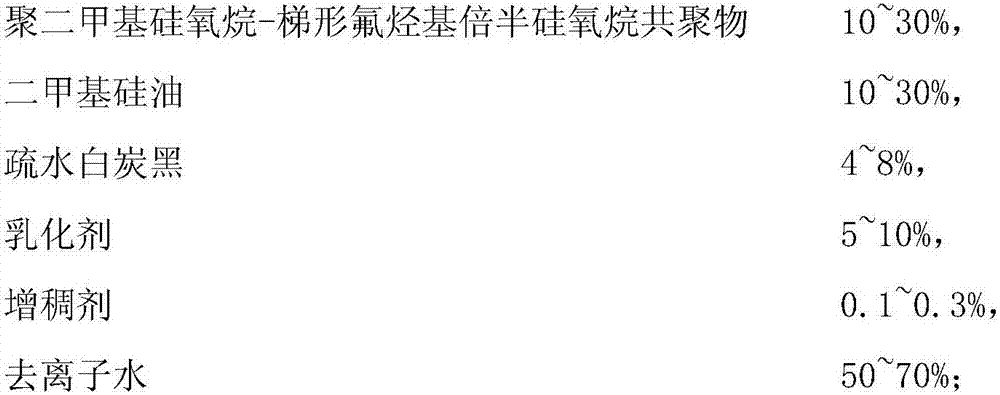

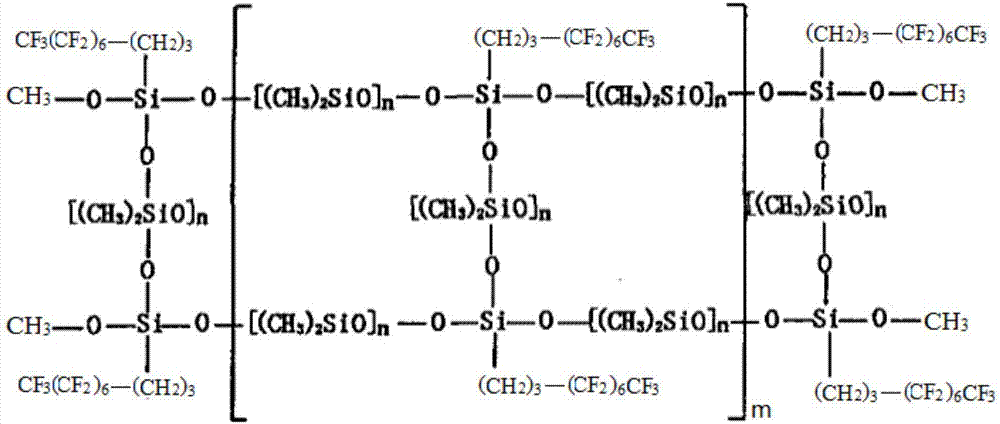

Organic silicon antifoaming agent with polymers and preparation method thereof

ActiveCN107469414AFast defoamingLong-lasting foam suppressionFoam dispersion/preventionEmulsionEmulsion polymerization

The invention discloses an organic silicon antifoaming agent with polydimethylsiloxane-trapezoid fluoro-hydrocarbons radical silsesquioxane copolymer and a preparation method thereof. The organic silicon antifoaming agent is prepared from, by weight, 10-30% of polydimethylsiloxane-trapezoid fluoro-hydrocarbons radical silsesquioxane copolymer, 10-30% of simethicone, 4-8% of hydrophobic white carbon black, 5-10% of emulgator, 0.1-0.3% of thickener and 50-70% of deionized water. The organic silicon antifoaming agent is quick in defoaming, lasting in foam inhibition and stable in emulsion, shrinkage cannot be caused on base materials such as PVC thin film, and the agent is wide in application range. The organic silicon antifoaming agent is simple in preparation technology and low in product cost, and the product has excellent defoaming effect on emulsion polymerization reaction in particular to polyurethane emulsion polymerization reaction.

Owner:优美特(北京)环境材料科技股份公司

Defoaming agent for sewage treatment and preparation method of defoaming agent

InactiveCN105836833AGood stabilityLow costEnergy based wastewater treatmentWater/sewage treatment by degassingChemistryStearic acid

The invention discloses a defoaming agent for sewage treatment and a preparation method of the defoaming agent. The defoaming agent comprises the following raw materials by weight: modified silicone polyether, polyether siloxane, an emulsifying agent, polyethylene glycol, diethanol glycerolipid, ethylene bis stearamide, heavy liquid paraffin, dimethyl silicon oil, white carbon black, compound fatty acid salt, a texturing agent, propylene glycol stearic acid ester, a dispersant and a stabilizer, wherein the texturing agent comprises more than two types of chemical substance in molasses, polyaluminium chloride, polyaluminium sulfate, aluminum sulfate, calcium chloride and modified bentonite. The defoaming agent is good in stability and low in cost, greatly reduces the sewage treatment cost, does not cause secondary pollution, has high effect on reducing surface tension, has good and rapid defoaming and antifoaming effect, does not poison microorganisms in sewage, does not change COD and BOD performances of the sewage, and is beneficial to the subsequent water treatment technology, simple in production process and convenient to use.

Owner:张能力

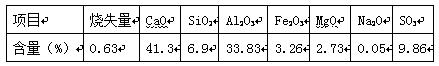

High corrosion resistant marine cement cementing material and preparation method thereof

The invention relates to the construction field, and in particular relates to a high corrosion-resistant marine cement cementing material and a preparation method thereof, and the high corrosion-resistant marine cement cementing material comprises 20-25 parts of wollastonite; 80-100 parts of sulphoaluminate cement; 30-50 parts of nano-like hydrotalcite; 20-30 parts of fiber; 80-100 parts of coralreef sand; 50-60 parts of polyacrylamide; 20-30 parts of modified acrylic emulsion and 10-15 parts of additives; the invention aims to overcome the defects of the prior art and provide the high corrosion-resistant marine cement cementing material and the preparation method thereof. The high corrosion-resistant marine cement cementing material has the characteristics of good mechanical strength, durability and corrosion resistance, improved bending strength, improved cement density, better flocculation property, capability of reducing friction resistance between liquids, excellent impermeability, quick hardening, early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

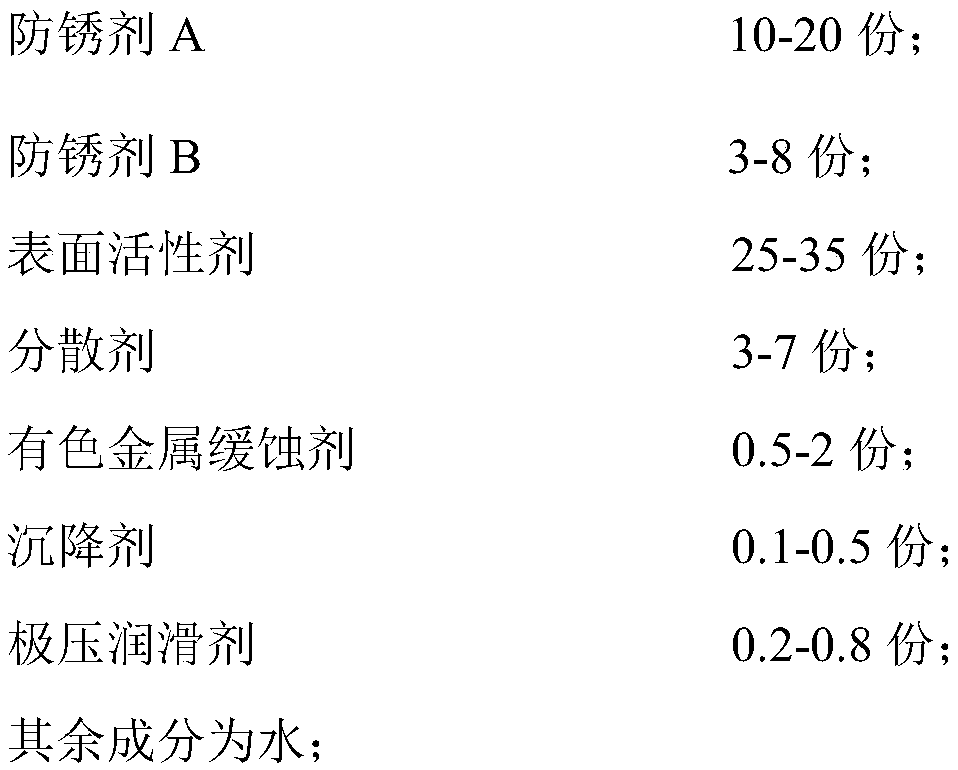

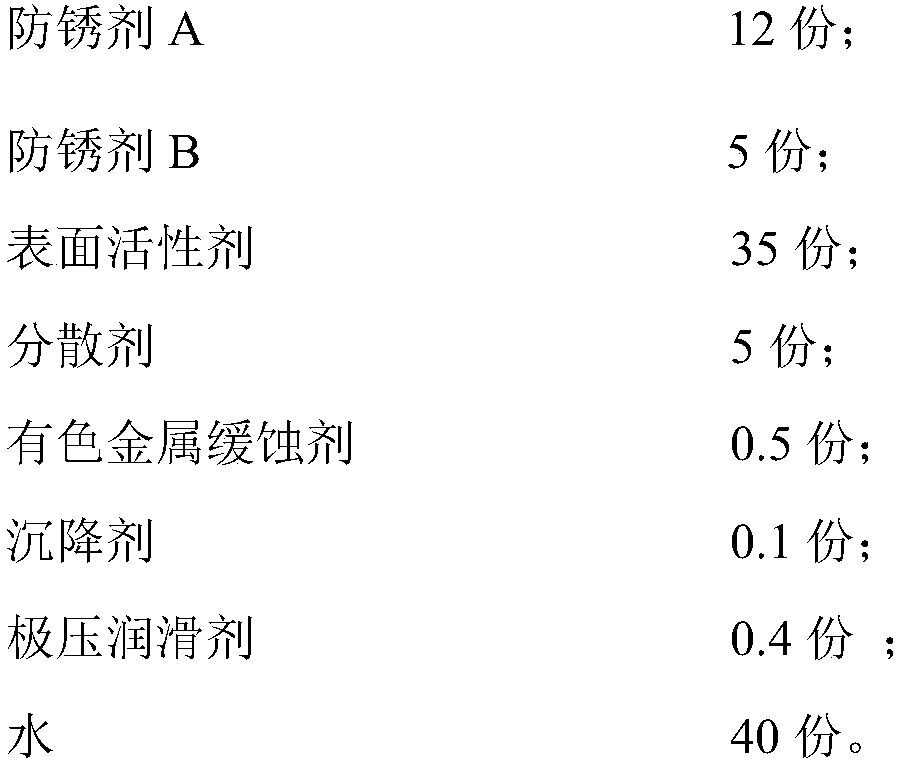

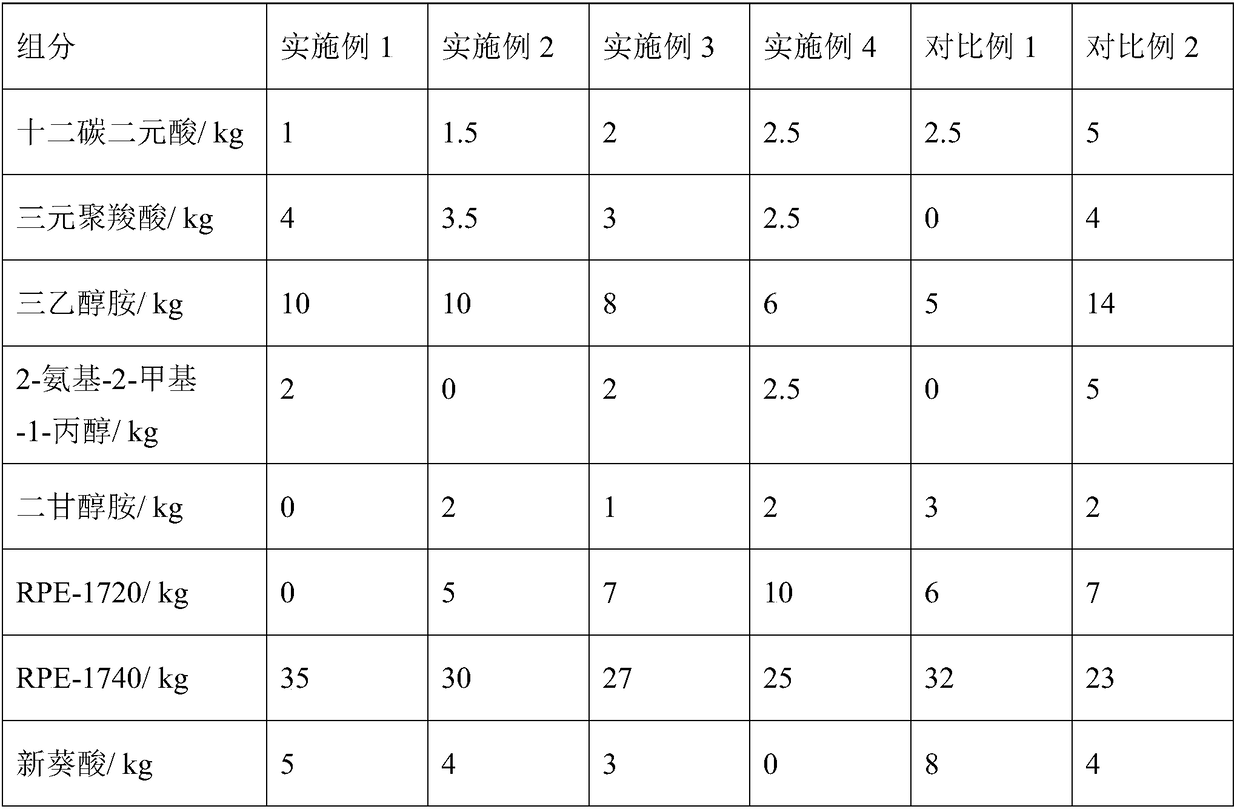

Synthesized high-gloss cutting fluid for smart phone frame and preparation method of cutting fluid

ActiveCN108998183AFast defoamingImprove processing qualityLubricant compositionWater basedEngineering

The invention discloses a synthesized high-gloss cutting fluid for a smart phone frame. The cutting fluid comprises the following components in parts by weight: 10-20 parts of a rust inhibitor A, 3-8parts of a rust inhibitor B, 25-35 parts of a surfactant, 3-7 parts of a dispersing agent, 0.5-2 parts of a nonferrous metal corrosion inhibitor, 0.1-0.5 part of a settling agent, 0.2-0.8 part of an extreme pressure lubricant and the balance of water. The invention further provides a preparation method of the synthesized high-gloss cutting fluid. The cutting fluid provided by the invention is a water-based completely-transparent liquid, so that a clean environment of a processing site is guaranteed. Rapid defoaming can be finished within 5 seconds, and the processing state of a workpiece can be clearly observed during a using process, so that the product processing quality is guaranteed. Nano particles are selected as the extreme pressure lubricant, and a maximum non-seizure load value canbe up to 1380 N, so that the anti-friction and anti-wear performance of the cutting fluid is greatly improved. The hard water adaptability is up to 20000 ppm, and the dispersion characteristic of calcium soaps and magnesium soaps are achieved, so that the cutting fluid has extremely high hard water resistance. Long-term stability of lubricating performance and cleaning performance of the cuttingfluid is guaranteed, and the service life of the cutting fluid is prolonged.

Owner:广州市方川润滑科技有限公司

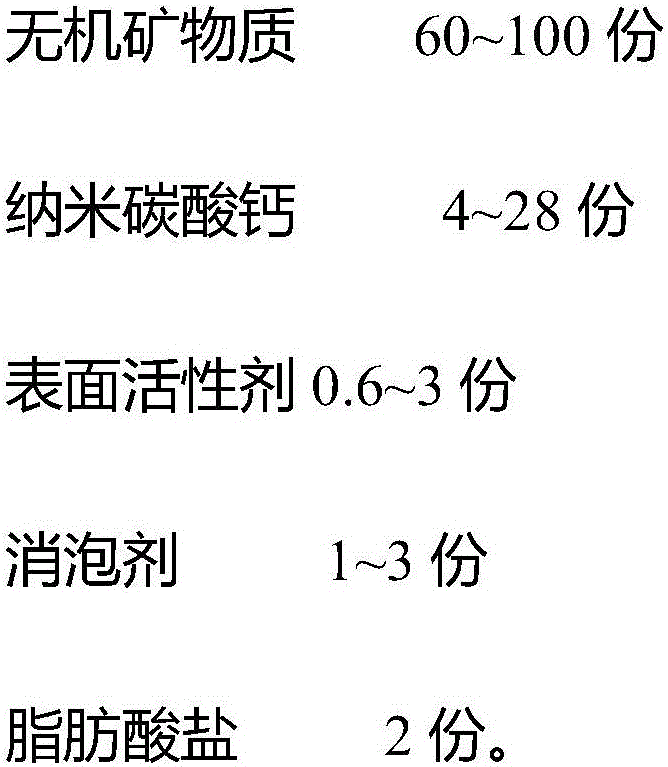

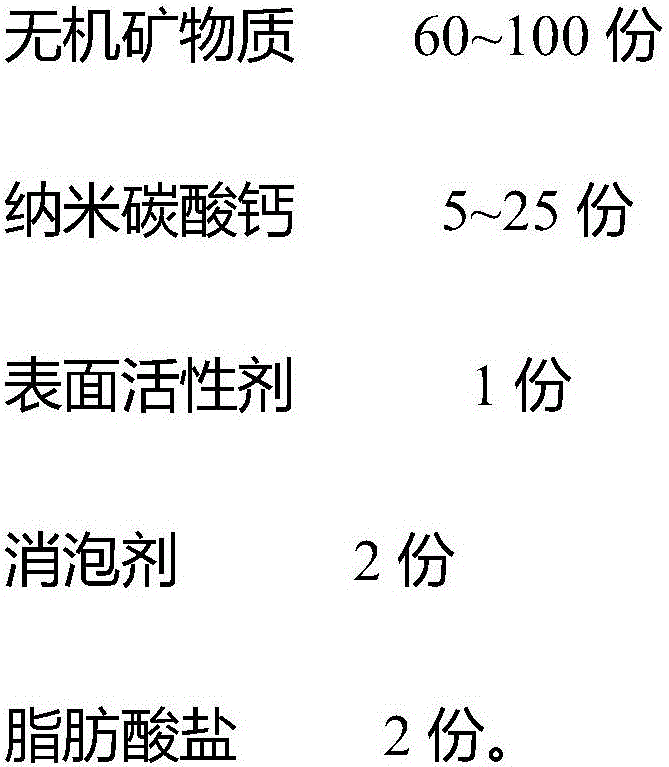

Powdered rubber isolating agent

The invention discloses a powdered rubber isolating agent which is prepared from the following raw materials in parts by weight: 50-110 parts of inorganic minerals, 3-30 parts of nanometer calcium carbonate, 0.5-5 parts of a surfactant, 0.5-5 parts of a defoamer and 1-3 parts of fatty acid. The powdered rubber isolating agent is little in foaming, rapid in defoaming and not liable to precipitation, does not have influence on the performance of rubber, is used for airing a film without powder dropping from the surface and has excellent isolation effect on the film.

Owner:XIAMEN BAOXIANG PLASTIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com