Oil field industry defoaming agent composition and preparing method thereof

A technology of composition and defoamer, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as unsatisfactory defoaming effect, high viscosity, large dosage, etc., and achieve excellent defoaming and suppression Good compatibility, anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

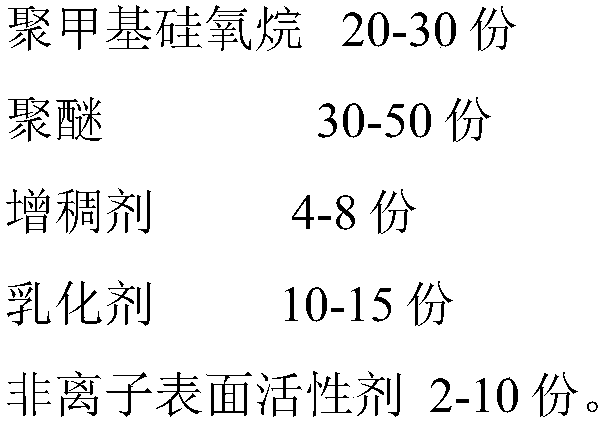

[0024] An oilfield industrial defoamer composition is prepared from the following components in parts by mass:

[0025]

[0026]

[0027] The viscosity of the polymethylsiloxane at 25°C is 10000cst, and the structural formula of the polyether is C 8 h 17 O(EO) 15 (PO) 29 H, the nonionic surfactant is a nitrogen-containing nonionic surfactant, the thickener can be selected from diatomaceous earth, and the emulsifier can be selected from octylphenol polyoxyethylene ether.

Embodiment 2

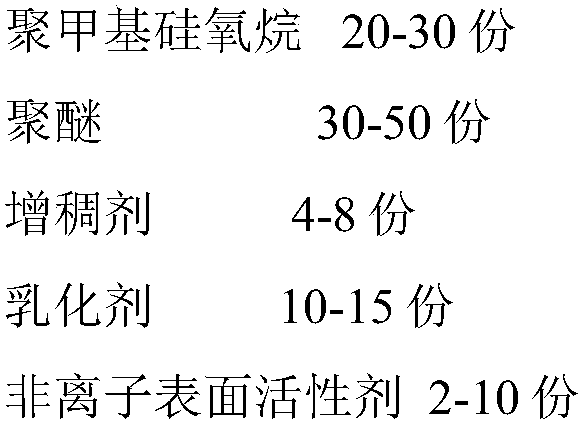

[0029] An oilfield industrial defoamer composition is prepared from the following components in parts by mass:

[0030]

[0031] The viscosity of the polymethylsiloxane at 25°C is 20000cst, and the structural formula of the polyether is C 10 h 21 O(EO) 3 (PO) 20 H, the nonionic surfactant is a nitrogen-containing nonionic surfactant, the thickener can be selected from hydroxyethyl cellulose, and the emulsifier can be selected from nonylphenol polyoxyethylene ether.

Embodiment 3

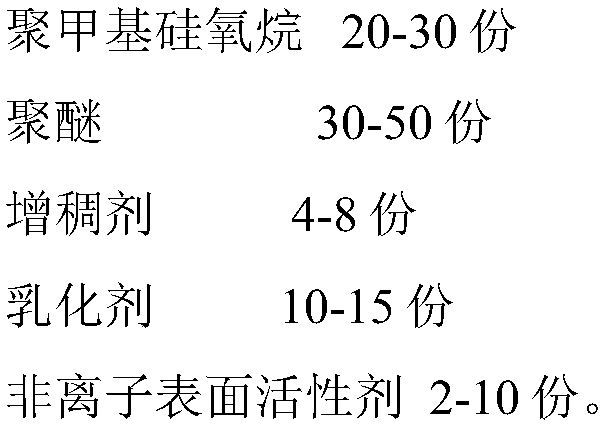

[0033] An oilfield industrial defoamer composition is prepared from the following components in parts by mass:

[0034]

[0035] The viscosity of the polymethylsiloxane at 25°C is 50000cst, and the structural formula of the polyether is C 16 h 33 O(PO) 75 H, the emulsifier is an alkyl sulfate, the nonionic surfactant is a nitrogen-containing nonionic surfactant, the thickener can be selected from fumed silica, and the emulsifier can be selected from temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com