Mineral oil antifoam agent and production method thereof

A mineral oil and defoamer technology, applied in chemical instruments and methods, foam dispersion/prevention, chemical/physical processes, etc., can solve high dosing concentration, high water solubility of silicone oil, poor defoaming performance of emulsified silicone oil, etc. problems, to achieve the effects of rapid defoaming, long anti-foaming period, and reduced use costs

Inactive Publication Date: 2008-11-26

ZHEJIANG FORESTRY UNIVERSITY

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in the same scope of application of the defoamers mentioned above, there are silicone defoamers and polyether (ie non-silicone) defoamers, but there are still many unsatisfactory silicone defoamers. Disadvantages: Poor defoaming performance of emulsified silicone oil, too high concentration; difficult to control the dosage of Taikoo oil, and difficult to control the anti-foaming effect; high water solubility of silicone oil, it needs a larger dosage to be effective, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

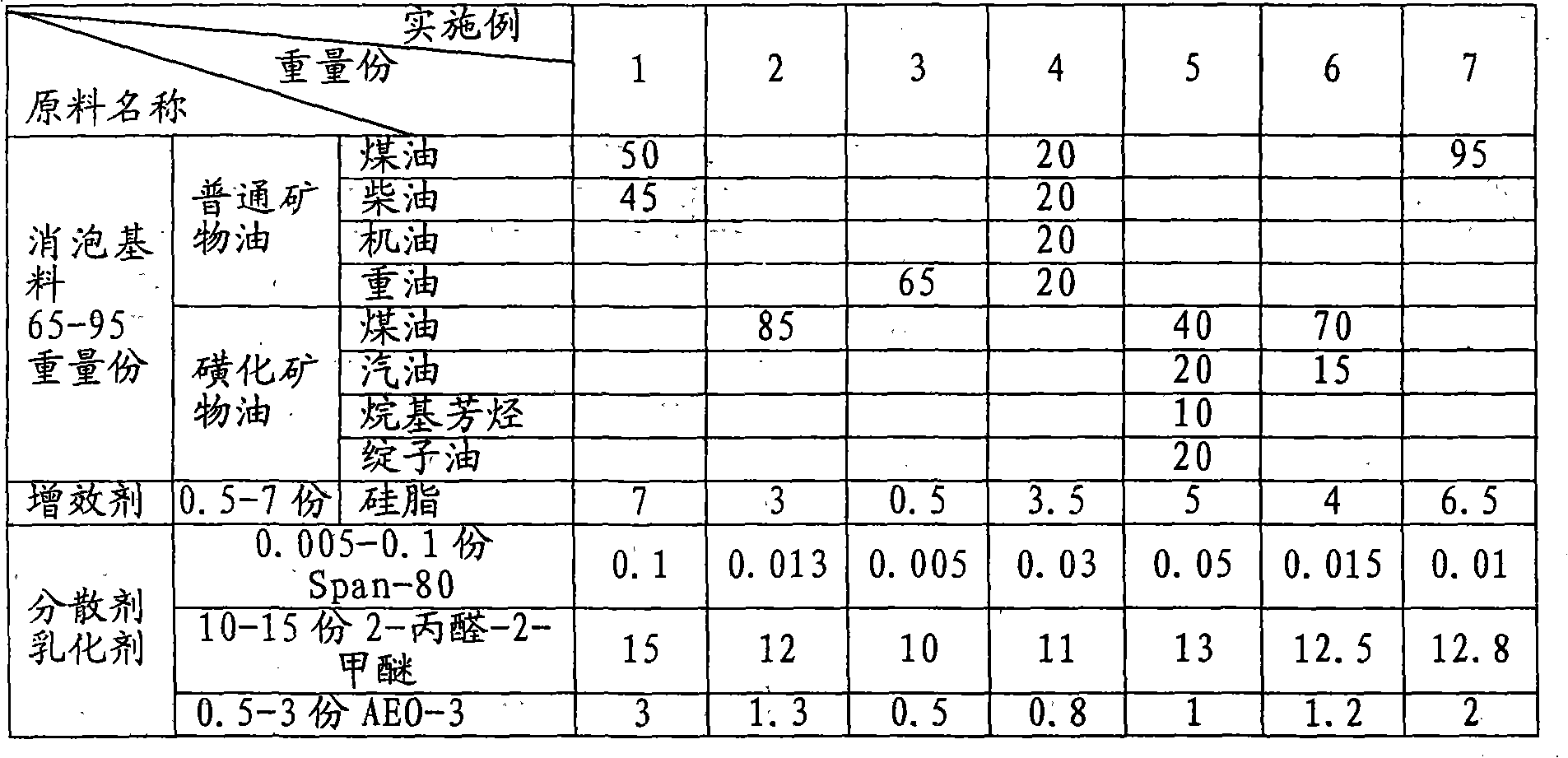

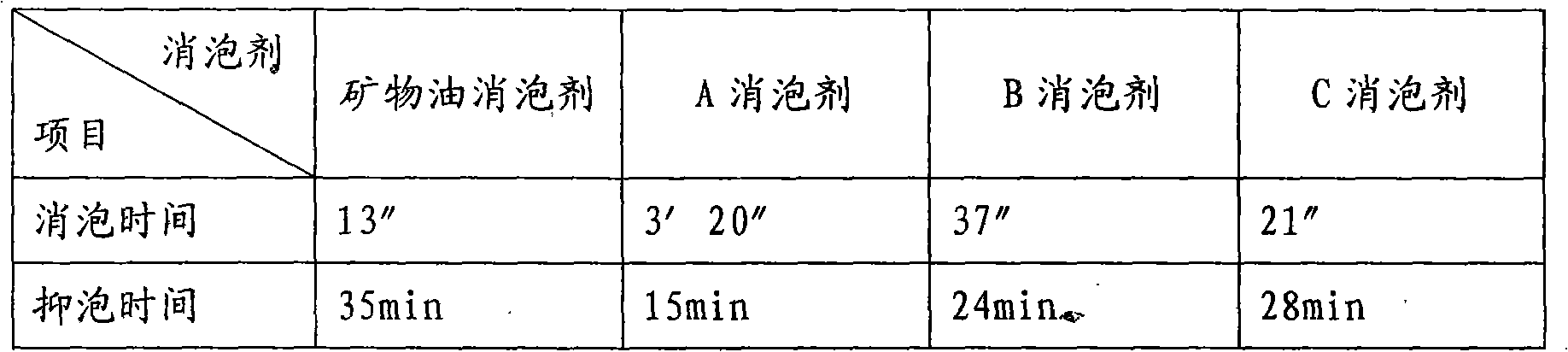

The invention relates to a mineral oil defoamer and a production method thereof, the mineral oil deforamer is composed of raw materials with the following parts by weight: 65 to 95 parts by mineral oil, 0.5 to 7 parts of silicon grease, 0.005 to 0.1 part of Span-80, 10 to 15 parts of 2-propanal-2-methyl ether and 0.5 to 3 parts of AEO-3; the mineral oil defoamer is colorless or light yellow or light brown oily liquid, the specific gravity is 0.87 to 0.95g / ml, the pH is equal to 6.5 to 8.0, the lead content is less than or equal to 5ppm, the defoaming rate is more than or equal to 95 percent and the foam suppressing rate is more than or equal to 95 percent; the production process is as follows, the raw materials are weighted for preparing the materials according to the mix ratio, the prepared mineral oil is poured in a reaction kettle, the silicon grease is added, the stirring is carried out, the temperature raises to 60 to 80 DEG C, the temperature is kept for 50 to 70min, and other three raw materials are sequentially added during the full stirring for preparation. The defoamer is applied in oil production, well drilling, oil-gas separation, oil fermentation, oil ink production, waste water treatment and other processes, thus having the advantages of small using amount, stable effect, rapid defoaming, long foam suppressing time and low using cost, etc.

Description

technical field The invention relates to a defoamer used in processes such as oil extraction, well drilling, oil-gas separation, petroleum fermentation, ink production, especially waste water treatment, and a production method thereof. Background technique At present, in the same scope of application of the defoamers mentioned above, there are silicone defoamers and polyether (ie non-silicone) defoamers, but there are still many unsatisfactory silicone defoamers. Disadvantages: emulsified silicone oil has poor defoaming performance, and the concentration is too high; it is difficult to control the dosage of Swire oil, and the effect of defoaming and antifoaming is not easy to control; silicone oil is highly water-soluble, and it needs a large dosage to be effective, etc. All these show that the silicone defoamer needs to be improved, while reducing the cost and improving the overall performance. CN85105343A discloses the patent technology of "solid dispersion defoamer" of J...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D19/04B01F17/00C09K23/00

Inventor 肖继波张立钦

Owner ZHEJIANG FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com