Organic silicon antifoaming agent with polymers and preparation method thereof

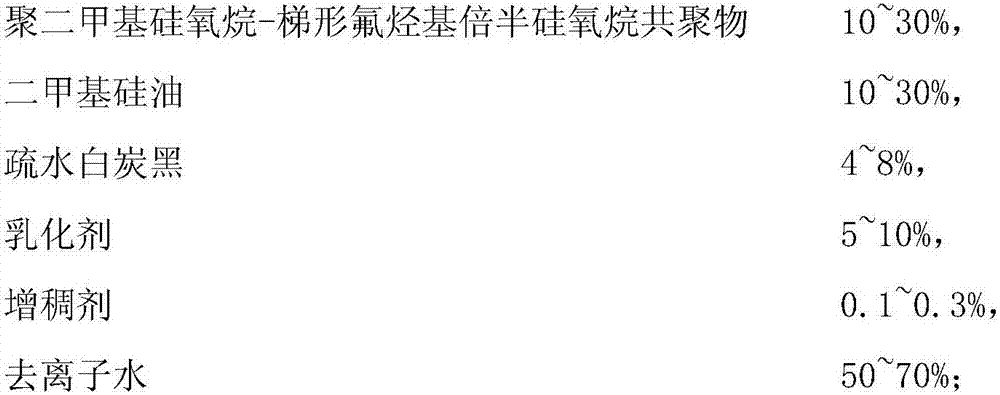

A technology of silicone defoamer and polydimethylsiloxane, which is applied in the field of silicone additives, can solve the problems of large differences in the solubility parameters of silicone additives, and achieve good defoaming and anti-foaming effects, dilution Better stability and emulsion stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

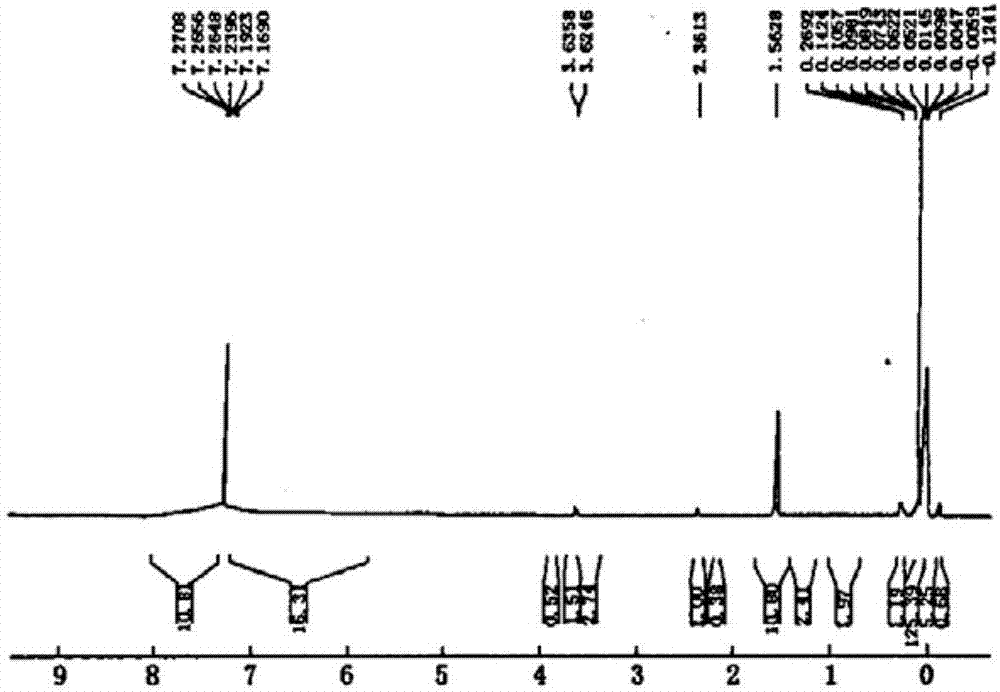

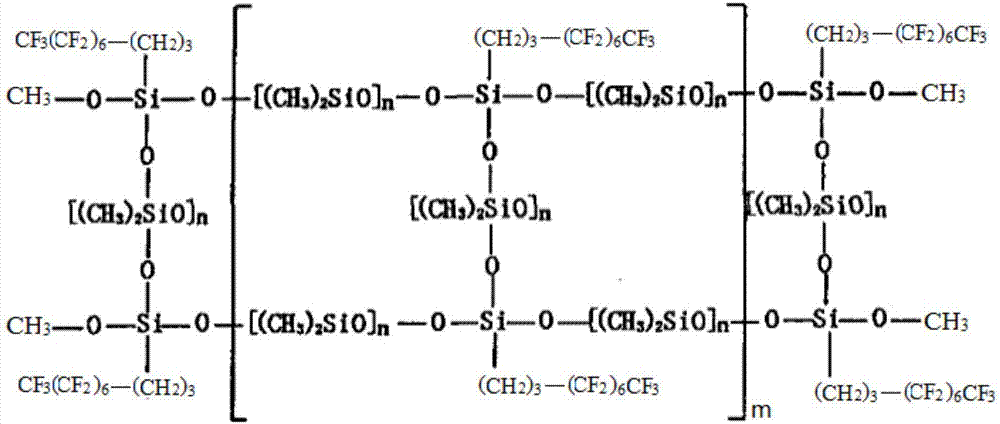

[0034] Dissolve 100g of 100g / mol hydroxy silicone oil in 50g of toluene, and 585g of dodecafluoroheptylpropyltrimethoxysilane in 200g of ethanol, and then add them in turn to a 2000mL three-necked flask equipped with a stirring blade, a reflux condenser and a thermometer , after stirring until pure and transparent, adjust pH=12 with saturated NaOH solution, and react at 80°C for 6h. Then distilled under reduced pressure at 150°C to obtain polydimethylsiloxane-ladder fluorocarbon silsesquioxane copolymer;

[0035] Knead 200g of simethicone oil, 200g of polydimethylsiloxane-trapezoidal fluorocarbon silsesquioxane copolymer, and 40g of hydrophobic silica in a double planetary mixer, and then stir for 30min with a disperser at 1000r / min. Add 50g of emulsifier, stir at 1000r / min for 30min, add dropwise 400g of deionized water for 30min, add dropwise 1% thickener aqueous solution made of 1g of thickener and 100g of deionized water, stir at 1000r / min for 30min, and obtain the A sili...

Embodiment 2

[0037] Dissolve 150g of 300g / mol hydroxy silicone oil in 100g of toluene, 320g of dodecafluoroheptylpropyltrimethoxysilane in 100g of ethanol, and then add them in turn to a 2000mL three-necked flask equipped with a stirring paddle, a reflux condenser and a thermometer. After stirring until pure and transparent, adjust pH=13 with KOH saturated solution, and react at 70°C for 7h. Then distilled under reduced pressure at 140°C to obtain polydimethylsiloxane-ladder fluorocarbon silsesquioxane polymer;

[0038] Knead 300g of simethicone oil, 100g of polydimethylsiloxane-trapezoidal fluorocarbon silsesquioxane copolymer, and 50g of hydrophobic white carbon black in a double planetary mixer, and then stir with a disperser at 1000r / min for 30min. Add 60g of emulsifier, stir at 1500r / min for 30min, add dropwise 400g of deionized water for 30min, then dropwise add 1% thickener aqueous solution made of 1.5g of thickener and 150g of deionized water, and stir at 1500r / min for 30min to obt...

Embodiment 3

[0040] Dissolve 200g of 600g / mol hydroxyl silicone oil in 100g of toluene, and 231g of dodecafluoroheptylpropyltrimethoxysilane in 100g of ethanol, and then add them in turn to a 2000mL three-necked flask equipped with a stirring blade, a reflux condenser and a thermometer. After stirring until pure and transparent, adjust pH=14 with NaOH saturated solution, and react at 60°C for 6.5h. Then distilled under reduced pressure at 130°C to obtain polydimethylsiloxane-ladder fluorocarbon silsesquioxane polymer;

[0041] Knead 100g of simethicone oil, 300g of polydimethylsiloxane-trapezoidal fluorocarbon silsesquioxane copolymer, and 60g of hydrophobic silica in a double planetary mixer, and then stir for 30min with a disperser at 1500r / min. Add 80g of emulsifier, stir at 2000r / min for 30min, add dropwise 400g of deionized water for 30min, add dropwise 1% thickener aqueous solution made of 2g of thickener and 200g of deionized water, stir at 2000r / min for 30min, and obtain the A sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com