Synthesized high-gloss cutting fluid for smart phone frame and preparation method of cutting fluid

A technology for smart phones and cutting fluids, applied in lubricating compositions, petroleum industry, etc., can solve problems such as short service life, mildew, water pollution, etc., to avoid tool blockage and wear, improve friction and anti-wear performance, and reduce cleaning. the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

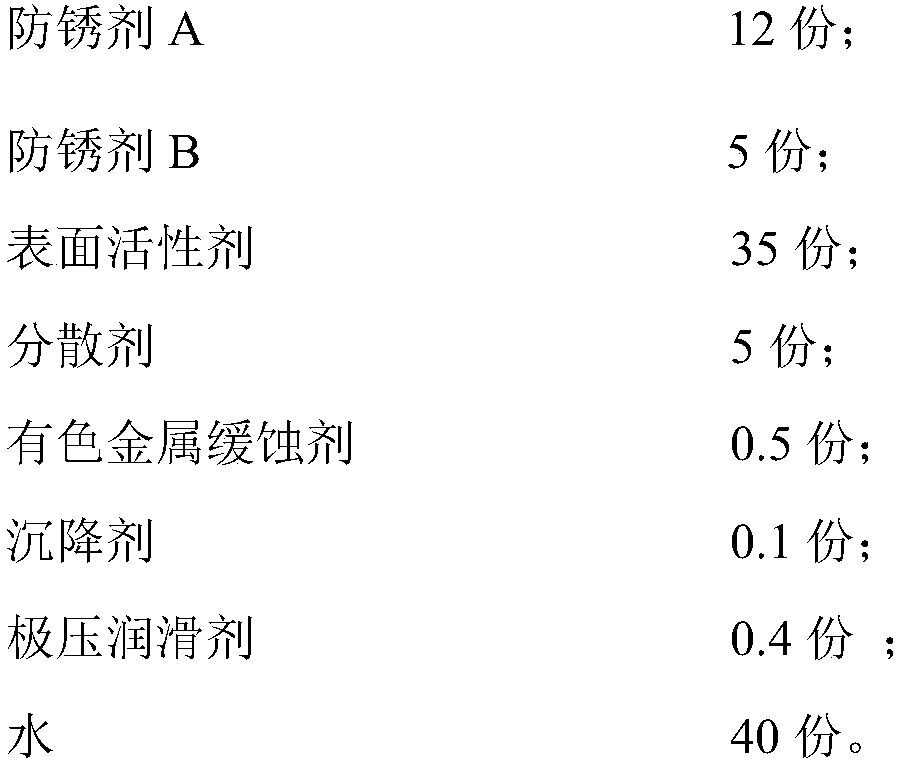

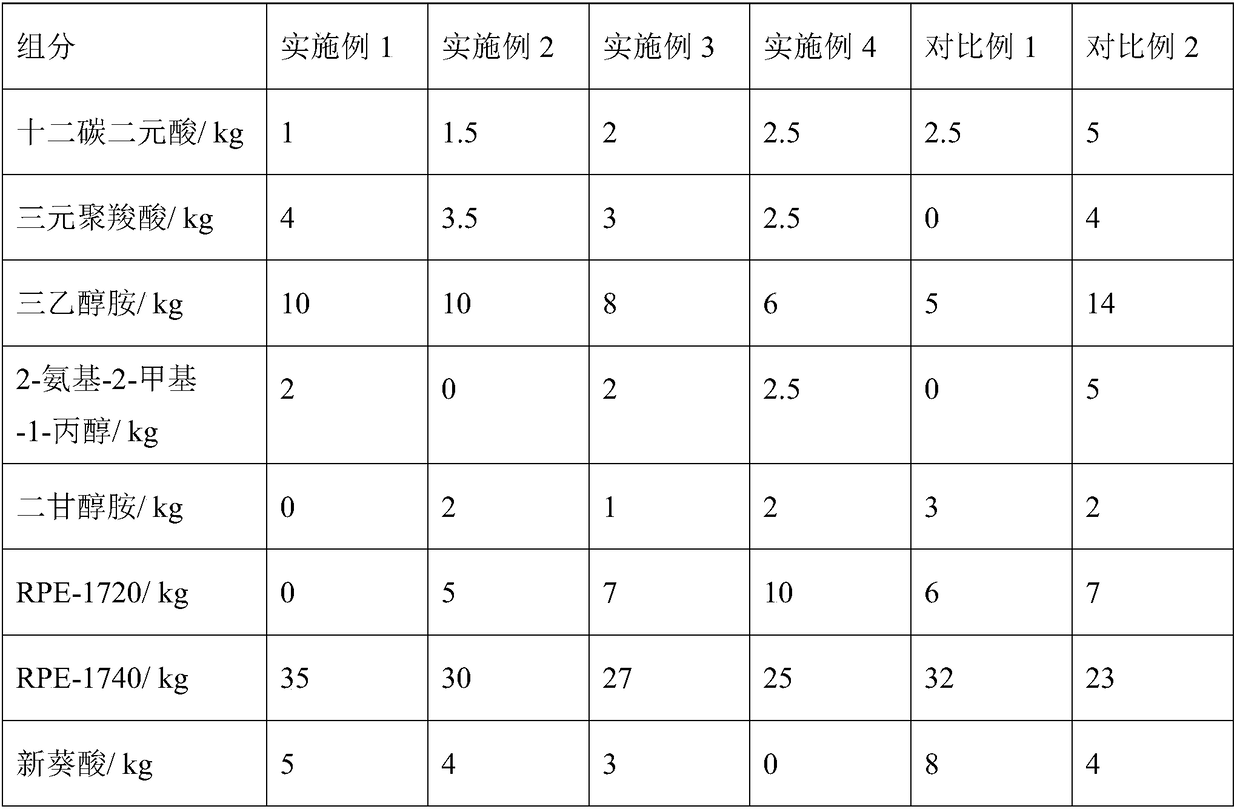

[0043] Synthetic high-gloss cutting fluid for smartphone frames, the components and parts by weight are shown in Table 1, and it is prepared by the following steps:

[0044] (1) Weigh 10kg of triethanolamine, 2kg of 2-amino-2-methyl-1-propanol, 4kg of dodecanedibasic acid, 1kg of ternary polycarboxylic acid and 42kg of water, stir and mix, then heat to 80°C, Stir the reaction at 500rpm for 20min until completely dissolved;

[0045] (2) After cooling the solution in the above step (1) to 55°C, add 35kg RPE-1740, 5kg neodecanoic acid and 0.5kg alkyl phosphonate derivatives in parts by weight and stir at 400rpm for 25min until uniform;

[0046] (3) After cooling the solution in the above step (2) to 40° C., add 0.1 kg of cationic copolymer and 0.4 kg of nano-molybdenum oxide, and stir at 300 rpm for 10 minutes until the solution becomes transparent to obtain a high-gloss cutting fluid.

Embodiment 2

[0048] Synthetic high-gloss cutting fluid for smartphone frames, the components and parts by weight are shown in Table 1, and it is prepared by the following steps:

[0049] (1) Weigh 10kg of triethanolamine, 3.5kg of dodecanedibasic acid, 2kg of diglycolamine, 1.5kg of ternary polycarboxylic acid and 42kg of water, stir and mix, heat to 75°C, and stir at 450rpm for 25min to completely dissolved;

[0050] (2) After cooling the solution in the above step (1) to 50°C, add 5kgRPE-1720, 30kgRPE-1740, 4kg neodecanoic acid, 1kg isononanoic acid and 1kg alkyl phosphonate derivatives in parts by weight and stir in Stir at 450rpm for 30min until uniform;

[0051] (3) After cooling the solution in the above step (2) to 45°C, add 0.2kg of cationic copolymer sedimentation agent and 0.5kg of nano-copper powder, and stir at 300rpm for 15min until the solution becomes transparent to obtain a high-gloss cutting fluid.

Embodiment 3

[0053] Synthetic high-gloss cutting fluid for smartphone frames, the components and parts by weight are shown in Table 1, and it is prepared by the following steps:

[0054] (1) Weigh 8kg of triethanolamine, 2kg of 2-amino-2-methyl-1-propanol, 1kg of diglycolamine, 3kg of dodecanoic dibasic acid, 2kg of ternary polycarboxylic acid and 44kg of water after stirring and mixing , heated to 85°C, stirred at 450rpm for 30min until completely dissolved;

[0055] (2) After cooling the solution in the above step (1) to 50°C, add 7kgRPE-1720, 27kgRPE-1740, 3kg neodecanoic acid, 2kg isononanoic acid and 1.6kg alkyl phosphonate derivatives in parts by weight and stir Stir at 450rpm for 30min until uniform;

[0056] (3) After cooling the solution in the above step (2) to 45°C, add 0.2kg of cationic copolymer sedimentation agent and 0.2kg of nano-copper powder, and stir at 300rpm for 15min until the solution becomes transparent to obtain a high-gloss cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com