Patents

Literature

76results about How to "Long foam suppression time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

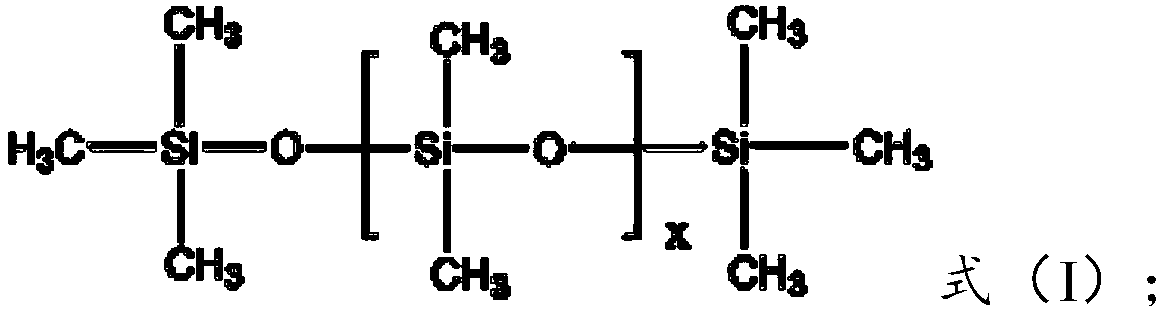

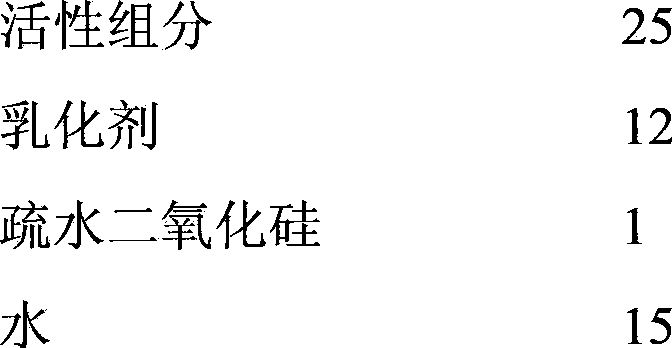

Preparation method of defoaming agent for waterborne system

ActiveCN105148571AActive ingredient reductionReduce manufacturing costCoatingsFoam dispersion/preventionAdjuvantNitrogen gas

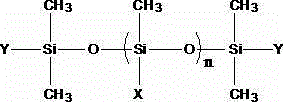

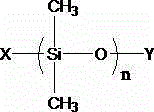

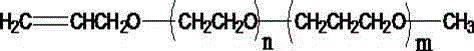

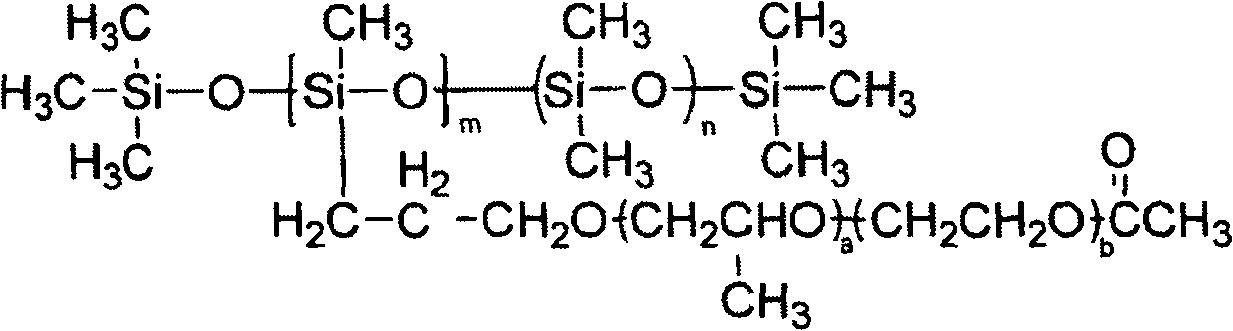

The invention relates to a preparation method of a defoaming agent for a waterborne system. The preparation method of the defoaming agent for the waterborne system comprises the following steps: a) adding silicon oil, gaseous silicon dioxide and catalyst into a reaction container according to proportions, and preparing silicon cream under an agitating condition protected by nitrogen; b) adding hydrogen-containing silicon oil and allyl polyether into the reaction container, agitating under the protection of nitrogen, increasing temperature and adding an initiator for reaction to obtain polyether modified organic silicon; c) jading the silicon cream obtained in step a), the polyether modified organic silicon obtained in step b) and an emulsifier into the reaction container, adding water for emulsification under a high-speed agitating condition, and adding a thickening agent to regulate viscosity to obtain a product. The defoaming agent prepared by adopting the preparation method provided by the invention has the advantages that the active components are low, the manufacturing cost is low and the environmental friendliness is better; the emulsification is stable, the compatibility in the waterborne system is good, the defoaming agent is easy to disperse, the surface tension is low, the defoaming speed is quick, the foam inhibiting time is long, the thermal resistance, shear resistance and acid and alkali resistance thereof are good, and the defoaming agent can adapt to various places; the defoaming agent can be separately used and can also be jointly used with other adjuvants, the stability is good, the phenomenon of oil floating due to demulsification does not occur, no sediment is produced and shrinkage cavities during coating are not caused; and the defoaming agent is also very effective to non-waterborne systems.

Owner:KITO CHEM CO LTD

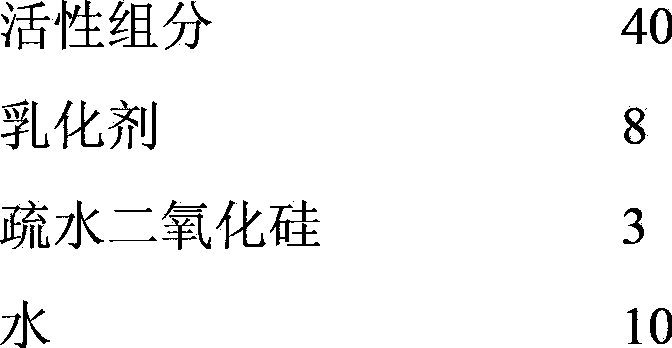

High-efficiency antifoaming agent

InactiveCN102949867AGood anti-foam performanceStrong antifoam performanceFoam dispersion/preventionAdditive ingredientBULK ACTIVE INGREDIENT

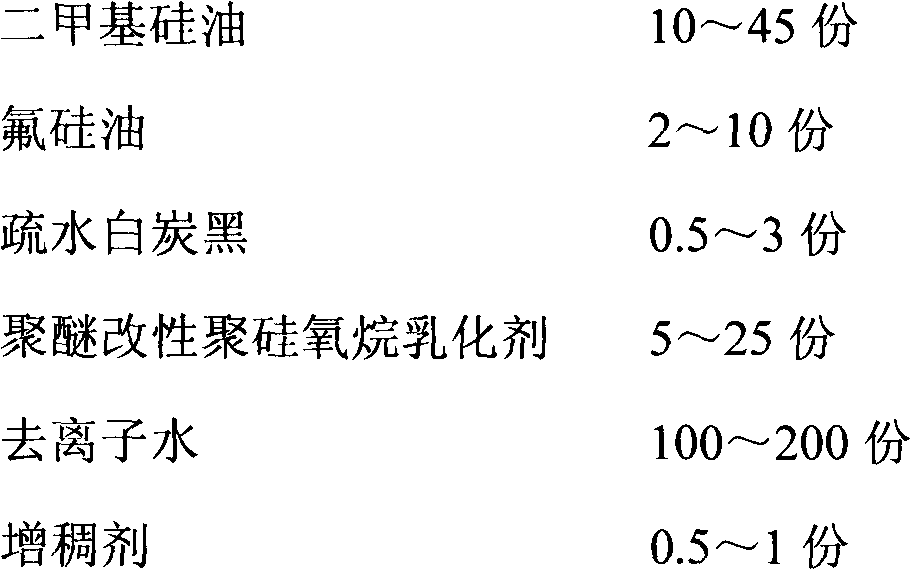

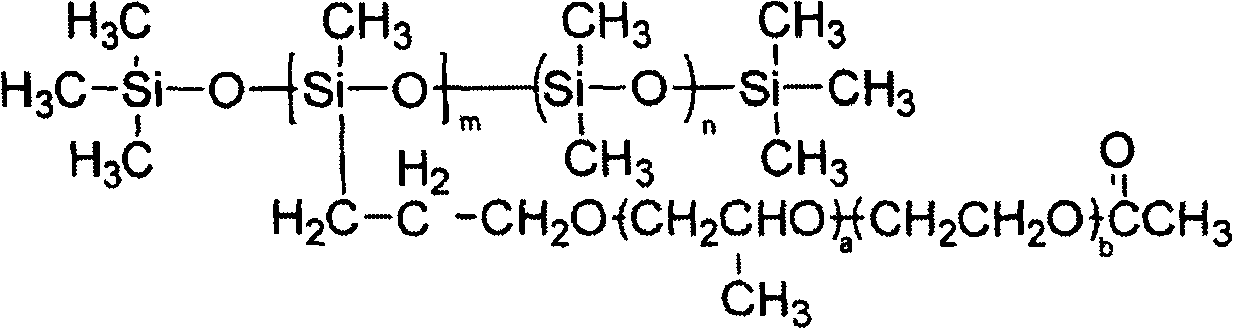

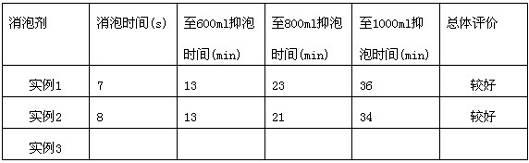

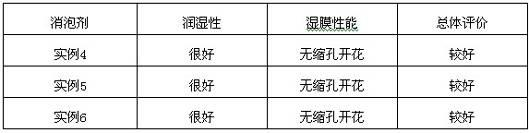

The invention relates to a high-efficiency antifoaming agent which comprises the following raw materials based on parts by weight: 10-45 parts of simethicone, 2-10 parts of fluorosilicone oil, 0.5-3 parts of hydrophobic white carbon black, 5-25 parts of polyether-modified polysiloxane emulgator, 100-200 parts of deionized water and 0.5-1 part of thickening agent. The antifoaming agent takes composition of the simethicone and the fluorosilicone oil as a main antifoaming active ingredient; and after the fluorosilicone oil is added, the surface tension of an antifoaming agent system can be reduced, and the antifoaming and foam-inhibiting performances can be improved. According to the polyether-modified polysiloxane emulgator, not only can the antifoaming active ingredients be emulsified, but also the effect enhancing action can be achieved due to the fact that the high-efficiency antifoaming agent further has good antifoaming ingredients. The antifoaming agent is high in antifoaming capacity, long in foam-inhibiting time, wide in application range, capable of being applied to various foam systems, and suitable for antifoaming and foam-inhibiting under severe conditions, i.e. high acid-base, high temperature and the like.

Owner:TIANJIN SCIPHARMACN

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939AStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

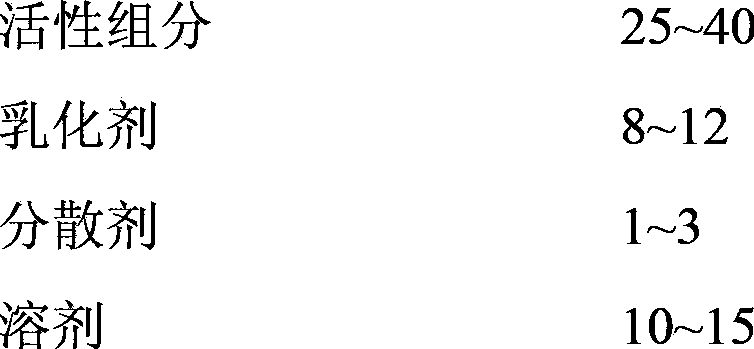

Environment-friendly highly efficient mighty defoamer prescription and production process

InactiveCN1765459AImprove surface activityReduce surface tensionFoam dispersion/preventionSolventDefoaming Agents

The invention relates to an emulsion defoaming agent and ití»s preparing method. The invention comprises (a) silicon oil; (b) olefin hydrocarbon; (c) auxiliary defoaming component; (d) emulsifier; (e) dispersant which is polyisobutene or polybutene or the assembly of them; (f) solvent. The inventive defoamting agent has high defoaming ability, long foam-restrain time, stable property, environment-friendly ability, innocuity, lower dosage and lower cost.'

Owner:SHANGHAI NORMAL UNIVERSITY

Polyether modified organic silicon defoamer and preparation method thereof

The invention discloses a polyether modified organic silicon defoamer and a preparation method thereof. The defoamer comprises compounding raw materials in percentage by weight as follows: 5%-40% of polyether modified silicone oil, 10%-40% of dimethyl silicone oil, 5%-30% of white carbon black, 2%-30% of an emulsifying agent, 0.01%-8% of a regulator and 10%-80% of water, and the sum of components is 100%. According to the preparation method of the polyether modified organic silicon defoamer, the polyether modified organic silicon defoamer is prepared by the compounding raw materials in percentage by weight, the technological method is as follows: (a), the polyether modified silicone oil, the white carbon black and the dimethyl silicone oil in different weight ratios are put in a reaction kettle, stirred and heated to the temperature of about 200 DEG C, and a silicon paste is prepared; and (b), the emulsifying agent is added into the silicon paste and heated to the temperature of about 50 DEG C-75 DEG C, the regulator is added, water is dropwise added, the mixture is stirred for 5-10 hours, cooled, discharged and packaged, and the polyether modified organic silicon defoamer is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Antifoaming agent for flue gas desulphurization system and preparing method thereof

InactiveCN106334349AIncrease surface tensionLower free energyDispersed particle separationFoam dispersion/preventionEmulsionFlue gas

The invention discloses an antifoaming agent for a flue gas desulphurization system. The antifoaming agent is prepared from, by mass, 30%-60% of antifoaming components, 10%-20% of foam inhibition components, 5%-10% of an emulsion stabilizer, 5%-10% of a synergist and the balance deionized water. The antifoaming agent is suitable for a thermal-power-plant limestone-gypsum wet flue gas desulfurization system adapting to high chlorine, fluorion and solid-content slurry liquid and aeration, and has the advantages of being good in antifoaming effect and long in foam inhibition time; the foaming characteristic of desulfuration slurry liquid can be improved, the stability of a slurry-liquid oxidation zone is effectively controlled, the foam content of the slurry liquid is reduced, losses of the slurry liquid of a circulating pump are reduced, the circulation amount of the slurry liquid is increased, and it is avoided that foam overflows to a pipe zone, the slurry liquid is deposited in a pipe, and scale formation corrosion is caused.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Air purification heath protection mud and production process thereof

ActiveCN102302927ASufficient antifreeze strengthFast defoaming speedOther chemical processesDeodrantsCelluloseInorganic pigments

The invention provides air purification heath protection mud and a production process thereof. The health protection mud consists of a component I and a component II, wherein the component I comprises diatomite, zeolite powder, maifanitum powder, nano zinc oxide, negative ion powder, dispersible latex powder, methyl cellulose and an inorganic pigment; and the component II comprises water, an anti-freezing agent, a dispersing agent, an antifoaming agent, an emulsifying agent, a stabilizing agent, a macromolecule packaging agent, and cypress oil, clove oil or eucalyptus oil. The health protection mud has the effect of eliminating harmful substances such as formaldehyde, benzene and the like and improving indoor geomagnetic intensity, can produce negative ions, has the functions of deodorization, smell elimination, inflaming retardant, sound insulation and noise reduction, and can adjust indoor air humidity.

Owner:王钟贤

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Defoaming agent

PendingCN110681187AImprove defoaming abilityLong foam suppression timeFoam dispersion/preventionPtru catalystPreservative

The invention relates to the technical field of chemical additives, and specifically discloses a defoaming agent. The defoaming agent is at least prepared from the following preparation raw materials:10 to 30 parts of an organic silicon composition, 1 to 10 parts of hydrogen-containing polysiloxane, 1 to 10 parts of vinyl polysiloxane, 2 to 12 parts of allyl polyether, 0.1 to 2 parts of a catalyst, 5 to 20 parts of an emulsifier, 1 to 5 parts of a thickener, 1 to 5 parts of a preservative and 50 to 90 parts of water. The organic silicon defoaming agent which is high in defoaming speed, long in foam inhibition time, excellent in dispersing performance and outstanding in defoaming durability is prepared through a special formula and process, and what's more important, the defoaming agent prepared through the preparation method is good in product stability, not prone to demulsification and free of oil floating under the conditions of high temperature and strong alkali, and the preparation method is simple and low in cost.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Compound defoaming agent

InactiveCN106731034AFast defoamingLong foam suppression timeWater/sewage treatment by degassingFoam dispersion/preventionIsooctyl alcoholGlycol ethers

The invention discloses a compound defoaming agent which comprises the following ingredients: 20-25 parts of polyoxyethylene polyoxypropylene glycol ether, 20-25 parts of dimethicone, 15-20 parts of polyether modified siloxane, 15-20 parts of glycerol tristearate, 5-10 parts of sodium dodecyl sulfate and 5-10 parts of isooctyl alcohol. The compound defoaming agent has the characteristics of quick defoaming, long foam inhibition time, alkali resistance, acid resistance, high-temperature resistance and good compatibility, and can be widely used for removing harmful foam in industrial production.

Owner:新疆水处理工程技术研究中心有限公司

Preparation method of defoaming agent for wastewater treatment

ActiveCN105152255AGood chemical stabilityStrong defoaming and antifoaming abilityWater/sewage treatment by degassingPulp and paper industrySilicone paste

The invention discloses a preparation method of a defoaming agent for wastewater treatment, and belongs to the field of water treatment agents. The preparation method of the defoaming agent comprises the following steps of organic silicone oil modification treating, silicone paste preparing and defoaming agent compounding. The defoaming agent is prepared by compounding the organic silicone oil which is good in chemical stability and is modified through polyether with silicone paste, emulsifying auxiliaries and the like. The defoaming agent is high in chemical stability and defoaming and anti-foaming capacity, capable of resisting strong acid and strong base, small in additive amount and long in anti-foaming time, and the COD of wastewater can not be increased, so that wastewater secondary pollution caused by defoaming agent adding can be avoided.

Owner:SUZHOU JIMCEL ELECTRONICS NEW MATERIAL

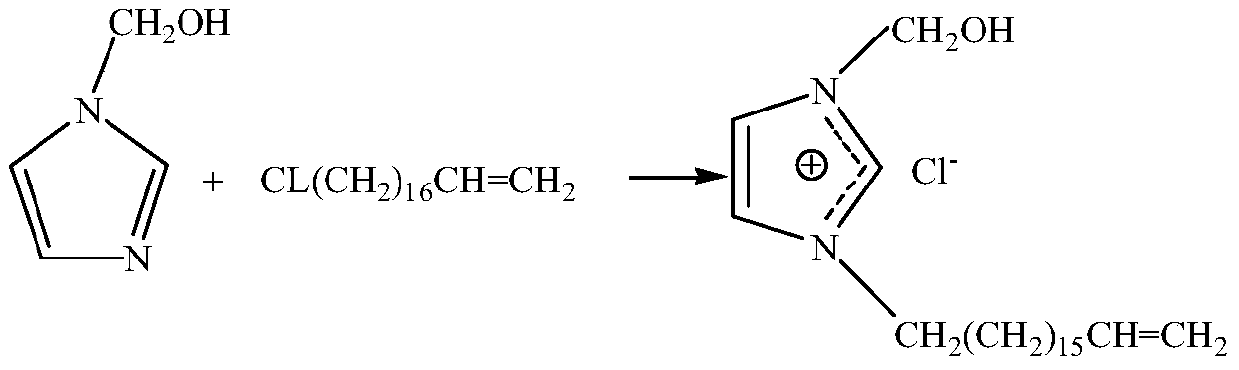

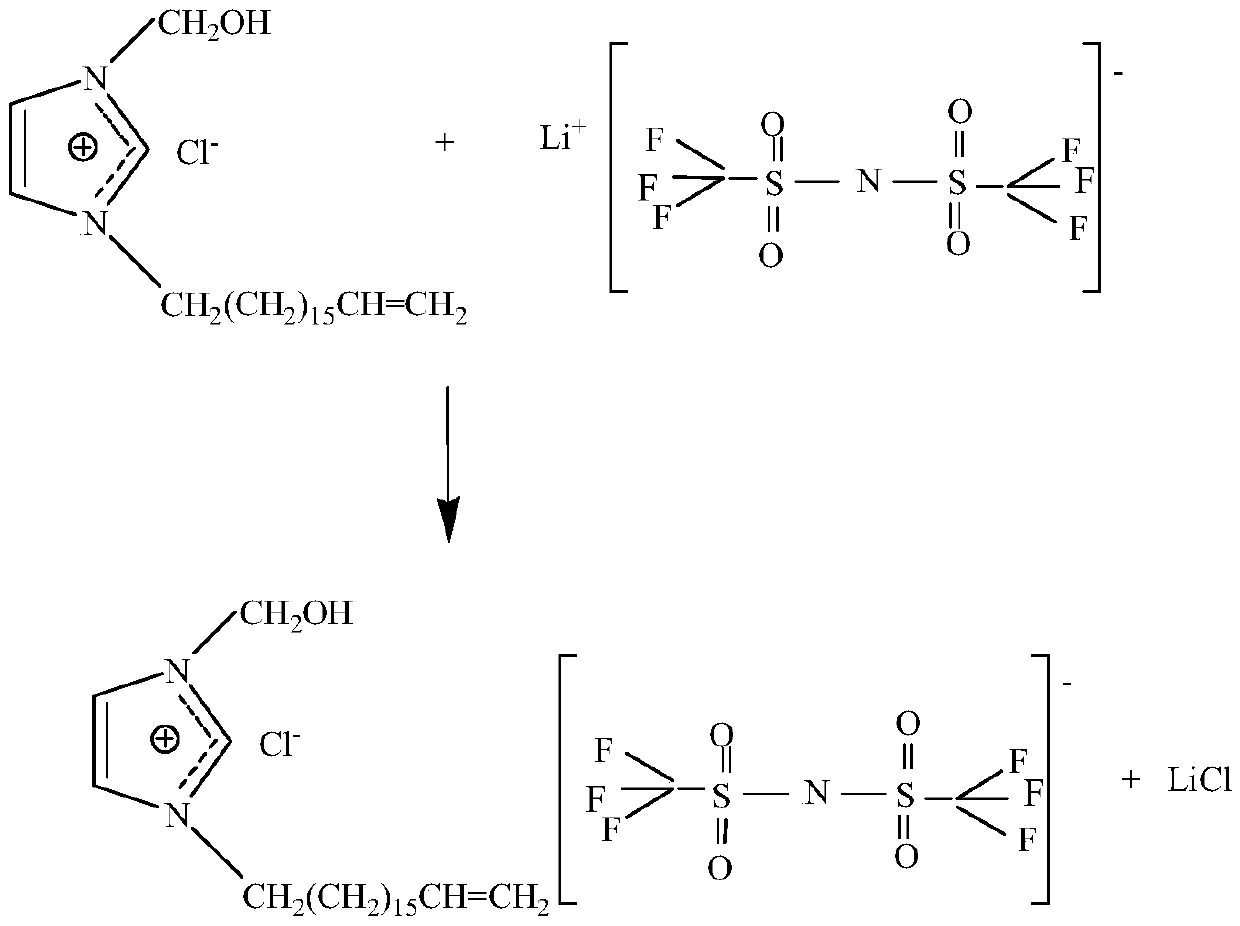

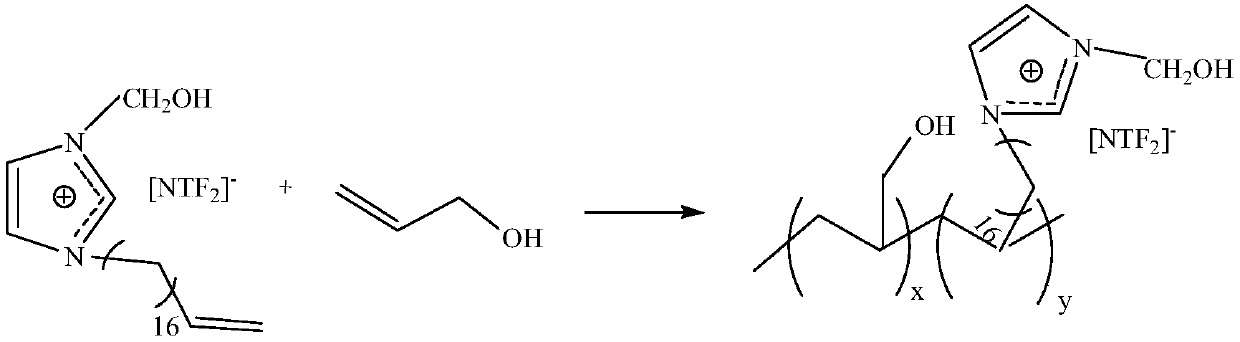

Flexibility-enhanced polyurethane

ActiveCN109897517AGood film-forming performanceImprove softnessFireproof paintsPolyurea/polyurethane coatingsPrepolymerPolymer chemistry

The invention provides a flexibility-enhanced polyurethane. A preparation method of the flexibility-enhanced polyurethane comprises the following reaction steps: 1, preparation of an ionic liquid polymer with a dihydroxy group; 2, preparation of an ionic liquid polymer modified polyurethane prepolymer; and 3, preparation of the flexibility-enhanced polyurethane. The modified polyurethane preparedby the preparation method has the advantages of high flexibility, good film forming property, strong mechanical properties, high thermal stability, high chemical stability, high tensile strength, difficult shedding or explosion, energy saving, environmental protection and wide application range.

Owner:广州精点高分子材料制品有限公司

Antifoaming agent for food fermentation

InactiveCN103816699AGood dispersionFast defoaming speedFoam dispersion/preventionPolyethylene glycolGlycerol

The invention provides an antifoaming agent for food fermentation. The antifoaming agent is obtained by stirring an active ingredient which is a mixture of polyethylene glycol, polyoxyethylene polyoxypropylene glycerol and high-carbon alcohol and accessories comprising an active emulsifying agent and a dispersant, wherein the mass ratio of the polyethylene glycol, the polyoxyethylene polyoxypropylene glycerol to the high-carbon alcohol is (1-3):(1-3):(1-3); the active emulsifying agent is glycerol monostearate, fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylate; the dispersant is hydrophobic silicon dioxide; the high-carbon alcohol is C7 to C9 alcohol.

Owner:季爱英

Novel organic silicon defoamer for landfill leachate treatment and preparation method of novel organic silicon defoamer

ActiveCN112495000AGood defoamingGood anti-foam performanceSustainable biological treatmentFoam dispersion/preventionEnvironmental engineeringFatty acid

A novel organic silicon defoamer for landfill leachate treatment is prepared from the following raw materials in percentage by mass: 10-20% of polyether modified polydimethylsiloxane with the viscosity of 500-1500 mPa.s; 1-5% of nanoscale fumed silica with the particle size of 10-30 nm; 1-5% of modified silicone oil; 2-8% of fatty acid polyoxyethylene ester with the HLB value of 6-12; 3-10% of anemulsifier; 1-6% of a thickening agent; 1-2% of a biological inhibitor; and the balance of deionized water. The organic silicon defoamer for landfill leachate treatment not only has the characteristics of rapid defoaming and good foam inhibition, but also can resist the high temperature of 100-120 DEG C, and is not easy to demulsify and separate out in a complex organic matter system.

Owner:沈阳瑞驰表面技术有限公司

Polyether modified organic silicon defoamer safe to strains and preparation method thereof

PendingCN112057905AGood defoaming effectGuaranteed stabilityFoam dispersion/preventionMicrosphereCentrifugation

The invention belongs to the technical field of defoamers and discloses a polyether modified organic silicon defoamer safe to strains and a preparation method thereof. The preparation method includesthe following steps that: silicon dioxide nanometer microspheres, dimethyl silicone oil, DMF and deionized water are sequentially added into a reaction flask, ammonia water is added while stirring isconducted, heating is conducted to 50-70 DEG C, a reaction is conducted for 1-2 hours, cooling is conducted to the room temperature, and centrifugation is conducted, a precipitate is washed with ethanol, and drying is performed to obtain dimethicone grafted and modified silicon dioxide nano microspheres; 30-60 parts of the dimethicone grafted and modified silicon dioxide nano microspheres, 30-50 parts of polyether modified silicon oil, 1-10 parts of a thickener, 2-10 parts of an emulsifier and 10-50 parts of water are added into a dispersion tank, heating is conducted to 180-200 DEG C, stirring is performed for 2-3 hours, gradient cooling is carried out to 50-60 DEG C in a stirring state, and finally natural cooling is performed to obtain the polyether modified organic silicon defoamer. The defoamer has the advantages of being low in surface tension, high in defoaming speed, long in foam inhibition time, small in dosage, free of toxicity and harm to strains, wide in application range and the like.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

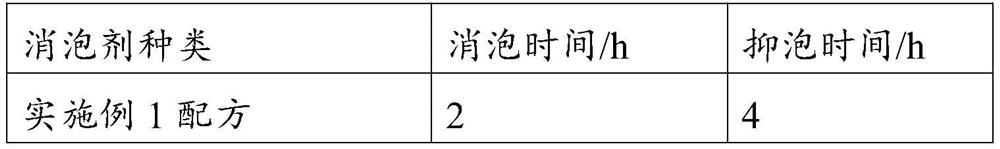

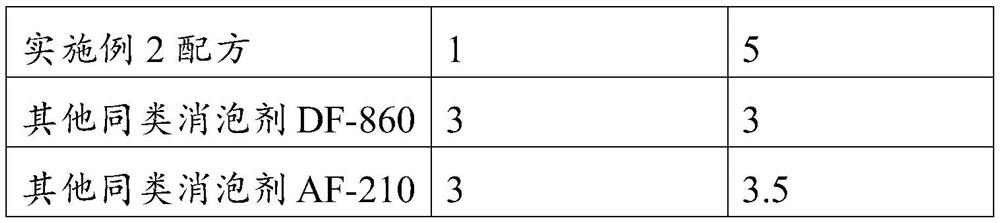

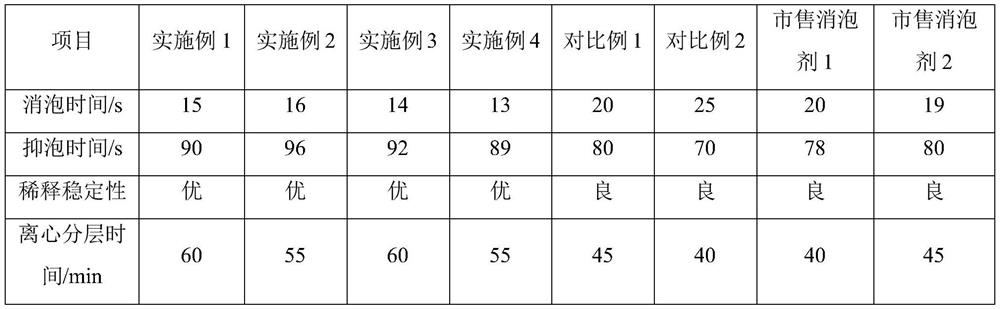

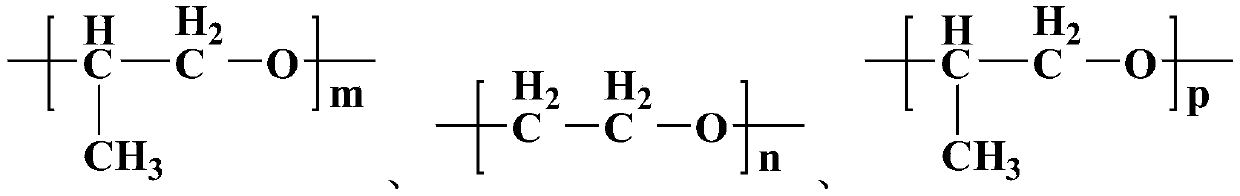

Preparation method of high-molecular-weight block polyether, silyl ether mixed defoaming agent and preparation method thereof

PendingCN111019116ANot easy to decomposeLong foam suppression timeFoam dispersion/preventionAlkanePolymer science

The invention provides a silyl ether mixed defoaming agent. The silyl ether mixed defoaming agent comprises the following components in parts by weight: 24-40 parts of high molecular weight block polyether; 20-30 parts of polymer polyether modified polysiloxane; 10-30 parts of fatty alcohol; and 15-35 parts by weight of a cosolvent; wherein the high-molecular-weight block polyether is obtained bypolymerizing polyol and alkylene oxide; wherein the high-molecular silyl ether modified polysiloxane is prepared from high-molecular-weight block polyether modified polysiloxane. Compared with the prior art, the polyether chain segment with hydrophilicity is grafted to the polysiloxane chain segment with hydrophobicity, so that the formed silyl-ether copolymer has the advantages of two defoaming agents, namely silicon and ether; the high molecular polyether modified polysiloxane and the high molecular weight block polyether are compounded for use, so that the good defoaming effect of the highmolecular polyether modified polysiloxane and the good foam inhibition effect of the high molecular weight block polyether have a synergistic effect, the reduction of the foam amount is effectively ensured, and meanwhile, the fatty alcohol with high surface activity is matched, so that the improvement of the defoaming efficiency is promoted.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Flue gas desulfurization degreasing defoaming agent and preparation method thereof

InactiveCN108079621AFast defoamingLong foam suppression timeTransportation and packagingDispersed particle separationEthylene oxideAlkylphenol

The invention discloses a flue gas desulfurization degreasing defoaming agent and a preparation method thereof. The flue gas desulfurization degreasing defoaming agent comprises 10% to 20% of Tween 80; 10% to 20% of alkylphenol polyoxyethylene ether; and 60% to 80% of a non-ionic defoamer, the non-ionic defoamer is ethylene oxide block polymer polyether or propylene epoxide block polymer polyether. The flue gas desulfurization degreasing defoaming agent has the advantages of thorough degreasing, fast defoaming, long defoaming time, acid and alkali resistance, high temperature resistance, and integrated degreasing, defoaming and foam suppression functions, and can be widely applied to power plant limestone wet flue gas desulfurization systems.

Owner:德州绿能水处理科技有限公司

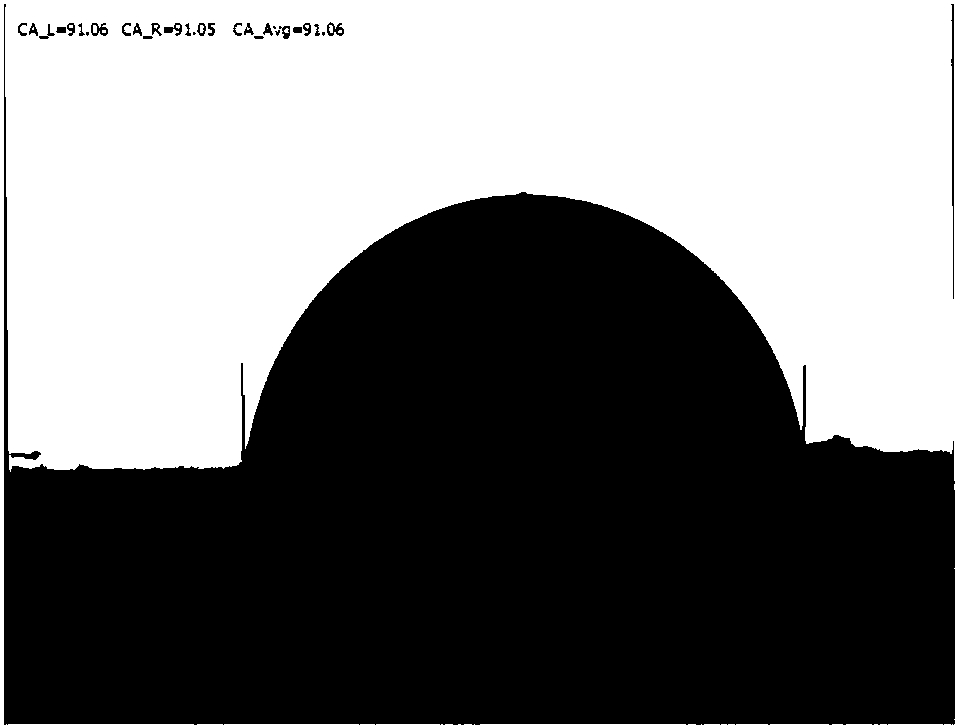

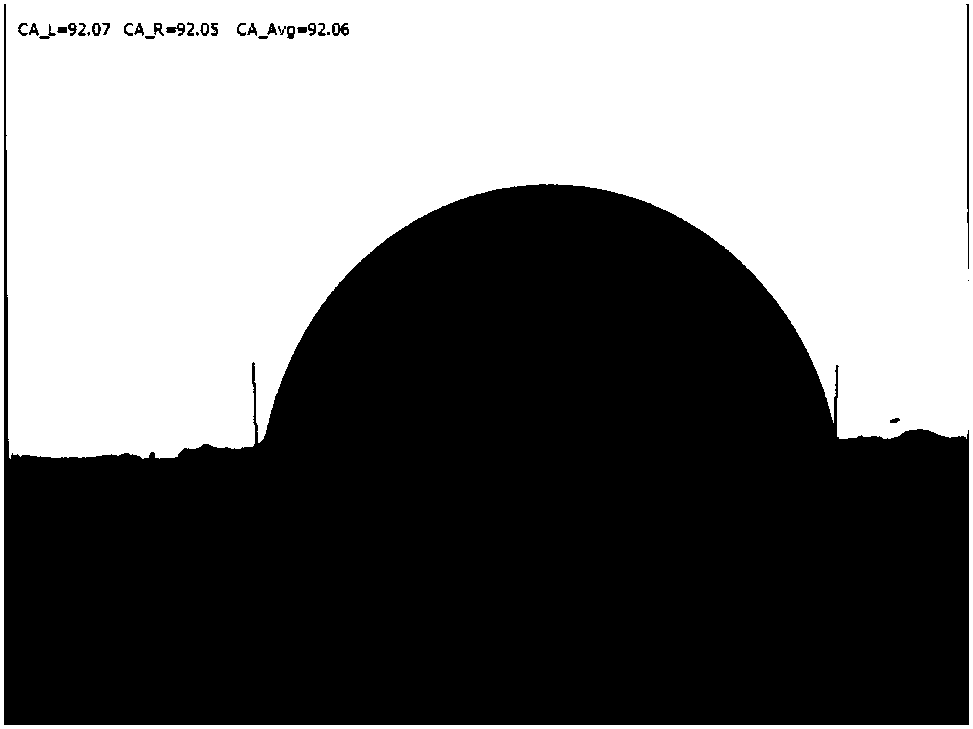

Greenhouse thin film water-based hydrophobic coating as well as preparation method and application thereof

The invention discloses a water-based hydrophobic coating as well as a preparation method and application thereof. The coating comprises the following components in mass fraction: 57-80% of modified fluorocarbon resin, 2.4-4.8% of coalescing agent, 0.5-0.8% of base material wetting agent, 0.3-0.8% of leveling agent, 0-0.2% of antifoaming agent, 0-1% of thickener, 1-2% of hydrophobic agent, 3.8-7.7% of curing agent, and the balance liquid paraffin. The prepared fluorocarbon resin water-based hydrophobic coating has excellent film forming property and hydrophobicity, has high coating adhesion, is safe and environment-friendly, has simple process, and is easy for industrial production and large-scale popularization and application.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Antistatic high-elasticity bulk blended yarn

InactiveCN110644096AImprove smoothness and softnessImprove antistatic performanceYarnAnimal fibresYarnPolymer science

The invention relates to the technical field of bulk blended yarns, in particular to an antistatic high-elasticity bulk blended yarn. Vinylon fibers are removed in a dissolved manner to obtain the bulk blended yarn, the bulk blended yarn is prepared from acrylic fibers and wool fibers and has a sheath-core structure, the blended mass ratio of the acrylic fibers to the wool fibers is 50%-70%:30%-50%, the vinylon fibers account for 10-40% of the total weight of the blended yarn before dissolution, the acrylic fibers are treated by acrylic oil agents, and the wool fibers are treated by antistaticfinishing agents. The acrylic fibers and the wool fibers are blended to form the bulk blended yarn and have good elasticity, so that a woven fabric is good in elasticity, the wool fibers are treatedby the antistatic finishing agents, so that the woven fabric has durability and antistatic properties, the antistatic properties of the fabric are improved, and potential safety hazards are reduced.

Owner:肇庆市高要区长河毛纺有限公司

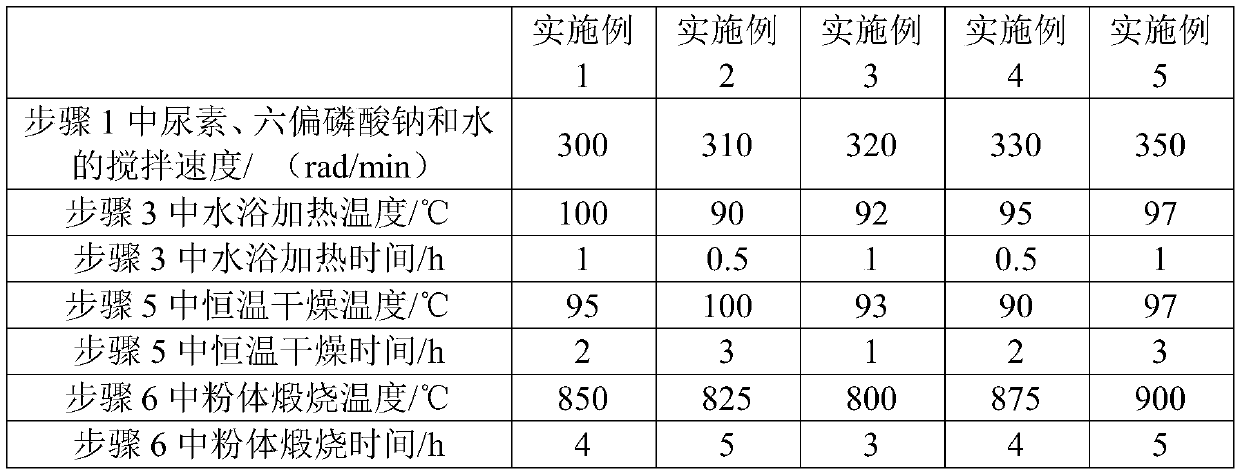

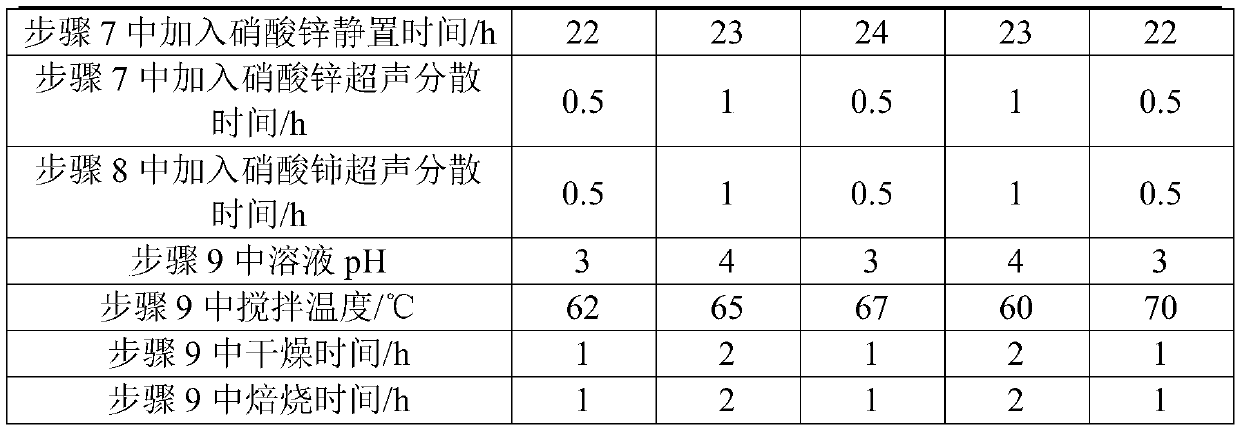

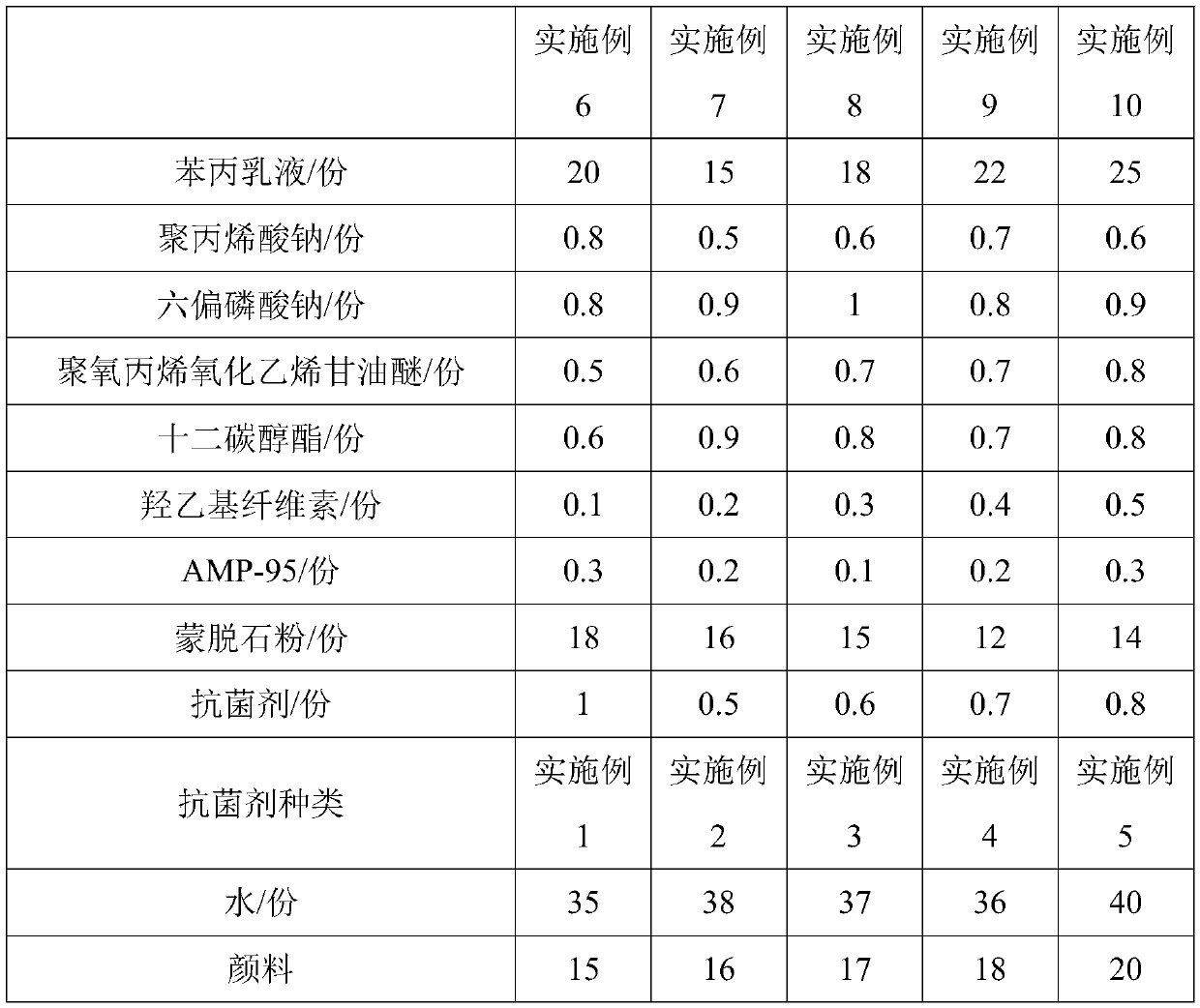

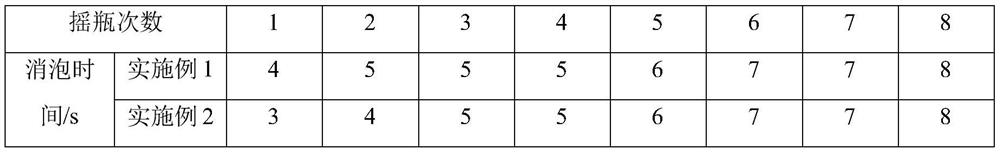

Antibacterial interior wall coating and preparation method thereof

ActiveCN109796814AStrong adhesionImprove aging resistanceAntifouling/underwater paintsPaints with biocidesEmulsionMontmorillonite

The invention discloses an antibacterial interior wall coating and a preparation method thereof. The antibacterial interior wall coating is prepared from, by weight, 15-25 parts of styrene-acrylic emulsion, 0.5-0.8 part of sodium polyacrylate, 0.8-1 part of sodium hexametaphosphate, 0.5-0.8 part of polyoxyethylene oxide glycerol ether, 0.6-0.9 part of texanol, 0.1-0.5 part of hydroxyethyl cellulose, 0.1-0.3 part of AMP-95, 12-18 parts of montmorillonite powder, 0.5-1 part of an antibacterial agent, 35-40 parts of water and 15-20 parts of pigment. The antibacterial interior wall coating and thepreparation method thereof have the advantage that the antibacterial interior wall coating has excellent antibacterial performance.

Owner:山西亚鑫能源集团有限公司

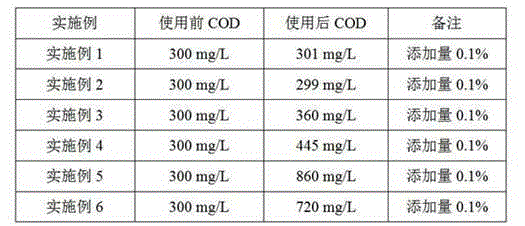

Water body-oriented low-COD defoaming agent non-toxic to microorganisms and preparation method of defoaming agent

PendingCN112057906AGood chemical stabilityReduce dosageFoam dispersion/preventionPtru catalystOrganosolv

The invention belongs to the technical field of chemical additives, and particularly discloses a water body-oriented low-COD defoaming agent non-toxic to microorganisms and a preparation method of thedefoaming agent. The defoaming agent is prepared from the following components in parts by weight: 10-20 parts of polydimethylsiloxane, 20-40 parts of mineral oil, 20-40 parts of amino silicone oil modified epoxy castor oil, 1-10 parts of hydrophobic white carbon black, 0.5-5 part of a defoaming aid and 0.1-10 part of an emulsifier.The preparation method comprises the following steps of: adding the epoxy castor oil and amino silicone oil into an organic solvent; adding a basic catalyst; performing stirring for reaction for 8-12 hours at the temperature of 60-80 DEG C; performing centrifugingto obtain supernatant; and carrying out rotary evaporation to remove the organic solvent, thereby obtaining the silicone oil modified epoxy castor oil. The defoaming agent disclosed by the invention is good in chemical stability, small in dosage, high in defoaming speed, long in foam inhibition time, high in efficiency, non-toxic to microorganisms and easy to disperse in sewage, and can reduce thesurface tension of a foam film, quickly eliminate foam and solve the problem of foam generated by biochemical sewage treatment.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

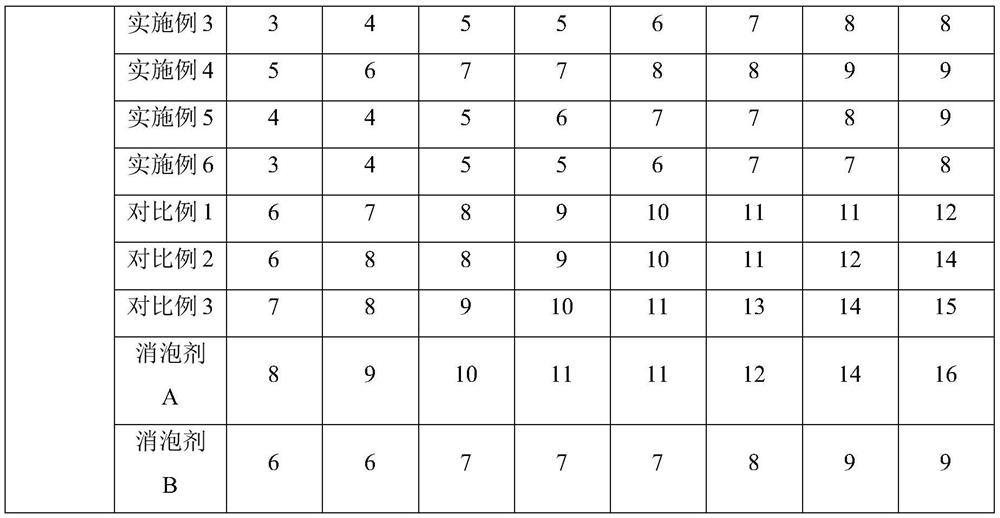

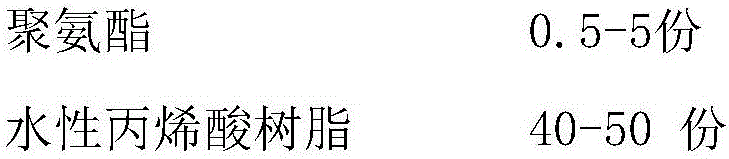

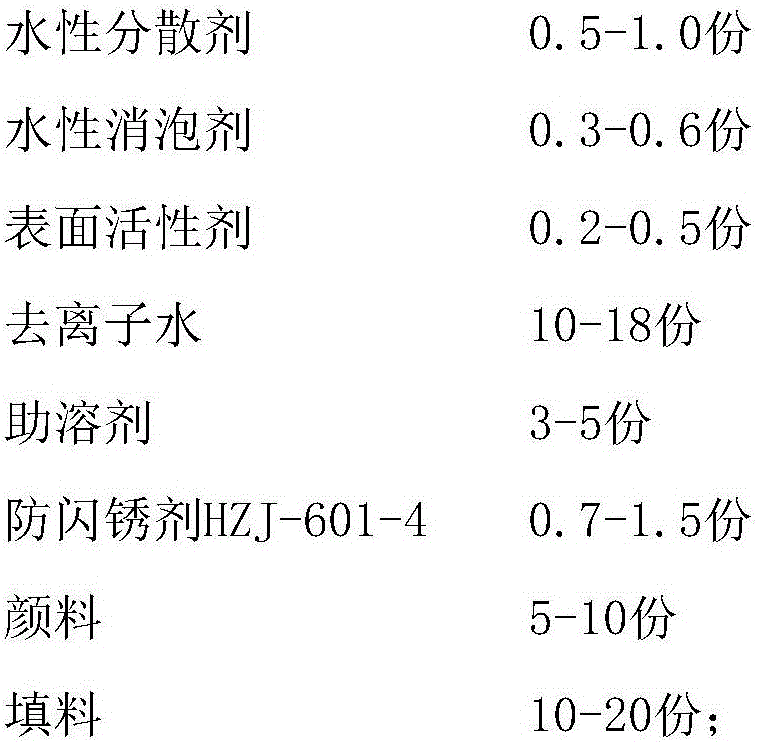

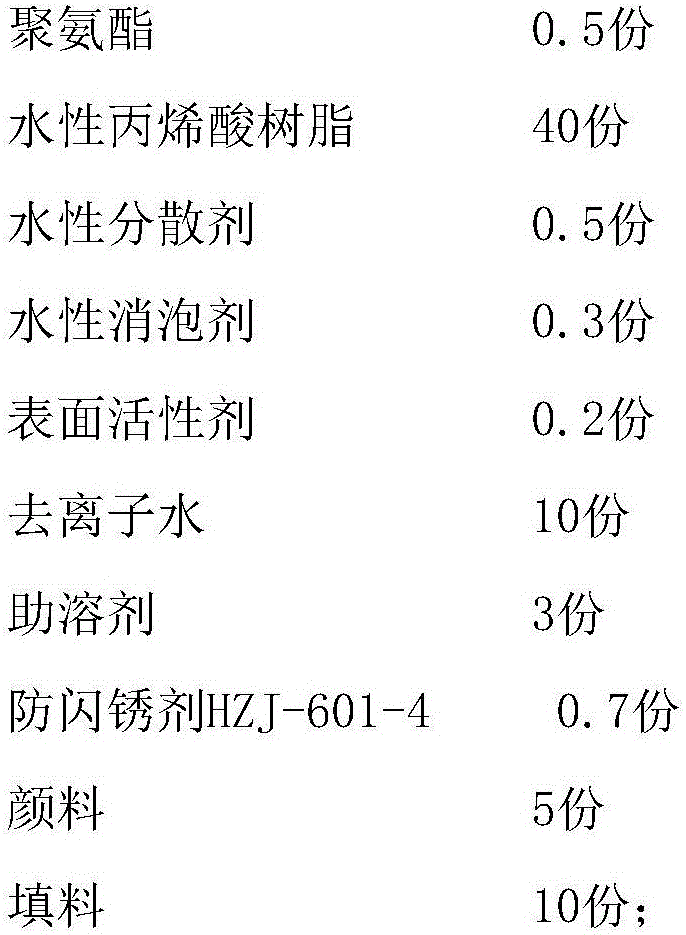

Waterborne polyurethane paint and method for preparing same

InactiveCN105860811ADefoaming stabilityFast defoamingAnti-corrosive paintsPolyurea/polyurethane coatingsOrganic solventHeat resistance

The invention provides waterborne polyurethane paint and a method for preparing the same. The waterborne polyurethane paint comprises components A and components B according to a mass ratio of 5:1. The components A comprise polyurethane, waterborne acrylic resin, waterborne dispersing agents, waterborne defoaming agents, surfactants, deionized water, solubilizers, anti-flash rusting agents HZJ-601-4, pigment and fillers; the components B comprise waterborne polyurethane curing agents, deionized water and waterborne defoaming agents. The waterborne polyurethane paint and the method have the advantages that the waterborne polyurethane paint is excellent in performance for various base materials, and the performance in the aspects of the abrasion resistance, the acid resistance, the alkali resistance, the water resistance, the oil resistance, the heat resistance and the like of the waterborne polyurethane paint is far superior to the performance of like products; organic solvents are omitted, accordingly, environments can be protected, and the waterborne polyurethane paint is harmless to human bodies.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

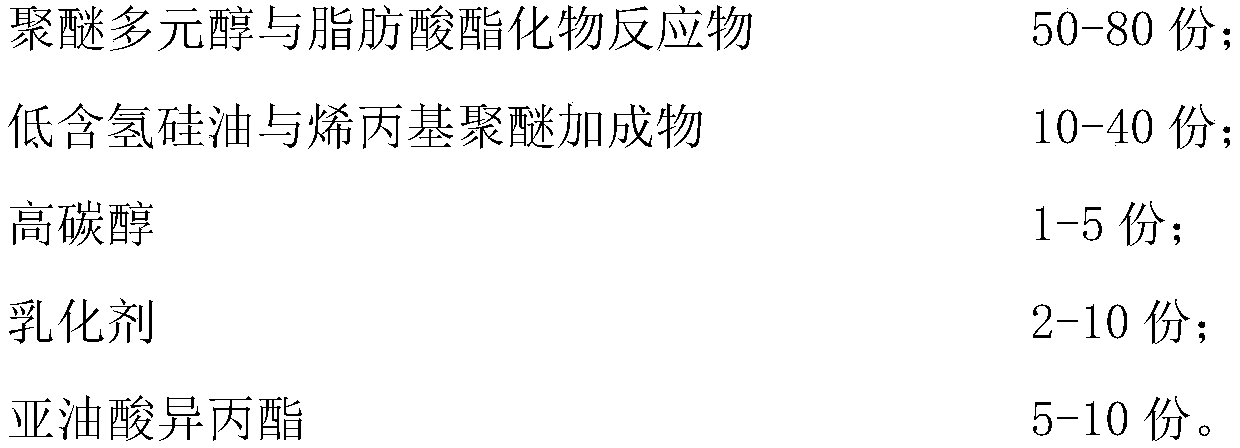

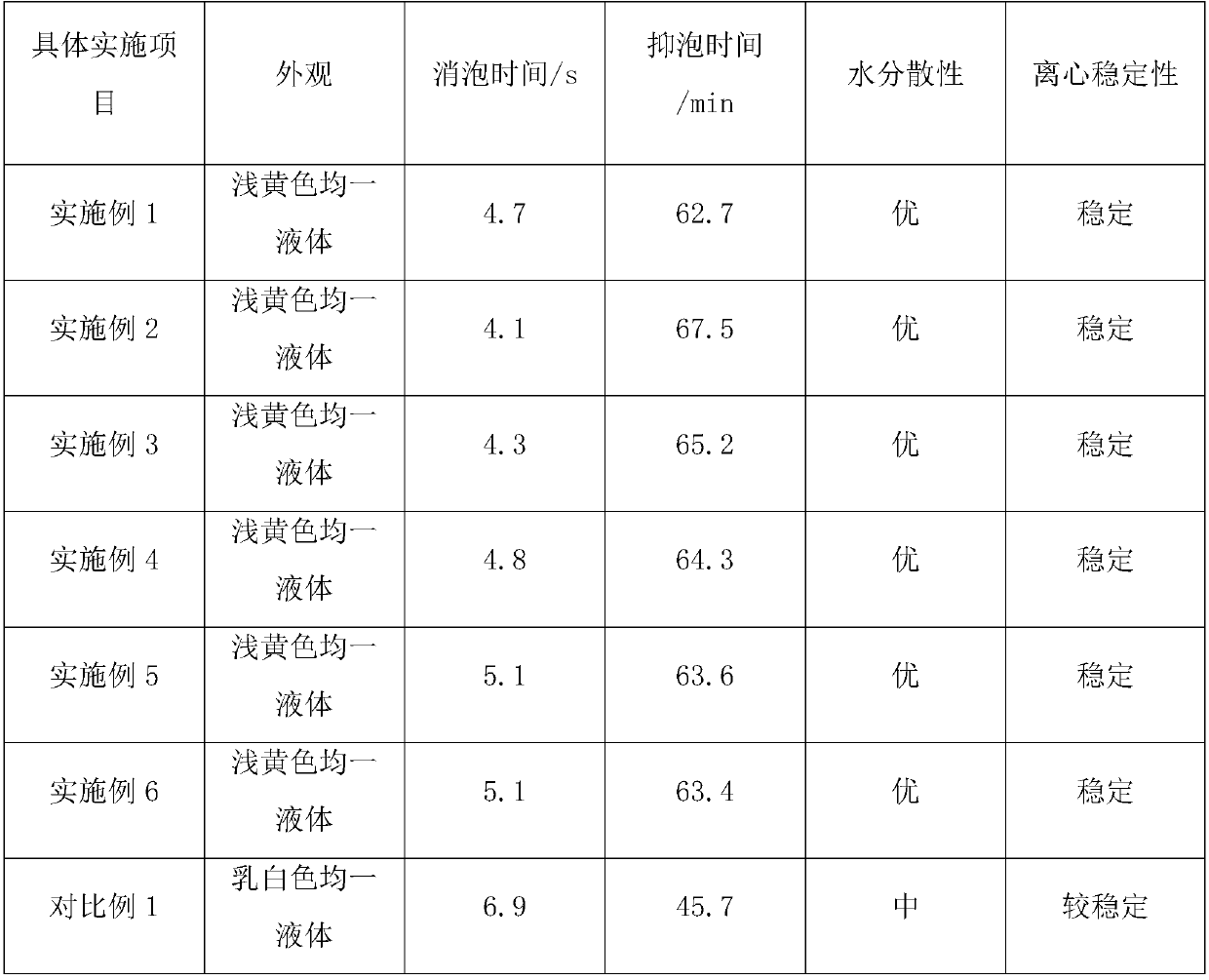

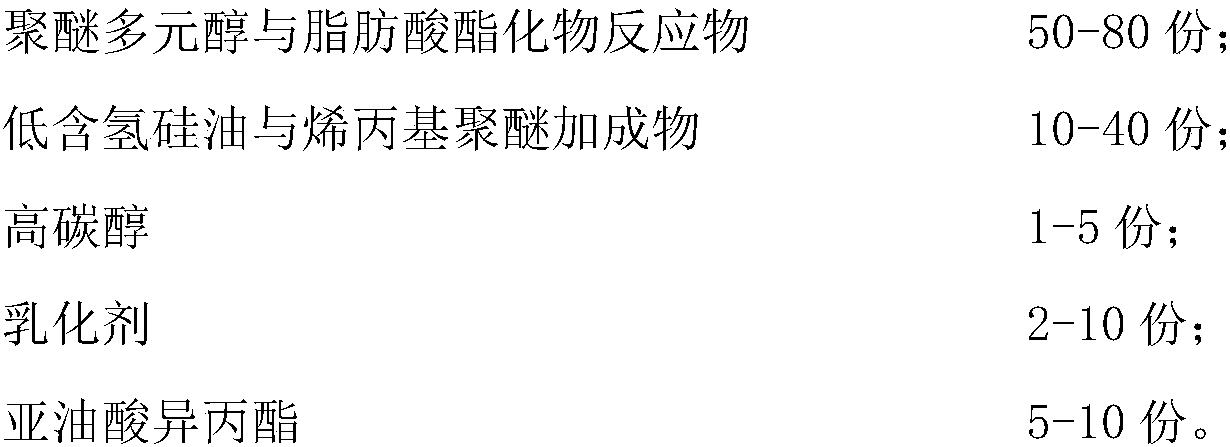

A bulk type power plant desulfuration defoamer and a preparing method thereof

A bulk type power plant desulfuration defoamer is provided and is an emulsion formed by substep reactions and mixing. The defoamer includes, by weight, 50-80 parts of an esterification product of polyether polyol and fatty acid, 10-40 parts of an addition product of silicone oil having a low hydrogen content and allyl polyether, 1-5 parts of a higher alcohol, 2-10 parts of an emulsifier, and 5-10parts of isopropyl linoleate. A preparing method of the defoamer is also provided and the method includes S1) preparing the esterification product of polyether polyol and fatty acid through a reaction, S2) preparing the addition product of silicone oil having a low hydrogen content and allyl polyether through a reaction; and S3) mixing the materials to obtain the defoamer. The objective of the invention is to provide the bulk type power plant desulfuration defoamer which is higher in defoaming speed, longer in foam inhibition time and better in effect and the preparing method thereof.

Owner:湖北新四海化工股份有限公司

Waterborne epoxy resin antirust paint and preparation method thereof

InactiveCN108178965AFast defoaming speedLong foam suppression timeAnti-corrosive paintsEpoxy resin coatingsEpoxyFoaming agent

The invention relates to the technical field of high molecular materials and in particular relates to waterborne epoxy resin antirust paint and a preparation method thereof. The waterborne epoxy resinantirust paint is prepared from the following components in parts by weight: 40 to 60 parts of epoxy resin emulsion, 30 to 40 parts of de-ionized water, 0.1 to 0.8 part of a corrosion inhibitor, 0.2to 1 part of a dispersant, 35 to 40 parts of pigment and filler, 0.1 to 0.5 part of a de-foaming agent, 1 to 2 parts of a film-forming agent, 0.5 to 1 part of a thickening agent and 3 to 5 parts of asilane coupling agent. The high-performance waterborne coating adopts auxiliary agents including the epoxy resin emulsion, the silane coupling agent, the thickening agent, the corrosion inhibitor, thefilm-forming agent and the like so that the waterborne epoxy resin antirust paint has excellent performance.

Owner:吕绍淼

Defoaming agent for printing and dyeing wastewater

InactiveCN103818980AGood dispersionFast defoaming speedWater/sewage treatment by degassingHydrophobic silicaSolvent

The invention provides a defoaming agent for printing and dyeing wastewater. The defoaming agent is obtained by stirring and emulsifying a mixture which consists of simethicone, monoglyceric stearate and sodium carboxymethylcellulose and serves as an active substance and a non-ionized surfactant, a dispersing agent and a solvent carrier which serve as auxiliary materials. The mass ratio of the simethicone, the monoglyceric stearate to the sodium carboxymethylcellulose is (1-5): (1-3): (1-3); the non-ionized surfactant is a span type surfactant or a tween type surfactant; the dispersing agent is hydrophobic silica; the solvent carrier is water.

Owner:季爱英

Antifoaming agent

InactiveCN109173352AImprove efficiencyHigh yieldFoam dispersion/preventionFood scienceEpoxyFood additive

The invention discloses an antifoaming agent and belongs to the technical field of food additives. Ethylene glycol, sodium chloride, sucrose and lard are mixed so that a lard solidifying point is reduced, and formic acid and hydrogen peroxide epoxy-modify the lard so that the storage stability is improved. N-butyl alcohol modifies the white carbon black so that modified hydrophobic white carbon black is prepared. The modified lard, the modified hydrophobic white carbon black and Tween 80 as a surfactant are uniformly mixed and deionized water is added dropwisely added into the mixture so thata uniform emulsion is obtained and is an antifoaming agent special for monosodium glutamate fermentation. The modified hydrophobic white carbon black particles reduce the repulsive force between the lard oil beads and the foam liquid film and help the oil beads to reach the surface of the liquid film more easily so that the defoaming time is shortened and the defoaming performances are improved. The antifoaming agent solves the problem that the traditional antifoaming agent for monosodium glutamate production has poor defoaming ability.

Owner:金福珍

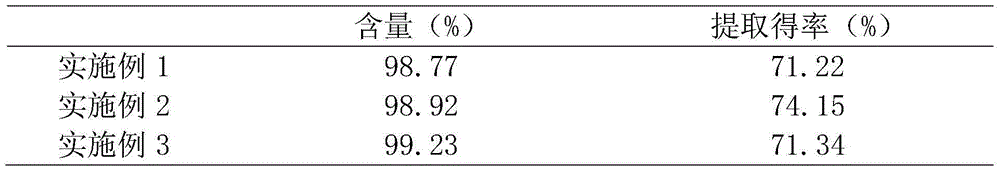

Method for extracting gynostemma pentaphyllum saponins from gynostemma pentaphyllum

The invention discloses a method for extracting gynostemma pentaphyllum saponins from gynostemma pentaphyllum. The method comprises the following steps of treating raw materials, carrying out high-pressure extraction, carrying out aqueous two-phase extraction, desalting, concentrating and drying, thereby obtaining the gynostemma pentaphyllum saponins. The method has the advantages of high content, high extraction ratio, simple process, suitability in production, low production cost and the like.

Owner:桂林三宝生物科技有限公司

Special anti-foaming agent for resin

InactiveCN106807121AImprove defoaming abilityLong foam suppression timeFoam dispersion/preventionFoaming agentVegetable oil

The invention discloses a special anti-foaming agent for resin. The special anti-foaming agent is prepared from, by weight, 15-25% of modified dimethicone, 10-15% of modified polymethylacrylic acid glyceride, 3-18% of paraffin, 4-15% of vegetable oil, 5-10% of glycerin, 3-10% of ethyl alcohol, 3-15% of aluminum stearate, 2-8% of an emulsifying agent, 1-8% of a dispersing agent and 0.1-0.3% of catalysts. The materials are added and stirred for 30-50min to obtain the special anti-foaming agent for resin. The molecular weight of polydimethyl siloxane fluid is 10000-30000, and density of the vegetable oil is 0.837-0.934g / cm<3> below 20 DEG C. The special anti-foaming agent has advantages of high anti-foaming performance, long foam inhibition time, stability in performance, environmental friendliness, nontoxicity, harmlessness, low addition quantity, low cost, easiness in storage and transport and the like.

Owner:广东中联邦精细化工有限公司

Desulfurization specific defoaming agent by using wet flue gas desulfurization processing water as recycled water

ActiveCN109589651AQuality is not affectedGood initial defoamingFoam dispersion/preventionCyclohexanoneSulfonate

The invention discloses a desulfurization specific defoaming agent by using wet flue gas desulfurization processing water as recycled water, and belongs to the technical field of wet flue gas desulfurization. The defoaming agent is prepared from the following components in percentage by mass: 40-6- percent of methyl amylketone, 10-30 percent of cyclohexanone, 10-20 percent of sodium dodecyl benzene sulfonate, 8-15 percent of sodium cocoyl glutamate, 1-5 percent of hydroxyl-alkyl sodium sulfonate, 0.1-0.5 percent of polypropylene resin and 0.05-0.2 percent of sodium carboxymethylcellulose, totally 100 percent. Compared with the prior art, the defoaming agent is a high-efficiency nontoxic environment-friendly defoaming agent, is applicable to defoaming and foam inhibition of complicated ingredients in water aqueous solutions having relatively high content of heavy metals, COD, BOD, suspending substances and the like, and is especially applicable to defoaming in the field of recycled water application.

Owner:JILIN ELECTRIC POWER RES INST LTD +2

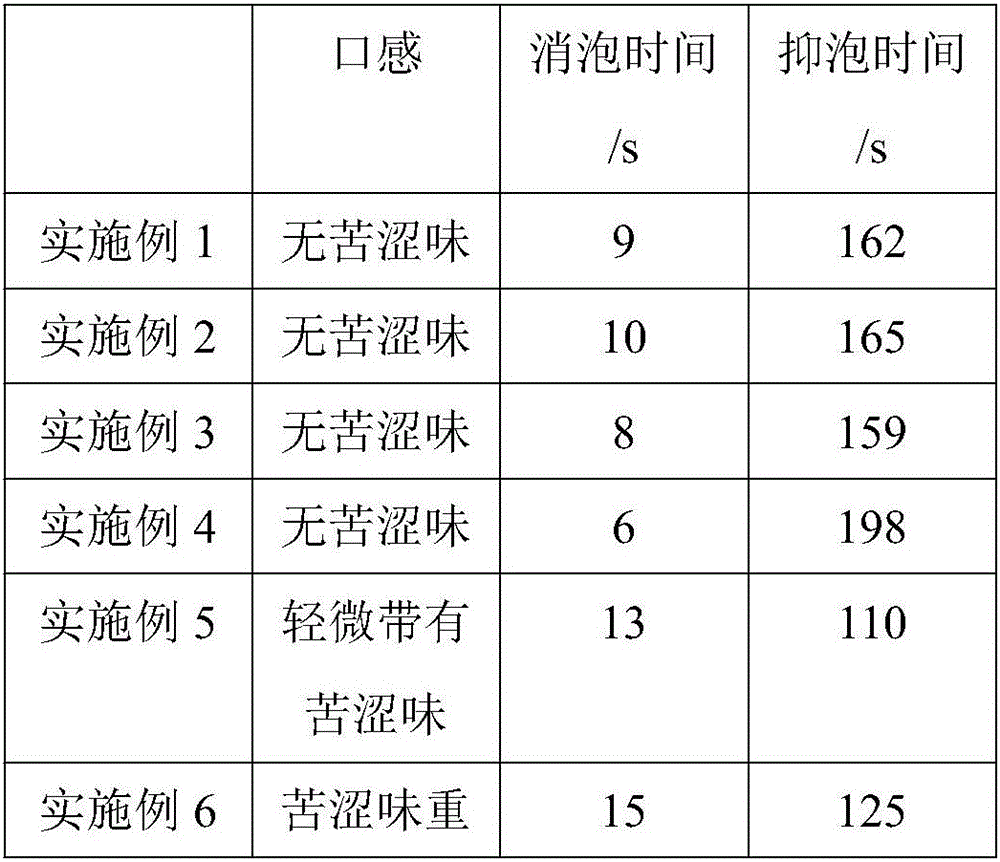

Food antifoaming agent and preparation method thereof

ActiveCN106621476ANo bitternessGreat tasteFoam dispersion/preventionReaction temperatureSilicon dioxide

The invention relates to a food antifoaming agent without bitterness and a preparation method thereof. The antifoaming agent is prepared from the raw materials of dimethicone, silicon dioxide, glyceryl polyether, span, tween and water. By means of regulating matching, reaction temperature and time, temperature rise speed, emulsification temperature and emulsification time of all components, the food antifoaming agent prepared through the method has no any bitterness. The preparation method avoids adding a thickening agent and is simple; a prepared product has the advantages of being stable and free of layering for a long time and having short defoaming time and long antifoaming time.

Owner:LINYI YUWANG VEGETABLE PROTEIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com