Polyether modified organic silicon defoamer safe to strains and preparation method thereof

A technology of organosilicon defoamer and polyether modified silicone oil, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of ineffective extinguishing of foam, difficulty in removing silicon spots, and influence on bacterial growth To achieve the effect of improving dispersibility and anti-foaming ability, fast defoaming speed and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

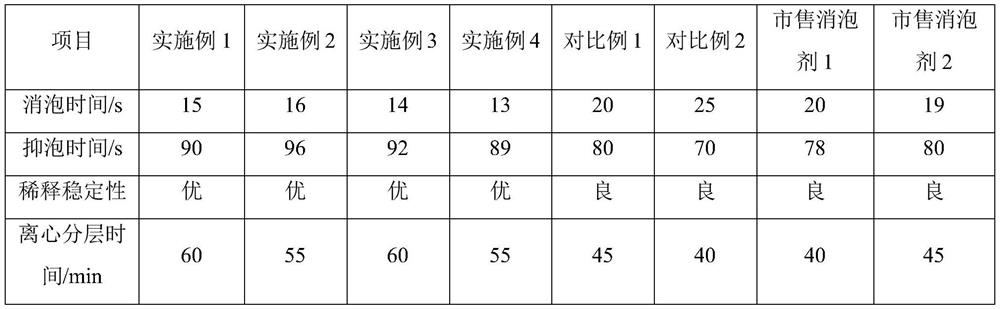

Examples

preparation example Construction

[0021] The invention provides a polyether modified silicone antifoaming agent safe to strains, comprising the following components in parts by weight: 30-60 parts of modified silicon dioxide nano-microspheres, 30-50 parts of polyether modified silicone oil part, 1-10 parts of thickener, 2-10 parts of emulsifier and 10-50 parts of water, and its preparation method comprises the steps:

[0022] (1) Add ammonia water to absolute ethanol, add tetraethyl orthosilicate (TEOS) drop by drop under vigorous stirring, then stir at 20-30°C for 20-24 hours, centrifuge after the reaction, and use free Washing with water and ethanol, centrifuging again, repeated several times, and finally vacuum freezing to obtain silicon dioxide nanometer microspheres.

[0023] (2) The silicon dioxide nano-microspheres obtained in step (1), dimethyl silicone oil, N, N-methylformamide (DMF) and deionized water are added to the reaction flask successively, and ammonia water is added under stirring, and heated...

Embodiment 1

[0034] In this example, the preparation method of the polyether modified silicone defoamer that is safe to strains is as follows:

[0035] (1) Add 3mL of ammonia water to 100mL of absolute ethanol, add 5mL of tetraethyl orthosilicate (TEOS) dropwise under vigorous stirring, then stir at 20°C for 24 hours, centrifuge after the reaction, and remove the precipitate with anhydrous Washing with ethanol, centrifuging again, repeated several times, and finally vacuum freezing to obtain silicon dioxide nanometer microspheres.

[0036] (2) Get 1g of silica nanospheres obtained in step (1), 0.5mL of dimethyl silicone oil, 20mL of N, N-methylformamide (DMF) and 10mL of deionized water into the reaction flask successively, and stir Add 1mL of ammonia water under low temperature, heat to 70°C and react for 2 hours, then naturally cool to room temperature, centrifuge, take the precipitate, wash it with ethanol, and dry it in an oven at 60°C to obtain simethicone grafted modified silica nano...

Embodiment 2

[0040] In this example, the preparation method of the polyether modified silicone defoamer that is safe to strains is as follows:

[0041] (1) Add 4mL of ammonia water to 100mL of absolute ethanol, add 6mL of tetraethyl orthosilicate (TEOS) dropwise under vigorous stirring, then stir at 30°C for 20 hours, centrifuge after the reaction, and remove the precipitate with anhydrous Washing with ethanol, centrifuging again, repeated several times, and finally vacuum freezing to obtain silicon dioxide nanometer microspheres.

[0042] (2) Get 2g of silica nanospheres obtained in step (1), 1.0mL of dimethyl silicone oil, 30mL of N, N-methylformamide (DMF) and 10mL of deionized water into the reaction flask in turn, and stir Add 2mL of ammonia water under low temperature, heat to 60°C and react for 1.5 hours, then naturally cool to room temperature, centrifuge, take the precipitate, wash it with ethanol and dry it in an oven at 50°C to obtain simethicone grafted modified silica nanopart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com