Slanting axial piston pump

A technology of axial piston pump and swash plate, applied in the field of axial piston pump/motor, can solve the problems of increasing the axial load of the drive shaft, reducing the self-priming performance of the pump, and decreasing the volumetric efficiency, so as to increase the rated working pressure , to achieve sealing performance, improve the effect of starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

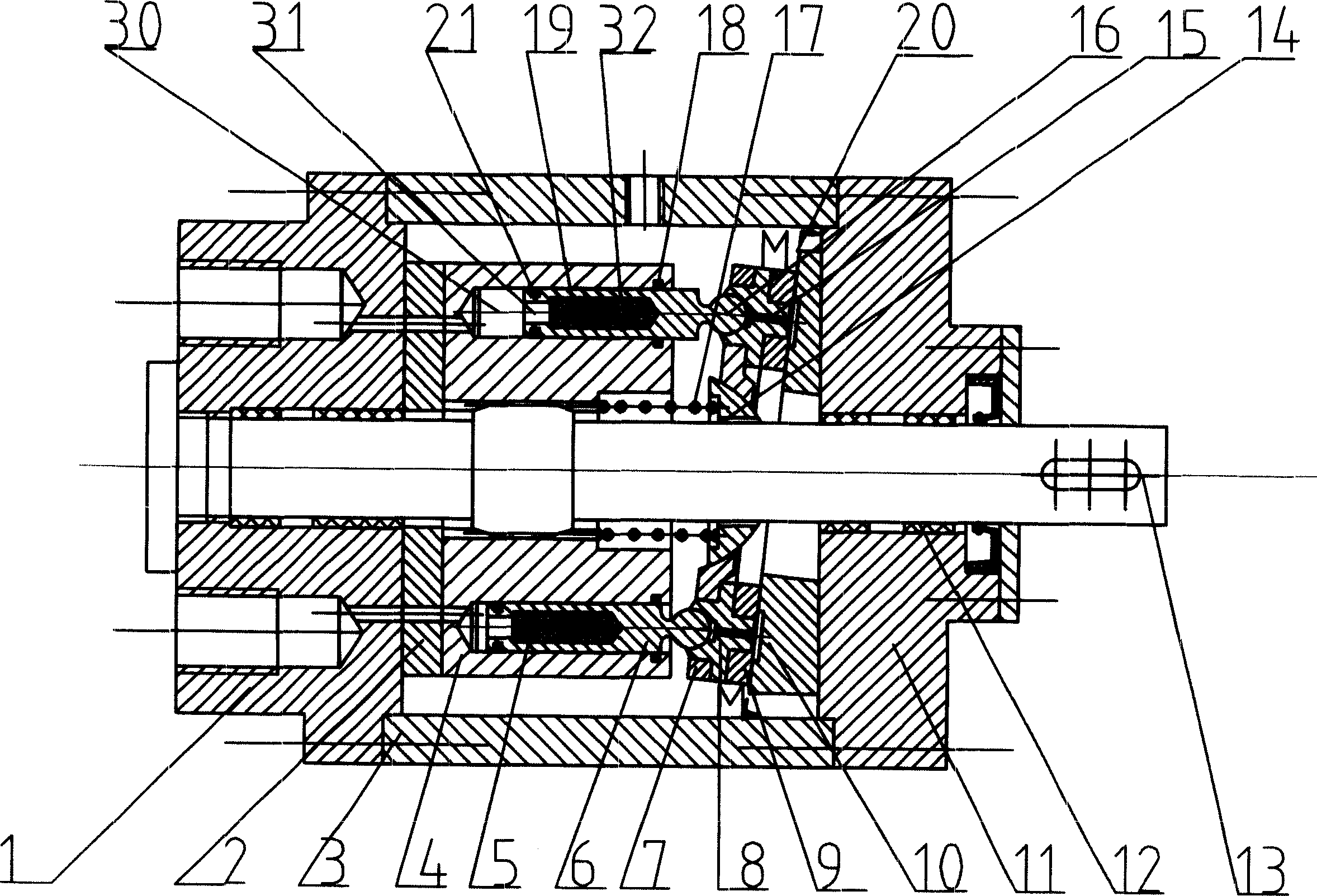

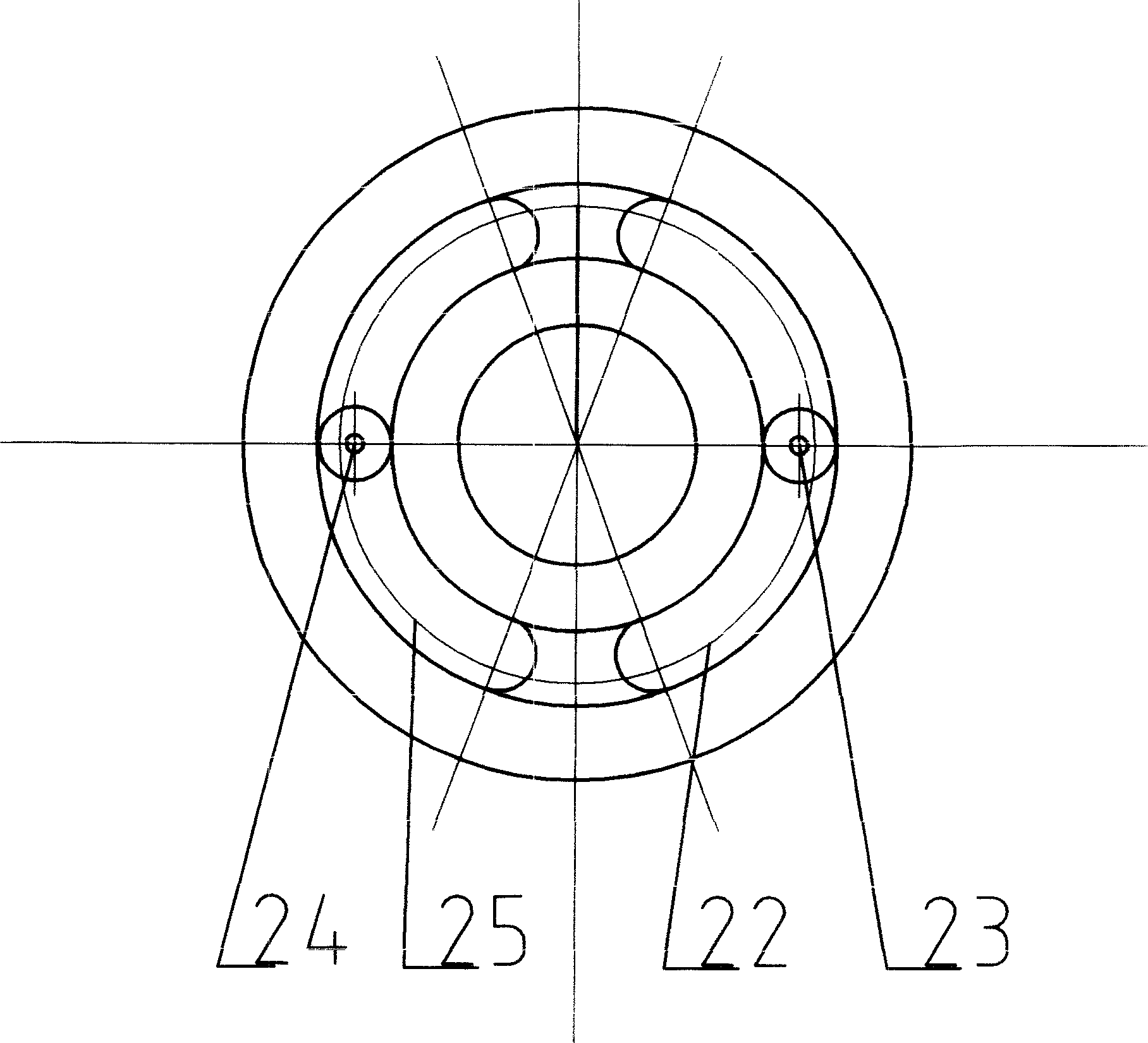

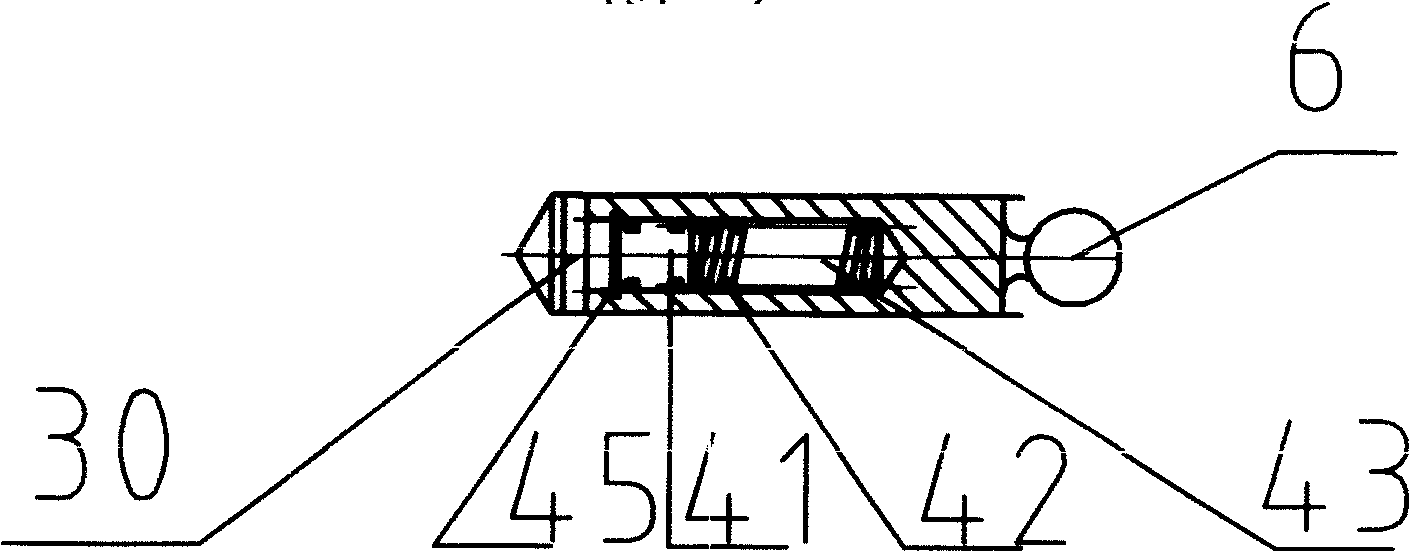

[0051] Such as figure 1 , figure 2 As shown, the patent of the present invention includes a front pump cover 11, a rear pump cover 1, and a pump body 3 connected with the front pump cover 11 and the rear pump cover 1 by bolts; the cylinder body with a plunger cavity 30 parallel to its axis is evenly distributed inside 4. The cylinder 4 can slide axially along the drive shaft 13; the flow distribution device 2 installed between the cylinder 4 and the rear pump cover 1;-one end is ball-hinged with the sliding shoe 8 and the other end is placed in the plunger cavity 30 The plunger 6, the plunger 6 has an inner plunger cavity 19 that communicates with the plunger cavity 30 on the side facing the flow distribution device 2, which is a blind cavity; the plunger inner cavity 19 has a small hole section facing the flow distribution device side 31. There is a large hole section 32 towards the blind end, and polyurethane elastomer is poured into the large hole section as the accumulator 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com