Patents

Literature

160results about How to "Fast defoaming speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Delaying coking non-silicon defoaming agent with multiple active components and preparation method thereof

ActiveCN101780382ANo effectGood defoaming at high temperatureTransportation and packagingMixingAlcoholHigh carbon

The invention discloses a delaying coking non-silicon defoaming agent with multiple active components and a preparation method thereof, and the defoaming agent is formed by compounding 30-50 parts by weight of polyether or modified polyether polymer, 25-35 parts by weight of high-carbon alcohol mixture, 10-15 parts by weight of high-carbon alcohol fatty acid ester or fatty acyl amide and 15-20 parts by weight of alkymer. The preparation method of the defoaming agent comprises the following steps: adding the polyether or the modified polyether polymer, the high-carbon alcohol mixture, the high-carbon alcohol fatty acid ester or the fatty acyl amide and the alkymer into a reaction kettle according to the proportion, stirring, slowly increasing the temperature to 50-100 DEG C, carrying out reaction for 1-2h, finally stopping stirring, cooling, filtering for removing solid impurities and finally preparing the delaying coking non-silicon defoaming agent. The defoaming agent can effectively suppress and eliminate the formation of bubbles in a delayed coking reaction tower, improve the treatment capacity of the reaction tower, prolong the coking time of coke and prevent clogging phenomenon.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

Organic silicon defoaming agent and preparation method thereof

ActiveCN103877755AImprove stabilityFast defoaming speedFoam dispersion/preventionFatty amineEngineering

The invention relates to an organic silicon deforming agent and a preparation method thereof. The organic silicon deforming agent consists of the following components in parts by weight: 10-20 parts of dimethicone, 5-10 parts of hydroxyl silicone oil, 1-4 parts of silicon dioxide, 2-10 parts of fatty amine polyoxyethylene ether, 1-2 parts of alkymer, 5-15 parts of emulgators, 2-4 parts of thickening agents and 60-80 parts of water. The preparation method of the organic silicon deforming agent comprises the following steps of heating, stirring and heat preservation. The prepared organic silicon deforming agent has the characteristics of good stability, rapid defoaming speed, less dosage, no toxicity and odor and the like, and has an excellent using effect in elimination and inhibition of foam in the industries of paper making, oil ink, painting, chemical engineering and the like.

Owner:SUZHOU HENGKANG NEW MATERIALS

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Defoaming agent

InactiveCN1426827APerformance is not affectedFast defoaming speedFoam dispersion/preventionAlcoholFoaming agent

A defoaming agent for anionic or non-ionic foaming agent used in production of rubber and plastics is prepared from hydrocarbonylated oil 40-60 wt portions, C4-C8 alcohol amine 3-29 portions, C10-C18 fatty acid 2-30 portions, alcohol amine ester of C10-C18 fatty acid 3-15 portions, codefoaming agent 5-15 portions, and disperser 3-8 portions through emulsifying with water. Its advantages are high defoaming speed and strong power on suppressing foams.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Air purification heath protection mud and production process thereof

ActiveCN102302927ASufficient antifreeze strengthFast defoaming speedOther chemical processesDeodrantsCelluloseInorganic pigments

The invention provides air purification heath protection mud and a production process thereof. The health protection mud consists of a component I and a component II, wherein the component I comprises diatomite, zeolite powder, maifanitum powder, nano zinc oxide, negative ion powder, dispersible latex powder, methyl cellulose and an inorganic pigment; and the component II comprises water, an anti-freezing agent, a dispersing agent, an antifoaming agent, an emulsifying agent, a stabilizing agent, a macromolecule packaging agent, and cypress oil, clove oil or eucalyptus oil. The health protection mud has the effect of eliminating harmful substances such as formaldehyde, benzene and the like and improving indoor geomagnetic intensity, can produce negative ions, has the functions of deodorization, smell elimination, inflaming retardant, sound insulation and noise reduction, and can adjust indoor air humidity.

Owner:王钟贤

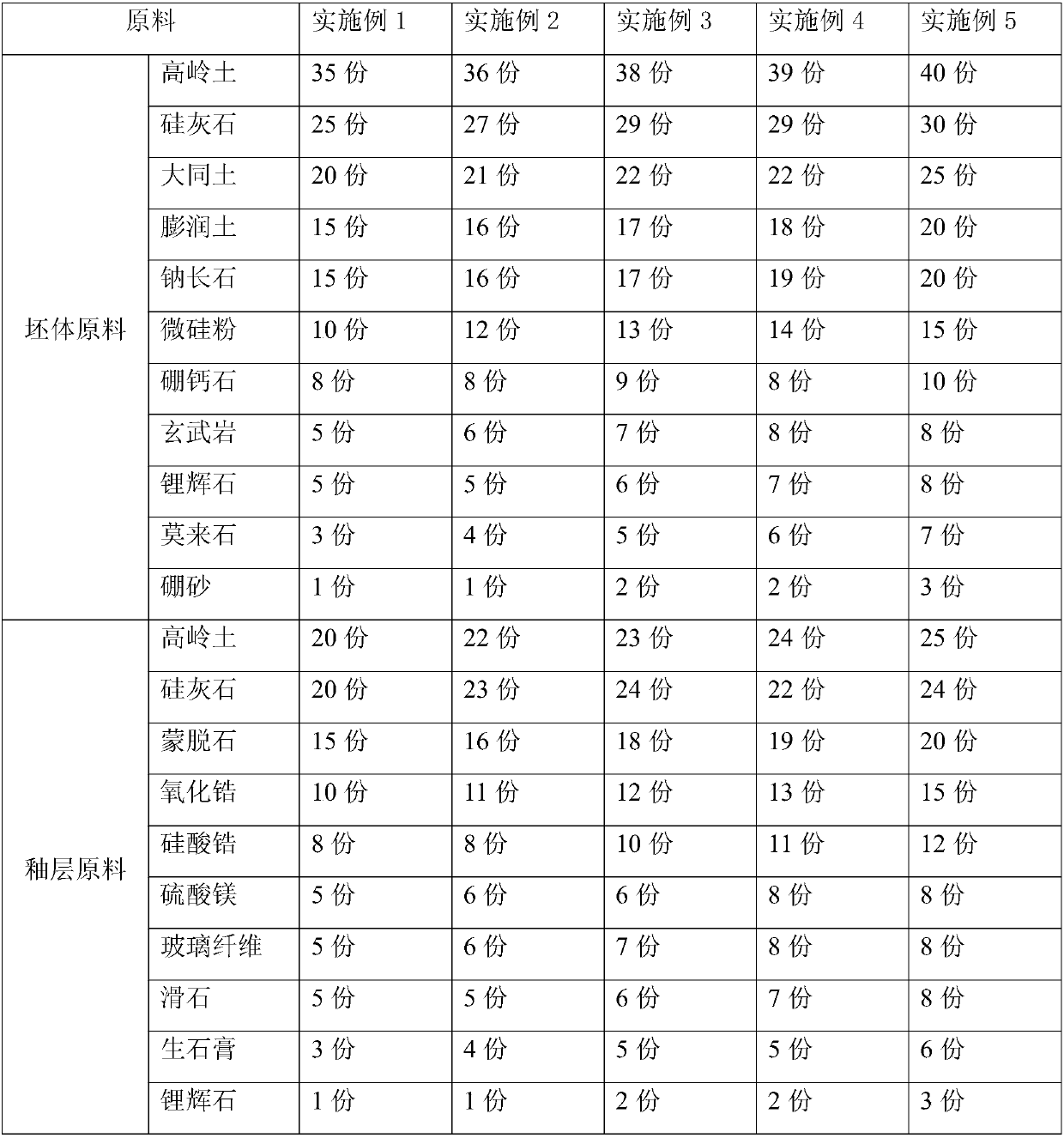

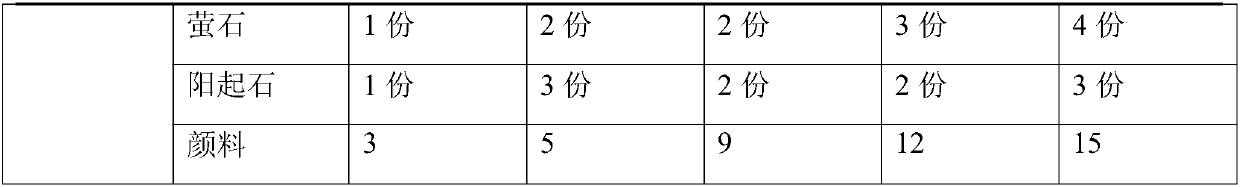

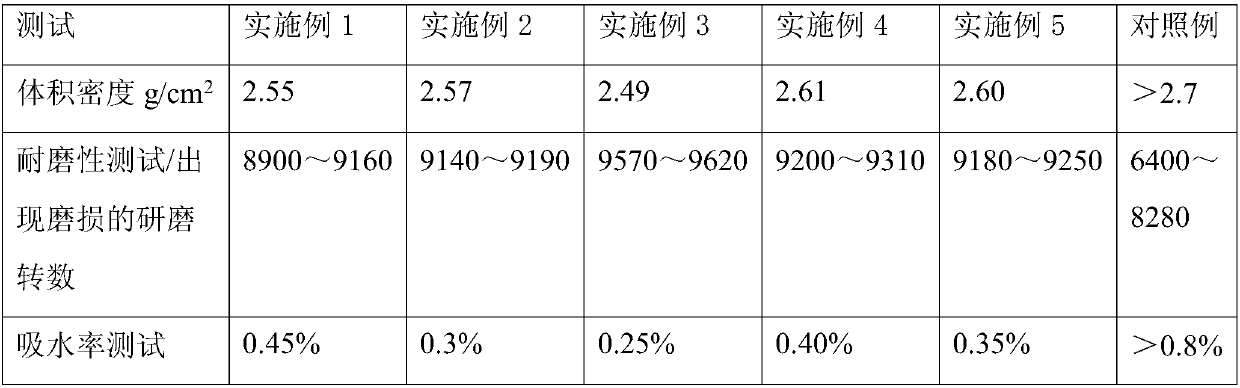

One-time low-temperature fast-firing light ceramic product and preparation process thereof

The invention provides a one-time low-temperature fast-firing light ceramic product. The one-time low-temperature fast-firing light ceramic product comprises a green body and an enamel layer applied to the surface of the green body, wherein kaolin, wollastonite and Datong soil are adopted in raw materials of the green body as main aggregates, and bentonite, albite, silica fume, borocalcite, basalt, spodumene, mullite and borax are adopted as accessories; the kaolin, the wollastonite and montmorillonite are adopted as main aggregates of the enamel layer, and zirconium oxide, zirconium silicate,magnesium sulfate, glass fibers, talcum, gypsum, spodumene, fluorite and actinolite are adopted as accessories. A one-time low-temperature fired ceramic product which is light in weight and has certain abrasion resistance and water resistance is prepared in conjunction with a preparation process provided by the invention. The raw materials and the process provided by the invention can be appliedto preparation of domestic ceramic dinnerware, ceramic plates, ceramic artwork and the like.

Owner:福建省德化业美陶瓷有限公司

Emulsion-type organosilicone defoamer and preparation method thereof

ActiveCN105688452AImprove bindingLong-lasting defoaming effectFoam dispersion/preventionEmulsionSodium phosphates

The invention discloses an emulsion-type organosilicone defoamer and a preparation method thereof. The preparation method includes: at 90-100 DEG C, using a hydrophobic treatment agent and ammonium dihydrogen phosphate to pre-treat hydrophobic gas-phase white carbon black; bending obtained gas-phase white carbon black with dimethicone at 170-200 DEG C to obtain silicone cream; under action of a compound emulsifier, compounding the silicone cream, fatty alcohol and sodium phosphate to obtain the emulsion-type organosilicone defoamer. The defect that existing emulsion-type organosilicone defoamers are prone to inactivation and poor in foam inhibiting performance is overcome, the organosilicone defoamer obtained has excellent alkali resistance and good continuous application performance, and is high in defoaming speed, foam inhibiting performance and emulsion stability and long in defoaming activity time, and the preparation process is clean and environment-friendly, free of emission of 'three wastes' and suitable for industrial production.

Owner:FUZHOU UNIV

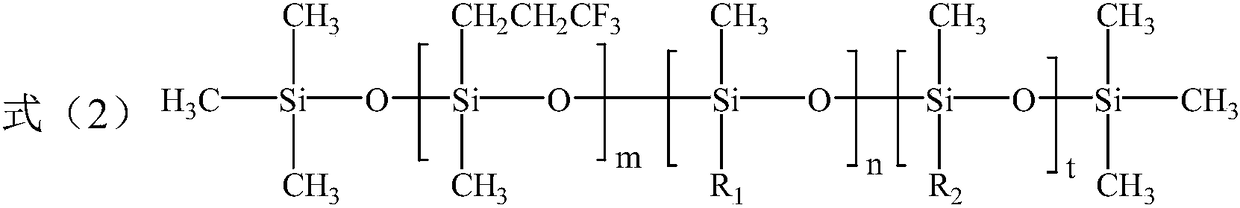

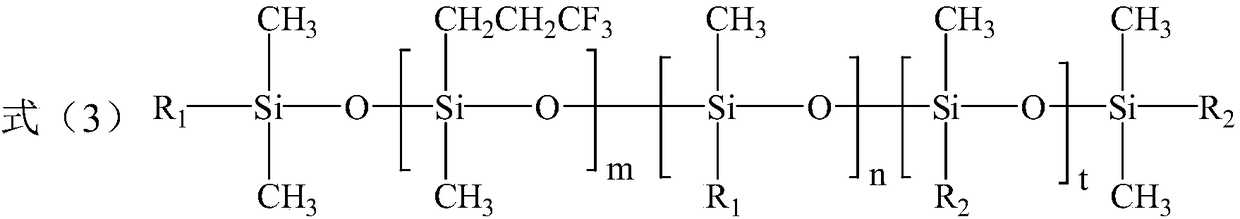

Ddelay coking defoaming agent composition and preparation method thereof

ActiveCN103768832AImprove defoaming abilityReduce the amount addedThermal non-catalytic crackingFoam dispersion/preventionAlcoholSolvent

The invention relates to a delay coking defoaming agent composition and a preparation method thereof, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, glycerin type dendritic polyether, high carbon alcohol and a solvent. The preparation method of the defoaming agent is as follows: dispersing the fluorine-containing polysiloxane in the high carbon alcohol, stirring for 1 to 2 hours at 10-30 DEG C, then adding the glycerin type dendritic polyether and the solvent, stirring for 1 to 5 hours at 100-150 DEG C, and cooling to obtain a defoaming agent product. The delay coking defoaming agent has excellent defoaming antifoaming performances at 400-500 DEG C, in a high temperature delay coking process, the delay coking defoaming agent can still maintain good defoaming antifoaming performances and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water- and solvent-resistant diazo screen printing platemaking photoresist

A water and solvent resistant diazo-photoresist for making the silk screen printing plate is prepared from polyvinyl alcohol homopolymer / polyvinyl alcohol-aldehyde modified polymer, poly(vinyl acetate) homopolymer / vinyl acetate-acrylate copolymer, organosilicon modified high-molecular compound, and the monomer with optical cross-linking activity through mixing. Said silk screen printing plate is made up through applying said photoresist on silk screen, baking to become film, ultraviolet irradiation, optical solidifying reaction, developing in water, and removing the part which is not photosensed. It can resist against water, solvent, acidic dye and reactive dye.

Owner:SHANGHAI JAROS NEW MATERIAL

Polyether antifoaming agent and preparation method thereof

The invention belongs to the field of chemical auxiliaries and particularly relates to a polyether antifoaming agent and a preparation method thereof. The polyether antifoaming agent is prepared from, by weight, 89-95% of polyoxypropylene oxyethylene glycol ether, 0.6-2.1% of fatty high-carbon alcohols, 4-7.7% of silicon grease and silicon oil, 0.1-0.5% of a penetrating agent, 0.1-0.2% of a catalyst, 0.1-0.2% of a diffusing agent and 0.1-0.3% of a stabilizer, wherein viscosity of the silicon oil is 260mpa.s. The polyether antifoaming agent is high in stability, antifoaming strength and antifoaming speed, and nutrients are provided for hyphae in a fermentation process while toxicity is reduced. In addition, the polyether antifoaming agent is effective in foam elimination and inhibition in industries of papermaking, fermentation, foods, medicines and the like.

Owner:ZIBO HUISHENG IND & TRADE CO LTD +1

Flexibility-enhanced polyurethane

ActiveCN109897517AGood film-forming performanceImprove softnessFireproof paintsPolyurea/polyurethane coatingsPrepolymerPolymer chemistry

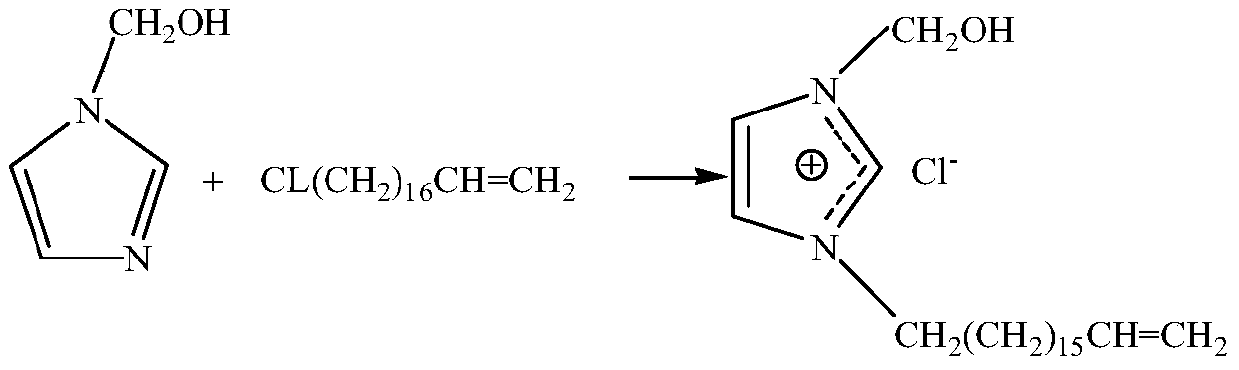

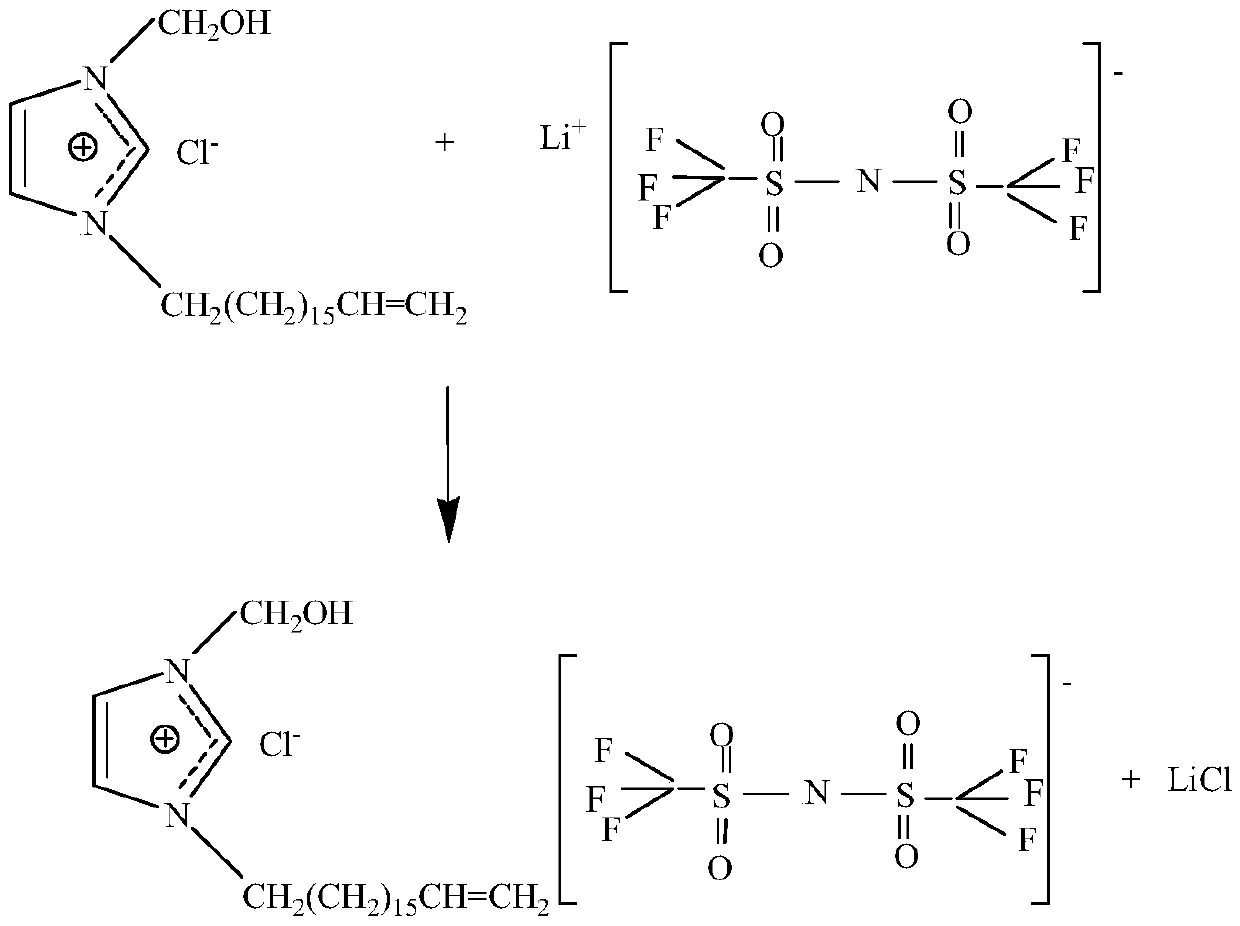

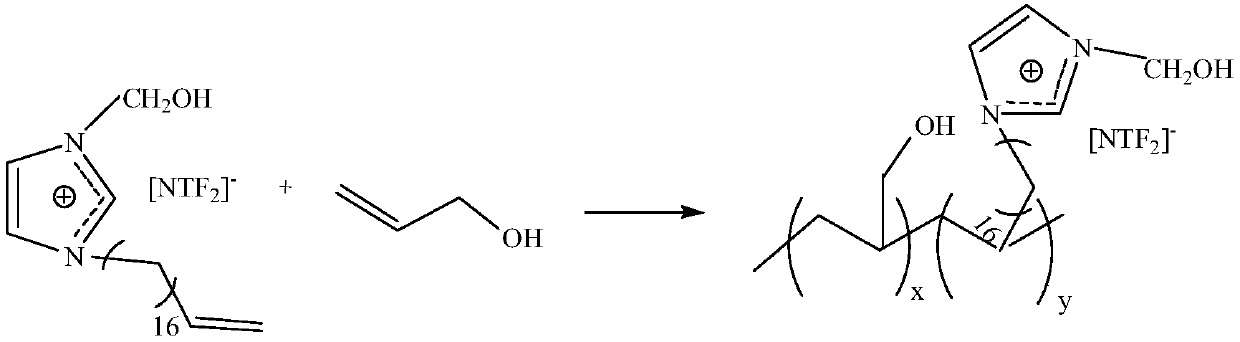

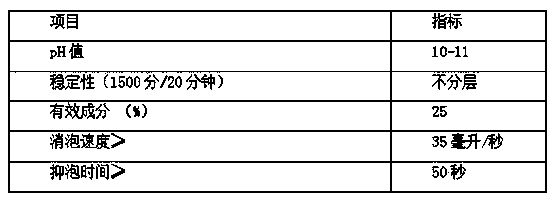

The invention provides a flexibility-enhanced polyurethane. A preparation method of the flexibility-enhanced polyurethane comprises the following reaction steps: 1, preparation of an ionic liquid polymer with a dihydroxy group; 2, preparation of an ionic liquid polymer modified polyurethane prepolymer; and 3, preparation of the flexibility-enhanced polyurethane. The modified polyurethane preparedby the preparation method has the advantages of high flexibility, good film forming property, strong mechanical properties, high thermal stability, high chemical stability, high tensile strength, difficult shedding or explosion, energy saving, environmental protection and wide application range.

Owner:广州精点高分子材料制品有限公司

Defoaming agent for sewage treatment and preparation method thereof

InactiveCN102976429BReduce processing costsHigh cost of solutionEnergy based wastewater treatmentWater/sewage treatment by degassingSewage treatmentSilicone oil

The invention relates to a defoamer for sewage treatment and a preparation method thereof, belonging to the technical field of defoamer production. The defoamer of the present invention comprises the following components in parts by weight: 0.8 to 1 part of diethyl glyceride, 0.8 to 1 part of ethylene bisstearamide, 2.4 to 3.6 parts of heavy liquid paraffin, 45 to 40 parts of machine oil, 20-25 parts of kerosene, 30-32 parts of dimethyl silicone oil, and 1-1.4 parts of white carbon black. The present invention solves the problem that the price of organosilicon and polyether defoamers and defoamers in the prior art is high, which makes the cost of sewage treatment high. The invention is superior to existing defoamers, can improve its defoaming effect, defoaming speed and foam suppression time, has good stability and low cost, and greatly reduces the cost of sewage treatment.

Owner:YIBIN HIEST FIBER +1

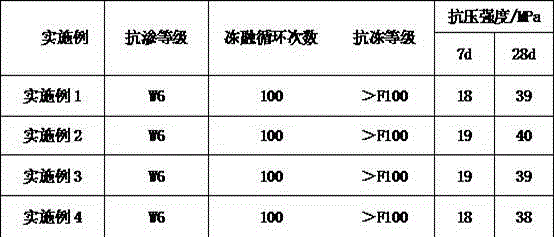

Method for producing concrete channel prefabricated part from mineral slag

InactiveCN106007593AImprove anti-seepage effectImprove flexibilitySolid waste managementAluminateSlag

The invention relates to a method for producing a concrete channel prefabricated part from mineral slag. The method is characterized in that the concrete channel prefabricated part is prepared from the following raw materials in parts by weight: 60-70 parts of fine and coarse aggregate, 10-20 parts of 42.5 sulfoaluminate cement, 5-10 parts of fly ash, 5-10 parts of slag micropowder, 1-3 parts of early-strength admixture, 1-3 parts of high efficiency water reducing agent and 0.1-0.5 part of defoaming agent. The high efficiency water reducing agent is a calcium lignosulphonate water reducing agent. The concrete channel prefabricated part has the advantages of low cost, excellent properties, stable quality, excellent compression strength, excellent compression strength, excellent freeze resistance and excellent water impermeability. The method aims to further enhance the standard construction of irrigation projects, comprehensively enhance the construction level and management and protection level of agricultural hydraulic engineering in China, increase the utilization ratio of irrigation water and implement high-efficiency utilization of water resources.

Owner:象州县科学技术局

Antifoaming agent for food fermentation

InactiveCN103816699AGood dispersionFast defoaming speedFoam dispersion/preventionPolyethylene glycolGlycerol

The invention provides an antifoaming agent for food fermentation. The antifoaming agent is obtained by stirring an active ingredient which is a mixture of polyethylene glycol, polyoxyethylene polyoxypropylene glycerol and high-carbon alcohol and accessories comprising an active emulsifying agent and a dispersant, wherein the mass ratio of the polyethylene glycol, the polyoxyethylene polyoxypropylene glycerol to the high-carbon alcohol is (1-3):(1-3):(1-3); the active emulsifying agent is glycerol monostearate, fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylate; the dispersant is hydrophobic silicon dioxide; the high-carbon alcohol is C7 to C9 alcohol.

Owner:季爱英

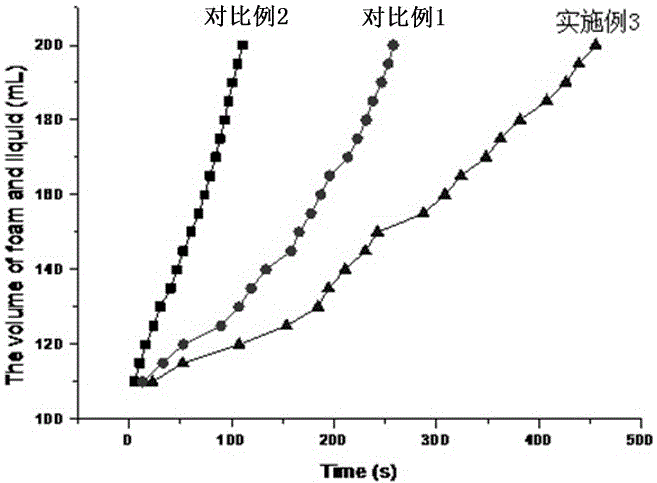

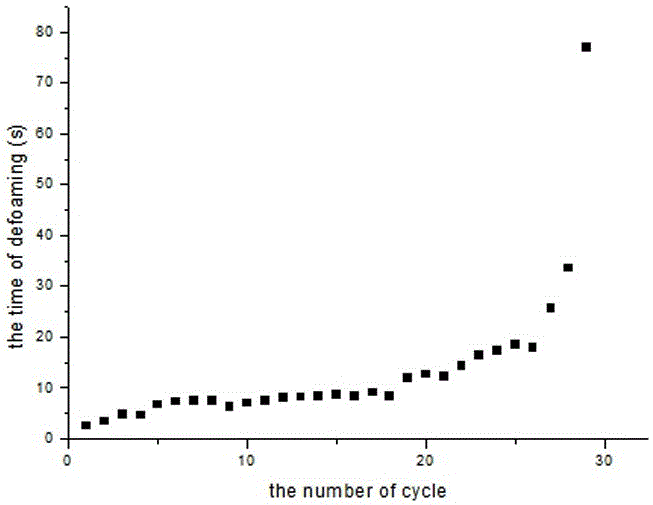

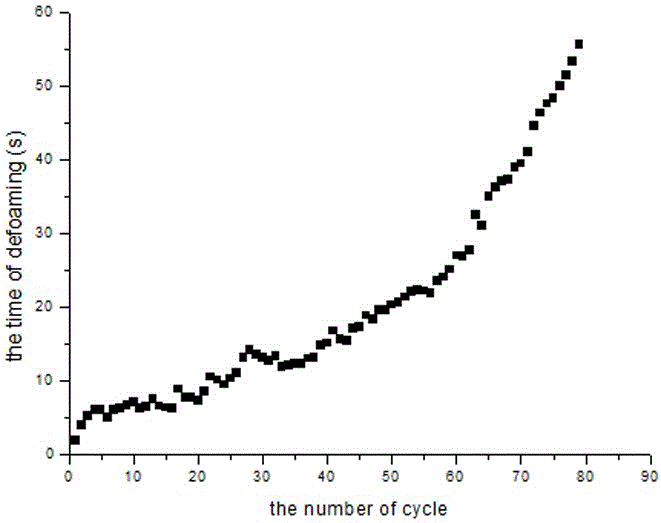

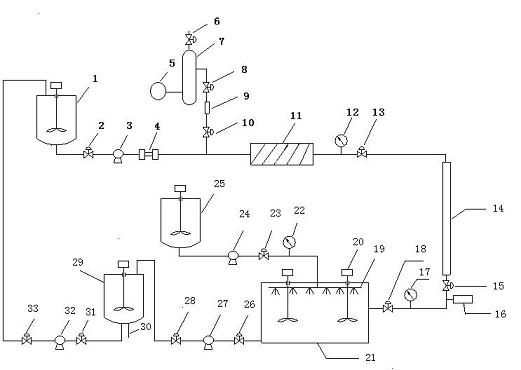

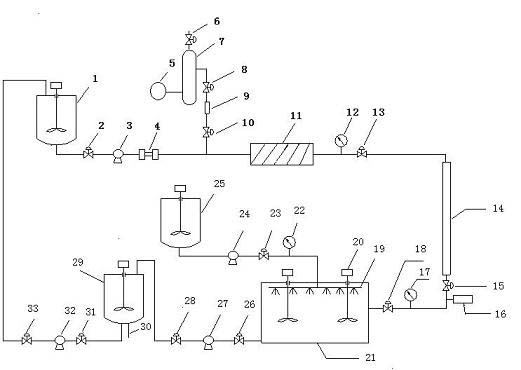

Foam cyclic utilization method by utilizing low carbon alcohol to realize foam drilling

InactiveCN101871330AFast defoaming speedLower Drilling CostsConstructionsFlushingFoaming agentAlcohol

The invention discloses a foam cyclic utilization method by utilizing low carbon alcohol to realize foam drilling. Foam returned from wellhead after mineshaft circulation is added with low carbon alcohol for defoaming, foam liquid after defoaming is foamed and then is reused in the well, thus realizing cyclic utilization of foam. The added defoaming agent includes at least low carbon alcohol the structural formula of which is R-OH, wherein R is alkyl containing four carbon atoms or five atoms; and the low carbon alcohol has both foaming and defoaming functions. By adopting the method for realizing foam circulation, only low carbon alcohol is required to be added for defoaming, base fluid after defoaming can be foamed again and then be reused in the well; if low carbon alcohol volume content in foam base fluid after a plurality of times of circulation accounts for more than 5% of foam base fluid volume, the low carbon alcohol is removed, then foaming agent is added for foaming, thus realizing the cyclic utilization of foam base fluid; the removed low carbon alcohol can be reused, the low carbon alcohol has no selectivity to the foaming agent, and defoaming speed is rapid, and foam drilling cost can be reduced, thus being environmentally friendly.

Owner:SOUTHWEST PETROLEUM UNIV

Novel organic silicon defoamer for landfill leachate treatment and preparation method of novel organic silicon defoamer

ActiveCN112495000AGood defoamingGood anti-foam performanceSustainable biological treatmentFoam dispersion/preventionEnvironmental engineeringFatty acid

A novel organic silicon defoamer for landfill leachate treatment is prepared from the following raw materials in percentage by mass: 10-20% of polyether modified polydimethylsiloxane with the viscosity of 500-1500 mPa.s; 1-5% of nanoscale fumed silica with the particle size of 10-30 nm; 1-5% of modified silicone oil; 2-8% of fatty acid polyoxyethylene ester with the HLB value of 6-12; 3-10% of anemulsifier; 1-6% of a thickening agent; 1-2% of a biological inhibitor; and the balance of deionized water. The organic silicon defoamer for landfill leachate treatment not only has the characteristics of rapid defoaming and good foam inhibition, but also can resist the high temperature of 100-120 DEG C, and is not easy to demulsify and separate out in a complex organic matter system.

Owner:沈阳瑞驰表面技术有限公司

Organosilicon defoamer with bactericidal action

InactiveCN106390533AFast defoaming speedStrong anti-foaming abilityFoam dispersion/preventionChemistryActivated carbon

The invention discloses an organosilicon defoamer with a bactericidal action. The organosilicon defoamer is prepared from the following raw materials in parts by weight: 40-60 parts of simethicone, 20-30 parts of silicon dioxide, 0.3-0.5 part of stearamide, 0.3-0.5 part of potassium iodide, 0.3-0.5 part of sodium carbonate, 0.4-0.6 part of tributyl phosphate, 4-6 parts of clinoptilolite powder, 0.3-0.4 part of sodium tripolyphosphate, 0.3-0.5 part of mannitol, 2-3 parts of common salt, 0.3-0.6 part of barium stearate, 1-3 parts of glycerine, 0.4-0.6 part of copper sulfate, 0.5-0.7 part of activated carbon and 10-20 parts of water.

Owner:合肥新万成环保科技有限公司

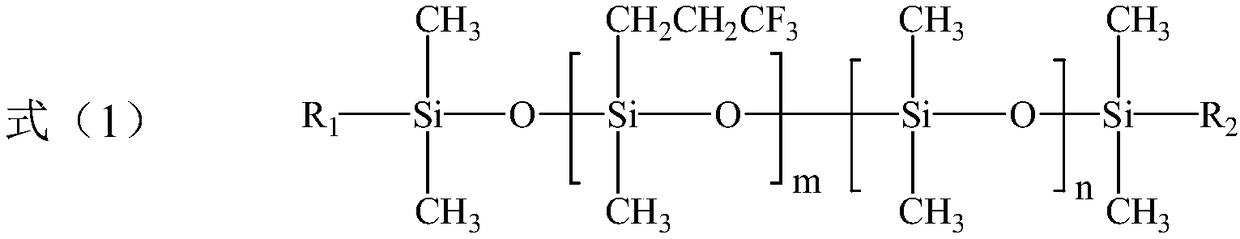

Emulsion type fluorine-containing organosilicone defoaming agent for oil and aqueous two-phase system and preparation method thereof

ActiveCN108159738AGood defoaming and anti-foaming effectHigh activityFoam dispersion/preventionOrganic solventOil phase

The invention provides an emulsion type fluorine-containing organosilicone defoaming agent for an oil and aqueous two-phase system and a preparation method thereof, wherein the defoaming agent includes the following components: polyether and acrylate co-modified fluorine-containing silicone oil, silicon paste, silicon resin, an emulsifier, a thickener and water. The defoaming and foam inhibition performance of an aqueous phase and an oil phase are improved by introducing the silicon resin and a fluorine-containing group into the system. When the defoaming agent is used in the aqueous phase system, solubilization of the silicone oil in the aqueous-phase system can be effectively inhibited, the defoaming and foam inhibition performance is improved, and the high-temperature strong alkaline resistance can be improved. When the defoaming agent is used in the oil phase system, the oil resistance of dimethicone can be significantly increased, and the defoaming agent becomes a highly efficientdefoaming agent in raw oil, lubricating oil, organic solvents and other oil-phase systems.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

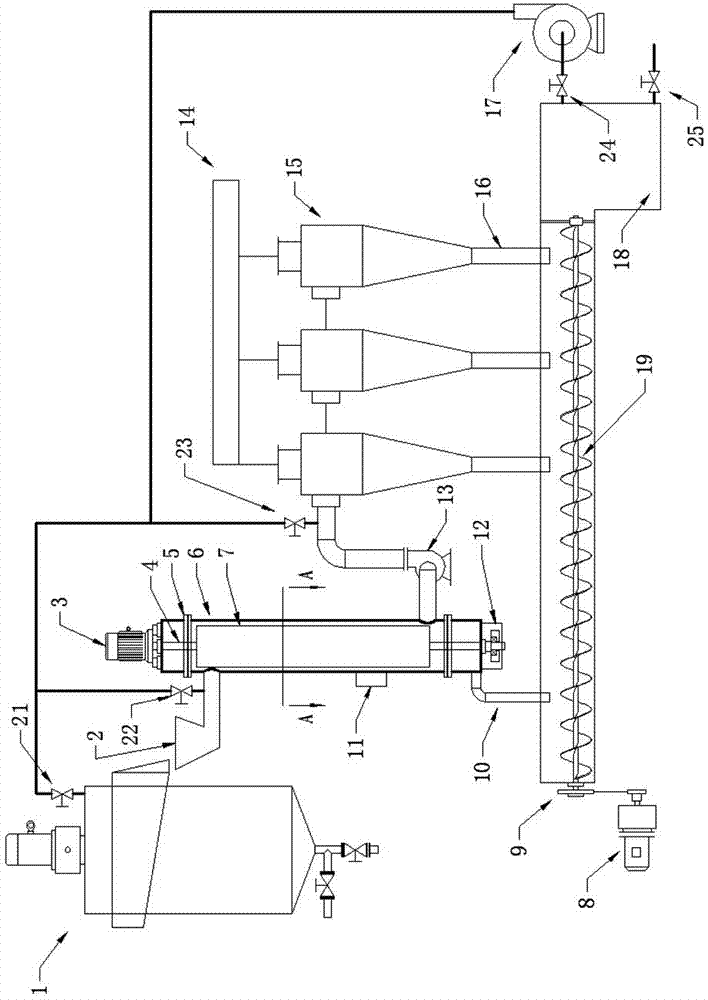

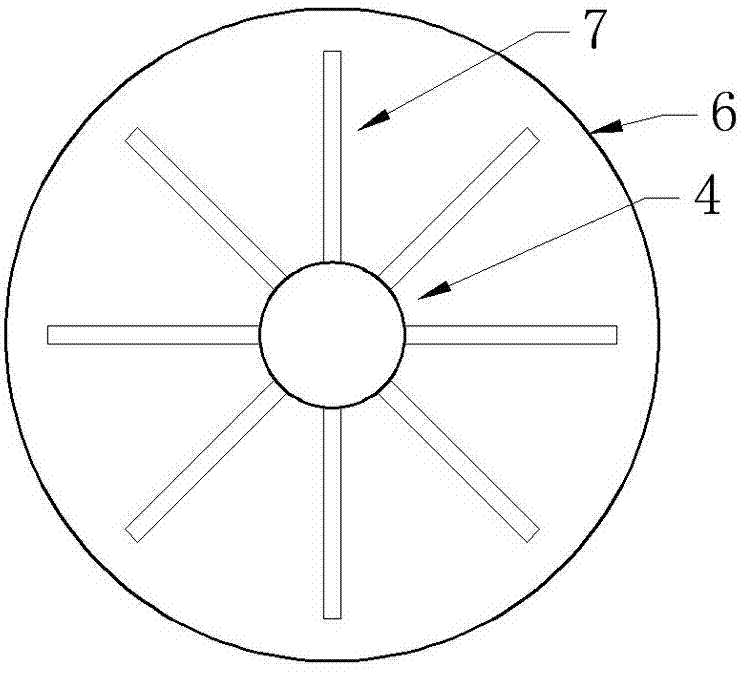

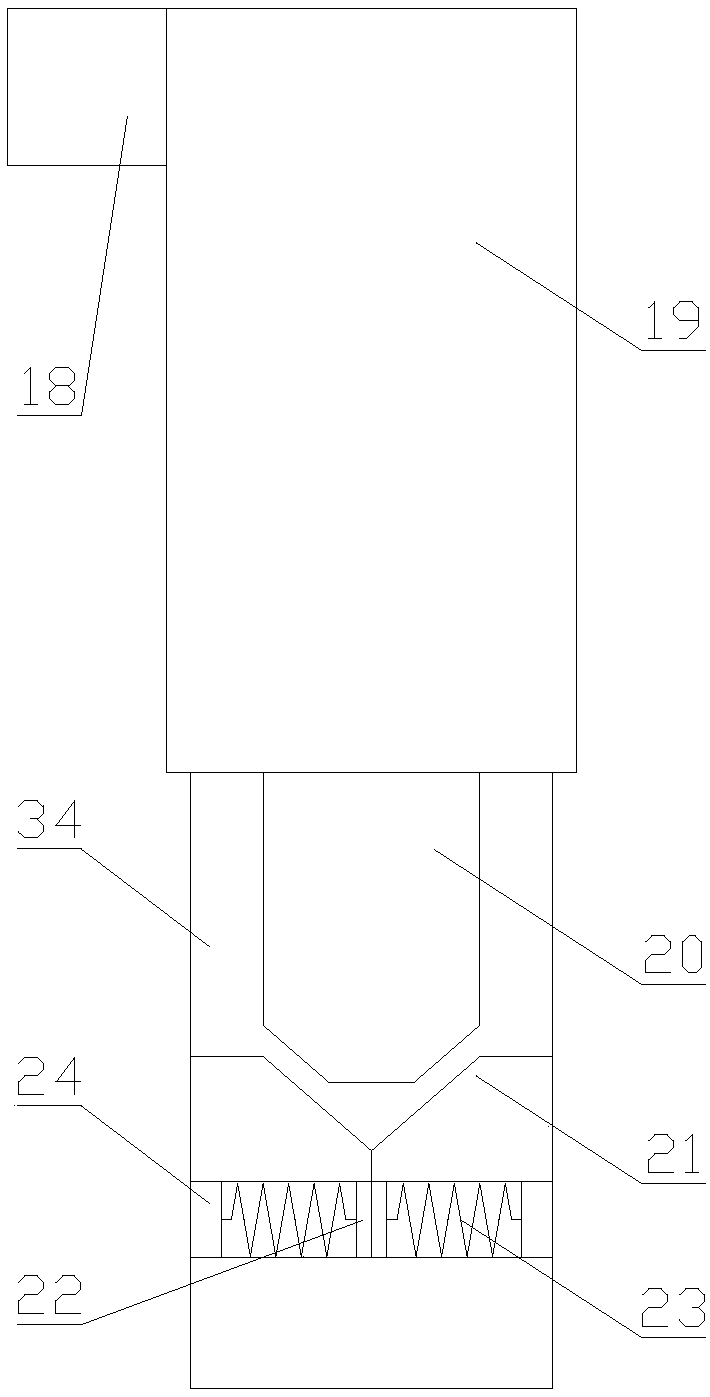

Rotor cyclone two-stage tandem type mineral flotation and defoaming device

InactiveCN104259014AHigh foam breaking efficiencyFast defoaming speedDispersed particle separationSettling tanks feed/dischargeCyclonic separationMineral flotation

The invention discloses a rotor cyclone two-stage tandem type mineral flotation and defoaming device which comprises a flotation machine, a foam feeding hopper, a rotor, an exhaust fan, a cyclone separation device, an exhaust pipe, a spiral conveyor and a sedimentation pond. The rotor is located in a barrel and composed of a rotary shaft and blades, and a barrel discharging pipe is connected with the spiral conveyor. The flotation machine is connected with the foam feeding hopper, the foam feeding hopper is connected with the exhaust fan through the barrel, the exhaust fan is connected with the cyclone separation device, the top of the cyclone separation device is connected with the exhaust pipe, the bottom of the cyclone separation device is connected with the spiral conveyor through a discharging pipe, and a material outlet of the spiral conveyor is connected with the sedimentation pond. The rotor cyclone two-stage tandem type mineral flotation and defoaming device is simple and reliable in cyclone separation and high in rotor defoaming efficiency, facilitates continuity achievement, rapidly and efficiently performs defoaming and air separation in a rotor cyclone two-stage tandem mode, does not use a defoaming agent, recycles supernate in the sedimentation pond, can reduce discharge and save agent and water consumption and is systematically quick and convenient to clean, clear and dredge.

Owner:JISHOU UNIVERSITY

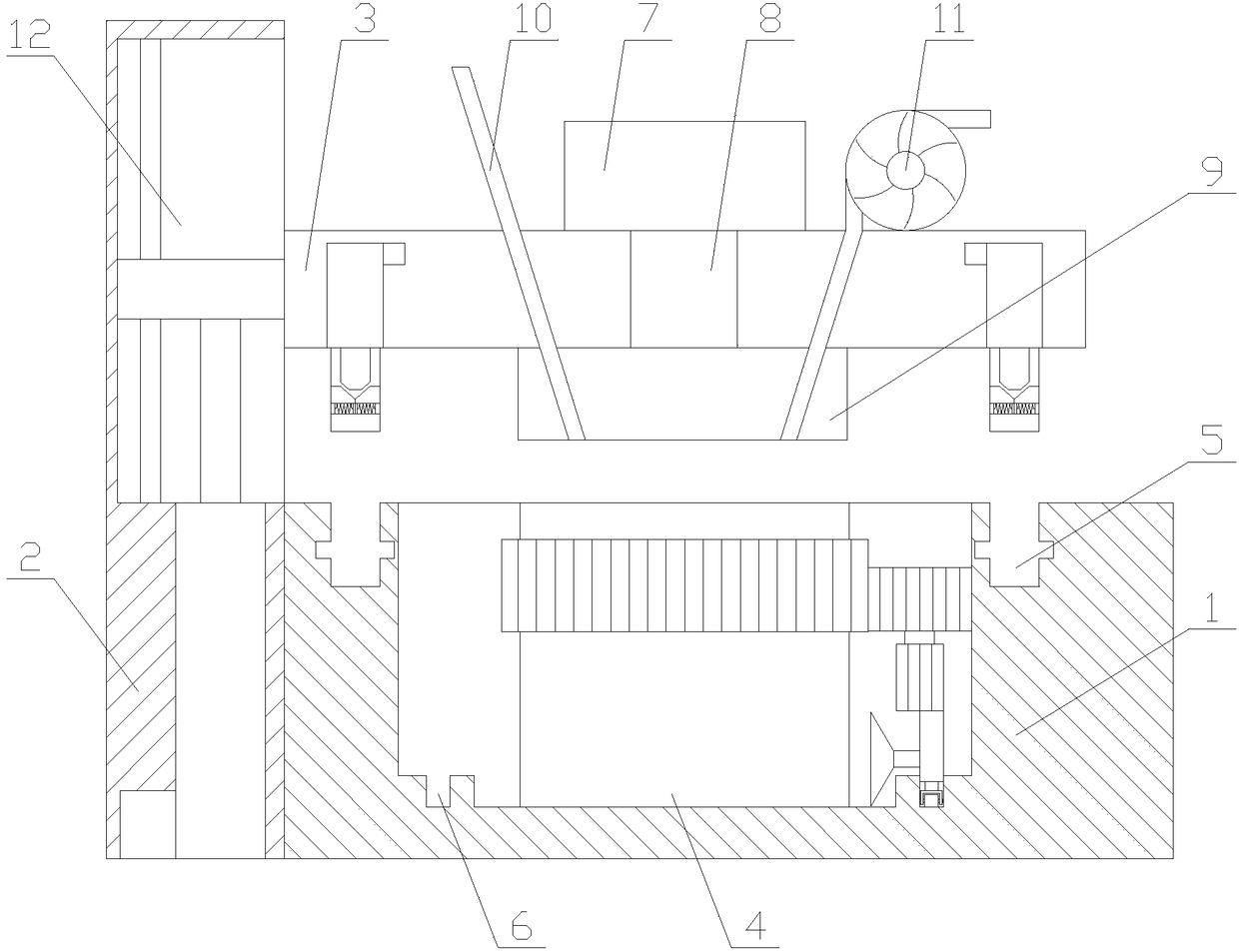

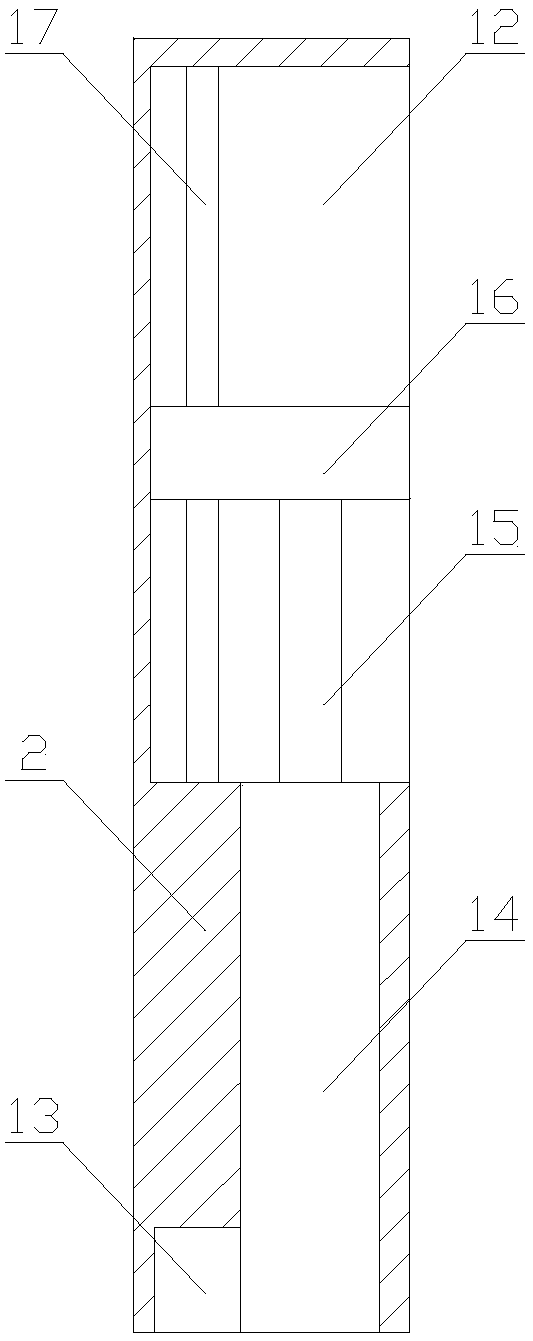

Wheel hub casting equipment with defoaming function

InactiveCN108176840AWill not be damagedImprove casting precisionFoundry mouldsFoundry coresGear wheelAir pump

The invention relates to wheel hub casting equipment with the defoaming function. The wheel hub casting equipment comprises a base, a lifting box, a lifting plate, a hydraulic device, a pressing block, an upper die, a liquid inlet pipe and an air pump, wherein a defoaming mechanism, a sliding chute, a lower die and two limiting grooves are arranged in the base; a groove and a lifting mechanism arearranged in the lifting box; two fixing mechanisms are arranged on two sides of the lifting plate; each of the fixing mechanisms comprises a driving unit and a limiting unit; and the defoaming mechanism comprises a first gear, a rotating unit, a defoaming unit and a limiting unit. According to the wheel hub casting equipment, the fixing mechanisms can prevent the upper die from displacement, so that a to-be-solidified wheel hub in the lower die is not damaged, the casting precision of the wheel hub is improved; and in addition, through the defoaming mechanism, the wheel hub casting equipmentcan effectively remove air bubbles in high-temperature molten metal, so that the cooled and solidified wheel hub does not contain plenty of cavities, and the strength of the wheel hub is improved.

Owner:SUMEC WHEELS CO LTD

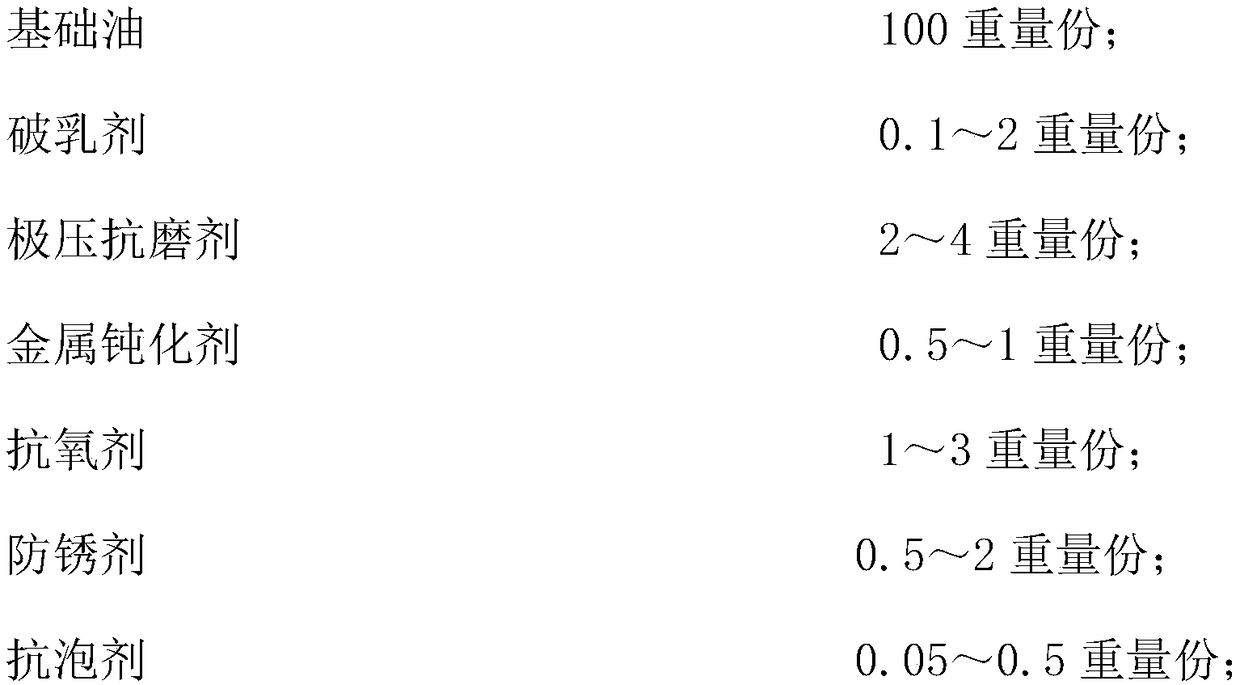

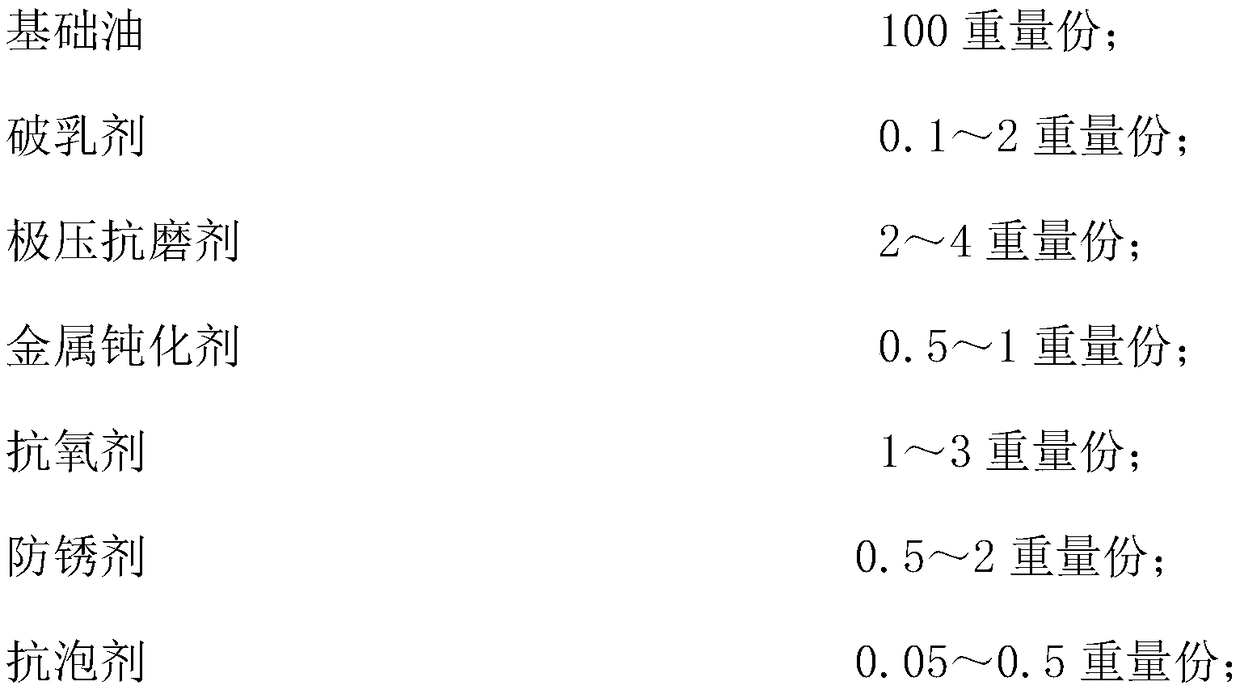

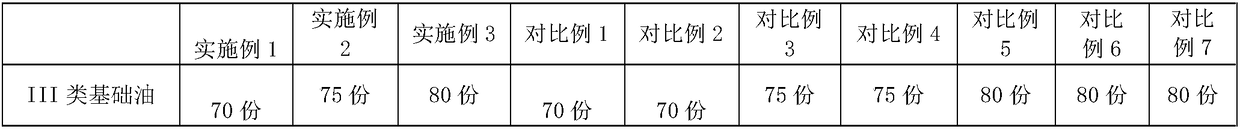

A steam turbine lubricating oil composition

ActiveCN108728230AImprove Oxidation StabilityImprove high temperature stabilityLubricant compositionDemulsifierChemical composition

The invention discloses a steam turbine lubricating oil composition. The composition is prepared from the following materials, by weight: 100 parts of base oil, 0.1-2 parts of a demulsifier, 2-4 partsof a extreme pressure anti-wear agent, 0.5-1 part of a deactivator, 1-3 parts of an antioxidant, 0.5-2 parts of an antirust agent, and 0.05-0.5 part of an antifoaming agent. The base oil includes 70%-80% of III base oil, 10%-20% of polyglycol ether, and 10%-20% of pentaerythritol ester of rosin. Through performing optimization on the formula of the lubricating oil, the oxidation stability, the high temperature stability, the extreme pressure performance, the demulsification performance and the liquid phase antirust performance of the lubricating oil are improved, and the service life is prolonged.

Owner:苏州福瑞斯德新材料科技有限公司

Polyether modified organic silicon defoamer safe to strains and preparation method thereof

PendingCN112057905AGood defoaming effectGuaranteed stabilityFoam dispersion/preventionMicrosphereCentrifugation

The invention belongs to the technical field of defoamers and discloses a polyether modified organic silicon defoamer safe to strains and a preparation method thereof. The preparation method includesthe following steps that: silicon dioxide nanometer microspheres, dimethyl silicone oil, DMF and deionized water are sequentially added into a reaction flask, ammonia water is added while stirring isconducted, heating is conducted to 50-70 DEG C, a reaction is conducted for 1-2 hours, cooling is conducted to the room temperature, and centrifugation is conducted, a precipitate is washed with ethanol, and drying is performed to obtain dimethicone grafted and modified silicon dioxide nano microspheres; 30-60 parts of the dimethicone grafted and modified silicon dioxide nano microspheres, 30-50 parts of polyether modified silicon oil, 1-10 parts of a thickener, 2-10 parts of an emulsifier and 10-50 parts of water are added into a dispersion tank, heating is conducted to 180-200 DEG C, stirring is performed for 2-3 hours, gradient cooling is carried out to 50-60 DEG C in a stirring state, and finally natural cooling is performed to obtain the polyether modified organic silicon defoamer. The defoamer has the advantages of being low in surface tension, high in defoaming speed, long in foam inhibition time, small in dosage, free of toxicity and harm to strains, wide in application range and the like.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

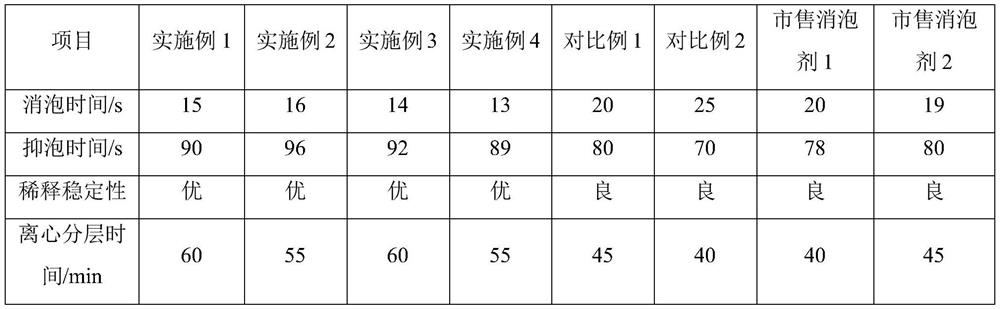

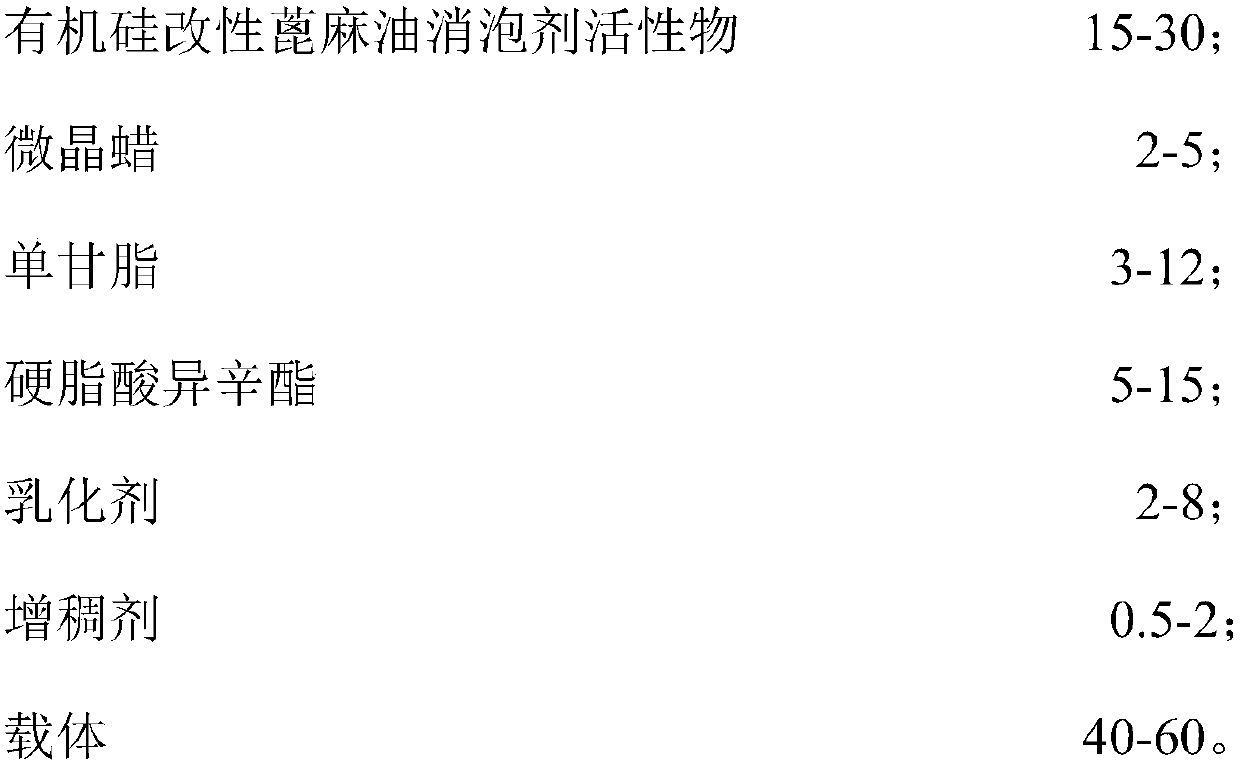

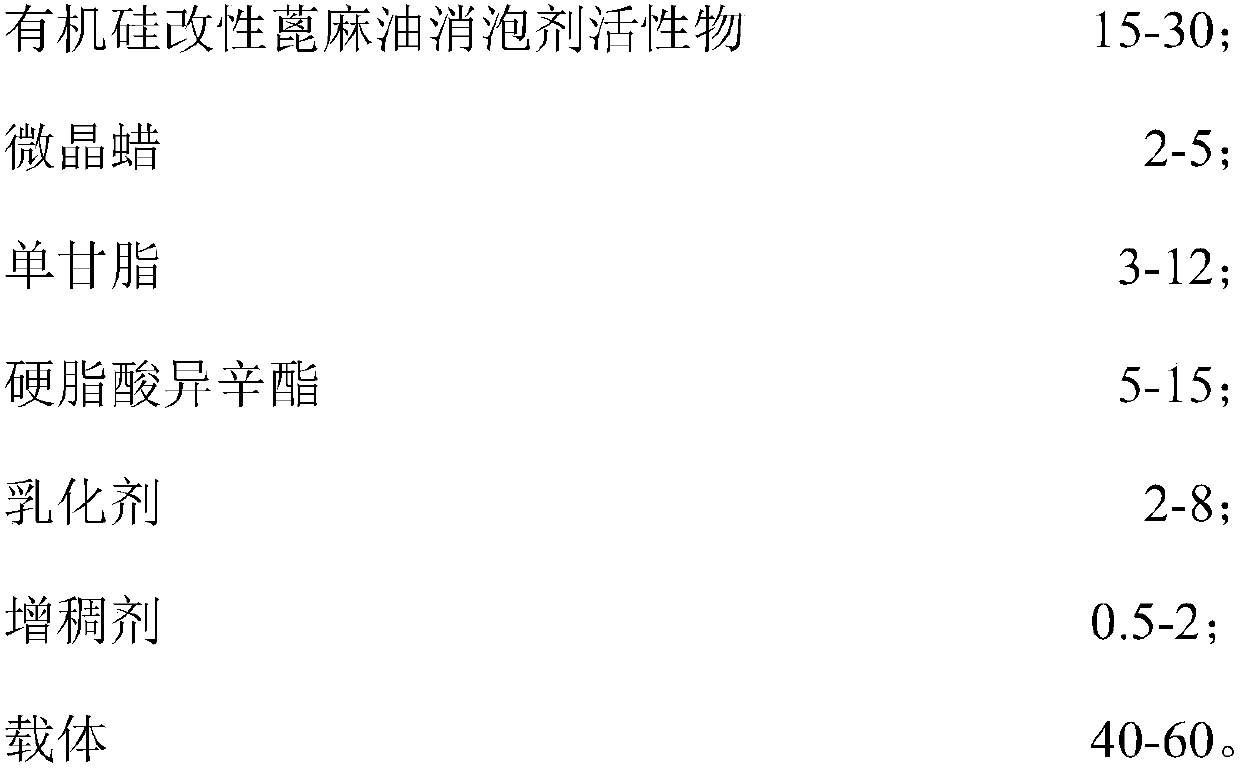

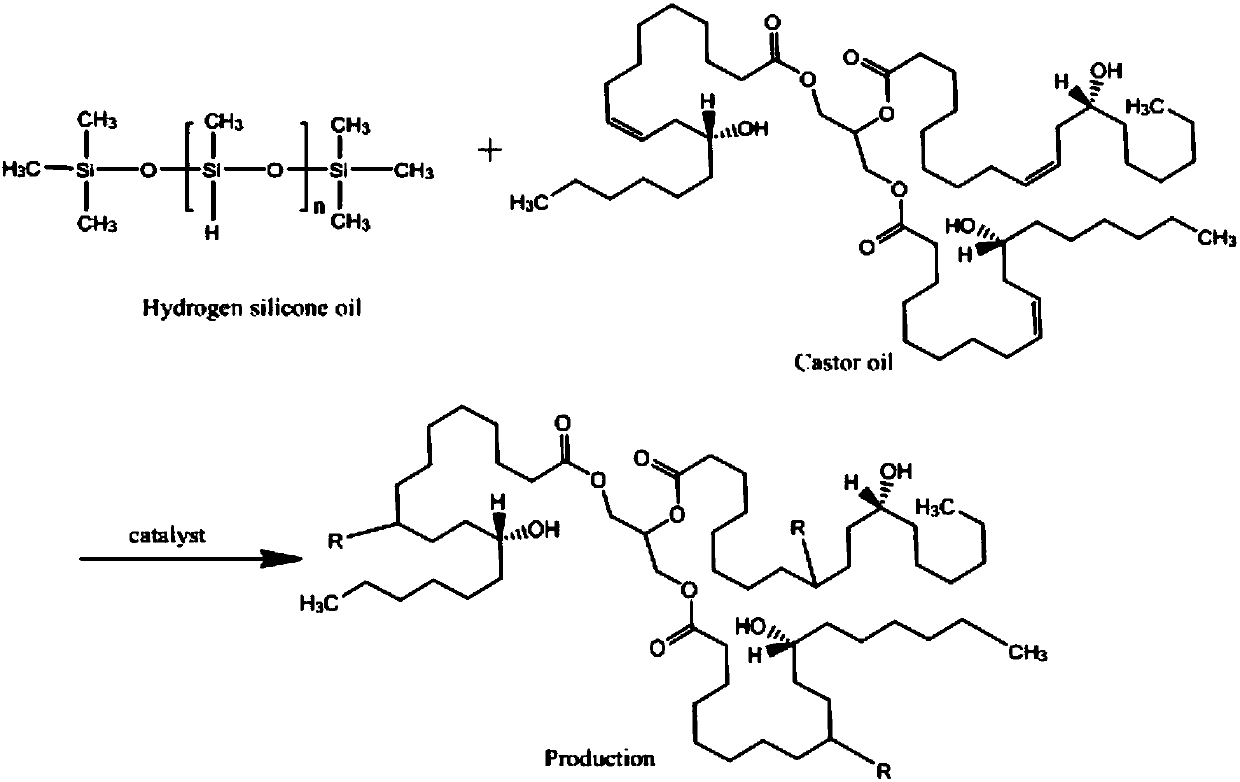

Antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and preparation method of antifoaming agent

ActiveCN107551609AReduce adhesionReduce negative impactFoam dispersion/preventionMicrocrystalline waxMonoglyceride

The invention discloses an antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and a preparation method of the antifoaming agent and belongs to the field of organosilicone modified antifoaming agents. The preparation method comprises the following steps: carrying out an addition reaction between hydrogen containing silicone oil and castor oil in an N2 protective catalyst system so as to obtain an organosilicone modified castor oil antifoaming agent active matter; and by utilizing the modified antifoaming agent active matter as well as microcrystalline wax, monoglyceride, isooctyl stearate, an emulsifier, a thickening agent and a carrier, thereby obtaining the antifoaming agent containing organosilicone modified castor oil. The antifoamingagent containing organosilicone modified castor oil produced according to the method disclosed by the invention is applied to eliminating foam produced in PVA production, has tiny negative effects onadhesiveness of slurry and mechanical property of slurry membranes, and has the characteristics of being small in dose, high in antifoaming speed, high in foam inhibition ability, nontoxic, harmless,simple in process and the like.

Owner:XIAN SUNY FINE CHEM

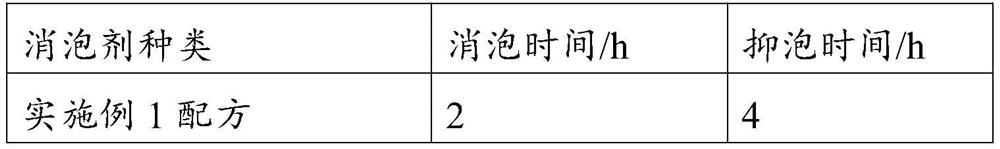

Safe and efficient edible defoamer and preparation method thereof

InactiveCN106165879AAnti-foaming effect is stablePromote industrial productionFood scienceSodium carboxymethylcelluloseChemistry

The invention relates to a safe and efficient edible defoamer used in the food making process and a preparation method of the safe and efficient edible defoamer. The safe and efficient edible defoamer is fast in defoaming, few in insoluble substances and small in consumption. The defoamer comprises hydrogen silicone oil, fumed silica, polyoxypropylene glycerol ether, sodium carboxymethyl cellulose, tween, span and water. The preparation method includes: subjecting hydrogen silicone oil and fumed silica to reaction at the temperature of 150-250 DEG C for 6-8 hours prior to cooling to 40-50 DEG C, adding polyoxypropylene glycerol ether for continuous stirring reaction for 3-4 hours, and then adding water, sodium carboxymethyl cellulose, span and tween for 24-hour emulsion reaction to obtain a finished product. Defoaming rate of the defoamer is increased by 30-50% as compared with that of commercially available normal defoamer, usage is lowered by 50%, water insoluble matters after the defoamer is used are reduced, and heavy metal and arsenic content of the product is far lower than that of existing products.

Owner:CHONGQING YINGLONG CHEM PLANT

Antifoam agent and production technique thereof

InactiveCN101310813AStrong anti-foaming abilityImprove permeabilityTransportation and packagingMixingParaffin waxEmulsion

The invention relates to a defoaming agent and a production process, and the defoaming agent is composed of components with the following parts by weight: 60 parts of dimethyl silicone oil, 15 parts of glyceryl polyether 3050, 15 parts of liquid paraffin and 10 parts of water. The production process comprises the following steps: 10 parts by weight of water is added in a reactor; 60 parts by weight of dimethyl silicone oil is slowly added in the reactor to be stirred at the normal temperature, thus forming emulsion-like solution; 15 parts by weight of glyceryl polyether 3050 is added to be continuously stirred at the normal temperature till the glyceryl polyether 3050 is fully dissolved in the emulsion-like solution; 15 parts by weight of liquid paraffin is further added to be continuously stirred at the normal temperature till the liquid paraffin is fully dissolved in the emulsion-like solution; the low-speed stirring is carried out for 30 minutes, the solution is kept at 18 DEG C to 22 DEG C, and the defoaming agent is prepared by carrying out the reactor for 24 hours. The defoaming agent and the production process have the advantages that: the production process has no waste gas, no waste water and no noise to be discharged to the outside; the product is fully dissolved in the water and non-toxic, thus not producing secondary environmental pollution, the product is used in a big water region, the defoaming speed is fast, the using amount is small and the cost is low.

Owner:闫承慧

Method for producing prefabricated member of concrete ditch by using coal gangue

InactiveCN106045423AImprove anti-seepage effectImprove flexibilityCeramic shaping apparatusSuperplasticizerWater resources

The invention relates to a method for producing a prefabricated member of a concrete ditch by using coal gangue. The method is characterized in that the prefabricated member of the concrete ditch is prepared from the following raw materials in parts by weight: 50-60 parts of coarse and fine aggregates, 5-10 parts of coal gangue powder, 10-15 parts of 42.5 sulfoaluminate cement, 2-5 parts of early strength agent, 2-5 parts of thickening and reinforcing agent, 1-3 parts of efficient water reducing agent and 0.1-0.5 part of antifoamer, wherein the efficient water reducing agent is a calcium lignosulfonate water reducing agent. According to the method, the prefabricated member of the concrete ditch is low in cost, excellent in performance and stable in quality and has excellent compressive strength and antifreeze and impervious performance; and the standardized construction of farmland water conservancy is further strengthened, the construction level and management level of farmland water conservancy projects in China are comprehensively increased, the utilization ratio of irrigation water is increased, and the efficient utilization of water resources is achieved.

Owner:象州县科学技术局

Organic silicon defoaming agent with anti-cracking function

InactiveCN106362443AHas anti-crack effectGood compatibilityFoam dispersion/preventionKerosenePotassium iodine

The invention discloses an organic silicon defoaming agent with an anti-cracking function. The defoaming agent is prepared from, by weight, 40-70 parts of simethicone, 20-30 parts of silicon dioxide, 10-20 parts of water, 1-2 parts of acrylic acid emulsion, 0.3-0.5 part of potassium iodide, 0.2-0.4 part of prenyl alcohol, 0.5-1 part of oxidized polyethlene wax, 0.3-0.5 part of kerosene, 0.4-0.8 part of tributyl citrate, 2-4 parts of calcium stearate, 0.4-0.8 part of nonylphenol polyoxyethylene ether, 2-4 parts of bentonite, 1-2 parts of stearamide, 1-2 parts of fatty acid and 0.2-0.4 part of butyl stearate.

Owner:合肥新万成环保科技有限公司

Water-based metal cleaning agent convenient for workpiece oil removal

The invention relates to a water-based metal cleaning agent convenient for workpiece oil removal. The water-based metal cleaning agent comprises, by weight, 4.76% of sodium carbonate, 4.07% of sodium borate, 2.53% of sodium hydroxide, 11.54% of triethanolamine oleate, 15.36% of fatty alcohol polyoxyethylene ether, 12.65% of triethanolamine, 0.94% of an antifoaming agent, 0.97% of urea and 47.18% of water. The water-based metal cleaning agent has good stain removal effects, does not corrode and damage metals, has low alkalinity, has fast cleaning rate, can be rinsed easily, has a long use period and lasting effects, realizes corrosion inhibition and rust prevention of a cleaned workpiece, does not contain harmful elements such as heavy metals and phosphor, reduces environmental pollution and operator diseases, can be used at a normal temperature, can produce less foam, and has simple processes and a low production cost.

Owner:广州蜀晨化工科技有限公司

Hyper branched polyether-modified organosilicon antifoaming agent capable of rapidly defoaming and preparation method thereof

InactiveCN106474776AImprove shear resistanceSuitable for many occasionsFoam dispersion/preventionEnd-groupDouble bond

The invention discloses a hyper branched polyether-modified organosilicon antifoaming agent capable of rapidly defoaming. The antifoaming agent comprises the following raw materials in parts by weight: 25-40 parts of polysiloxanes, 14-22 parts of hyper branched polyether, 17-26 parts of allyl glycidyl ether, 46-60 parts of epoxypropane, 0.2-0.5 parts of a bimetallic cyanidation complex, 50-70 parts of isopropanol, 0.2-0.6 parts of a chloroplatinic acid catalyst, 3-6 parts of ultrafine alumina silicate, 1-2 parts of sorbitol, 1-2 parts of tween 60, 2-4 parts of carboxymethylcellulose sodium, a proper amount of deionized water, 0.5-1 part of sodium carbonate, 2-3 parts of coke, and 1-3 parts of fluorite. The end contains a lot of hydroxy hyper branched polyethers as a raw material, the end-allyl hyper branched polyether is prepared, a double-bond structure of the modified hyper branched polyether end group is used for performing a hydrosilylation with polysiloxanes, the hyper branched polyether-modified polysiloxanes can be synthesized, and the prepared antifoaming agent has excellent anti-shearing performance.

Owner:合肥新万成环保科技有限公司

High-efficiency antifoaming agent

InactiveCN105289050AFast defoaming speedStrong anti-foaming abilityFoam dispersion/preventionSolubilityDefoamer

The invention discloses a high-efficiency antifoaming agent. The high-efficiency antifoaming agent is prepared from low-hydrogen silicone oil, n-amyl alcohol, white carbon black, malonic acid, amino silicon oil, 1.5% concentrated sulfuric acid, octamethylcyclotetrasiloxane, trifluoropropionic acid, polyether silicone oil, carboxymethyl cellulose sodium, and sorbitol. According to a preparation method, low-hydrogen silicone oil is subjected to chemical modification so as to obtain the high-efficiency antifoaming agent, defoaming speed of the high-efficiency antifoaming agent is increased greatly, foam inhibition performance is improved, using amount is one third less than that of common antifoaming agents, and the high-efficiency antifoaming agent possesses excellent water solubility.

Owner:宣城市聚源精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com