Method for producing prefabricated member of concrete ditch by using coal gangue

A technology for concrete and prefabricated parts, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as hidden dangers of farmland water conservancy construction quality, poor lap jointing of channels, affecting anti-seepage effects, etc. Low, saving effect of cement clinker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

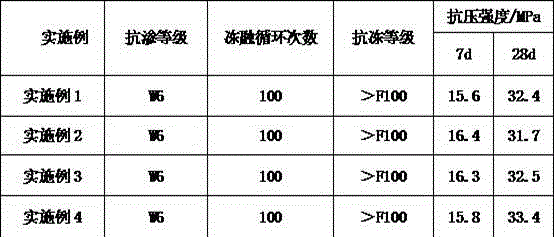

Examples

Embodiment 1

[0028] The method for utilizing coal gangue to produce concrete trench prefabricated parts described in the present embodiment mainly includes the following steps:

[0029] The concrete channel prefabricated part includes the following raw materials in parts by weight: wherein, 50 parts of coarse and fine aggregate, 10 parts of coal gangue powder, 10 parts of 42.5 sulfoaluminate cement, 5 parts of early strength agent, and 5 parts of thickening and strengthening agent 3 parts, 3 parts of high-efficiency water reducer, 0.5 part of defoamer, described high-efficiency water reducer is calcium lignosulfonate water reducer;

[0030] The production method of the prefabricated part of the concrete trench is: mix the coarse and fine aggregate, coal gangue powder and 42.5 Portland cement according to the ratio, and then add the early strength agent, thickening enhancer, high-efficiency water reducer and dispersant The water of the foaming agent, mix well; install the formwork that has be...

Embodiment 2

[0032] The method for utilizing coal gangue to produce concrete trench prefabricated parts described in the present embodiment mainly includes the following steps:

[0033] The concrete channel prefabricated part includes the following raw materials in parts by weight: wherein, 55 parts of coarse and fine aggregate, 6 parts of coal gangue powder, 12 parts of 42.5 sulfoaluminate cement, 3 parts of early strength agent, and 3 parts of thickening and strengthening agent 2 parts, 2 parts of high-efficiency water reducer, 0.4 part of defoamer, described high-efficiency water reducer is calcium lignosulfonate water reducer;

[0034] The production method of the prefabricated part of the concrete trench is: mix the coarse and fine aggregate, coal gangue powder and 42.5 Portland cement according to the ratio, and then add the early strength agent, thickening enhancer, high-efficiency water reducer and dispersant The water of the foaming agent, mix well; install the formwork that has b...

Embodiment 3

[0036] The method for utilizing coal gangue to produce concrete trench prefabricated parts described in the present embodiment mainly includes the following steps:

[0037] The concrete trench prefabricated part includes the following raw materials in parts by weight: wherein, 58 parts of coarse and fine aggregate, 8 parts of coal gangue powder, 14 parts of 42.5 sulfoaluminate cement, 4 parts of early strength agent, and 4 parts of thickening and strengthening agent 2 parts, 2 parts of high-efficiency water reducer, 0.2 part of defoamer, described high-efficiency water reducer is calcium lignosulfonate water reducer;

[0038] The production method of the prefabricated part of the concrete trench is: mix the coarse and fine aggregate, coal gangue powder and 42.5 Portland cement according to the ratio, and then add the early strength agent, thickening enhancer, high-efficiency water reducer and dispersant The water of the foaming agent, mix well; install the formwork that has be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com