Patents

Literature

100results about How to "Improve casting precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum negative pressure real type phenolic sand molding lost foam casting method

InactiveCN101342573AImprove casting precisionGuaranteed to be smooth and tidyFoundry mouldsFoundry coresVacuum pumpingProduct gas

The present invention relates to a method for casting a vacuum sub-pressure solid resin sand molding lost mould, and belongs to the casting technical field, in particular relates to a method for casting a vacuum sub-pressure lost mould, which mainly comprises the steps such as molding, coating, sand-box patternmaking, tapping, pouring, vacuum pumping, heat preservation and cooling, and adopts the casting steps: a. foam plastic mould is made according to the shape of the casting piece; b. the outer surface of the foam plastic mould is coated with coating; c. the foam plastic mould that is coated with coating is arranged inside a sand box, and the patternmaking is performed with resin sand; d. the sand box after the patternmaking is arranged inside a tapping device so as to tap the patternmaking sand inside the box and to be dried; e. while pouring the iron liquid, the sand box is vacuum pumped synchronically by a vacuum pumping machine, and the gas that is obtained from the vacuum pumping is discharged after being purified; f. after the pouring is completed, the vacuum pumping is stopped, and the casting piece is taken out to be arranged inside a heat-preservation oven, so that the temperature is increased to 1100 DEG C, and the casting piece can be produced after the heat preservation and cooling. The method of the present invention has simple process, precise processing, easy operation and low production cost.

Owner:QUEJING CHENGJIE SHIXIN FOUND

Method for producing heat-resistant steel automobile exhaust pipes by iron mold sand lining process

ActiveCN102873279AImprove casting precisionGuaranteed compactnessFoundry mouldsMoulding machinesAutomotive engineeringMechanical engineering

The invention discloses a method for producing heat-resistant steel automobile exhaust pipes by an iron mold sand lining process. The method includes modeling, core feeding, flask combining, casting, sand shakeout. Chilling position in casting of automobile exhaust pipes is determined before modeling. The special iron mold sand lining process is applied to production of heat-resistant steel, the characteristic that a sand shell cannot be separated from an iron mold during the modeling can be utilized, deformation of the sand shell is avoided, and accordingly precision of the casting is increased. Chilling points are controlled manually by controlling thickness of the sand shell, flasks of the iron mold can function in chilling and feeding sufficiently for places needed to be chilled, so that compactedness of the casting is guaranteed, product yield and quality are improved.

Owner:西峡县众德汽车部件有限公司

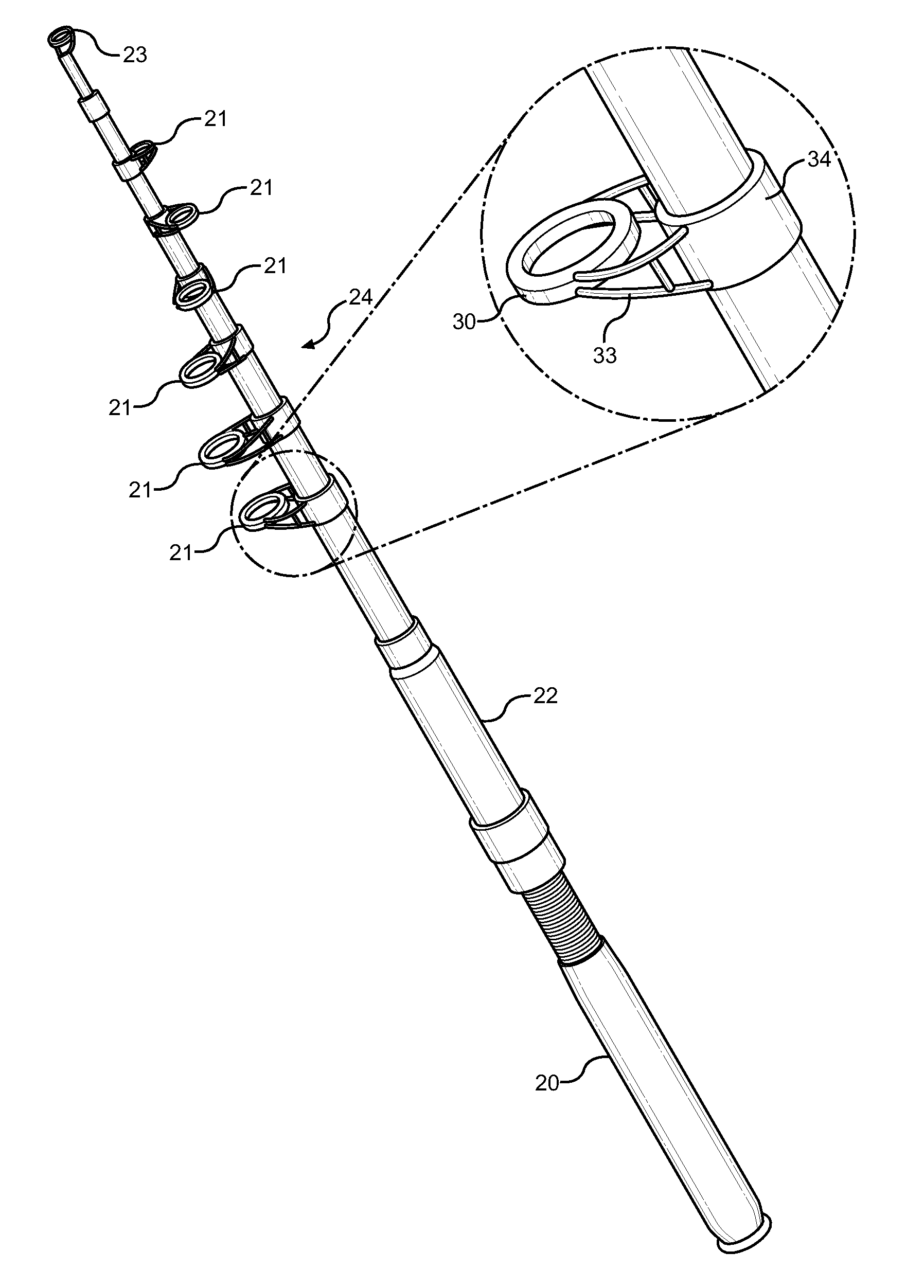

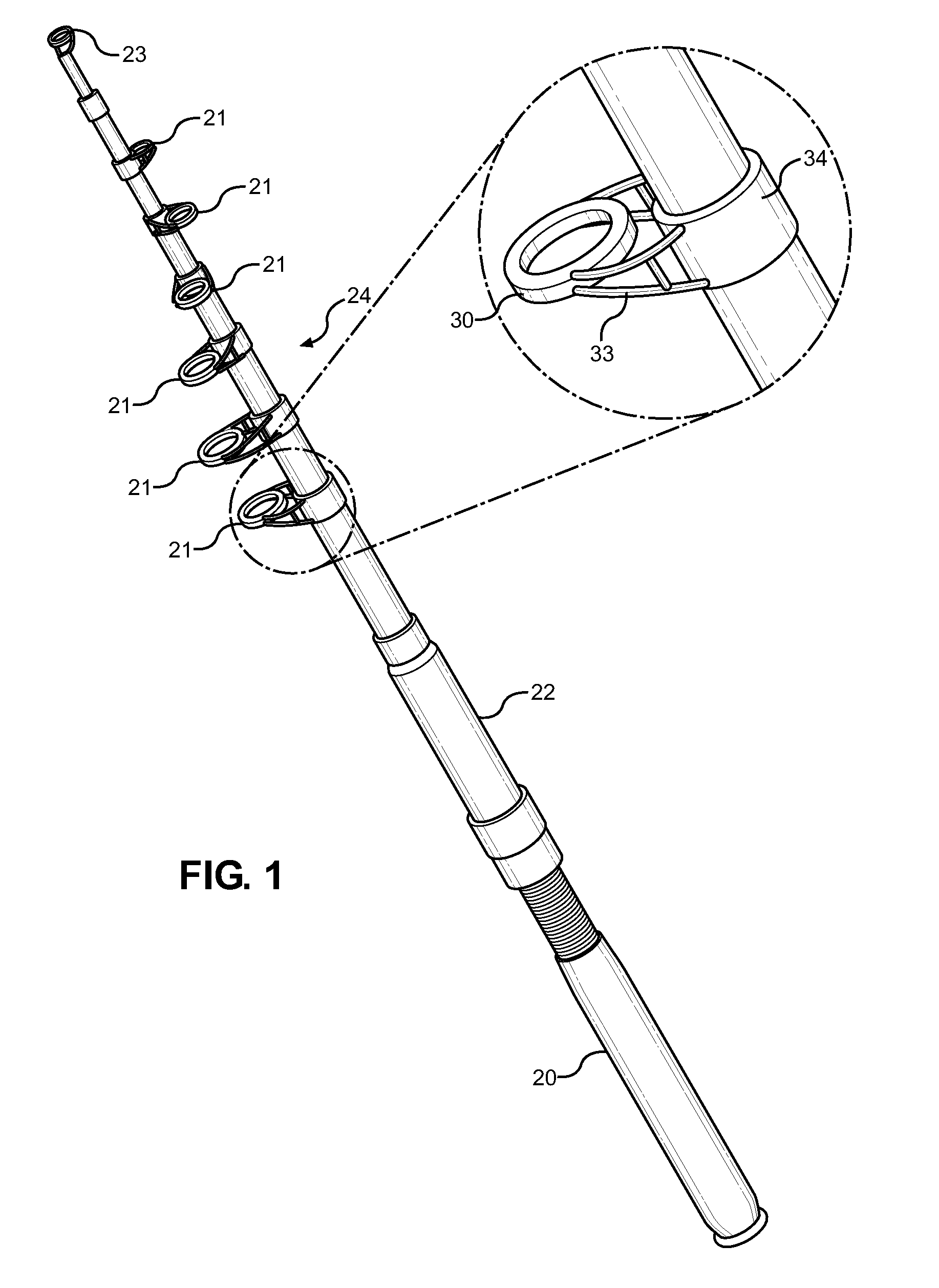

Fishing rod with spiral fishing line guides

Disclosed is an improved fishing rod adapted to increase the durability of the fishing rod and fishing line and to improve casting distance and accuracy. The fishing rod comprises an elongated cylindrical rod blank having a working end and a terminal end, wherein the working end is attached to a handle. The rod blank further comprises a plurality of fishing line guides disposed in a gradual spiral configuration along the length of the rod blank. The fishing line guides are adapted to receive a fishing line therethrough. The guides are also low profile so as to minimize snagging. When in use, the fishing line wraps around the rod blank, thereby evenly distributing the weight of the fishing line around the rod. In this way, the present invention eliminates line memory and increases the tensile strength of the rod blank and the fishing line.

Owner:STENDER SCOTT

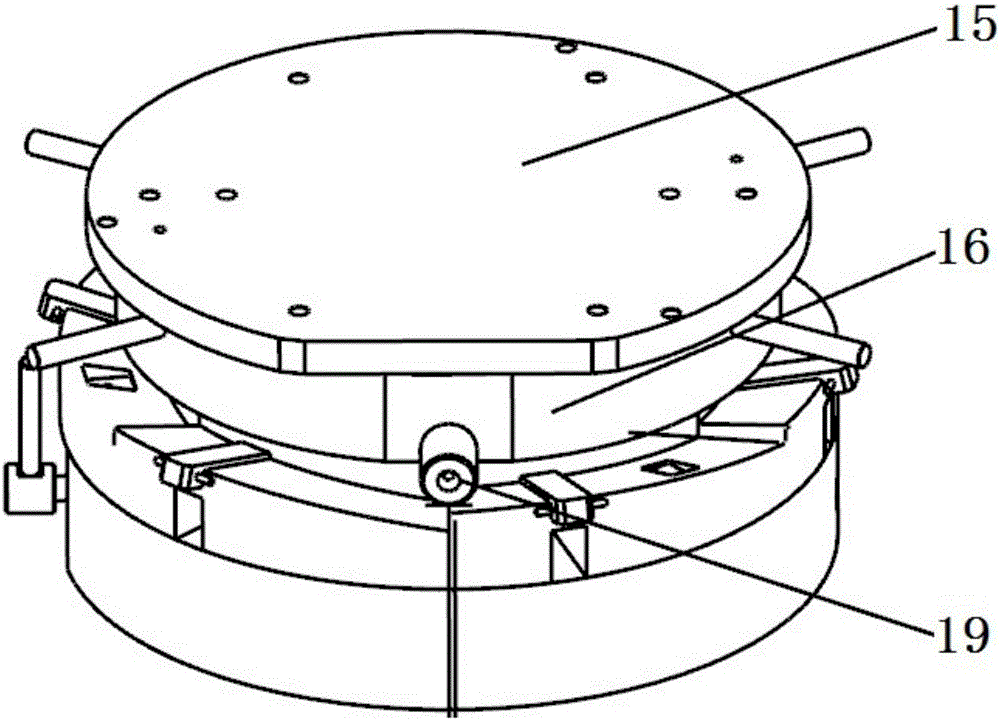

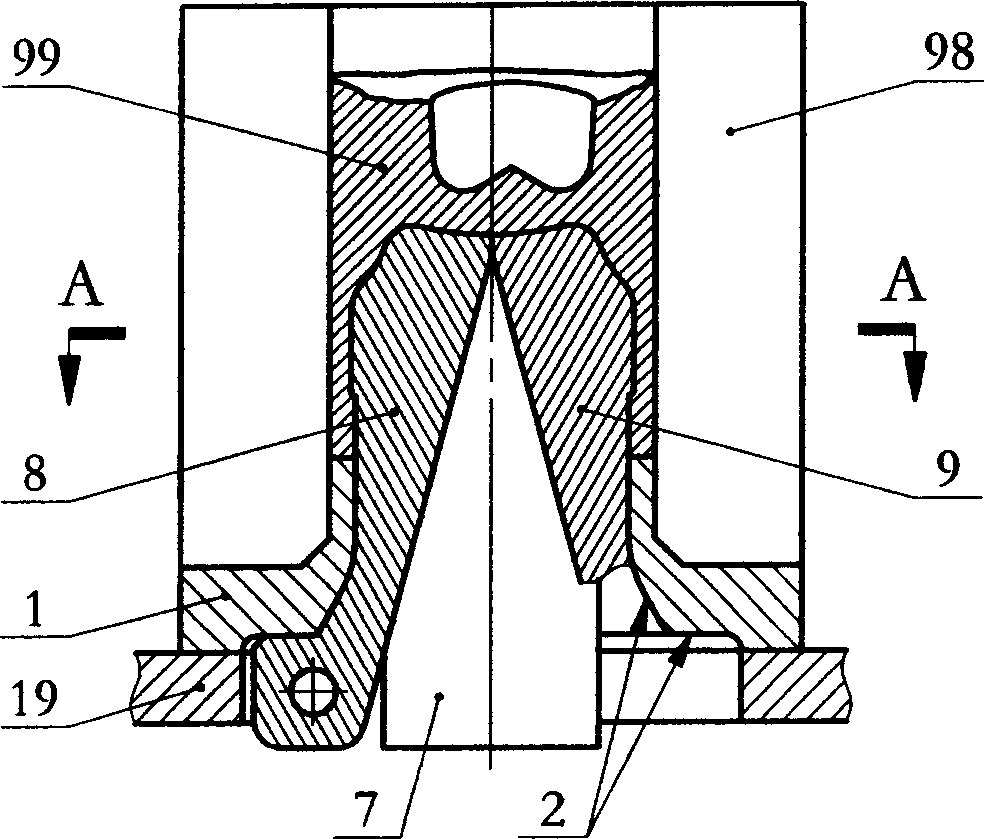

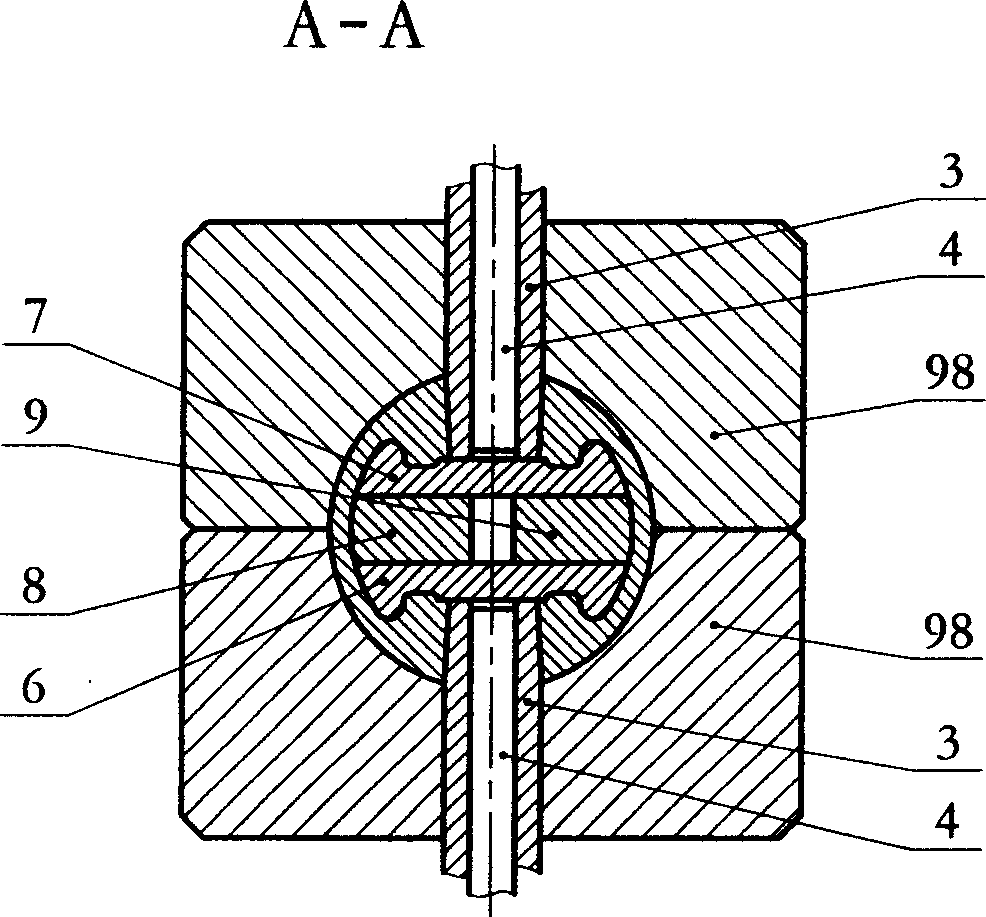

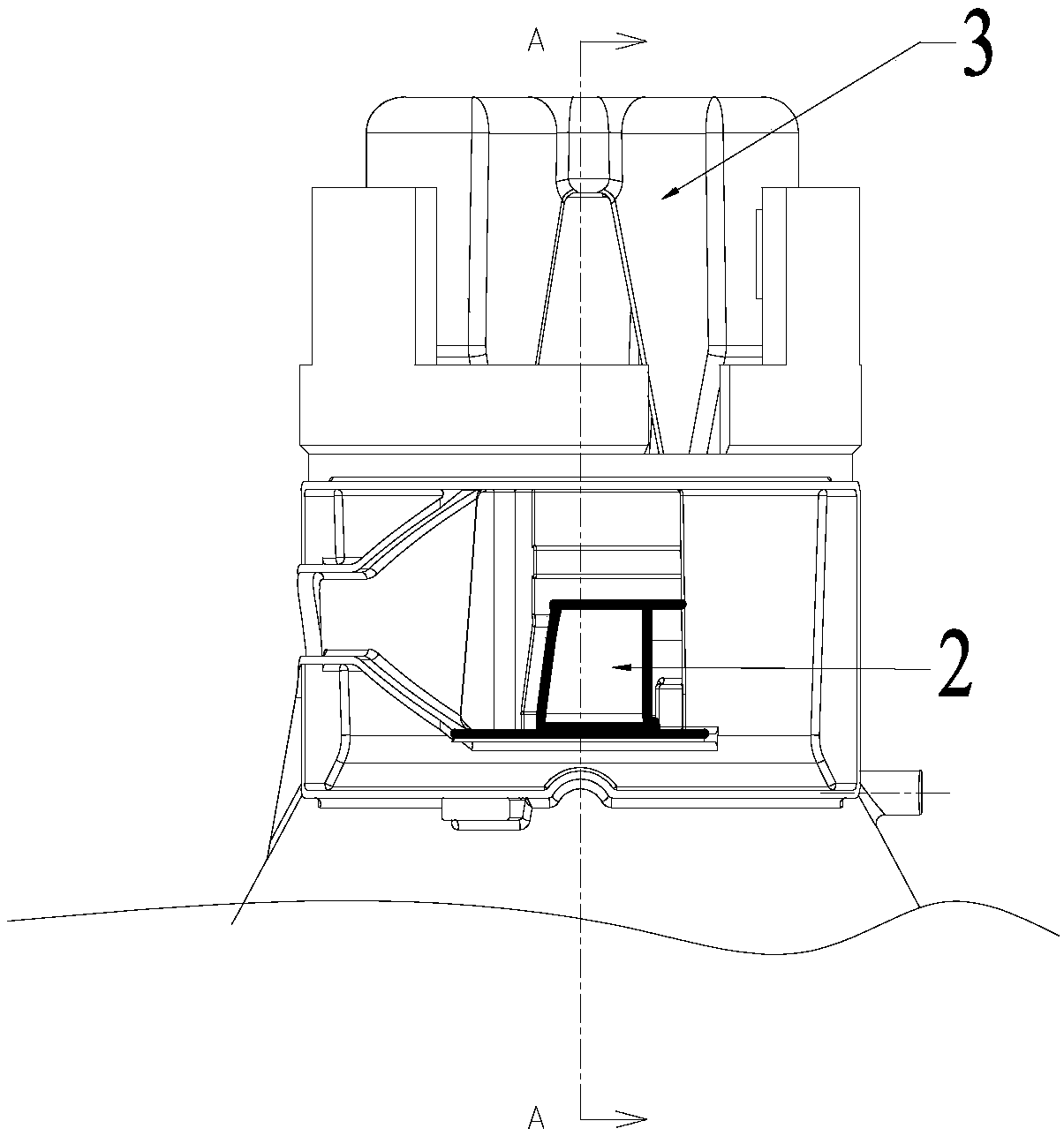

Integrally casting mold for aero-engine diffuser

ActiveCN106623772ASolve the deformationSolve problems such as damageFoundry moulding apparatusWaxCasting mold

The invention discloses an integrally casting mold for an aero-engine diffuser. The mold comprises a pedestal and an upper cover plate, wherein an inner ring-shaped cavity structure of the diffuser is integrally formed between the pedestal and the upper cover plate, a frustum cone-shaped loose core is arranged at the center position of the inner ring-shaped cavity structure, a wax injection nozzle communicating with the inner ring-shaped cavity is arranged on the inner ring-shaped cavity structure; and an ejection structure for ejecting the molded diffuser is arranged at the bottom of the inner ring-shaped cavity structure. According to the mold provided by the invention, the diffuser cast can be integrally formed into a ring at a time without subsequent wax molding adhesion, and the problem of reverse pulling of the wax on the mold can be solved, and forming of the aero-engine diffuser with the thick wall is ensured.

Owner:AECC AVIATION POWER CO LTD

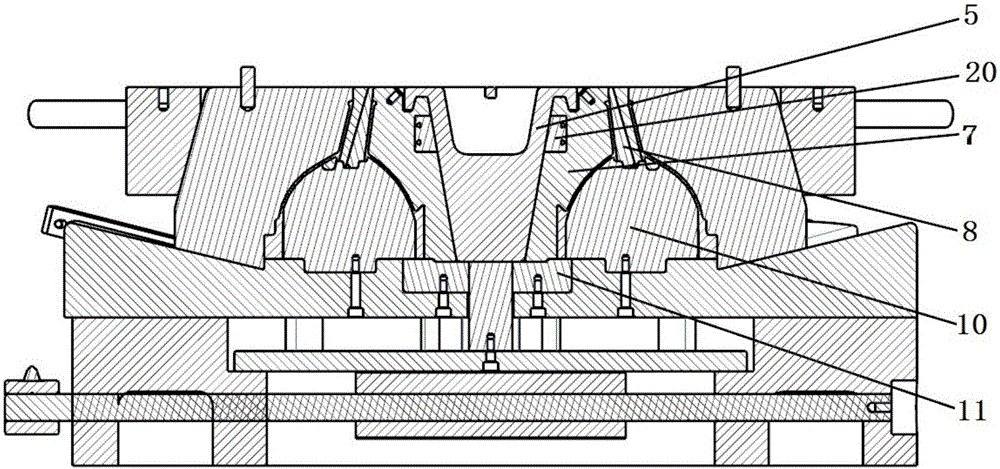

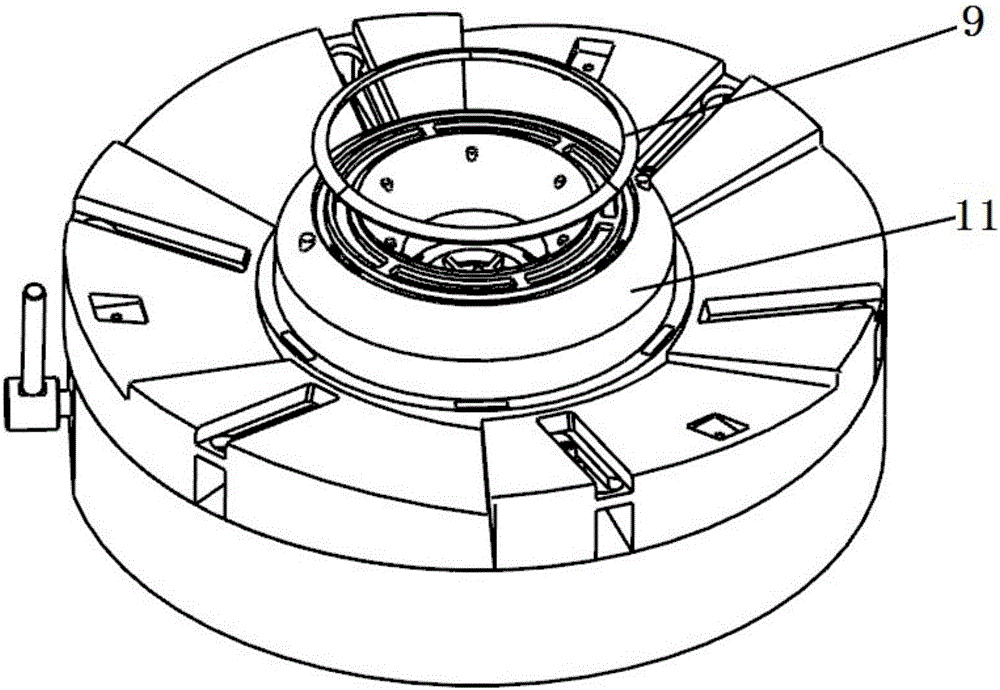

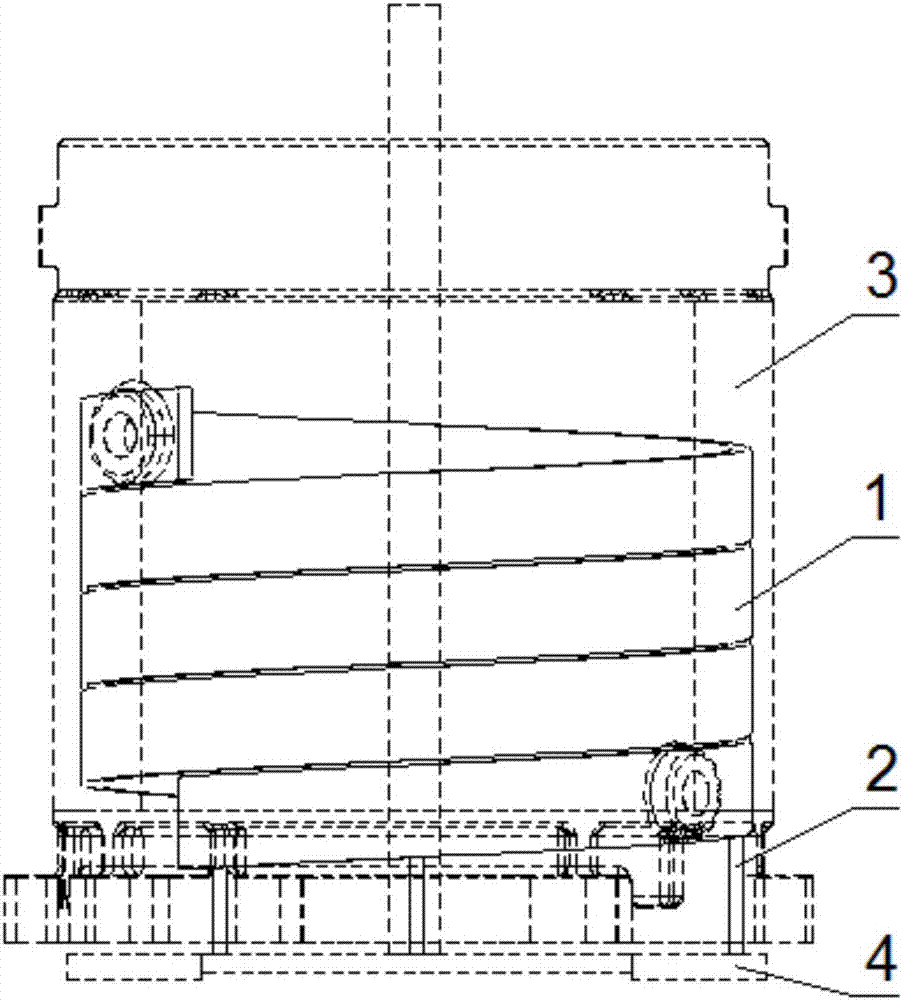

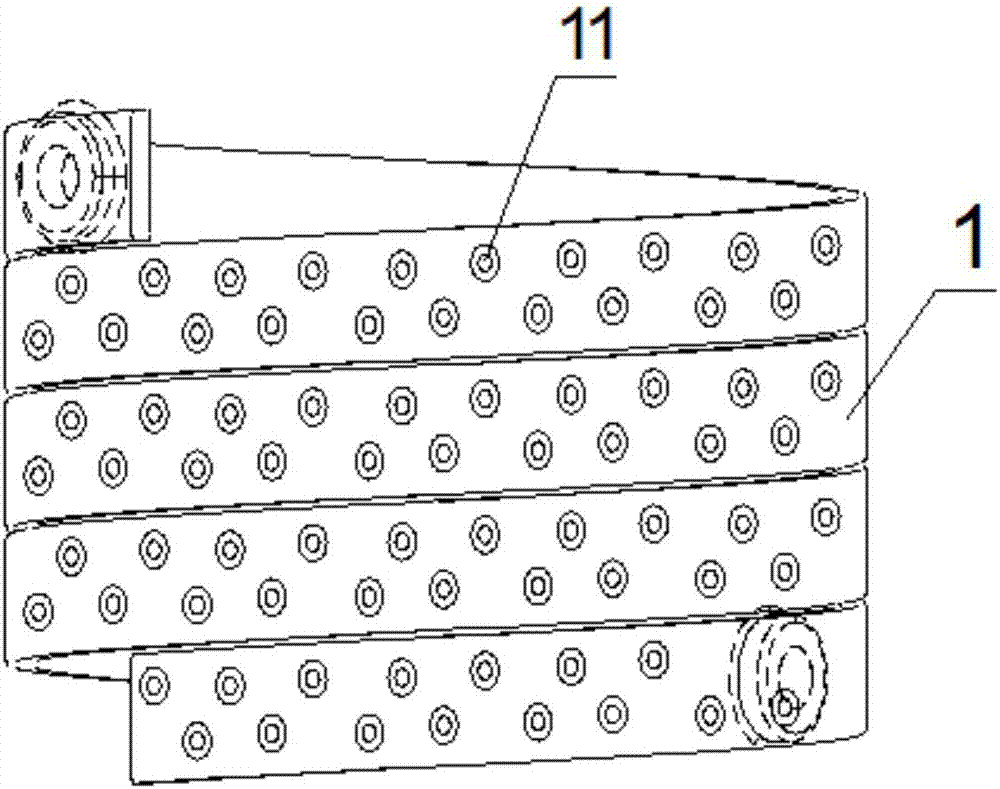

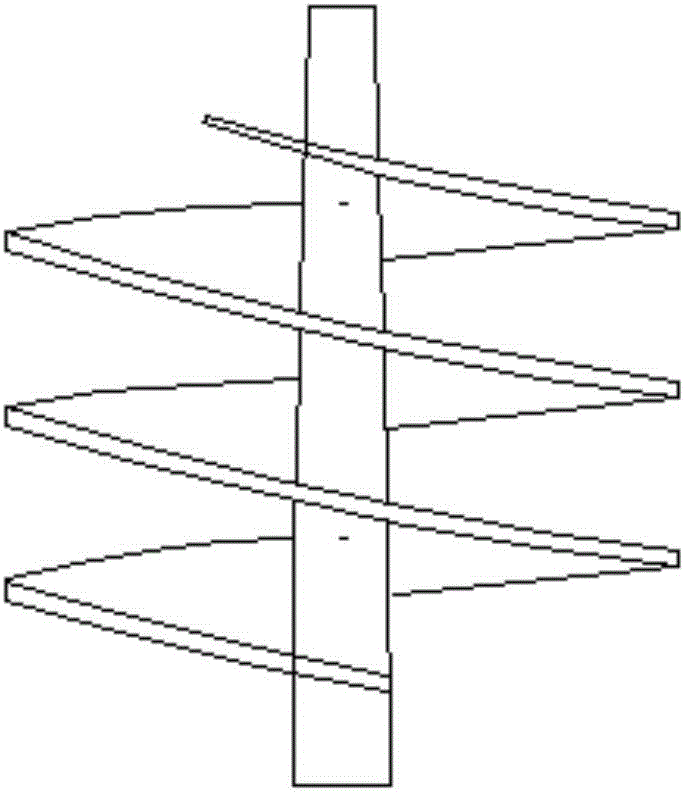

Expendable pattern casting technique for aluminum alloy internally provided with spiral coiled tube water passage

InactiveCN107282886ATightly boundReduce internal stressFoundry mouldsFoundry coresCooling effectCopper

The invention discloses an expendable pattern casting technique for an aluminum alloy internally provided with a spiral coiled tube water passage. According to the technique, the spiral coiled tube water passage made of stainless steel or copper is prefabricated firstly, and the upper end and the lower end of the spiral coiled tube water passage are provided with a water inlet and a water outlet which are capable of being exposed out of the column face of a motor shell correspondingly. A foaming mold is utilized for positioning and forming, an integrated motor shell EPS white mold internally comprising the prefabricated spiral coiled tube water passage can be machined through one-time forming, and then through the expendable pattern casting technique, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage in an embedded mode is casted. An auxiliary structure capable of being tightly combined with the casted aluminum alloy shell is arranged on the spiral coiled tube water passage, internal stress generated by cold-hot change is reduced, and the shell is prevented from cracking. The spiral coiled tube water passage is further connected with a casting technique supporting framework, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage can be stably and reliably casted on a large scale through an expendable pattern, the prefabricated spiral coiled tube water passage does not need to be filled with sand before casting, the water passage is smooth and not prone to being plugged, and it is ensured that the cooling effect is good.

Owner:FUJIAN JU NENG MACHINERY MFG CO LTD

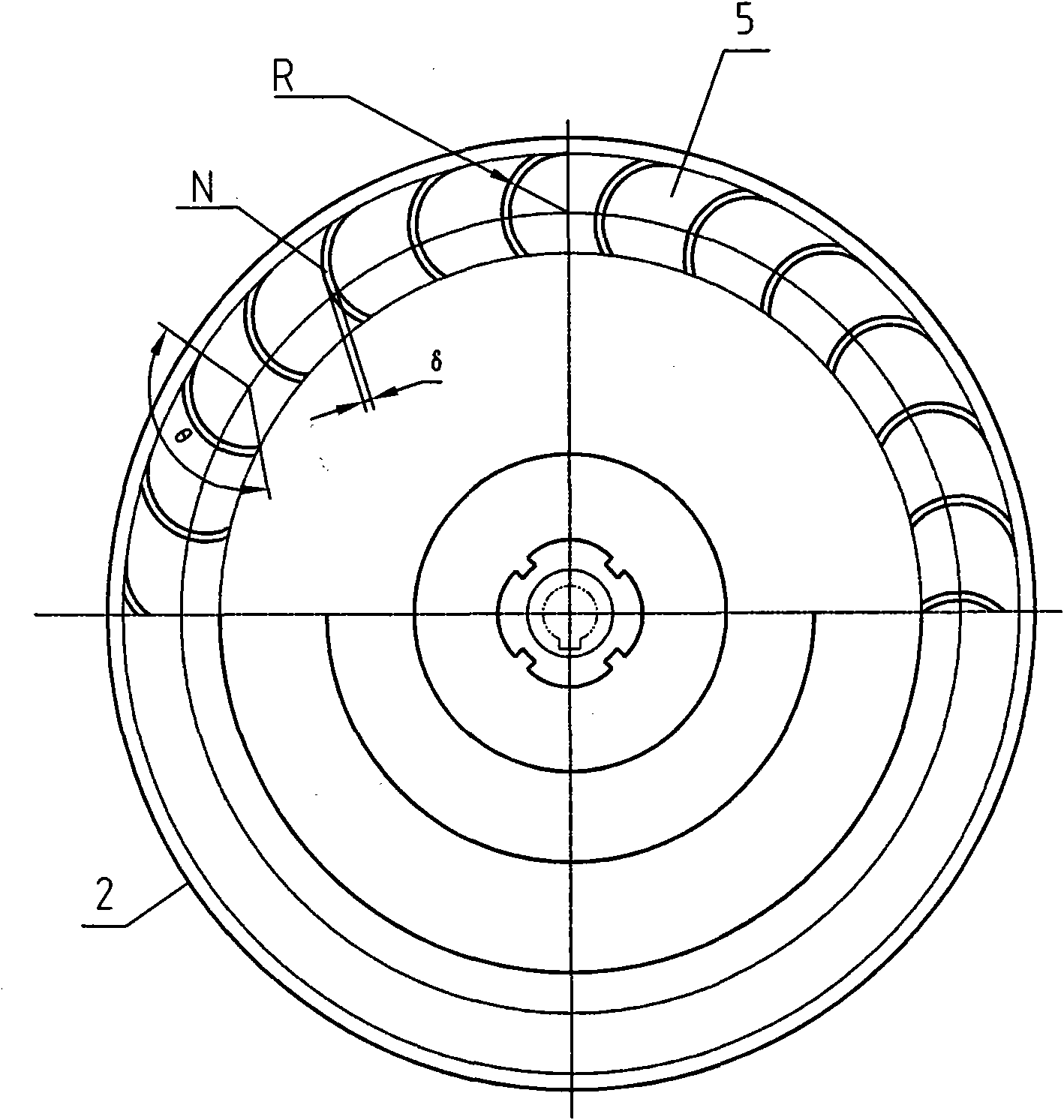

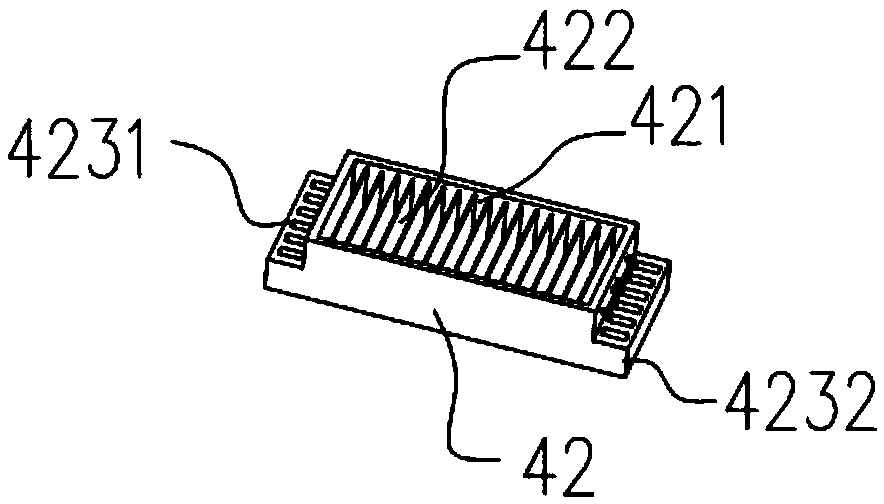

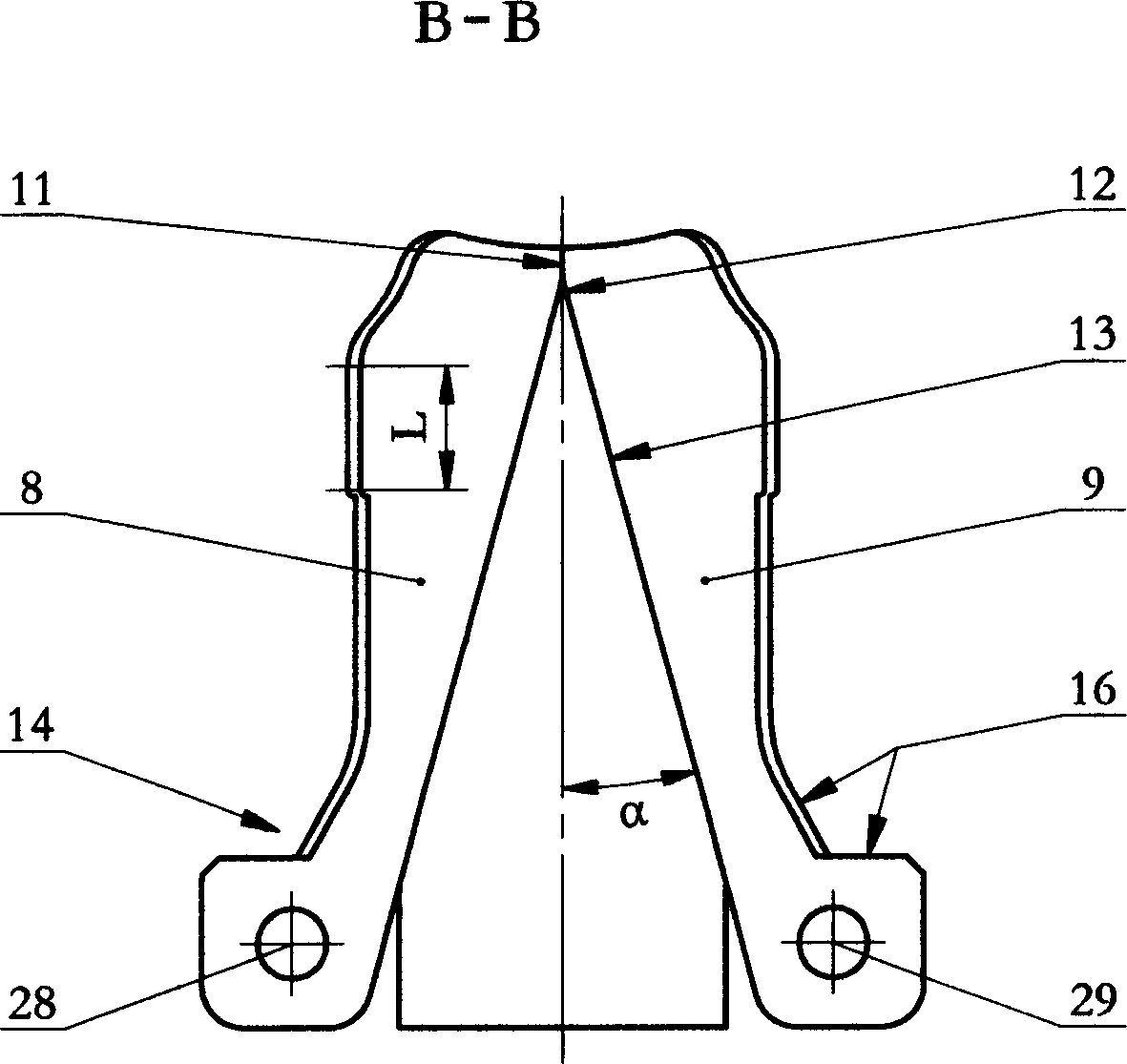

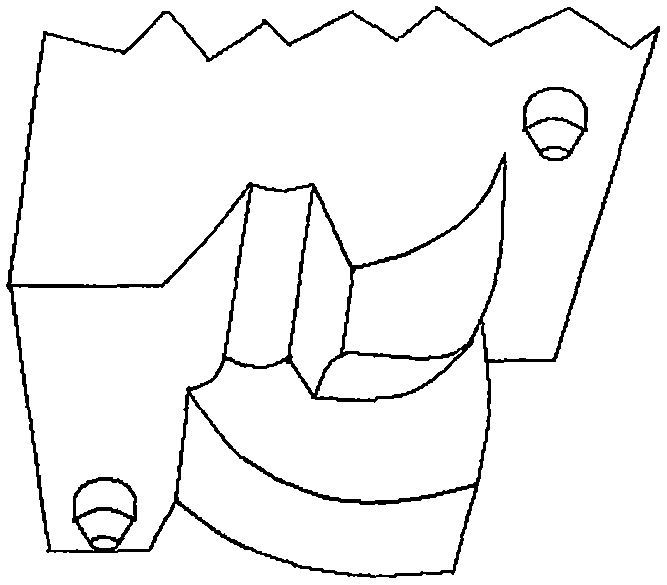

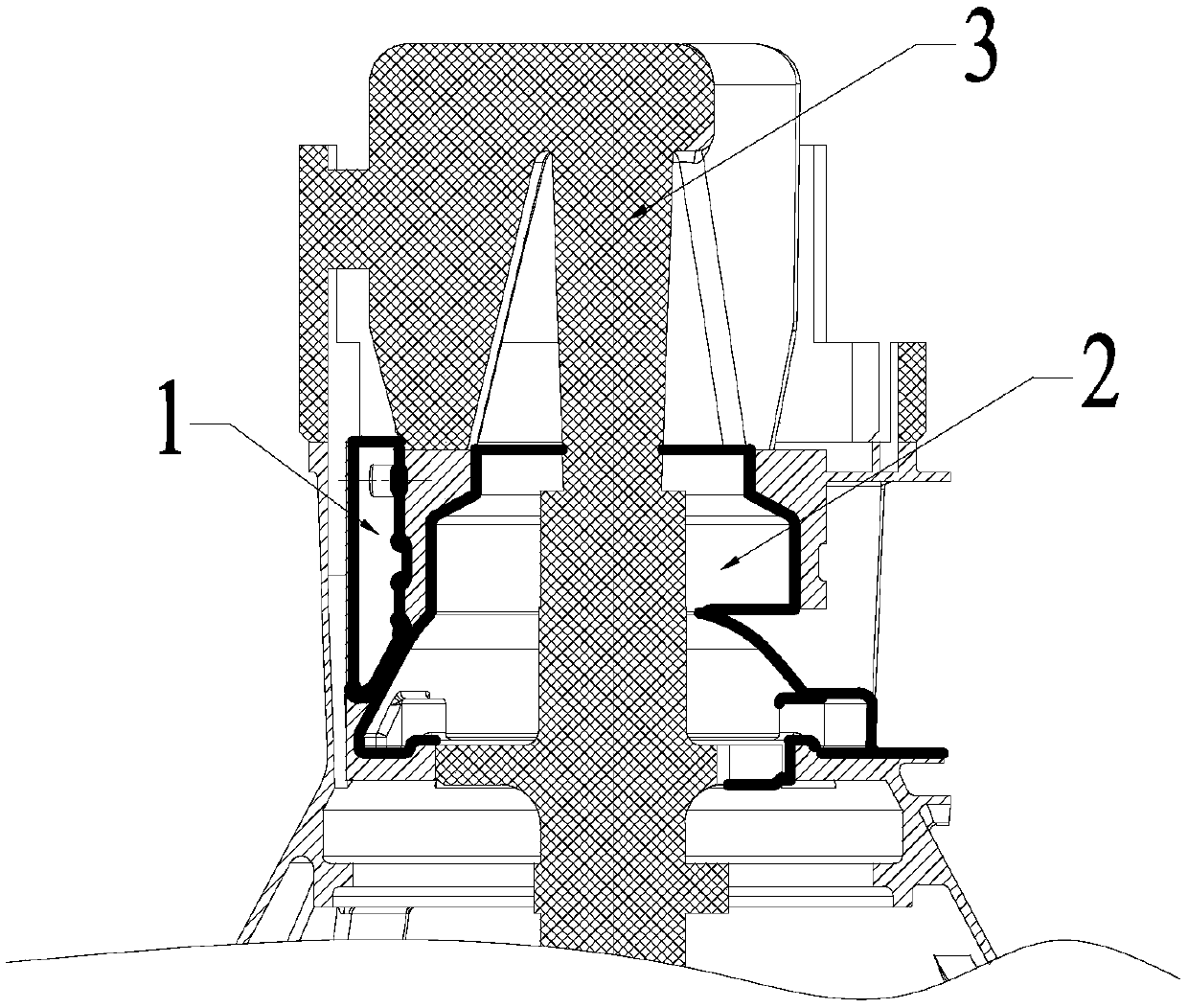

Forward skewed multi-blade impeller with narrow cavity and integral casting technique thereof

ActiveCN101787984ACompact structureReduce noisePump componentsPumpsImpellerUltimate tensile strength

The invention relates to a forward skewed multi-blade impeller with a narrow cavity, which is used for a centrifugal fan and is low in noise, and an integral casting technique thereof. The impeller comprises a base plate and a hollow front plate, and narrow blades are installed along the circumference between the base plate and the front plate. The difference lies in that the blades are arc-shaped; the radial length of each blade is 20mm-30mm; the outlet height H of the meridian plane of each blade is 10mm-20mm; the number of the blades distributed along the circumference is 20-60; and the whole impeller is integrally cast. The impeller is compact in structure, low in noise, light in weight, high in structural strength and simple and convenient in maintenance. By adopting a moveable blade mold structure to fabricate an impeller inner core blank removing mold so as to finish the integral casting of the impeller, the invention solves the technical problem of blank removal failure of a closed impeller with a narrow cavity and has the advantages of high casting precision and good quality of the impeller, low casting cost and high production efficiency. The technique is widely applicable for integral casting of various multi-blade impellers, with the effect obviously better than that of similar products.

Owner:CHINA SHIP DEV & DESIGN CENT +1

7-series aluminum alloy and preparation method thereof

The invention relates to 7-series aluminum alloy which is prepared from the following components in percentage by weight: 1.32-1.40 percent of magnesium, 0.014-0.016 percent of titanium, 7.50-7.70 percent of zinc, 0.003-0.005 percent of manganese, no larger than 0.05 percent of silicon, no larger than 0.08 percent of iron, no larger than 0.004 percent of copper, no larger than 0.001 percent of nickel, no larger than 0.001 percent of chromium, smaller than 0.0003 percent of zirconium and the balance of aluminum. The invention also relates to a preparation method for the 7-series aluminum alloy. The 7-series aluminum alloy has the advantages of high tensile strength, high yield strength, high ductility and excellent grain size grade.

Owner:SICHUAN FURONG TECHNOLOGY CO LTD

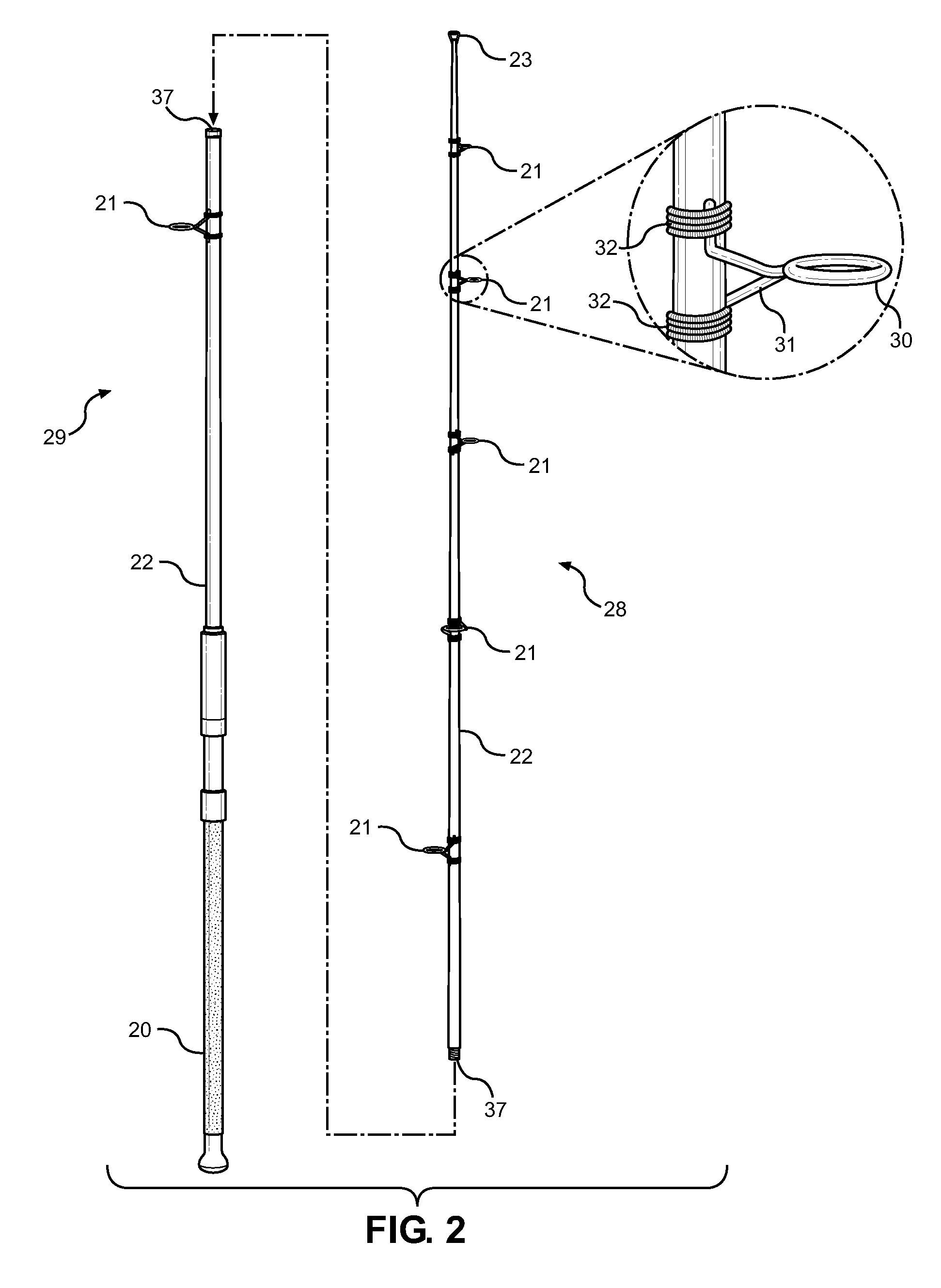

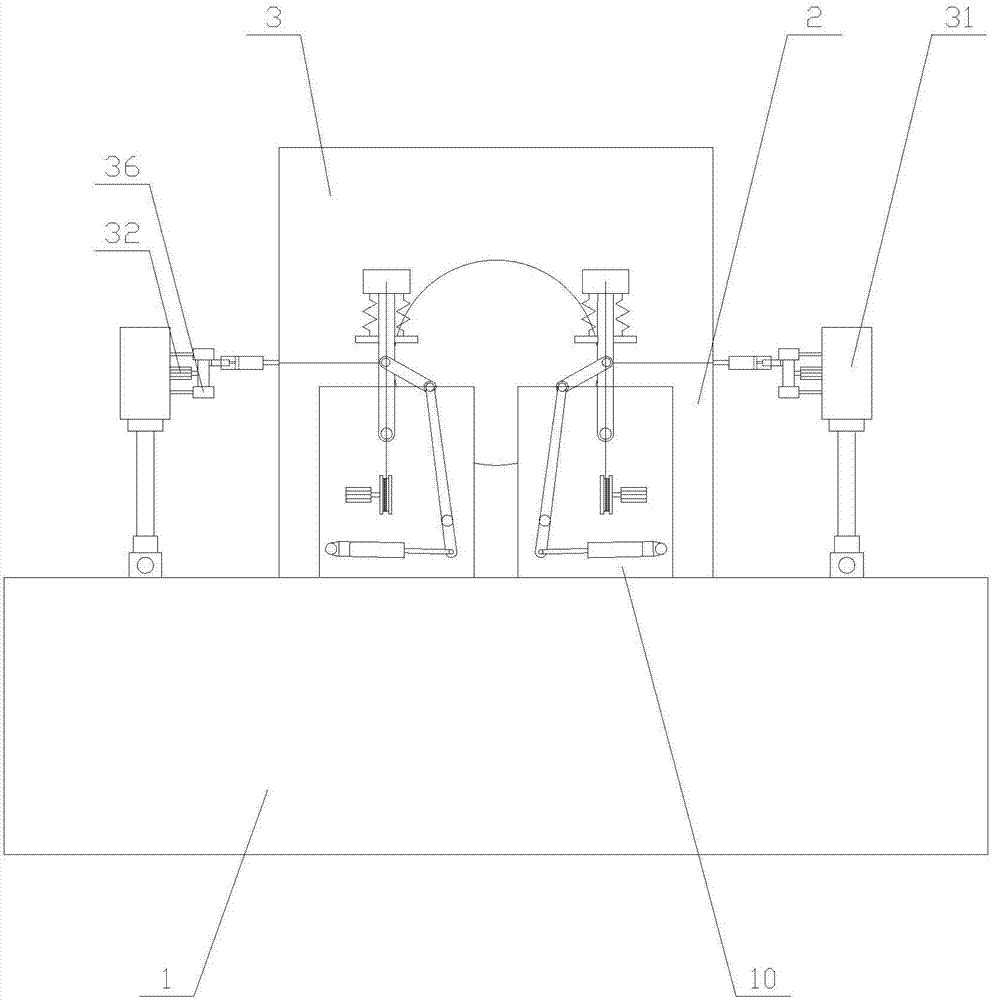

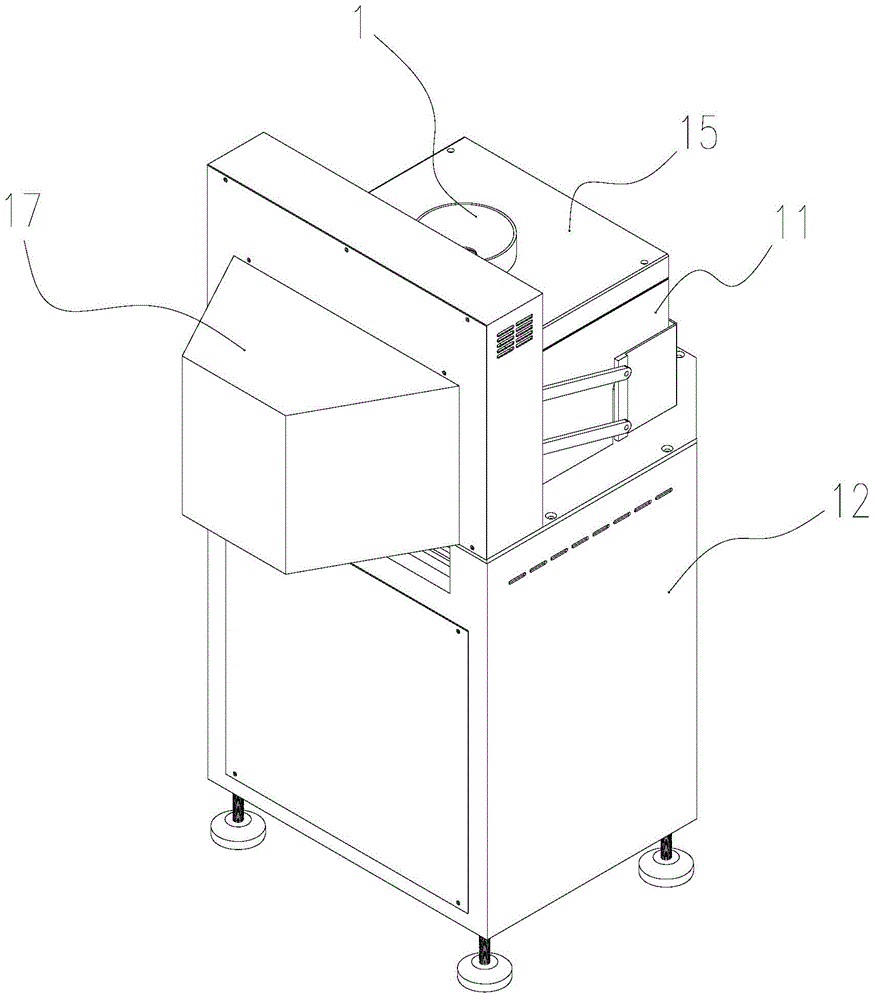

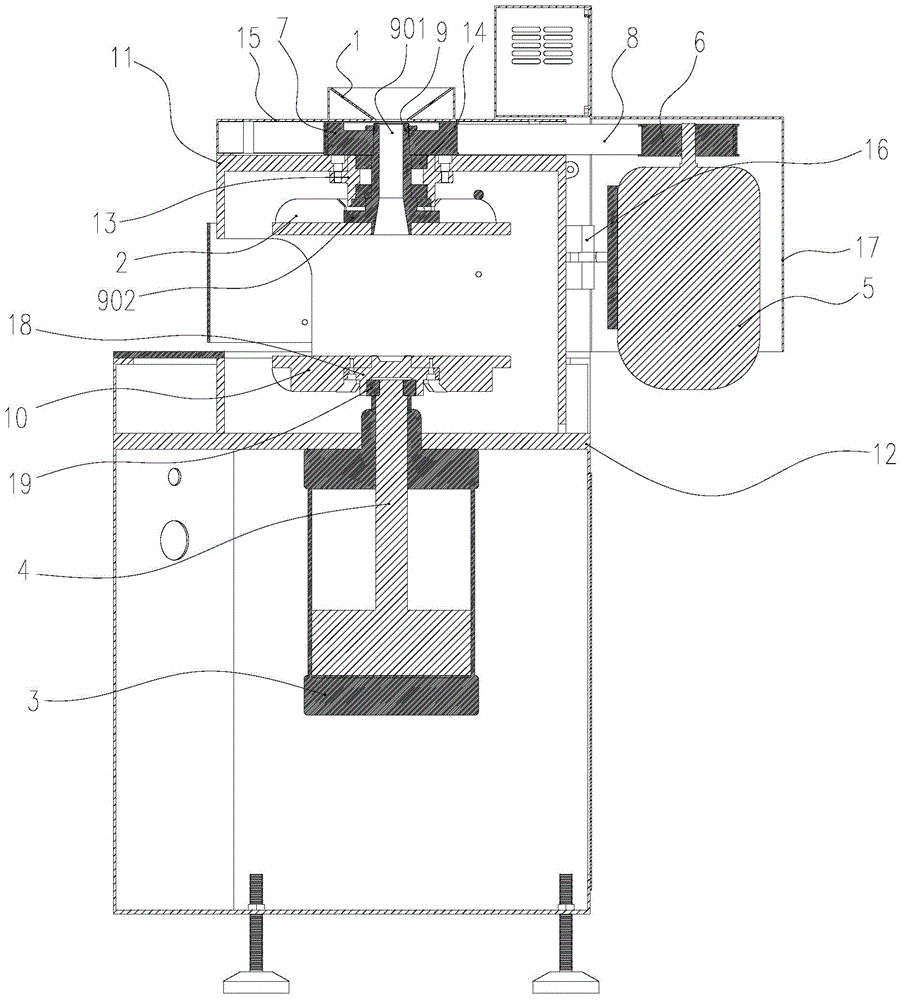

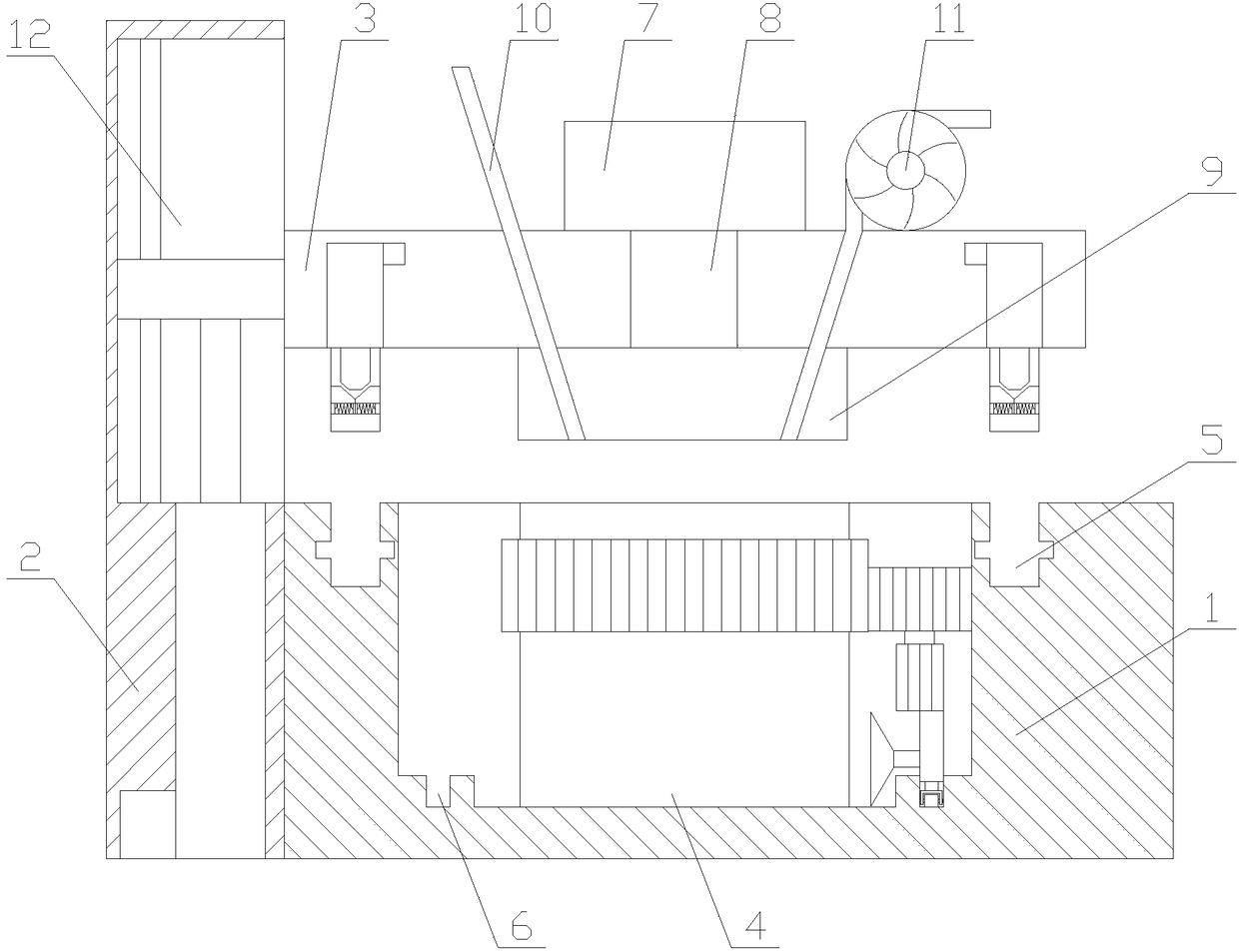

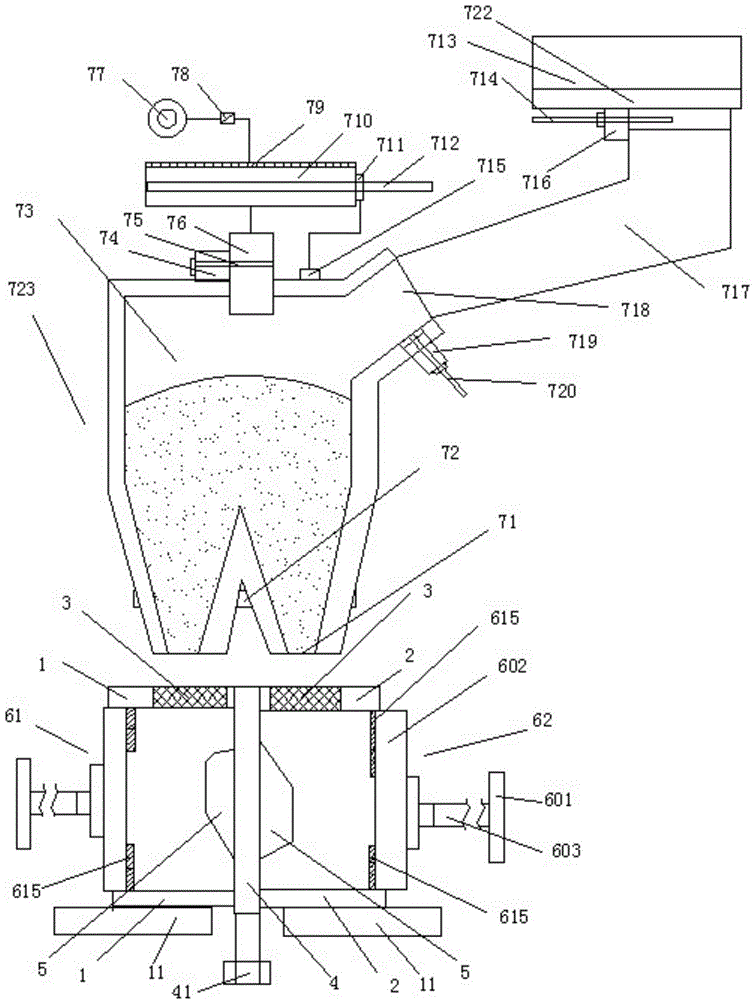

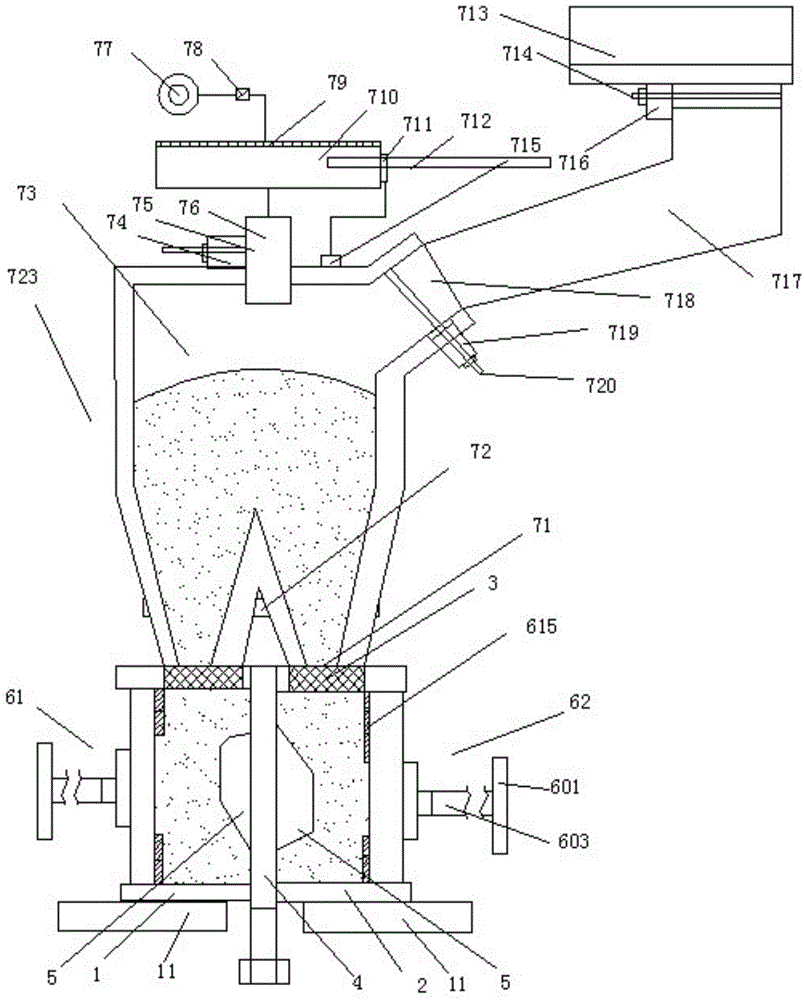

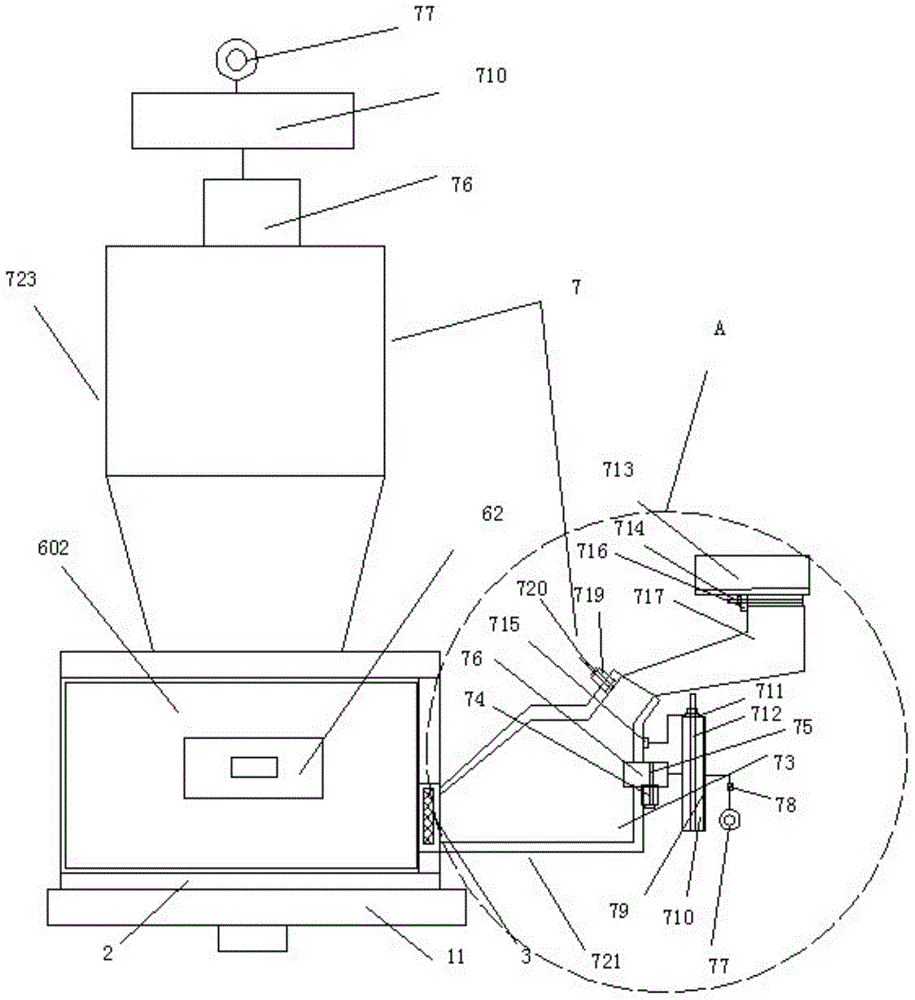

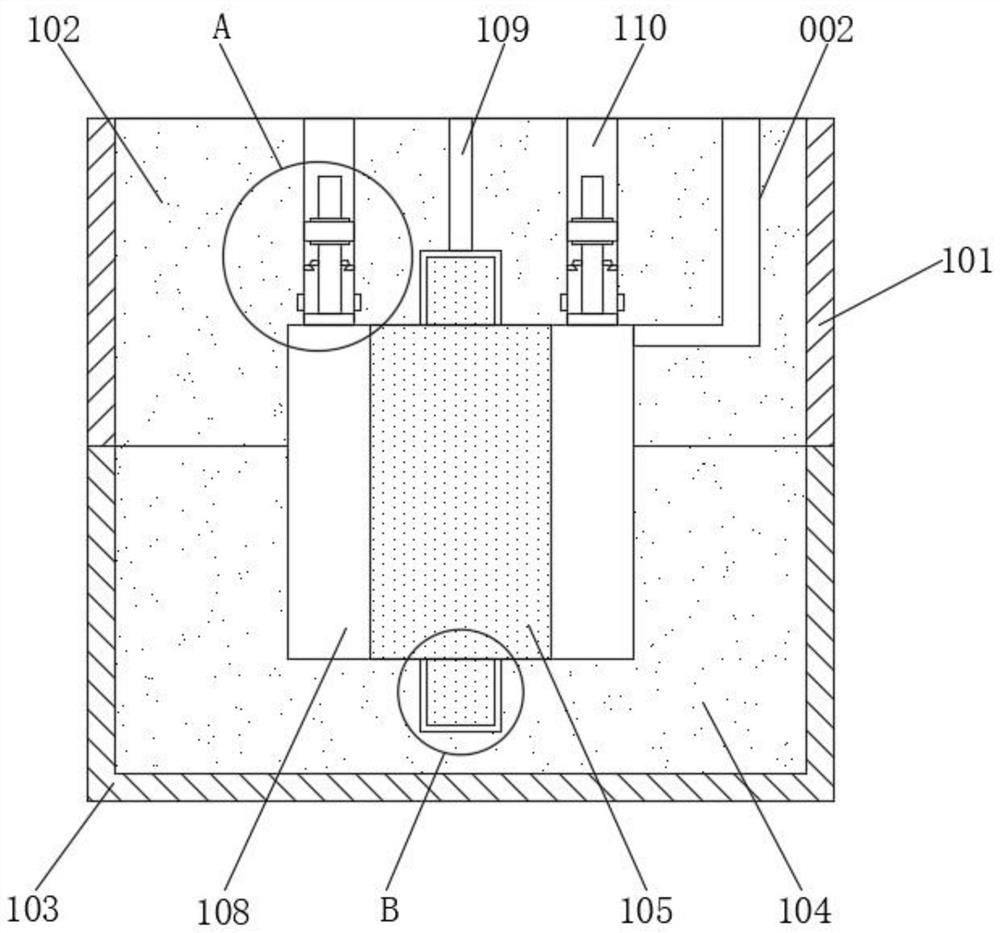

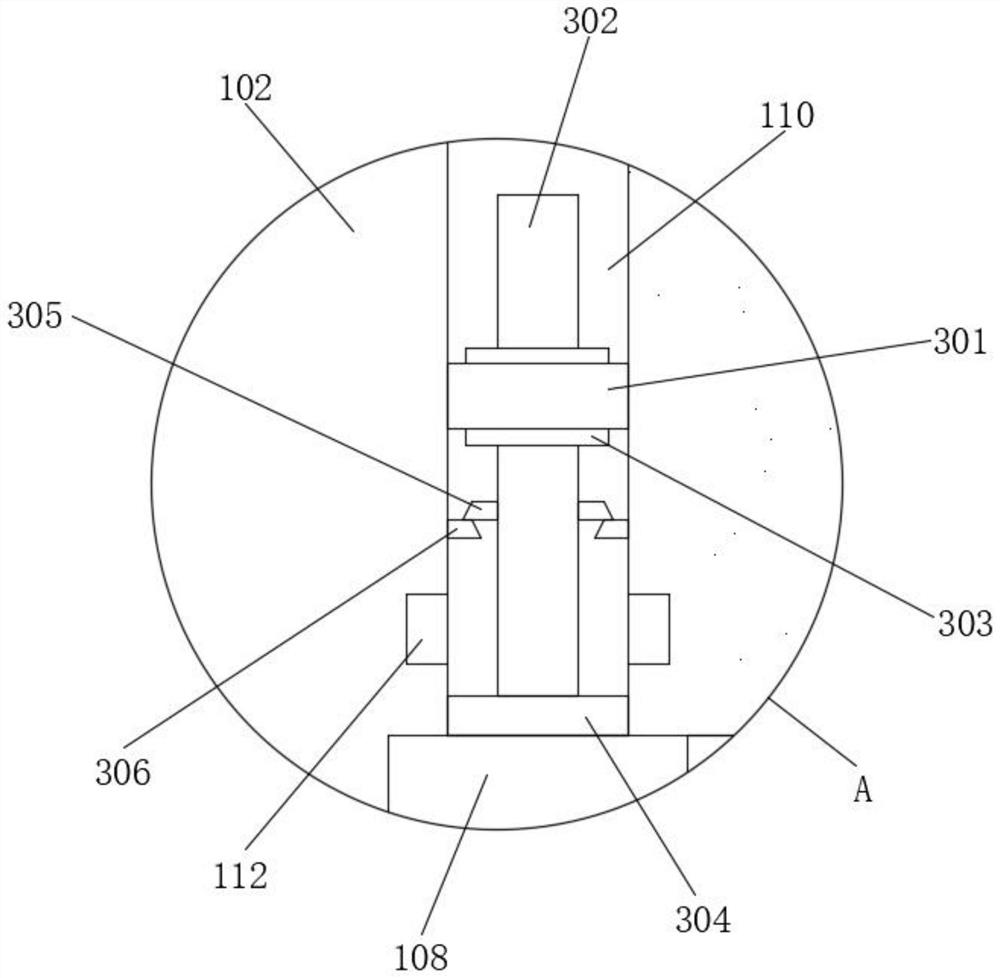

Hub casting system

InactiveCN107999707AImprove sealingImprove casting precisionFoundry mouldsFoundry coresTemperature controlAir pump

The invention relates to a hub casting system. The hub casting system is provided with a machining table, a lower die and an upper die, and further comprises two fixing plates, two temperature controlmechanisms and two sealing mechanisms. Each sealing mechanism comprises a lifting assembly, a moving assembly and a sealing assembly. Each sealing assembly comprises a first air pump, a first air cylinder, a first piston, a push plate, a sleeve and an injection tube. Each temperature control mechanism comprises a drive assembly, a drive rod, a transmission rod, a driven rod, a cooling block and areset assembly. According to the hub casting system, the upper die or the lower die is locally cooled through the temperature control mechanisms, so that the local cooling speed is increased, the probability that molten metal at the local position flows around is lowered, and accordingly the casting precision of the hub casting equipment is improved; and as a gap between the upper die and the lower die is filled up through the sealing mechanisms, the molten metal is prevented from flowing out from the gap, and thus the sealing performance of the hub casting equipment is improved.

Owner:南京卓茨机电科技有限公司

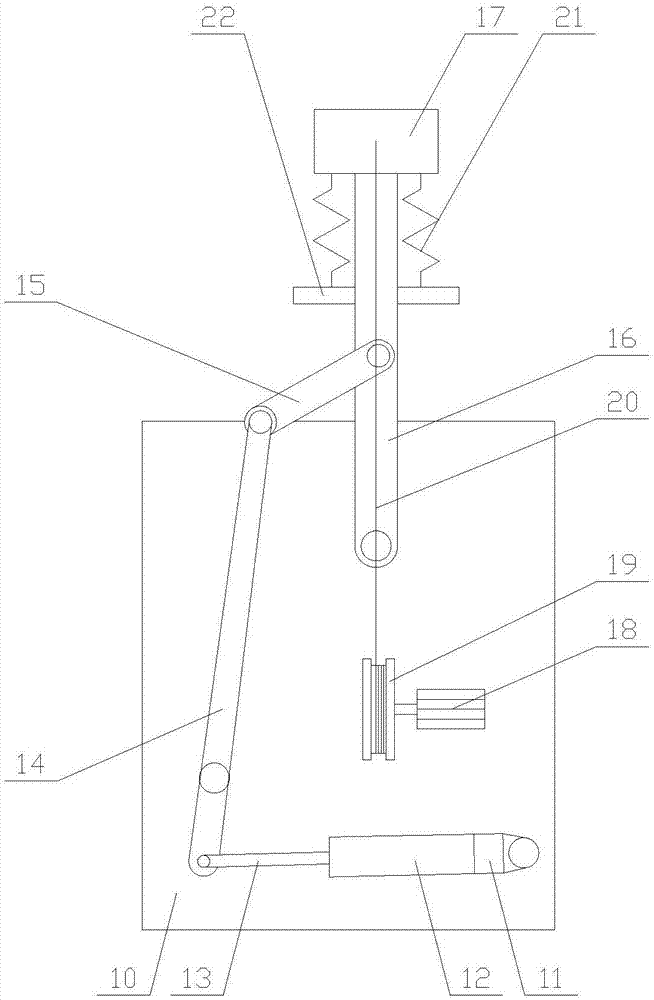

Novel vertical-type centrifugal casting machine

The invention provides a novel vertical-type centrifugal casting machine which comprises a feeding hopper, a rotating mechanism, an air cylinder, an upper pressing plate and a lower pressing plate. An inner cavity of the feeding hopper is communicated with a space under the upper pressing plate, and the upper end of a piston rod is supported at the bottom of the lower pressing plate in a jacking mode and connected with the lower pressing plate through a second bearing; the rotating mechanism comprises a motor, a driving wheel, a driven wheel and a belt, and the top of the upper pressing plate is provided with a rotation shaft. According to the novel vertical-type centrifugal casting machine, the rotating mechanism and the air cylinder used for lifting are separated and arranged to be connected with the upper pressing plate and the lower pressing plate respectively, when the rotating mechanism drives the upper pressing plate to rotate, the piston rod of the air cylinder is in a static state, therefore, the motor does not need to drive the air cylinder to rotate, and the energy consumption in the casting process can be reduced; in addition, due to the static state of the air cylinder, it can be guaranteed that the upper pressing plate, the lower pressing plate and a mould between the upper pressing plate and the lower pressing plate rotate steadily and efficiently to fully supply centrifugal force needed by casting, the casting precision is improved, and the quality of casting products is guaranteed.

Owner:杨一舟

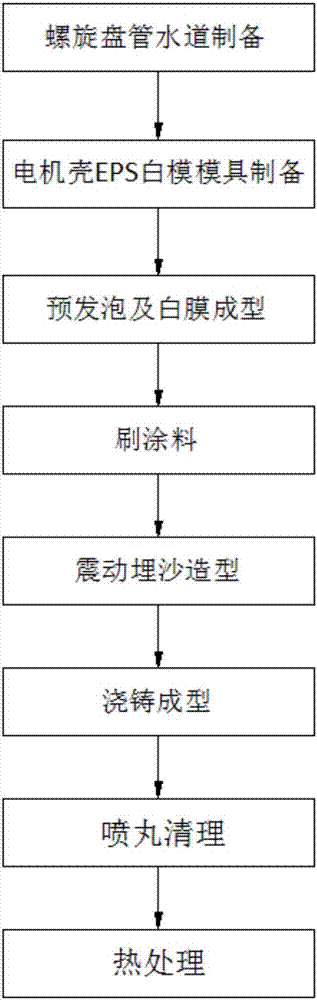

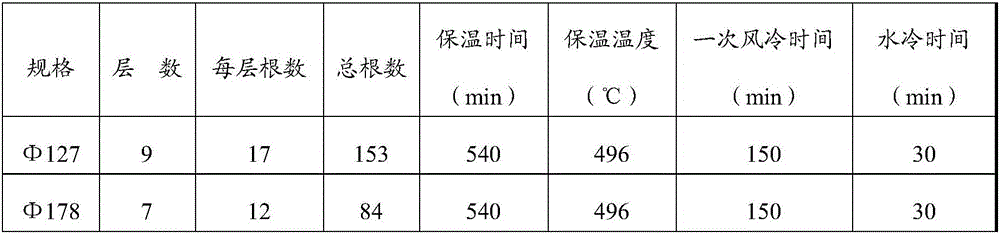

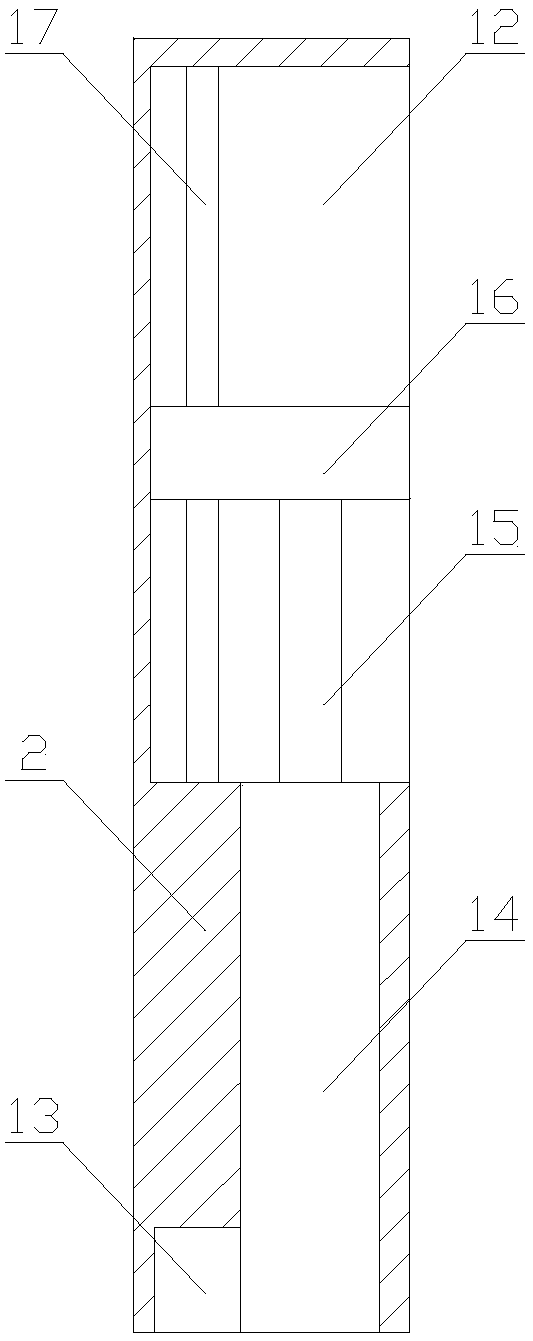

Casting technology of water-cooled motor shell, provided with nine turns of spiral waterways, for new energy automobile

InactiveCN105618711AImprove casting precisionGood product qualityFoundry mouldsFoundry coresElectric machineryEngineering

The invention relates to a casting technology of a water-cooled motor shell, provided with nine turns of spiral waterways, for a new energy automobile, and belongs to the field of motor shell manufacturing. Nine turns of spiral waterway cores are manufactured by adopting a hot box precoated sand coremaking method, 17 positioning core prints are arranged on the nine turns of spiral waterway cores, the 17 positioning core prints and the nine turns of spiral waterway cores are integrally formed, and the nine turns of spiral waterway cores are fixed in a water-cooled motor shell die through the matching of the 17 positioning core prints and positioning holes in the water-cooled motor shell die so as to pour molten aluminum smelted in a gas stove under low pressure in the water-cooled motor shell die by a low-pressure casting process to obtain a water-cooled motor shell casting blank. The casting technology has the advantages that the production process is simple, time and labor are saved, the production efficiency is high, the manufacturing cost is low, the radiating performance is high, the comprehensive performance of the product is stable, and the requirement of the water-cooled driving motor for the new energy automobile can be well met.

Owner:SHANDONG HONGYUAN NEW MATERIALS CO LTD

Manufacturing process of robot joints

The invention discloses a manufacturing method of robot joints with high-strength thin wall and high accuracy, which adopts a mode that expanding model and expanding core. Casting hot node embedding contoured chill and process strengthening rib, process lug boss and machine tooling are respectively provided with rough machining and finish machining pressing force, thereby increasing the casting accuracy of the joints, and improving the casting stress deformation and the machining pressing deformation. The quality of the joints reaches the international advanced level. The manufacturing process is stable and reliable, has high efficiency, lowers the cost, realizes the product localization, and replaces the import.

Owner:JIANGSU WANSHENG FOUNDRY

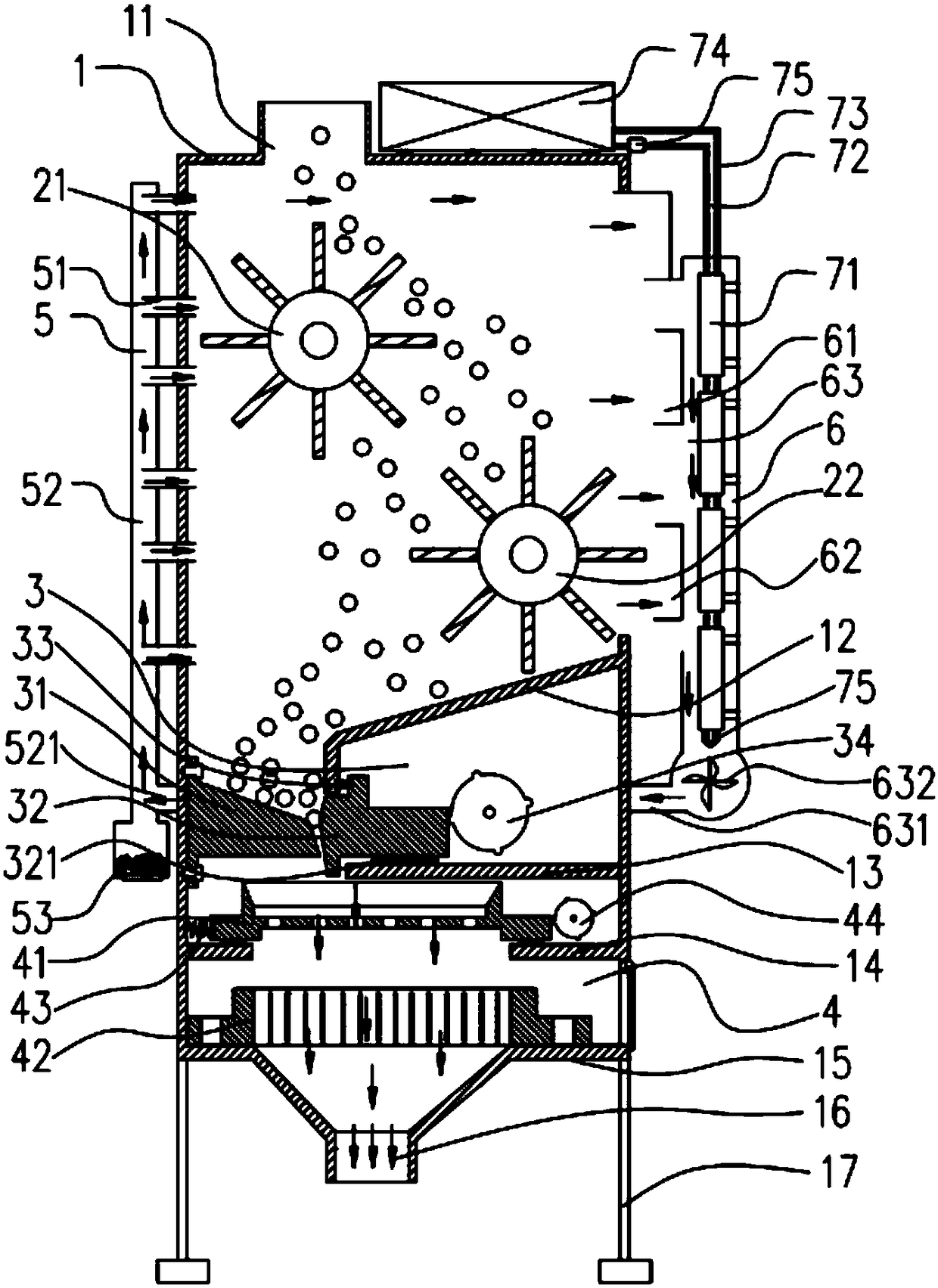

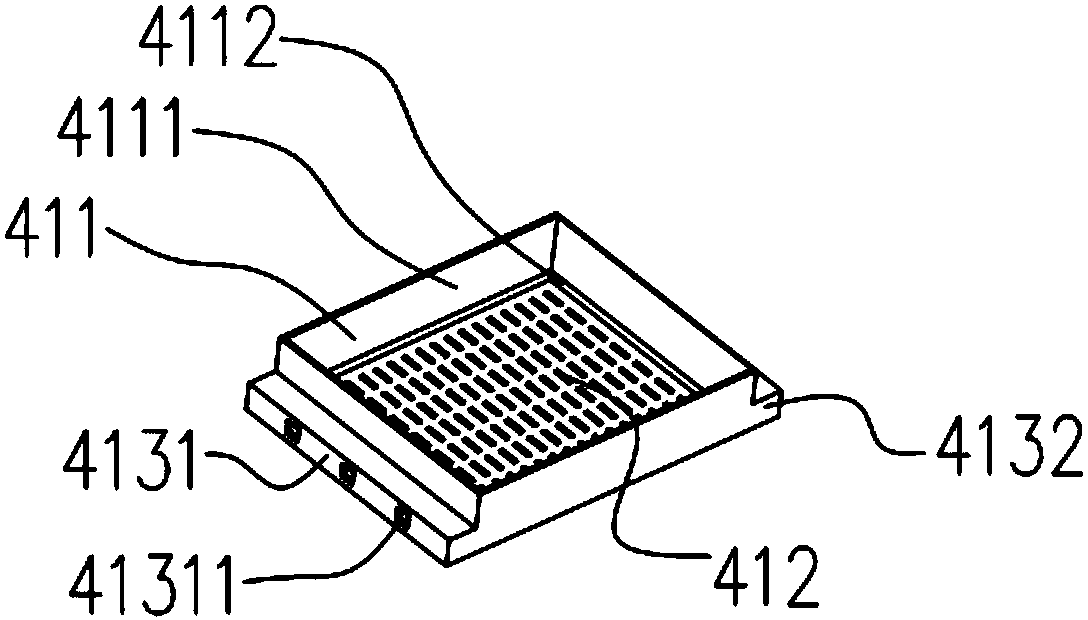

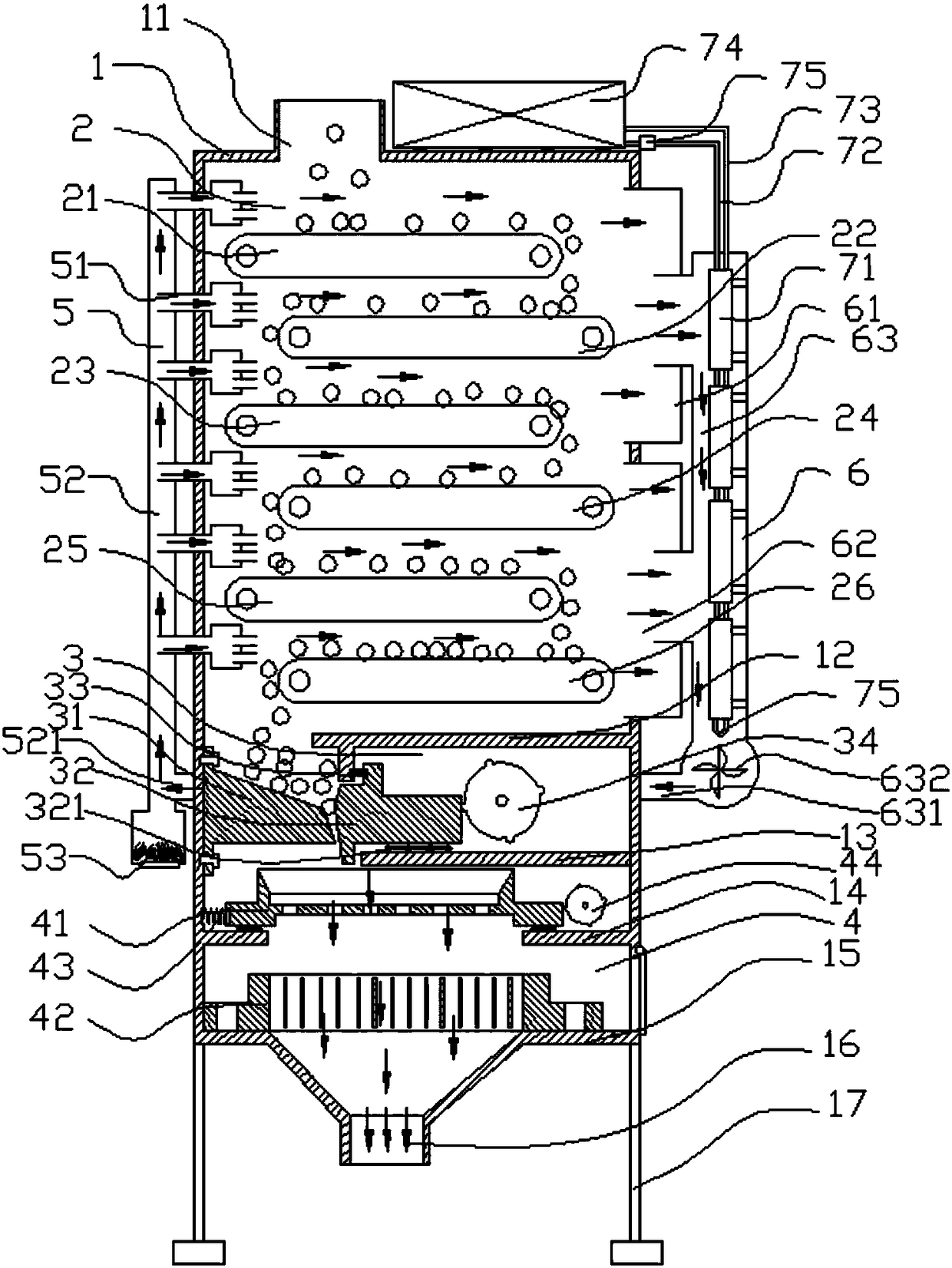

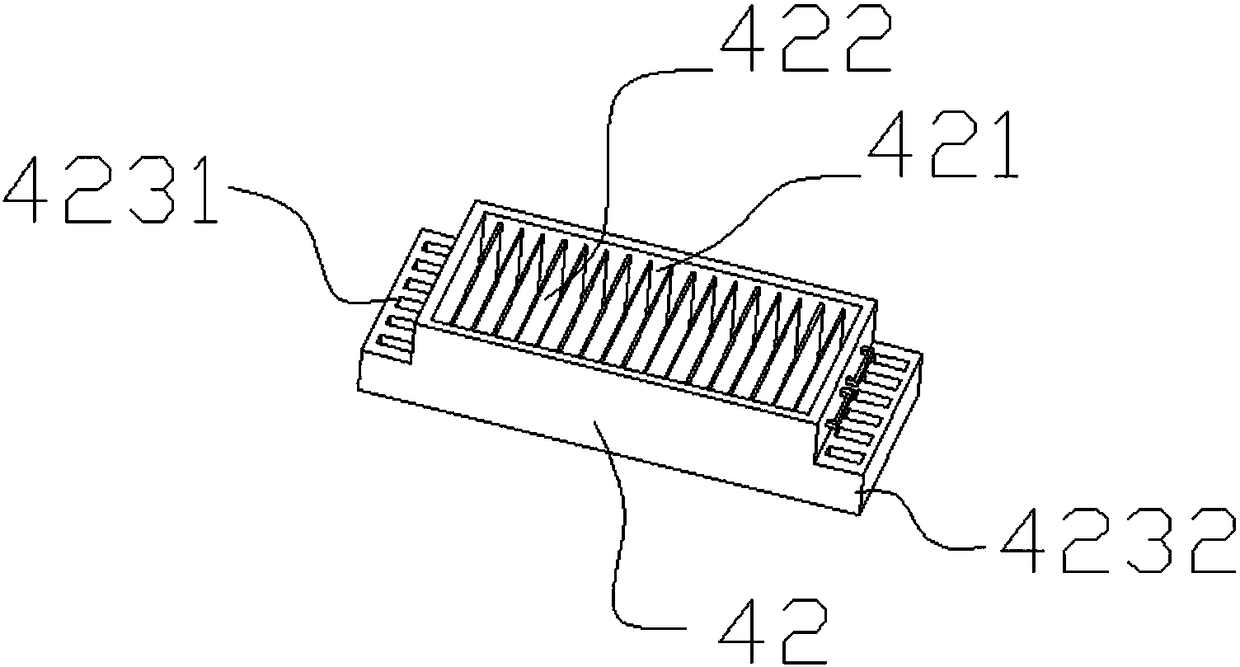

Environmental-protection molding sand cooling recovery device

InactiveCN108436030AGuaranteed homogeneityReduce the temperatureMould handling/dressing devicesCooling effectEngineering

The invention discloses an environmental-protection molding sand cooling recovery device. The device comprises a tower body, and a first separation plate, a second separation plate and a blanking collecting plate arranged in the tower body in sequence from top to bottom; a crushing bin is fixedly connected with a fixed inclined surface end, a slide inclined surface end and a first driving cam in sequence from left to right; a first return spring is arranged between the slide inclined surface end and the first separation plate; the first driving cam is matched with the right side surface of theslide inclined surface end, and can butt against the slide inclined surface end to move to the left side to realize pressing of the first return spring; when the first return spring is reset, the slide inclined surface end can be driven to move to the right side; a discharge port is formed in the lower part of the blanking collecting plate; and the tower body is provided with a cooling intake endon the left side wall and an air collecting device on the right side wall. The device cools molding sand through the cooling intake end and the air collecting device, achieves better cooling effect,and is compact in structure, convenient to use, energy-saving, environment-friendly and suitable for wide application in cooling recovery of the molding sand.

Owner:李同贵

Wheel hub casting equipment with defoaming function

InactiveCN108176840AWill not be damagedImprove casting precisionFoundry mouldsFoundry coresGear wheelAir pump

The invention relates to wheel hub casting equipment with the defoaming function. The wheel hub casting equipment comprises a base, a lifting box, a lifting plate, a hydraulic device, a pressing block, an upper die, a liquid inlet pipe and an air pump, wherein a defoaming mechanism, a sliding chute, a lower die and two limiting grooves are arranged in the base; a groove and a lifting mechanism arearranged in the lifting box; two fixing mechanisms are arranged on two sides of the lifting plate; each of the fixing mechanisms comprises a driving unit and a limiting unit; and the defoaming mechanism comprises a first gear, a rotating unit, a defoaming unit and a limiting unit. According to the wheel hub casting equipment, the fixing mechanisms can prevent the upper die from displacement, so that a to-be-solidified wheel hub in the lower die is not damaged, the casting precision of the wheel hub is improved; and in addition, through the defoaming mechanism, the wheel hub casting equipmentcan effectively remove air bubbles in high-temperature molten metal, so that the cooled and solidified wheel hub does not contain plenty of cavities, and the strength of the wheel hub is improved.

Owner:SUMEC WHEELS CO LTD

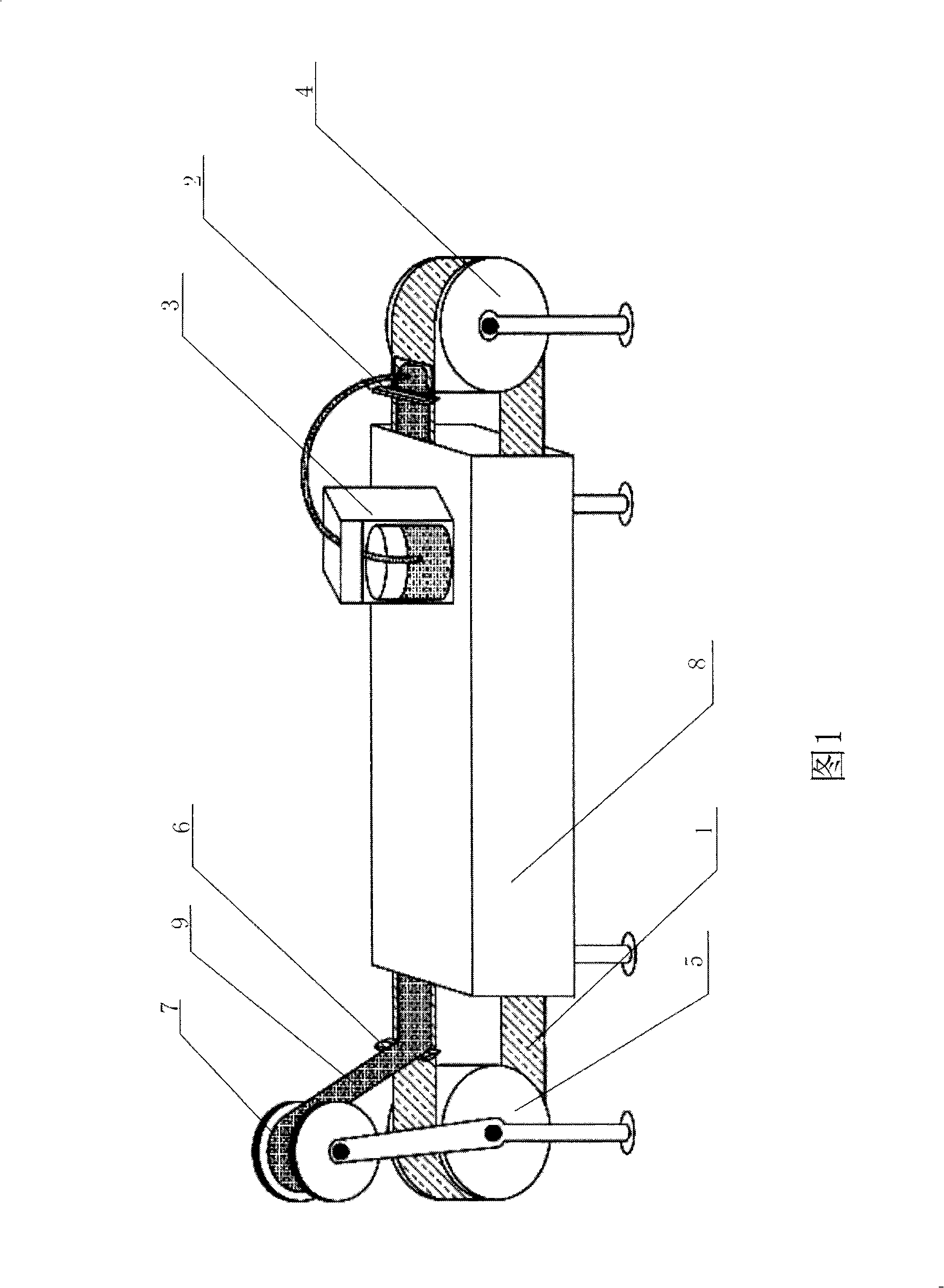

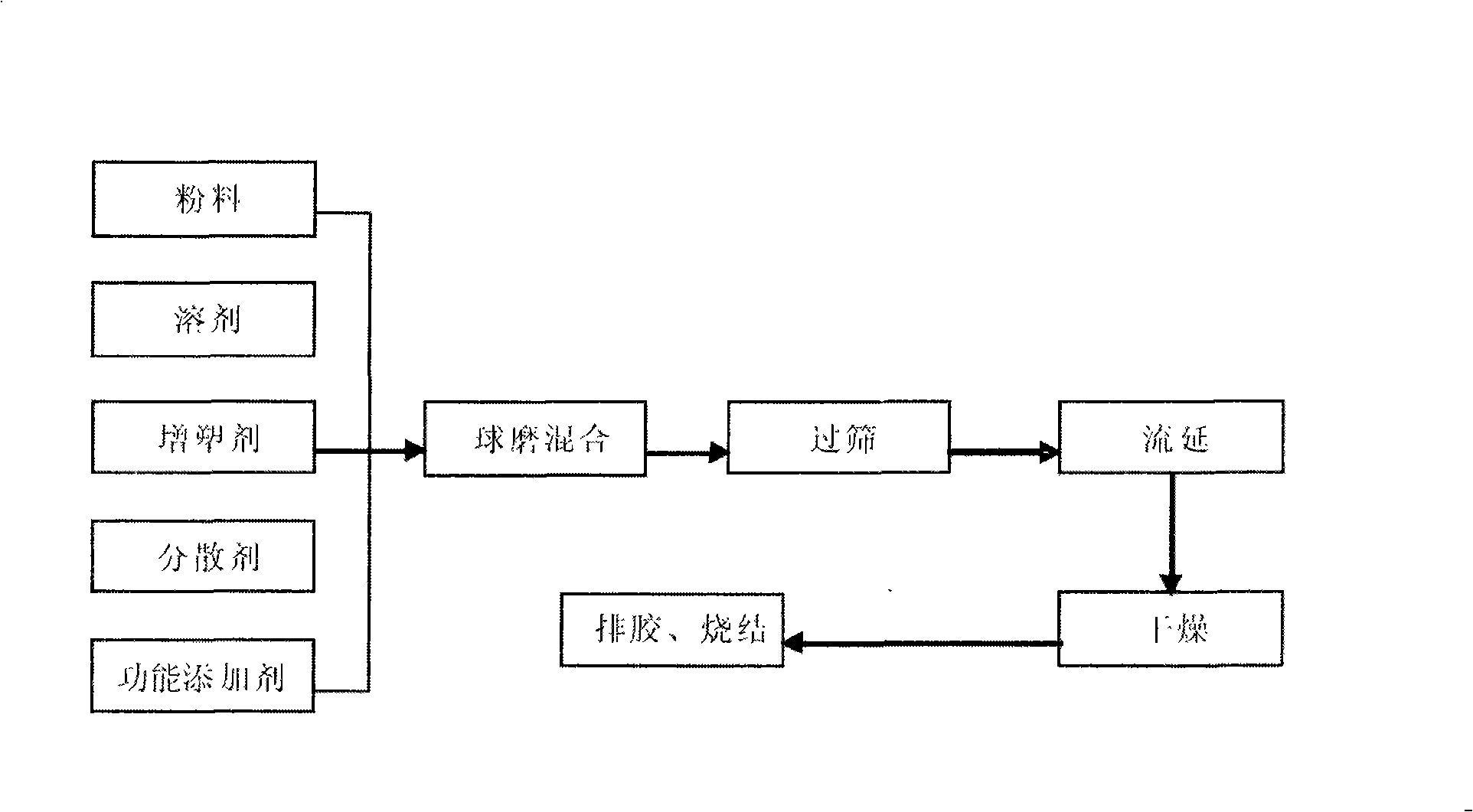

Full-automatic tape-casting machine and techniques for producing piezoelectric electronic ceramics and sheet type electronic ceramics

InactiveCN101323132AImprove casting precisionSimple and efficient operationCeramic shaping apparatusElectricitySteel belt

The invention discloses a fully automatic casting machine that comprises a steel strip, a scraper box, an automatic charging system and a trolley. The steel strip is arranged on a closed belt between two trolleys. The steel strip goes through the inner part of a baking tunnel between two trolleys. The scraper box and the automatic charging system are arranged on a driving trolley end. A skinning knife and a take-up rotating axis are arranged on a driven trolley end. The automatic casting machine can be used for manufacturing piezoelectric electric ceramics and chip electric ceramics.

Owner:严红光

Environment-friendly casting sand cooling and recovery device

InactiveCN108284198AGuaranteed homogeneityEnable recyclingMould handling/dressing devicesCooling chamberEngineering

The invention discloses an environment-friendly casting sand cooling and recovery device. The device comprises a tower body outer shell. A scrap iron separation cabin is arranged in the tower body outer shell. A cooling chamber and a crushing cabin are partitioned through a first partition plate. The crushing cabin and the scrap iron separation cabin are partitioned through a second partition plate and a third partition plate. A feeding inlet is formed in the upper end of the tower body outer shell. A mounting port is formed in the lower end of the tower body outer shell. A discharging collection plate is mounted in the mounting port. A discharging outlet is formed in one side of the discharging collection plate. Supporting frames are connected with the two ends of one side of the tower body outer shell. Casting sand blocks are put in through the feeding inlet, move circularly in the cooling chamber to be blown by cooling air and be cooled, then subjected to crushing operation in the crushing cabin, and subjected to scrap iron separation in the scrap iron separation cabin, the homogeneity of casting sand is ensured, and the casting precision is improved through repeated utilization; recovery and reutilization of casting sand in a closed space are achieved, diffusion of dust is effectively controlled, and environment pollution is reduced.

Owner:蒯进永

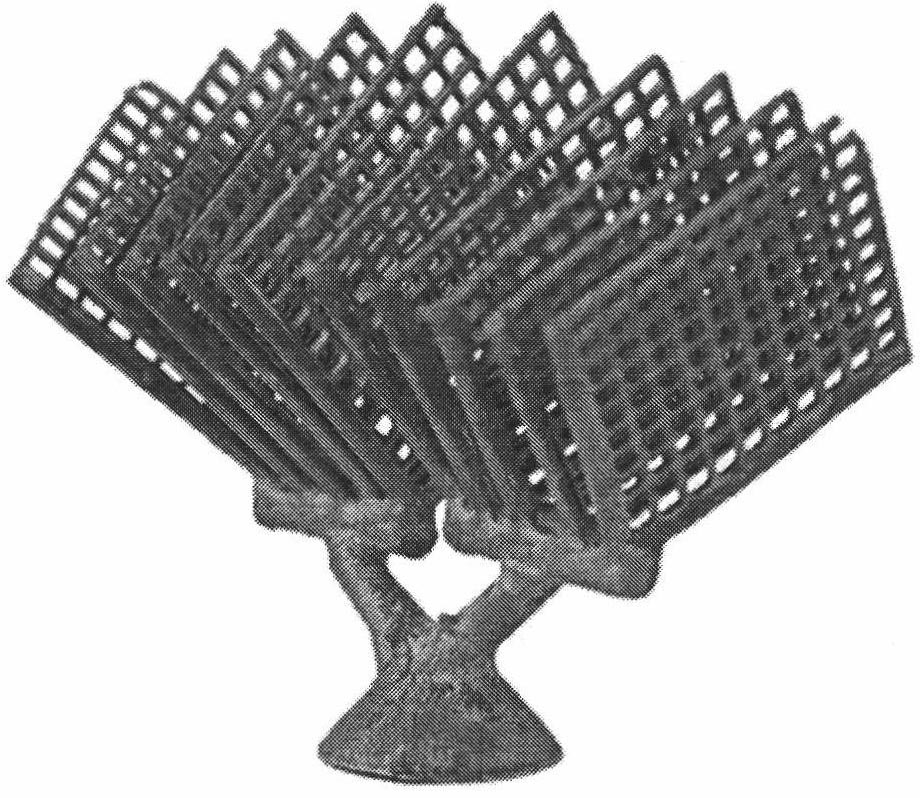

Water-soluble 3D-printing supporting wax and preparation method thereof

The invention discloses a water-soluble 3D-printing supporting wax. The water-soluble 3D-printing supporting wax comprises the following components in parts by weight: 20-90 parts of polyethylene glycol wax, 5-50 parts of a water-soluble tackifier, 0.1-1 part of a nucleating agent, and 0.1-0.5 part of an antioxidant. The invention further provides a preparation method of the supporting wax. The supporting wax has the characteristics of being fast in dissolving speed in water, high in printing accuracy, simple in removing processes, safe, environmentally friendly, and suitable for massive application; meanwhile, a printing wax die cannot be damaged, so that the wax die printing accuracy and the casting accuracy are improved.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

Zirconia oral dedicated embedded material and casting mold manufacture method thereof

The invention discloses a zirconia oral dedicated embedded material and a casting mold manufacture method thereof, belonging to the filed of oral titanium casting embedding materials. The zirconia oral dedicated embedded material comprises the following components by weight ratio: ZrO2: MgO: NH4H2PO4: Al2O3: H3BO3 = (100-150): (10-30): (10-20): (20-50): (1.5-3.9). The casting mold manufacture method comprises the following steps: (1) weighting powder, stirring and dryly blending evenly, and proportionally mixing; (2) manually stirring and then carrying out vacuum stirring; (3) instantly embedding or casting a fire-resistant mold, solidifying and demolding, and carrying out naturally air drying; (4) baking at low temperature; (5) baking at high temperature; (6) cooling down with a furnace, and discharging; and (7) carrying out cold mold casting. The oral dedicated embedded material disclosed in the invention not only can be used for casting dedicated cast molds by pure titanium, but also can be used for fine casting in which titanium is taken as a raw material, and has the advantages of simple process, low cost, good demolding performance, high quality of casting surfaces and high accuracy.

Owner:BEIJING UNIV OF TECH

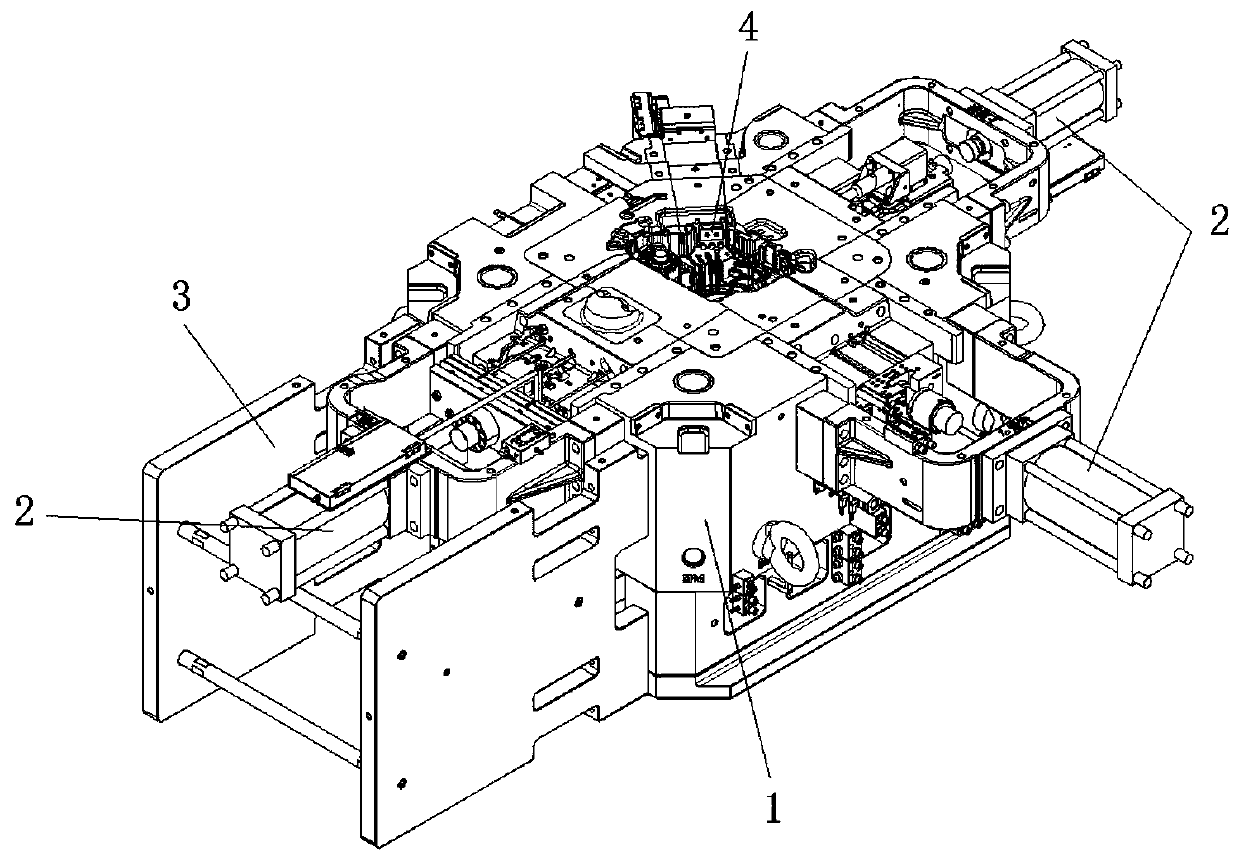

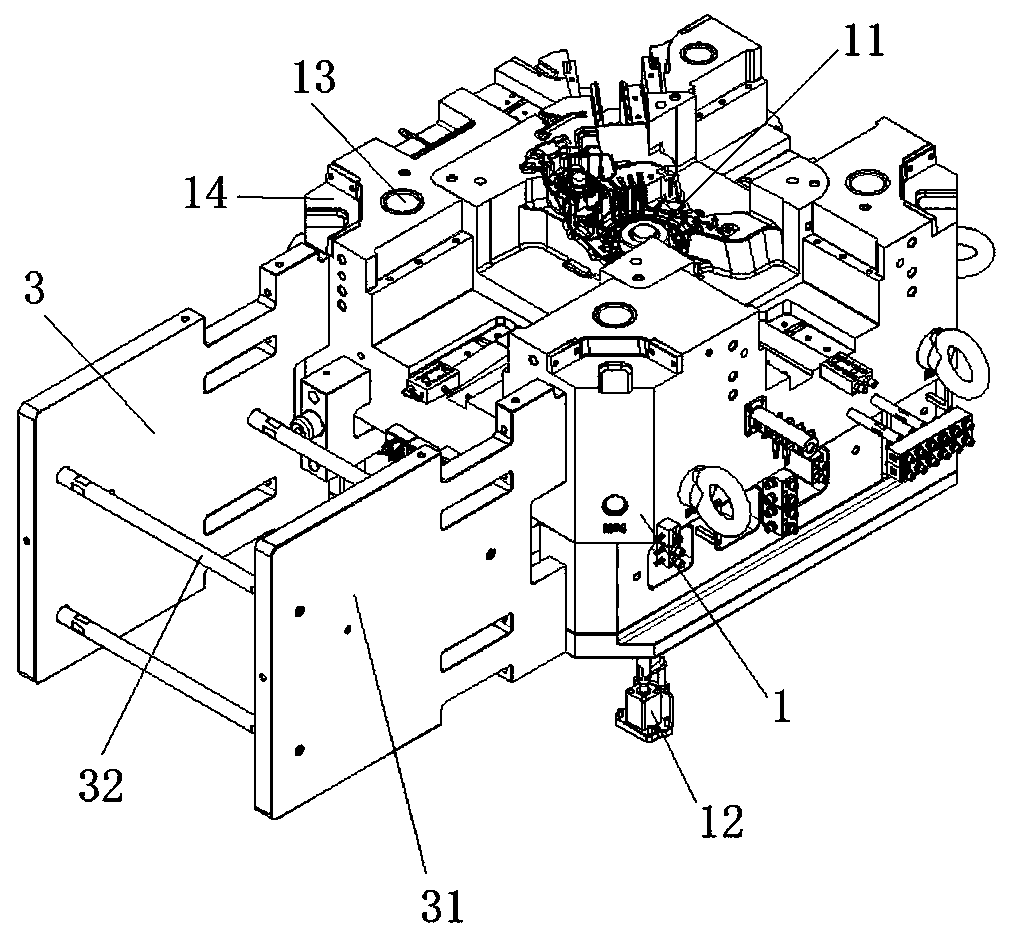

Quartered core device and its application method

InactiveCN1836807ASimplify the operating mechanismAvoid deformationFoundry mouldsFoundry coresHydraulic cylinderEngineering

The present invention relates to metal casting technology, and is especially one kind of quartering mold core unit for casting aluminum piston and its application method. The quartering mold core unit includes one pair of side cores, one pair of middle cores, one crow bar, one hinge flap, one cross beam, one hydraulic cylinder and other parts. It features the side core pair and the middle core pair combined into one integral quartering mold core, and the cross beam, the curved cross beam, the penta articulation structure, etc. below the quartering mold core. Compared with available technology, the present invention has simple operation structure, casting machine top height smaller than 900 mm, reasonable and balanced core force distribution, less core deformation, high casting quality and long core life.

Owner:BEIJING TAIHE TECH

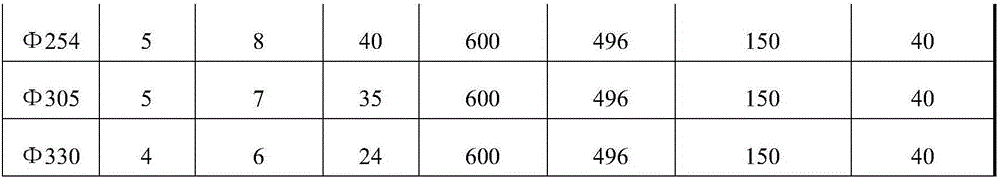

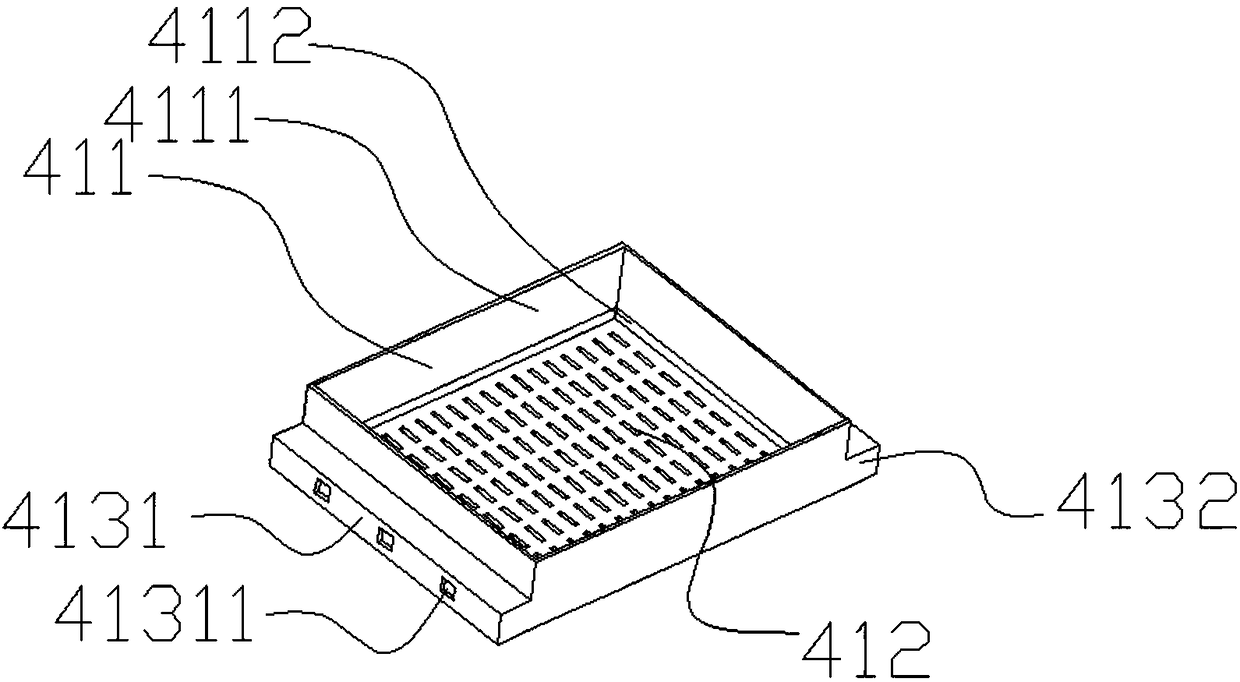

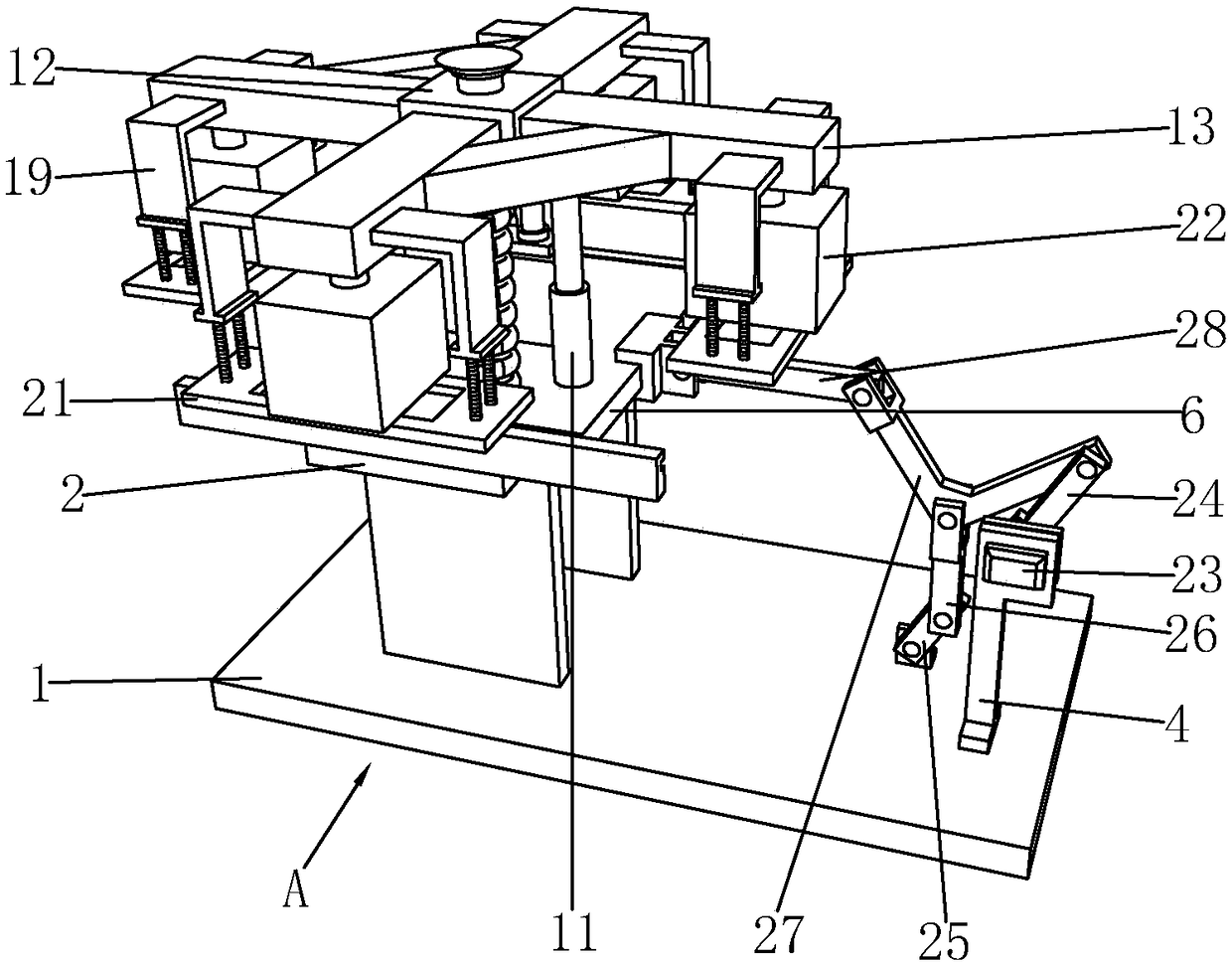

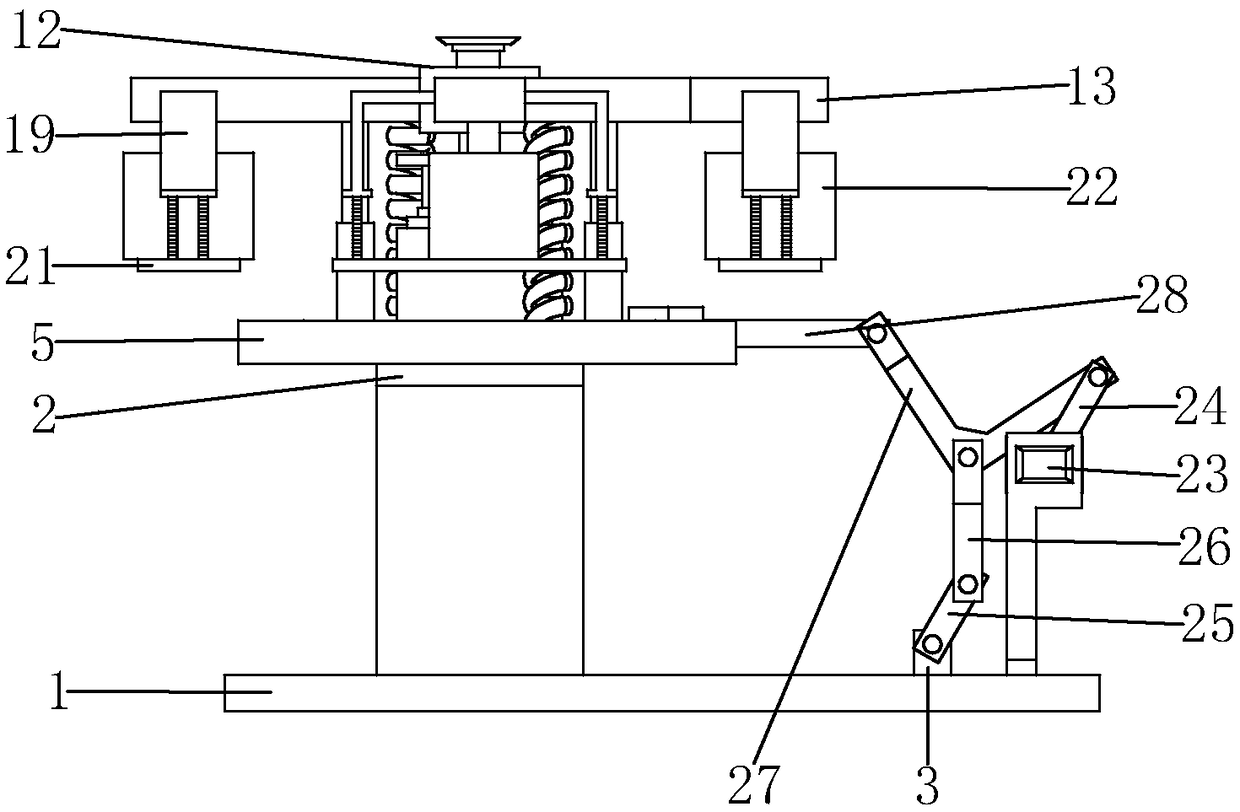

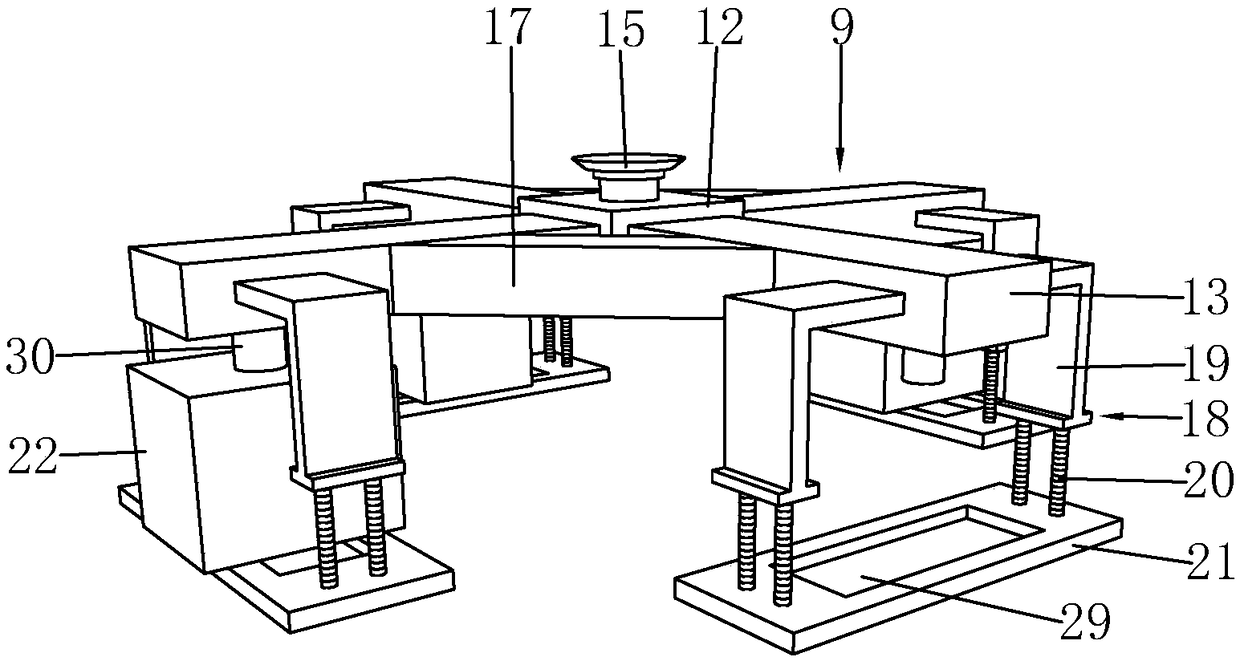

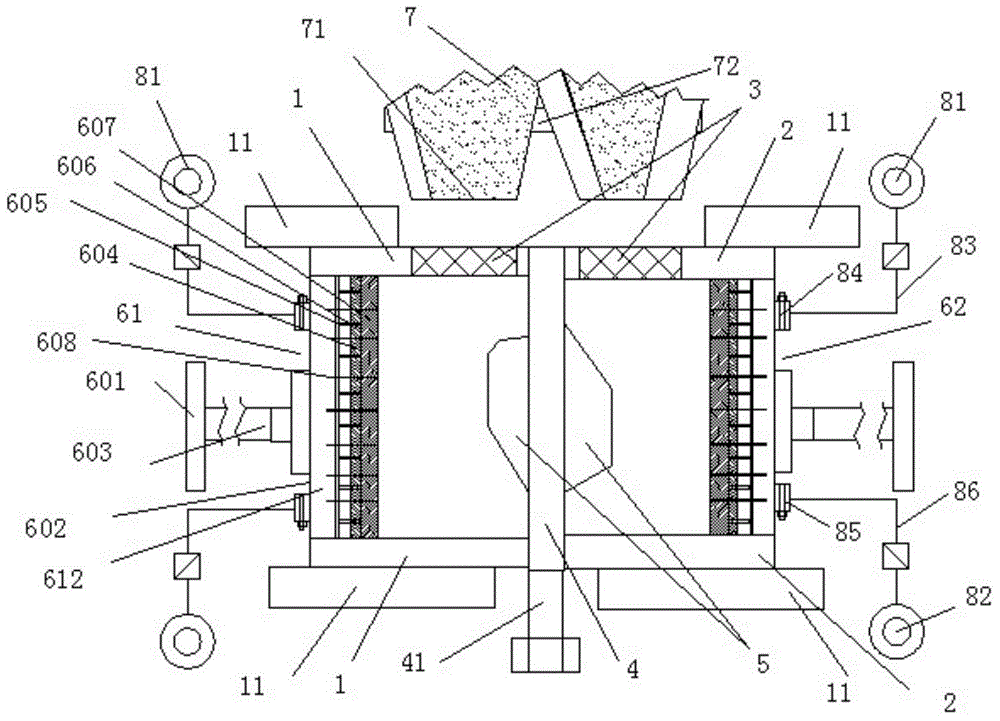

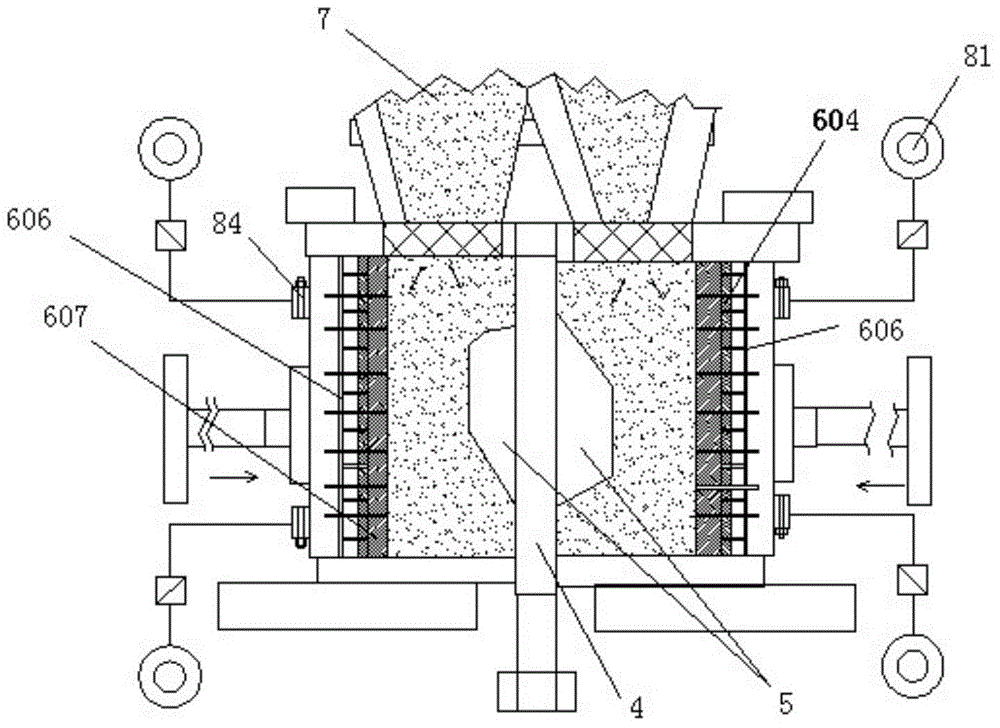

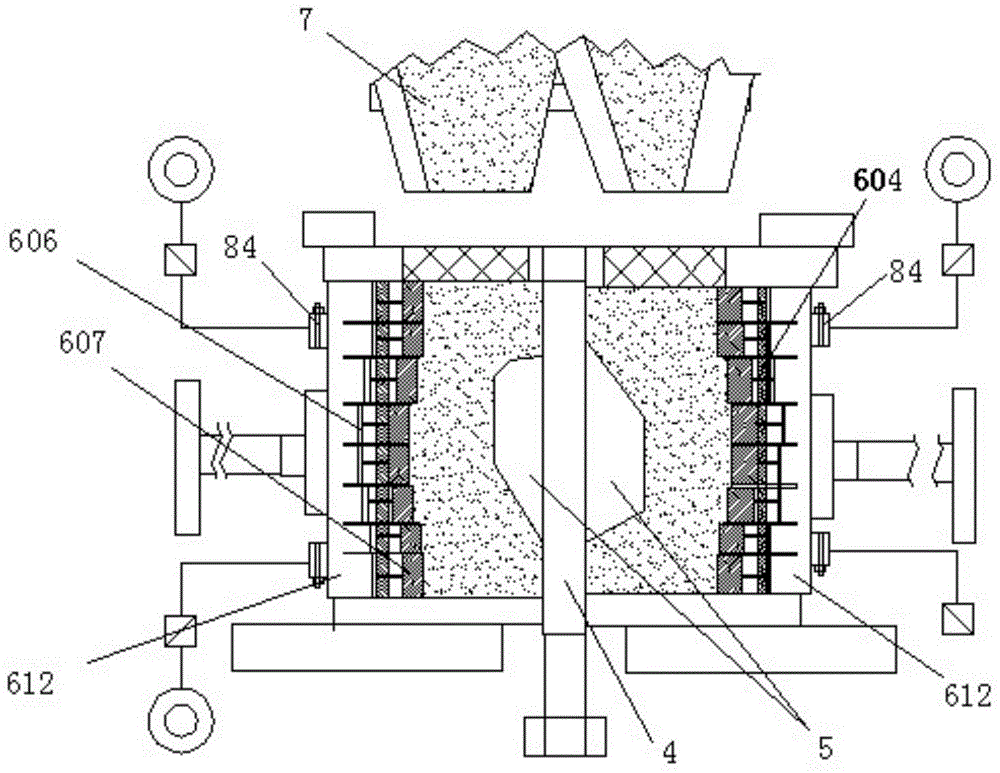

Top-bottom bidirectional uniform sand ejection casting and modeling device and method for manufacturing sand mold by device

ActiveCN104368766AImprove casting precisionMake up for the problem of low uniformityMoulding machinesDensity differenceEnergy consumption

The invention discloses a top-bottom bidirectional uniform sand ejection casting and modeling device and a method for manufacturing a sand mold by the device. The top-bottom bidirectional uniform sand ejection casting and modeling device comprises a left sand box, a right sand box, a replaceable double-sided mold plate, a sand box moving device, a left and right horizontal extruding device and a top-bottom bidirectional vertical sand ejection device. When the sand mold is manufactured by adopting the top-bottom bidirectional uniform sand ejection casting and modeling device, sand is added and compressed twice and gas is exhausted, so that the density differences in the sand mold casting process are reduced greatly; according to the top-bottom bidirectional uniform sand ejection casting and modeling device, the molding is accurate, firm impaction is realized, the sand compaction effect is good, the energy consumption is low, the efficiency is high, and multiple defects caused by pure air impulse modeling can be overcome.

Owner:山东时风(集团)有限责任公司

Manufacturing method of centrifugal pump induction wheel

ActiveCN109317625AImprove liquidityResidue reductionFoundry mouldsFoundry coresEngineeringCentrifugal pump

The invention discloses a manufacturing method of a centrifugal pump induction wheel. The manufacturing method comprises the following steps that (a) a shell is manufactured; (b) a liquid is injected;(c) vibration is carried out; (d) adjustment is carried out; and (e) post-processing is carried out. The manufacturing method is high in feasibility and easy to control, the induction wheel without parting surfaces can be cast, the forming quality is good, and the problems that the casting precision is poor, the surface defects are large and the quality of a finished product is low in a traditional manufacturing method are solved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

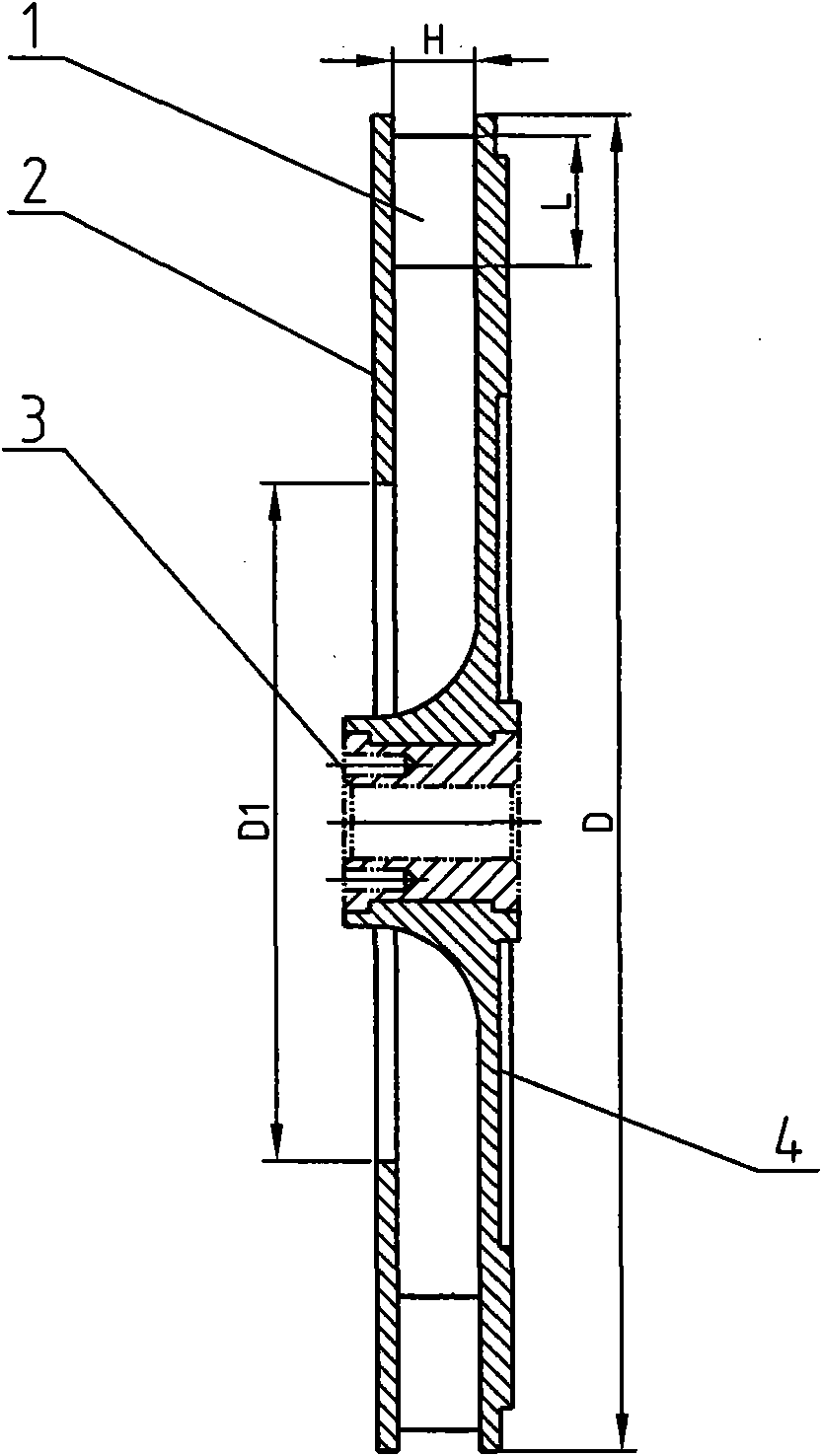

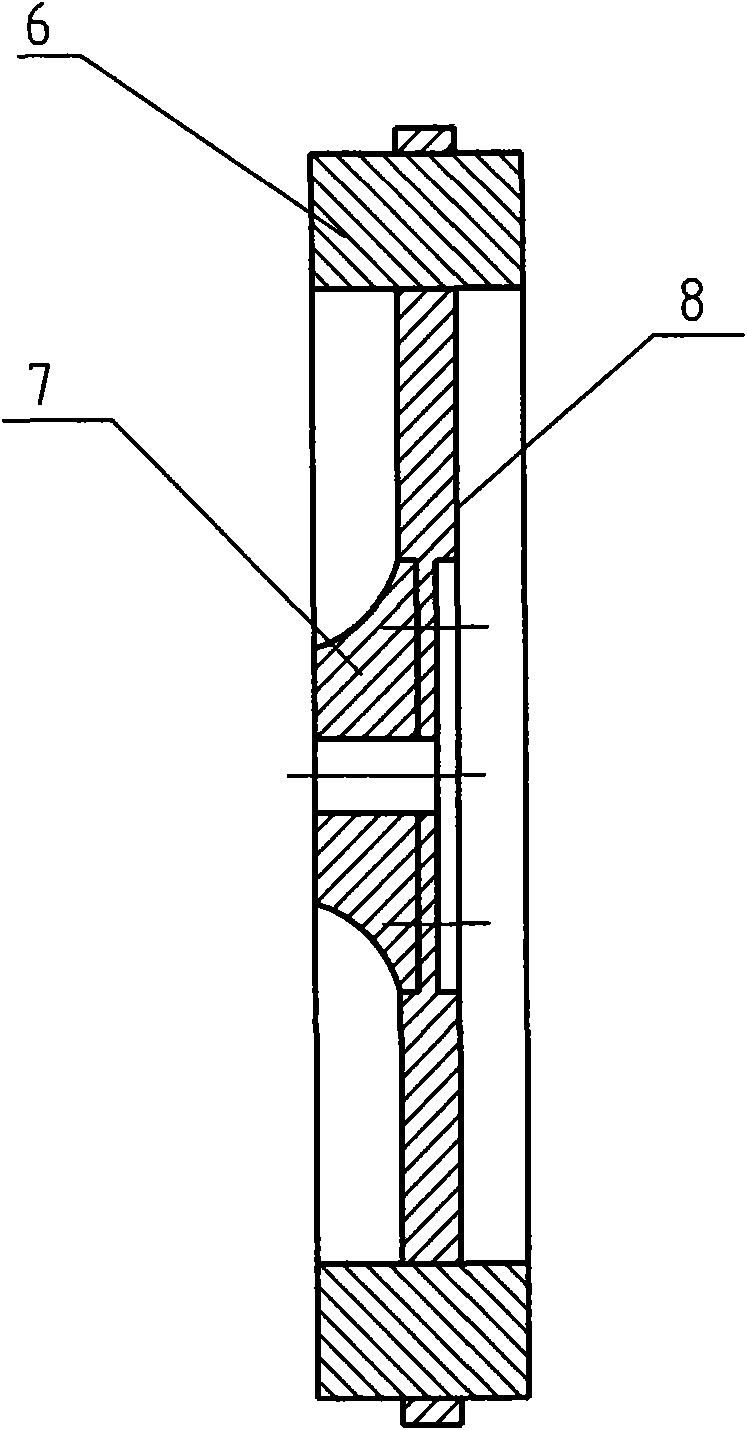

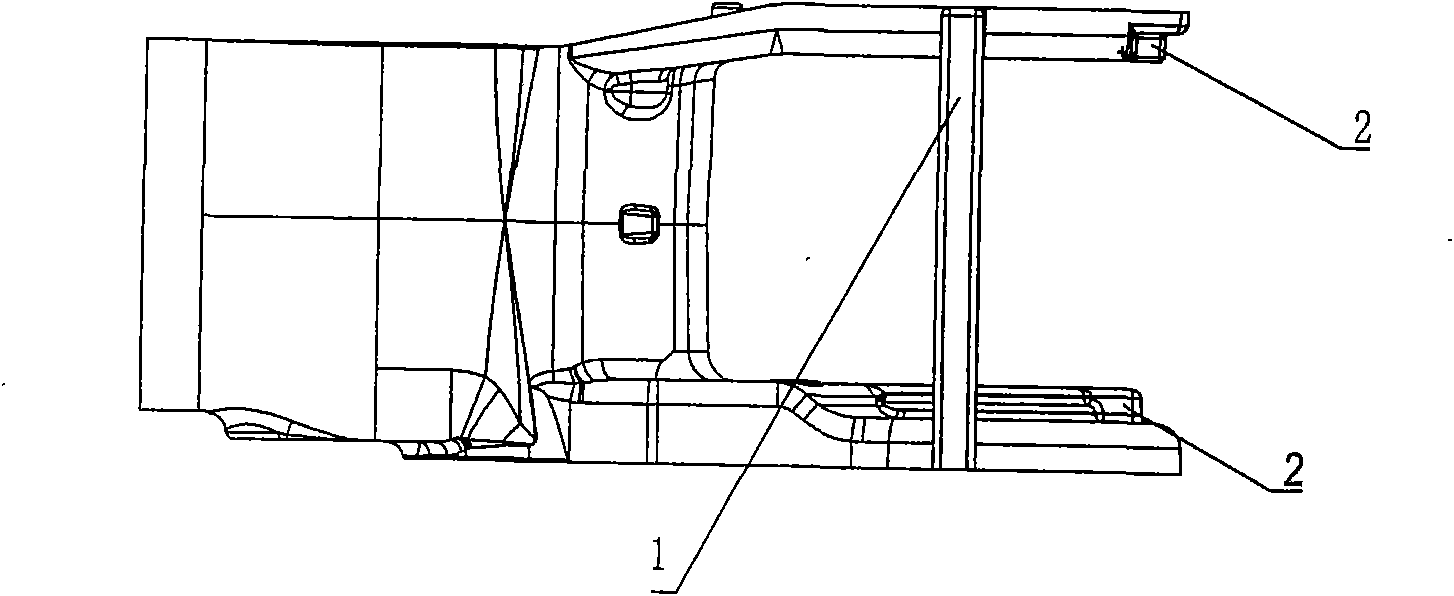

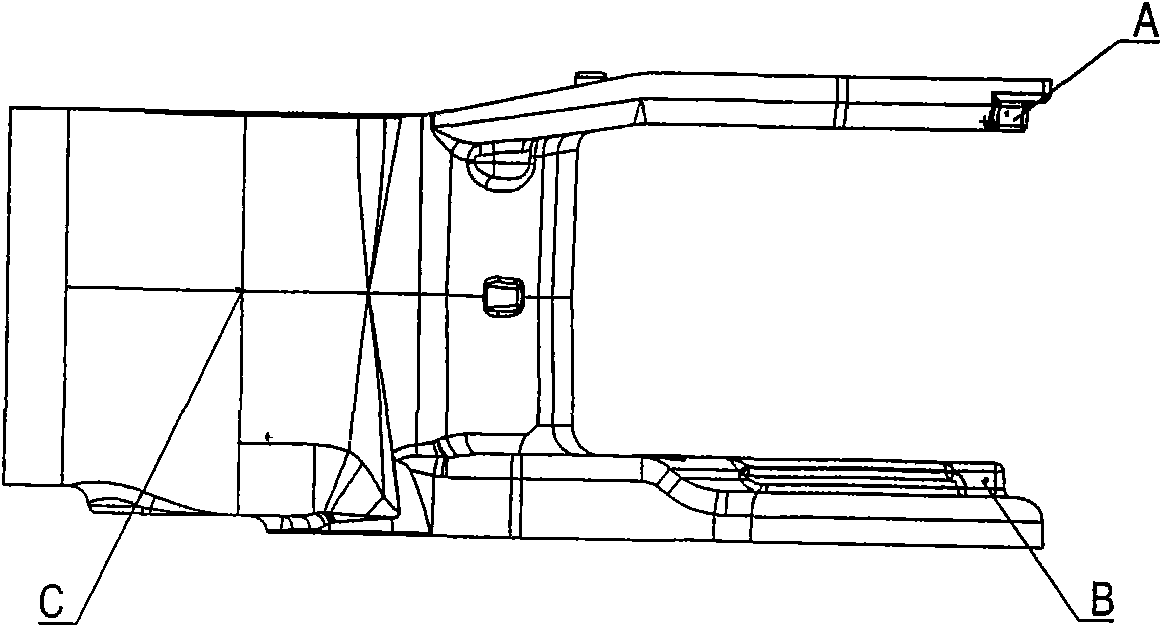

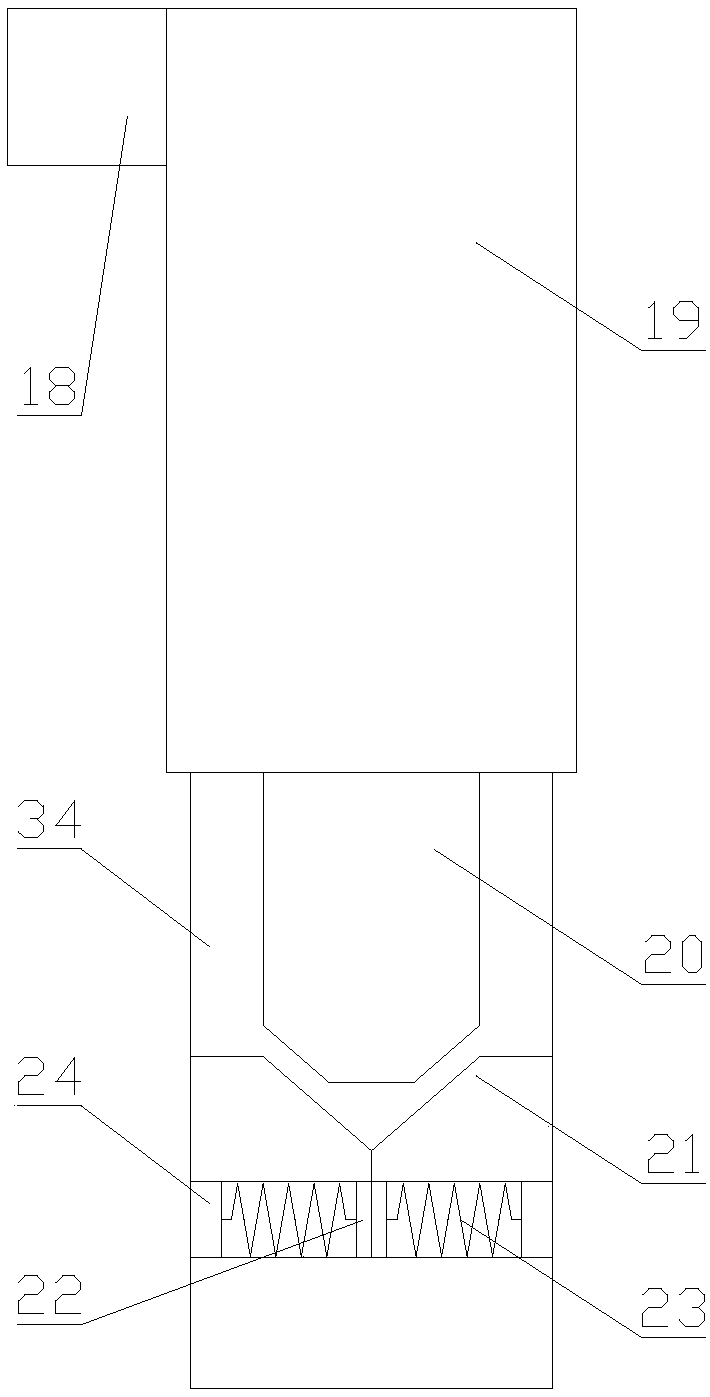

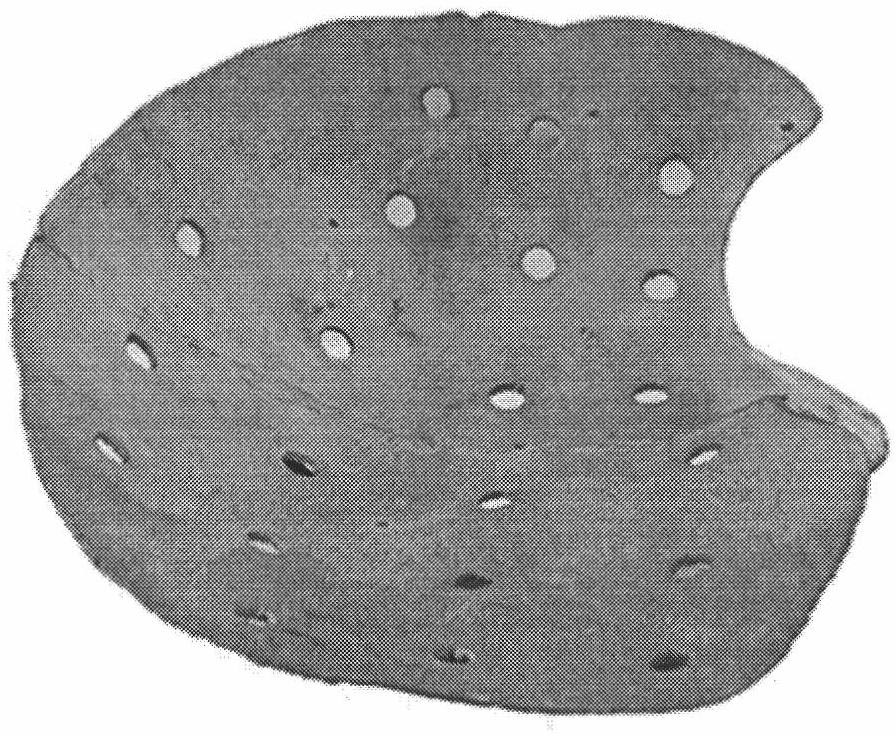

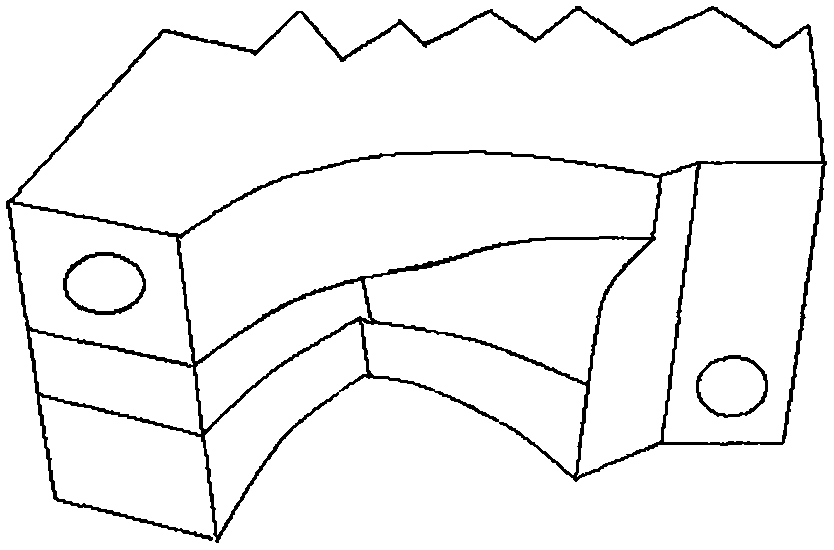

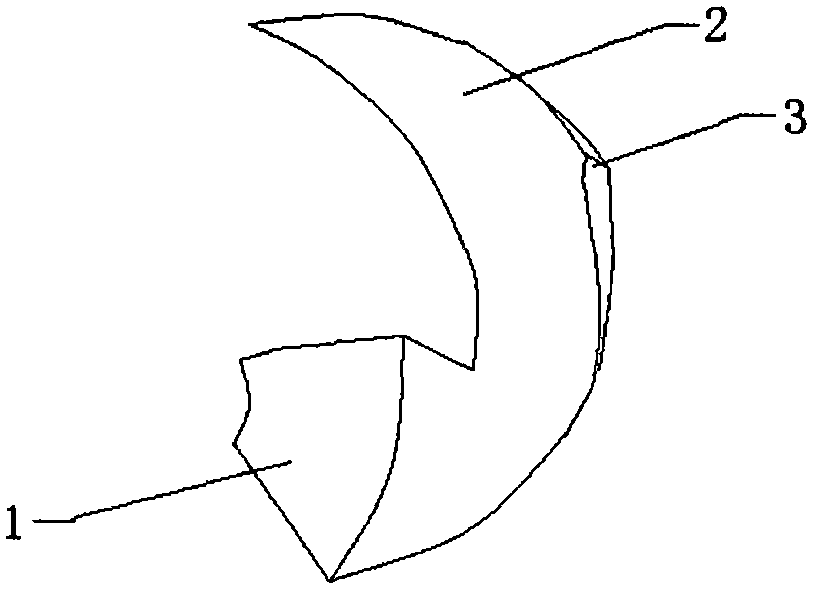

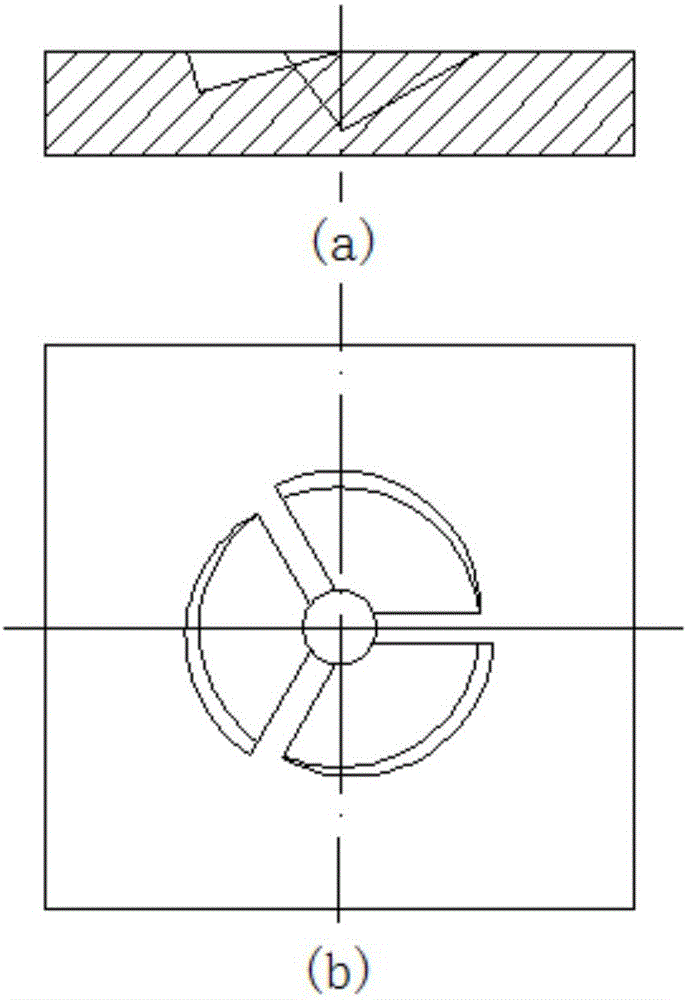

Precoated sand casting method for submerged pump impeller

The invention discloses a precoated sand casting method for a submerged pump impeller. A precoated sand shell mould is used for replacing a wet sand mould. The traditional core box method is changed into a hot box precoated sand parting core manufacturing method. The scheme is realized by combining two moulds into a precoated sand model with impeller core petals. The precoated sand model with impeller core petals comprises a core petal mould head (1) and a core petal mould tail (2), wherein the upper surface of the core petal mould head (1) is fan-shaped; a petal tail mould heave (3) is arranged on the outer side of the core petal mould tail (2); a plurality of precoated sand models with impeller core petals are combined into an impeller core precoated sand model; the petal tail mould heave (3) causes the impeller core precoated sand model to have a core petal mould clearance (4); and after the core petal mould clearance (4) is poured, an impeller blade (5) of the submerged pump impeller is formed. According to the precoated sand casting method provided by the invention, the gloss finish and casting precision of the impeller blade are increased; the problem of long time consumption of the traditional core manufacturing is solved; and the core manufacturing is simple and the processing is easier.

Owner:刘士超

Preparation method for precision cast mold shell and preparation method and application for precision cast casting

ActiveCN109604523AImprove casting precisionHigh precisionFoundry mouldsFoundry coresWaxCooling effect

The invention discloses a preparation method for a precision cast mold shell and a preparation method and application for a precision cast casting. According to the preparation method for the precision cast mold shell, the mold shell is made of the casting with an integrated structure of an oil cavity and an inner ring, the preparation method for the precision cast mold shell comprises the following steps that a bearing casing wax mold is prepared, and the wax mold is combined with a pouring gate to form a mold set tree; at least two layers of shell making is performed on the surface of the mold set tree, and a blind cavity end mouth and an inner ring opening are reserved; slot blocking materials are filled into a blind cavity of a bearing casing through the blind cavity end mouth and theblind cavity end mouth is sealed, drying is performed, and a blind cavity inner mold shell is formed; after the blind cavity inner mold shell is prepared, the at least two layers of shell making is performed on the surface of the mold set tree again, and the inner ring opening is reserved; and high cooling effect materials are filled into the inner ring through the inner ring opening and the innerring opening is sealed, the drying is performed, at least one layer of shell making is performed on the surface of the mold set tree again, dewaxing and sintering are performed, and the mold shell isobtained. By means of the mold shell prepared by the preparation method for the precision cast mold shell, blind cavity pouring steel leakage can be solved, and the problem of thick and large inner ring loose can be improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Simple preparation method of stripping pattern mold for casting of three-blade isometric screw inducer

InactiveCN106734892AEasy to makeSolve poor casting precisionFoundry mouldsFoundry coresComposite materialInducer

The invention provides a simple preparation method of a stripping pattern mold for casting of a three-blade isometric screw inducer. By preparing an inducer mold and carrying out an appropriate sand excavation operation, a cover box mold and a stripping pattern blank are cast, and thus a stripping pattern plate is obtained. The cover box mold is combined with the stripping pattern plate, and a support frame, a connecting shaft, a guide shaft sleeve and a rotating rod are fabricated and constituted to obtain a whole set of mold. With this technological equipment, an inducer without parting surface may be cast by a sand mold casting method; thus, the problems of poor casting accuracy, high grinding difficulty and low yield of inducers are solved, and the production efficiency and casting precision of isometric screw inducers are significantly improved with reduced production costs.

Owner:中船重工西安东仪科工集团有限公司

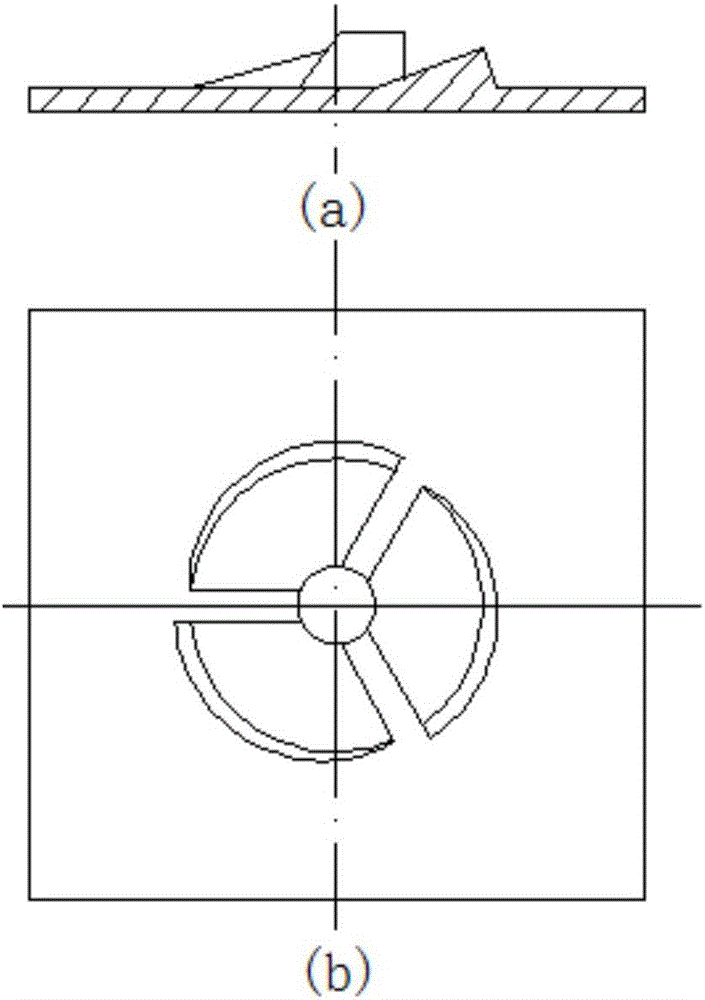

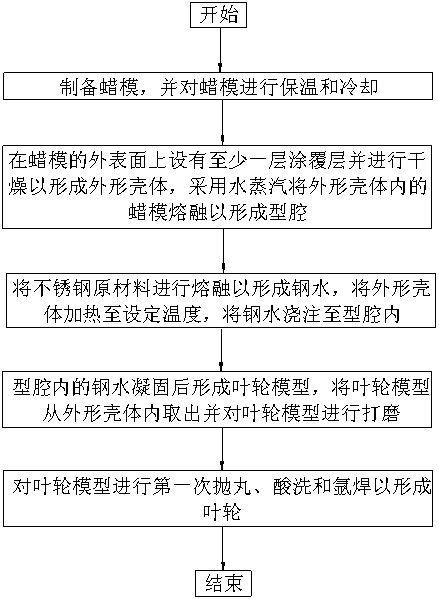

Impeller manufacturing process method and impeller

InactiveCN110523924AImprove casting precisionImprove structural stabilityPump componentsFoundry mouldsImpellerWax

The invention discloses an impeller manufacturing process method and an impeller. The process method comprises the following steps: preparing a wax mold, subjecting the wax mold to heat preservation and cooling, coating the outer surface of the wax mold with at least one coating layer and drying to form an outer shell; melting the wax mold in the outer shell by adopting water vapor to form a cavity; fusing stainless steel raw materials to form molten steel, heating the outer shell to a set temperature, pouring the molten steel into the cavity, forming an impeller model after the molten steel in the cavity is solidified, taking the impeller model out of the outer shell and polishing, and carrying out primary shot blasting, acid pickling and argon welding on the impeller model to form the impeller. According to the impeller manufacturing process method, the operation is convenient, the casting precision of the impeller can be greatly improved, the structural firmness of blades can be improved on the premise that the thickness of the blades is reduced, and therefore the service life of the blades can be prolonged.

Owner:潍坊盛龙精密铸件有限公司

Transformation impact case-free tightly molding device and method for molding by using same

ActiveCN104439106AImprove casting precisionImprove compactnessMoulding machinesEnergy consumptionDisadvantage

The invention discloses a transformation impact case-free tightly molding device and a method for molding by using the transformation impact case-free tightly molding device. The transformation impact case-free tightly molding device comprises a left sand case and a right sand case, a replaceable two-sided plate, a sand case moving device, and a left-right horizontal extrusion device; when the device is used for modeling, the compactness difference in the sand mold cast process is effectively improved by adding sand twice, compressing and exhausting twice, the modelling is precise, the impact is tight, the solid sand effect is good, the energy consumption is low, the efficiency is high, and numerous disadvantages caused by simple air-impacting modelling can be overcome.

Owner:山东时风(集团)有限责任公司

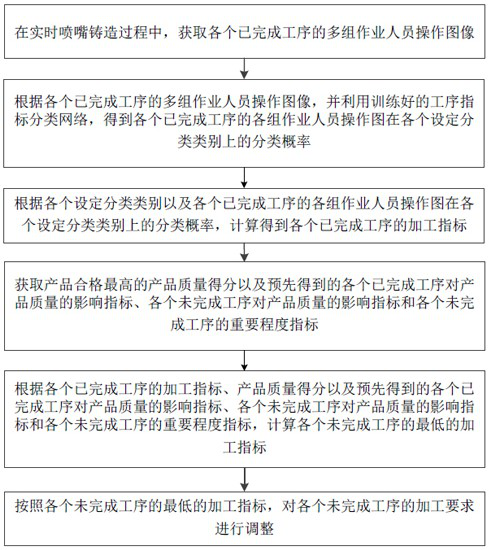

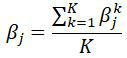

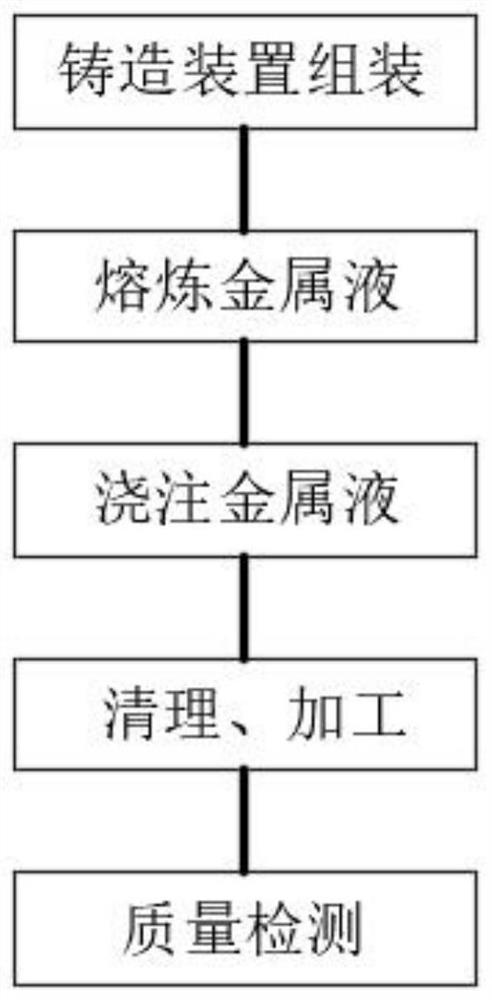

Nozzle casting monitoring method and system based on image processing

ActiveCN113360838AImprove casting precisionQuality assuranceCharacter and pattern recognitionResourcesImaging processingImage manipulation

The invention relates to the technical field of artificial intelligence, and provides a nozzle casting monitoring method and system based on image processing, and the method comprises the steps of obtaining a plurality of groups of operator operation images of each completed process in a real-time nozzle casting process, and further obtaining a machining index of each completed process; and determining the lowest processing index of each uncompleted process according to the product quality score of a qualified product, the processing index of each completed process, the influence index of each completed process on the product quality, the influence index of each uncompleted process on the product quality and the importance index of each uncompleted process. The completed processes are monitored in real time, the machining indexes of all the remaining processes are dynamically obtained according to the monitoring result, the casting process of the nozzle is guided, the product quality is guaranteed, and the casting precision of the nozzle is improved.

Owner:山东大拇指喷雾设备有限公司

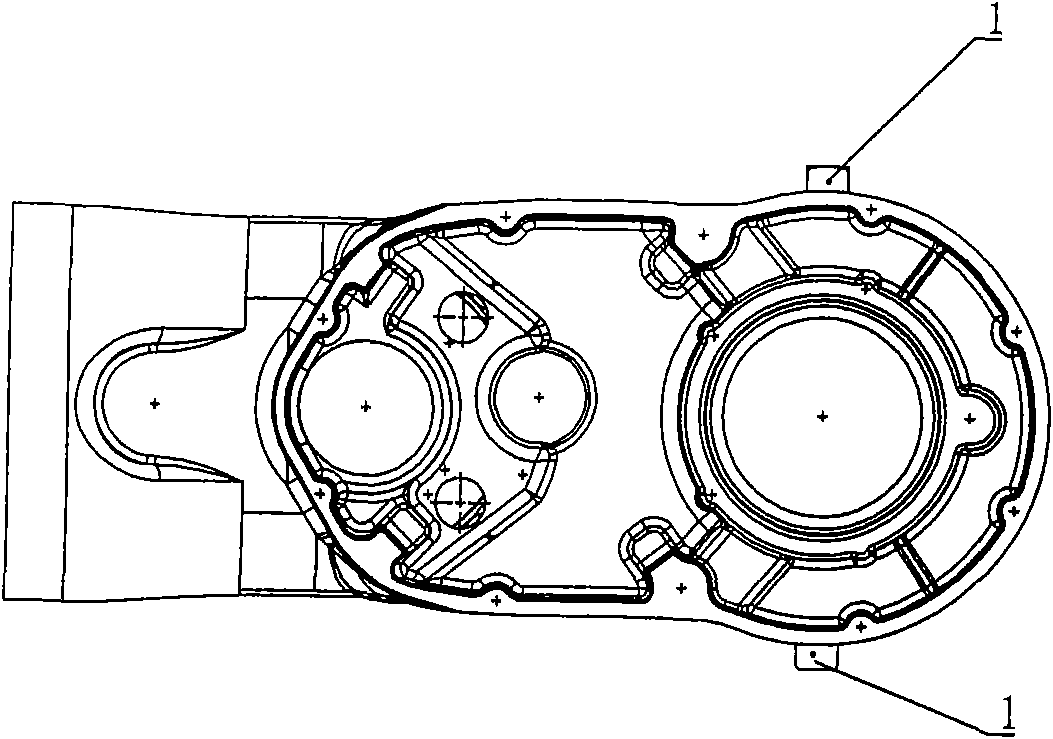

Gearbox cavity die moving die

The invention discloses a gearbox cavity die moving die. The gearbox cavity die moving die comprises a moving die base and multiple sliding mechanisms. A first die core matched with the shape of a gearbox is arranged in the middle of the moving die base. A moving die extrusion oil cylinder is arranged on one side of the moving die base. A piston rod of the moving die extrusion oil cylinder vertically faces the moving die base and can be connected with the first die core in an abutting manner. The multiple sliding mechanisms are arranged along the periphery of the moving die base. Each of the multiple sliding mechanisms comprises a sliding cylinder and a sliding die. A piston rod of each sliding cylinder is connected with a corresponding sliding die. Pistons rods of the sliding cylinders vertically face the first die core. A second die core matched with the shape of the gearbox is arranged on a side edge of each sliding die. According to the gearbox cavity die moving die, the moving dieextrusion oil cylinder is arranged on one side of the moving die base, and the multiple sliding mechanisms are arranged; and when a gearbox is cast, accurate location can be conducted on the first die core and the second die cores so that die closing is accurate, and thus the casting precision and quality of the gearbox are improved.

Owner:GUANGZHOU DIE & MOLD MFG

Machining process of gear

The invention discloses a machining process of a gear. The process comprises following steps that a demolding agent is coated on an inner cavity of a gear pressure casting mold; an inner gear pressurecasting mold body is preheated; a steel ingot raw material is heated to molten steel in the molten condition, heat preservation is carried out, the heat preservation temperature ranges from 1300 to 1500 DEG C, and the heat preservation time ranges from 40 to 60 min; the pressure casting mold in the S10 is continuously heated, the temperature ranges from 1200 to 1400 DEG C, molten steel in S30 ispoured into the pressure casting mold, after pouring, the pressure casting mold at the constant temperature is pressurized from a sprue gate, the pressure ranges from 0.01 to 0.015 MPa, the pressurizing time is kept 40 to 50 min, the pressure casting mold is cooled to the room temperature, a gear is subjected to demolding treatment, and the gear is ground and polished to form a gear finished product. The machining process improves the casting precision, is low in cost, and high in structural strength and improves the production efficiency.

Owner:XUZHOU XIANGQIAO MACHINERY CO LTD

Precise bubble-free casting process for hardware castings

The invention discloses a precise bubble-free casting process for hardware castings, and belongs to the technical field of casting. A specially-made casting device is arranged, and a hardware sleeve is cast through the casting device. A core vent hole and an inner through core hole are formed in the casting device, so that gas generated at a core head can flow out conveniently in the casting process, and then the generation of invasive bubbles can be effectively reduced. A pouring liquid gas evolution pipe is arranged in the casting device, so that a dual acceleration effect can be provided for molten metal, therefore the evolution of gas in the molten metal is remarkably improved, and the generation of evolved bubbles is reduced. A cavity self-gas-leakage assembly is arranged in the casting device, so that the outflow of gas generated by pouring in a cavity can be facilitated, and therefore the generation of invasive bubbles is further reduced. The bubbles can be effectively preventedfrom appearing on the hardware sleeve from the reason of bubble generation, so that the yield of the sleeve is remarkably improved, resources are saved, and the production efficiency is improved.

Owner:黄勇平

Preparation method for lost foam casting of high-entropy alloy particle-reinforced magnesium-based composite material

PendingCN111719074AGood heredityReduce coarseningFoundry mouldsFoundry coresMagnesium matrix compositeHigh entropy alloys

The invention relates to a preparation method for a magnesium-based composite material, in particular to a preparation method for lost foam casting of a high-entropy alloy particle-reinforced magnesium-based composite material. The method aims to solve the technical problem that in the preparation process of an existing magnesium-based composite material, the addition proportion of magnesium alloywaste is small, and the strength is poor when a large amount of magnesium alloy waste is added. By adopting a lost foam casting method, utilizing two-way shear stirring, adding high-entropy alloy particles and performing ultrasonic treatment in the casting process, structure heredity is effectively improved, uneven dispersion of the particles at different positions of a magnesium alloy melt is avoided, structure coarsening is reduced, grain growth in the solidification process is inhibited, grains are refined, the utilization rate of magnesium alloy waste is increased, and the performance ofthe lost foam casting product is improved. In the method, the utilization rate of AZ91D waste is high, the maximum waste addition amount accounts for 34% of the total mass, raw materials are saved, and costs are reduced. The method is also suitable for continuous production operation and is an environment-friendly method.

Owner:哈尔滨吉星机械工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com