Precise bubble-free casting process for hardware castings

A casting process and a technology without air bubbles, which is applied in the field of casting castings. It can solve the problems of affecting the production efficiency of the casing, the casing is prone to bubbles, and the strength of the casing is reduced, so as to reduce intrusive air bubbles, improve production efficiency, and improve casting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

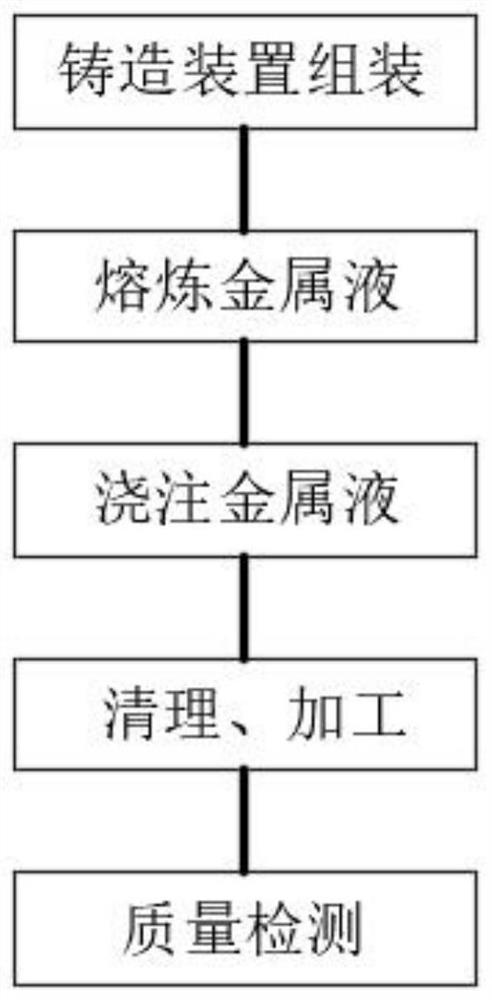

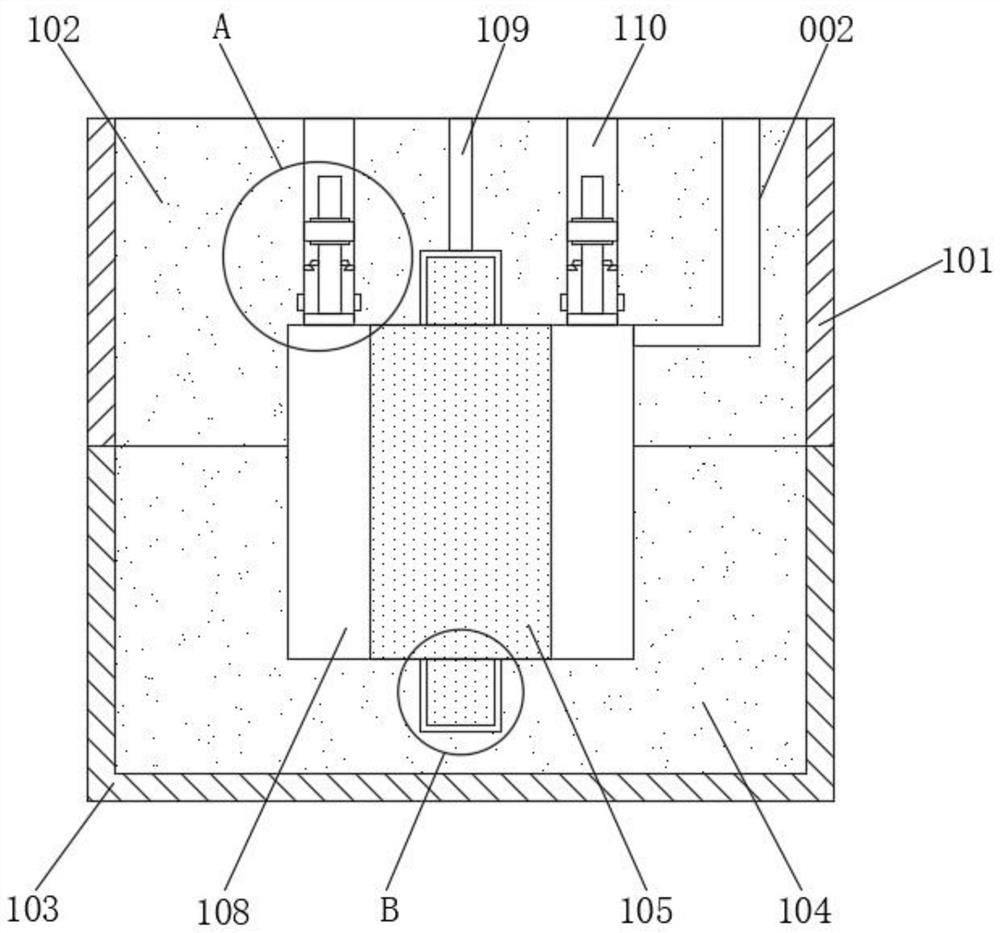

[0046] see Figure 1-6 , a precision bubble-free casting process for metal castings, comprising the following steps:

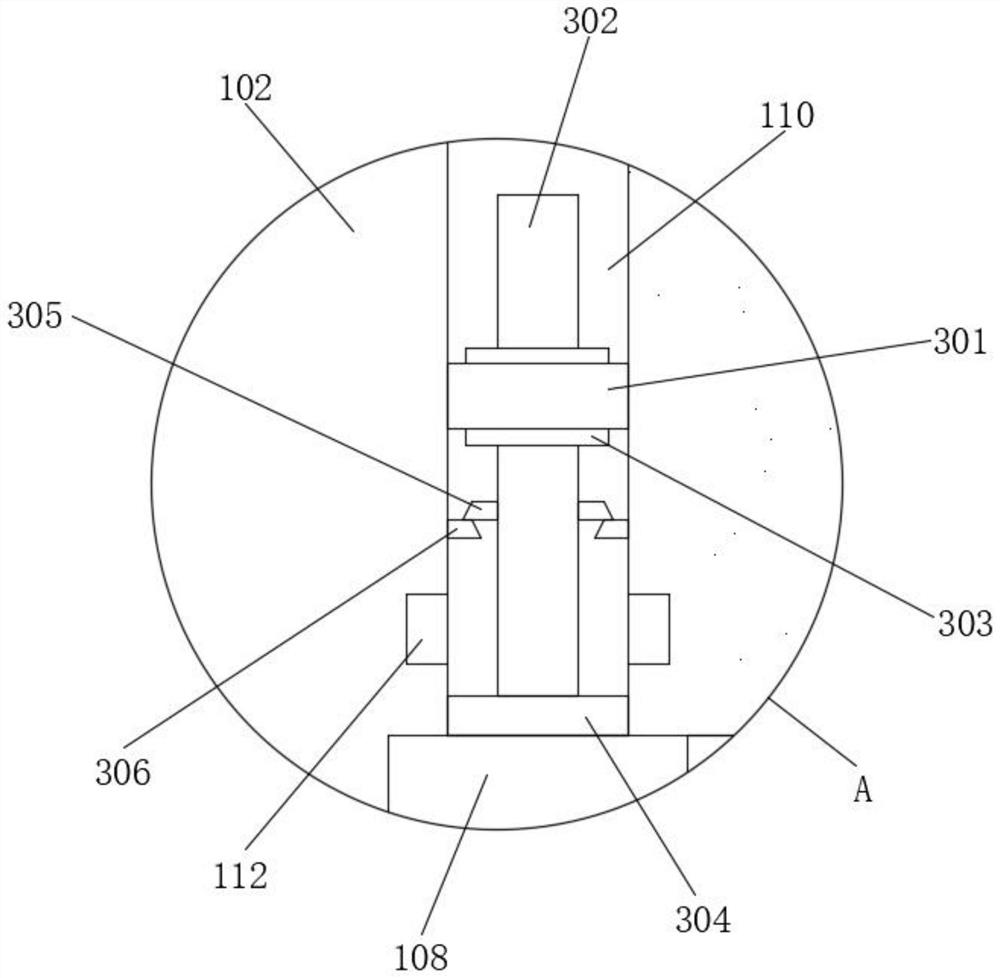

[0047] S1. Put the core 105 between the upper sand mold 102 and the lower sand mold 104, align the core 105 through the core head 106 and the positioning groove 107, and complete the assembly of the casting device;

[0048] S2. Putting the metal raw material into the smelting equipment, smelting the metal raw material to obtain molten metal, and the temperature of the molten metal is 750-785°C;

[0049] S3. Pouring the molten metal in S2 into the mold cavity 108 through the pouring and degassing pipe 002, and controlling the pouring temperature between 730-745°C;

[0050] S4. After the molten metal is solidified, a blank casting is obtained, and the blank casting is taken out and cleaned, and then polished after cleaning;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com