7-series aluminum alloy and preparation method thereof

An aluminum alloy and alloying technology, applied in the field of 7-series aluminum alloys and its preparation, can solve the problems of unstable oxide film, low decorative aesthetics, and unequal surface quality, achieve excellent elongation and grain size, and avoid Effect of stress corrosion and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

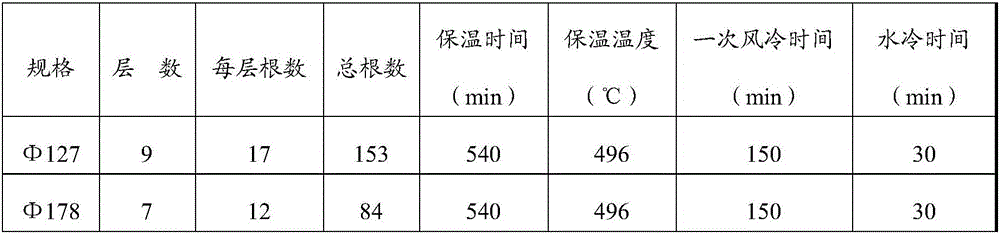

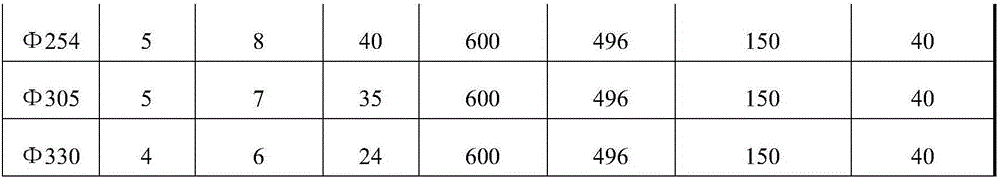

[0019] A method for preparing a 7-series aluminum alloy, comprising sequentially performing batching, melting, slag removal, alloying, casting, homogenization and sawing operations according to the composition of the above-mentioned 7-series aluminum alloy to obtain the 7-series aluminum alloy, The temperature of the casting operation is greater than or equal to 690°C, and the hydrogen content is controlled not to exceed 0.15ml / 100gAl during the casting operation; the holding temperature of the homogenization operation is 494-498°C, and the holding time is 540-600min.

[0020] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0021] (1) Under the constant adjustment of the experimental direction and continuous testing, redesign the composition ratio of the 7-series aluminum alloy, specifically, increase the content of zinc to 7.50-7.70%, increase the content of magnesium to 1.32-1.40%, and increase the content of magnesium to ...

Embodiment 1

[0040]A 7-series aluminum alloy consisting of the following components in weight percent: 1.32% magnesium, 0.014% titanium, 7.50% zinc, 0.003% manganese, 0.05% silicon, 0.08% iron, 0.004% copper, 0.001% 0.001% of nickel, 0.001% of chromium and 0.00029% of zirconium, and the balance is aluminum. The content of the total impurity elements in the 7-series aluminum alloy is lower than 0.10%, and the content of a single impurity element in the 7-series aluminum alloy is not higher than 0.05%.

[0041] A method for preparing a 7-series aluminum alloy, comprising sequentially performing batching, melting, slag removal, alloying, casting, homogenization and sawing operations according to the composition of the above-mentioned 7-series aluminum alloy to obtain the 7-series aluminum alloy, The temperature of the casting operation is equal to 690°C, and the hydrogen content is controlled to be 0.15ml / 100gAl during the casting operation; the holding temperature of the homogenization opera...

Embodiment 2

[0043] A 7-series aluminum alloy consisting of the following components in weight percent: 1.40% magnesium, 0.016% titanium, 7.70% zinc, 0.005% manganese, 0.03% silicon, 0.04% iron, 0.002% copper, 0.0005% nickel, 0.0005% chromium and 0.0001% zirconium, and the balance is aluminum. The content of the total impurity elements in the 7-series aluminum alloy is lower than 0.10%, and the content of a single impurity element in the 7-series aluminum alloy is not higher than 0.05%.

[0044] A method for preparing a 7-series aluminum alloy, comprising sequentially performing batching, melting, slag removal, alloying, casting, homogenization and sawing operations according to the composition of the above-mentioned 7-series aluminum alloy to obtain the 7-series aluminum alloy, The temperature of the casting operation is equal to 720°C, and the hydrogen content is controlled to be 0.10ml / 100gAl during the casting operation; the holding temperature of the homogenization operation is 498°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com