Preparation method for precision cast mold shell and preparation method and application for precision cast casting

A technology of precision casting and casting, which is applied in the preparation of precision casting castings and the preparation of precision casting shells. It can solve the problems of loose inner ring structure and achieve the effects of simple casting method, increased impact resistance and avoiding looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

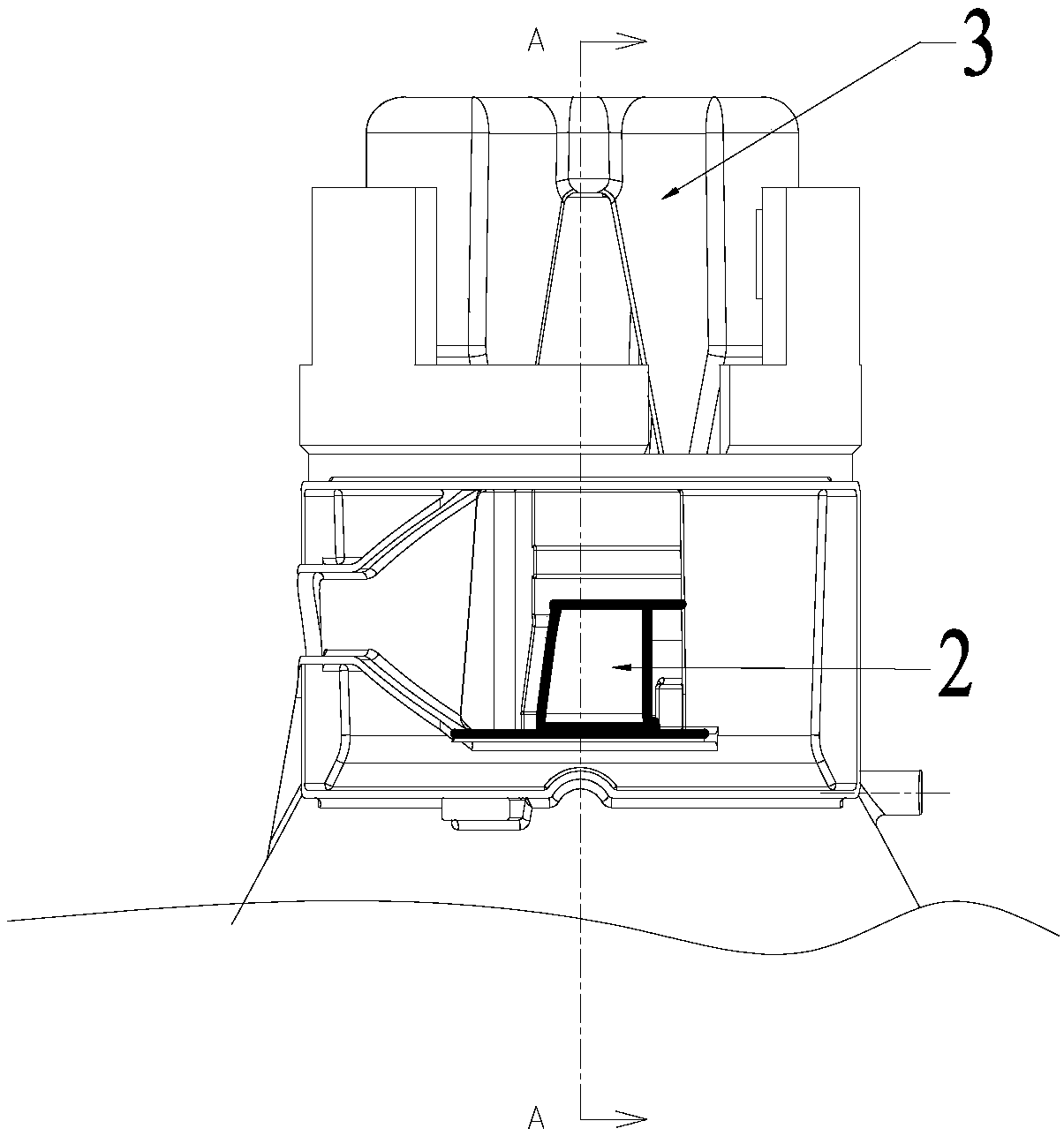

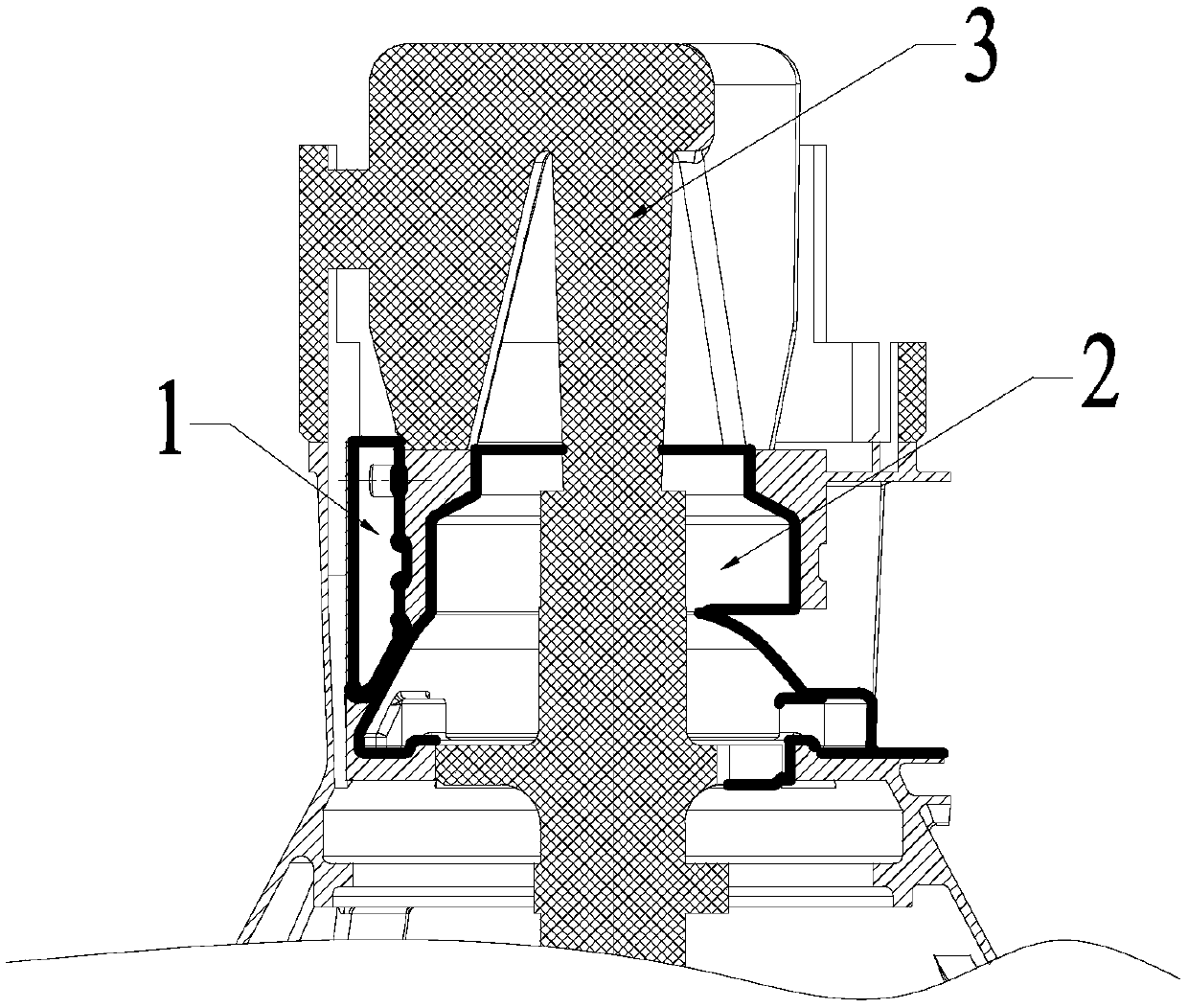

[0031] like figure 1 and figure 2 As shown, the preparation method of the precision casting mold shell of this embodiment, the mold shell is prepared by a casting with an integrated structure of an oil chamber and an inner ring, including the following steps:

[0032] a. Prepare a load-bearing casing wax mold, and combine the wax mold with the sprue 3 to form a module tree;

[0033] b. Carry out at least two layers of casing on the surface of the module tree, and reserve blind cavity ports and inner ring openings;

[0034] c. Fill the plugging material into the blind cavity 1 of the load-bearing casing through the blind cavity port, seal the blind cavity port, and dry to form the blind cavity inner shell;

[0035] d. After the inner shell of the blind cavity is prepared, at least two layers of shells are made on the surface of the module tree, and the opening of the inner ring is reserved;

[0036] e. Fill the inner ring 2 with high cooling efficiency material through the ...

Embodiment

[0049] Preparation method of investment casting mold shell

[0050] a. Select the mold material, and make the mold material be pressed in a compressible state to form a wax mold with a certain strength, size and shape, and combine the wax mold with the sprue 3 to form a module tree;

[0051] b. Immerse the module tree in the paint, which includes 60% 325-mesh zircon powder and 40% silica sol, and a layer of refractory material is adhered to the surface of the formed coating. The material layer is formed into a hard shell, which is naturally dried to form a 1.5mm shell. Use compressed air to blow air at the blind cavity port and the opening of the inner ring to clean the refractory material floating on the surface. The formed shell is formed with a ball The head-shaped flexible tool is compacted into a 1mm shell; repeat the above operation until a three-layer shell is formed;

[0052] c. Mix 100g of ethyl silicate hydrolyzate paint with 40g of 100μm corundum sand components ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com