Patents

Literature

48results about How to "Reduce coarsening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

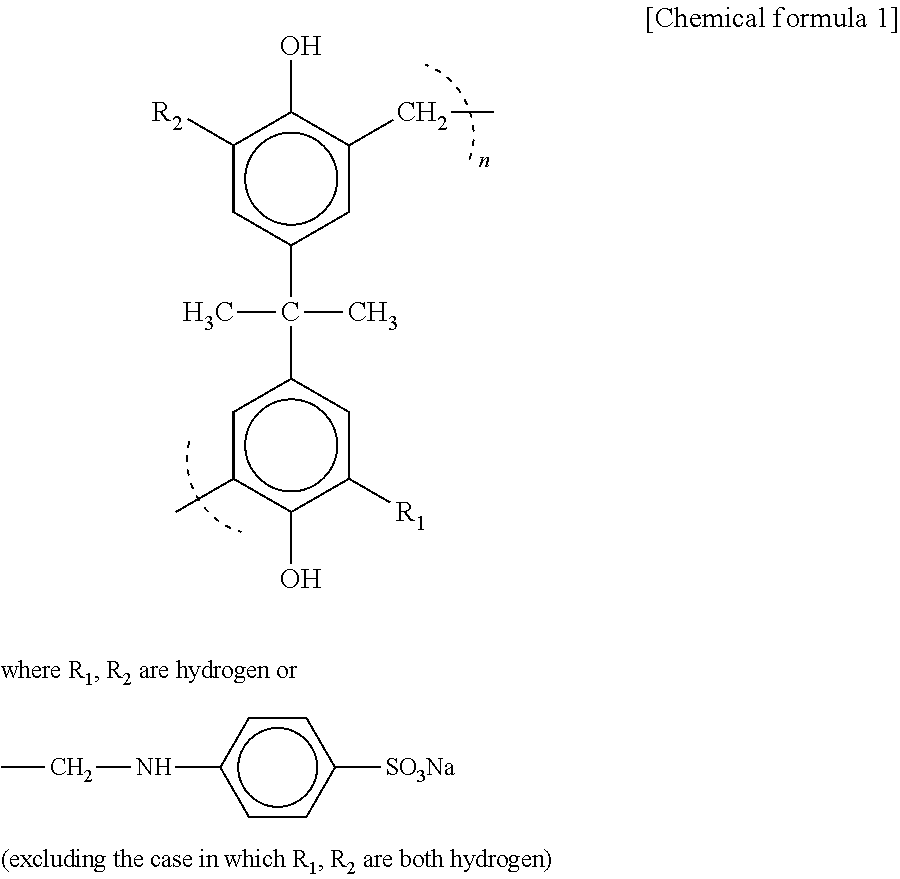

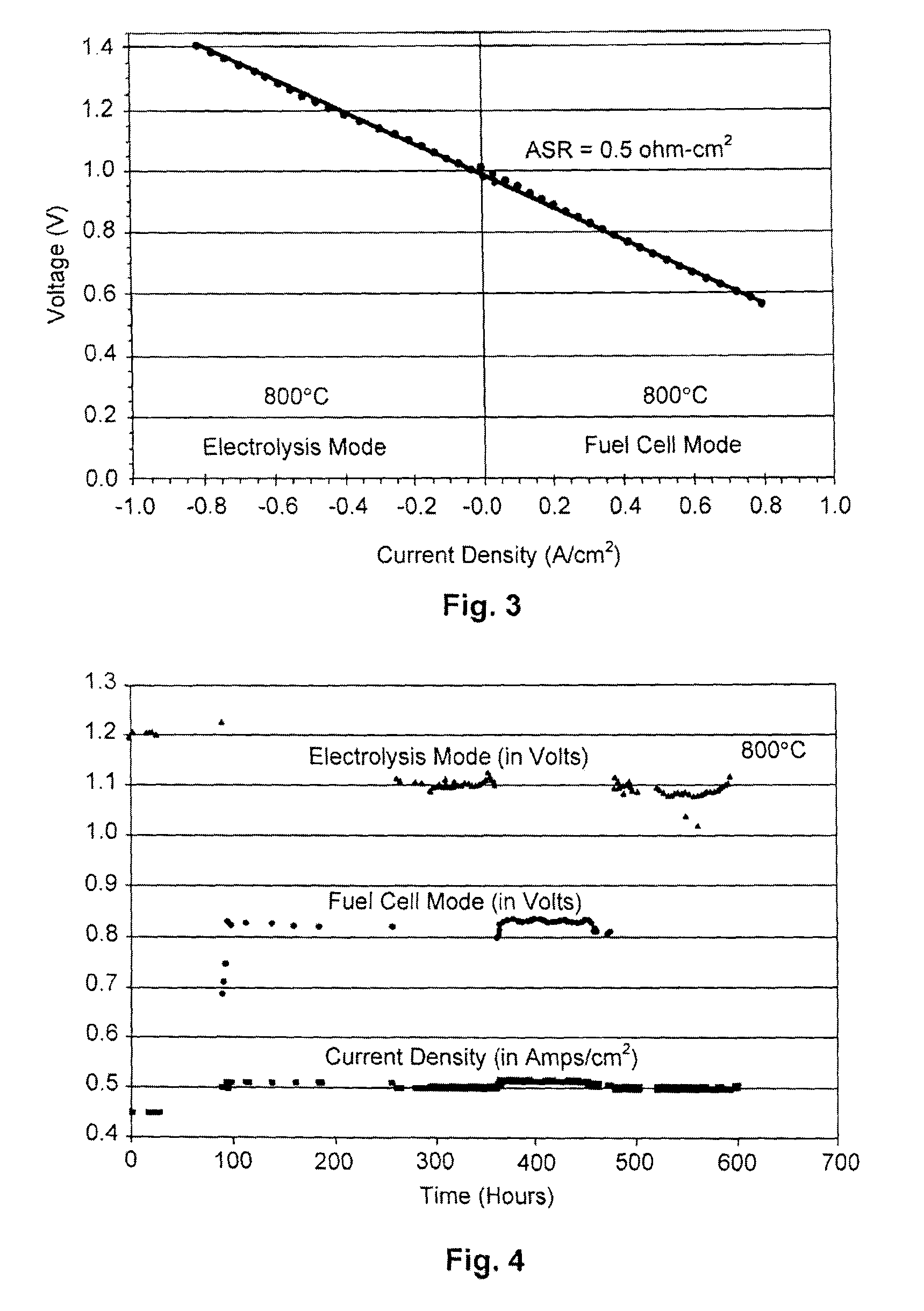

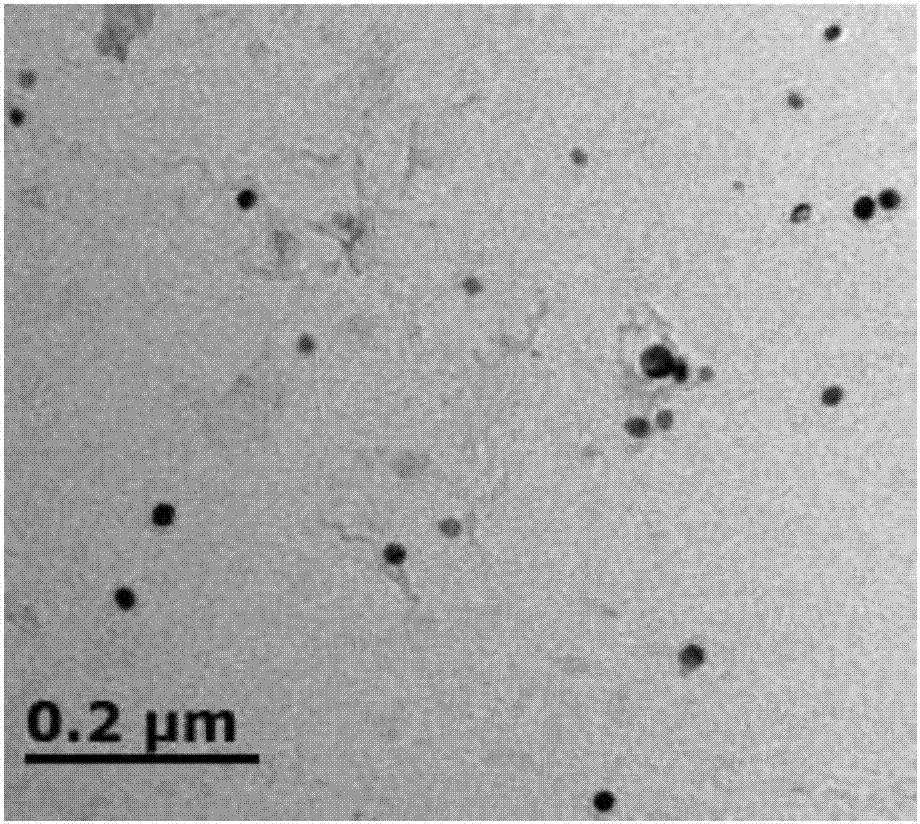

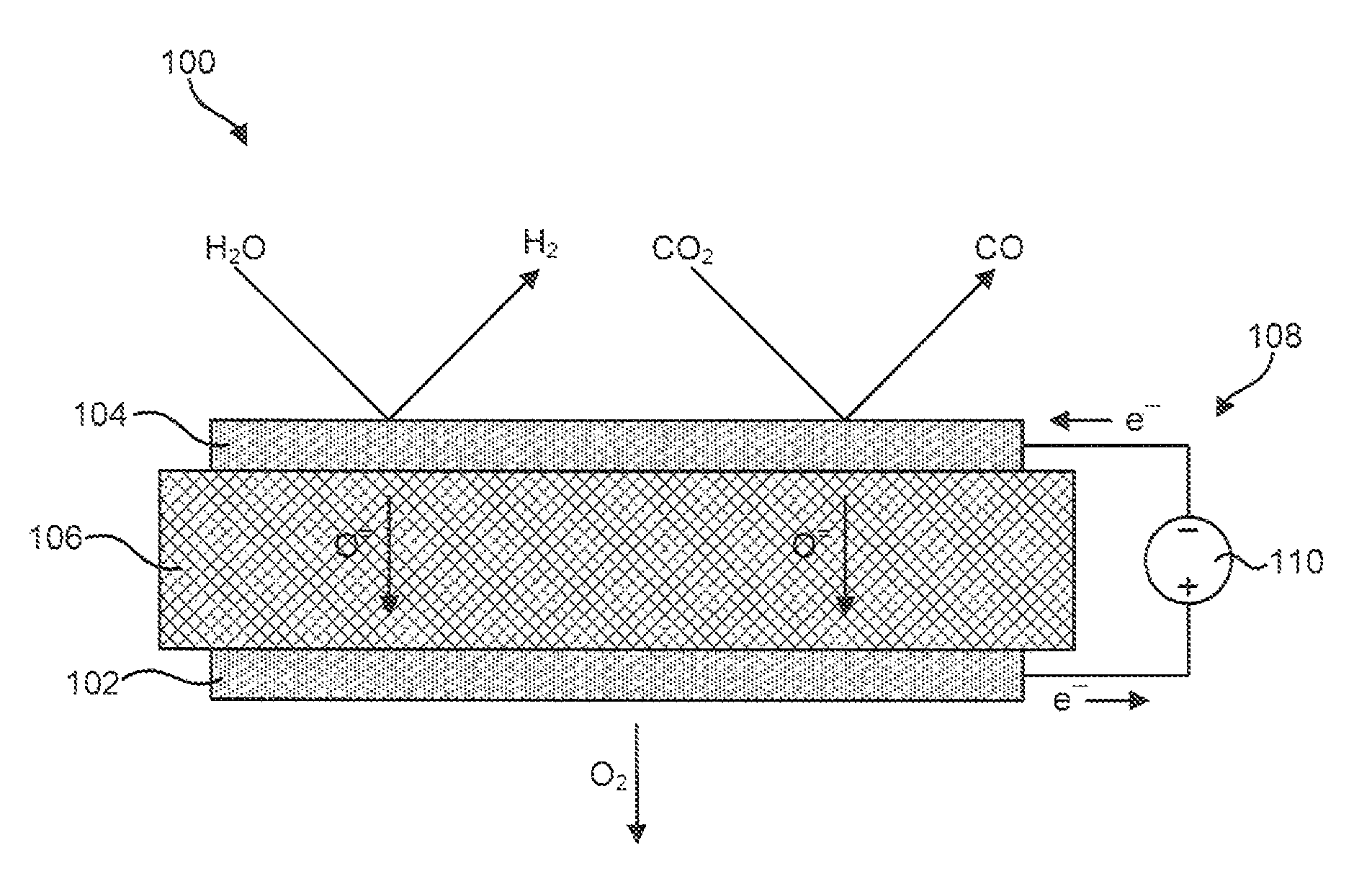

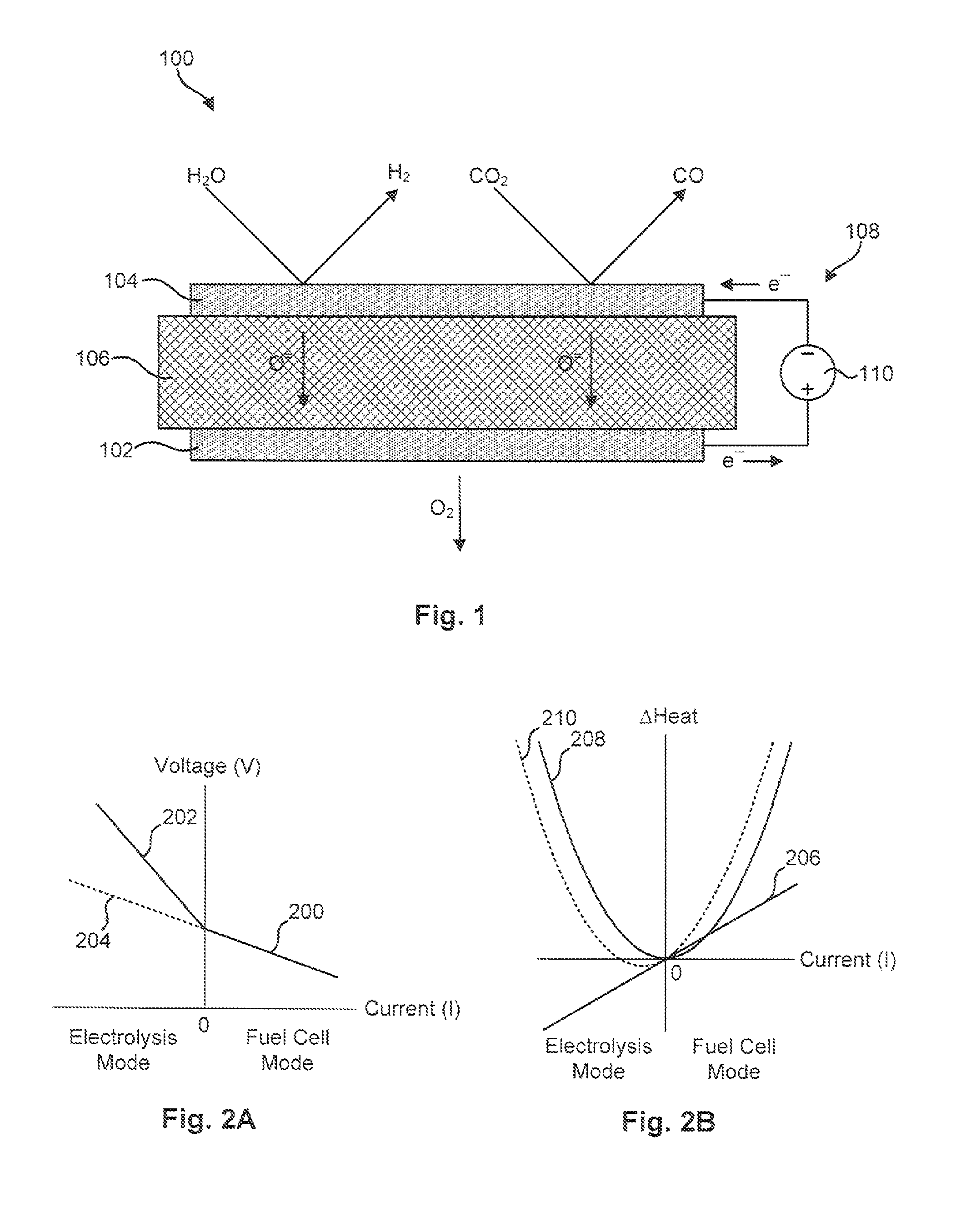

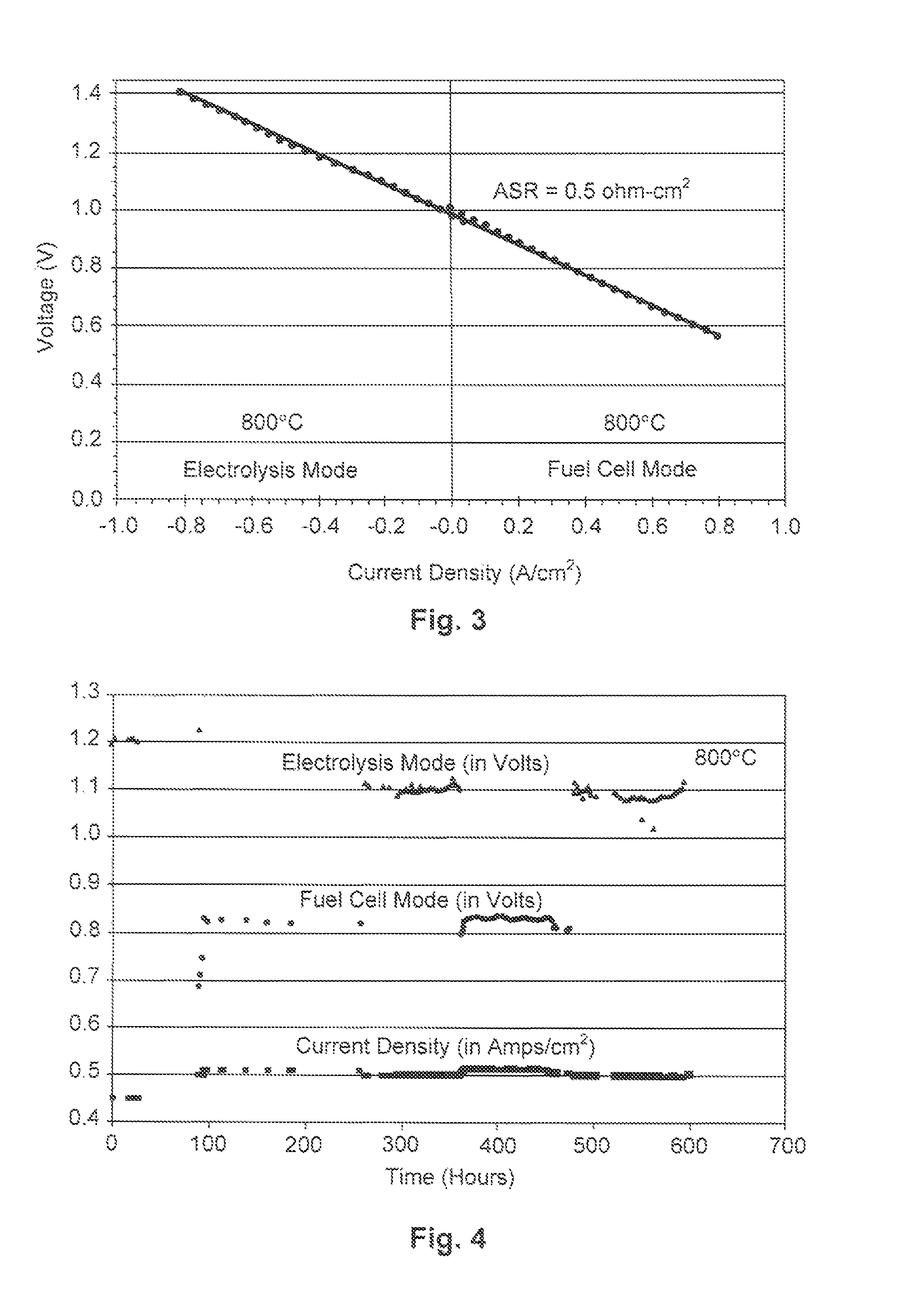

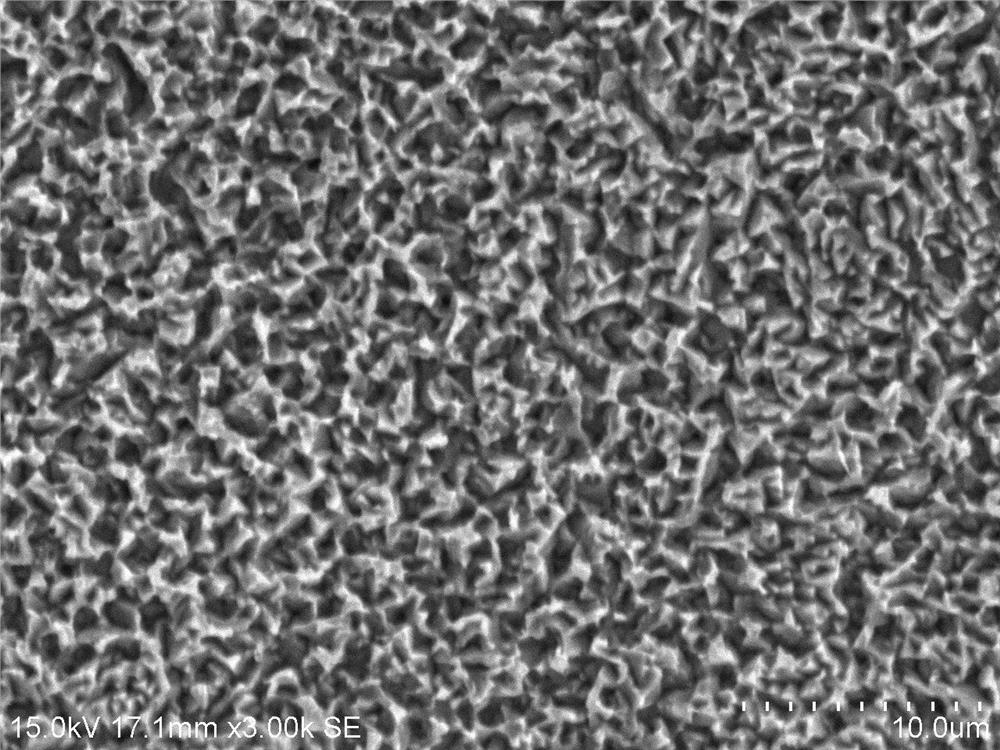

Efficient Reversible Electrodes For Solid Oxide Electrolyzer Cells

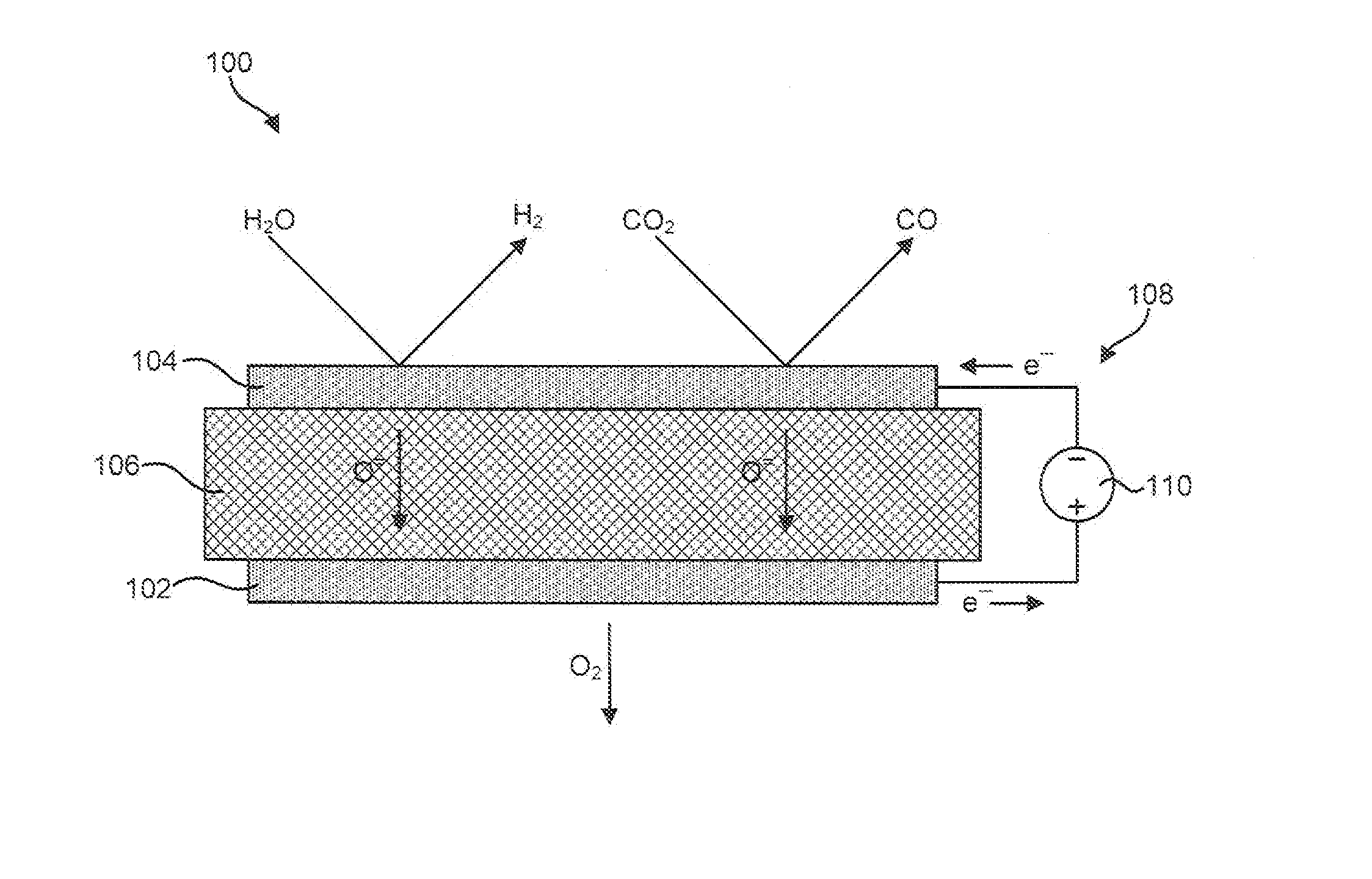

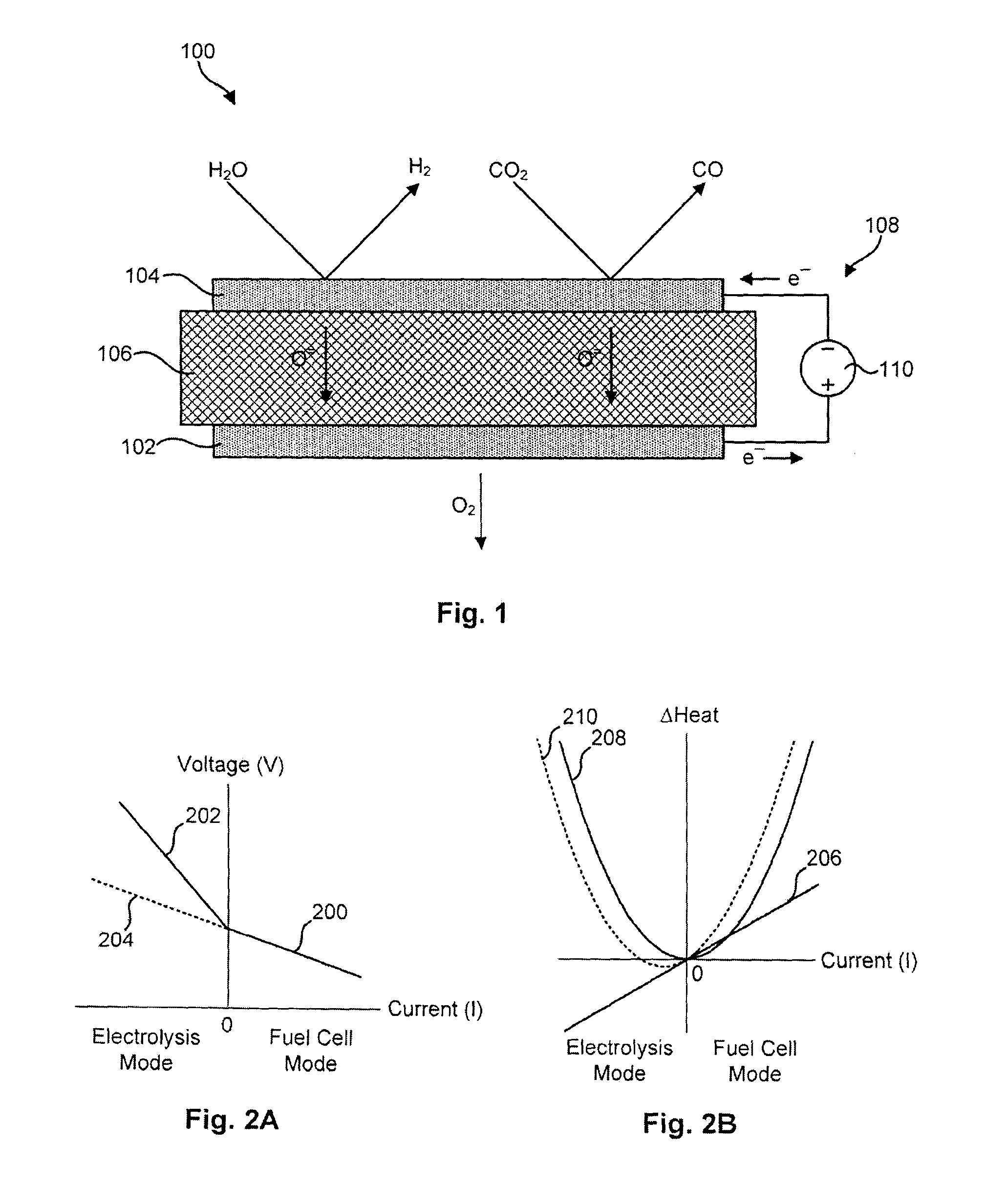

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0≦x≦0.5, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:COORSTEK INC

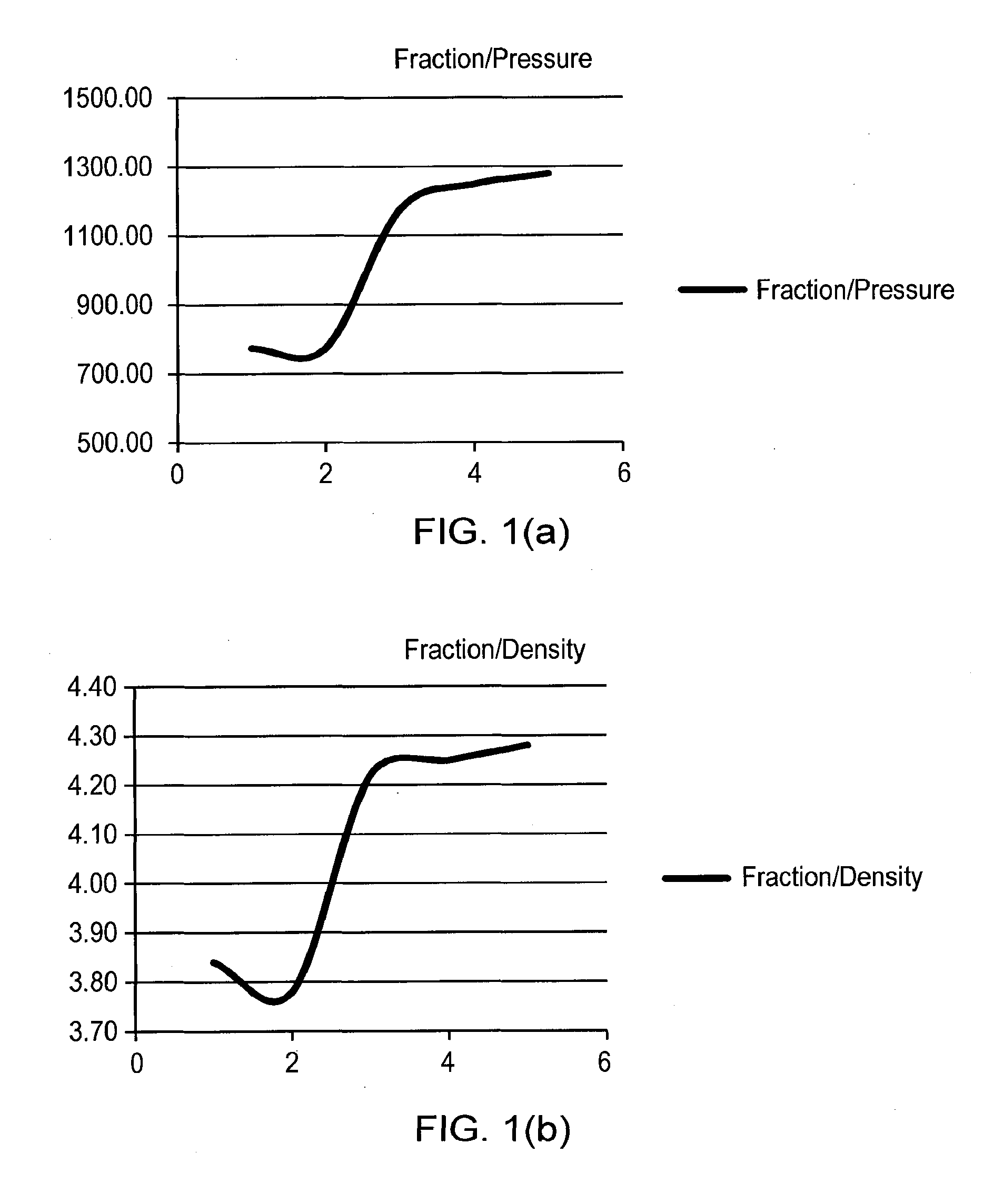

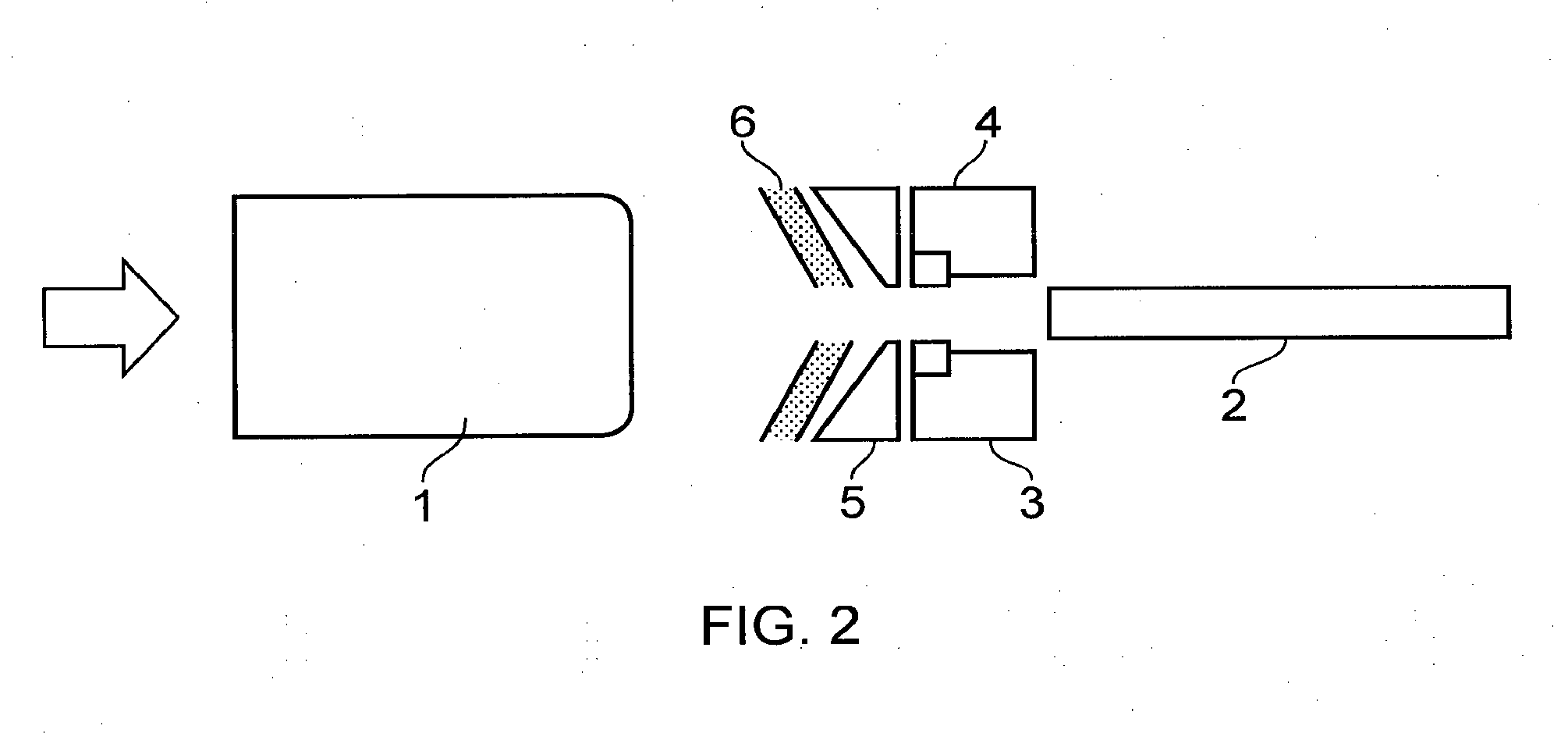

Aerated food products with improved foam stability

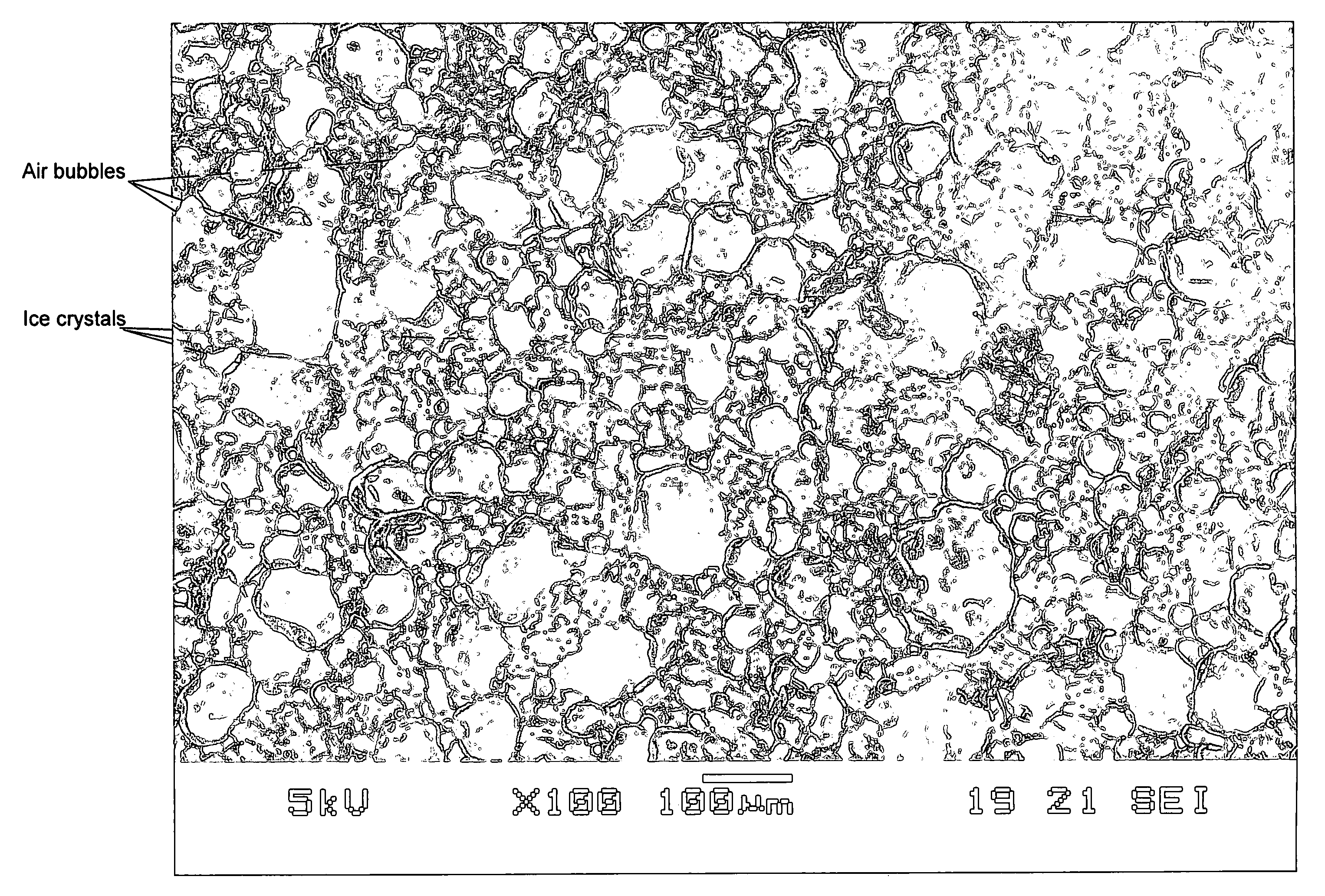

InactiveUS20140335255A1Improved thermal shock stabilityLow amountMilk preparationFrozen sweetsFiberFood products

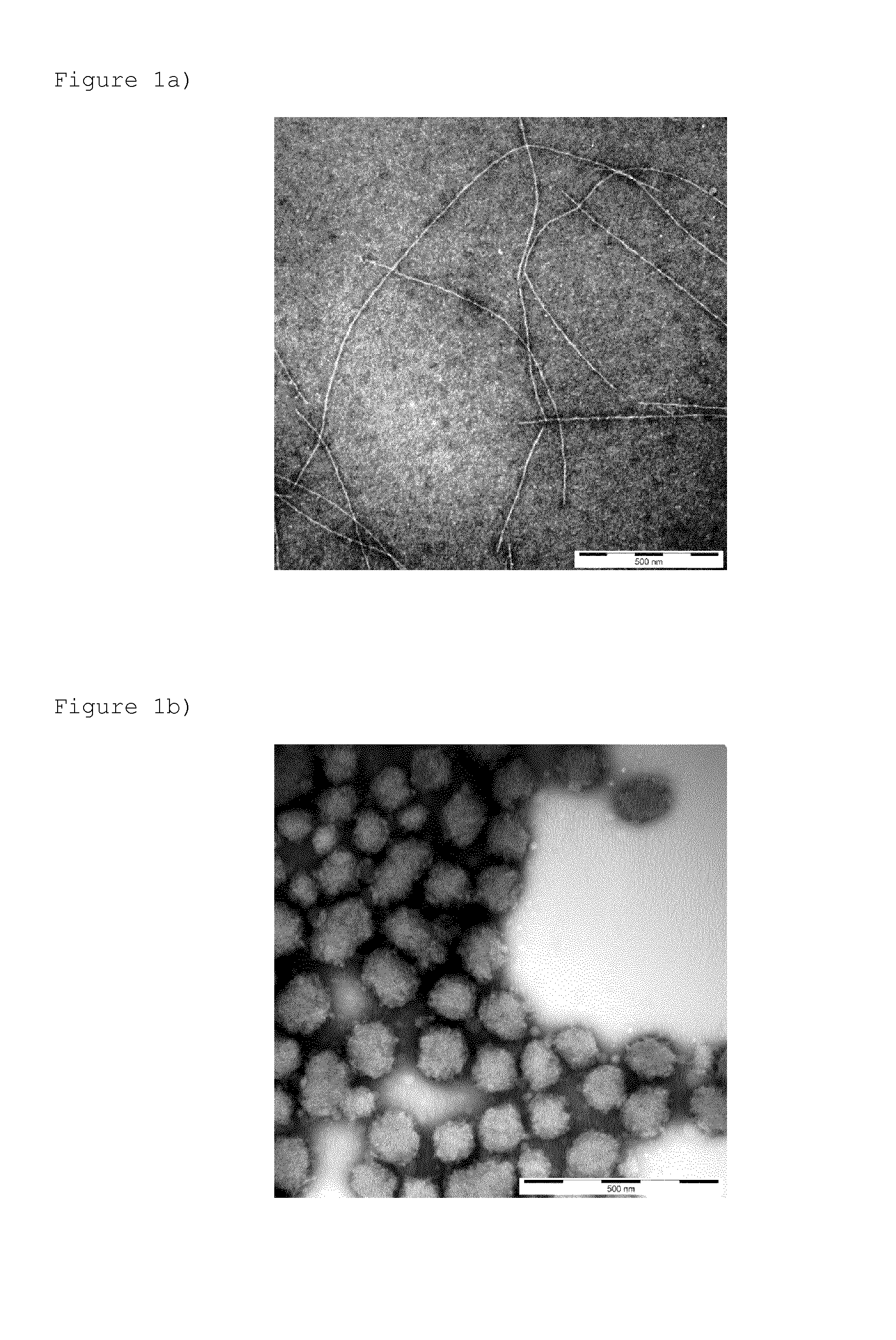

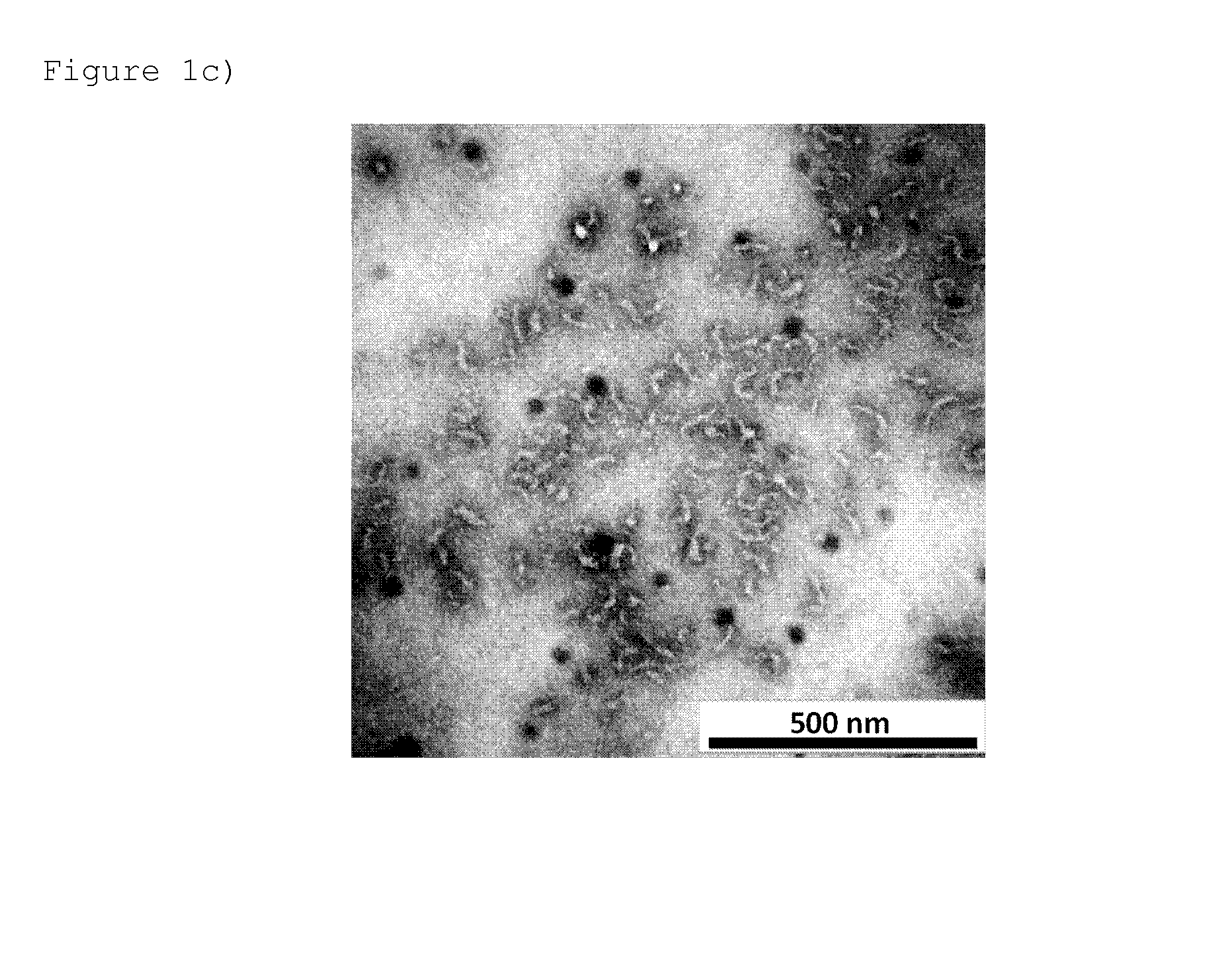

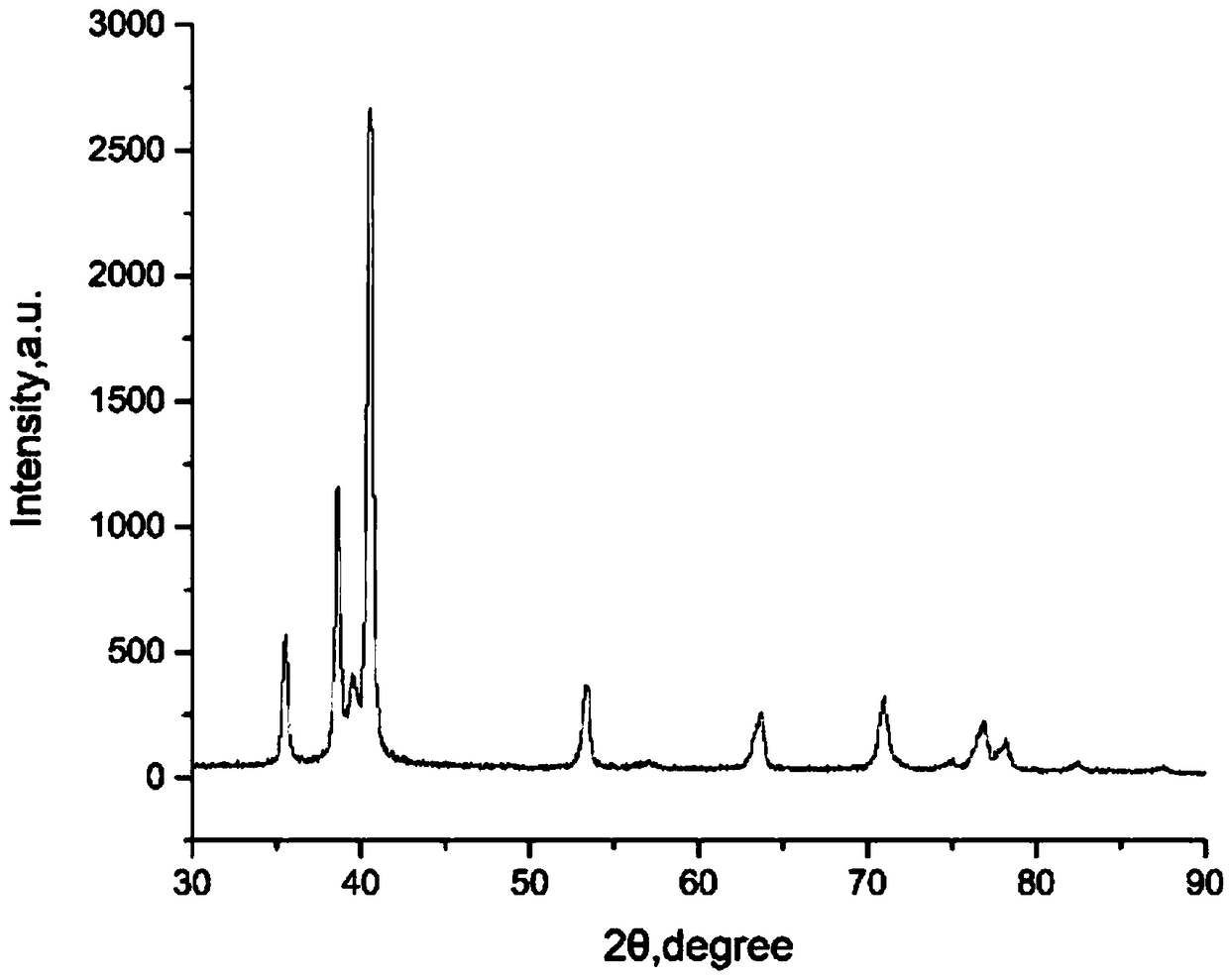

The present invention relates to aerated food products with enhanced foam stability comprising aggregated proteins in the form of mixtures of fibrils together with at least one other type or structure of aggregates such as worm-like aggregates and / or spherical like aggregates.

Owner:NESTEC SA

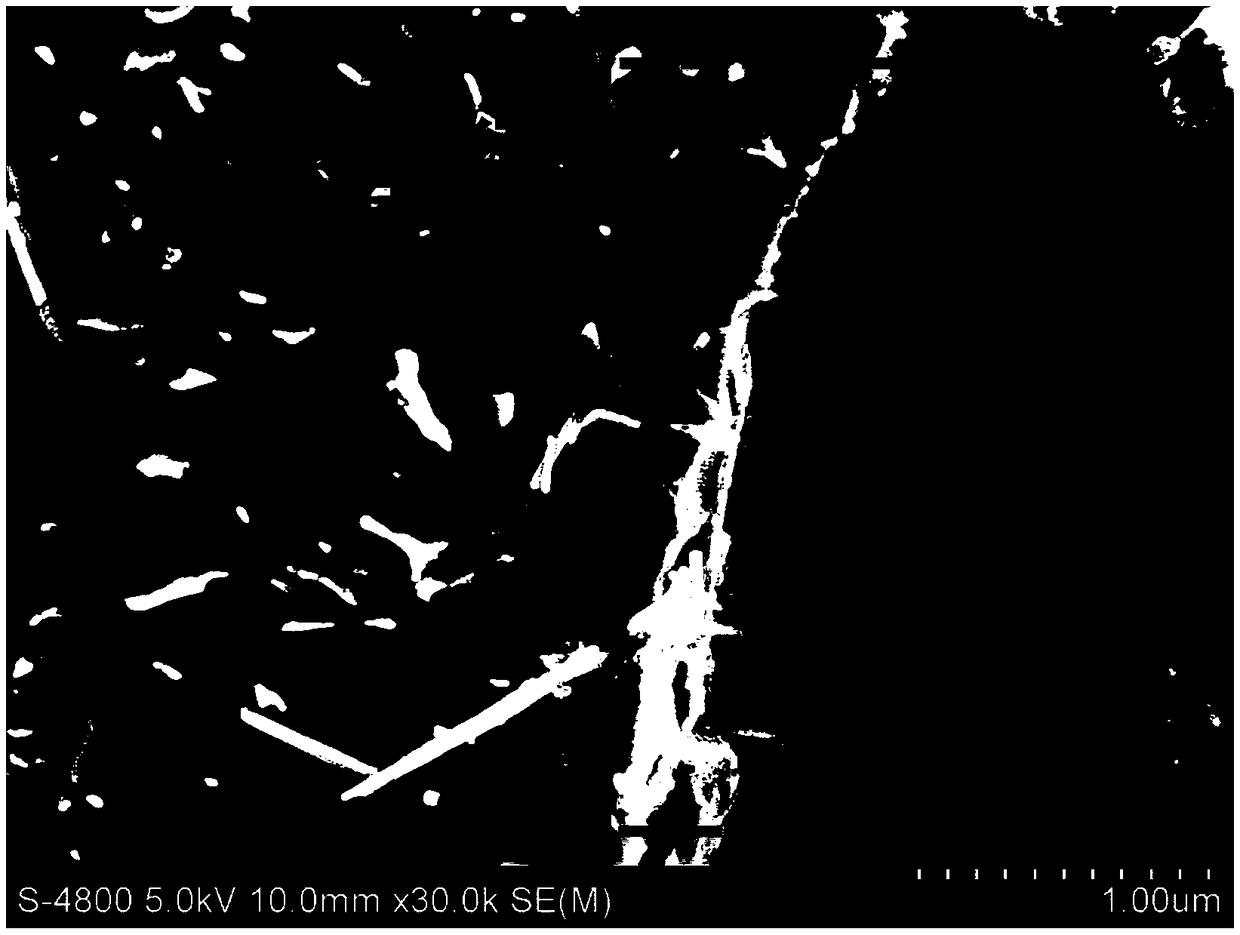

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

Preparation method of directionally-distributed TiB whisker reinforced titanium-based composite material

ActiveCN108796264AEffectively regulate organizational evolutionSolve problems such as a sharp drop in aspect ratioTitanium matrix compositesThermal deformation

The invention relates to a preparation method of a directionally-distributed TiB whisker reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. Thepreparation method comprises the following steps that nano TiB2 powder and titanium powder, or nano TiB2 powder and titanium alloy powder are uniformly mixed; sintering treatment is carried out on themixed powder by adopting a discharge plasma system to obtain a composite material block body; and the dried composite material block body is packaged in a quartz tube in a vacuum mode, heat treatmentis carried out in a heat treatment furnace, and then the composite material is obtained by step-by-step cooling. The method can effectively regulate and control the organization evolution of a TiB whisker in the titanium-based composite material, the problem that the orientation regulation and control means of the TiB whisker is single is fully solved, a thermal deformation means is used for regulating and controlling the crystal whisker form, and the crystal whisker length-diameter ratio is greatly reduced and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

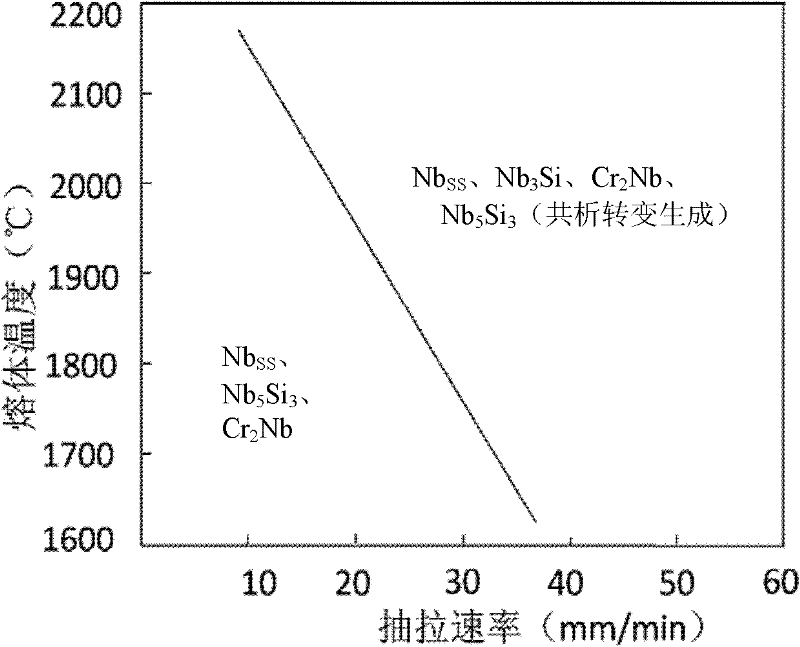

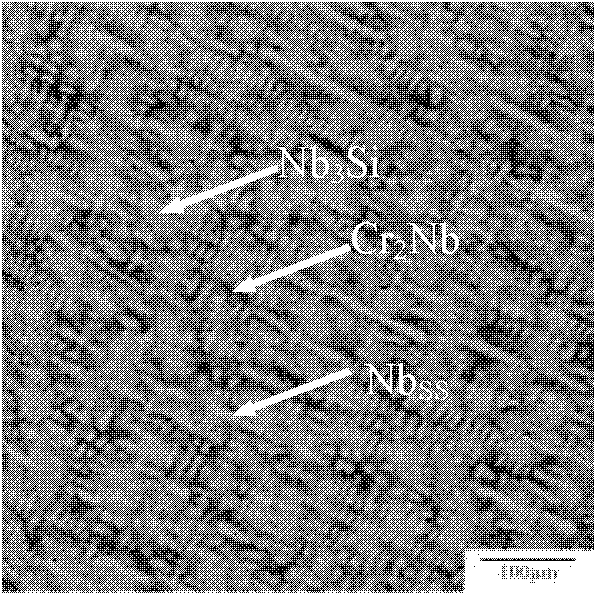

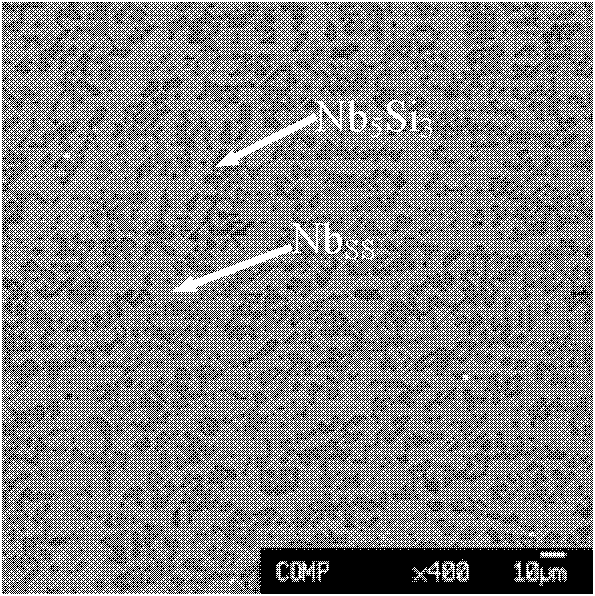

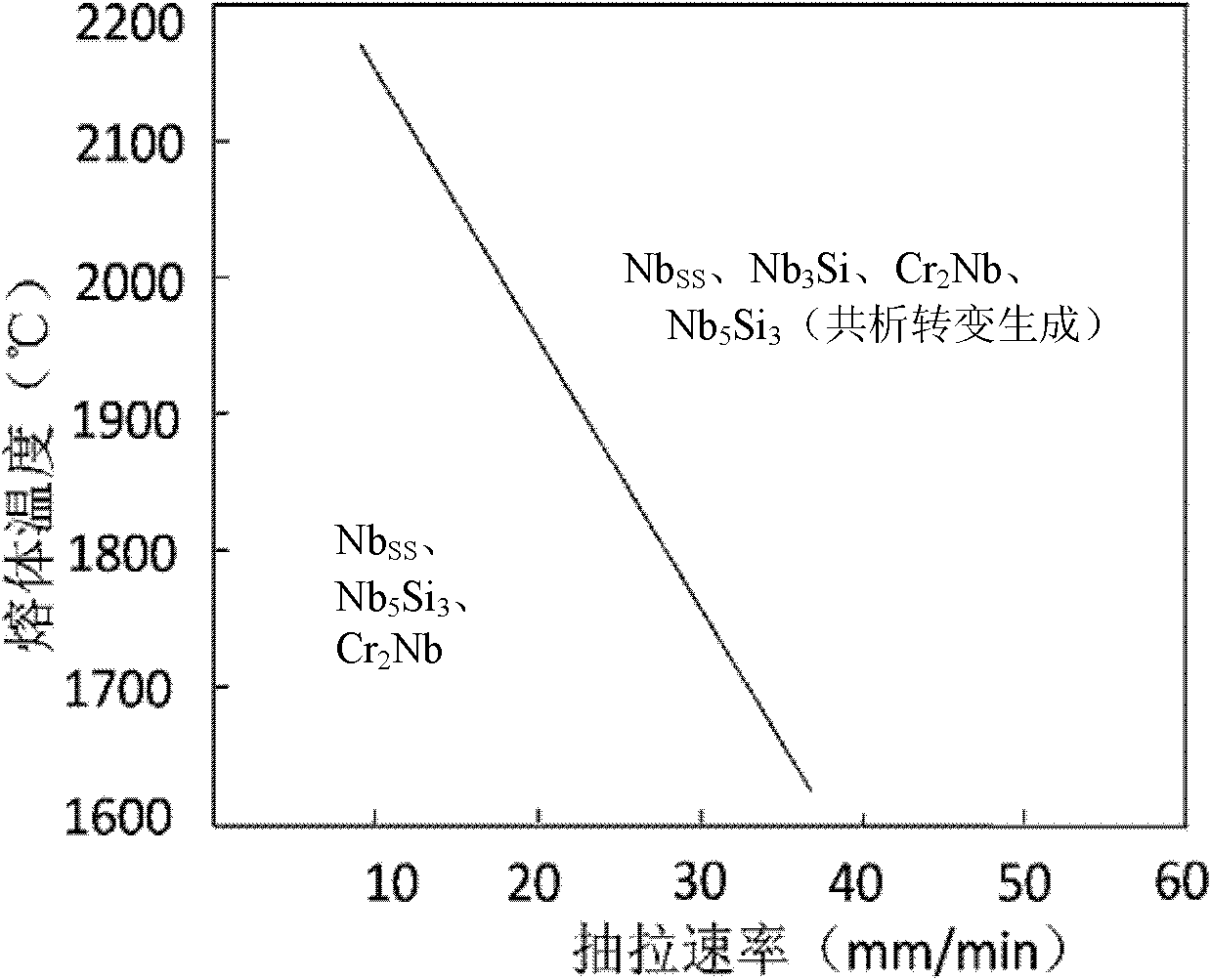

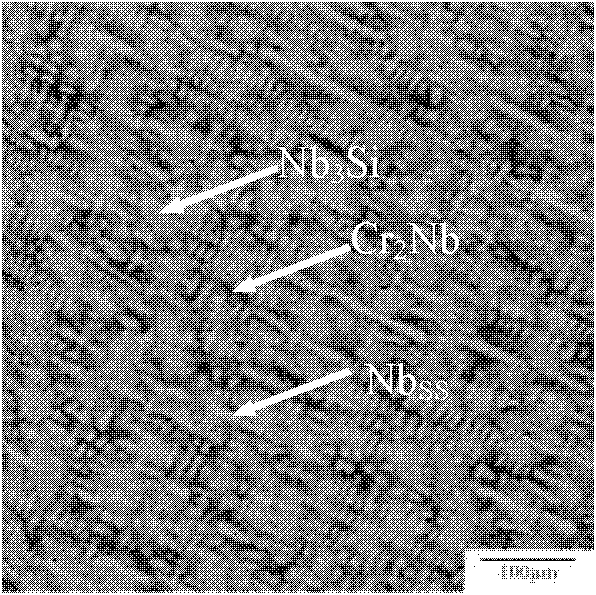

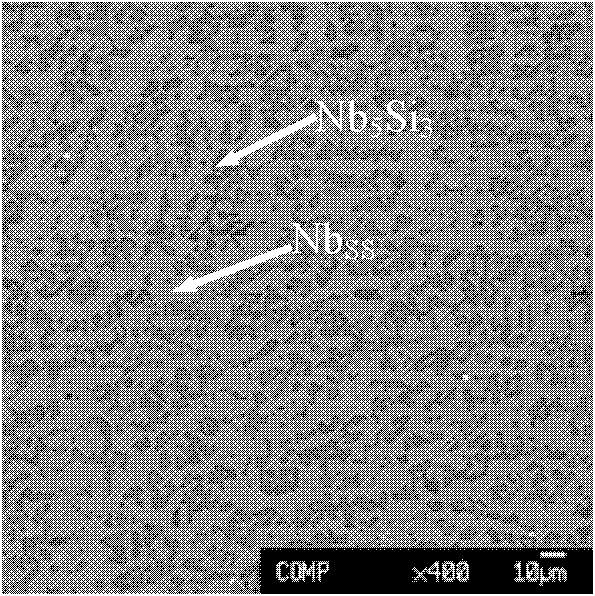

Structure controlled preparation method for Nb-Si-based complex alloy

InactiveCN102418025AImproved room temperature performanceShort preparation cycleOxidation resistantDuctility

The invention discloses a structure controlled preparation method for an Nb-Si-based complex alloy. According to the method, the structure of the Nb-Si-based complex alloy is controlled by adopting a combined process of unbalanced quick directional solidification and heat treatment; and the faceted growth property of silicide in the alloy is weakened, dimensions of a reinforcing phase Nb5Si3 and an anti-oxidation phase Cr2Nb in the alloy are remarkably reduced, a Nbss phase is used as the matrix in the steady-state structure of the Nb-Si-based complex alloy, the reinforcing phase Nb5Si3 is uniformly distributed on the matrix in a wormlike shape, and the anti-oxidation phase Cr2Nb is uniformly distributed or fixedly dissolved in the matrix in a granular shape, wherein the average length of the wormlike Nb5Si3 phase is less than 20 microns, the width of the Nb5Si3 phase is 5 microns, the size of the granular Cr2Nb phase is less than 10 microns, and the content of the two phases is not less than 35 percent. By structure control, the alloy contains enough Nb5Si3 and Cr2Nb phases, so that the alloy has good room temperature toughness and ductility on the premise of achieving excellent high-temperature mechanical property and oxidation resistance.

Owner:BEIHANG UNIV

Frozen aerated confection

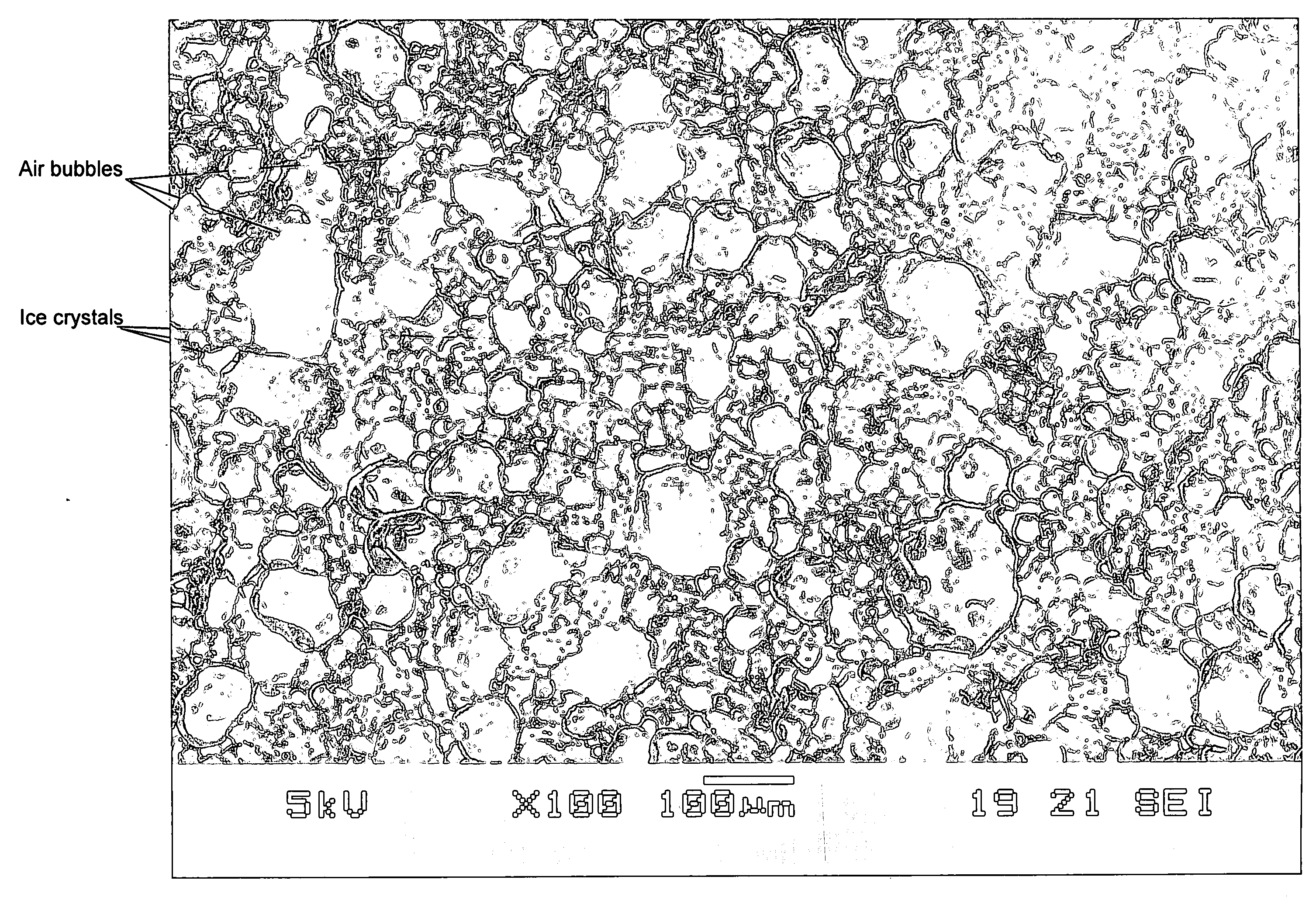

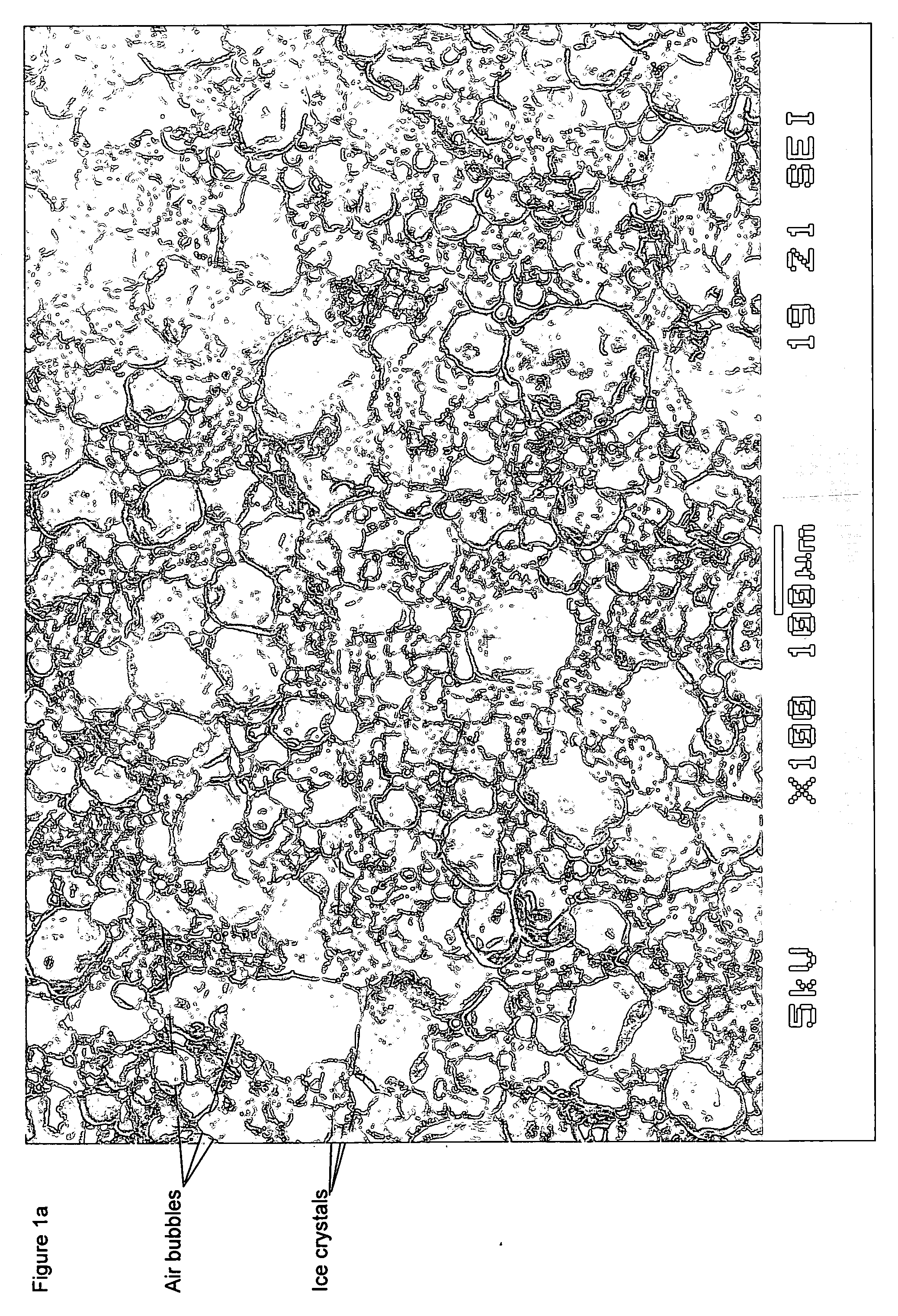

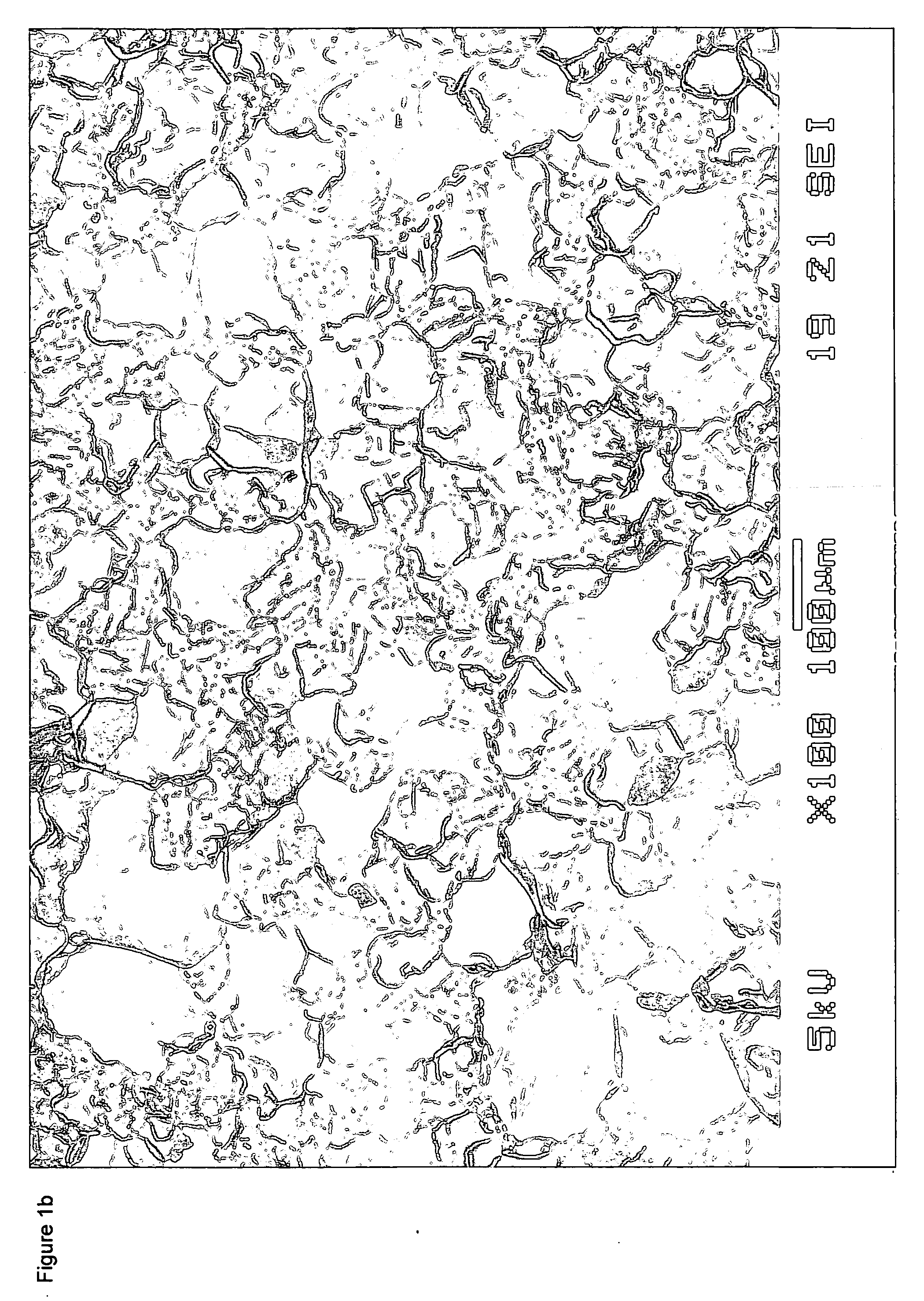

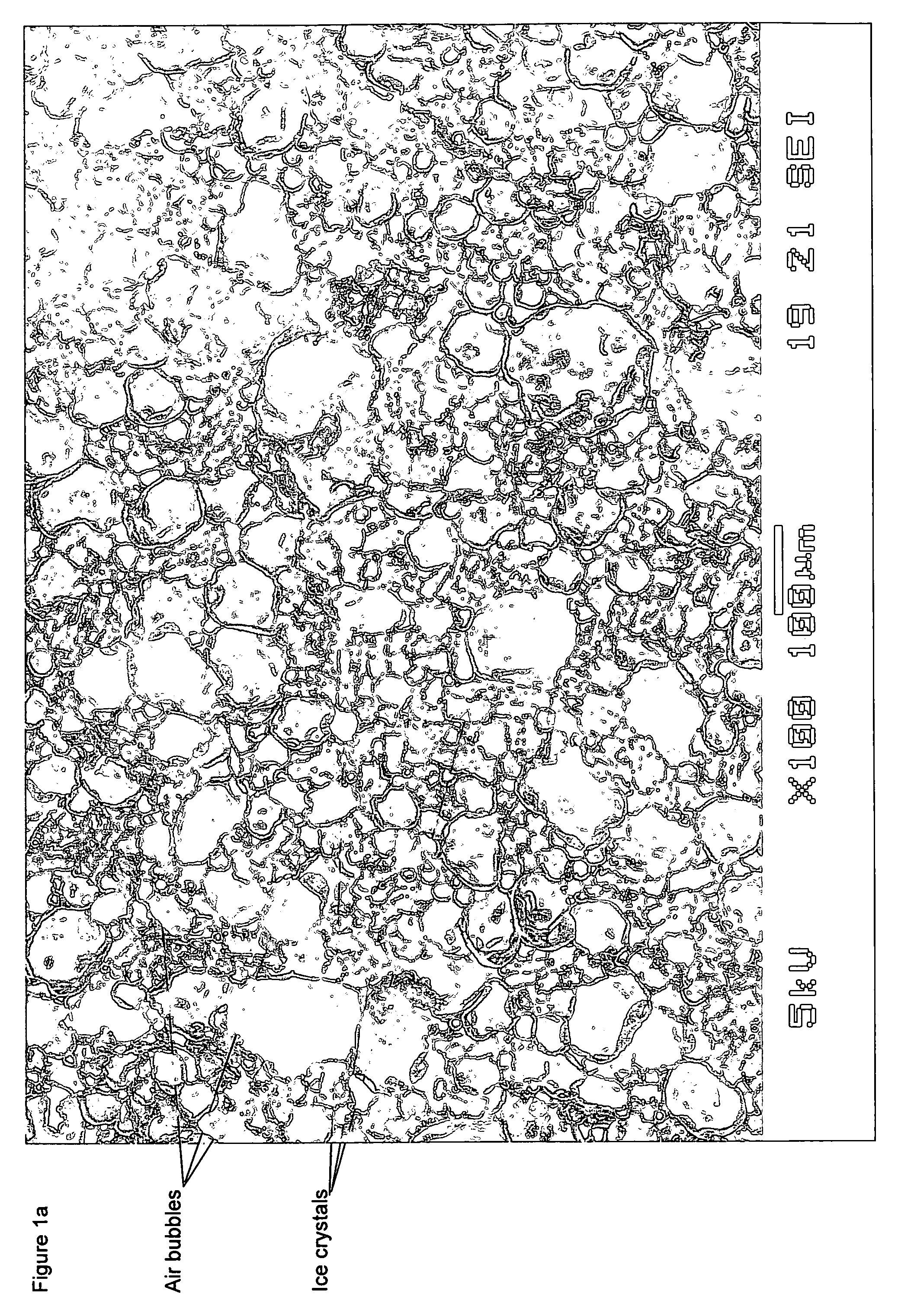

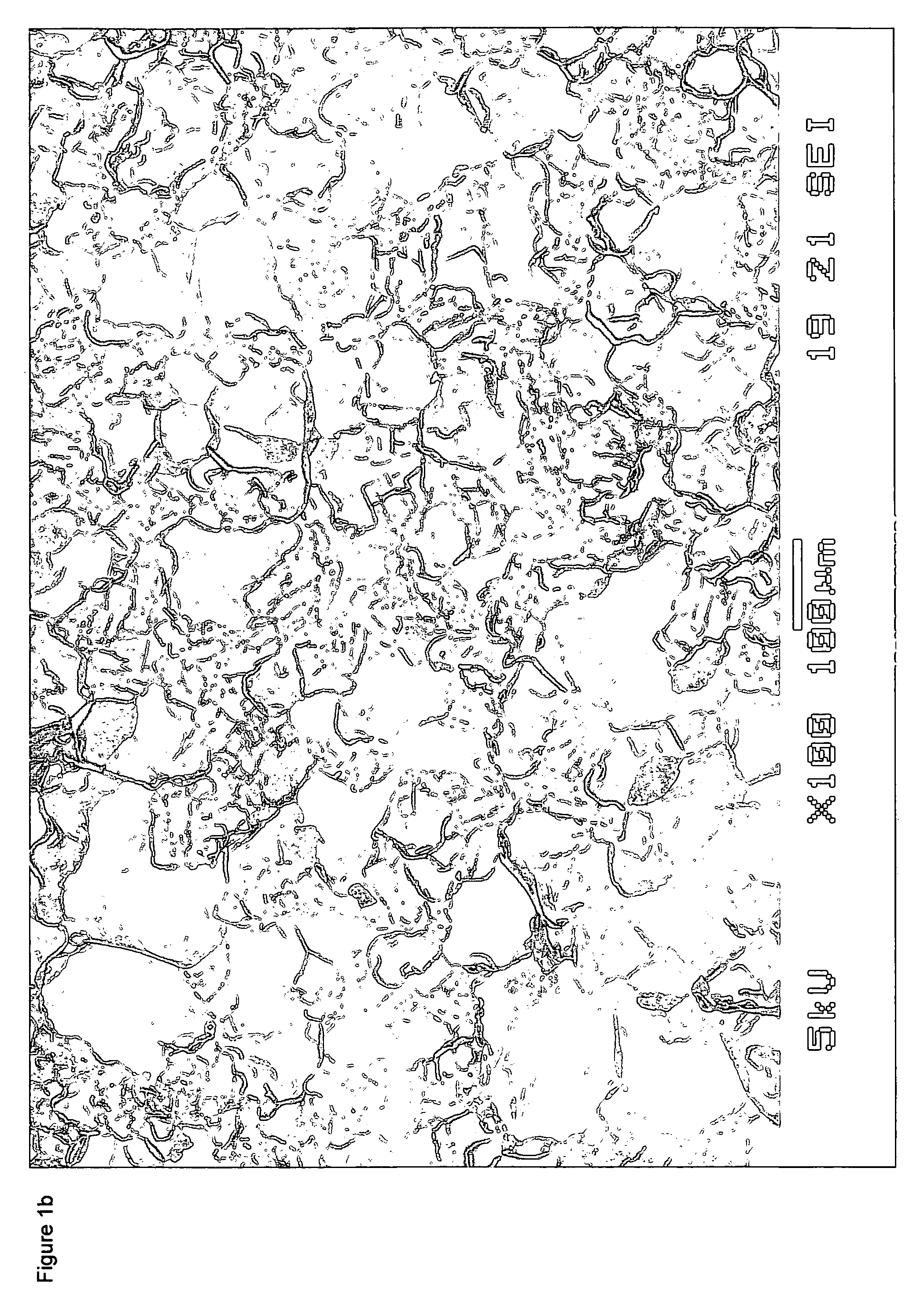

InactiveUS20070141206A1Improve stabilityCoarsening of both the air bubbles and ice crystals is reducedFrozen sweetsConfectioneryHydrophobinFood science

A frozen aerated confection comprising an ice structuring protein (ISP) and a hydrophobin is provided.

Owner:CONOPCO INC D B A UNILEVER

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

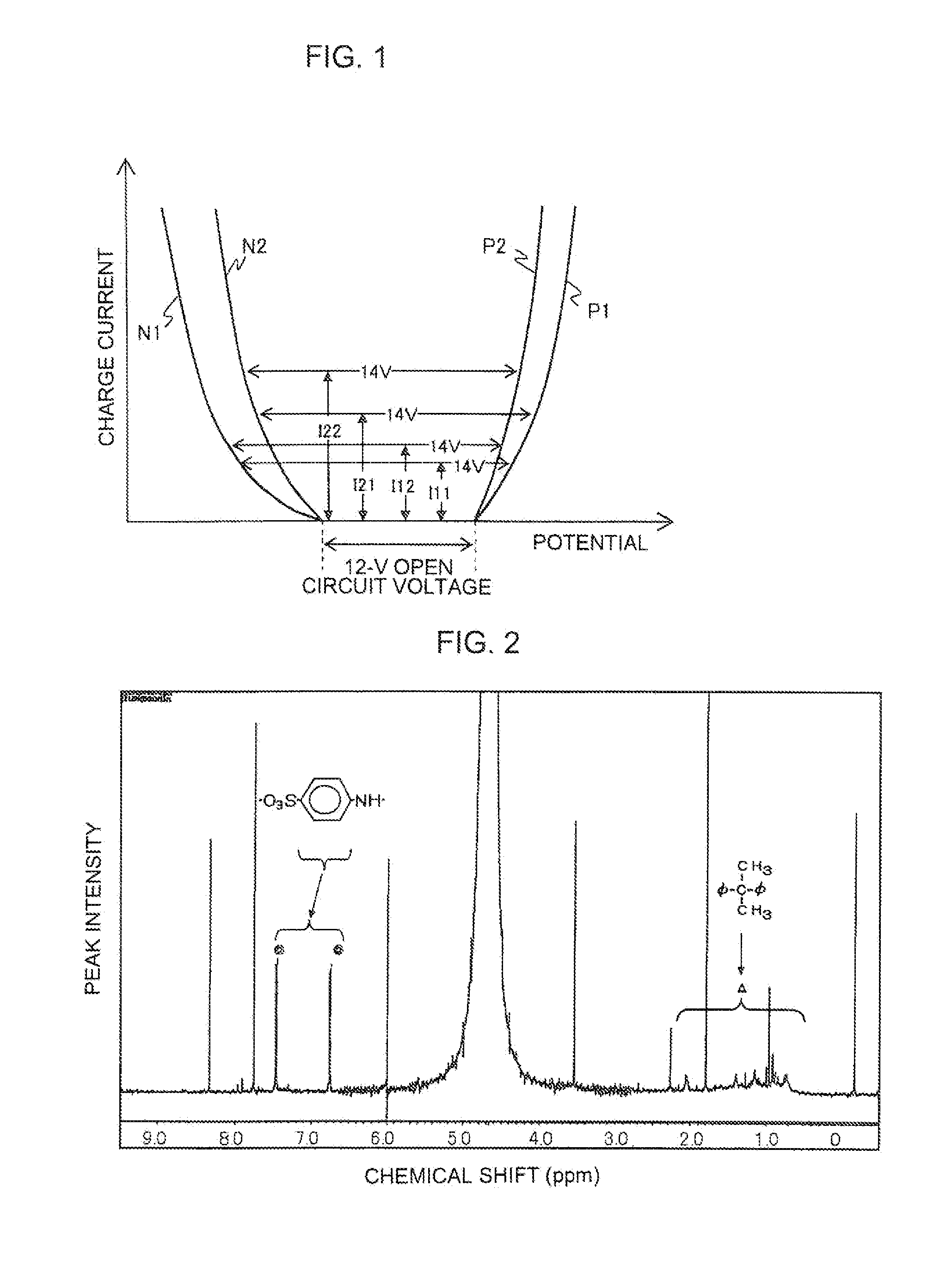

Lead acid storage battery

InactiveUS20130022860A1Improve service life effectHigh acceptanceLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersPolyolefinState of charge

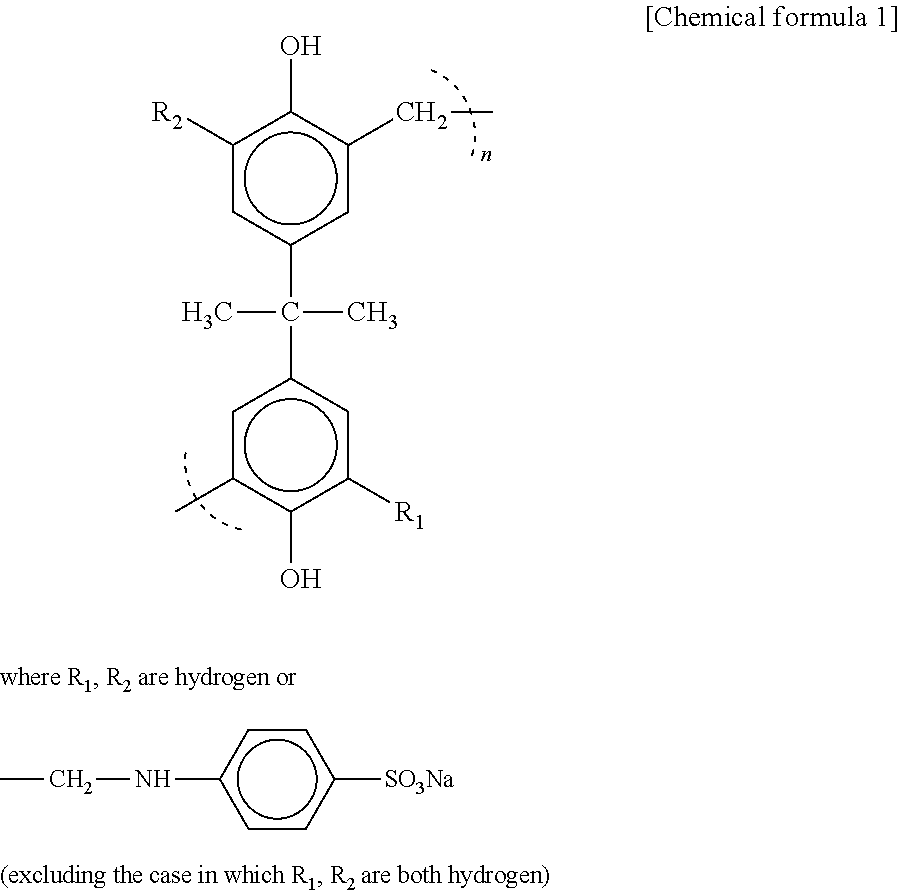

A flooded-type lead acid storage battery in which charging is intermittently carried out in a short period of time and high-efficiency discharge to a load is carried out in a partial state of charge, wherein the charge acceptance and service life characteristics are improved by using a positive plate in which the specific surface area of the active material is set to 6 m2 / g or more; a negative plate with improved charge acceptance and service life performance obtained by adding a carbonaceous electrically conductive material, and a bisphenol aminobenzenesulfonic acid formaldehyde condensate to the negative active material; and a separator formed from a nonwoven in which the surface facing the negative plate is composed of material selected from glass, pulp, and polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

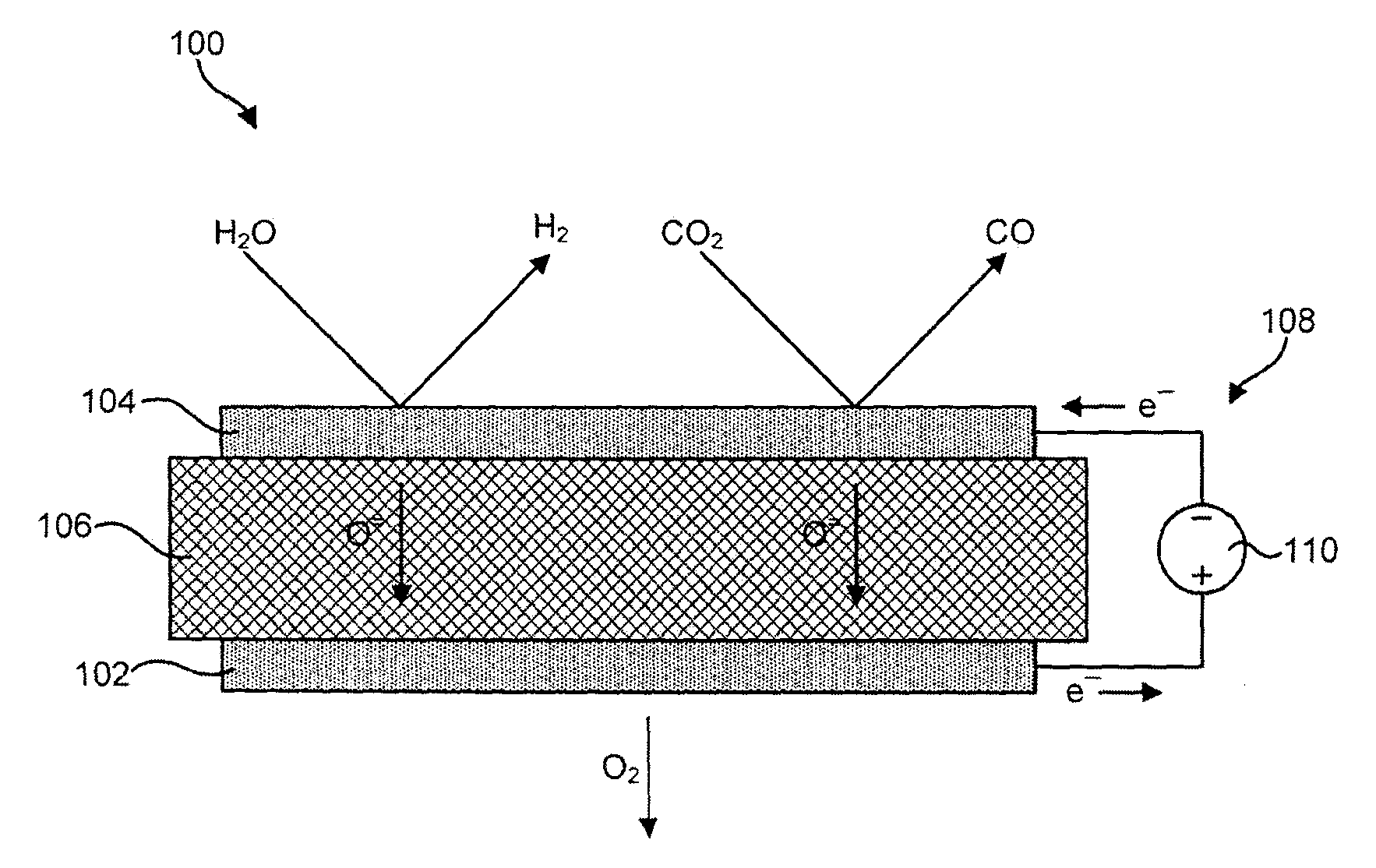

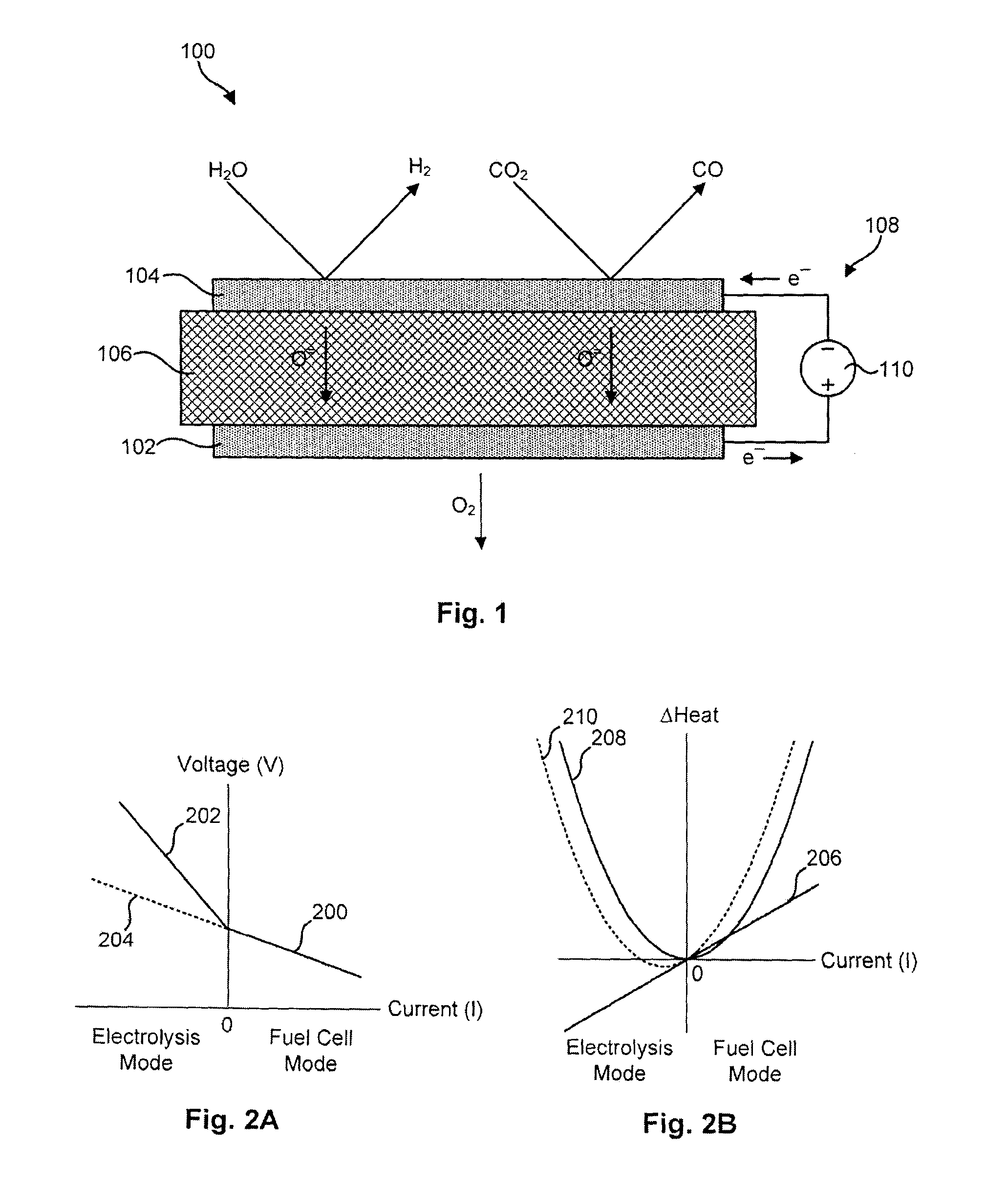

Efficient reversible electrodes for solid oxide electrolyzer cells

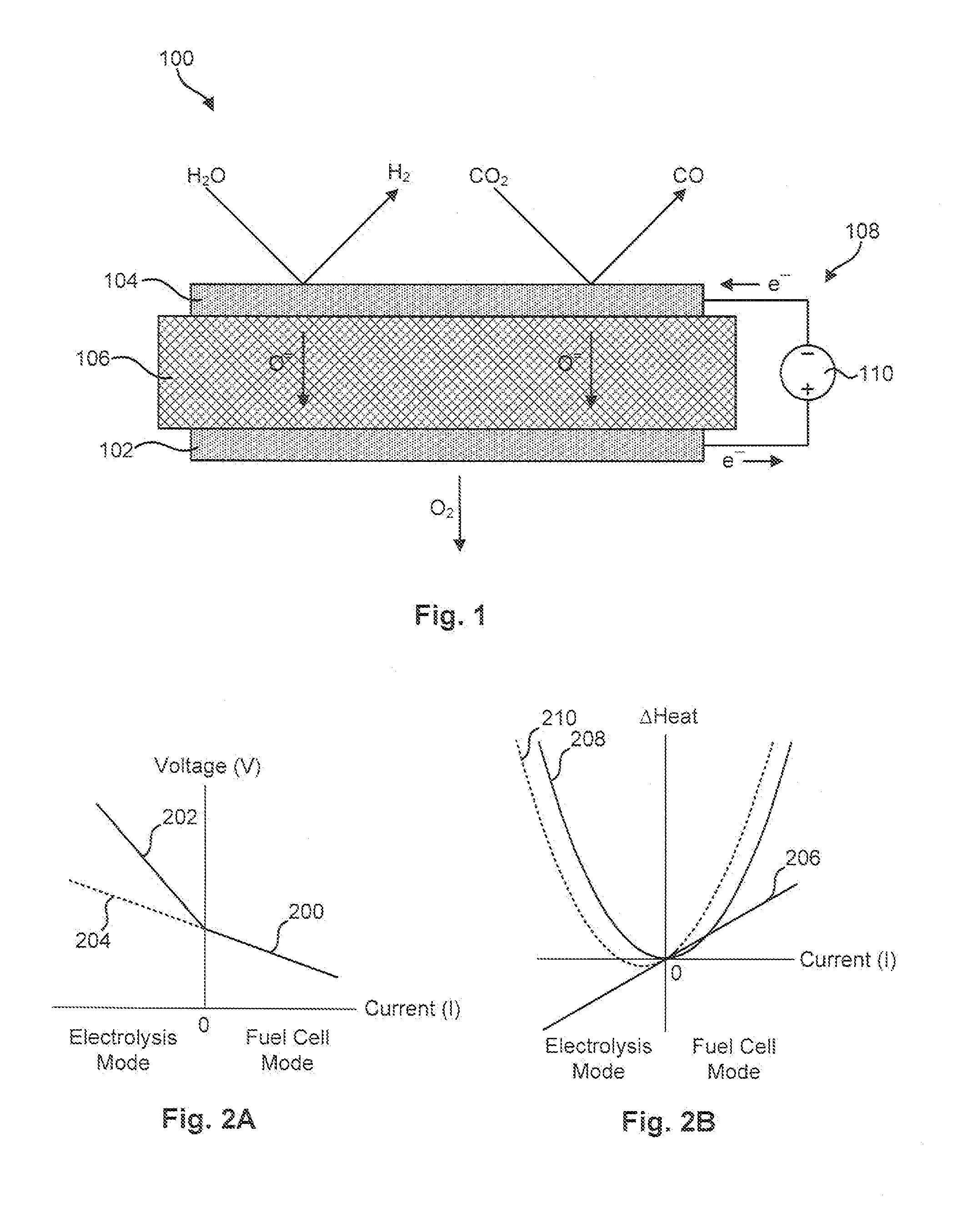

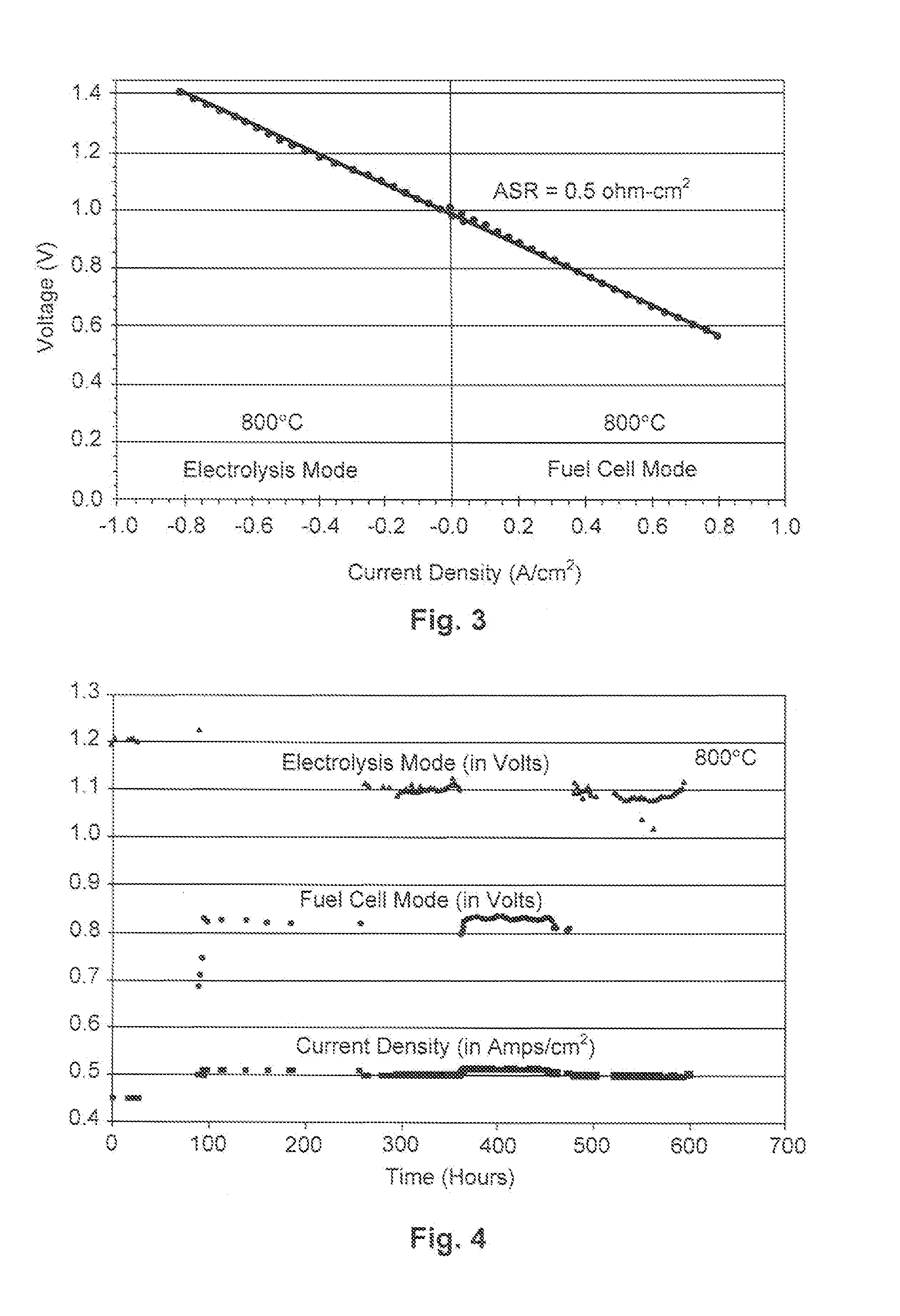

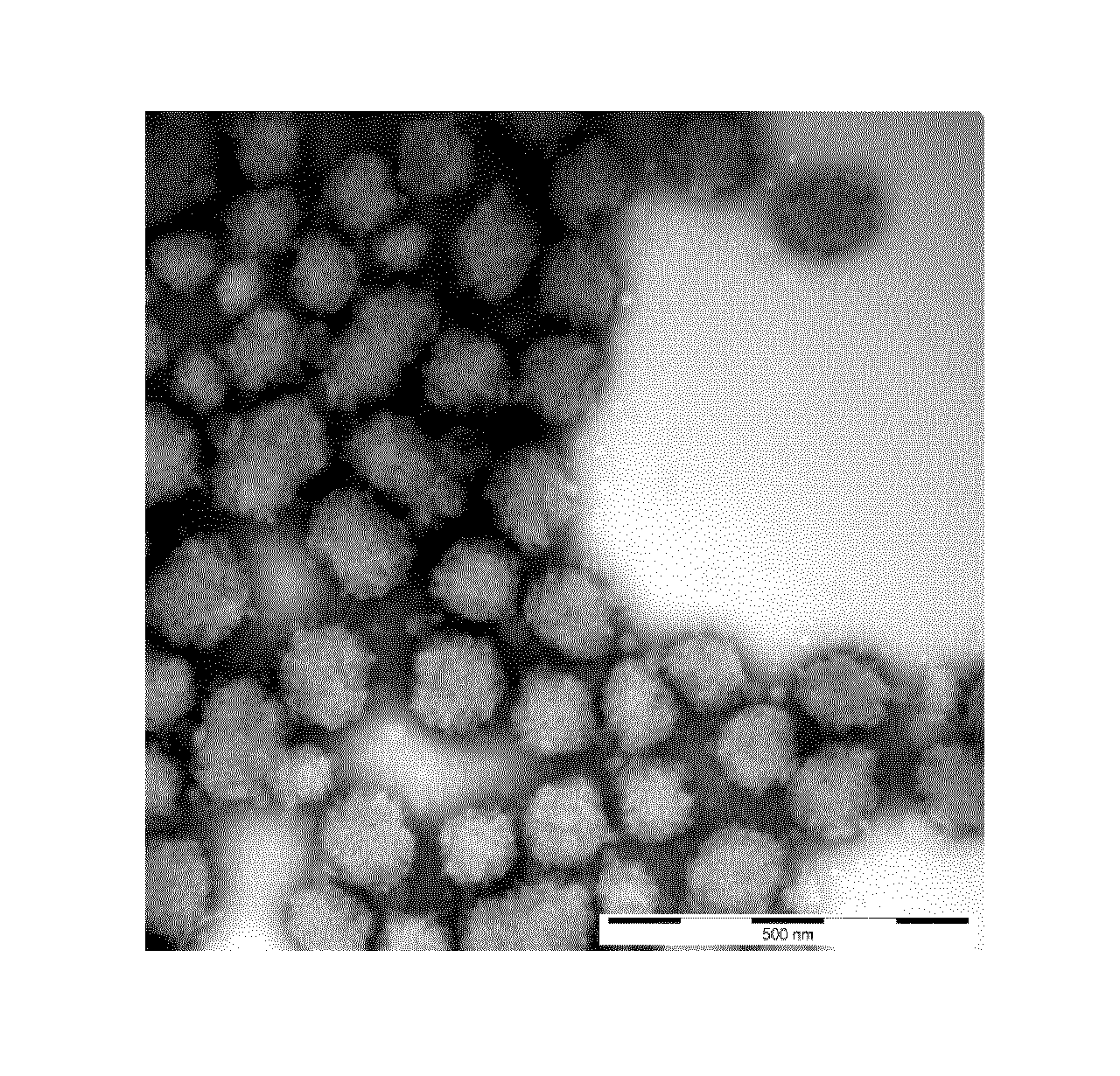

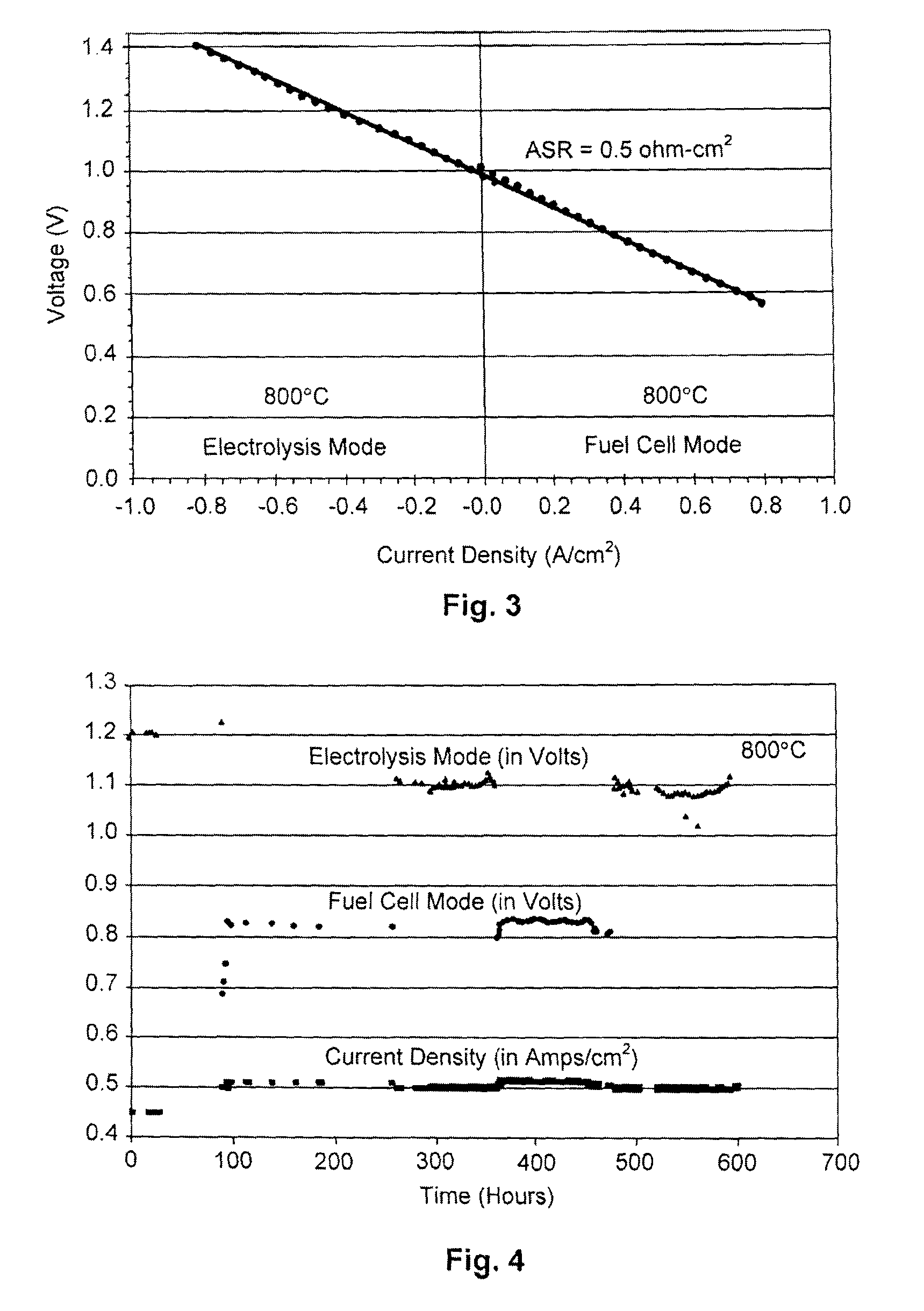

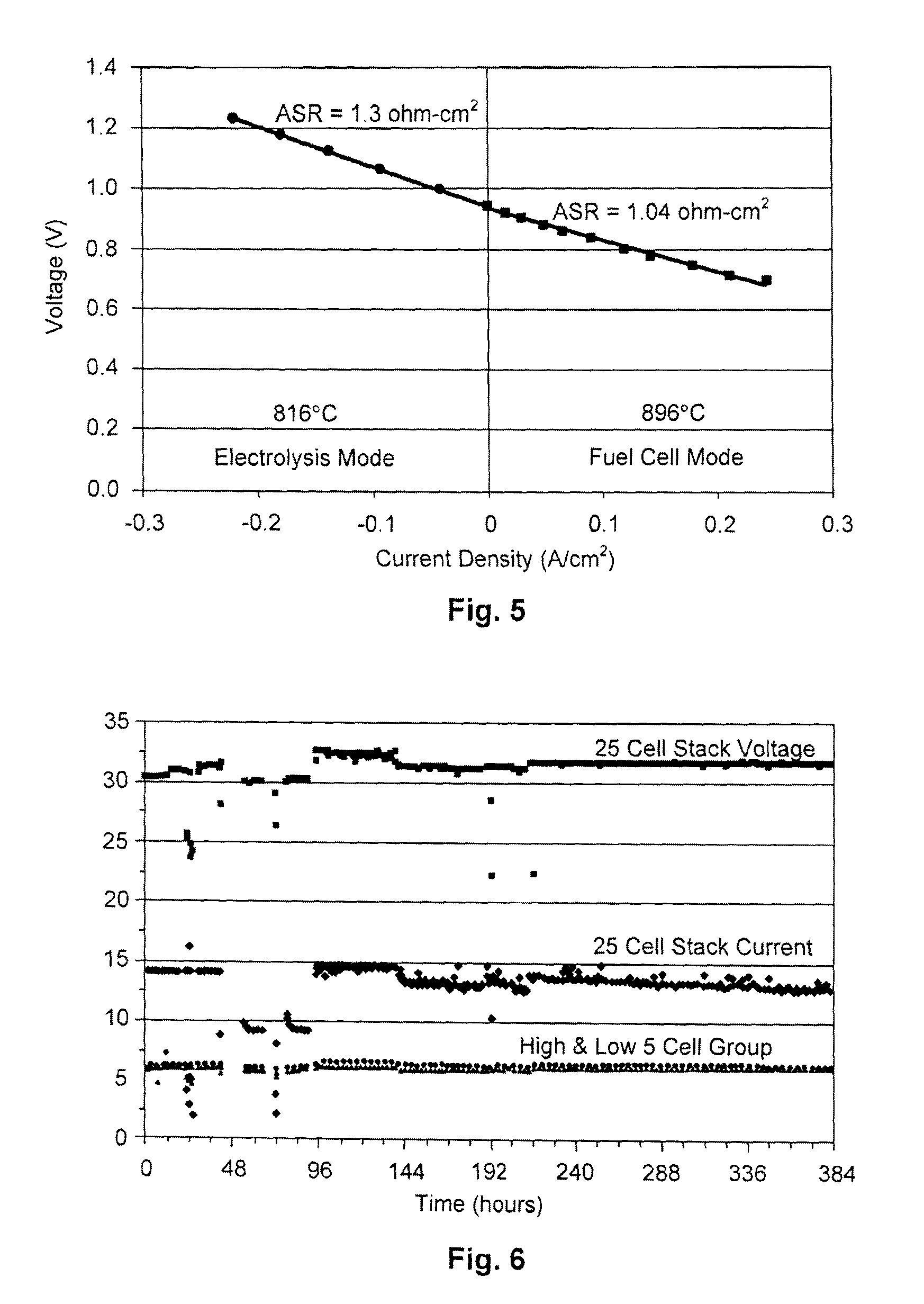

InactiveUS20110062017A1Improve electrochemical efficiencyImprove efficiencyCellsActive material electrodesOxygen ionsElectron

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0<x<1, 0≦y≦0.5, and 0.8 ≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:CERAMTEC

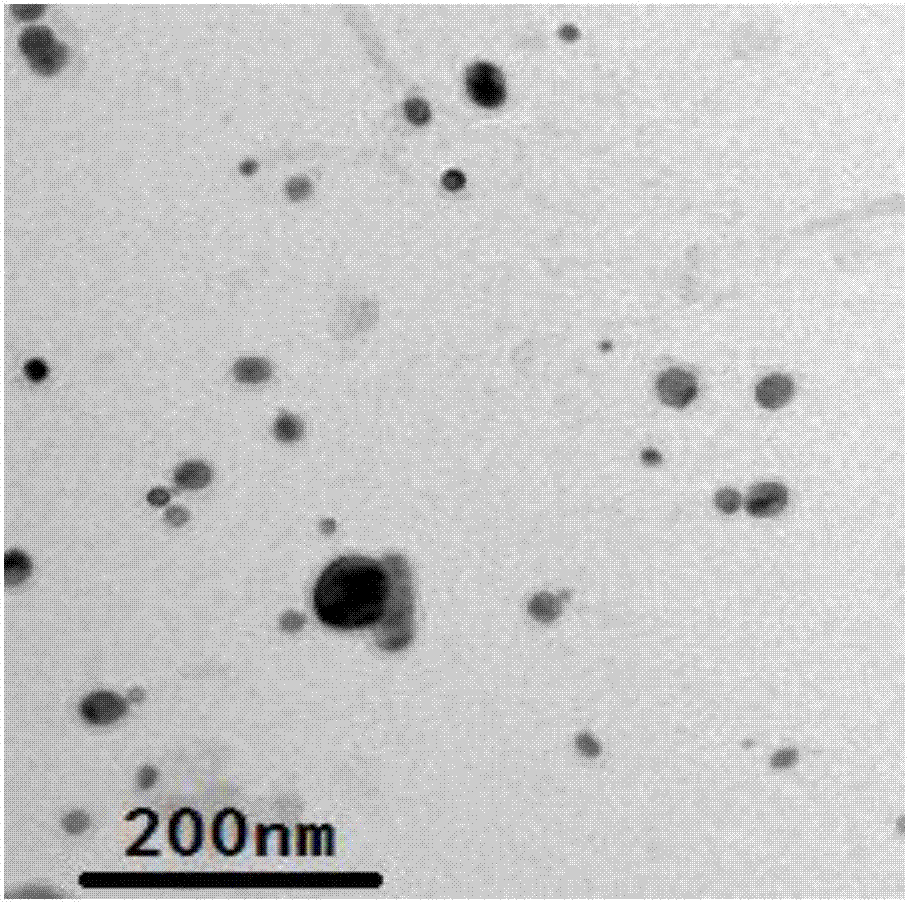

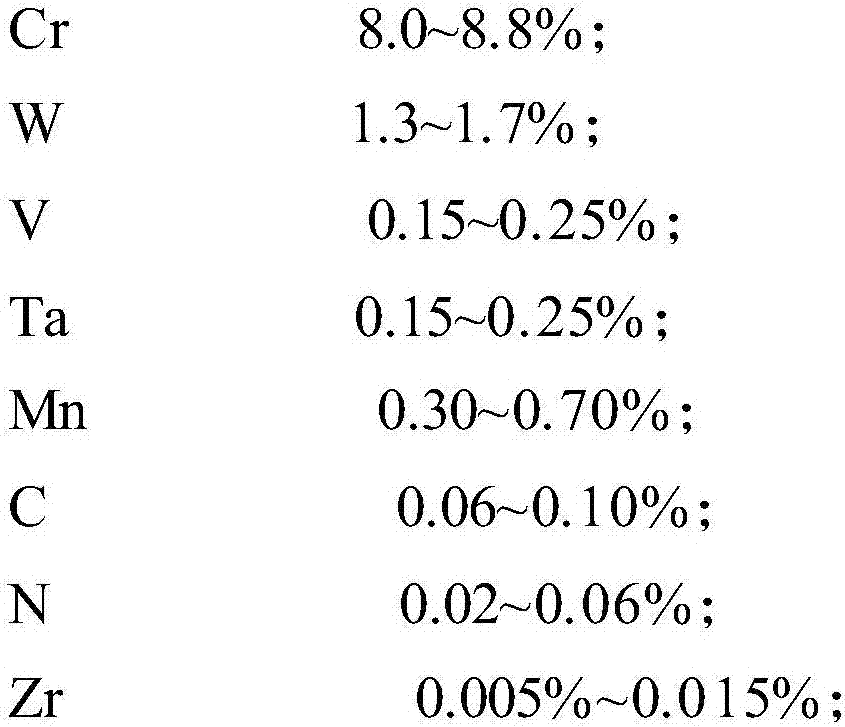

Novel dispersion-strengthened low-activation radiation-resistant martensitic steel and heat treatment technology thereof

InactiveCN107130185AImprove mechanical propertiesImprove high temperature performanceRadiation resistantBiological activation

The invention provides a martensitic steel whose main elements include: 8.0-8.8wt% Cr, 1.3-1.7wt% W, 0.15-0.25wt% V, 0.15-0.25wt% Ta, 0.30- 0.70wt% Mn, 0.06-0.10wt% C, 0.02-0.06wt% N, 0.005-0.015wt% Zr; this application reduces Cr content and adds N element to partially replace C element, so that the material can be processed During the process, the precipitation of M23C6 is reduced; and by strictly controlling the composition ratio of each forming element of the MX phase, it is ensured that Ta and V are precipitated in the form of MX phase to the greatest extent. At the same time, the application adopts a special heat treatment process to obtain dispersed and fine MX phases, effectively improving the high-temperature performance of the material during service.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-performance cobalt-based high-temperature alloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

Efficient reversible electrodes for solid oxide electrolyzer cells

InactiveUS8354011B2Improve efficiencyReduce coarseningCellsActive material electrodesOxygen ionsElectron

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0<x<1, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:CERAMTEC

Frozen aerated confection

InactiveUS8178151B2Improve stabilityCoarsening of both the air bubbles and ice crystals is reducedFrozen sweetsConfectioneryHydrophobinFood science

A frozen aerated confection comprising an ice structuring protein (ISP) and a hydrophobin is provided.

Owner:CONOPCO INC D B A UNILEVER

Efficient reversible electrodes for solid oxide electrolyzer cells

An electrolyzer cell is disclosed which includes a cathode to reduce an oxygen-containing molecule, such as H2O, CO2, or a combination thereof, to produce an oxygen ion and a fuel molecule, such as H2, CO, or a combination thereof. An electrolyte is coupled to the cathode to transport the oxygen ion to an anode. The anode is coupled to the electrolyte to receive the oxygen ion and produce oxygen gas therewith. In one embodiment, the anode may be fabricated to include an electron-conducting phase having a perovskite crystalline structure or structure similar thereto. This perovskite may have a chemical formula of substantially (Pr(1-x)Lax)(z-y)A′yBO(3-∂), wherein 0≦x≦0.5, 0≦y≦0.5, and 0.8≦z≦1.1. In another embodiment, the cathode includes an electron-conducting phase that contains nickel oxide intermixed with magnesium oxide.

Owner:COORSTEK INC

Single-arc dual-wire pipeline welding method

InactiveCN109202229AReduce coarseningReduce softeningArc welding apparatusAdaptive controlEngineering

The invention discloses a single-arc dual-wire pipeline welding method. The single-arc dual-wire pipeline welding method comprises the following steps of firstly, carrying out preparation before welding, wherein the specifications and the quality of two pipelines to be welded are checked, and groove preparation and polishing are carried out; secondly, carrying out groove condition checking, wherein the two sides of each groove are cleaned, and it is guaranteed that grooves are flat and smooth; thirdly, sending the two pipelines to be welded into a spot welder for butt joint, and completing root welding; fourthly, setting the mode and technological parameters of self-adaptation control automatic welding apparatus; and fifth, using the set self-adaptation control automatic welding apparatusto carry out hot welding, and filling welding and cosmetic welding on the pipelines subjected to root welding till completing the whole process of welding operation. With the single-arc dual-wire pipeline welding method, the welding deposition rate is large, the welding speed is high, welding cracks are effectively lessened, the welding speed is obviously increased, the welding quality is obviously improved, the degree of welding heat affected zone microstructure coarsening and softening is reduced, and it is beneficial for improvement on the mechanical properties of a welded joint.

Owner:天津依海管道有限公司

Heat treatment process of low-alloying Al-Mg-Si alloy

ActiveCN108866463AMatch mechanicsMatch electrical propertiesIncreasing energy efficiencyThree levelManufacturing technology

The invention belongs to the technical field of nonferrous metal material manufacturing, and particularly relates to a heat treatment process of a low-alloying Al-Mg-Si alloy. The process is aimed atthe phenomenon that the low-alloying Al-Mg-Si alloy is used for extruding a product, the special heat treatment systems of high-temperature extrusion, three-level online quenching cooling and dual-stage aging high firstly and low at the later period are adopted, and the alloy obtains mechanical property and electrical property good matching. The heat treatment process is adopted, the low-alloyingAl-Mg-Si alloy can obtain the property matching with the tensile strength being 150 MPa, the elongation being 14%, and the specific conductance being 59% IACS or above, or the tensile strength being 180 MPa, the elongation being 12%, and the specific conductance being 57% IACS or above, and through the process, the application of the Al-Mg-Si alloy to the power industry is effectively promoted.

Owner:福建祥鑫股份有限公司

Copper surface super-coarsening solution for circuit board as well as preparation method and application of copper surface super-coarsening solution

ActiveCN114686885AReduce coarseningPrevent false points in detection reportsInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCyclohexanonePhosphoric Acid Esters

The invention discloses a copper surface super-roughening solution for a circuit board as well as a preparation method and application of the copper surface super-roughening solution, and relates to the field of circuit board manufacturing. The coarsening solution comprises 70-200 g / L of sulfuric acid, 20-60 g / L of hydrogen peroxide, 2-18 g / L of a coarsening homogenizing agent, 1.2-9.8 g / L of a coarsening and stabilizing agent, 2-18 g / L of an antioxidant and water as a solvent. The coarsening homogenizing agent is selected from at least one of methoxylated polyethylene glycol and cyclohexanone; the coarsening and stabilizing agent is selected from at least one of 1, 4-butanediol, 2-acetamido-5-sulfydryl-1, 3, 4-thiadiazole, and 2-sulfydryl-1-methylimidazole; the antioxidant is selected from at least one of acetic acid and butanol phosphate. According to the copper surface super-coarsening solution for the circuit board, all the components are matched with one another, and the preparation method and application are combined, so that the super-coarsening solution is stable, the coarsening effect meets the requirements of dry film pasting in a subtraction method (negative film method) production process, copper surface oxidation is reduced, and the AOI detection efficiency in a negative film production process is improved.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

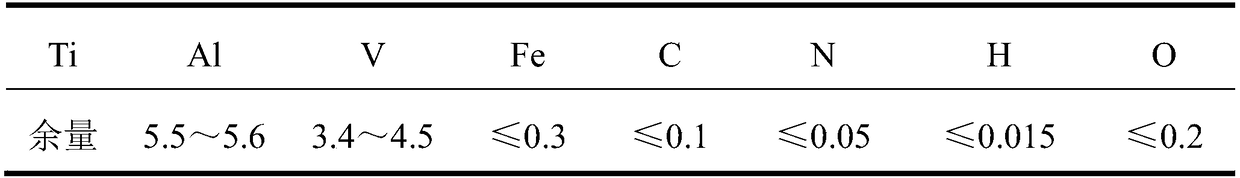

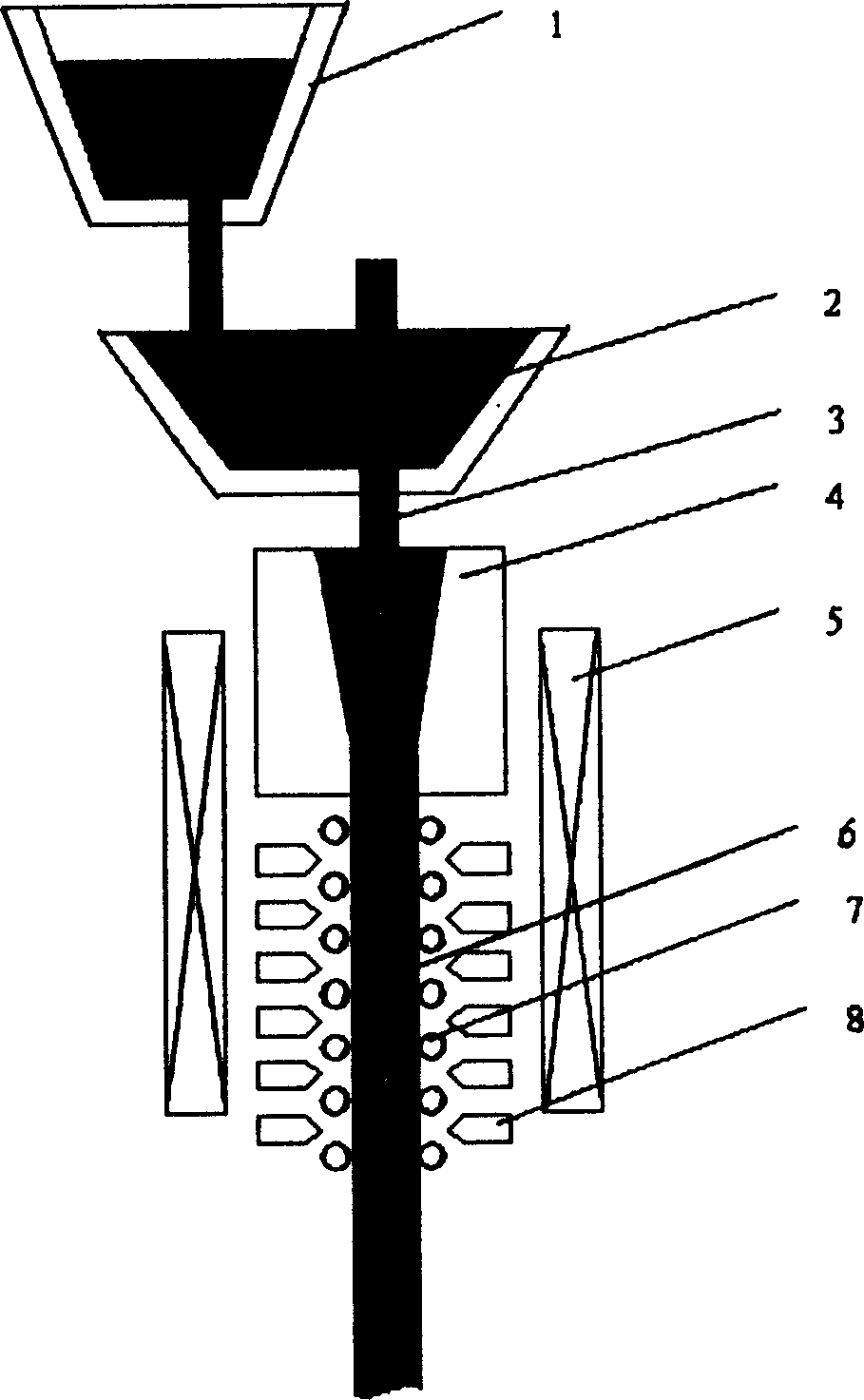

Method for production of alloyed titanium welding wire

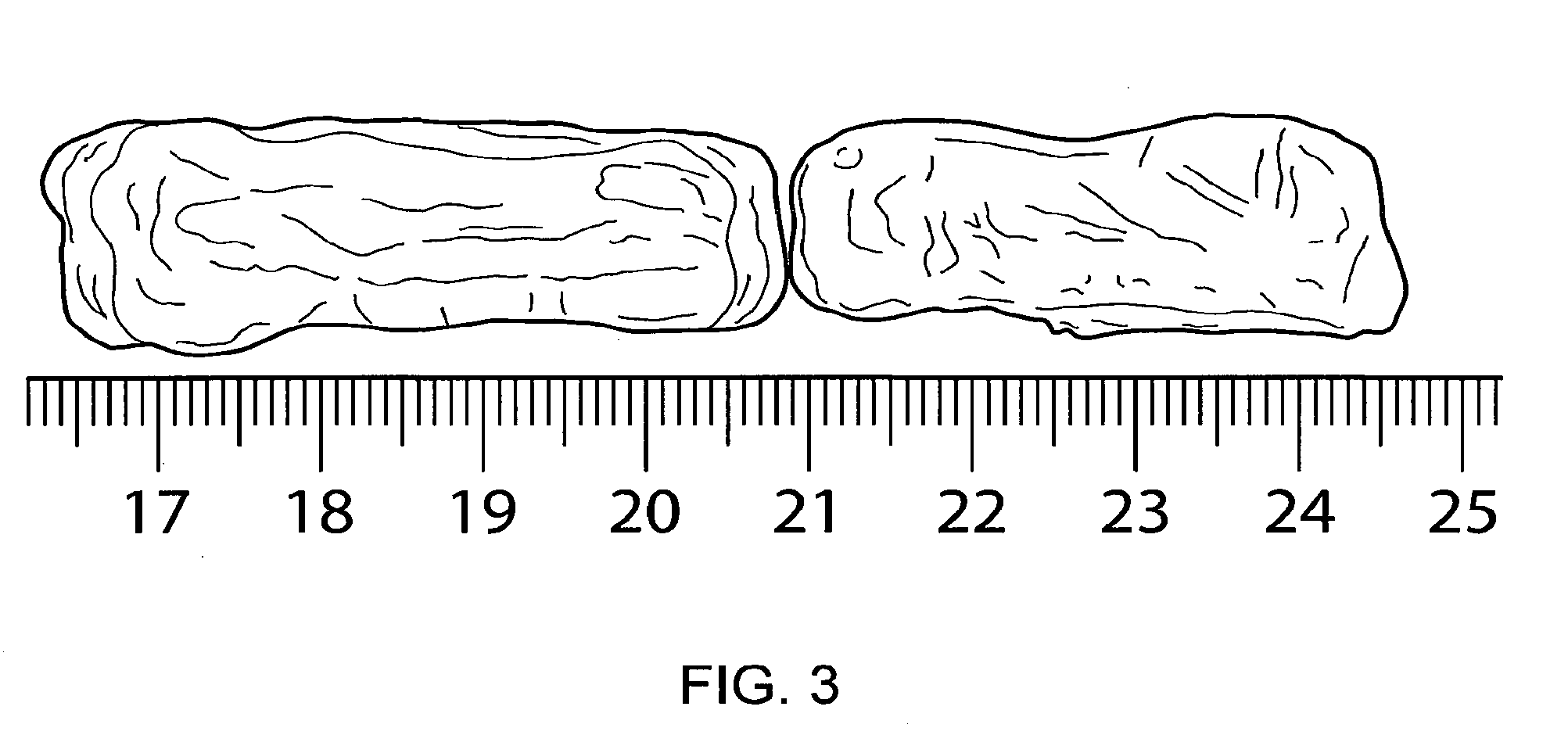

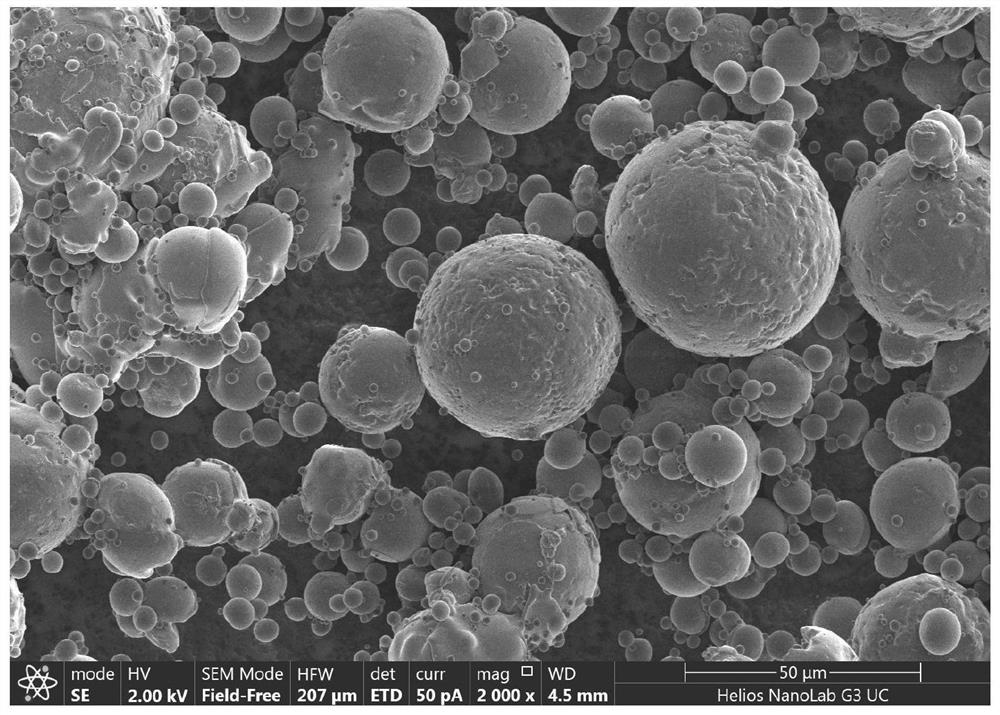

InactiveUS20160151865A1Increase shear forceSerious problemExtrusion diesIncreasing energy efficiencyParticulatesTitanium

A method for producing a weldable titanium alloy and / or composite wire. The method includes: a) forming a green object by blending particulates of titanium sponge with one or more powdered alloying additions and cold compacting the blended mixture and subjecting the blended mixture including lubricant to pressure; b) forming a work body of alloyed titanium by heating the green object in a protected atmosphere and holding the temperature for a period of at least 4 hours, and then hot working the green object at a temperature of less than 200° C. apart from the beta transition temperature of the titanium alloy and shaping the green object to obtain an elongated profile; and c) forming the welding wire by placing the elongated profile of the work body in a rolling mill having one or more rolls disposed in series.

Owner:NORSK TITANIUM

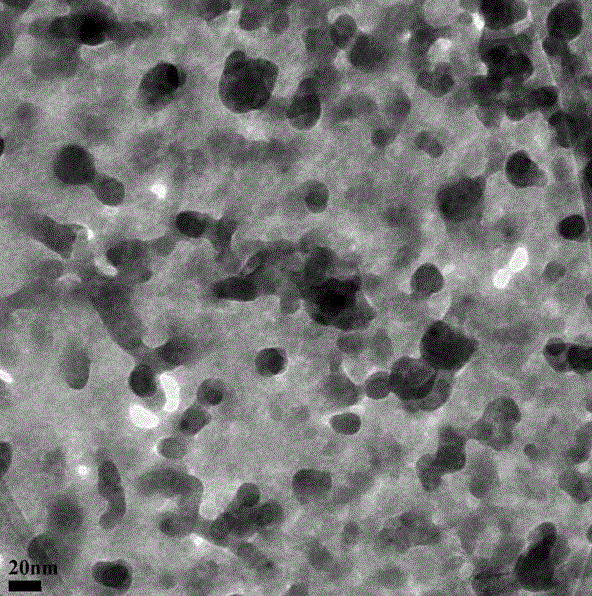

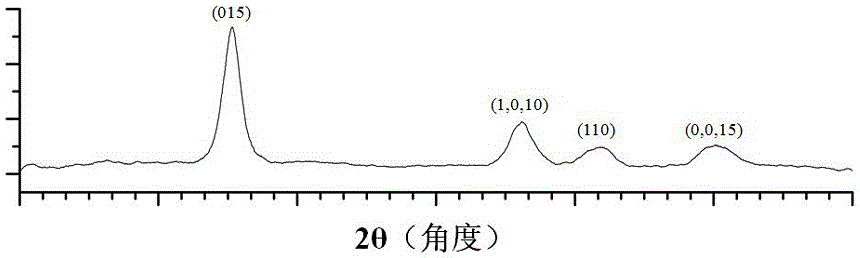

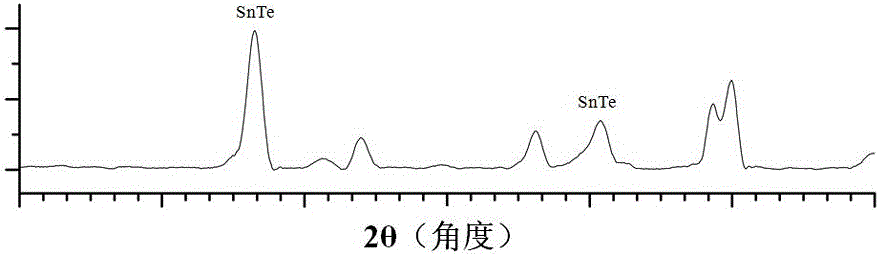

Bismuth telluride nanoparticle strengthened tin, silver and copper solder and using method thereof

ActiveCN105935845AReduce churnChurn ControlWelding/cutting media/materialsSoldering mediaBismuth tellurideNanoparticle

The invention discloses a bismuth telluride nanoparticle strengthened tin, silver and copper solder and a using method thereof. The solder is prepared from, by weight percent, 0.5%-1% of bismuth telluride nanoparticles, 80%-90% of tin, silver and copper micrometer powder and 10%-20% of soldering flux. The average particle size of the bismuth telluride nanoparticles is 20 nm, and the atom ratio of the tellurium element to the bismuth element is 3:2. The average particle size of the tin, silver and copper micrometer powder is 30 microns, and the weight percentage of the tin element to the silver element to the copper element is 96.50%:3.0%:0.5%. The soldering flux is a rosin soldering flux. The invention further provides the using method of the bismuth telluride nanoparticle strengthened tin, silver and copper solder. According to the bismuth telluride nanoparticle strengthened tin, silver and copper solder and the using method of the bismuth telluride nanoparticle strengthened tin, silver and copper solder, by selecting the proper nanoparticles, the problems, such as nanoparticle losses, nanoparticle coarsening and interfaces of the nanoparticles and the tin, silver and copper solder, of the nanoparticle strengthened tin, silver and copper solder are solved.

Owner:SHANGHAI RADIO EQUIP RES INST

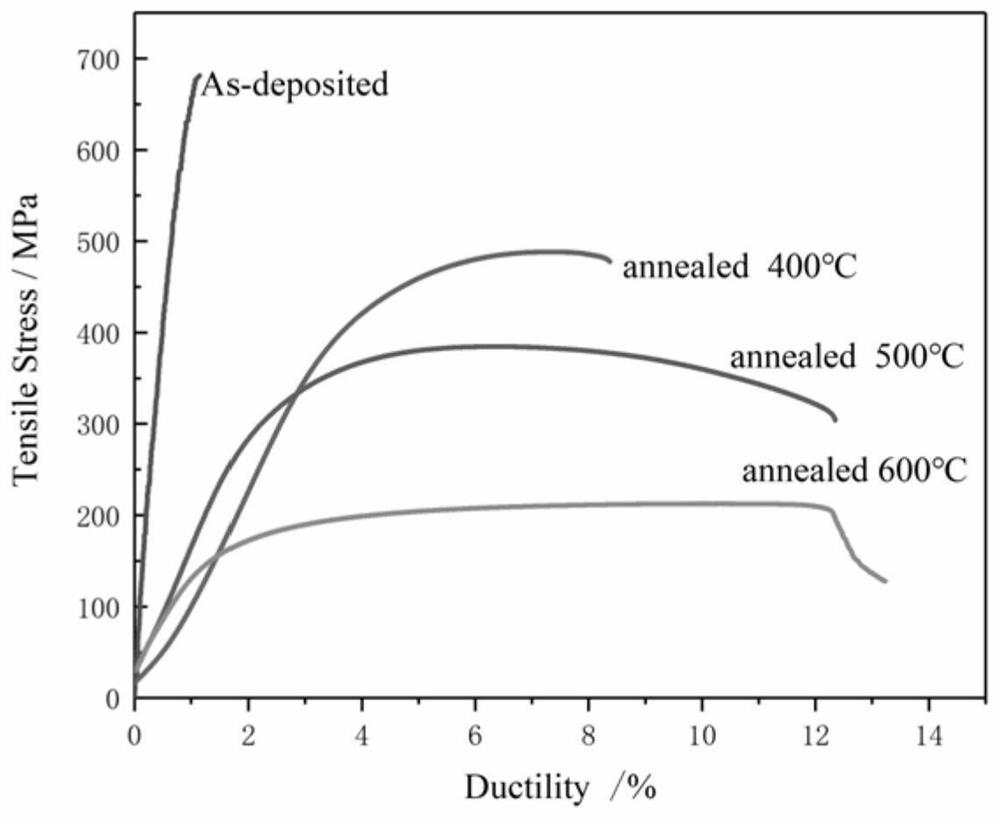

High-strength high-toughness heat-resistant aluminum-iron alloy and 3D printing method thereof

ActiveCN113430422ALow costImprove liquidityAdditive manufacturing apparatusIncreasing energy efficiencyRare-earth elementStress relief

The invention relates to the field of 3D printing, in particular to a high-strength high-toughness heat-resistant aluminum-iron alloy and a 3D printing method thereof. The high-strength high-toughness heat-resistant aluminum-iron alloy comprises the following raw materials in percentage by mass: 2.0%-9.0% of Fe, 1.0%-3.5% of Cr, 0.2%-0.8% of M, 0.1%-0.5% of rare earth elements and the balance of Al and inevitable impurities. M is selected from at least one of Ta and Nb; the high-strength high-toughness heat-resistant aluminum-iron alloy is prepared through a laser 3D printing process. After optimization, the density of the product can reach 98% or above, the tensile strength is about 680 MPa, the product is free of plasticity, the tensile strength is about 495 MPa and the ductility is about 5.5% after proper stress relief annealing and plasticity and toughness control treatment, and the tensile strength can still be about 245 MPa and the ductility is about 8.8% at the high temperature of 315 DEG C.

Owner:CENT SOUTH UNIV

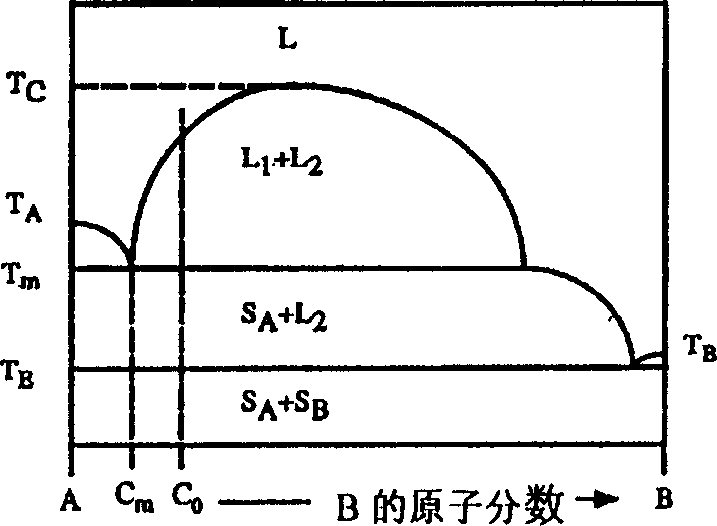

Continuous casting process of monotectic alloy sheet

The present invention relates to continuous casting technology of monotectic alloy, and is especially continuous casting process of monotectic alloy sheet. In a common continuous sheet casting apparatus, constant magnetic field of 0.3-1 tesla strength is applied to the cooling section and the crystallizing section. The constant magnetic field can increase the effective viscosity of alloy melt, retard the moving speed of dispersed phase liquid drop in liquid-liquid phase change temperature region in monotectic alloy, reduce the collision coalescence coursing speed of dispersed phase liquid drop and the separation speed of two liquid phase and decrease segregation of alloy, so that the said process of the present invention can obtain monotectic alloy with homogeneous dispersed phase particle distribution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

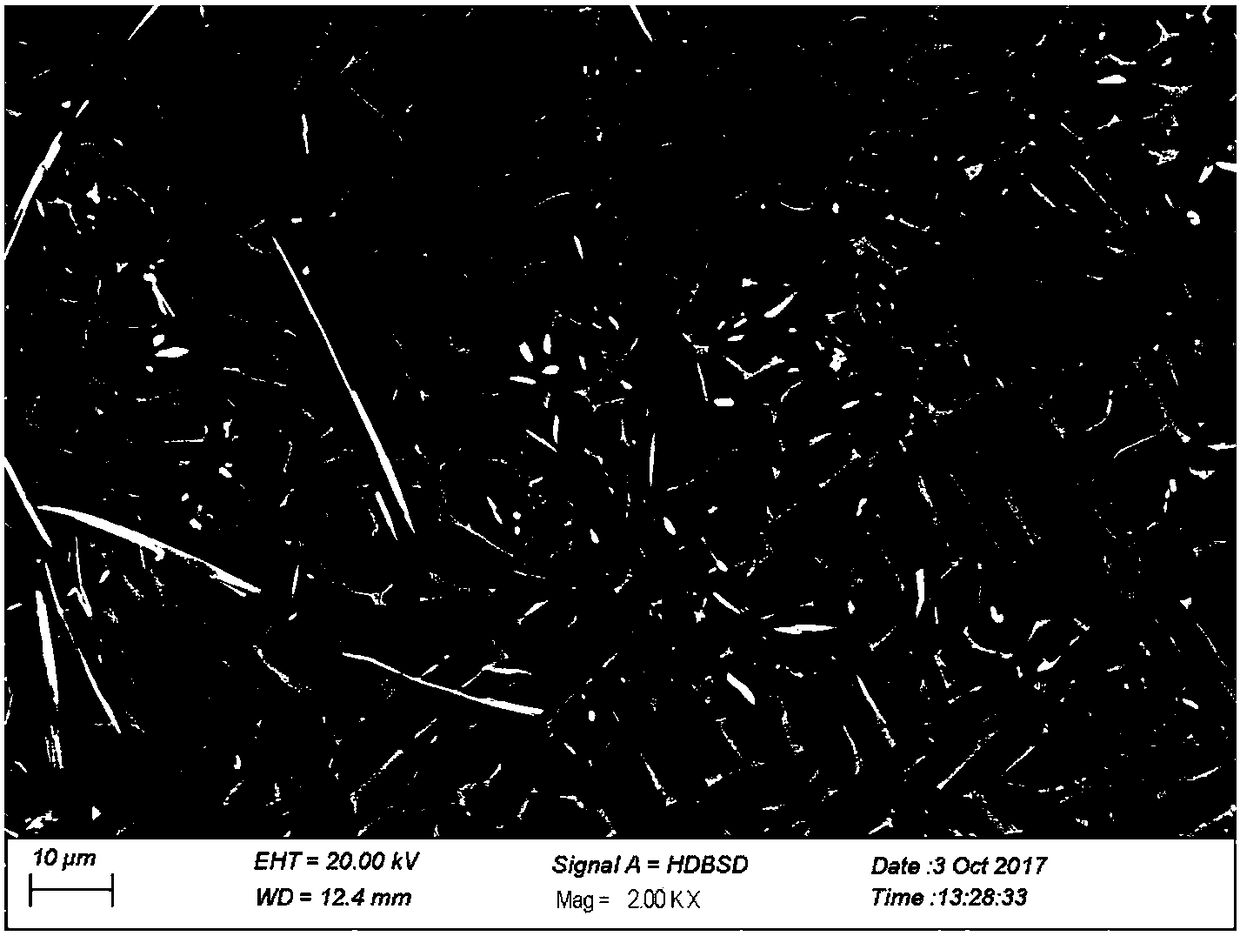

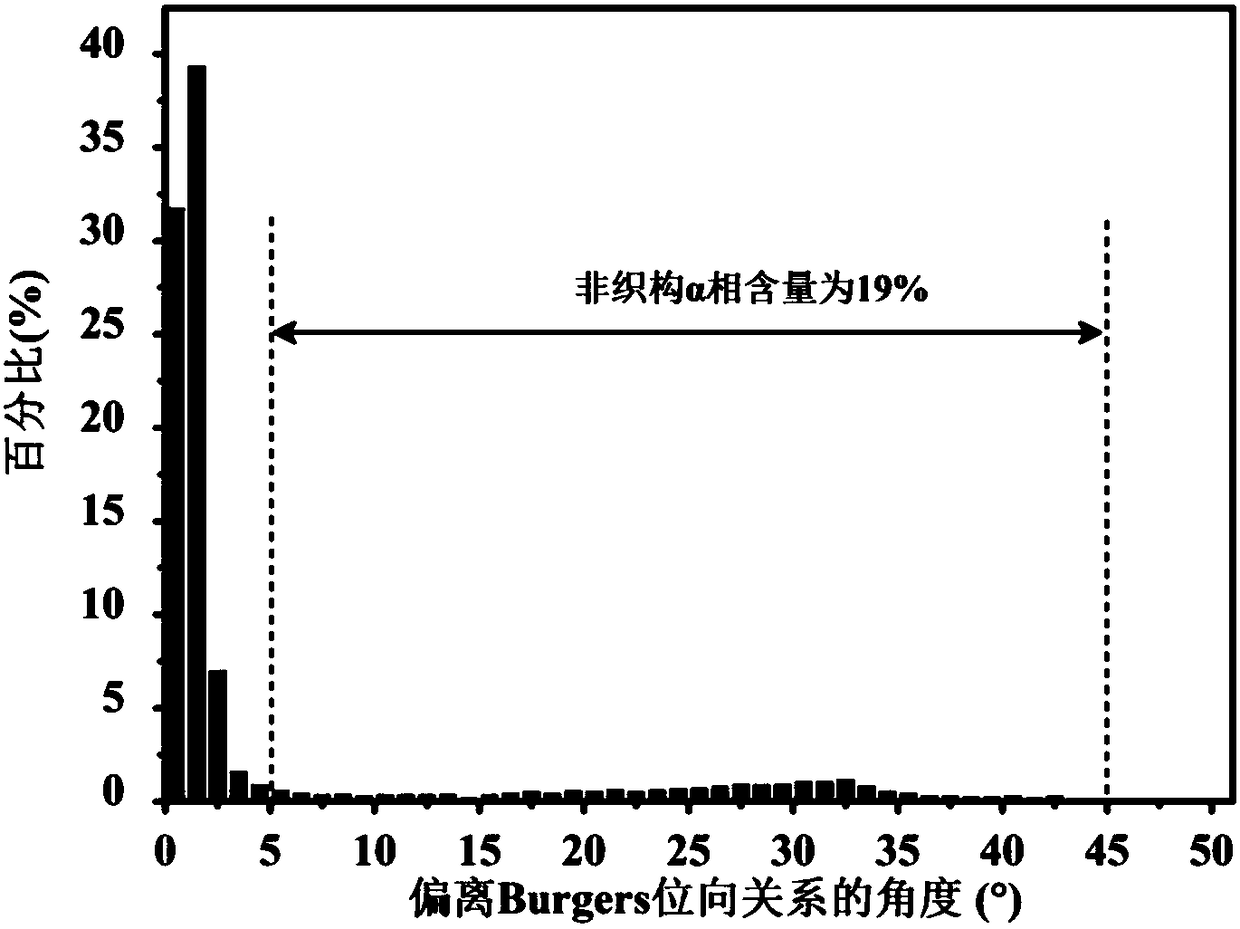

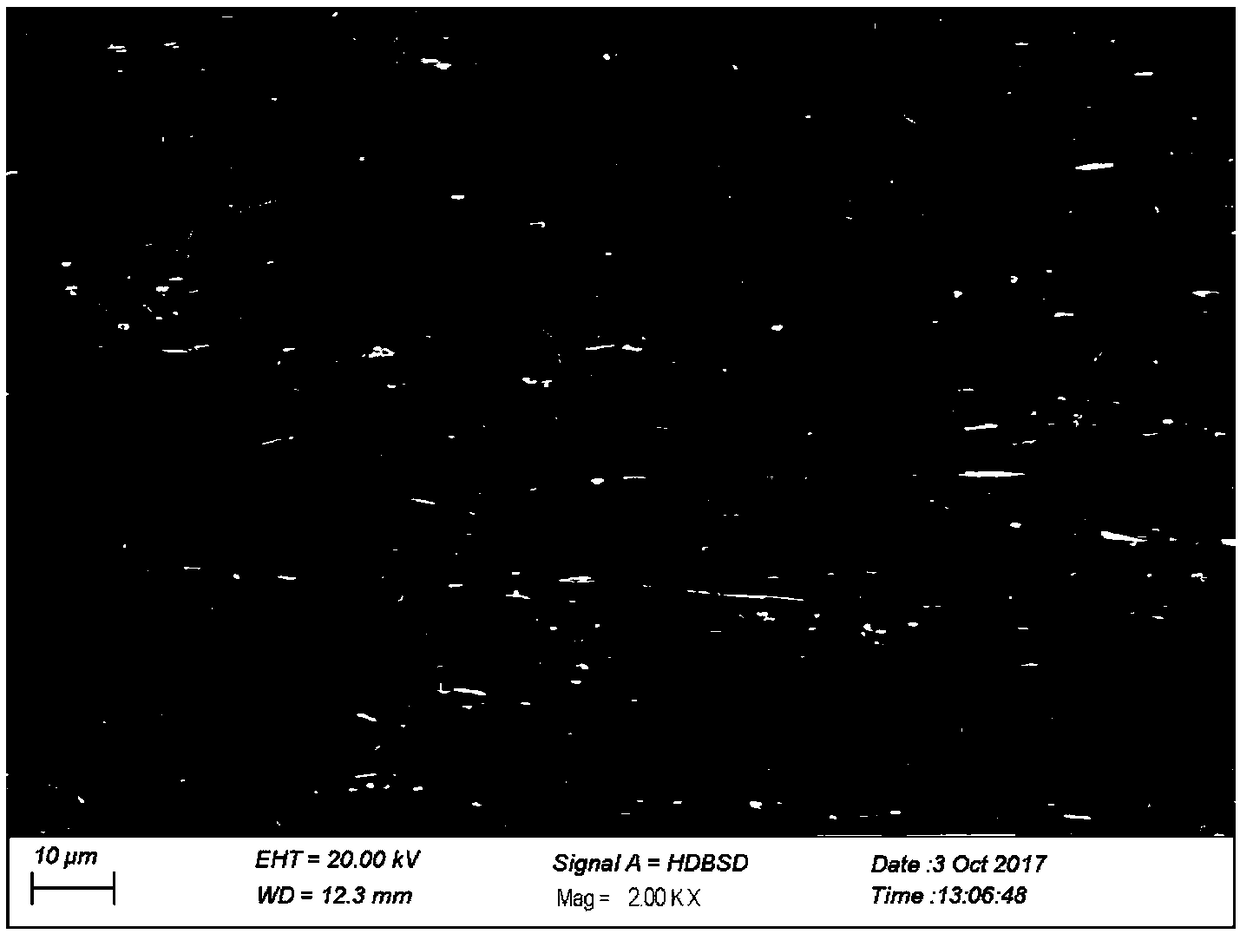

Method for weakening phase-change texture of high-niobium titanium-aluminum alloy

The invention discloses a method for weakening the phase-change texture of a high-niobium titanium-aluminum alloy, and belongs to the technical field of metal hot-working. According to the method forweakening the phase-change texture of the high-niobium titanium-aluminum alloy, the phase-change texture of the titanium-aluminum alloy is weakened through pre-deformation of a beta single-phase area,operation is easy, the cycle is short, and the production cost is greatly reduced. Compared with a heat treatment method, the method has a short cycle. Compared with a boron adding method, through pre-deformation of the beta single-phase area of the high-niobium titanium-aluminum alloy, thick strip-shaped TiB can be crushed, and thus, the number of heterogeneous nucleation mass points for promoting a non-texture alpha phase is increased. Meanwhile, due to different deformation mechanisms of TiB and a beta phase, the orientation relationship between TiB and the beta phase is changed in the pre-deformation process, the original orientation relationship: {110}betaI (001) and (111) betaI [001] TiB is destroyed, so that it is ensured that the alpha phase separated from borides is a non-texturealphas phase, stress concentration of the high-niobium titanium-aluminum alloy is reduced, crank growth channels are made random, and the tearing tendency of the alloy is weakened.

Owner:SHAANXI UNIV OF SCI & TECH

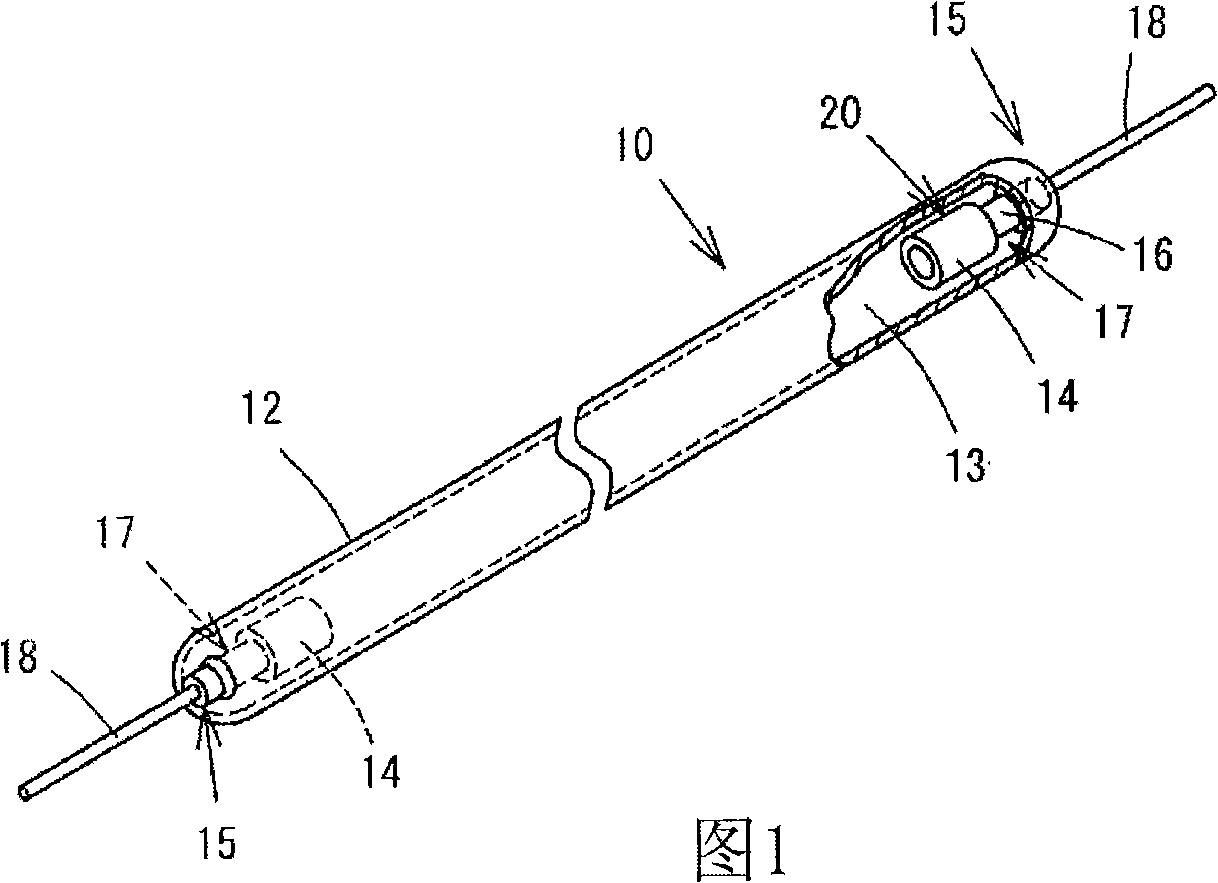

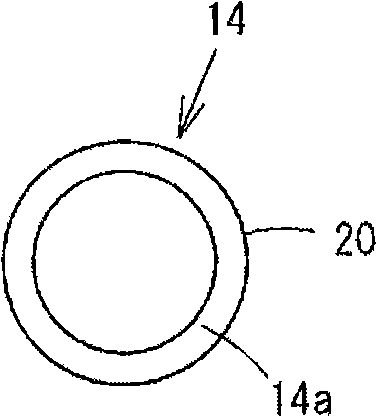

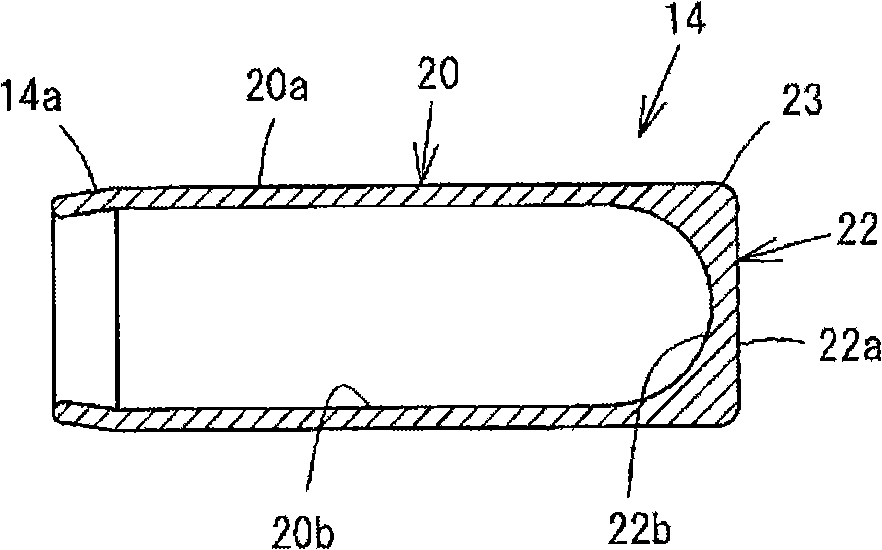

Electrode for cold cathode fluorescent tube

The present invention provides a electrode for a cold-cathode fluorescent tube, which is composed of a tube body and a tube bottom with integrated molding of plastic property cylindrical metal billet, further having: forming a cylindrical tube body outer peripheral surface; the outer peripheral surface of the tube body being right-angle and forming a even bottom outer peripheral surface; forming a cylindrical tube body inner peripheral surface at the tube body outer peripheral surface; and forming a bottom inner peripheral surface with a rotator-shape concave surface at the central shaft to from the tube body inner peripheral surface gently and continuously. The thickness of the wall observing from the tube body to the tube bottom, the corner part between the tube body outer peripheral surface and the tube bottom outer peripheral surface, is bigger than that between the tube body outer peripheral surface and the tube body inner peripheral surface continuously.

Owner:FINECS

Preparation method for Nb-Si-based complex alloy

InactiveCN102418025BImprove room temperature performanceShort manufacturing cycleRoom temperatureOxidation resistant

The invention discloses a structure controlled preparation method for an Nb-Si-based complex alloy. According to the method, the structure of the Nb-Si-based complex alloy is controlled by adopting a combined process of unbalanced quick directional solidification and heat treatment; and the faceted growth property of silicide in the alloy is weakened, dimensions of a reinforcing phase Nb5Si3 and an anti-oxidation phase Cr2Nb in the alloy are remarkably reduced, a Nbss phase is used as the matrix in the steady-state structure of the Nb-Si-based complex alloy, the reinforcing phase Nb5Si3 is uniformly distributed on the matrix in a wormlike shape, and the anti-oxidation phase Cr2Nb is uniformly distributed or fixedly dissolved in the matrix in a granular shape, wherein the average length of the wormlike Nb5Si3 phase is less than 20 microns, the width of the Nb5Si3 phase is 5 microns, the size of the granular Cr2Nb phase is less than 10 microns, and the content of the two phases is not less than 35 percent. By structure control, the alloy contains enough Nb5Si3 and Cr2Nb phases, so that the alloy has good room temperature toughness and ductility on the premise of achieving excellent high-temperature mechanical property and oxidation resistance.

Owner:BEIHANG UNIV

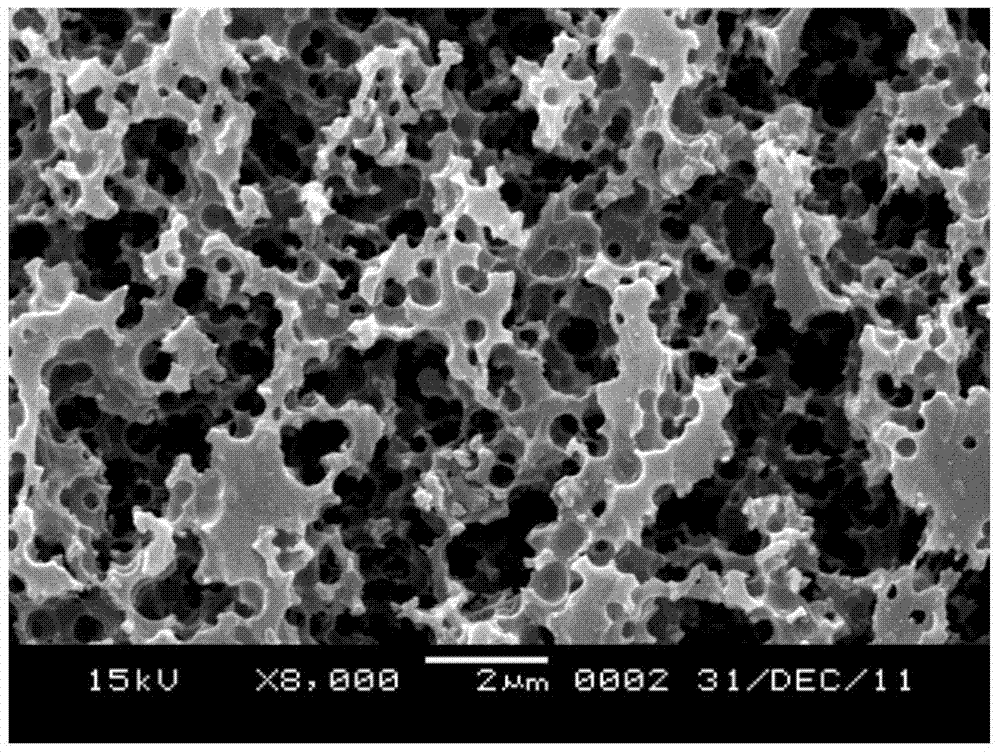

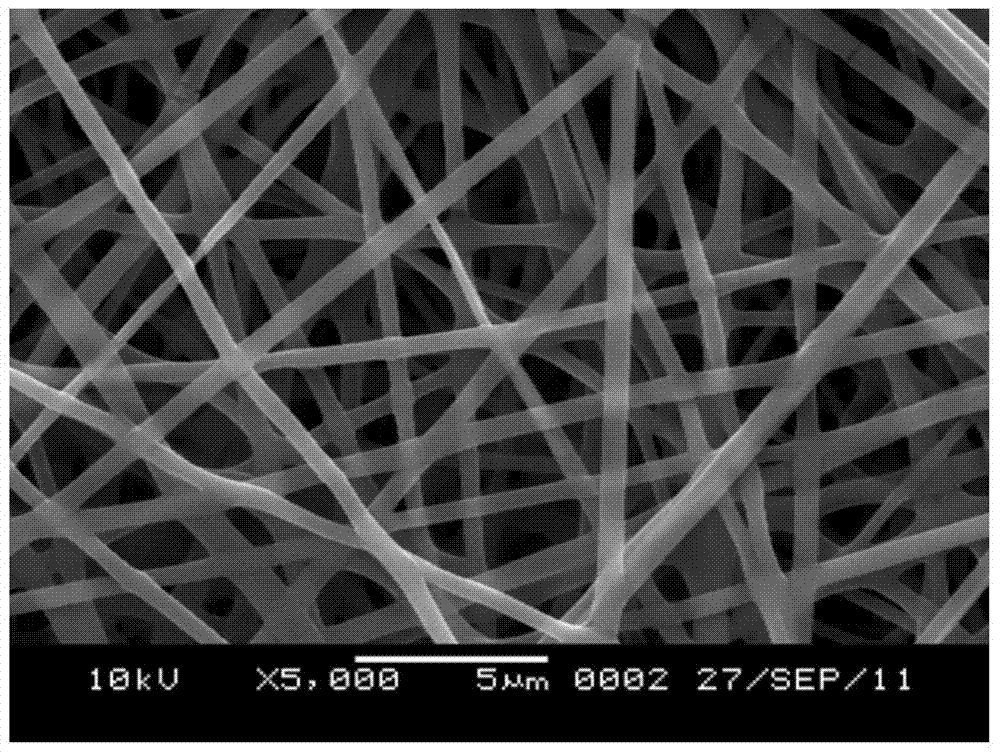

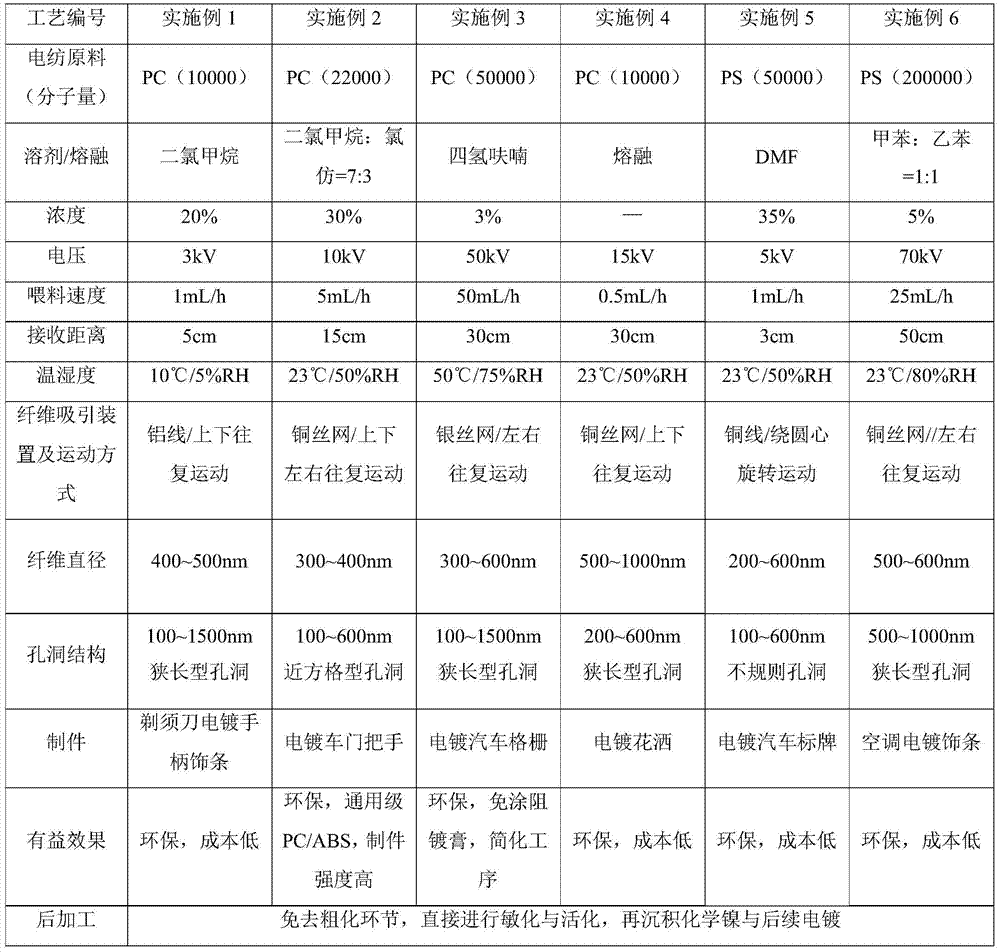

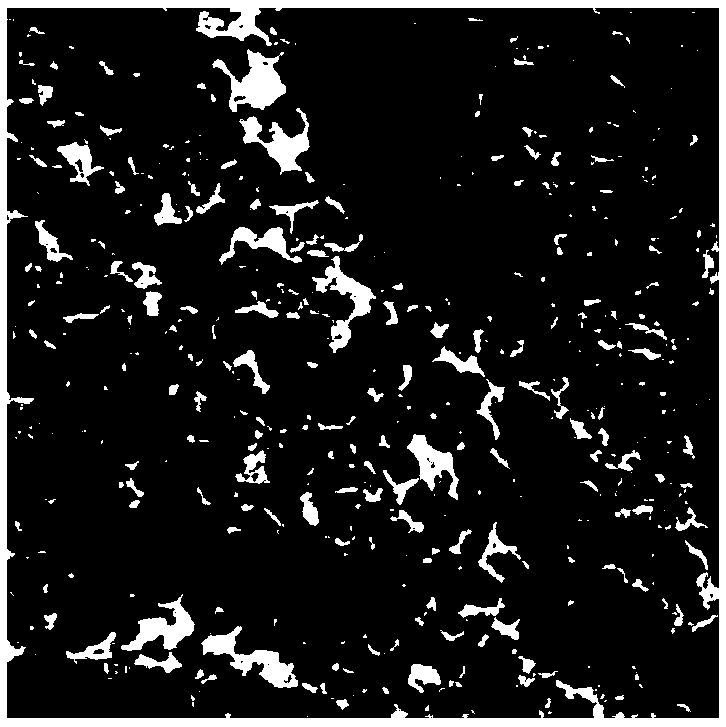

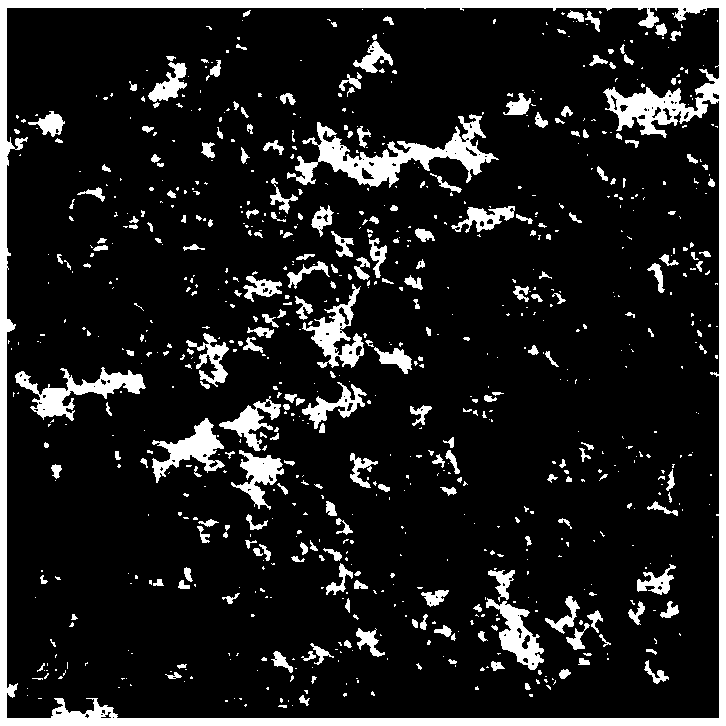

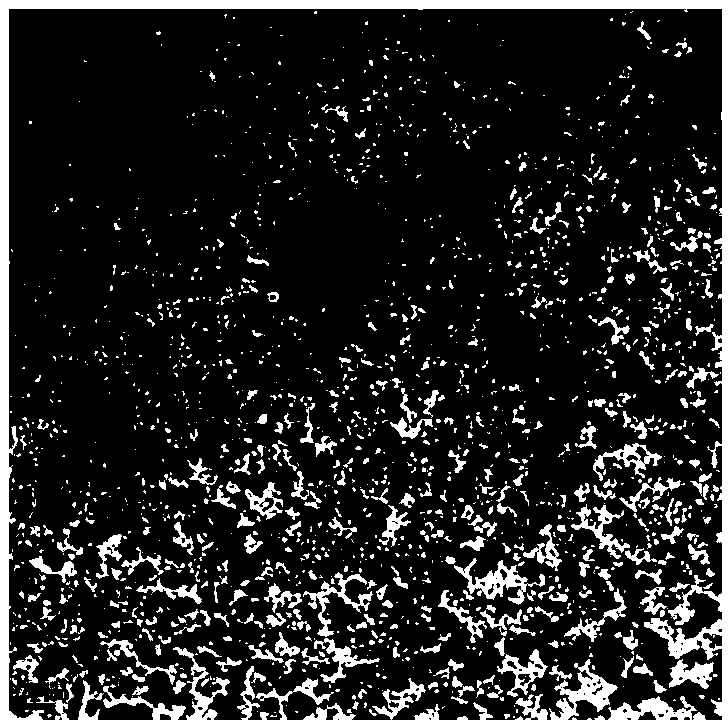

A kind of pre-plating treatment method of plastic parts for electroplating

ActiveCN105200669BReduce coarseningReduce usageFilament/thread formingNon-woven fabricsFiberPretreatment method

The invention relates to an electroplating pretreatment method for plastic parts for electroplating, and belongs to the technical field of plastic material treatment. The method comprises the steps that a plastic part for electroplating is fixed to a receiving pole of an electrostatic spinning device, and a polymer solution or melt forms nano-scale fiber through the electrostatic spinning device to be deposited on the surface of the plastic product, so that an electrospun film layer with a large number of submicron-order holes is formed on the surface of the plastic part. Compared with the prior art, the proper surface hole structure is given to the plastic part to be plated through the electrostatic spinning technology, so that the plastic part treated through the method can obtain the surface appearance where metal can be deposited without roughening, and can be put on a line for directly conducting sensitization, activation and electroplating.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Heat treatment method of promoting precipitation of nano-scale carbide in W-containing alloy steel

Owner:WUHAN UNIV OF SCI & TECH

Preparation method for lost foam casting of high-entropy alloy particle-reinforced magnesium-based composite material

PendingCN111719074AGood heredityReduce coarseningFoundry mouldsFoundry coresMagnesium matrix compositeHigh entropy alloys

The invention relates to a preparation method for a magnesium-based composite material, in particular to a preparation method for lost foam casting of a high-entropy alloy particle-reinforced magnesium-based composite material. The method aims to solve the technical problem that in the preparation process of an existing magnesium-based composite material, the addition proportion of magnesium alloywaste is small, and the strength is poor when a large amount of magnesium alloy waste is added. By adopting a lost foam casting method, utilizing two-way shear stirring, adding high-entropy alloy particles and performing ultrasonic treatment in the casting process, structure heredity is effectively improved, uneven dispersion of the particles at different positions of a magnesium alloy melt is avoided, structure coarsening is reduced, grain growth in the solidification process is inhibited, grains are refined, the utilization rate of magnesium alloy waste is increased, and the performance ofthe lost foam casting product is improved. In the method, the utilization rate of AZ91D waste is high, the maximum waste addition amount accounts for 34% of the total mass, raw materials are saved, and costs are reduced. The method is also suitable for continuous production operation and is an environment-friendly method.

Owner:哈尔滨吉星机械工程有限公司 +1

Low-chrome-alloy grinding ball

The invention belongs to the field of casing manufacturing and particularly relates to a low-chrome-alloy grinding ball. The low-chrome-alloy grinding ball is prepared from 2.0-3.3% of C, 1.75-2.2% ofSi, 1.3-2.6% of Mn, 1.5-2.5% of Cr, 0.25-0.50% of Cu, 0.05-0.12% of Ti, smaller than or equal to 0.02% of S, smaller than or equal to 0.02% of P and the balance Fe. According to the low-chrome-alloygrinding ball, through reasonable matching of high chrome alloy, the content of precious metal Mo is lowered, and the cost is reduced. The obtained high-chrome casting gold material is high in rigidity and impact toughness, the HRC can reach 60, and the impact value reaches 12 J / cm<2>. The impact fatigue life of a falling sphere is greater than or equal to 9,500 times, the damage percentage is smaller than 0.9%, and the cost is lowered.

Owner:安徽宁星铸造有限公司

Electroplating process and electroplated part prepared by applying electroplating process

InactiveCN103184495AThe material is not particularly limitedReduce coarseningPretreated surfacesCoatingsMetal powderIrradiation

The invention discloses an electroplating process. The electroplating process comprises the following steps of: providing a plastic matrix; forming a paint layer containing a metal powder and a paint on the surface of the plastic matrix by spraying; performing laser irradiation treatment on the paint layer to change the paint layer into a combined coating; and performing electroplating on the surface of the combined layer to form an electroplated layer. The electroplating process is simple, the manufacturing procedures of coarsening and activating of the conventional electroplating process are reduced, and special limits on the material of the plastic matrix are not required. Additionally, the invention further provides an electroplated part prepared by the process aforementioned.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Sn-Bi alloy material and preparation method and application thereof

ActiveCN114807676AReduce coarseningReduce brittlenessAdditive manufacturing apparatusIncreasing energy efficiencyThermal fatigueAlloy

The invention provides a Sn-Bi alloy material and a preparation method and application thereof, and relates to the technical field of alloy materials. The Sn-Bi alloy material provided by the invention comprises the following components in percentage by mass: 40% of Sn, 58% of Bi, 0.04% of Cu, 1.76% of Al and 0.2% of Me, and Me is one or more of La, Ce and Sr. By adding Cu, Al and Me into the Sn-Bi alloy, coarsening and brittleness of Bi can be relieved, and the alloy performance is improved; a proper amount of Al can improve the alloy strength of the solder, improve the plasticity of the solder and improve the thermal fatigue strength; a proper amount of La, Ce and Sr can improve the physical and chemical properties of the alloy, improve the room-temperature and high-temperature mechanical properties of the alloy, increase the ductility, improve the wettability and improve the impact strength, and can meet the requirements of a low-melting-point alloy material for 3D printing.

Owner:カン州晨光希土新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com