Method for production of alloyed titanium welding wire

a technology of alloyed titanium and welding wire, which is applied in the direction of metal-working equipment, extrusion dies, welding/cutting media/materials, etc., can solve the problems of restricted range of titanium alloys that are commercially feasible, and loss of reinforcing particles, etc., to avoid pollution of titanium alloys, increase lubrication effect, and resist high shear forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

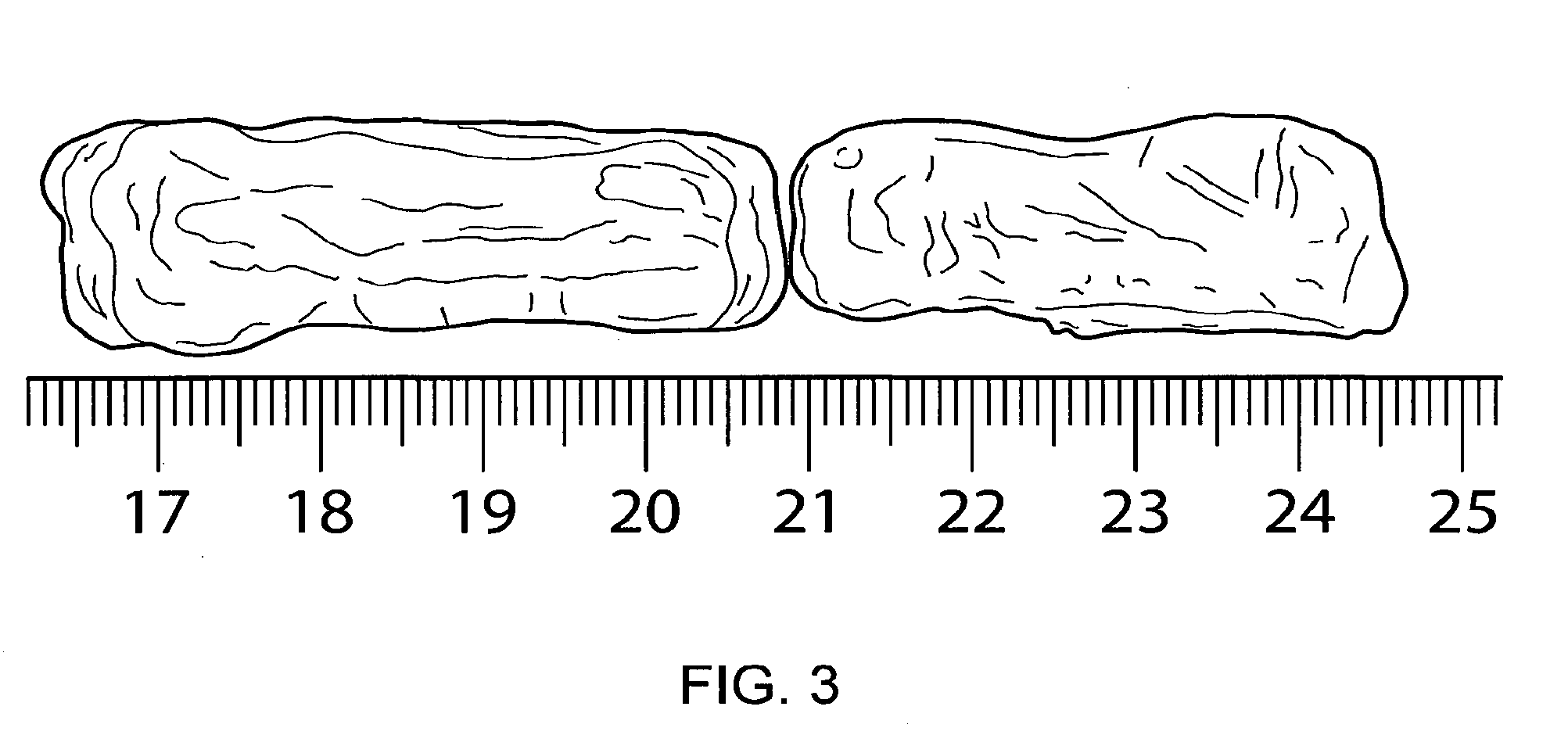

[0044]A series of 18 cylindrical billets with diameter 80 mm were made as follows: Crushed titanium sponge with particle sizes from 0.5 to 8 mm, with the main fraction of 1 to 4 mm was mixed with 10 weight % (based on weight of titanium sponge) of master-alloy 433-6 with average particle size fraction from 100 to 250 μm and 0.8 weight % (based on total amount of the mixture) of a commercial composite lubricant sold under the trademark Metallub® from Höganes AB of Sweden. The mixture was blended in a cement mixer until substantially homogeneous composition.

[0045]Each billet was then made by compacting an amount of the powder by loading it stepwise into the chamber of a uniaxial press with a floating die and subject the powder to a stepwise pressure increase. Typical pressing procedure was; initially loading about ¼ of the mixture into the press chamber and applying a pressure of about 20 MPa. Then add another ¼ of the mixture into the press chamber and applying a pressure of about 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size fraction | aaaaa | aaaaa |

| particle size fraction | aaaaa | aaaaa |

| particle size fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com