Copper surface super-coarsening solution for circuit board as well as preparation method and application of copper surface super-coarsening solution

A circuit board and ultra-roughening technology, applied in the field of circuit board manufacturing, can solve the problems of unstable roughening solution, increased process, easy oxidation of copper surface, etc., so as to improve AOI detection efficiency, prevent false point problems, and reduce copper The effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

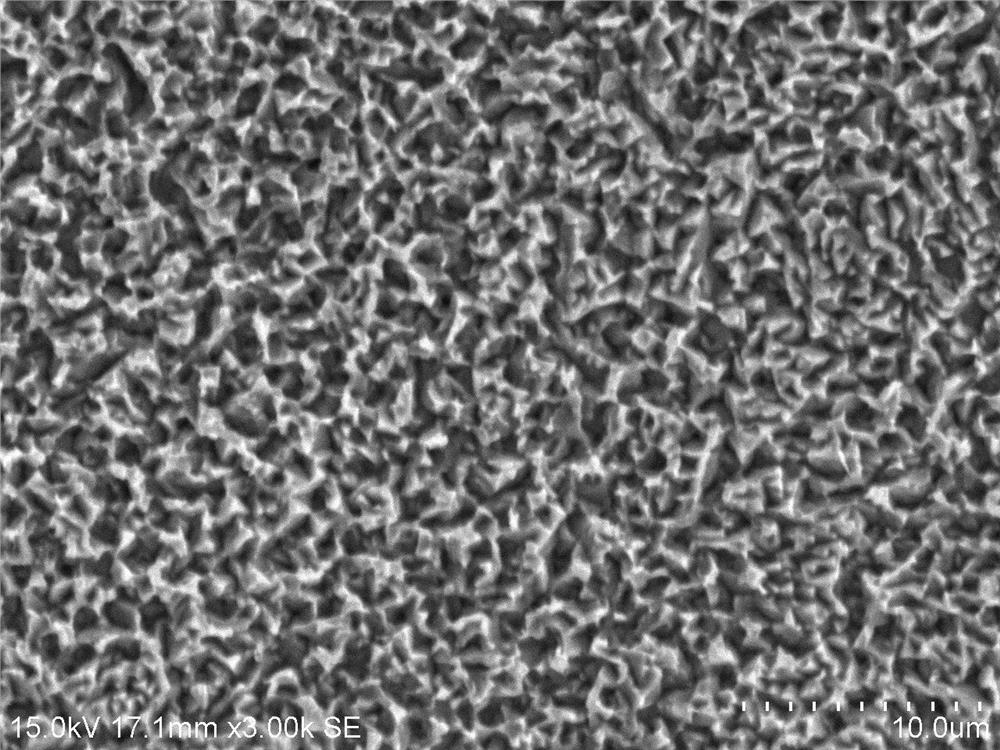

Image

Examples

preparation example Construction

[0031] The preparation method of copper surface ultra-roughening solution for circuit board:

[0032] S1. Add sulfuric acid into an appropriate amount of water, stir and dissolve, and mix evenly to obtain a phase A solution;

[0033] S2. Add 1,4-butanediol, 2-acetamido-5-mercapto-1,3,4-thiadiazole and 2-mercapto-1-methylimidazole to the phase A solution, stir to dissolve, and mix evenly The B-phase solution is then obtained;

[0034] S3. Add hydrogen peroxide to the B-phase solution, stir to dissolve, and mix evenly to obtain a C-phase solution;

[0035] S4. Add cyclohexanone, methoxylated polyethylene glycol, acetic acid, butanol phosphate to the C-phase solution, stir to dissolve, and add water to a standard volume to obtain the copper surface ultra-roughening solution for circuit boards.

[0036] Ultra-coarsening method:

[0037] a. Board surface cleaning (degreasing or brushing); b. The first washing; c. The copper surface is super-roughened; d. The second washing; e. Pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com