Heat treatment method of promoting precipitation of nano-scale carbide in W-containing alloy steel

A heat treatment method and carbide technology, applied in the field of heat treatment to promote the precipitation of nano-carbides in W-containing alloy steel, can solve the problems of complex heat treatment process, complex alloy composition, low production efficiency, etc., and achieve improved solid solution strengthening and process The effect of simple process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A heat treatment method for promoting the precipitation of nano-carbides in W-containing alloy steel. First, the steel billet is soaked at 1100-1150° C. for 36-48 hours, and then cooled to room temperature with the furnace. Then austenitize at 900-1000°C for 20-30min, and quench in ice-brine, the temperature of which is -3--1°C. Then at a vacuum of 10 -3 ~10 -2 Under the conditions of Pa and magnetic field strength of 10-13T, heat to 700-750°C at a rate of 3-7°C / min, hold the temperature for 0.5-2.5h, and cool to room temperature.

[0021] The chemical composition of the billet is: C is 0.06-0.12wt%, W is 1.50-2.50wt%, P<0.01wt%, S<0.005wt%, and the rest is Fe and unavoidable impurities.

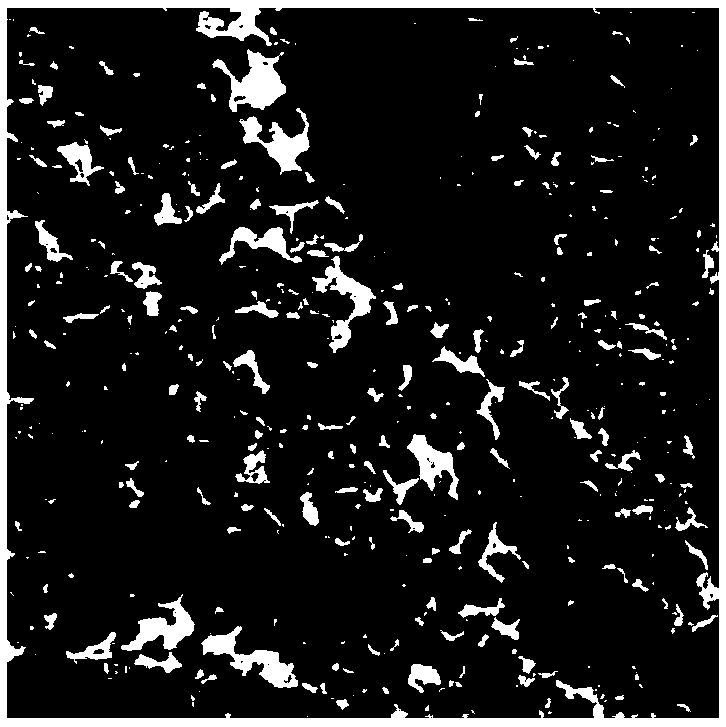

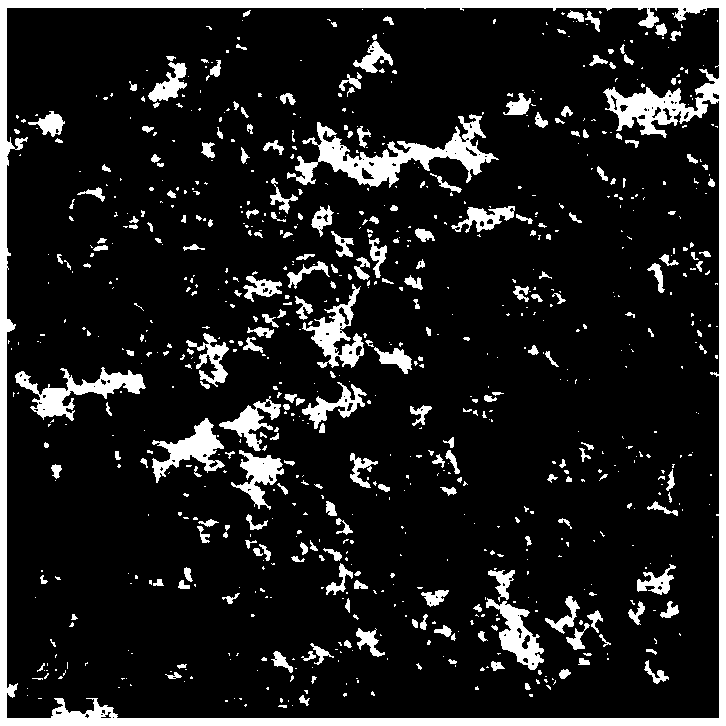

[0022] figure 1 It is a transmission electron microscope image of nano-precipitation of W-containing alloy steel obtained by a kind of heat treatment method described in this embodiment, figure 2 It is the same as the rest except no strong magnetic field figure 1 The transmissio...

Embodiment 2

[0025] A heat treatment method for promoting the precipitation of nano-carbides in W-containing alloy steel. Firstly, the billet is soaked at 1150-1200° C. for 24-36 hours, and then cooled to room temperature with the furnace. Then austenitize at 850-950°C for 30-40min, and quench in ice-brine, the temperature of the ice-brine is -3--1°C. Then the vacuum is 10 -3 ~10 -2 Under the conditions of Pa and magnetic field strength of 11-14T, heat to 650-700°C at a rate of 3-7°C / min, hold the temperature for 1.0-3.0h, and cool to room temperature.

[0026] The chemical composition of the billet is: C is 0.08-0.14wt%, W is 2.00-3.00wt%, P<0.01wt%, S<0.005wt%, and the rest is Fe and unavoidable impurities.

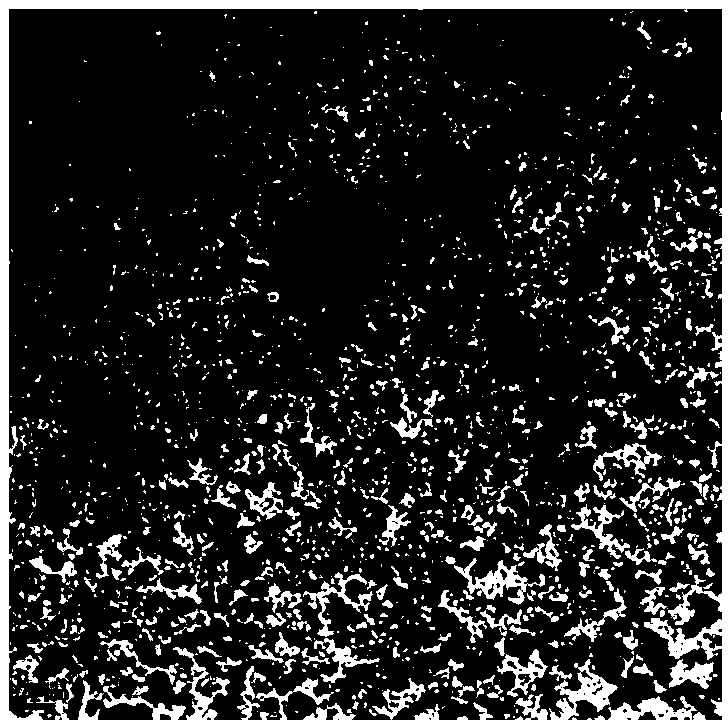

[0027] image 3 It is a transmission electron microscope image of nano-precipitation of W-containing alloy steel obtained by a kind of heat treatment method described in this embodiment, Figure 4 It is the same as the rest except no strong magnetic field image 3 The transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com