Sn-Bi alloy material and preparation method and application thereof

An alloy material, sn-bi technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems of affecting processing performance, plasticity reduction, and small ductility, so as to improve thermal fatigue strength, improve wettability, and increase ductility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

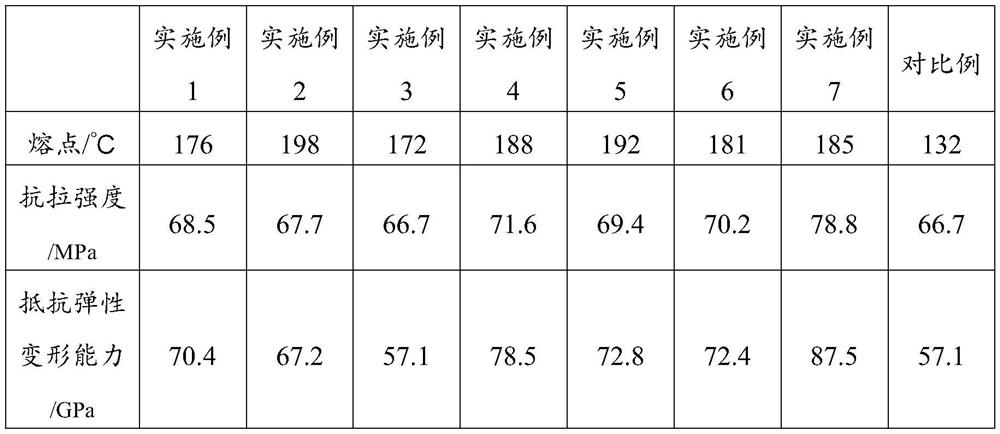

Examples

preparation example Construction

[0021] The present invention provides the preparation method of the Sn-Bi alloy material described in the above technical solution, comprising the following steps:

[0022] The Sn-Bi alloy, the Al-Cu-Me alloy and the covering agent are mixed and smelted to obtain an alloy liquid; the ratio of the Sn-Bi alloy and the Al-Cu-Me alloy is the same as that of the Sn-Bi system described in the above technical solution. The composition of the alloy material is the same;

[0023] The alloy liquid was cast to obtain a Sn-Bi-based alloy material.

[0024] In the present invention, the Sn-Bi alloy, the Al-Cu-Me alloy and the covering agent are mixed and smelted to obtain the alloy liquid. In the present invention, the preparation method of the Sn-Bi alloy preferably includes: placing tin and bismuth in a graphite crucible, melting, and cooling to obtain the Sn-Bi alloy. In the present invention, the mass ratio of tin and bismuth is 40:58. In the present invention, the melting temperatu...

Embodiment 1

[0034] Weigh 400 g of metallic tin and 580 g of metallic bismuth, put them into a graphite crucible, place them in a resistance furnace and heat up to 300 ° C to melt, keep warm for 1 hour under the protection of an inert gas argon gas, mechanically stir 3 times during this period, and naturally cool to obtain a Sn-Bi alloy. .

[0035] Weigh 50 g of Al-10wt% La alloy, 1 g of copper powder, and 12 g of 48wt% NaCl-52wt% KCl covering agent, put them into a graphite crucible, put them in a resistance furnace and heat up to 850 ℃ to melt, keep the temperature for 1 hour, and mechanically stir for 3 Second, natural cooling to obtain Al-2wt%Cu-10wt%La alloy.

[0036] Mix 500g of the Sn-Bi alloy, 10g of the Al-2wt%Cu-10wt%La alloy and 100g of the 48wt%NaCl-52wt%KCl covering agent, melt each component at 750℃ for 30min, reduce the temperature to 350℃ and keep warm During 1 hour, mechanical stirring was performed twice, poured into a mold, and cast to obtain a 40wt% Sn-58wt%Bi-0.04wt%C...

Embodiment 2

[0039] Weigh 400 g of metallic tin and 580 g of metallic bismuth, put them into a graphite crucible, place them in a resistance furnace and heat up to 300 ° C to melt, keep warm for 1 hour under the protection of an inert gas argon gas, mechanically stir 3 times during this period, and naturally cool to obtain a Sn-Bi alloy. .

[0040] Weigh 50 g of Al-10wt% Ce alloy, 1 g of copper powder, and 12 g of 48wt% NaCl-52wt% KCl covering agent, put them into a graphite crucible, place them in a resistance furnace and heat up to 850 ℃ to melt, keep the temperature for 1 hour, and mechanically stir for 3 Second, natural cooling to obtain Al-2wt%Cu-10wt%Ce alloy.

[0041] Mix 500g of the Sn-Bi alloy, 10g of the Al-2wt%Cu-10wt%Ce alloy and 100g of a 48wt%NaCl-52wt%KCl covering agent, melt each component at 750°C for 30min, and reduce the temperature to 350°C for heat preservation During 1 hour, mechanical stirring was performed twice, poured into a mold, and cast to obtain a 40wt% Sn-58...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com