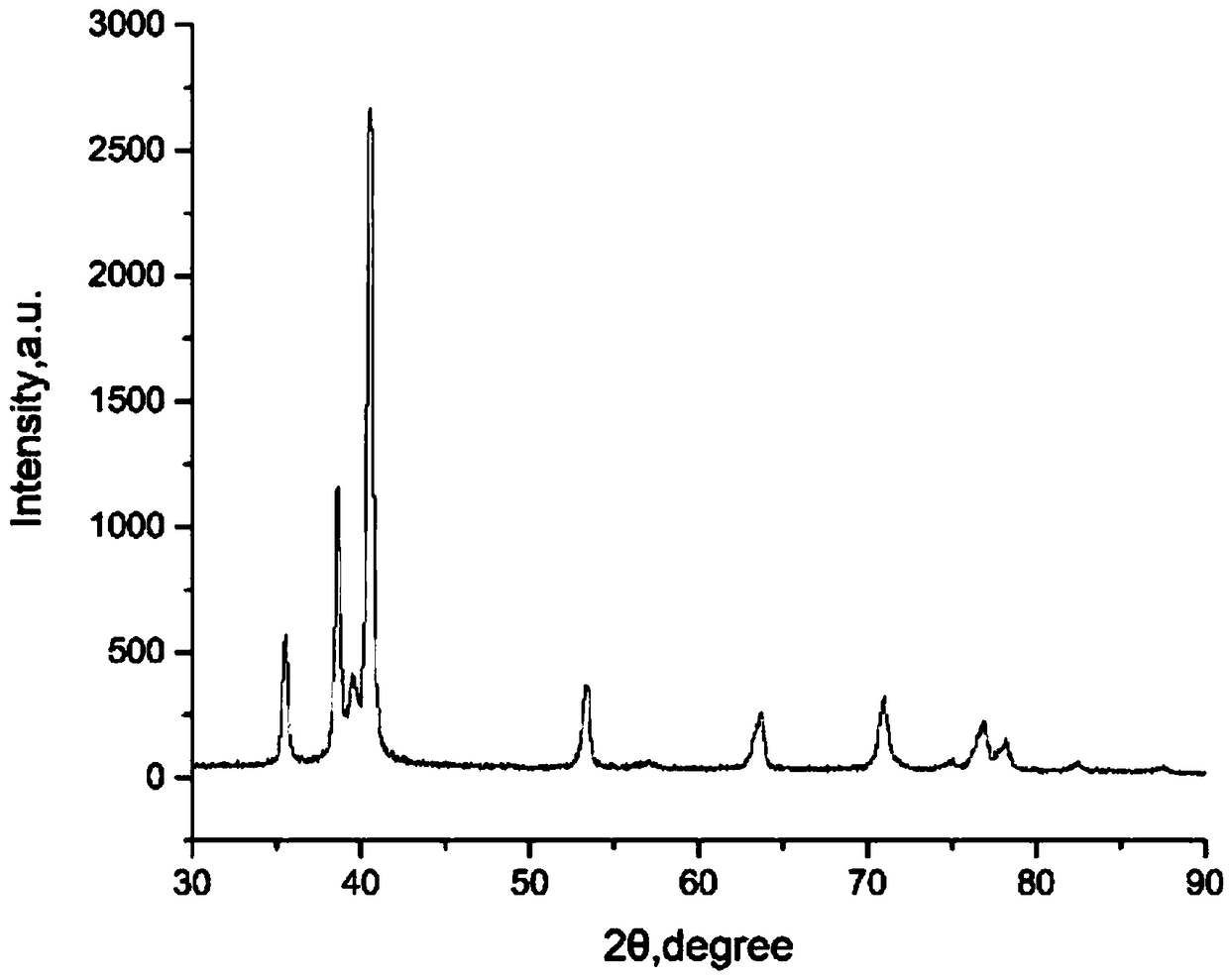

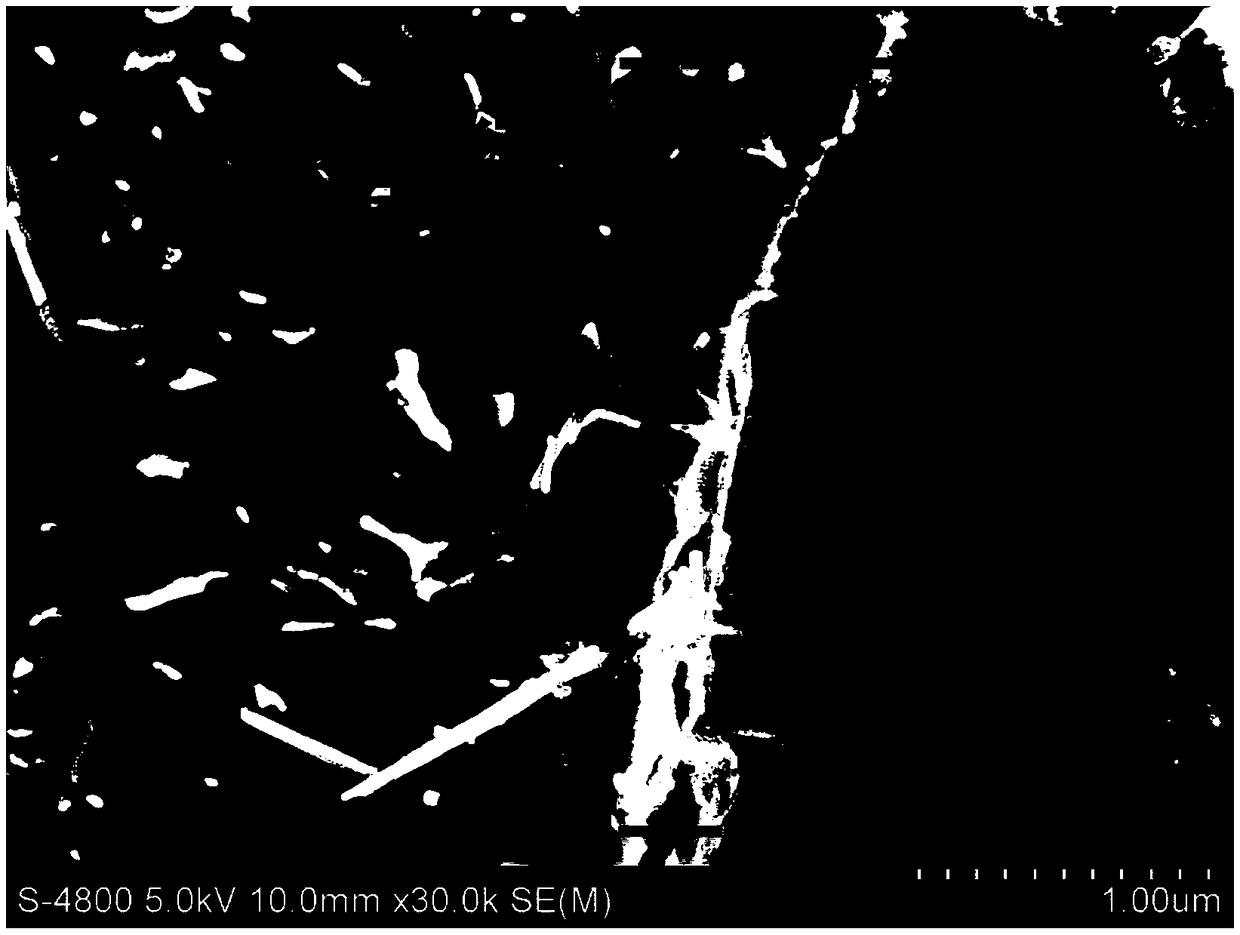

Preparation method of directionally-distributed TiB whisker reinforced titanium-based composite material

A titanium-based composite material, directional arrangement technology, applied in the field of metal-based composite materials, can solve the problem of not being able to maximize the strengthening effect of TiB whiskers, achieve good interface bonding and coherent relationship, small diameter, reduce matrix The effect of grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

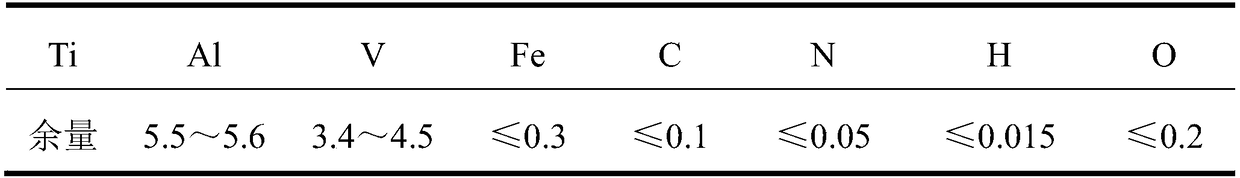

Embodiment 1

[0053] A preparation method of oriented TiB whisker reinforced titanium-based composite material, the method steps are as follows:

[0054] (1) Add 0.02g nano TiB 2 Add the powder and 19.98g TC4 powder into the ball mill tank of the SM-QB planetary ball mill, and add the ball and excess ethanol according to the ball-to-battery ratio of 2:1; ball mill for 0.5h at 600r / min and mix well Obtain a mixed slurry; pour the mixed slurry into a vacuum rotary evaporator, steam for 0.2h at a speed of 100r / min and a water bath temperature of 80°C, and obtain a mixed powder precursor after the ball milling medium is volatilized; The powder precursor is put into an electric heating constant temperature blast drying box and dried at 60° C. for 1 hour to obtain a mixed powder.

[0055] Among them, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 0.1:1, the diameter of the large agate ball is 10mm, and the diameter of the small agate ball is 1mm.

[0056...

Embodiment 2

[0081] A preparation method of oriented TiB whisker reinforced titanium-based composite material, the method steps are as follows:

[0082] (1) Add 0.09g nano TiB 2 Add powder and 19.91g of TC4 powder into the ball mill tank of SM-QB planetary ball mill, and add the ball and excess ethanol according to the ball-to-battery ratio of 4:1; ball mill for 2h at 300r / min, and mix well. Mixed slurry; Pour the mixed slurry into a vacuum rotary evaporator, and steam for 2 hours at a speed of 40r / min and a water bath temperature of 70°C. After the ball milling medium is volatilized, a mixed powder precursor is obtained; before the mixed powder The body is put into an electric heating constant temperature blast drying box and dried at 30°C for 0.5 h to obtain a mixed powder.

[0083] Among them, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 1:1, the diameter of the large agate ball is 10mm, and the diameter of the small agate ball is 5mm.

[008...

Embodiment 3

[0109] A method for preparing TiB whisker-reinforced titanium-based composite material with directional arrangement, the method steps are as follows:

[0110] (1) Add 6.00g nano TiB 2 The powder and 14.00g Ti powder are added to the ball milling tank of the SM-QB planetary ball mill, and the ball and excess ethanol are added according to the ball-to-battery ratio of 10:1; at a speed of 150r / min, the ball is milled for 5.0h and mixed evenly Obtain a mixed slurry; pour the mixed slurry into a vacuum rotary evaporator, steam for 0.5h at a speed of 40r / min and a water bath temperature of 70°C, and obtain a mixed powder precursor after the ball milling medium is volatilized; The powder precursor is put into an electric heating constant temperature blast drying box and dried at 30°C for 0.5 h to obtain a mixed powder.

[0111] Among them, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 10:1, the diameter of the large agate ball is 30mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com