High-performance light magnesium-based alloy material and preparation method thereof

A technology based on alloys and light magnesium, which is applied in the field of metal material processing, can solve problems such as the difficulty in balancing the mechanical properties and structural properties of rare earth elements, affecting the strength and plasticity of material alloys, and the safety of high-risk experiments, so as to achieve organizational optimization. , uniform organization, and the effect of avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

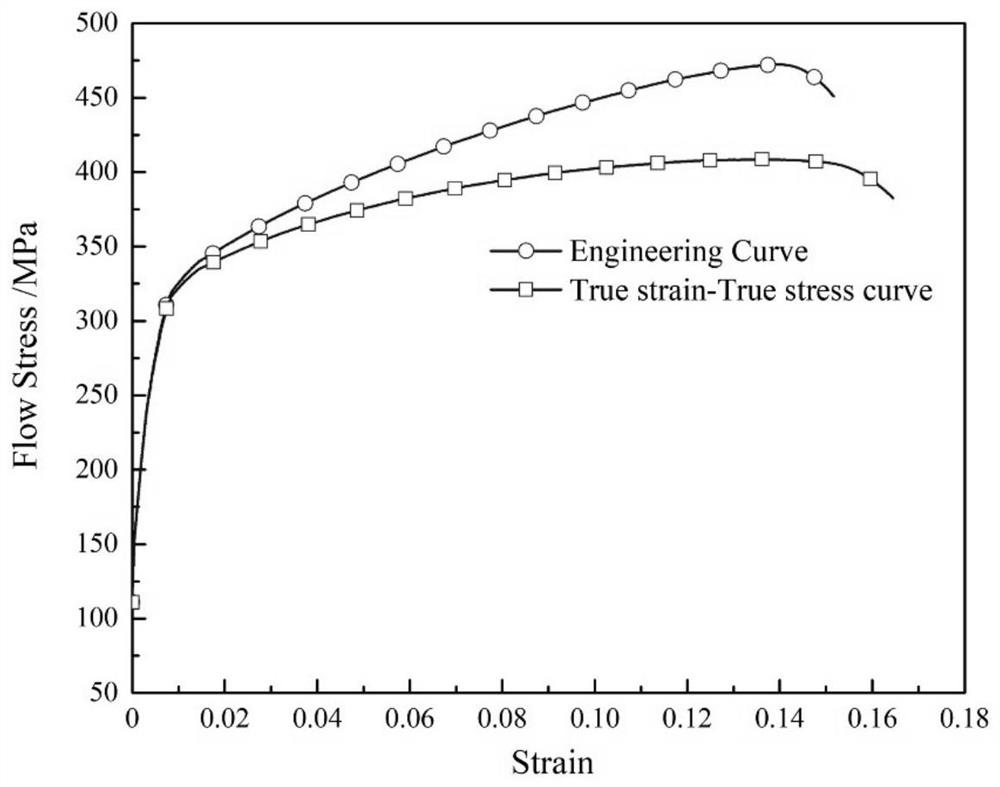

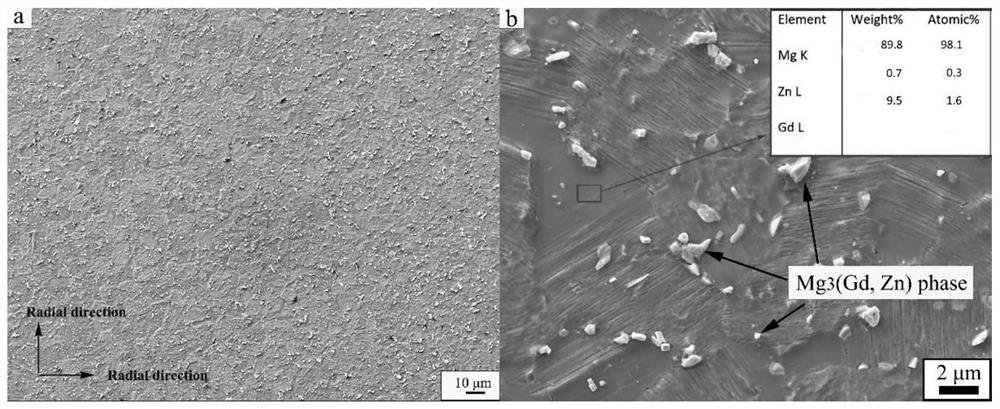

[0033] This embodiment of the high performance (uniform tissue, excellent mechanical properties) preparation of magnesium-based light alloy material, including mother alloy melting, rapid solidification step Tissue Preparation, spark plasma sintering, comprises:

[0034](1) Configuration mother alloy composition: composition according to the mother alloy to be synthesized is performed Mg-15Gd-1Zn (percent by mass wt%) of ingredients, melting the master alloy is cast alloy by resistance heating furnace smelting, specific: first, the total amount of the ingredients 60wt% magnesium, Mg-Gd master alloy ingot into a stainless steel material or a graphite crucible, crucible, and placed in a resistance heating furnace, the temperature was raised to 740 ℃, incubated 5min, until the starting material melted, then all of the remaining 40wt% of raw material charging into a crucible, and continue to heat up to 720 ℃ incubated 10min, followed by sufficient stirring and the solution was allowed...

Embodiment 2

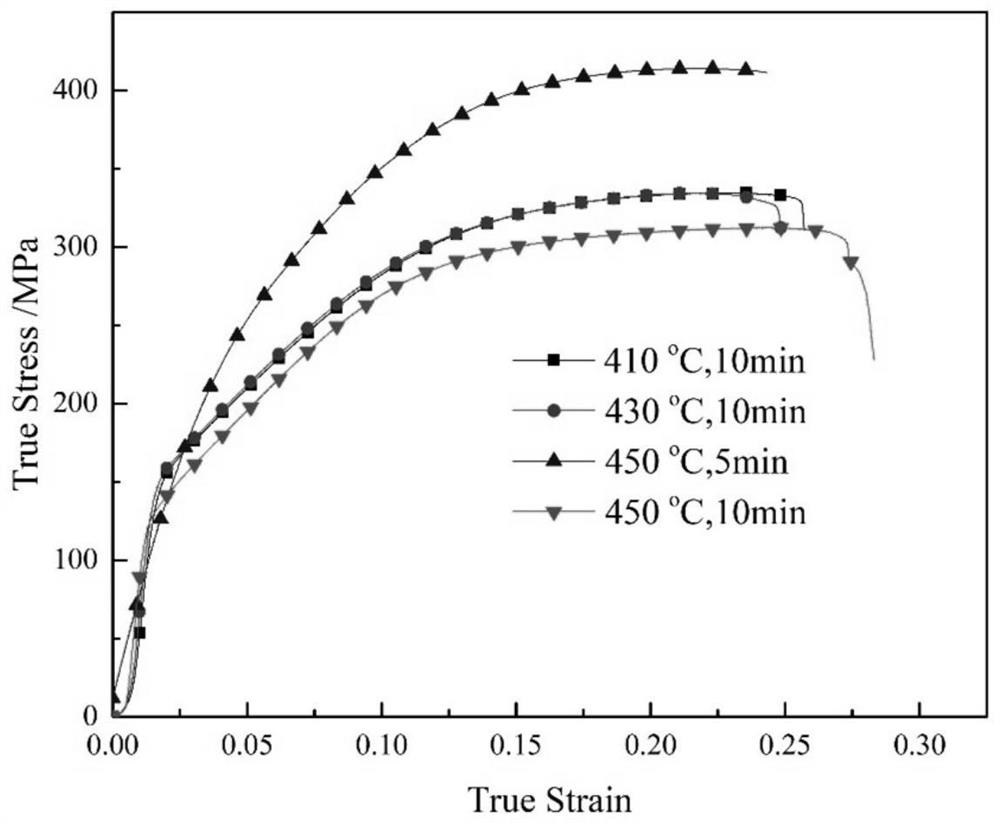

[0039] This embodiment of the high performance (uniform tissue, excellent mechanical properties) preparation of magnesium-based light alloy material, including mother alloy melting, rapid solidification step Tissue Preparation, spark plasma sintering, comprises:

[0040] (1) Configuration mother alloy composition: composition according to the mother alloy to be synthesized Mg-6Gd-5Zn (percent by mass) as compounding, melting of the master alloy is cast alloy by resistance heating furnace smelting, specifically: First, 70wt% of the total amount of the ingredients of magnesium, Mg-Gd master alloy ingot into a stainless steel material or a graphite crucible, crucible, and placed in a resistance heating furnace, the temperature was raised to 720 ℃, incubated 5min, until the raw material is melted, then the remaining 30wt% of all raw materials put into the crucible, and continue to heat up to 720 ℃ incubated 10min, followed by sufficient stirring and the solution was allowed to stand 3...

Embodiment 3

[0045] This embodiment of the high performance (uniform tissue, excellent mechanical properties) preparation of magnesium-based light alloy material, including mother alloy melting, rapid solidification step Tissue Preparation, spark plasma sintering, comprises:

[0046] (1) Configuration mother alloy composition: composition according to the mother alloy to be synthesized Mg-10Gd-2Zn (percent by mass) as compounding, melting of the master alloy is cast alloy by resistance heating furnace smelting, specifically: First, 50wt% of the total amount of the ingredients of magnesium, Mg-Gd master alloy ingot into a stainless steel material or a graphite crucible, crucible, and placed in a resistance heating furnace, the temperature was raised to 730 ℃, incubated 5min, until the raw material is melted, then the remaining 40wt% of all raw materials put into the crucible, and continue to heat up to 720 ℃ incubated 10min, followed by sufficient stirring and the solution was allowed to stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com