Patents

Literature

105 results about "Tissue Preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are four steps in tissue preparation. Fixation stabilizes and preserves the tissue. Embedding converts the tissue into a solid form which can be sliced ("sectioned"). Sectioning (slicing) provides the very thin specimens needed for microscopy.

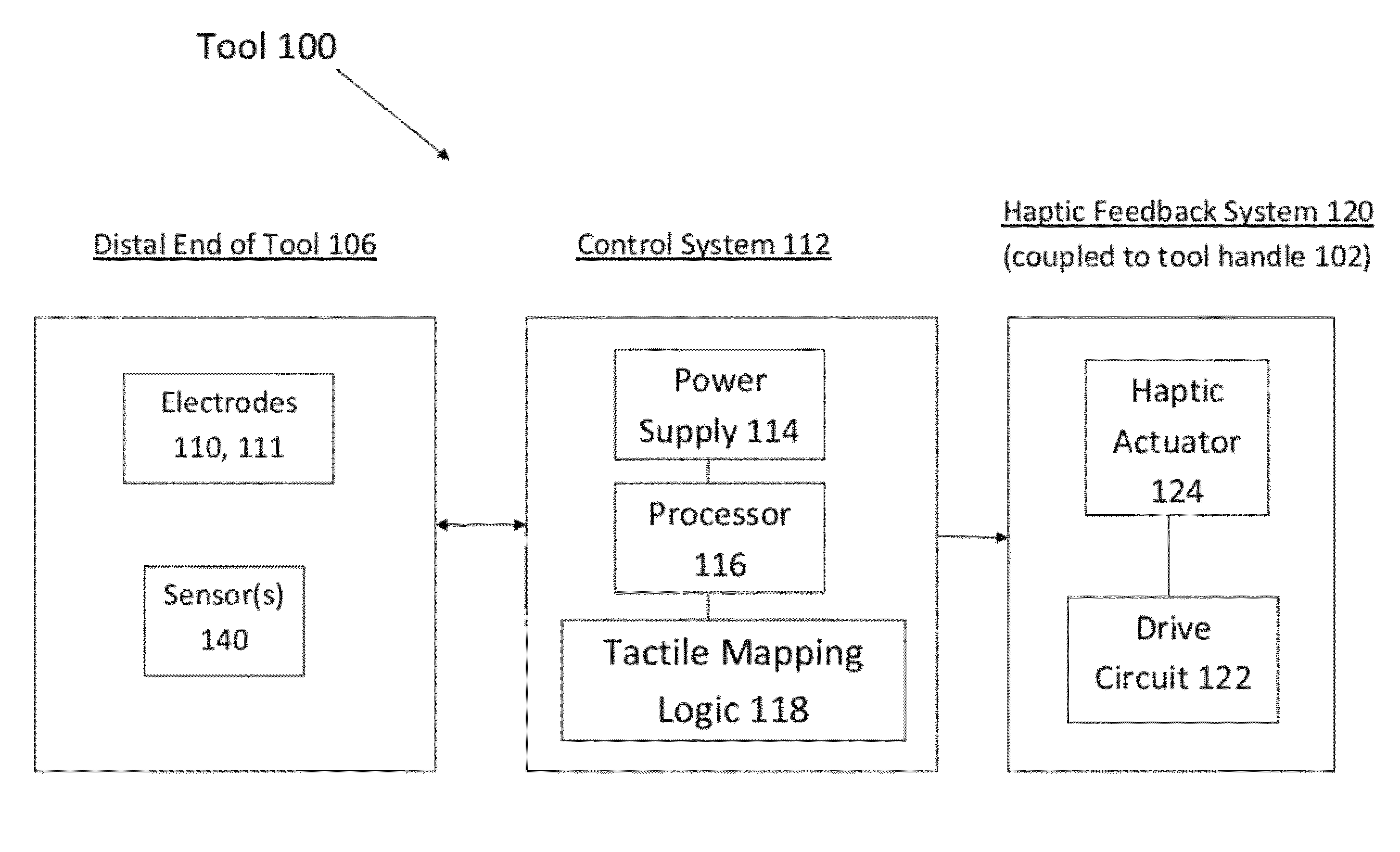

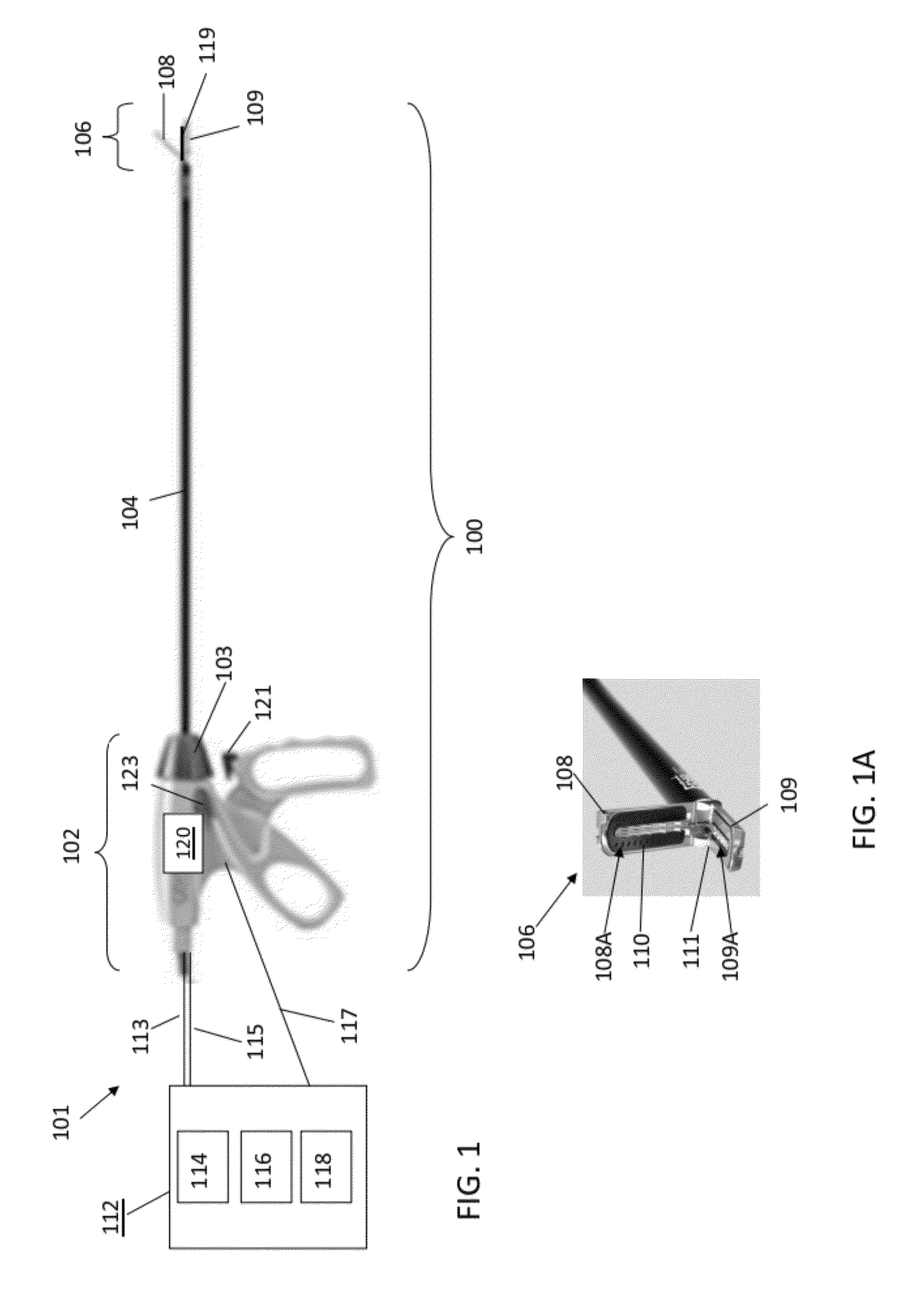

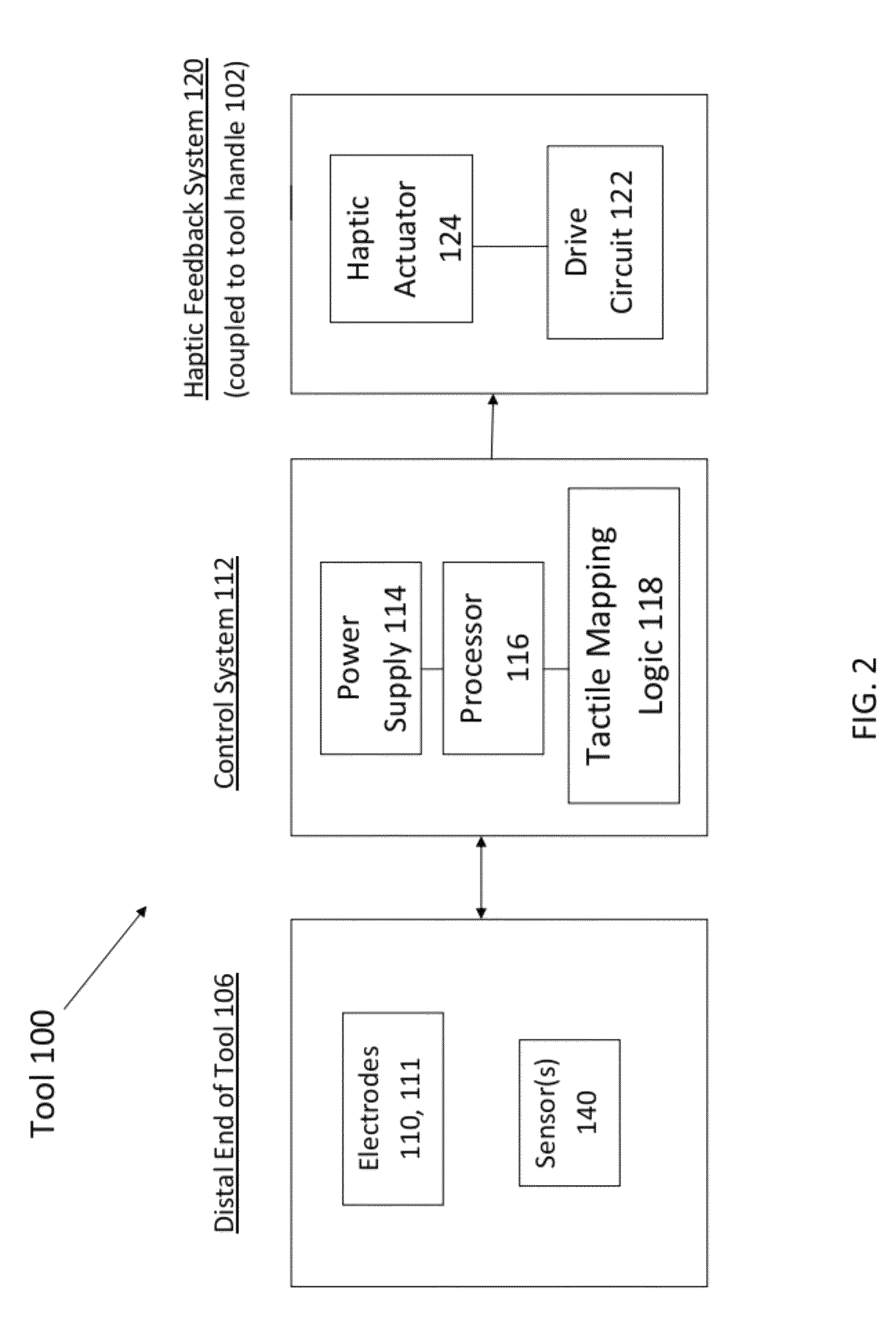

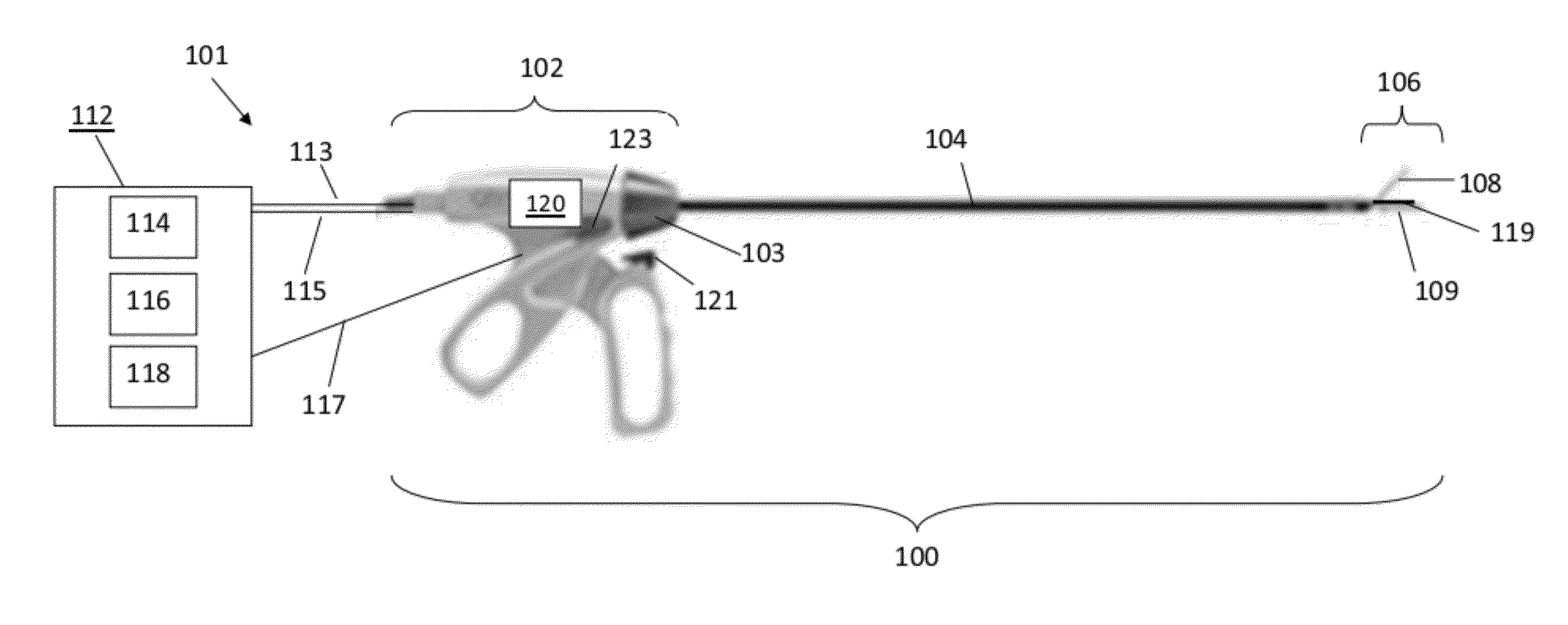

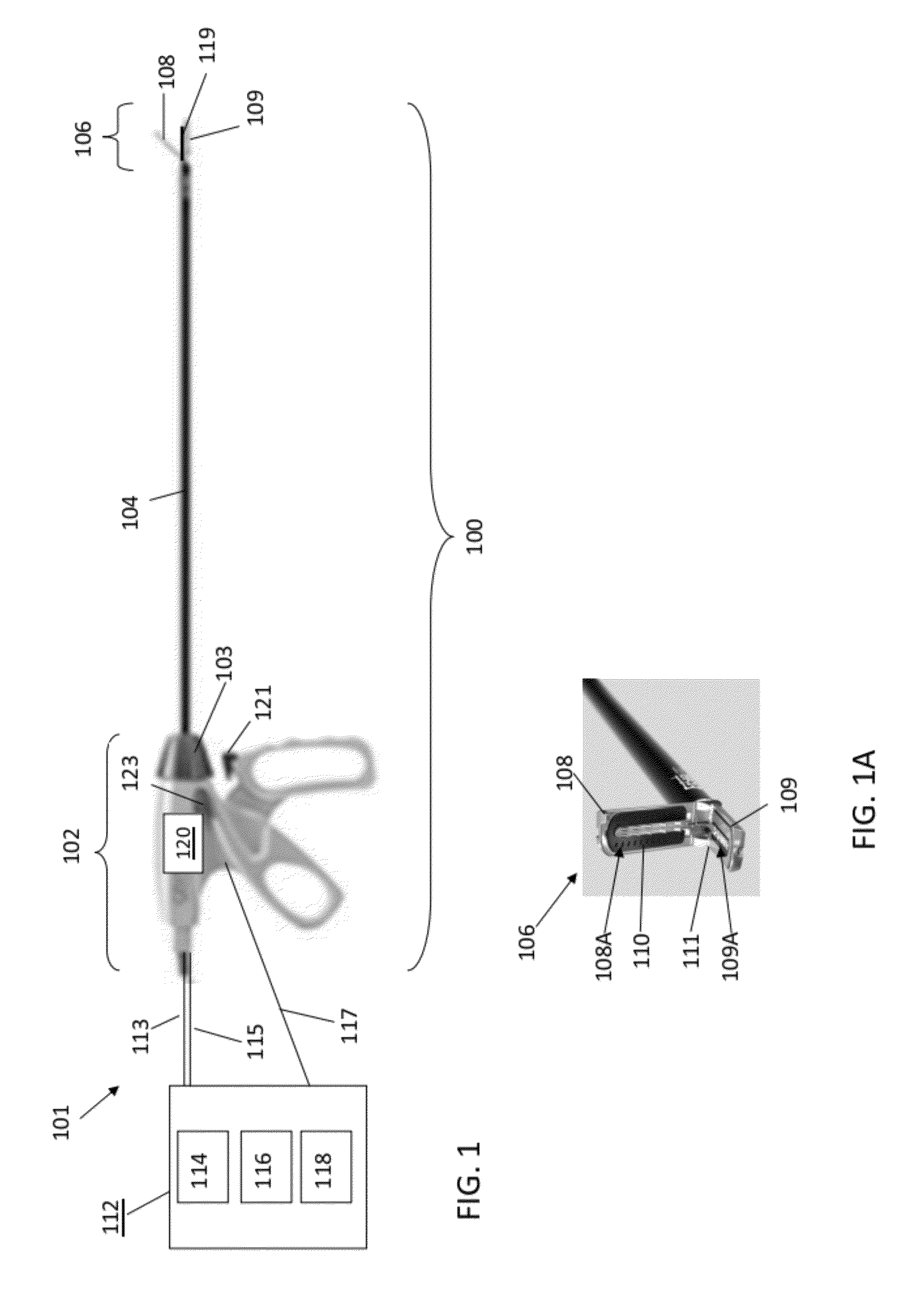

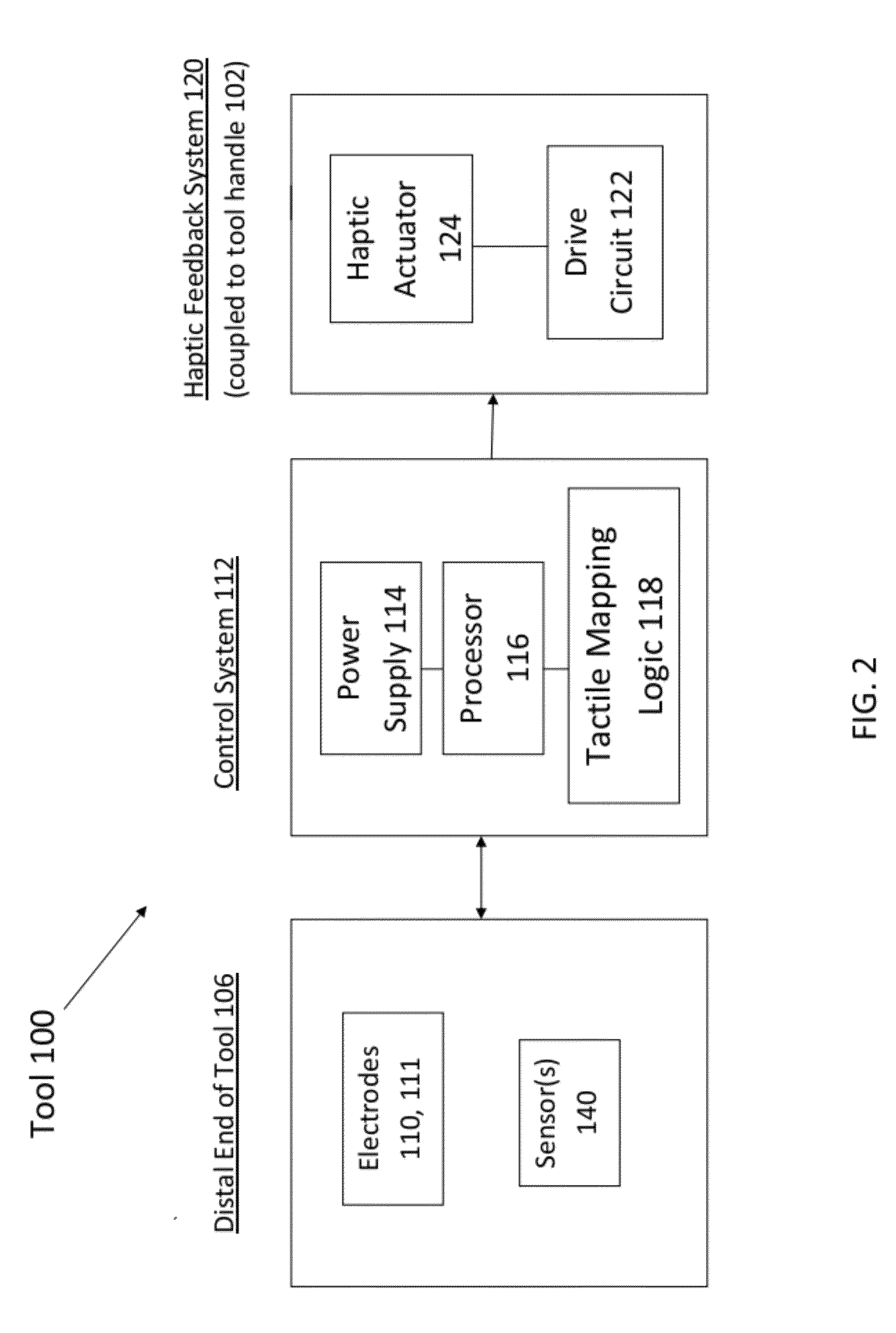

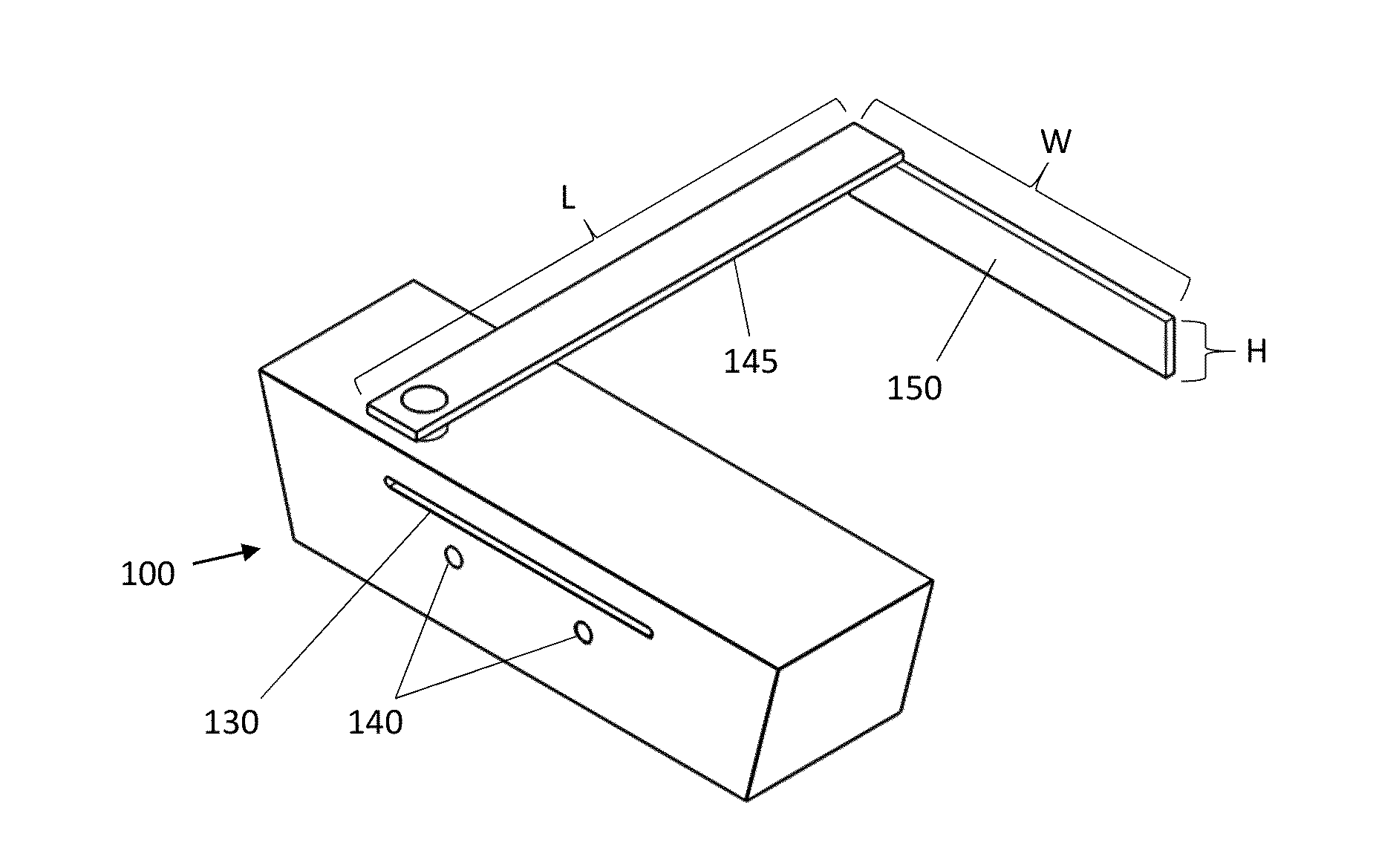

Electrosurgical sealing tool having haptic feedback

A surgical tool system includes an electrosurgical tool for sealing and transecting tissue and a tactile feedback system integrated onto a handle of the tool that generates relevant feedback in at least the form of haptic effects to the user. The tactile feedback alerts the user of tissue properties, i.e., when tissue located within jaws of the tool is completely sealed, when the tissue is ready to be cut, the cutting rate or speed, the quantity of tissue located within jaws of the tool, and whether a blood vessel is fully located within jaws of tool. In addition, the tactile feedback alerts the user to the operating status of energy application during the procedure.

Owner:IMMERSION CORPORATION

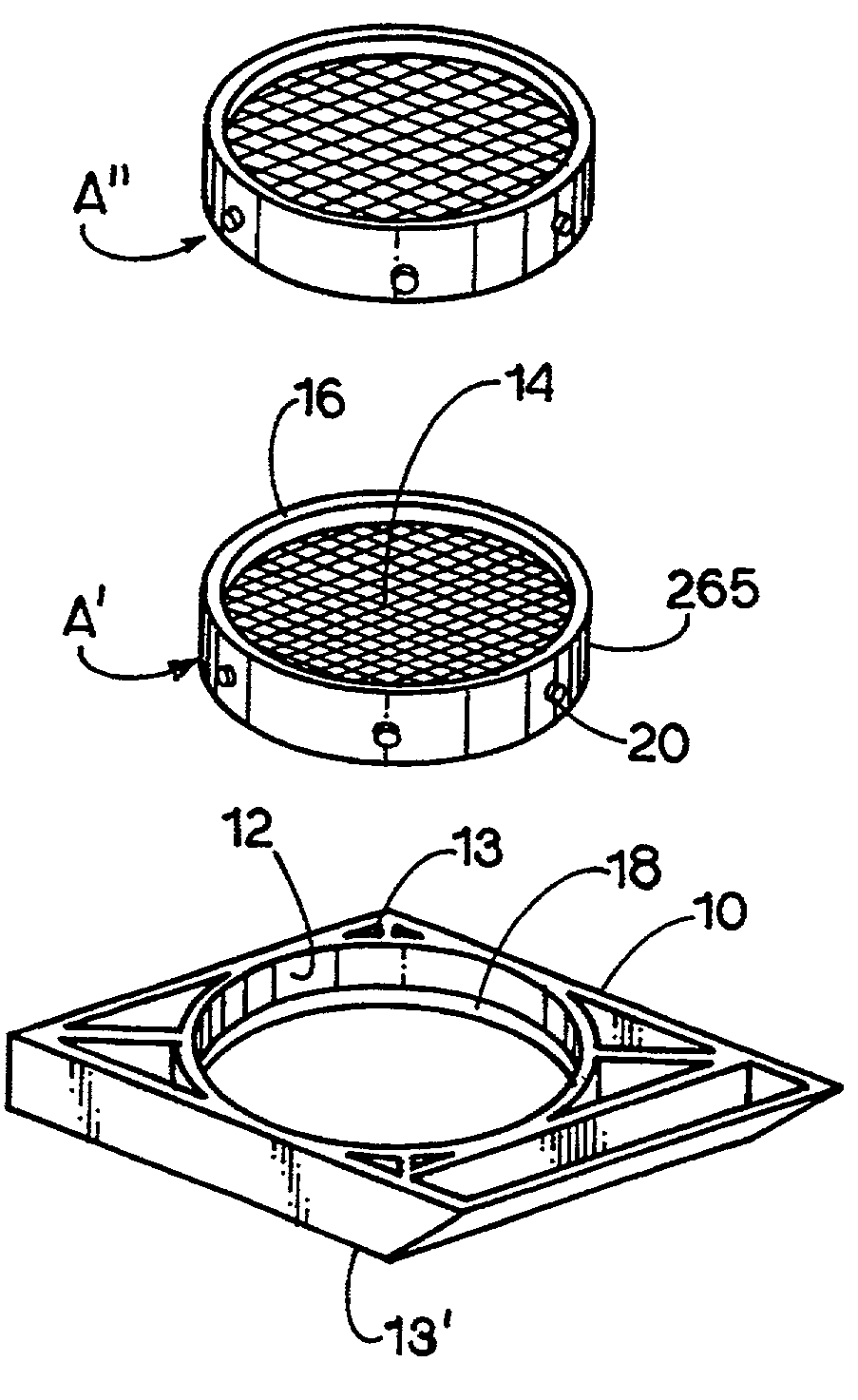

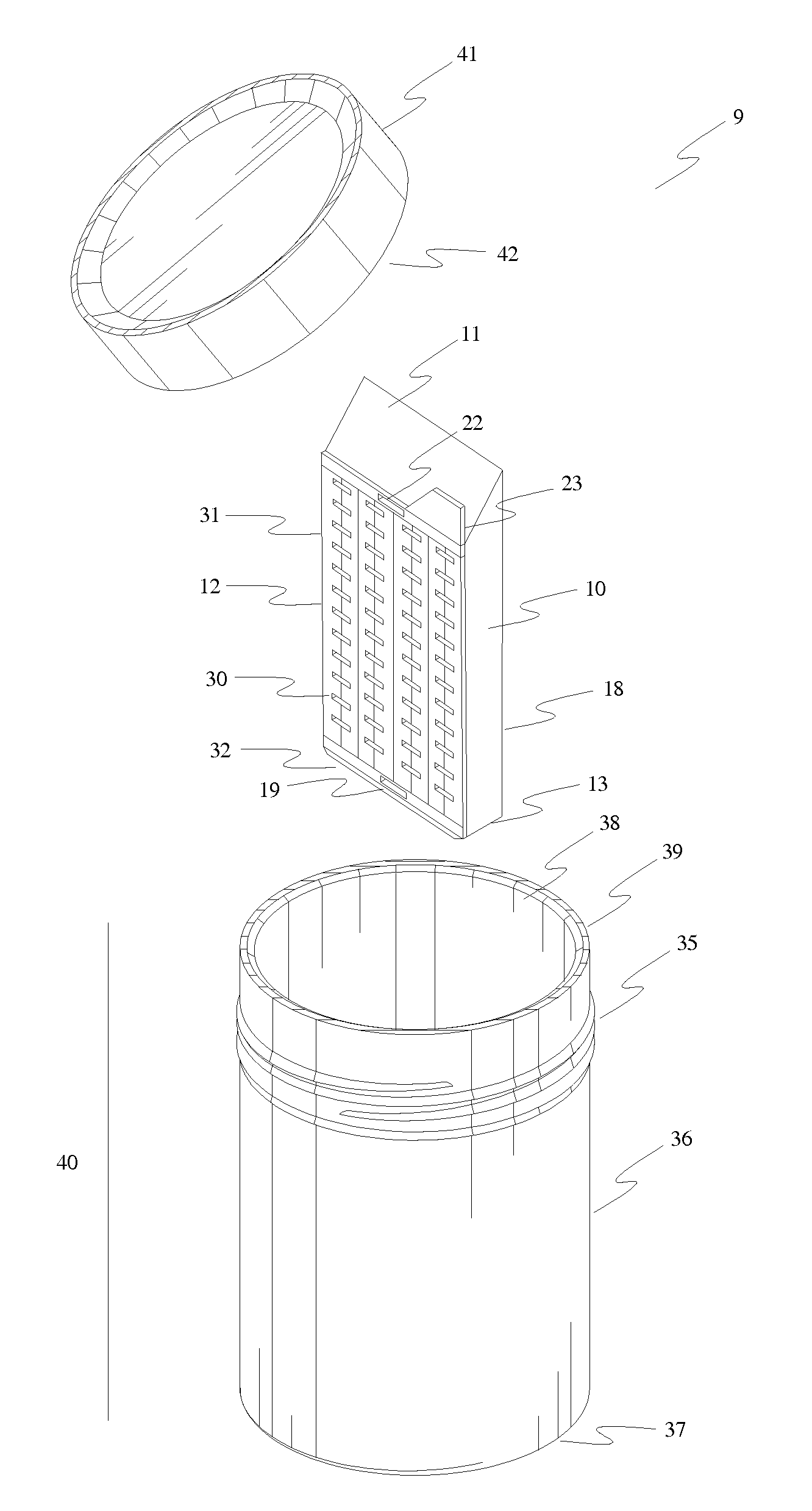

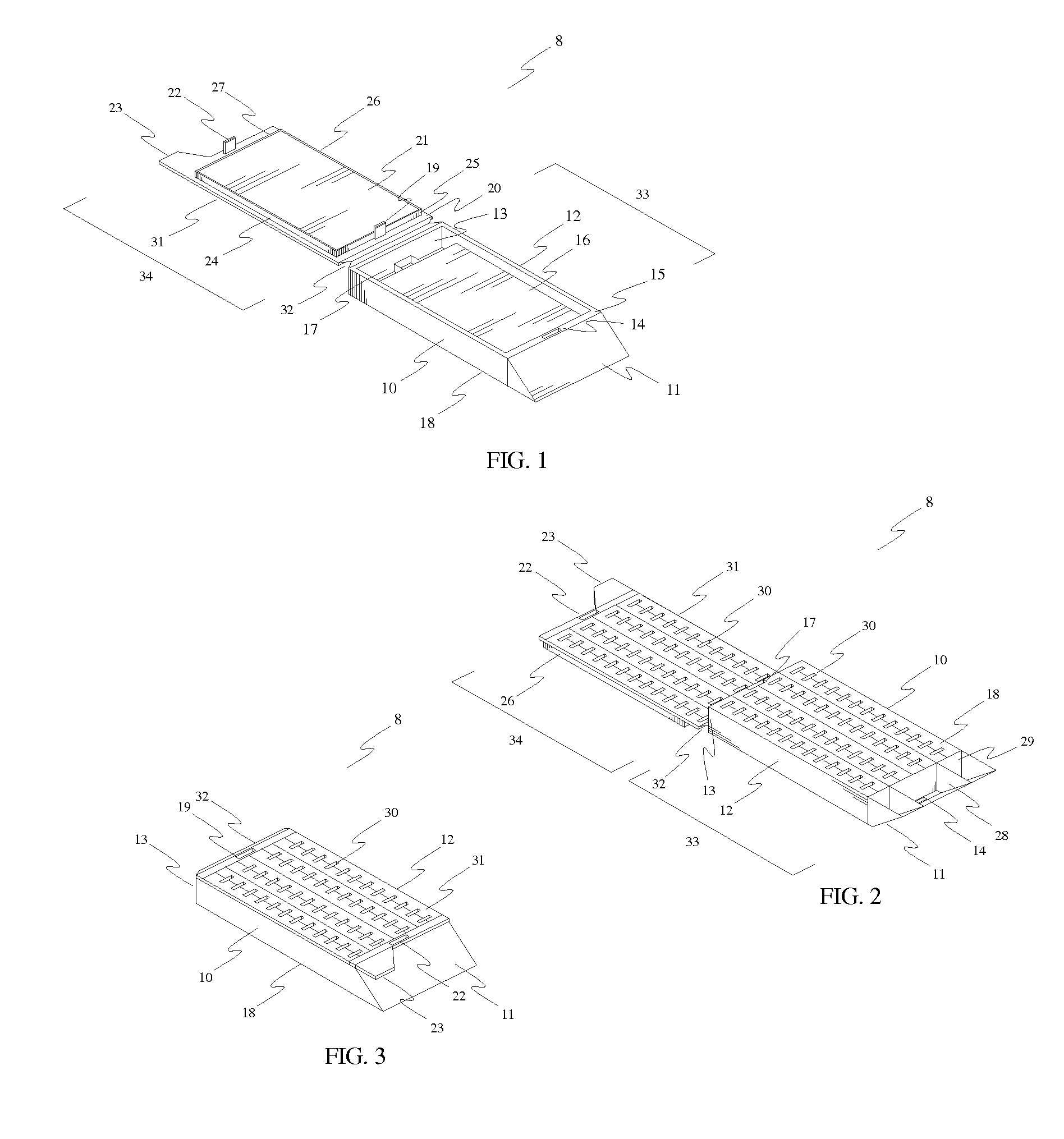

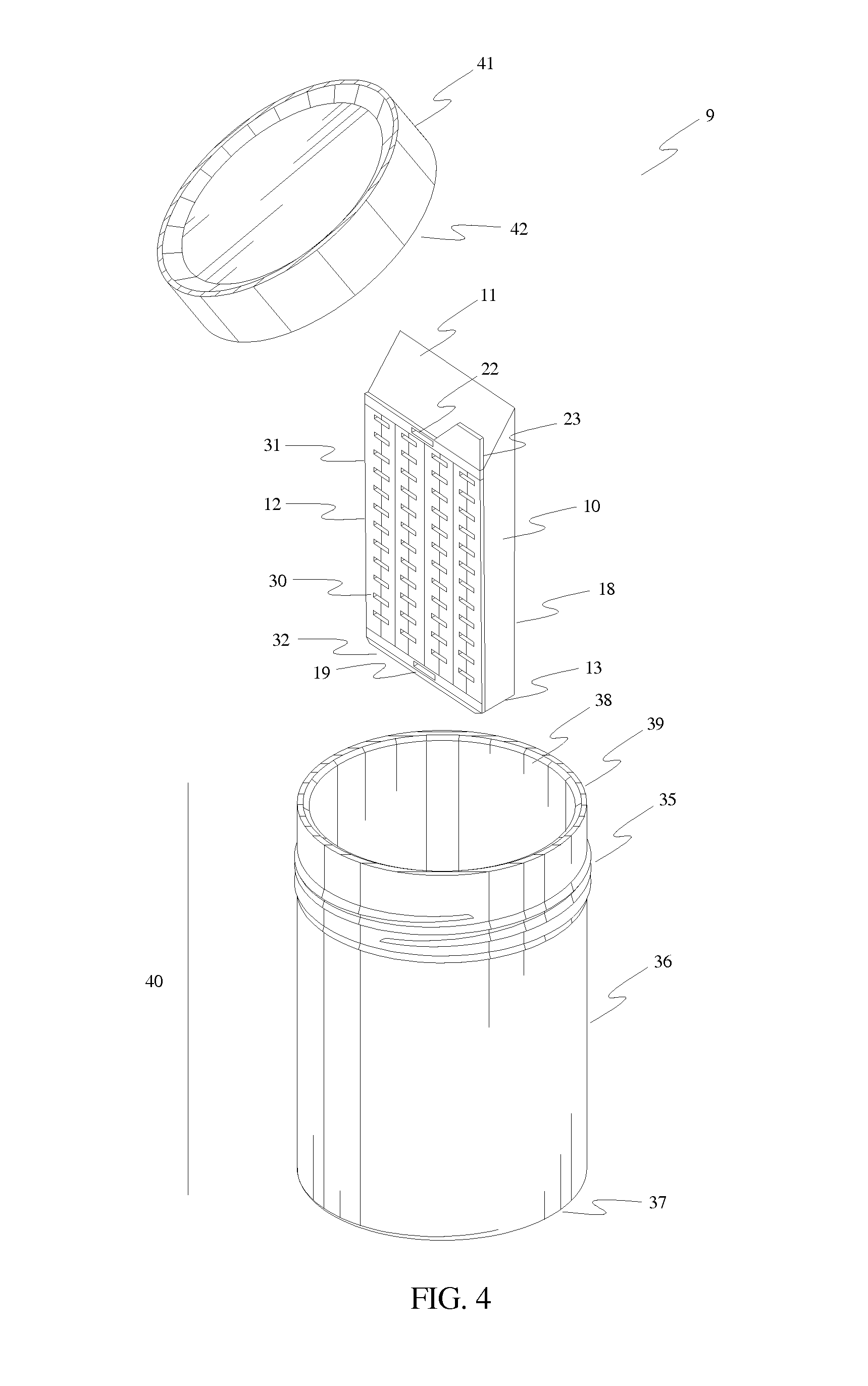

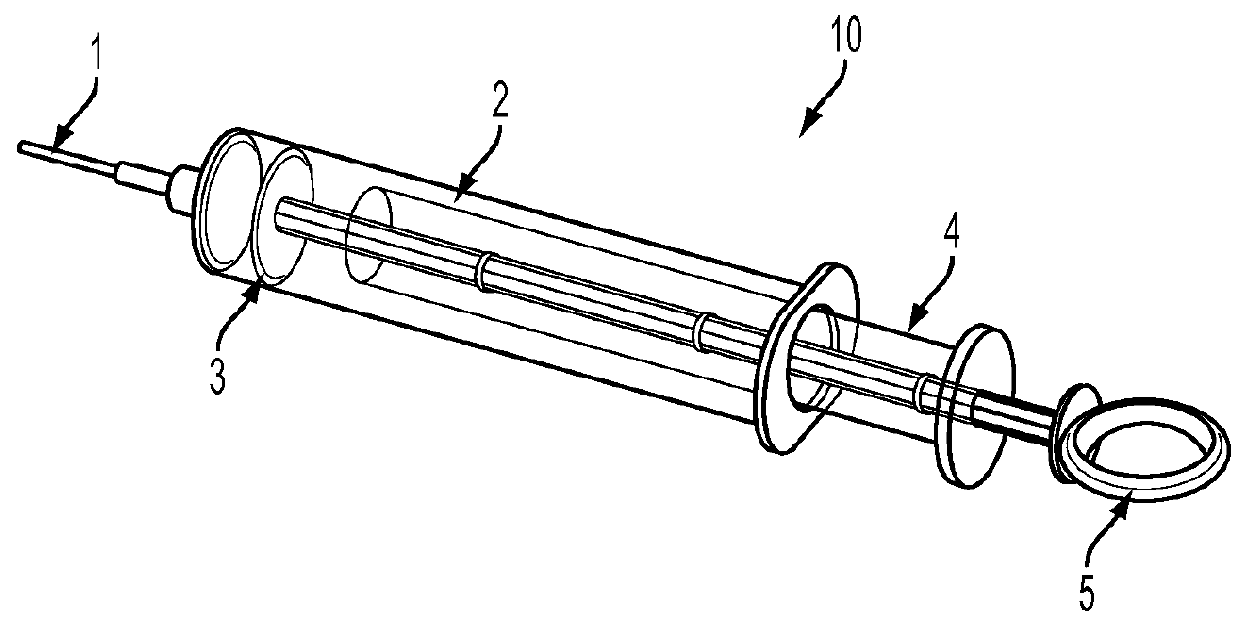

Apparatus and method for harvesting and handling tissue samples for biopsy analysis

InactiveUS7156814B1Exemption stepsReduce the numberBioreactor/fermenter combinationsBiological substance pretreatmentsTissue biopsyTissue fluid

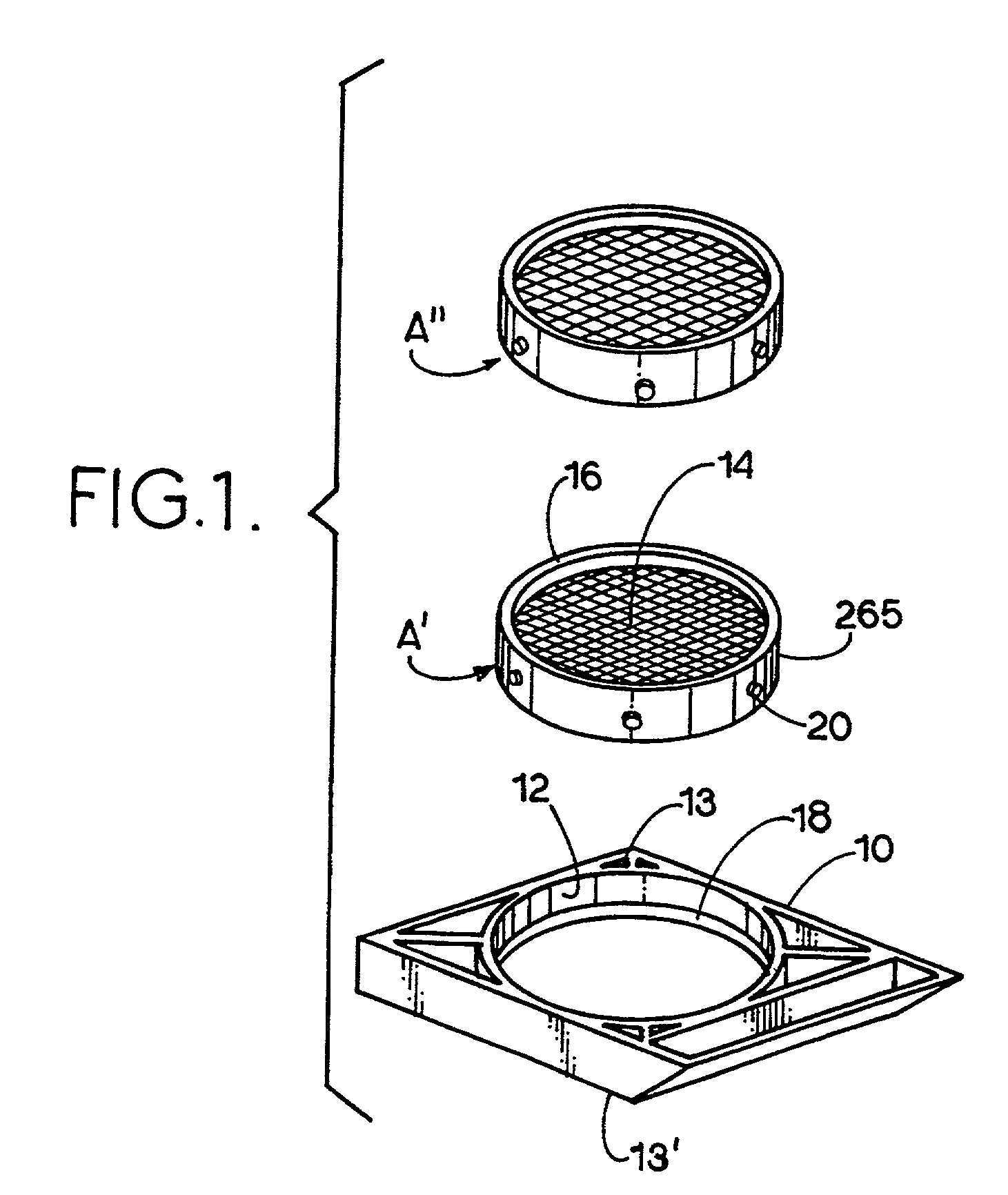

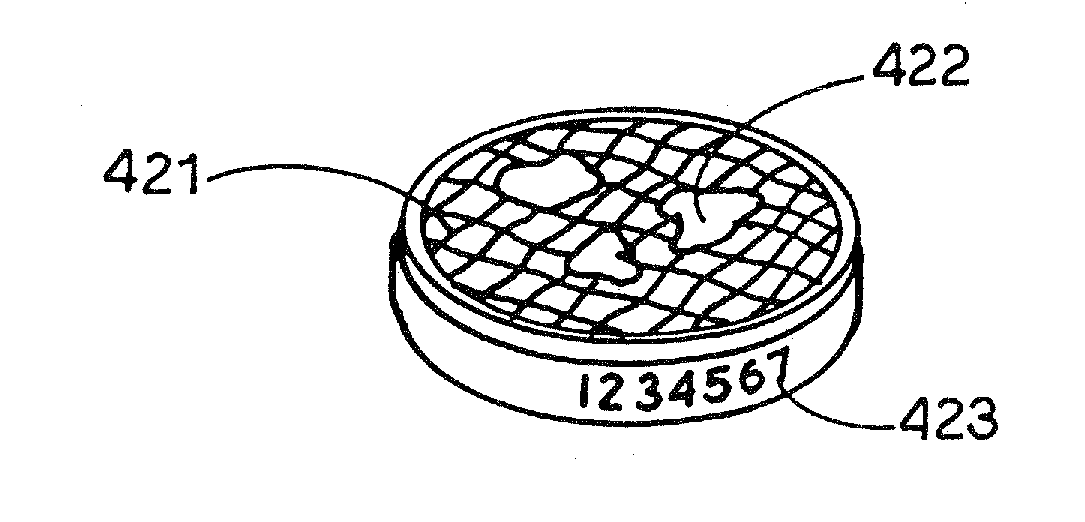

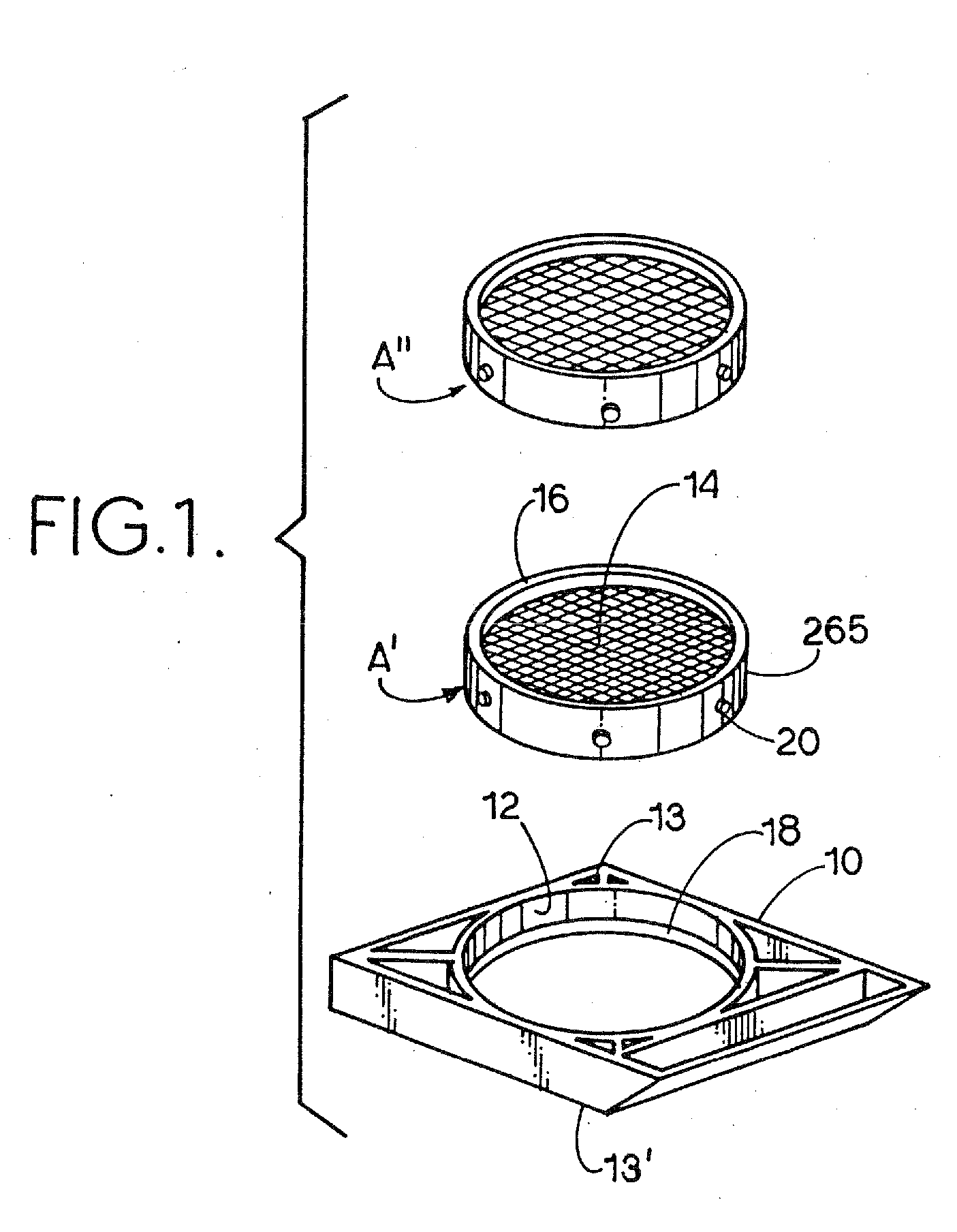

A sectional cassette (10) for use in a process for harvesting and handling tissue samples for biopsy analysis is disclosed. In the procedure, a tissue biopsy sample is placed on a tissue trapping supporting material (A′) that can withstand tissue preparation procedures, and which can be cut with a microtome. The tissue is immobilized on the material, and the material and the tissue are held in the cassette (10) subjected to a process for replacing tissue fluids with wax. The tissue and supporting material are sliced for mounting on slides using a microtome. Harvesting devices and containers (200) using the filter material (202) are disclosed. An automated process is also disclosed.

Owner:BIOPATH AUTOMATION

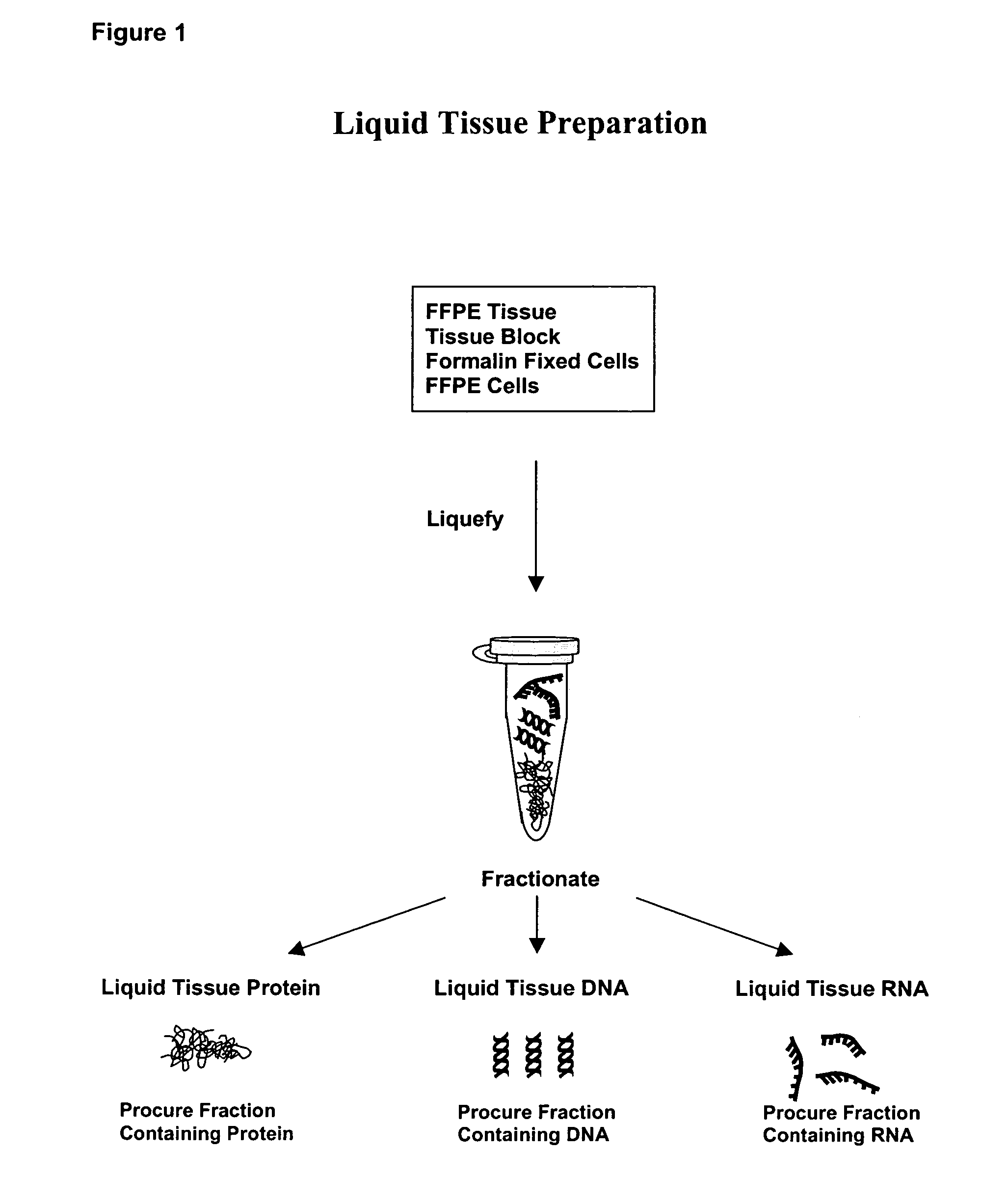

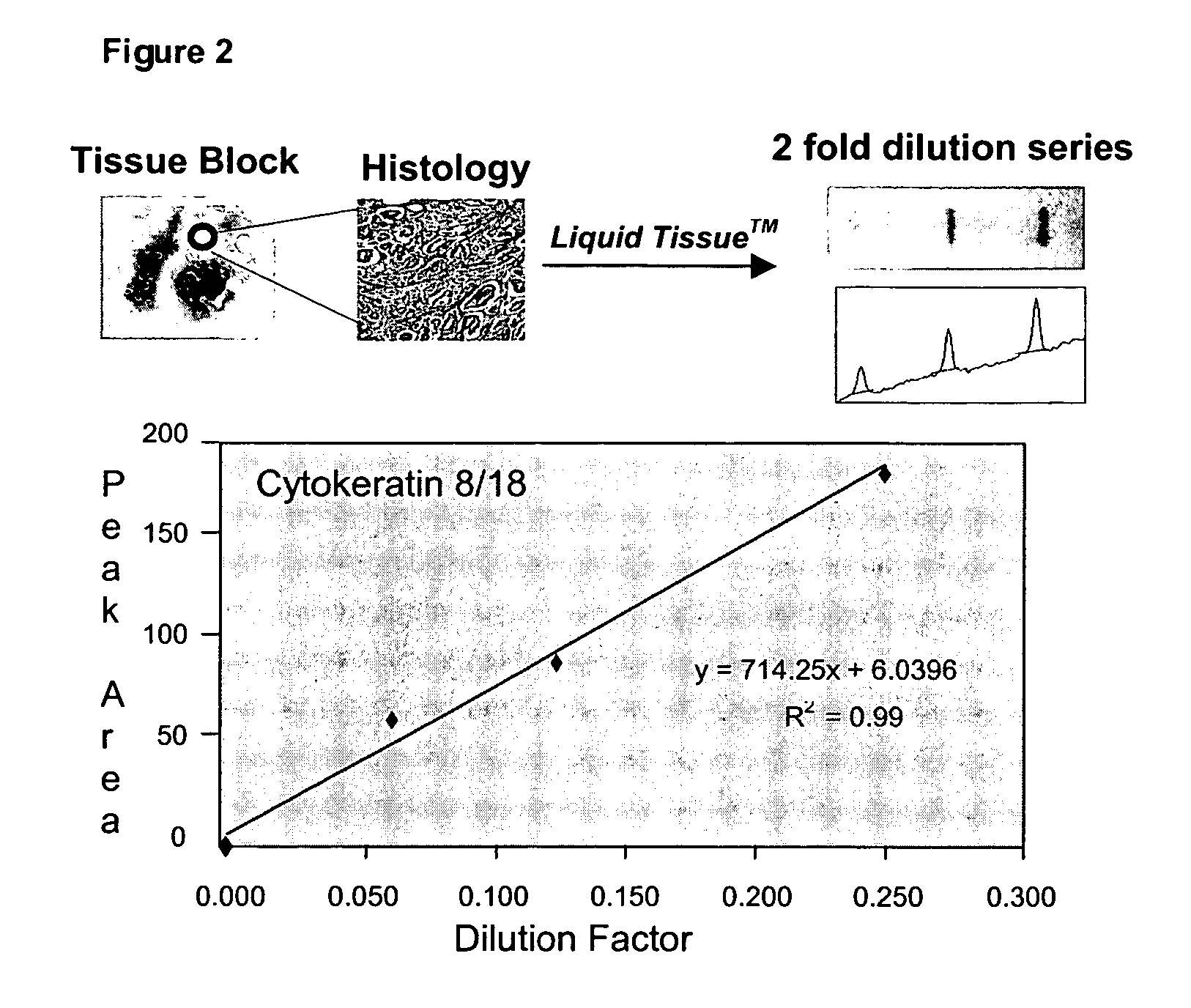

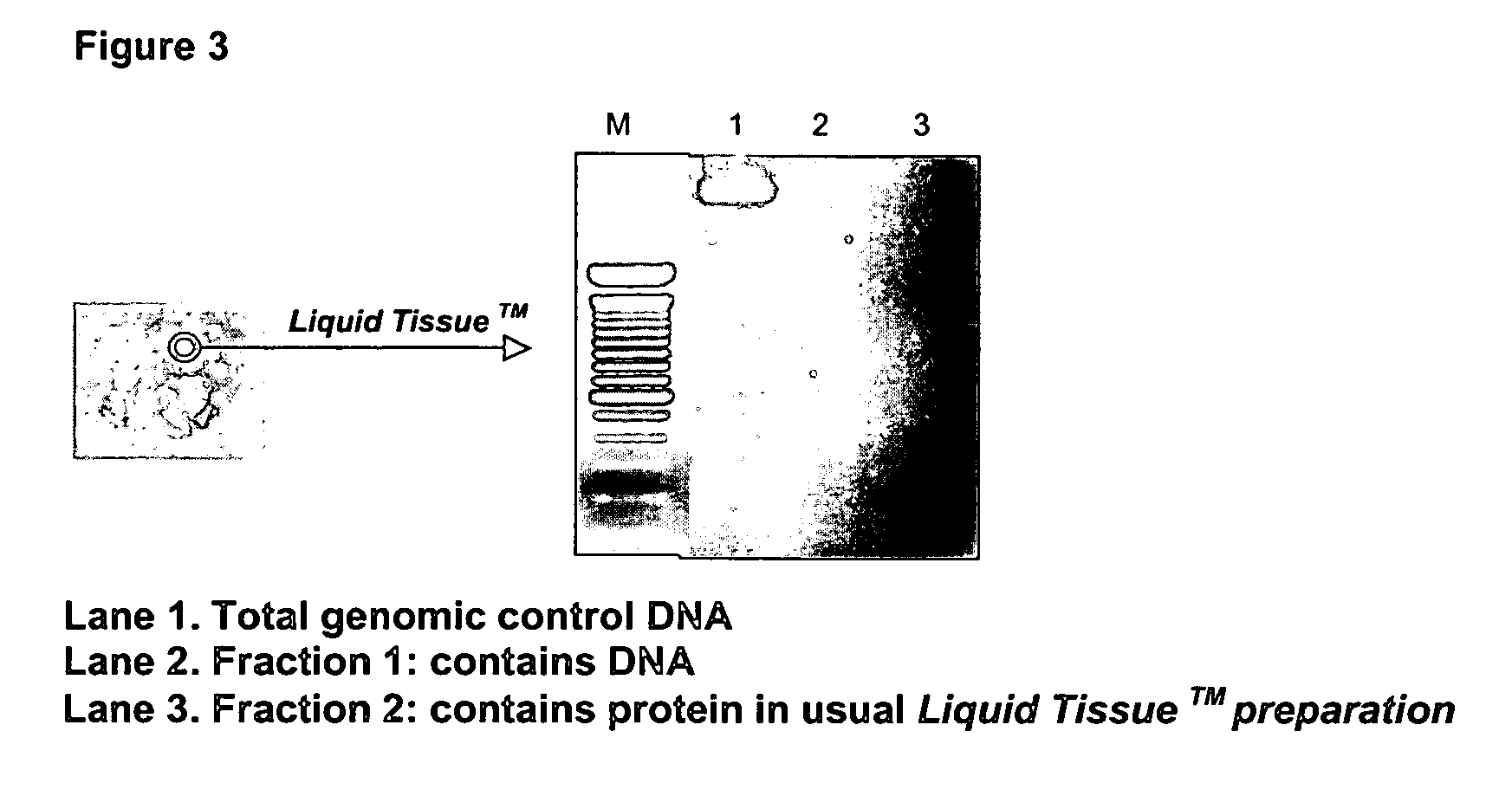

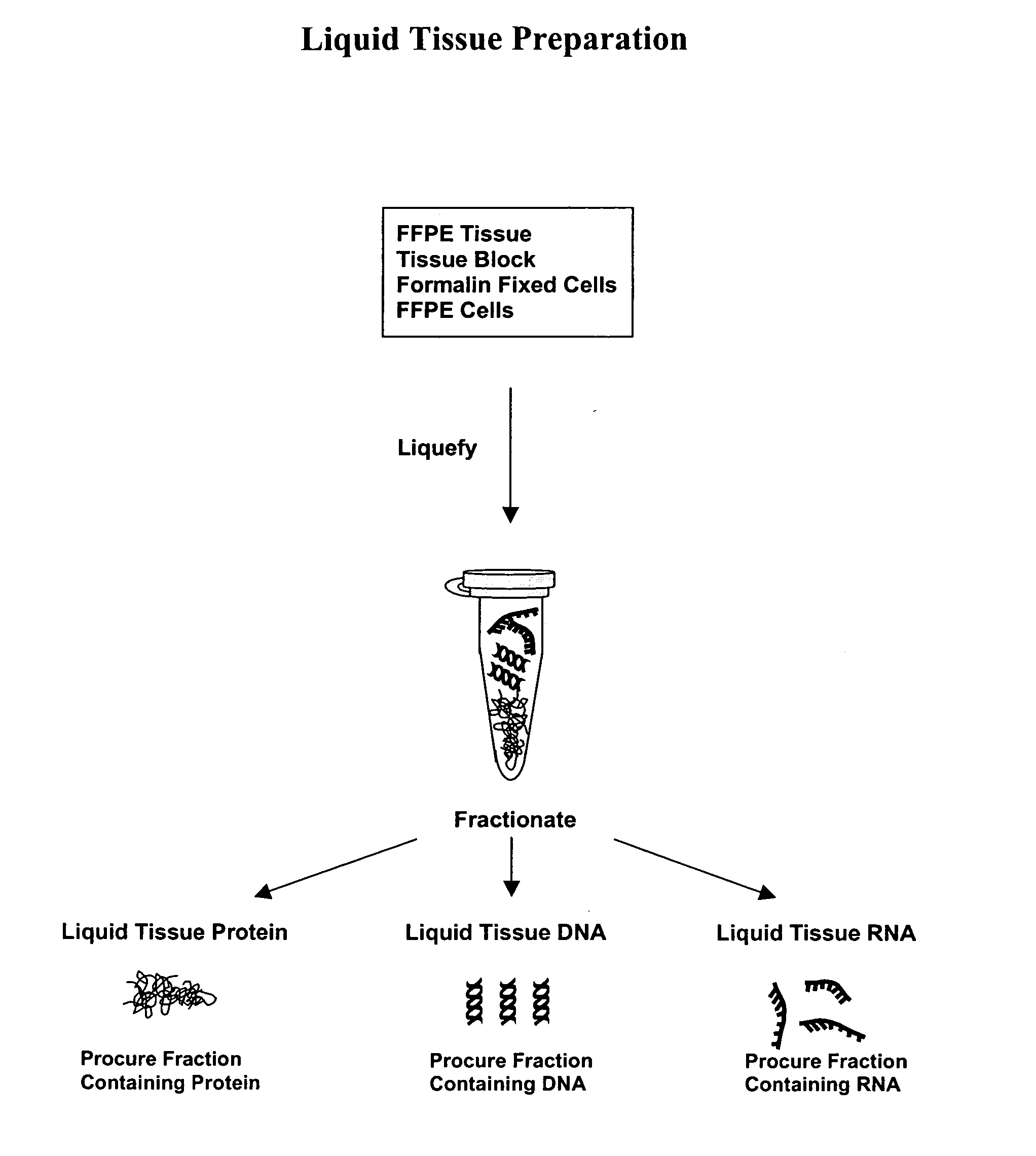

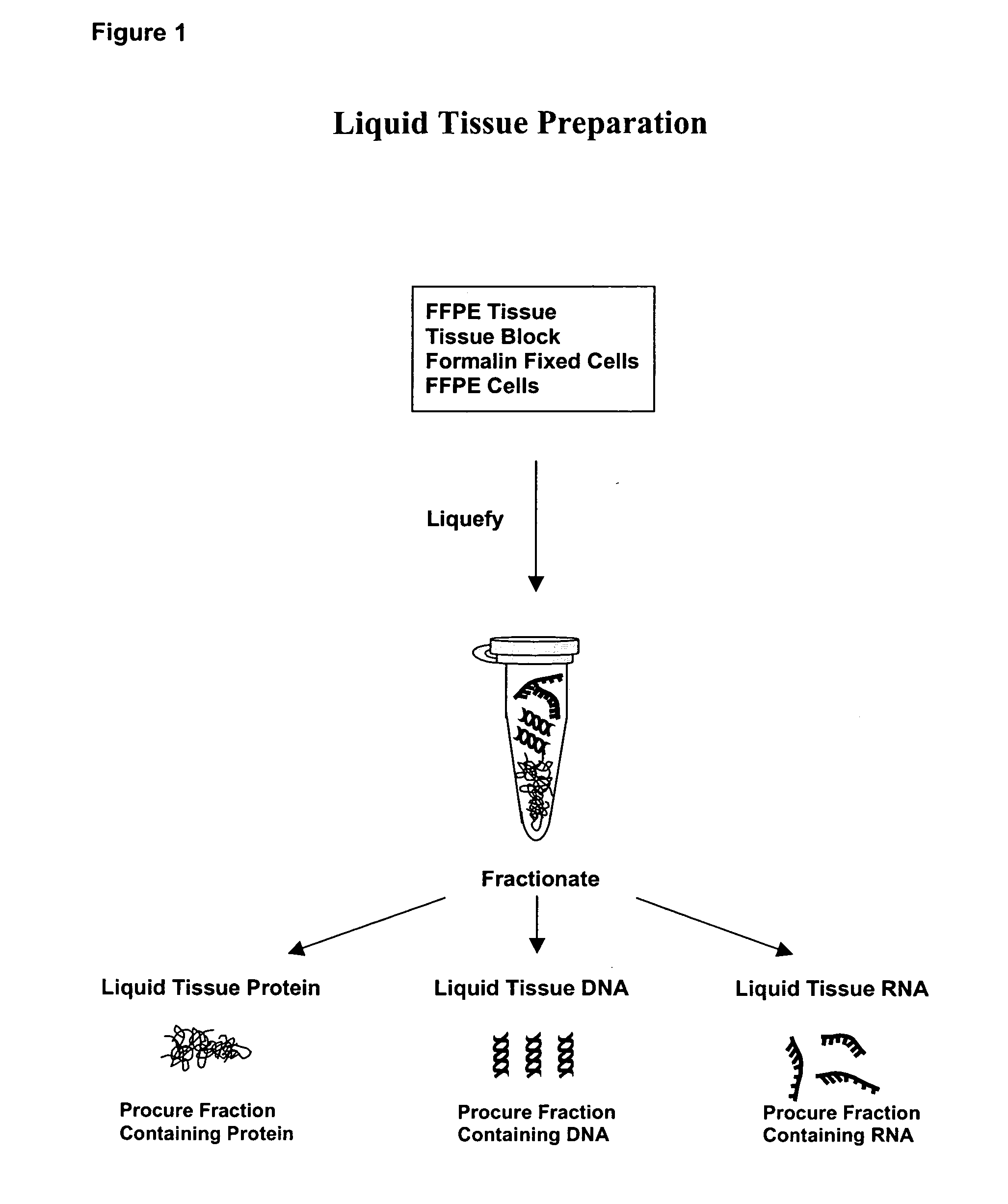

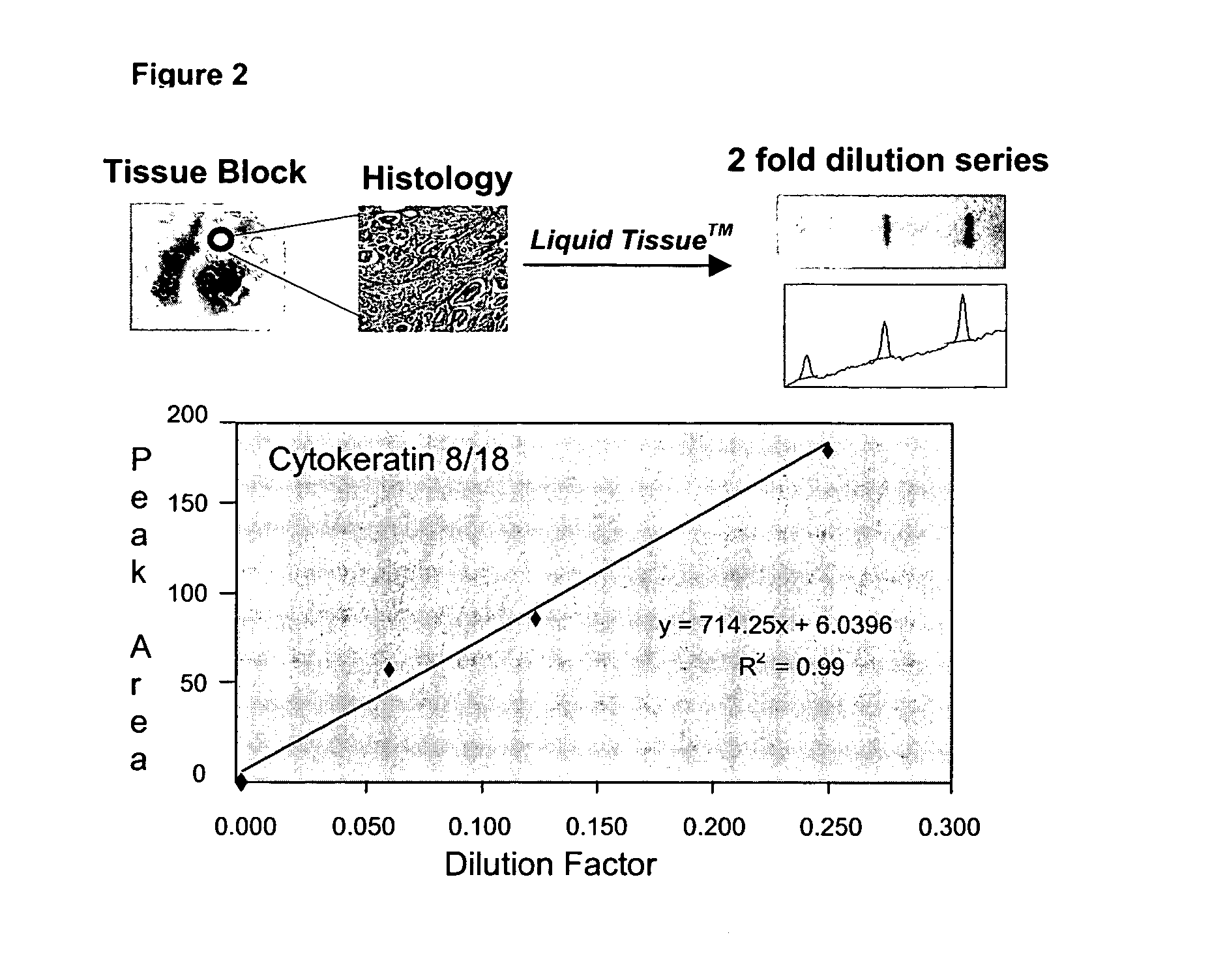

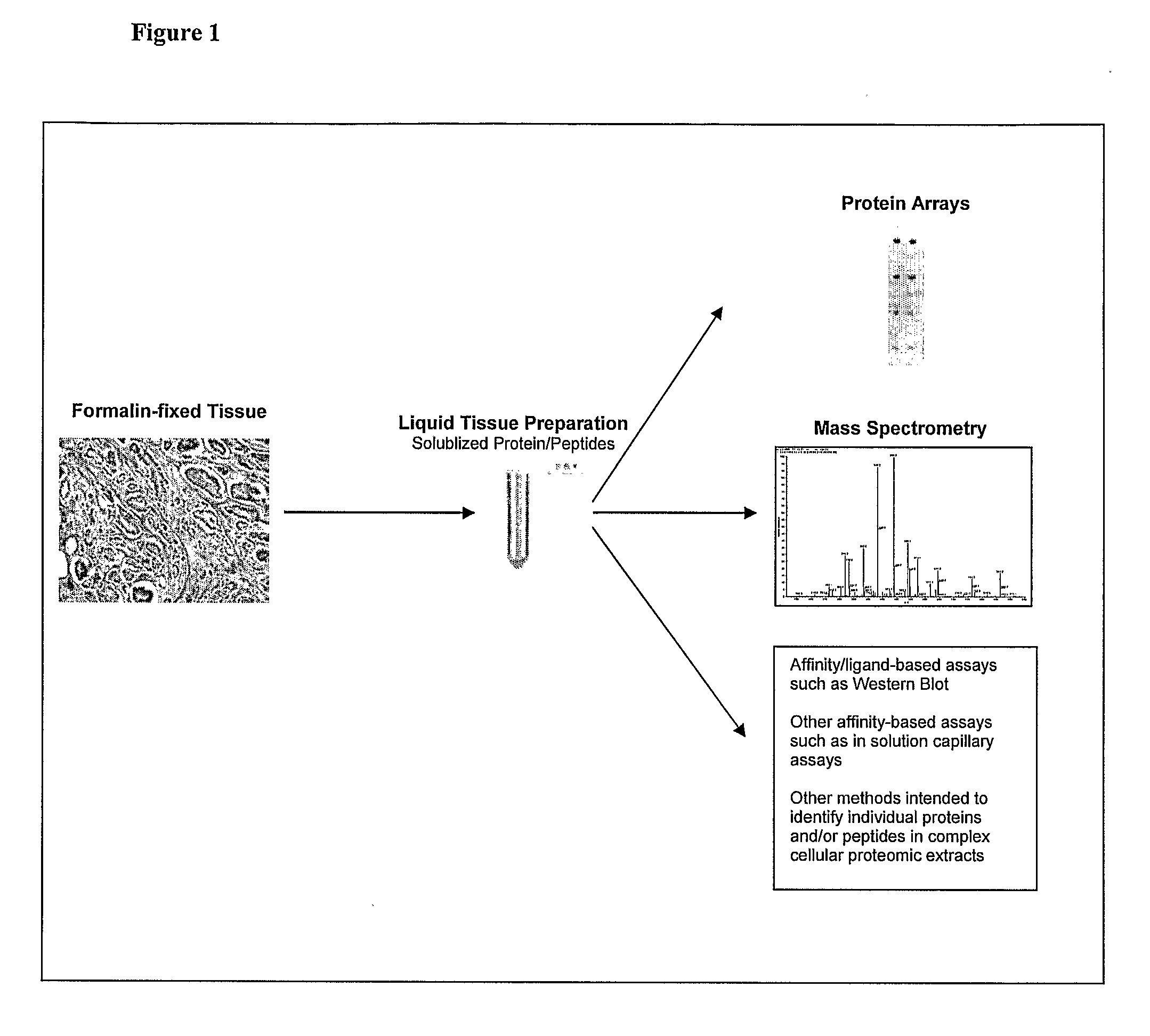

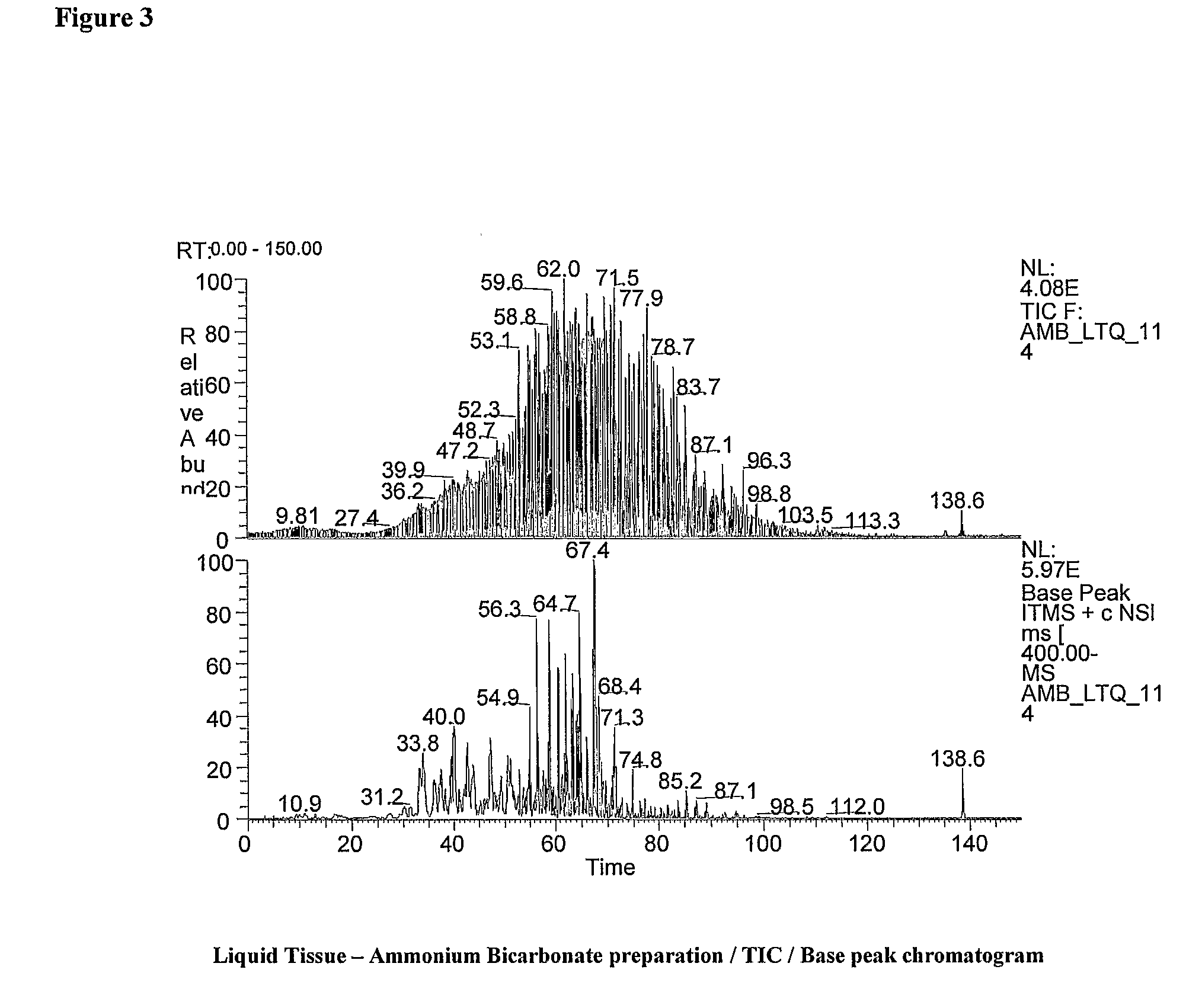

Liquid tissue preparation from histopathologically processed biological samples, tissues and cells

The current invention provides a method for directly converting histopathologically processed biological samples, tissues, and cells into a multi-use biomolecule lysate. This method allows for simultaneous extraction, isolation, solublization, and storage of all biomolecules contained within the histopathologically processed biological sample, thereby forming a representative library of said sample. This multi-use biomolecule lysate is dilutable, soluble, capable of being fractionated, and used in any number of subsequent experiments.

Owner:EXPRESSION PATHOLOGY

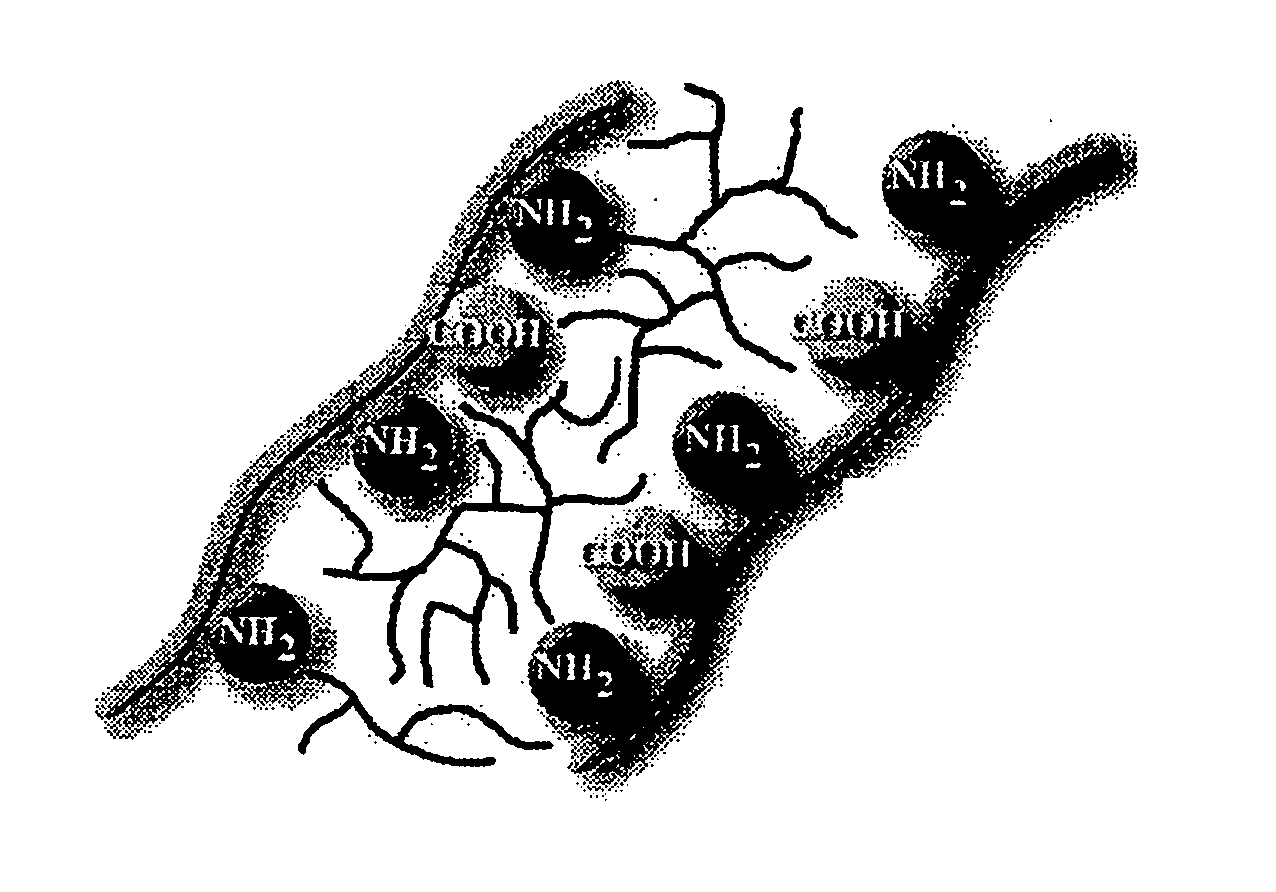

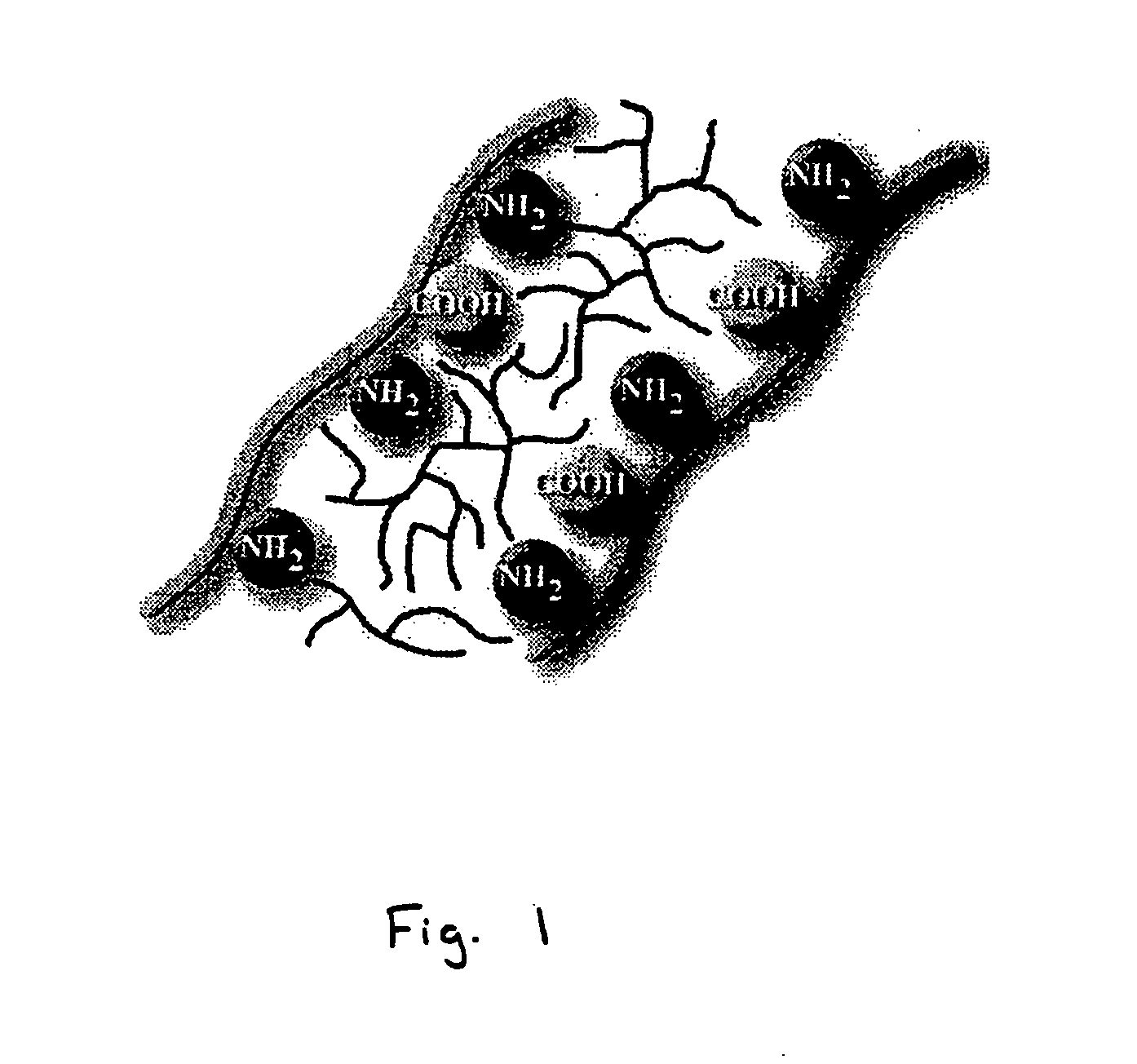

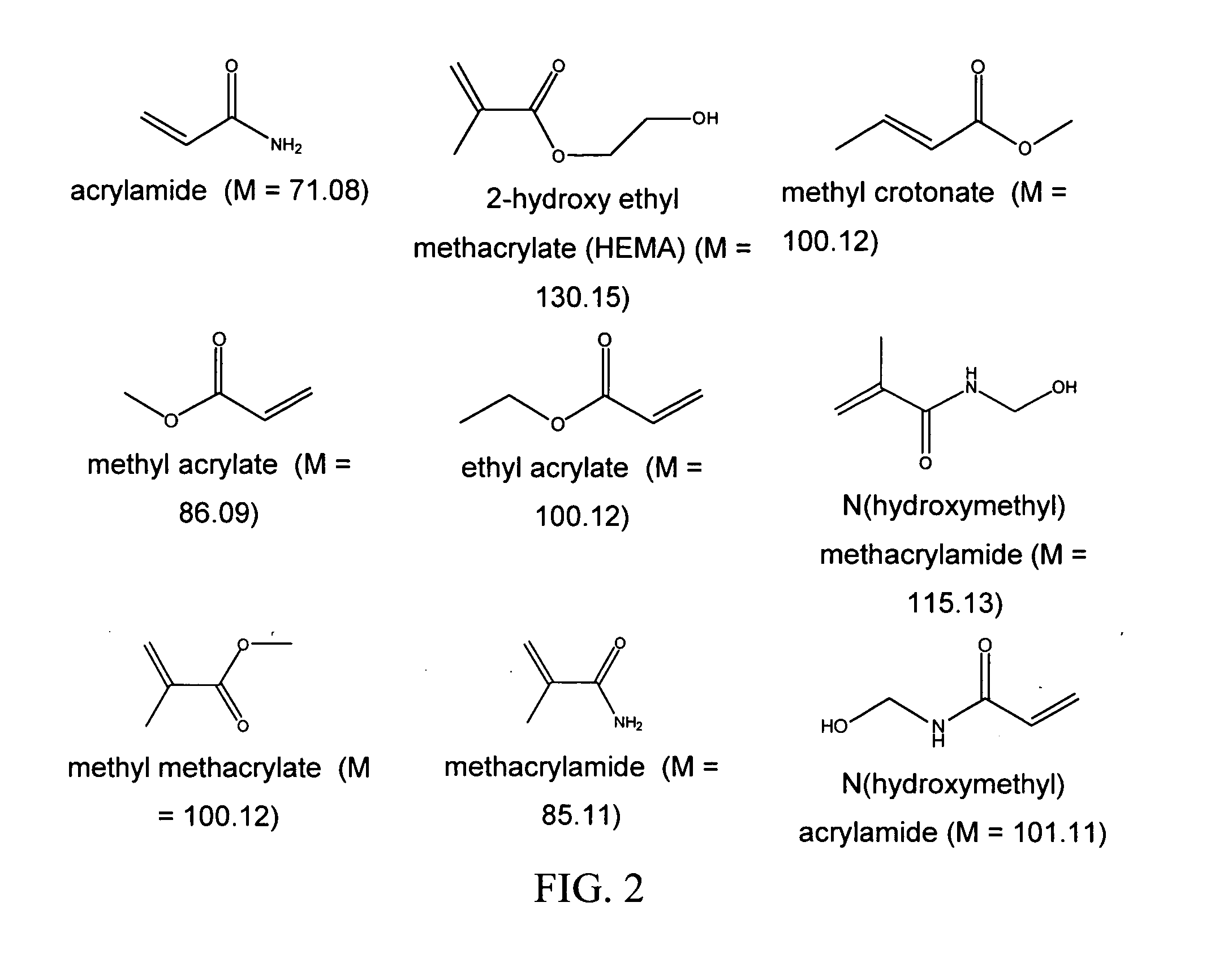

Bioprosthetic tissue preparation with synthetic hydrogels

ActiveUS20050119736A1Reduce calcificationReduce stiffnessSuture equipmentsHeart valvesCross-linkIn situ polymerization

Methods for treating xenogenic tissue for implantation into a human body including in-situ polymerization of a hydrogel polymer in tissue, and tissue treated according to those methods, where the polymerization takes place in tissue that has not been fixed with glutaraldehyde. The polymerization may only fill the tissue, bind the polymer to the tissue, or cross-link the tissue through the polymer, depending on the embodiment. One method includes free radical polymerization of a first vinylic compound, and can include cross-linking through use of a second compound having at least two vinyl groups. Another method utilizes nucleophilic addition polymerization of two compounds, one of which can include PEG and can further include hydrolytically degradable regions. In one embodiment, applicants believe the in-situ polymerization inhibits calcification, and that the polymerization of tissue un-fixed by glutaraldehyde allows for improved penetration of the polymer. The methods find one use in the treatment of porcine heart valve tissue, intended to extend the useful life of the valves by inhibiting calcification. The incorporation of degradable hydrogel regions may initially fill the tissue and reduce any initial inflammatory response, but allow for later infiltration by cells to remodel the tissue.

Owner:MEDTRONIC INC

Apparatus and method for harvesting and handling tissue samples for biopsy analysis

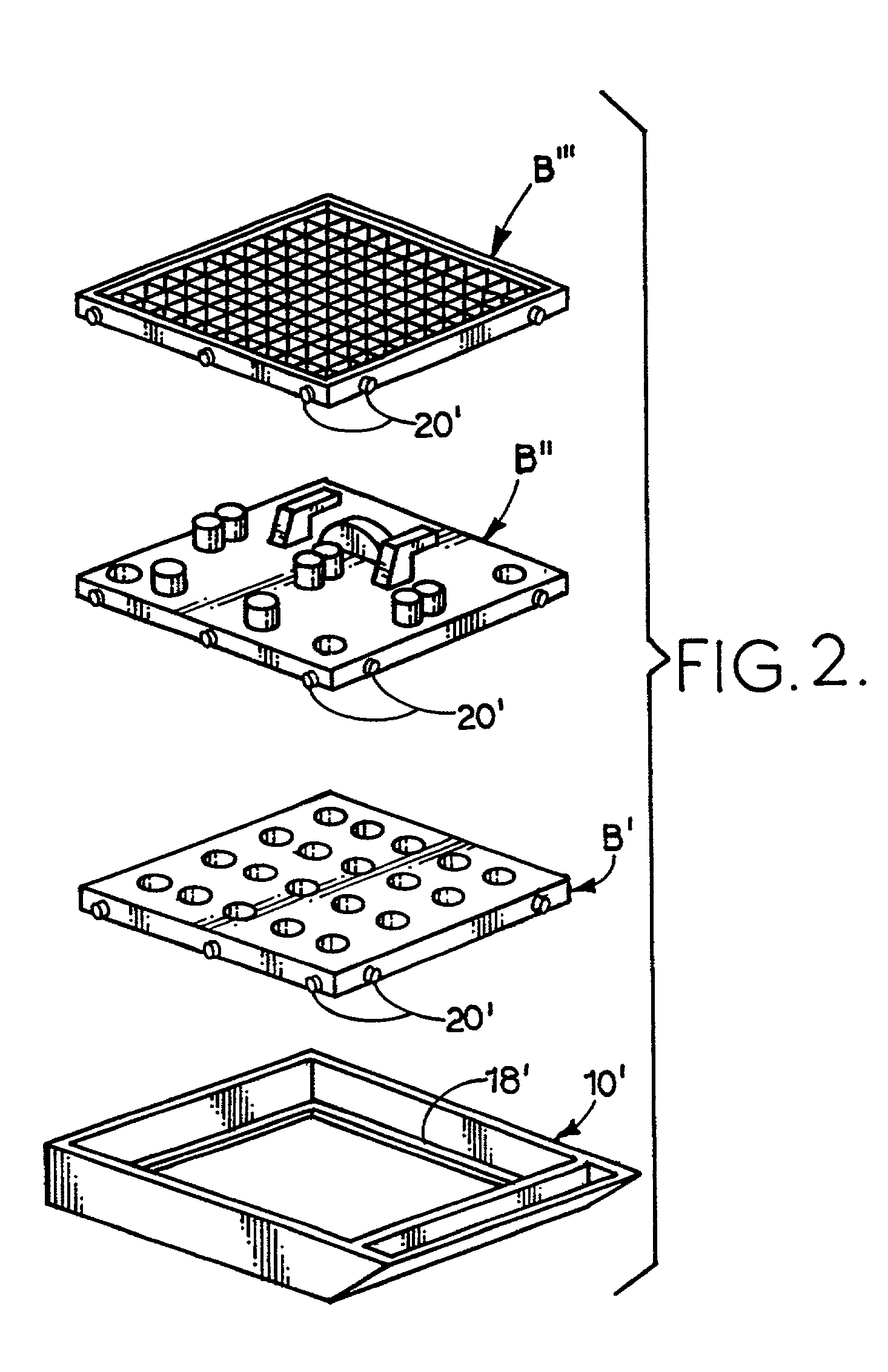

InactiveUS20070166834A1Exemption stepsReduce the numberPreparing sample for investigationBiological testingWaxTissue biopsy

A sectionable cassette for use in a process for harvesting and handling tissue samples for biopsy analysis is disclosed. In the procedure, a tissue biopsy sample is placed on a tissue trapping and supporting material that can withstand tissue preparation procedures and which can be cut with a microtome. The tissue is immobilized on the material and the material and the tissue are held in the cassette and are subjected to a process for replacing tissue fluids with wax, and then the tissue and the supporting material are sliced for mounting on slides using a microtome. Harvesting devices and containers using the filter material are disclosed. An automated process is also disclosed. One embodiment has the tissue trapping and supporting material porous and another embodiment includes a tissue supporting material that is not easily microtomed.

Owner:BIOPATH AUTOMATION

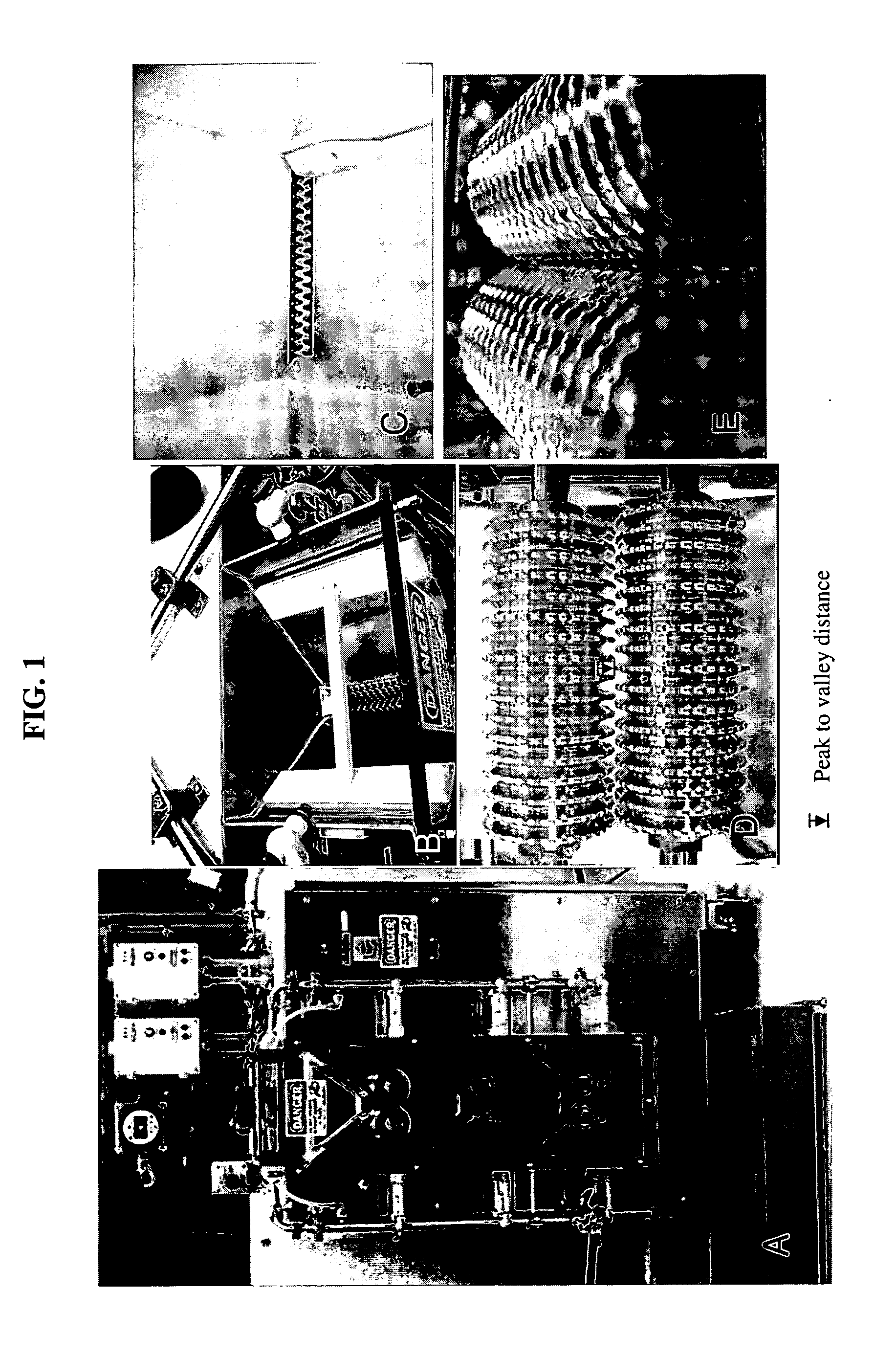

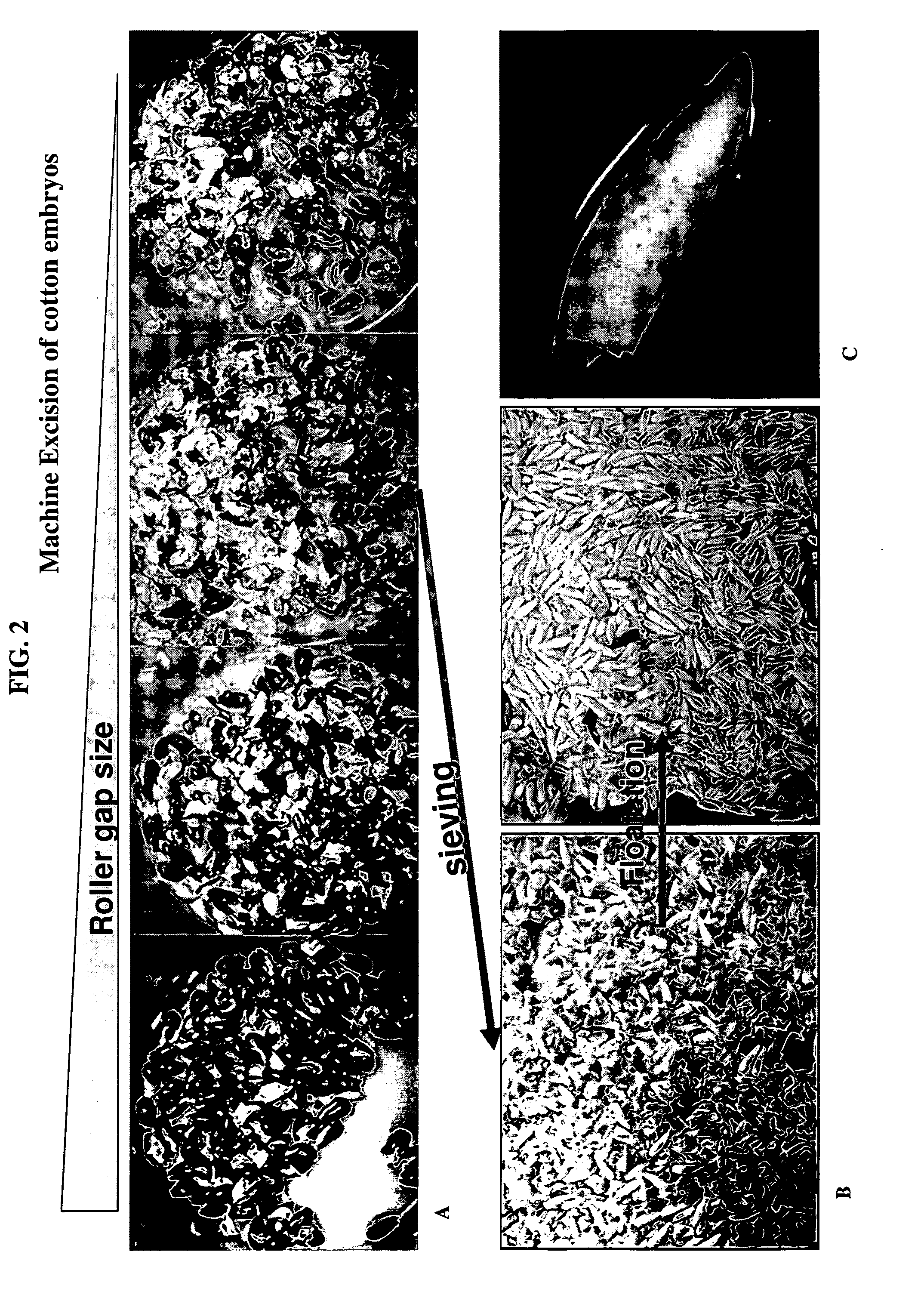

Preparation and use of plant embryo explants for transformation

ActiveUS20080280361A1Bioreactor/fermenter combinationsBiological substance pretreatmentsEmbryoBiology

The present invention relates to excision of explant material comprising meristematic tissue from seeds, and storage of such material prior to subsequent use in plant tissue culture and genetic transformation. Methods for tissue preparation, storage, and transformation are disclosed, as is transformable meristem tissue produced by such methods, and apparati for tissue preparation.

Owner:MONSANTO TECH LLC

Liquid tissue preparation from histopathologically processed biological samples, tissues and cells

The current invention provides a method for directly converting histopathologically processed biological samples, tissues, and cells into a multi-use biomolecule lysate. This method allows for simultaneous extraction, isolation, solublization, and storage of all biomolecules contained within the histopathologically processed biological sample, thereby forming a representative library of said sample. This multi-use biomolecule lysate is dilutable, soluble, capable of being fractionated, and used in any number of subsequent experiments.

Owner:EXPRESSION PATHOLOGY

Supercritical fluid extraction process for tissue preparation

ActiveUS7008591B2Penetration thoroughlyShort timeSolvent extractionMammal material medical ingredientsPeriprostheticChemical agent

The present invention provides methods for preparing tissue for incorporation into xenografts and bioprosthetic devices. The methods of the invention make use of supercritical fluids to remove infectious materials and chemical agents from tissues, as well as to permeate a tissue with a chemical agent (e.g. tanning, cross-linking, and bioactive agents).

Owner:REGENT OF THE UNIVESITY OF MICHIGAN THE +1

Electrosurgical sealing tool having haptic feedback

InactiveUS20120143182A1DiagnosticsMechanical features of instrumentBlood vesselBiomedical engineering

A surgical tool system includes an electrosurgical tool for sealing and transecting tissue and a tactile feedback system integrated onto a handle of the tool that generates relevant feedback in at least the form of haptic effects to the user. The tactile feedback alerts the user of tissue properties, i.e., when tissue located within jaws of the tool is completely sealed, when the tissue is ready to be cut, the cutting rate or speed, the quantity of tissue located within jaws of the tool, and whether a blood vessel is fully located within jaws of tool. In addition, the tactile feedback alerts the user to the operating status of energy application during the procedure.

Owner:IMMERSION CORPORATION

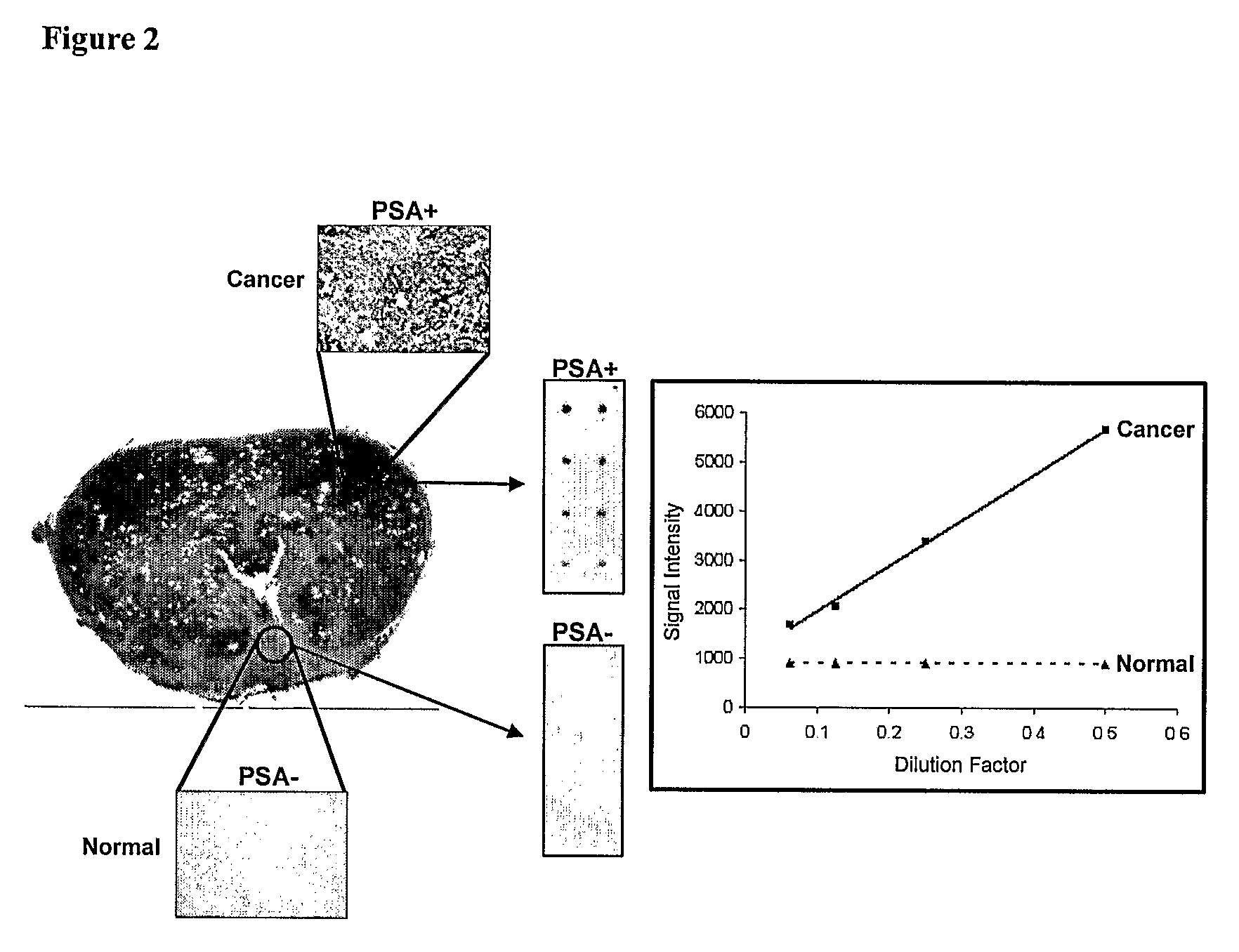

Diagnosis of diseases and conditions by analysis of histopathologically processed biological samples using liquid tissue preparations

ActiveUS20090215636A1Increased predispositionMicrobiological testing/measurementLibrary screeningAnalyteFluid tissues

Owner:EXPRESSION PATHOLOGY

Method of meristem excision and transformation

ActiveUS20080256667A1Enrich the fraction of explants amenable to transformationMicroorganismsMicroorganism based processesBiologyTissue Preparation

The present invention relates to excision of explant material comprising meristematic tissue from cotton seeds. Methods for tissue preparation, storage, transformation, and selection or identification of transformed plants are disclosed, as are transformable meristem tissues and plants produced by such methods, and apparati for tissue preparation.

Owner:MONSANTO TECH LLC

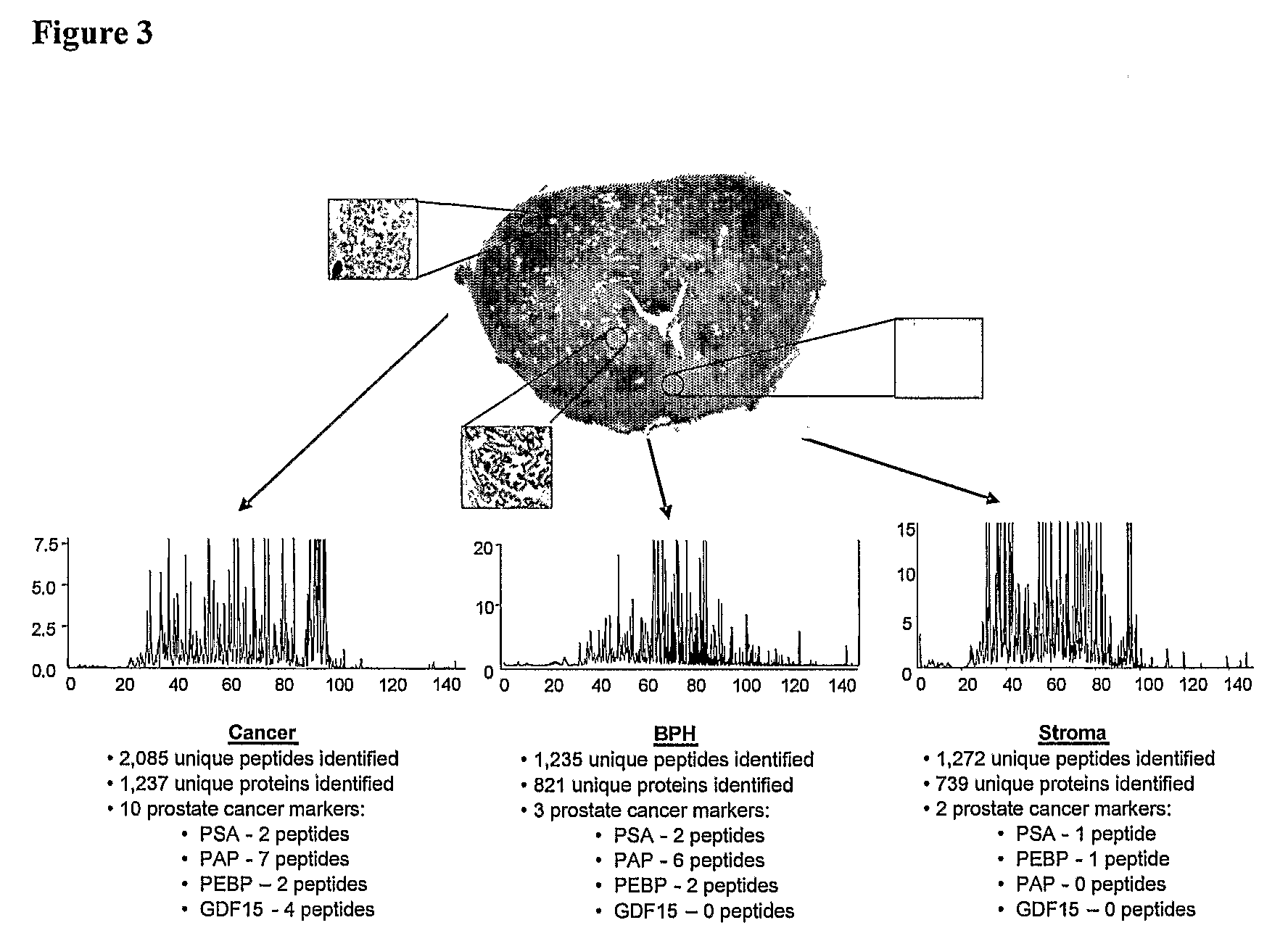

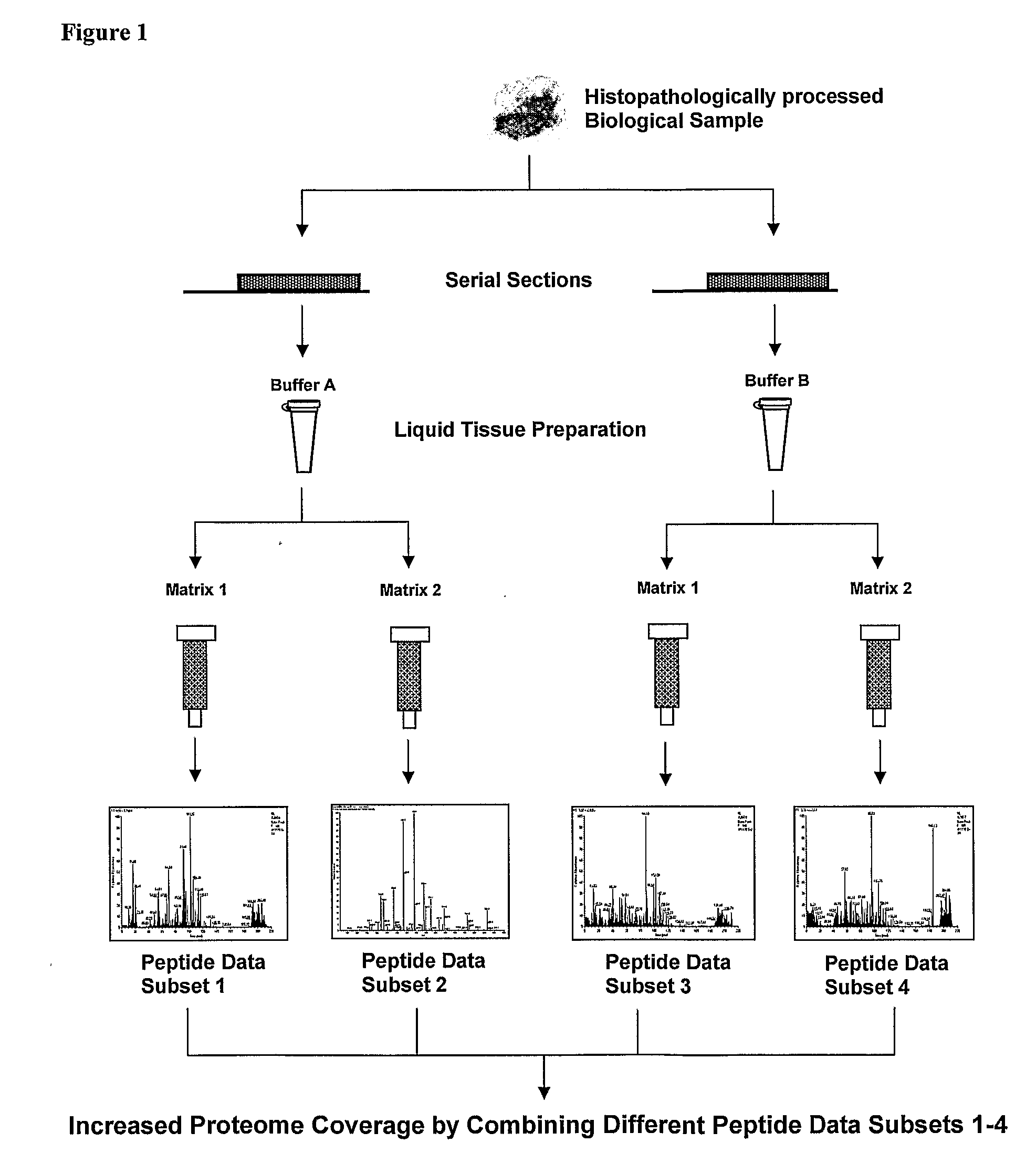

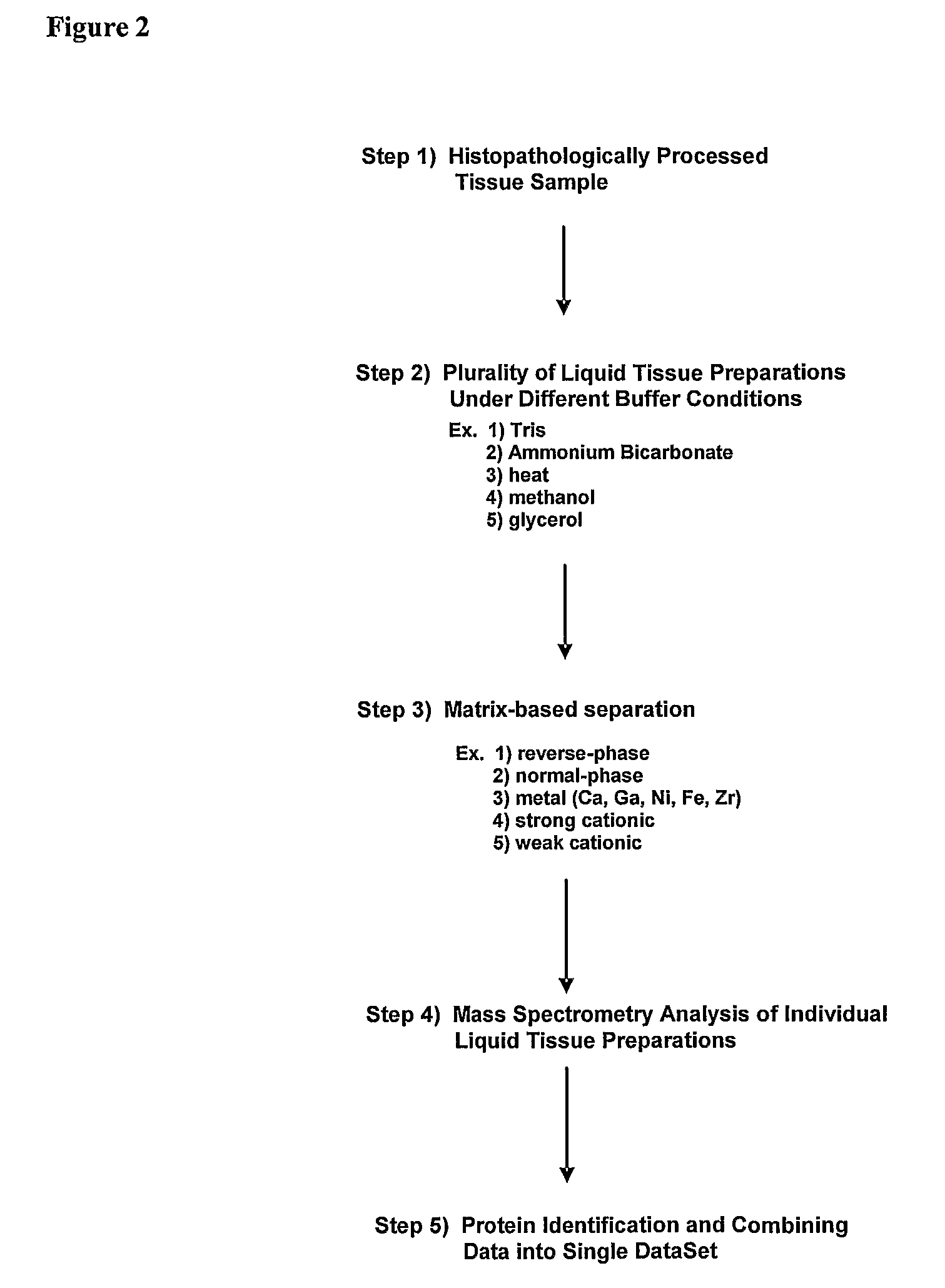

Multiplex liquid tissue method for increased proteomic coverage from histopathologically processed biological samples, tissues, and cells

ActiveUS20090136971A1Microbiological testing/measurementPreparing sample for investigationFluid tissuesProteomic Profile

The invention provides methods for multiplex analysis of biological samples of formalin-fixed tissue samples. The invention provides for a method to achieve a multiplexed, multi-staged plurality of Liquid Tissue preparations simultaneously from a single histopathologically processed biological sample, where the protocol for each Liquid Tissue preparation imparts a distinctive set of biochemical effects on biomolecules procured from histopathologically processed biological samples and which when each of the preparations is analyzed can render additive and complementary data about the same histopathologically processed biological sample.

Owner:EXPRESSION PATHOLOGY

Reusable Tissue Biopsy Kit with Padded Cassette

InactiveUS20100075410A1Promote resultsBig errorBioreactor/fermenter combinationsAnalysis using chemical indicatorsTissue biopsySample integrity

An improved biopsy kit for the collection, storage, transportation, and processing of biopsy tissue samples is disclosed. The disclosed biopsy kit consists of a typical specimen container and an improved tissue cassette with adhesively attached polyvinyl alcohol foam pads on both the base and lid portions. An excised tissue sample is sandwiched between the pads upon cassette closure, simultaneously isolating and securing the sample in its original orientation. Superior wicking, absorbency, and moisture retention rate of these polyvinyl alcohol pads allows maximum tissue fixation as well as maintains sample integrity. Once the tissue is placed by the physician at the patient's side, it remains there until the tissue is ready to be processed. This eliminates transfer errors as well as tissue loss.

Owner:DESAI VIRENDRA +1

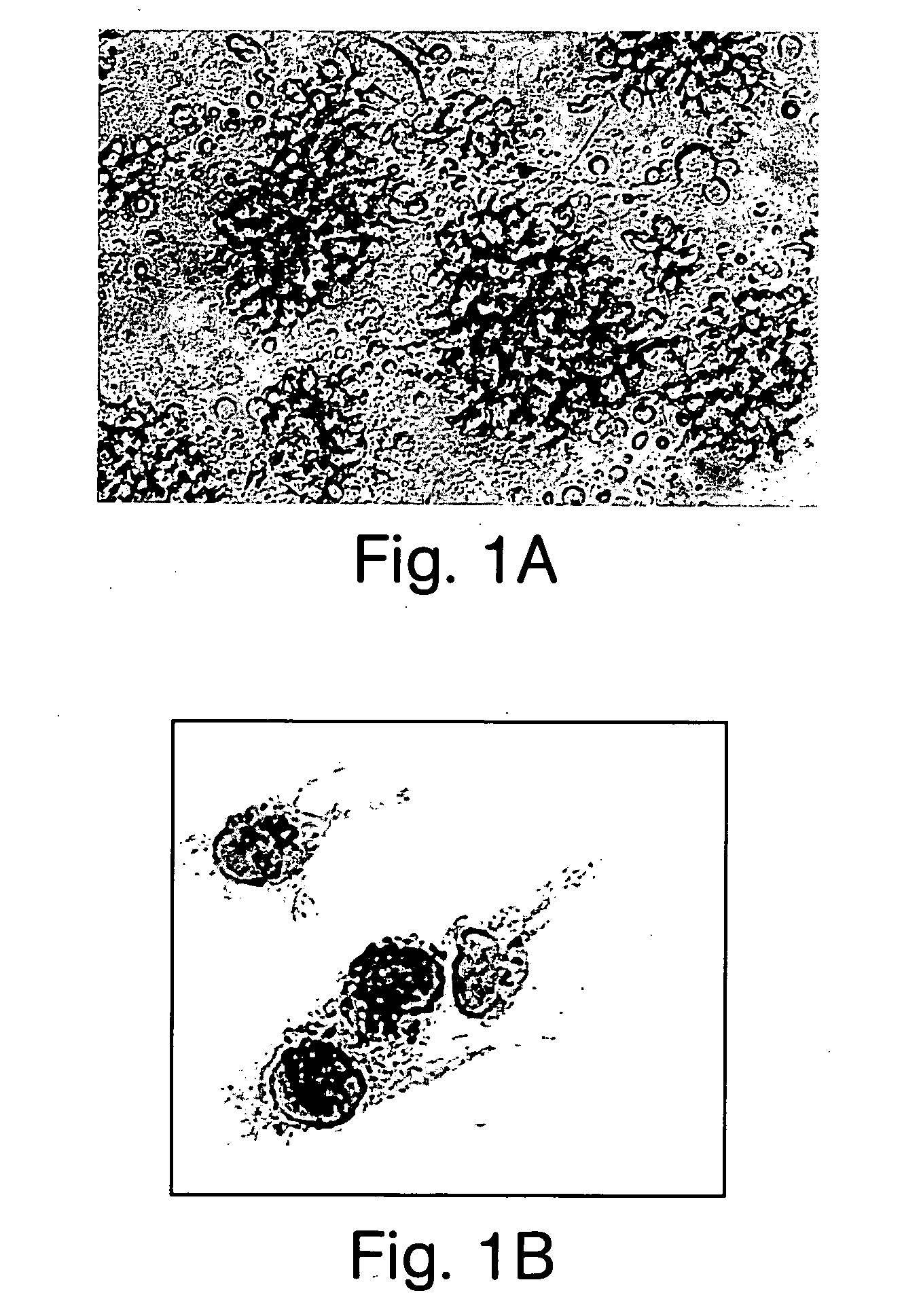

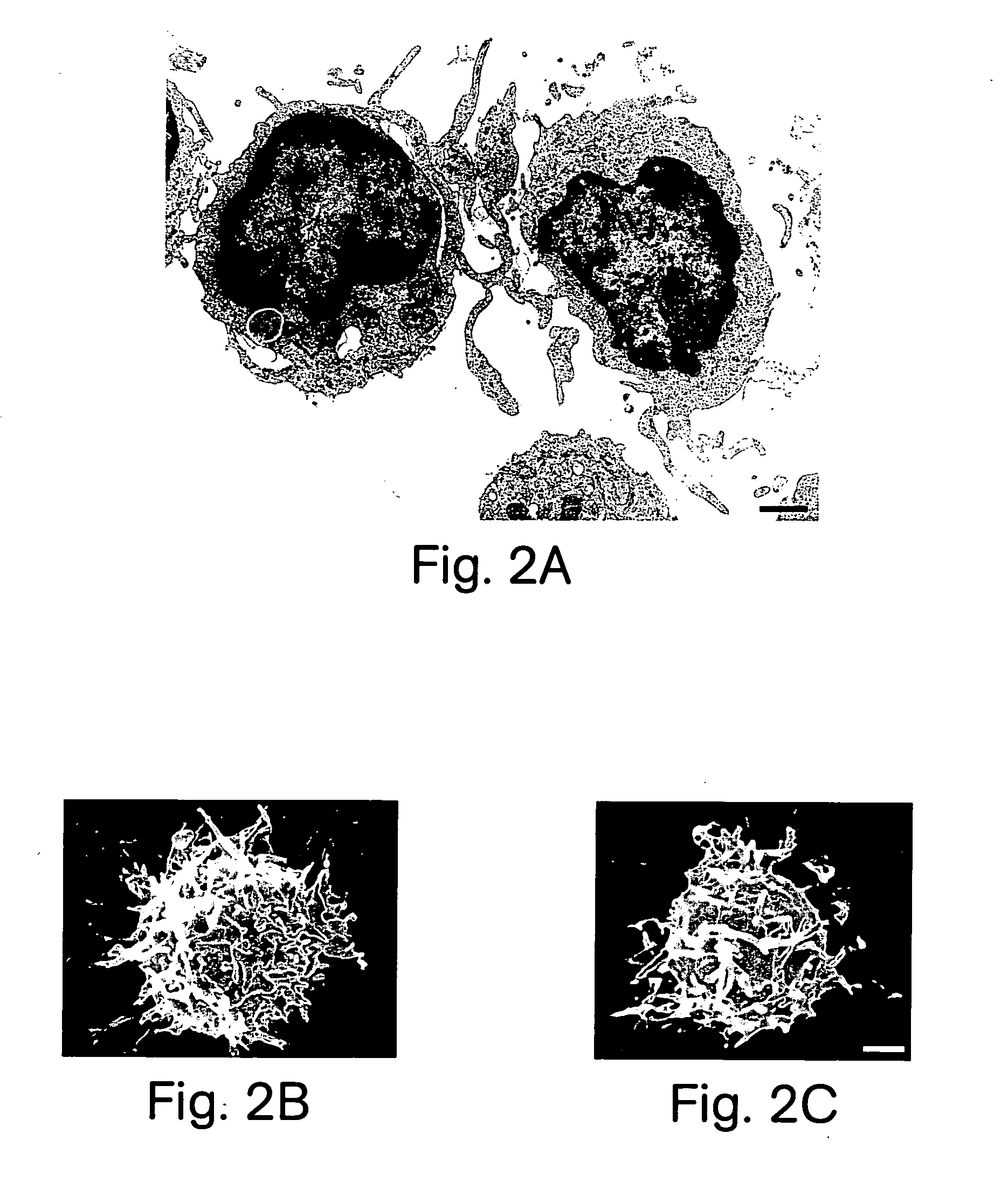

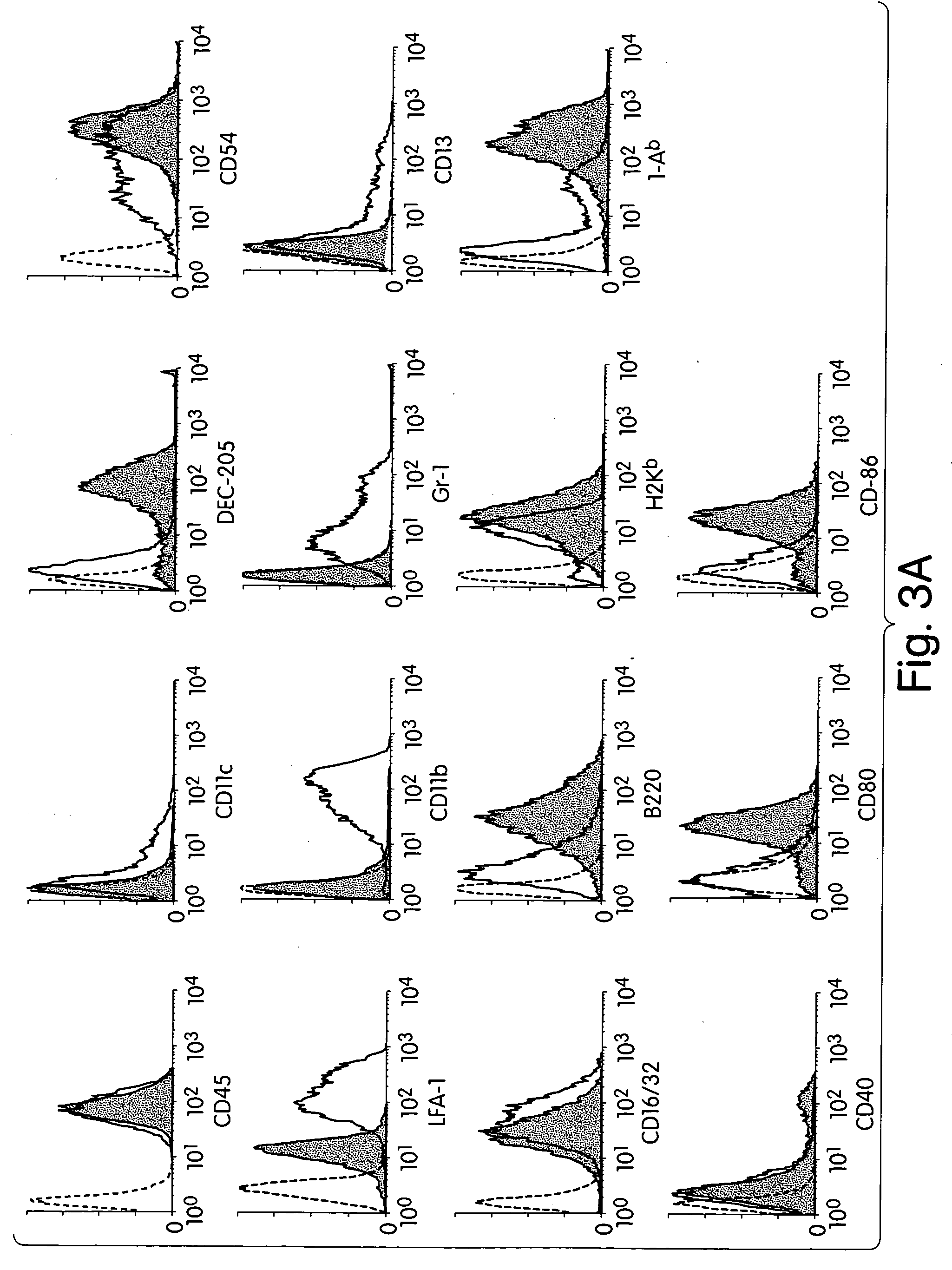

Novel tolerogenic dendritic cells and therapeutic uses therefor

The present invention relates to tolerogenic dendritic cells (DCs) and methods for enriching for these cells in tissue preparations and using the cells for preventing or minimizing transplant rejection or for treating or preventing an autoimmune disease.

Owner:UNIVERSITY OF PITTSBURGH

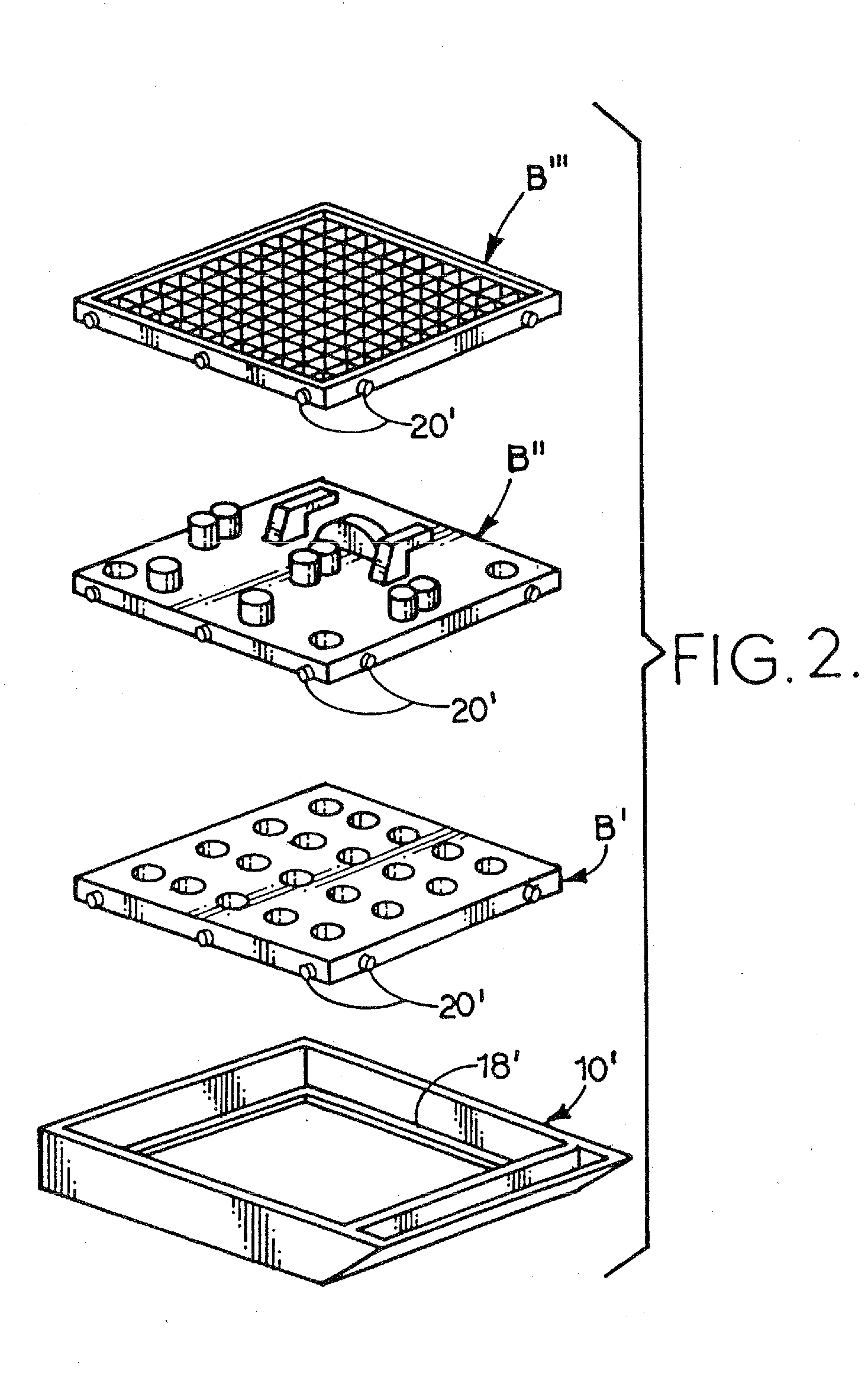

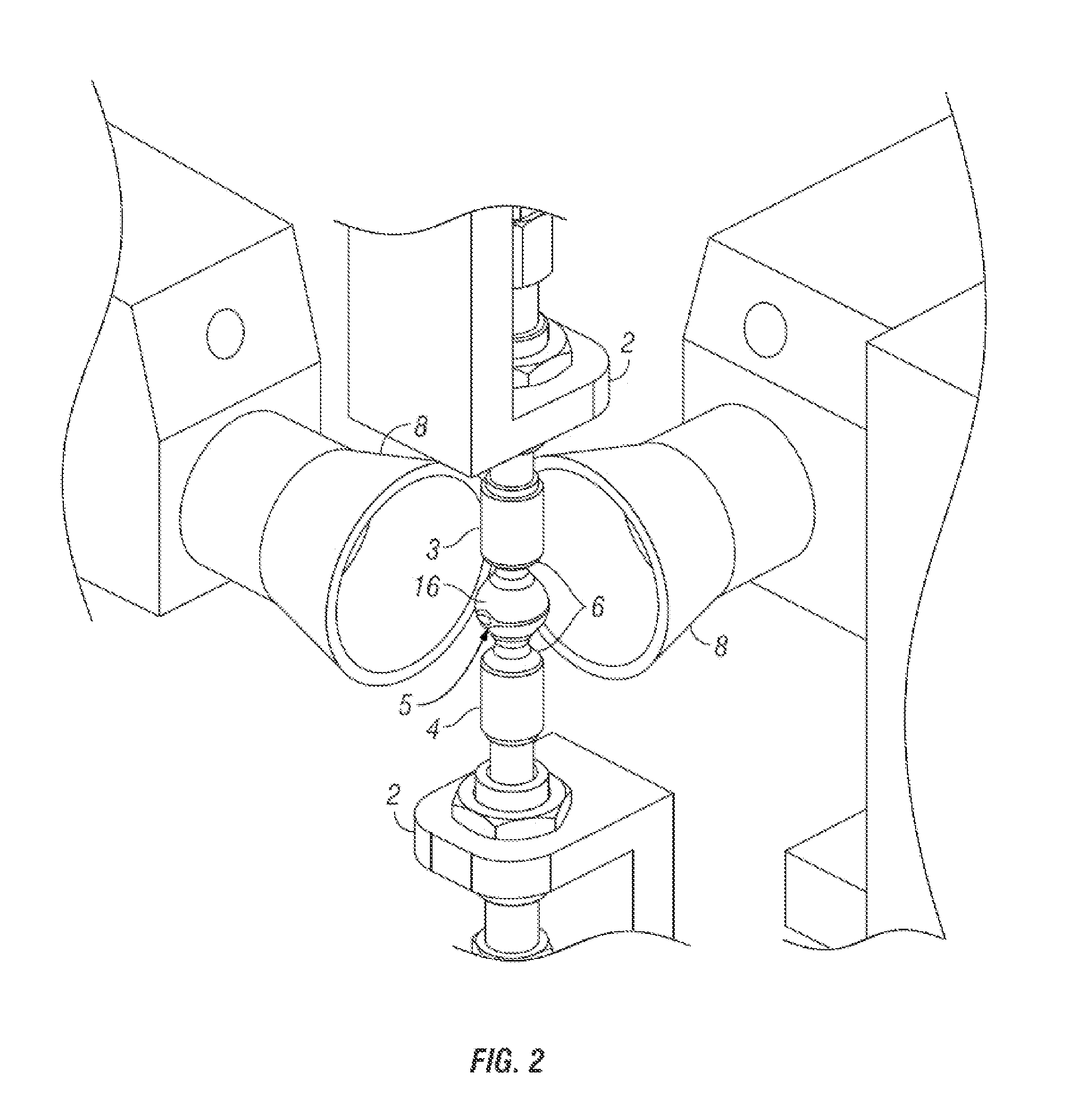

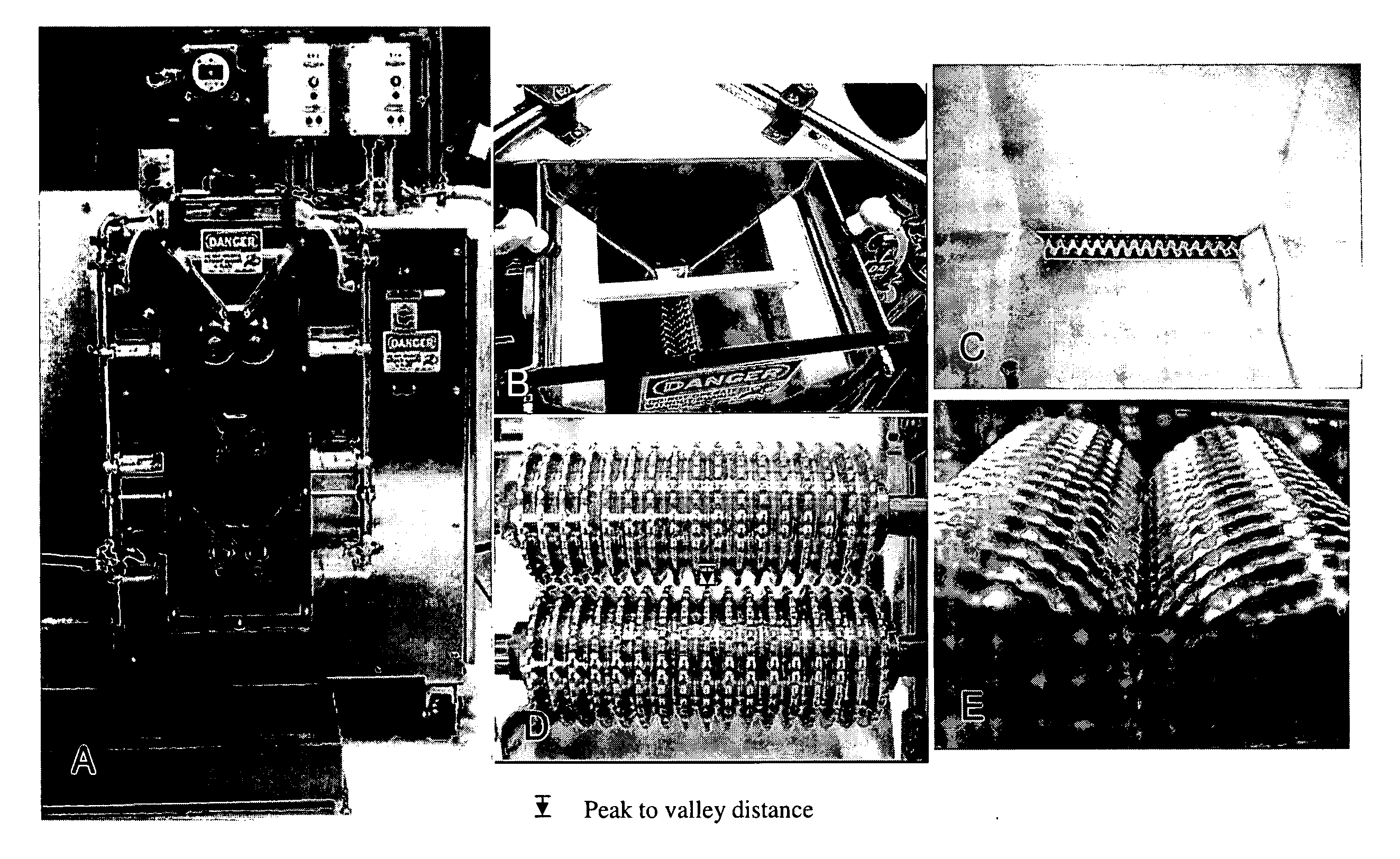

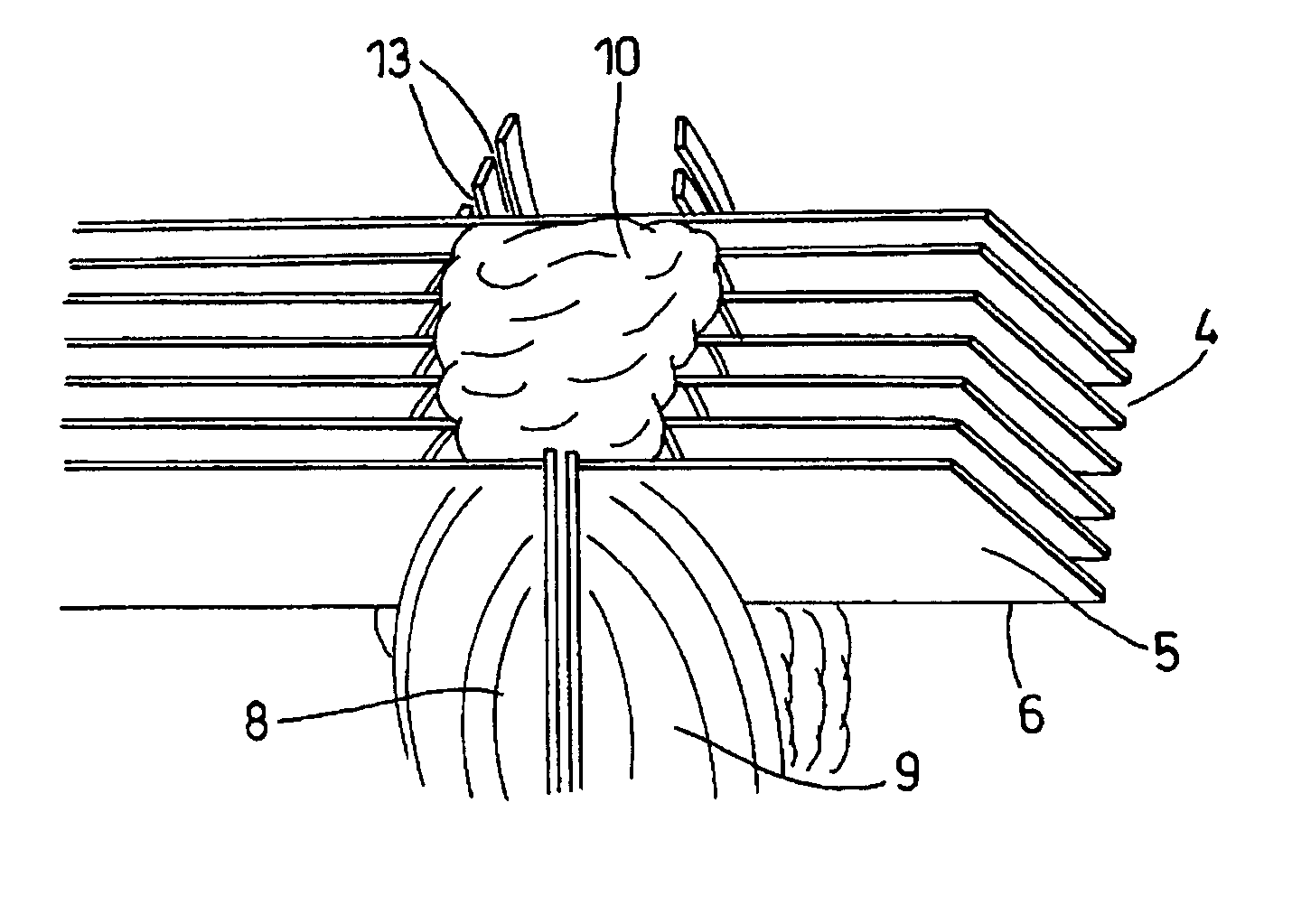

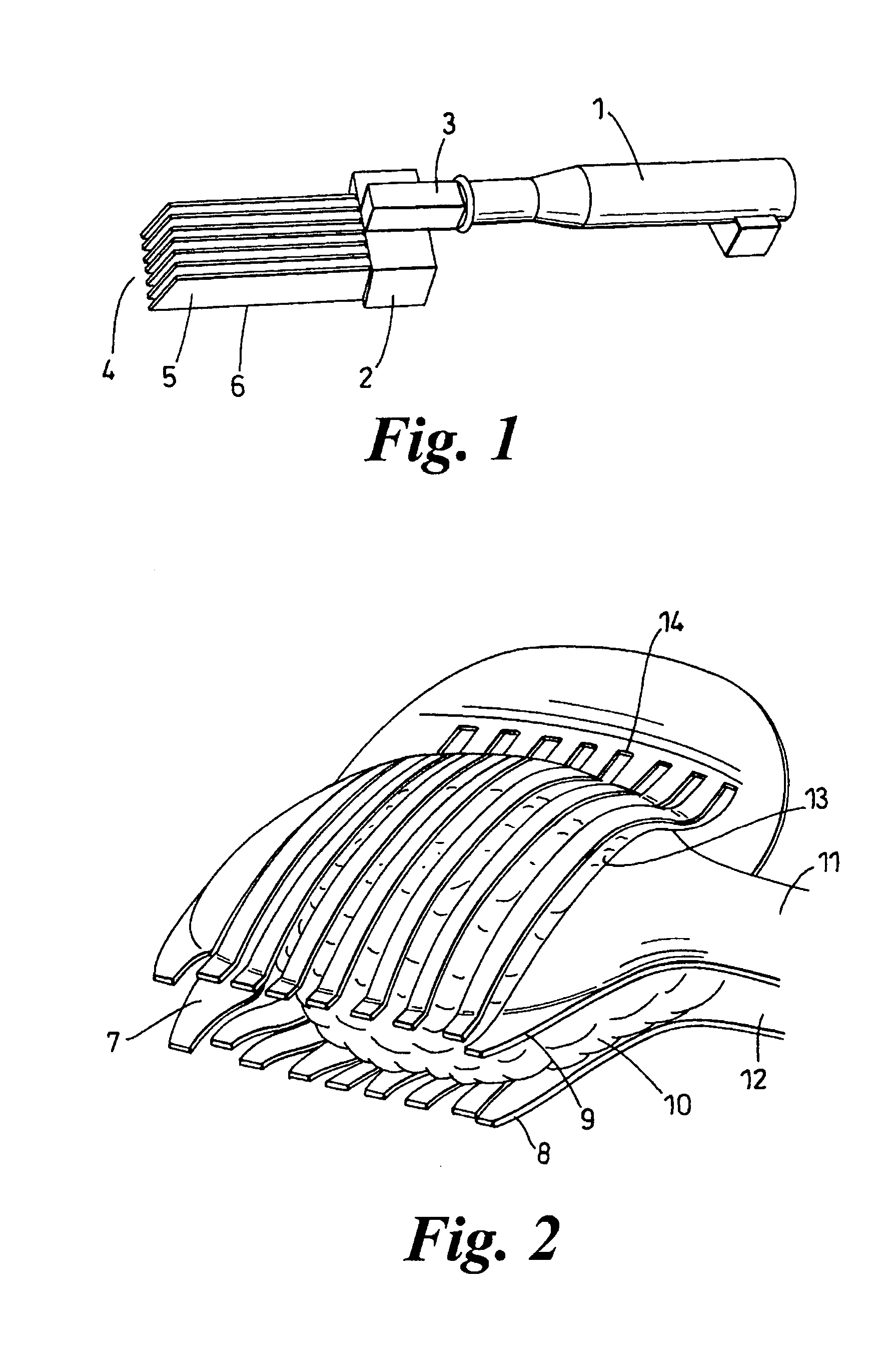

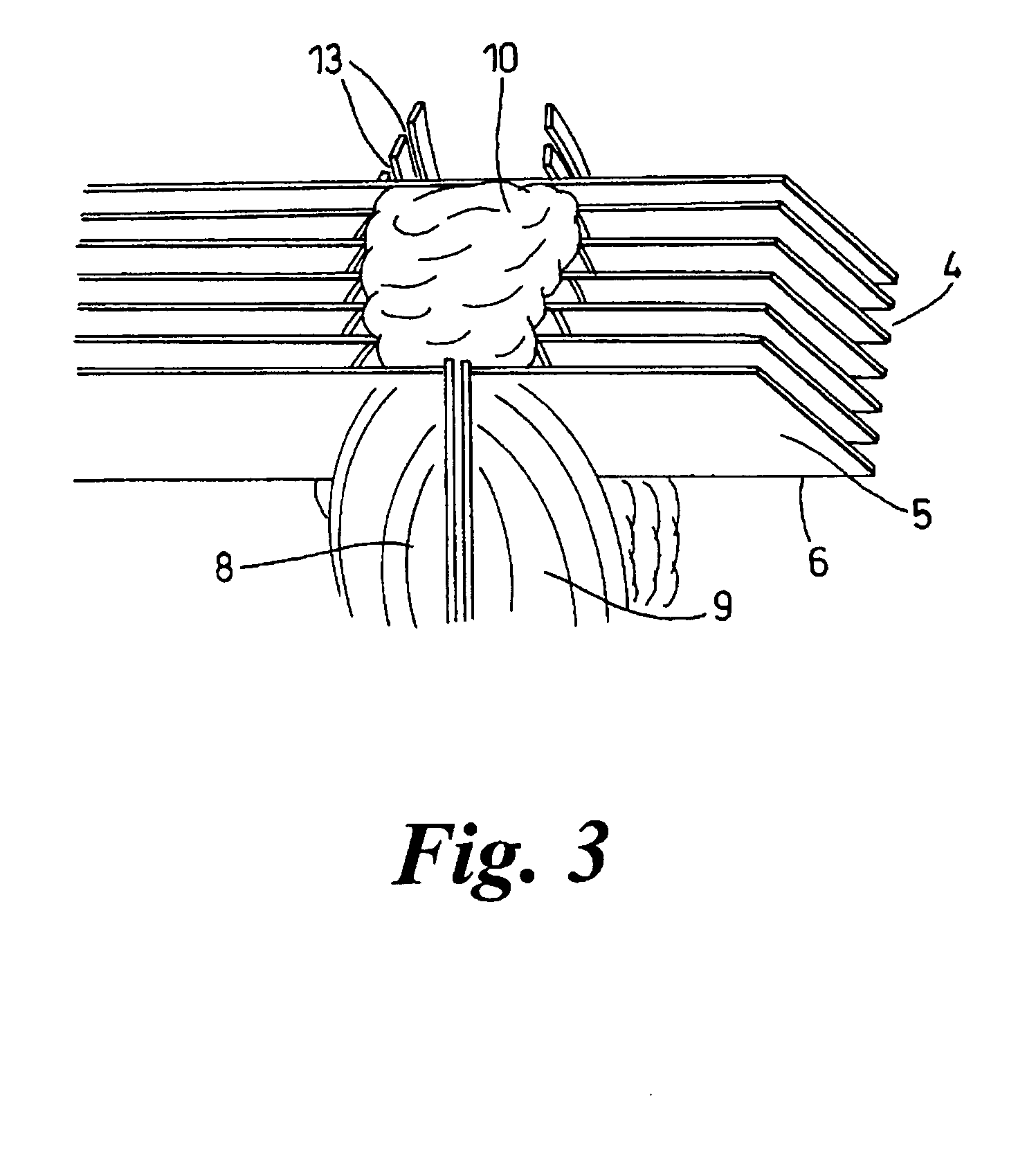

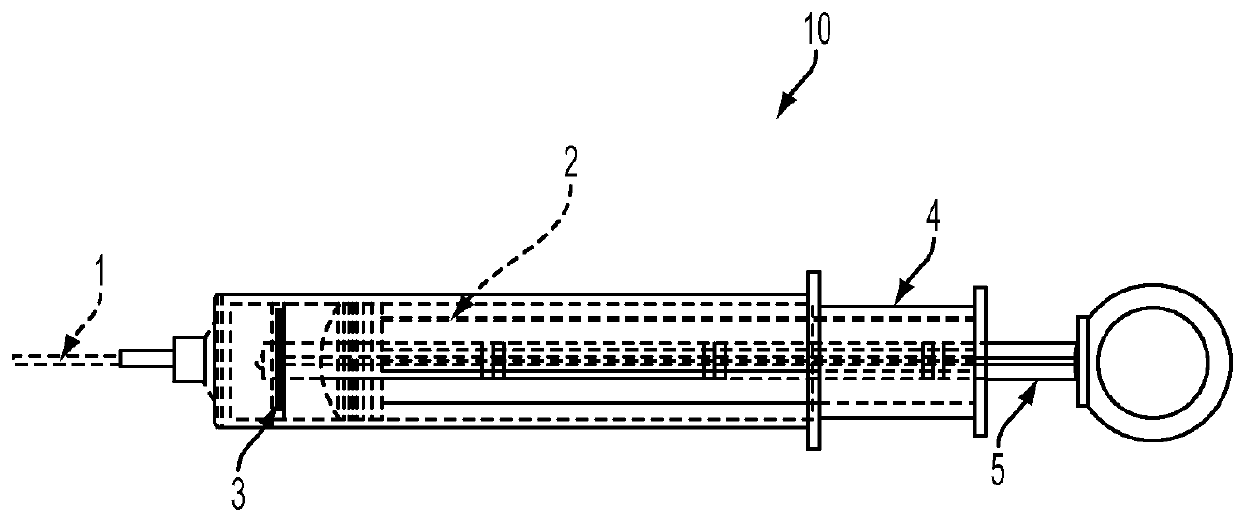

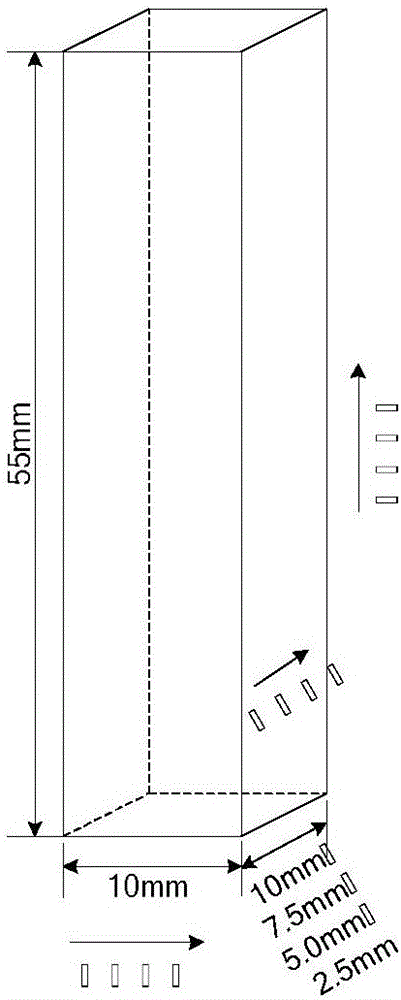

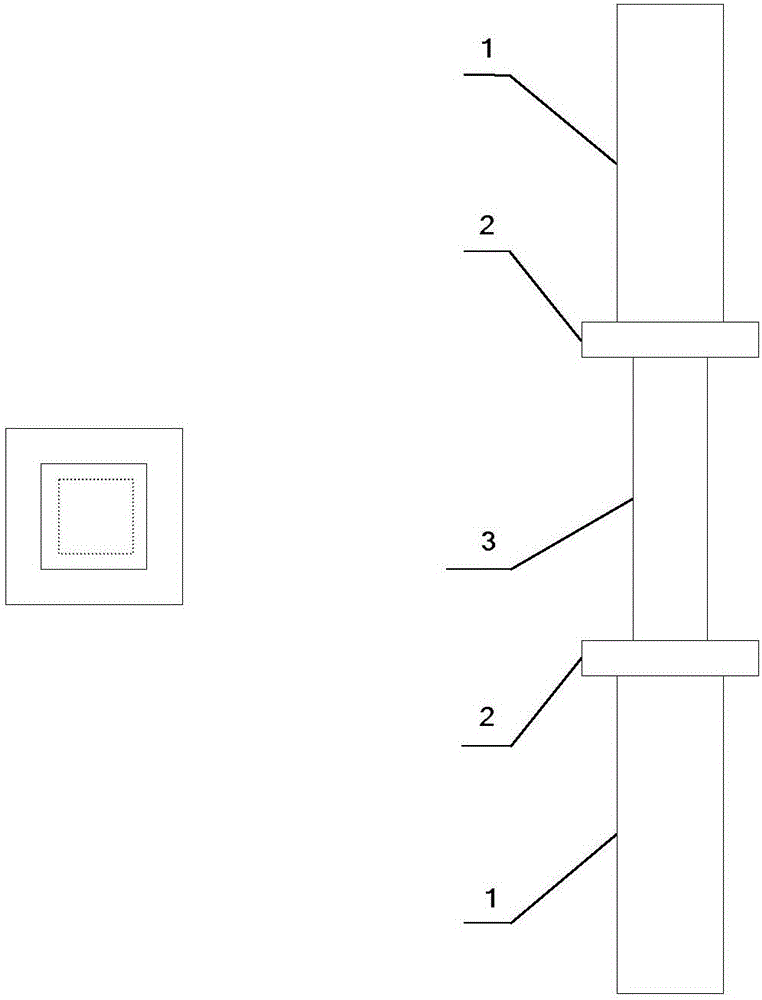

Apparatus and methods for tissue preparation

InactiveUS20050095666A1Avoid deformationIncision instrumentsWithdrawing sample devicesTissue sampleBiomedical engineering

The present invention features a multi-bladed cutter and a cradle adapted to grip a tissue sample 10 during cutting. The cutter has a series 4 of juxtaposed blades 5 and the cradle has a series of slits 13 adapted to receive the blades during cutting. The cradle may have opposing curved walls 8,9 which may be brought together to clasp the sample. The apparatus is suitable for cutting tissue such as prostate tissue, which is difficult to section. The apparatus is particularly suited to cutting tissue where chemical fixing is undesirable because nucleic acids are to be sampled from the tissue.

Owner:THE INST OF CANCER RES ROYAL CANCER HOSPITAL +1

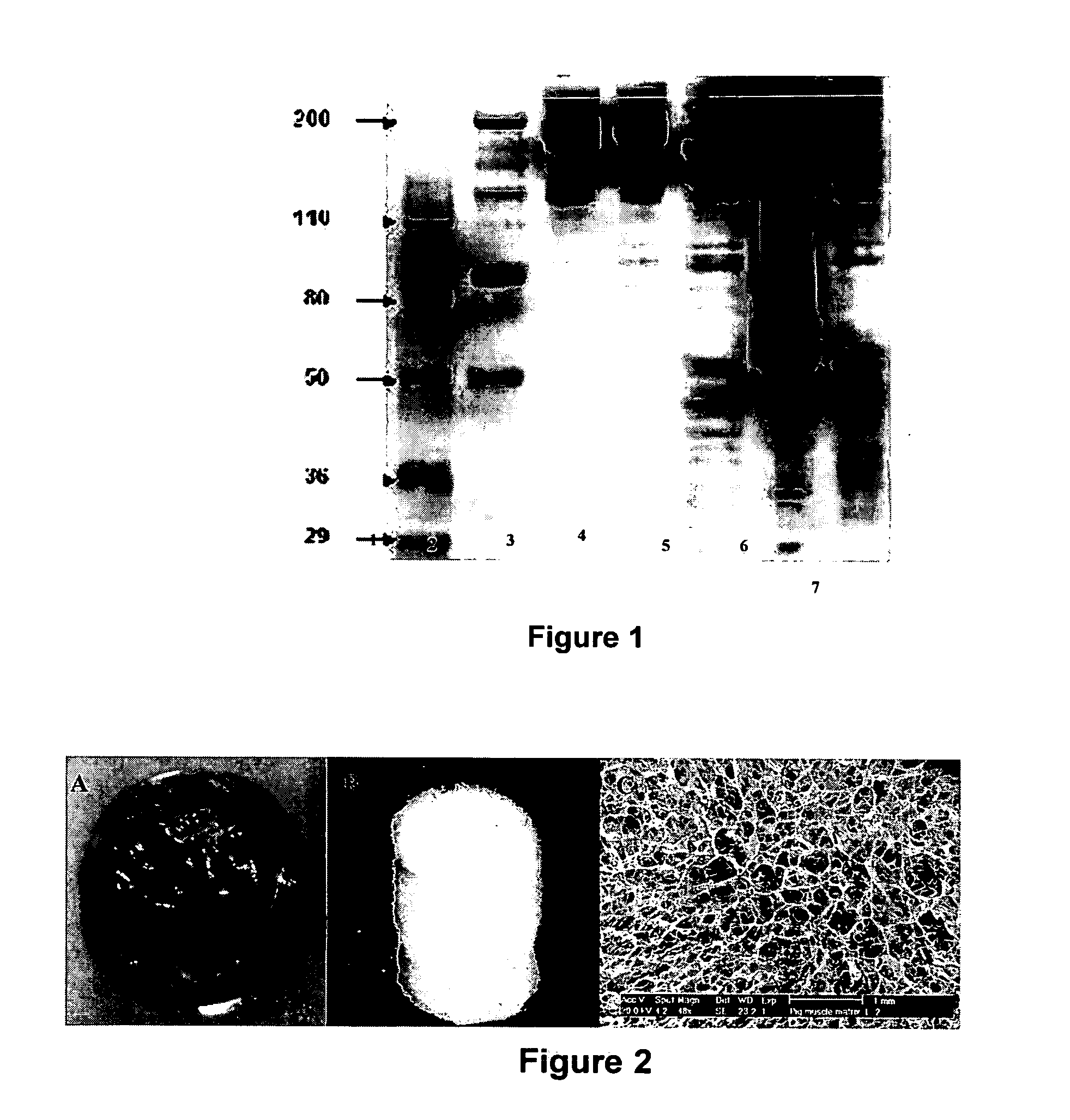

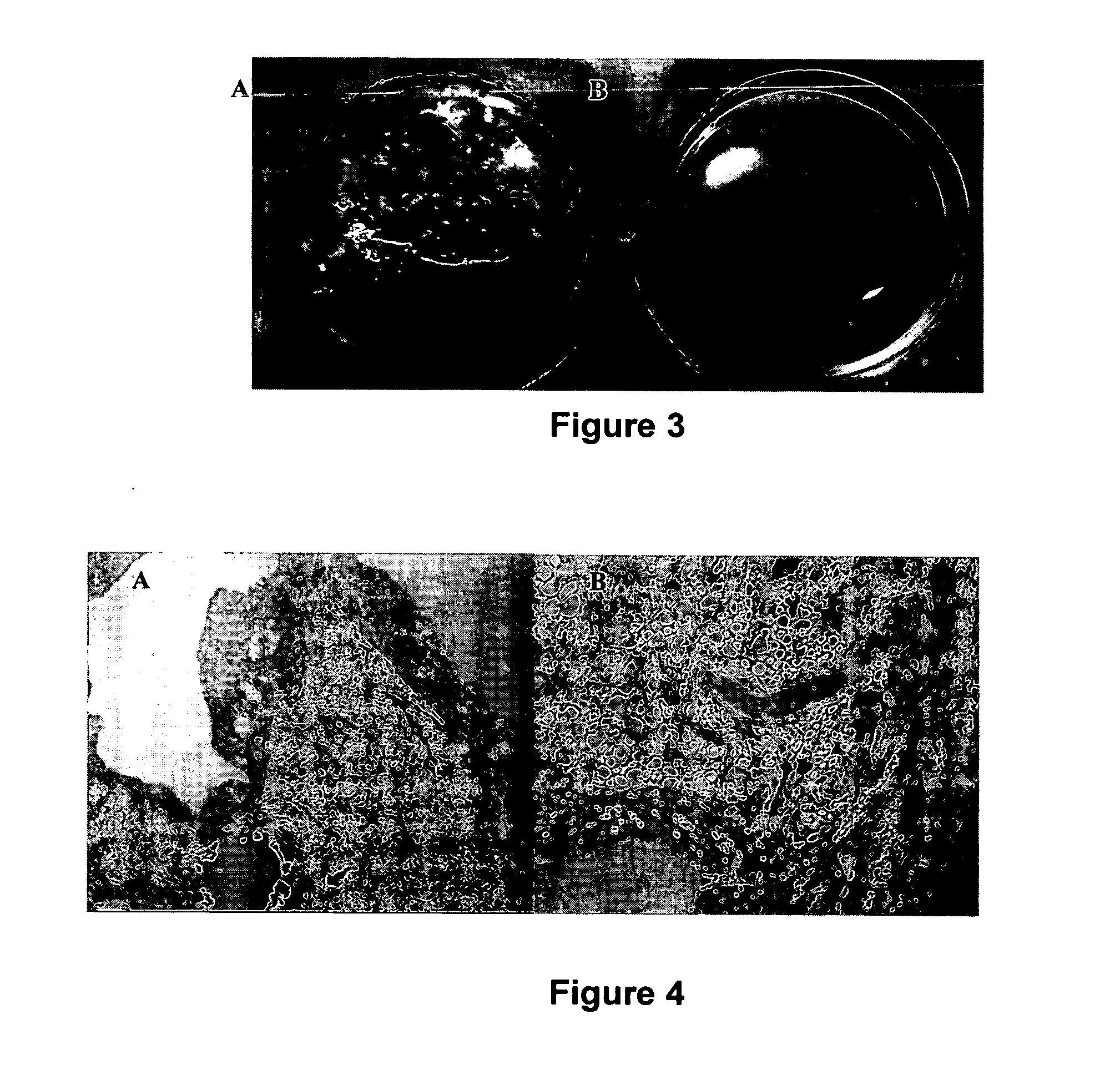

Tissue material and matrix

InactiveUS20060153797A1Organic active ingredientsNervous disorderCell-Extracellular MatrixTissue material

The present invention relates generally to a tissue preparation including tissue cells and extracts thereof useful for promoting or facilitating the growth, development and differentiation of cells and tissues. More particularly, the present invention provides muscle-derived material comprising intact or extracted extracellular matrix and / or cells as well as cytokines, growth factors and other components. The muscle preparations of the present invention resemble basement membrane and are derived from cellular-based material. The muscle preparation may be used in vitro or in vivo as inter alia, a cellular scaffold in various tissue engineering applications and in other cell culture systems for nurturing and enriching a range of cell types including, but not limited to, precursor and stem cells such as pre-adipogenic cells. The muscle preparation is also useful as a base for creams, such as in the cosmetic and topical therapeutic industries and as a matrix or additive in the food industry.

Owner:VICTORIAN TISSUE ENG CENT

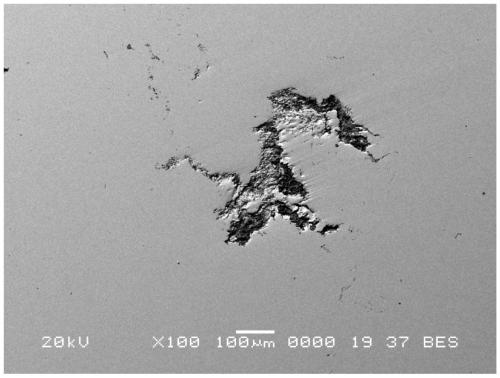

Post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills

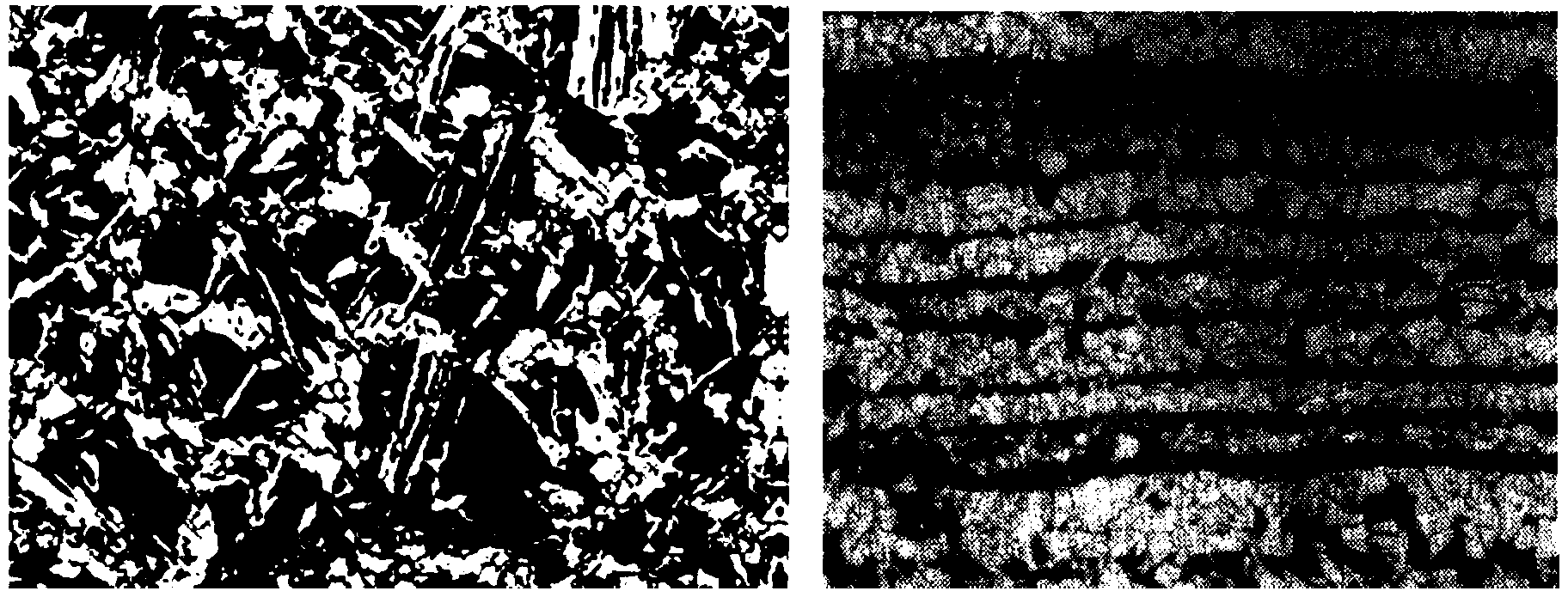

InactiveCN102417965AAvoid white spotsFurnace typesHeat treatment process controlHeat treatingCrystallite

The invention belongs to the technical field of large forging heat treatment processes, and mainly relates to a post-forging heat treatment process for 45Cr4NiMoV alloy steel large back-up rolls of rolling mills. A forged back-up roll is cooled to 400 DEG C to 500 DEG C by the air and put into a furnace, and the material temperature in the heat treatment furnace is not lower than 600 DEG C; a high-temperature normalizing plus low-temperature normalizing plus spheroidizing annealing plus high-temperature tempering process is adopted, and air cooling is carried out. The adopted post-forging heat treatment process disclosed by the invention is characterized in that: crystalline grains are thinned; the structure is regulated, so that the network structure is removed; the carbon segregation ofthe upper part of the large steel ingot is considerable, temperature higher than Ac1 is kept for a long time, consequently, part of carbide is remelted, the remaining unmelted carbide is spheroidized, and a granular pearlite structure is obtained during cooling; consequently, the structure toughness is high, and structure preparation is done for the next step of heat treatment; and fish eyes are prevented.

Owner:洛阳中创重型机械有限公司

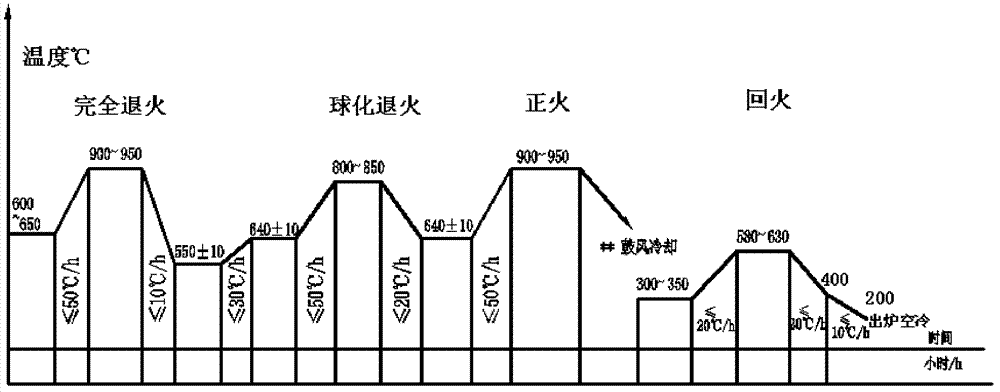

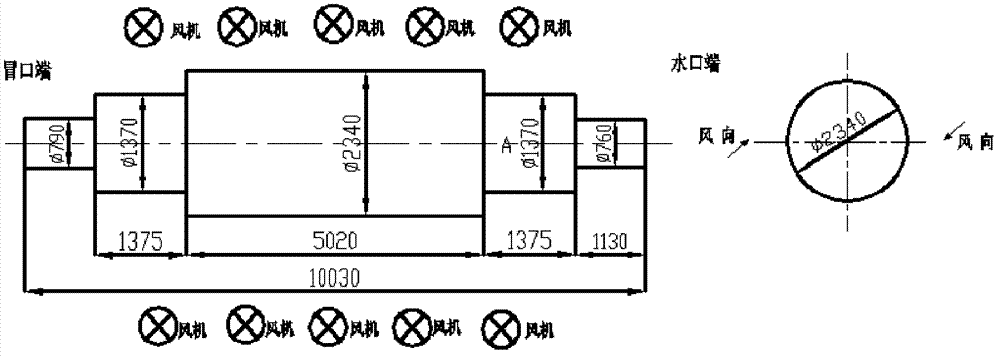

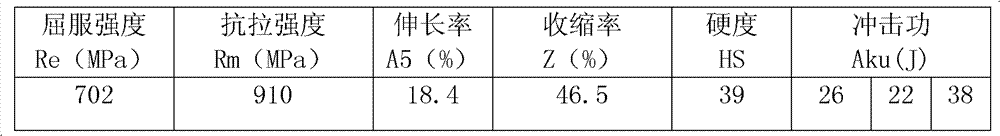

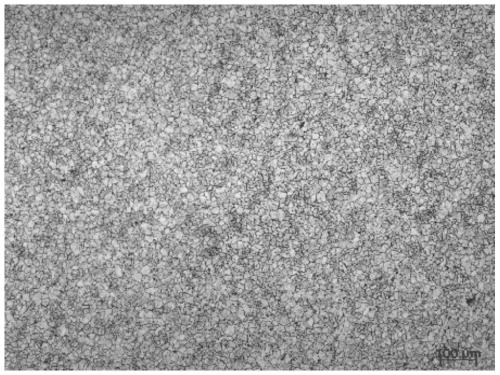

Heat treatment method after forging for forged steel bearing roller used for large heavy plate mill

ActiveCN103088199AEasy to shapeMeet the hardnessFurnace typesHeat treatment furnacesStrip millHardness

The present invention discloses a heat treatment method after forging for forged steel bearing roller used for large heavy plate mill, which is used for heat treatment after forging of supporting rollers used for a rolling mill with a plate width of above 2500 mm. The method comprises the following steps of: first, fully annealing; second, spheroidizing annealing; third, normalizing; and fourth, tempering. The operation method of once heat treatment after forging is used for supporting rollers used for the rolling mill with the plate width of above 2500 mm, so that the roll neck stiffness and other mechanical properties of the workpiece meet technical requirements through a manner of normalizing blast cooling. A preheat treatment process is reduced, the production cycle is shortened, and the production cost is reduced. The large plate supporting roller after heat treatment after forging can acquire pearlitic structure and sorbite structure with good mechanical properties, so that the hardness of the roll neck is up to 30-40 HS. The mechanical properties meet the technical requirements. The structure preparation for subsequent heat treatment is made.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

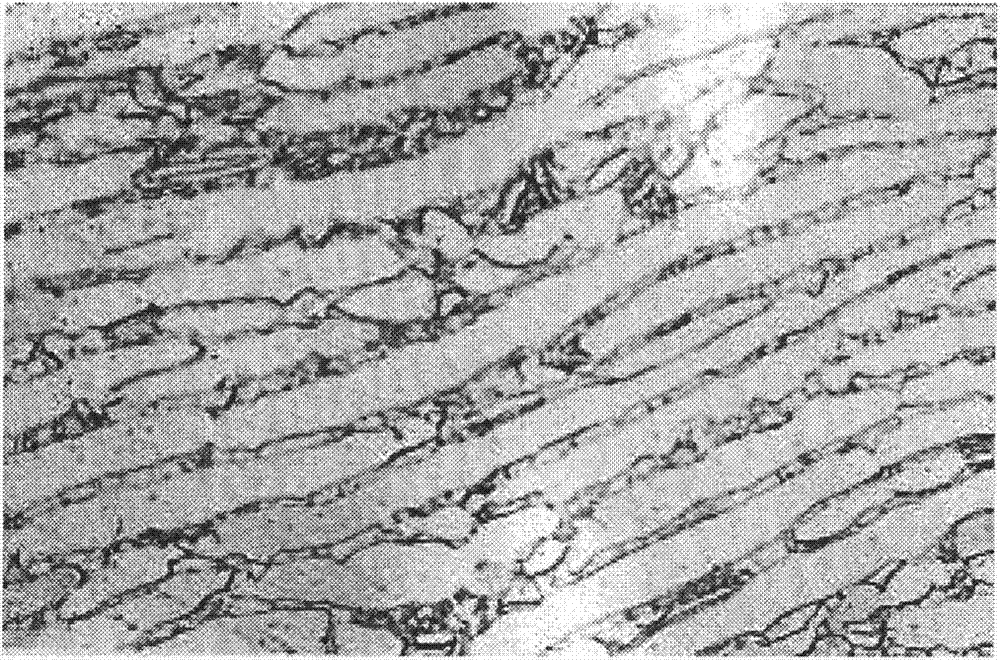

Heat treatment technology method for improving obdurability of high-speed steel

InactiveCN102392124AChange in strengthImprove performanceHeat treatment process controlPre treatmentQuenching

The invention discloses a heat treatment technology method for improving the obdurability of high-speed steel. The method comprises the following steps: carrying out isothermal spheroidizing pretreatment on high-speed steel pieces, and carrying out isothermal quenching, step quenching, subzero treatment and tempering composite final heat treatment. After the isothermal spheroidizing pretreatment,machining is convenient to carry out, and organization preparation is made for subsequent quenching treatment; final heat treatment is carried out after preheating treatment and comprises the following steps: carrying out oil quenching at the lower bainite transformation temperature; then carrying out subzero treatment for 24 hours or above; and carrying out secondary circulation treatment: carrying out step quenching at 520-600DEG C and subzero treatment; and finally, and carrying out heat insulation for 1-2 hours at 520-600DEG C.

Owner:SOUTHWEST JIAOTONG UNIV

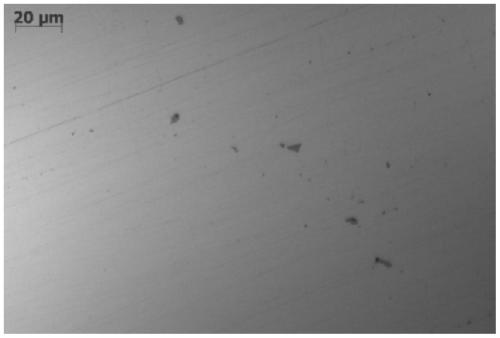

Method for changing structure uniformity of large-specification titanium alloy bar

ActiveCN103938137AImprove uniformitySolve the performance homogenization problemGreek letter betaTitanium alloy

The invention relates to a method for changing the structure uniformity of a large-specification titanium alloy bar. The method comprises the following steps: I, bar cutting and first-fire all-direction upsetting and stretching; II, second-fire all-direction upsetting and stretching; III, third-fire upsetting and stretching. Through three-fire six-time all-direction upsetting and stretching, an equiaxial uniform duplex microstructure with primary alpha phase (10-40%) plus beta transformation structure can be provided for a forged piece. The substituting forging technology does a good preparation for next-step blank production and die forging.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

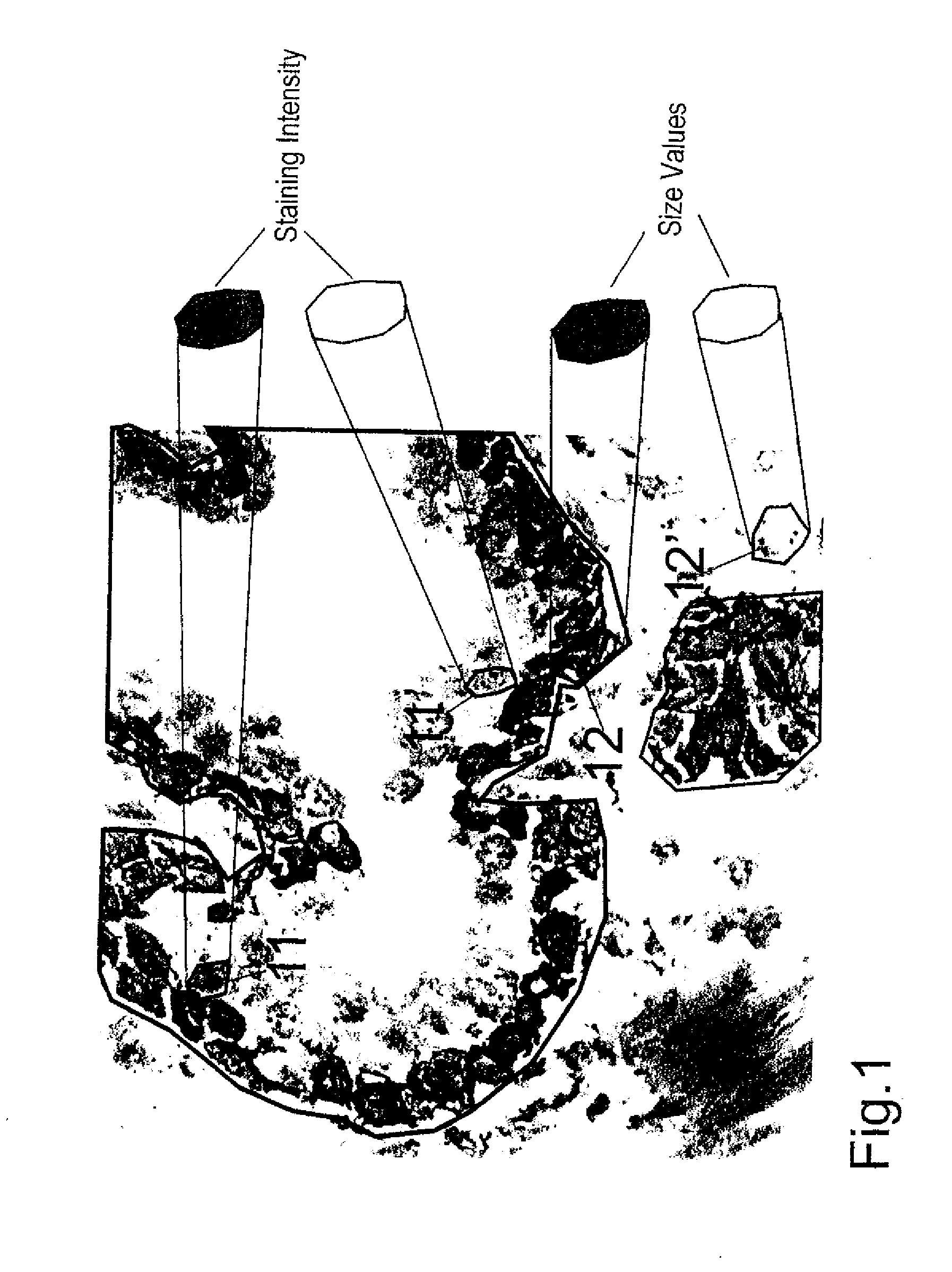

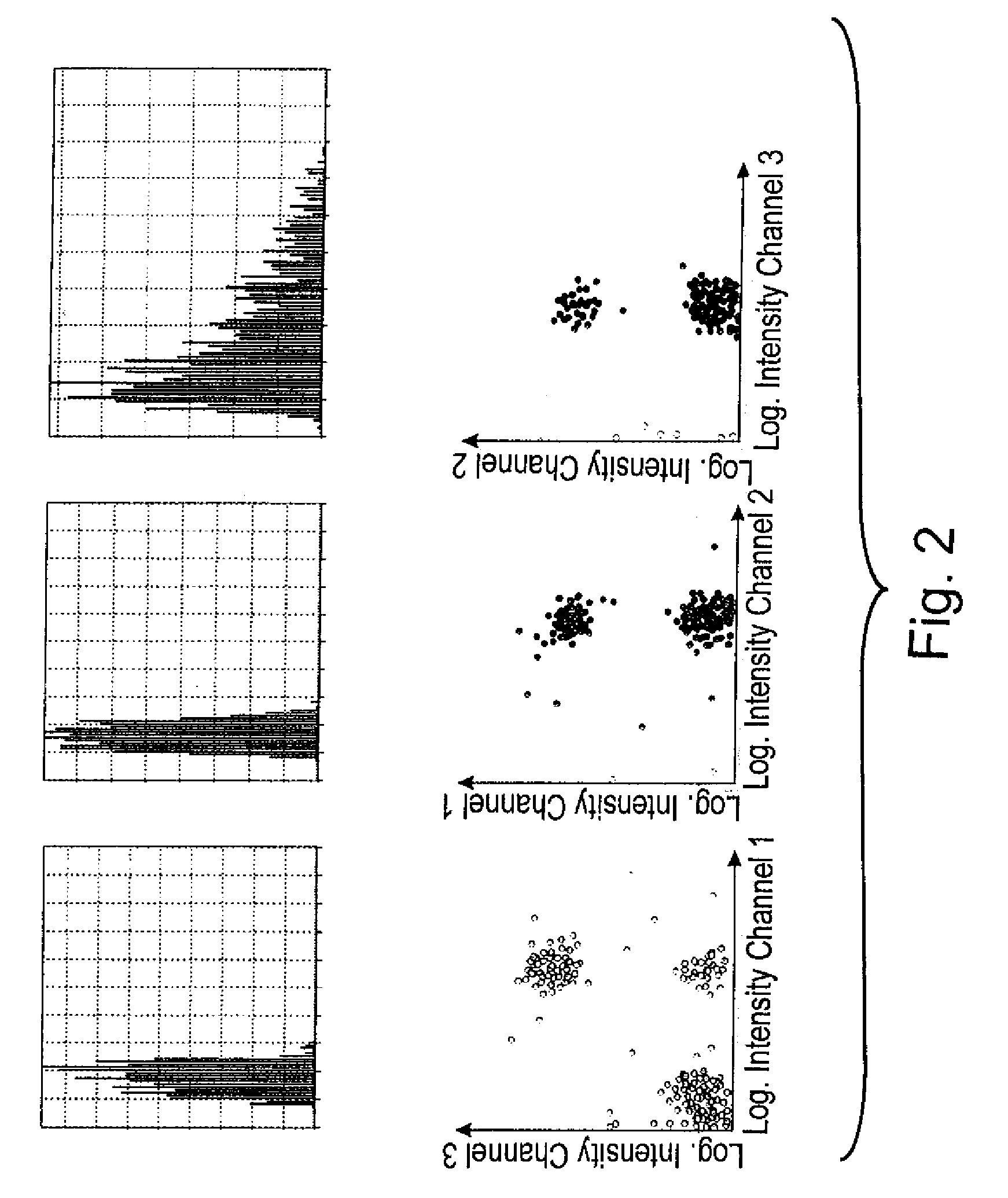

Methods and system for analyzing cells

InactiveUS20100279341A1High riskSeparate controlPreparing sample for investigationBiological testingStainingObject label

The invention relates to a method for analyzing cells that are present as closed clusters. According to said method, a planar tissue preparation is subjected to an identification staining of the cell nuclei and a target structure staining of cell objects that is different from the identification staining. Digital images are recorded of the stained tissue preparation by means of an electronic image recording device and at least one image of a subsection of the tissue cut is displayed in at least one coloration. According to the inventive method, at least one parameter of the cell nuclei and at least one parameter of the cell objects labeled by target structure staining is restricted to a predetermined range of values. Cell nuclei and cell objects whose parameters correspond to the respective parameter range(s) are detected and optionally displayed using image processing algorithms in the image of said subsection. The image content of at least one image detected for the cell nuclei is correlated with the image content of at least one image detected for the target-structure stained cell objects to detect the individual cells. On the basis of the cell nuclei identified a cell growth or a cell enlargement is induced using a predetermined arithmetic algorithm to reconstruct the individual cells. In doing so it is made sure that neighboring cells do not fuse. The number of reconstructed individual cells is determined and / or the individual cells are divided into populations according to certain parameters.

Owner:TISSUE GNOSTICS GMBH

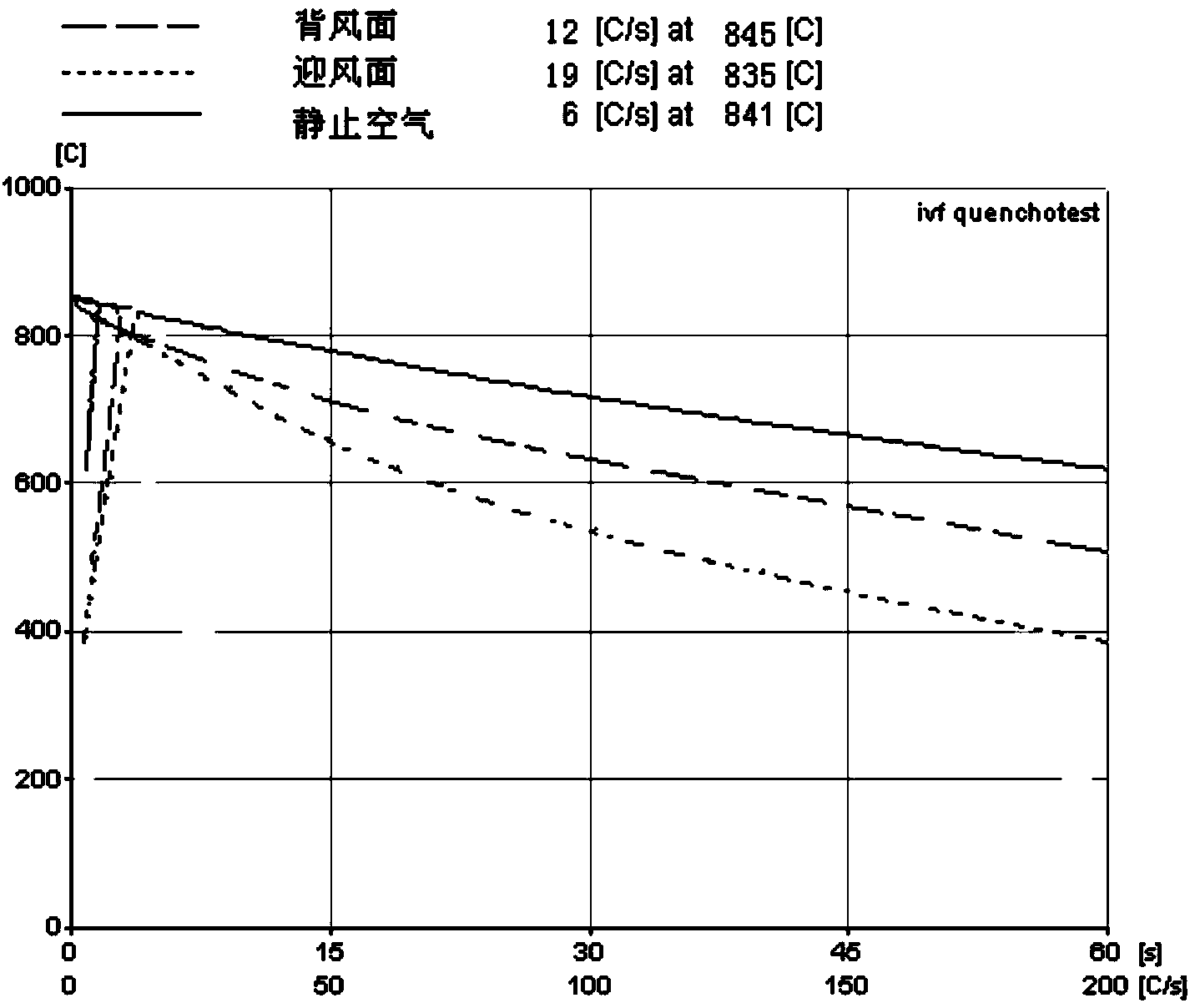

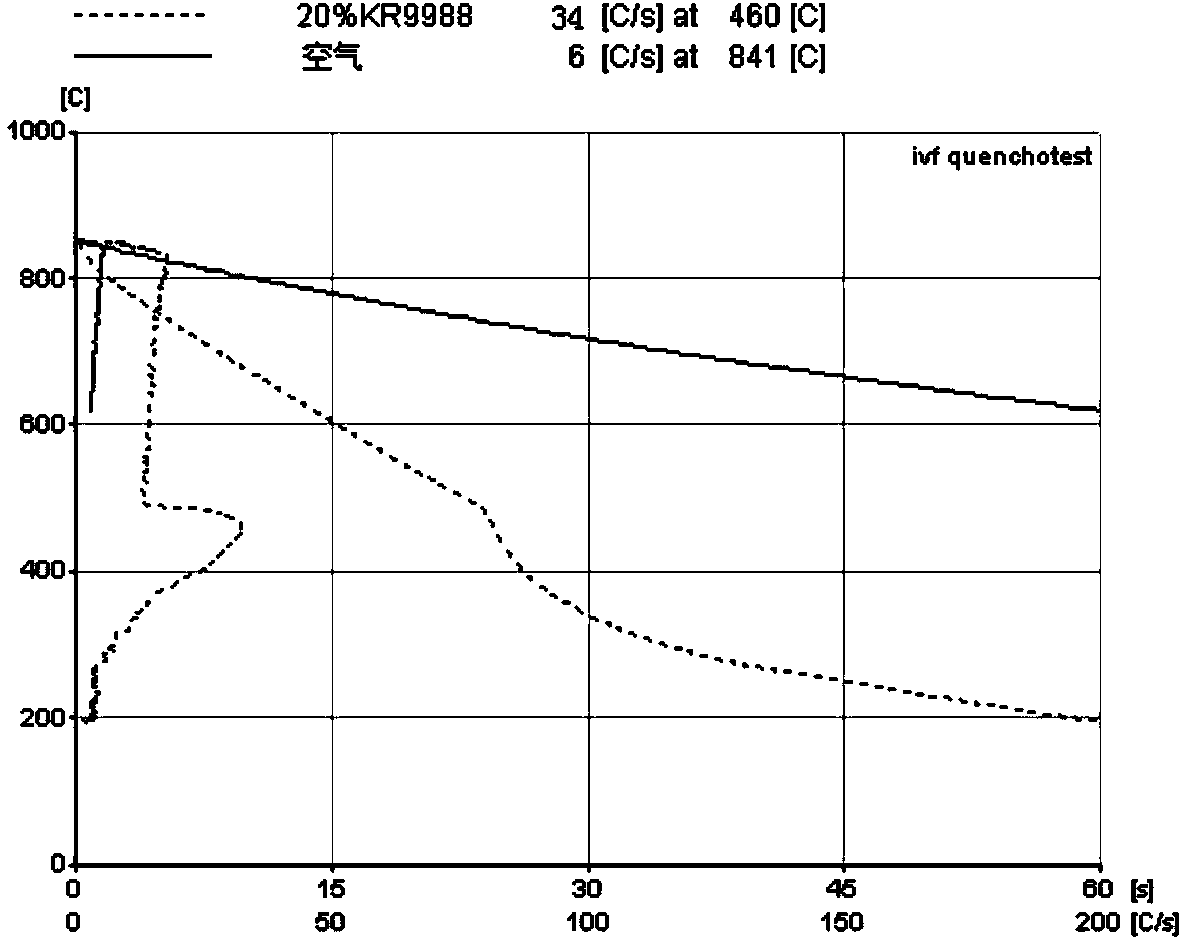

Constant-speed cooling medium with extremely-stable cooling property

ActiveCN103509530ASolve uneven cooling effectSolve the problem of insufficient traditional cooling capacityHeat-exchange elementsQuenching agentsPollutionHeat treated

The invention provides a constant-speed cooling medium with an extremely-stable cooling property, which is characterized in that the constant-speed cooling medium is an aqueous solution of high molecular polymers, the aqueous solution of the high molecular polymers comprises 5-15% of polyvinylpyrrolidone (PVP), 3-8% sodium carboxymethylcellulose (CMC) and 0-3% of sodium polyacrylate (ACR) and further comprises 3-8% of a defoamer, a rust inhibitor and a microbicide, and water in balancing amount. When a forged product is cooled in the constant-speed cooling medium, the cooling process of the surface and the core of the product can be coordinated, so as to effectively control the problem of secondary segregation after forging and solve the problems such as thick and big core structure to prepare for the subsequent heat treatment. Besides, the constant-speed cooling medium has the characteristics of cleanness, environmental friendliness and no pollution, improves the operational environment of a production site and ensures safe production. The conventional extensive cooling mode is replaced, the energy consumption is reduced, and the cost input of related auxiliary equipment is reduced.

Owner:NANJING KERUN LUBRICANTS

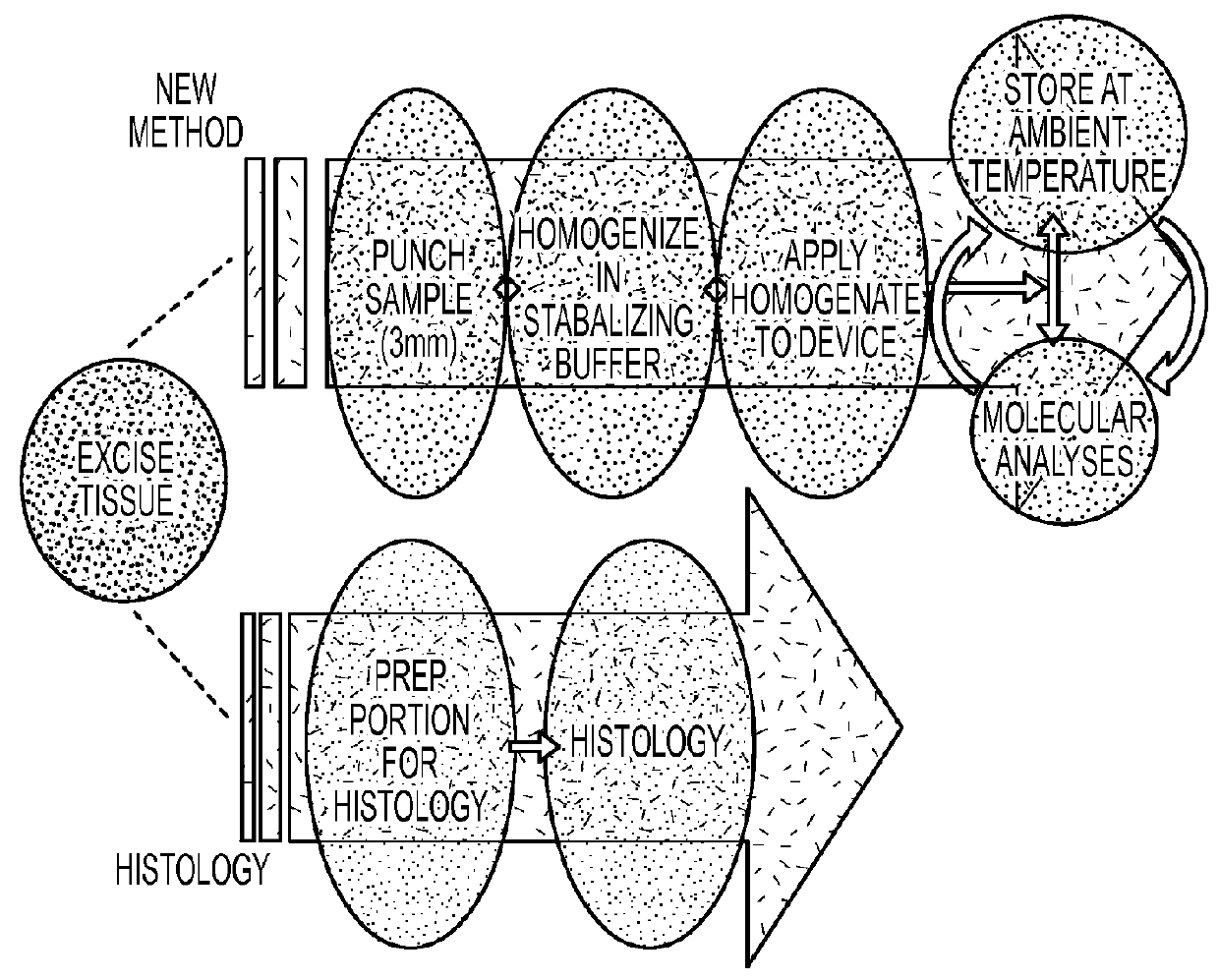

Biological sample collection and preservation

An embodiment of the claimed invention is directed to a method that greatly streamlines and reduces costs for tissue preparation, preservation, long-term storage and sample retrieval for molecular analysis using a method based on dried blood spot (DBS) technology. In this method, a small needle punch sample of freshly excised tissue will be homogenized in stabilizing reagent and inserted into a device containing absorbent material and drying agent. This device is suitable for long-term sample storage at ambient temperature and allows for easy removal of sections for biomarker analysis.

Owner:SPOT BIOSCI LLC

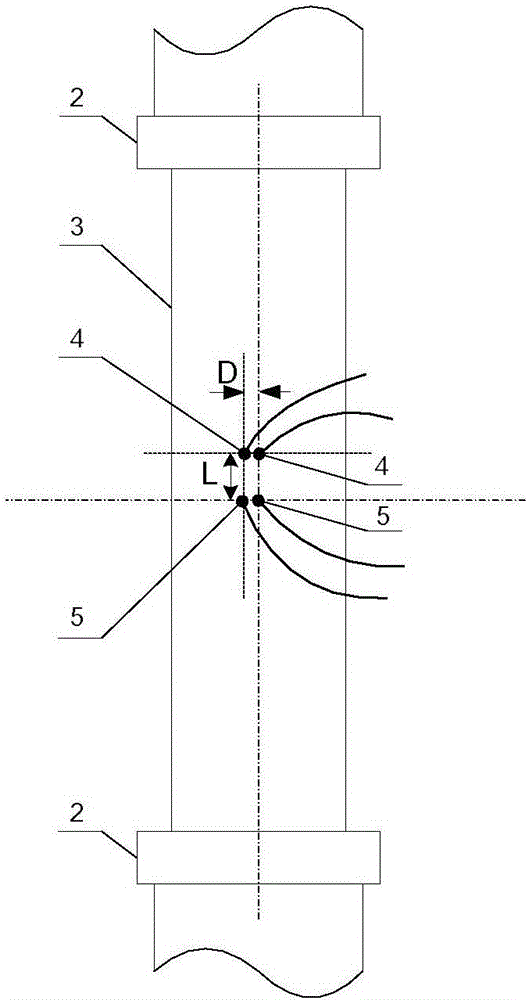

Thermal simulation method of thermal-mechanical treatment of high strength automobile steel impact specimen

ActiveCN106525563AAchieve high precision controlSmall fluctuation rangePreparing sample for investigationRepeatabilityCompression test

The invention provides a thermal simulation method of thermal-mechanical treatment of high strength automobile steel impact specimen, and belongs to the technical field of thermal simulation. The method comprises the steps of (1) based on the size the a standard impact specimen, determining the simulation specimen size, the simulation specimen comprises a simulation rectangle, two ladder platforms and two clamp ends, determining the high temperature thermal-mechanical treatment process parameters applied in the heat simulation process, (2) welding a thermal couple on the surface of the simulation rectangle of the simulation specimen, (3) installing the simulation specimen on a thermal simulator, (4) conducting heat treatment to the simulation specimen, determining the average temperature area of the post-heated simulation specimen, (5) conducting compression test to the simulation specimen, determining the post-compression average temperature area of the simulation specimen, (6) conducting cooling treatment to the simulation specimen, (7) checking the simulation specimen surface, (8) processing the simulation specimen into a standard impact specimen, and verifying if the impact process is effective. The method can enhance the repeatability of the organization and preparation of the impact specimen of high strength automobile steel and the control precision of process parameters.

Owner:NORTHEASTERN UNIV

Grain refining method of high-strength long-service-life gear steel

The invention relates to a grain refining method of high-strength long-service-life gear steel. The grain refining method of the high-strength long-service-life gear steel comprises the following steps of controlling the steel 0. 020%-0.030% of Al, 0.010%-0.060% of Nb, 0.0060%-0.0100% of N, Ti is less than or equal to 0.035%, O is less than or equal to 0.012%, the content of Al and Ti is reduced,Nb is increased, a part of N is matched, and the crystal grains are refined by the co-action of Al+Nb+N. The rolling process has a key influence on grain refinement, in the aspect of rolling, according to the melting of AlN, NbC, NbN, Nb (C, N), the research on the precipitation temperature and the precipitation phase is improved in a targeted manner, during heating, Nb, C, Al and N are fused intogamma-Fe, a large compression ratio is adopted for the first several times of rolling, so that large deformation is formed; the tissue is refined, tissue preparation is provided for separation of theposterior particle AlN and NbC; the final rolling temperature is controlled, so that a large amount of particles such as NbC, AlN and the like after rolling are separated out; after rolling, slow cooling is carried out, the cooling speed is less than or equal to 8 DEG c. / min, the precipitation time of Al, Nb carbide, nitride or carbonitride is prolonged, through the above improvement, the grainsize of the gear steel is ensured to be fully refined.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

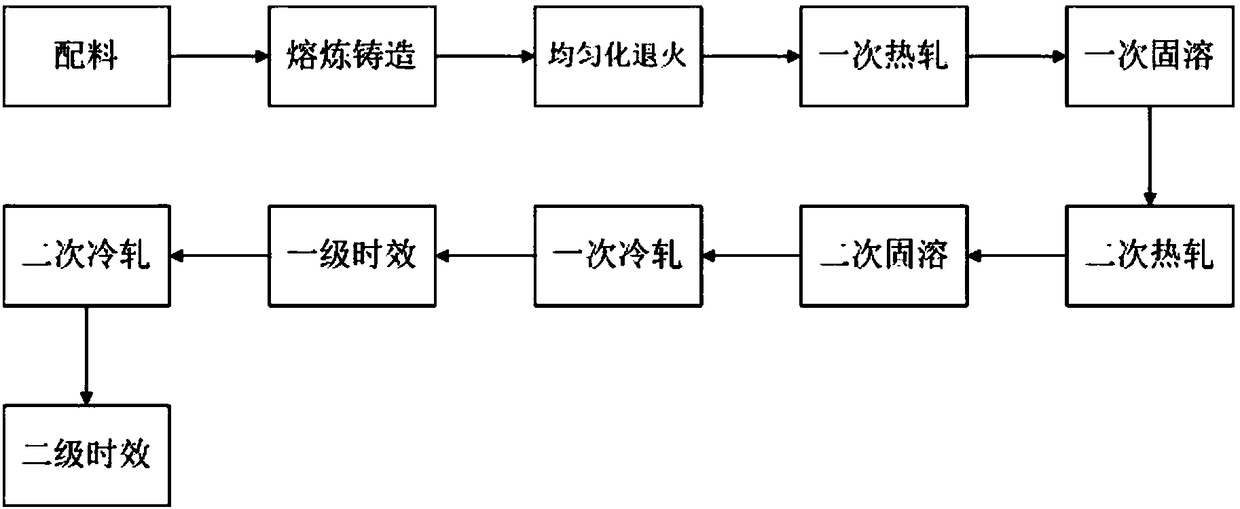

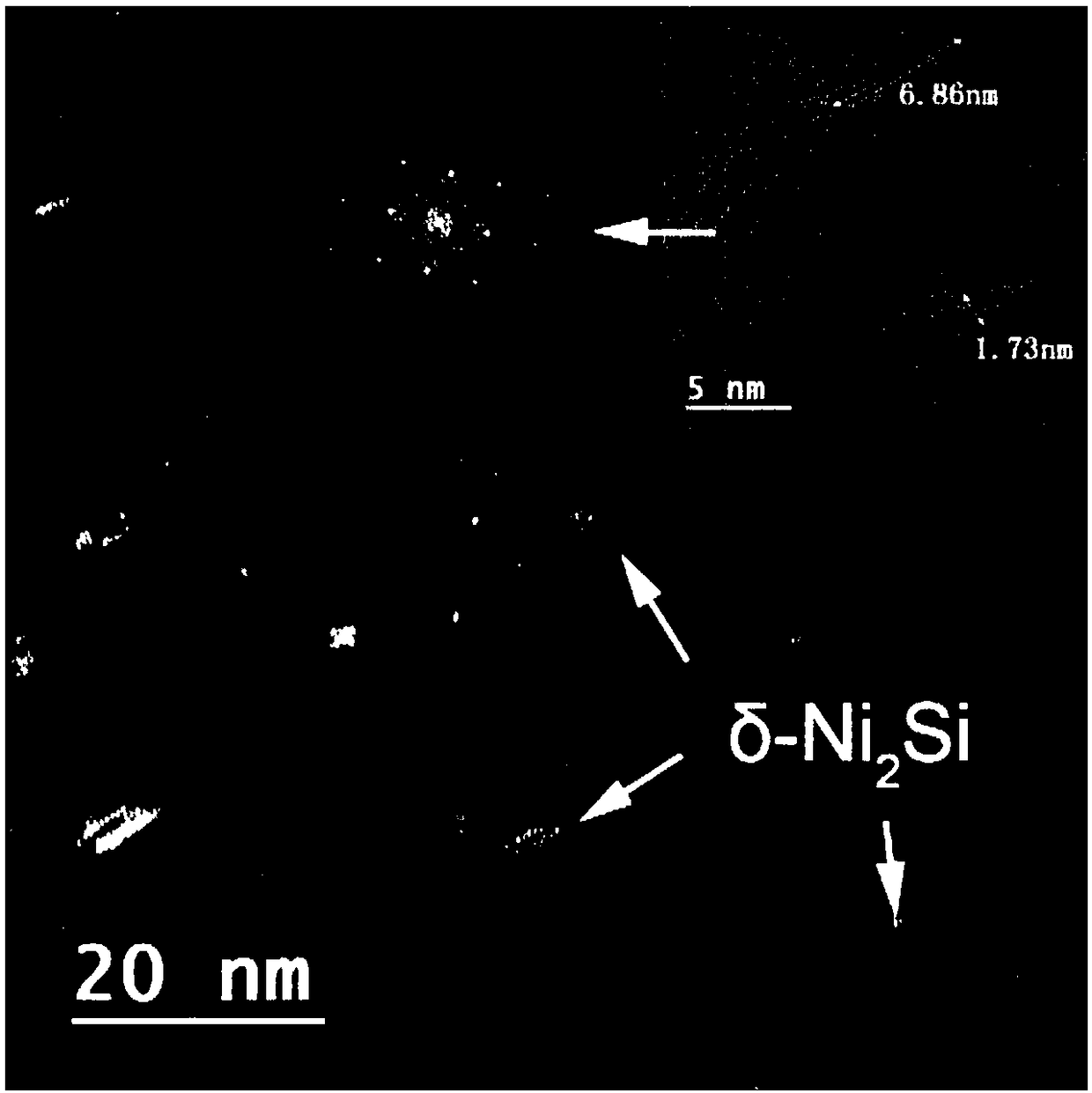

Ultrahigh-strength high-conductivity copper alloy and preparation method thereof

ActiveCN108149062AImprove mechanical propertiesImprove plasticityMetal/alloy conductorsEnvironmental resistanceDislocation

The invention discloses an ultrahigh-strength high-conductivity copper alloy. The copper alloy comprises the following components of, by weight, 4.6-6.0% of Ni, 1.0-2.0% of Co, 1.0-2.0% of Si, 0.05-0.4% of Mg, 0.01-0.1% of Sr, 0.01-0.1% of Nb and the balance Cu, wherein the sum of the mass percentages of all the components is 100%. The preparation method of the copper alloy comprises the steps ofsmelting, casting, homogenization, hot rolling, solid solution treatment and combined deformation heat treatment. According to the ultrahigh-strength high-conductivity copper alloy, an element Be which is easy to burn is replaced by elements which are environment-friendly, easy to add and not easy to burn, second-phase particles are separated out through alloy element component design to prevent dislocation movement, and meanwhile, the solid solution elements in a matrix are reduced; a special two-stage hot rolling and solid solution treatment process is adopted, so that tissues are more uniform, coarse precipitation phase redissolution is promoted, and tissue preparation is provided for subsequent deformation heat treatment; and the precipitation of the nano-reinforced phase is promoted through combined deformation heat treatment, so that the system alloy has excellent mechanical property and conductivity, and the obtained copper alloy is excellent in mechanical property and high in conductivity.

Owner:CENT SOUTH UNIV

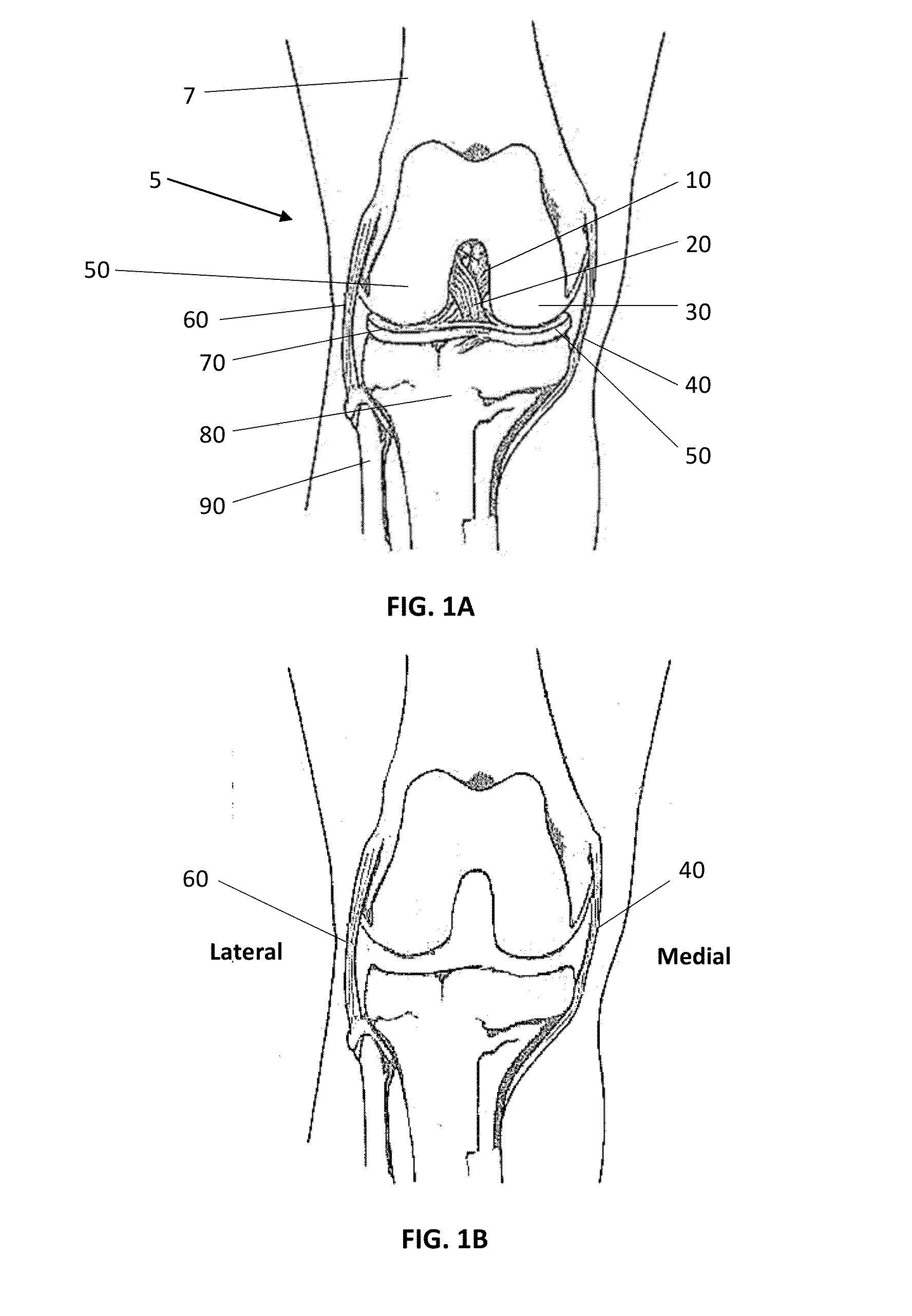

Patient specific soft tissue protectors and retractors

InactiveUS20140114320A1Easily and accurately maintainedAvoid easy injuryDiagnosticsNon-surgical orthopedic devicesDistractionPredictability

Disclosed are devices, methods and / or systems for tissue protectors and / or retractors having patient specific and / or patient adapted features that facilitate the accuracy and predictability of bone resection and tissue preparation during joint surgery, as well as improve the distraction of soft tissues, desirably preventing accidental injury to surrounding soft tissue structures and improving visualization.

Owner:KURTZ WILLIAM B

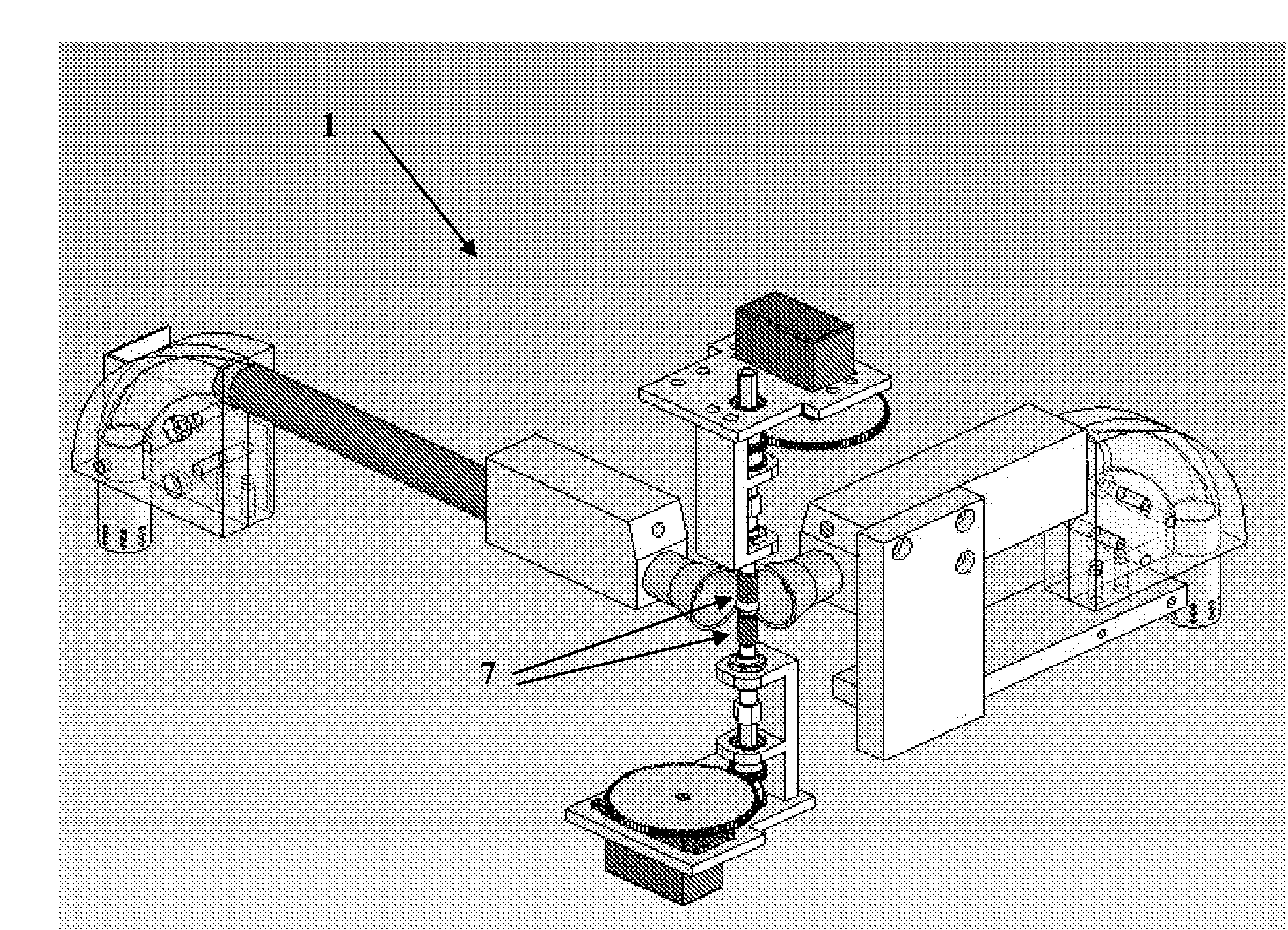

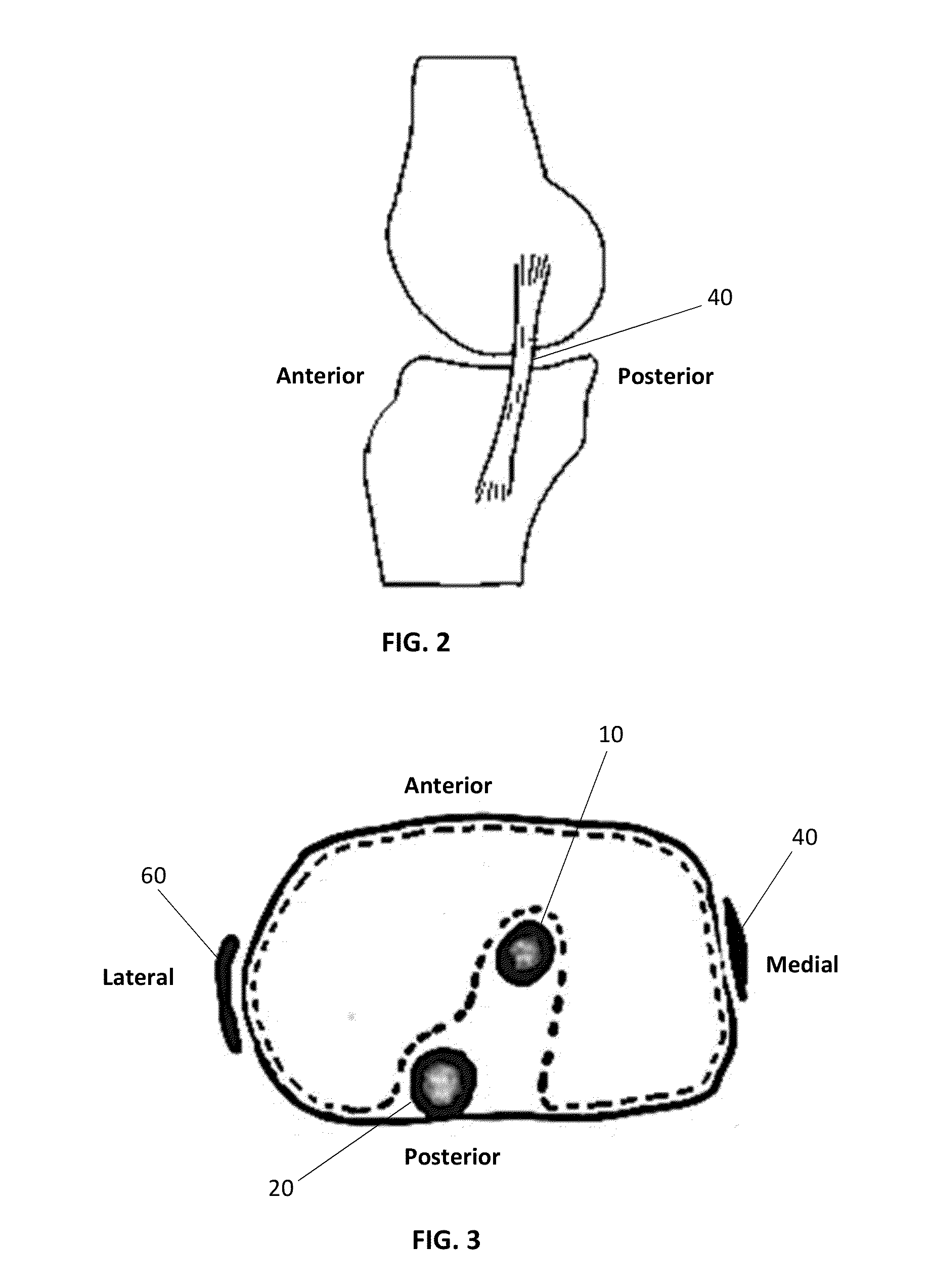

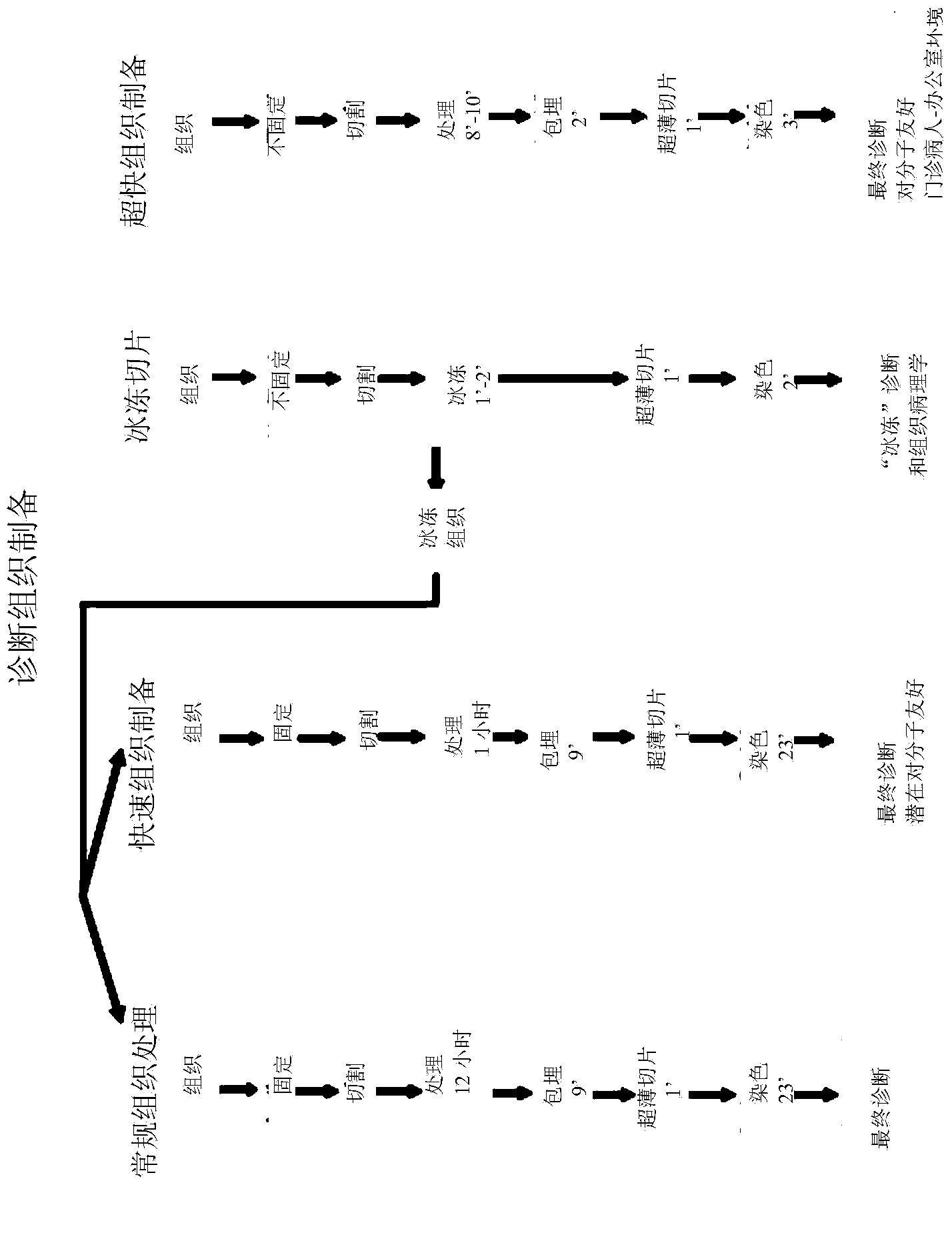

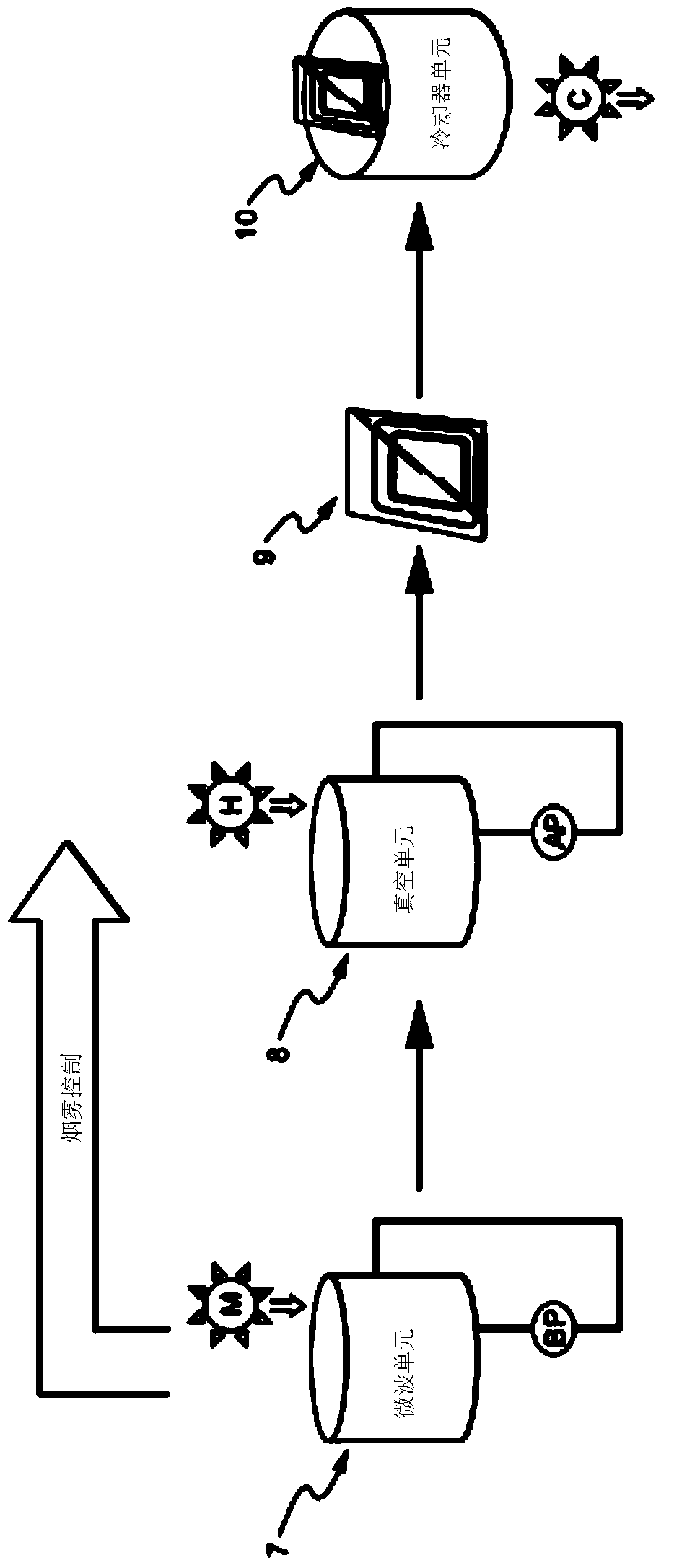

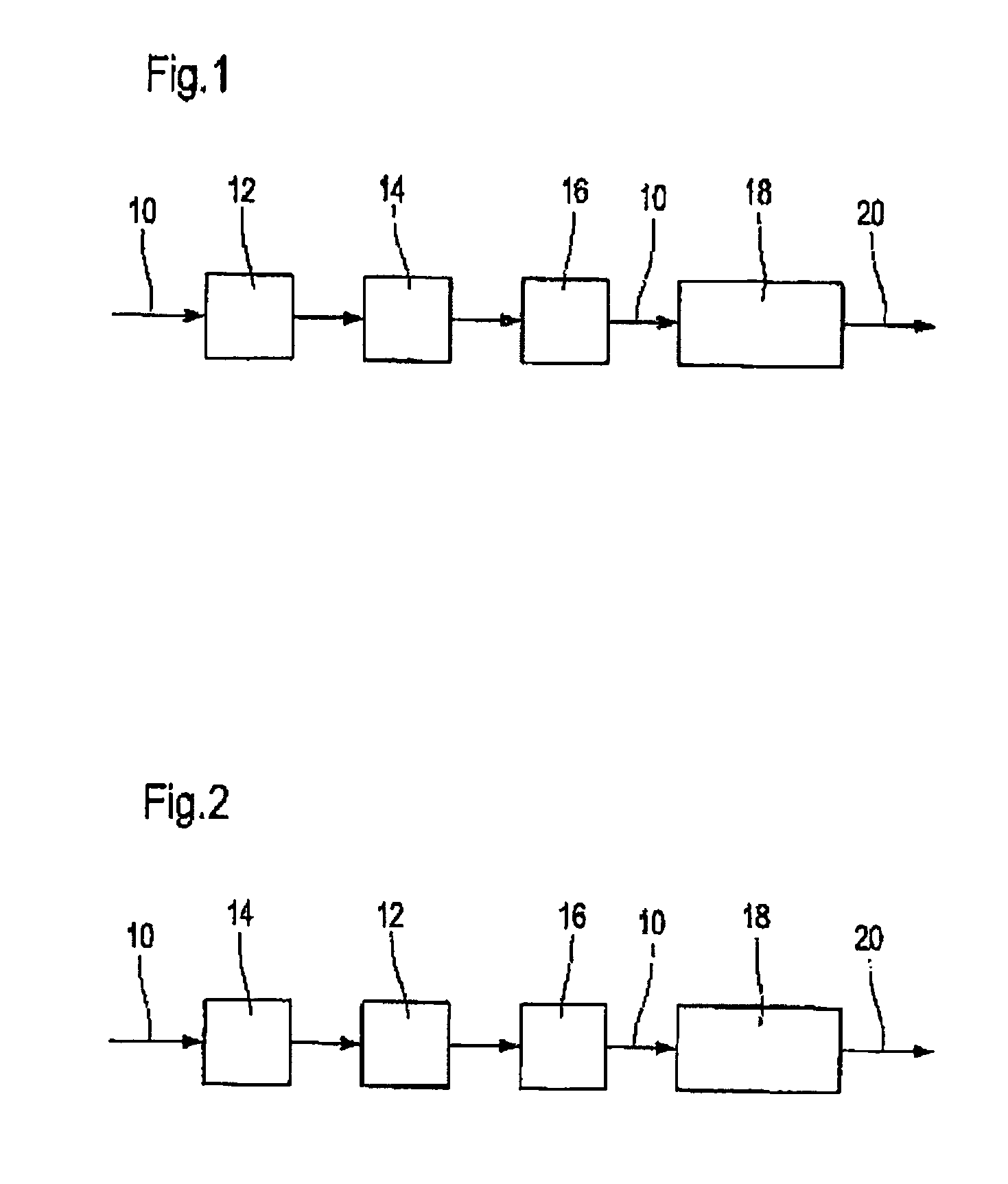

Ultra-rapid diagnostic tissue preparation as an alternative to frozen section

ActiveCN103975229AAnimal cellsMicrobiological testing/measurementSurgical operationChemical mixtures

Improved methods and systems for processing of solid tissue are described. The method may be performed manually or automatically. The system may have modules such as (i) a grossing module where a fresh tissue is sliced to prepare a tissue specimen, (ii) a hardening module that hardens the tissue specimen, (iii) an impregnating module that impregnates the tissue specimen that was hardened, and (iv) an embedding module that embeds a tissue specimen that was hardened and impregnated. Fresh (i.e., not fixed or frozen) tissue, which was excised to diagnose disease or to assess surgical treatment, is grossed to about 0.6 mm Preferably, the hardening of fresh tissue is initiated, but not completed, during grossing by contact with a chemical admixture. Preferably, dry ice, a thermoelectric device, or a gas condenser cools a metal mold containing the embedded specimen. It is sectioned and then microscopically examined as an alternative to histologic examination of a frozen section to avoid the known problems of discordant and deferred diagnosis.

Owner:UNIV OF MIAMI

Method for creating a fibrous substance suspension used for producing a tissue web or hygiene web

InactiveUS20060113051A1Efficiency and cost-effectiveness of the production of corresponding tissue or hygiene products is further optimizedNatural cellulose pulp/paperPulp properties modificationFiberFiber suspension

Method and device for producing a fibrous suspension used for producing a tissue web or hygiene web. The fibers contained in the fibrous suspension are, in an online process, directly loaded with a filler in the tissue preparation line by a chemical precipitation reaction.

Owner:VOITH PATENT GMBH

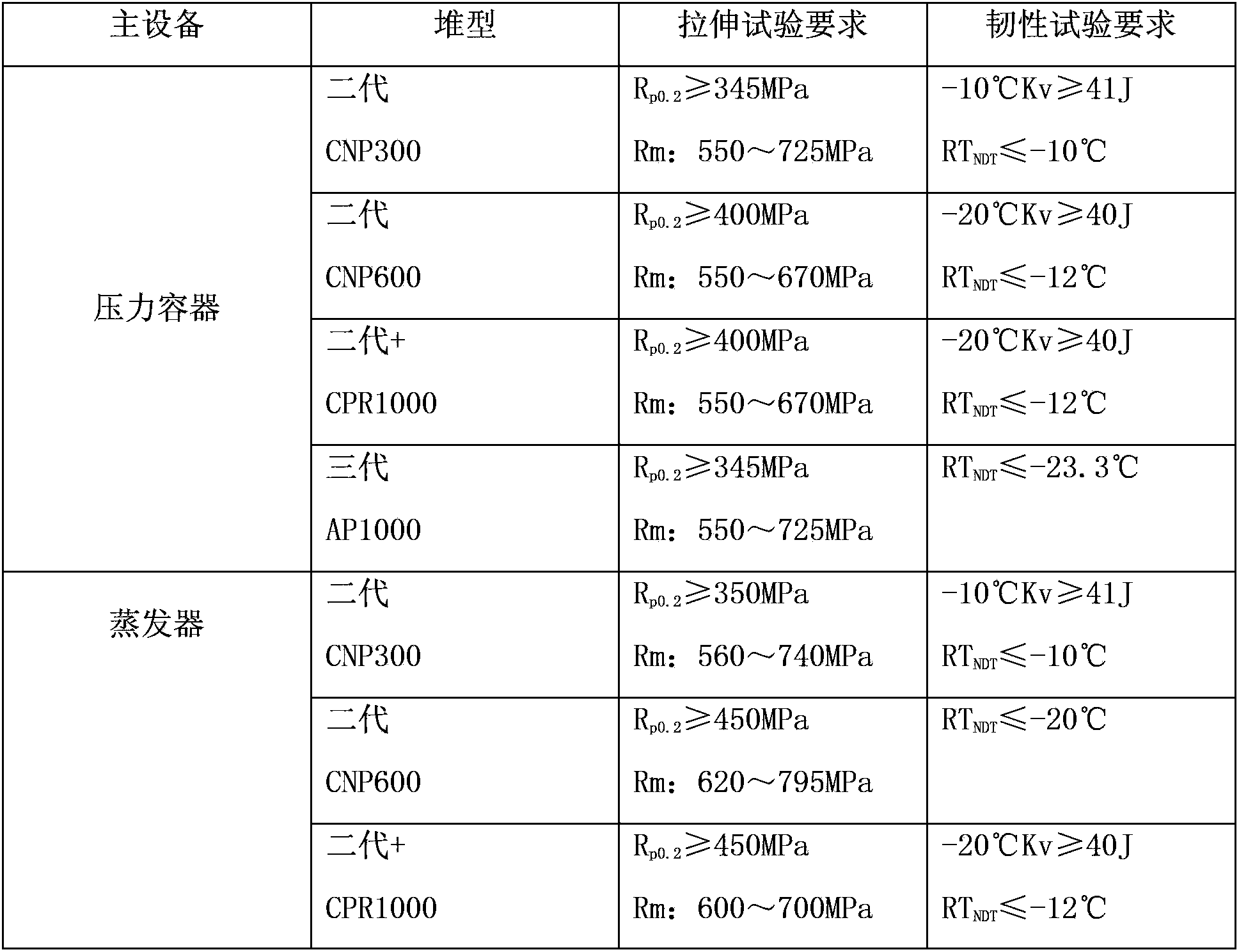

Property thermal treatment method for improving toughness of large forging used in nuclear power container

ActiveCN103820610AGood refinement effectEasy to organizeFurnace typesHeat treatment furnacesNuclear powerQuenching

The invention discloses a property thermal treatment method for improving the toughness of a large forging used in a nuclear power container. The method is applied to property thermal treatment on the forging used in the nuclear power container that the material is SA508-3, the outer diameter is 3.5-6.5 m, the height is not higher than 5 m, and the wall thickness is 100-250 mm; an electric heating annular furnace is adopted; the temperature control precision of the electric heating annular furnace is + / -10 DEG C. The method comprises the following steps: 1, performing subcritical quenching; 2, quenching; 3, tempering. According to the method, one-time subcritical quenching is added before quenched-tempered heat treatment, as the temperature is low in subcritical quenching, a forging material is not completely austenitized, the unmelted ferrite can prevent crystal particles from growing up, superfine austenite crystal grains can be formed along an original large austenite crystal boundary before quenching, a good crystal grain refining effect can be achieved, and good tissue preparation is provided for later quenching-tempering treatment. Through the adoption of the method, the low-temperature toughness of the forging is improved on the basis of ensuring the qualified strength, so as to meet the requirements on properties of large nuclear power forgings.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com