Method for changing structure uniformity of large-specification titanium alloy bar

A technology with uniform structure and large size, applied in the field of forging of large-size titanium alloy bars, can solve the problems of large deformation dead zone, small size of forged bars, and poor deformation uniformity, so as to achieve small deformation dead zone and improve the structure. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

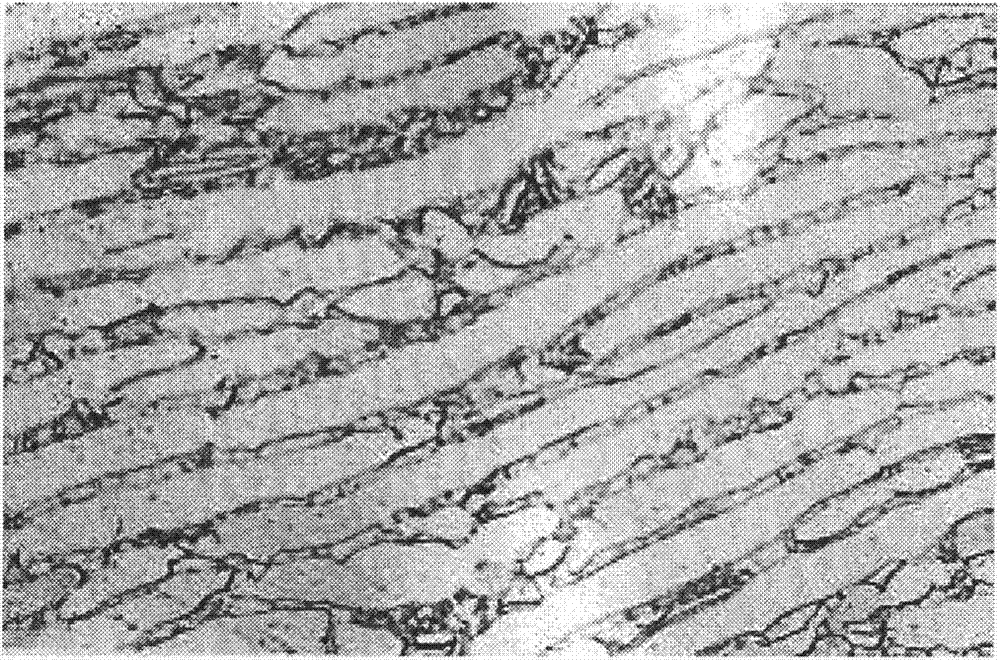

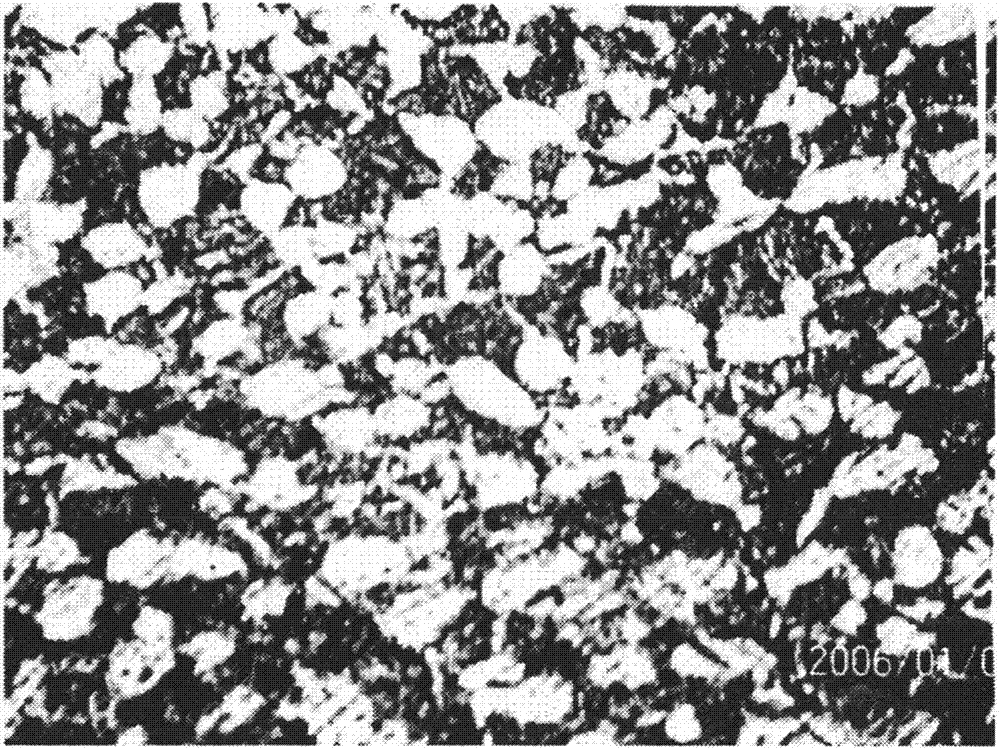

Image

Examples

specific Embodiment approach

[0023] Cut Φ350mm large-scale titanium alloy bar with a length of 840mm.

[0024] The first fire: heating to 960°C, upsetting to about 500mm in thickness and about 400mm in height, and then drawing in an octagonal shape to about 350mm in thickness and about 840mm in height (along the fiber direction), and it will not round after drawing . Then continue to upsetting, upsetting to about 500mm in diameter and about 400mm in height, and then draw in an octagonal shape to about 350mm in diameter and about 840mm in height.

[0025] The second fire: heat the forged billet after the second upsetting to 960°C, and the phase transition point is 990°C, and perform the third upsetting to a roughness of about 500mm and a height of about 400mm, and then The octagon is elongated to a diameter of about 350 mm and a height of about 840 mm (along the fiber direction). Under this fire, repeat the fourth upsetting, upsetting to about 500mm in diameter and about 400mm in height, and then elongat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com