Grain refining method of high-strength long-service-life gear steel

A technology of grain refinement and gear steel, applied in the field of gear steel, can solve the problems of nozzle nodules and insufficient floating, and achieve the effect of reducing Al content, avoiding early failure and improving fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

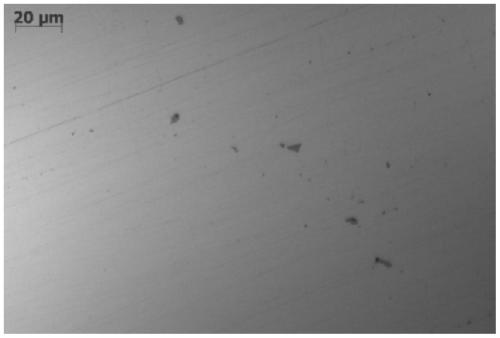

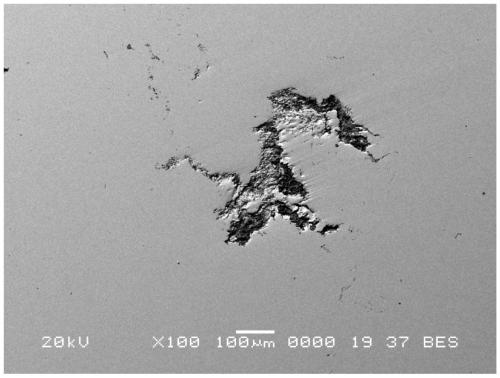

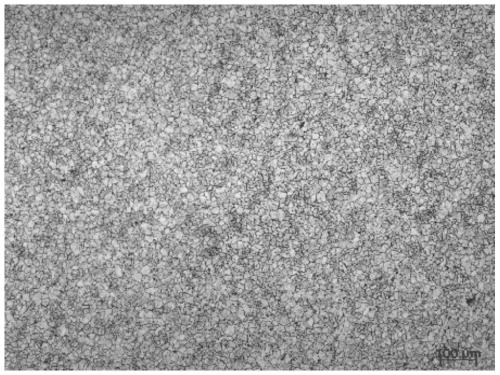

Image

Examples

Embodiment 1

[0031] Melt 40 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.25%, Si: 0.26% , Mn: 0.85%, P≤0.008%, S≤0.006%, Cr: 1.35%, Mo: 0.21%, Al: 0.022%, Nb: 0.035%, Ni: 0.75%, Ti: 0.0004%, Cu: 0.12% , N: 0.0074%, O: 0.0008%, B: 0.0006%, and the balance is Fe and unavoidable impurity elements.

[0032] The molten steel is continuously cast into continuous casting slabs, with 6 continuous casting furnaces, the continuous casting slabs are heated to above 1120°C, the holding time is ≥3 hours, and the billet is rolled at a temperature above 1050°C. The rolling method is continuous rolling, and the intermediate rolling process No water leakage is allowed. In the first five passes of rolling, a large compression ratio is adopted, and the compression ratio of a single pass is ≥1.33. Reasonable al...

Embodiment 2

[0034] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.26%, Si: 0.27% , Mn: 0.86%, P≤0.010%, S≤0.003%, Cr: 1.36%, Mo: 0.25%, Al:0.021% , Nb: 0.033% , Ni: 0.80%, Ti: 0.0008%, Cu: 0.12%, N:0.0068% , O: 0.0007%, B: 0.0005%, and the balance is Fe and unavoidable impurity elements.

[0035]Continuous casting of molten steel into continuous casting slabs, with 6 continuous casting furnaces, heating the continuous casting slabs to above 1120°C, holding time ≥ 3 hours, starting rolling at temperatures above 1050°C of the billet, the rolling method is continuous rolling, intermediate rolling The process can't leak water. In the first five passes of rolling, a large compression ratio is adopted, and the compression ratio of a single pass is ≥1.33. In the middle pass, the deformat...

Embodiment 3

[0037] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 300mm×340mm. The chemical composition of the obtained continuous casting slab includes: C: 0.26%, Si: 0.27% , Mn: 0.86%, P≤0.010%, S≤0.003%, Cr: 1.36%, Mo: 0.25%, Al:0.023% , Nb: 0.045% , Ni: 0.80%, Ti: 0.0008%, Cu: 0.12%, N:0.0090% , O: 0.0007%, B: 0.0005%, and the balance is Fe and unavoidable impurity elements.

[0038] Continuous casting of molten steel into continuous casting slabs, with 6 continuous casting furnaces, heating the continuous casting slabs to above 1120°C, holding time ≥ 3 hours, starting rolling at temperatures above 1050°C of the billet, the rolling method is continuous rolling, intermediate rolling The process must not allow water to escape. In the first five passes of rolling, a large compression ratio is adopted, and the compression ratio of a single pass is ≥ 1.33, and the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com