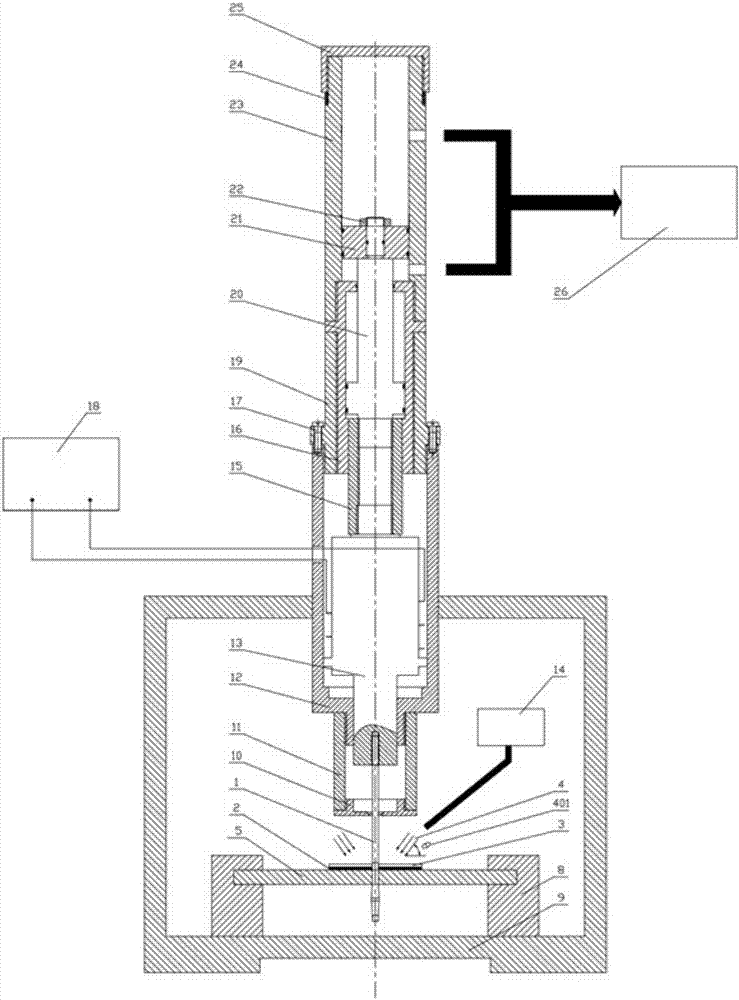

Laser shock and supersonic vibration extrusion co-strengthening device and method

An ultrasonic vibration and laser shock technology, applied in the field of surface strengthening of parts, can solve the problems of insignificant strengthening effect, limitation, hole wall tensile stress and aperture size, etc., and achieve the effects of not easy mandrel breakage, convenient operation and reasonable stress distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

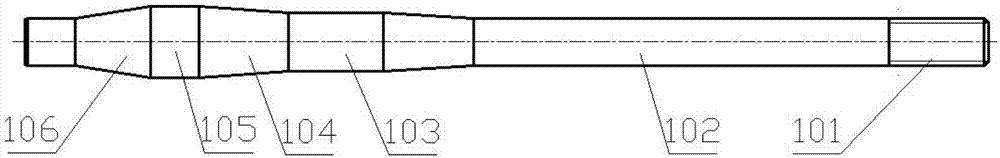

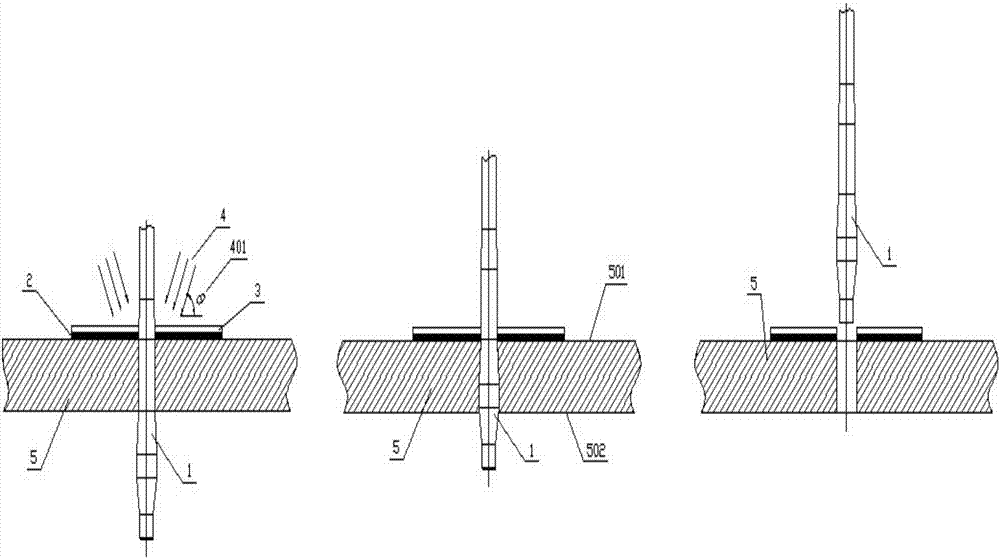

[0080] For the 6mm thick metal sheet, the holes with a hole diameter of 2.6mm are strengthened. The outer surface of the metal sheet is pretreated, and aluminum foil is pasted around the hole as the absorbing layer 2, and water is used as the constraining layer 3, so that the water flows through the surface of the aluminum foil at a uniform speed. Select the model size of the mandrel 1, the diameter of the mandrel fitting section 103 is 2.6 mm, the fitting section 103 forms a clearance fit with the hole 7, and the fit tolerance is H7 / h6, so as to ensure the restraint effect of the mandrel 1 in the hole 7. The axial length of the front cone section 104 and the rear cone section 105 of the mandrel is 6mm, the surface roughness Ra of the front cone section 104 and the rear cone section 105 is 0.2μm, the front cone angle and the rear cone angle are 3°, and the diameter of the working ring is It is determined according to the size of the hole 7 to be strengthened. In this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com