Patents

Literature

225results about How to "Not prone to breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

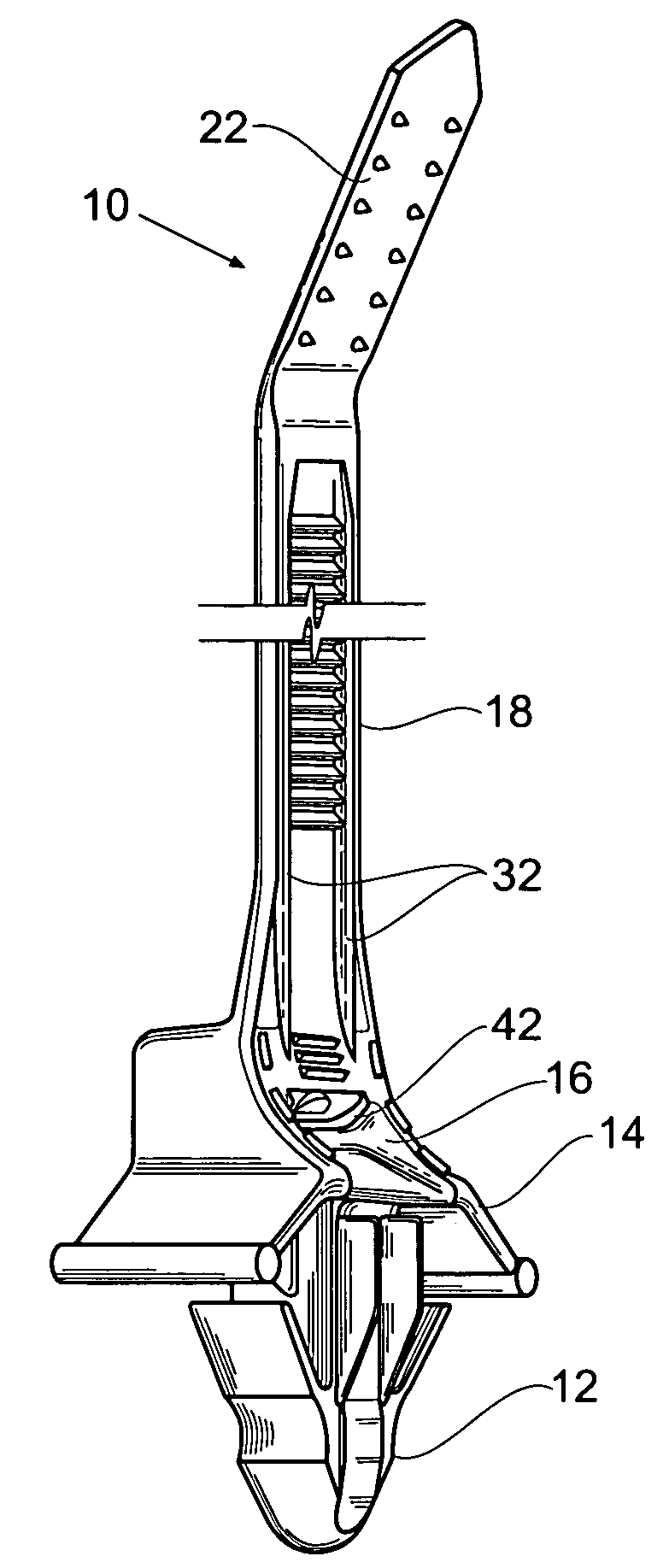

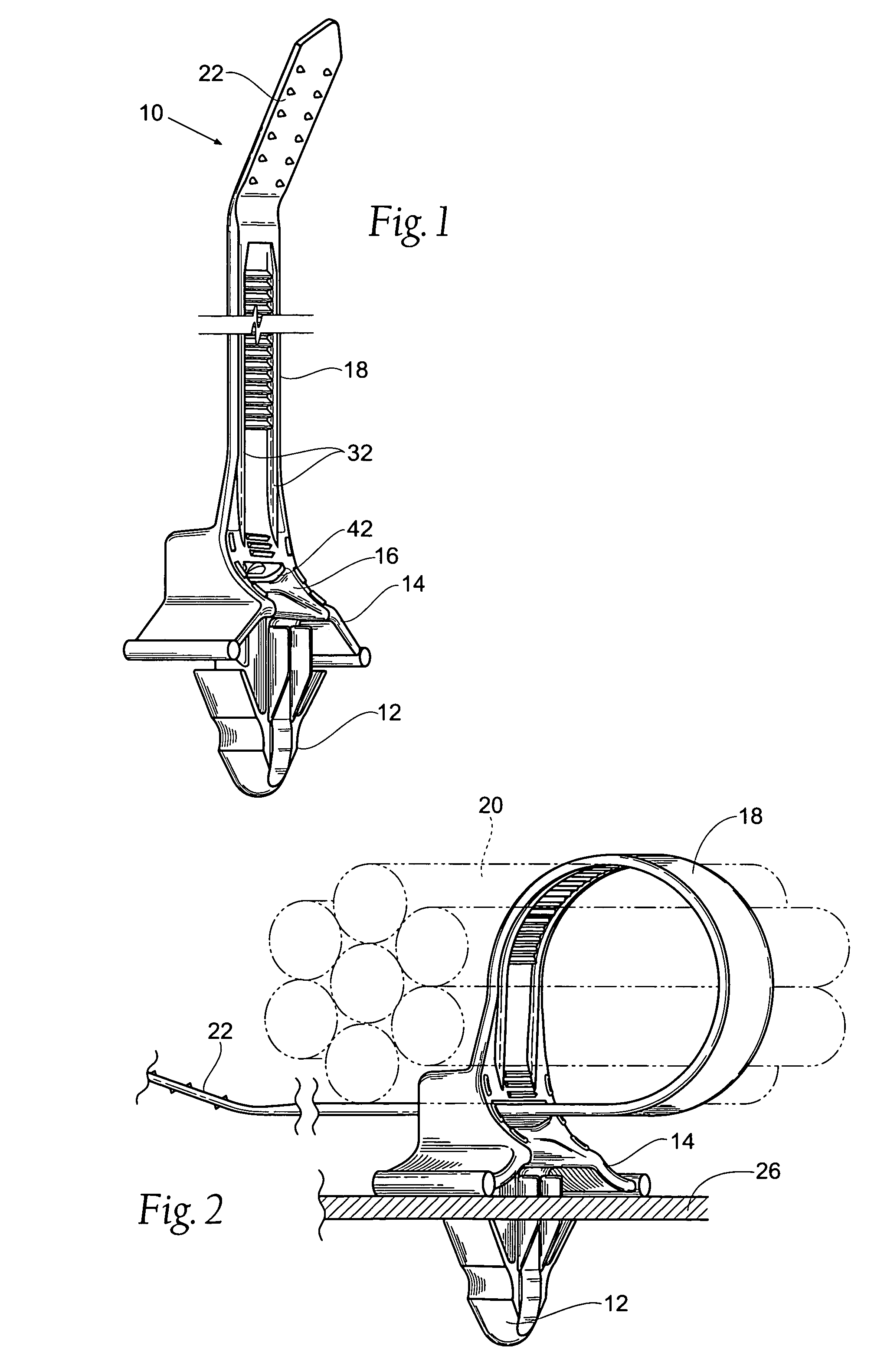

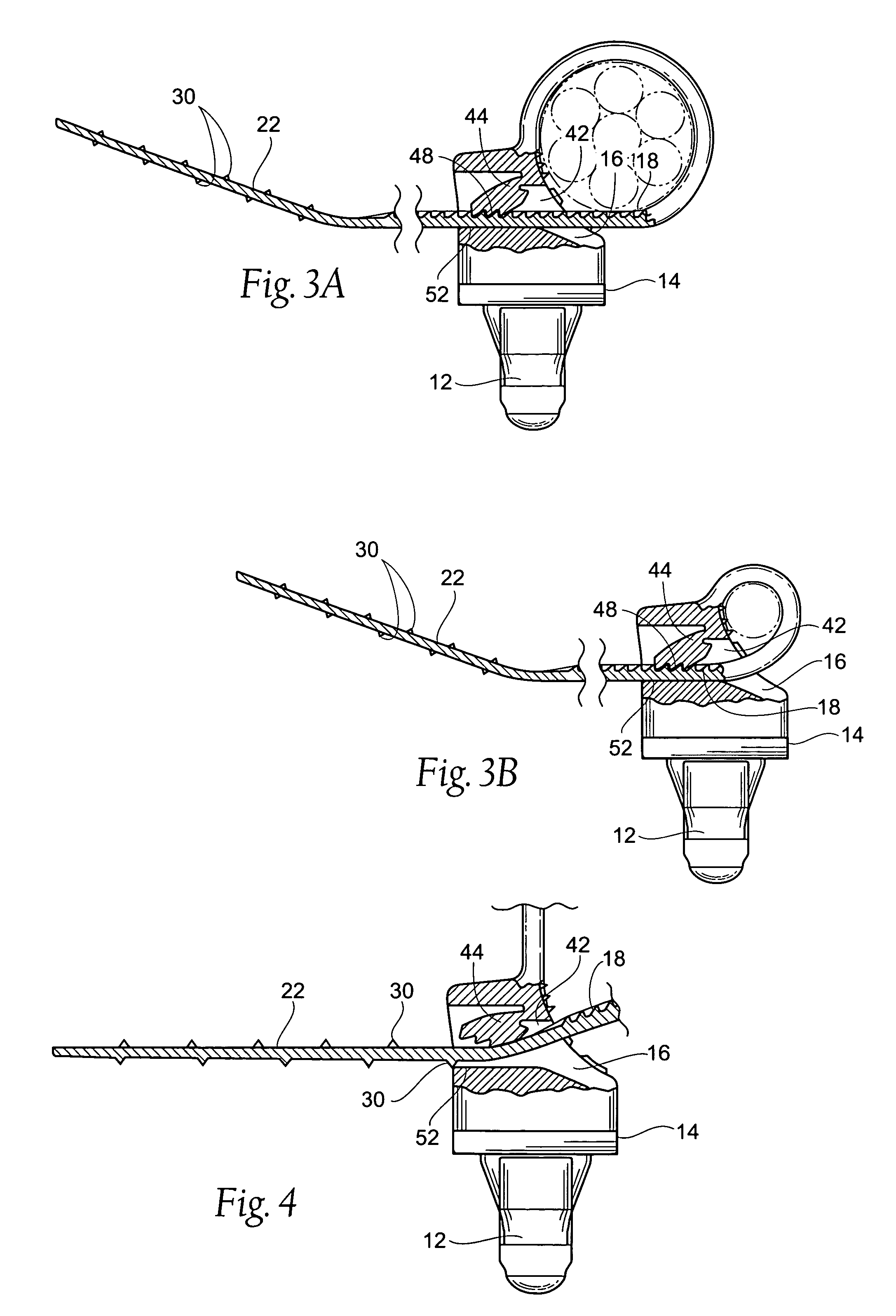

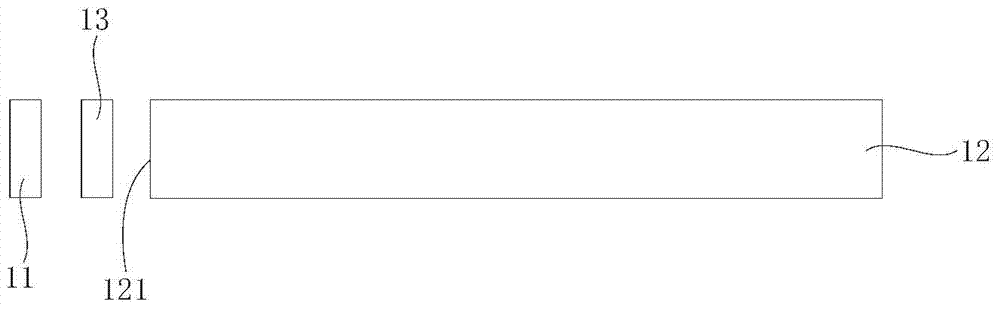

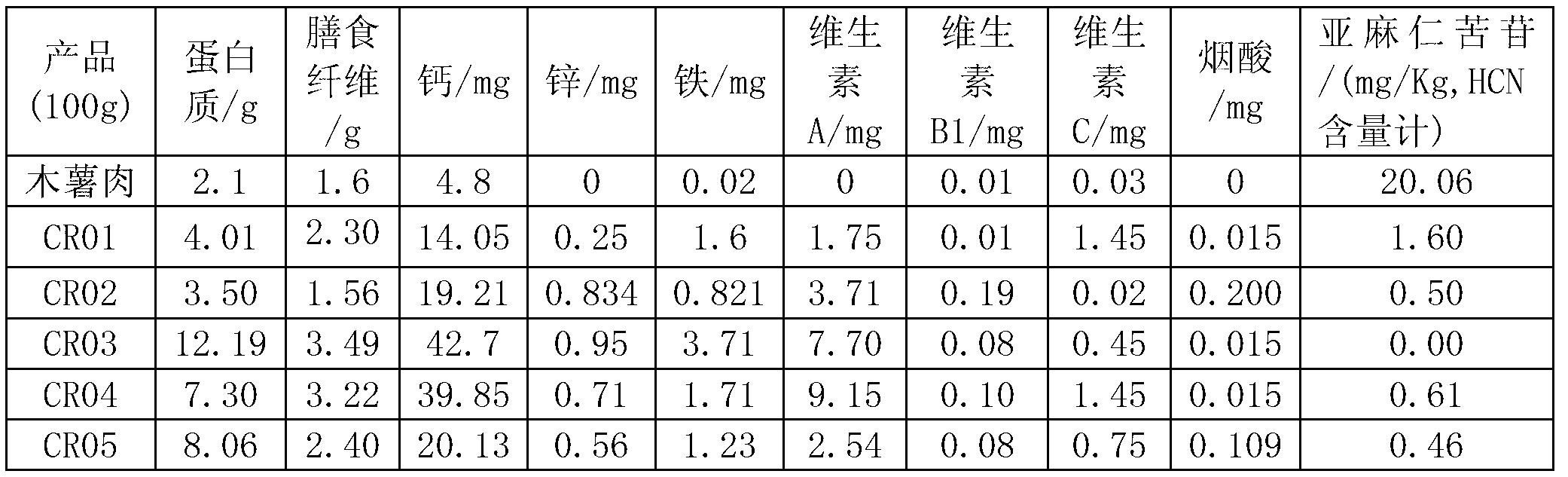

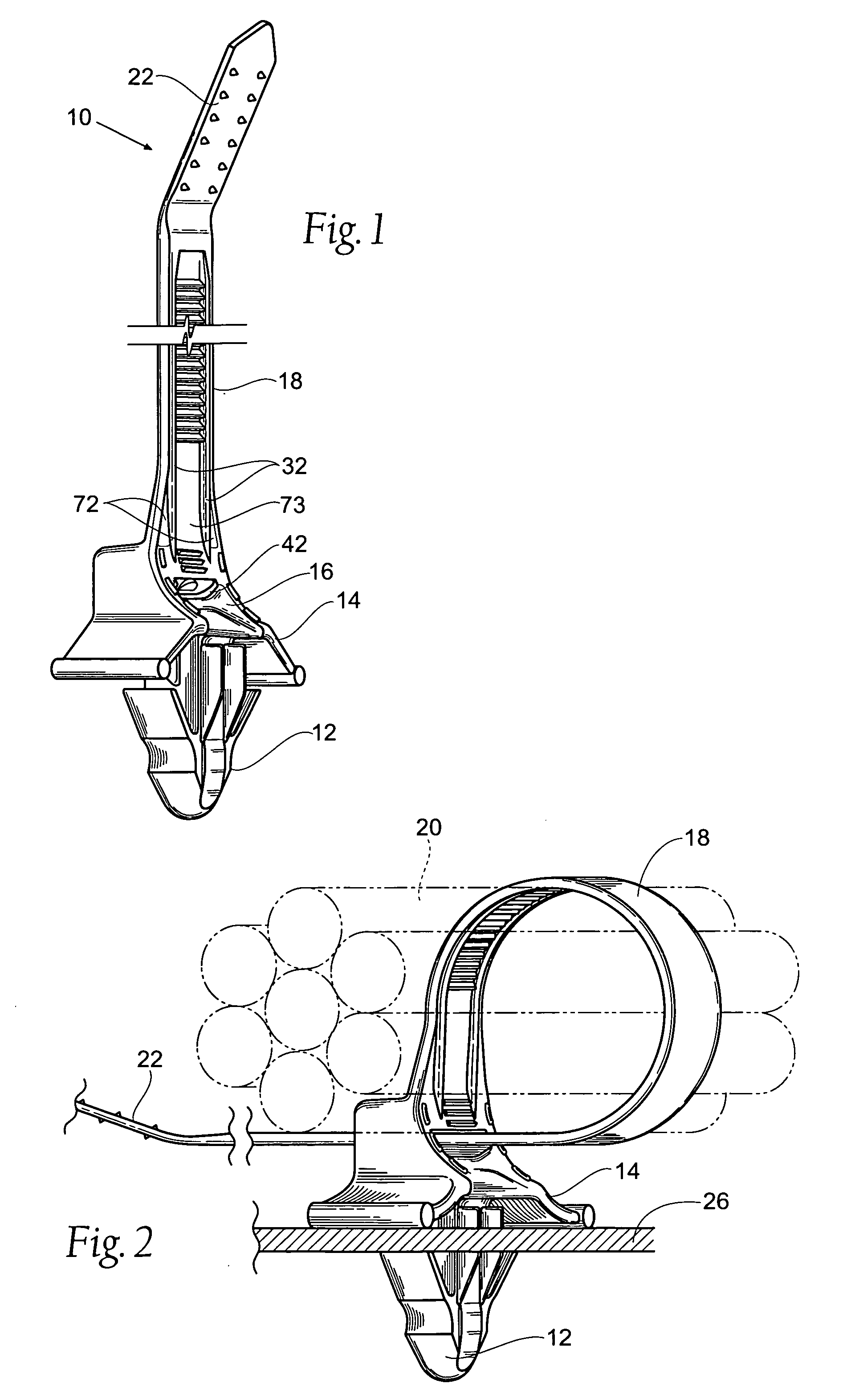

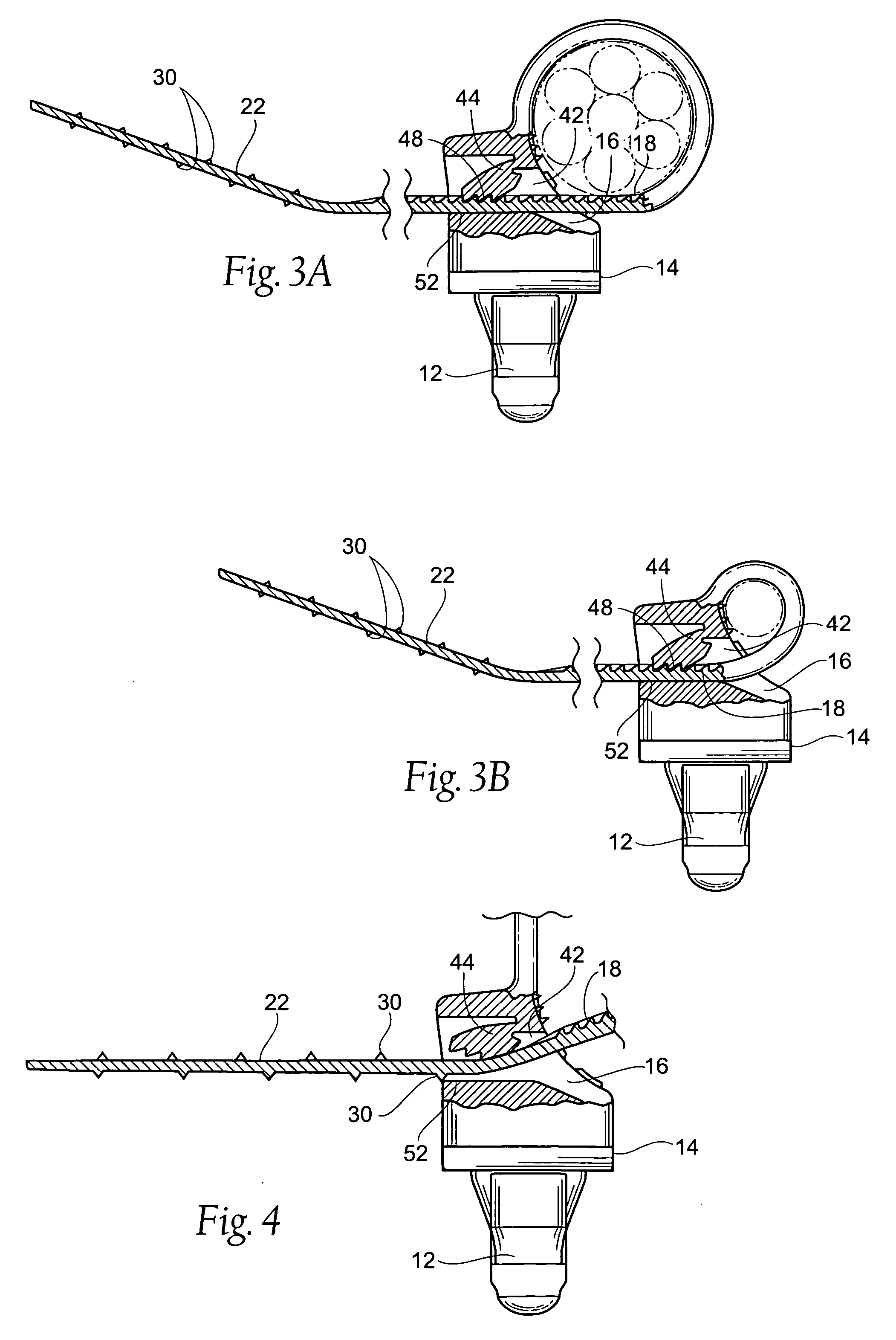

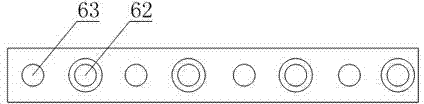

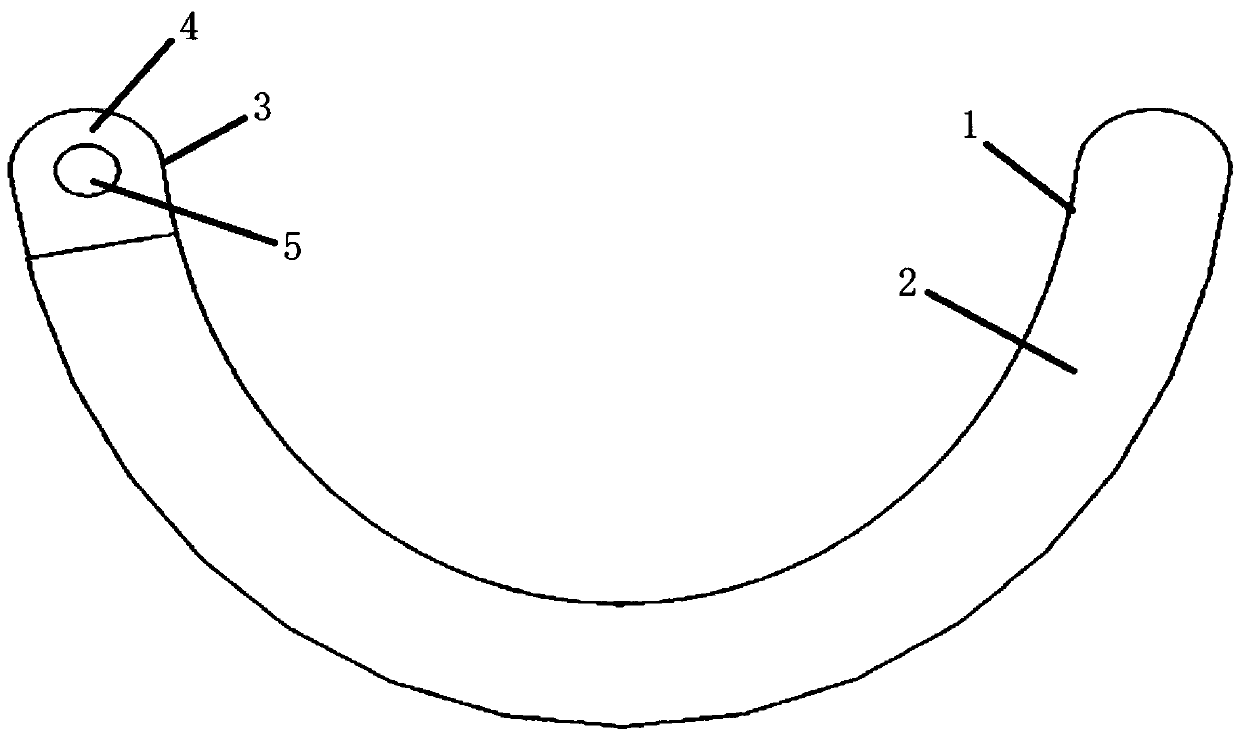

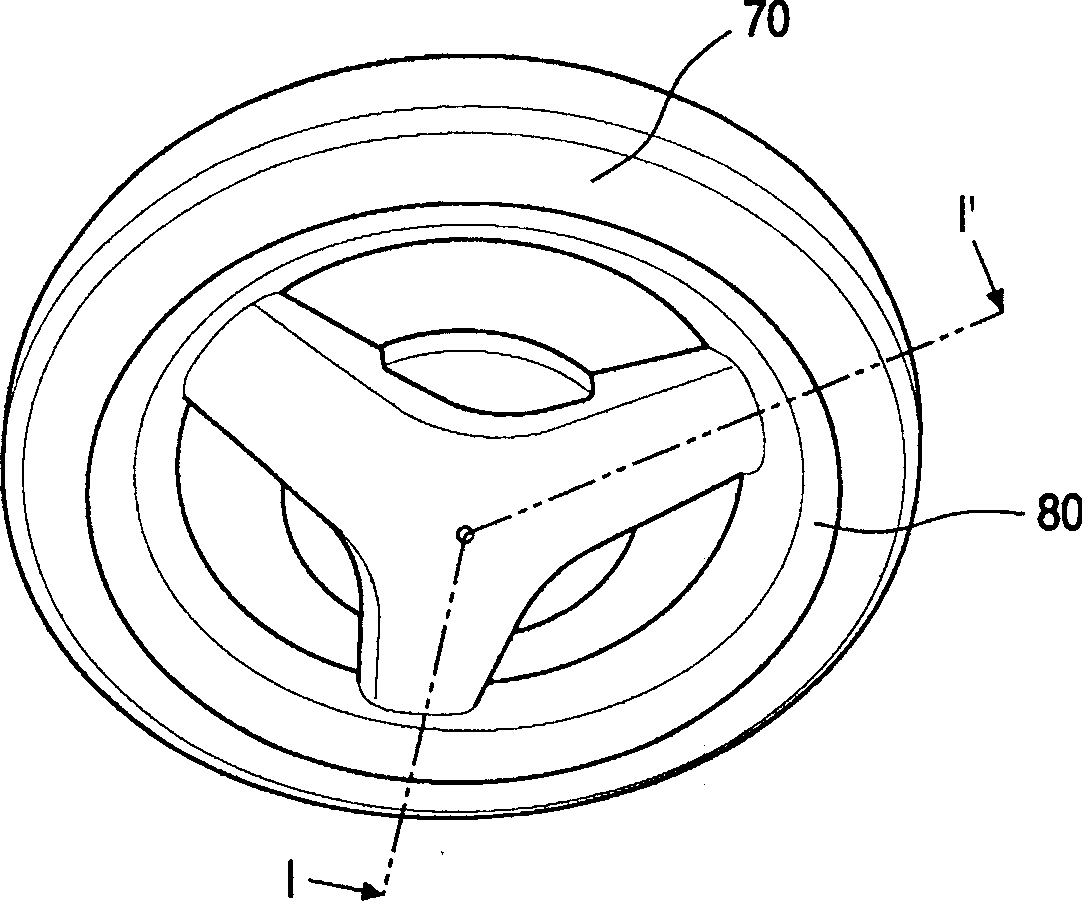

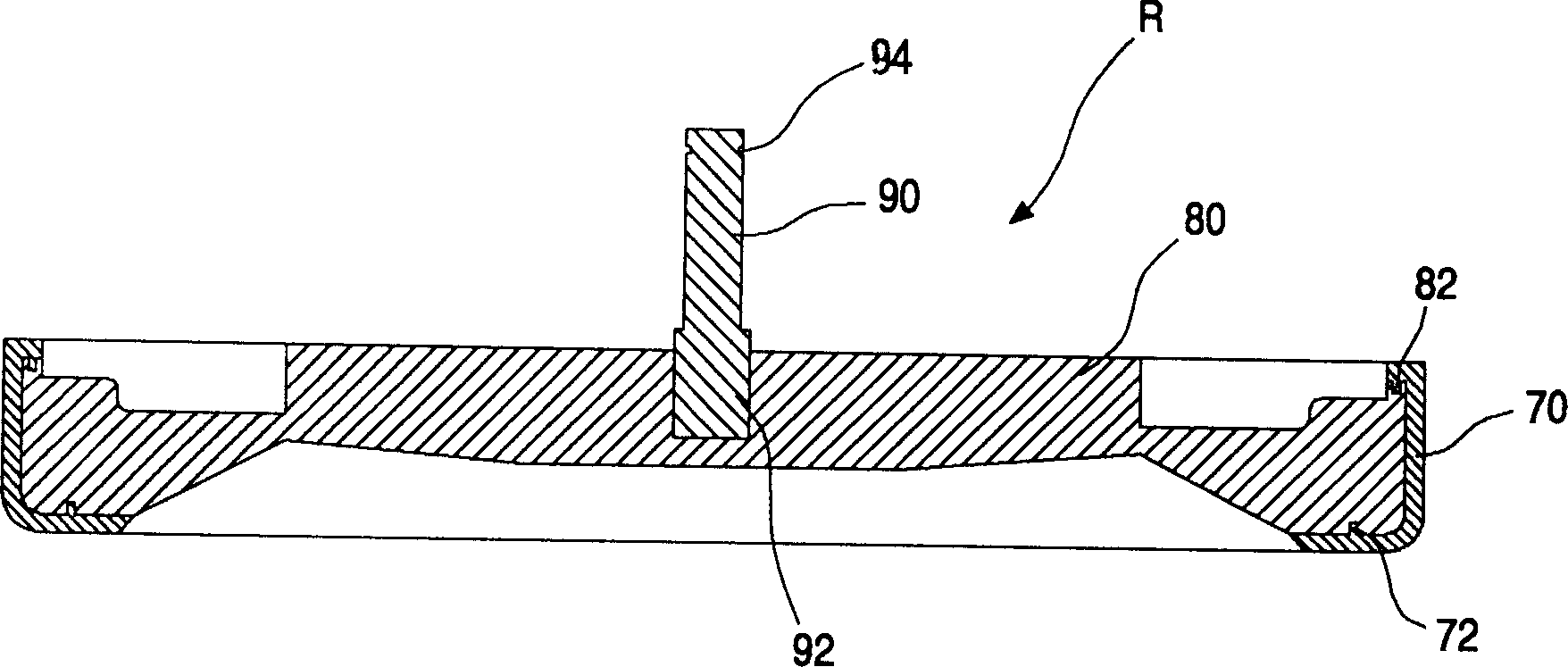

Harness clamp tie

InactiveUS20070023586A1Reduced installation tensionIncreased fastener stabilityPipe supportsElectrical apparatusEngineeringFrenulum

A harness clamp tie includes a locking head and a flexible strap extending outwardly from the locking head. The strap is insertable through the locking head to form a loop that can be used at least one item. A pawl in the locking head secures the strap. Nonslip rails formed along the outer edge of the strap face and clamping rails formed on the locking head aid in securing small items. Conic friction points are formed on both sides of the strap surface to provide a mechanical grip for pulling the strap through the locking head. A mounting fastener extends from the locking head in the opposite direction. The fastener secures the tie to a mounting structure such as an aperture in a panel. The fastener includes a pair of flexible winged springs which help to stabilize the tie and hold the tie perpendicular to the panel.

Owner:HELLERMANNTYTON CORP

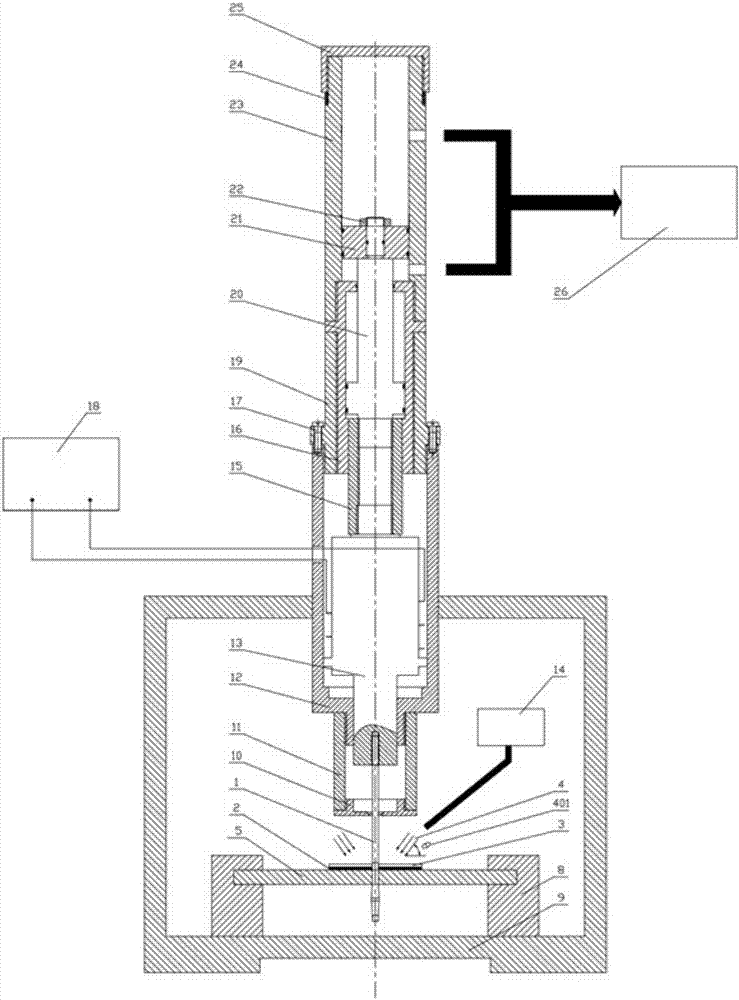

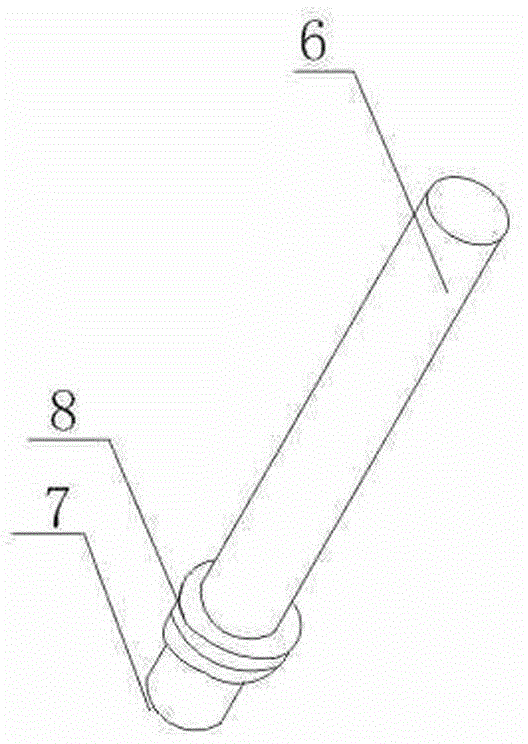

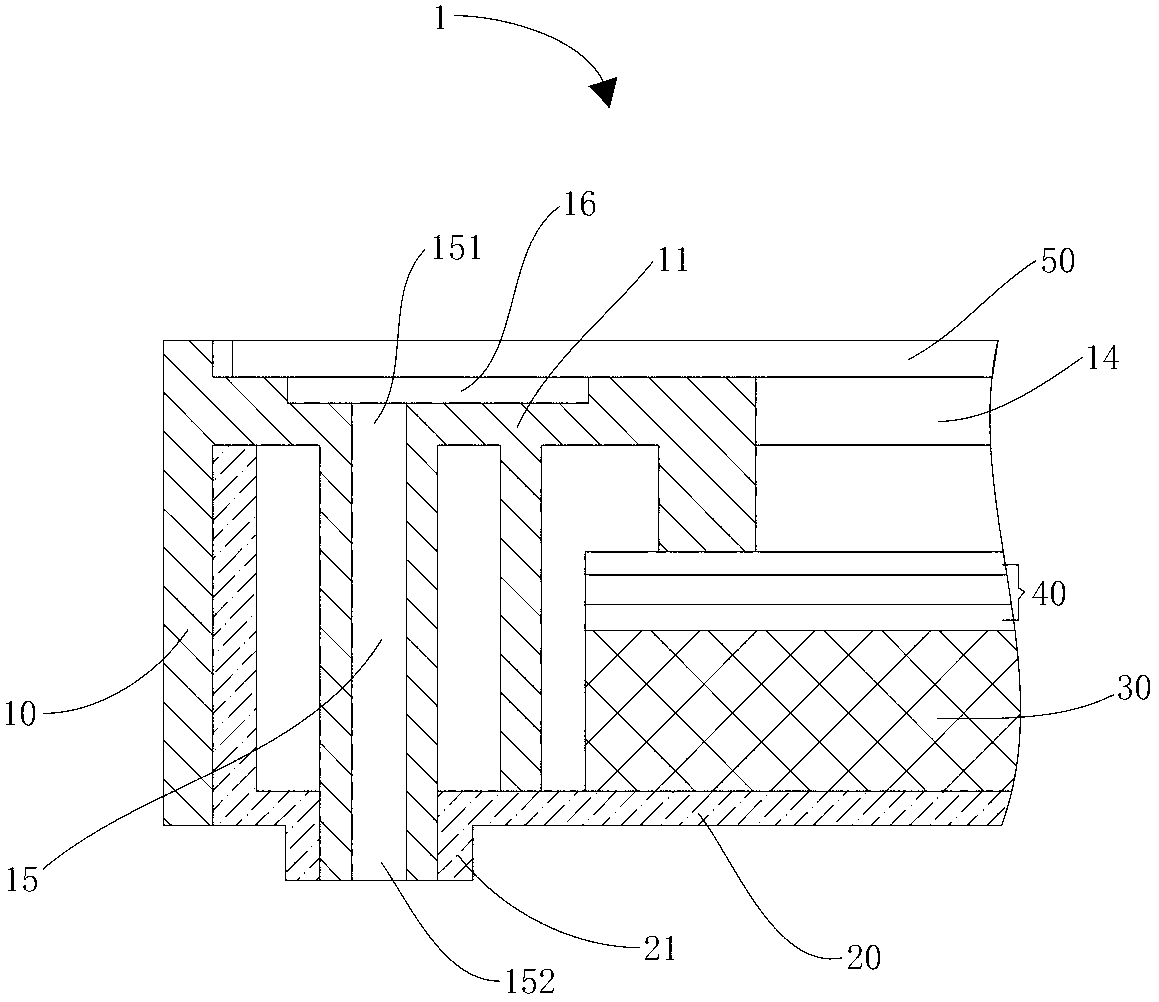

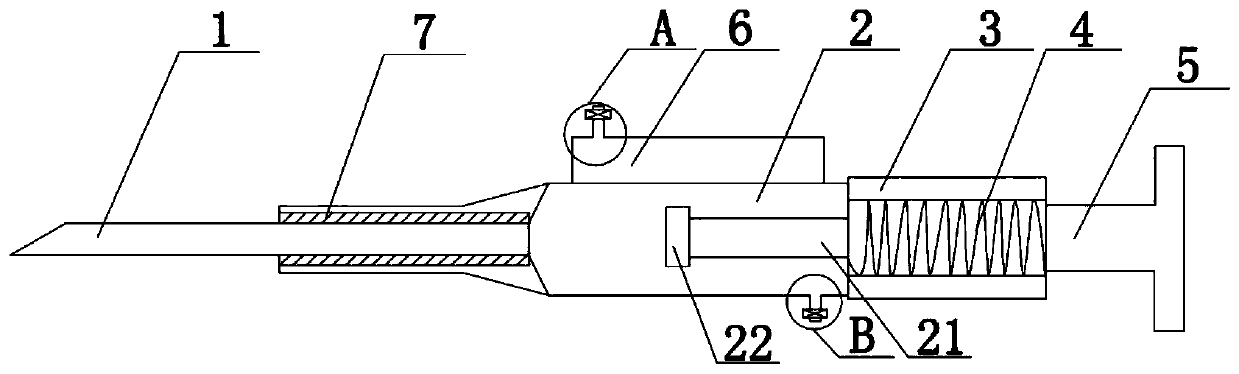

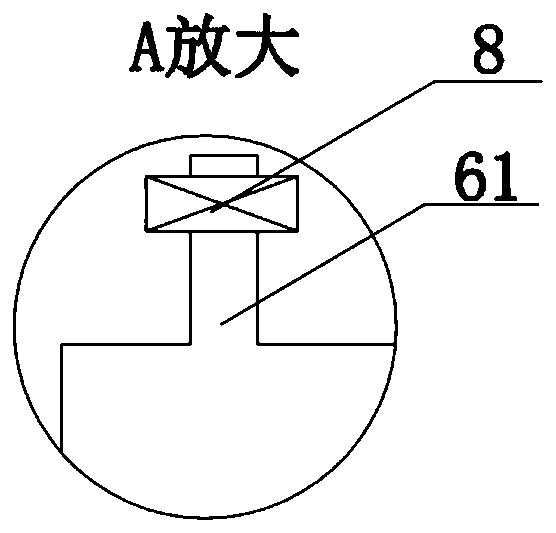

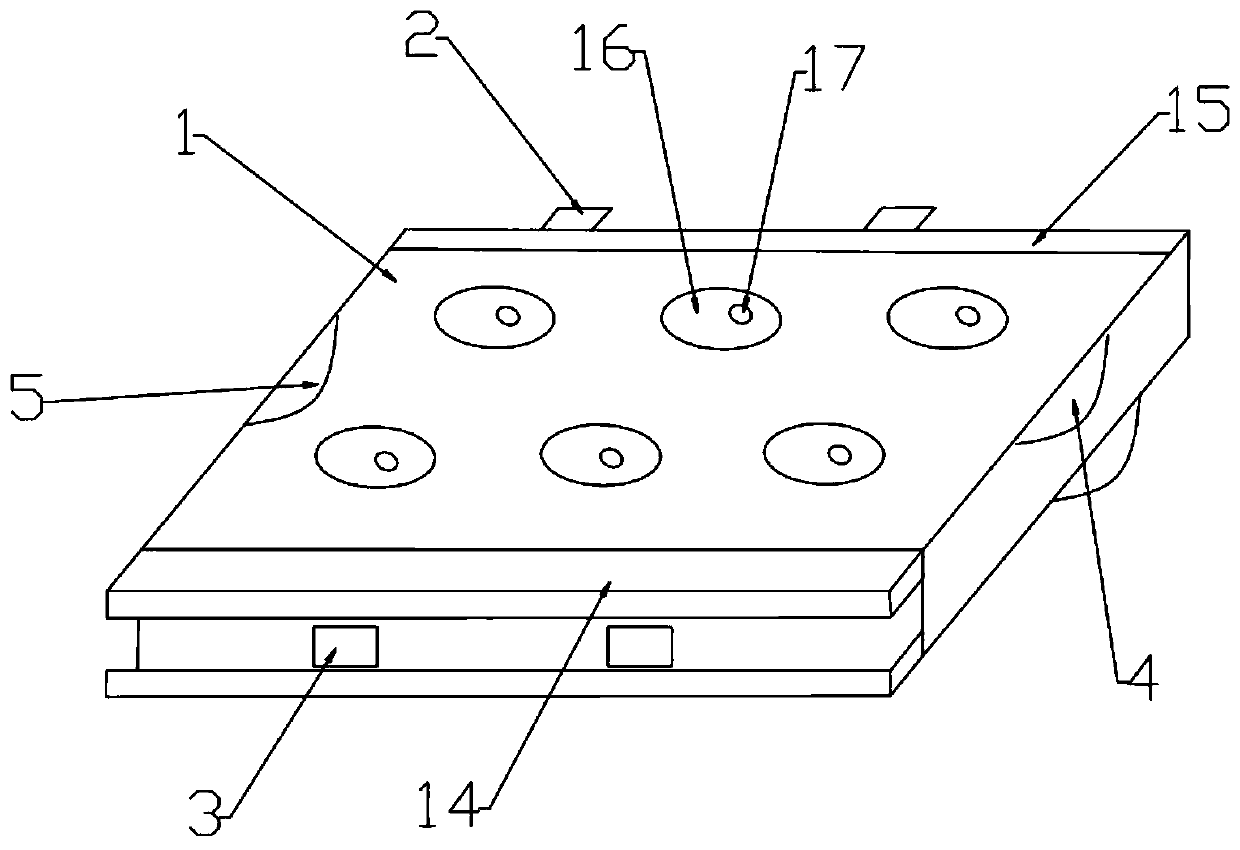

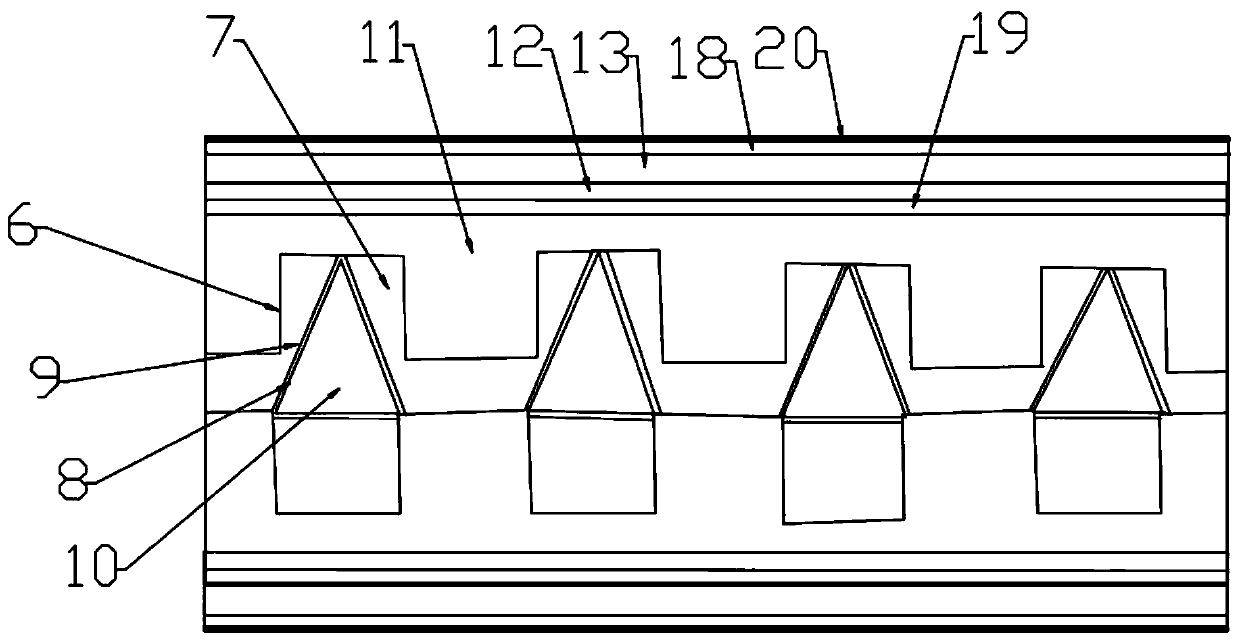

Laser shock and supersonic vibration extrusion co-strengthening device and method

ActiveCN107254581AImprove fatigue resistanceSmooth inner surfaceLaser beam welding apparatusShock waveUltrasonic vibration

The invention provides a laser shock and supersonic vibration extrusion co-strengthening device and method. The device comprises a laser assembly, a vibration assembly, a hydraulic assembly and a connecting assembly. The method comprises steps as follows: a hole formed on sheet metal is strengthened while laser shock strengthening and supersonic vibration extrusion strengthening are adopted, a mandrel forms clearance fit with the hole to constrain the hole, so that distortion of hole and a hole angle when the laser shock is performed on the outer surface of a workpiece is prevented, and the strengthening effect of the hole wall is improved; when the laser shock is performed on the outer surface of the sheet metal, supersonic vibration is applied to the mandrel in the hole, three-dimensional pressure stress distribution is formed nearby the hole wall at certain depth under the interaction produced by laser shock waves and power ultrasound at certain frequency, amplitude and modal, and higher anti-fatigue performance and smoother inner surface of the hole are obtained. With the adoption of the device and the method, defects of a traditional strengthening technology are overcome, and the problem that the hole is strengthened through either single laser shock or single supersonic vibration extrusion is solved.

Owner:JIANGSU UNIV

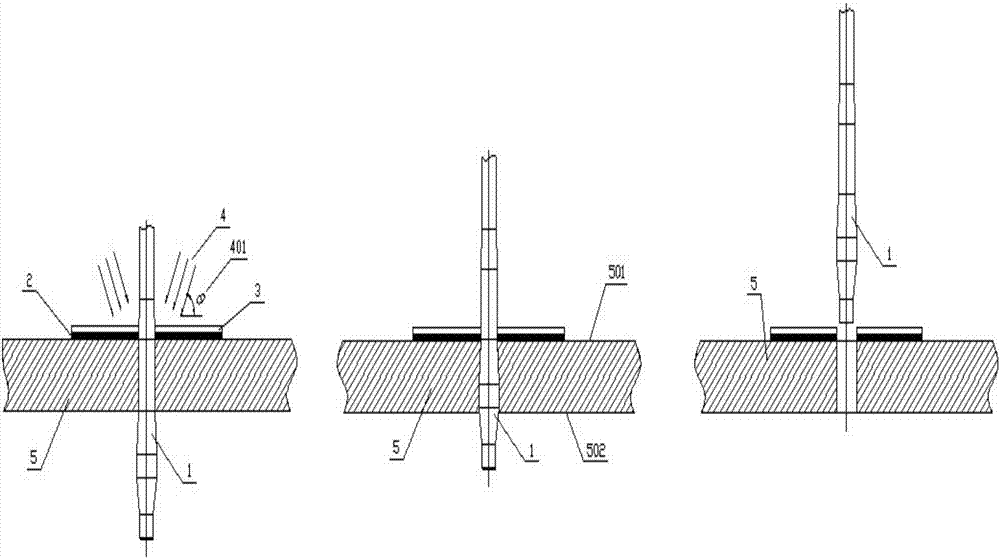

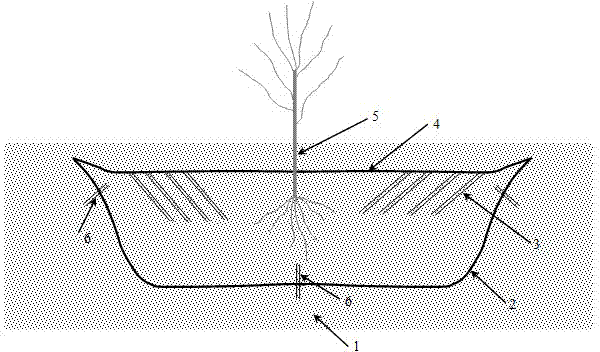

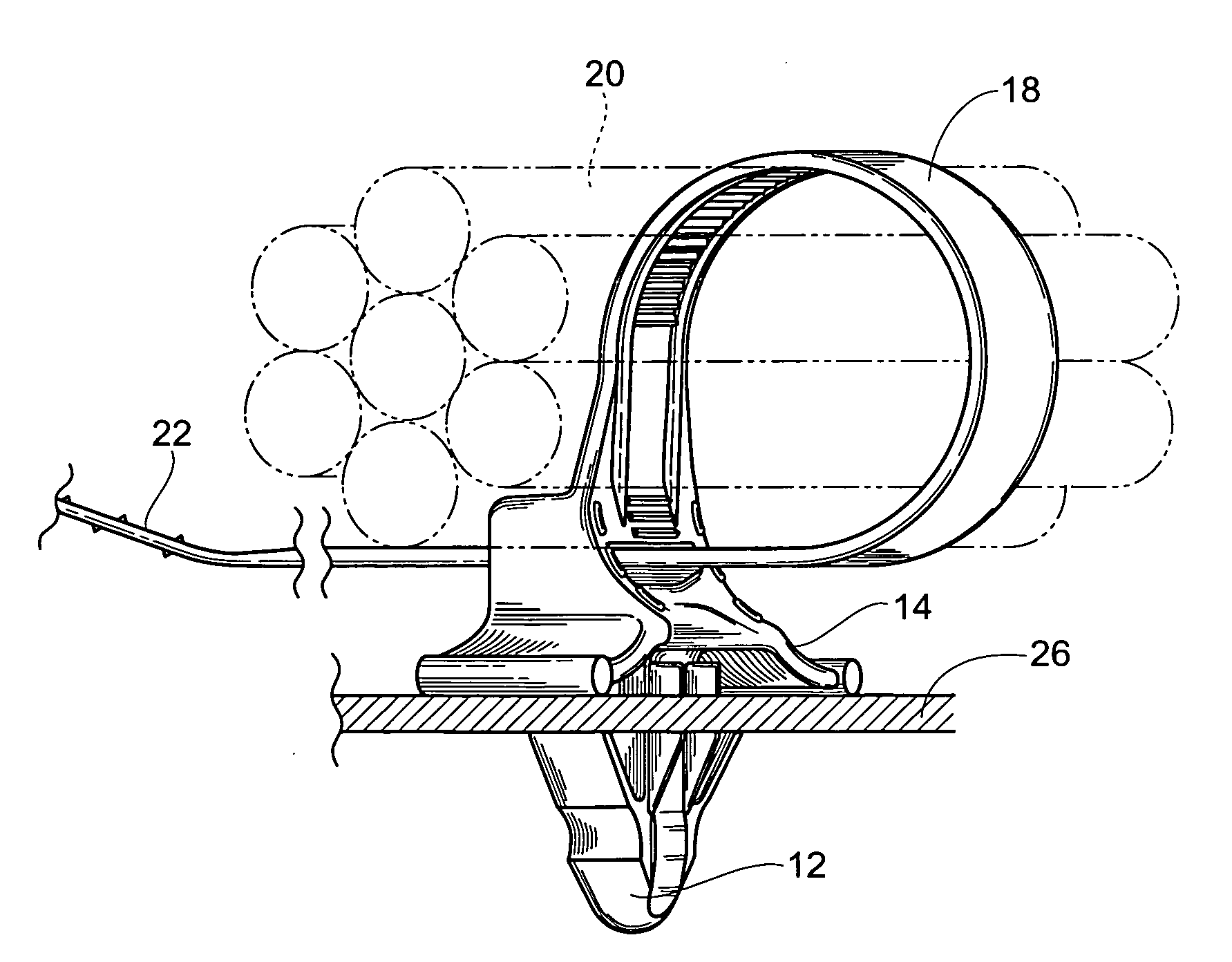

Planting structure in arid desert regions and planting method of planting structure

InactiveCN103583172AReduce moisture leakageHigh porosityWatering devicesCultivating equipmentsAridGrowth plant

The invention discloses a planting structure and a planting method thereof, aiming to solve the problem of water shortage for plant growth in arid regions and guarantee good plant growth and vegetation recovery in the arid regions. The planting structure comprises a planting pit and a planting soil layer in the planting pit. An impermeable film is arranged on the surface of the planting pit. An evaporation-resisting cover film is arranged at the upper end of the planting soil layer. A cover soil layer is arranged at the upper end of the cover film. By the planting structure, permeation and evaporative loss of moisture are remarkably reduced, rainwater collection, confluence and storage into the planting pit are facilitated, the planting pit can have sufficient moisture for plants to absorb, and accordingly, survival rate of planted plants is guaranteed. The planting method is simple in technology, low in cost and obvious in effect in the acid regions, and is of great significance in improving planting survival rate of plants in the acid regions and recovering vegetation.

Owner:SOUTHEAST UNIV +1

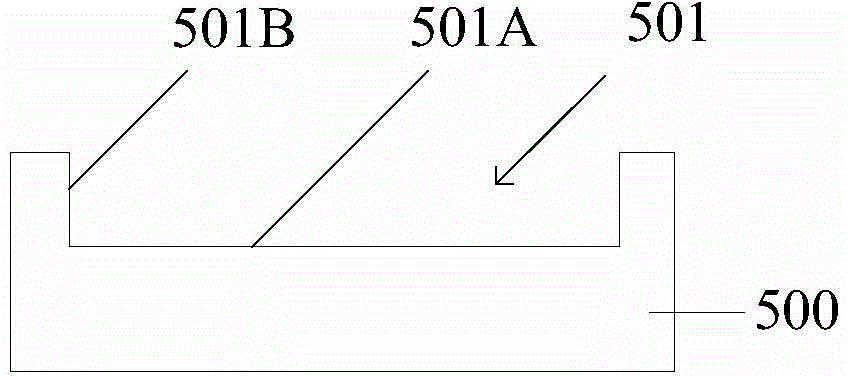

Welding method of tungsten target material component

ActiveCN104551381AReduce deformationUnbreakableWelding/soldering/cutting articlesMetal working apparatusHot isostatic pressingWeld strength

The invention discloses a welding method of a tungsten target material component. The welding method comprises the following steps: providing a tungsten target material and a copper back plate; turning threads in the welding surface of the tungsten target material; forming a groove in the copper back plate; mounting the tungsten target material in the groove; welding the tungsten target material and the copper back plate by a hot isostatic pressure method. Through the use of the welding method, the threads are turned in the welding surface of the tungsten target material, the groove is formed in the copper back plate, and the tungsten target material and the copper back plate are mounted together, so that the tungsten target material is positioned in the groove; then welding by the hot isostatic pressure method is performed, in the welding process, the deformation quantity of the tungsten target material is small, and a fragmentation phenomenon not easily occurs; in addition, because of the threads, the area of the welding surface of the tungsten target material is enlarged, and the welding strength of the tungsten target material component is improved; after welding, the threads are embedded in the copper back plate from the welding surface of the tungsten target material, so that the welding strength of the tungsten target material component is further improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

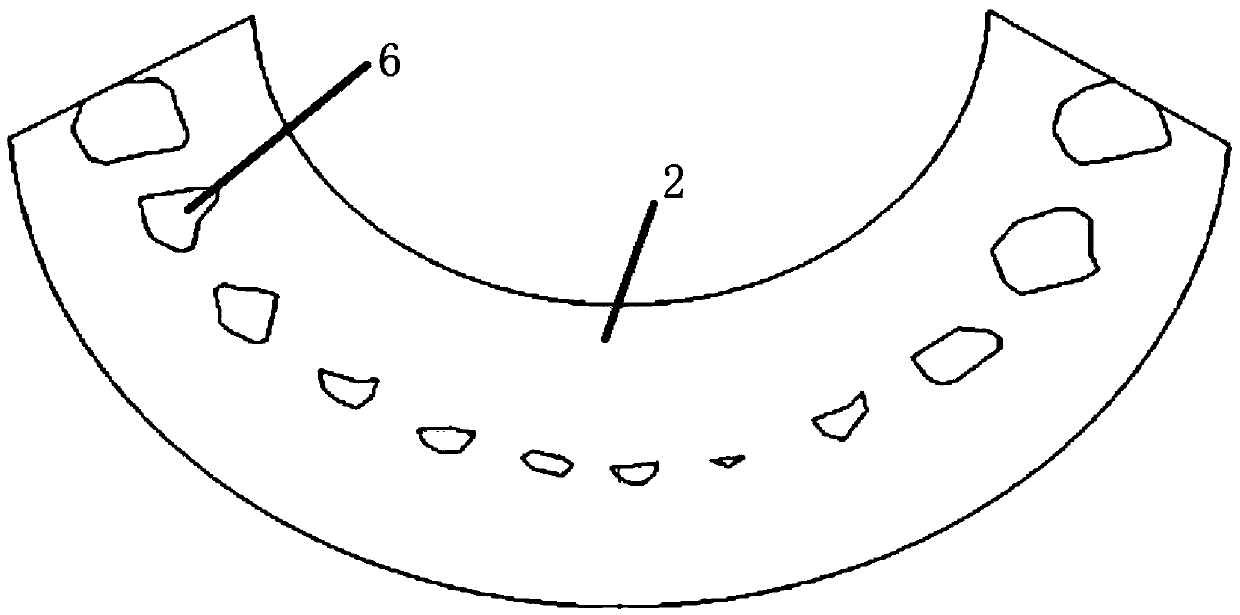

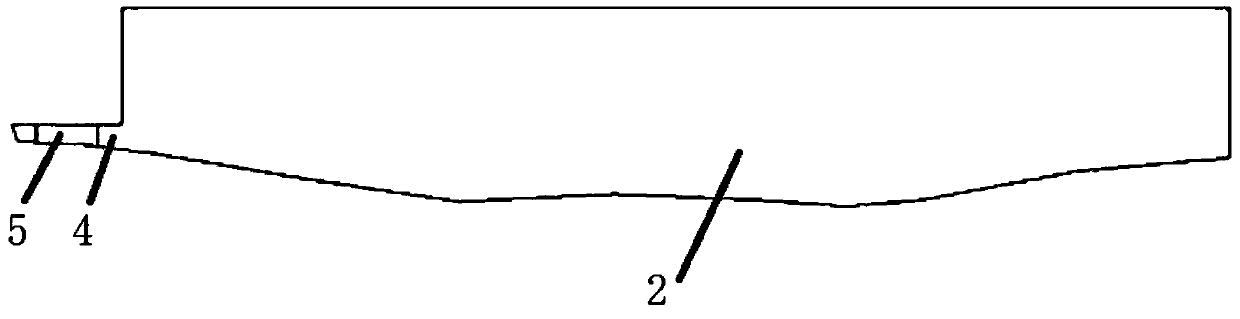

Method for producing diamond tool for grinding concrete floor

InactiveCN101518890ALow priceImprove stabilityAbrasion apparatusGrinding devicesHot pressHot pressing

The invention discloses a method for producing a diamond tool for grinding a concrete floor, which comprises the following steps: proportional irregular glomerocryst diamond and man-made diamond are uniformly distributed on the surface of a tire casing; a gap between the diamond is filled with metallic bond, and according to the ratio by weight, the metallic bond comprises 40 to 70 percent of cobaltco, 10 to 20 percent of copper, 15 to 20 percent of tungsten carbide, 5 to 10 percent of stannum and 0.5 to 3 percent of trace element; the operation of cold press molding is carried out, sections formed by the cold press molding are delivered to a vacuum hot press sintering furnace to be sintered, and the temperature is kept from 850 DEG C to 900 DEG C and the pressure from 10 to 15 tons; and the sintered sections are welded on a metal base body. The diamond tool produced by the method not only can increase the grinding efficiency and maintain the stable performance, but also can greatly prolong the service life.

Owner:邓国川 +2

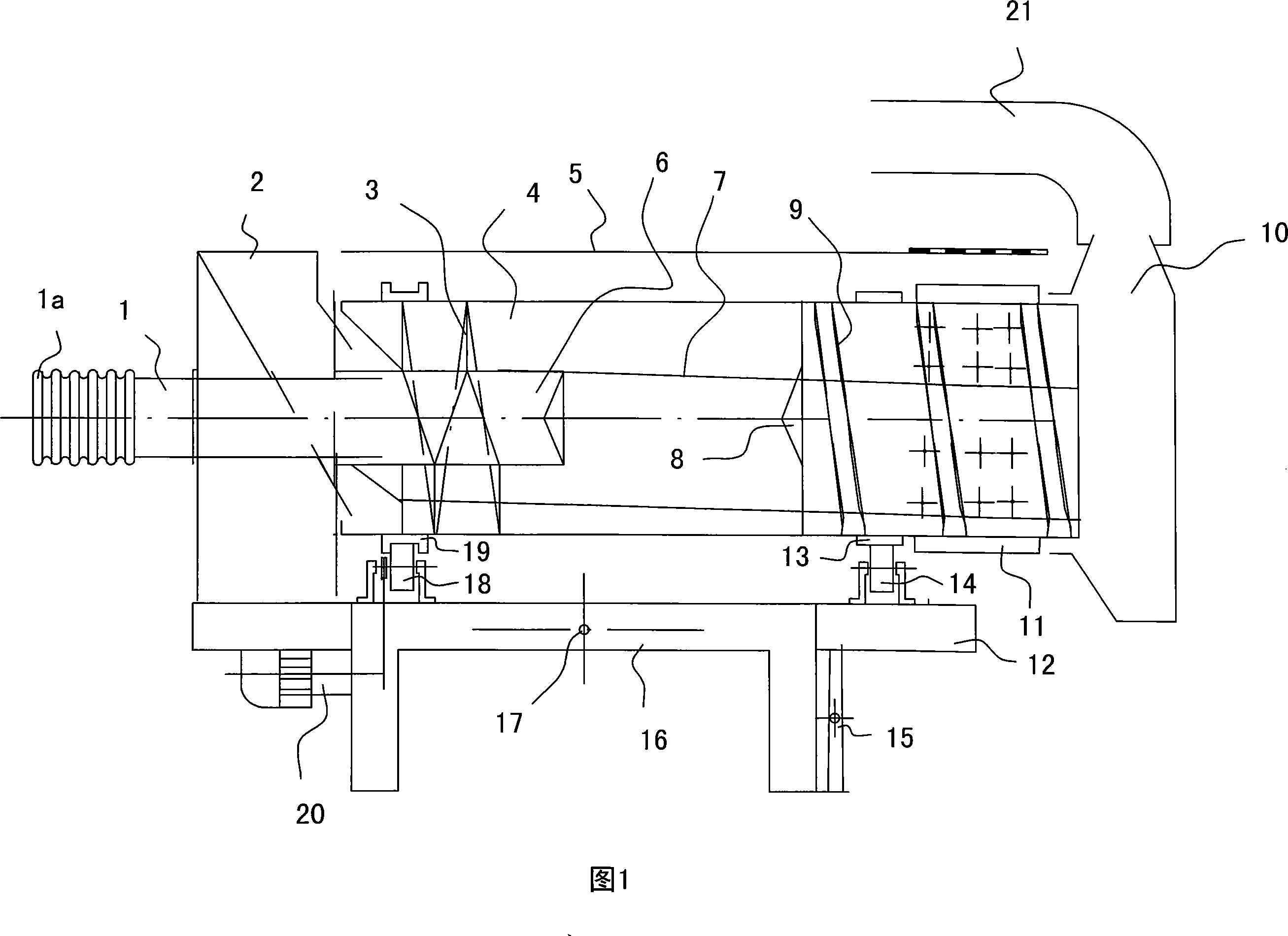

Tea hot air water-removing machine

ActiveCN101238838AIncrease profitImprove thermal efficiencyPre-extraction tea treatmentEngineeringThermal efficiency

The invention provides a tea hot-air green removing machine, including drum and tea inlet bucket, the machine rack is placed on a stand which can adjust the horizontal angle of the machine rack. The inner cavity of the drum is divided into three functional areas of leaf pushing section, green removing section and desiccation section, the leaf pushing section is provided with guide-leaf plate and helix guide-leaf plate, and longitudinal central wind pipe. Part of the rampart of the central wind pipe and the closed surface are provided with small intensive hole; the green removing section is equipped with guide-leaf gluten, the centre shaft passage is equipped with wind cap; the desiccation section is equipped with guide-leaf gluten and many groups of spiral laminas, the drum wall on the tea inlet end is equipped with intensive air holes; interval dynamic-static connected wind wheel cover is equipped along radial direction on the tea outlet end, the upper part of the wind wheel cover is adapted to one end of return vent pipe, the other end of the return vent pipe is adapted to the inlet opening of the heat source device. The machine uses hot air to do the jobs of green removing and parching, the product has the merits of high thermal efficiency, sturdy leaves, good desiccation effect, and the green removing time of tea in the drum can be effectively controlled according to the tea producing methods.

Owner:浙江上洋机械股份有限公司

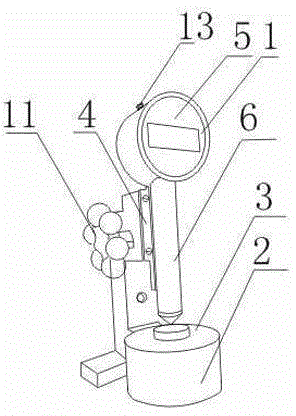

Device facilitating measurement of hardness of workpiece

The invention relates to a device facilitating the measurement of the hardness of a workpiece. The device comprises a hardness meter and a base, wherein the base comprises a testing platform and a vertical column connected with the testing platform; the vertical column is of a cavity structure with an opening at one end; the hardness meter is arranged in the vertical column in a sliding manner and comprises a cylindrical cavity shell; a hardness converter is arranged in the cylindrical cavity shell; the hardness meter also comprises a guide pipe connected on the cylindrical cavity shell; a testing head is arranged in the guide pipe in a sliding manner; the bottom end of the guide pipe is provided with a hole; an electronic coil is wound above the hole; the hardness converter is electrically connected with the electronic coil; and the hardness meter also comprises a transmission device. The device has the beneficial effects that and height adjustment of the hardness meter can be realized by gear-rack meshing when a hand wheel rotates, and the distance between the testing head and the coil is shortest by directly winding the electronic coil on the guide pipe, so that the obtained final testing result is accurate.

Owner:四川富临集团成都机床有限责任公司

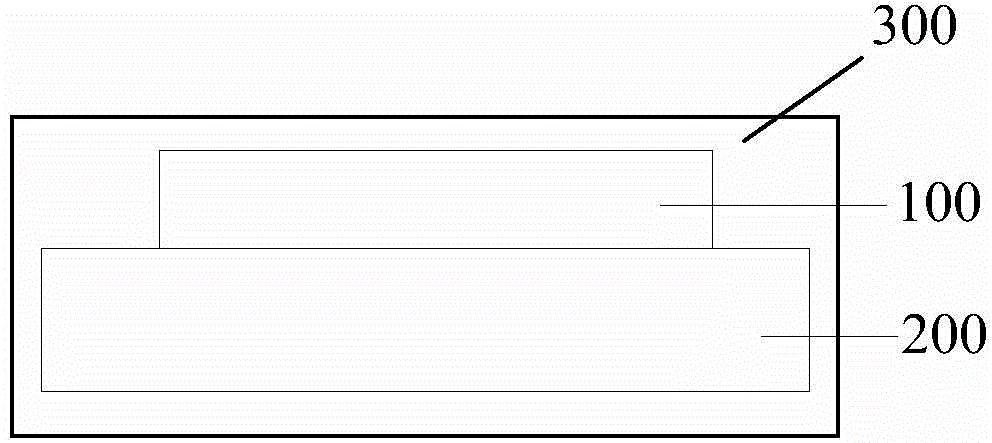

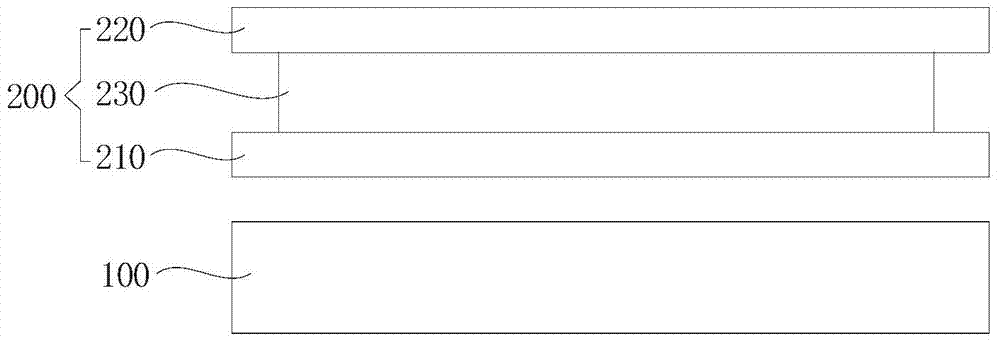

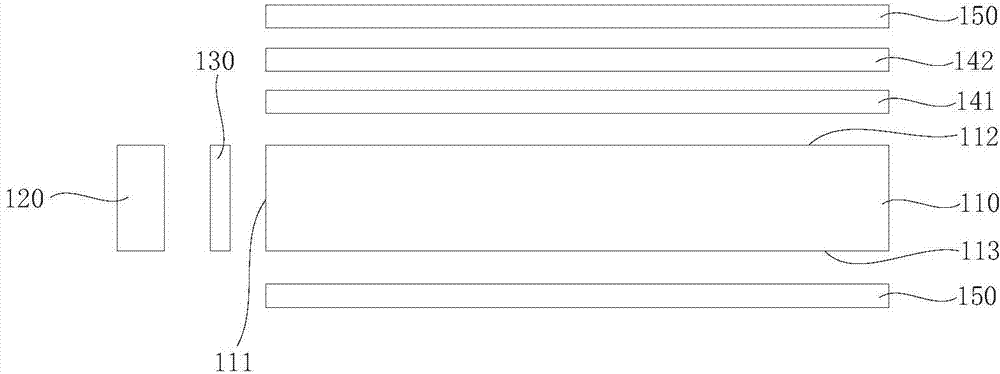

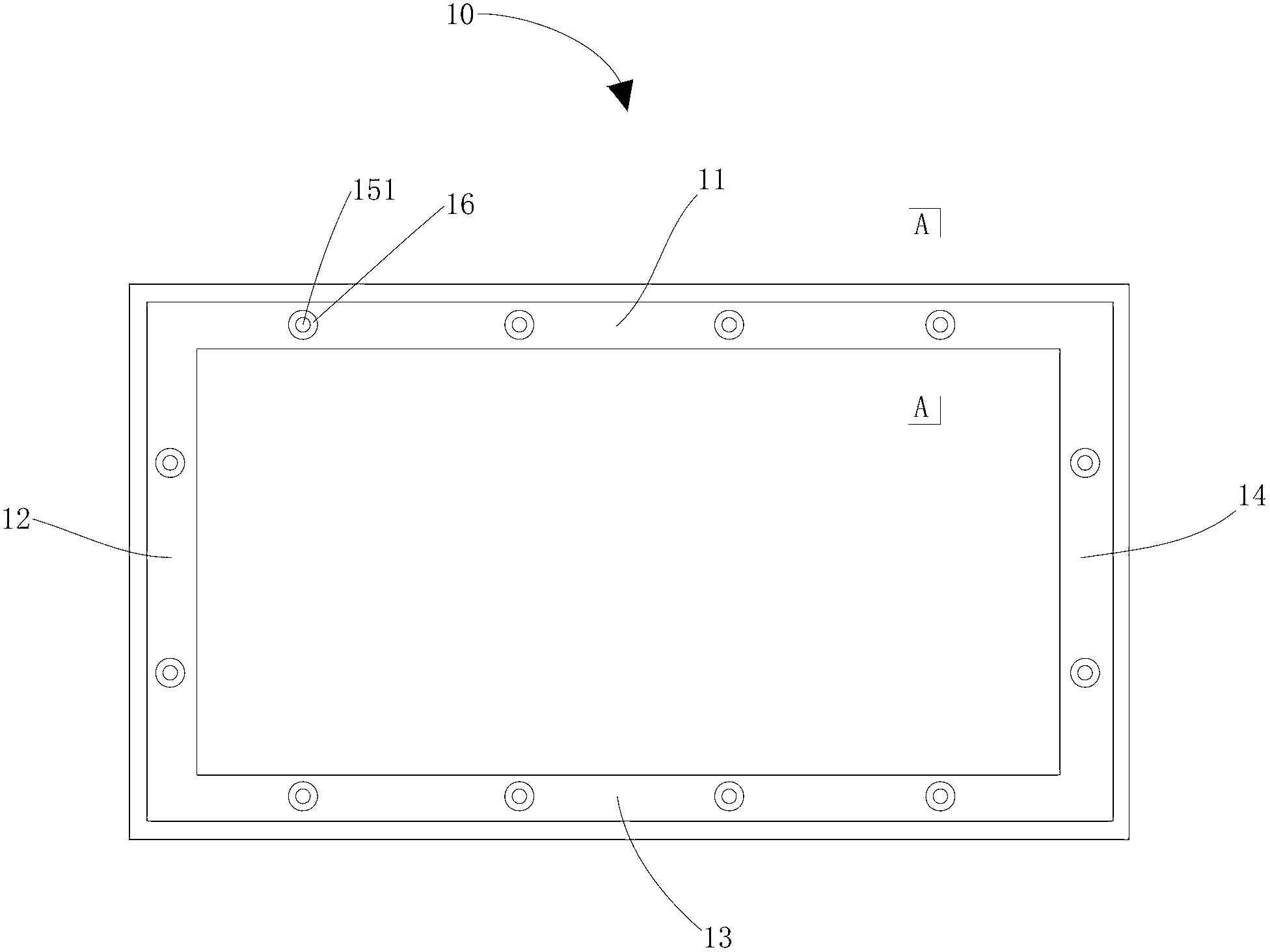

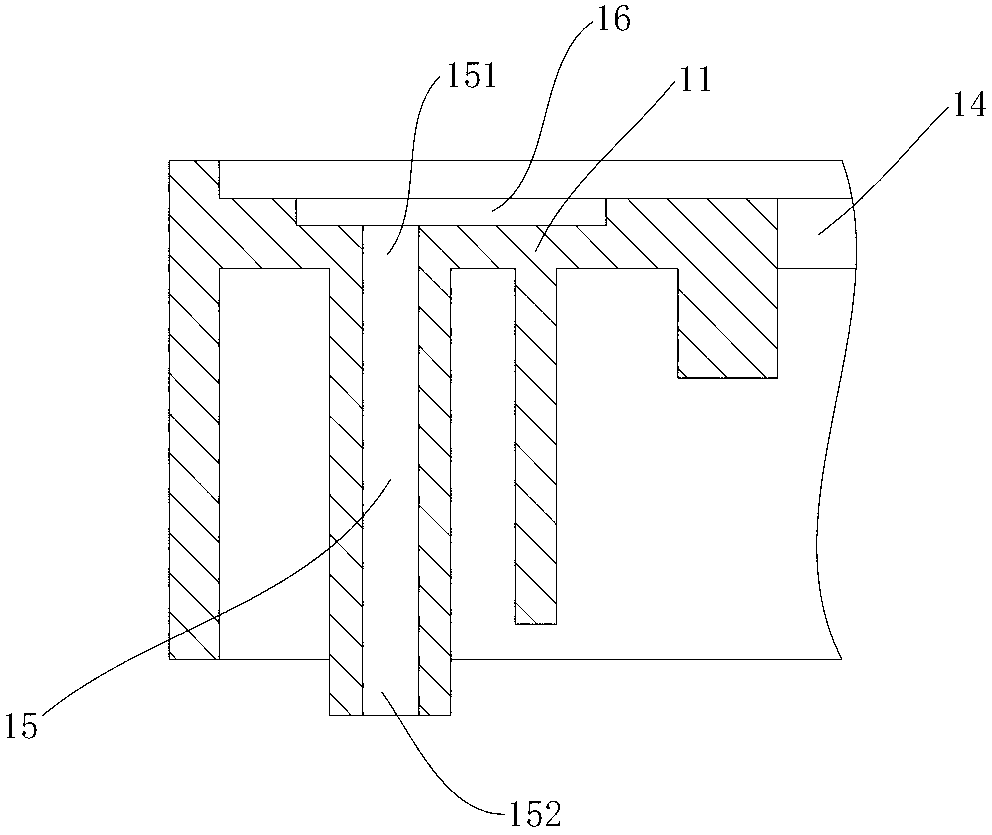

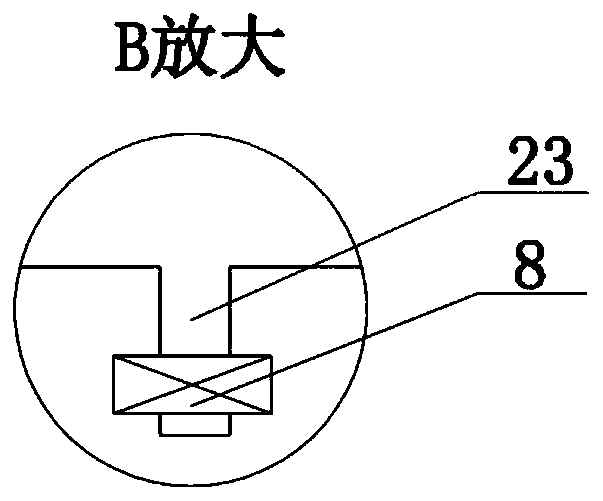

Backlight module and liquid crystal display with same

InactiveCN104503137AEasy to makeLow costPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a backlight module, which comprises a light guide plate (110), a light source strip (120) and a plurality of quantum dot films (130); the light guide plate (110) is provided with at least one incident light side face(111); the light source strip (120) is arranged close to the incident light side face(111); the quantum dot films (130) are arranged between the light source strip (120) and the incident light side face(111); the light emitted by the light source strip (120) passes through the quantum dot films (130) to irradiate the incident light side face(111). The invention also discloses a liquid crystal display with the backlight module. Since the short quantum dot films are arranged between the light source and the incident light side face of the light guide plate to replace a long quantum dot film of the prior art and the short quantum dot films are easy to fabricate, are low in cost and cannot easily break, the safety and reliability of the quantum dot films are enhanced. Furthermore, because uniform-chromaticity white light distribution is formed on the incident light side face of the light guide plate, the optical quality of the backlight module is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

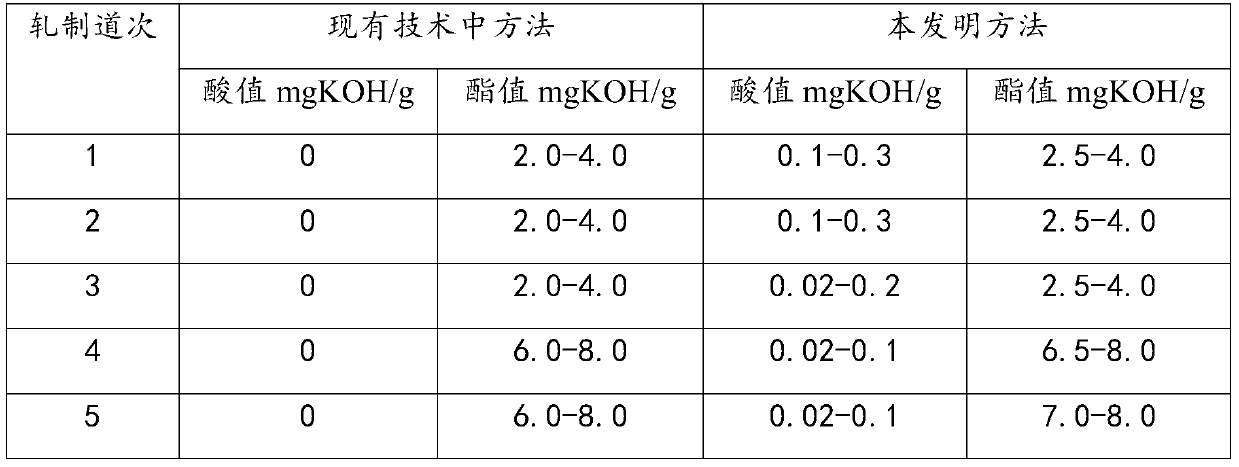

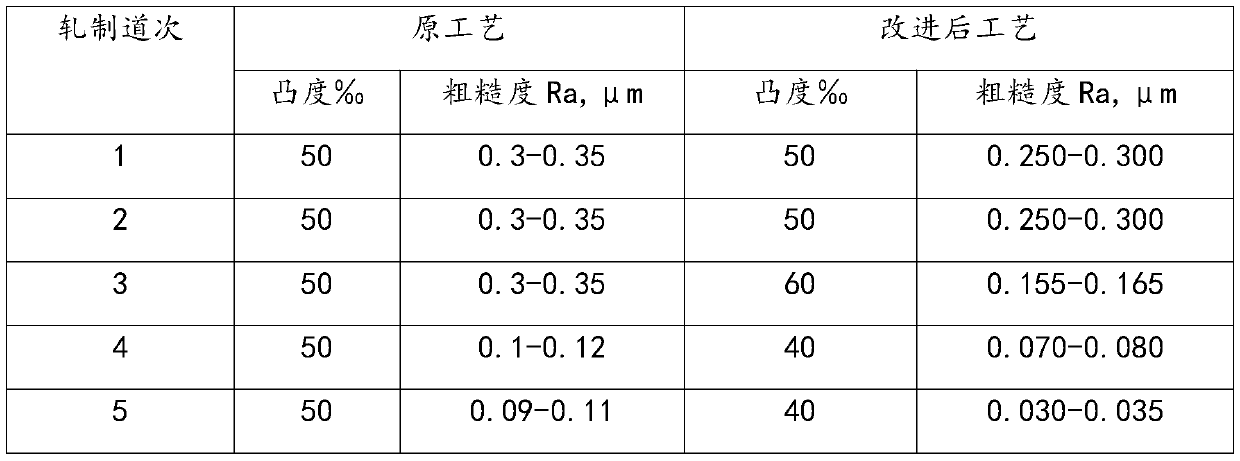

Production technology for rolled copper foil for lithium battery

ActiveCN105057354ANot prone to breakageImprove uniformityMetal rolling arrangementsWork in processCopper foil

The invention discloses a production technology for rolled copper foil for a lithium battery. Rough rolling, intermediate annealing, intermediate rolling, semi-finished product annealing, finished product rolling, anti-sticking agent spraying, finished product annealing, finished product cleaning and splitting processing are conducted on a selected TU2 anaerobic copper casting blank, then the rolled copper foil for the lithium battery is obtained, and the content of copper of the copper foil product is larger than 99.97%, the copper foil is in a soft state M, the tensile strength of the copper foil is larger than or equal to 140 MPa, ductility is larger than or equal to 10%, and electrical conductivity is larger than or equal to 100% of the IACS. The performance movement and balance of the copper foil are good, most obviously, ductility is improved, so that in the production technology of the lithium ion battery production technology, the copper foil is not prone to being broken when being pressed, and the finished product rate is increased.

Owner:江苏富威科技股份有限公司

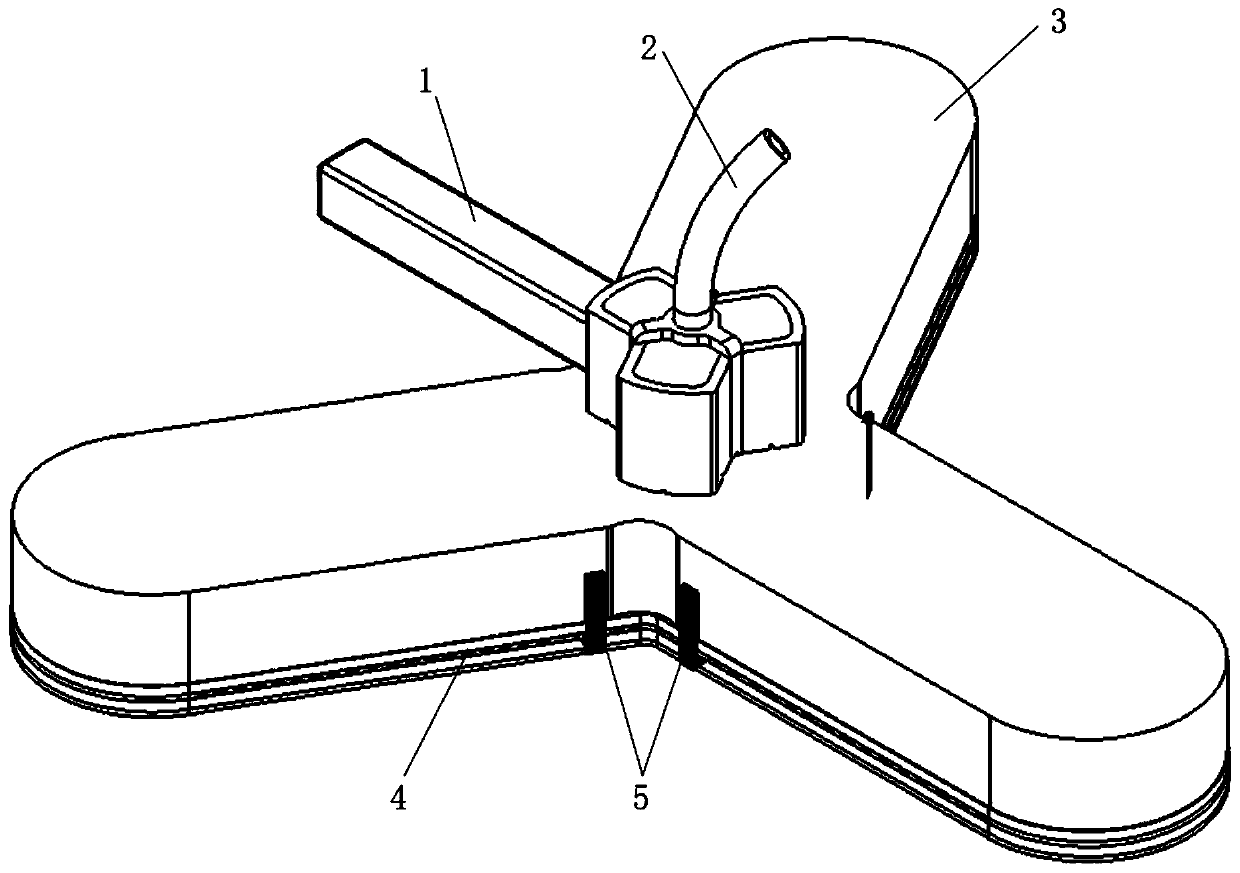

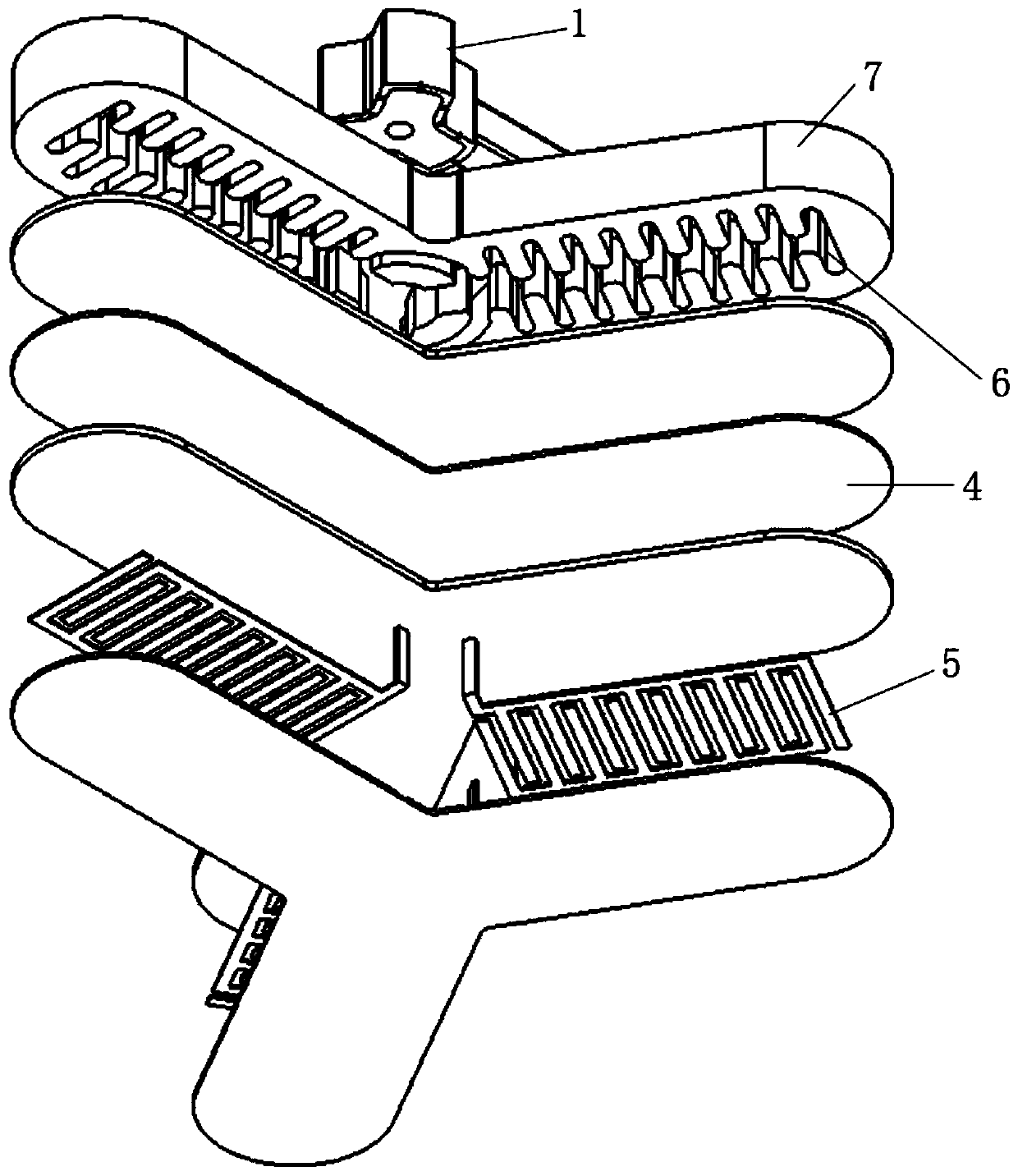

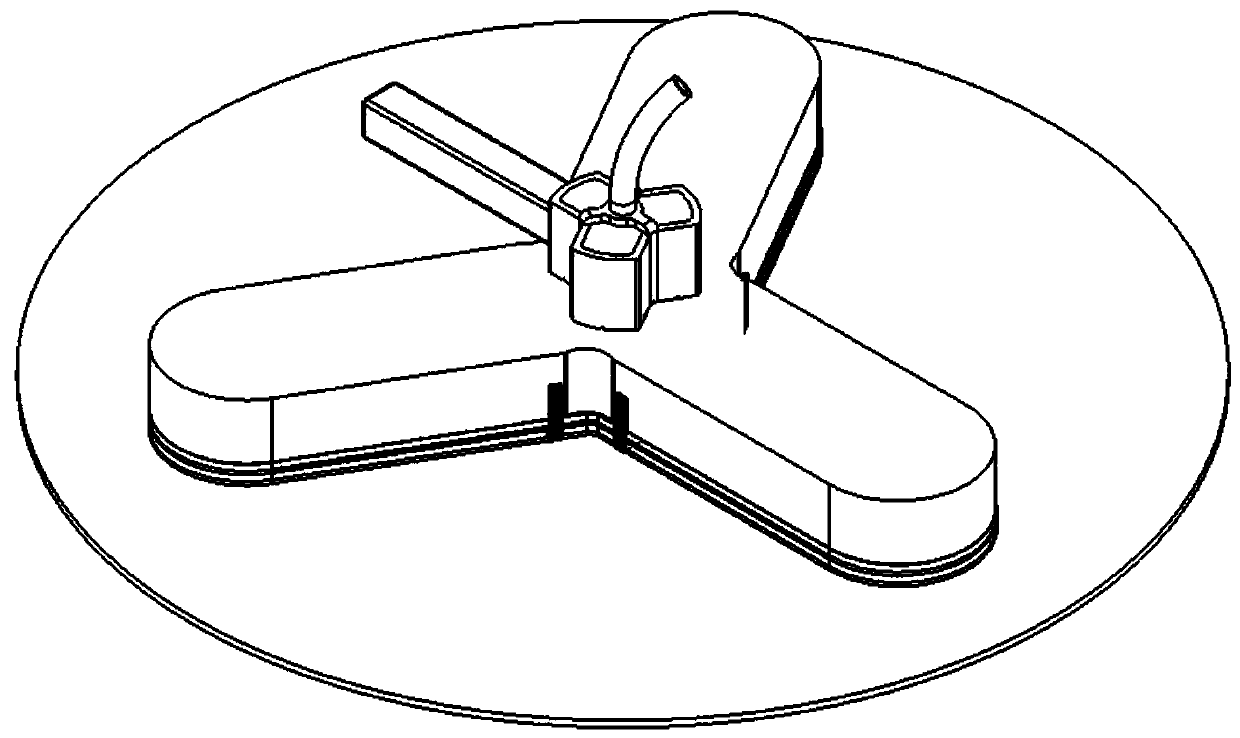

Electrostatic adsorption pneumatic soft gripper

The invention discloses an electrostatic adsorption pneumatic soft gripper. The gripper is designed as a centrosymmetric three-finger flexible structure body and comprises a gripper support, a soft gripper body, a restraining layer, an air duct, an air passage, an electrostatic adsorption membrane and an outer auxiliary device; the gripper support is connected with the soft gripper body and the outer auxiliary device for fixing the positions of the soft gripper body and the outer auxiliary device; the soft gripper body is flattened in a free state; the air passage is inflated deflated by the outside so as to drive the soft gripper to contract and stretch, and thus target objects are gripped; and the electrostatic adsorption membrane is attached to the gripping surface of the soft gripper body for generating electrostatic adsorption force. The soft pneumatic manipulator which clamps objects in various complicated shapes through electrostatic adsorption force and flexible mechanical clamping force is designed, and the problems such as wrapping gripping and plane object gripping are solved, and the objects in various complicated shapes are gripped.

Owner:CHONGQING UNIV

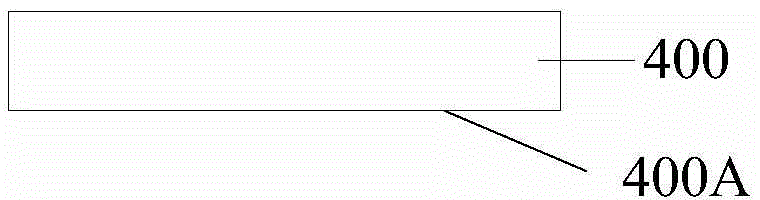

Liquid crystal display device and rubber frame thereof

The invention discloses a liquid crystal display device and a rubber frame thereof. The liquid crystal display device comprises the rubber frame, a back plate, an optical plate, at least one optical diaphragm and a liquid crystal display panel, wherein the optical plate is arranged on the back plate, the optical diaphragm is arranged on the optical plate, the rubber frame is fixedly connected with the back plate, and the optical diaphragm is fixedly pressed by the rubber frame so as to fix the optical plate and the optical diaphragm. The rubber frame comprises at least one rim and a plurality of vacuum absorption pipes, wherein first ports of the vacuum absorption pipes are arranged on the rims, the liquid crystal display panel is arranged on the rims and covers the first ports, and air in the vacuum absorption pipes are extracted from second ports of the vacuum absorption pipes so as to enable the liquid crystal display panel to be absorbed and fixed. The liquid crystal display device enables the liquid crystal display panel to be absorbed and fixed through the vacuum absorption pipes arranged on the rubber frame, is free of frame, simple in absorption operation and not prone to break when the liquid crystal display panel is expanded or contracted, and improves process yield and competitiveness of products.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

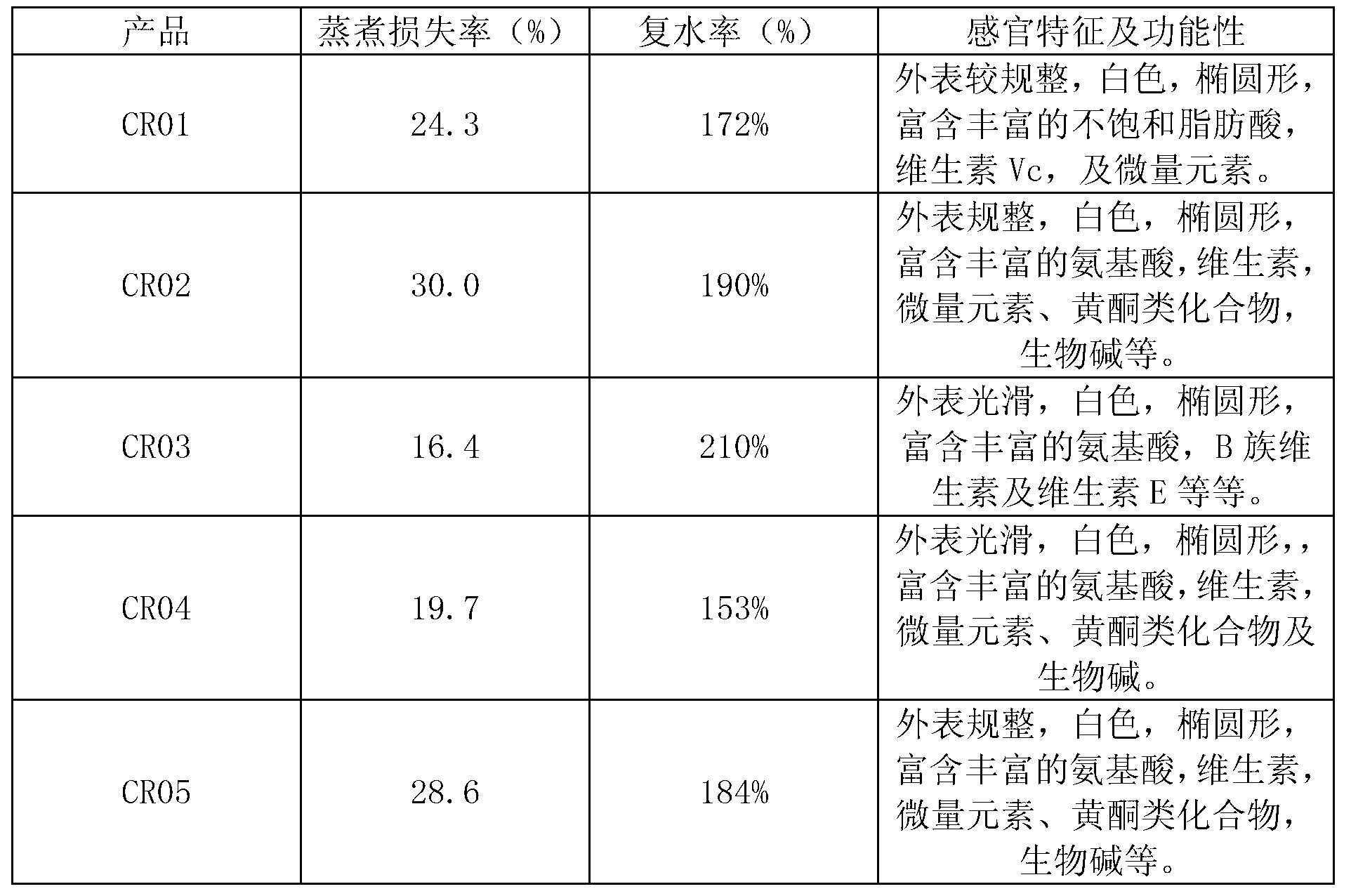

Cassava rice and processing method thereof

InactiveCN103156141AImprove eating effectIncrease the degree of staple foodFood preparationNutritive valuesEdible oil

The invention provides cassava rice which consists of raw powder and a mixture. The raw powder comprises the following components in percentage by weight: 30-60 percent of a component A, 30-60 percent of a component B and 5-10 percent of a component C, wherein the component A is cassava starch; the component B is one or a mixture of broken rice meal, corn starch and soybean meal; and the component C is one or a mixture of chestnut powder, yam flour, beautiful millettia root powder and banana meal. The mixture is a proper amount of edible oil, gelatin and edible alcohol. The cassava rice takes the cassava starch as a main raw material, is additionally provided with other side crops, the chestnut powder, the yam flour, the beautiful millettia root powder and the like an auxiliary mode, is convenient to eat, reasonable in formula, fine and smooth in mouthfeel, is easily cured and less prone to breakage in a cooking process, is enriched in vitamins, amino acid and trace metal elements, can improve the nutritive value of cassava and make non-food crops become principle foods, does not have odor and is neat in appearance and good in mouthfeel.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Harness clamp tie

ActiveUS20080296444A1Reduce tensionImprove stabilityPipe supportsElectrical apparatusEngineeringFrenulum

Owner:HELLERMANNTYTON CORP

Preparation method for double-sided light aluminum foil

InactiveCN109759474AIncrease pass reduction rateGuarantee the shape qualityReduction rateRoom temperature

The invention discloses a preparation method for a double-sided light aluminum foil. The preparation method comprises the following steps that (1) cast-rolling is performed, wherein an aluminum alloymaterial and an aluminum ingot are put into a melting furnace for melting, after standing is performed through a standing furnace, a molten liquid is filtered, and a cast-rolled plate is obtained after multiple times of cast-rolling is performed by a cast-rolling machine; (2) cold rolling is performed, wherein the cast-rolled plate is cooled to room temperature, multiple times of cold pressing isperformed by a cold press, and then multiple times of annealing treatment is performed to obtain an aluminum foil stock; (3) an aluminum foil working procedure is performed, wherein the aluminum foilstock undergoes five passes of rolling working procedures to obtain a finished aluminum foil, the first pass of the rolling working procedure to the third time of the rolling working procedure are rough rolling, the thickness of the obtained aluminum foil is 0.03 mm, the fourth pass of the rolling working procedure is intermediate rolling, the thickness of the obtained aluminum foil is 0.014 mm, the fifth pass of rolling working procedure is finish rolling, and the aluminum foil with the thickness of 0.009 mm is obtained. According to the method, the distribution of reduction pass of an aluminum foil rolling working procedure is adjusted again, the pass reduction rate of the third pass is properly improved, the pass reduction rate of the fifth pass, namely, the pass reduction rate of the final pass is reduced, so that the reduction process speed is reduced, and the thickness of the product is reduced easier.

Owner:HANGZHOU FIVE STAR ALUMINUM

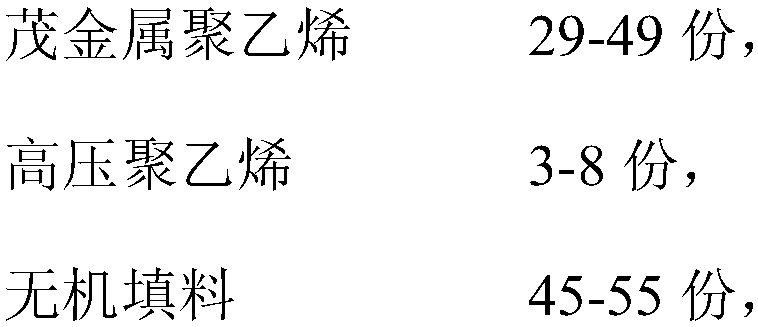

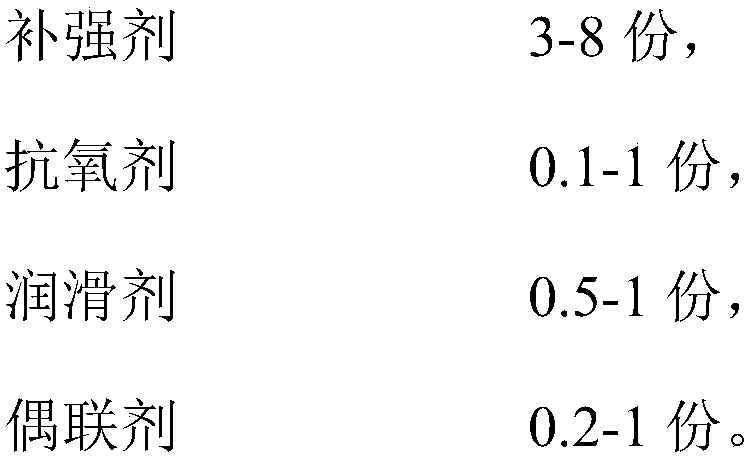

Composite for waterproof breathable film and preparation method of composite

The invention discloses a composite for waterproof breathable film and a preparation method of the composite. The composite for the waterproof breathable film is prepared from 29-49 parts of metallocene polyethylene, 3-8 parts of high pressure polyethylene, 45-55 parts of inorganic fillers, 3-8 parts of reinforcing agents, 0.1-1 part of antioxidant, 0.5-1 part of lubricant and 0.2-1 part of coupling agents by mixing, extruding and granulating. The reinforcing agent added can effectively improve melt strength of the composite and the composite is not easy to be broken when being pulled, so thatproduction efficiency of cast film can be increased greatly, particularly, the production rate can be up to 150-180 meter / minute, and compared with the conventional production rate of 80-120 meter / minute, the production efficiency is increased by 50%. The preparation method of the composite is simple and low in price, and capable of effectively reducing production cost of the cast film.

Owner:HEFEI GENIUS NEW MATERIALS

Manufacture method for ceramic base of LED illuminating lamp

The invention provides a method for a low-cost manufacturing method for a ceramic base of an LED illuminating lamp. The method is characterized by: 1) adopting waste ceramics in a ceramic industry; 2) mixing and grinding the waste ceramics and kaolin; 3) respectively adding water glass, a tetramethylammonium hydroxide solution and a ammonium sulfate solution to the mixture through spraying; 4) heating paraffin wax, followed by adding accessory ingredients, mixing the resulting mixture through stirring, then adding the resulting mixture to the mixture from the step 3), followed by carrying outimpact briquetting to form a green body in a die; 5) annealing the green body to obtain the finished product. According to the present invention, demolding can be performed in 10-100 seconds; a forming process does not contain a green body dehydration process, such that forming time is substantially saved, efficiency is improved. In addition, the green body has high intensity so as to form an exquisite shape and an exquisite structure through matching with a steel mould, and satisfy a precision requirement of a structure size of the base of the LED illuminating lamp.

Owner:汕头市乐易得光电有限公司

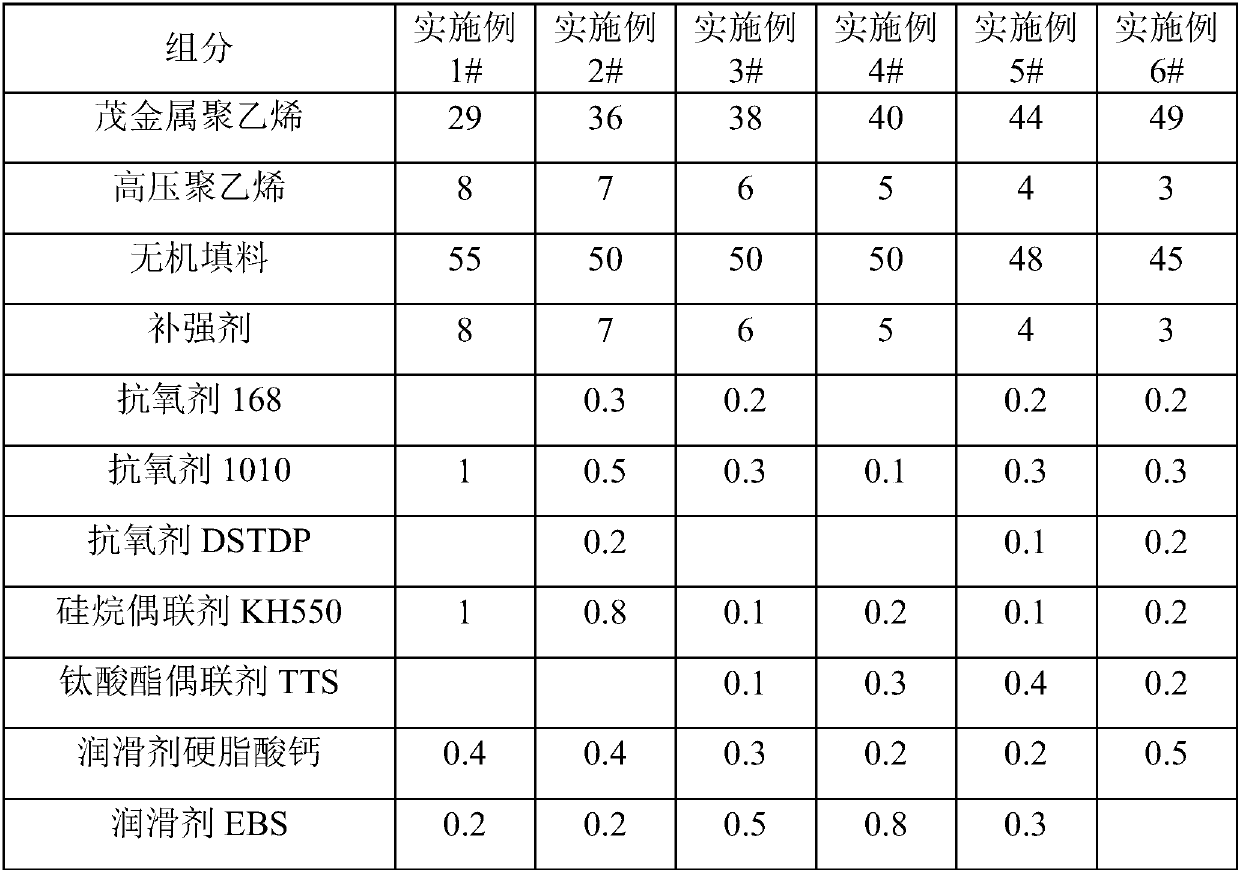

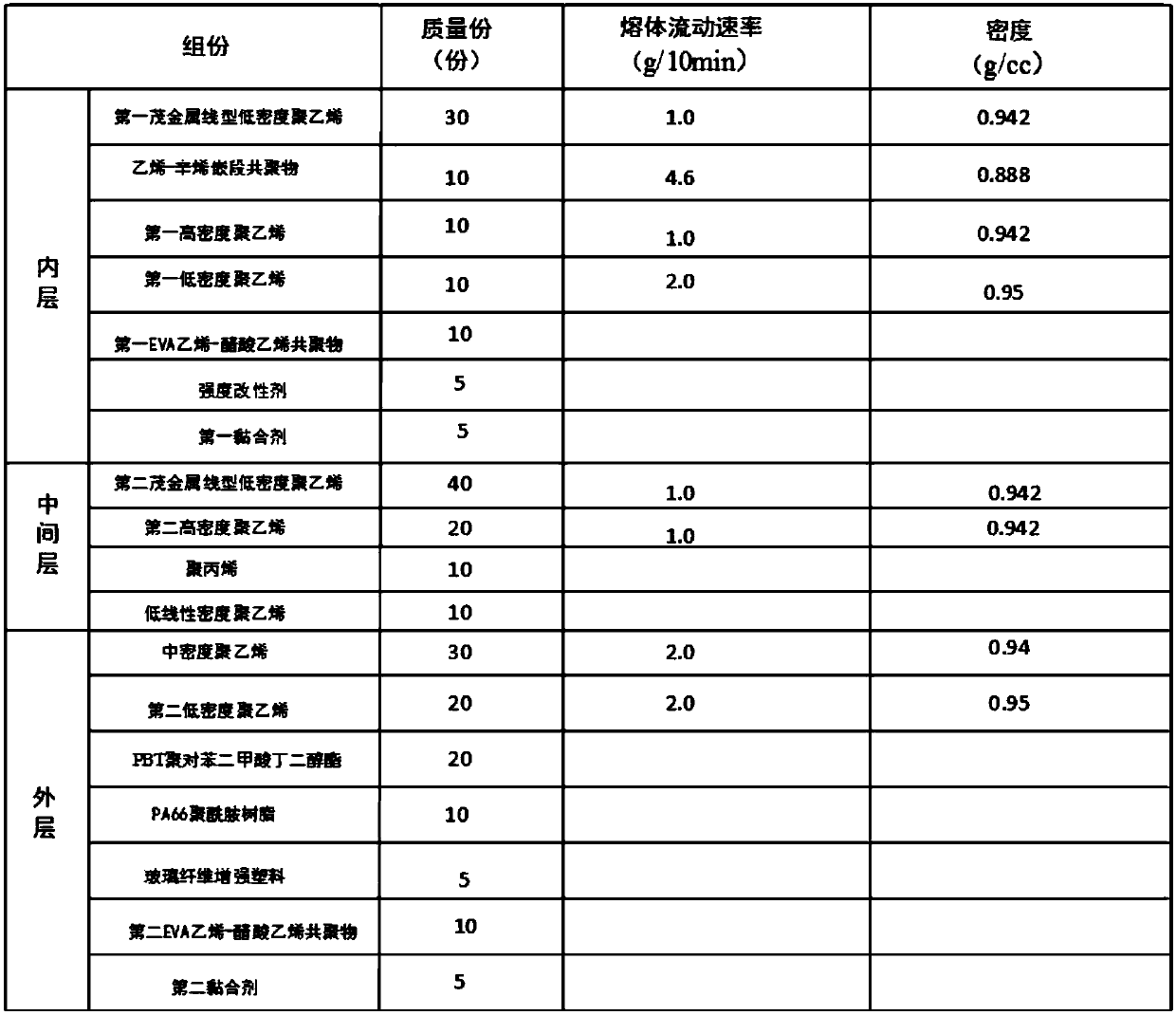

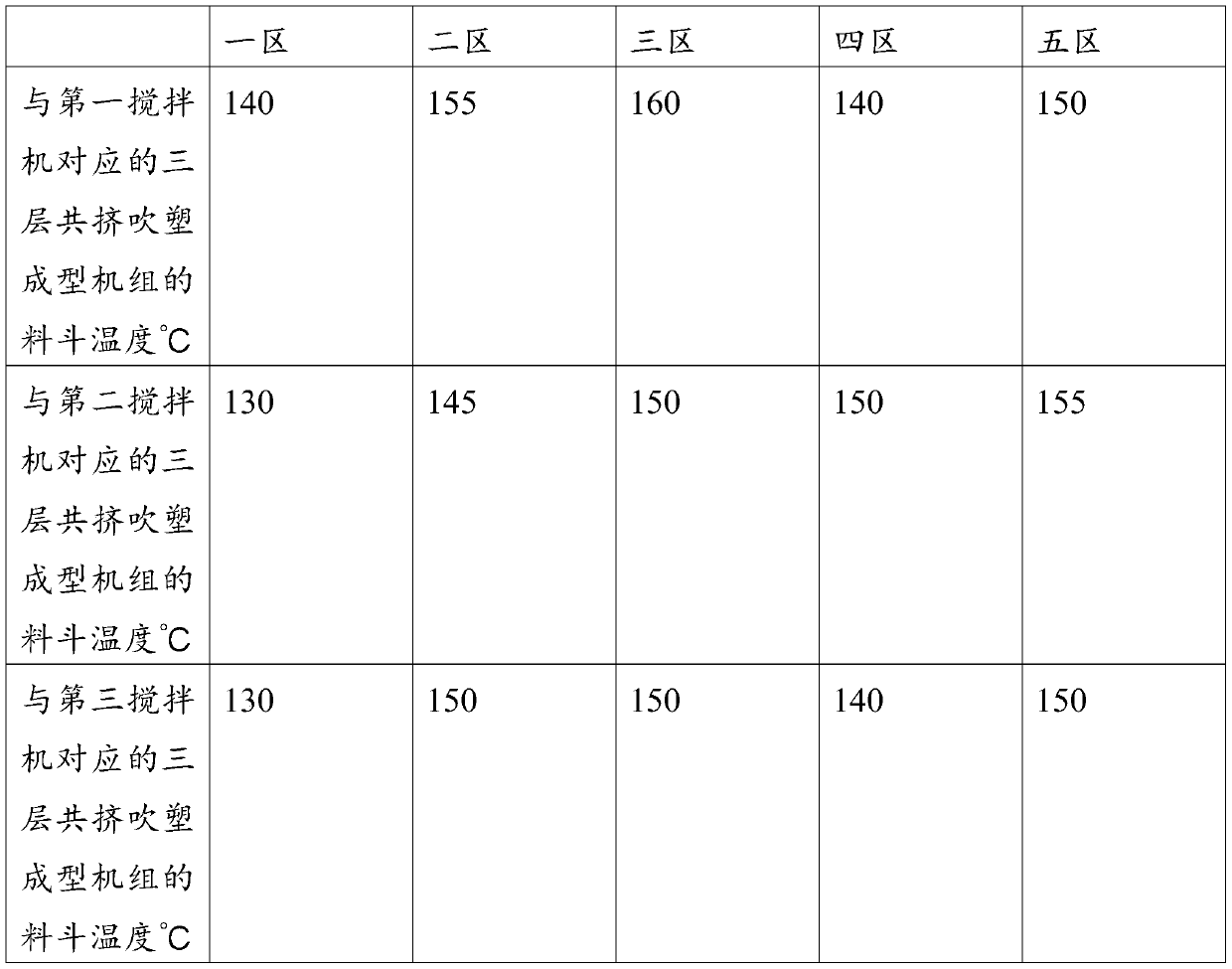

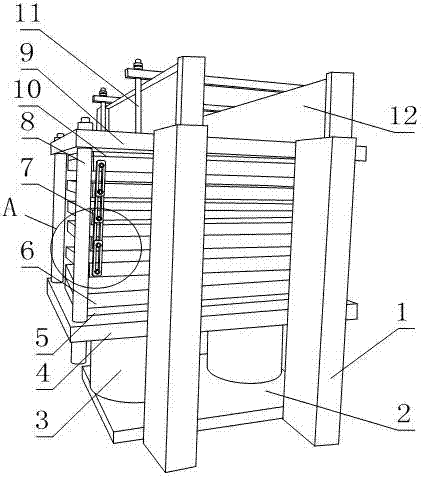

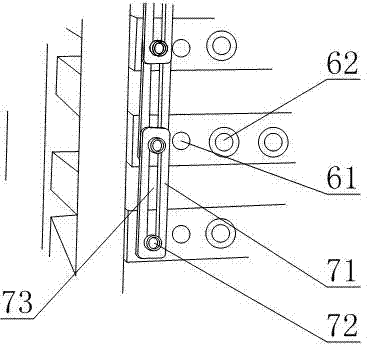

Preparation method of hydrophobic three-layer co-extrusion compound film

ActiveCN110254012AImprove toughnessHigh strengthFlexible coversWrappersPolyethylene terephtalateCo extrusion

The invention discloses a preparation method of a hydrophobic three-layer co-extrusion compound film. According to the hydrophobic three-layer co-extrusion compound film, an inner layer is composed of, by weight part, 30-40 parts of first metallocene linear low-density polyethylene, 10-20 parts of ethylene-octylene block copolymer, 10-30 parts of first high-density polyethylene, 10-30 parts of first low-density polyethylene, 10-20 parts of first ethylene-vinyl acetate copolymer and 5-15 parts of polypropylene flexibilizer; a middle layer is composed of 40-60 parts of second metallocene linear low-density polyethylene, 20-30 parts of second high-density polyethylene and 10-20 parts of polypropylene; an outer layer is composed of 30-40 parts of medium-density polyethylene, 20-40 parts of second low-density polyethylene and 20-30 parts of polybutylene terephthalate. The preparation method of the hydrophobic three-layer co-extrusion compound film can achieve the aim of avoid damage of the hydrophobic three-layer co-extrusion compound film.

Owner:福建省凯安包装科技有限公司

Thermoforming device

The invention discloses a thermoforming device. The device comprises a rack and a plurality of pressing plates which are arranged on the rack, wherein the pressing plates are of plate-like structures in which electric heating blocks are built; the rack comprises a vertical frame, a bottom plate and a top plate; the bottom plate is also fixedly provided with a jack; a connecting buckle is also arranged between adjacent pressing plates; the connecting buckles comprise strip-shaped buckling plates; the buckling plates are provided with strip-shaped holes; two connecting bolts are arranged in the strip-shaped holes; the upper end of the vertical frame is also provided with a cross beam; the cross beam is also provided with a threaded rod; the pressing plates are also provided with a plurality of mounting holes; at least one electric heating block is arranged in the mounting holes; each electric heating block comprises a metal casing, a plurality of porcelain bushings and an electric heating rod; the two ends of the metal casing are also in threaded connection with caps. The device has a simple structure; the temperature of each point of a balance press plate is conveniently balanced, the service life is long, and the machining efficiency and the machining quality of a pre-pressing forming process in a carbon crystal heating film manufacturing process are favorably improved.

Owner:CHENGDU YANGZHONG NEW ENERGY TECH

Spontaneous-heating and anti-static garment fabric

InactiveCN106012219AAntistaticImprove breathabilityCarbon fibresLiquid/gas/vapor removalPolyesterCarbon fibers

A spontaneous-heating and anti-static garment fabric is formed by interweaving warp and weft. The warp is prepared from the following raw materials in parts by weight: 5-8 parts of graphene oxide, 20-25 parts of modal fibers, 6-8 parts of lonicera tangutica fibers, 6-8 parts of ramie fibers, 5-8 parts of phosphorous permanent flame-retardant polyester fibers, 6-8 parts of cushaw stem fibers, 1-2 parts of copper fibers and 4-6 parts of nano-alumina; the weft is prepared from the following raw materials in parts by weight: 3-5 parts of magnetic fibers, 2-3 parts of tourmaline, 4-5 parts of polyborosiloxane, 1-2 parts of aluminum hydroxide, 15-20 parts of carbon fibers, 12-16 parts of dogbane leaf fibers, 1-2 parts of copper fibers and 18-22 parts of lysimachia alfredii hance fibers. The fabric contains graphene oxide and tourmaline which have certain spontaneous heating capacity; the fabric also has anti-static performance, thereby preventing electrostatic sparks during friction; meanwhile, the fabric has good breathability and flame retardancy, can be directly contacted with skin, is comfortable to wear and cannot cause damage to skin.

Owner:广德毅维纺织有限公司

Polybutylece terephthalate (PBT) reinforced material with high thermal conductivity

InactiveCN109553938AImprove insulation performanceHigh thermal conductivityHeat-exchange elementsAdhesiveHeat conducting

The invention discloses a polybutylece terephthalate (PBT) reinforced material with high thermal conductivity. The PBT reinforced material comprises the following components in percentage by mass: 30-40% of PBT resin, 12-16% of phenolic resin, 5-10% of polycarbonate, 6.5-8.2% of heat-conducting powder, 4.2-5.3% of heat-conducting filler, 2.87-3.65% of a fire retardant, 2.12%-2.56% of an anti-hydrolysis agent, 1.86%-2.24% of a wear-resistant agent, 3.45-4.26% of an antioxidant, 2.34-3.28% of a toughening agent, and the balance of a heat-conducting adhesive. The formula of the PBT reinforced material is more scientific and reasonable. According to the PBT reinforced material with high thermal conductivity, the PBT resin is taken as a main raw material, and the phenolic resin and the polycarbonate are added cooperatively, so that insulation performance of the material can be improved; the heat-conducting powder, the heat-conducting filler and the heat-conducting adhesive are added, so that heat conduction performance of the material can be greatly enhanced; wear resistance and surface strength of the material can be improved through the cooperative addition of the wear-resistant agent; and toughness of the material can be reinforced through the cooperative addition of the toughening agent, so that the formed material does not fracture easily, overall performance of the PBT material can be enhanced, and therefore, a good popularization effect is achieved.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

Embedded tooth individualized bone fenestration guide plate based on three-dimensional printing technology

PendingCN109662788AGood compatibilityReduce the chance of sheddingAdditive manufacturing apparatusOthrodonticsEmbedded teethEngineering

The invention relates to the technical field of medical treatment, in particular to an embedded tooth individualized bone fenestration guide plate based on a three-dimensional printing technology. Theembedded tooth individualized bone fenestration guide plate based on the three-dimensional printing technology adopts the three-dimensional printing technology, and is based on titanium alloy materials, and prints the bone fenestration positioning guide plate based on the tooth supporting type according to an optimal traction design scheme; the guide plate assembly is positioned by the tooth around the embedded tooth, is stable and does not loosen, and the positioning through hole of the guide ring part protruding from the other end tightly fits to the bone surface so as to surround the partof the simulated fenestration. Compared with the traditional stainless steel, the titanium alloy material is adopted to form the guide plate assembly, the structure compatibility is obviously superior, and soft and hard tissue inflammation reactions are not easy to occur; compared with a resin material guide plate, the titanium alloy material guide plate is lighter and thinner in volume and smaller in thickness, and is more suitable for operation in a narrow space of a posterior tooth molar area. The integrated structure is firmer and is not easy to break. The optimal position of the bone fenestration is determined according to the optimal traction and extraction path of the impending teeth.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

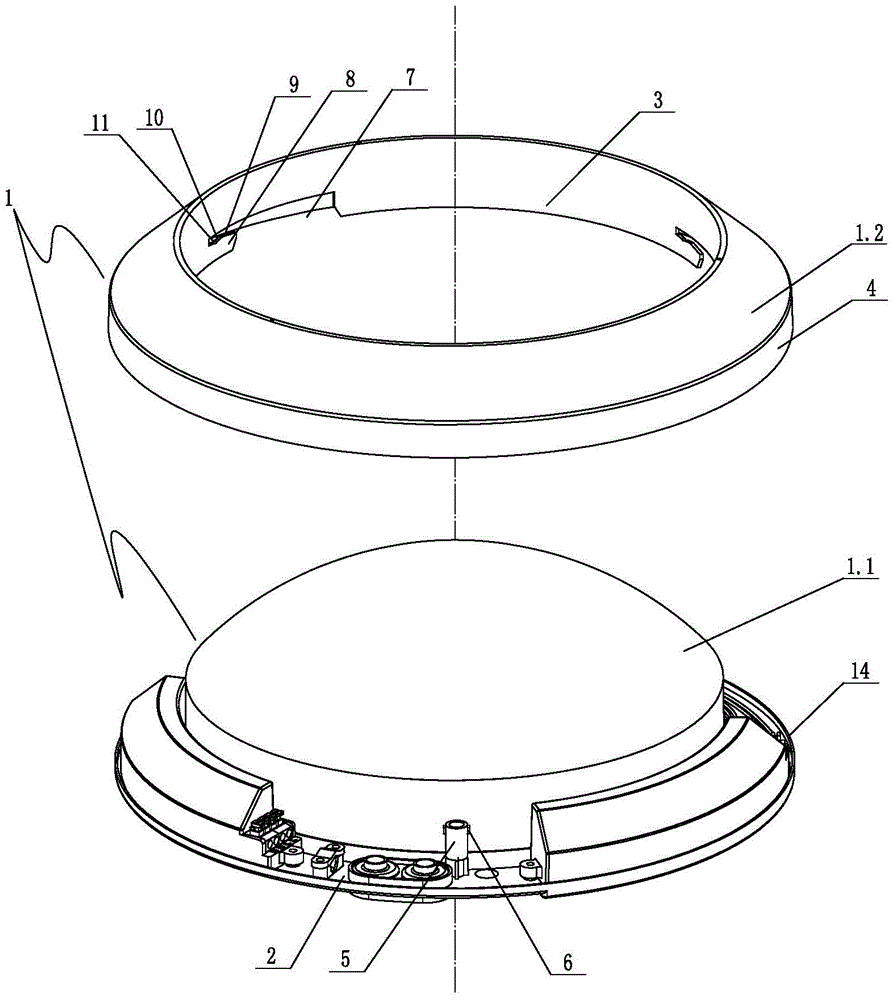

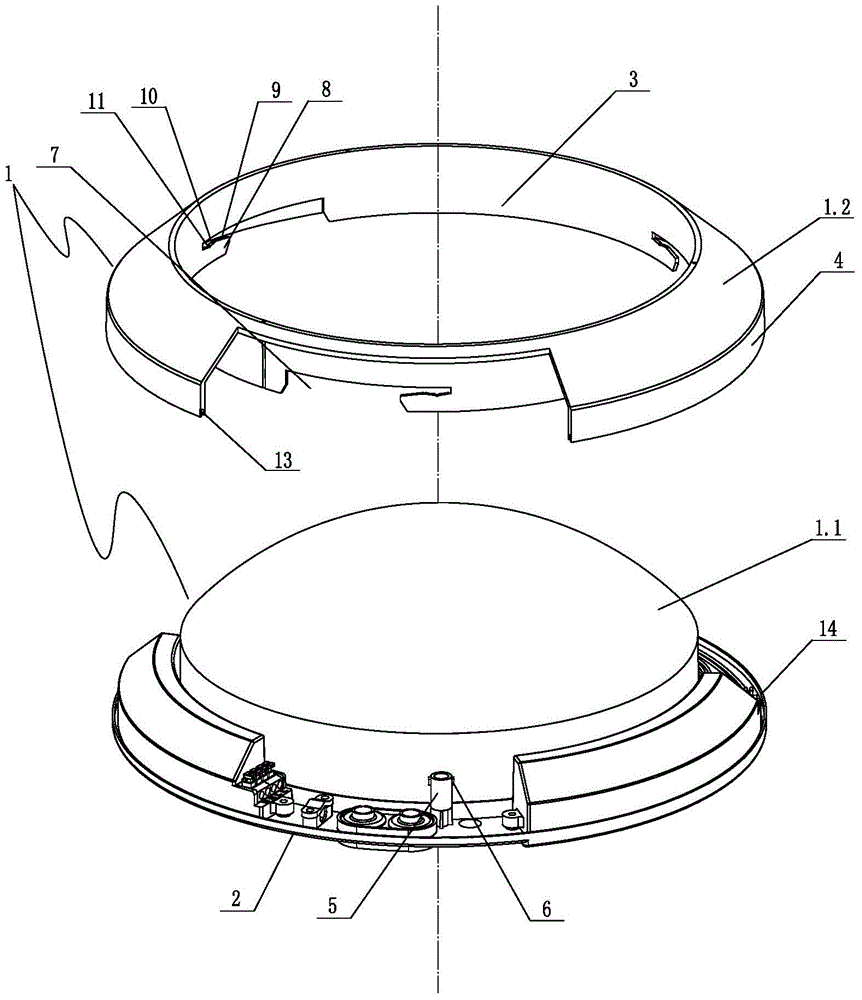

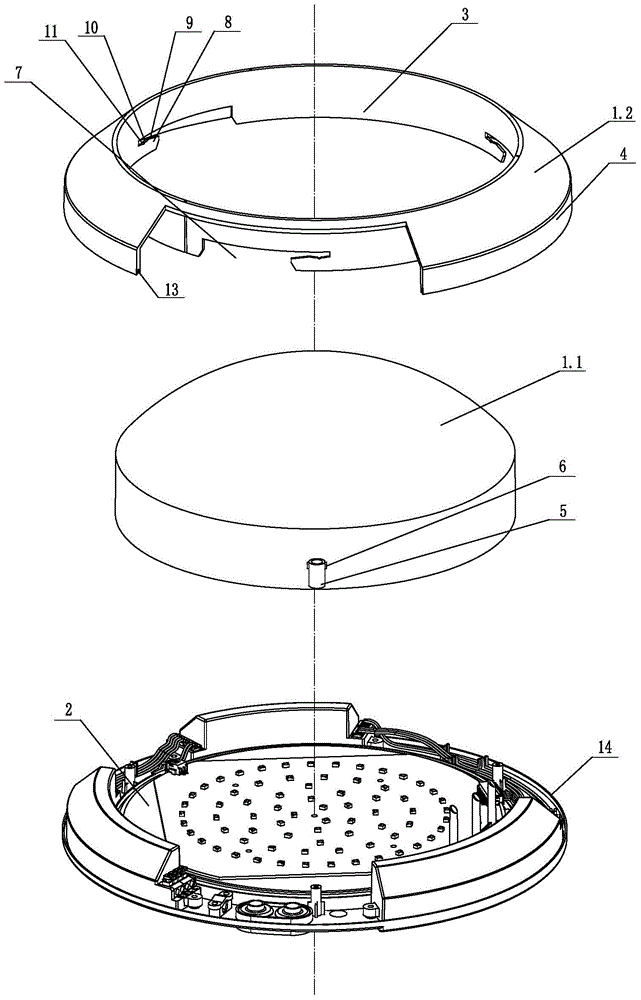

LED (light emitting diode) lampshade connecting structure

ActiveCN104315410AConsistent thicknessReduce manufacturing costPoint-like light sourceGas-tight/water-tight arrangementsEngineeringLED lamp

The invention relates to an LED (light emitting diode) lampshade connecting structure. The LED lampshade connecting structure comprises a lampshade and a lamp holder, wherein the lampshade is divided into a spherical notched inner cover and an annular outer cover, the outer diameter of the inner cover is equal to the inner diameter of the outer cover, and the outer cover is provided with an annular inner dustproof plate and an outer dustproof plate; the inner cover is provided with at least two fixing columns which are connected with the lamp seat, the axis of each fixing column is parallel to that of the inner cover, the fixing columns are uniformly distributed along the circumferential direction of the inner cover, the fixing columns are fixedly connected with the inner cover through connecting blocks, and the width of each connecting block is greater than or equal to the thickness of a clamping hook; the inner dustproof plate is provided with notches which are identical to the quantity of the connecting blocks, the notches are uniformly distributed along the circumferential direction of the inner dustproof plate, the side wall of each notch is provided with the clamping hook corresponding to the connecting blocks one by one, each connecting block is arranged on between the clamping hook and the top surface of respective notch, and the distance from the end part of a movable end of each clamping hook to the notch and the distance between the opposite side walls of the clamping hook are greater than the length of each connecting block. Compared with the prior art, the LED lampshade connecting structure has characteristics of relatively simple structure, relatively low preparation cost, simplicity in clamping connection, good application stability and long service life.

Owner:NINGBO LEXING INDUCTOR ELECTRONIC CO LTD

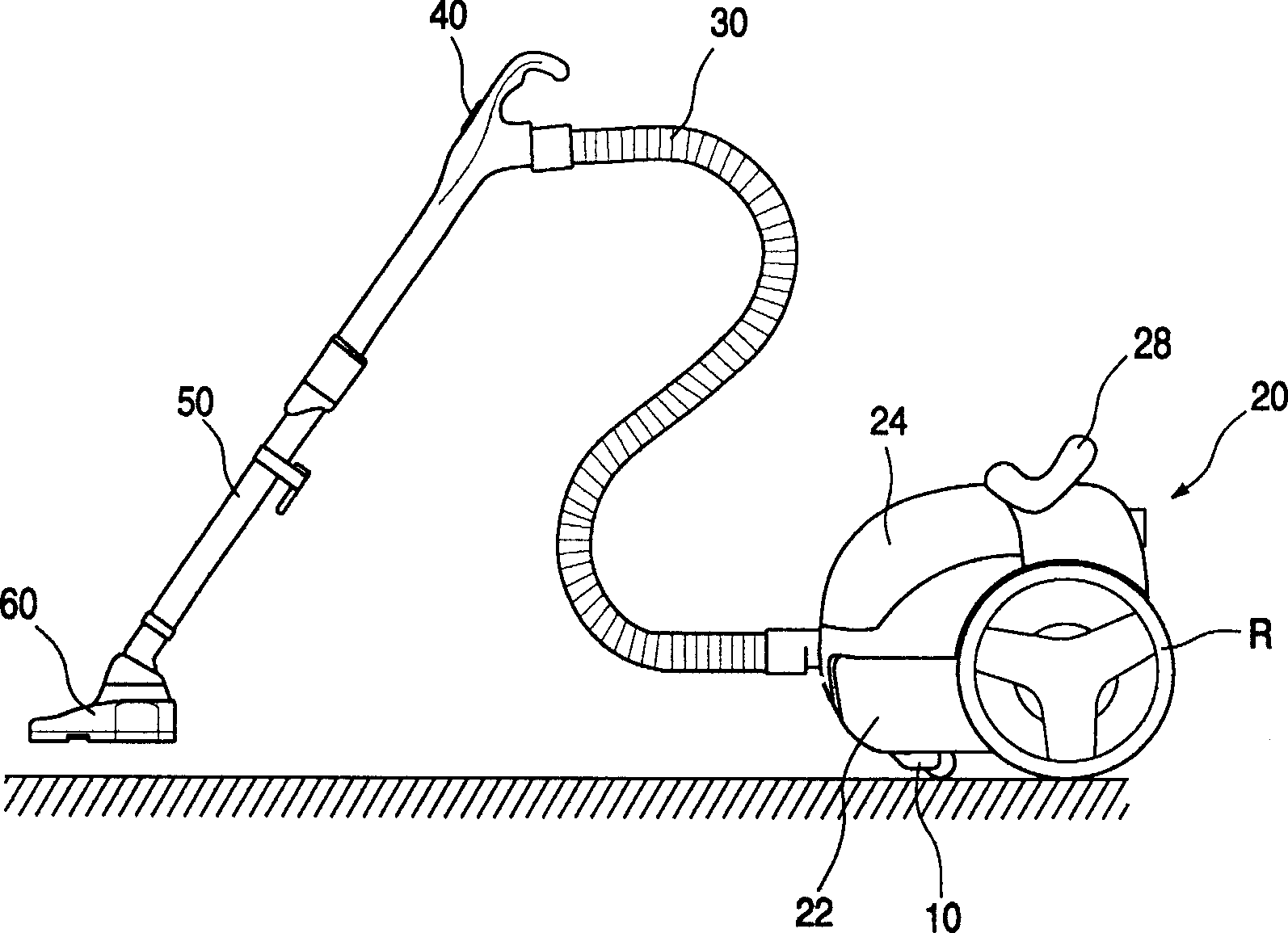

Dust collector roller

InactiveCN1768669AIncrease binding forceNot prone to breakageSuction cleanersRotational axisRotation function

The invention relates to an idler wheel of vacuum dust-collector which inserts the inner wheel into the casting mould to form the outer wheel without using special combination element, to integrate the inner and outer wheels as a whole. The inventive idler wheel comprises: a lower part to generate suction force; an outer wheel contacting the ground when moving machine body; an inner wheel embedded into the inner side of outer wheel to support the weight of machine body; and a rotational shaft inserted and mounted at the centers of inner and outer wheels with the rotation function. Wherein, the rotational shaft is formed by an anti-drop groove along the periphery with a certain depth to insert the stop ring S; and a friction part beside the anti-drop groove along the periphery with a certain length of projection. Said structure can avoid the slide between the inner and outer wheel and reduce the producing process and cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Organic framework modified epoxy resin scratch-resistant water-based coating

InactiveCN111808499AImprove stabilityGood flexibilityLiquid/solution decomposition chemical coatingEpoxy resin coatingsEpoxyChemical plating

The invention discloses an organic framework modified epoxy resin scratch-resistant water-based coating, and relates to the technical field of coating processing. The specific process comprises the following steps of: (1) treating graphene oxide, and carrying out chemical copper plating; (2) preparing a powdery organic metal framework material compound by using cobalt chloride, manganese nitrate,terephthalic acid and copper-plated graphene as precursors; (3) introducing the organic metal framework material compound in the synthesis process of epoxy resin to obtain modified epoxy resin; and (4) emulsifying the organic metal framework modified epoxy resin to obtain an epoxy resin emulsion, and uniformly dispersing the epoxy resin emulsion and the prepared raw materials. According to the invention, the organic metal framework material compound with good stability and flexibility is introduced into the epoxy resin, so that the epoxy resin polymer network forms powerful high-toughness chemical connection, the epoxy resin molecular chain is not easy to slip, the deformation can be completely recovered after the external force is removed, and the scratch resistance of the coating is improved.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

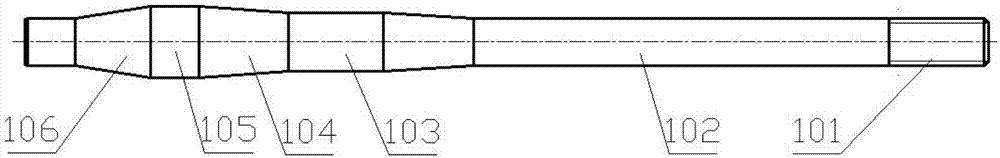

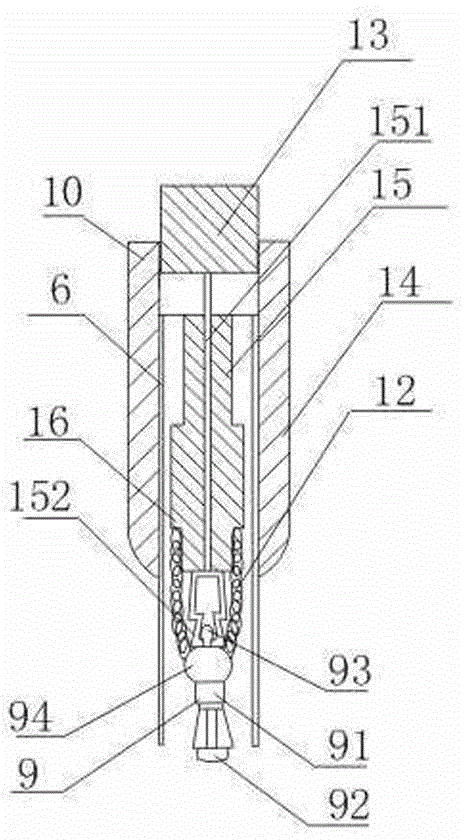

Special needle for hair transplantation and shaving-free hair transplanting method

The invention relates to the technical field of hair transplantation, in particular to a special needle for hair transplantation and a shaving-free hair transplanting method. The special needle for hair transplantation comprises a needle end, a middle bin, an ejector rod, bristles, a drain port, a needle handle, a spring, a push handle, a water tank, a water inlet and a sealing strip, wherein oneend of the needle end is inlaid in the middle bin, the sealing strip is arranged on the outer surface of the right side of the needle end, the ejector rod and the bristles are arranged in the middle bin, the bristles are arranged at the left end of the ejector rod, the right end of the ejector is fixed on the needle handle, the drain port is formed in the middle bin, the spring is arranged in theneedle handle, the push handle is arranged on the right side of the needle handle, the water tank is arranged above the middle bin, and the water inlet is arranged on the water tank. After adoption ofthe technical scheme, the special needle for hair transplantation has the beneficial effects as follows: the special needle for hair transplantation has good hair transplantation effects and higher hair survival rate, and hair transplant epidermis cannot be damaged easily.

Owner:广州青逸医疗美容门诊部有限公司

Ecological light partition wallboard

The invention belongs to the technical field of buildings, and particularly relates to an ecological light partition wallboard. The partition wallboard comprises a partition wallboard body, a protruding block is arranged on one side of the partition wallboard body. A groove is formed in one side corresponding to the protruding block; a semicircular protruding block is arranged on the other side ofthe partition wallboard body; a semicircular groove is formed in one side corresponding to the semicircular protruding block; two rows of symmetrical convex steel frameworks are arranged in the partition wallboard body, triangular structure frames are arranged in the convex steel frameworks, light foamed concrete is arranged in the triangular structure frames, high-pressure decorative refractoryboards are arranged on the convex steel frameworks, ceramic heat insulation coatings are arranged on the high-pressure decorative refractory boards, and sound insulation felts are arranged on the ceramic heat insulation coatings. The overall strength of the partition wallboard is improved through cooperation of the protruding block and the groove and cooperation of the semicircular protruding block and the semicircular groove, the partition wallboard body is internally provided with the triangular structure frameworks, the partition wallboard is firmer and not prone to breakage, the practicability is higher, and the good shockproof effect is achieved.

Owner:重庆领固新材料科技有限公司

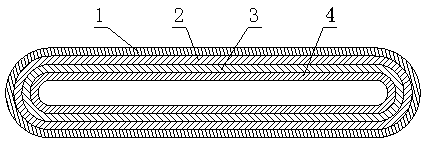

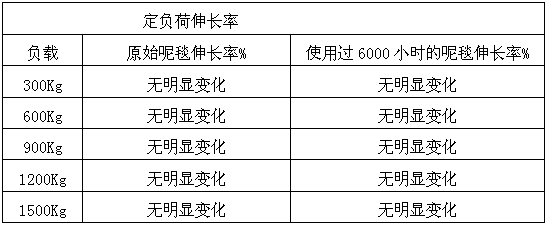

Pre-shrinking machine woolen cloth blanket and manufacturing process of same

ActiveCN103255588ANot easy to wrinkleNot prone to breakageHeating/cooling textile fabricsNon-woven fabricsShrinkage ratePulp and paper industry

The invention discloses a pre-shrinking machine woolen cloth blanket, and further discloses a manufacturing process of the pre-shrinking machine woolen cloth blanket. The pre-shrinking machine woolen cloth blanket is formed by the following four layers from outside to inside: a high-temperature-resistant fiber layer, a woolen layer, a base cloth layer and a woolen web layer. The pre-shrinking machine woolen cloth blanket is formed by the compounding of the four layers, adjacent two layers are connected in an embedded needling mode, and therefore the woolen cloth blanket is seamless, the whole pre-shrinking machine woolen cloth blanket is not easy to fracture, and service life of the pre-shrinking machine woolen cloth blanket is relatively prolonged. All kinds of materials ensure that the blanket is not easy to crinkle and low in shrinkage rate.

Owner:新疆阿勒泰工业用呢有限责任公司

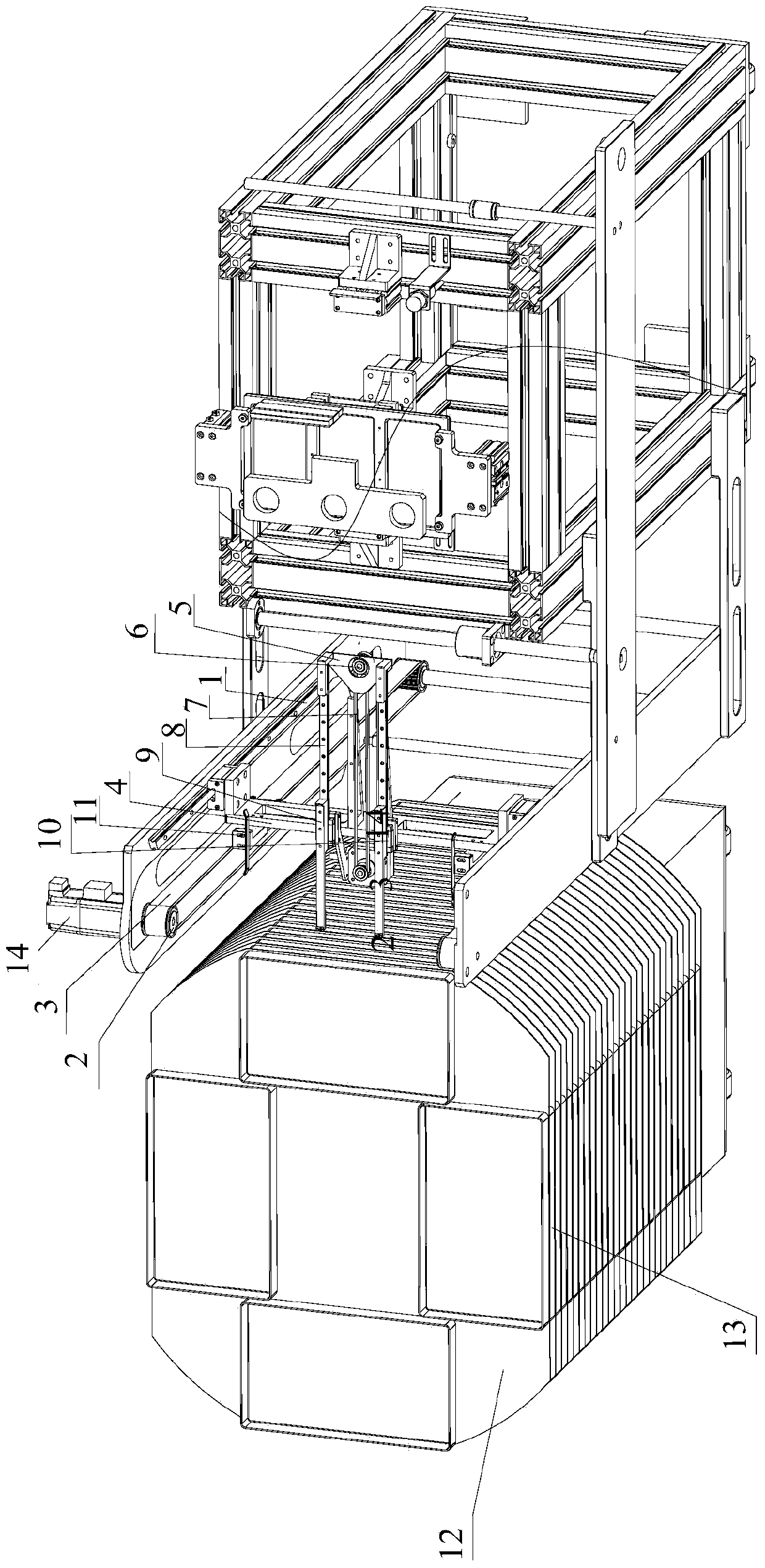

Board feeding assembly applied to PCB production line

The invention relates to the technical field of track PCB production, in particular to a board feeding assembly applied to a PCB production line. The board feeding assembly comprises a board feeding mechanism and a lifting mechanism. The lifting mechanism comprises a lifting frame, a lifting slide rail, lifting synchronous wheels and a lifting synchronous belt, wherein the lifting slide rail, the lifting synchronous wheels and the lifting synchronous belt are vertically arranged on corresponding faces of the lifting frame respectively. The board feeding mechanism comprises a first support and a second support, wherein the first support is mounted on the lifting mechanism in a perpendicular connection mode, the second support is used for horizontally pushing PCBs, the two ends of the first support are clamped into the lifting slide rail through fixing pieces, one side of each fixing piece is connected to the lifting synchronous belt through a connecting piece, and the first support is driven by the lifting synchronous belt to ascend and descend. The lifting mechanism and the board feeding mechanism are matched with a multilayer skid bed, so the PCBs subjected to adhesive dispensing can be sequentially placed on the skid bed from top to bottom; since each PCB has an independent containing space, the PCBs are not prone to contamination or damage in the conveying process, and the production efficiency is high.

Owner:KUSN MAIZHI FIXTURE TECH

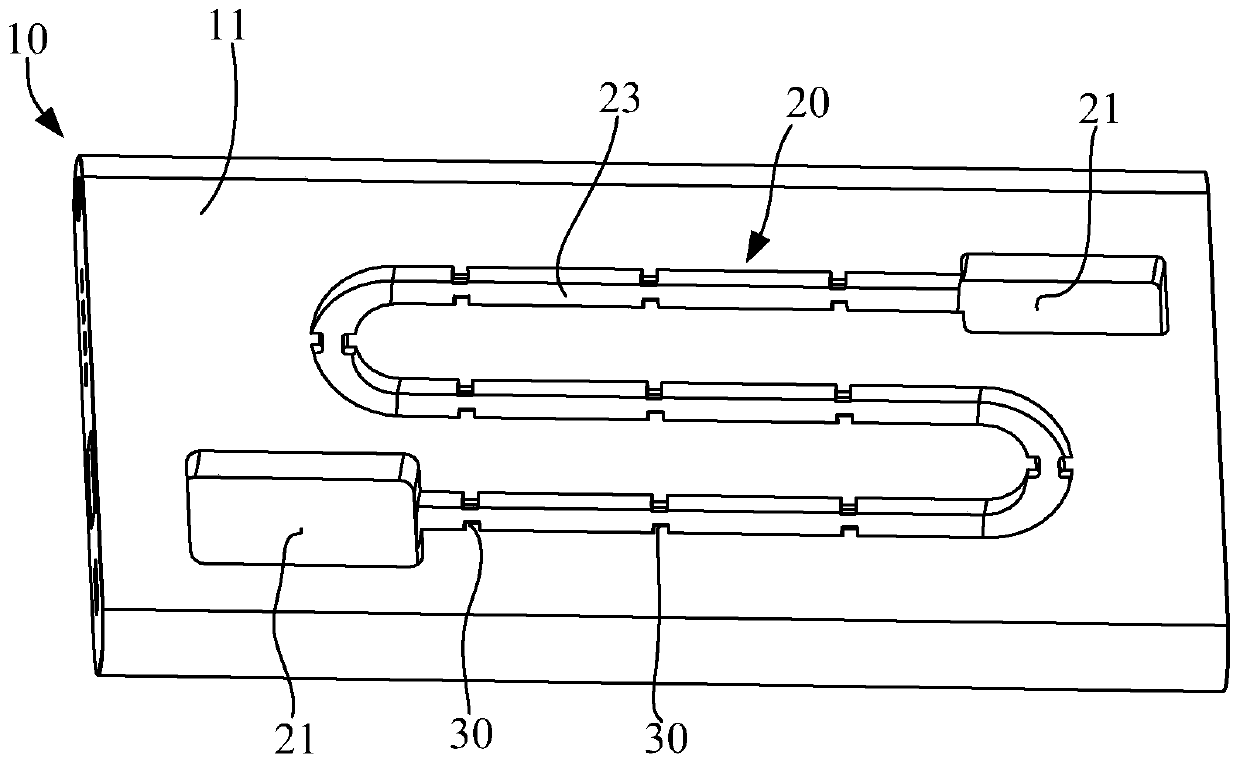

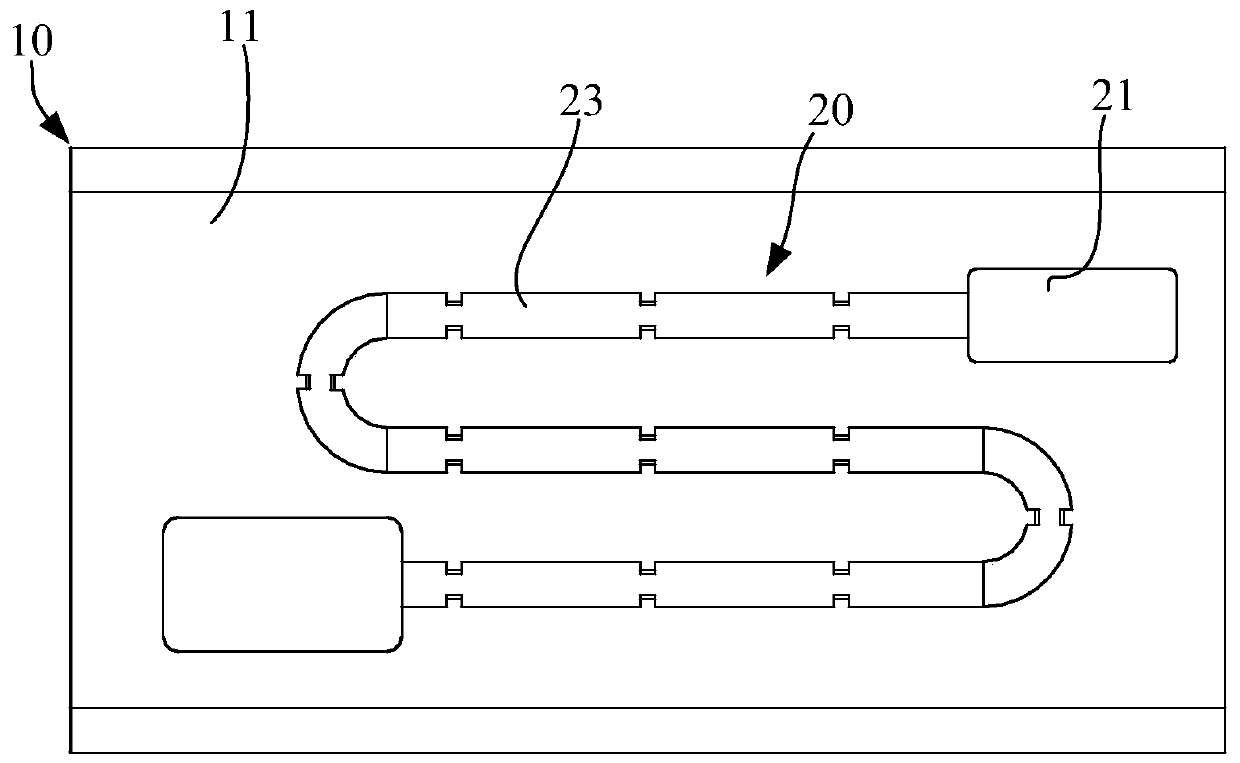

Power bank and power bank assembly

PendingCN110649668ACompact structureAvoid easily lost situationsBatteries circuit arrangementsElectric powerControl theoryMechanical engineering

The invention relates to the technical field of a power bank and particularly relates to a power bank and a power bank assembly. The power bank comprises a power bank body, wherein an accommodating groove for accommodating a charging wire is formed in the power bank body, the accommodating groove comprises a joint groove matched with a joint of the charging wire, and a wire slot matched with a charging wire connecting wire, and the wire slot is at least partially distributed in a U shape. The power bank is provided with the accommodating groove for accommodating the charging wire on the charger baby body, and the wire slot matched with the charging wire in the accommodating groove is at least partially distributed in the U shape, and thereby an integrated storage mode of the charging wireand the power bank is achieved, the situation that the charging wire is easy to lose is avoided, the space occupied by the charging wire on the power bank is reduced, and the structure of the whole power bank is more compact.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

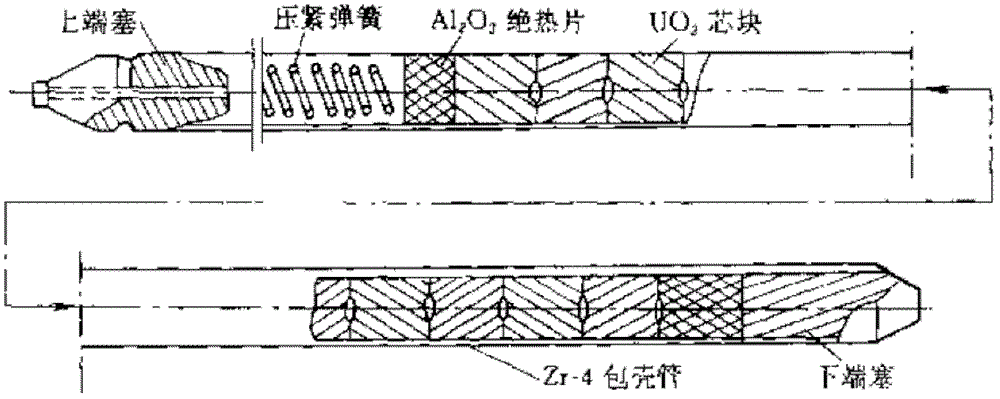

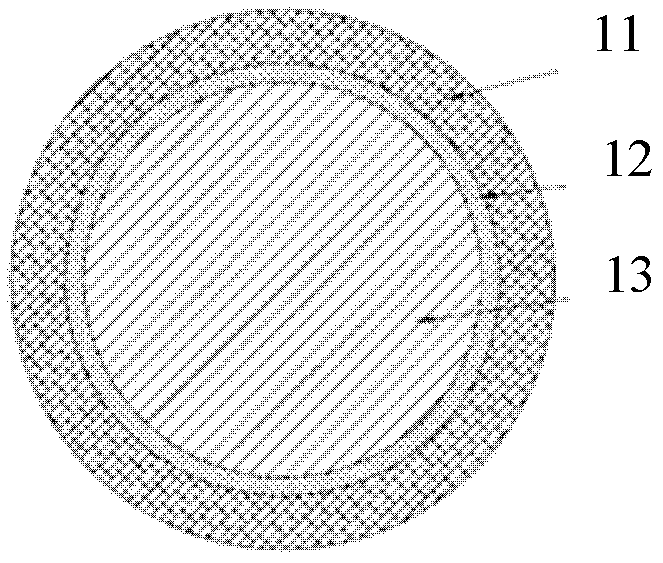

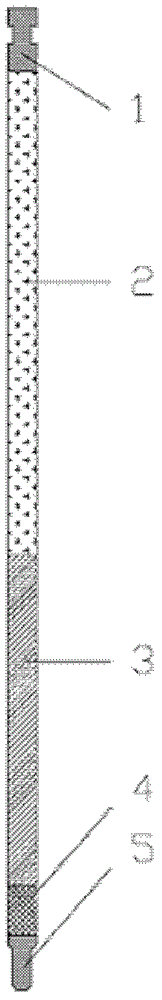

Nuclear Fuel Rods Using Ceramic Clad Metal Pellets

ActiveCN103295652BImprove mechanical propertiesReduce breakageOptical rangefindersNuclear energy generationComposite ceramicHeat conducting

The invention aims at providing a nuclear fuel rod with ceramic cladding and metallic pellet. The nuclear fuel rod with ceramic cladding and metallic pellet has the advantages that the heat-conducting property of the nuclear fuel rod can be improved, the central temperature of the fuel pellet is lowered or the fuel power density is effectively improved, the fuel rod cladding mechanical property, corrosion resistance and radiation resistance are greatly improved, the breakage rate of the fuel rod is lowered, the discharge burnup of the fuel rod is remarkably increased and the fuel utilization rate is greatly improved; meanwhile, the fuel rod has good neutronics performance, and can be widely used in a fast reactor or a thermal reactor. The cladding of the nuclear fuel rod provided by the invention is a SiCf / SiC composite ceramic material cladding, the metallic fuel pellet adopts a U-Zr or U-Pu-Zr alloy fuel pellet; a gap between the cladding and the fuel pellet is filled with low-melting-point metal; and a lengthened air cavity is designed at the upper part of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com