Patents

Literature

59 results about "Embedded tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

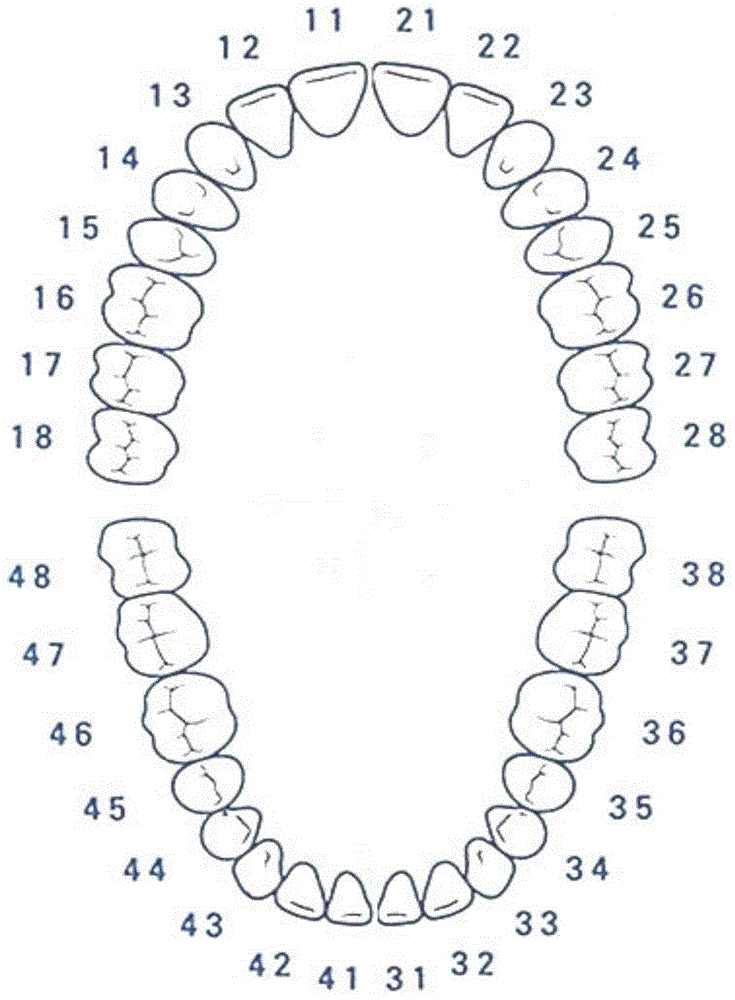

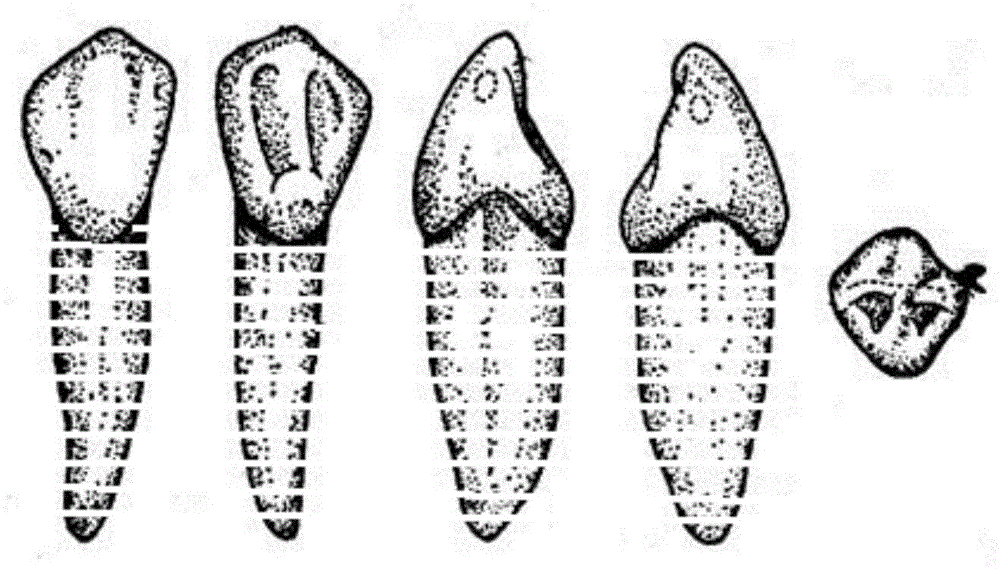

Embedded teeth. An impacted tooth is one that fails to erupt into the dental arch within the expected developmental window. Because impacted teeth do not erupt, they are retained throughout the individual's lifetime unless extracted or exposed surgically.

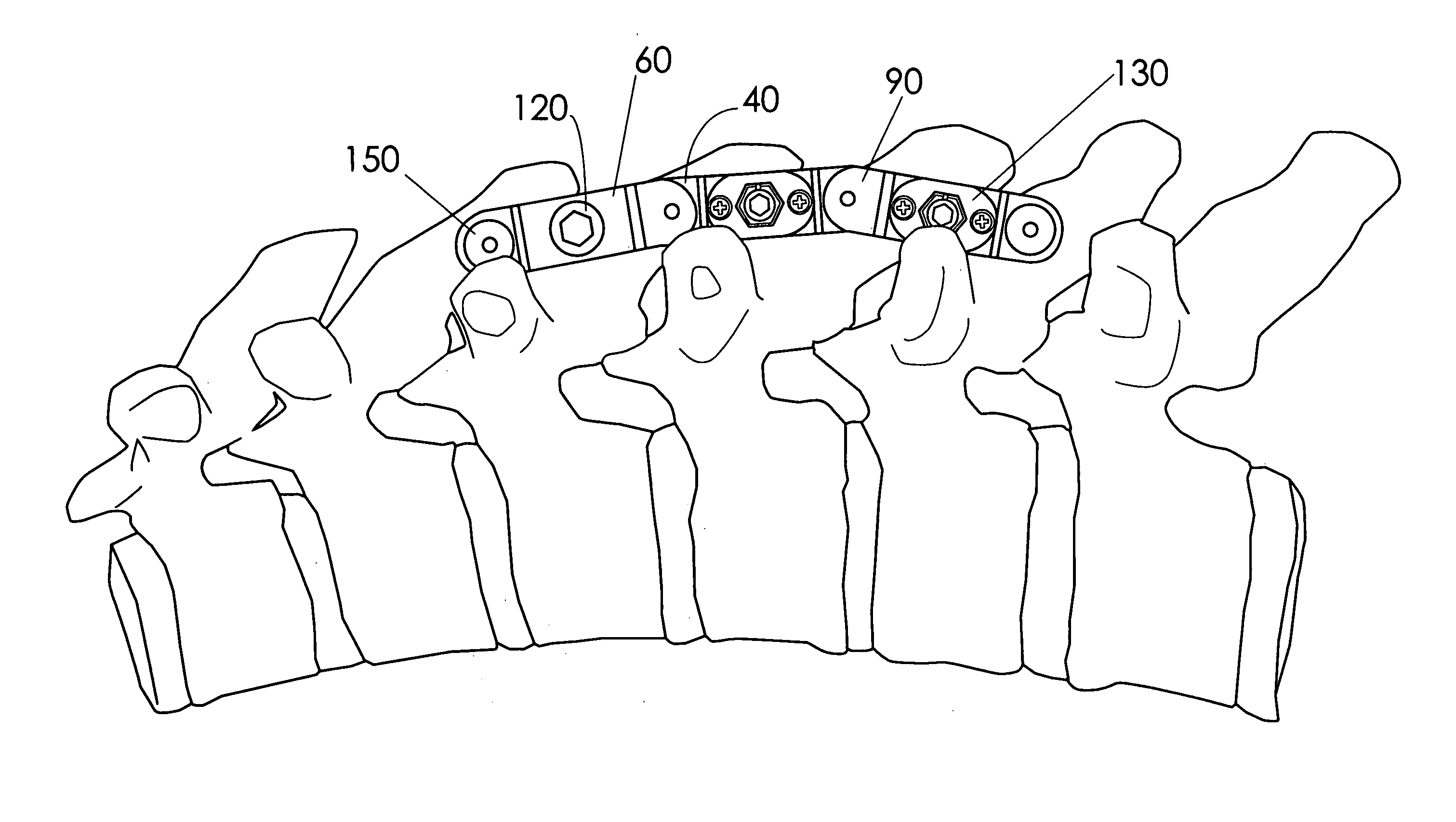

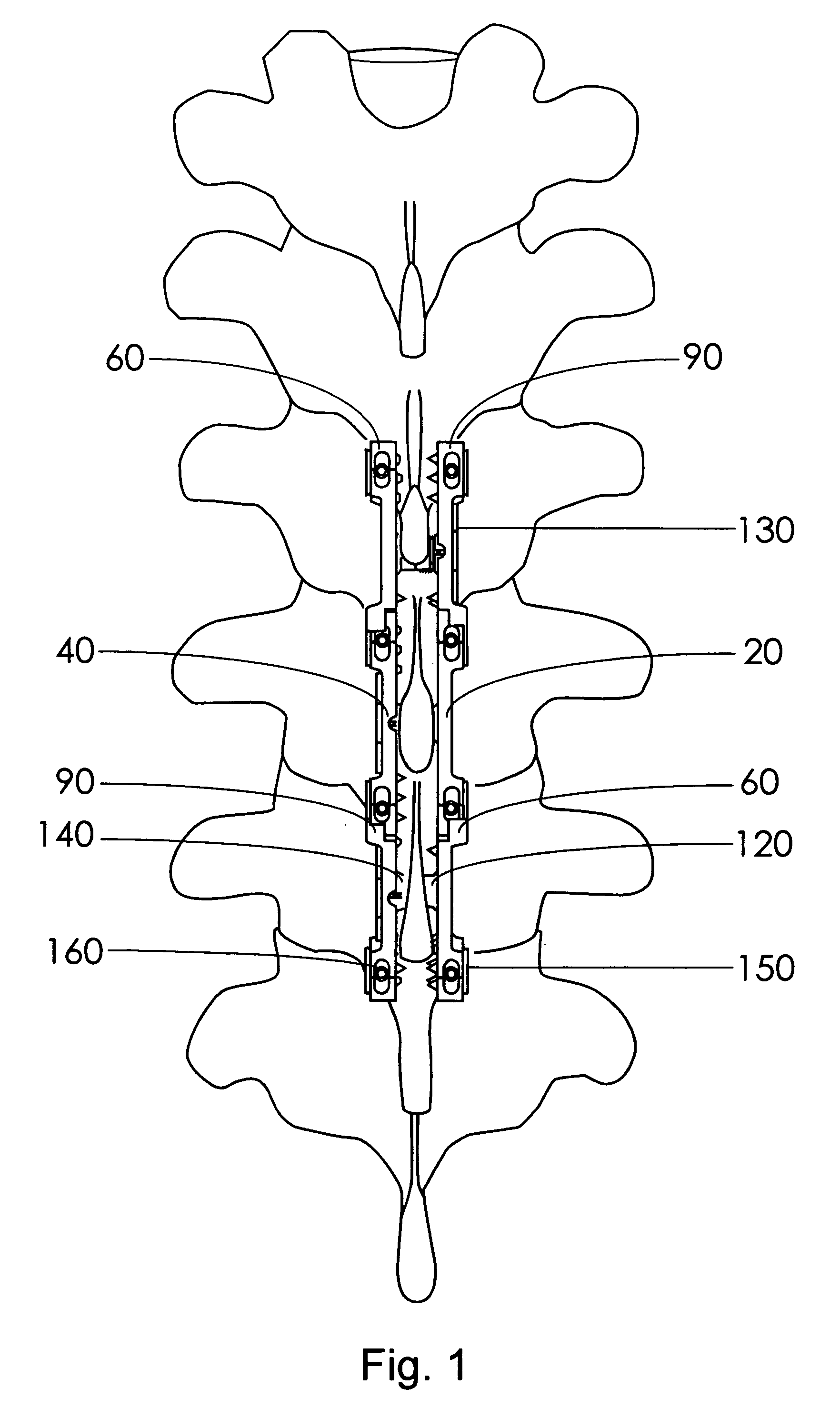

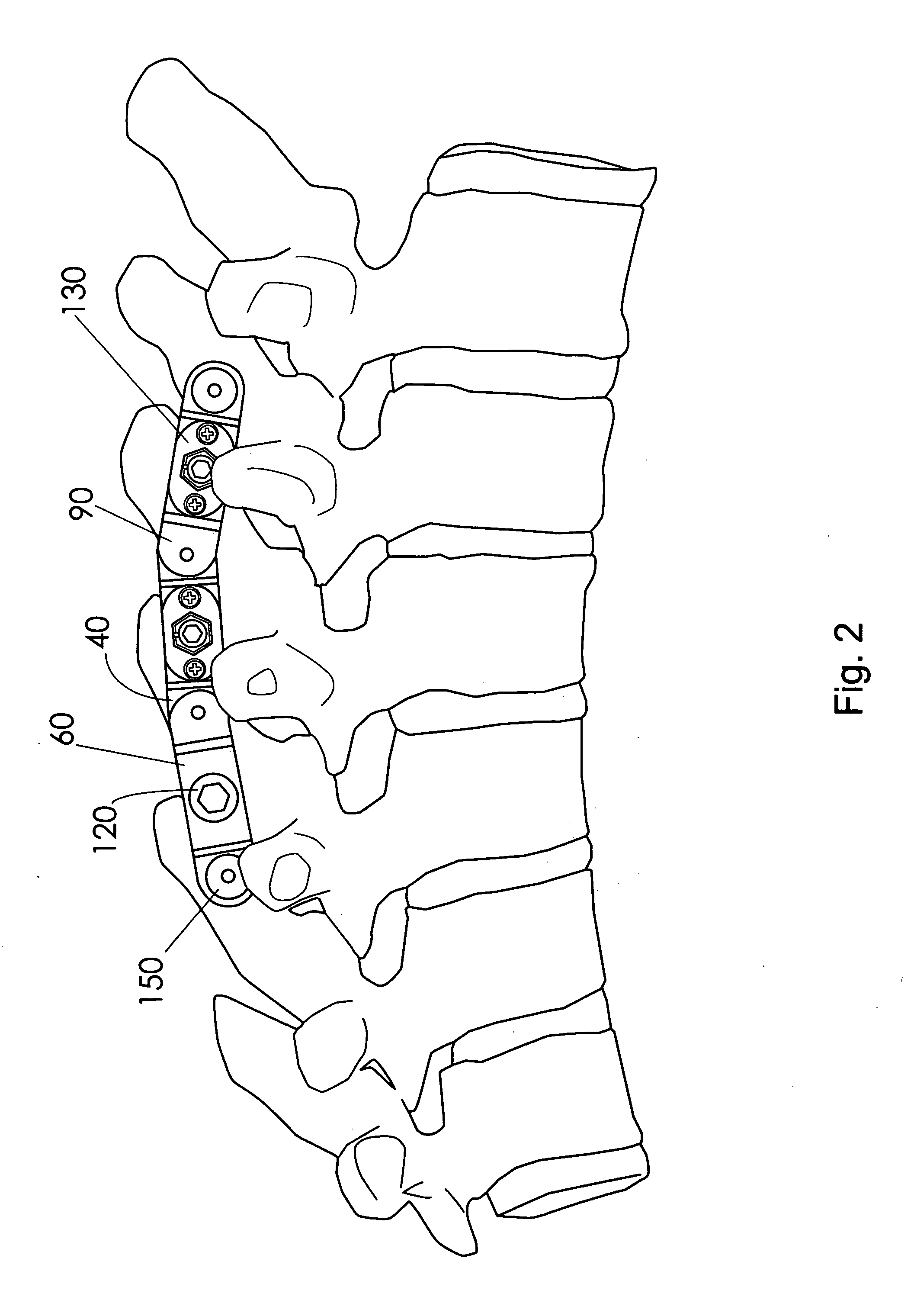

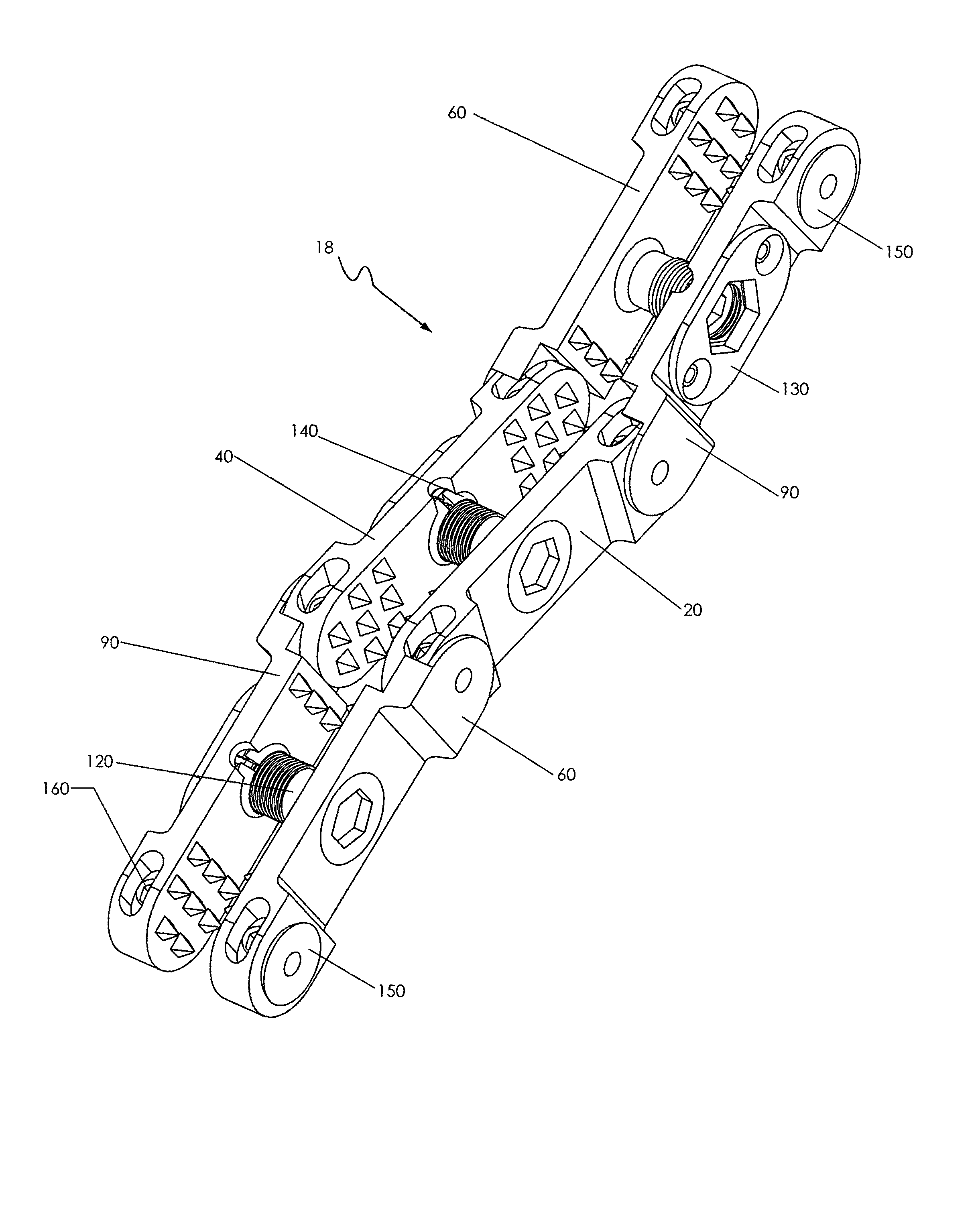

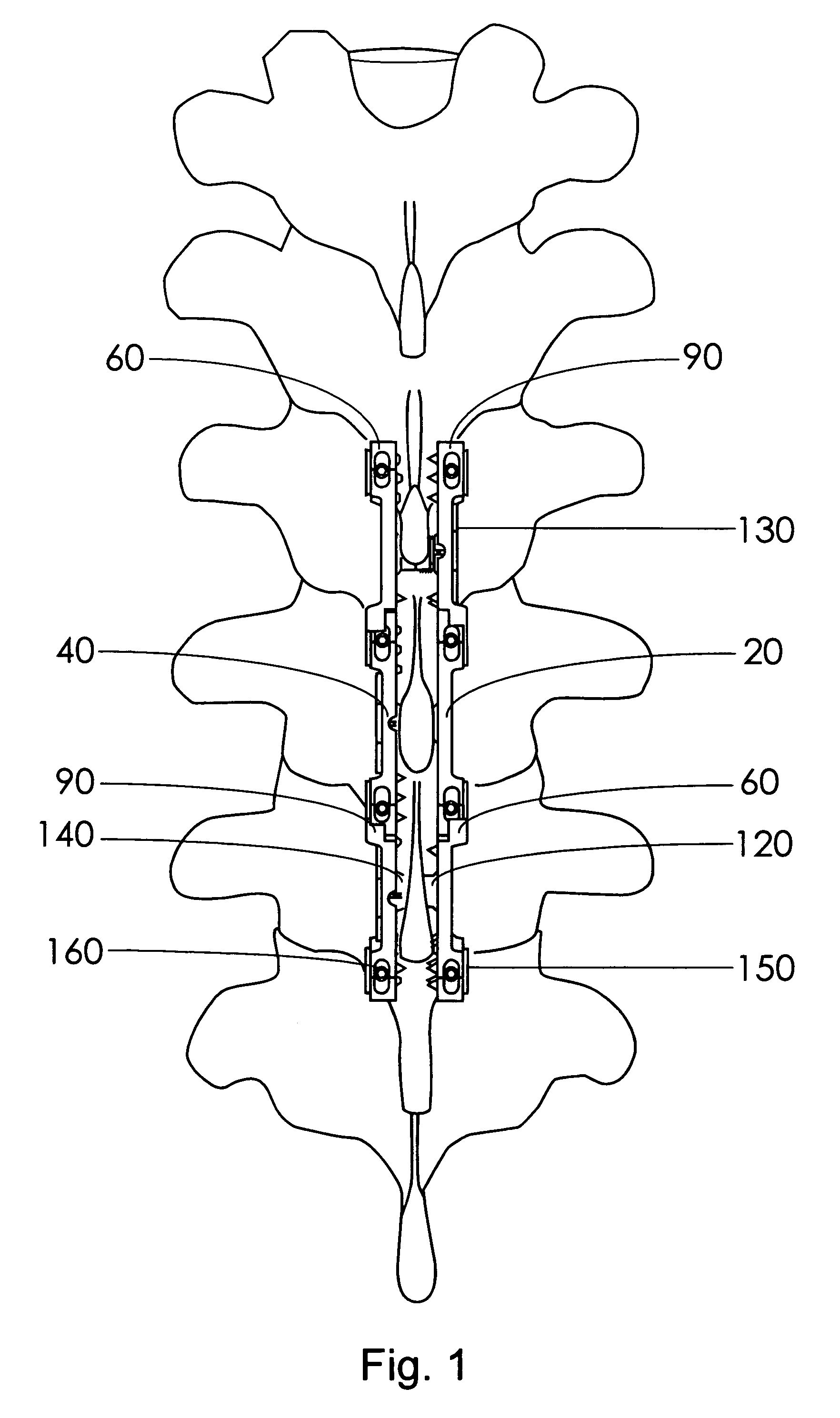

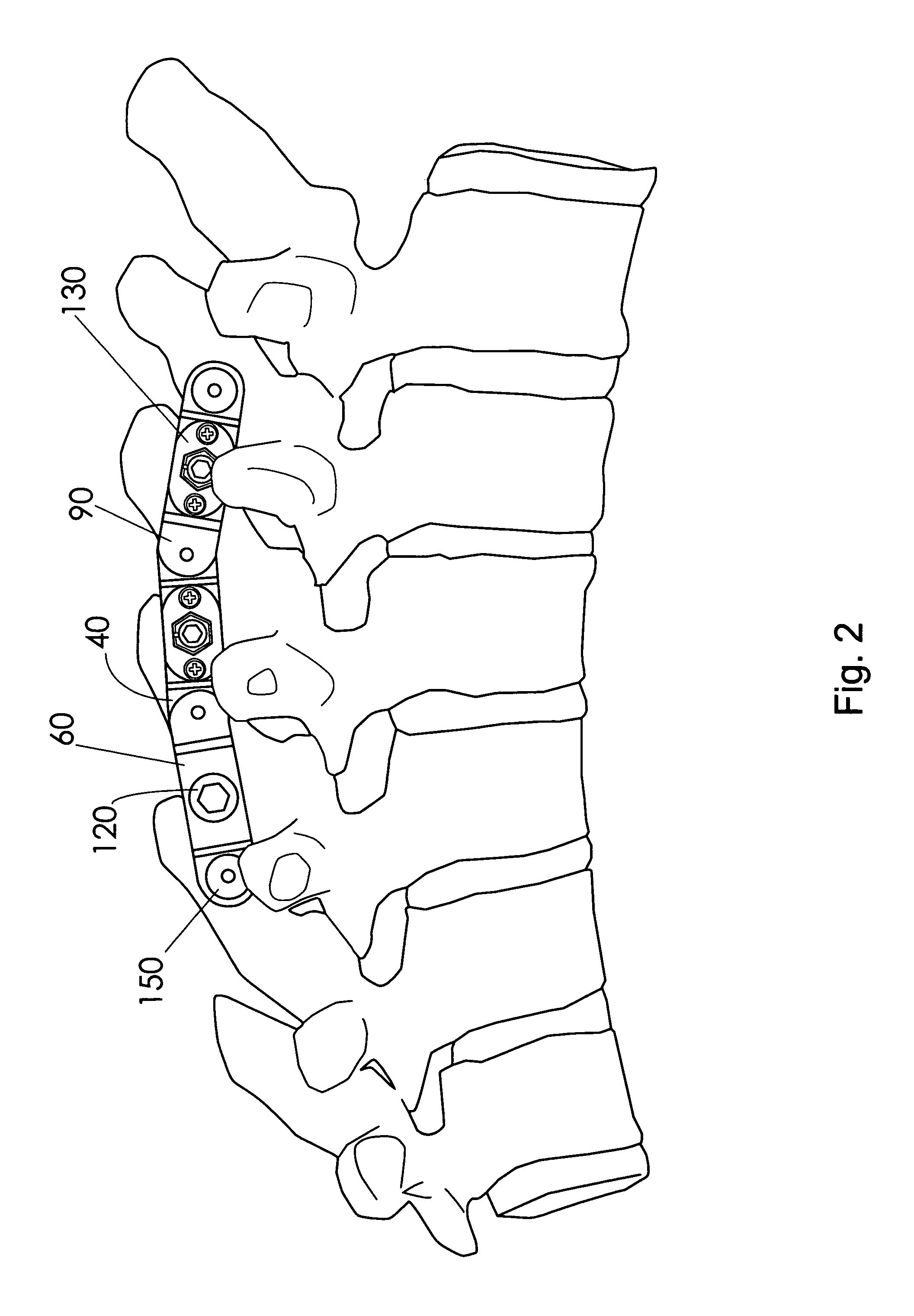

Spinous process stabilization device and method

InactiveUS20090264927A1Easy to integrateInternal osteosythesisJoint implantsCoronal planeEmbedded teeth

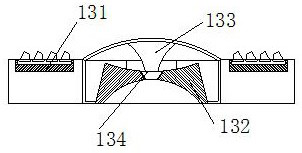

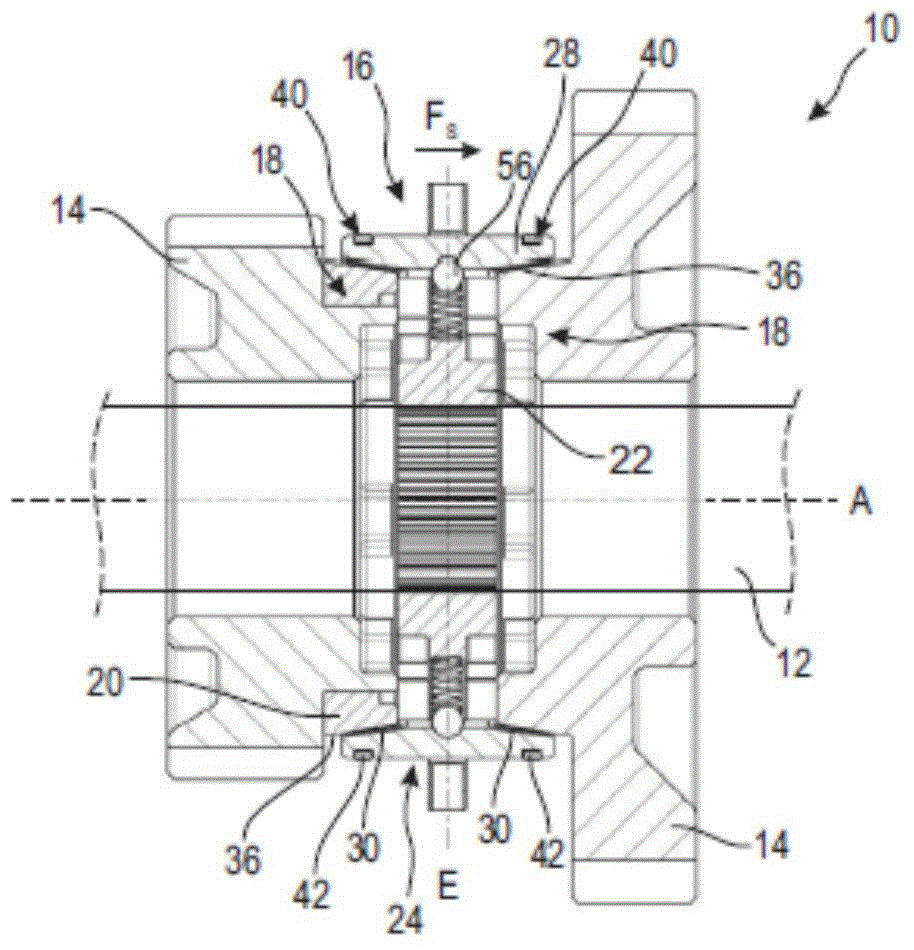

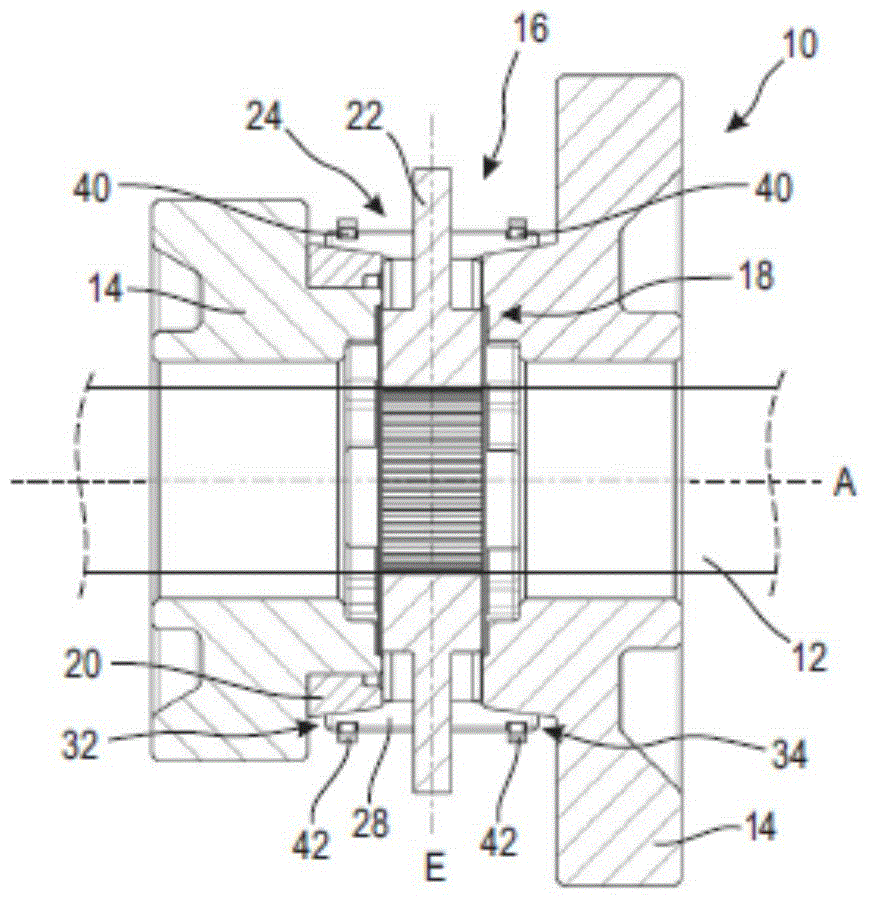

A fixation device to immobilize a spinal motion segment and promote posterior fusion, used as stand-alone instrumentation or as an adjunct to an anterior approach. The device functions as a multi-level fusion system including modular single-level implementations. At a single-level the implant includes a pair of plates spanning two adjacent vertebrae with embedding teeth on the medially oriented surfaces directed into the spinous processes or laminae. The complementary plates at a single-level are connected via a cross-post with a hemi-spherical base and cylindrical shaft passed through the interspinous process gap and ratcheted into an expandable collar. The expandable collar's spherical profile contained within the opposing plate allows for the ratcheting mechanism to be correctly engaged creating a uni-directional lock securing the implant to the spine when a medially directed force is applied to both complementary plates using a specially designed compression tool. The freedom of rotational motion of both the cross-post and collar enables the complementary plates to be connected at a range of angles in the axial and coronal planes accommodating varying morphologies of the posterior elements in the cervical, thoracic and lumbar spine. To achieve multi-level fusion the single-level implementation can be connected in series using an interlocking mechanism fixed by a set-screw.

Owner:GINSBERG HOWARD JOESEPH +2

Spinous process stabilization device and method

A fixation device is provided to immobilize a spinal motion segment and promote posterior fusion, used as stand-alone instrumentation or as an adjunct to an anterior approach. The device functions as a multi-level fusion system including modular single-level implementations. At a single-level the implant includes a pair of plates spanning two adjacent vertebrae with embedding teeth on the medially oriented surfaces directed into the spinous processes or laminae. The complementary plates at a single-level are connected via a cross-post passed through the interspinous process gap The freedom of rotational motion of both the cross-post and collar enables the complementary plates to be connected at a range of angles in the axial and coronal planes accommodating varying morphologies of the posterior elements in the cervical, thoracic and lumbar spine. To achieve multi-level fusion the single-level implementation can be connected in series using an interlocking mechanism fixed by a set-screw.

Owner:GINSBERG HOWARD JOESEPH +2

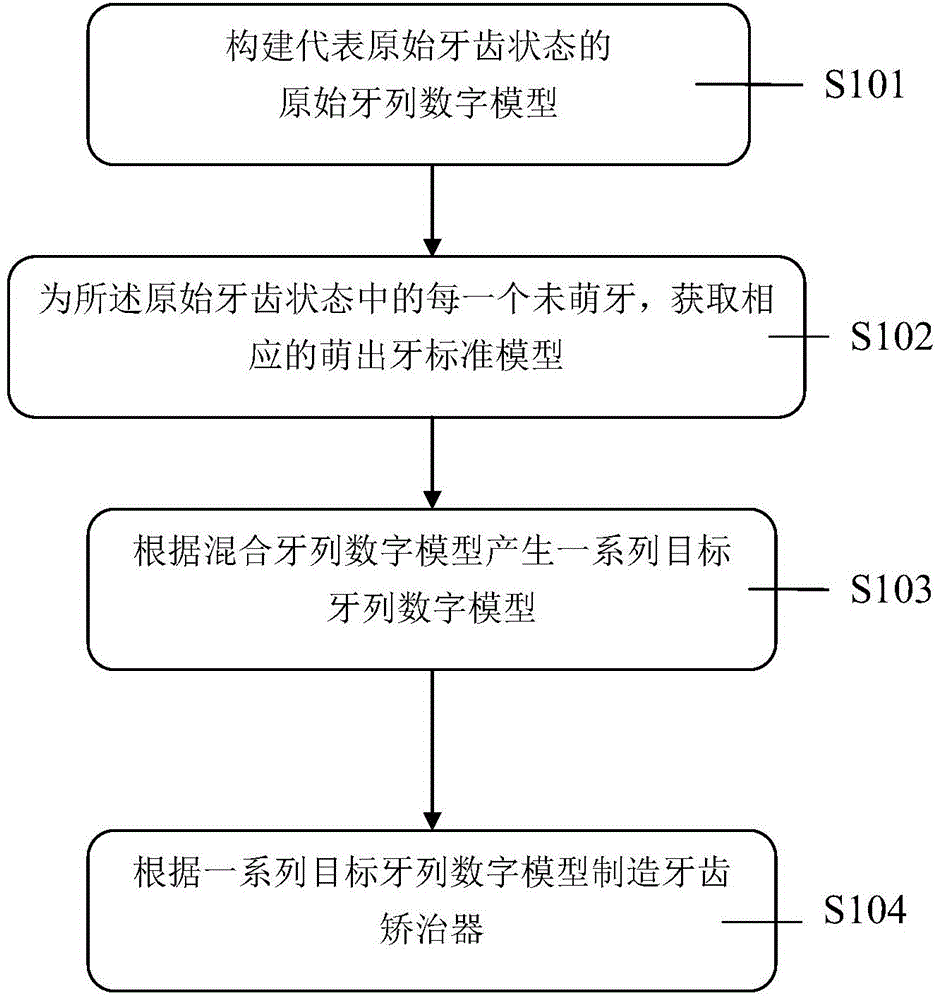

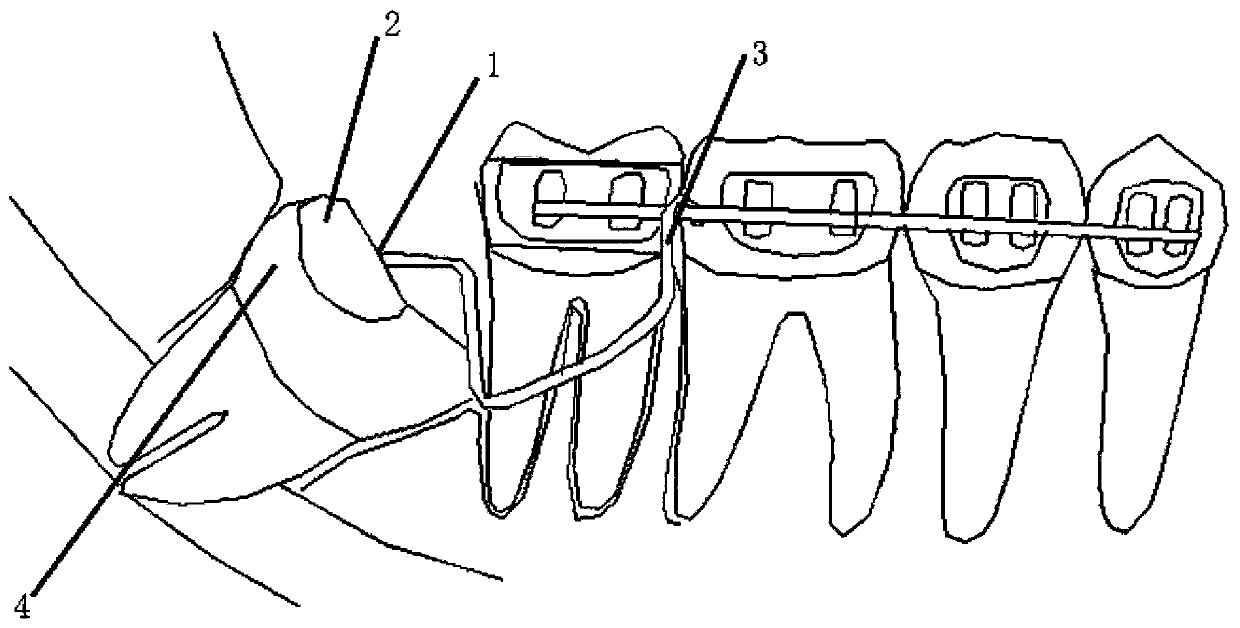

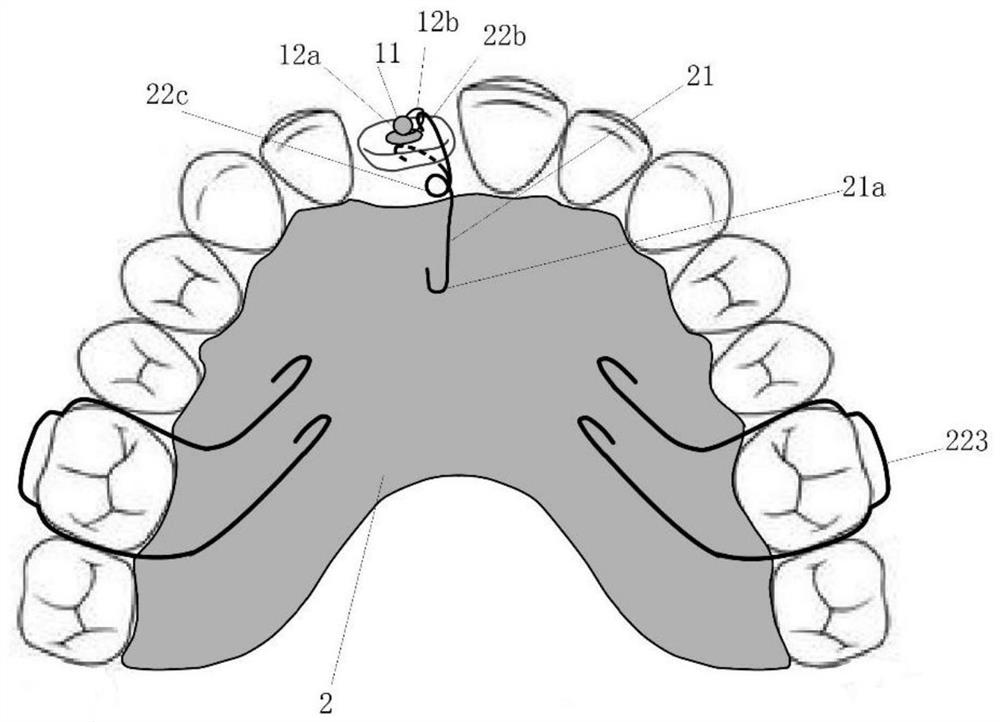

Tooth correctional system suitable for mixed dentition and manufacturing method

ActiveCN105266905ASave time and effort in the treatment processGood treatment effectOthrodonticsUnerupted dentitionEmbedded teeth

The present invention provides a tooth correctional system suitable for mixed dentition and a manufacturing method of the tooth correctional system, wherein the method comprises the following steps: building an original dentition digital model representing the original tooth state which includes at least one embedded tooth; acquiring a corresponding eruption tooth standard model for each embedded tooth in the original tooth state to obtain a mixed dentition digital model; producing a series of target dentition digital models according to the mixed dentition digital model; and manufacturing a tooth correctional device according to the produced series of target dentition digital models. The tooth correctional system can be used for correction of teeth of patients of any ages, and is especially suitable for dental transitional period adolescent patients simultaneously with deciduous teeth and permanent teeth.

Owner:SHANGHAI EA MEDICAL INSTR CO LTD

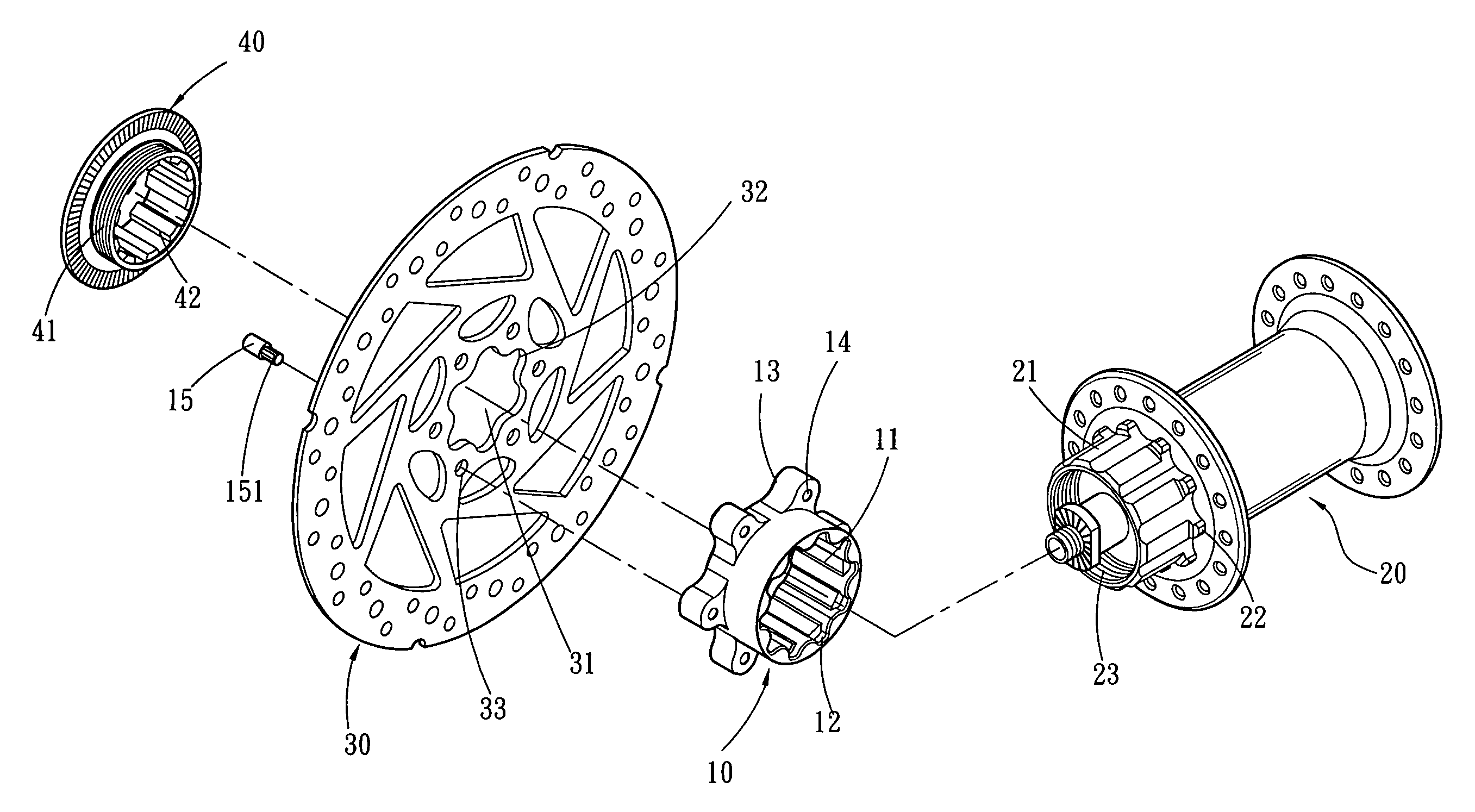

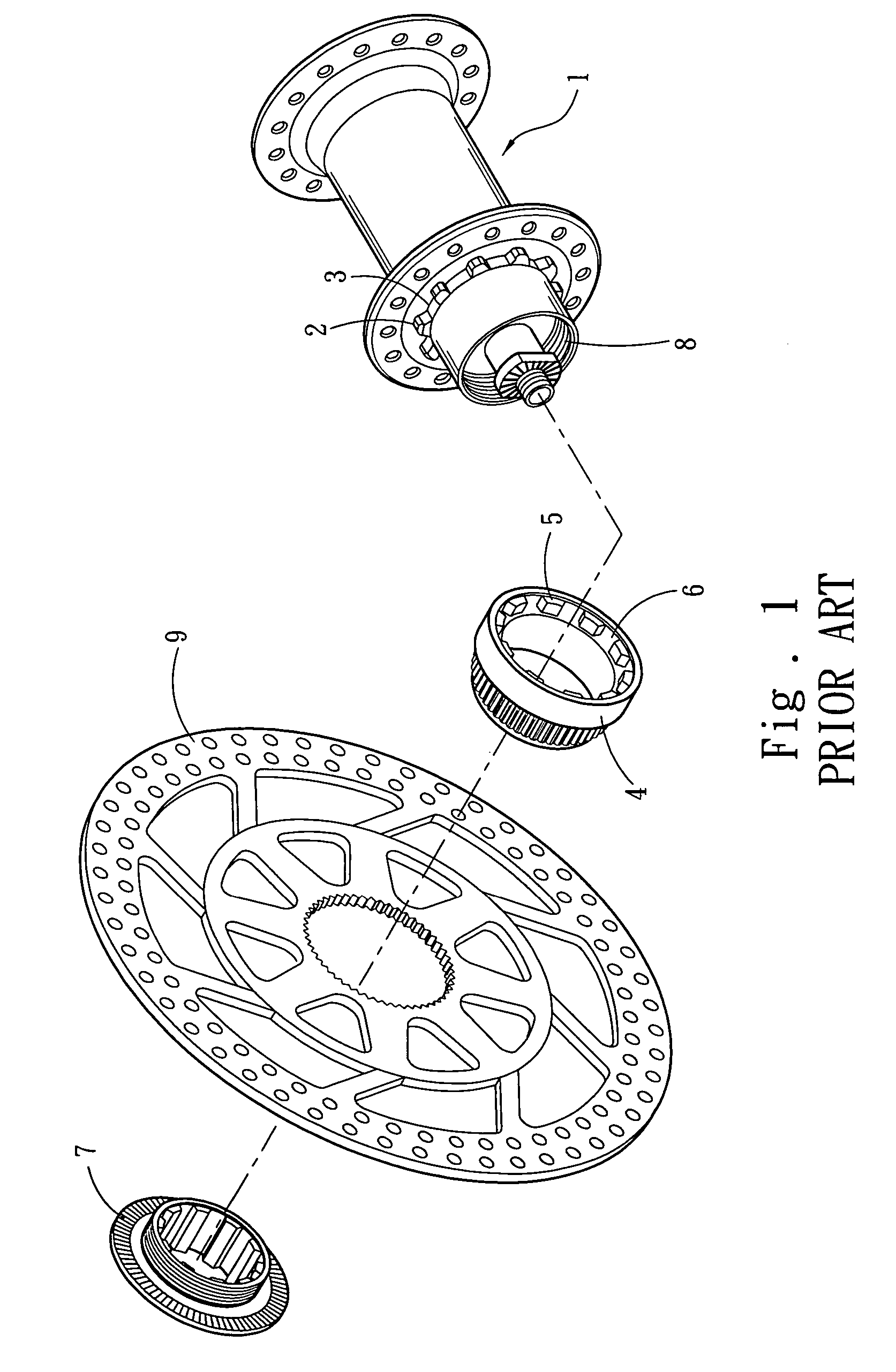

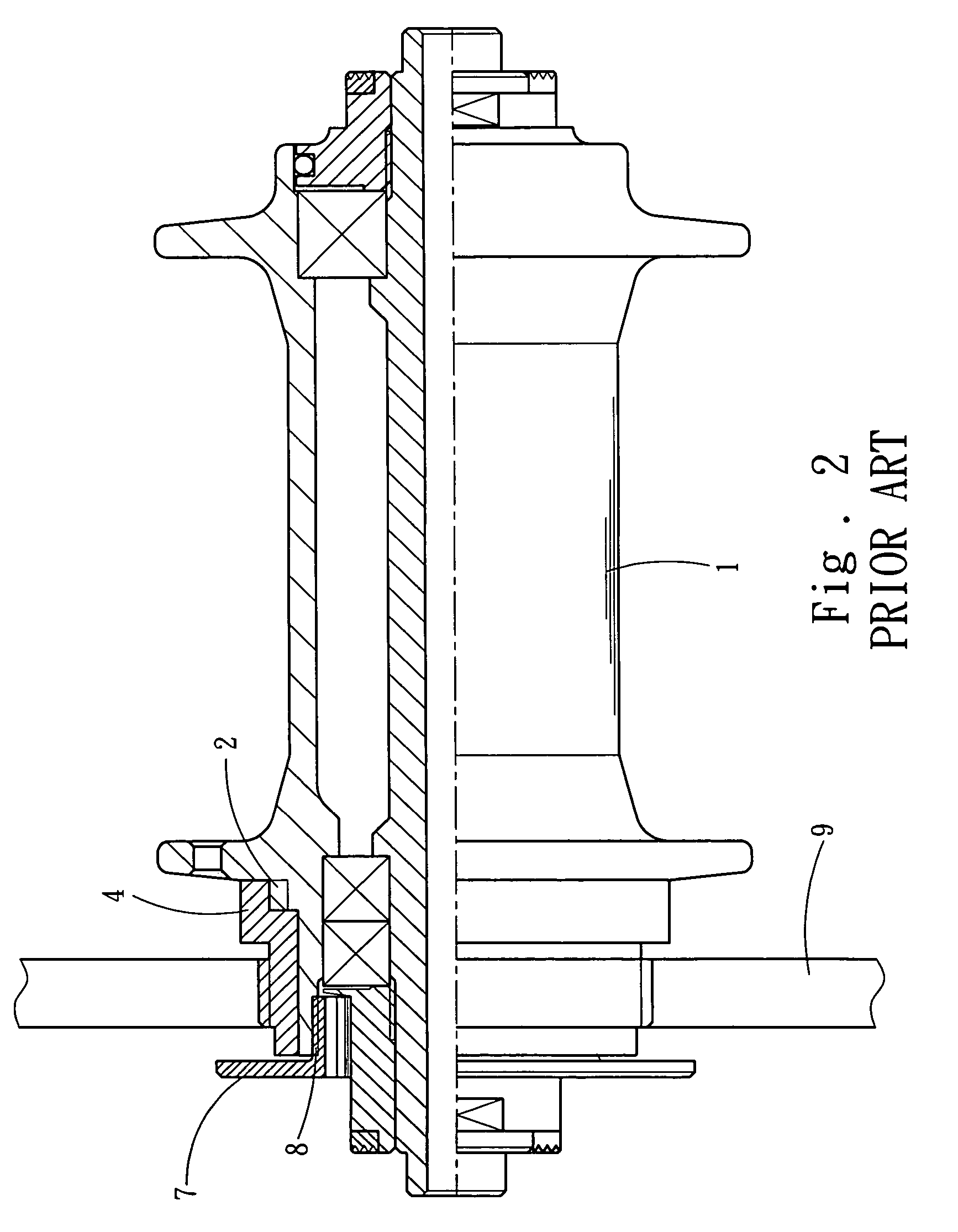

Disc brake hub adapter structure

The present invention discloses a disc brake hub adapter structure, which is a hollow cylinder having a plum blossom shaped wavy thread on its internal periphery to be engaged with an axle having a corresponding shape with the hub, and a plurality of embedding teeth disposed around the corner folding position is disposed at the internal side of the axle of the hub and engaged with a plurality of concave teeth around the internal side of the adapter, wherein the adapter has a connecting section extended outward from a side ring at the external periphery of the adapter. The connecting section has a plurality of holes for receiving a connecting device and connecting a brake disc with a plum blossom shaped center hole.

Owner:JOY IND

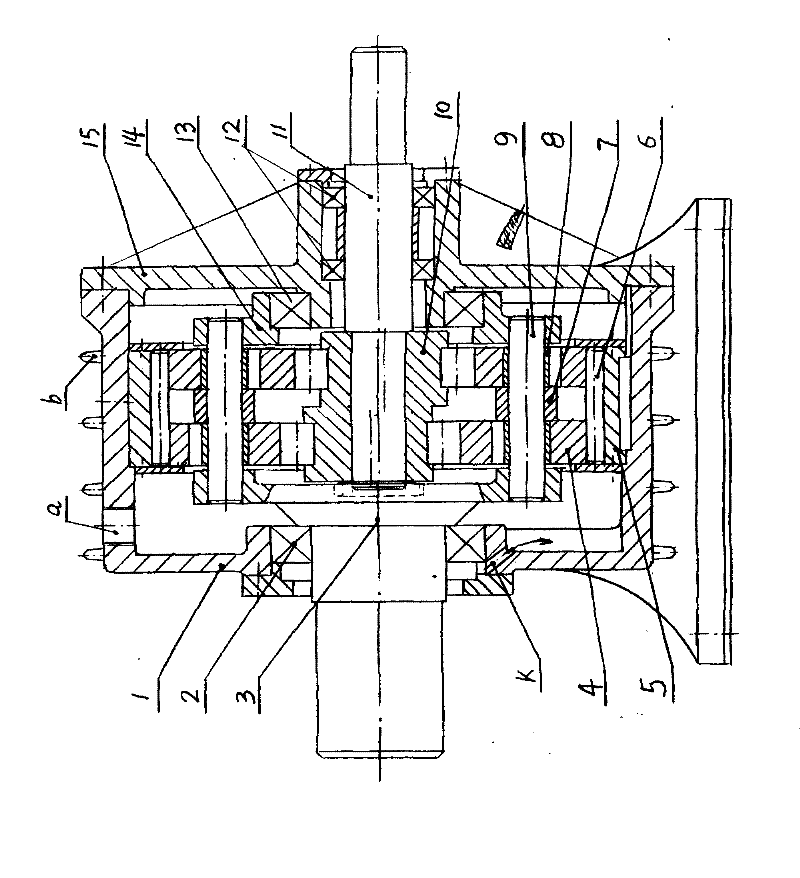

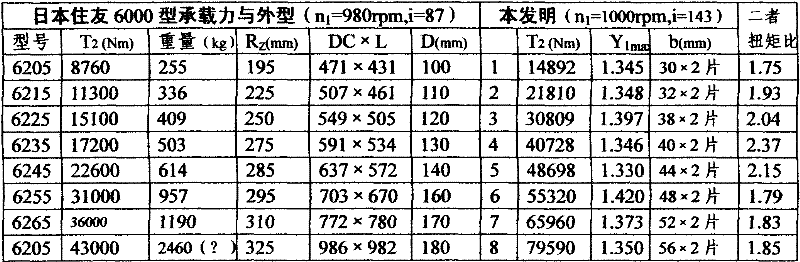

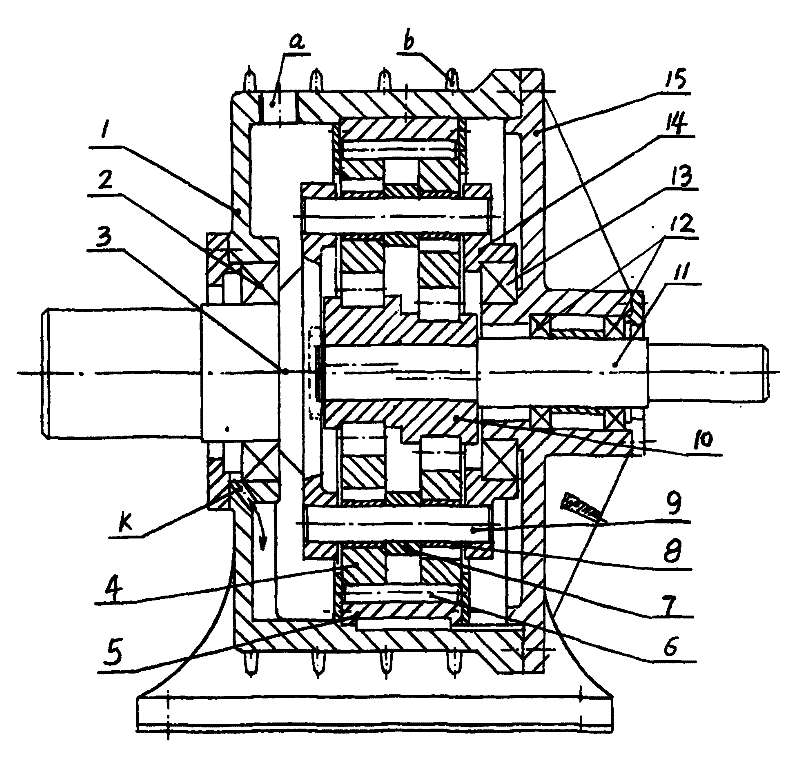

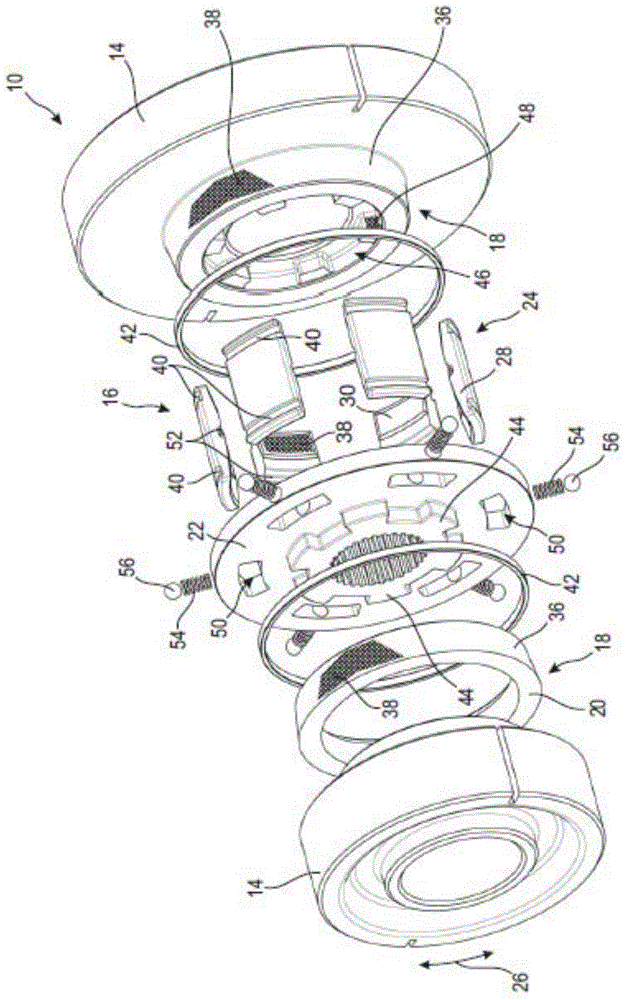

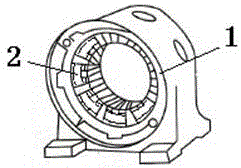

Novel horizontal needle-guard-free cycloid speed reducer

InactiveCN102192277AReduce weightAxial dimension shortGearboxesGear lubrication/coolingEmbedded teethReducer

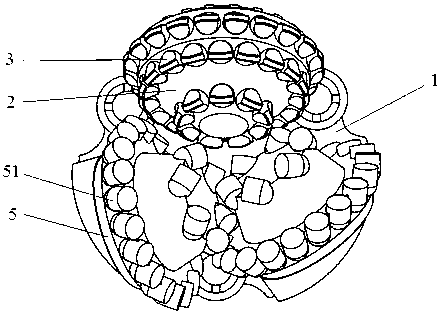

The invention relates to the technical field of cycloid speed reducers, and in particular relates to a novel horizontal needle-guard-free cycloid speed reducer which is composed of a body, an input shaft, a double-concentric bearing, a cycloid wheel, a needle tooth shell, a needle pin, a pin, a column sleeve, a W output mechanism and a bearing, wherein the speed reducer is characterized in that (A) the body is an external radiating rib and a thin wall cylinder body with mounting base feet at two sides; (B) the W output mechanism is composed of an output shaft, the pin and an equal loading disk; a ring plate on the pin enables the pin to form a simply support structure; in the W output mechanism, a bearing on the shaft neck of the output shaft is supported in the inner hole of the body by virtue of one bearing; and the other bearing in the inner hole of the equal loading disk is supported on the excircle of a flange in an end cover; (C) the needle tooth shell is installed in the inner hole of the body; and (D) the needle pin has no sleeve, and the needle pin is in movable fit with a semi-embedded hole. The speed reducer has the following beneficial effects: (1) the speed reducer is provided with the advanced thin-wall body and the W output mechanism, thus the weight is lightened by 20-30%, and the axial size is shortened by 25-35%; and (2) the needle tooth has no sleeve and is of a semi-embedded tooth, thus the bearing capability is 1.5-2 times that of a 6000 type.

Owner:吴小杰

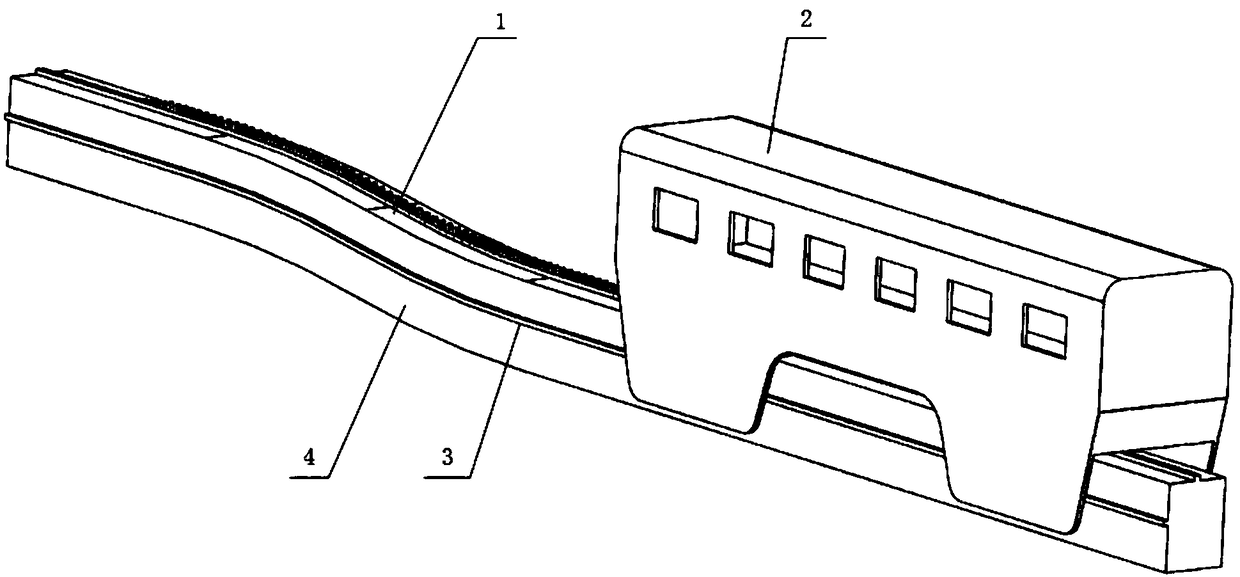

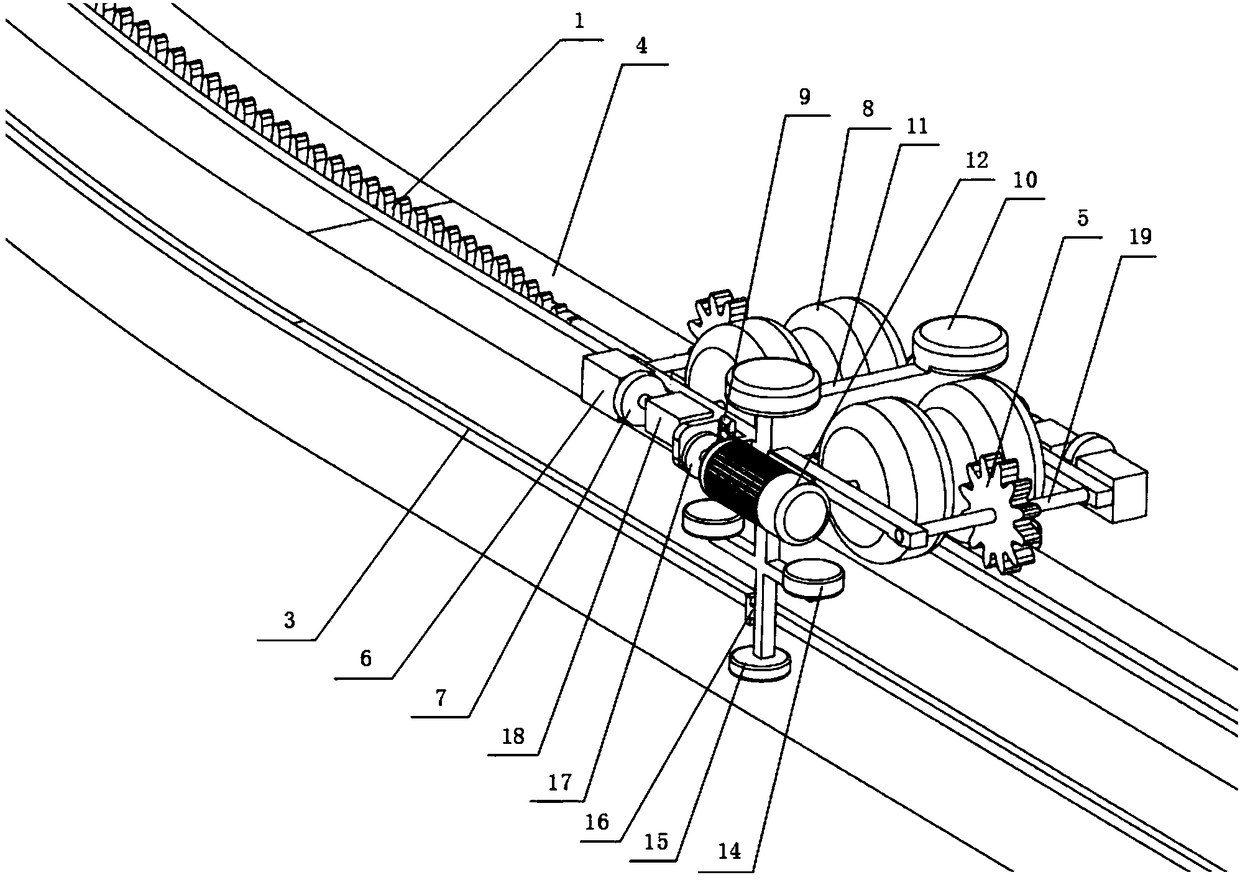

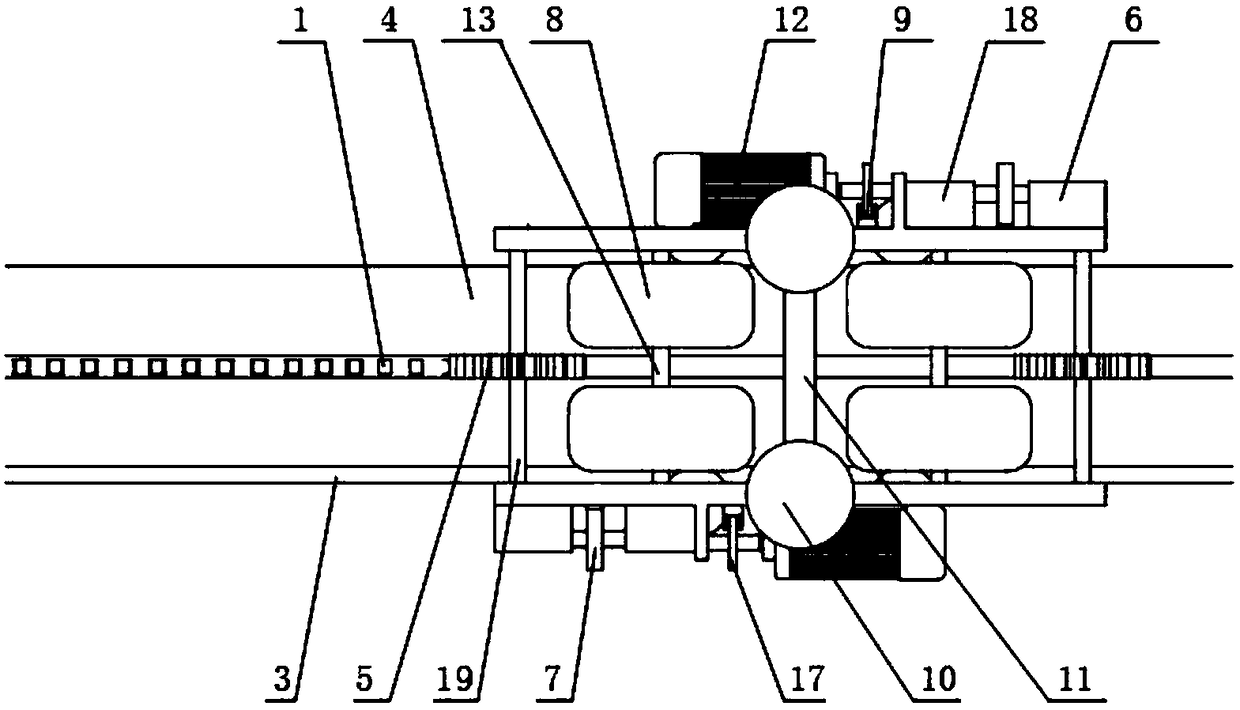

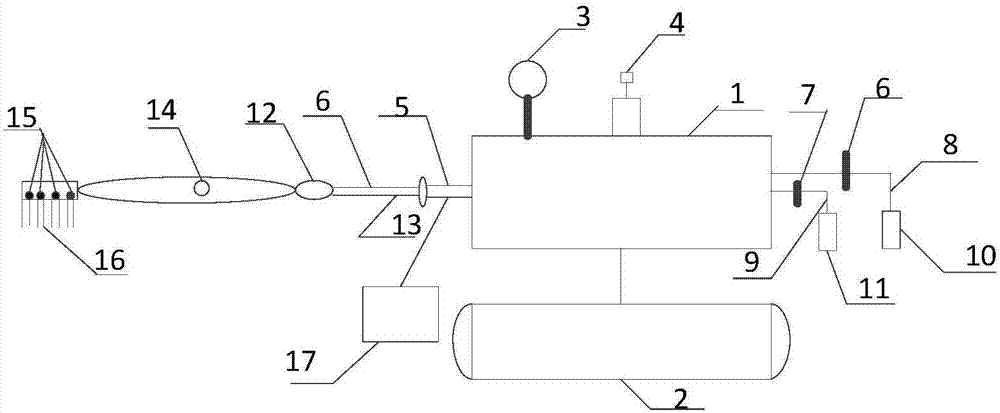

Ramp traction mountainous embedded tooth type monorail train and track system

ActiveCN108327731AImprove climbing abilityImprove climbing efficiencyMonorailsRack railwaysTerrainBogie

The invention discloses a ramp traction mountainous embedded tooth type monorail train and a track system. The train comprises a track, a train body, a bogie connected with the train body through an air spring suspension mechanism and gears arranged on the bogie. Rubber wheels and an electric drive device are installed on the bogie. The electric drive device is connected with axles of the rubber wheels and axles of the gears at the same time. The track comprises a track beam, a third rail arranged on the side face of the track beam and a toothed rail arranged in the middle position of the track beam and used for being engaged with the gears. The rubber wheels are supported on the track beam. In the climbing process, the electric drive device can provide torque output for the rubber wheelsand the gears, so that the climbing capacity of the train is improved, climbing efficiency is high, and the train can better operate on a line with large-gradient sections in complex terrains such asa mountainous region and a river valley.

Owner:SOUTHWEST JIAOTONG UNIV

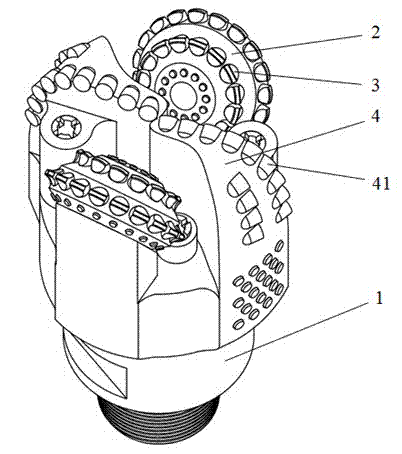

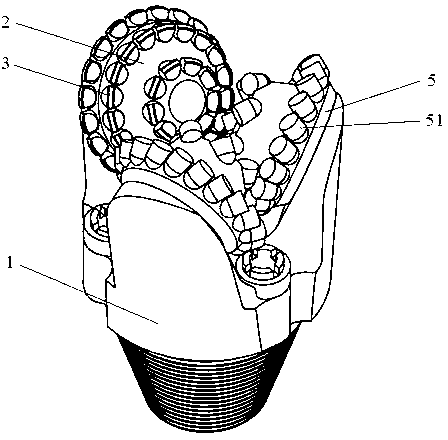

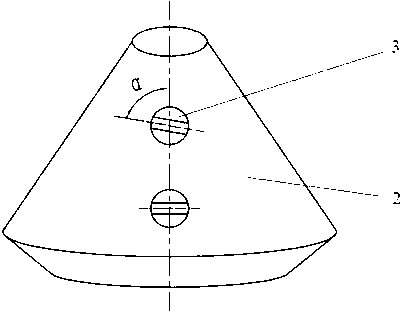

Wide-tooth cone composite drill bit

ActiveCN103089153AReduce discontinuityReduced spaceDrill bitsConstructionsEmbedded teethFoundation engineering

The invention discloses a wide-tooth cone composite drill bit, and belongs to the technical field of drilling equipment in petroleum and gas, mine engineering, building foundation engineering construction, geology, hydrology and the like. The wide-tooth cone composite bit comprises a drill bit body, a fixed cutting structure and at least one cone. The cone and the fixed cutting structure are arranged on the drill bit body. The fixed cutting structure is provided with fixed cutting teeth. The cone is connected with the drill bit body through a bearing structure in a rotating mode. Cross-embedded teeth are embedded and fixed in the cone. A value range of a deflection angle alpha of the tooth top of each cross-embedded tooth is 70 degrees <=|alpha|<= 90 degrees, and an outline of the cross section of the embedded and fixed part of each cross-embedded tooth is non-circular. A novel cone structure is adopted by the wide-tooth cone composite drill bit so that the cone is stable in working, and the drill bit is good in working stability. Compared with an existing composite drill bit, the wide-tooth cone composite drill bit is higher in rock breaking efficiency, and meanwhile service life of the drill bit teeth and the bearing is prolonged, and therefore the service life of the drill bit is prolonged.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

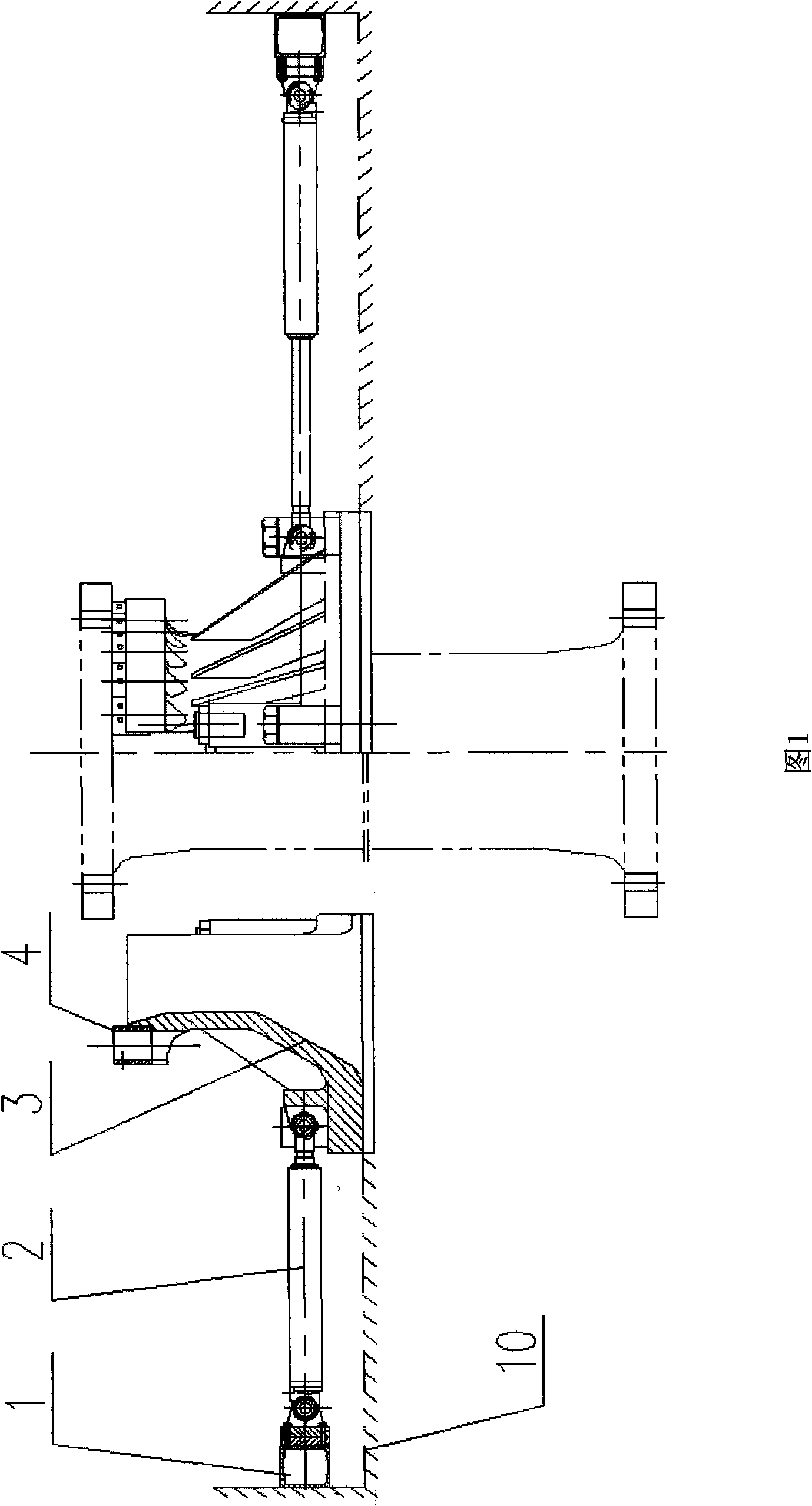

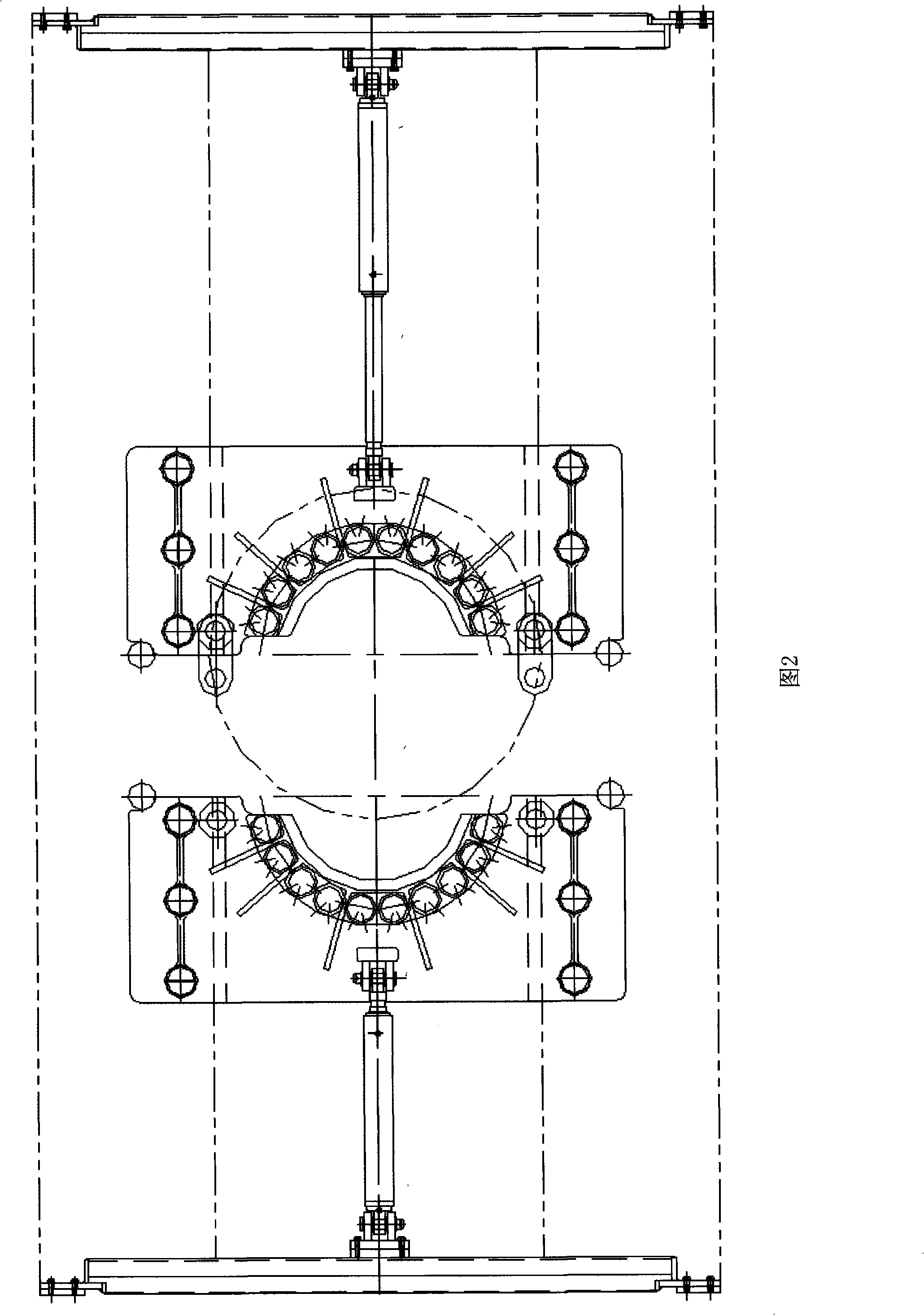

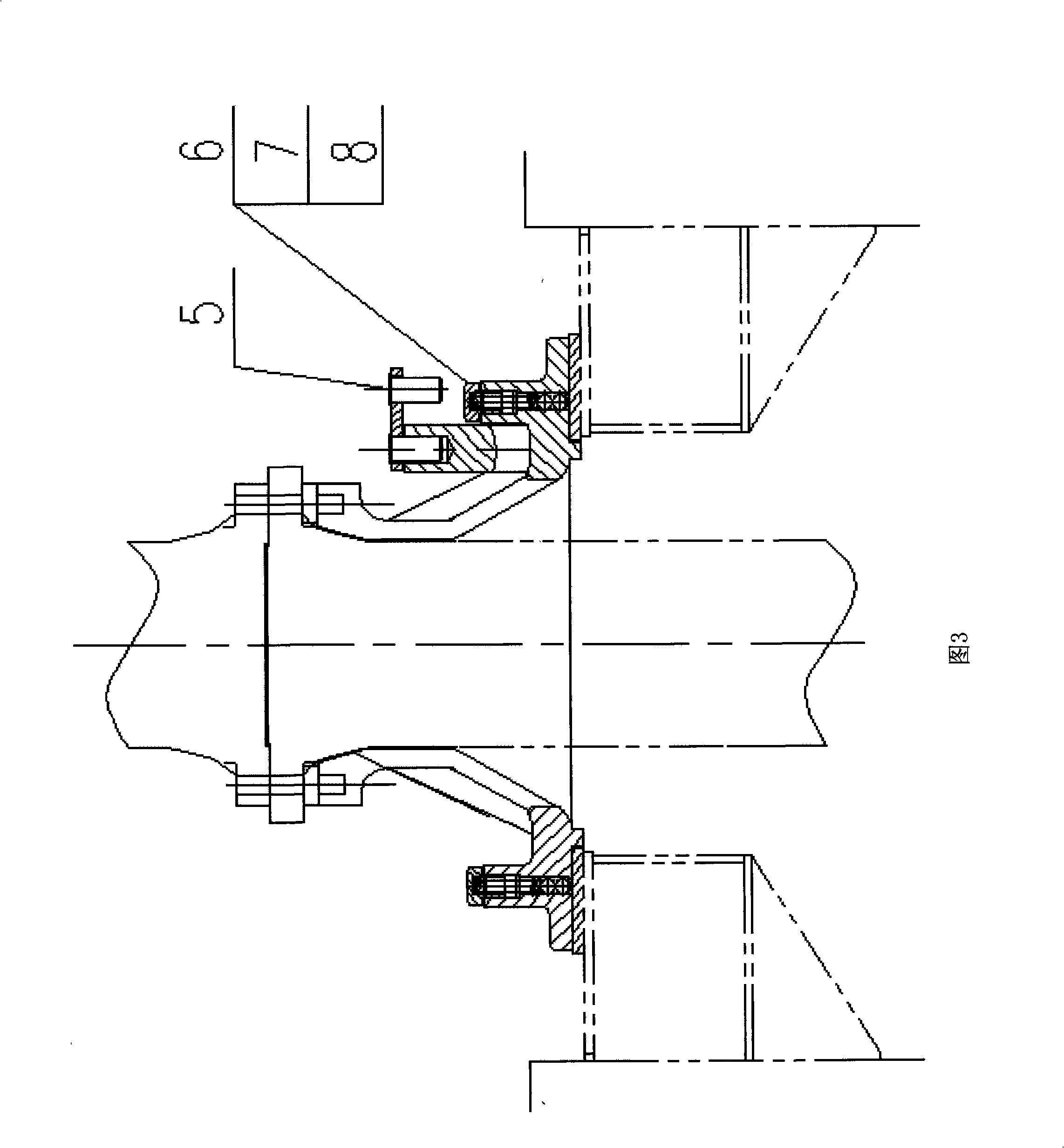

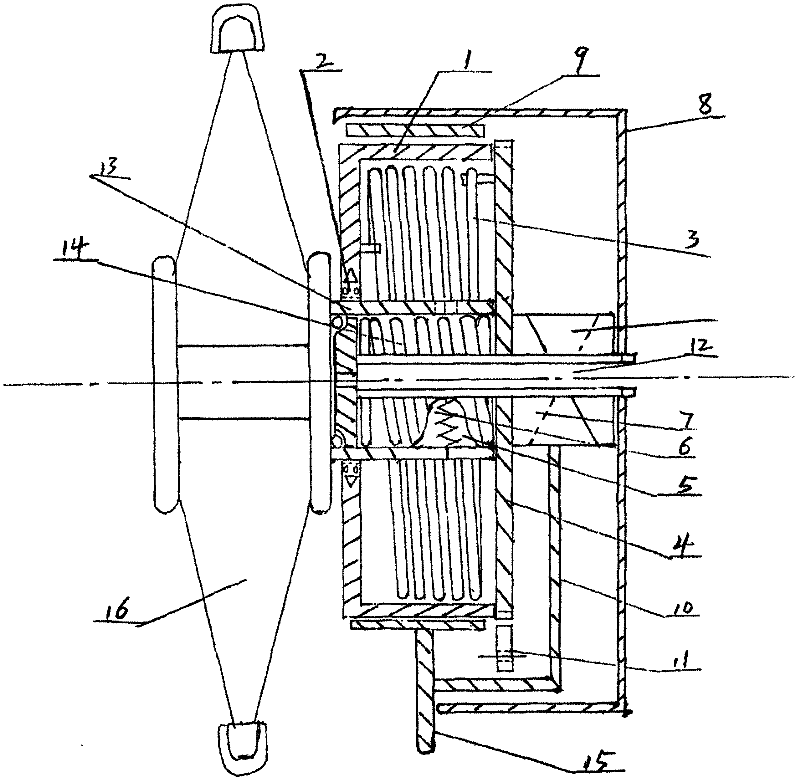

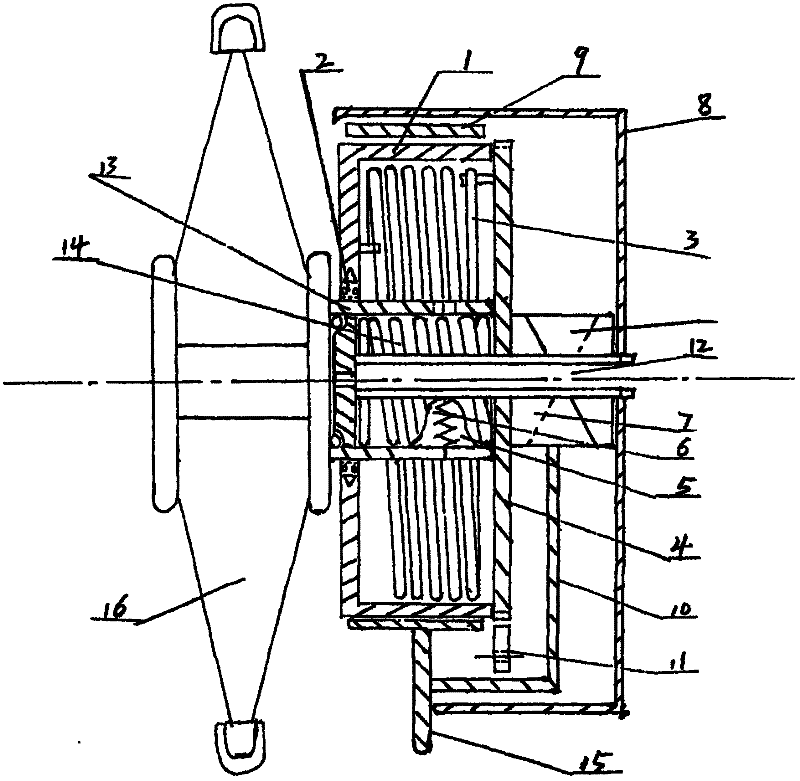

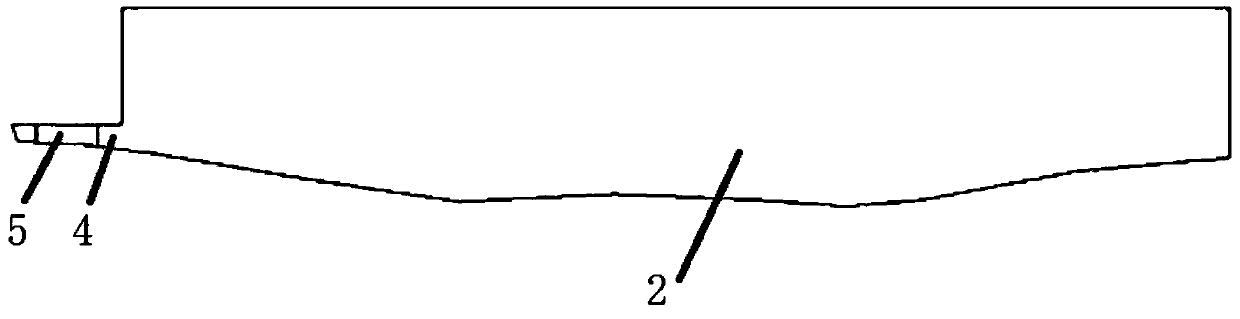

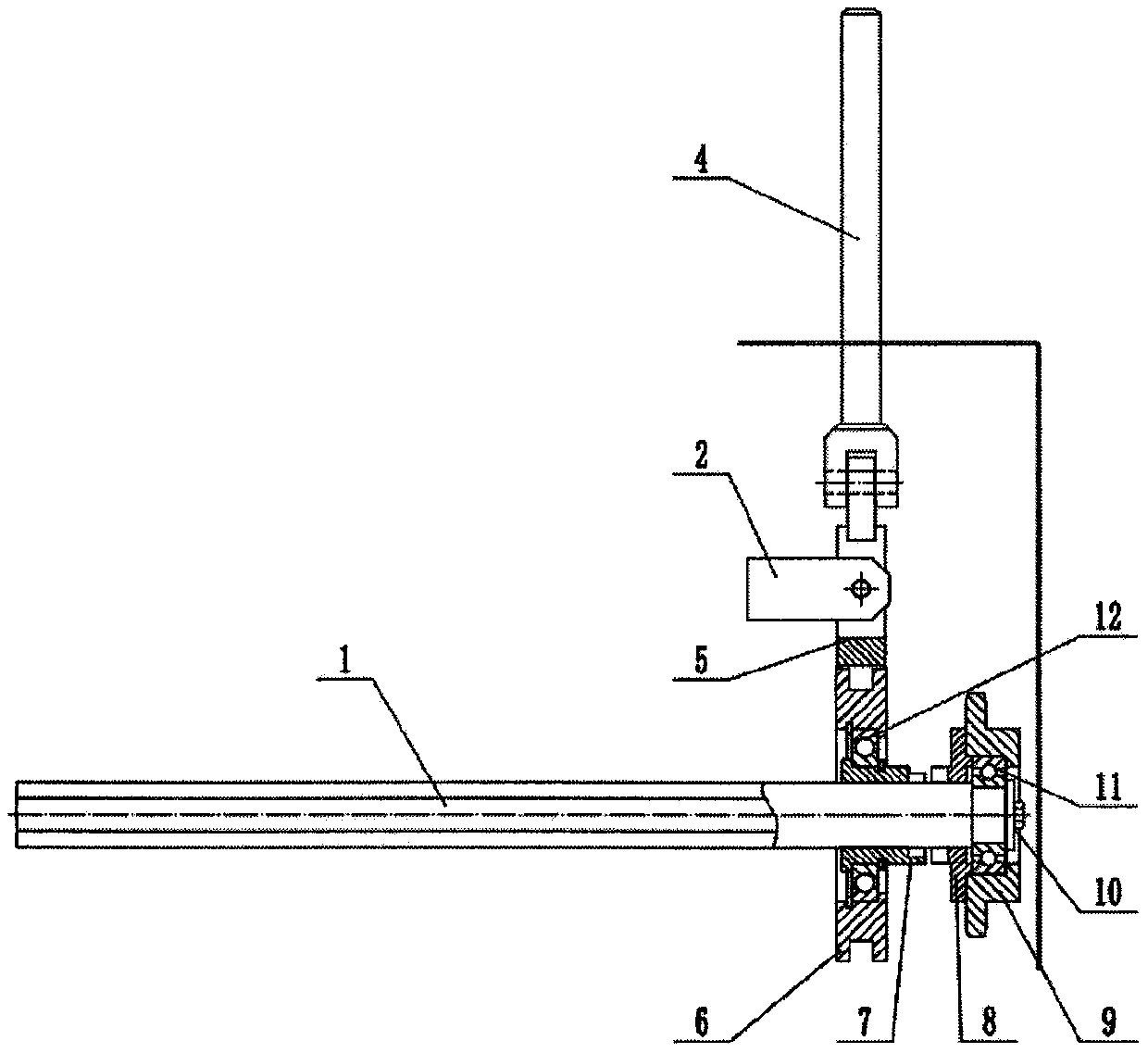

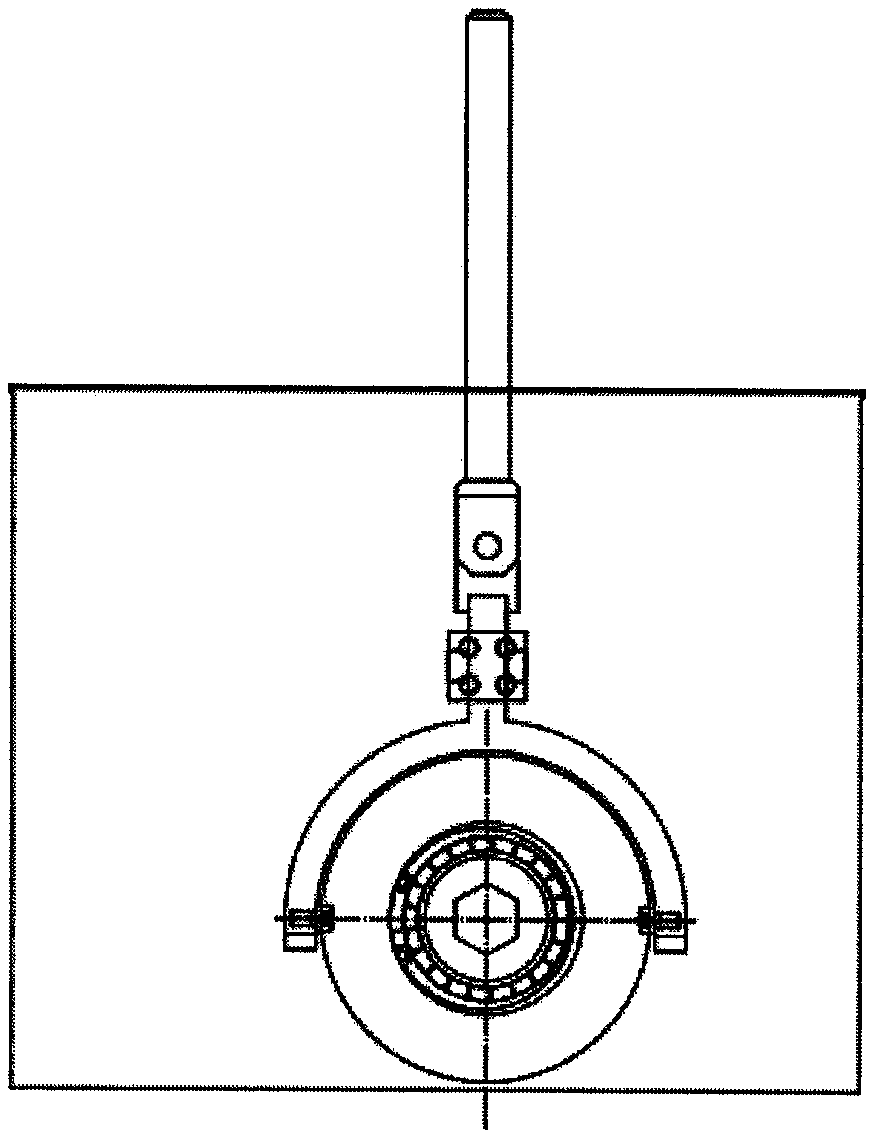

Fastener device for connecting and detaching bore rod

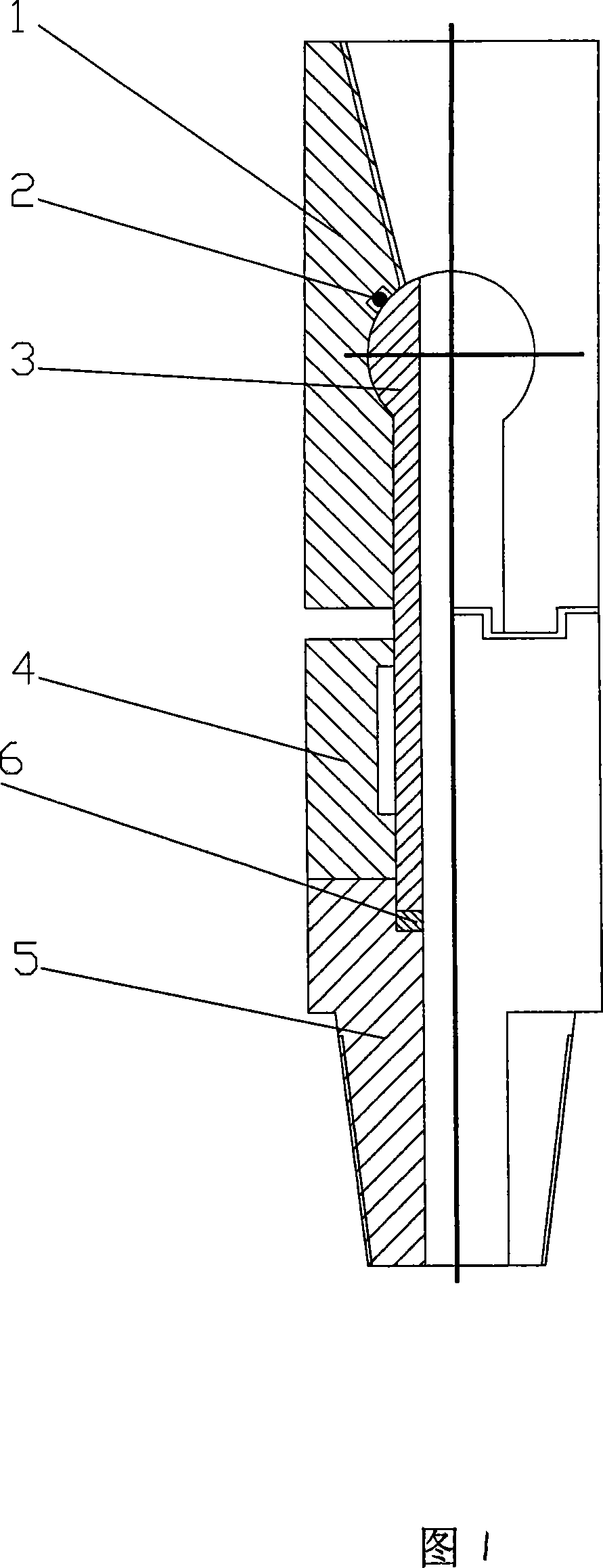

InactiveCN101333915AReduce wearExtended service lifeDrilling rodsDrilling casingsSteel ballEmbedded teeth

Disclosed is a hold-clamp device for the mounting and demounting of the drill rod, comprising a support (1), an oil cylinder (2), a semi hold-clamp (3), a liner (4), a bolt (6), a spring (7) and a steel ball (8); wherein, the support is fixed on an external reserved platform (10); one end of the oil cylinder is connected with the support and the other end is connected with the semi hold-clamp which is mounted on the external reserved platform; the support, the oil cylinder and the semi hold-clamp are connected together to form the hold-clamp device which is symmetrical along the axial line of the oil cylinder; the semi hold-clamp is designed to a special structure which has a small upper part and a big lower part; the upper part is shaped like a semicircular cylinder; the lower part is shaped like that a semicircular cone which is joint with a flat plate with large area; a lug boss is arranged on the top of the semicircular cylinder; the liner can be arranged on the position of the lug boss; an inner hole and a pin shaft hole are arranged on both sides of the lower part flat plate shaped position; the steel ball, the spring and the bolt are arranged in the inner hole. The hold-clamp device has the advantages of compact structure, reliable application, not only being used for mounting and demounting the flange drill rod, but also being used for mounting and demounting the embedded tooth drill rod, good generality and improving the work efficiency greatly.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

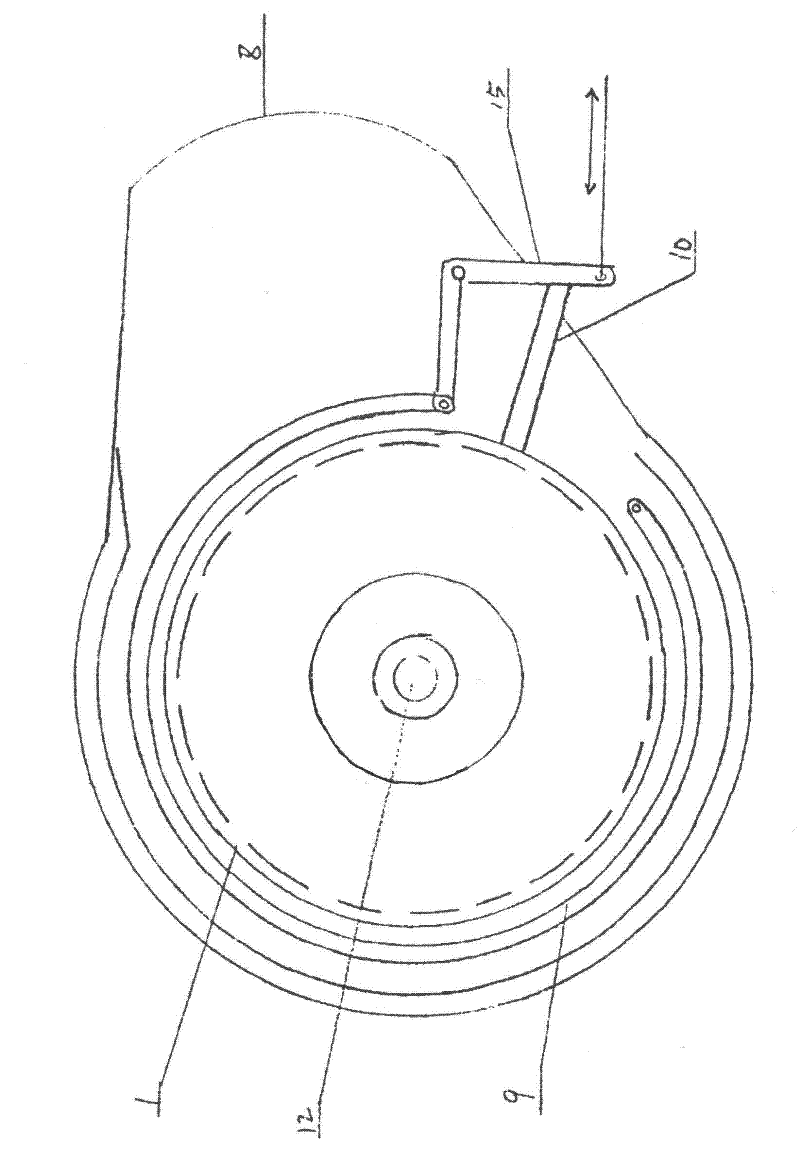

Bicycle braking system

The invention relates to a bicycle braking system, which is composed of a braking part and a force storage part. A flywheel is arranged between a brake drum and a hub; a booster spring is arranged in the inner-circle mesh of the brake drum; one end of the booster spring is fixed on the mesh, and the other end of the booster spring is connected a round fluted disc; a stop claw is arranged outside the teeth of the round fluted disc; the round fluted disc and an embedded tooth are in an integral structure; an embedded-tooth clutch and the hub are integrated into a whole; a clutch is arranged outside the fluted disc; a half of the clutch is connected with a draw bar, and the other half of the clutch is used for fixing a brake assembly shield; a brake pad and the brake assembly shield are in on-off contact; the inner side of the brake pad is connected with a general brake connecting rod; and a spring is sheathed outside a rear shaft sleeve. The bicycle braking system has the beneficial effects that inertia force formed by the braking of the rear wheel of the bicycle is stored by a brake force storage device, and the stored energy is released at any time and is fed back to a rear-wheel brake power assisting device so as to drive the rear wheel, thereby achieving the purposes of power saving and power supplying.

Owner:王达

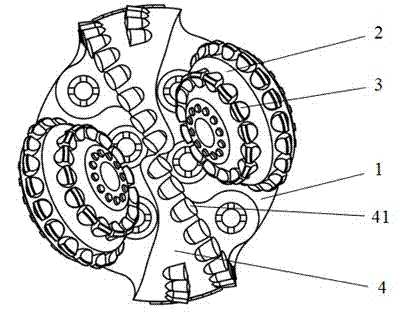

Composite drill bit

ActiveCN103089154AImprove rock breaking efficiencyEasy to splitDrill bitsConstructionsEmbedded teethEmbedded tooth

The invention discloses a composite drill bit, and belongs to the technical field of drilling equipment in petroleum and gas, mine engineering, building foundation engineering construction, geology, hydrology and the like. The mixed drill bit comprises a drill bit body, at least one cone and at least one cutter disk. The cone and the cutter disk are respectively connected with the drill bit body through a bearing structure in a rotating mode. A range of a deflection angle of the disk cutter is from 20 degrees to 90 degrees or from -90 degrees to -20 degrees. The cutter disk is provided with cutter disk cutting teeth. The cone is provided with cross-embedded teeth, and a value range of a deflection angle alpha of the tooth top of each cross-embedded tooth is 70 degrees <=|alpha|<= 90 degrees. A novel cone structure is adopted and is combined with the disk cutter structure with large deflection angle so as to form the composite drill bit. The composite drill bit is high in rock breaking efficiency, the cone is stable in working, the drill bit is good in working stability, and meanwhile service life of the drill bit teeth and the bearing is prolonged, and therefore the service life of the drill bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

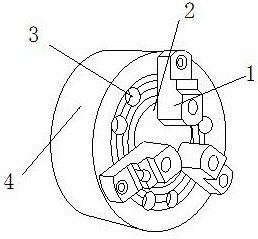

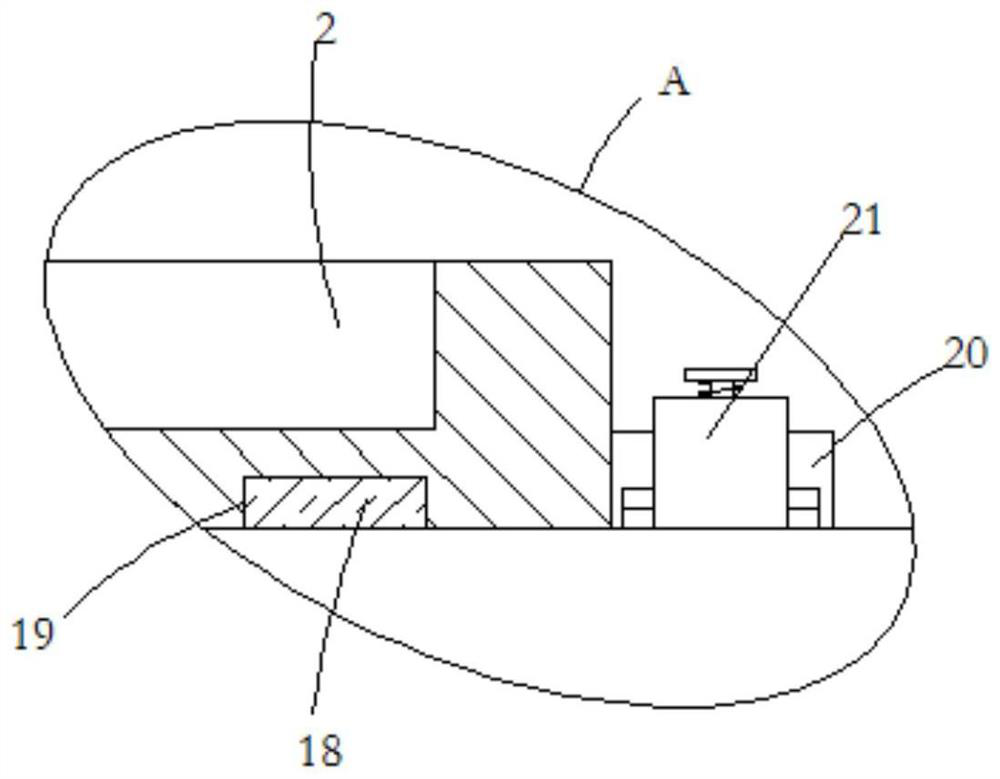

Universal chuck of numerical control tool grinding machine

ActiveCN112025474AImprove adsorption capacityIncrease frictionSpherical surface grinding machinesGrinding work supportsNumerical controlMachine parts

The invention discloses a universal chuck of a numerical control tool grinding machine. The universal chuck structurally comprises clamping teeth, a clamping opening, threaded openings and a chuck body, the clamping teeth are embedded in the end face of the inner side of the chuck body and are evenly distributed, the clamping opening is located in the transverse center of the chuck body, the threaded openings are evenly formed in the end face of the outer side of the chuck body, each clamping tooth comprises an embedding and fixing strip, embedding teeth, a fixed disc and a trapezoidal block,each trapezoid block is fixedly embedded in the upper end face of the corresponding embedding and fixing strip, the embedding teeth are embedded and attached under the corresponding embedding and fixing strip, the end face of the left side of each fixed disc is installed on the right side of the corresponding trapezoid block in a welded mode, each trapezoid block is arranged over the correspondingembedding teeth in an embedded mode, and a machined part is capable of extruding the surface of a closed rubber block to enable the closed rubber block to be sunken inwards. And the closed rubber block is inward extruded while being sunken inwards, so that embedded blocks on the left side and the right side contract inwards after the embedded blocks make contact with a limiting opening, and the inner end face of an air opening is gradually closed while contraction is conducted, so that a closed space is formed in the upper end faces of the fixed discs, and the surface adsorption force and friction force of the spherical machined part are increased.

Owner:尚特(广州)机器人智能装备有限公司

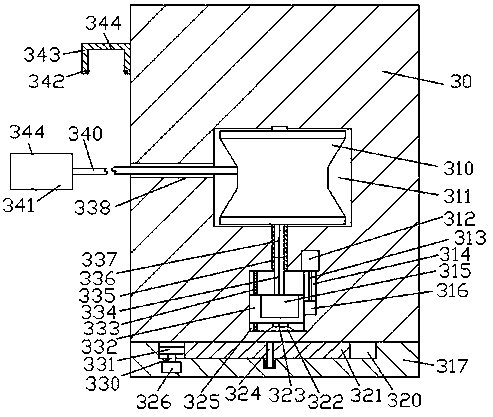

Novel automatic new energy automobile equipment

InactiveCN108099668ASimple structureEasy to operateVehicle connectorsCharging stationsEmbedded teethEmbedded tooth

The invention discloses novel automatic new energy automobile equipment. The equipment comprises a charging pile which is rotationally and fittingly mounted at the upper end of a base through a rotating mechanism. The rotating mechanism comprises an embedding tooth groove in the top end face of the base, an upward-extending center rotating shaft is rotationally and fittingly mounted at the centerof the embedding tooth groove, and a center gear is fixedly and peripherally mounted on the outer surface of the center rotating shaft in the embedding tooth groove. A driving gear meshed with the center gear and the embedding tooth groove is arranged in the left side of the embedding tooth groove, a driving rotating shaft is fixedly mounted on the bottom end face of the driving gear, the bottom extending tail end of the driving rotating shaft is in power fit connection with a first motor, and the inner wall of the charging pile is provided with a rotating cavity and a lifting cavity. The novel automatic new energy automobile equipment has advantages that the service life of a power line is prolonged, and safety in use is improved.

Owner:朱江帆

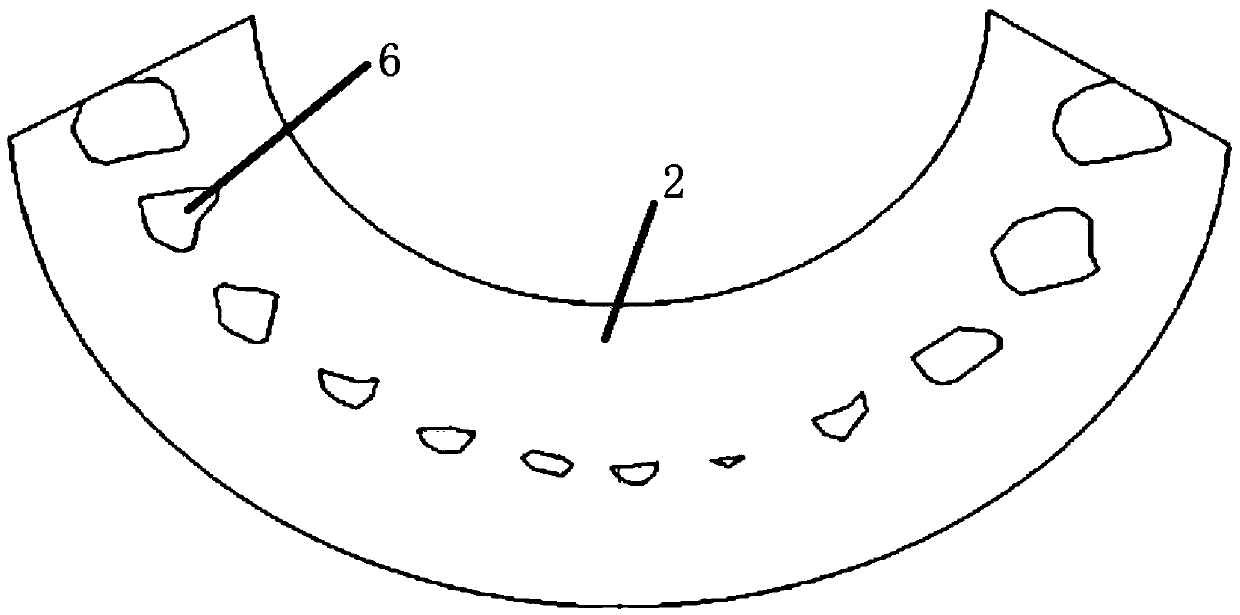

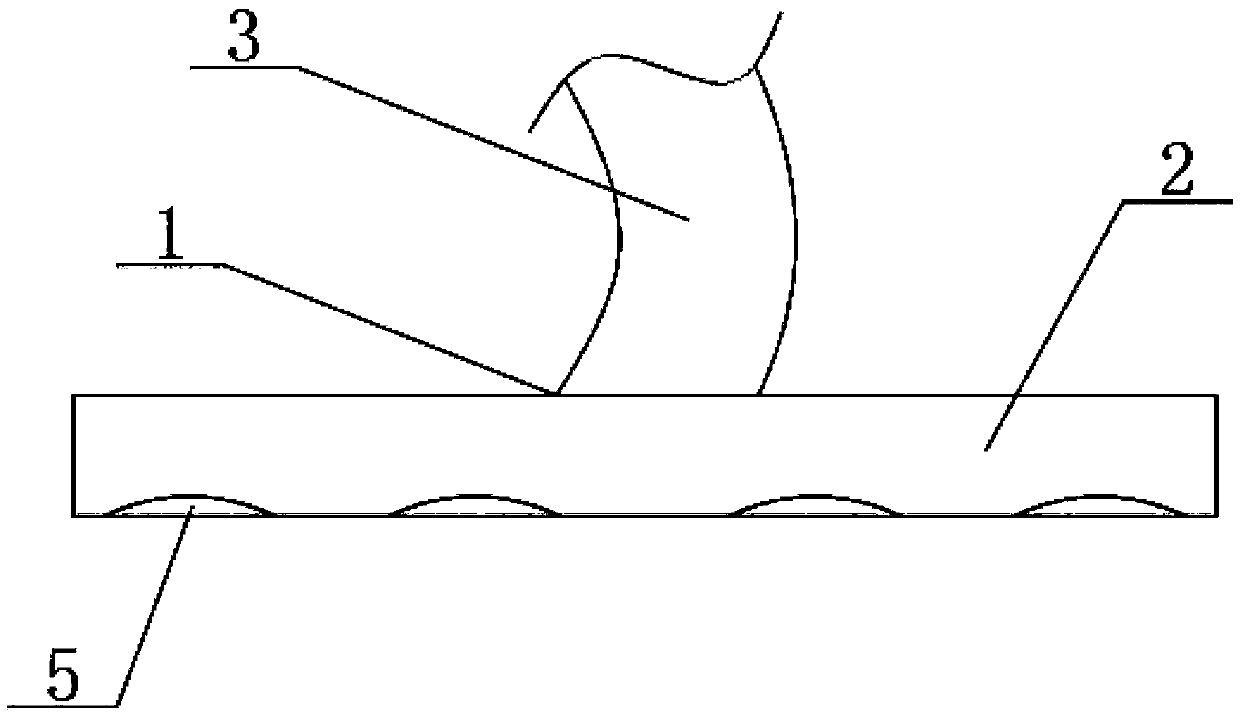

Method for manufacturing individualized bone fenestration guide plate for embedded teeth

InactiveCN110916817APrecise positioningPrecise incisal siteDental toolsIntraoral scannerEmbedded teeth

The invention discloses a method for manufacturing an individualized bone fenestration guide plate for embedded teeth. The individualized bone fenestration guide plate for embedded teeth is prepared on the basis of an intraoral scanner and CBCT data by utilizing a 3D printing technology. The guide plate is made of a resin material, and the embedded tooth fenestration guide plate based on a tooth support type is printed through the 3D printing technology. The guide plate assembly performs positioning through teeth around the embedded teeth, is stable and does not loosen, and guarantees accuratepositioning.

Owner:NANJING STOMATOLOGICAL HOSPITAL

Embedded tooth individualized bone fenestration guide plate based on three-dimensional printing technology

PendingCN109662788AGood compatibilityReduce the chance of sheddingAdditive manufacturing apparatusOthrodonticsEmbedded teethEngineering

The invention relates to the technical field of medical treatment, in particular to an embedded tooth individualized bone fenestration guide plate based on a three-dimensional printing technology. Theembedded tooth individualized bone fenestration guide plate based on the three-dimensional printing technology adopts the three-dimensional printing technology, and is based on titanium alloy materials, and prints the bone fenestration positioning guide plate based on the tooth supporting type according to an optimal traction design scheme; the guide plate assembly is positioned by the tooth around the embedded tooth, is stable and does not loosen, and the positioning through hole of the guide ring part protruding from the other end tightly fits to the bone surface so as to surround the partof the simulated fenestration. Compared with the traditional stainless steel, the titanium alloy material is adopted to form the guide plate assembly, the structure compatibility is obviously superior, and soft and hard tissue inflammation reactions are not easy to occur; compared with a resin material guide plate, the titanium alloy material guide plate is lighter and thinner in volume and smaller in thickness, and is more suitable for operation in a narrow space of a posterior tooth molar area. The integrated structure is firmer and is not easy to break. The optimal position of the bone fenestration is determined according to the optimal traction and extraction path of the impending teeth.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

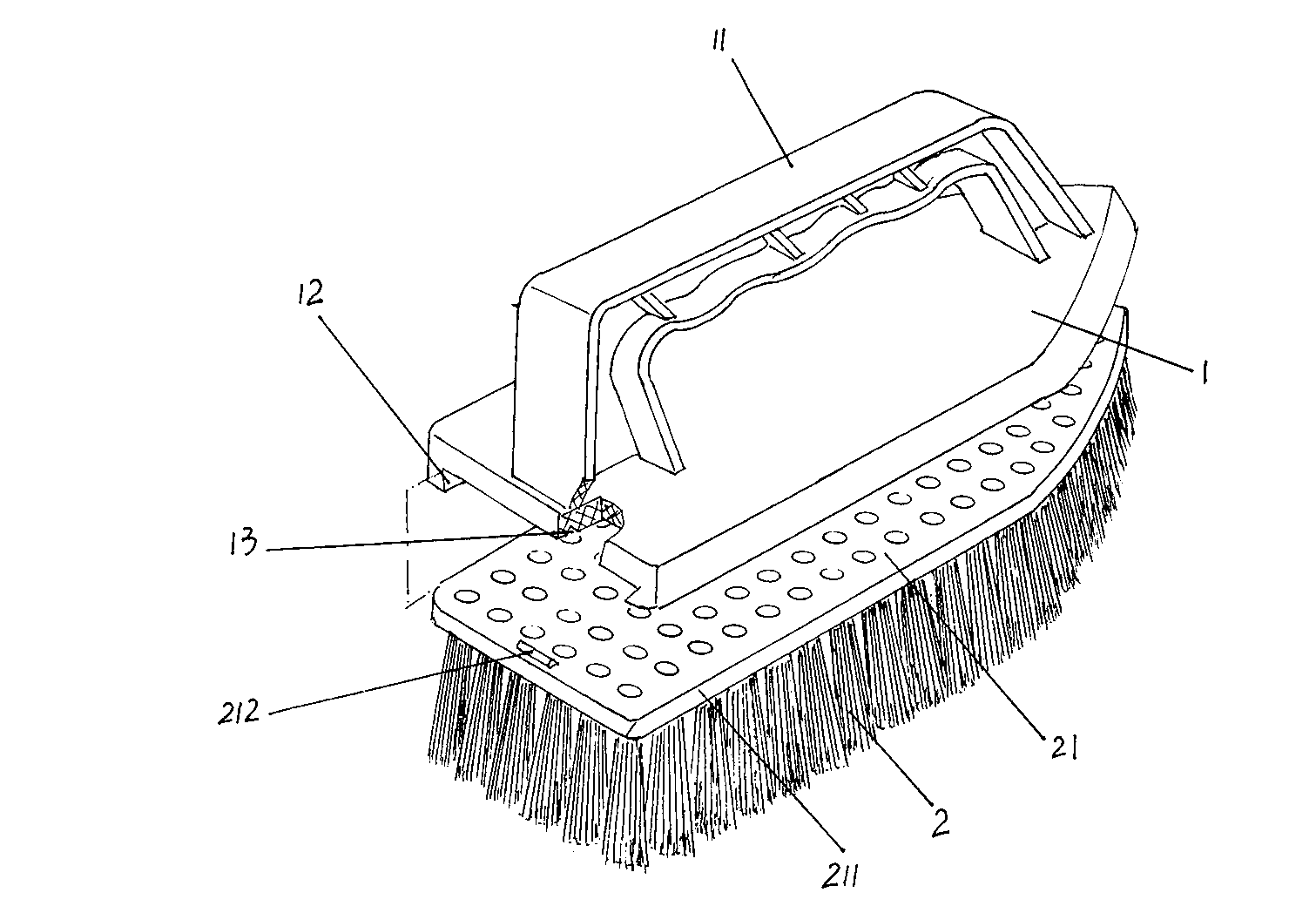

Brush with handle

InactiveCN103099425AQuick changeEasy to replaceBrush bodiesBristle carriersEngineeringEmbedded teeth

The invention provides a brush with a handle, and belongs to the technical field of cleaning appliance. The brush comprises a brush body and a brush board seat and is characterized in that the brush body is fixedly connected with a brush board, an embedding edges are formed on the edge portion of the brush board, and at least on embedding tooth is arranged on one side of an upper plane of the brush board in a protruded mode. The handle is arranged in the middle of the upper plane of the brush board seat, embedding grooves matched with the embedding edges are formed on two sides of a lower plane of the brush board seat, and a position of the lower plane of the brush board seat, corresponding to the position of the embedding tooth, is provided with an embedding tooth groove matched with the embedding tooth. The brush has the advantages of simple in structure, convenient to replace, and capable of meeting multi-purpose requirements through replacement of different brush bodies. The brush body can be replaced constantly, cost is saved, the brush is not easy to deform, bacteria are not easy to breed, and using safety and hygiene are guaranteed. In addition, by means of additional handle, holding is convenient, and operation is labor-saving.

Owner:CHANGSHU YONGXIANG ELECTROMECHANICAL

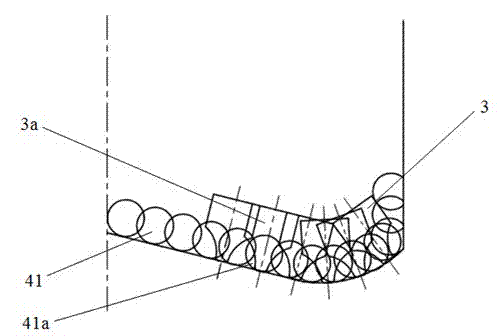

Petroleum drilling well drilling tool spherical flexible joint

InactiveCN101169031AUniform and stable curvatureSimple structureDrilling rodsDrilling casingsDirectional wellWell drilling

The invention relates to a spherical flexible tie-in for the oil-well drilling tool, which is in particular positioned in the drilling tool combination on the bottom of the oil-well. The invention is characterized in that a sphere is arranged on the front end of a spline shaft, the sphere is sleeved on a tie-in with embedded teeth, and a sealing piece is arranged between the sphere and the tie-in with embedded teeth for sealing. A tie-in of an inner spline is arranged on the outside of the lower part of the spline shaft, the tie-in of the inner spline is connected with a lower tie-in, an adjusting piece is arranged on the bottom of the spline shaft in the inner cavity of the lower tie-in with embedded teeth. The invention has simple, compact and rational structure. The pad in the adjusting lower tie-in can change the clearance of the embedded teeth, and then can change the degree of the rotation angle; can ensure that the track curvature of the well hole drilled during drilling horizontal well and directional well is even and stable (cannot be influenced by drilling pressure); thereby reaching the purposes of slope reducing and steadying when being positioned on a specific position of the aiguille during drilling straight well.

Owner:无锡浩安科技发展有限公司

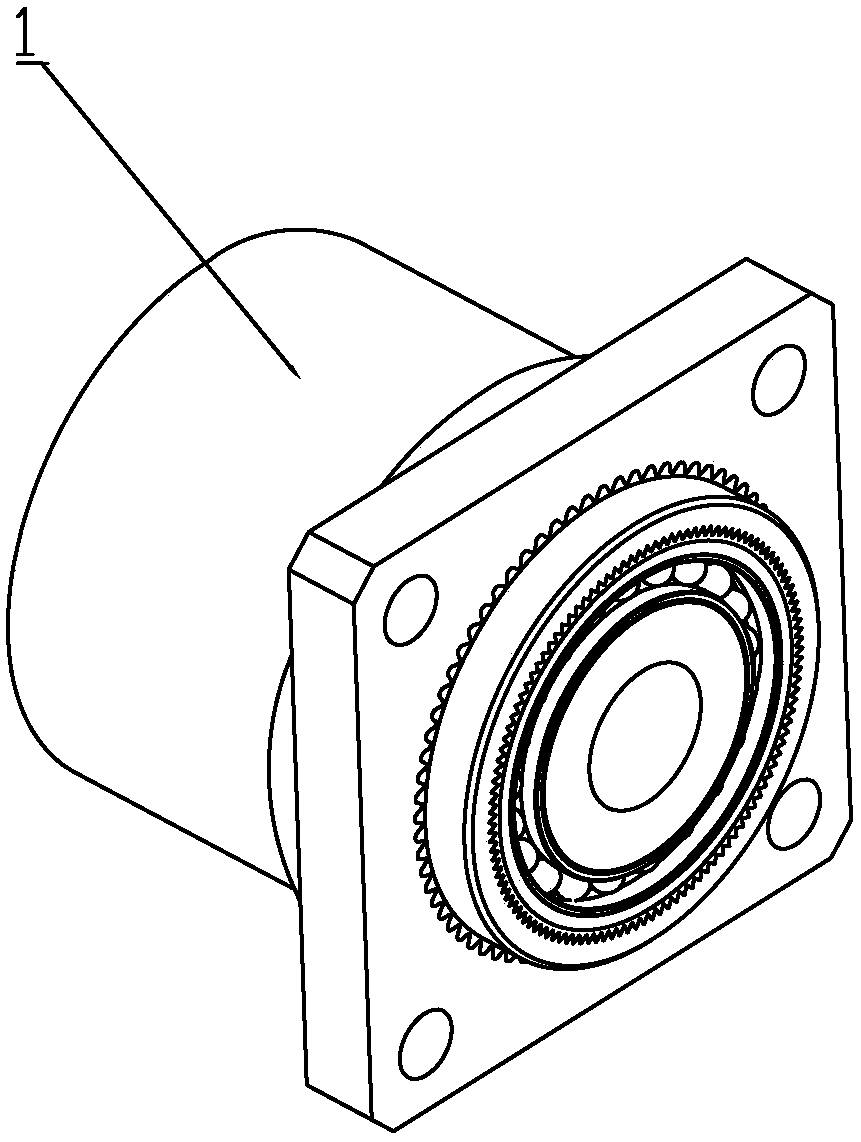

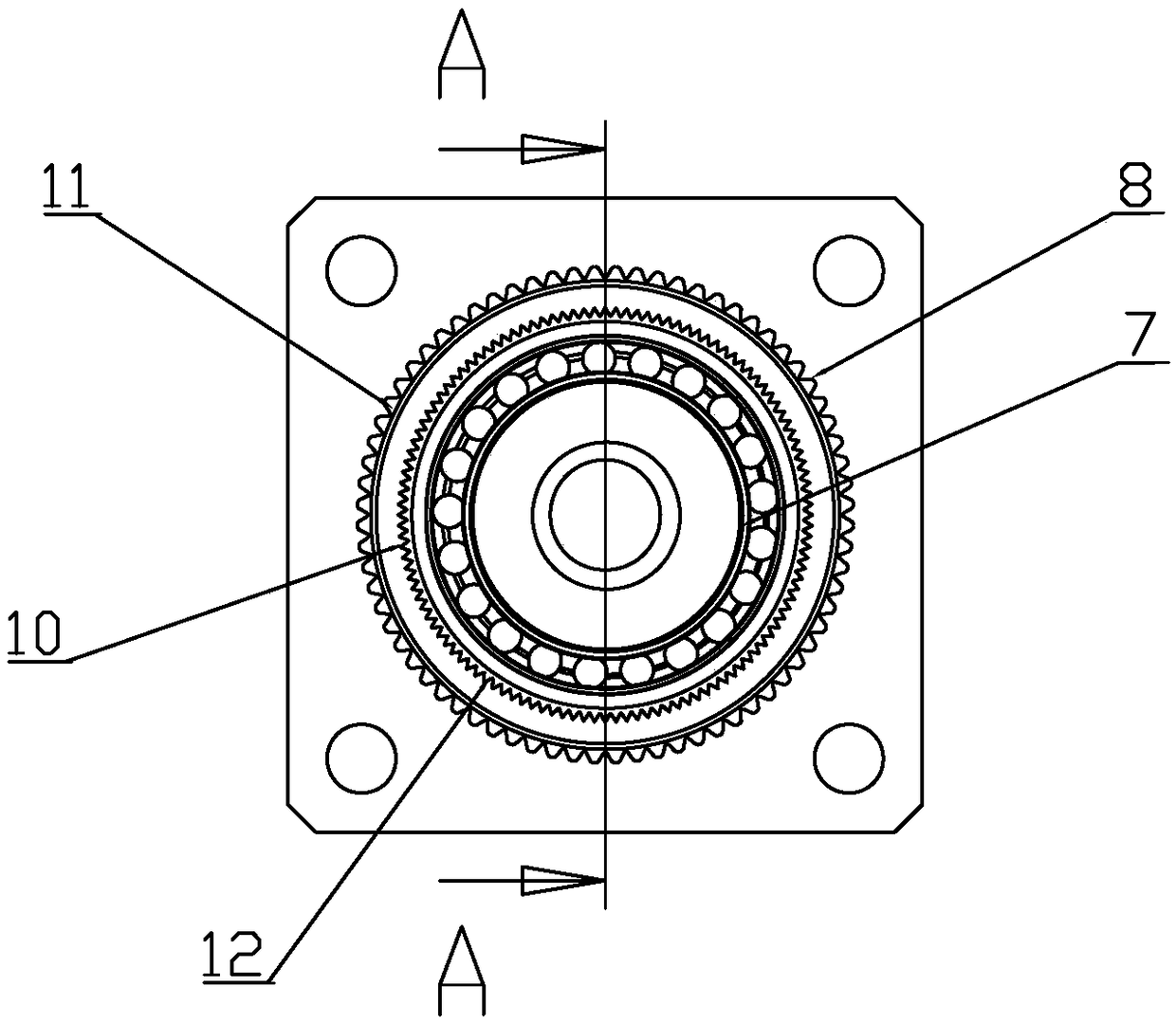

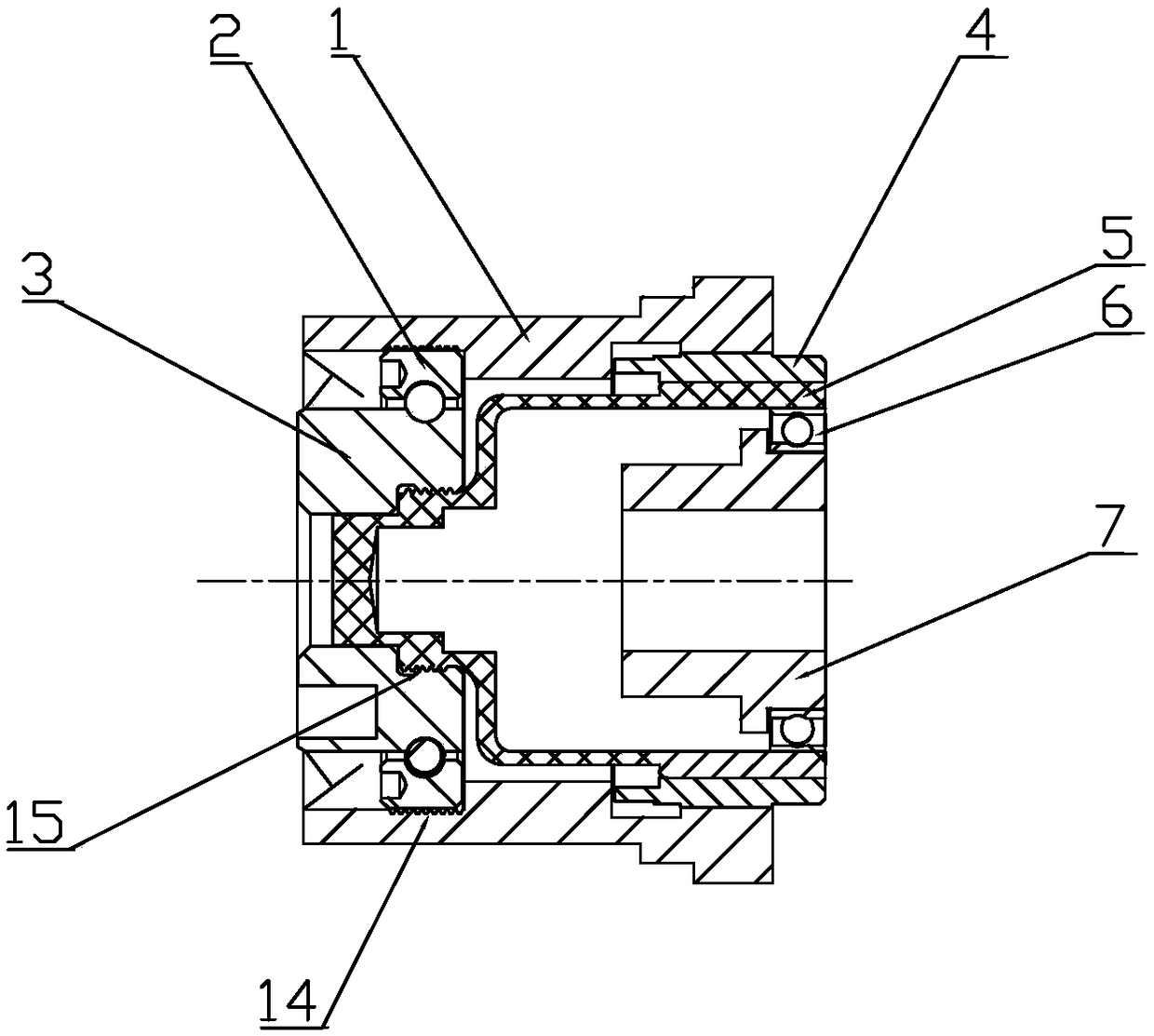

Micro harmonic speed reducer

The invention discloses a micro harmonic speed reducer. The micro harmonic speed reducer comprises a shell body, an outer bearing ring, an inner bearing ring, a rigid wheel, a flexible wheel, a flexible bearing, a wave generator, an inner shell head tooth ring, an inner shell tail thread, an inner rigid wheel tooth ring, an outer rigid wheel tooth ring, an outer flexible head tooth ring, an outerflexible tail thread, an outer bearing thread and an inner bearing thread, wherein the inner shell head tooth ring of the shell body and the outer rigid wheel tooth ring of the rigid wheel are mutually fixedly connected in an embedding manner; and the inner rigid wheel tooth ring and the outer flexible head tooth ring form tooth joint, the outer flexible head tooth ring is equipped with the wave generator through the flexible bearing, the inner shell tail thread and the outer bearing thread are mutually screwed and fixed, and the outer flexible tail thread and the inner bearing thread are mutually screwed and fixed. According to the micro harmonic speed reducer disclosed by the invention, the total volume and weight are relatively greatly reduced with the adoption of screw joint and the embedded tooth joint; the micro harmonic speed reducer is small in size, light in weight and stable in transmission; the micro harmonic speed reducer is of great significance in projects with quality and volume requirements; and moreover, a process of machining thread holes and a link of assembling screws are omitted, so that the assembly efficiency is greatly increased.

Owner:苏州习元智能科技有限公司

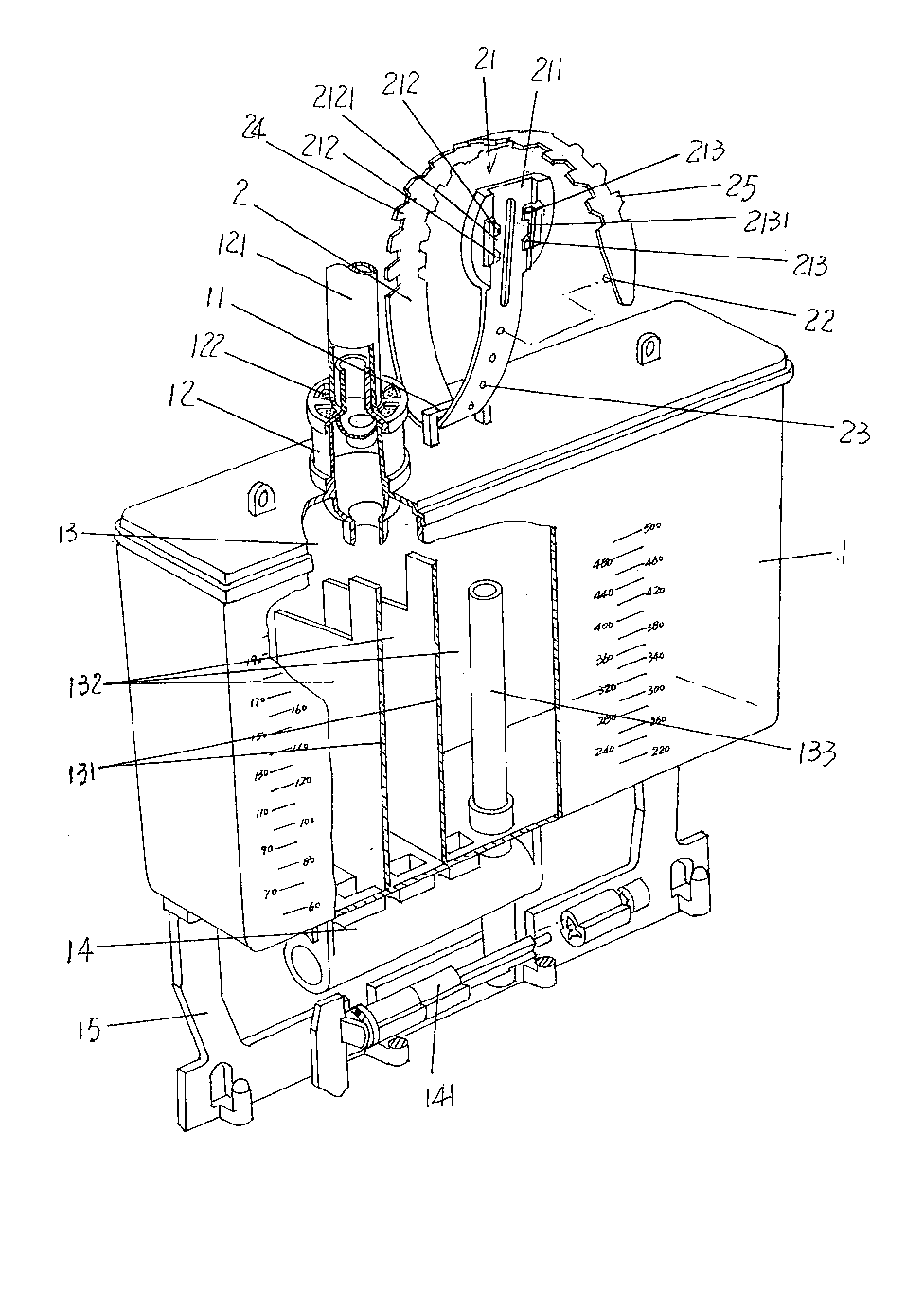

Household tooth flushing machine

The invention relates to a household tooth flushing machine which comprises a lithium battery for powering the machine, a mini water pump connected with the lithium battery, a purifed water bottle, a liquid toothpaste bottle and a toothbrush body mounted on the other side of the mini water pump through a water hose. The purified water bottle and the liquid toothpaste bottle are mounted on one side of the mini water pump through water pipes, the toothbrush body is movably connected with the water hose, and the mini water pump is further connected with a control device. By the household tooth flushing machine, the problem that interception in an oral cavity cannot be cleaned completely, the problem that strange teeth cannot be brushed well, such as, things stuffed in small gaps between teeth cannot be cleaned better and garbage in tooth cavities are even impossible to clean, the problem that rotten teeth cannot be brushed well and embedded teeth are even harder to brush well, the problem that damage is caused to gingiva while bleeding is accompanied and the problem that a user feels uncomfortable when the tongue is brushed can be solved.

Owner:孟峰

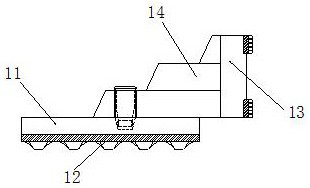

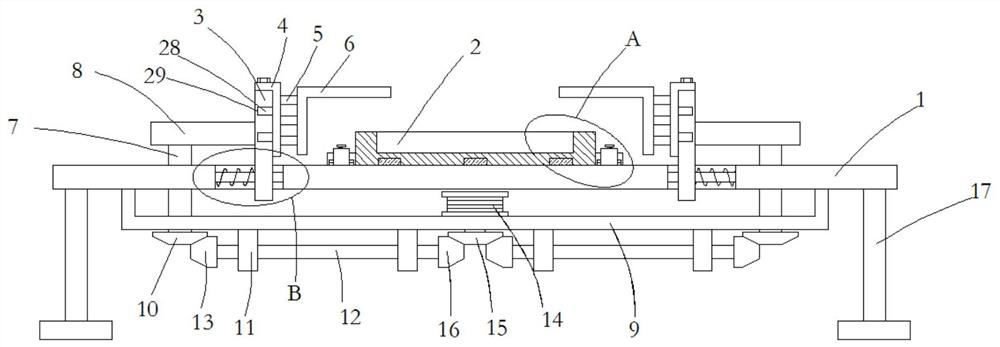

Eccentric clamping mechanism for embedded teeth in high hot-press casting

InactiveCN113601415AQuick squeeze limitGuaranteed holding stabilityWork holdersElectric machineryStructural engineering

The invention relates to the technical field of clamping mechanisms, and discloses an eccentric clamping mechanism for embedded teeth in high hot-press casting. The eccentric clamping mechanism comprises a workbench, wherein a die groove is fixedly clamped to the upper end of the middle of the workbench; moving plates are symmetrically and slidably connected to the left side and the right side of the upper end of the workbench; the opposite sides of the two moving plates are fixedly connected with the same L-shaped fixing plate; the side wall of the L-shaped fixing plate is fixedly connected with the same L-shaped pressing plate through a plurality of supporting columns; through holes are formed in the left side and the right side of the upper end of the workbench; rotating shafts are rotationally connected into the through holes in a sleeved mode through bearings; cams located on the rear sides of the moving plates are fixedly connected to the upper ends of the rotating shafts; and a U-shaped transverse plate is fixedly arranged at the lower end of the workbench. The eccentric clamping mechanism for embedded teeth in high hot-press casting has the advantages that a casting can be rapidly and stably extruded and limited, multi-face stable pressing can be completed only through one motor, the pressing stability is guaranteed, meanwhile economy is achieved, and follow-up maintenance and use are facilitated.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

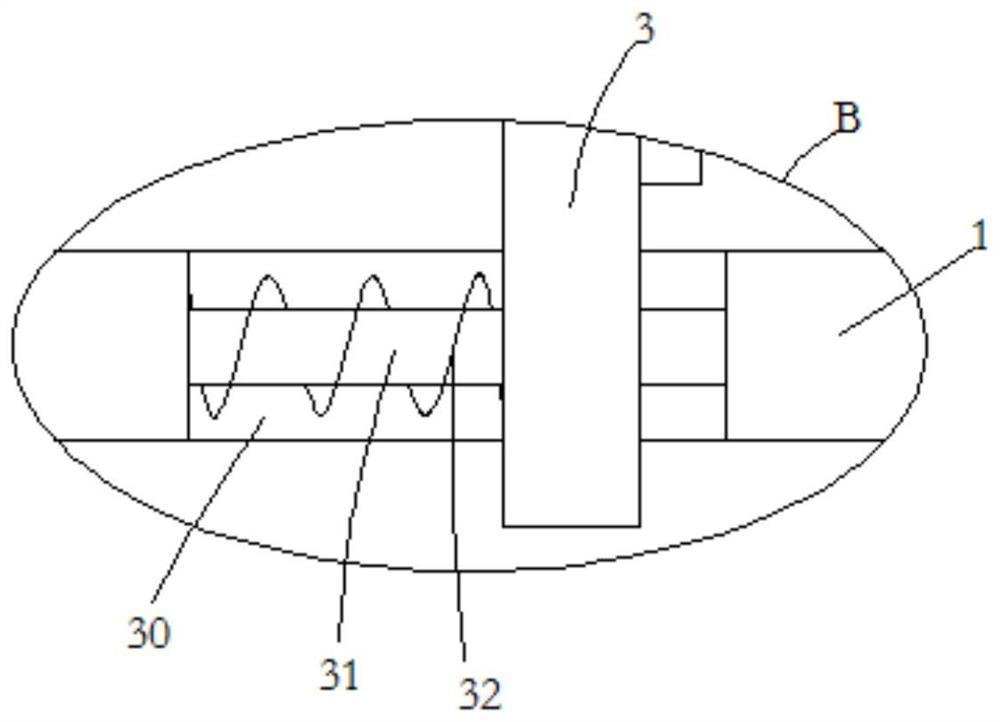

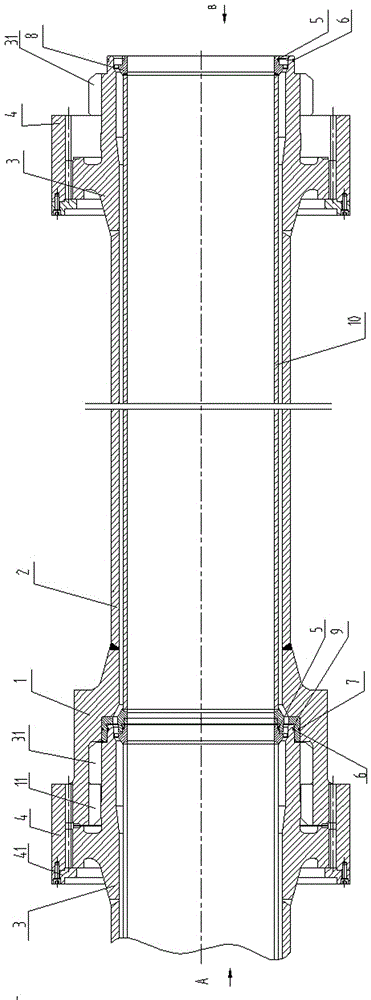

Inner embedding tooth and outer gear coupler type double-layer drill rod

ActiveCN105756574ARealize twistGuaranteed bending performanceDrilling rodsDrilling casingsUpper jointEmbedded tooth

The invention discloses an inner embedding tooth and outer gear coupler type double-layer drill rod, which comprises a double-layer drill rod body, wherein the double-layer drill rod body comprises an outer pipe, an inner pipe, an upper joint, a lower joint, an upper sealing ring and a lower sealing ring; the inner pipe and the outer pipe are arranged in the same axial direction; a gap is formed between the inner pipe and the outer pipe; the upper joint is arranged at the upper end of the outer pipe; the lower joint is arranged at the lower end of the outer pipe; the upper joint and the lower joint are respectively and fixedly connected with the outer pipe to form a bearing structure of the drill rod; the upper sealing ring and the lower sealing ring are respectively positioned in the upper joint and the lower joint of the drill rod and are connected with the inner pipe to form an inner layer structure of the drill rod; inner embedding teeth are arranged inside the upper joint along the circumferential direction; outer embedding teeth are arranged outside the lower joint along the circumferential direction; the outer periphery of the upper joint and the outer periphery of the lower joint are provided with outer gears in the same structures; an inner gear sleeve sleeves the outside of the outer gear of the lower joint. The drill rod provided by the invention is used as an engineering drilling machine drill rod, is used for power transmission and airlifting reverse circulation fluid transmission, and has the advantages that the bearing is safe, the fast dismounting can be realized, and the double-layer sealing is reliable.

Owner:PINGMEI JIANGONG GRP SPECIAL DRILLING ENG CO LTD +1

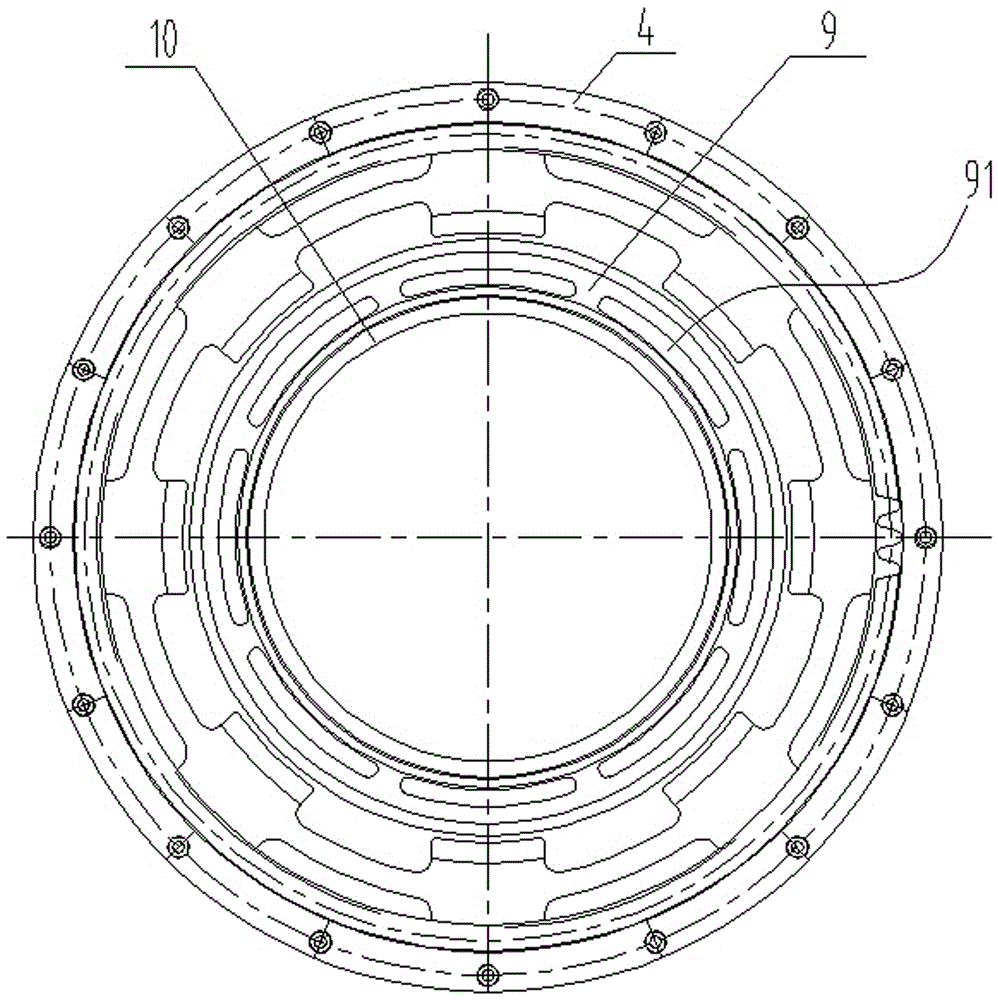

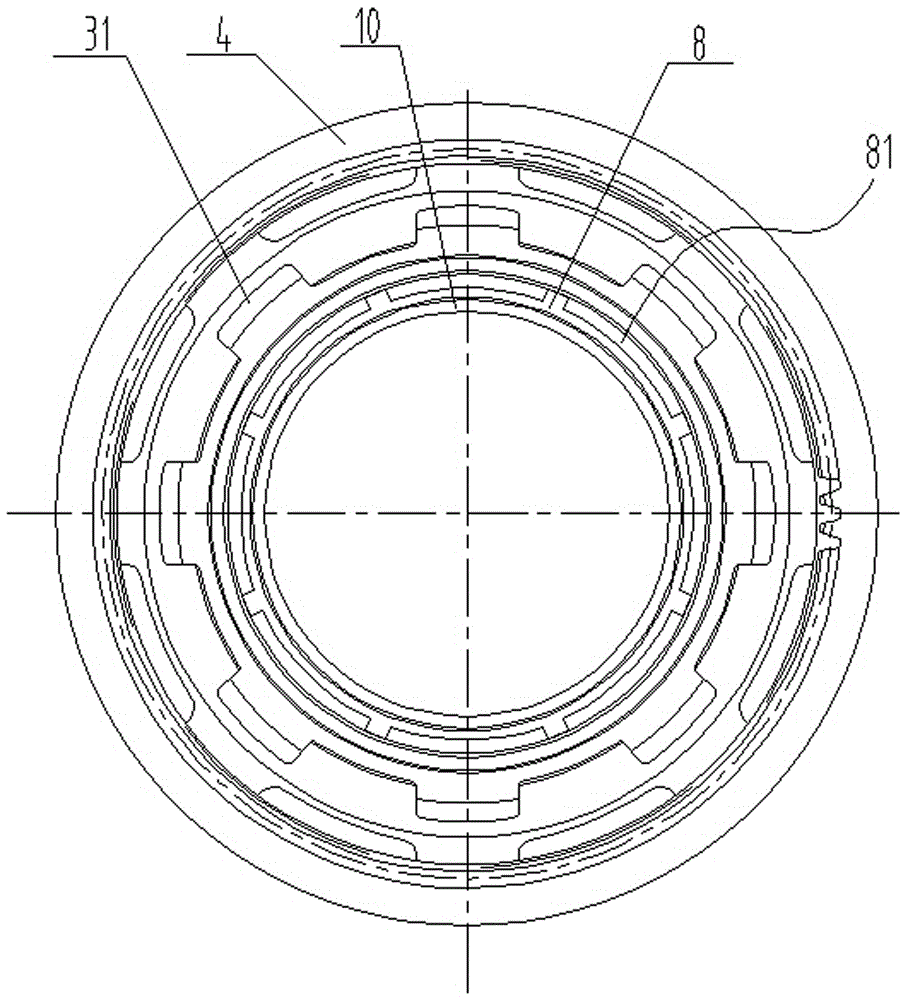

Embedded teeth joint used for automobile transmission

ActiveCN104455067AEasy to buildSave axial construction spaceMechanical actuated clutchesGearing controlEngineeringEmbedded teeth

The invention relates to an embedded teeth joint (16) used for an automobile transmission (10). The embedded teeth joint has at least one coupling main body (18), an annular control grabber (22), a friction unit (24) and the control grabber (22) are matched in shape and connected in a tangential direction (26), and the friction unit can axially functions through the control grabber (22), the control grabber (22) can be adjusted between a middle position, a synchronization position and a shift position relative to the coupling main body (18) in an axial direction, in the middle position, the control grabber (22) basically can freely rotate relative to the coupling main body (18), in the synchronization position, the control grabber (22) is coupled with the coupling main body (18) in the tangential direction (26) through frictional connection, and in the shift position, the control grabber (22) and the coupling main body (18) are matched in shape and connected in the tangential direction (26).

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Saliva suction device for adhering embedded dental accessories

PendingCN110897742AGuaranteed bonding performanceImprove adhesionSaliva removersEmbedded teethEmbedded tooth

The invention provides a saliva suction device for adhering embedded dental accessories. The saliva suction device comprises a saliva suction pipe, a hole, a negative pressure area between an inner layer and an outer layer, an oral cavity comprehensive treatment chair strong suction connecting pipe and a saliva suction pipe connecting pipe. Buried impairment of teeth is a clinically common problem, and is a common reason for malocclusion. Clinically, fenestration and germination assisting are commonly combined with surgery. In the germination assisting process, accessories need to be bonded onthe buried teeth; however, adhesion of accessories after fenestration of a bone embedded tooth is different from common orthodontic adhesion. Due to the fact that the fenestration position and area are limited and the embedded position is deep, if saliva is not sucked in time, an operation area is prone to being polluted; the adhesion effect is affected; and accessories fall off. A good saliva suction effect is the precondition for guaranteeing the adhesion force of accessories. According to the device, saliva suction is expanded from local punctiform saliva suction to circular saliva suctionwith a large relative area, so that a relatively closed and clean clinical operation visual field is formed; and the efficiency and the firmness of adhering accessories on embedded teeth are greatlyimproved.

Owner:NANJING STOMATOLOGICAL HOSPITAL

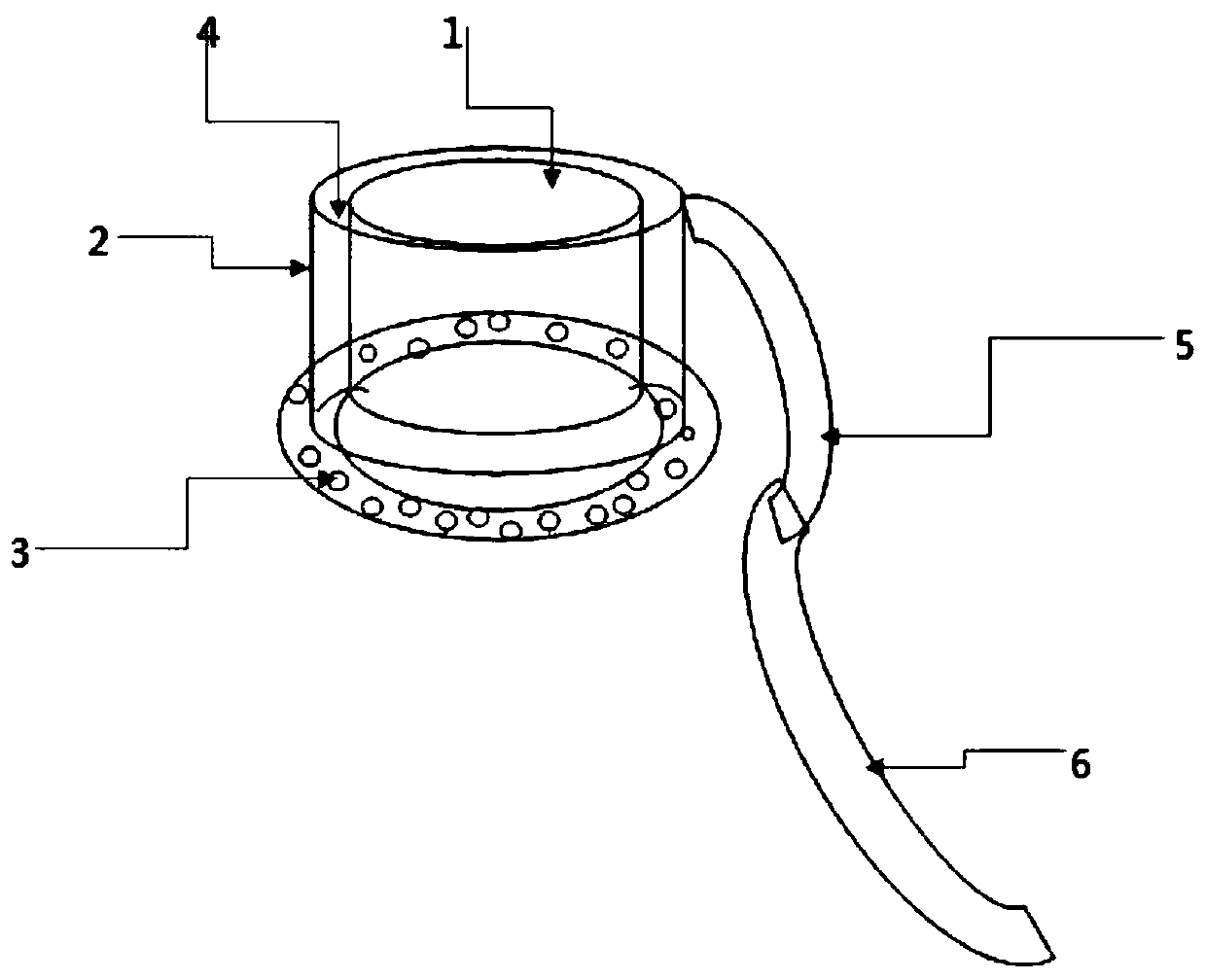

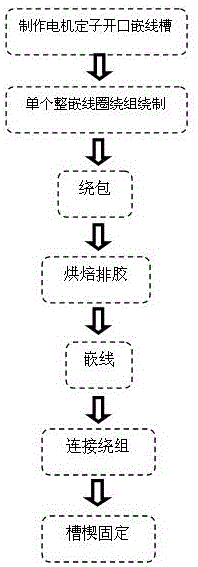

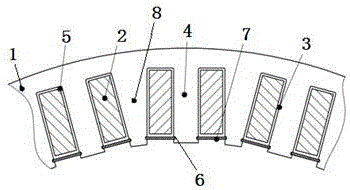

Single-layer overall wire embedding method for motor stator windings and motor stator

InactiveCN106208571AOrderly rowsHigh mechanical strengthEmbedding prefabricated windingsEngineeringEmbedded teeth

The invention provides a single-layer overall wire embedding method for motor stator windings. Overall embedding molding windings are wrapped with enamelled wires; motor stator open wire embedding slots with equal-width tooth structures are manufactured on an iron core of a motor stator; stator wire embedding teeth formed on the motor stator are equal-width teeth; and the overall embedding molding windings are embedded into the motor stator open wire embedding slots in a single-layer overall embedding manner. The overall embedding molding windings are directly embedded into the open slots as a whole. The equal-width tooth structures and the single-layer overall embedding molding windings are adopted, and fixing and molding are carried out through a mold, so that the windings become the overall embedding molding windings; the wires of the windings can be tightly attached together; and the problems of intersection and interference among the windings can be effectively solved. The end parts of the windings are relatively short, so that the wire embedding technology is greatly simplified; the space filling factor can reach over 90%; the overall embedding molding windings are reasonable in structure; and the mechanical strength is higher than that of dispersedly embedded coils.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

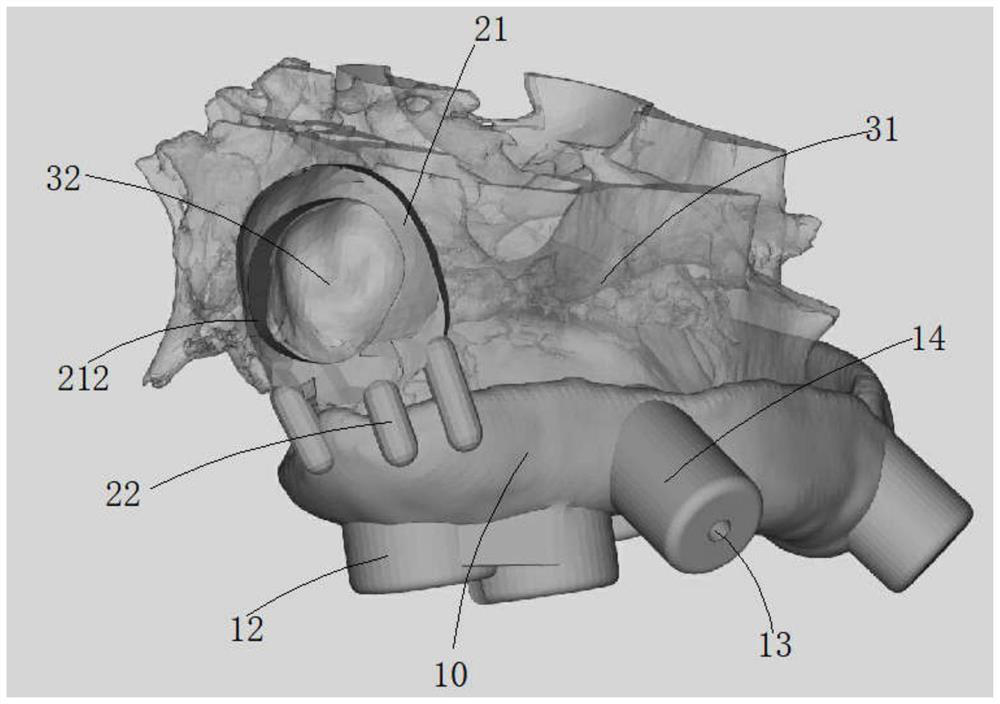

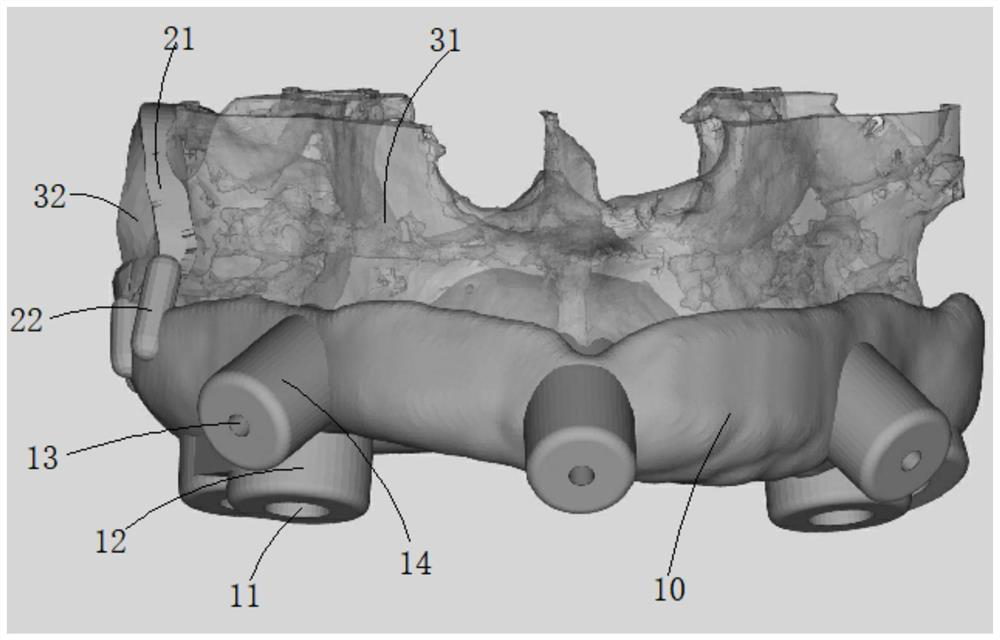

Admission passage pull-out guide plate on palate side of embedded tooth of upper jaw and manufacturing method thereof

PendingCN108888378AReduce unnecessary harmAvoid influenceAdditive manufacturing apparatusDentistryEmbedded teethUpper dentition

The invention relates to an admission passage pull-out guide plate on the palate side of an embedded tooth of an upper jaw and a manufacturing method thereof. The guide plate comprises a dentition supporting part, a guide bar and a positioning ring. The dentition supporting part is provided with a cavity matched with an upper dentition of a patient, the upper surface of the positioning ring is anarc-shaped curved face and is matched with the surface of the palate of the upper jaw bone of the patient in radian, the positioning ring is connected to the dentition supporting part through the guide bar, and the positioning ring corresponds to the position of a tooth extraction position of the embedded tooth to be pulled out. The manufacturing method comprises the following steps: reestablishing and matching the upper jaw bone and the upper dentition of the patient in a 1: 1 three-dimensional model; designing the dentition supporting part according to the upper dentition model; determiningthe tooth extraction point on the jaw of a CT reestablishing model of the upper jaw bone according to the position of the crown of the embedded tooth; designing the positioning ring according to the tooth extraction point and the surface radian of the jaw of the upper jaw bone model in the tooth extraction position; connecting the dentition supporting part and the positioning ring integrally through the guide bar; and carrying out 3D printing to obtain a finished product. The guide plate can position the tooth extraction position precisely and efficiently, so that the risk of damaging teeth isreduced.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

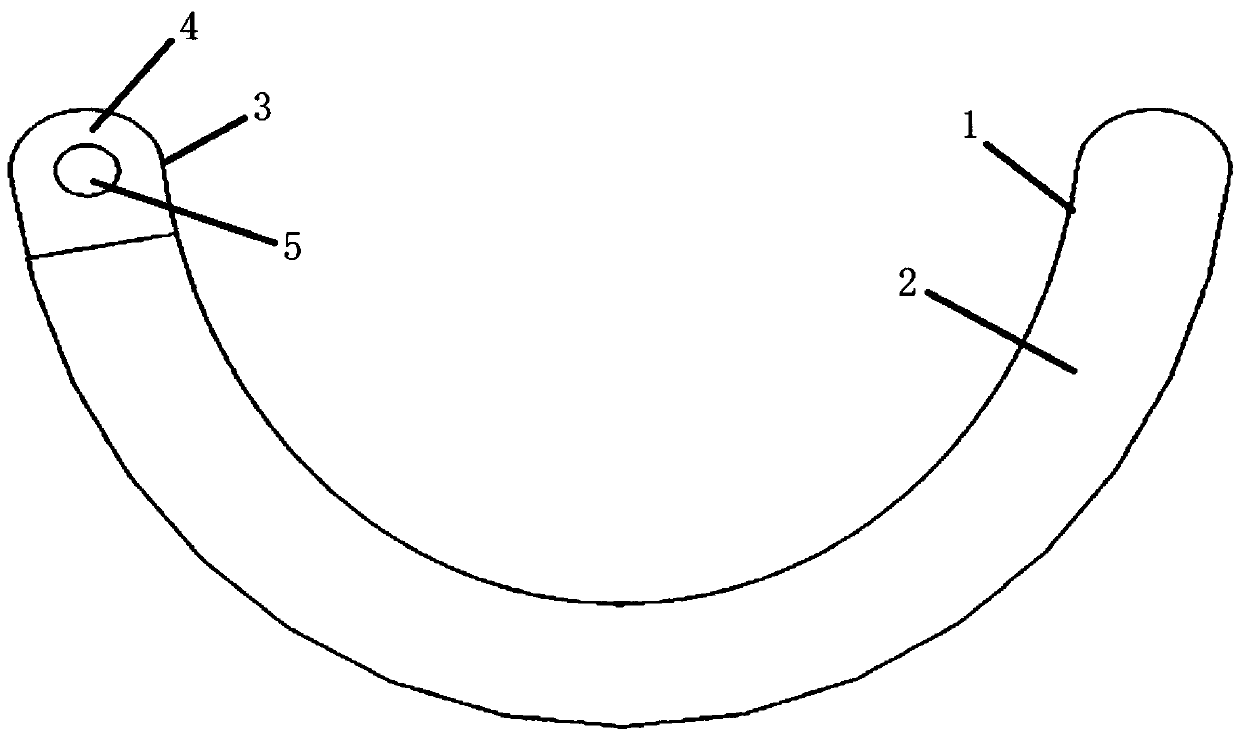

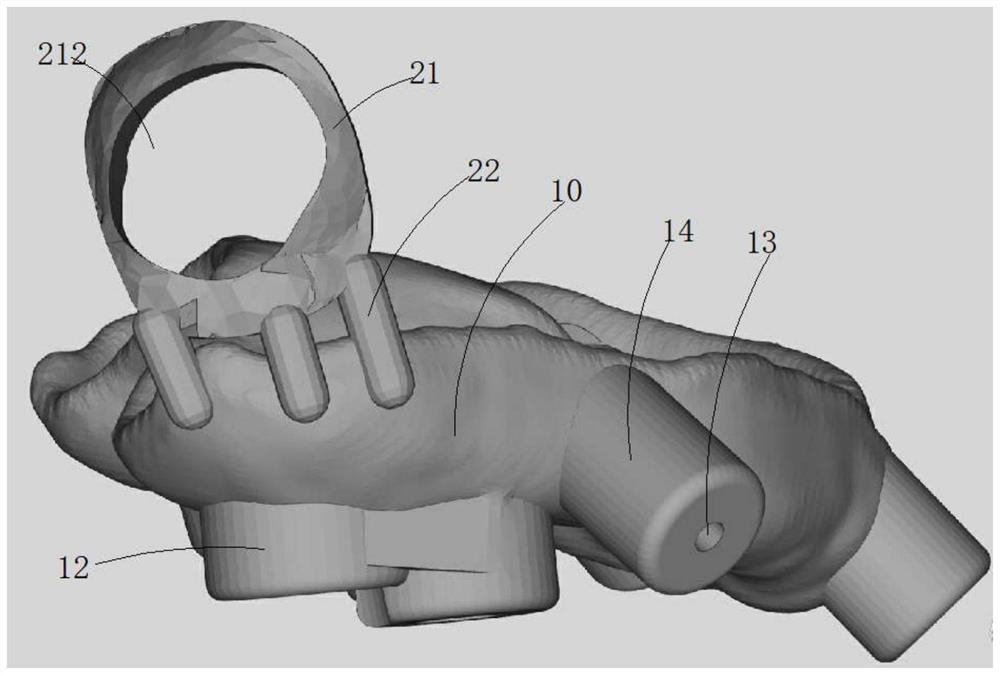

Titanium alloy embedded tooth individual traction accessory printed through three-dimensional technology

PendingCN109662787AGood compatibilityNot easy to fall offAdditive manufacturing apparatusOthrodonticsImpact toothImpacted tooth

The invention relates to the technical field of medical treatment, in particular to a titanium alloy embedded tooth individual traction accessory printed through a three-dimensional technology. According to the titanium alloy embedded tooth individual traction accessory printed through the three-dimensional technology, according to the best traction pulling path for an impacted tooth, an adhesionpart and the traction direction of the traction accessory are designed, and the best specific part of a main traction accessory body and the best position of a traction hook are determined. Based on atitanium alloy material, according to the best design scheme for the traction accessory device, the main traction accessory body and the traction hook which completely fit the corresponding tooth surface are printed, wherein the main traction accessory body and the traction hook are integrally formed. The main traction accessory body and the traction hook can completely fit the tooth surface, andafter adhesion, the main traction accessory body and the traction hook cannot easily fall; compared with traditional stainless steel, the titanium alloy material is significantly excellent, the phenomenon of the soft and sclerous tissue inflammatory reaction cannot easily occur; the integrated structure is firmer, and the phenomenon of fracturing cannot easily occur.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Manufacturing method of implant tooth guide plate and guide plate manufactured by adopting method

PendingCN114028010AAchieve removalReduce postoperative discomfortDental implantsAdditive manufacturing apparatusWound healingEmbedded teeth

The invention discloses a manufacturing method of an implant tooth guide plate and the guide plate manufactured by adopting the method. The manufacturing method comprises the following steps: S1, generating a digital guide plate with an implant tooth positioning hole in design software; S2, generating a positioning part for positioning the position of an embedded tooth on the digital guide plate through design software, and obtaining a guide plate model with an embedded tooth positioning function; and S3, conducting manufacturing according to the guide plate model with the embedded tooth positioning function obtained in the S2 to obtain the implant tooth guide plate. According to the manufacturing method of the dental implant guide plate provided by the invention, in the implant tooth operation process, the extraction of embedded teeth can be accurately realized, the size of a wound can be greatly reduced during the tooth extraction operation, the postoperative discomfort of a patient is relieved, the wound healing is accelerated, and the smooth implantation of an implant is ensured. In addition, by designing the guide plate, positioning of embedded teeth and positioning of implant teeth are achieved at the same time, the operation time is shortened, operation wounds are reduced, and the success rate of the operation is increased.

Owner:杭州数也医疗科技有限公司

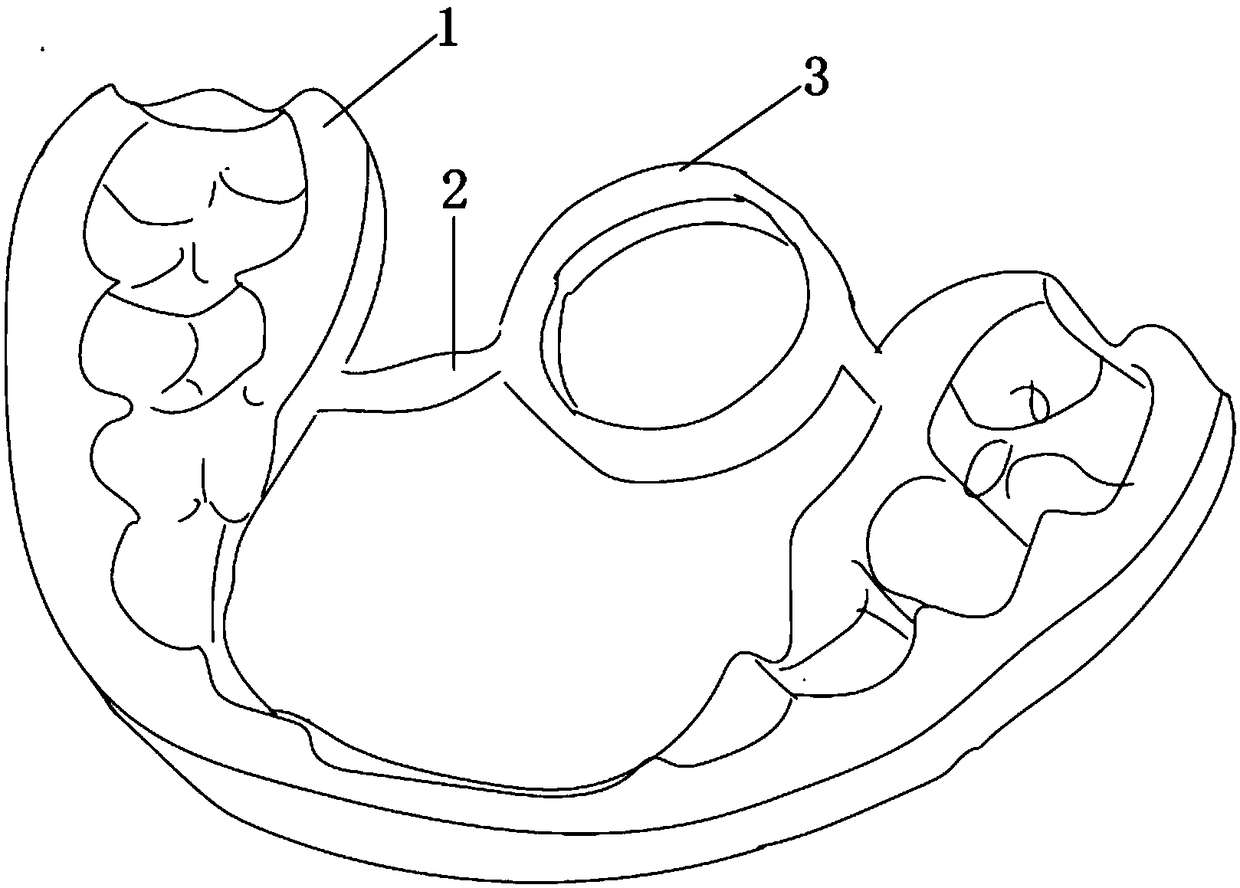

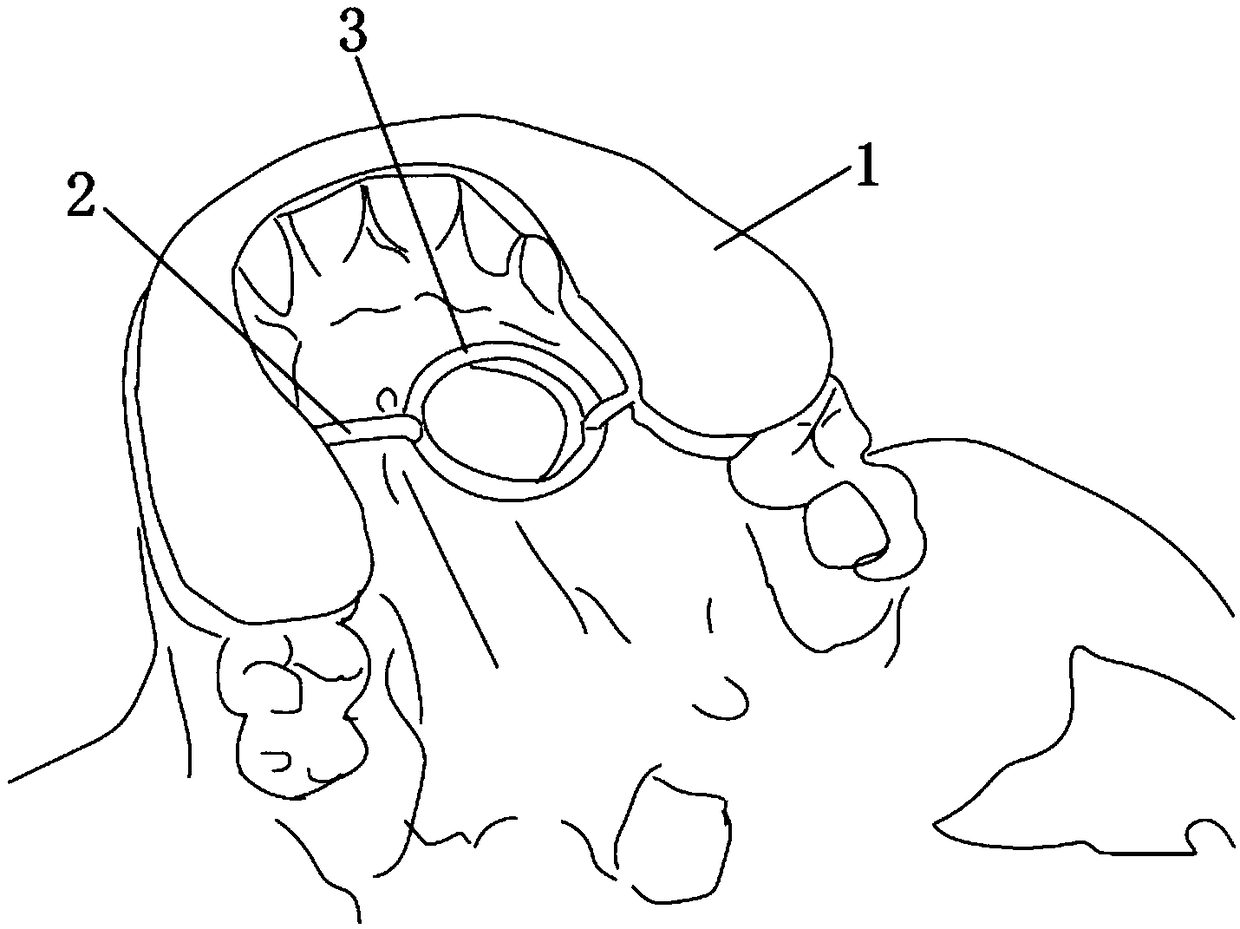

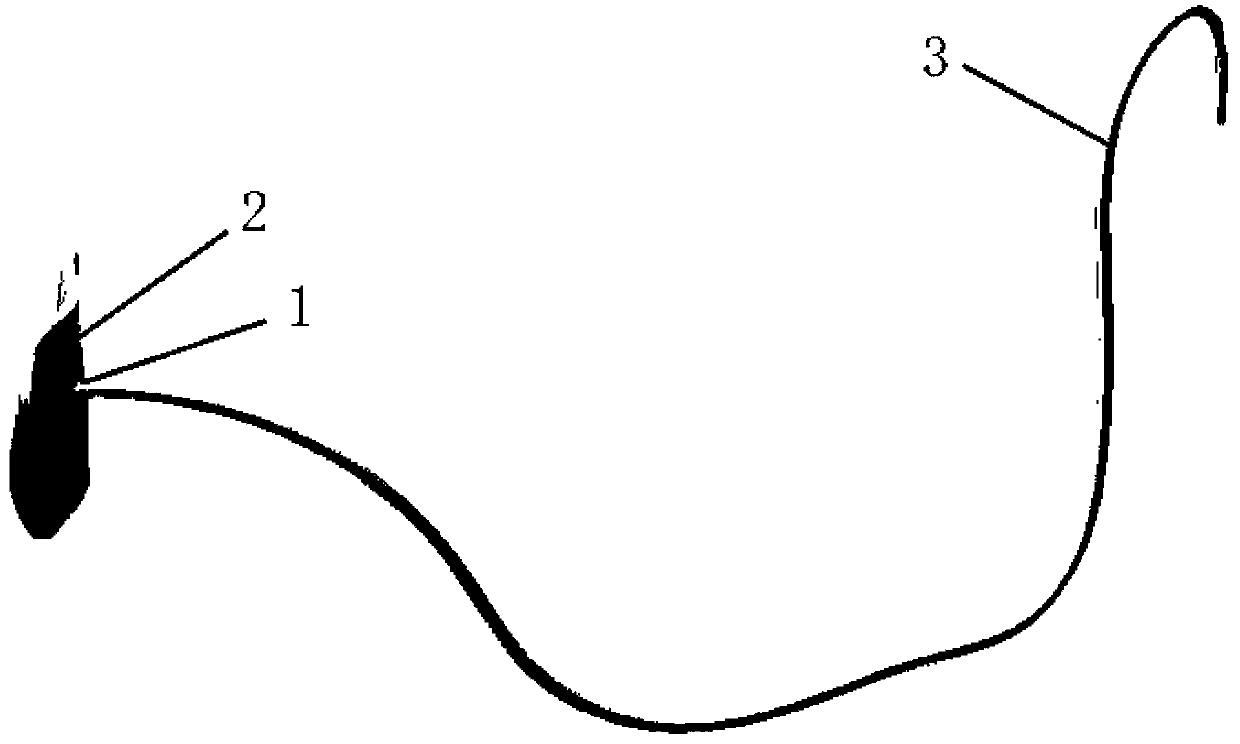

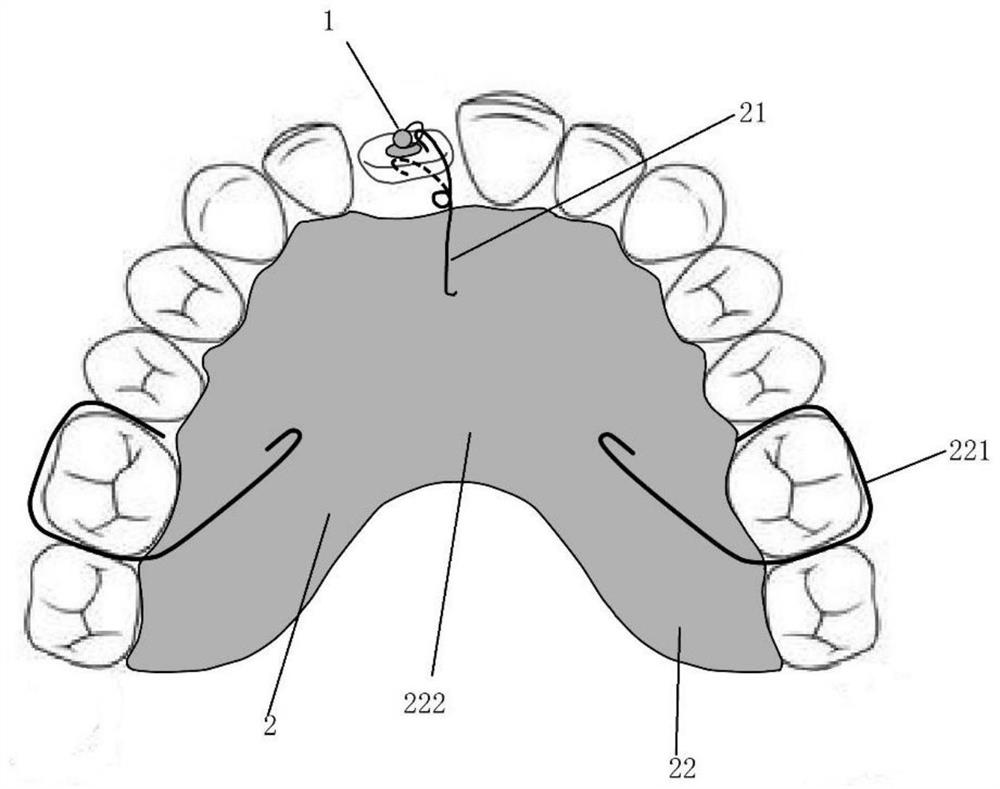

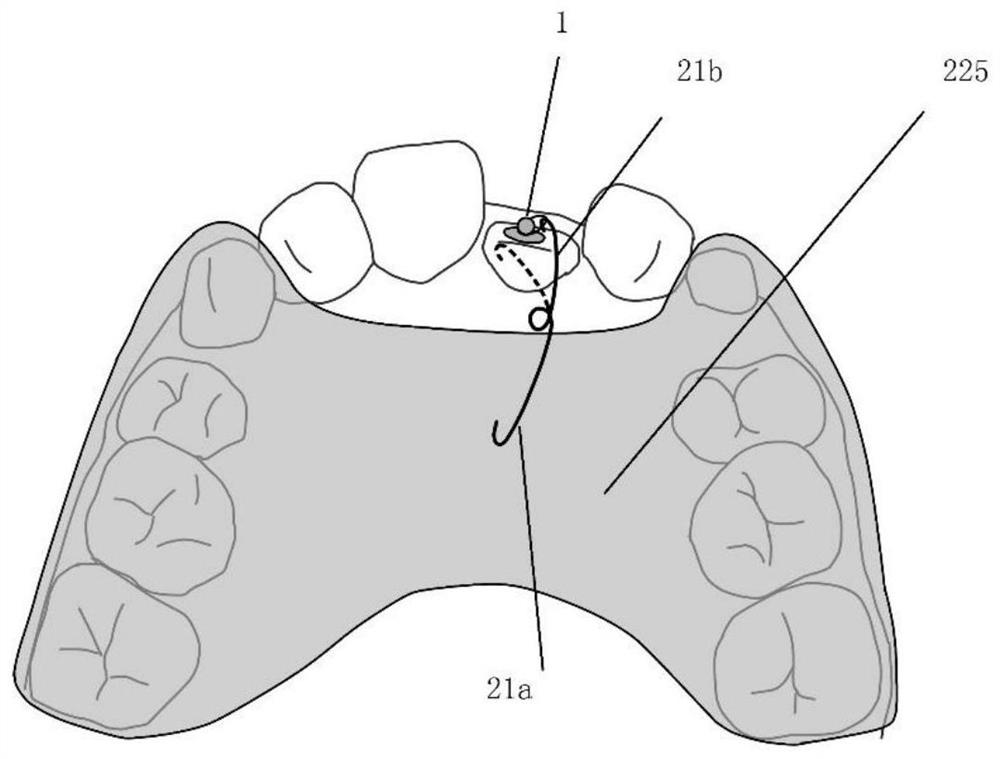

Embedded tooth traction device

The invention relates to the field of orthodontic tools, in particular to an embedded tooth traction device. The device is composed of a traction hook and an appliance, the traction hook is adhered to a dental crown of an embedded tooth needing traction, the traction hook is composed of an adhesion accessory and a ligature wire, one end of the ligature wire is tied to the adhesion accessory, and the other end of the ligature wire is free and bent into a hook. The appliance is composed of an elastic traction wire and a retention device, one end of the elastic traction wire is embedded in the retention device, and the other end of the elastic traction wire is bent and connected with the free bent end of the ligature wire on the traction hook. According to the device, the traction direction of the embedded teeth can be reasonably adjusted in a three-dimensional space, meanwhile, the embedded teeth in different dentition periods can be corrected, the requirement for anchorage teeth is low, and the device is easy to manufacture, low in price and remarkable in effect.

Owner:FIRST PEOPLES HOSPITAL OF YUNNAN PROVINCE

Sling structure used for hanging drainage, collecting and metering container

A sling structure used for hanging a drainage, collecting and metering container belongs to the field of medical equipment. The drainage, collecting and metering container comprises a container body, and the top of the container body forms a sling buckle. The sling structure comprises a sling body, a buckle head is formed at one end of the sling body, a sling body groove is formed in the middle of one side of the buckle head, a pair of first embedded teeth is arranged on one side of the sling body groove, a first teeth cavity is formed between the first embedded teeth, a pair of second embedded teeth is arranged on the other side of the sling body groove, a second teeth cavity is formed between the second embedded teeth, a sling pin is arranged at the other end of the sling body and matched with a sling pin hole on the sling body, a first toothed embedded sheet is arranged at the edge in the middle of the sling body, a second toothed embedded sheet is arranged on the other side, the first toothed embedded sheet is matched with the first teeth cavity, and the second toothed embedded sheet is matched with the second teeth cavity. The sling structure has the advantages that the container body is always kept in the initial state, the inclination is avoided, and the metering accuracy is ensured.

Owner:CHANGSHU 3S MEDICAL DEVICE

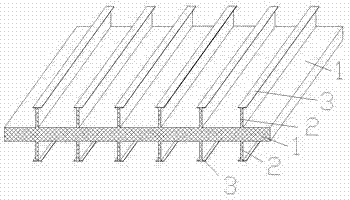

Geomembrane with anchoring nails

InactiveCN102926354AMeet anti-seepage requirementsProject quality is stableCoastlines protectionProtective foundationSoil scienceGeomembrane

The invention discloses a geomembrane with anchoring nails, belonging to the geomembrane for engineering. An anchoring nail layer is arranged on the geomembrane with the anchoring nails, an abreast structure of a plurality of longitudinal anchoring nails is adopted by the anchoring nail layer, an integrated structure is adopted by the root of the longitudinal anchoring nails and a membranous layer, horizontal wings are arranged at the end parts of the longitudinal anchoring nails, and the anchoring nail layer is arranged at the single side or double sides of the membranous layer. Due to the surface of the geomembrane with spiny embedded teeth, a membrane body can be fixed on a basic plane and a protective layer by the geomembrane, so that the geomembrane is specially use for the slip resistance of slope and elevation, and meets the impermeable requirements, and therefore, the geomembrane ensures the stability of the engineering quality.

Owner:大连恒大高新材料开发有限公司

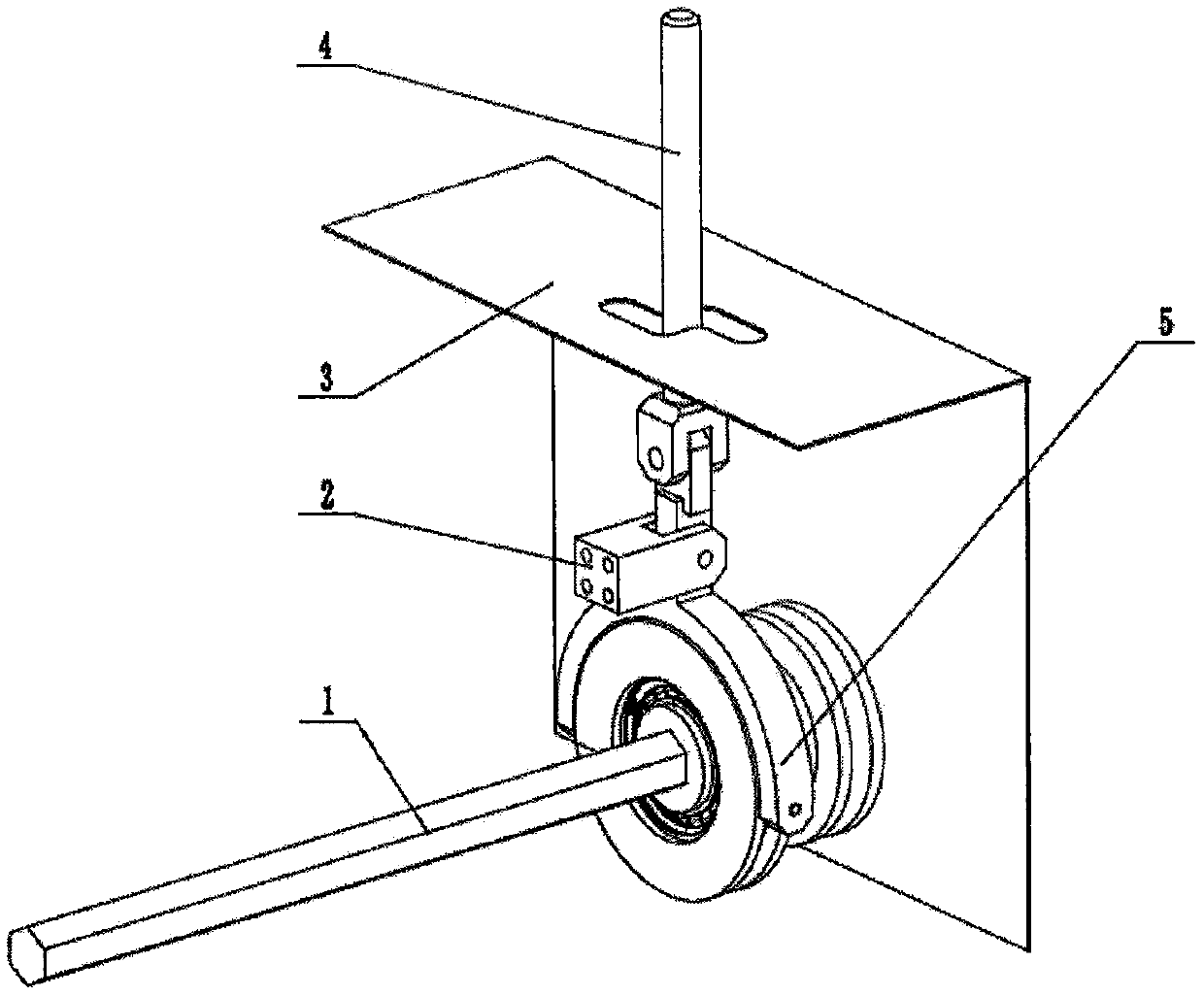

Mechanical clutch device

The invention provides a mechanical clutch device. The mechanical clutch device comprises a rotating shaft, a support, a track plate, a control handle, a shifting fork, a circular ring, a tooth embedding sliding sleeve, a tooth embedding cover, a chain wheel, a bearing pressing plate, a bearing A and a bearing B; the clutch device is applied to a whole machine system, the support, the track plate,the rotating shaft and the chain wheel are mounted on other parts of the whole machine system, and the rotating shaft and the chain wheel are in transmission connection with the whole machine system;when the control handle is manually pulled to move along an axial groove of the track plate, the shifting fork, the circular ring and the tooth embedding sliding sleeve are driven to axially move onthe rotating shaft, the tooth embedding sliding sleeve and the tooth embedding cover are connected in an embedded manner or separated, and power transmission between the chain wheel and the rotating shaft is executed or cut off; when the control handle is pulled to be in a vertical groove at two ends, embedding teeth are completely engaged or separated, and the clutch device is kept in a separation state or a reunion state; and when the control handle rod is pulled to move along the vertical groove to the tail end, the state of the embedding teeth is unchanged, the position of the handle rod is fixed, and the clutch device is reliably separated and engaged, until the state is changed by the next manual operation.

Owner:盐城永弘机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com