Single-layer overall wire embedding method for motor stator windings and motor stator

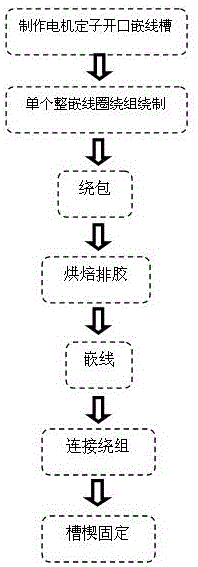

A motor stator and overall technology, applied in the direction of electric components, manufacturing motor generators, prefabricated windings embedded in motors, etc., can solve problems such as low slot fullness, interference, long end of winding structure, etc., to improve slot fullness , reasonable structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

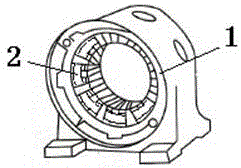

[0036] as attached figure 1 and 2 As shown, a motor stator, which is an annular outer stator, includes a stator core 1 and a winding 2. It is characterized in that the wire slot 3 of the stator core is an open slot, and the wire teeth 4 are equal-width teeth ; The winding 2 is an integrally formed winding; each integrally formed winding is integrally sleeved on the embedded wire teeth of a stator core, and the integrally formed winding is a single-layer structure in the embedded wire groove of the stator core, On the top of the equal-width teeth of the stator core, there is a slot wedge installation slot 6 at the side port of the embedding slot. The slot wedge 7 is inserted in the slot wedge installation slot 6, and the annular integrally formed winding is prevented from falling by the slot wedge 7. The integrally embedded winding is made of self-adhesive enameled wire, which is initially wound into a winding through a mold, and then the winding is shaped and fixed by a mold ...

Embodiment 2

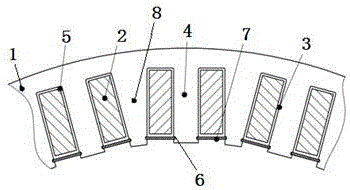

[0048] The basic principle of embodiment two is the same as embodiment one, but the structure is different (as attached image 3 shown); a motor stator, which is an annular inner stator structure, including a stator core 201 and a stator winding 202, and a motor stator opening slot 203 with an equal-width tooth structure on the stator core 201; the motor stator opening is inlaid The wire groove is a trapezoidal opening wire groove with a narrow slot width and a narrow bottom, and the stator wire teeth 204 formed on the motor stator are equal-width teeth through the motor stator opening wire groove; 202 is an integrally formed winding, which is sleeved on the equal-width teeth of the stator core, so that the integrally formed winding is just embedded in the opening embedding groove of the motor stator.

[0049] The integrally formed windings 202 are wound into a centralized structure with a pitch of 1 through a mold. Each set of integrally formed windings is placed on the equal...

Embodiment 3

[0062] The basic principle of the third embodiment is the same as that of the first embodiment. It is a motor stator, which is an annular outer stator structure, including a stator core and a stator winding. There is a motor stator with an equal-width tooth structure on the stator core; The stator opening slot of the motor described above is a rectangular opening slot having the same width as the bottom of the lower slot, and the stator slot teeth formed on the motor stator are equal-width teeth through the opening slot of the motor stator. ; The stator winding is an integrally formed winding, and the integrally formed winding is set on the equal-width teeth of the stator core, so that the integrally formed winding is just embedded in the opening embedding slot of the motor stator.

[0063] The integrally formed windings are wound into a centralized structure with a pitch of 1 through a mold. Each set of integrally formed windings is placed on the equal-width teeth of a stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com