Patents

Literature

36results about How to "Save axial construction space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

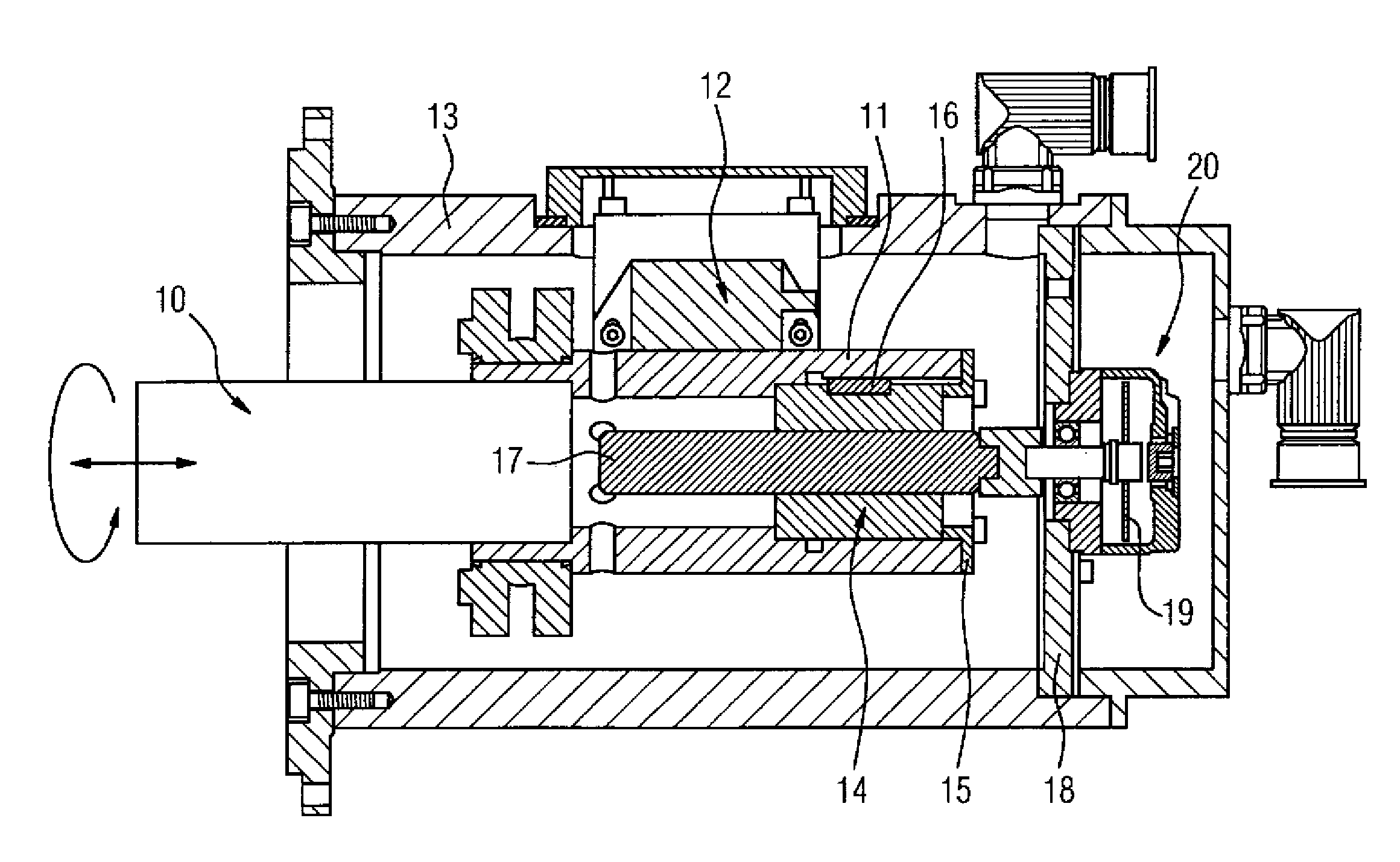

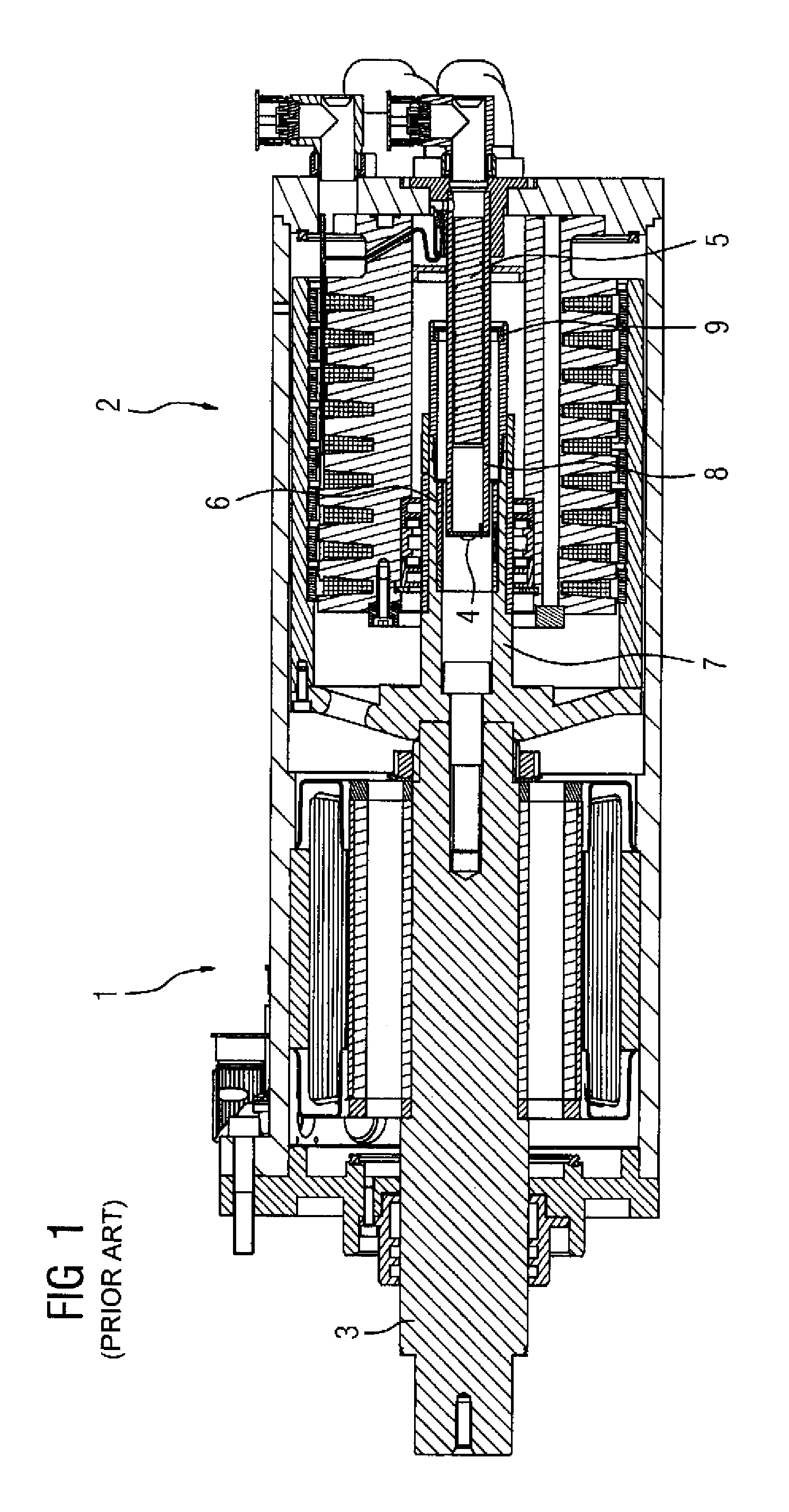

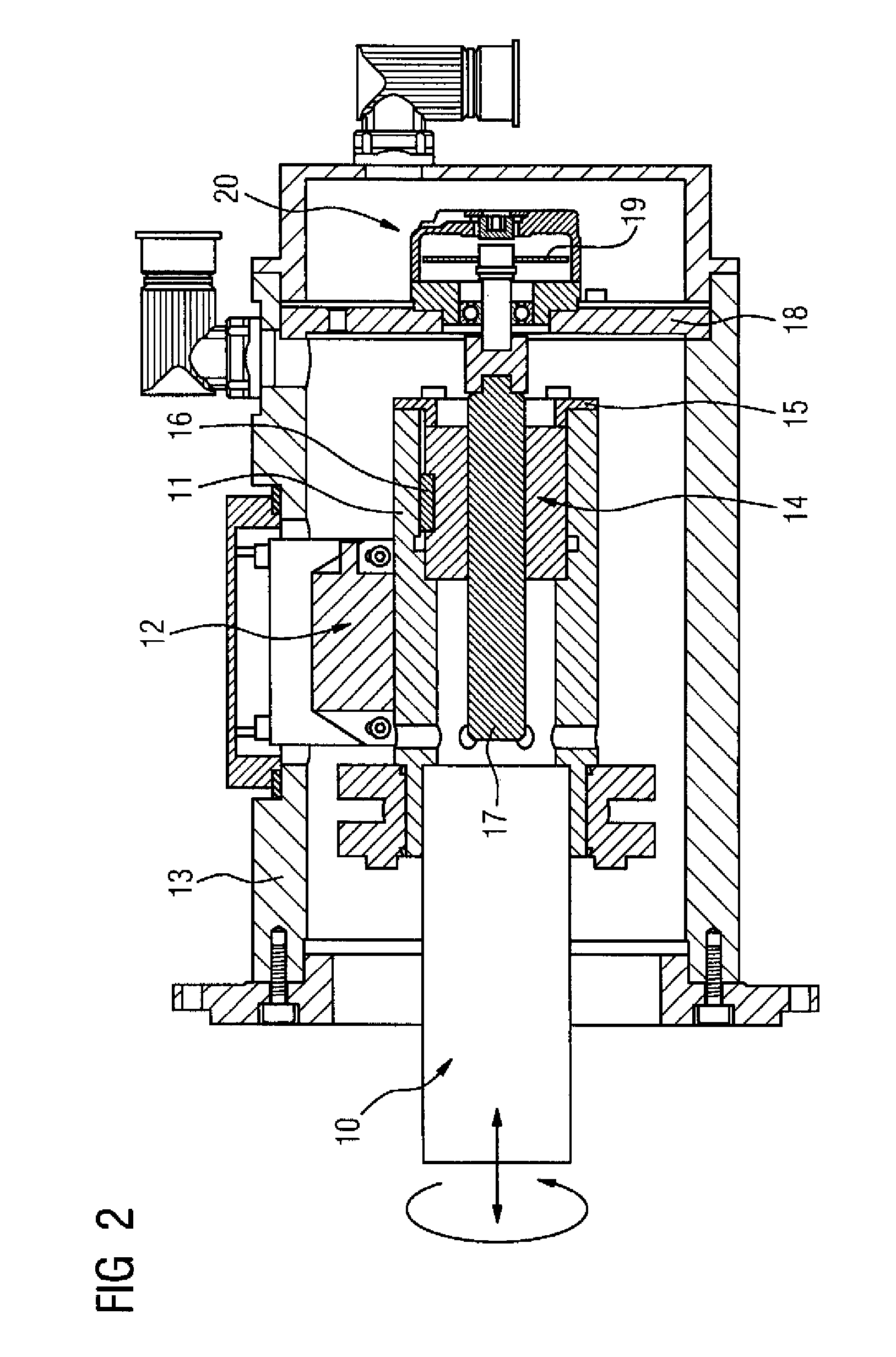

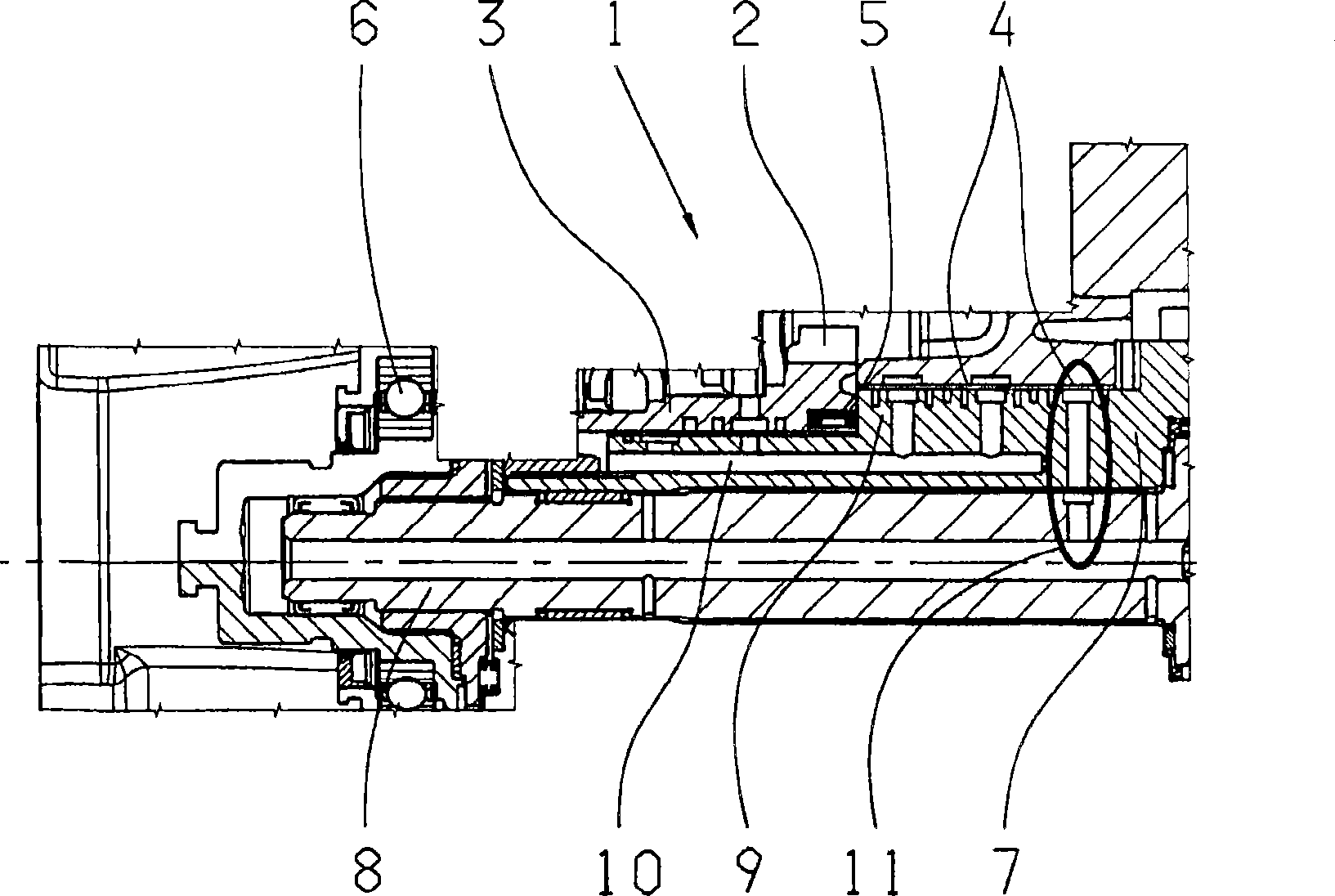

Measuring system for detecting a rotary-linear displacement and corresponding rotary-linear drive

InactiveUS8035371B2Save axial construction spaceSave radial construction spaceUsing electrical meansConverting sensor output electrically/magneticallyRotation sensorLinear displacement

The invention relates to more accurate rotative and linear positional measurement for a rotary-linear drive. A measuring system comprising a linear sensor (12) and a rotary sensor (20) is disclosed. A decoupling unit (11,14,17) decouples the rotary displacement from the linear displacement of a shaft (10). The decoupling unit (11,14,17) has either a first measuring section (11), which is coupled in a fixed manner to the shaft to be measured (10) and tapped by the linear sensor (12) and a second measuring section (17), which is exclusively non-rotatably coupled to the shaft to be measured (10) and is tapped by the rotary sensor (20), or a first measuring section, which is coupled in a fixed manner exclusively linearly to the shaft to be measured and is tapped by the linear sensor and a second measuring section, which is non-rotatably coupled to the shaft to be measured and is tapped by the rotary sensor. In each case, the linear displacement is decoupled from the rotary displacement for the measuring process, permitting high-resolution standard measuring sensors to be used.

Owner:SIEMENS AG

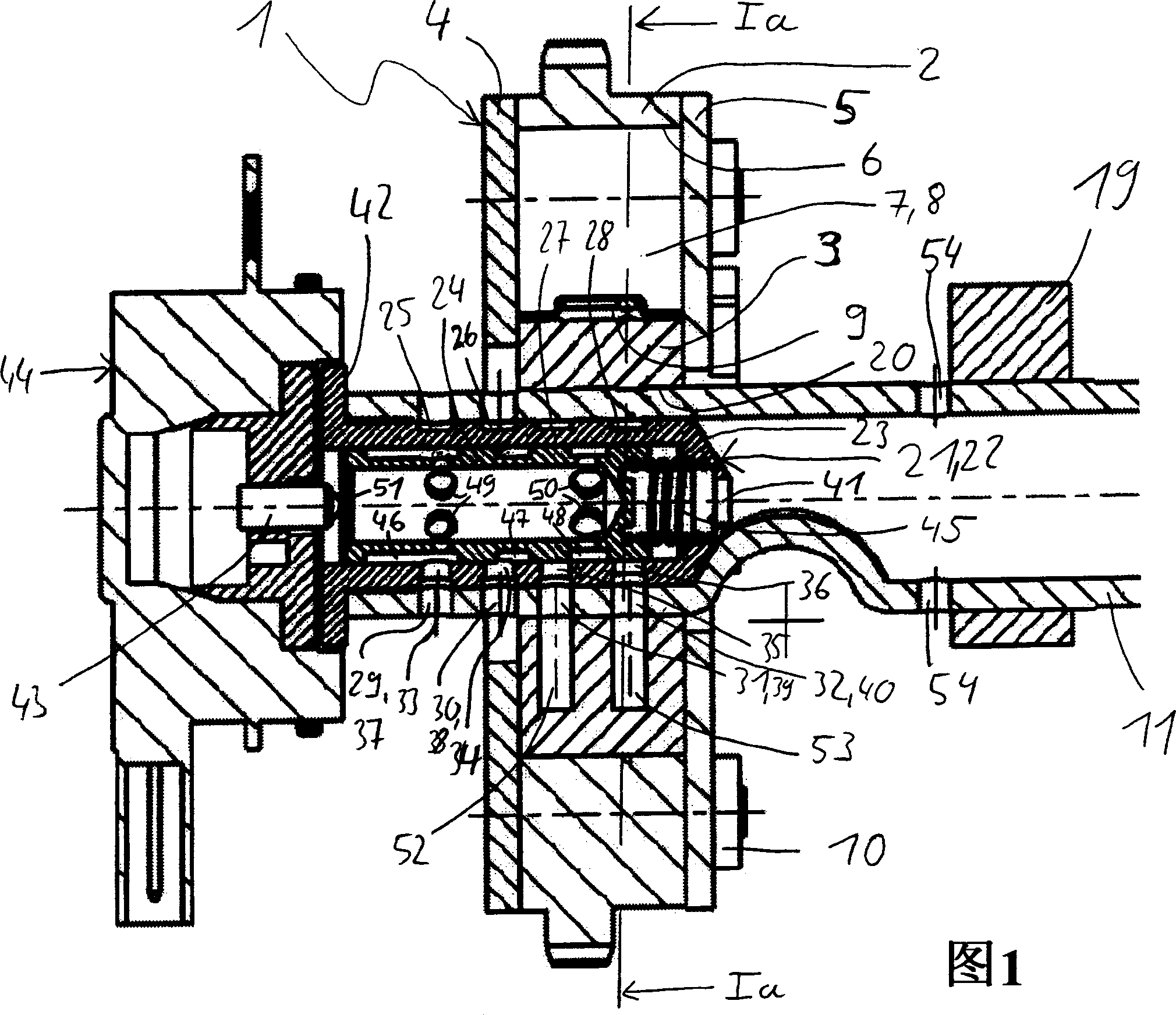

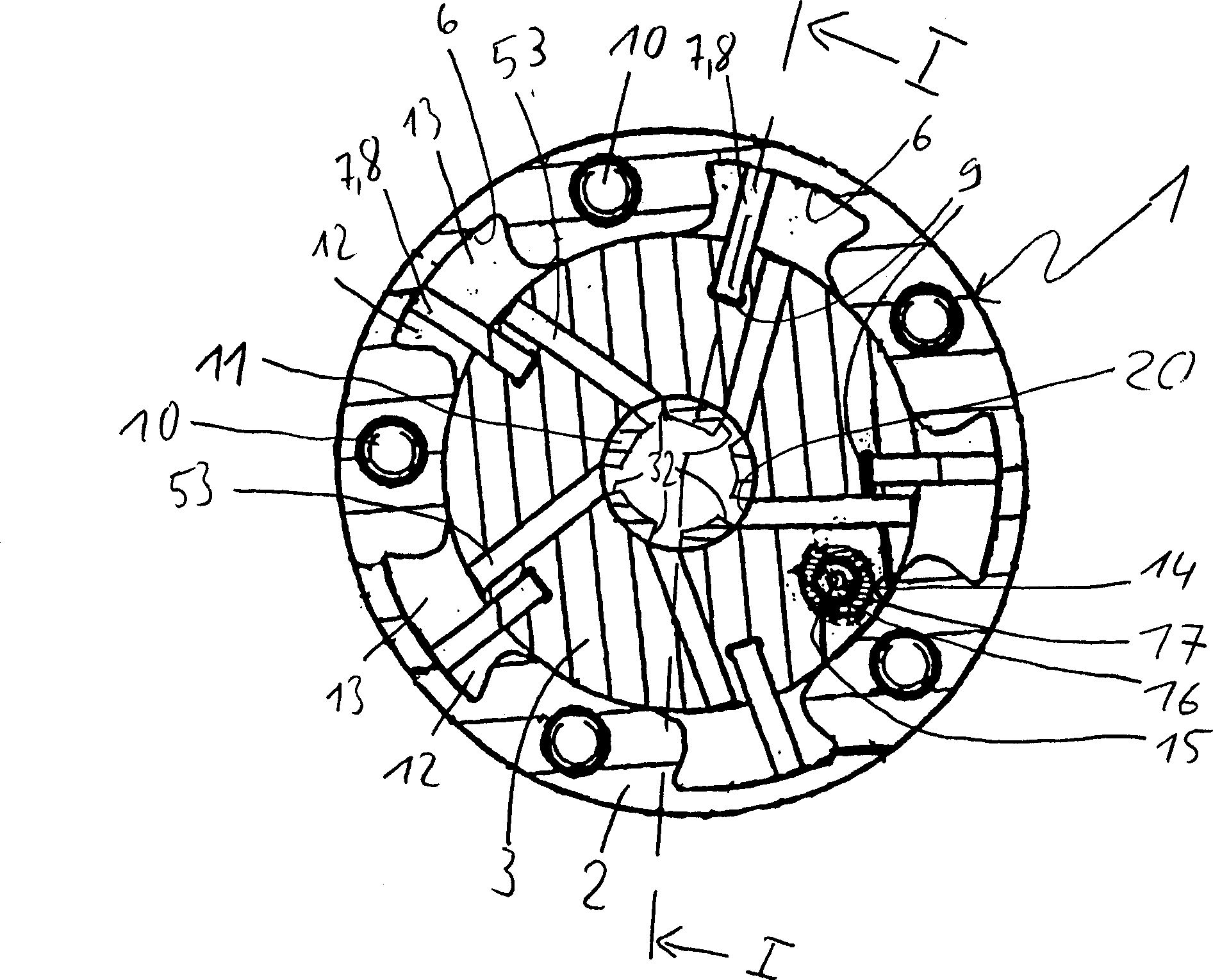

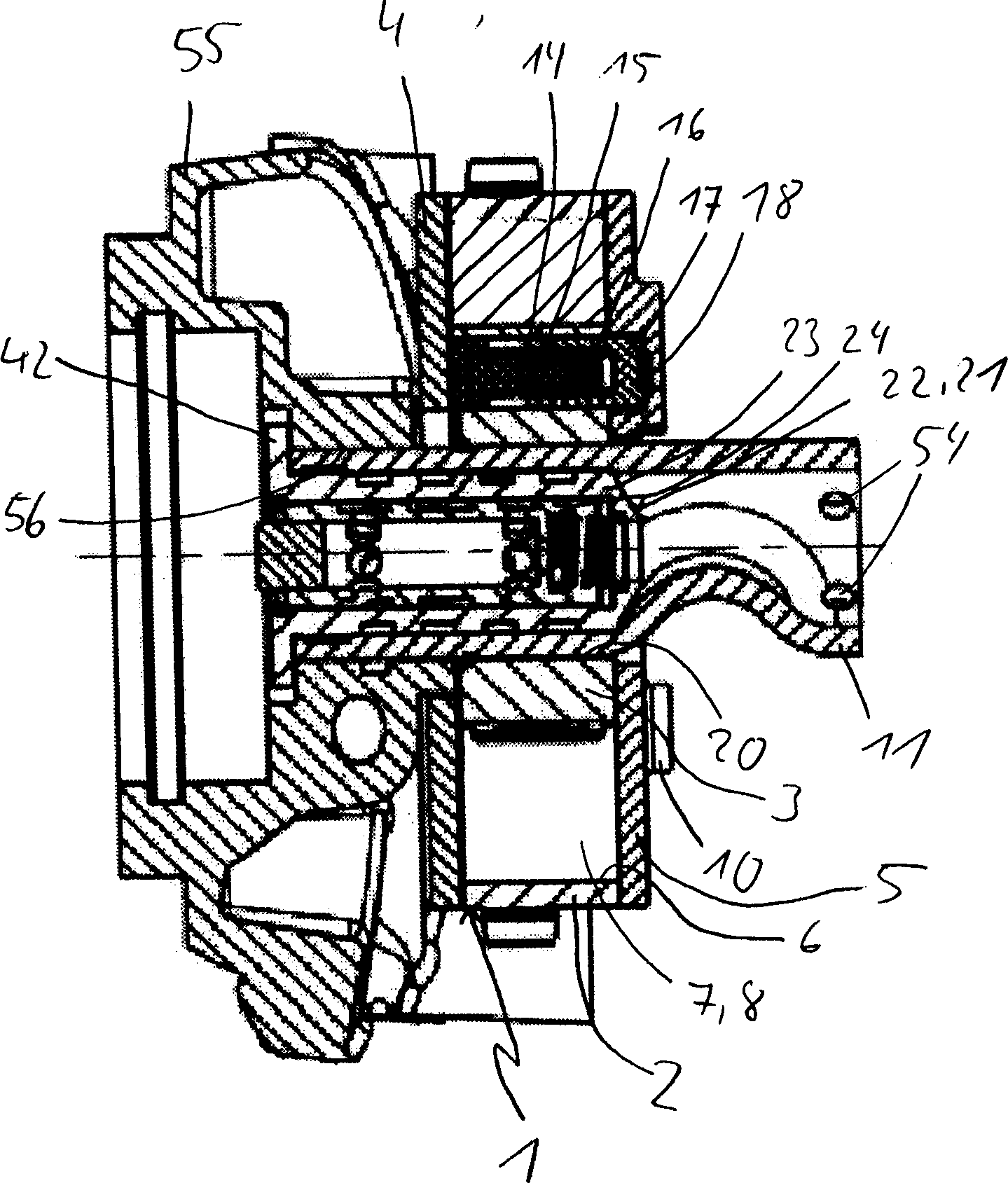

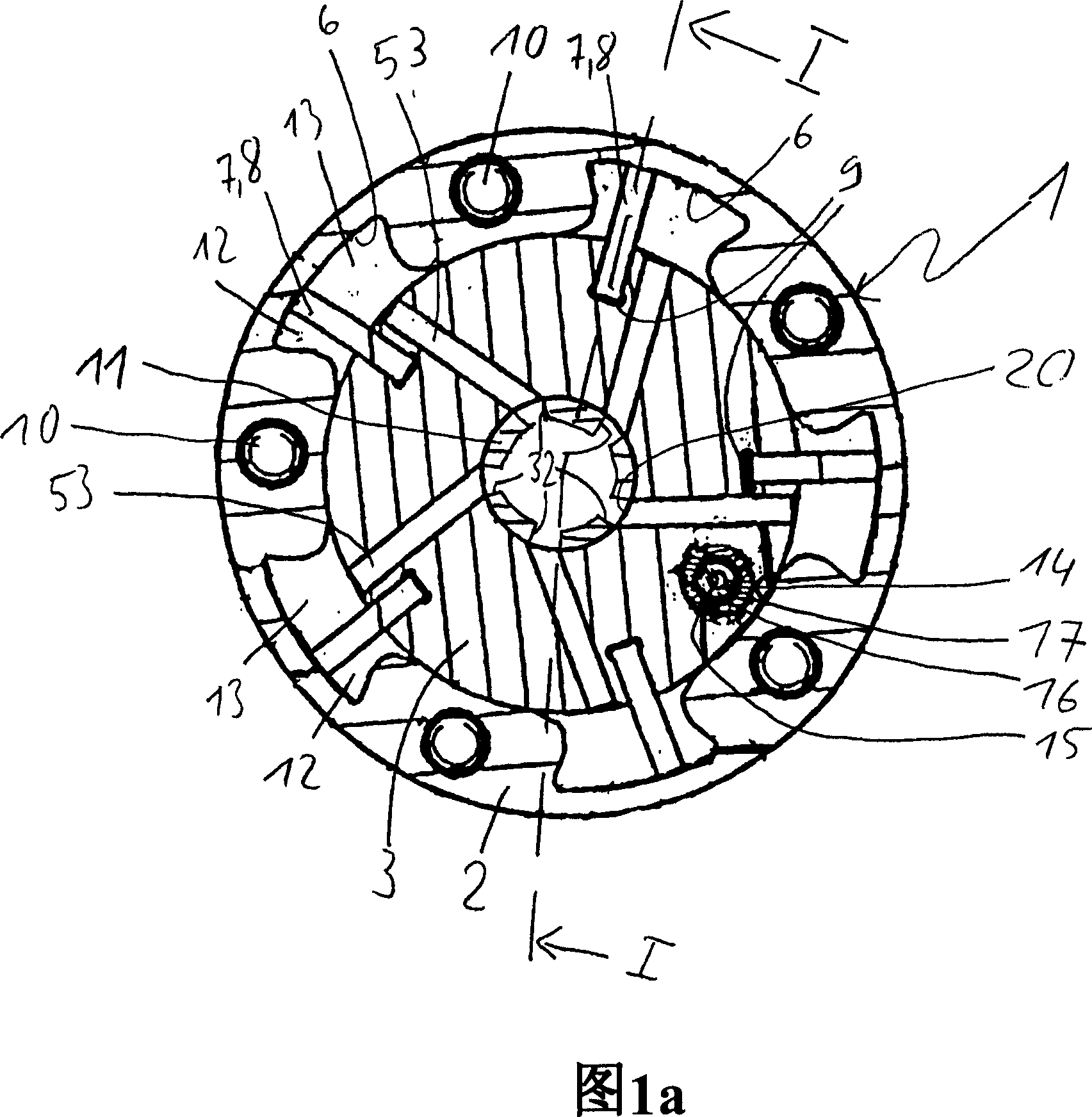

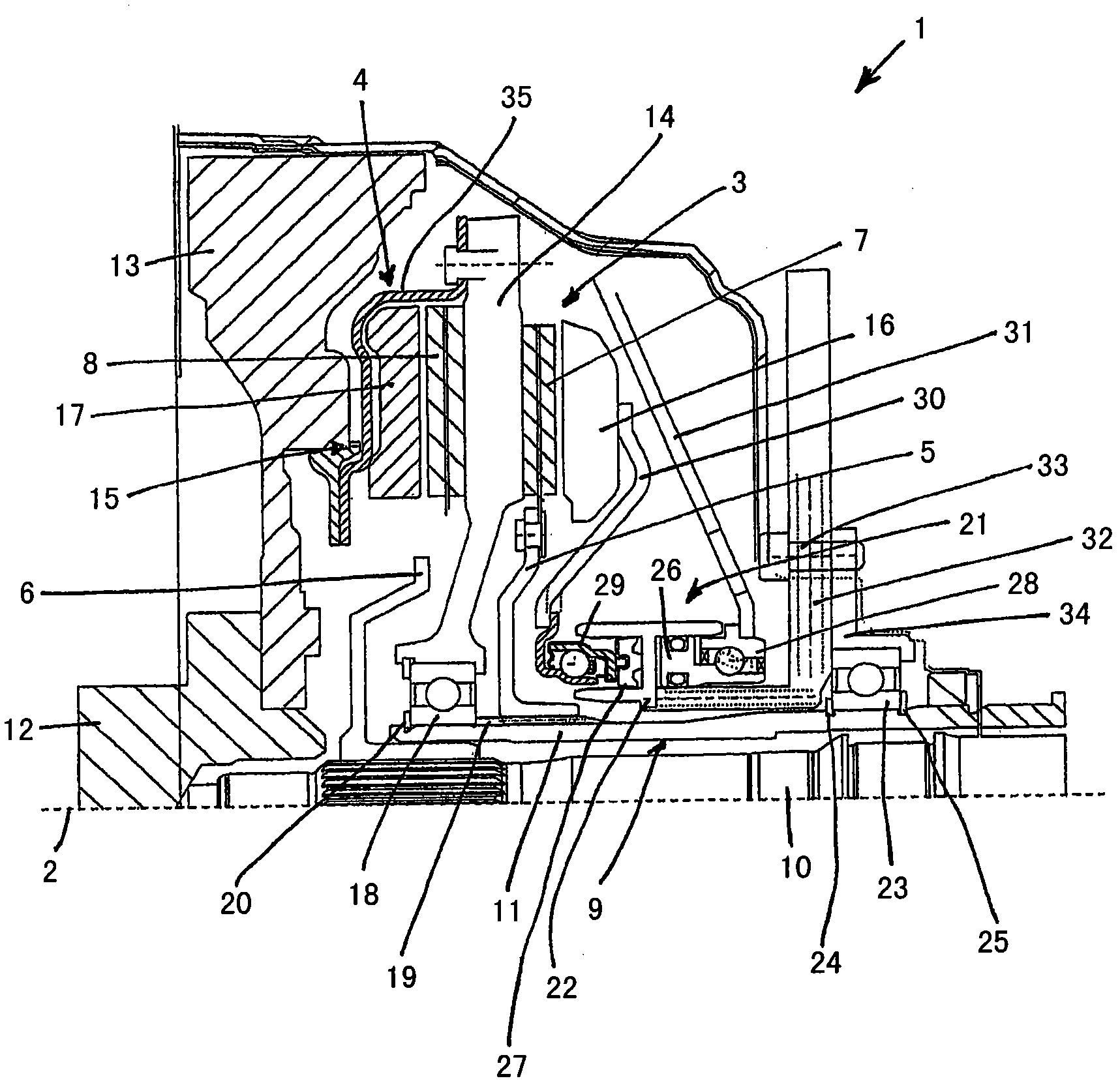

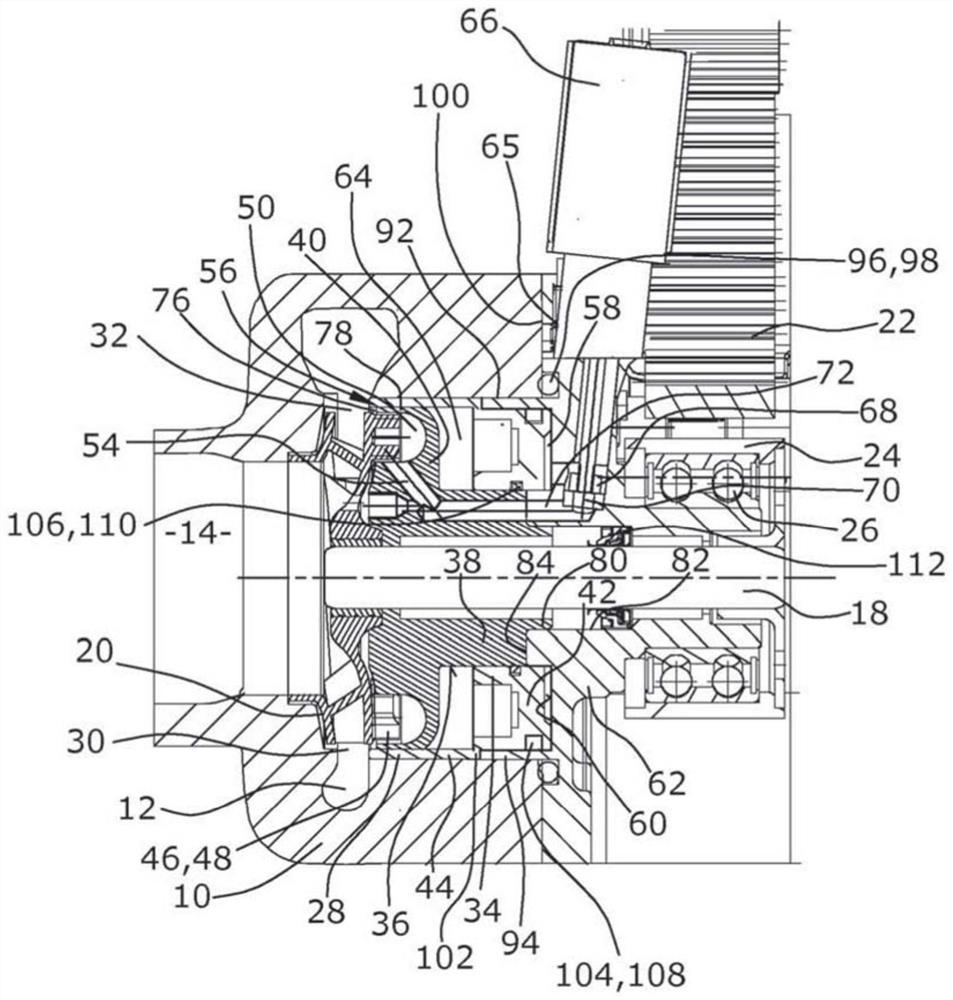

Double clutch

InactiveCN102187107APrevent drag torqueSave materialRolling contact bearingsMechanical actuated clutchesPower flowEngineering

The invention relates to a double clutch comprising two friction clutches, a central back pressure plate and a pressure plate pressurized by a hydrostatic engagement system. In order to be able to propose a cost-effective design having no clutch cover, two axially fixed shaft bearings are provided on the hollow shaft of the double-clutch transmission, said bearings rotatably receiving the back pressure plate and the engagement system such that the power flow can be closed by way of the hollow shaft when actuating the friction clutches.

Owner:SCHAEFFLER TECH AG & CO KG +1

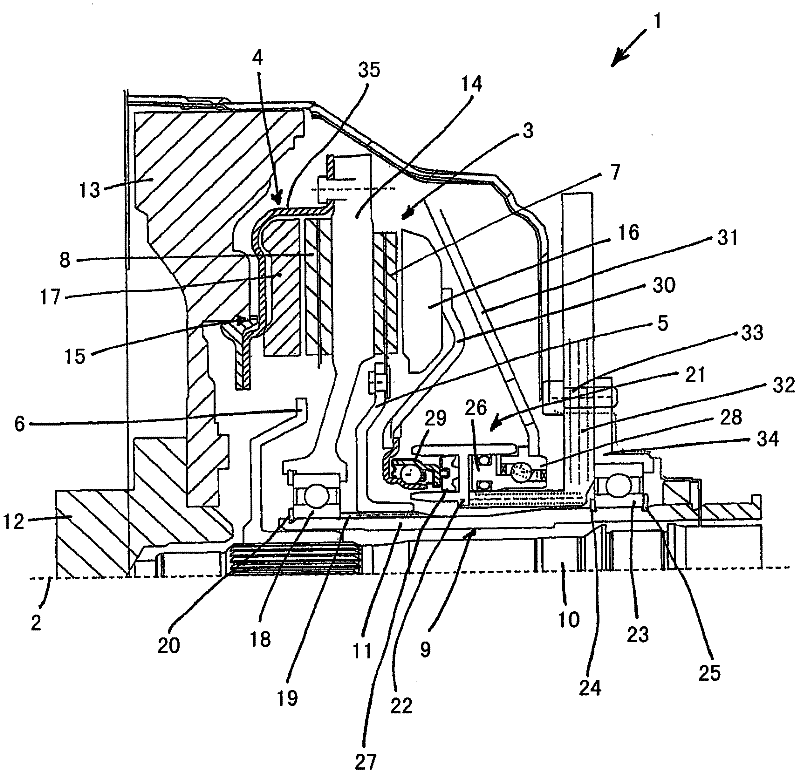

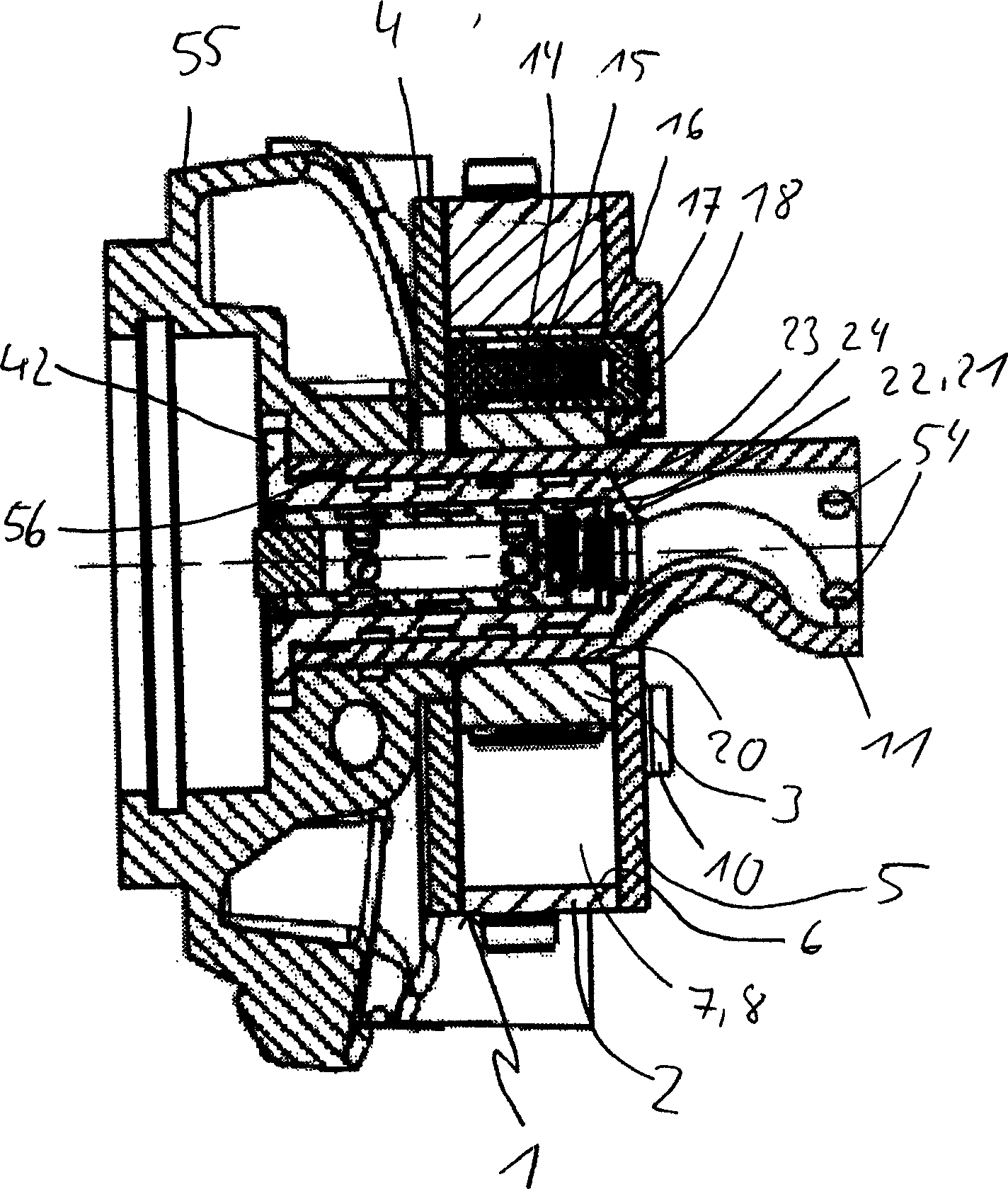

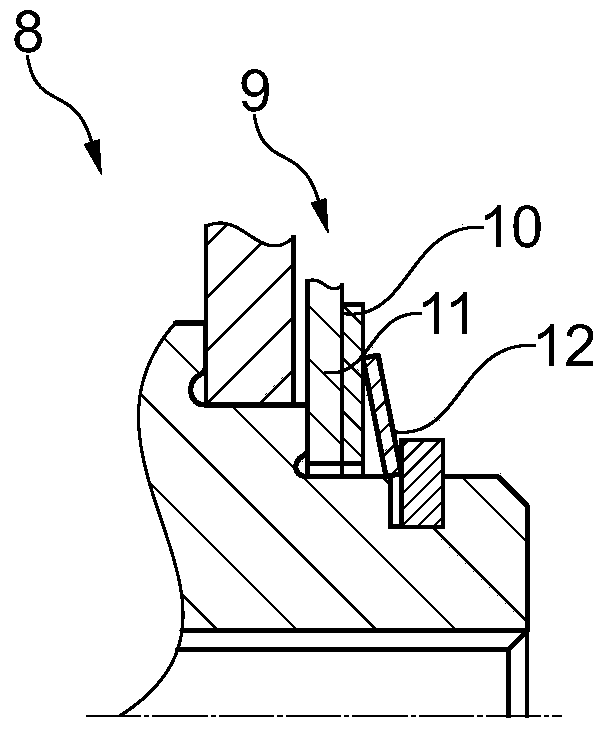

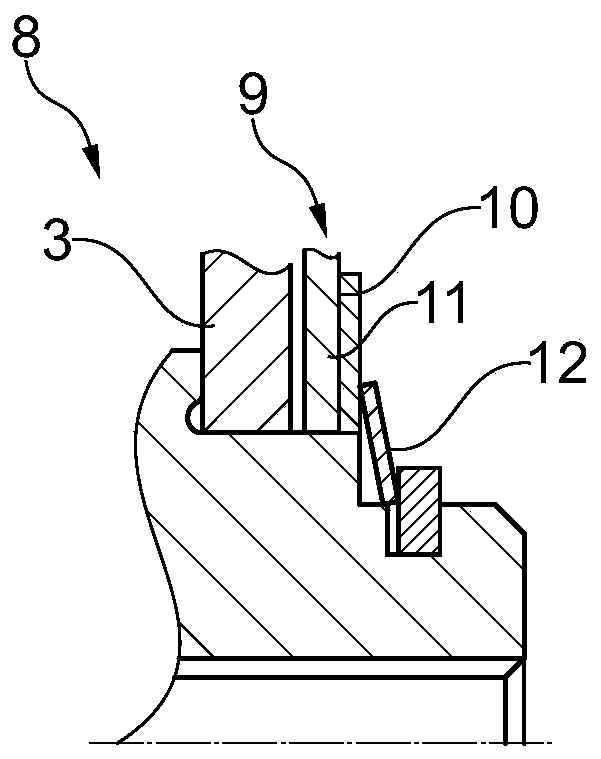

Camshaft regulator

ActiveCN1696475ALower unit costLower assembly costsValve drivesMachines/enginesEngineeringExternal combustion engine

A device for changing the control times of an internal combustion engine (camshaft adjuster ( 1 )) having a pressure medium distributor ( 21 ) arranged within a camshaft ( 11 ) is provided. The pressure medium distributor ( 21 ) is provided at its front end with a radially extending shoulder ( 42 ), this shoulder ( 42 ) forming part of the camshaft axial mounting.

Owner:SCHAEFFLER TECH AG & CO KG

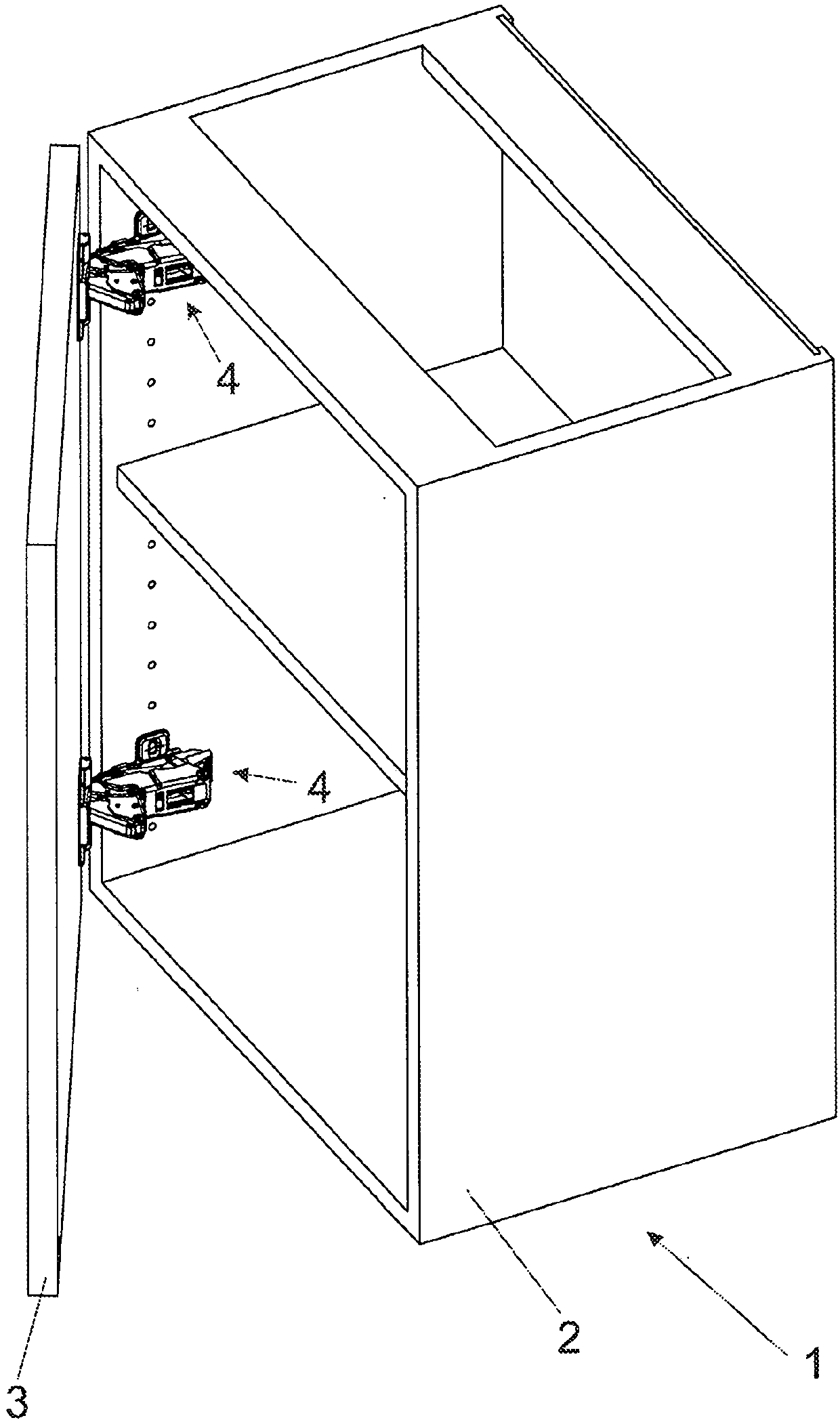

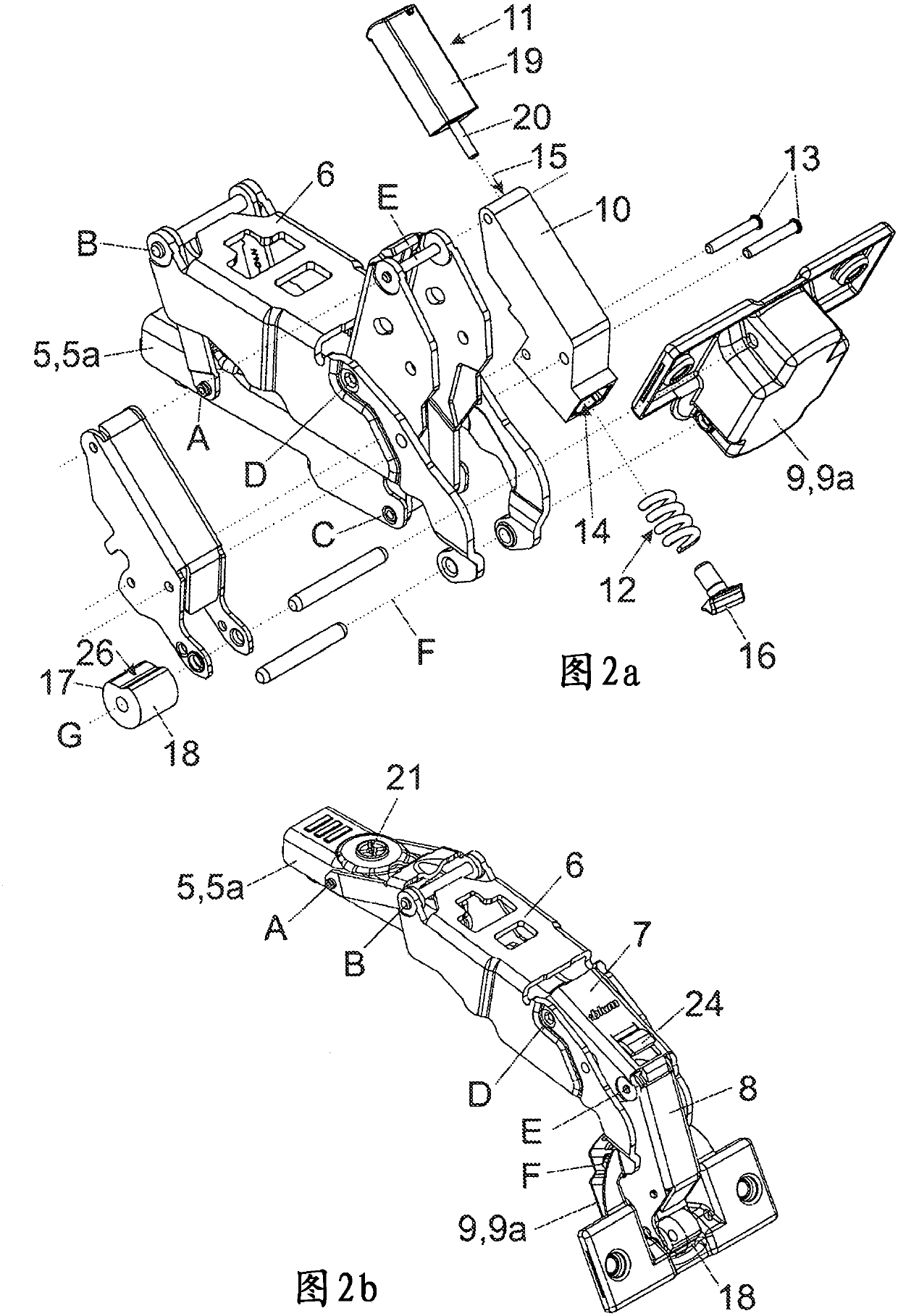

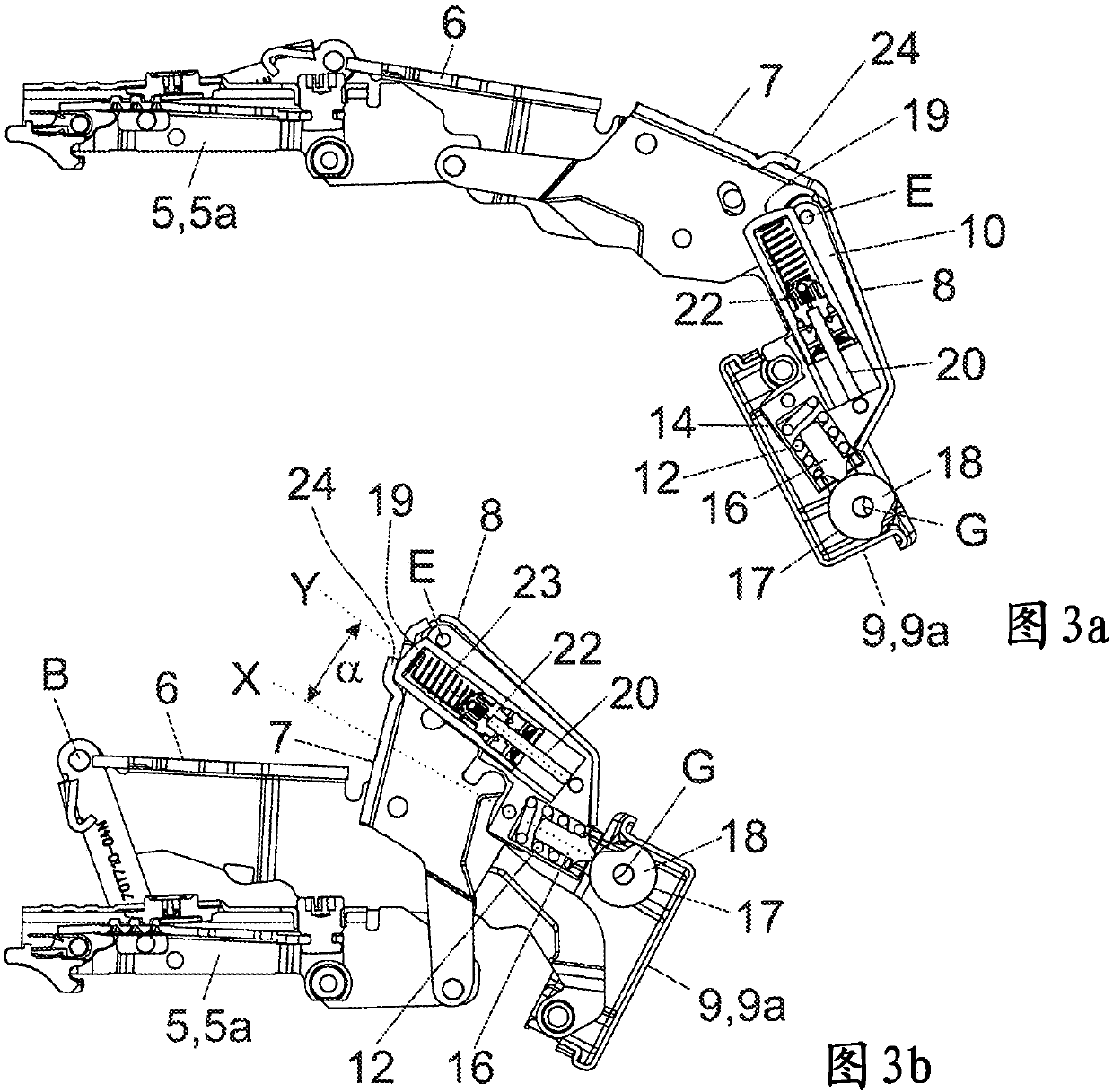

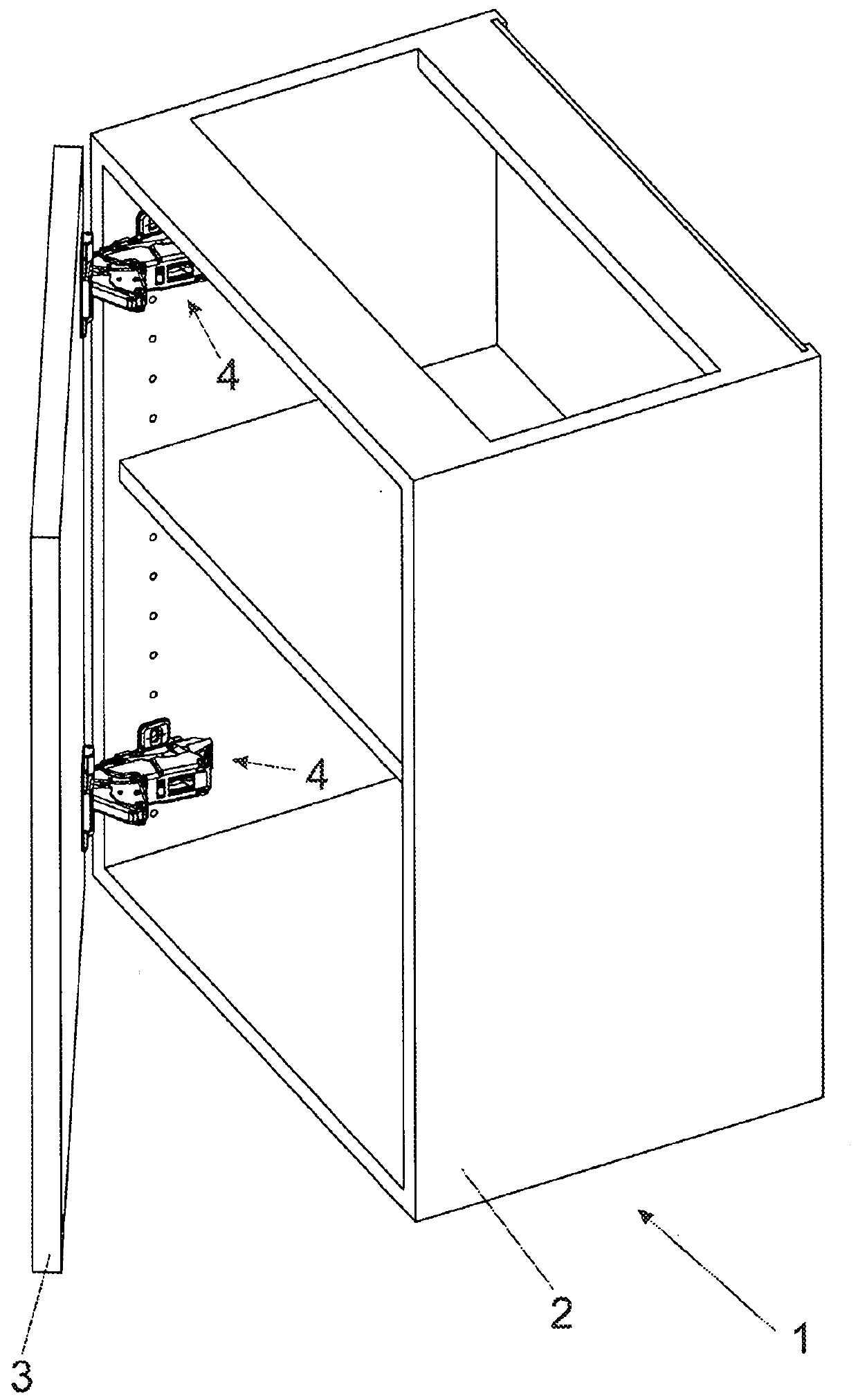

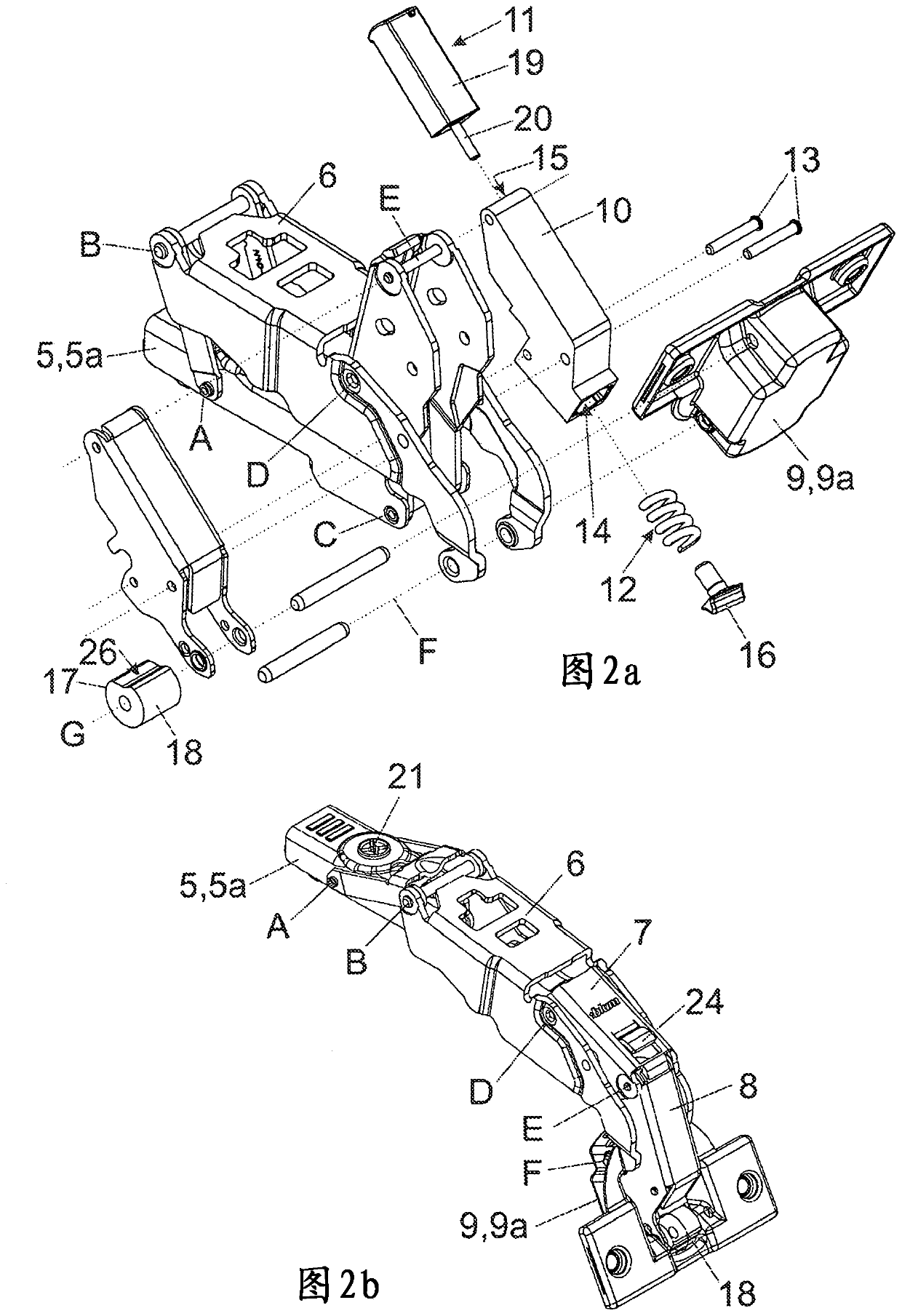

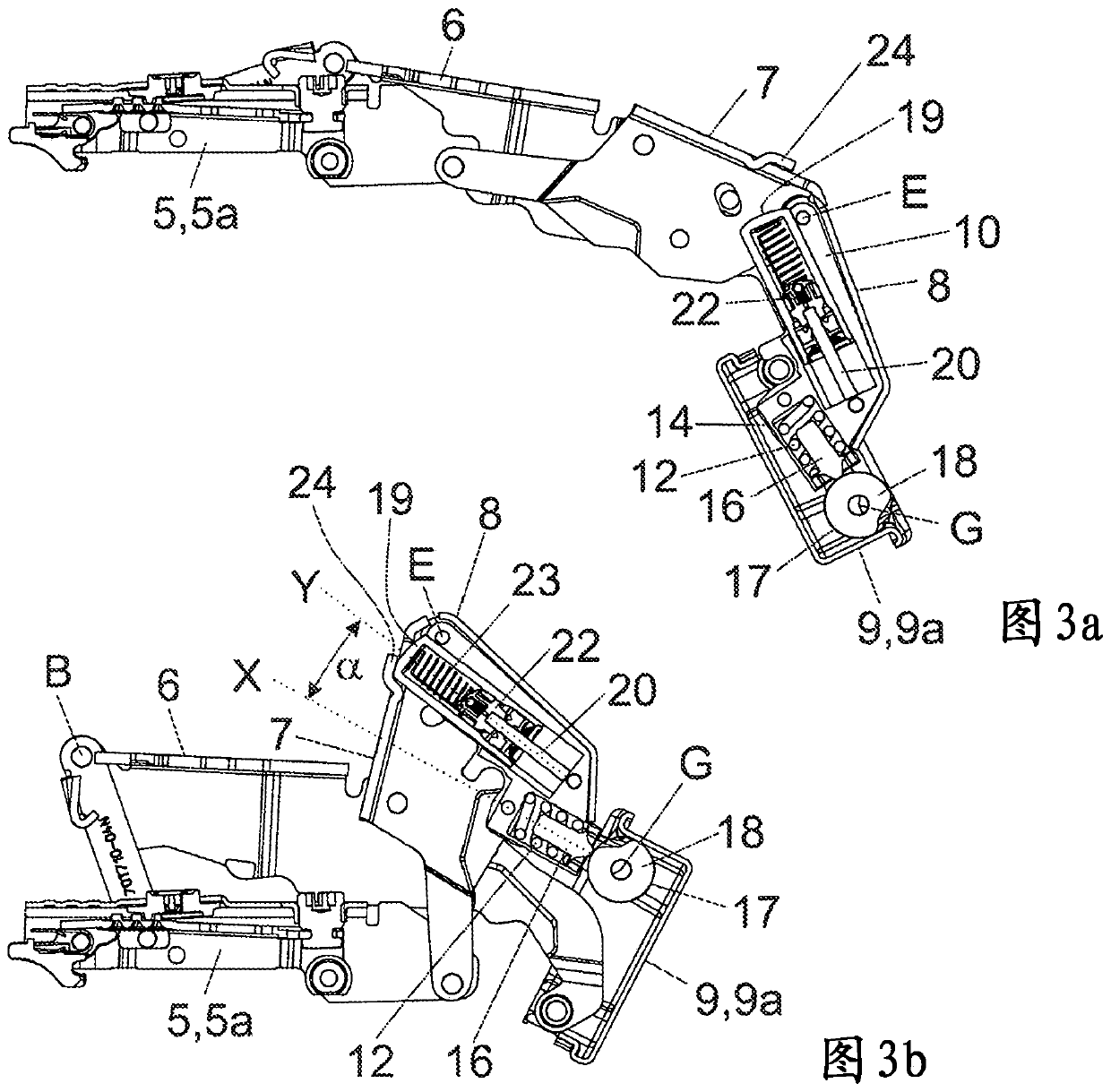

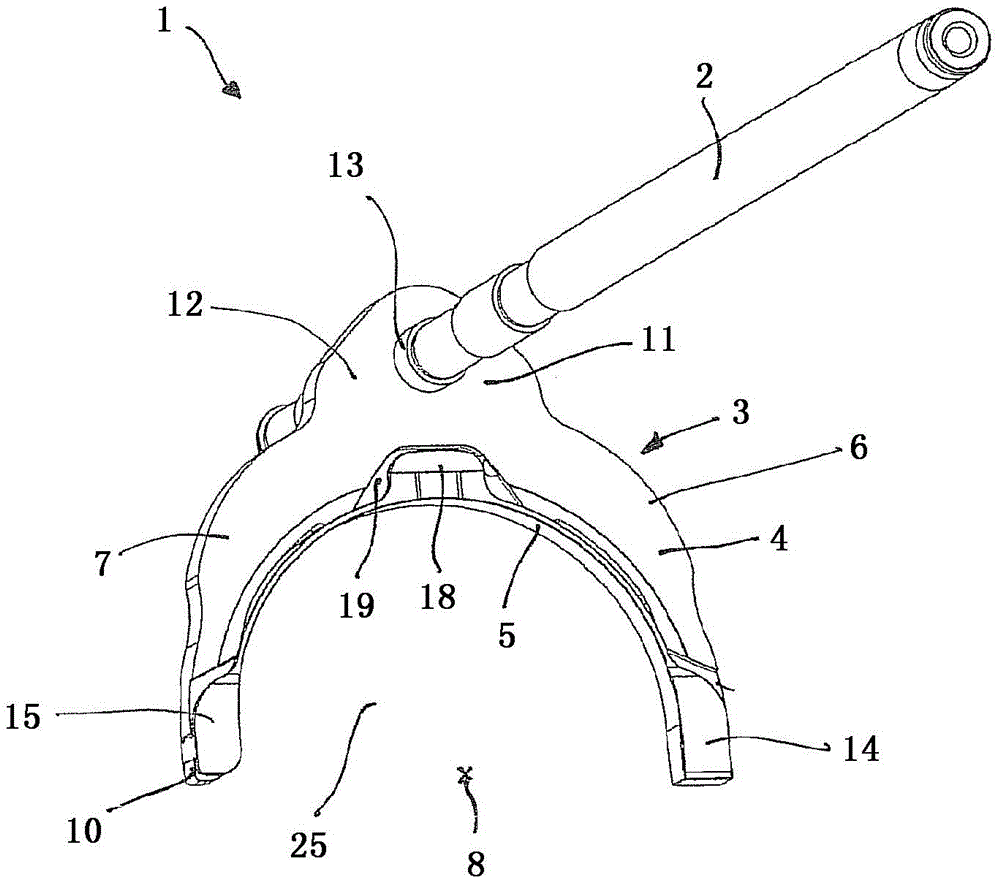

Furniture hinge

ActiveCN107810304ASave axial construction spaceReduce structural designBuilding braking devicesPin hingesPistonHinge angle

The invention relates to a furniture hinge (4), comprising:a first fitting part (5) for fastening to a furniture body (2),a second fitting part (9) for fastening to a movably mounted furniture part (3), wherein the second fitting part (9) is connected to the first fitting part (5) in an articulated manner,at least one helical spring (12) with an operating direction (X), wherein the furniture hinge(4) can be moved to a completely closed position and / or to a completely open position by the helical spring (12) starting from a prespecified angular position,a damping apparatus (11) for damping a hinge movement, wherein the damping apparatus (11) has at least one fluid chamber (25) in which a piston (22) with a piston rod (20) for executing a damping stroke which runs in a direction (Y) is accommodated, wherein the operating direction (X) of the helical spring (12) and the direction (Y) of the damping stroke run at a lateral parallel distance or obliquely in relation to one another, whereinthe helical spring (12) and the damping apparatus (11) are arranged in or on a common support (10) which is integrated in the furniture hinge (4).

Owner:JULIUS BLUM GMBH

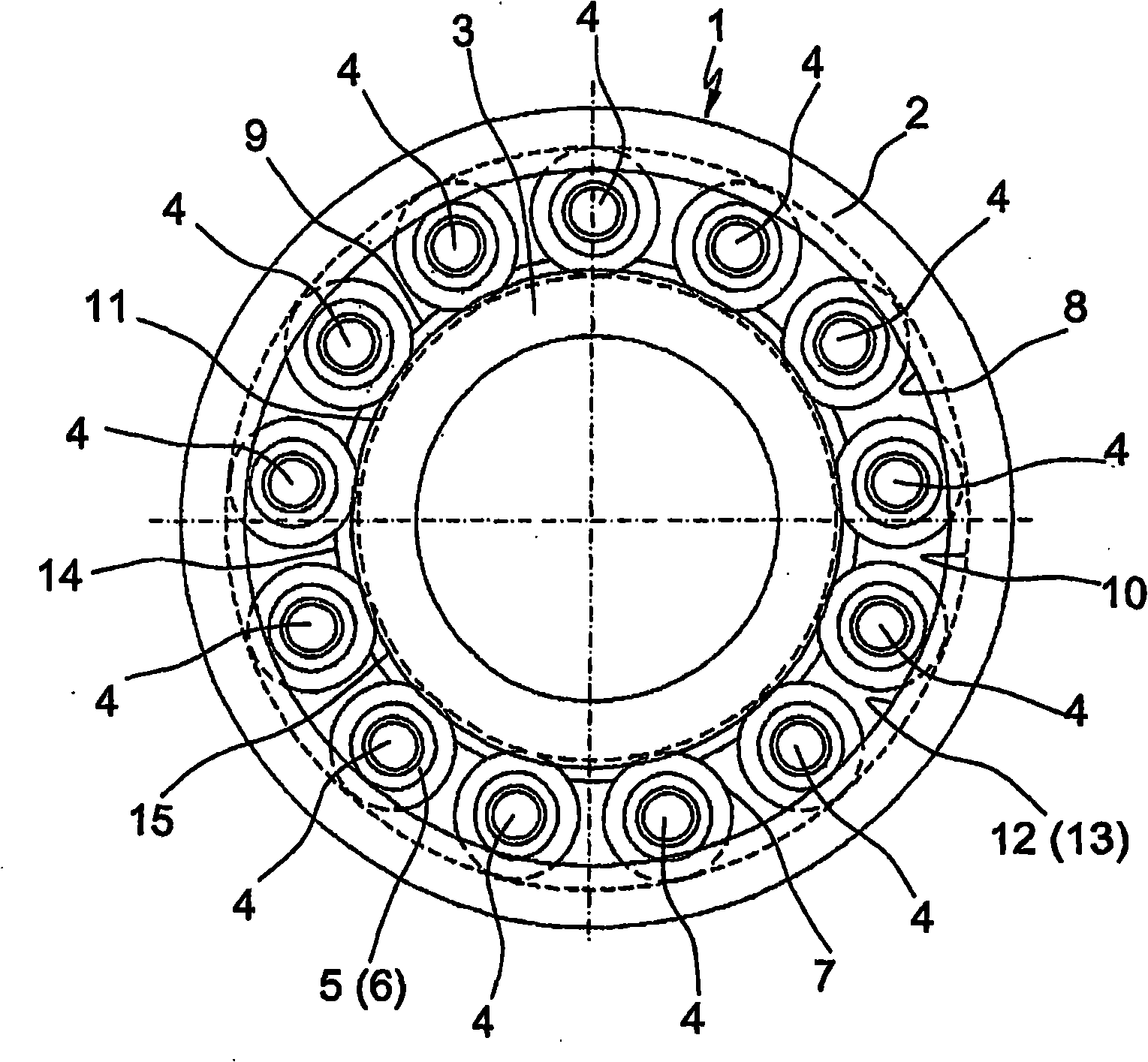

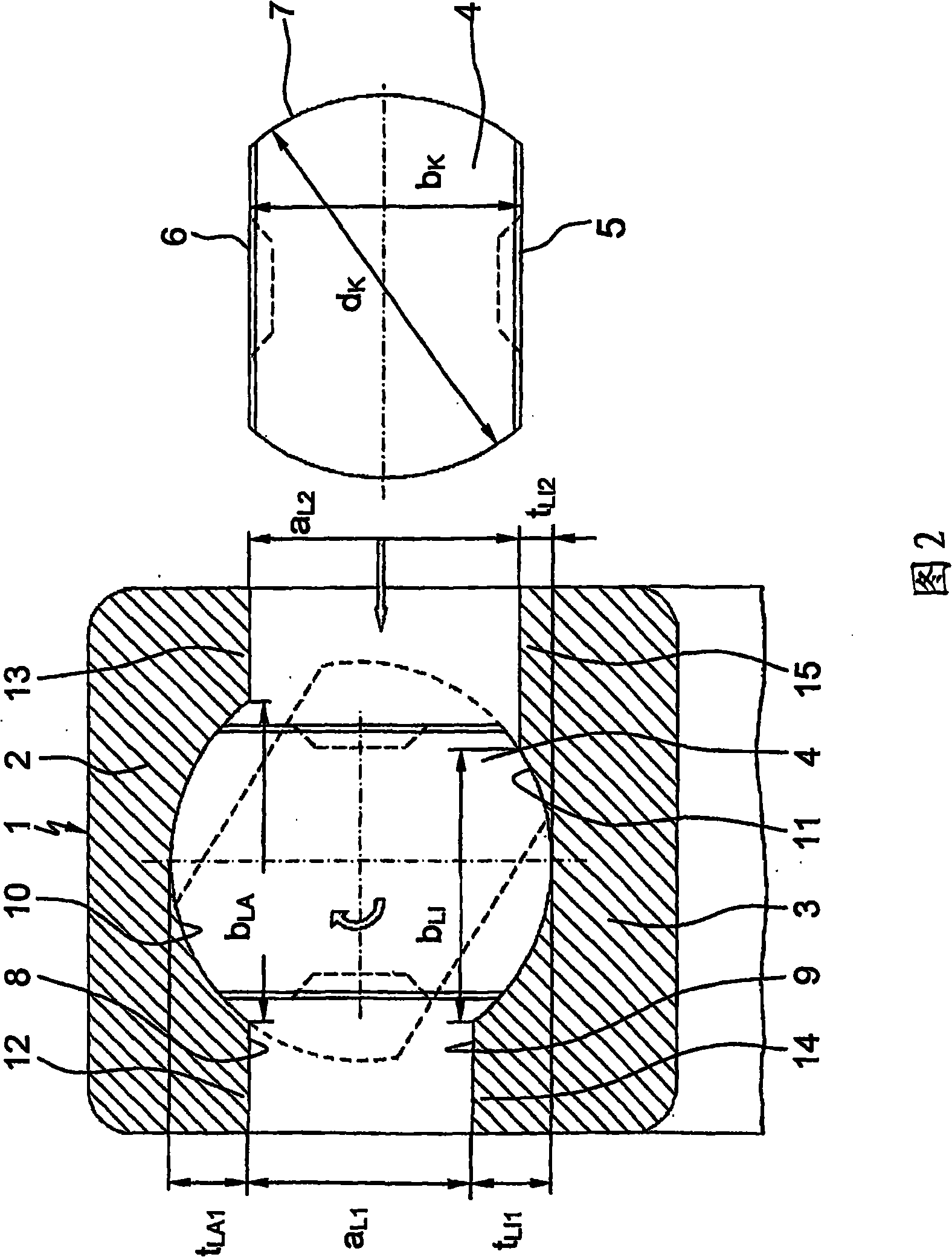

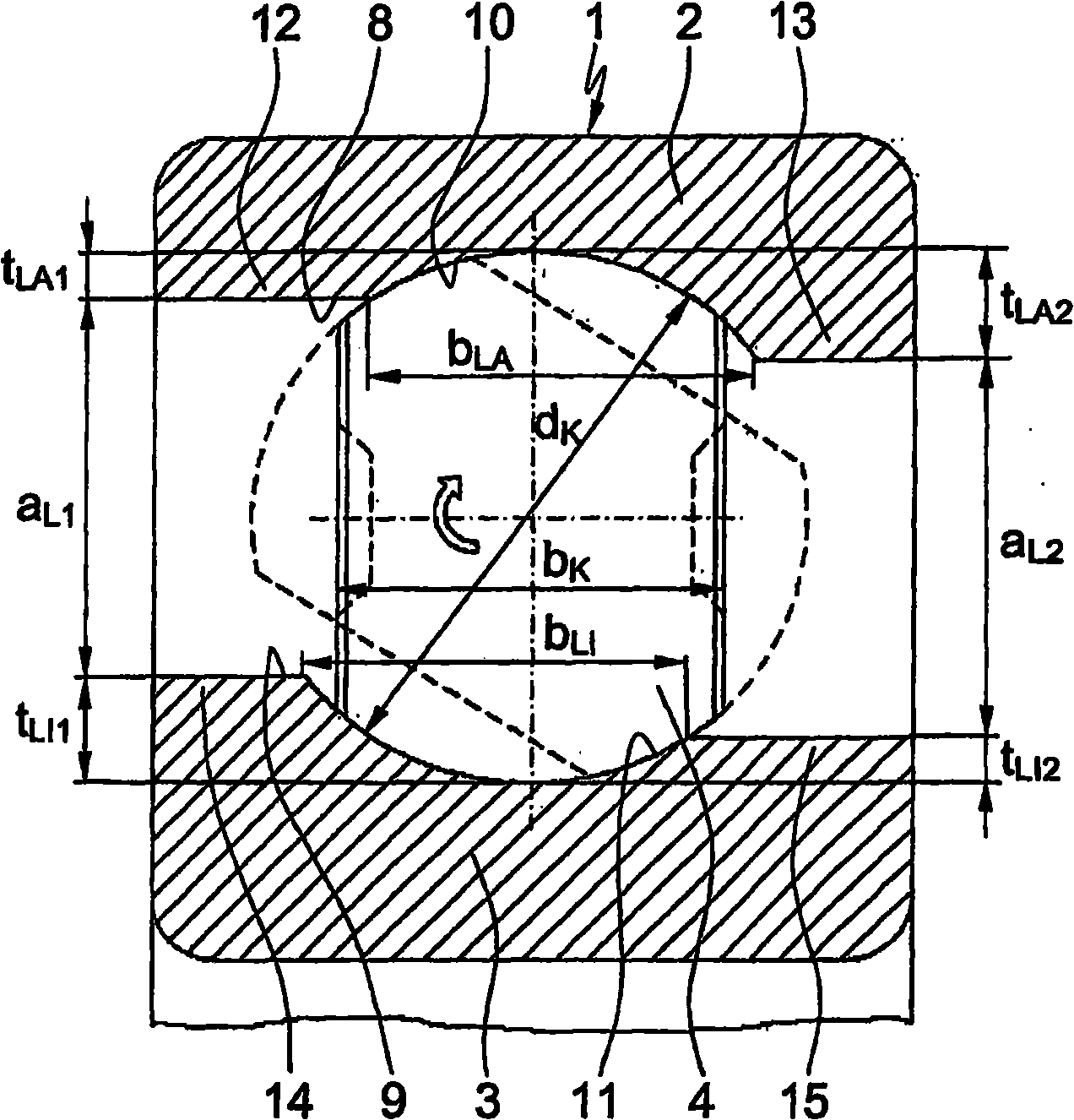

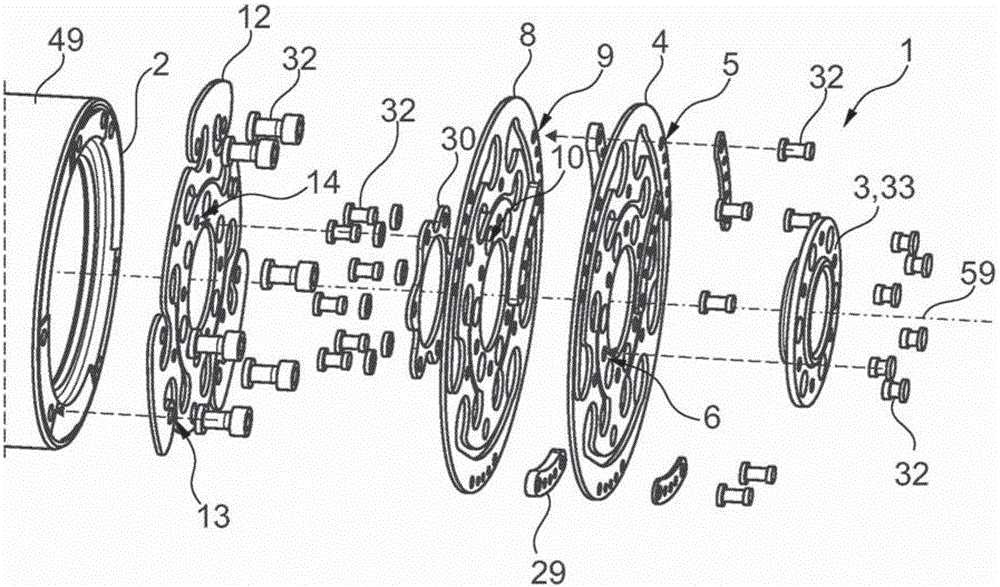

Radial rolling bearing, in particular single-row spherical-roller bearing

InactiveCN101346551AEasy to assembleLower the altitudeRoller bearingsShaftsRolling-element bearingEngineering

The invention relates to a radial rolling bearing, in particular single-row spherical-roller bearing, which is composed substantially of an outer bearing ring (2) and an inner bearing ring (3) and of a plurality of spherical rollers (4), which spherical rollers (4) are arranged between said bearing rings (2,3), which spherical rollers (4) have in each case two side faces (5,6) which are flattened symmetrically from a spherical basic shape and are arranged parallel to one another, and which spherical rollers (4) are retained with uniform spacing to one another in the peripheral direction by means of a bearing cage. Here, the spherical rollers (4) have a width (bk) between their side faces (5,6) of approximately 70% of the diameter (dk) of their spherical basic shape, and roll with their running faces (7) in two groove-shaped raceways (10,11) which are formed in the inner side (8) of the outer bearing ring (2) and in the outer side (9) of the inner bearing ring (3). According to the invention, at least one of the axial rims (12, 13, 14, 15) which delimit the groove-shaped raceways (10,11) in the bearing rings (2,3) is designed to be reduced in radial height such that the radial bearing (1) can, by means of the increased spacing (aL2) of said rim (12, 13, 14, 15) to the radially opposite rim (12, 13, 14, 15), be equipped with an increased number of spherical rollers (4) in an axial assembly process.

Owner:SCHAEFFLER KG

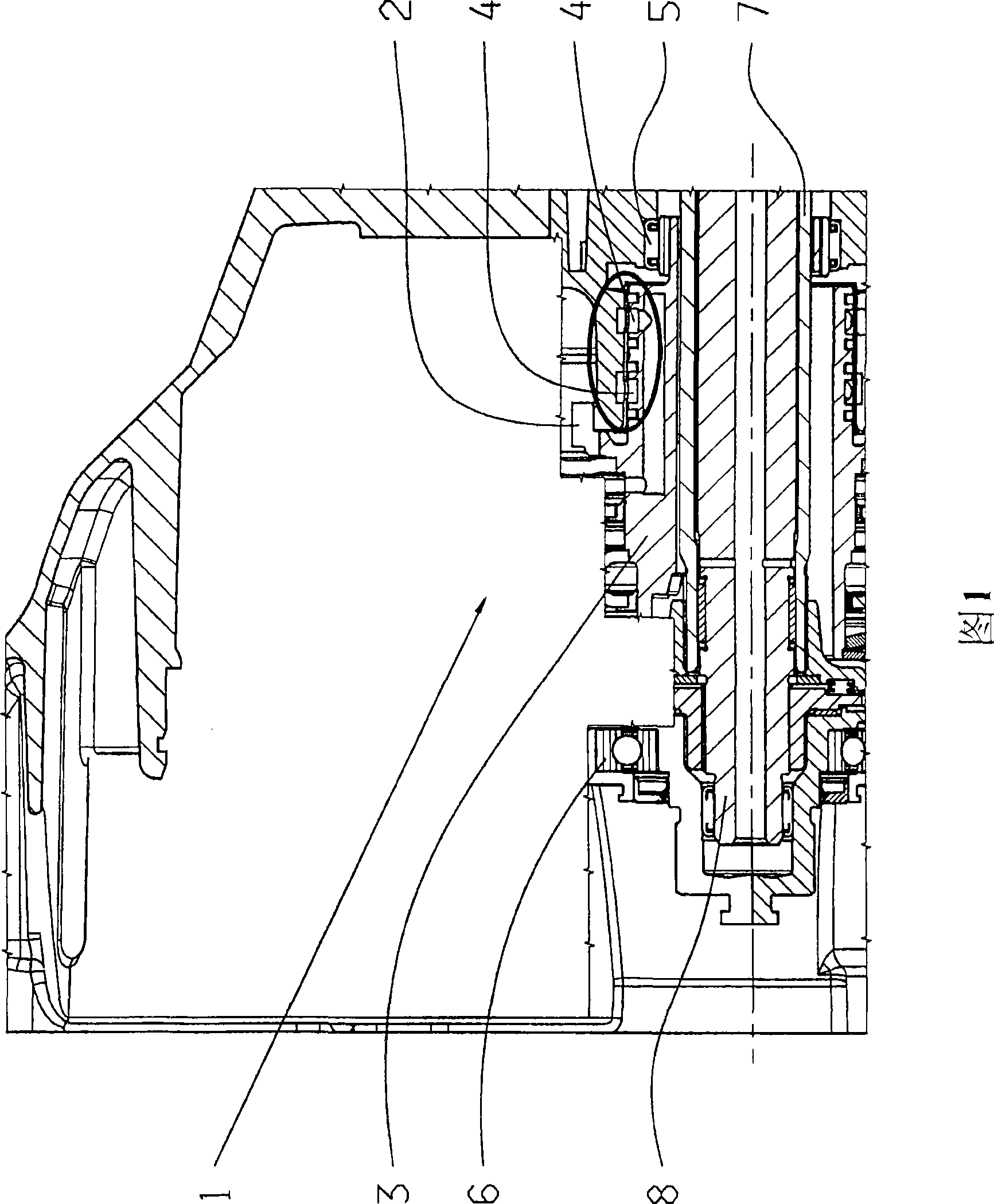

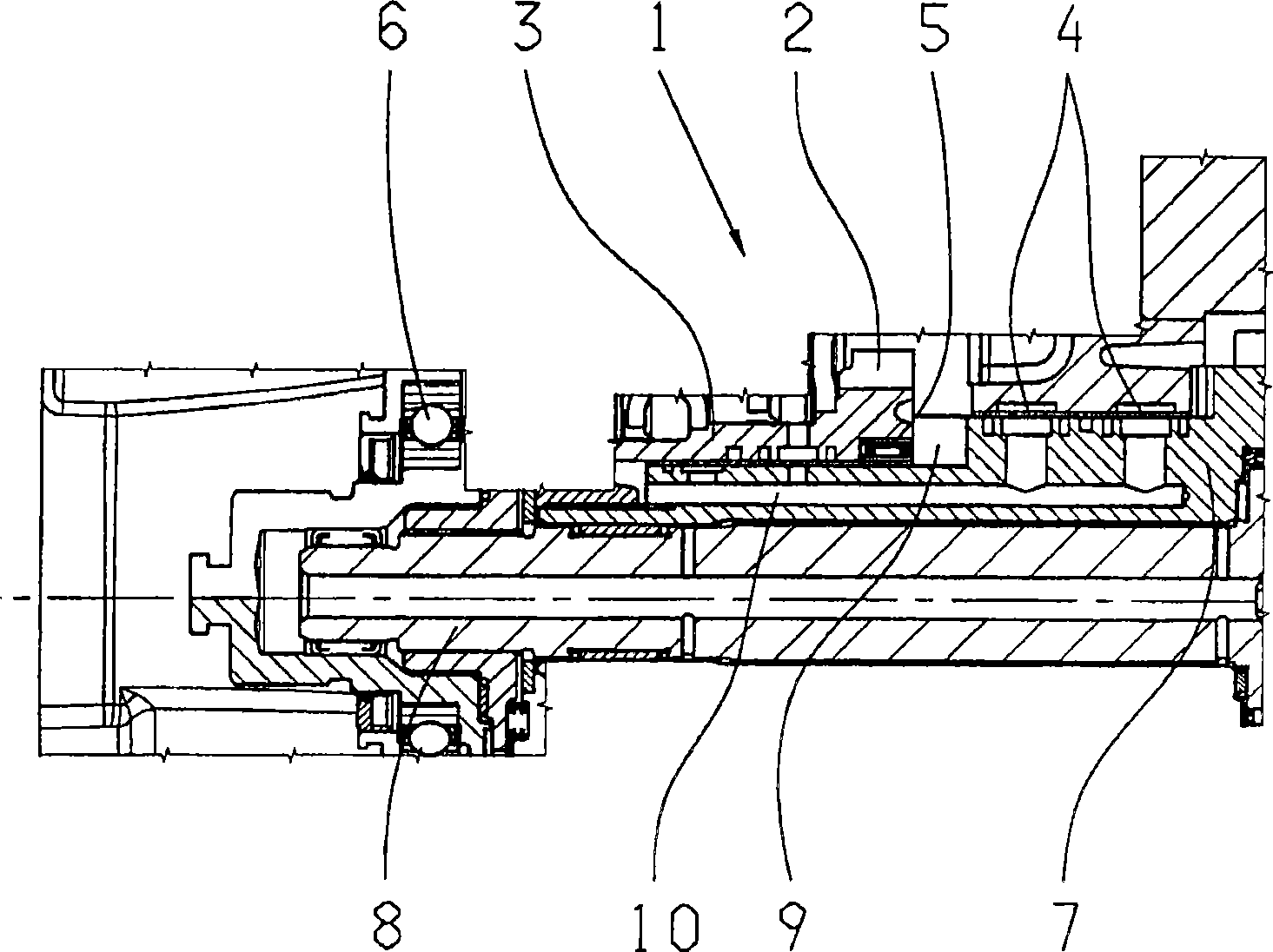

Method for feeding hydraulic fluid and coolant and lubricant for wet operation clutch of gear box

InactiveCN101457797ASave axial construction spaceFluid actuated clutchesGear lubrication/coolingDrive shaftEngineering

The supply unit has hydraulic fluid or coolant and lubricant. The clutch (1) is arranged around an external drive shaft (7) conducted as hollow shaft. Cables (10) for the hydraulic fluid and deliveries (4) of the hydraulic fluid are integrated at the clutch, and the cables for coolant and lubricant and the deliveries (11) for coolant and lubricant are integrated at the clutch in the drive shaft.

Owner:ZF FRIEDRICHSHAFEN AG

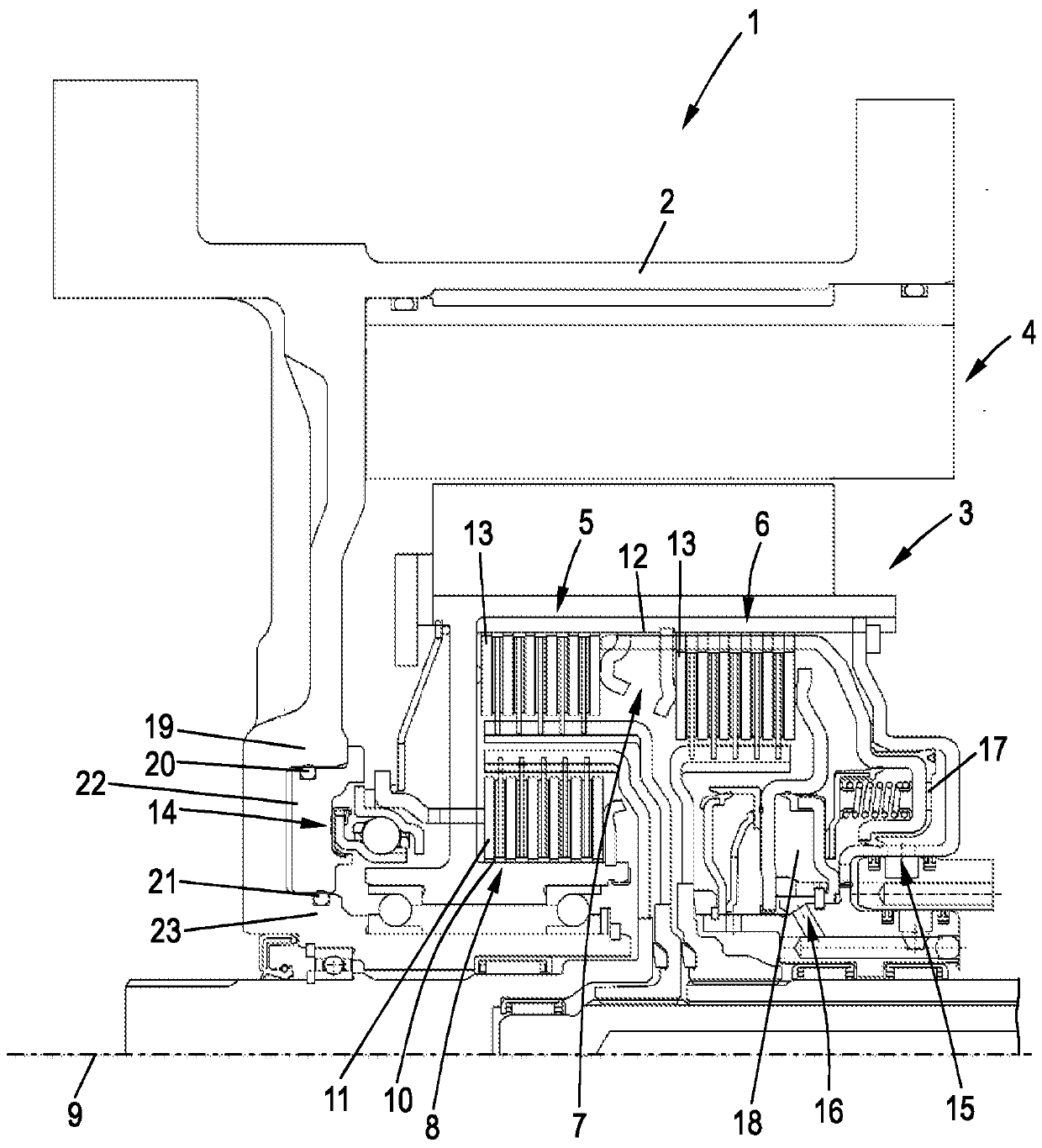

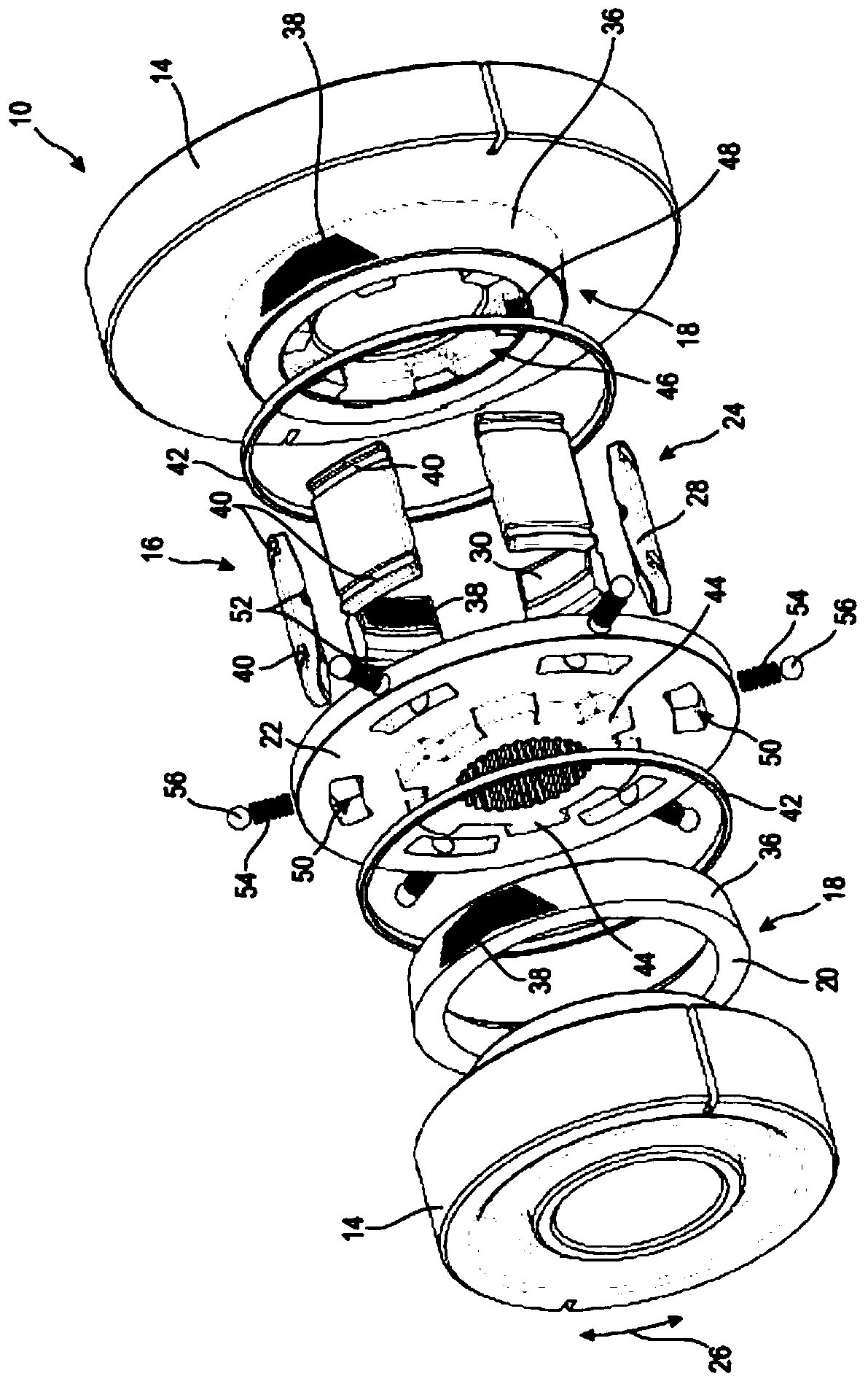

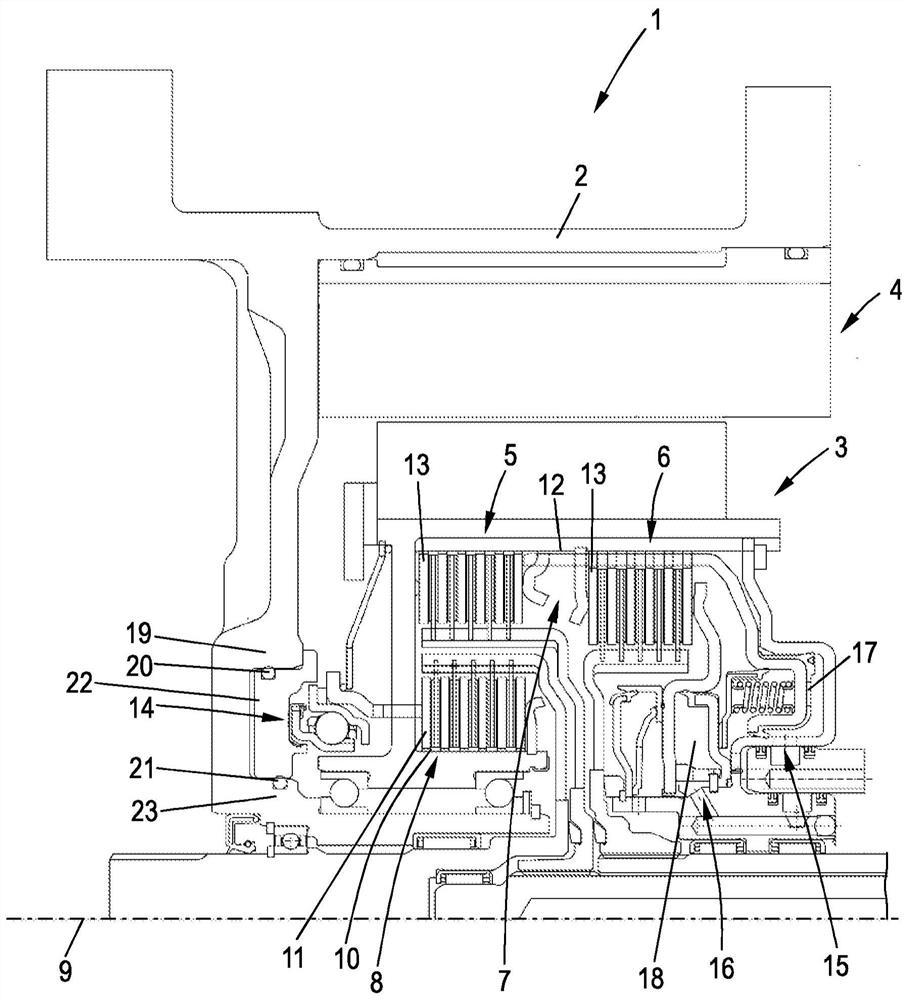

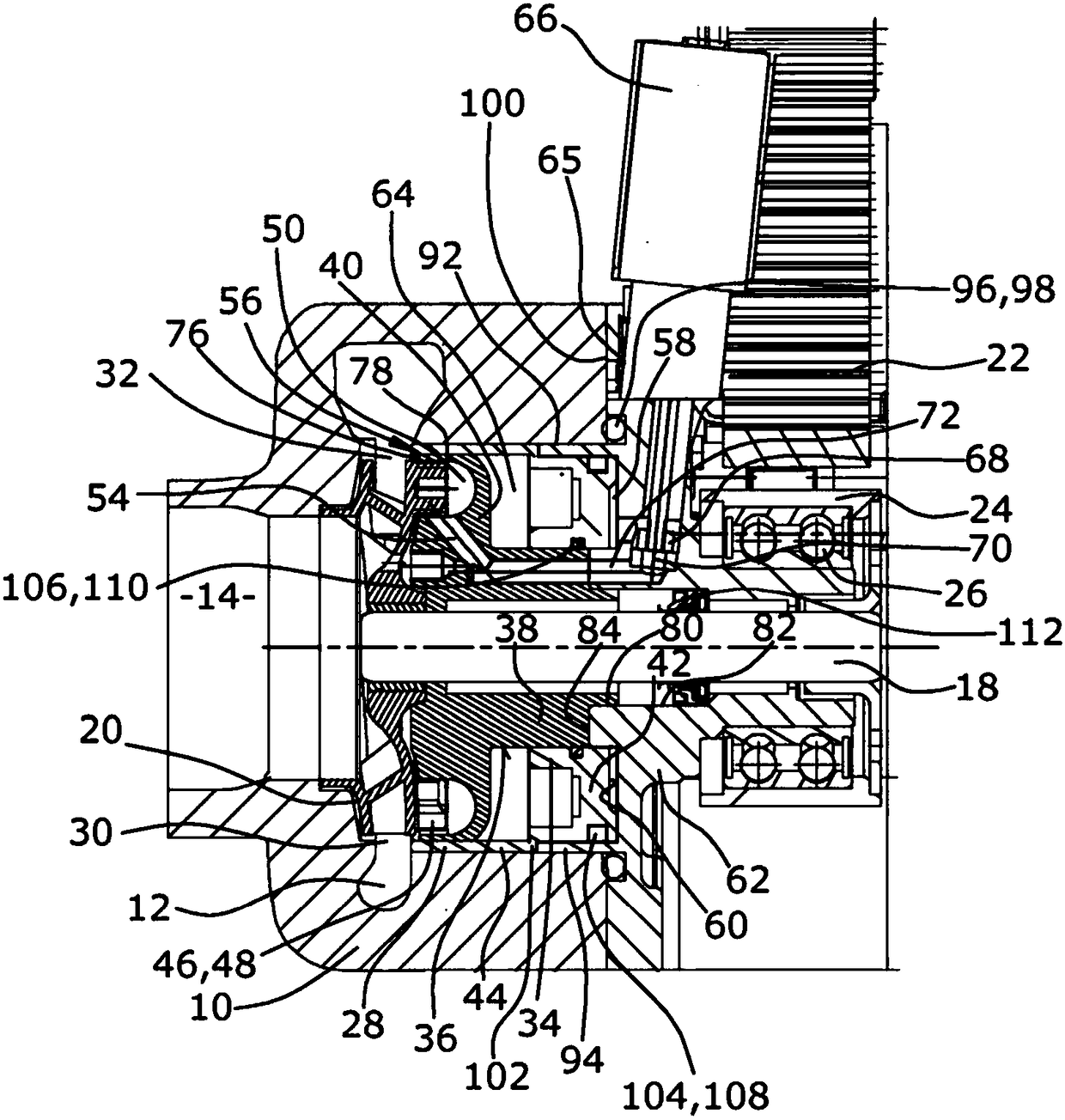

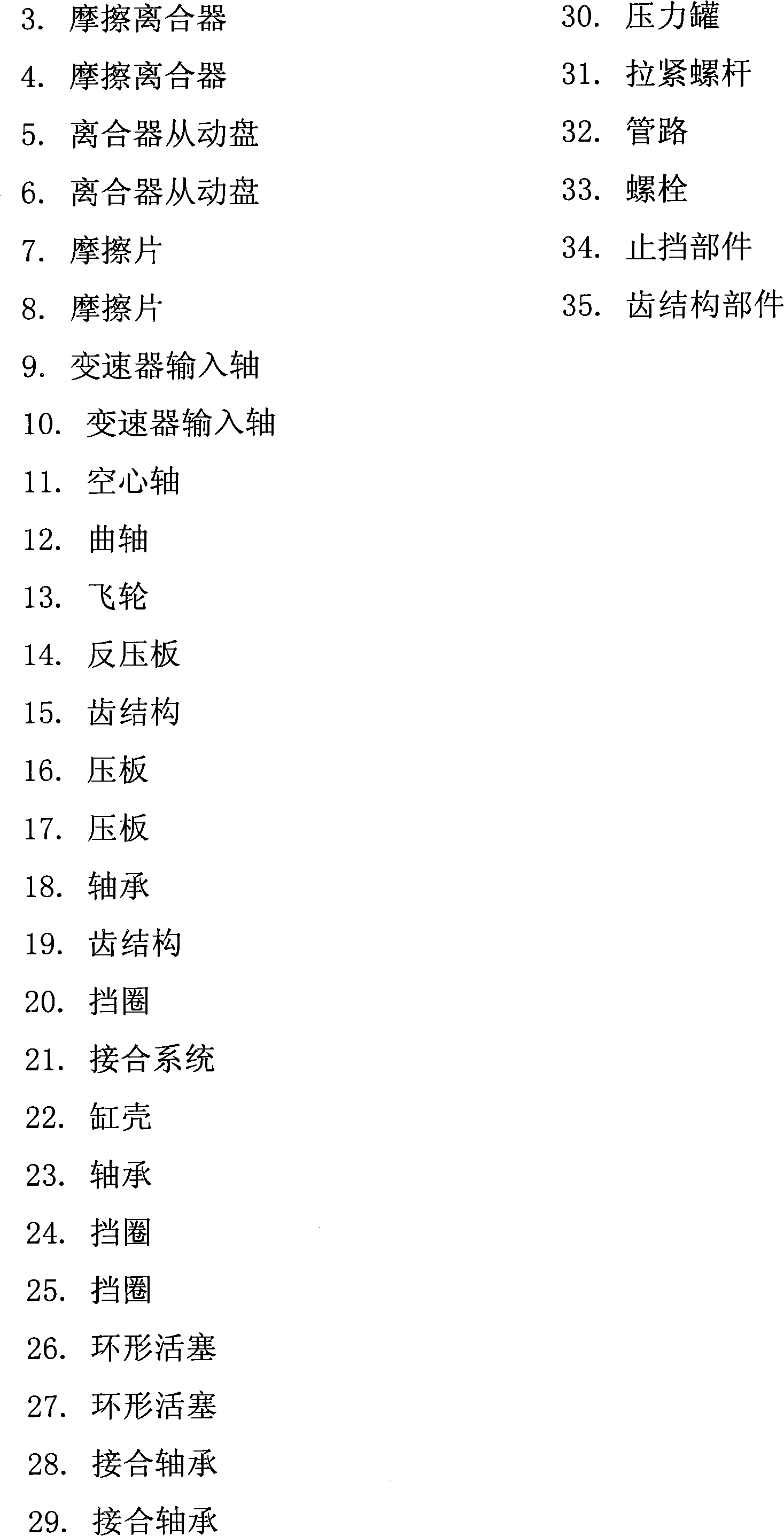

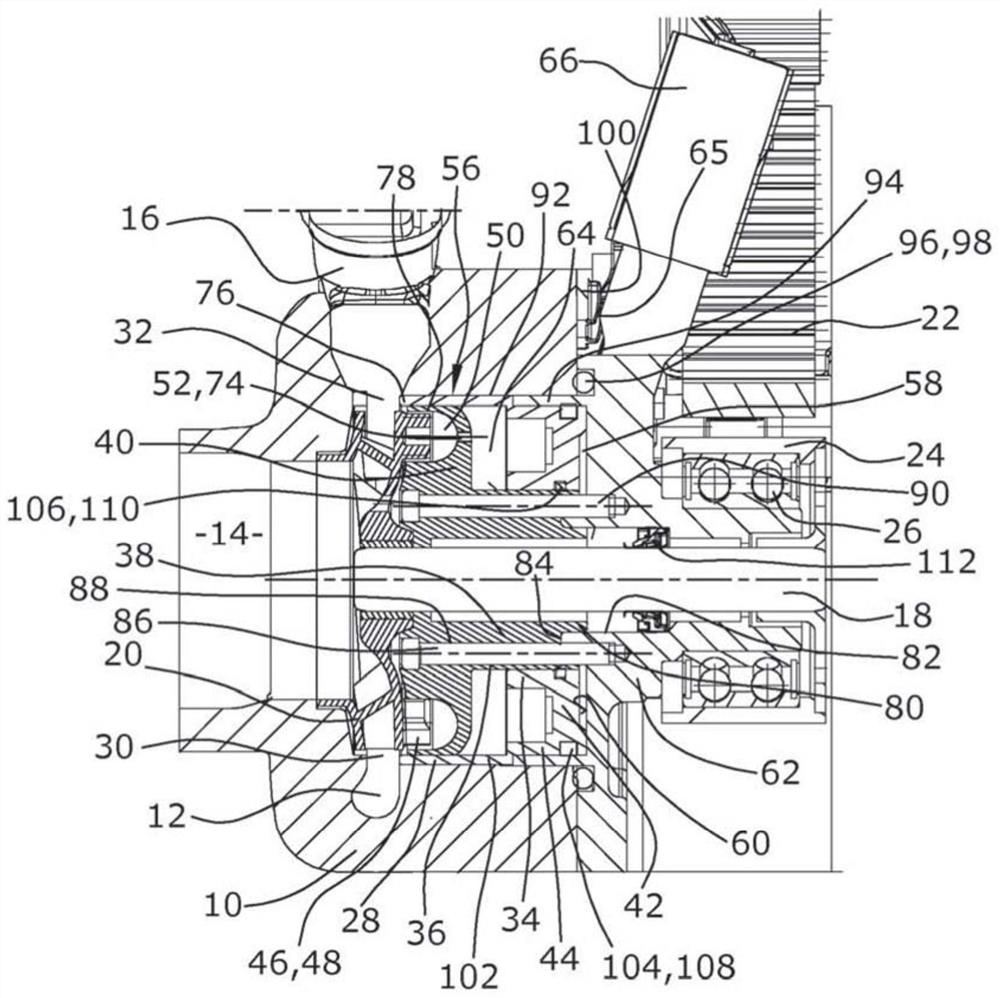

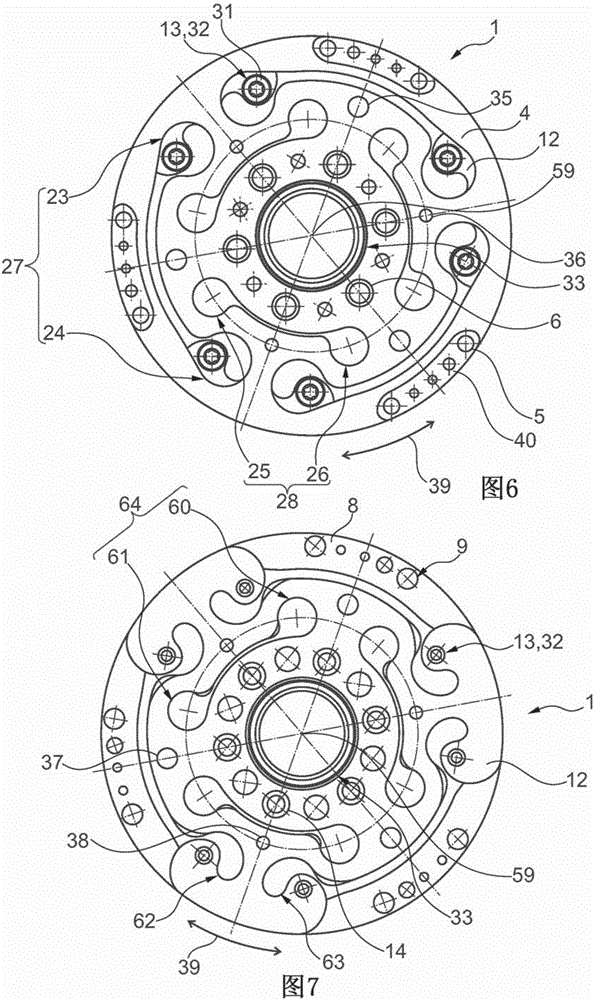

Hybrid module

ActiveCN109789764ACompact structureSave axial construction spaceHybrid vehiclesMechanical actuated clutchesRotational axisElectric machine

The invention relates to a hybrid module (1, 24) for a motor vehicle, comprising an electric machine (4) which has a stator (2) and a rotor (3), a double clutch (7) which has a first and second component clutch (5, 6) and is configured to couple the hybrid module (1, 24) to a transmission of the motor vehicle such that it can be disconnected, and a separating clutch (8) which is configured to couple an internal combustion engine of the motor vehicle to the hybrid module (1, 24) such that it can be disconnected, wherein the double clutch (7) and the separating clutch (8) are arranged radially and axially within the rotor (3), wherein the first and the second component clutch (5, 6) are arranged behind one another in the axial direction, and the separating clutch (8) is arranged closer in the radial direction to the rotational axis (9) of the rotor (3) than the double clutch (7).

Owner:SCHAEFFLER TECH AG & CO KG

Embedded teeth joint used for automobile transmission

ActiveCN104455067AEasy to buildSave axial construction spaceMechanical actuated clutchesGearing controlEngineeringEmbedded teeth

The invention relates to an embedded teeth joint (16) used for an automobile transmission (10). The embedded teeth joint has at least one coupling main body (18), an annular control grabber (22), a friction unit (24) and the control grabber (22) are matched in shape and connected in a tangential direction (26), and the friction unit can axially functions through the control grabber (22), the control grabber (22) can be adjusted between a middle position, a synchronization position and a shift position relative to the coupling main body (18) in an axial direction, in the middle position, the control grabber (22) basically can freely rotate relative to the coupling main body (18), in the synchronization position, the control grabber (22) is coupled with the coupling main body (18) in the tangential direction (26) through frictional connection, and in the shift position, the control grabber (22) and the coupling main body (18) are matched in shape and connected in the tangential direction (26).

Owner:HOERBIGER ANTRIEBSTECHN HLDG

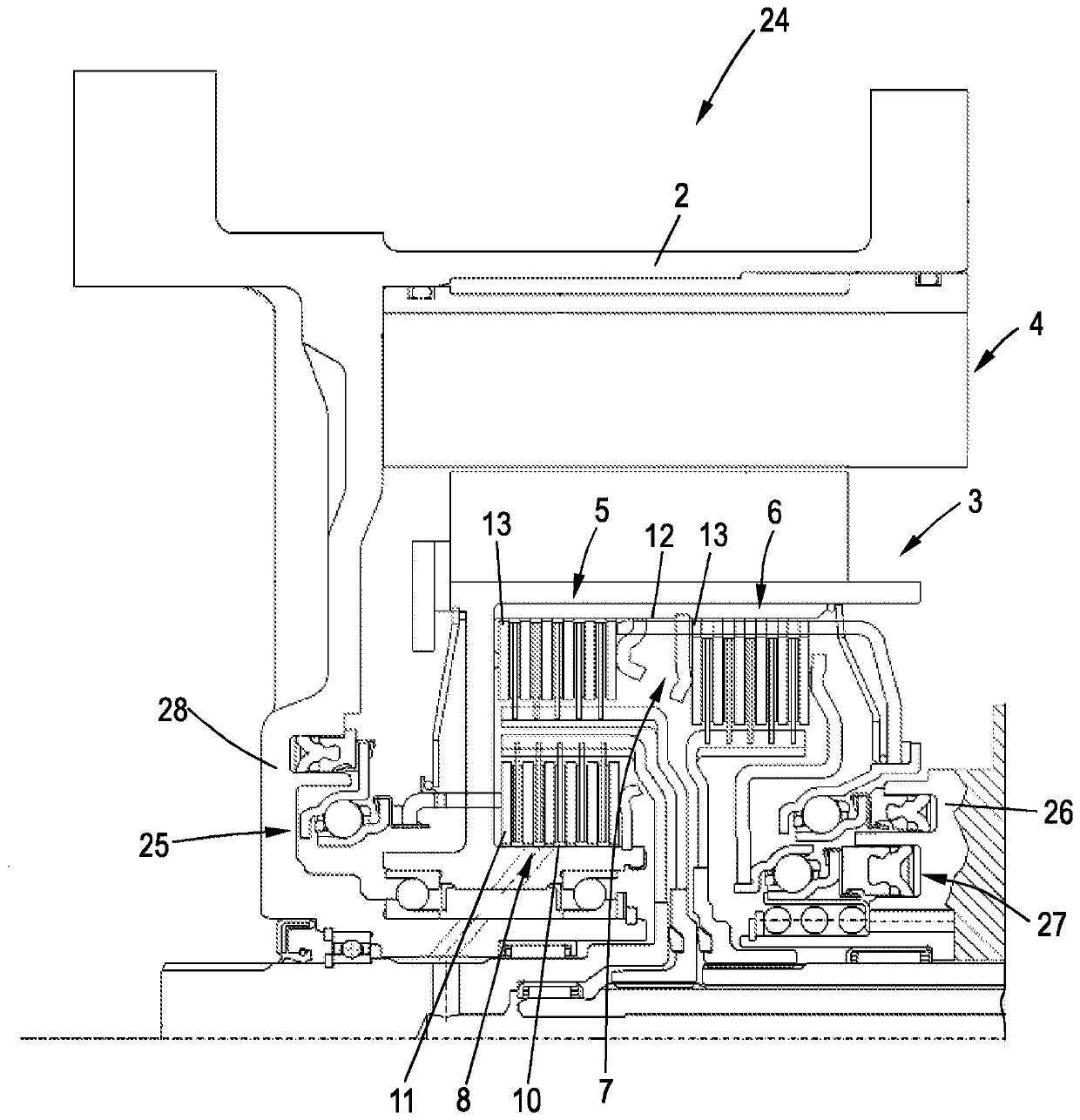

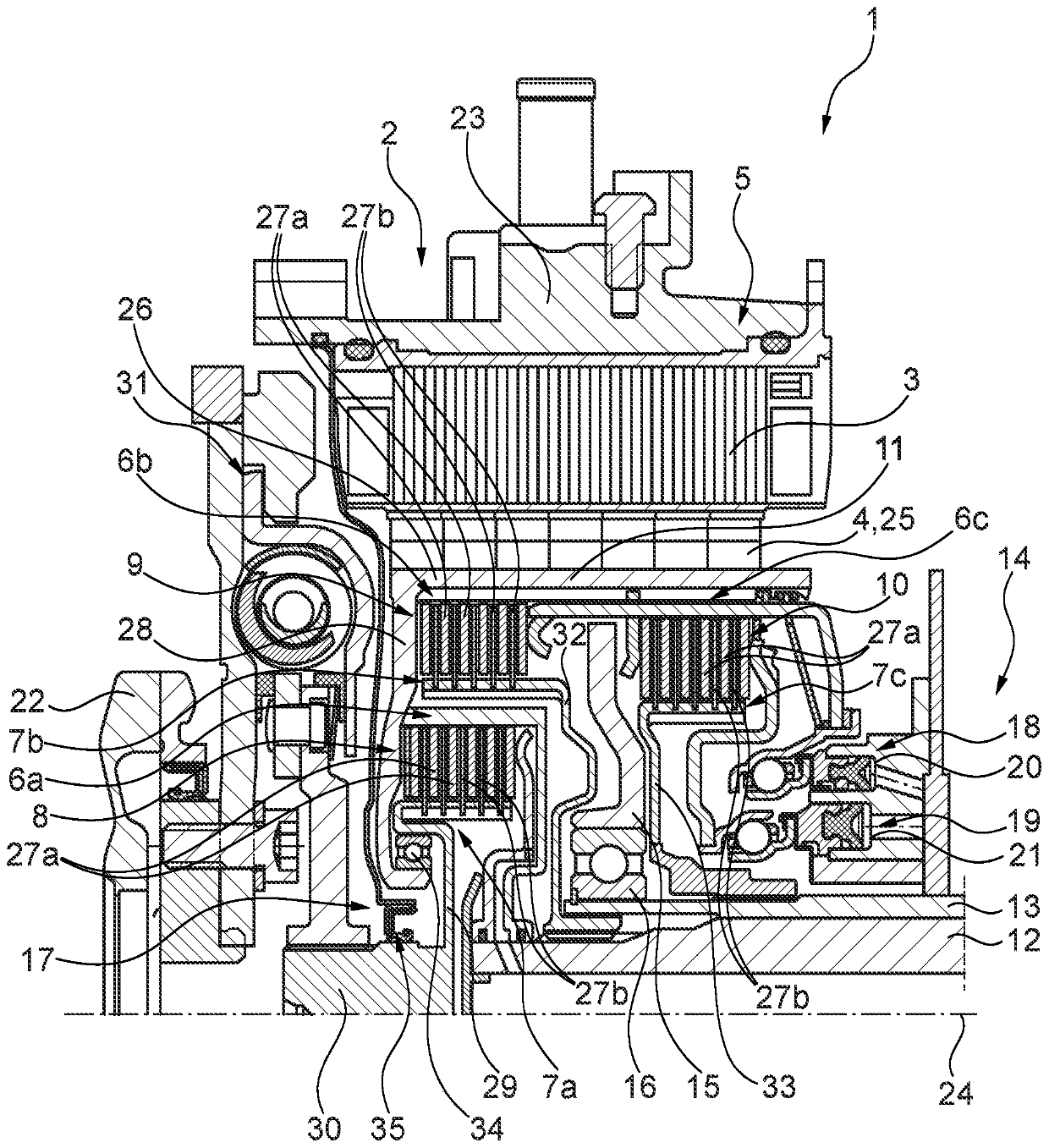

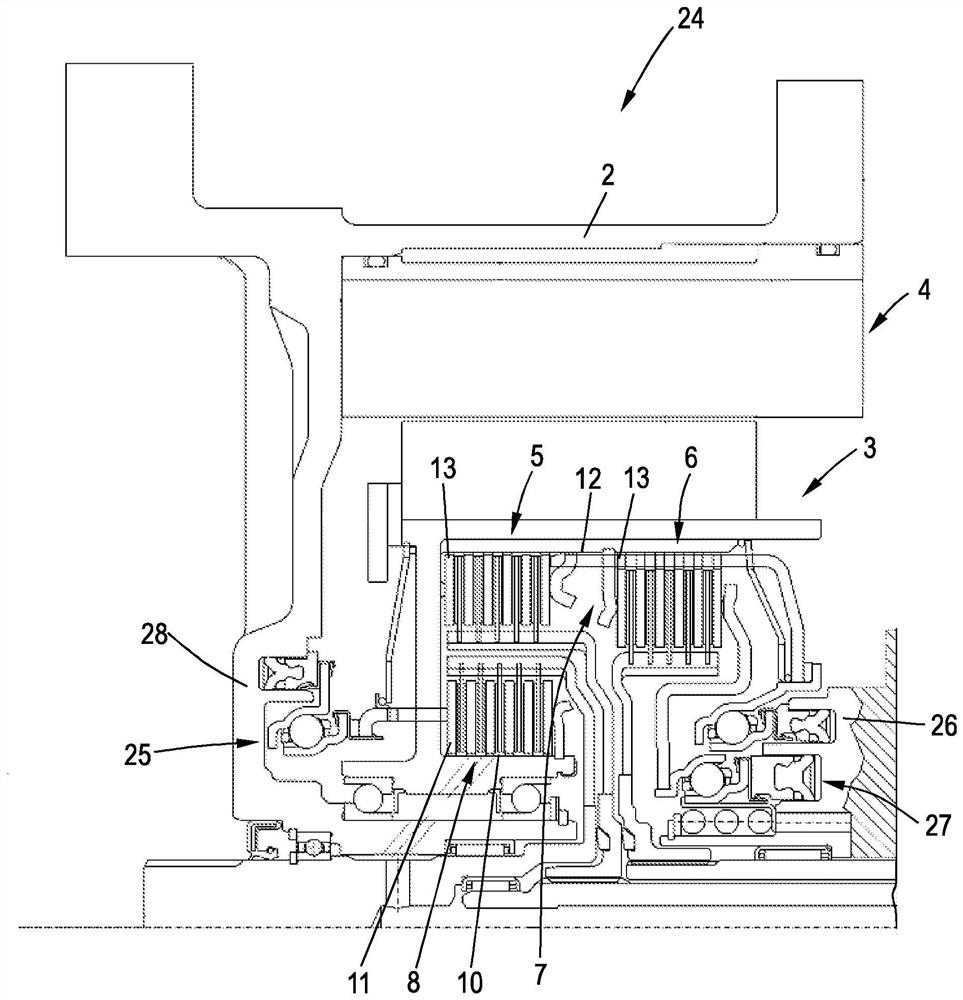

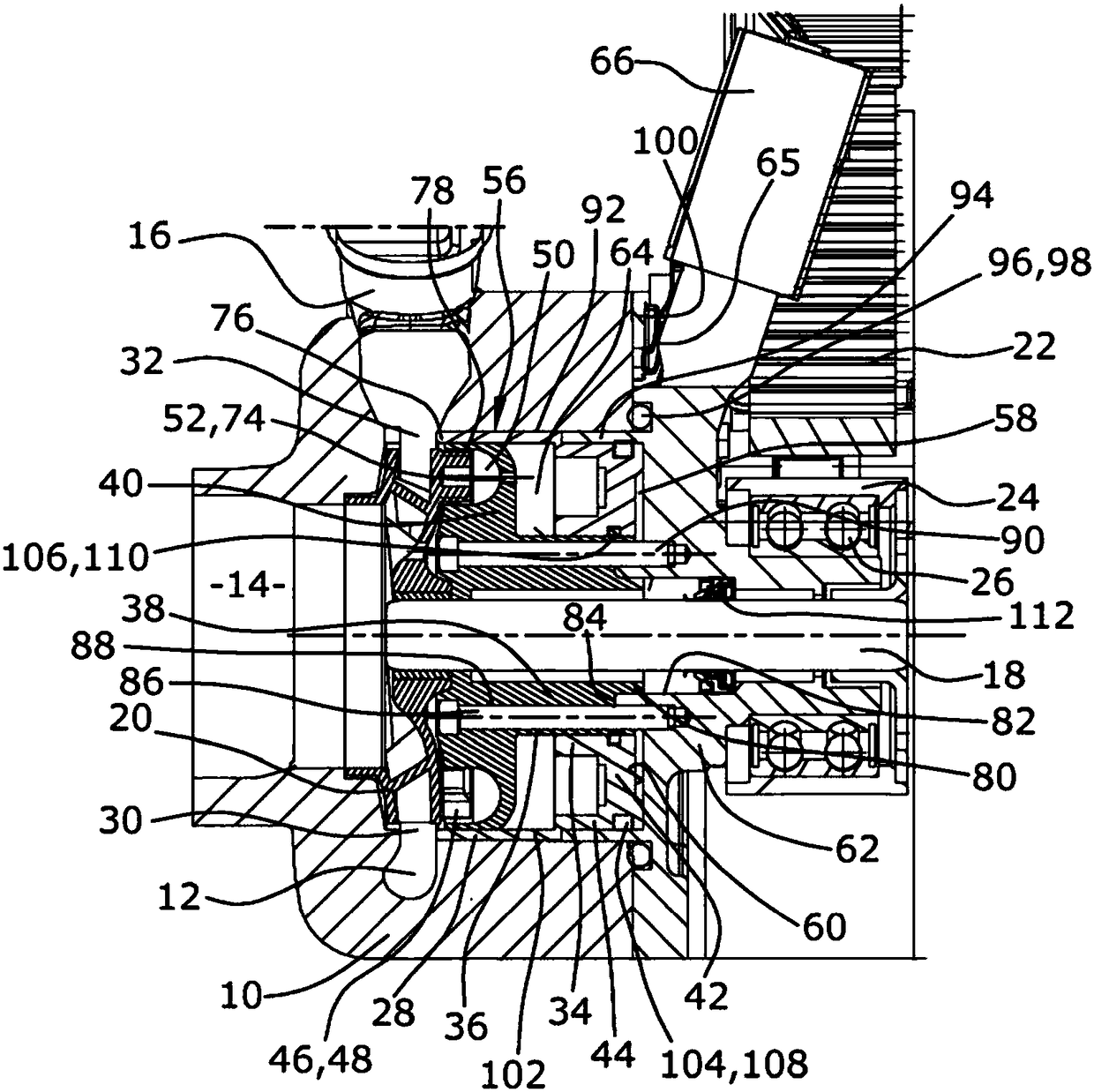

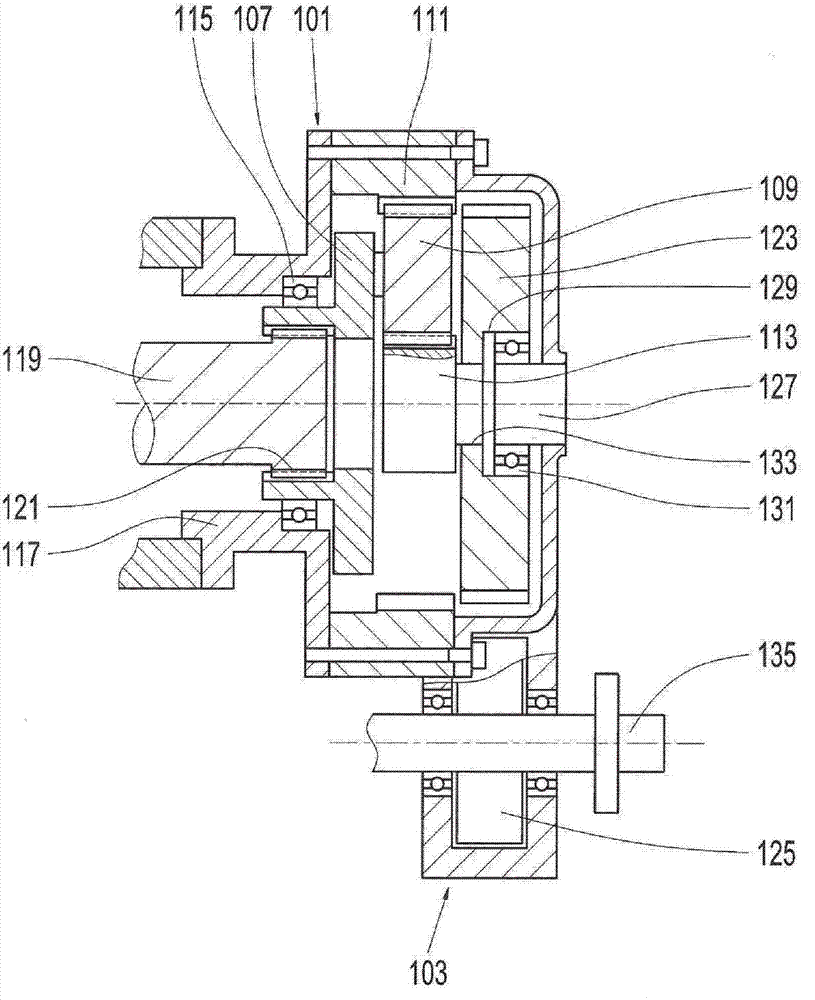

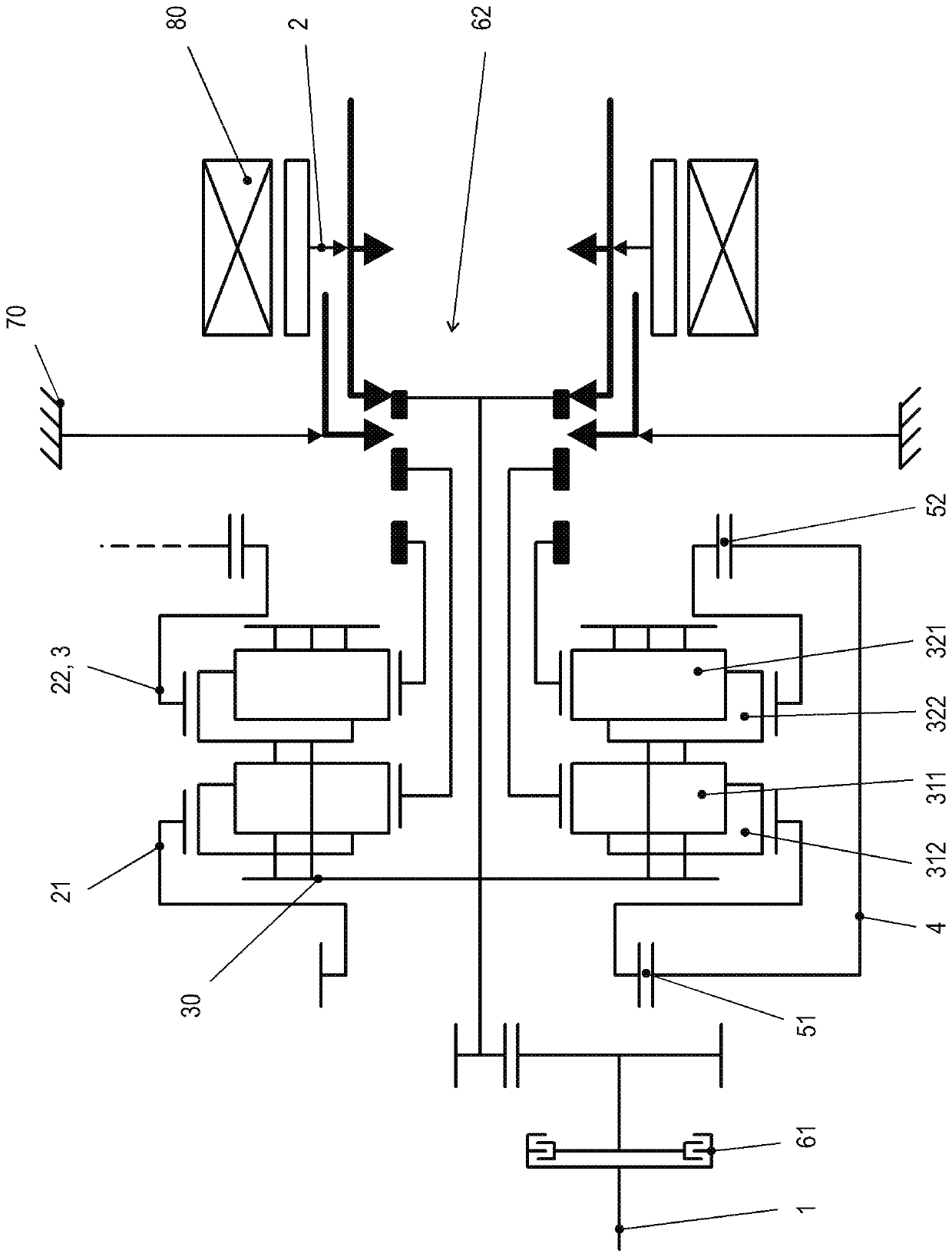

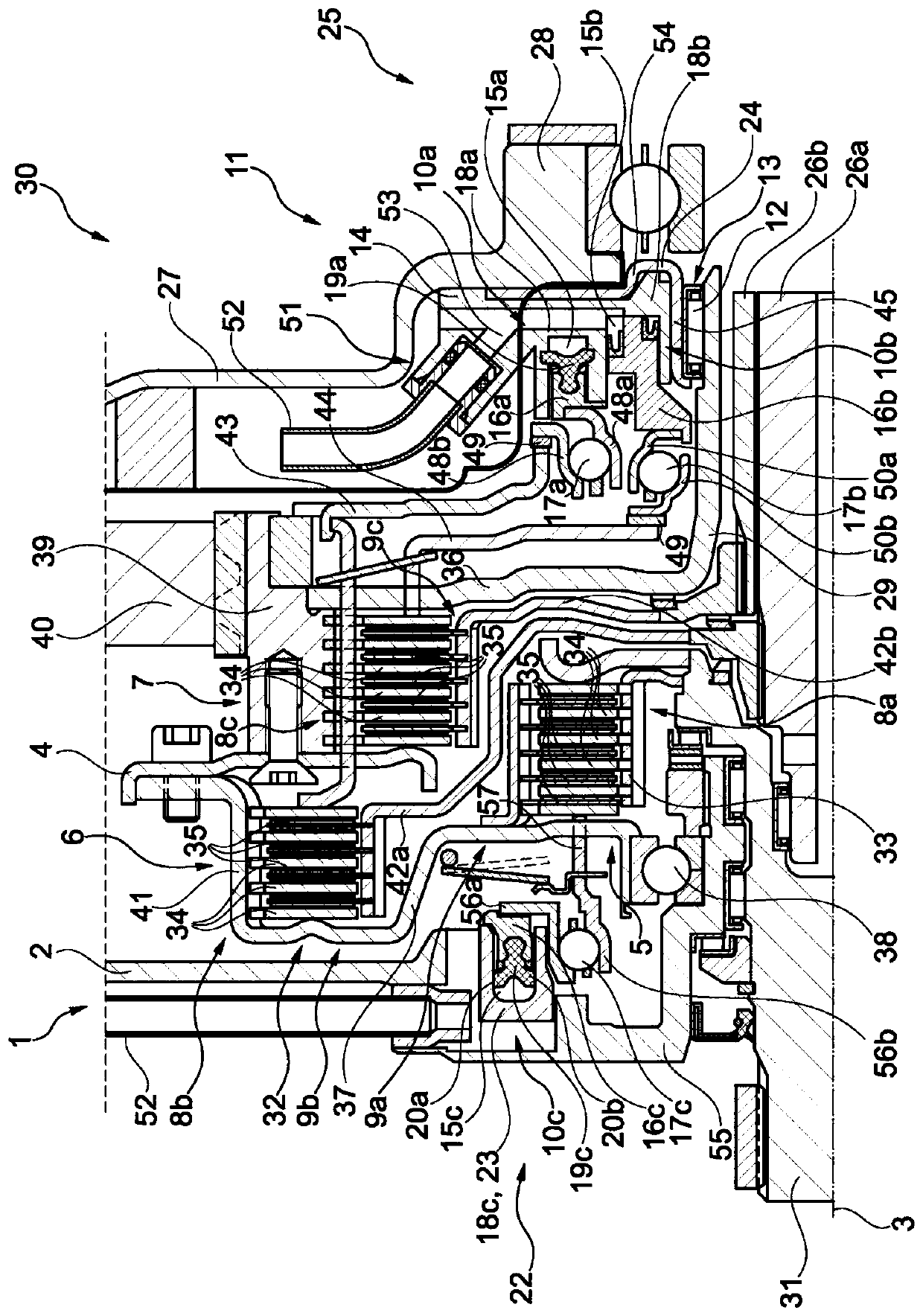

Drivetrain unit with transmission-side mounting of a triple clutch of a hybrid module

ActiveCN110419155ASave axial construction spaceImprove performanceHybrid vehiclesMechanical actuated clutchesDrivetrainElectric machinery

The invention relates to a drivetrain unit (1) for a motor vehicle, the drivetrain unit having a hybrid module (2), which is equipped with an electric machine (5) which has a stator (3) and a rotor (4), with at least two clutches (8, 9, 10) which have clutch parts (6a, 7a; 6b, 7b; 6c, 7c) which are respectively connectable to one another, and with a rotor carrier (11) to which the rotor (4) is attached and to which at a given time one clutch part (6a, 6b, 6c) of the at least two clutches (8, 9, 10) is non-rotationally connected, and having a transmission device (14) which interacts by means ofa transmission input shaft (13) with the hybrid module (2), wherein the rotor carrier (11) is mounted on the transmission input shaft (13) so as to be rotatable relative thereto.

Owner:SCHAEFFLER TECH AG & CO KG

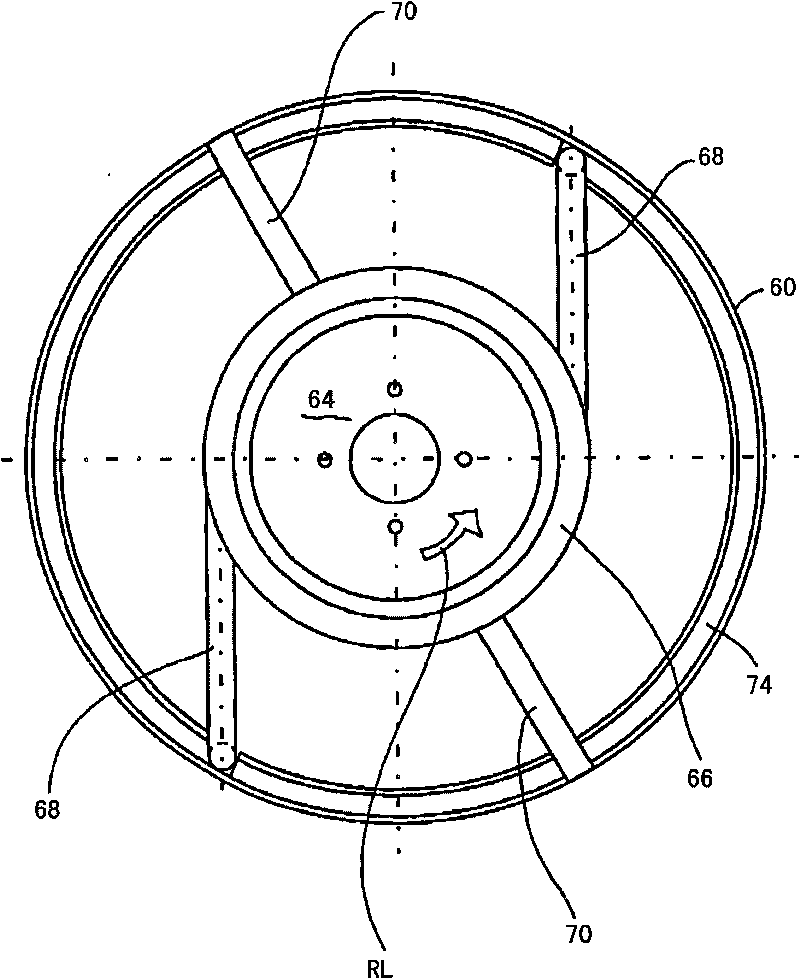

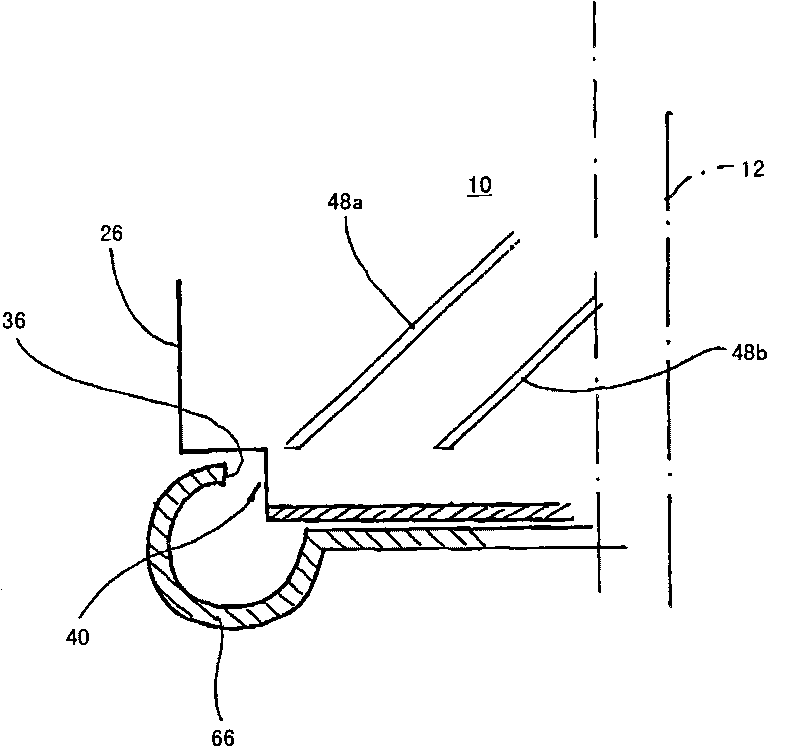

Fan mounted into a tube

InactiveCN101699076AReduce hindranceSave axial construction spacePump componentsPump installationsImpellerEngineering

The present invention relates to a device comprising a fan mounted in a tube, transferred in the axial direction, and driven by a motor. The fan is formed by an axial entry radial fan impeller comprising a driven bearing member, the bearing member extends basically vertical to a rotating axis and is provided with a blade device, and the fluid which enters basically along the axial direction turns outward along the radial direction by using the blade device. A discharging edge of the fan impeller blade locates on a pitch circle which is less than the inner diameter of the tube. The blades of the blade device are designed and / or oriented so that particles contained in a to-be-conveyed fluid are deflectable in a direction of a continuous gap in a preset axial extension between a bearing member and a collecting groove. The collecting groove is fixedly connected with a mounting plate for the motor, and a plurality of particle discharging pipes which are arranged in the circumferential direction and spaced apart from each other are tangentially led out from the collecting groove, and the dispcharging pipes are preferably fixed or welded on the inner wall of the pipes.

Owner:J·保韦蒂克

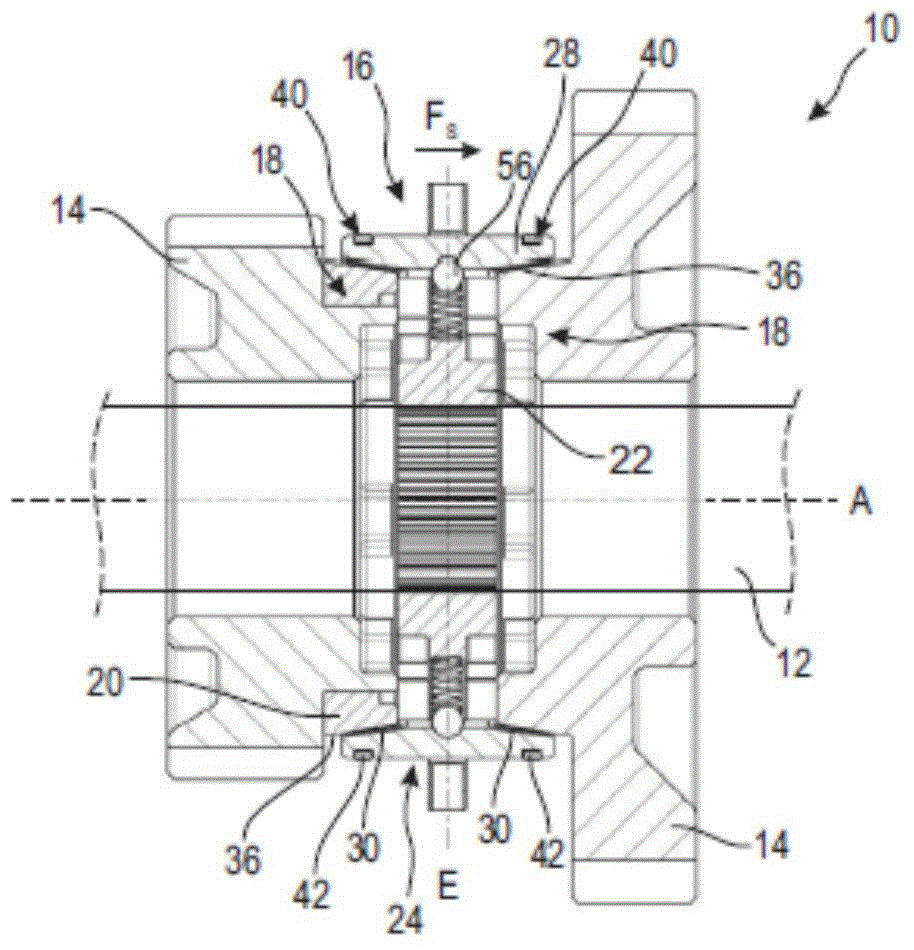

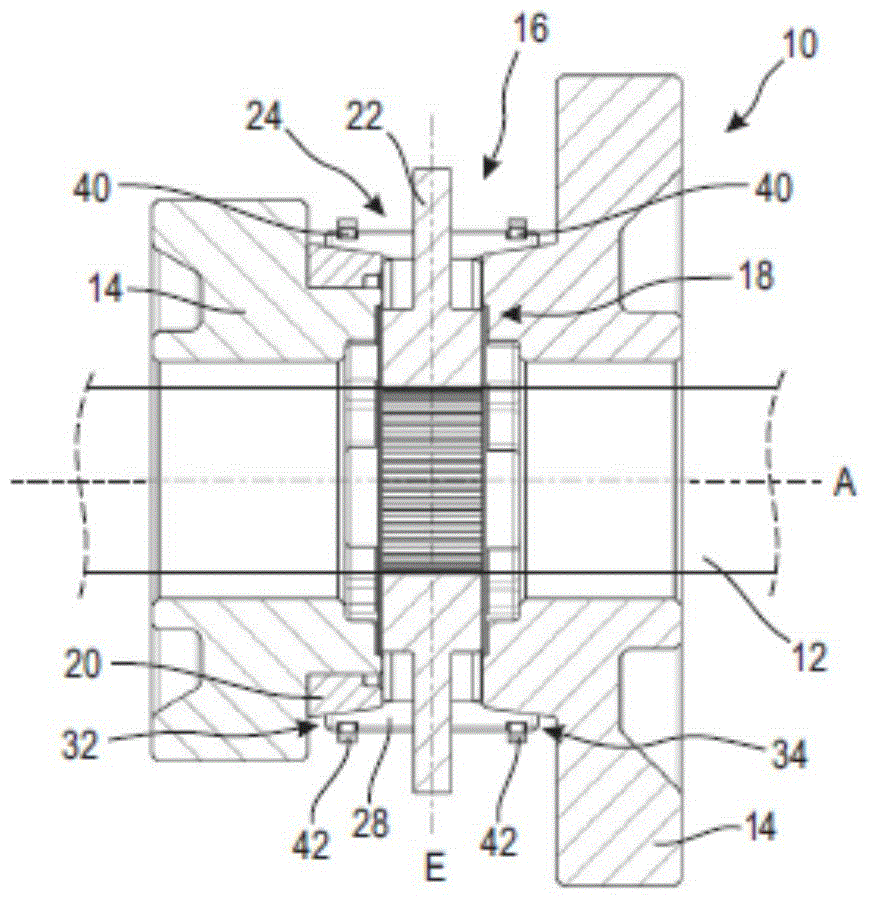

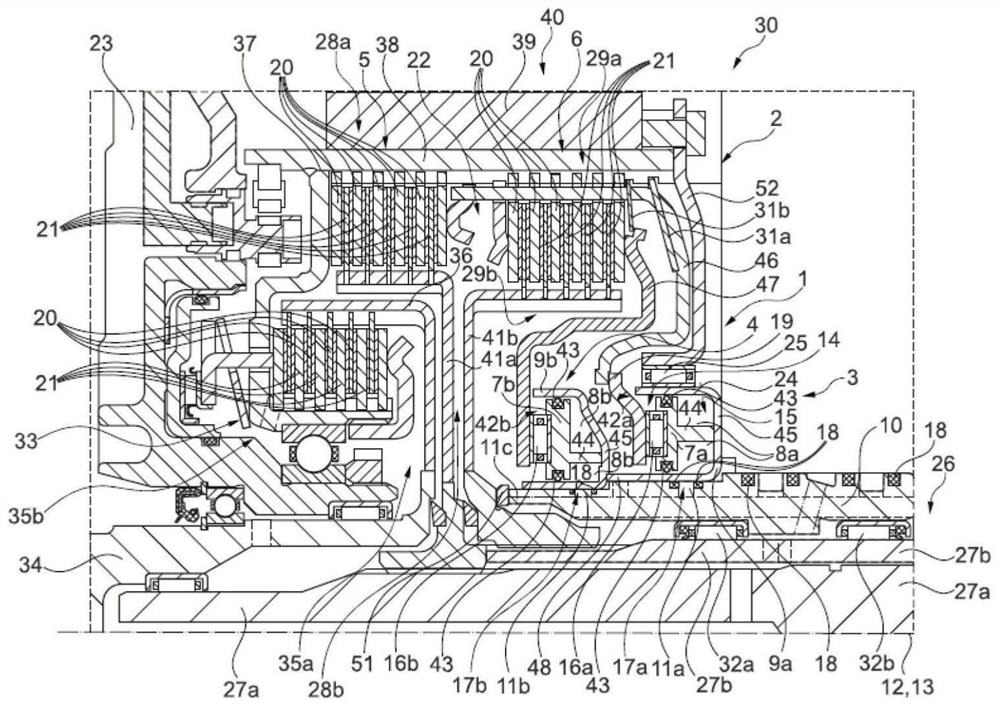

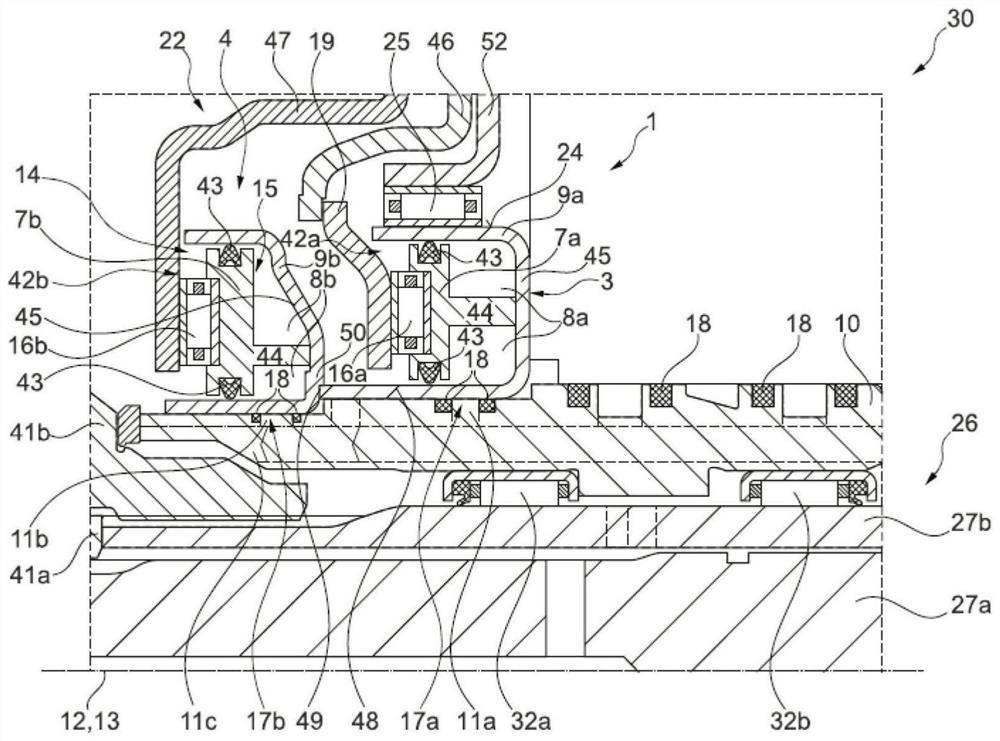

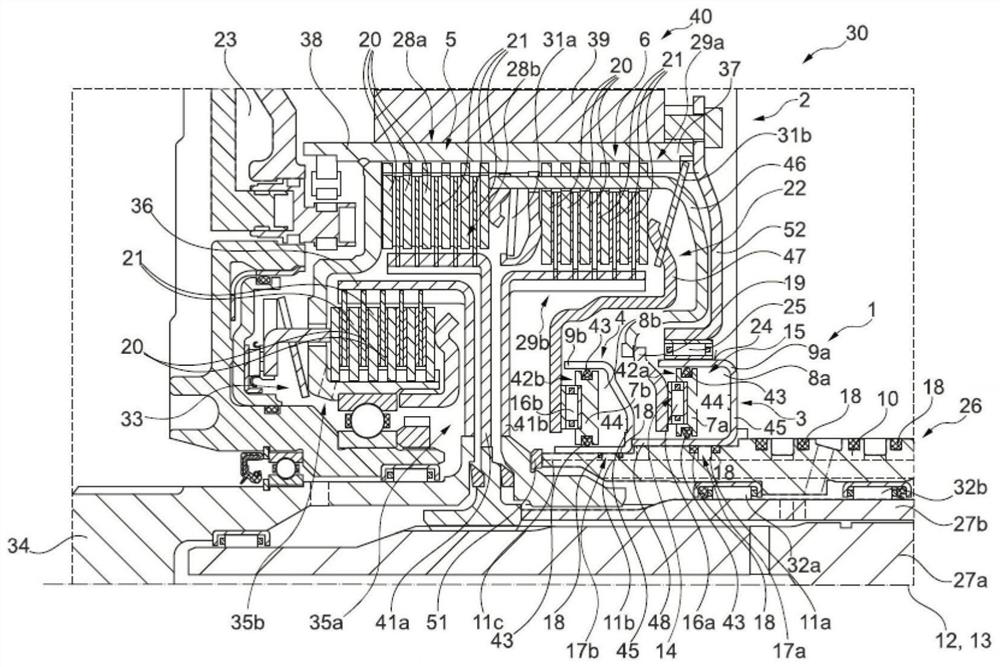

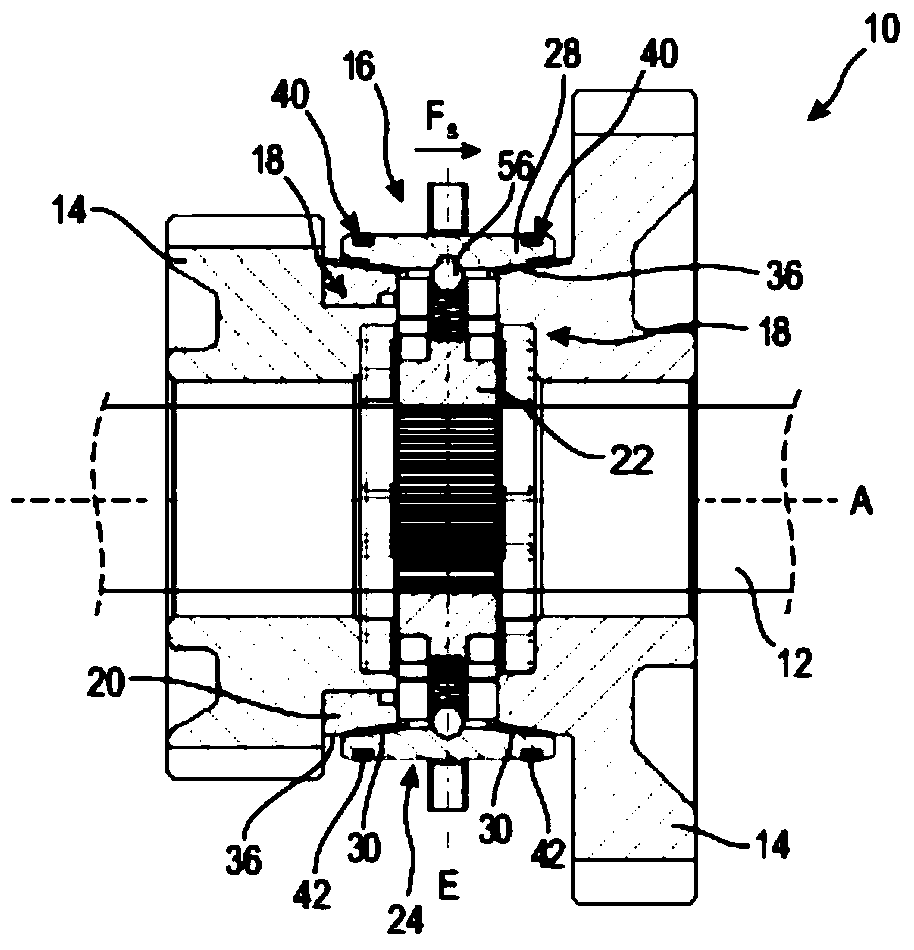

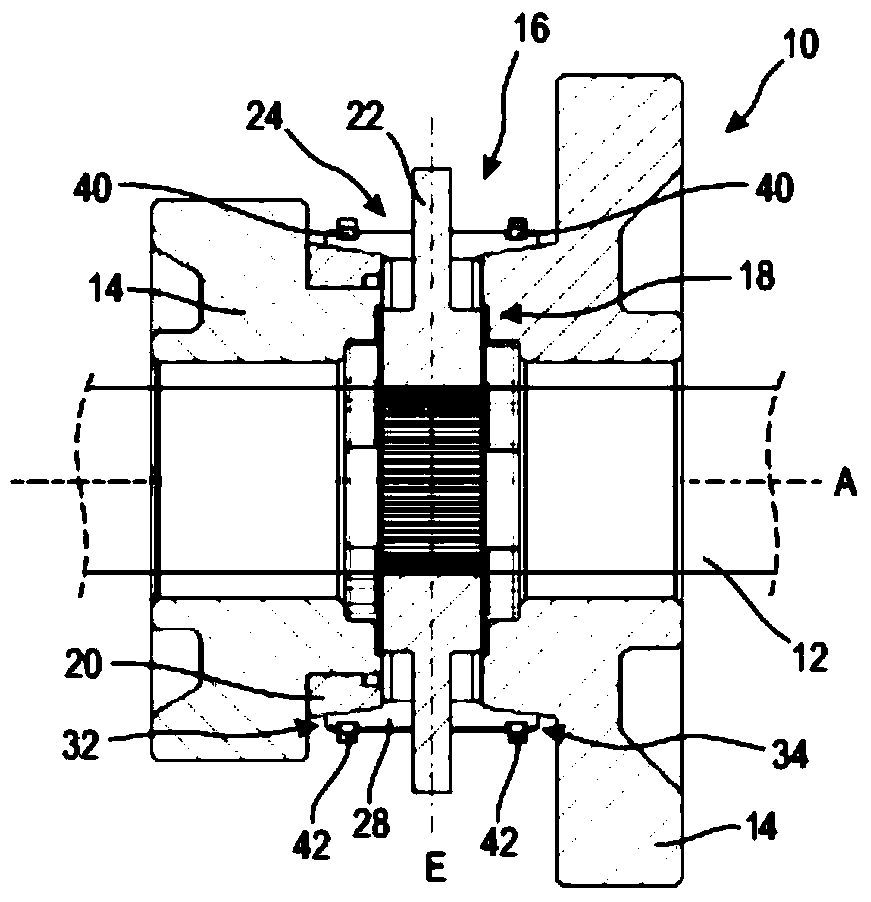

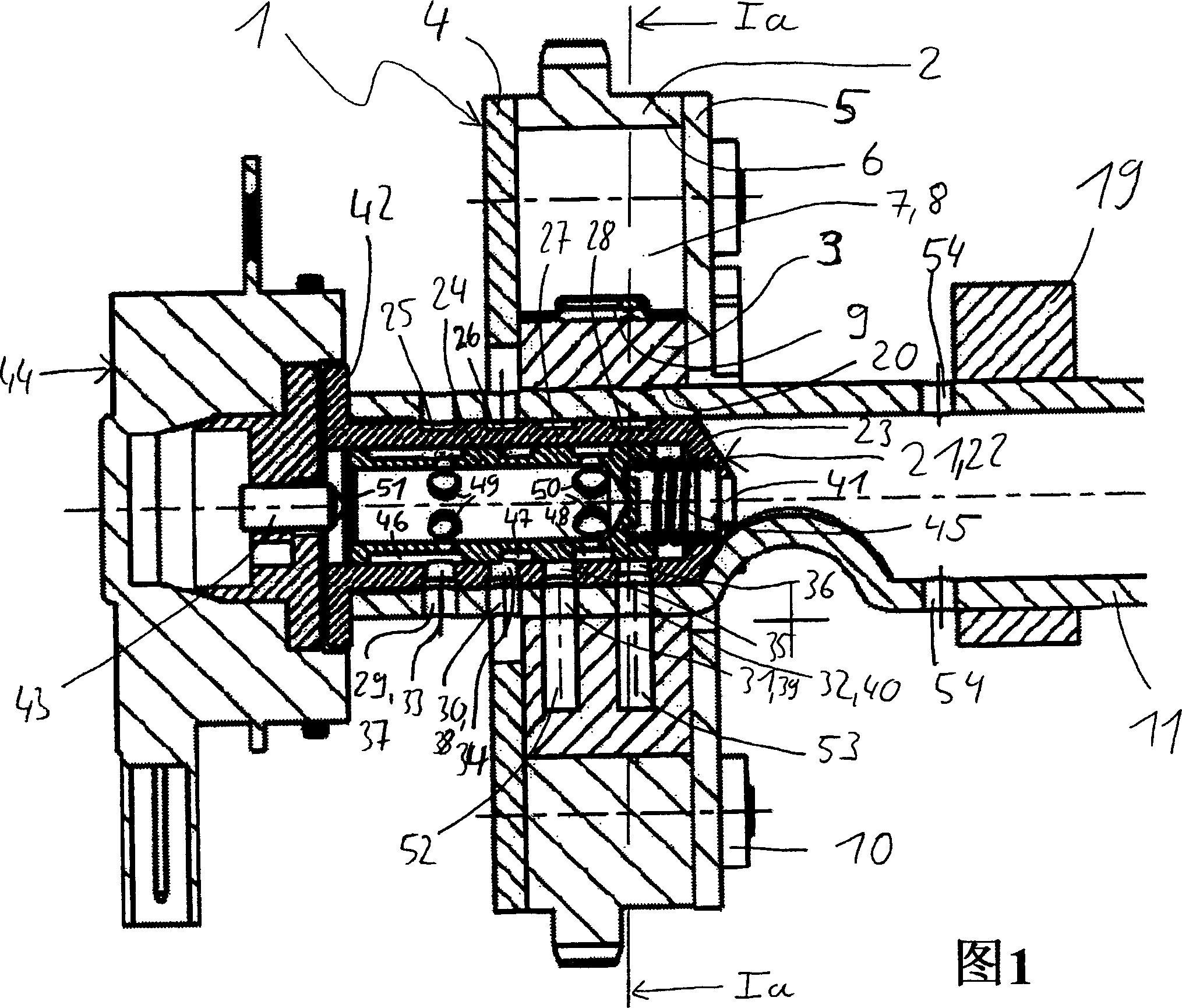

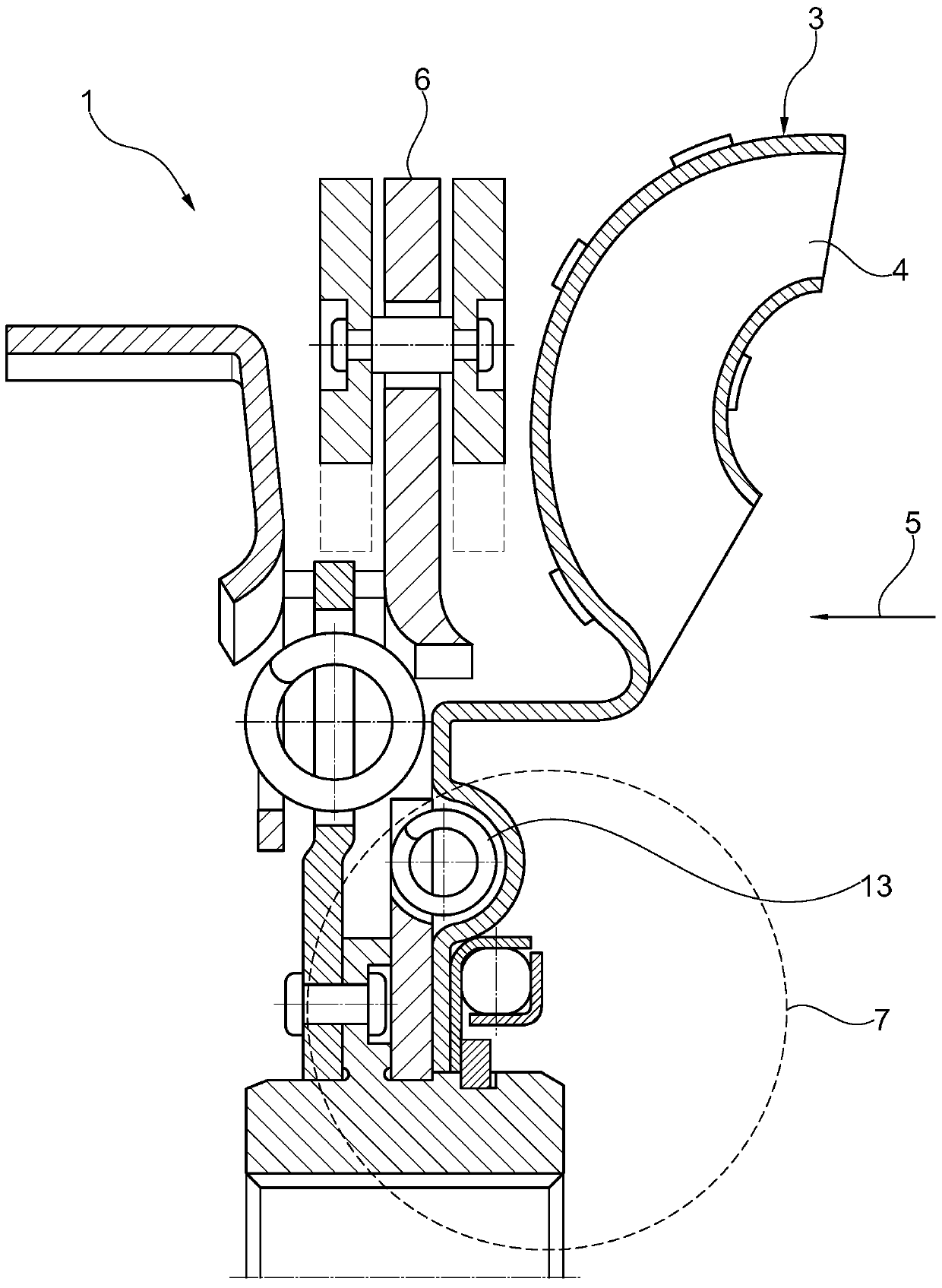

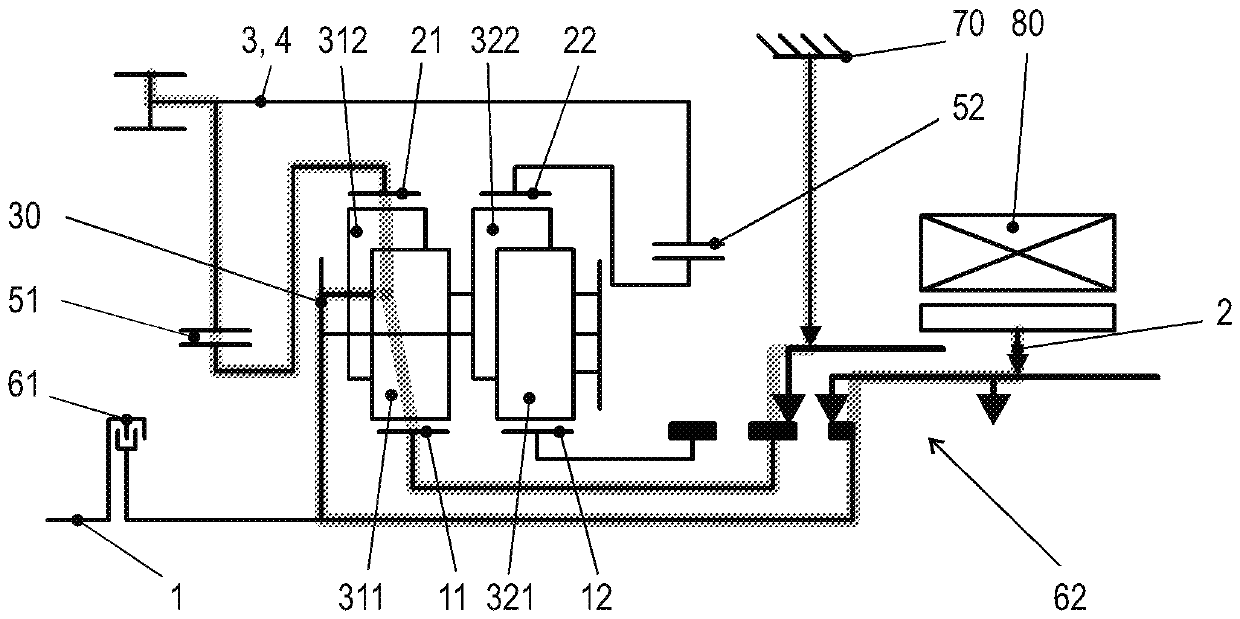

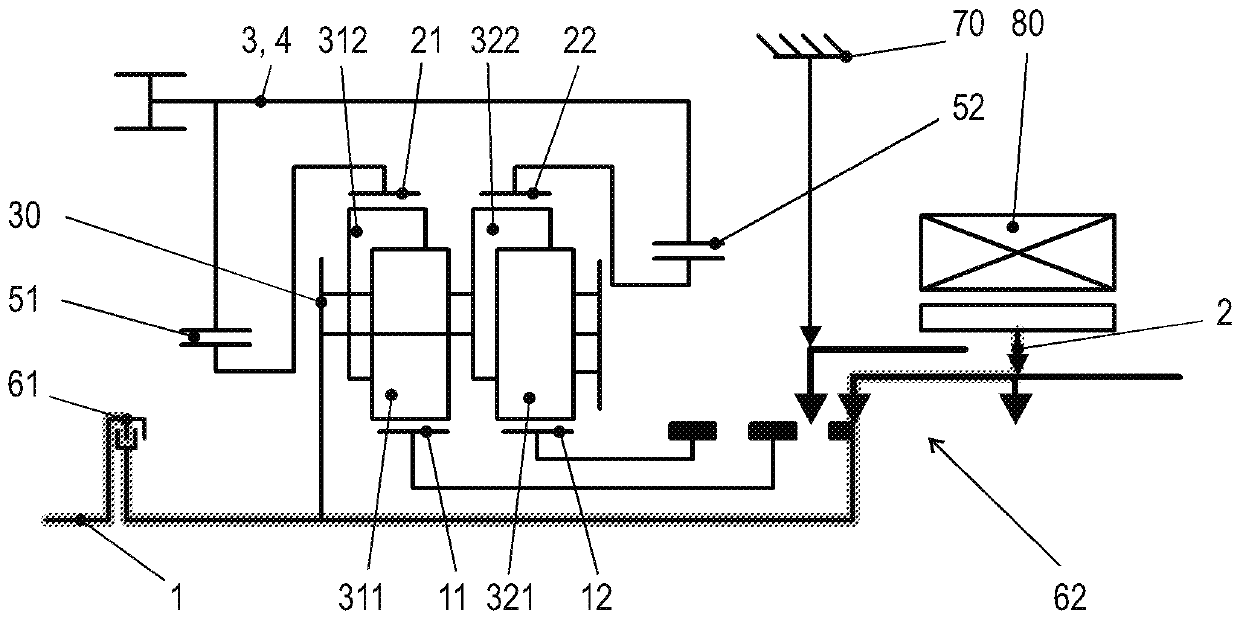

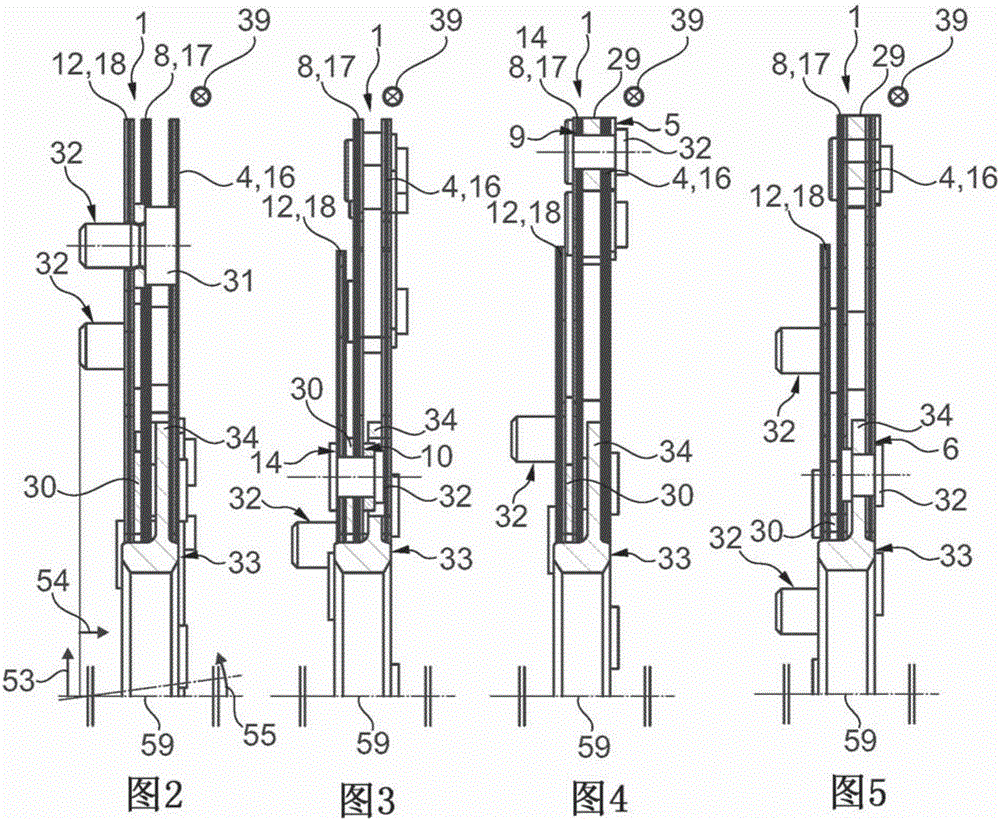

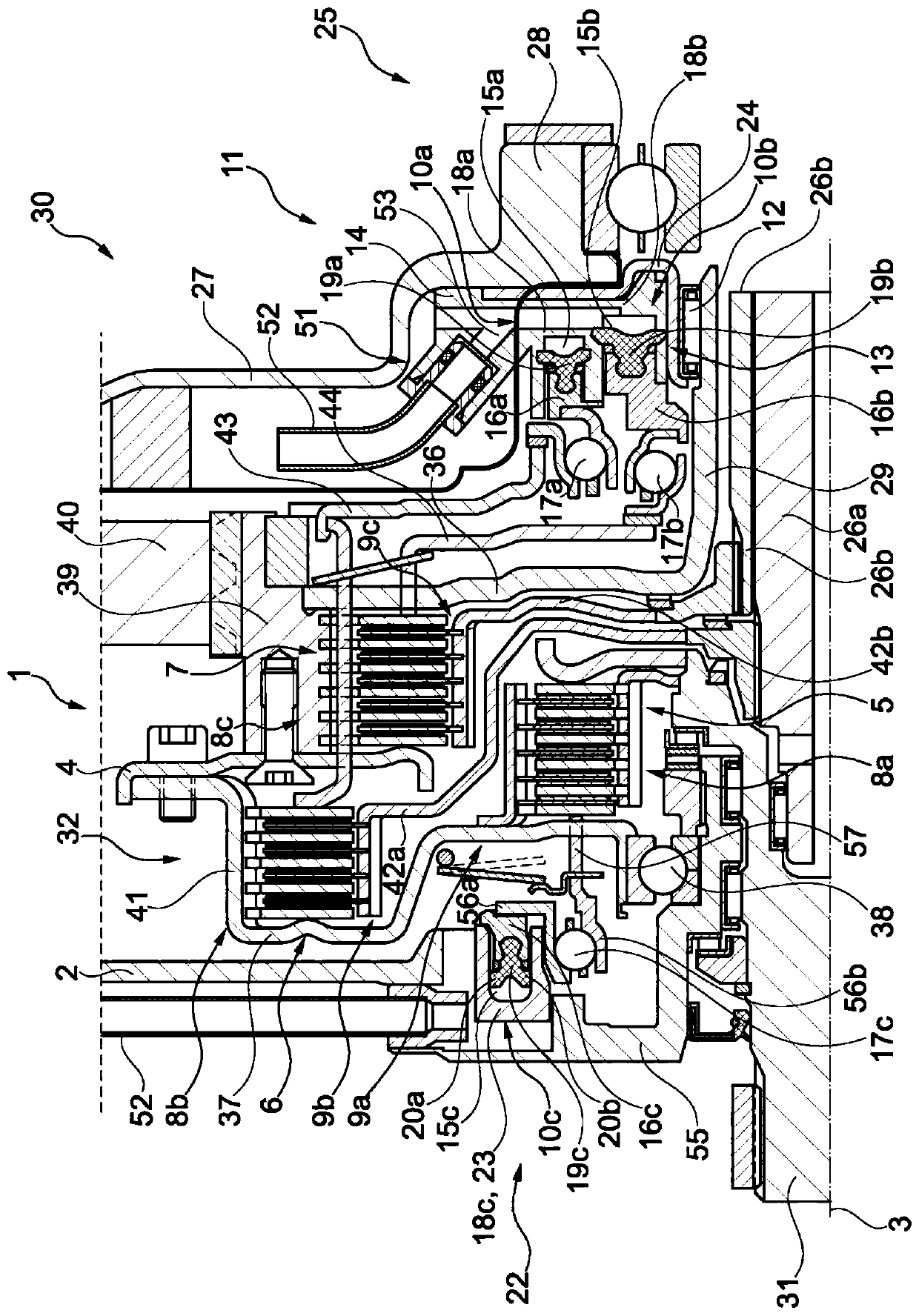

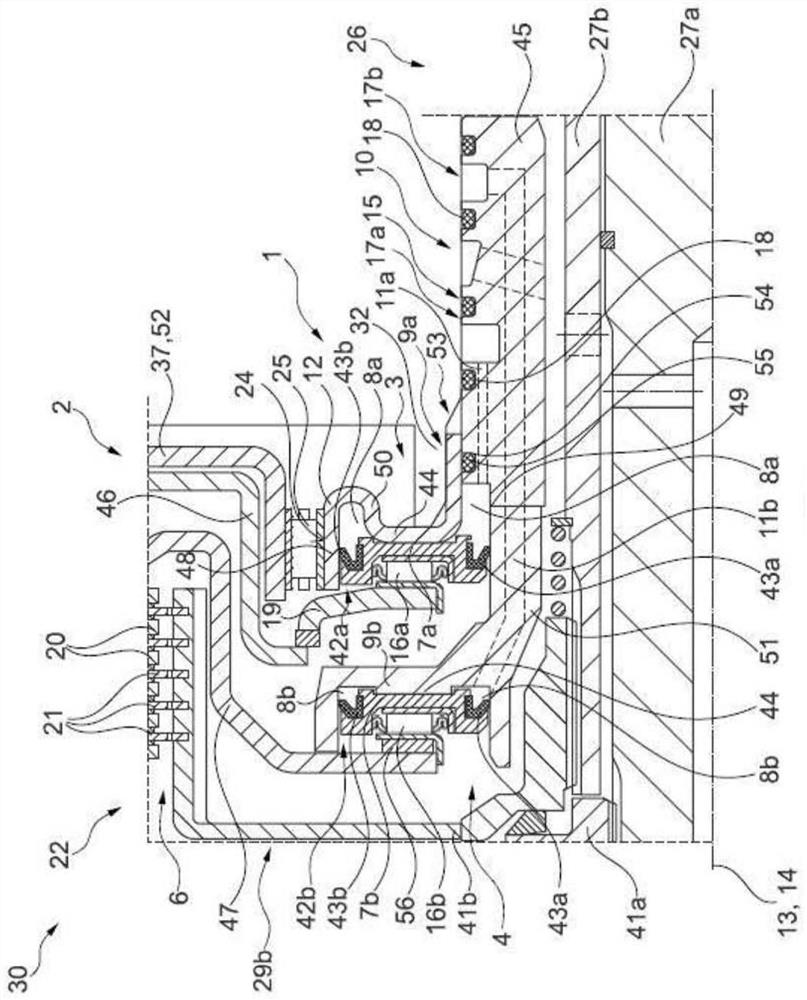

Actuation device having an axially nested slave cylinder, clutch system, and drive unit

ActiveCN111771070ASave axial construction spaceSave on installation costsMechanical actuated clutchesFluid actuated clutchesEngineeringPowertrain

The invention relates to an actuation device (1) for a clutch system (2) of a motor vehicle, having: two slave cylinders (3, 4) which are each designed to actuate a clutch (5, 6), each slave cylinder(3, 4) having a piston (7a, 7b) and a housing component (9a, 9b) which guides the piston (7a, 7b) in its displacement direction and, together with the piston (7a, 7b), delimits a fluid chamber (8a, 8b); and having a supply component (10), the slave cylinders (3, 4) being provided on the supply component (10) in such a way that, per slave cylinder (3, 4), a fluid supply channel (11a, 11b) of the supply component (10) is fluidically connected to the fluid chamber (8a, 8b), wherein the housing components (9a, 9b) of the two slave cylinders (3, 4) are supported directly on each other or on the supply component (10) in an axial direction of a longitudinal axis (12) of the supply component (10). The invention also relates to a clutch system (2) for a drive train of a motor vehicle, the clutch system having this actuation device (1); and to a drive unit (30).

Owner:SCHAEFFLER TECH AG & CO KG

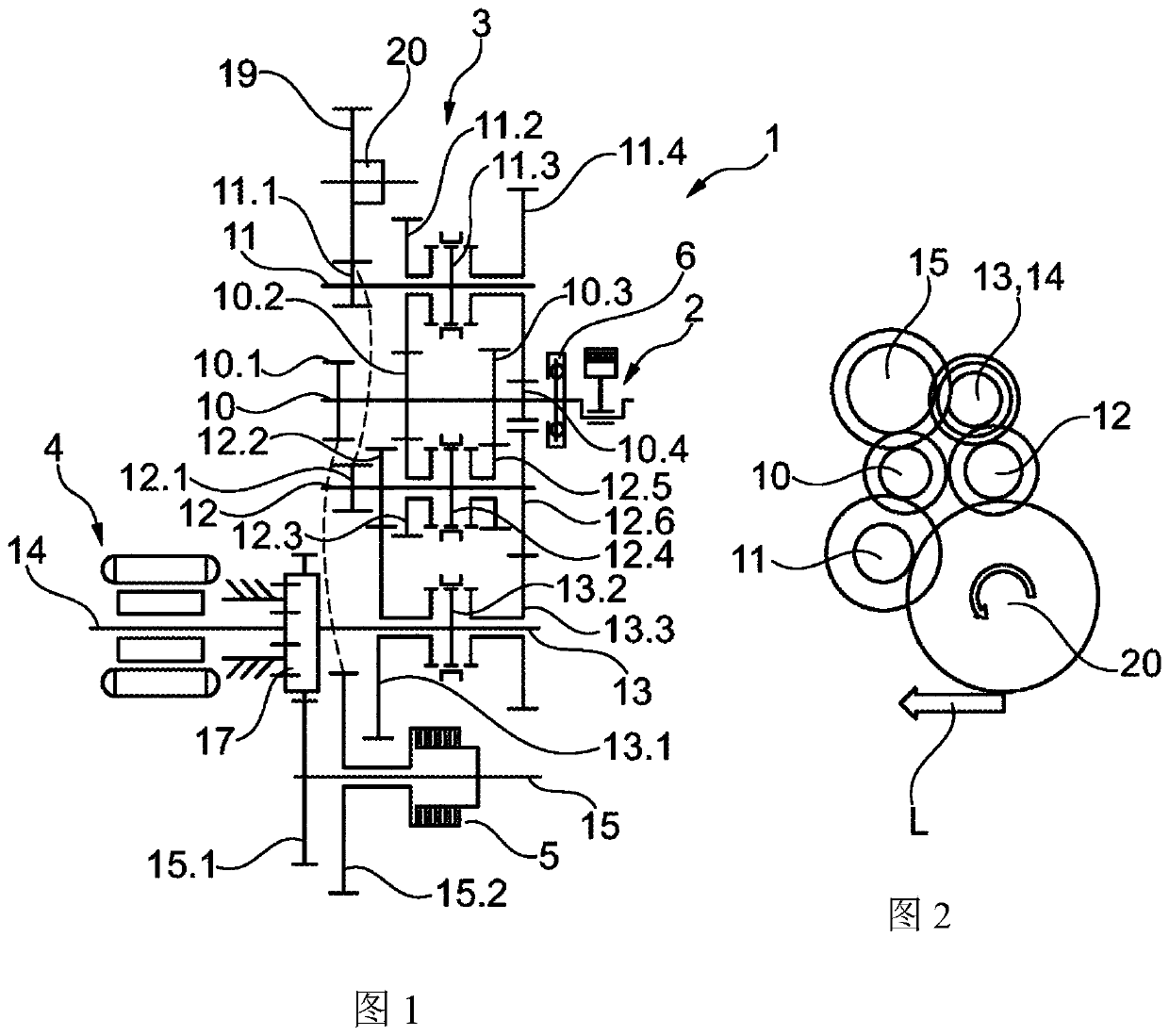

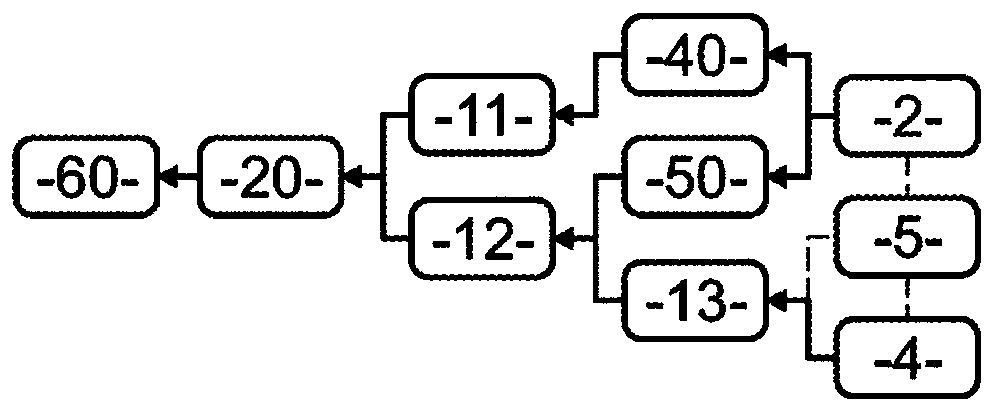

Drive train for a motor vehicle, and method for operating a drive train

The invention relates to a drive train for a motor vehicle, having an internal combustion engine (2), having an automated change-speed transmission (3), having an electric machine (4) with a switchable separating clutch (5) for selectively making a power flow possible between the electric machine (4) and the internal combustion engine (2), and having a differential gear mechanism (20), wherein theinternal combustion engine (2) has an output shaft (2.1) which is coupled without a separating clutch to a first transmission input shaft (10) of the automated change-speed transmission (3), whereinthe automated change-speed transmission (3) has a first transmission output shaft (11) and a second transmission output shaft (12) which are operatively connected to a differential drive gear (19) ofthe differential gear mechanism (20), wherein the separating clutch (5) is arranged coaxially with respect to a clutch shaft (15) which is connected to the separating clutch (5) and is arranged spacedapart in parallel from the first transmission input shaft (10), wherein the clutch shaft (15) is arranged spaced apart in parallel from the first transmission output shaft (11) and the second transmission output shaft (12).

Owner:SCHAEFFLER ENG

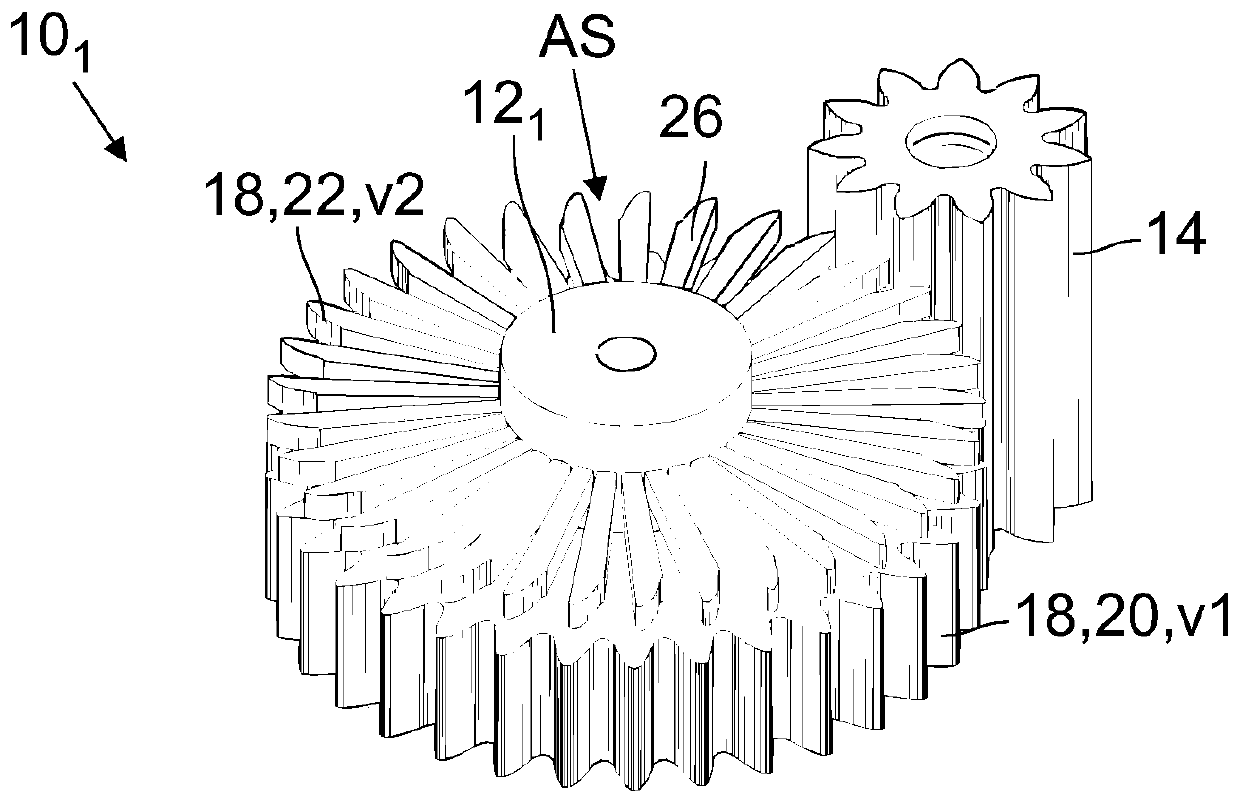

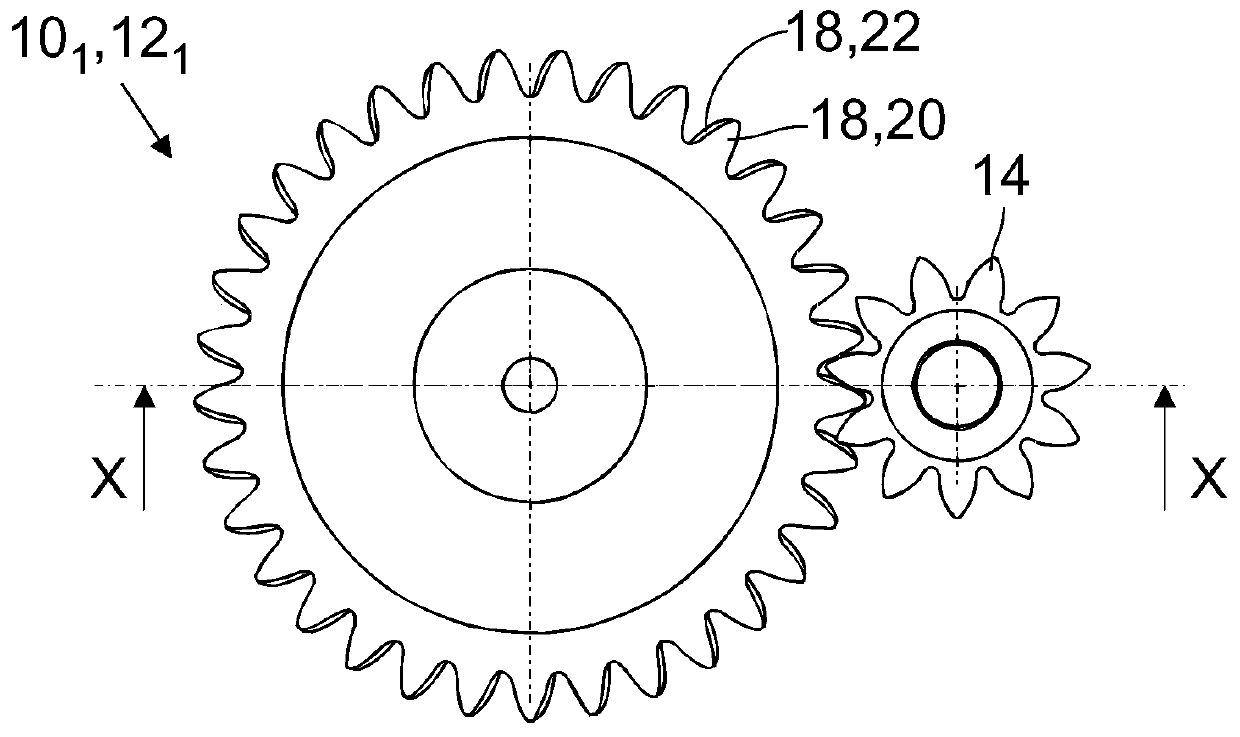

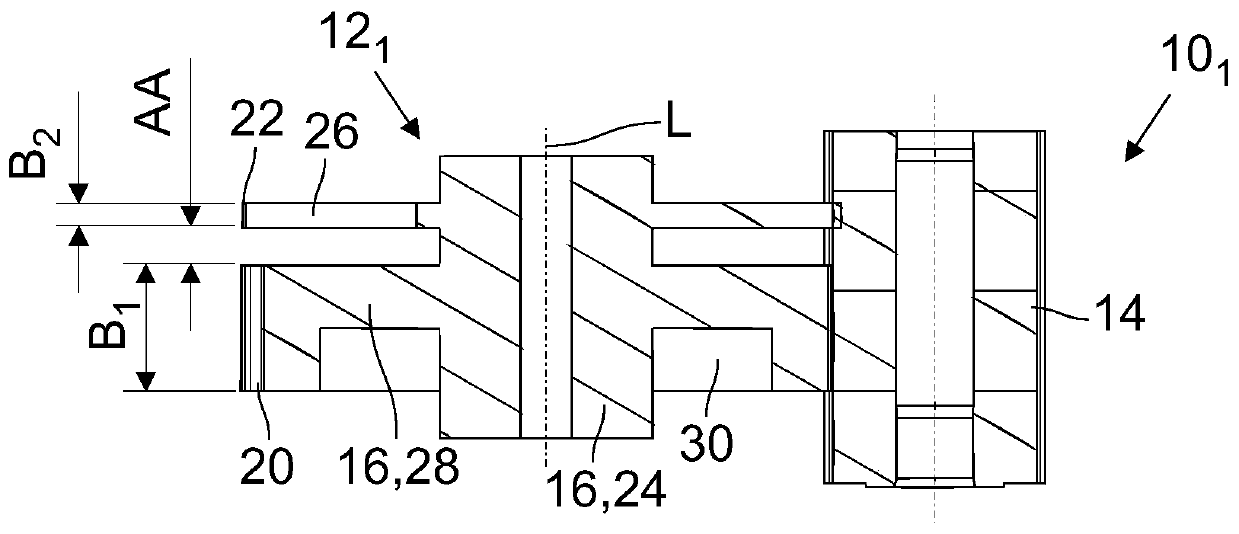

Toothed wheel for use in a gear transmission, gear pairing of a gear transmission and gear transmission with such a gear pairing

PendingCN111486194ASmooth runningEasy to manufacturePortable liftingToothed gearingsGear wheelGear tooth

A toothed gear 12 for use in a gear transmission 48, comprising a base body 16 that forms a ring gear 18 with a number of first teeth 20 having a first deformability v1 and a number of second teeth 22having a second deformability v2, wherein the second deformability v2 is greater than the first deformability v1 and to a gear pair 10 of the gear transmission, comprising such a toothed gear 12 andat least one further toothed gear 14 which can be made to mesh or is in mesh with the toothed gear. The invention relates moreover to the gear transmission 48 with such a gear pair 10.

Owner:IMS GEAR SE & CO KGAA

Tooth joints for automotive transmissions

ActiveCN104455067BEasy to buildSave axial construction spaceMechanical actuated clutchesGearing controlCouplingEngineering

The invention relates to a cog joint (16) for a vehicle transmission (10) having: at least one coupling body (18); an annular control claw (22); and a friction unit (24), wherein The friction unit (24) is positively connected to the control claw (22) in the tangential direction (26) and can act axially via the control claw (22), wherein the control claw (22) is opposite to the coupling The joint body (18) is axially adjustable between the intermediate position, the synchronous position and the shift position. In the intermediate position, the control claw (22) is basically free to rotate relative to the coupling body (18). The position control claw (22) is coupled with the coupling main body (18) in the tangential direction (26) through frictional connection, and the control claw (22) and the coupling main body (18) are tangentially coupled in the shift position. Direction (26) is connected in a form-fitting manner.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Hybrid Module

ActiveCN109789764BCompact structureSave axial construction spaceHybrid vehiclesMechanical actuated clutchesRotational axisElectric machinery

The invention relates to a hybrid module (1; 24) for a motor vehicle, said hybrid module comprising an electric machine (4), a double clutch (7) and a separating clutch (8), the electric machine having a stator (2) and a rotor (3), the dual clutch has a first sub-clutch and a second sub-clutch (5, 6), the dual clutch is configured to enable the hybrid module (1; 24) to be connected to the transmission of the motor vehicle in a detachable manner, and the separation clutch is configured In order to detachably connect the internal combustion engine of the motor vehicle to the hybrid module (1; 24), wherein the double clutch (7) and the separating clutch (8) are arranged radially and axially inside the rotor (3), wherein The first sub-clutch and the second sub-clutch (5, 6) are arranged axially one after the other, and the separating clutch (8) is located radially closer to the axis of rotation (9) of the rotor (3) than the double clutch (7) layout.

Owner:SCHAEFFLER TECH AG & CO KG

Coolant pump for an internal combustion engine

ActiveCN108291550APrecise axial movementEasy to installLiquid coolingCircumferential flow pumpsImpellerDrive shaft

The invention relates to a coolant pump for an internal combustion engine. The coolant pump is equipped with a drive shaft (18), having a coolant pump impeller (20) which is arranged at least rotationally conjointly on the drive shaft (18) and by means of which coolant can be delivered into a delivery duct (12) surrounding the coolant pump impeller (20), having an adjustable regulating slide (28)by means of which a throughflow cross section of a ring-shaped gap (30) between an outlet (32) of the coolant impeller (20) and the delivery duct (12) can be regulated, having a side channel pump (56)with a side channel pump impeller (46) which is arranged at least rotationally conjointly on the drive shaft (18), having a side channel (50) of the side channel pump (56), in which side channel a pressure can be generated as a result of rotation of the side channel pump impeller (46), having a pressure duct (72) via which an outlet (54) of the side channel (50) is fluidically connectable to a first pressure chamber (58) of the regulating slide (28), and having a valve (66) by means of which a throughflow cross section (70) of the pressure duct (72) can be closed and opened up, are known. Toshorten the structural space thereof in particular axially, it is proposed that the coolant pump impeller (20) is formed in one piece with the side channel pump impeller (46), and the side channel (50) is formed in a first housing part (40) on which the regulating slide (28) is slidingly guided.

Owner:PIERBURG GMBH & CO KG NEUSS

Camshaft regulator

ActiveCN1696475BPrevent axial movementPrevent movementValve drivesMachines/enginesExternal combustion engineInternal combustion engine

A device for changing the control times of an internal combustion engine (camshaft adjuster ( 1 )) having a pressure medium distributor ( 21 ) arranged within a camshaft ( 11 ) is provided. The pressure medium distributor ( 21 ) is provided at its front end with a radially extending shoulder ( 42 ), this shoulder ( 42 ) forming part of the camshaft axial mounting.

Owner:SCHAEFFLER TECH AG & CO KG

Double clutch

InactiveCN102187107BSave materialSave axial construction spaceRolling contact bearingsMechanical actuated clutchesEngineeringClutch

The invention relates to a double clutch comprising two friction clutches, a central back pressure plate and a pressure plate pressurized by a hydrostatic engagement system. In order to be able to propose a cost-effective design having no clutch cover, two axially fixed shaft bearings are provided on the hollow shaft of the double-clutch transmission, said bearings rotatably receiving the back pressure plate and the engagement system such that the power flow can be closed by way of the hollow shaft when actuating the friction clutches.

Owner:SCHAEFFLER TECH AG & CO KG +1

Compact planetary gearbox

InactiveCN107477169ASave axial construction spaceSave construction spaceToothed gearingsGearing detailsEngineeringSpur gear

Owner:ZF FRIEDRICHSHAFEN AG

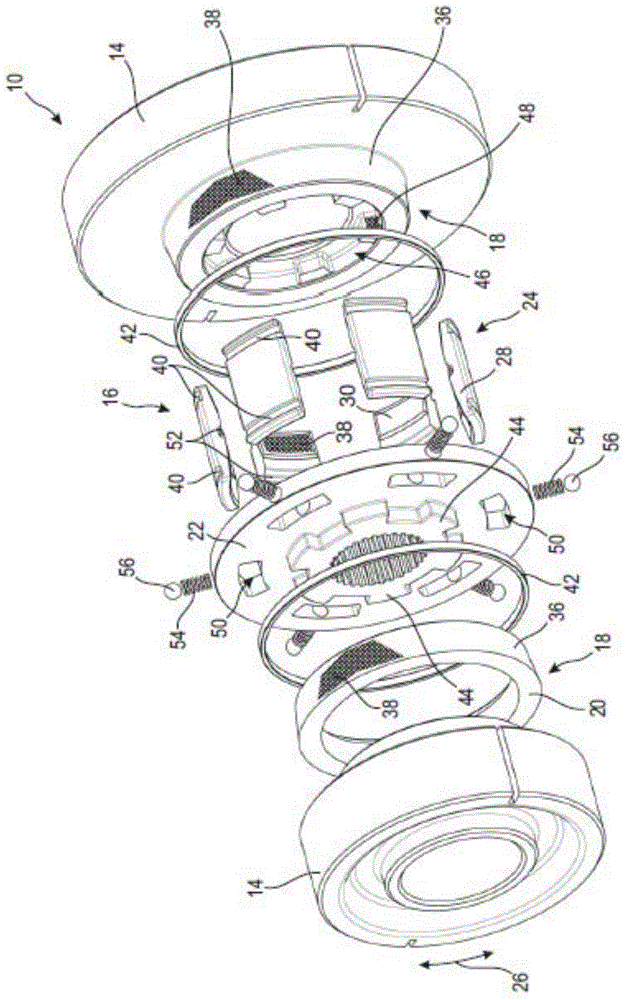

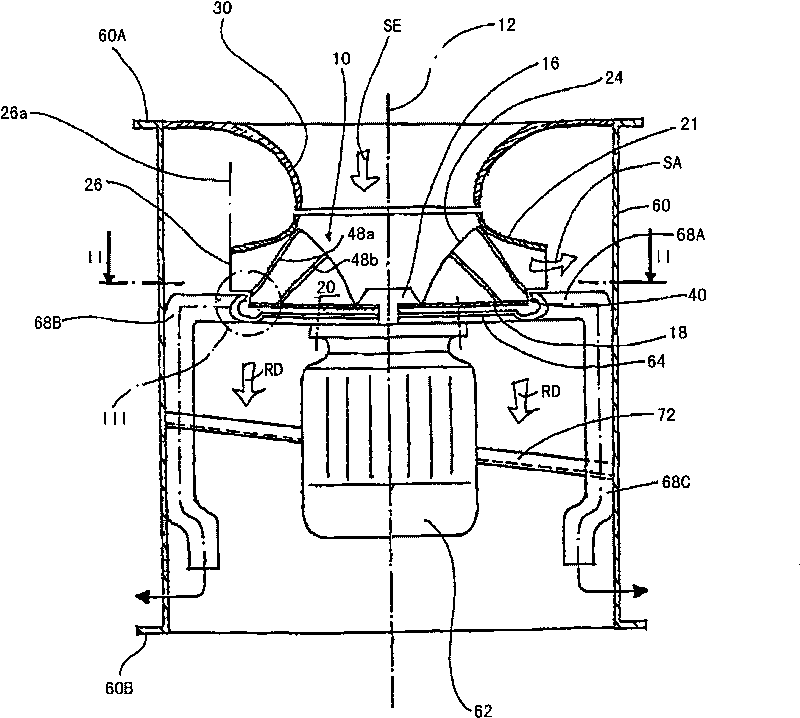

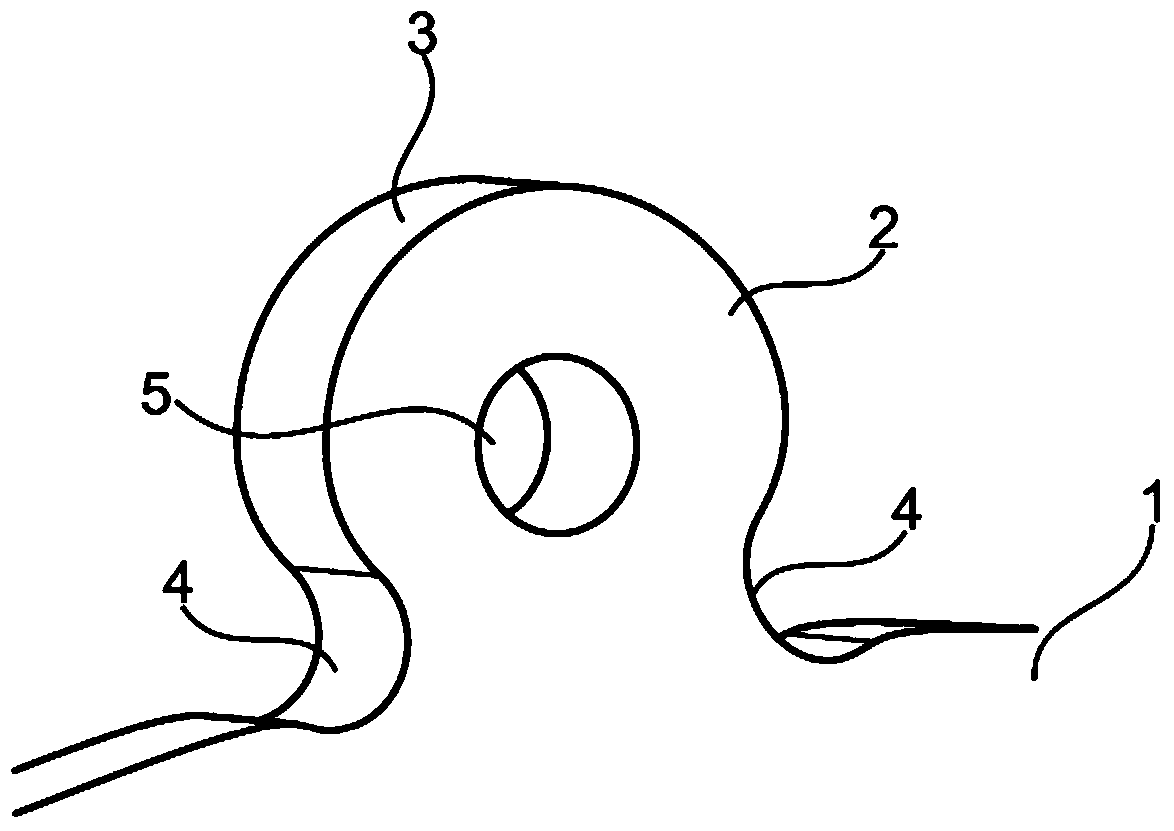

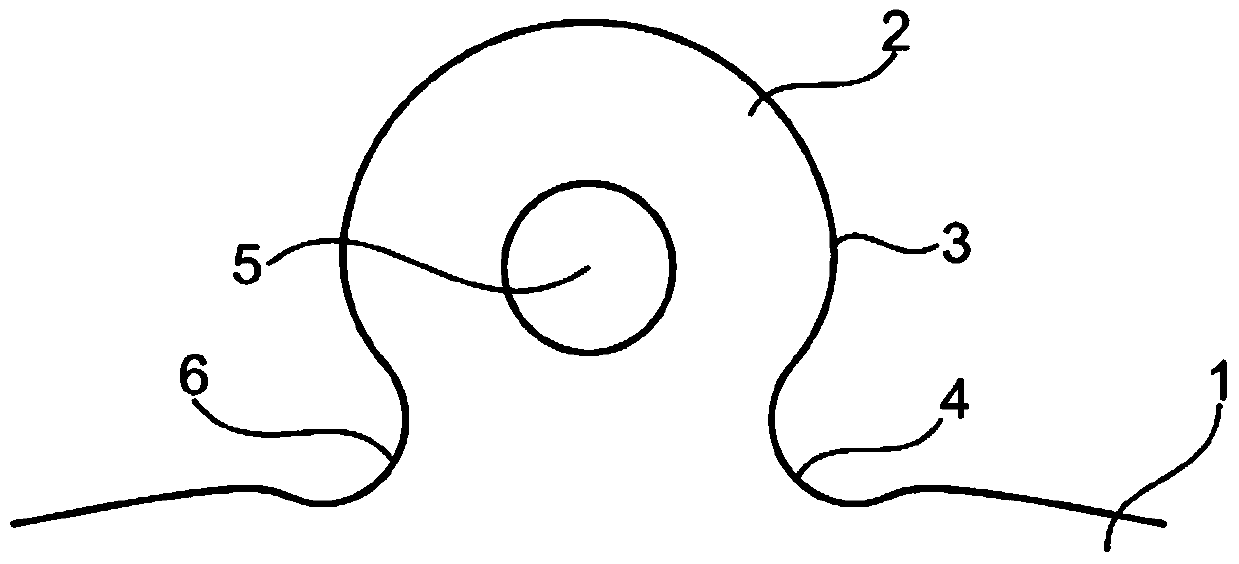

Torque converters for motor vehicles

ActiveCN104613156BIncrease heightSave axial construction spaceRotating vibration suppressionFluid gearingsTurbine bladeNoise reduction

Hydrodynamic torque converter for a motor vehicle, comprising at least the following components: a turbine with turbine blades for a hydrodynamic fluid; an anti-vibration device which includes at least one centrifugal pendulum, for emptying vibrations; an elastic connecting element between the turbine and the anti-vibration device, which transmit a rotary motion between the turbine and the anti-vibration device. Also, the invention relates to a hydrodynamic torque converter for a motor vehicle, comprising at least the following components: a turbine with turbine blades for a hydrodynamic fluid; an anti-vibration device for damping and / or emptying vibrations; a dissipation element, which connects the turbine with the anti-vibration device and which transmits a rotational movement between the turbine and the anti-vibration device. With the hydrodynamic torque converter proposed here, it is possible to achieve noise reduction and preservation of elements of an anti-vibration device in a small space.

Owner:SCHAEFFLER TECH AG & CO KG

Coolant pumps for internal combustion engines

InactiveCN108291550BCancel manufacturingShorten the axial structural lengthLiquid coolingCircumferential flow pumpsImpellerDrive shaft

The invention relates to a coolant pump for an internal combustion engine, said coolant pump having: a drive shaft (18); on the shaft (18), and through the coolant pump impeller, the coolant can be delivered to the delivery channel (12) around the coolant pump impeller (20); the adjustable control slider (28), through the The control slider can regulate the flow cross-section of the annular gap between the outlet (32) of the coolant pump impeller (20) and the surrounding delivery channel (12); the side channel with the side channel pump impeller (46) a pump (56), the side channel pump impeller being arranged at least torsionally fixed on the drive shaft (18); a side channel (50) of the side channel pump (56) through which the side channel The rotation of the pump impeller (46) can generate pressure; the pressure channel (72), through which the outlet (54) of the side channel (50) can be connected to the first pressure chamber of the control slider (28) (58) in fluid communication; and a valve (66) by which the flow cross-section (70) of the pressure channel (72) can be closed and opened. In order to shorten the construction space of the coolant pump in particular axially, it is proposed that the coolant pump impeller (20) is formed in one piece with the side channel pump impeller (46) and that the side channel (50) is formed in the first In the housing part (40), the control slide (28) is slidably guided on the first housing part.

Owner:PIERBURG GMBH & CO KG NEUSS

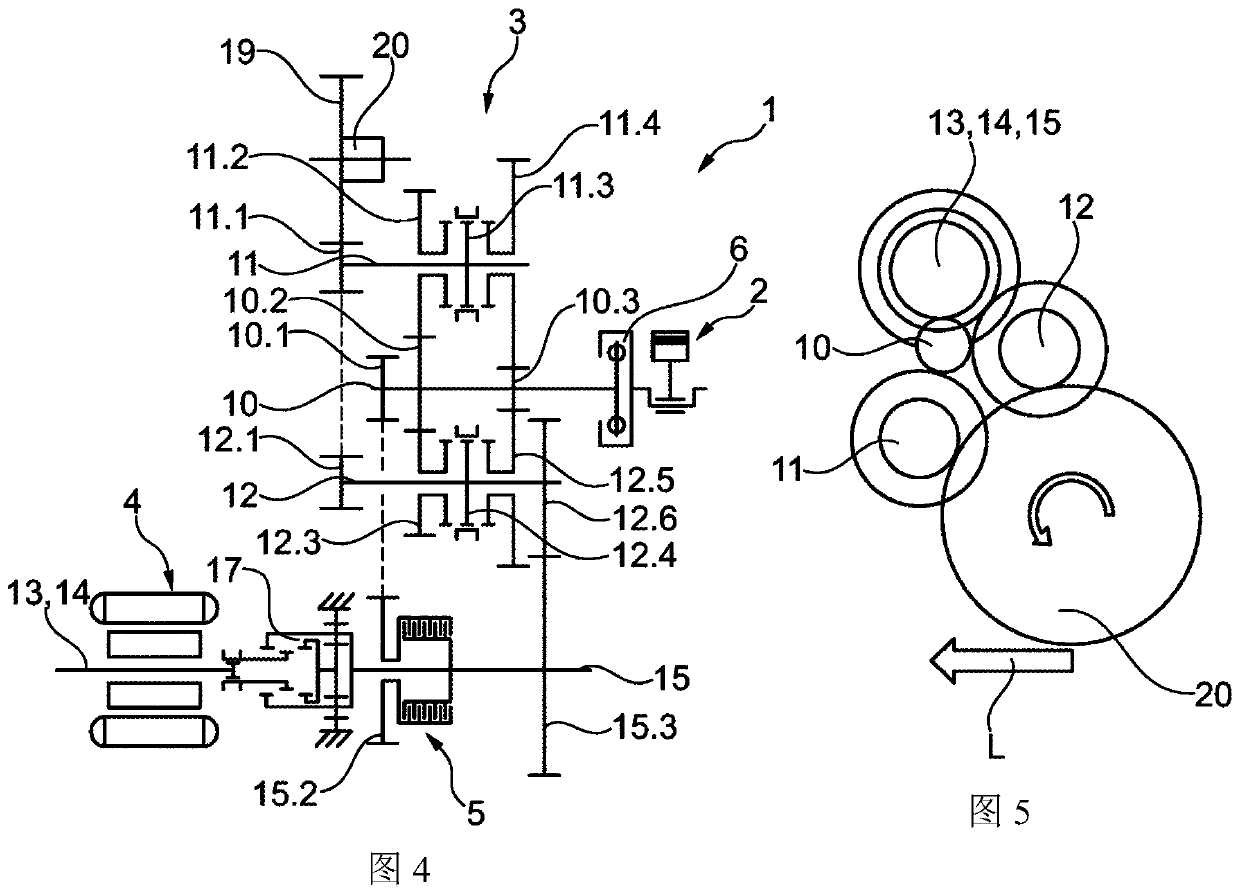

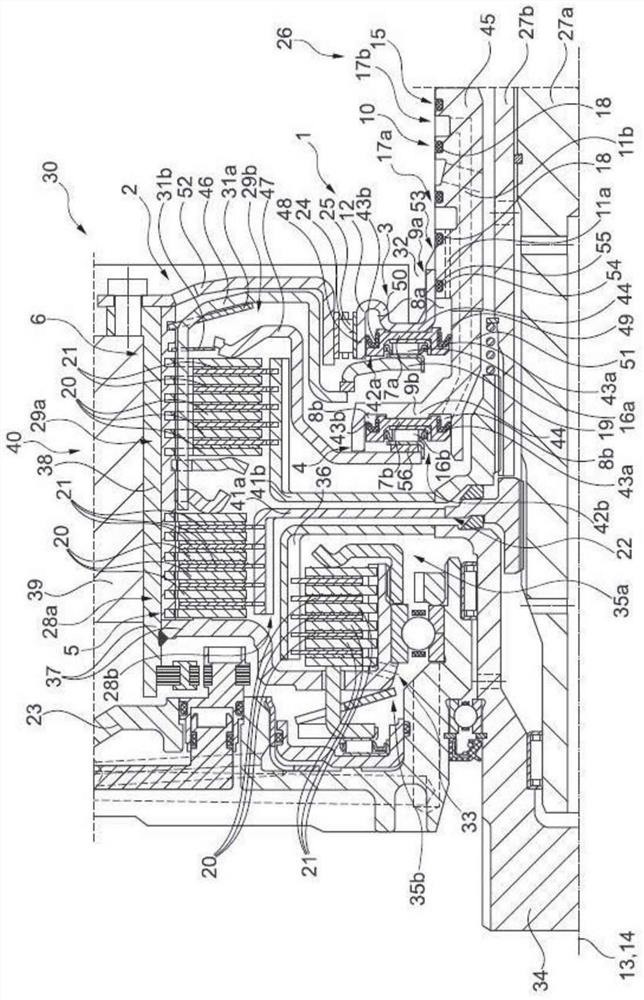

A drive assembly used for a hybrid vehicle

InactiveCN109915555AImprove efficiencySave axial construction spaceHybrid vehiclesGas pressure propulsion mountingInternal combustion engineHybrid vehicle

The invention relates to a drive assembly for a hybrid vehicle. The drive assembly includes an internal combustion engine input shaft (1) for connecting the drive assembly to an internal combustion engine of a hybrid vehicle; an electric motor input shaft (2) for connecting the drive assembly to an electric machine (80) of the hybrid vehicle; an output shaft (3) for connecting the drive assembly to a slave drive of the hybrid vehicle; a planetary transmission provided with two planetary groups connected via a common bridge portion (30), with the first planetary group being configured as a simple double planetary group; and a plurality of switching elements (61, 62) by means of which components of the planetary transmission are coupled, in a switchable manner, to the input shaft (1, 2) and / or a transmission housing (70). The drive assembly is characterized in that the second planetary group is also configured as a simple double planetary group.

Owner:VOLKSWAGEN AG

furniture hinge

ActiveCN107810304BSave axial construction spaceReduce structural designBuilding braking devicesPin hingesCoil springEngineering

The invention relates to a furniture hinge (4) comprising: - a first stop (5) for fixing to a furniture body (2); - for fixing to a movably supported furniture part (3) the second stop (9), the second stop (9) is hingedly linked to the first stop (5); - at least one helical spring (12) with direction of action (X), the furniture hinge (4 ) is movable by the helical spring (12) from a predetermined angular position into a fully closed position and / or a fully open position; - a damping device (11) for damping the movement of the hinge, which has at least one fluid chamber (25) in which the piston (22) with the piston rod (20) is accommodated for implementing a damping stroke extending in one direction (Y), the direction of action (X) of the helical spring (12) and the damping The direction of travel (Y) extends laterally at a parallel distance or obliquely to one another, wherein the helical spring (12) and damping device (11) are arranged on a common carrier (10) integrated in the furniture hinge (4) ) in or above.

Owner:JULIUS BLUM GMBH

Compensating device for torque-transmitting connection of input shaft and output shaft

ActiveCN106499738AFull torque rigidityLarge deformationHybrid vehiclesYielding couplingElectrical and Electronics engineeringEngineering

Owner:SCHAEFFLER TECH AG & CO KG

Design method of widened circulating circle hydraulic retarder

InactiveCN106709113ASave axial construction spaceReduce braking torqueSpecial data processing applicationsBrake torqueEngineering

The invention discloses a design method of a widened circulating circle hydraulic retarder. The design method comprises the steps that in the first step, based on a three dimensional integrated emulation technique, parameterization automatic modeling and simulating calculation of a widened circulating circle hydraulic retarder are achieved; in the second step, comparisons are made between distributions of the velocity field, the pressure field, and the turbulent kinetic energy dissipation rate of an internal flow passage of the hydraulic retarder with different aspect ratios; in the third step, analyses are conducted on the braking torque with different aspect ratios. The widened circulating circle hydraulic retarder through the building of a three dimensional integrated emulation platform achieves the automatic model building and simulation calculation of the parameterized hydraulic retarder based on the solution of the CFD; contrastive analyses of the internal flow field show that the speed of the internal flow field, the pressure and the dissipation rate of the turbulent kinetic energy are all lowered following the decrease in the aspect ratios on the value distribution; the braking torque is lowered following the decrease in the aspect ratios, the hydraulic retarder with small aspect ratios can effectively reduce the axial direction structure space.

Owner:HEILONGJIANG HENGNENG SELF CONTROL TECH CO LTD

Flexible area of the plate in the double clutch for recalibration of parallelism

ActiveCN105889349BEnsure plane parallelismSave axial construction spaceFriction clutchesCouplingsEngineeringRivet

The invention relates to a pressure plate (1) for a clutch of a motor vehicle, and the pressure plate at least has a rivet receiving area (2). The rivet receiving area is designed for receiving a rivet, and the pressure plate (1) can be fixed to another pressure plate (1) by means of the rivet; wherein the pressure plate (1) at least has a compliant area (4), and the compliant area is configured to permit torsion, inclination and / or bending of the pressure plate (1) with the compliant area (4), so that planar parallelism between the two pressure plates (1) is guaranteed. The invention also relates to a method for installing the clutch. The clutch comprises multiple pressure plates (1) which are connected in series connection, the pressure plates are mutually and rigidly connected by rivet connection, wherein a straightening process is carried out after riveting by means of a straightening tool (8), in order to ensure parallelism of friction surfaces (4), and the straightening tool exerts parallel forces at a coaxial direction along the rivet.

Owner:SCHAEFFLER TECH AG & CO KG

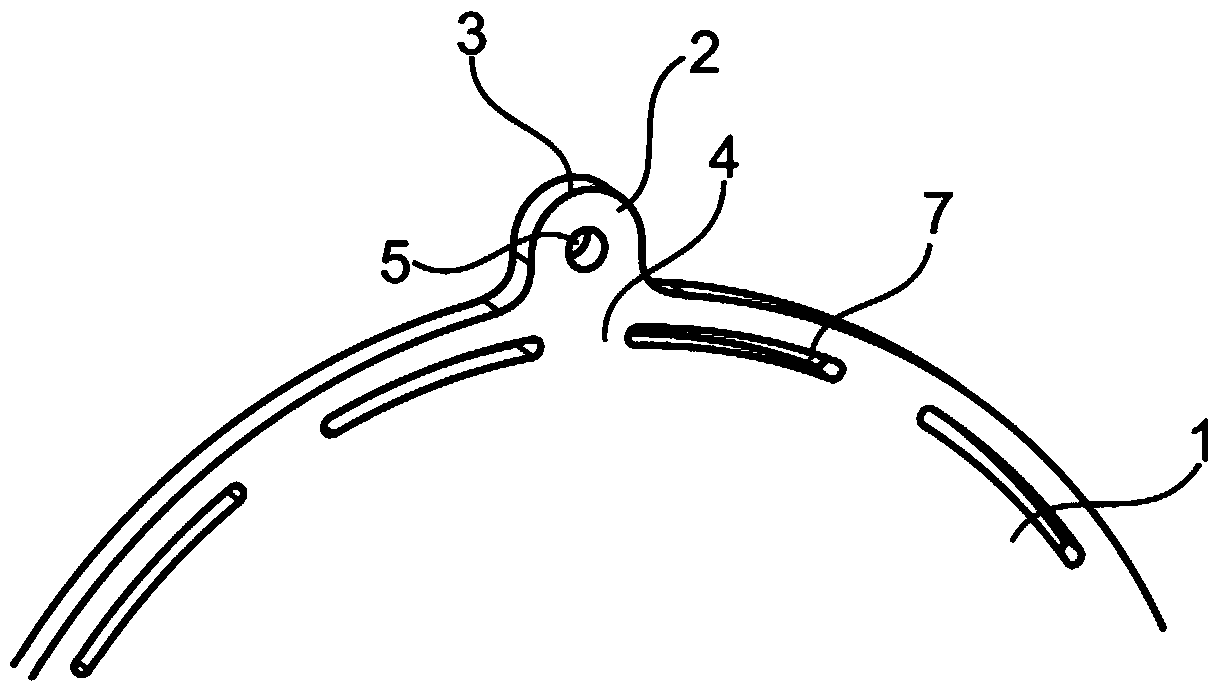

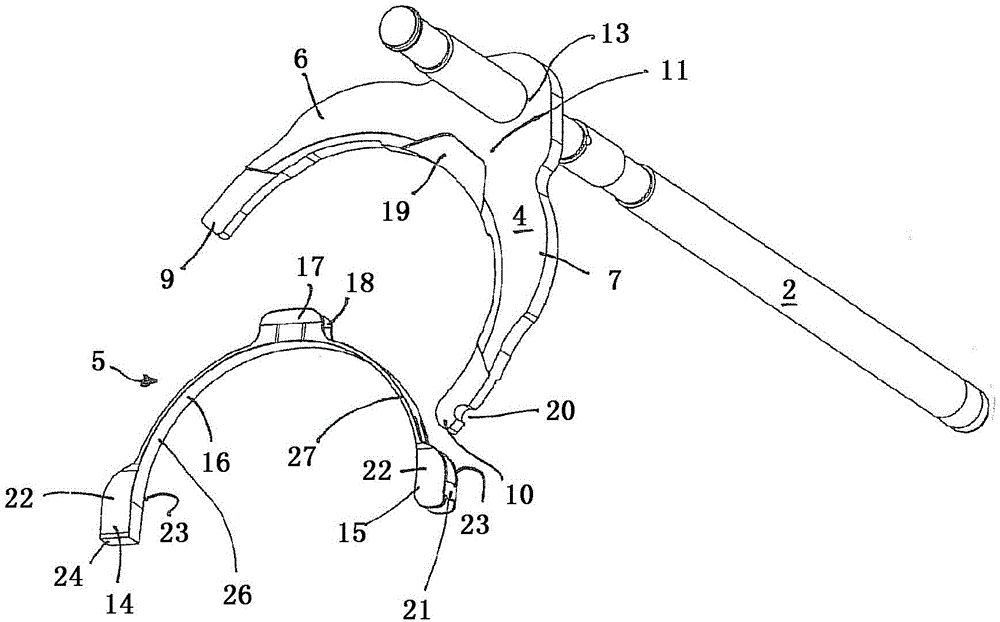

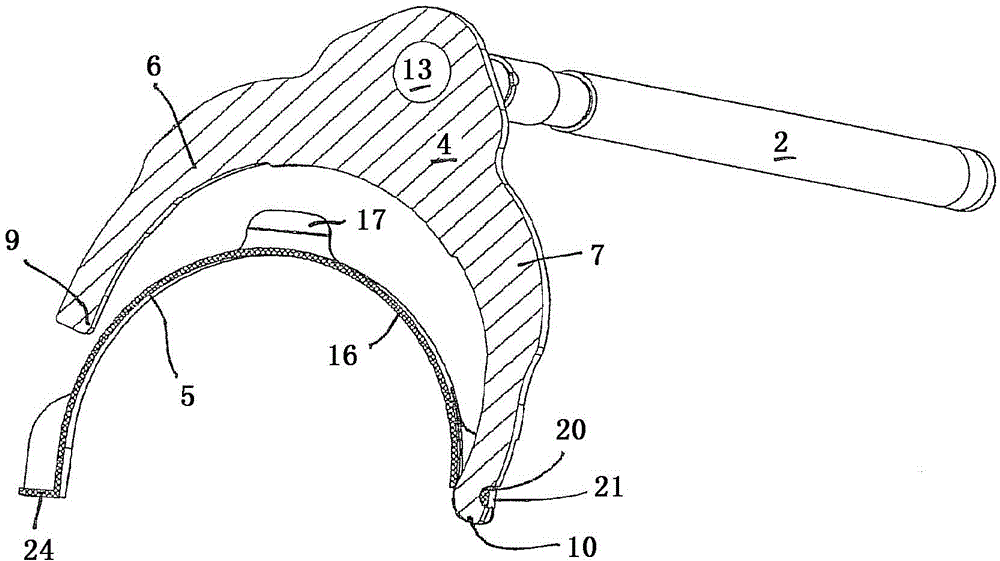

Shift fork and method for producing same

InactiveCN102971556BReduced axial space requirementsSave axial construction spaceControlled membersGearing controlEngineeringSectional plane

The invention relates to a shift fork (3) that has a fork-shaped main part (4) comprising fork limbs (6, 7) which lie opposite each other and which form a shift jaw (25) for guiding a shift collar. The shift fork also has a separately produced one-piece sliding element (5) for contacting the shift collar, said sliding element (5) having asymmetrical sliding limbs (26, 27) in the cross-sectional plane of the shift fork (3).

Owner:SCHAEFFLER TECH AG & CO KG

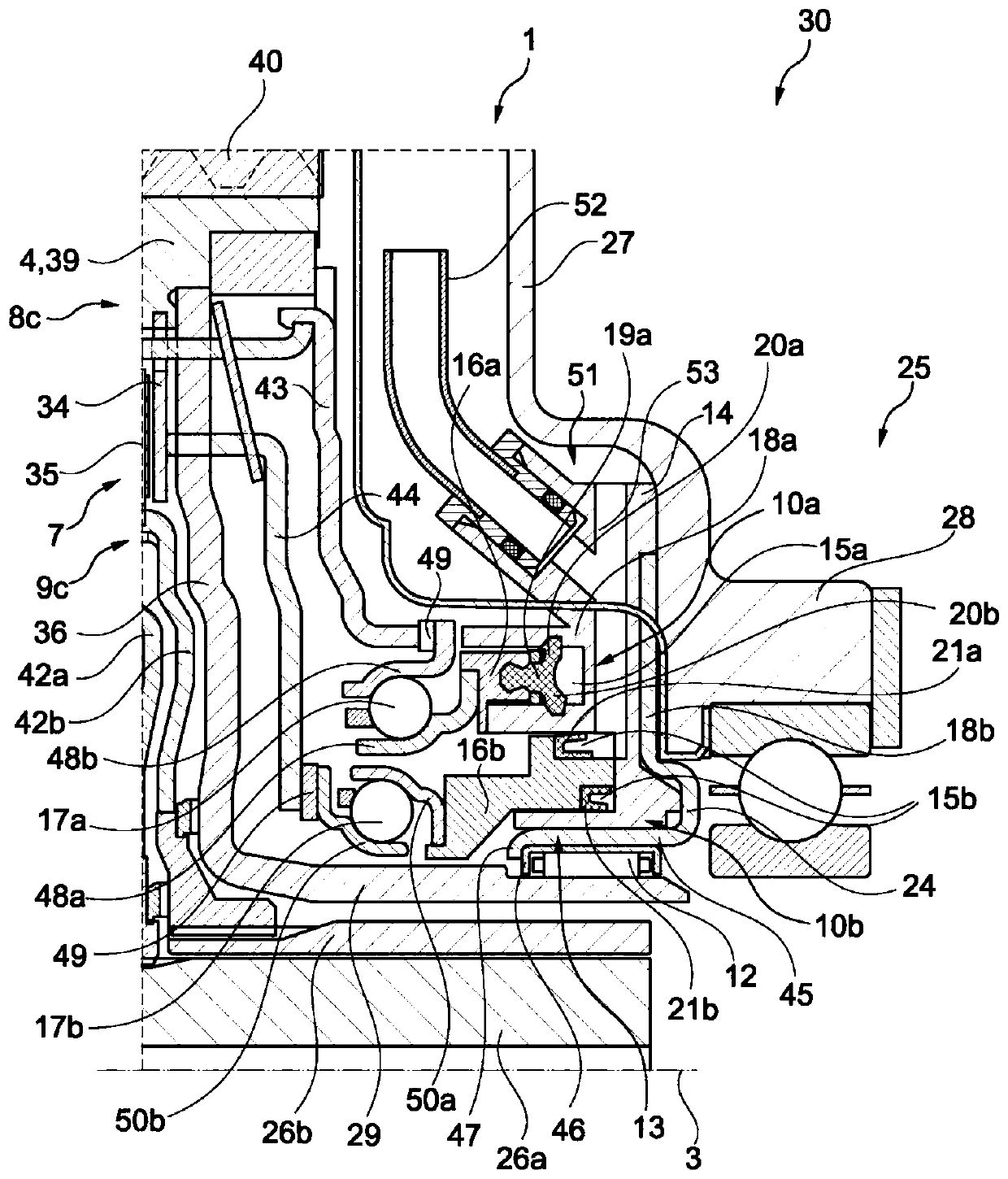

Clutch system with bearing in actuating device and drive unit

ActiveCN110067820ACompact and stable supportOptimized structural spaceHybrid vehiclesFluid actuated clutchesElectric machineEngineering

The invention relates to a clutch system (1) for a drive train of a motor vehicle, comprising: a housing (2); a carrier (4) which is mounted so as to be rotatable about an axis of rotation (3) relative to the housing (2); an electric machine, the rotor of which is rotationally coupled to the carrier (4); a plurality of clutches (5, 6, 7), wherein each clutch (5, 6, 7) is accommodated in a rotationally fixed manner on the carrier (4) by means of a clutch component (8 b, 8 c, 9 a); and an actuating device (11) having two auxiliary cylinders (10 a, 10 b), wherein each auxiliary cylinder (10 a, 10b) acts on the clutch (5, 6, 7) in an actuating manner, wherein the carrier (4) is supported via a support bearing (12) on the radially inner side (13) of an actuator housing (14) of the actuating device (11). The invention further relates to a drive unit (30) having the clutch system (1).

Owner:SCHAEFFLER TECH AG & CO KG

Operating device with axially nested slave cylinder; clutch system and drive unit

ActiveCN111788403BSave axial construction spaceSave on installation costsMechanical actuated clutchesFluid actuated clutchesEngineeringPowertrain

The invention relates to an actuating device (1) suitable for a clutch system (2) of a motor vehicle, said actuating device having two slave cylinders (3, 4) designed for actuating a clutch (5, 6), respectively, wherein each of said slave cylinders (3, 4) has a piston (7a, 7b) and guides said piston (7a, 7b) in the direction of movement and delimits a fluid chamber with said piston (7a, 7b) (8a, 8b) of the housing area (9a, 9b) with supply unit (10), the housing area of the first slave cylinder (3) of the two slave cylinders (3, 4) ( 9a) Consisting at least in part of a housing member (12) molded separately from said supply unit (10), the second slave cylinder (4) of said two slave cylinders (3, 4) The housing area (9b) of is formed directly by the supply unit (10). Furthermore, the invention relates to a clutch system (2) suitable for use in a motor vehicle drivetrain with the actuating device (1) and a drive unit (30).

Owner:SCHAEFFLER TECH AG & CO KG

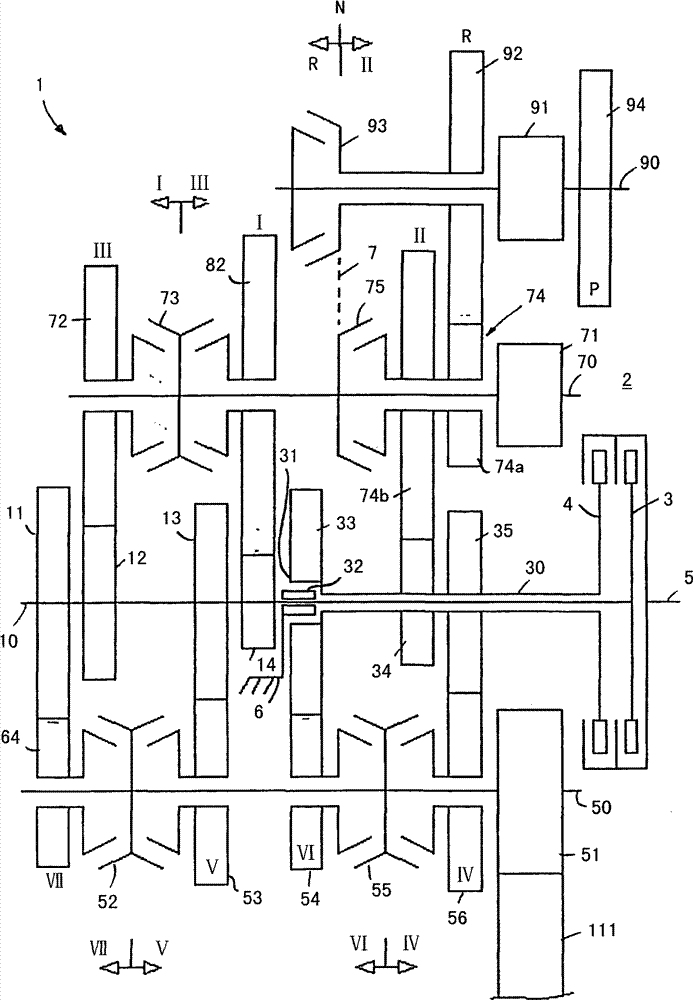

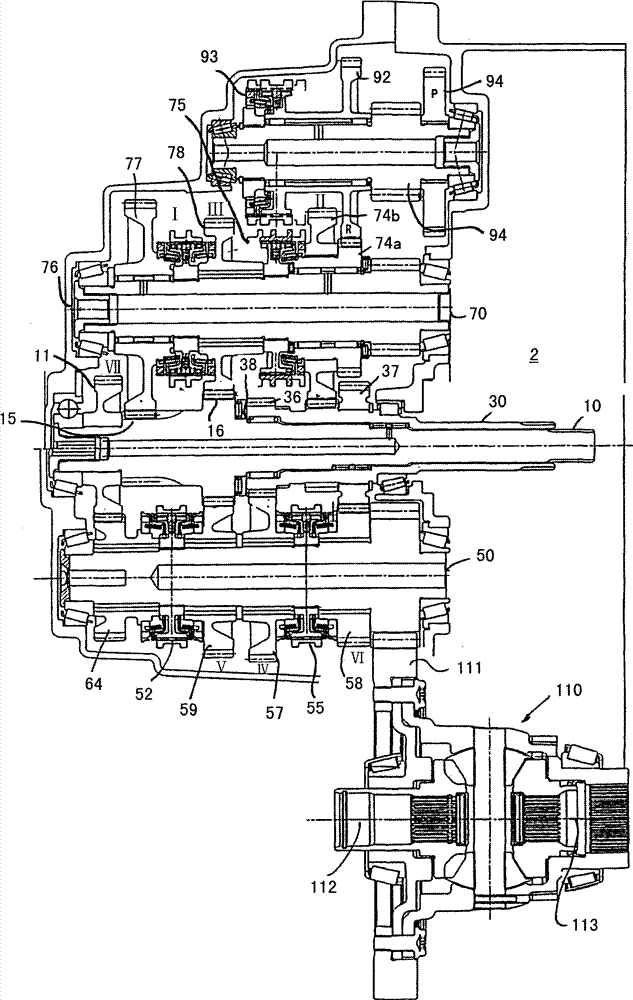

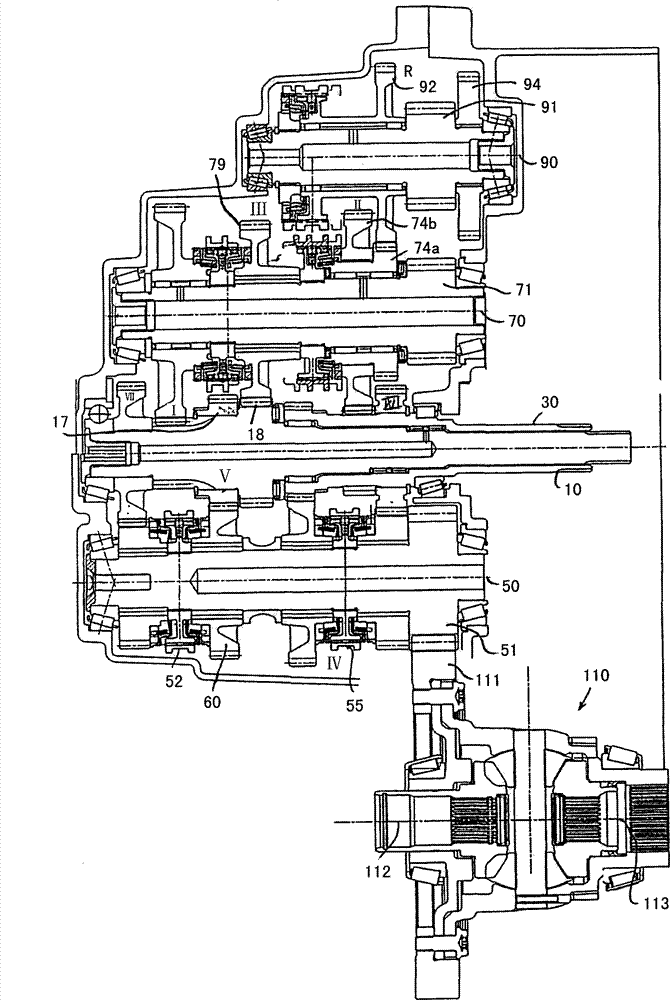

Dual clutch transmission

InactiveCN101876363BShort and compact structureMany degrees of freedomToothed gearingsTransmission elementsDrive shaftClutch

The transmission (1) has an output connected with drive shafts (50, 70, 90) in a torque proof manner. A stage toothed wheel (74) with a set of toothed wheels (74a, 74b) is provided on the drive shaft (70). A loose wheel (92) of a reverse gear (R) on the drive shaft (90) is combined with the toothed wheel (74a). The stage toothed wheel is connected with a gear shift clutch (75) arranged on the drive shaft (70). The gear shift clutch is used as a single-gear shift clutch, with which the stage toothed wheel is connected with the drive shaft (70) in a torque proof manner.

Owner:GETRAG FORD TRANSMISSIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com