Compensating device for torque-transmitting connection of input shaft and output shaft

A technology for compensating equipment and transmitting torque, which is applied in mechanical equipment, couplings, transportation and packaging, etc., and can solve the problems of expensive radial compensation components, large structural space, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

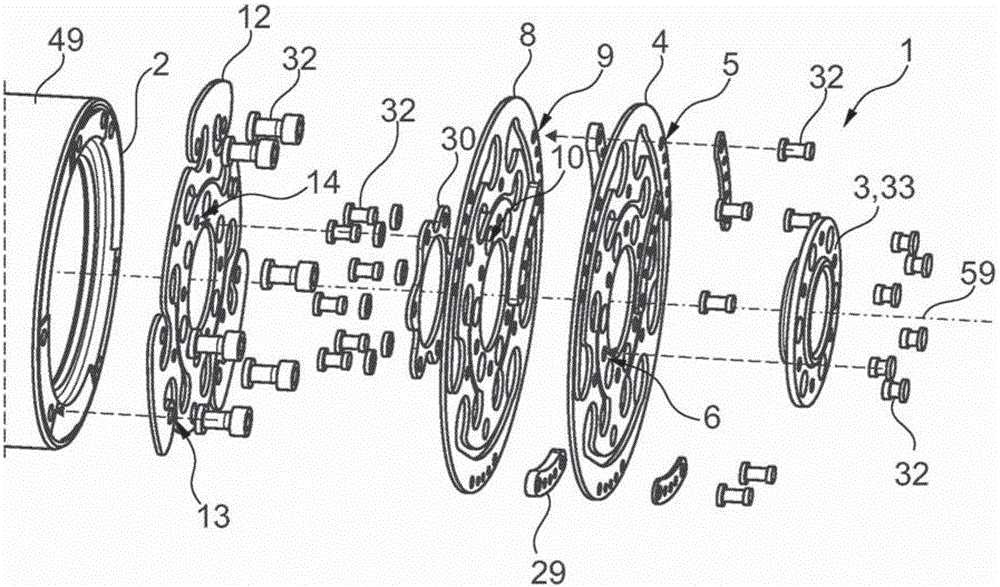

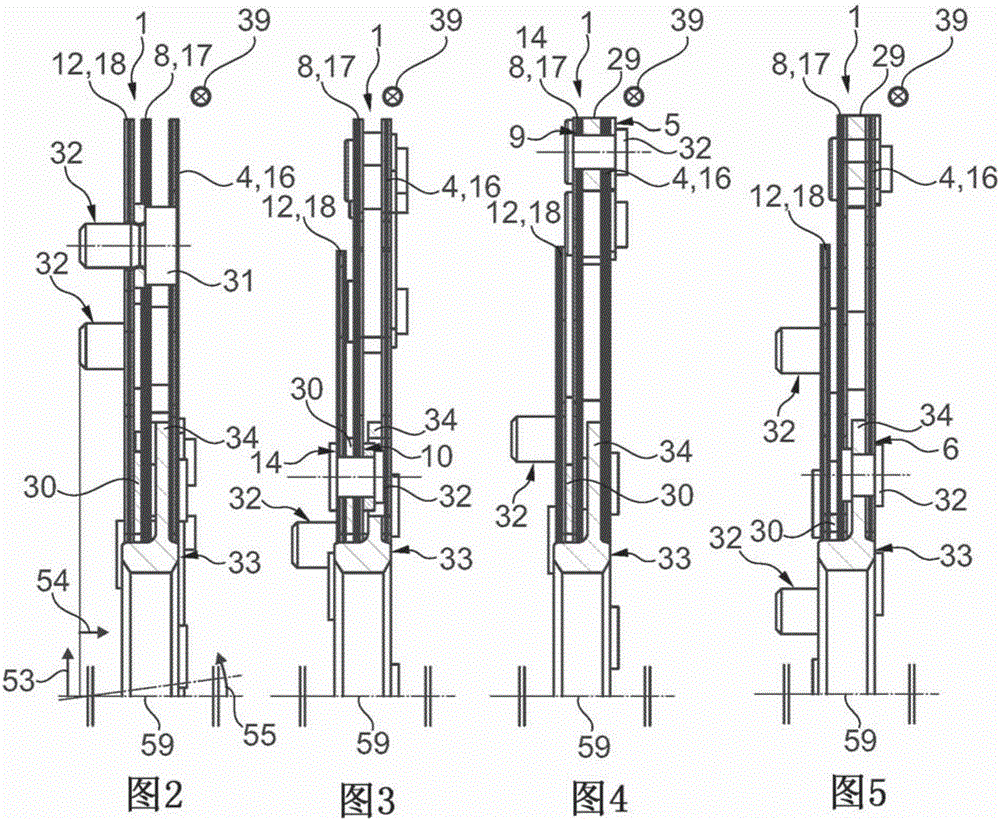

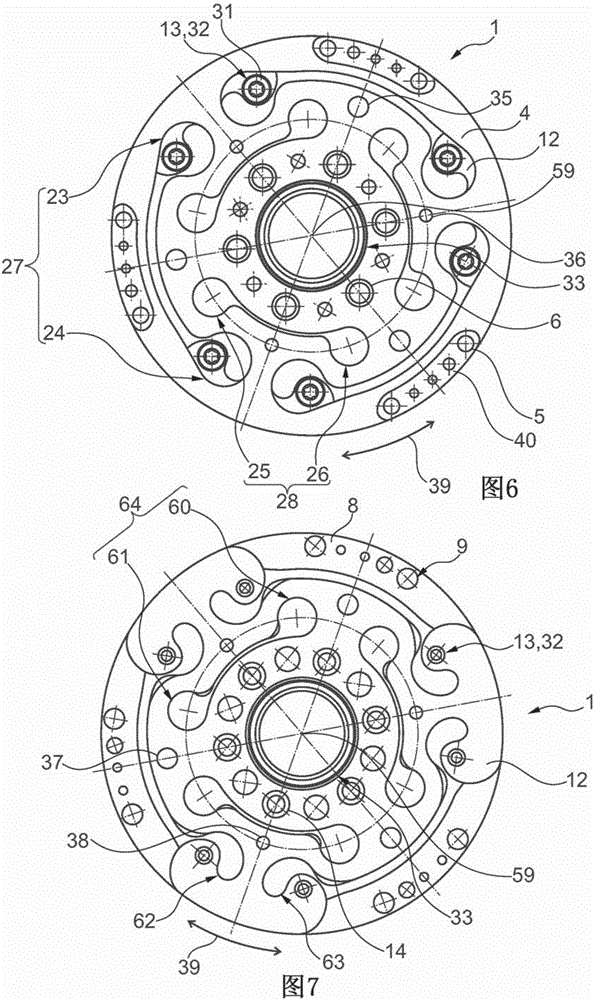

[0081] figure 1 An exploded view of the compensating device 1 is shown, the components connected in each case by dashed arrows being shown here. The input shaft 2 is shown on the left in the illustration, for example the rotor support 49 of the electric motor (see Figure 11 ), the third embossed disc 12 can be connected to the rotor support by means of its third outer connection 13, in this example by means of fastening means 32 (here bolts). The third inner web 14 can be connected to the second inner web 10 of the second embossed disk 8 indirectly via the second (ring-shaped) spacer element 30 , here by means of a plurality of rivets ( 32 ). The second outer web 9 can be connected to the first outer web 5 of the first embossed disc 4 here indirectly via a (separate) first spacer element 29 , here by means of a plurality of rivets ( 32 ). The first embossed disk 4 can in turn be connected via the first inner web 6 here by means of a plurality of rivets ( 32 ) to a hub eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com