Clutch system with bearing in actuating device and drive unit

A technology for operating equipment and driving units, which is applied in the field of clutch systems, can solve problems such as expensive installation, and achieve the effect of compact, compact and stable support of the clutch system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

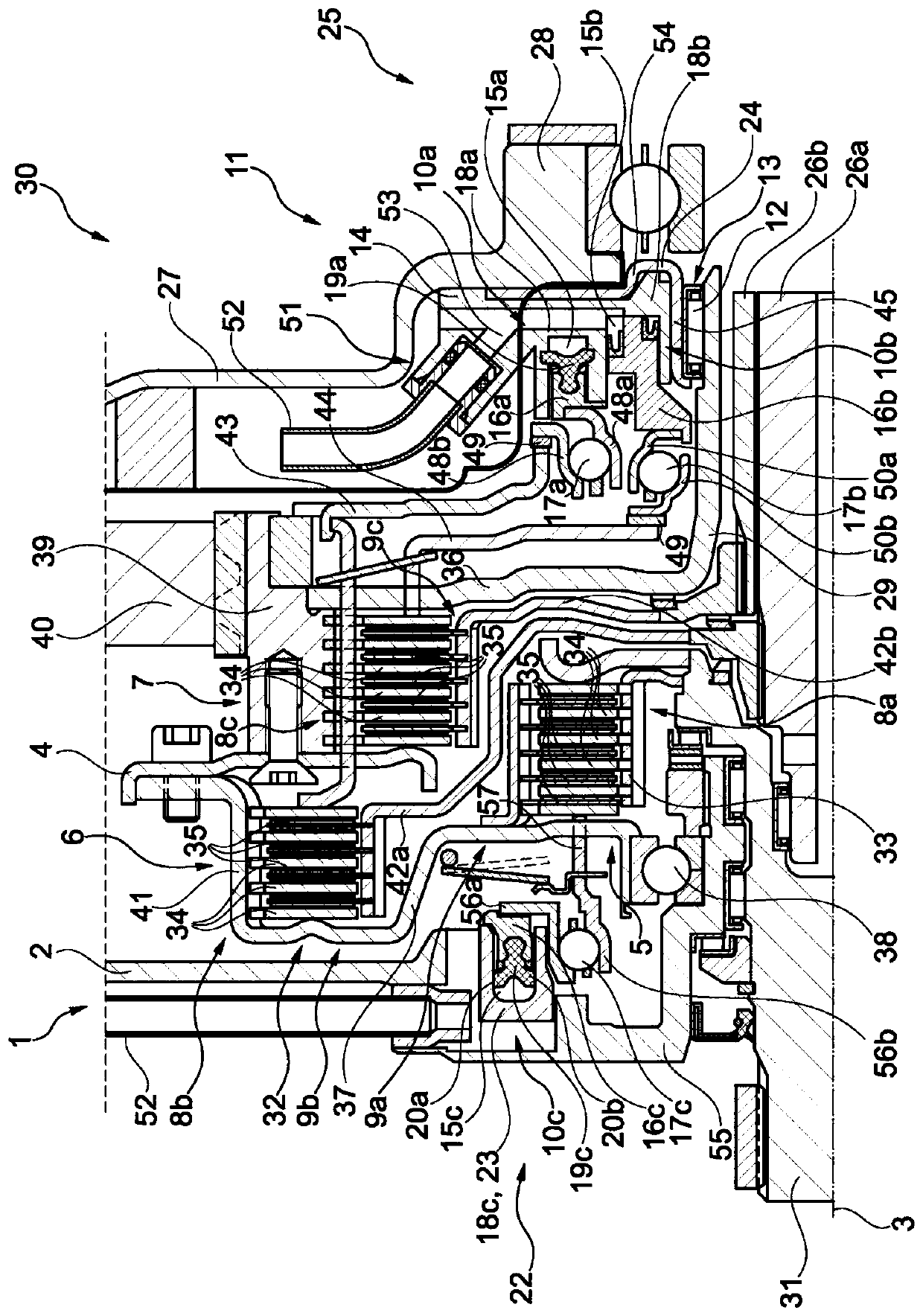

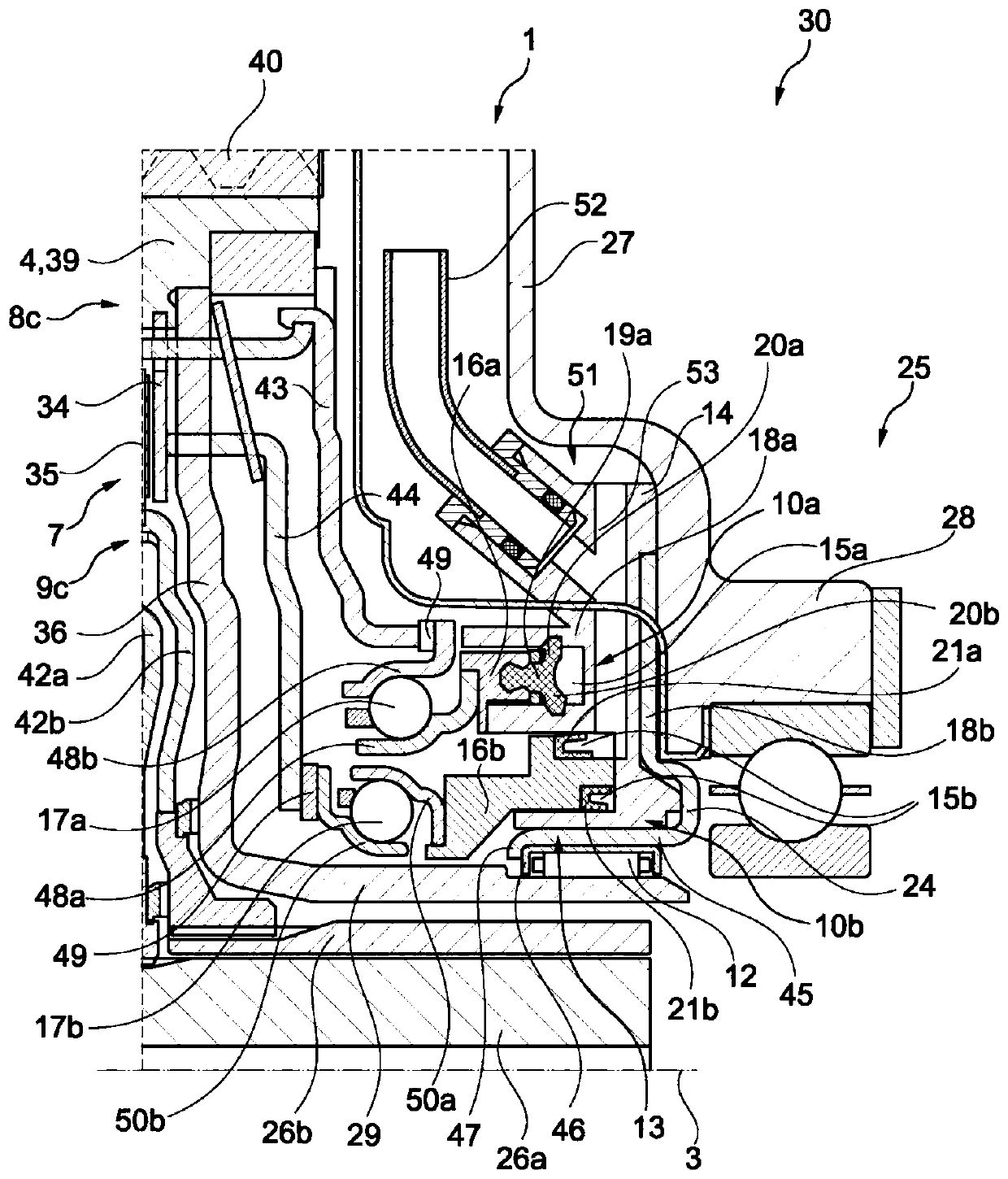

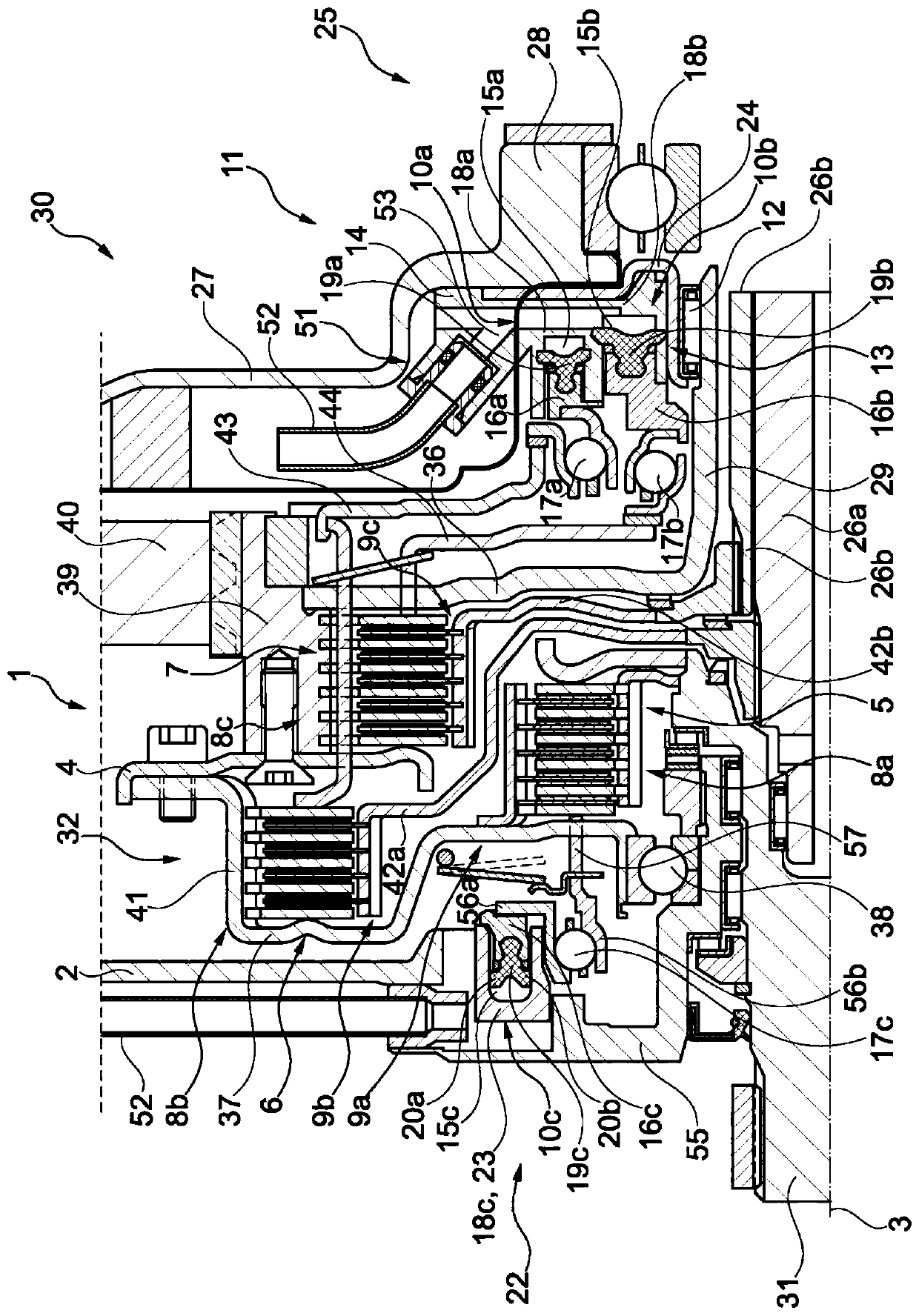

[0049] The first embodiment of the clutch system 1 according to the invention combines figure 1 Can be seen well. The clutch system 1 has been used in the drive unit 30 in this figure. The drive unit 30 forms a unit composed of the clutch system 1 and the transmission device 25 . With regard to the transmission device 25 , only the transmission housing 27 and the two transmission input shafts 26 a , 26 b rotatably accommodated in the transmission housing 27 are shown for the sake of clarity. During operation, drive unit 30 is typically a component of a hybrid drive train of a (hybrid) motor vehicle. As explained in detail below, the clutch system 1 is implemented as a hybrid module.

[0050] The clutch system 1 has a total of three clutches 5 , 6 , 7 . The clutch system 1 is therefore also referred to as a triple clutch. The first clutch 5 is arranged on the input side of the clutch system 1 in the form of a separating clutch. The input of the clutch system 1 is the regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com