Lever-shaped metal sheet cam component

A technology of metal plates and cams, applied to engine components, valve devices, machines/engines, etc., can solve structural space problems and other problems, and achieve the effect of avoiding extrusion creases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

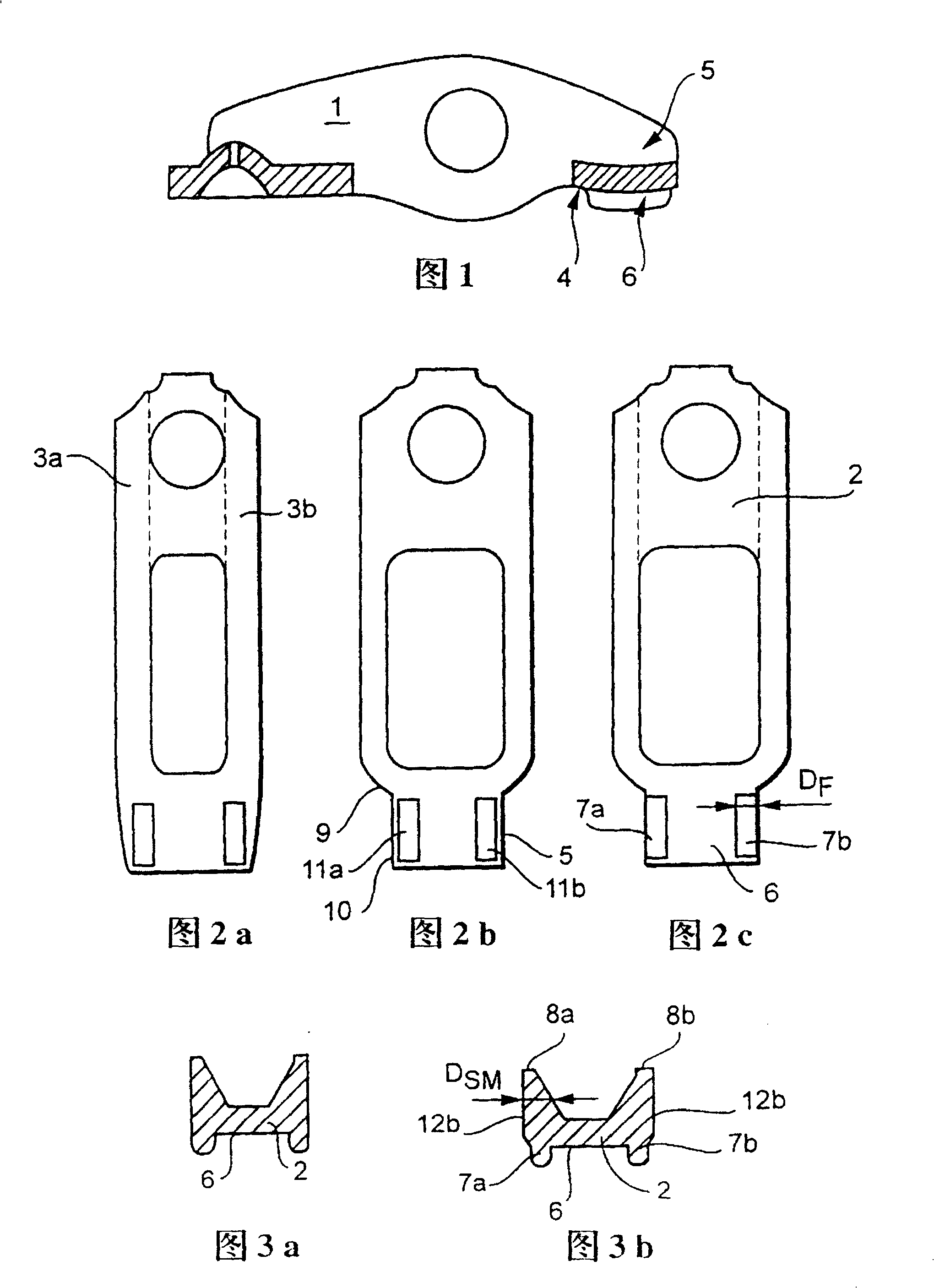

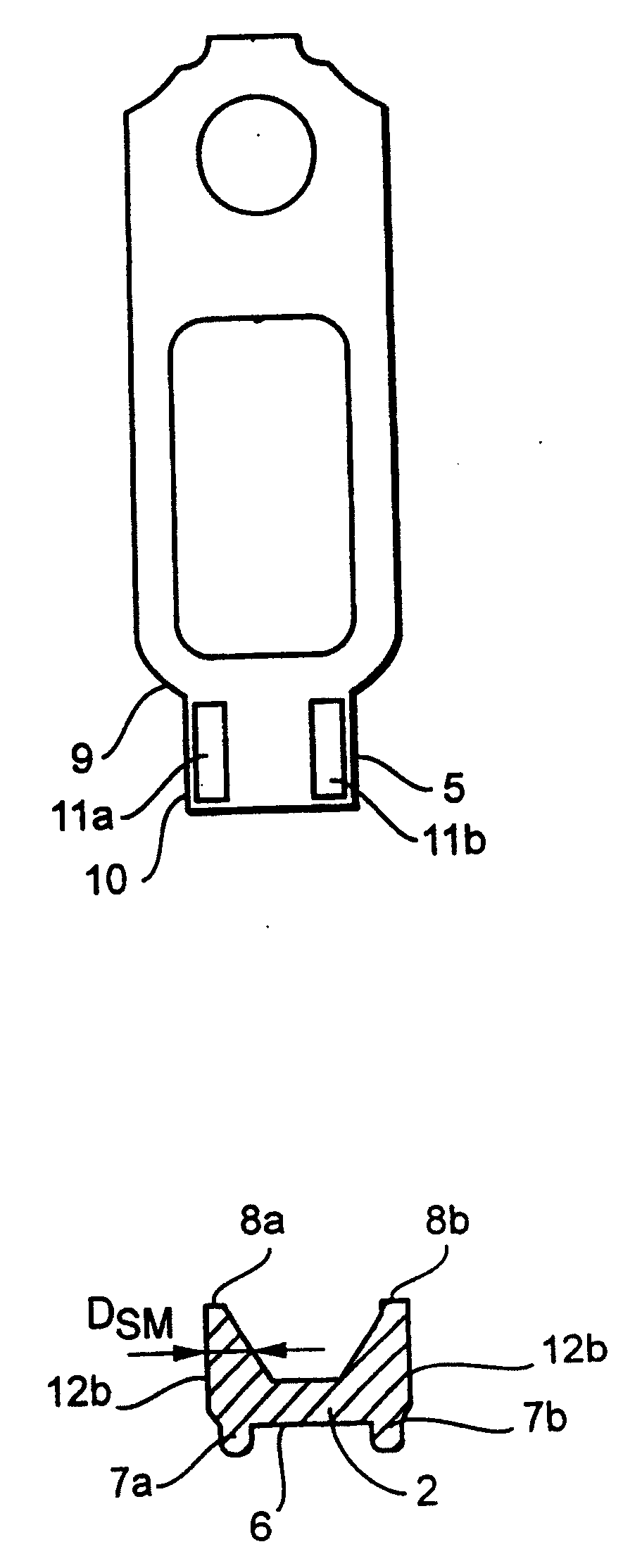

[0019] The drawing shows a cam assembly 1 of a valve train of an internal combustion engine, here in the form of a valve plunger, which consists of sheet metal. The cam assembly 1 has two parallel side walls 3 a , 3 b connected by a beam 2 . In cross section, the cam assembly 1 constitutes a U-shaped section that is open upward. The bottom surface 4 of the cam assembly 1 has a means 6 of valves on one end 5 . The device 6 is surrounded on both sides by clamping plates 7a, 7b.

[0020] FIG. 2 shows that the side walls 3 a , 3 b merge into a tapering portion 9 in the direction of the end 5 . A length 10 of the same width is attached to this portion 9 as shown in FIG. 2c. This end 5 is thus significantly narrower than the rest of the cam assembly 1 .

[0021] Clamps 7a, 7b are used over a length 10 at one end 5 . As shown in Fig. 2b, the splint is set back towards the side walls 3a, 3b and has a thickness D smaller than that of the side walls 3a, 3b F . It is particularly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com