Driving and brake integration system based on wheel hub motor

An in-wheel motor and integrated system technology, applied in electric braking systems, electric vehicles, motion deposition, etc., can solve problems such as excessive wear of brake pads and brake discs, affecting vehicle braking performance, and brake thermal degradation. Achieve the effect of reducing the degree of wear, good braking effect, reducing rotational moment and moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

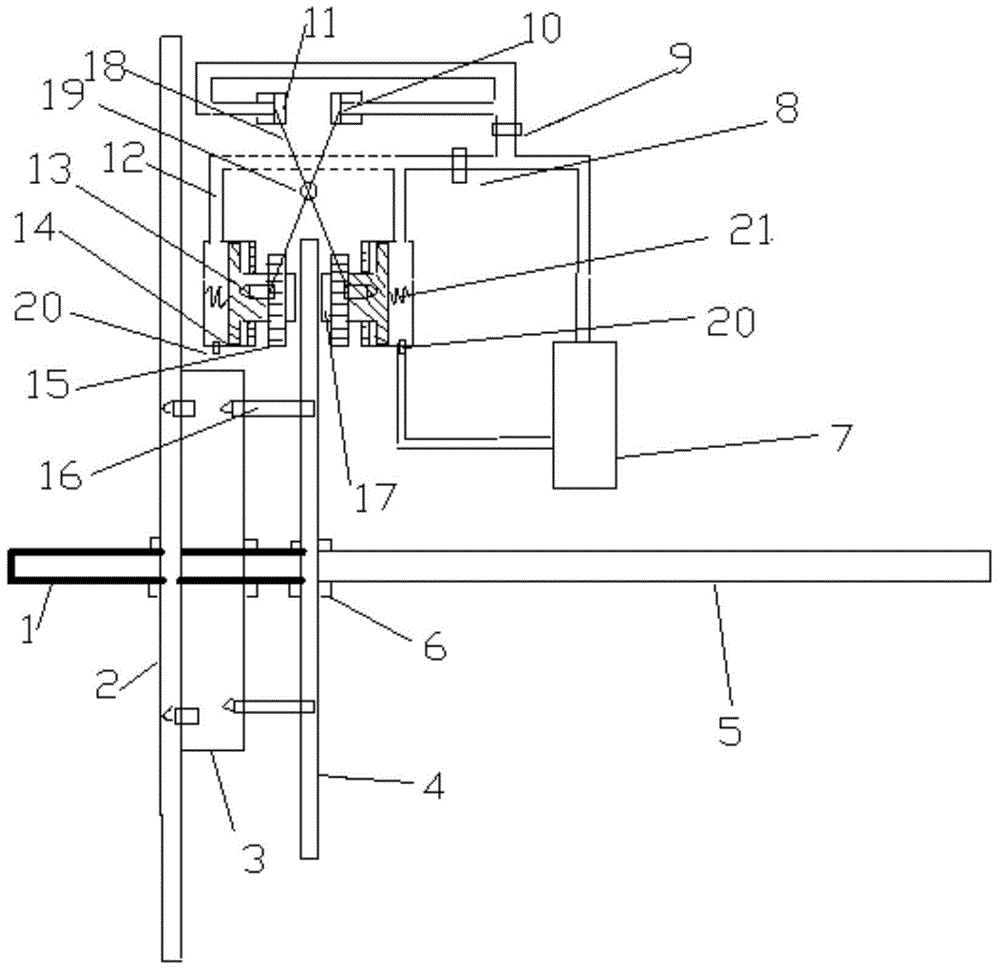

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0018] like figure 1 As shown, the hub motor-based drive and braking integrated system of the present invention includes a hub motor drive system, an electromagnetic and friction braking system, and a vehicle control system. The hub motor drive system includes an axle 5, which is welded coaxially with the axle 5 The motor stator 1, the hub 2, the motor rotor 3 and the brake disc 4, the hub 2, the motor rotor 3 and the brake disc 4 are installed on the motor stator 1 in turn, and are connected with the motor stator 1 through the bearing 6 in rotation, the motor The rotor 3 and the hub 2 are fixedly connected by bolts, and the electronic rotor 3 and the brake disc 4 are fixedly connected by long bolts 16 . In the present invention, the hub motor drive system uses the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com