Intelligent continuous mining equipment for open-pit mine

An open-pit mine, continuous technology, applied in the field of mining machinery and equipment, can solve the problems of poor processing technology, easy leakage of the system, large size of the reducer, etc., to achieve convenient maintenance and disassembly of equipment, ensure processing technology, and simplify the connection structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

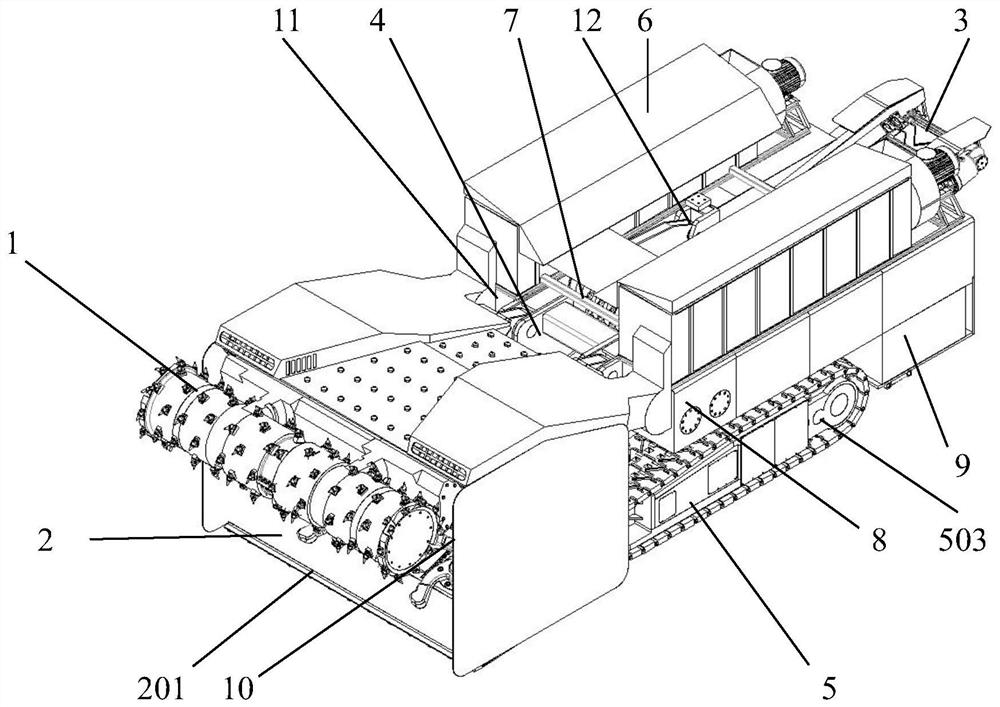

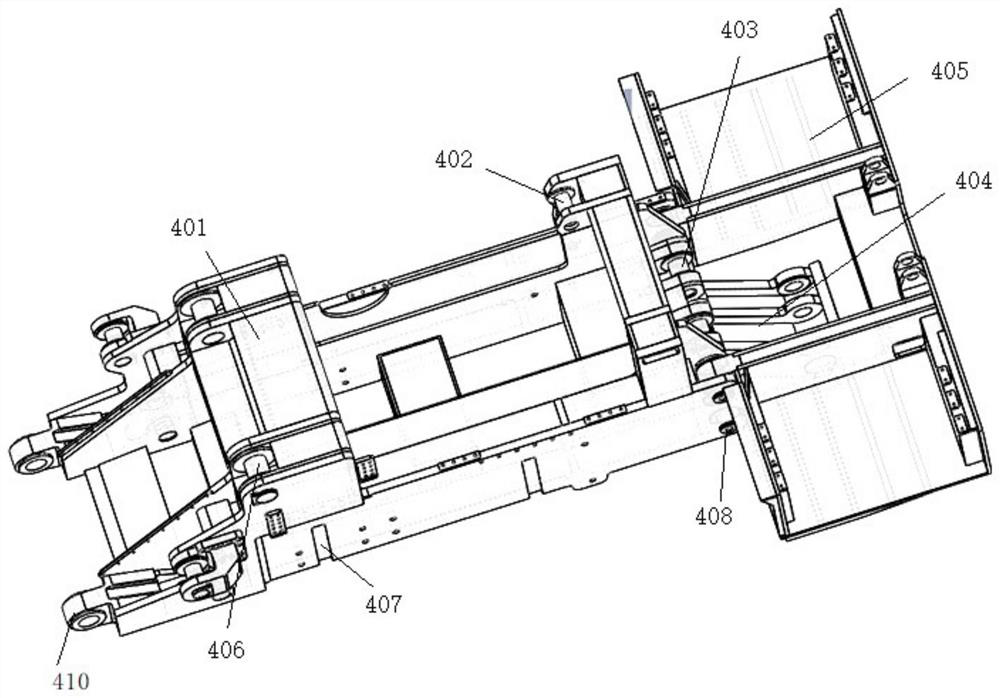

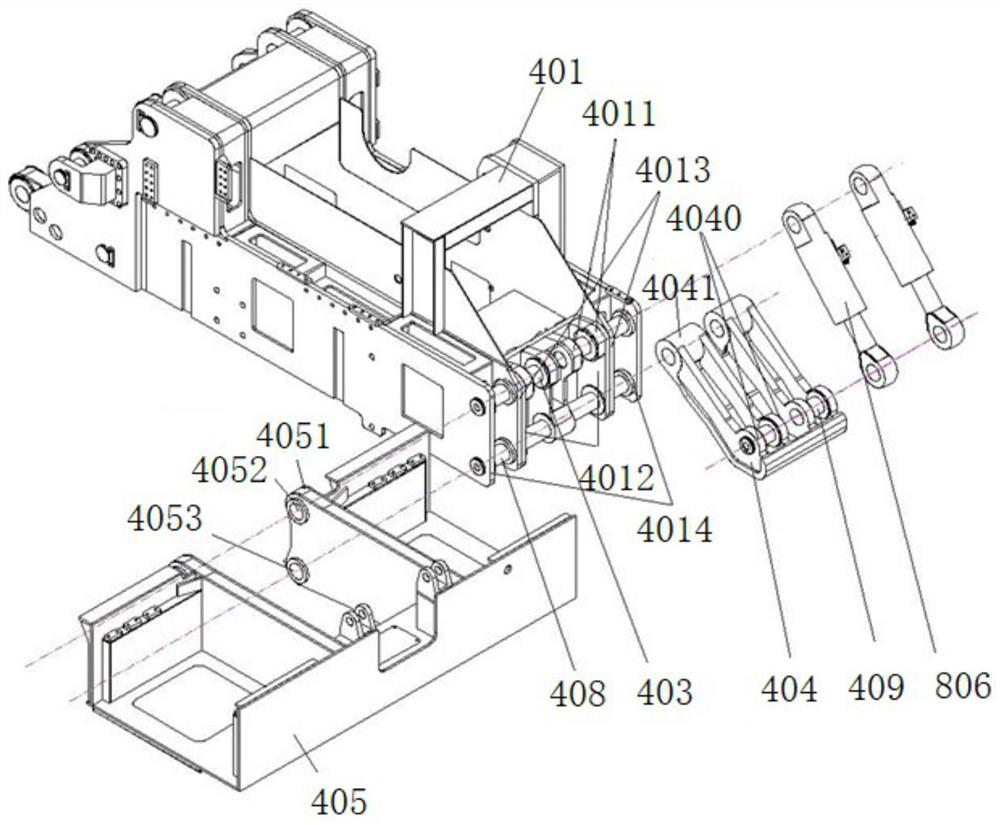

[0044] Such as figure 1 As shown, it is a schematic diagram of the open pit intelligent continuous mining equipment of the embodiment of the present invention, consisting of figure 1 It can be seen that the open pit intelligent continuous mining equipment of the embodiment of the present invention includes a frame part 4 and a walking part 5, and the frame part 4 includes a main frame body 401, a rear frame body 405 and a connecting main frame body 401, a rear frame body 405 connecting device, the running part 5 is installed on the bottom of the frame part 4.

[0045] Specifically, the open-pit intelligent continuous mining equipment of the embodiment of the present invention includes a frame part 4 that is used as a basic support component of the whole equipment and connects other parts into a whole, and is installed on the lower part of the frame part 4 for driving. Equipped with walking part 5 for walking. In addition, the equipment of the embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com