Patents

Literature

30results about How to "Easy maintenance and disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

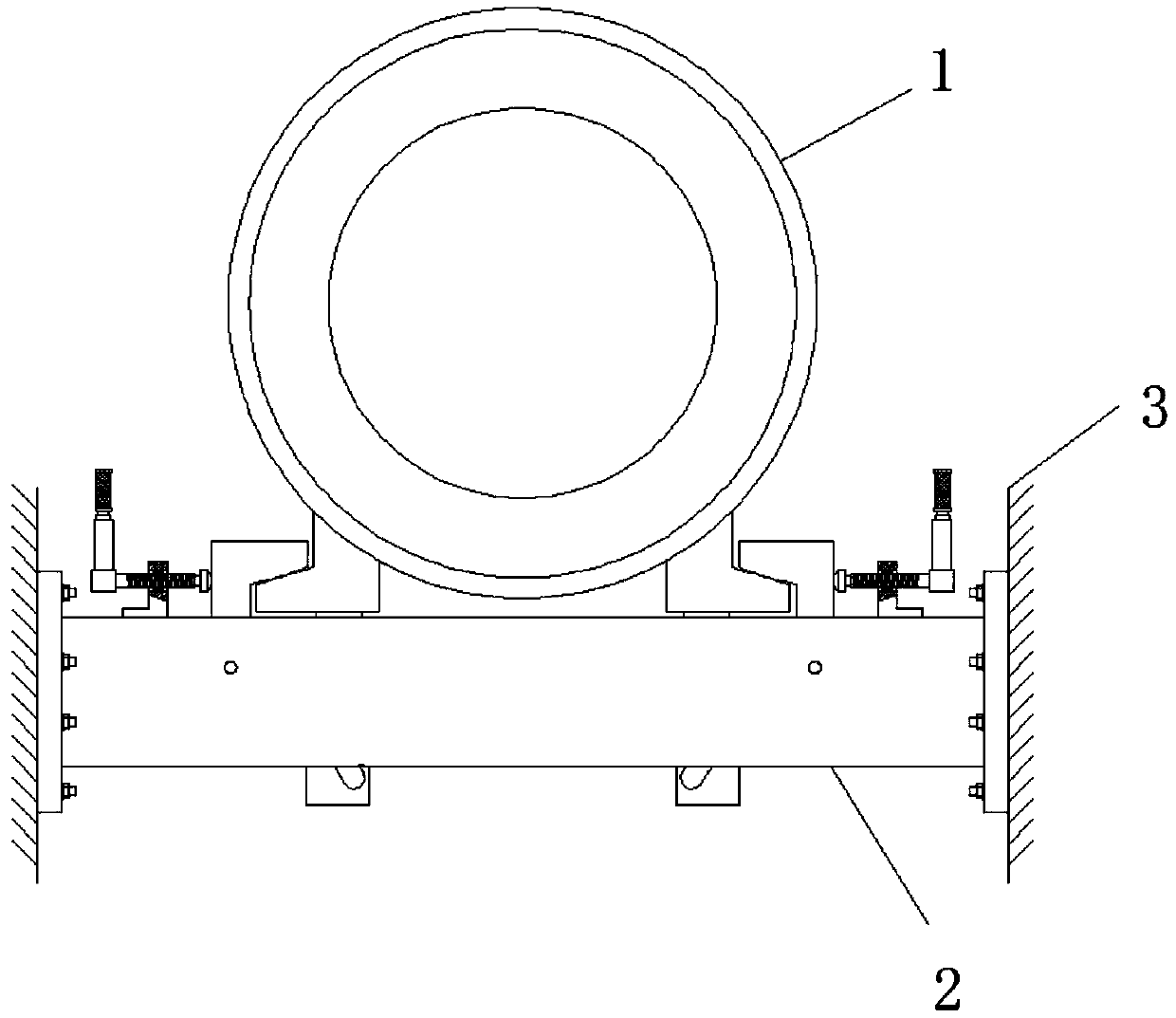

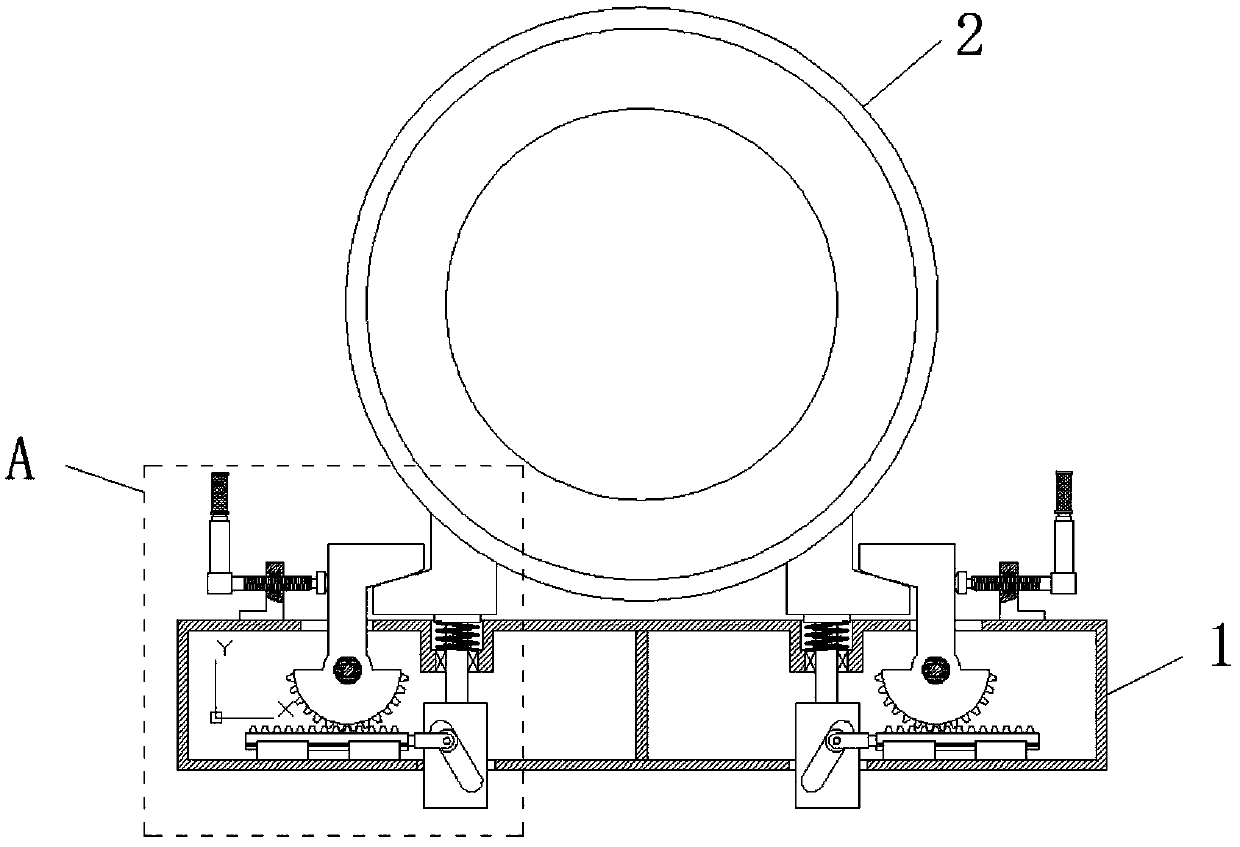

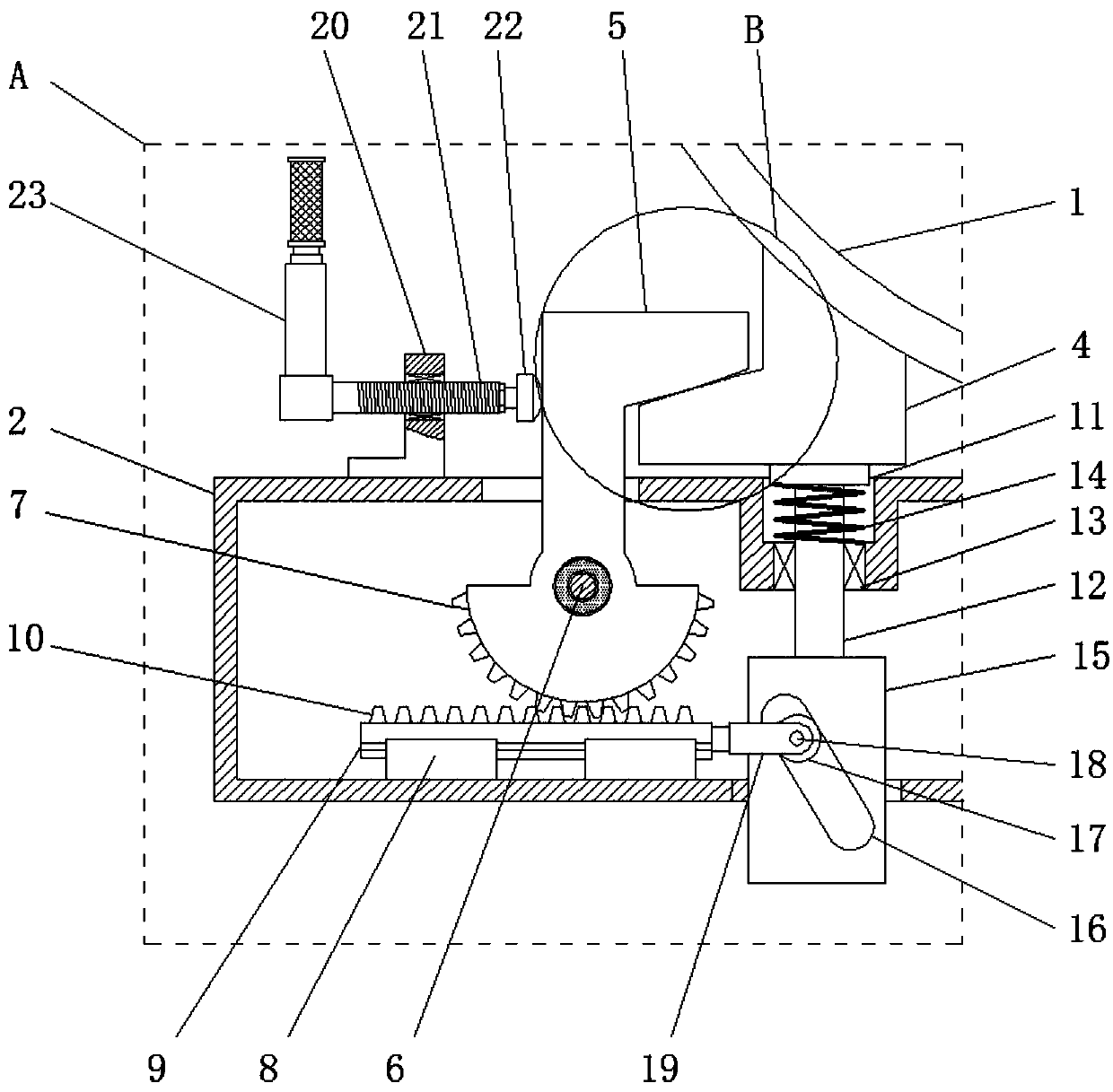

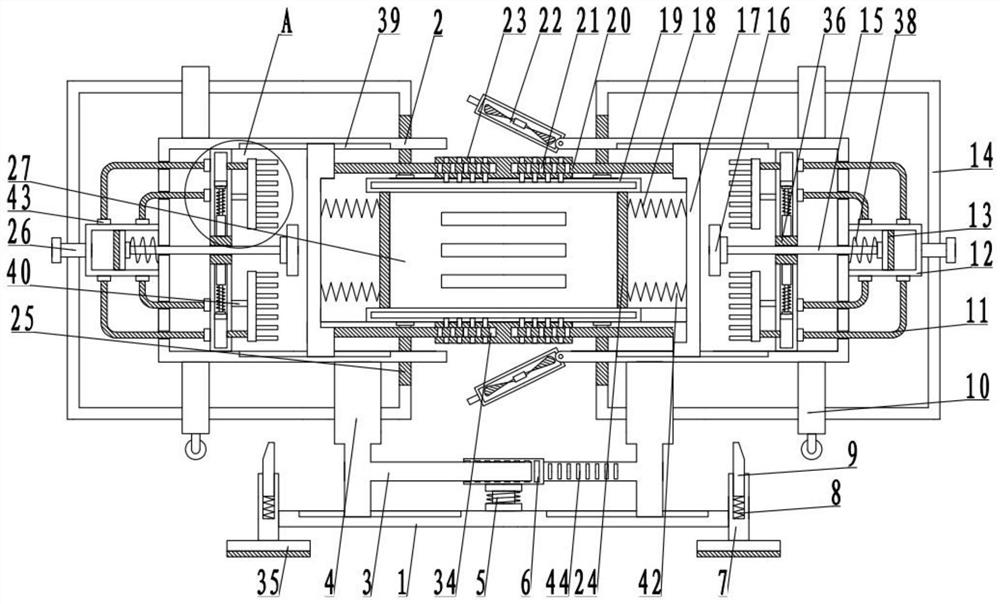

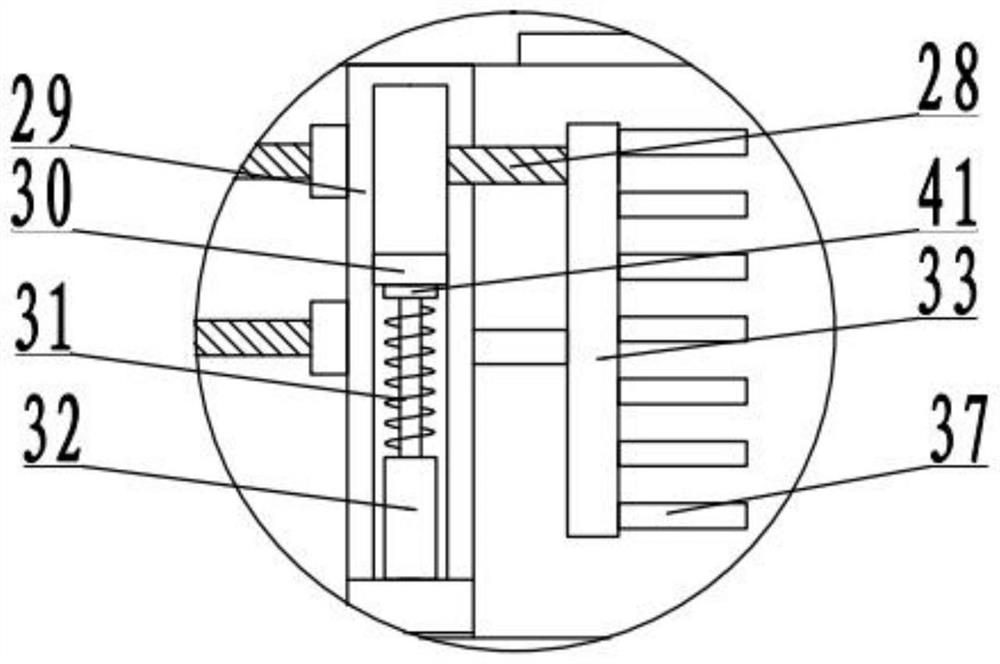

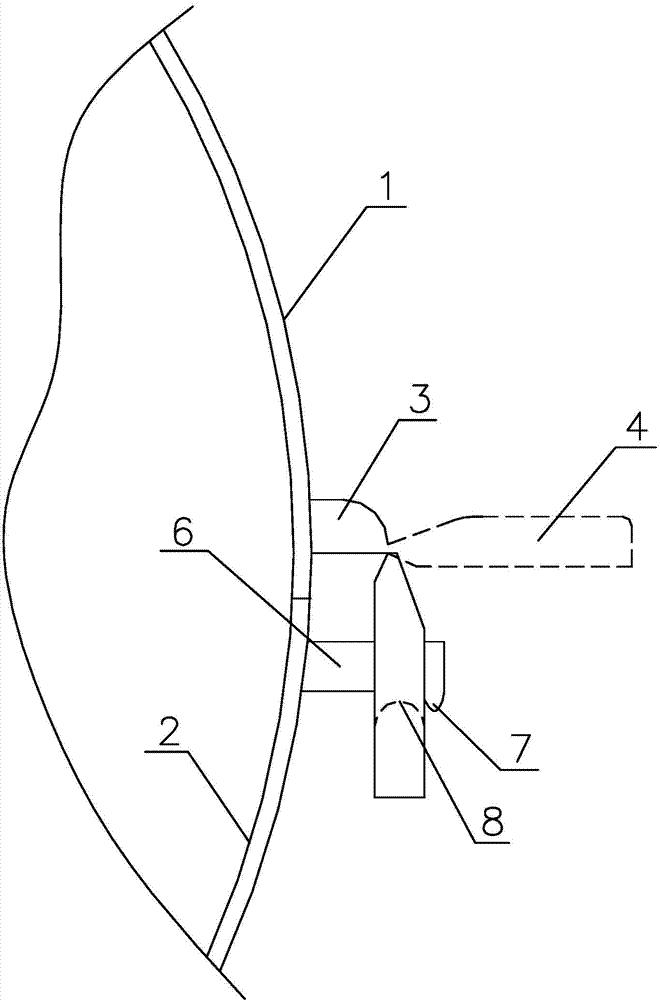

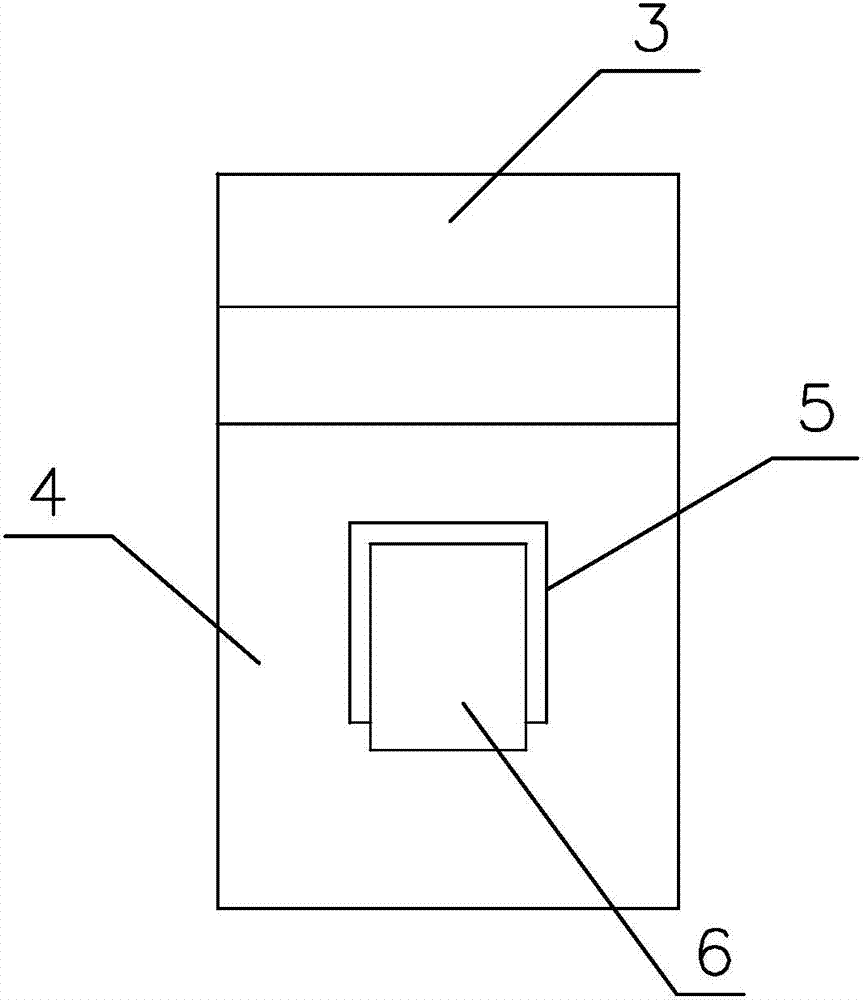

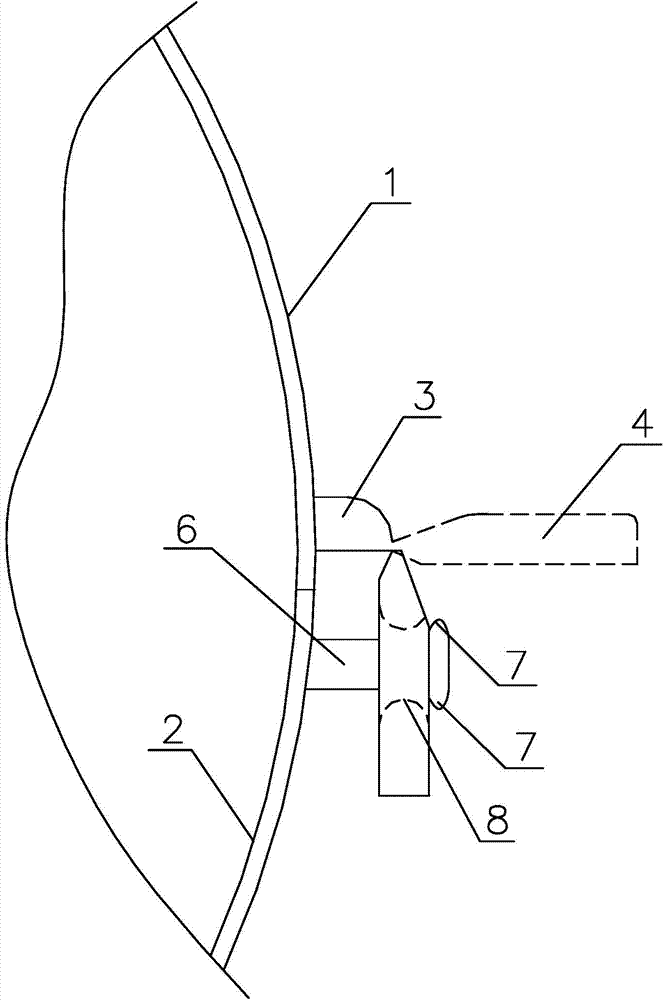

Fixing device for main engine of machine-room-free elevator

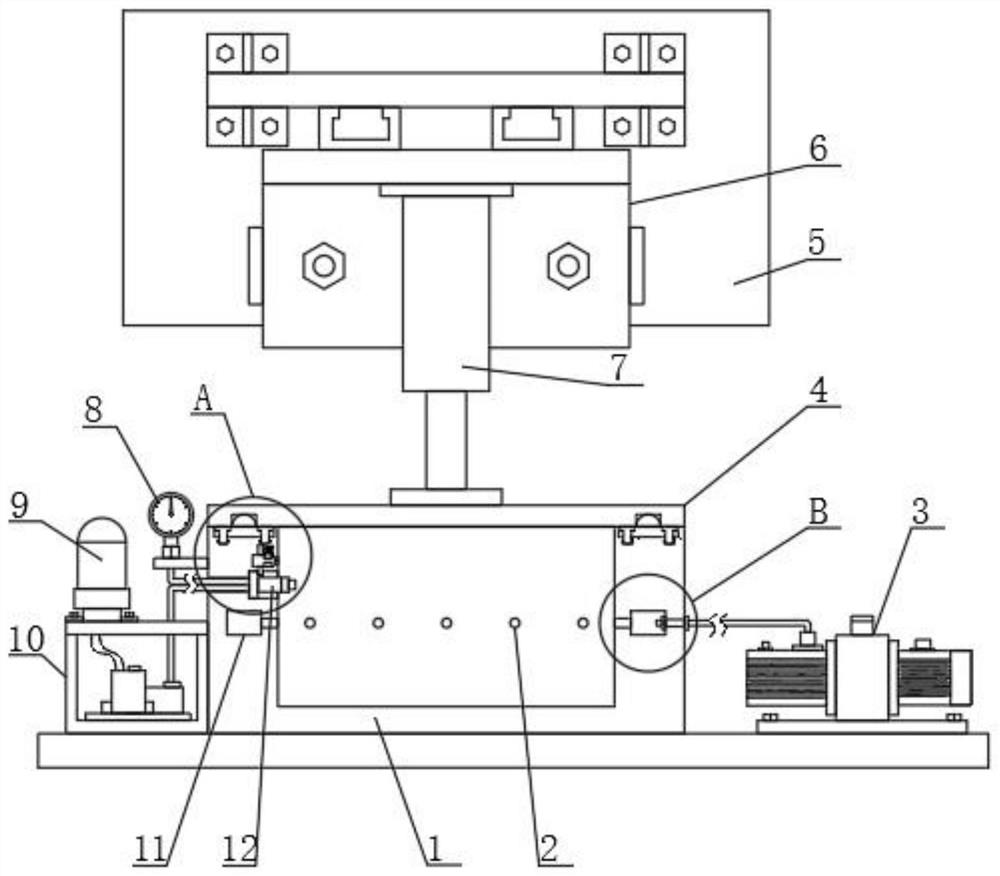

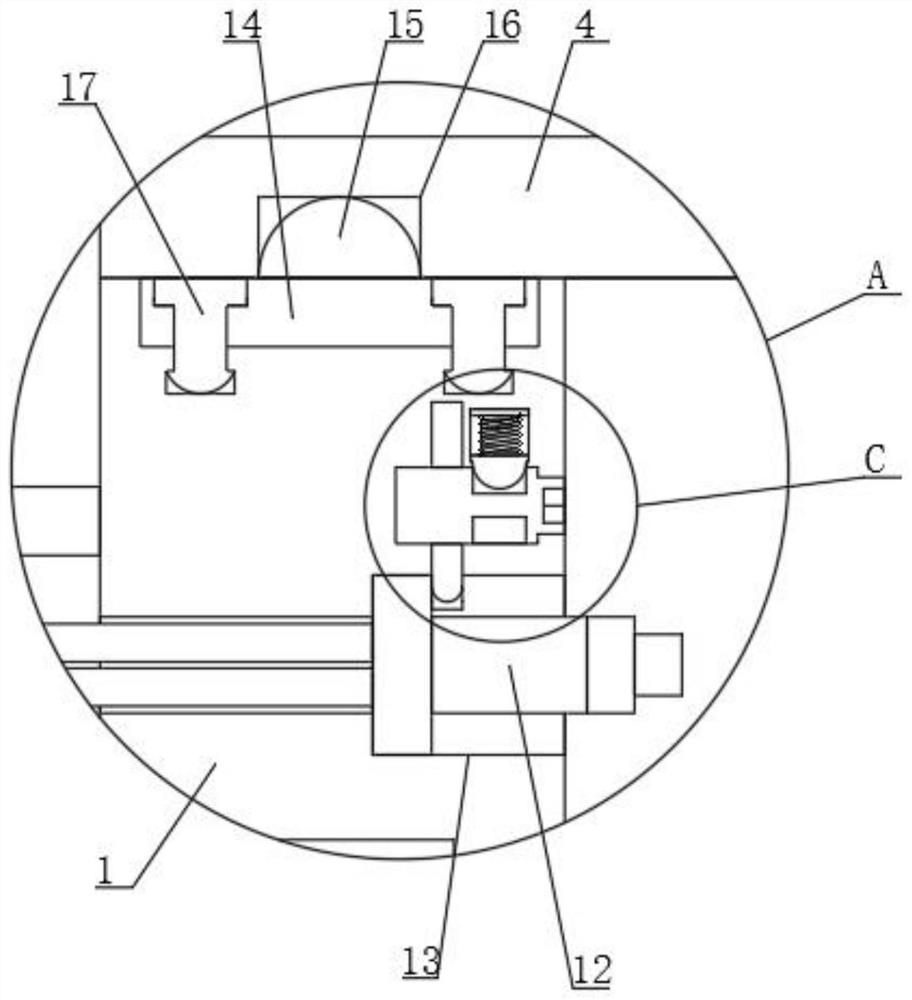

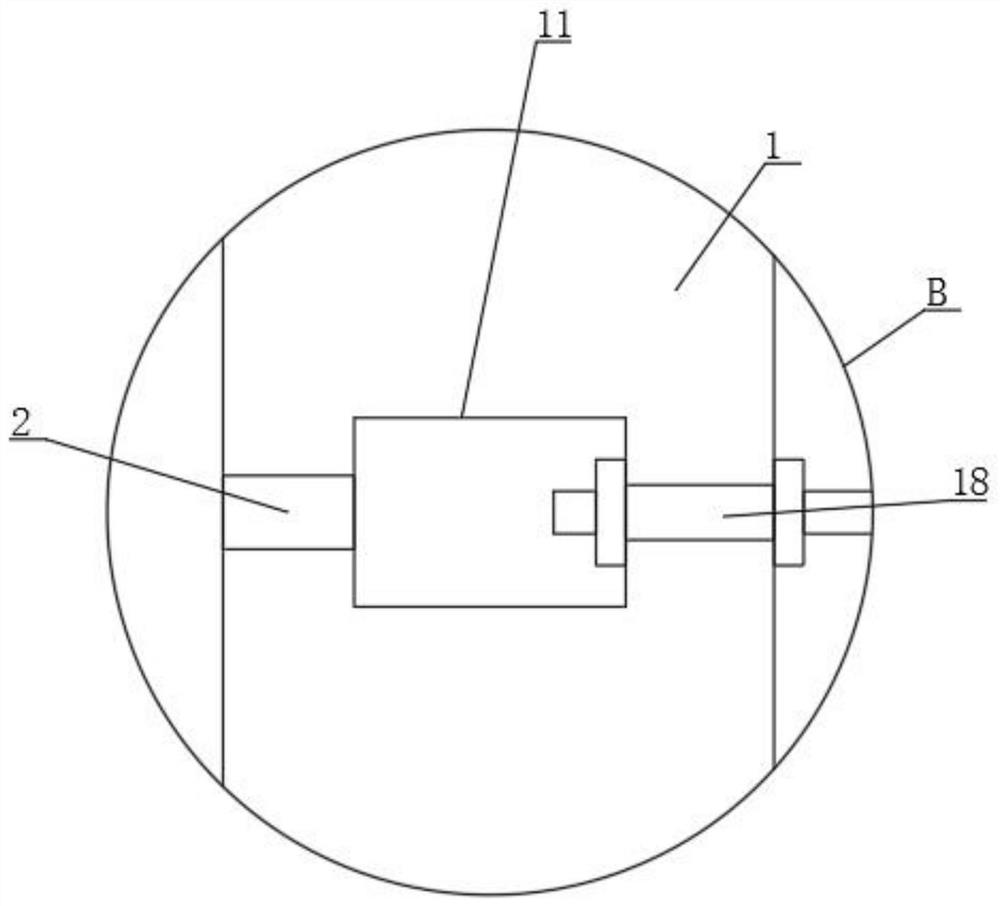

The invention discloses a fixing device for a main engine of a machine-room-free elevator in the technical field of machine-room-free elevators. The fixing device comprises a tractor main engine and afixing installation box base. Main engine installing feet of bilateral symmetry are arranged on the bottom of the tractor main engine. An inner cavity of the fixing installation box base is providedwith buckle fixing plates in a bilateral symmetry manner. Semi gear plates are connected to the bottoms of the buckle fixing plates. A fixing sliding base, a movable sliding bar and a moving rack arefixedly arranged on the bottom of the inner cavity of the fixing installation box base. The top of the fixing installation box base is sunken downwards to form a spring storing groove. An inner cavityof the spring storing groove is provided with a lifting rod. The outer wall of the lifting rod is provided with a jacking spring in a sleeved manner. A sliding groove plate is fixedly connected to the bottom end of the lifting rod and provided with a sliding groove. Rolling wheels are arranged in an inner cavity of the sliding groove in a sliding manner. The rolling wheels are installed on a rolling wheel support in a clamped manner through a rolling wheel shaft. The rolling wheel support is fixedly arranged at the right end of the movable sliding bar. The fixing device for the main engine ofthe machine-room-free elevator is convenient to maintain, assemble and disassemble, and prevents loosening faults.

Owner:施密特电梯有限公司

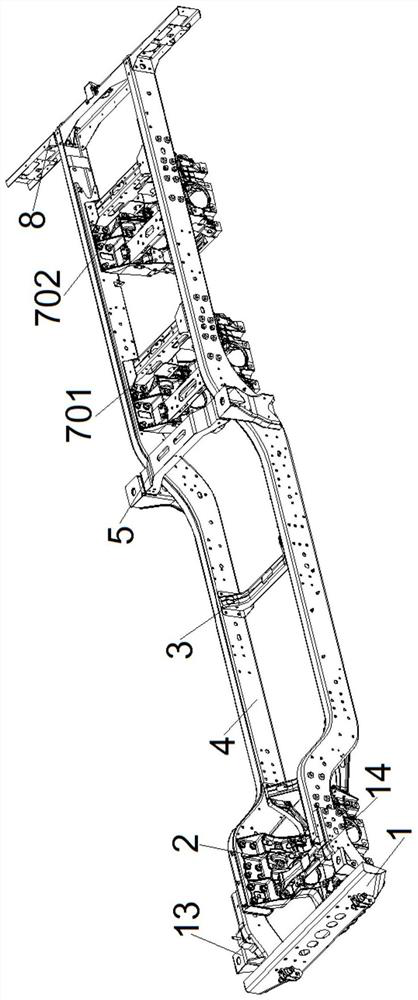

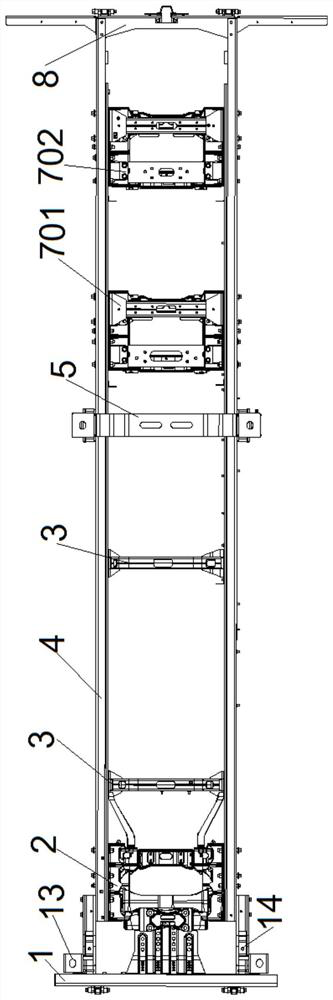

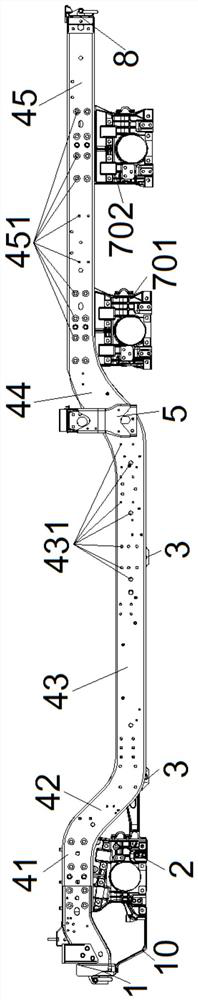

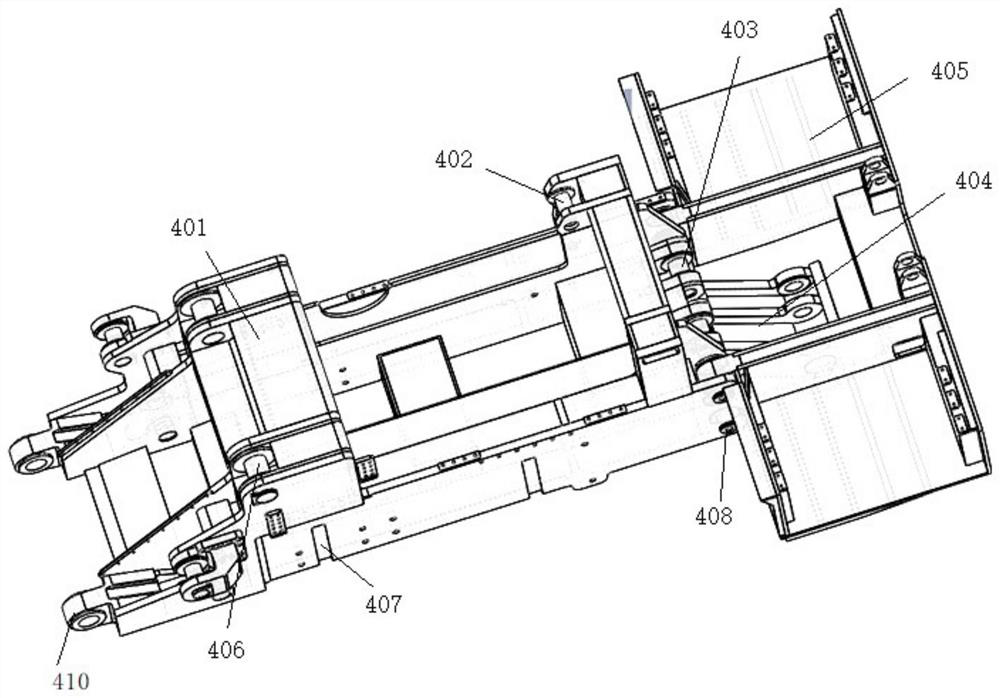

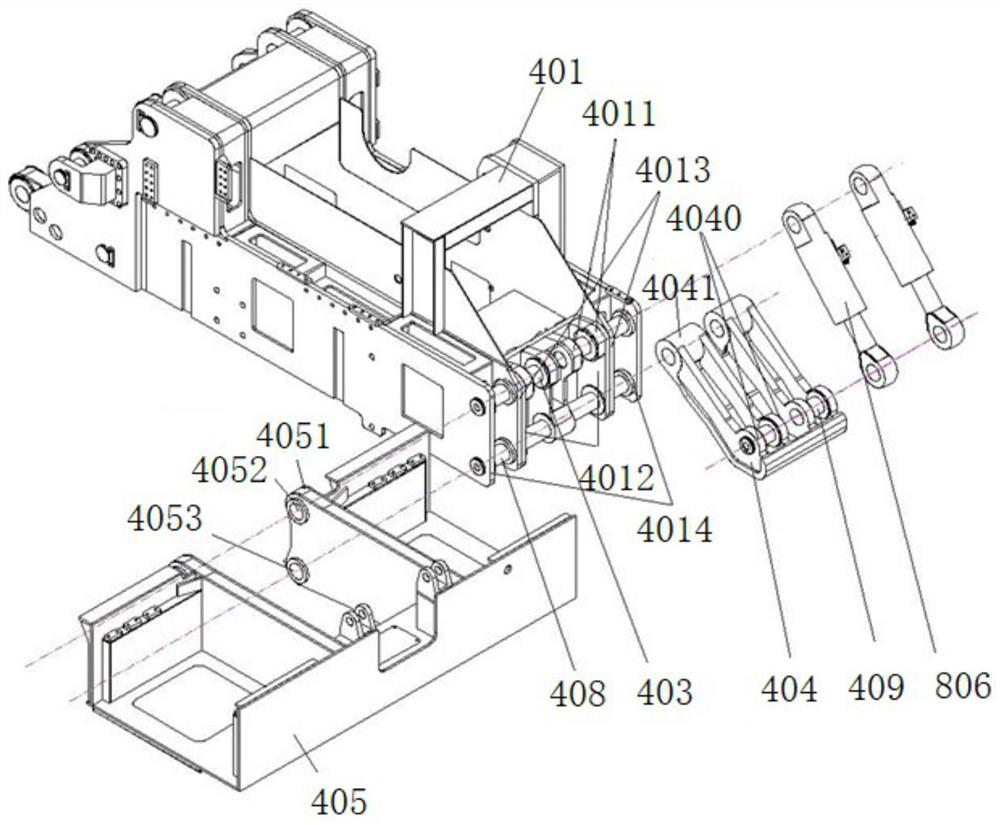

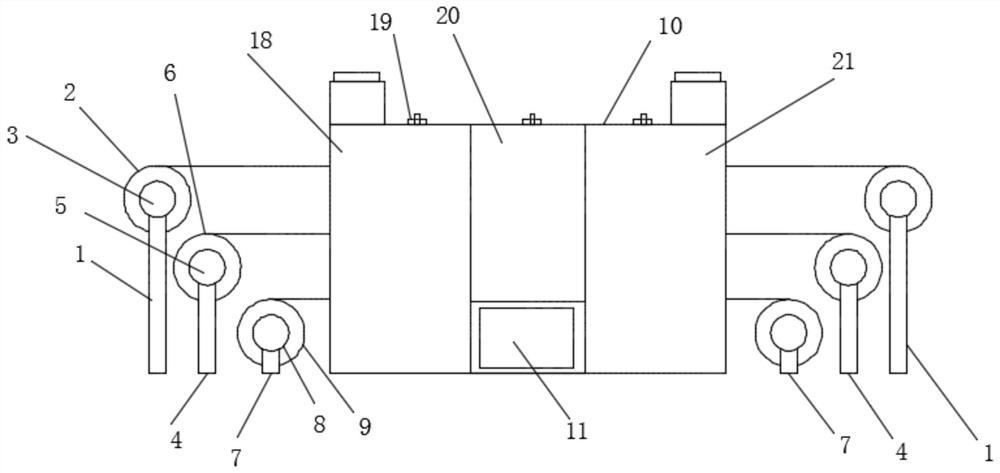

Multi-axle off-road vehicle frame structure with variable axle distance

InactiveCN112429082AIncrease layout spaceOptimize layoutUnderstructuresVehicle frameSuspension (vehicle)

The invention discloses a multi-axle off-road vehicle frame structure with a variable axle distance. The multi-axle off-road vehicle frame structure comprises a front bumper, a vehicle body front suspension beam, a front axle structure, a cross beam, longitudinal beams, a vehicle body rear suspension beam, a container supporting structure, a middle axle structure, a rear axle structure and a rearbumper. The two longitudinal beams are oppositely arranged in the left-right direction of a vehicle body and comprise the left longitudinal beam and the right longitudinal beam; each longitudinal beamis a box beam formed by tailor-welding two first channel beams along the left-right direction of the vehicle body; an engine mounting hole, a transmission mounting hole and a suspension mounting holeare formed in each longitudinal beam; each longitudinal beam comprises a vehicle front section, a vehicle middle section and a vehicle rear section which are integrally formed; each vehicle front section and each vehicle rear section are higher than the corresponding vehicle middle section, so that the longitudinal beams are arranged in the front-back direction of the vehicle body with two high ends and a low middle. According to the invention, the distance between the vehicle body front suspension and the vehicle body rear suspension can be adjusted to meet the requirements of vehicle bodieswith different lengths; and the distance among the front axle structure, the middle axle structure and the rear axle structure can be adjusted to adapt to different chassis arrangements and the performance requirements of the whole vehicle.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

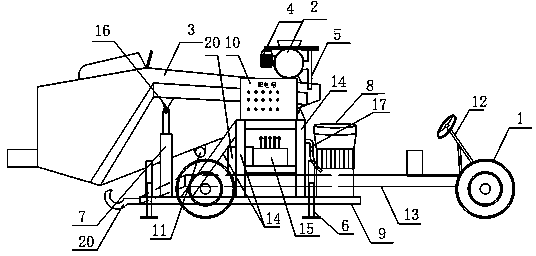

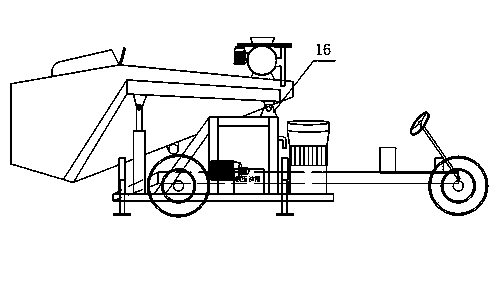

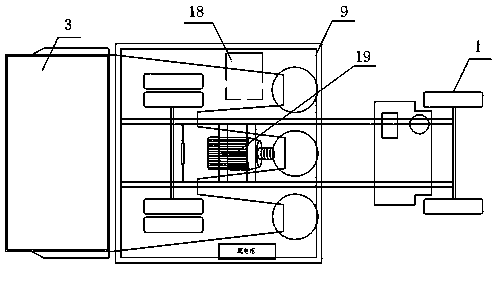

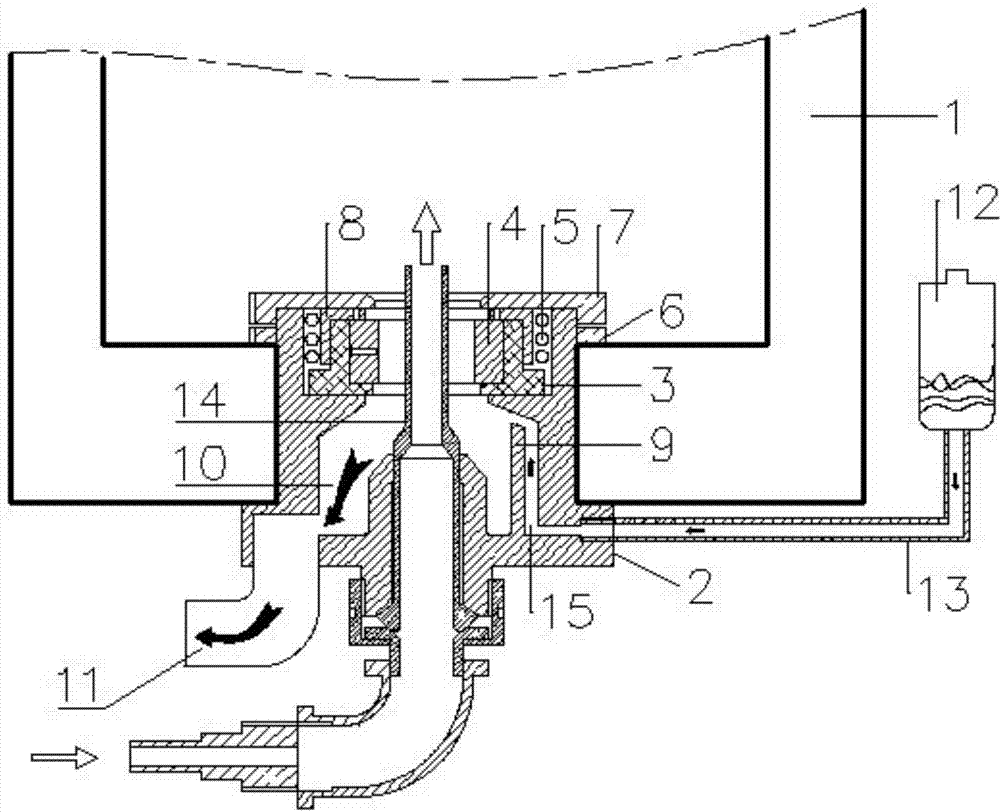

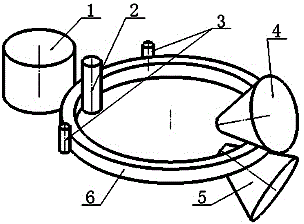

Full-automatic integrated guniting vehicle and using method thereof

InactiveCN104047616AAvoid affecting construction productionReduce connectivityUnderground chambersTunnel liningSlurryDevice breakage

The invention relates to a full-automatic integrated guniting vehicle and a using method of the full-automatic integrated guniting vehicle. The full-automatic integrated guniting vehicle and the using method of the full-automatic integrated guniting vehicle are used for solving the problems that in the prior art, abrasion to a power source is high, and air duct connection is complex. The full-automatic integrated guniting vehicle comprises a rack, a slurry storage device, a guniting machine and a traveling device, wherein a feeding device, the guniting machine and the traveling device are sequentially installed on the rear portion, the middle and the front portion of the rack respectively, the rack comprises a base plate, a vehicle body rack guard beam arranged on the base plate and a cab, a material inlet of the guniting machine is correspondingly arranged below an outlet of a bin, and the traveling device comprises a hook arranged at the rear end of the rack. The full-automatic integrated guniting vehicle and the using method of the full-automatic integrated guniting vehicle have the advantages that device damage due to a heavy vehicle body is avoided in the moving process; an air supply system is simple and convenient to use, the process of connecting air supply pipelines of a plurality of guniting machine vehicles is omitted, and working efficiency is improved; the accelerating agent additive amount is controlled in the field; space between the front end of the guniting vehicle and the cab is large, and a guniting device is convenient to maintain and disassemble when having a fault in the operation process.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

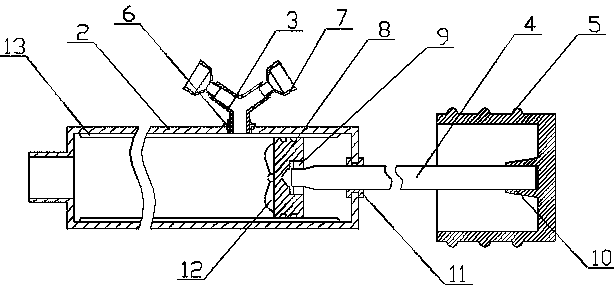

Hydraulic cylinder inner wall cleaner

ActiveCN109604284ASynchronous cleaningSimple structureRotary stirring mixersTransportation and packagingHydraulic cylinderEngineering

The invention relates to a hydraulic cylinder inner wall cleaner, and discloses a cleaner which is capable of extending in a cylinder body, conducting cleaning liquid preparation during cleaning, andwashing the inner wall of the cylinder with spraying holes formed in a circumferential mode. Impurities in the cleaning liquid can be filtered before washing. The hydraulic cylinder inner wall cleaneris characterized in that a connecting pipe is connected to the middle of one end of a hollow pipe and communicates with the hollow pipe; a cleaning shell is located on the connecting pipe and communicates with the connecting pipe; the diameter of the cleaning shell gradually increases from one end to the other end; a filtering plug is located on the inner side of the cleaning shell and corresponds to the connecting pipe; a supporting column is located on the filtering plug and is located in the cleaning shell; one end of the supporting column extends to an opening of the other end of the cleaning shell; the diameter of the supporting column gradually increases from the other end to the end; a plurality of flow distributing blocks are arranged outside the supporting column an equal angles;a distance is formed between the outer lateral surface of the flow distributing blocks and the inner wall of the cleaning shell; and a end cover is arranged on the outer wall of the other end of thecleaning shell in a sleeving mode.

Owner:钱俊

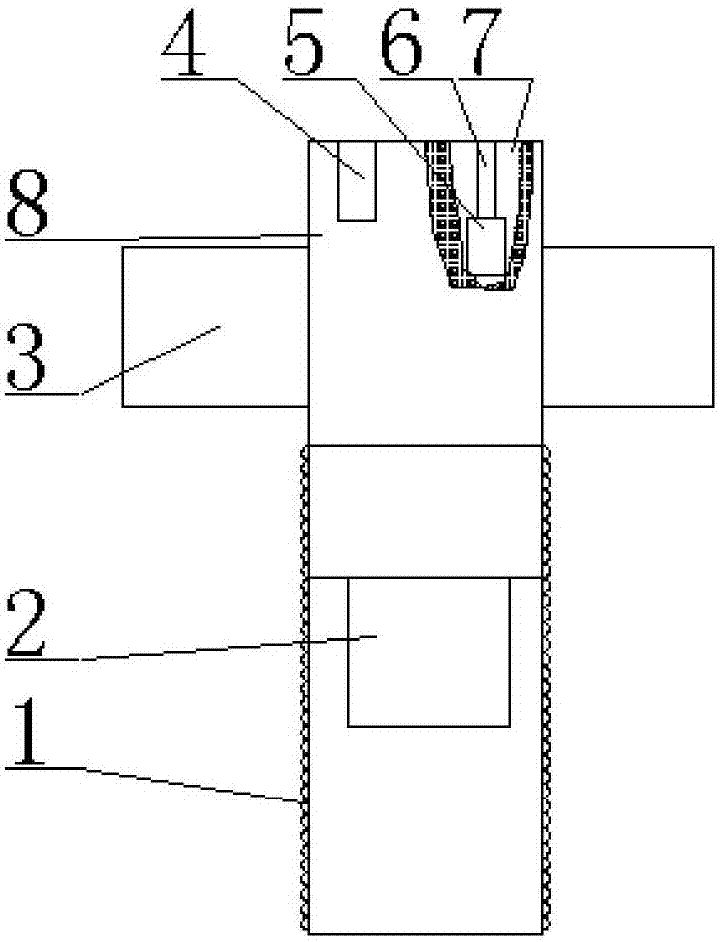

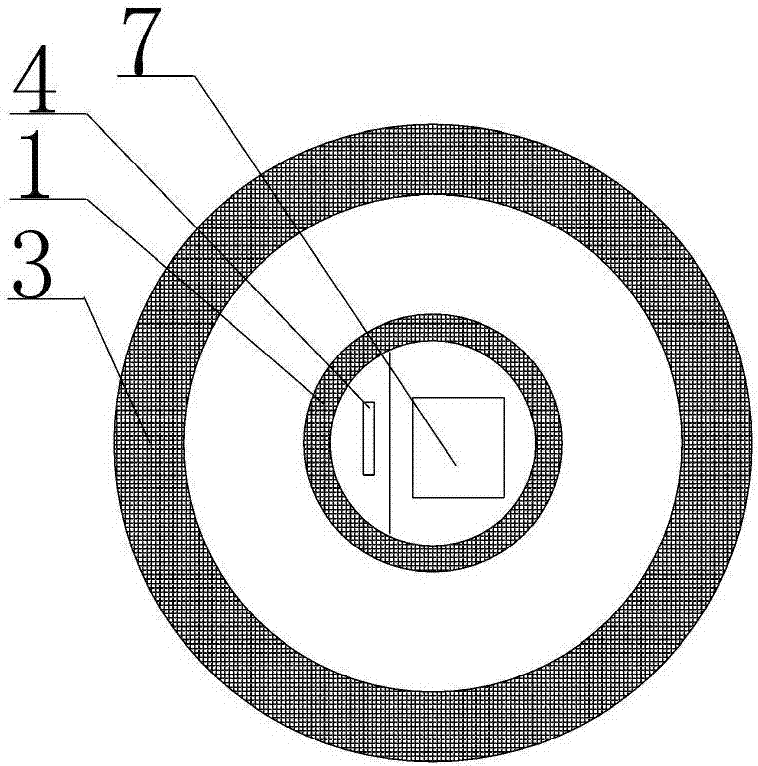

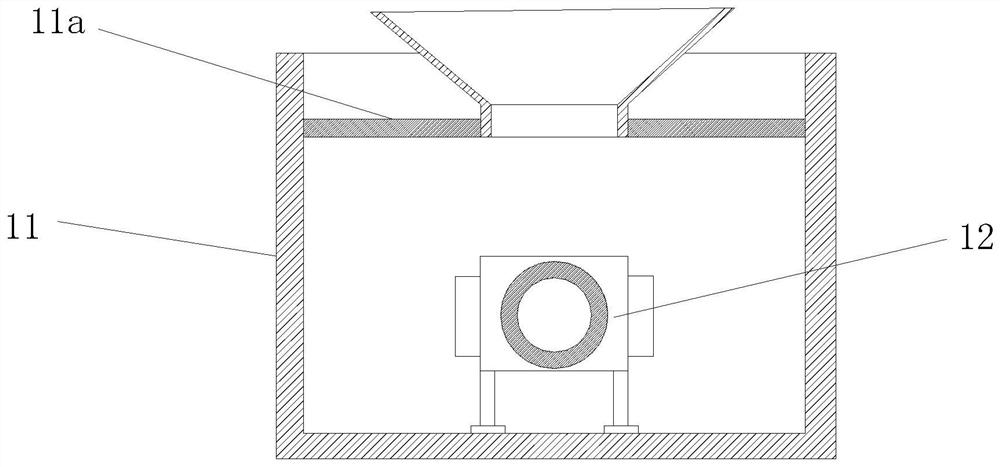

Lower bearing device without grease pollution of tube centrifuge and lubricating method

InactiveCN104741252AEasy maintenance and disassemblySimple structureCentrifugesEngine lubricationEngineeringMechanical engineering

The invention discloses a lower bearing device without grease pollution of a tube centrifuge. The lower bearing device comprises a lower bearing pedestal, a bearing bush and a bearing. The bearing bush is fixed in the lower bearing pedestal, and the bearing is mounted in the bearing bush. The lower bearing device further comprises a container. The lower bearing pedestal is provided with a liquid inlet, a liquid outlet and a corresponding channel, and the liquid inlet is connected with the container through a liquid conveying tube. The invention further discloses a lubricating method for the lower bearing device. According to the lower bearing device without grease pollution of the tube centrifuge, maintaining and dismounting operation are convenient, the structure is simple, and secondary grease atomization pollution of grease to products is avoided.

Owner:周毅

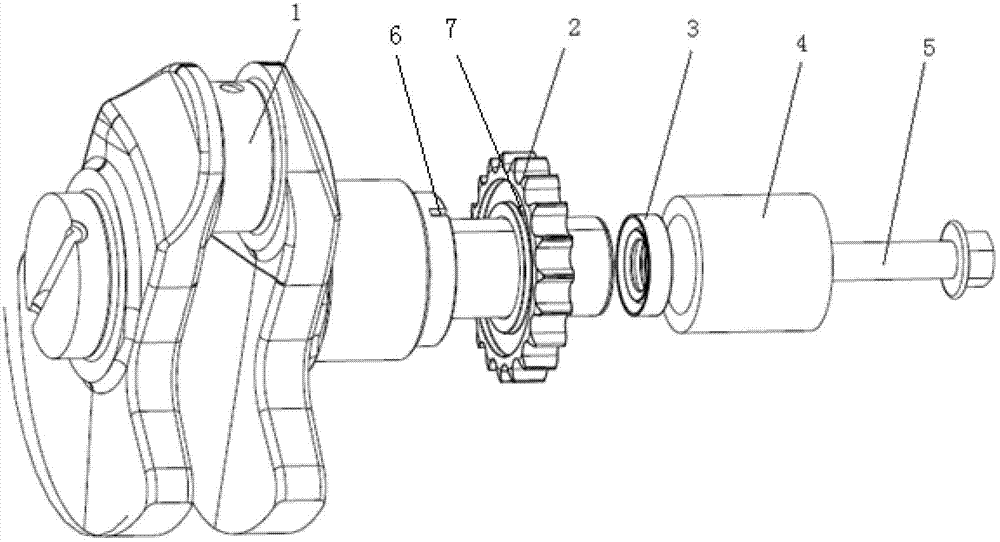

Connecting structure and mounting and fixing method for crankshaft and timing sprocket and engine

ActiveCN103195828AEasy to assembleEasy maintenance and disassemblyValve arrangementsCouplings for rigid shaftsSprocketEngineering

The invention discloses a connecting structure and a mounting and fixing method for a crankshaft and a timing sprocket and an engine and belongs to the field of engine design. The connecting structure for the crankshaft and the timing sprocket is arranged on the crankshaft and the timing sprocket, and comprises a locating slot, a locating key, a sleeve and a fixing bolt, wherein the timing sprocket and the sleeve are sequentially sleeved on the crankshaft journal, the locating slot is processed on the end face of the crankshaft, the locating key is processed on the surface where the timing sprocket is matched with the crankshaft, the timing sprocket and the crankshaft form key connection, the crankshaft is provided with a threaded hole, the fixing bolt penetrates through the threaded hole, and the sleeve and the timing sprocket are fixed on the crankshaft through the fixing bolt. According to the connecting structure and the mounting and fixing method for the crankshaft and the timing sprocket and the engine, the locating slot is processed on the end face of the crankshaft, the locating key is processed on the surface where the timing sprocket is matched with the crankshaft, and the crankshaft and the timing sprocket are located and assembled through a keyway, so that the assembly is easy, and the maintenance and dismounting are convenient.

Owner:CHERY AUTOMOBILE CO LTD

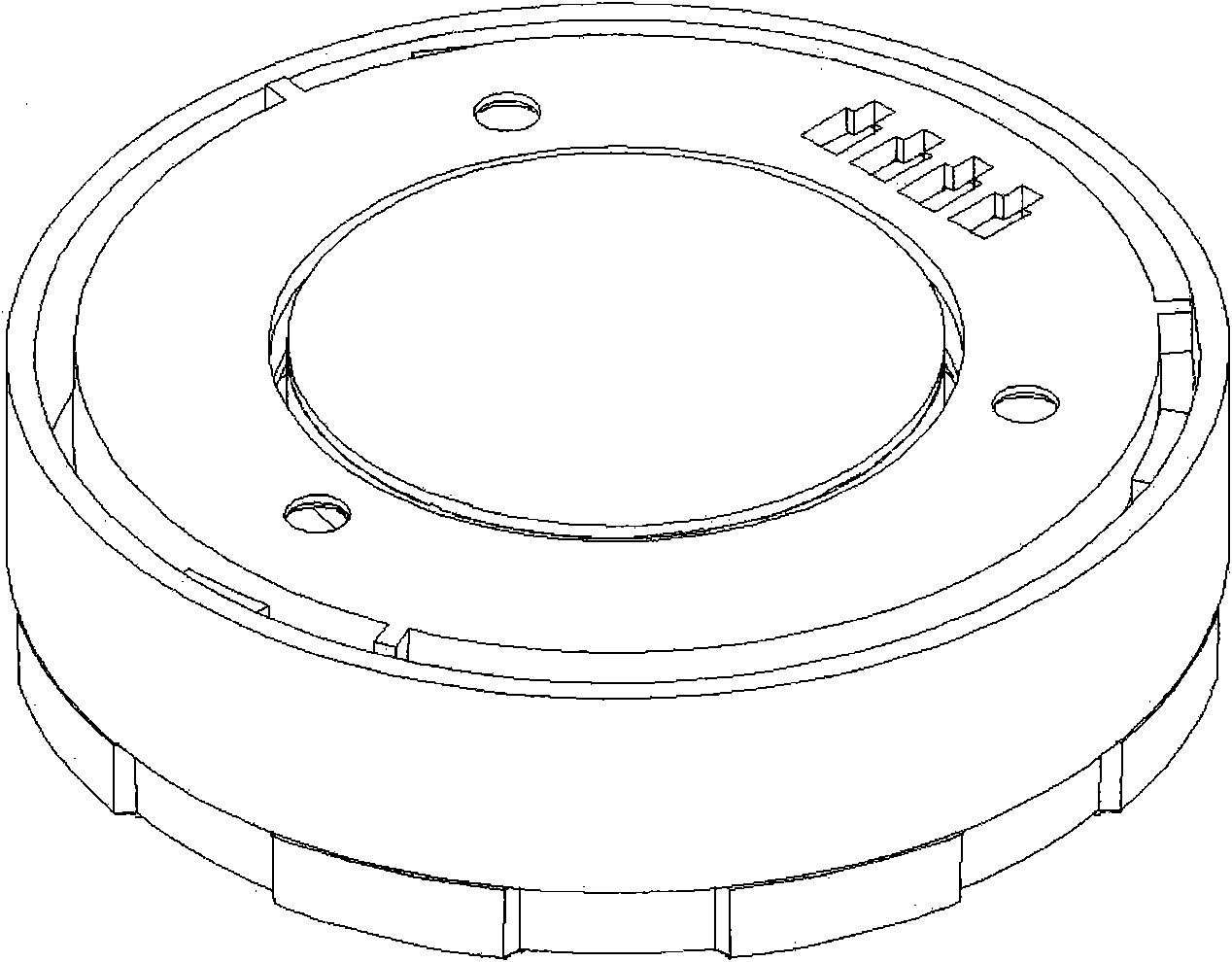

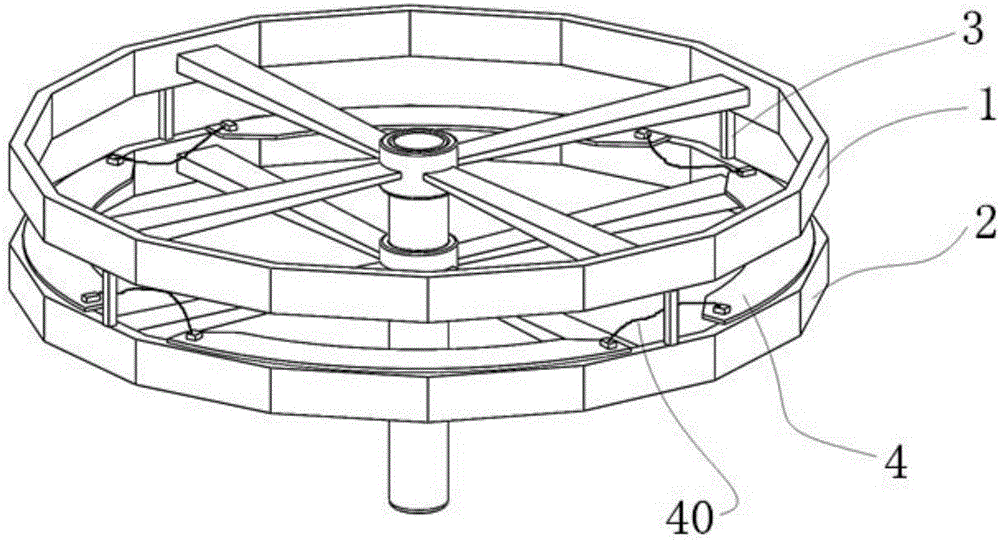

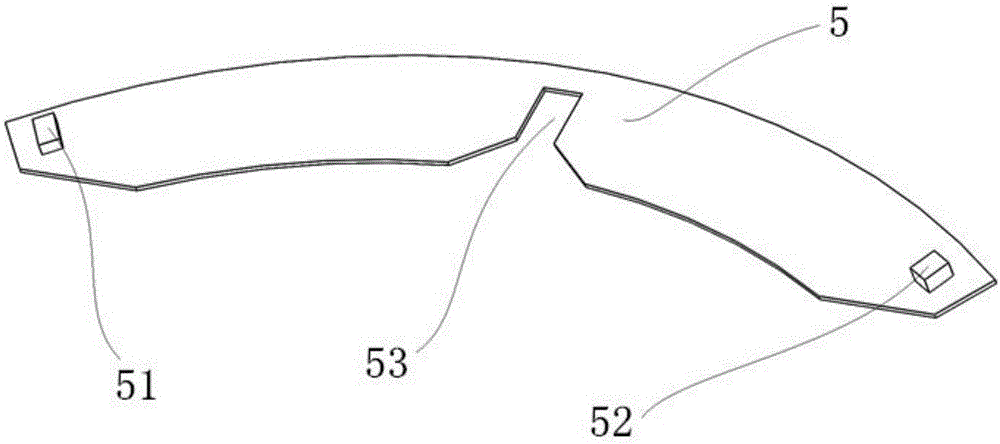

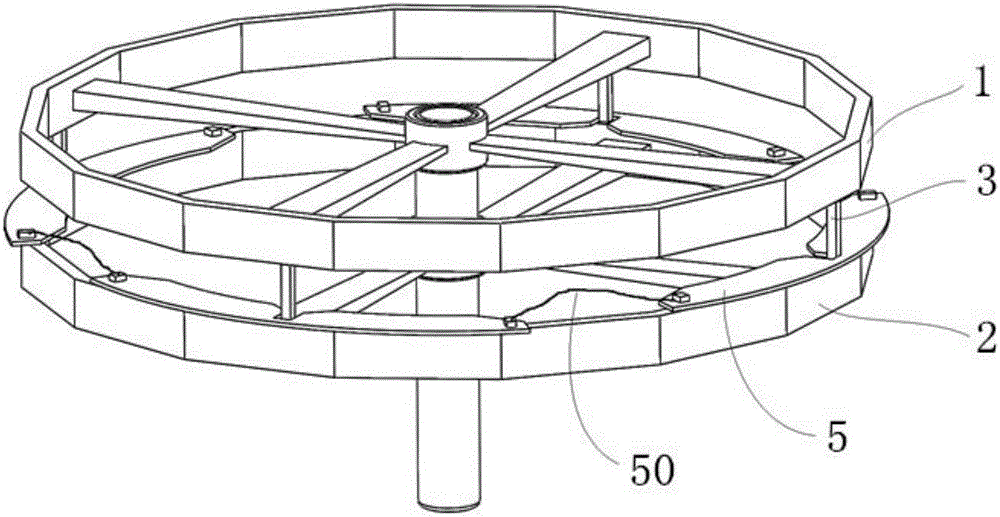

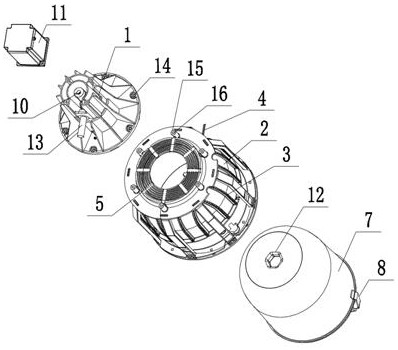

LED circular light source module easy to dismount and replace

InactiveCN102062317AHigh light efficiencyEasy maintenance and disassemblyPoint-like light sourceElectric circuit arrangementsUltrasound attenuationLight energy

The invention relates to an LED circular light source module easy to dismount and replace, which comprises an LED light source module, a rotary assembly and an installing assembly. The novel LED circular light source module easy to dismount and replace has the advantages of capability of recycle and unarmed replacement, efficient heat dissipation, low energy consumption, high stability, long service life, less light energy attenuation, good illuminating effect and novel appearance.

Owner:福建雨露光电科技有限公司

Novel light-burning kiln heating device

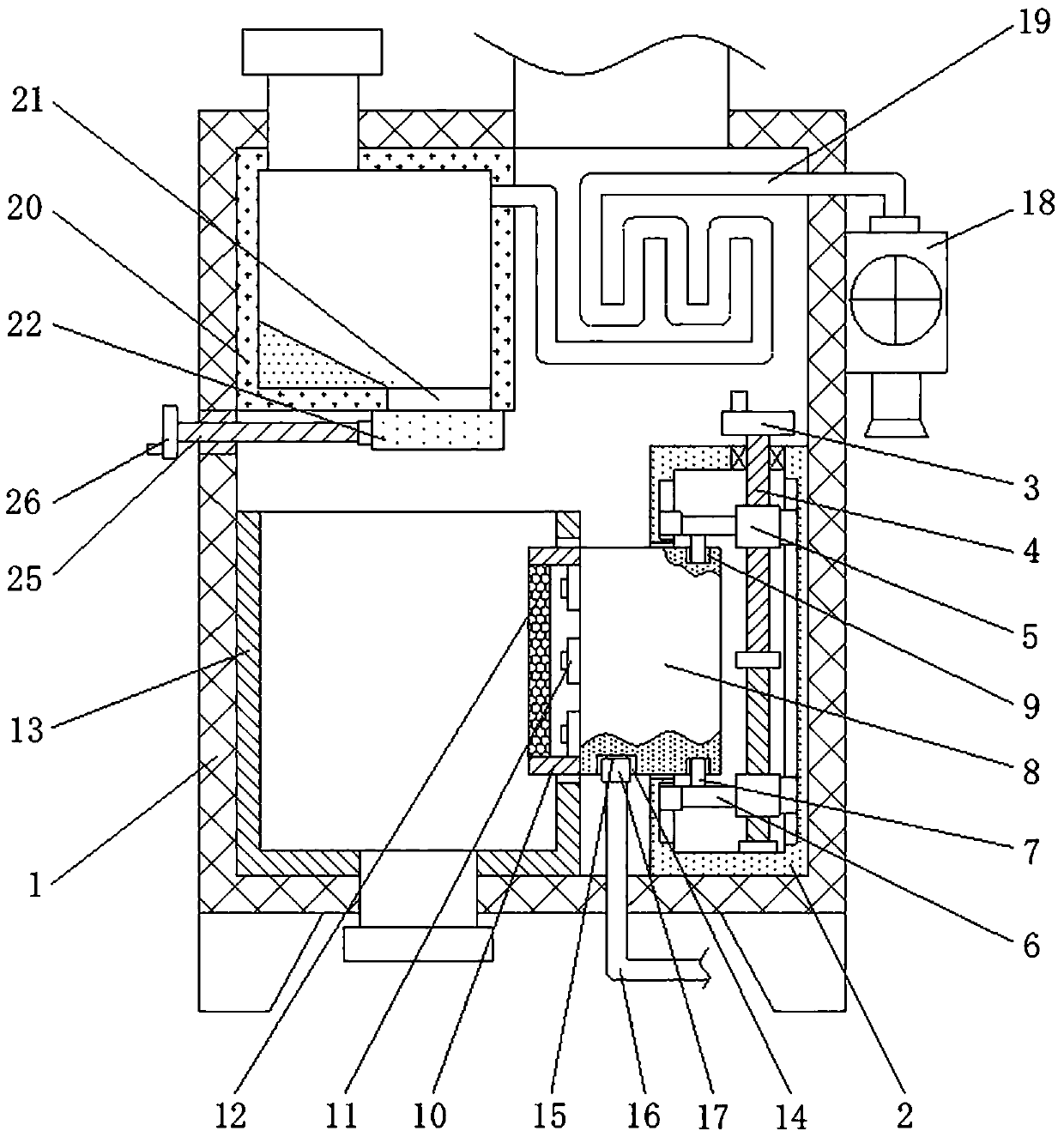

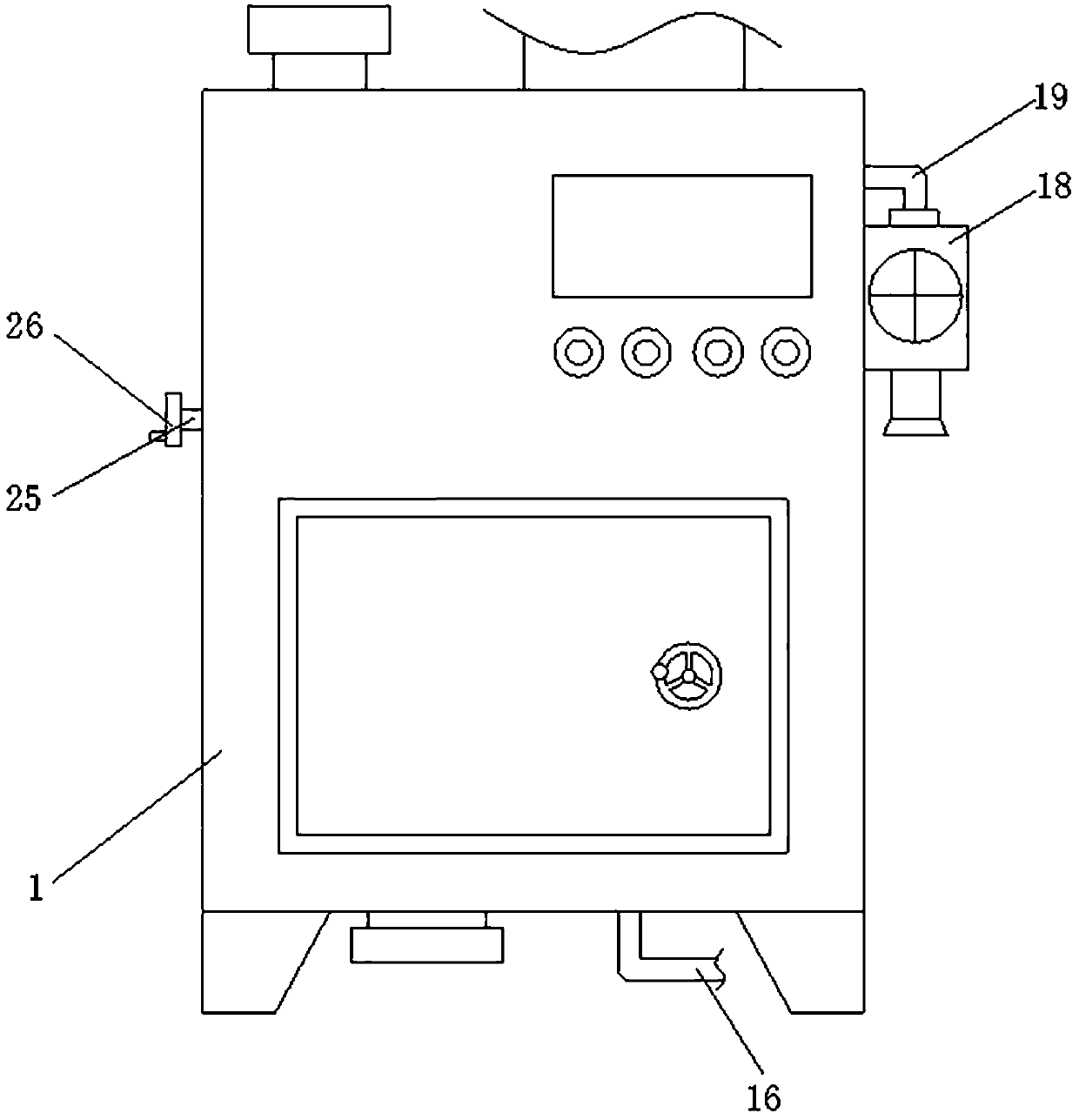

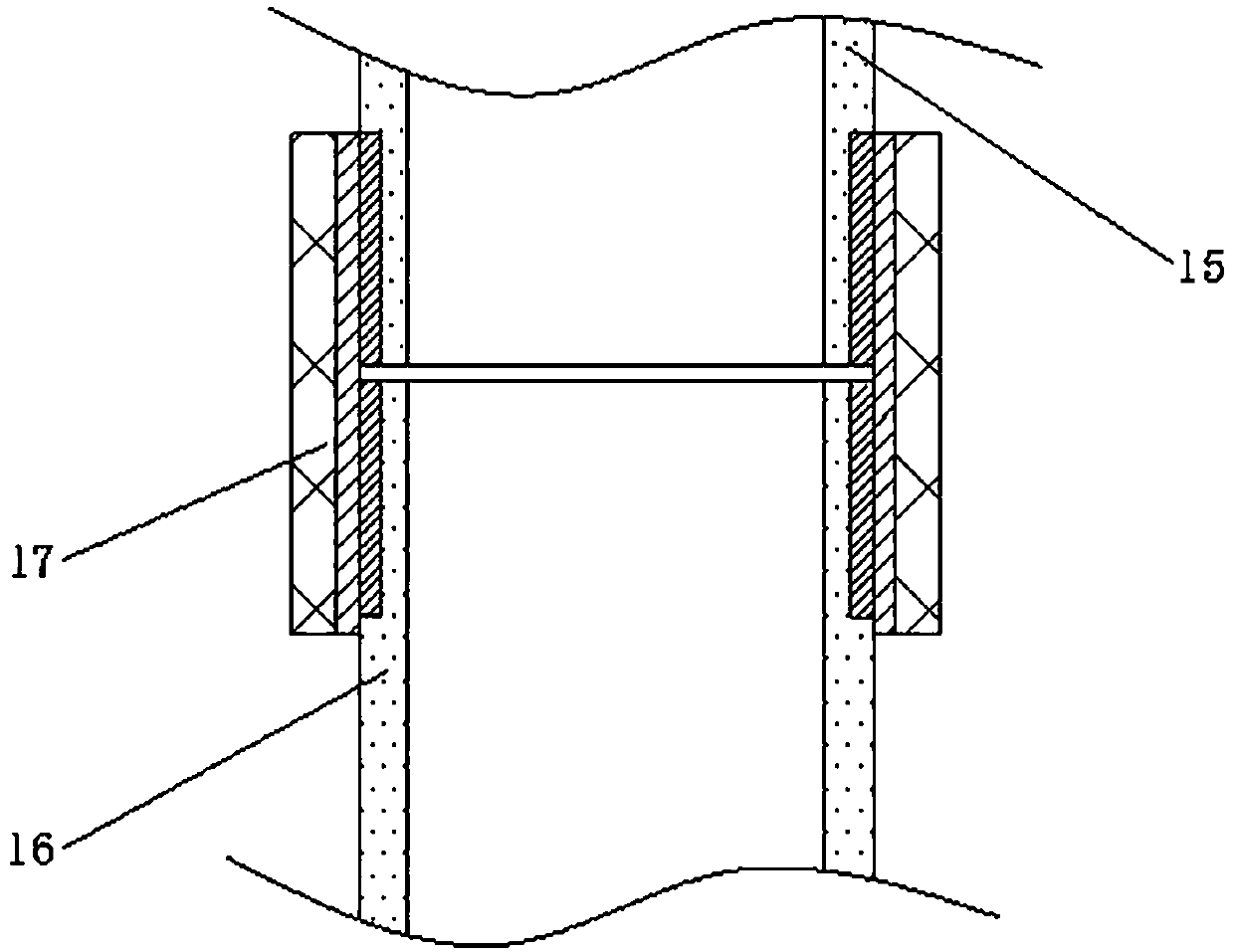

ActiveCN111306943AEasy maintenance and disassemblyPreheating availablePreheating chargesWaste heat treatmentPhysicsHot blast

The invention discloses a novel light-burning kiln heating device. The novel light-burning kiln heating device comprises a light-burning kiln body, wherein the bottom of the right side of an inner cavity of the light-burning kiln body is fixedly connected with a mounting box, a first hand wheel is arranged on the right side of the top of the mounting box, the bottom of the first hand wheel is fixedly connected with a first threaded rod, the bottom of the first threaded rod penetrates through an inner cavity of the mounting box and is movably connected with the inner wall of the mounting box, and threaded sleeves sleeve the surface of the first threaded rod and located at the top and the bottom of the inner cavity of the mounting box. According to the novel light-burning kiln heating device, through arranging the mounting box, the first hand wheel, the first threaded rod, the threaded sleeves, connecting rods, clamping rods, clamping grooves, a mounting groove, a mounting pipe, a fixingring, a fan, a hot air pipe, a preheating box, a discharging opening, a moving plate, limiting shells, moving blocks, a second threaded rod and a second hand wheel, the problems that an existing light-burning kiln heating device cannot pre-heat raw materials and maintenance and disassembly are inconvenient are solved; and the light-burning kiln heating device has the advantages of pre-heating theraw materials and being convenient to maintain and disassemble.

Owner:海城市光大高纯镁砂有限责任公司

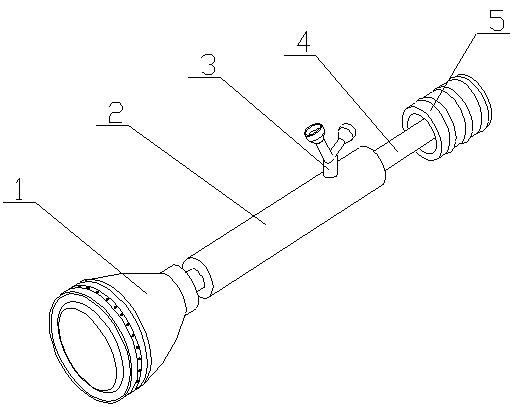

Spray component

ActiveCN107638979AEasy to cleanHelp boostWater resource protectionSpraying apparatusInjection pressureInterference fit

The invention discloses a spray component which comprises a spray pipe and a spray head. The spray pipe and the spray head are connected through a leak-proof connector therebetween, and water flow channel communicated with the spray pipe and the spray head is arranged in the leak-proof connector; a plurality of water outlets are formed in the spray pipe, the leak-proof connector is mounted on thewater outlets in interference fit connection, the spray head is mounted on the leak-proof connector in interference fit connection, and cleaning water flows into the spray head from the spray pipe viathe lead-proof connector and is then sprayed out via the spray head. The non-metallic, elastic and easy-assembling leak-proof connector is additionally arranged between the spray pipe and the spray head which are of stainless steel metal materials, the spray pipe and the spray head are connected in a interference and sealing manner, and the problem about water leakage is effectively avoided; whenproblems like plugging of a spray system occur, maintenance and dismounting are facilitated, leakproofness is still good when the spray system is mounted once more, stable injection pressure of the cleaning water is guaranteed, and cleaning effect of cleaning targets is improved.

Owner:江苏欧倍力洗碗设备制造有限公司

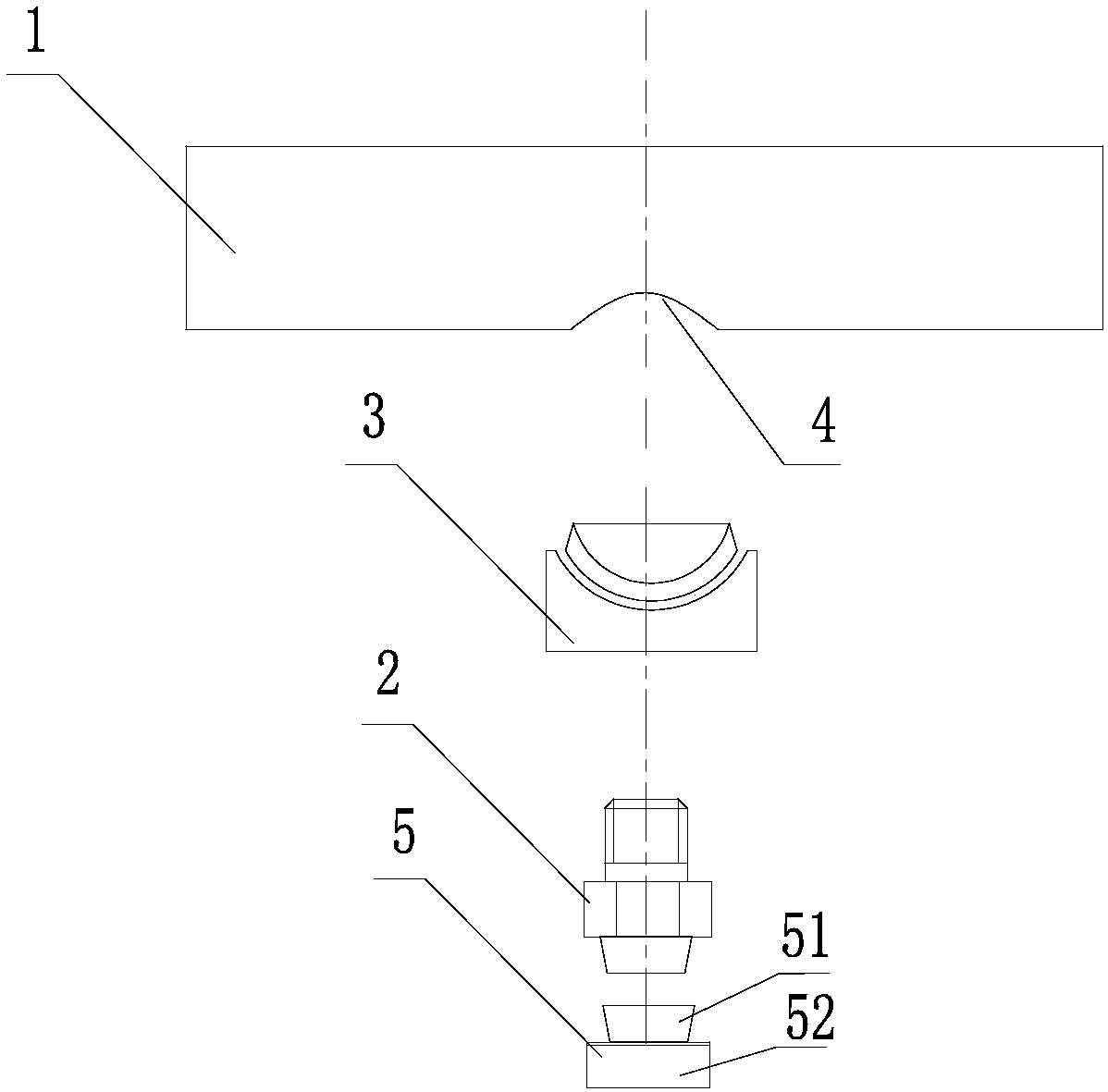

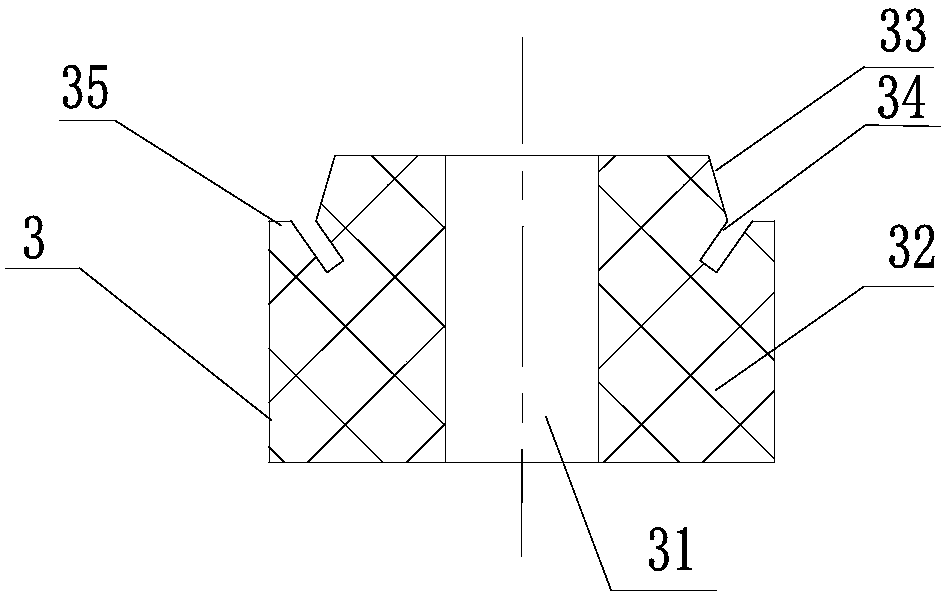

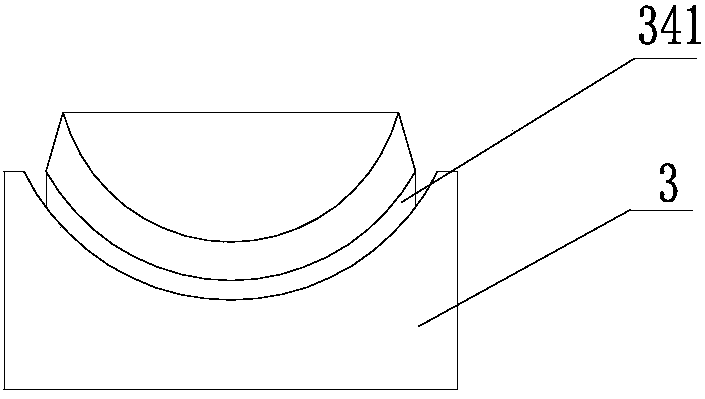

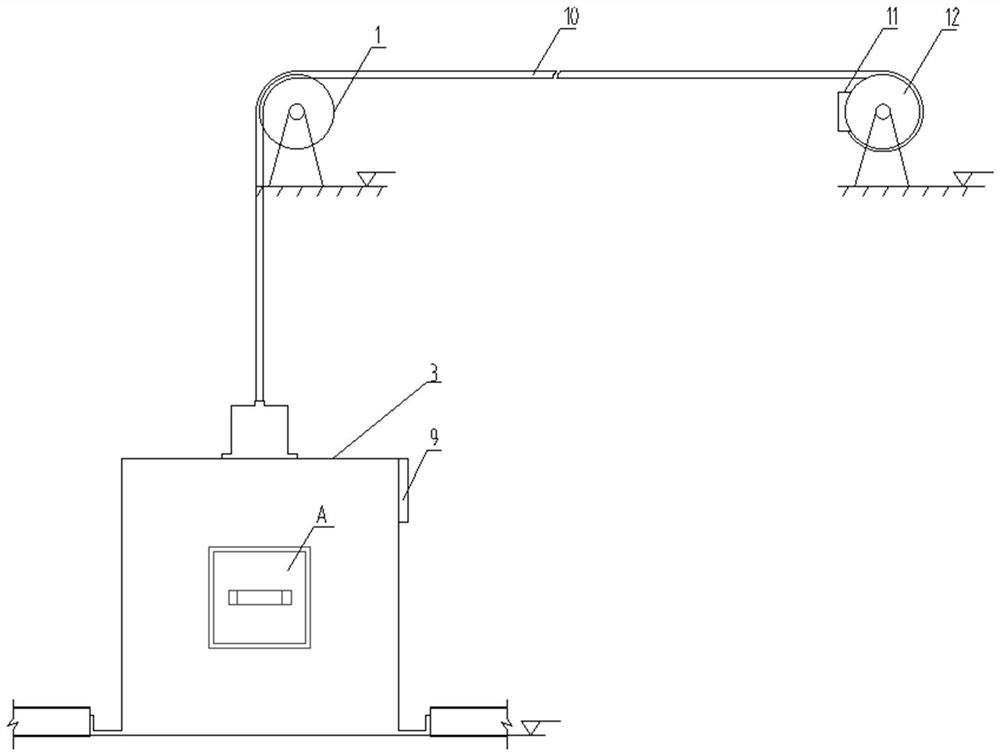

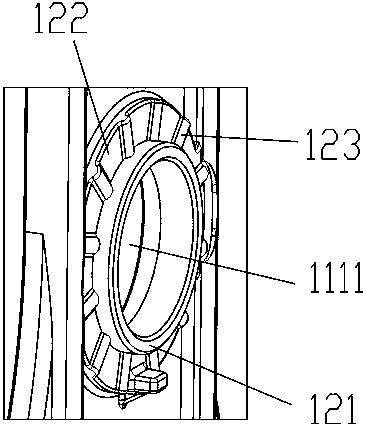

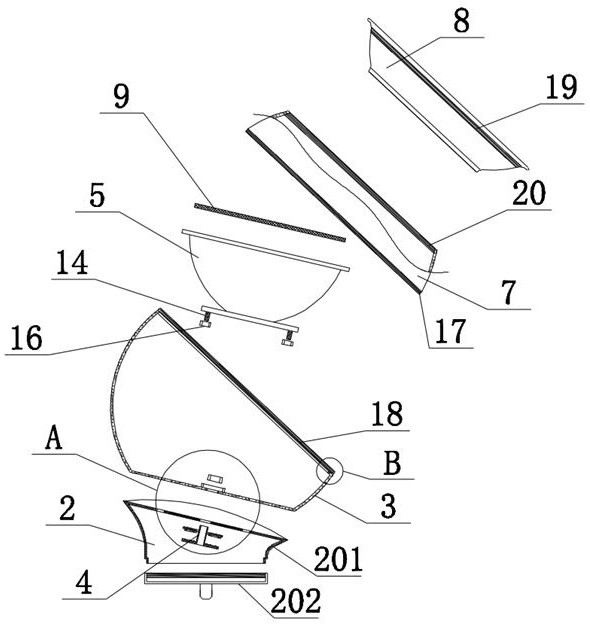

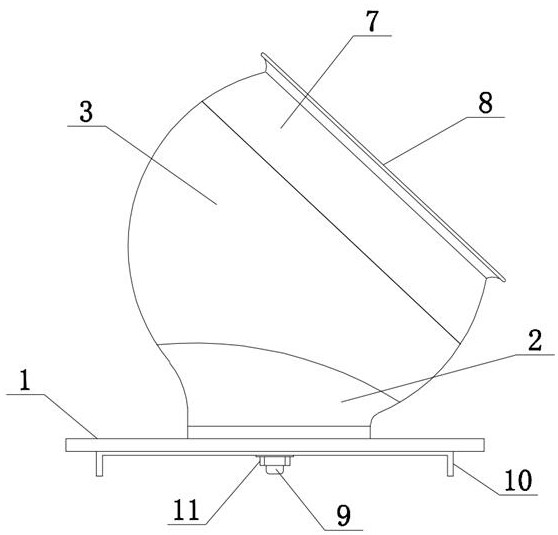

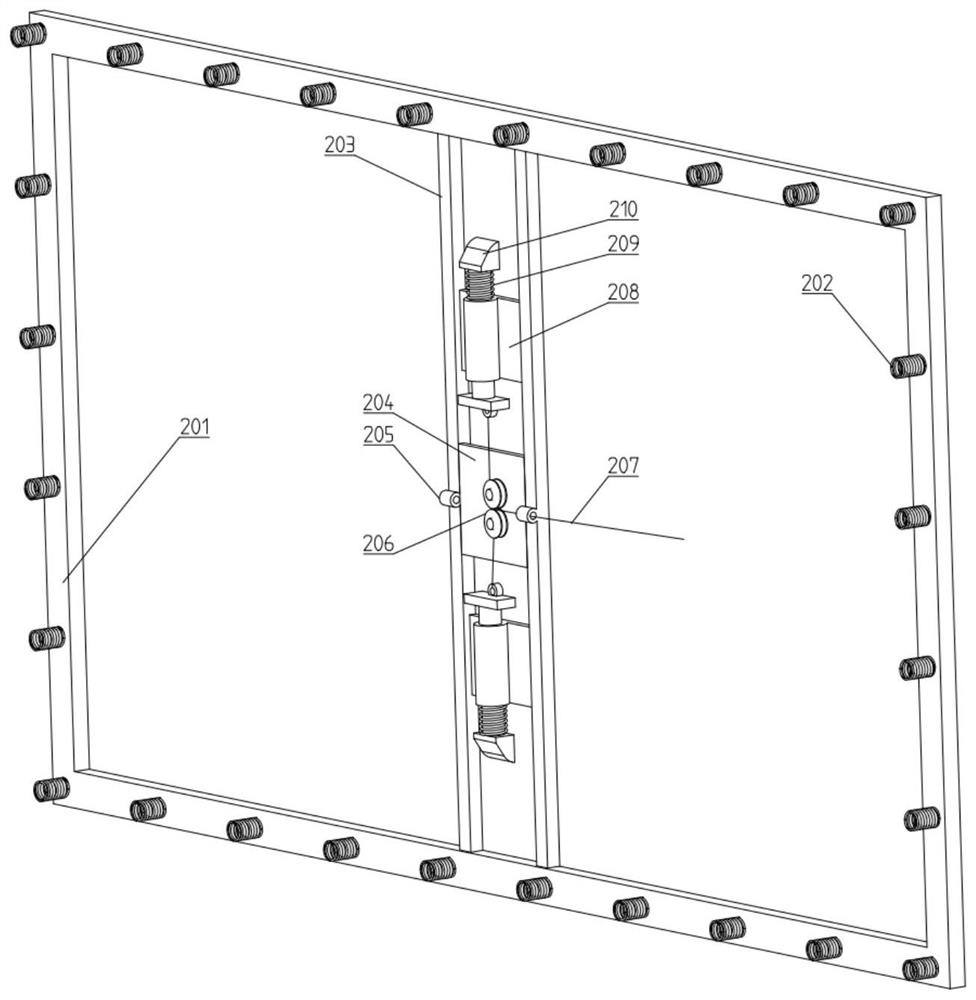

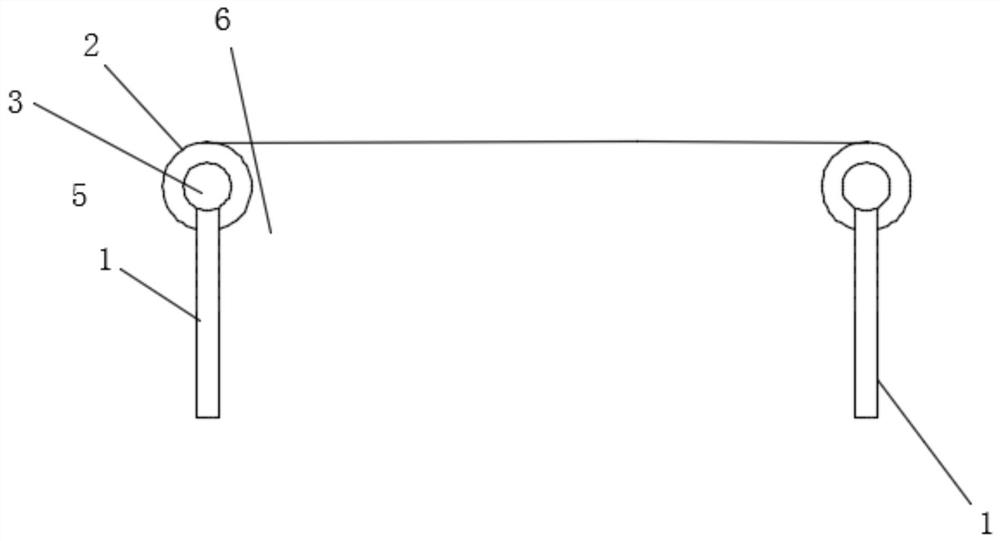

Winch lifting point shielding device for shielding room and using method thereof

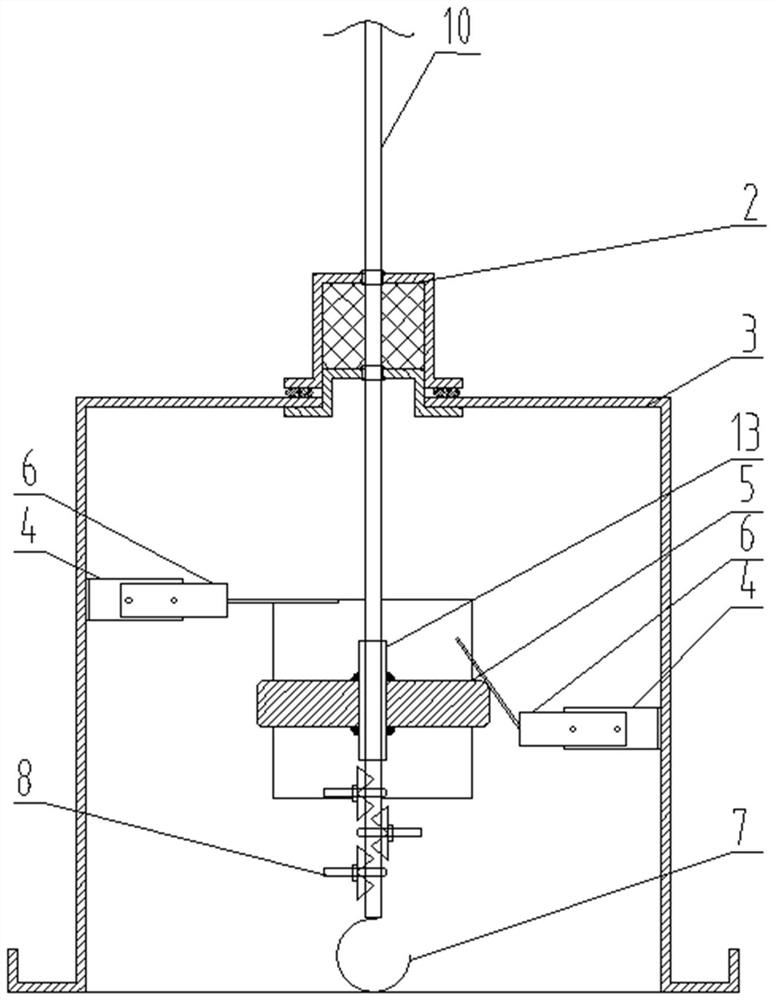

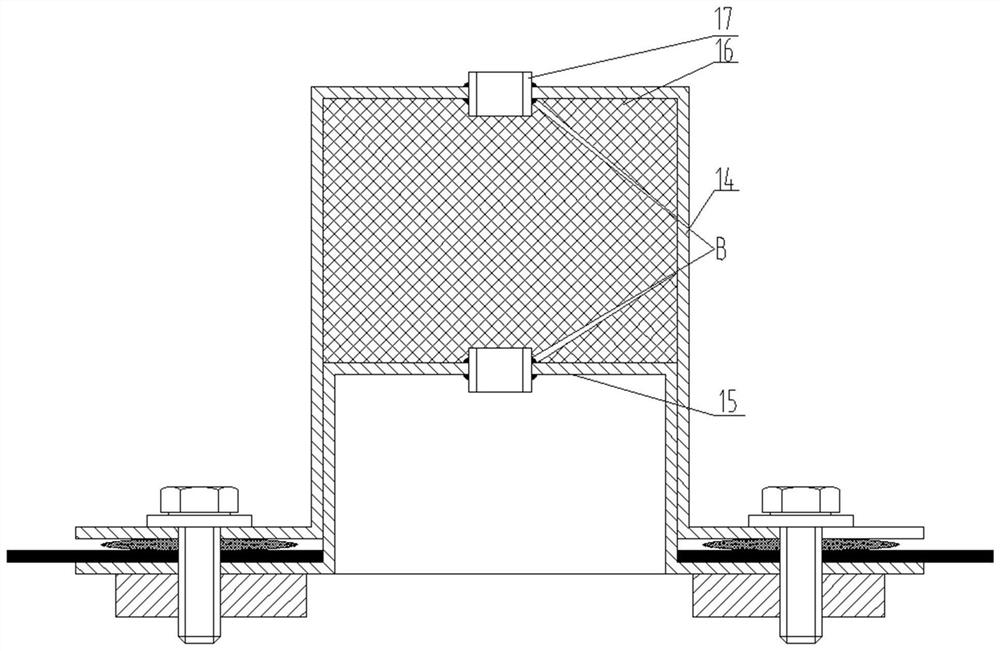

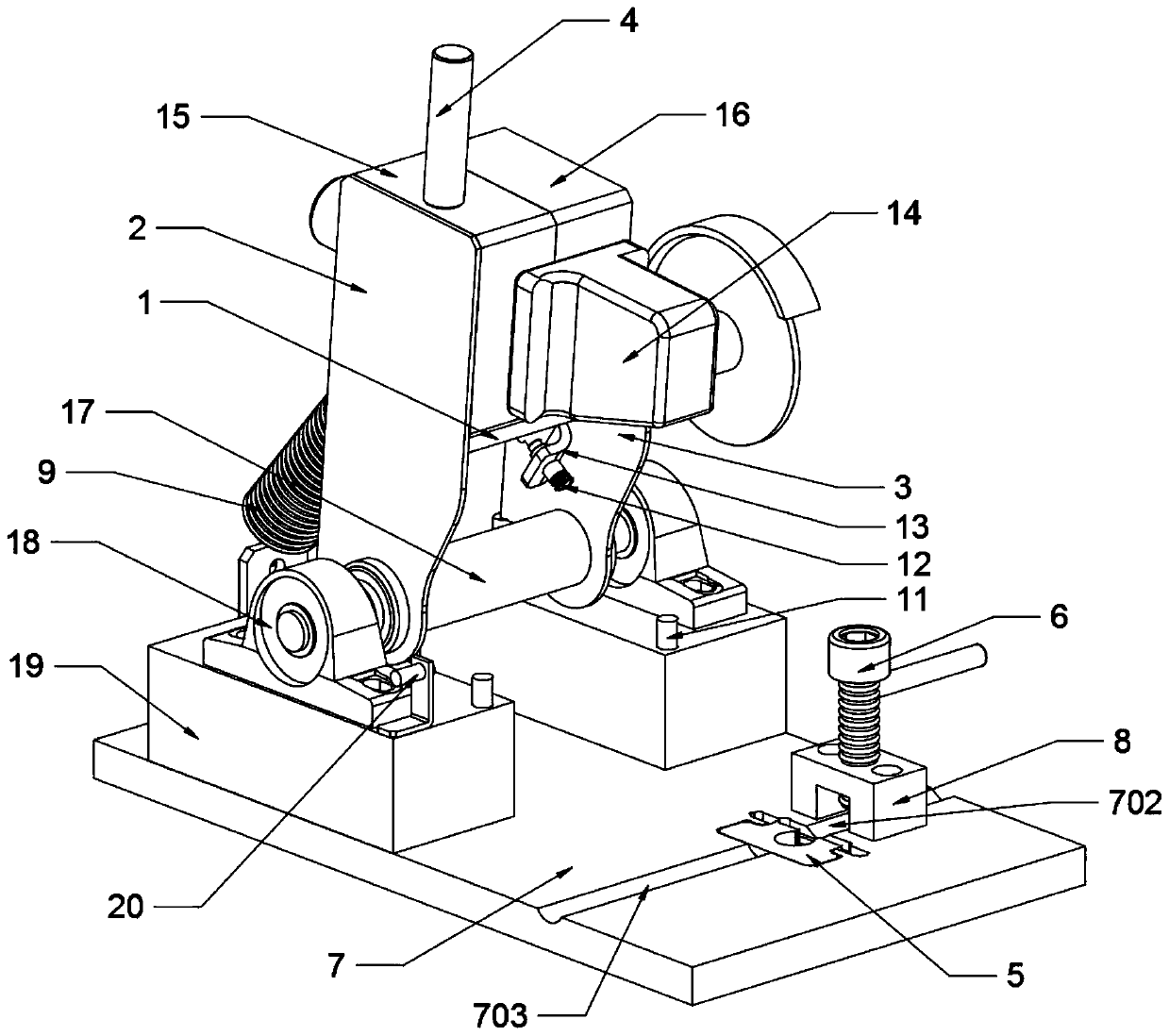

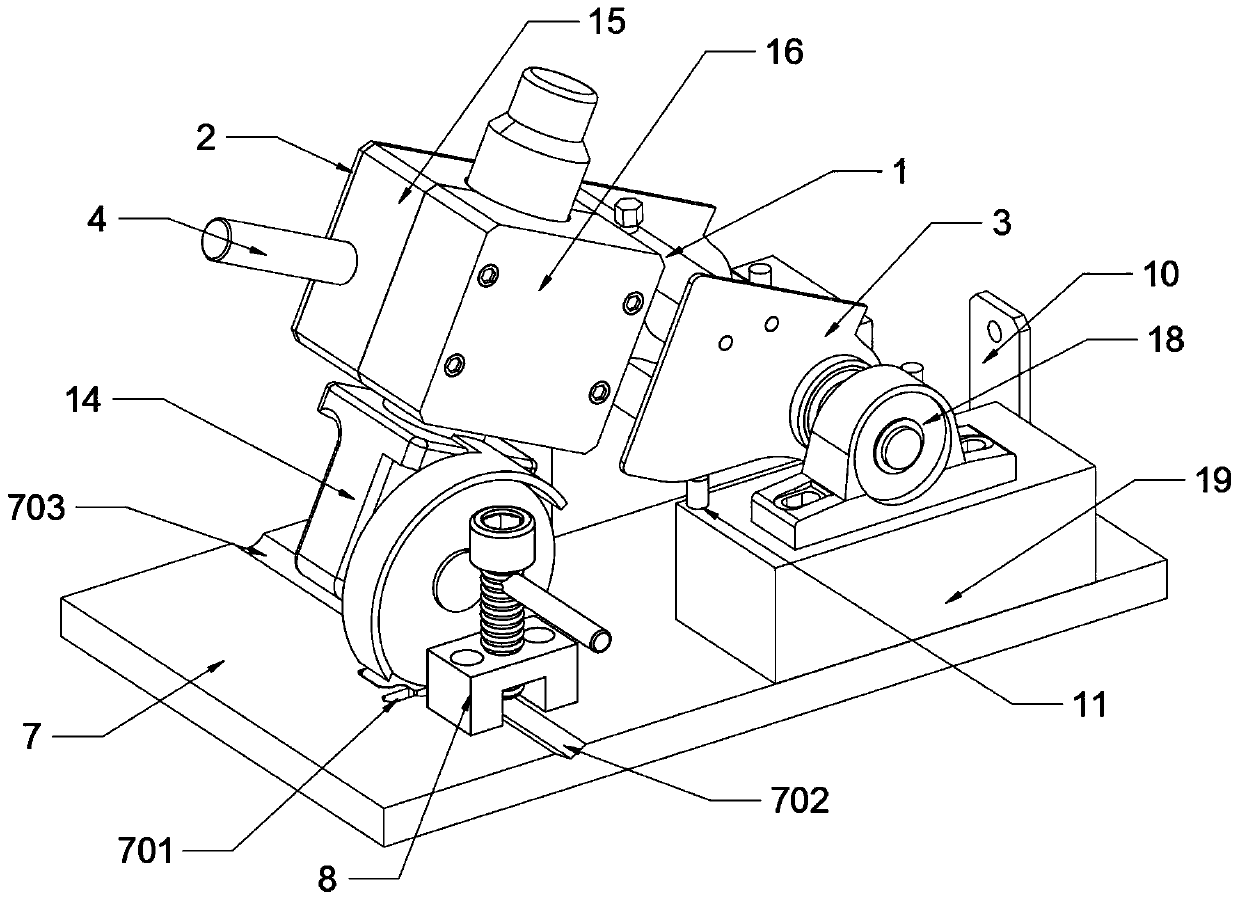

ActiveCN113860199AFix blocking issuesSolve the problem of hanging point positioningMagnetic/electric field screeningWinding mechanismsClassical mechanicsWinch

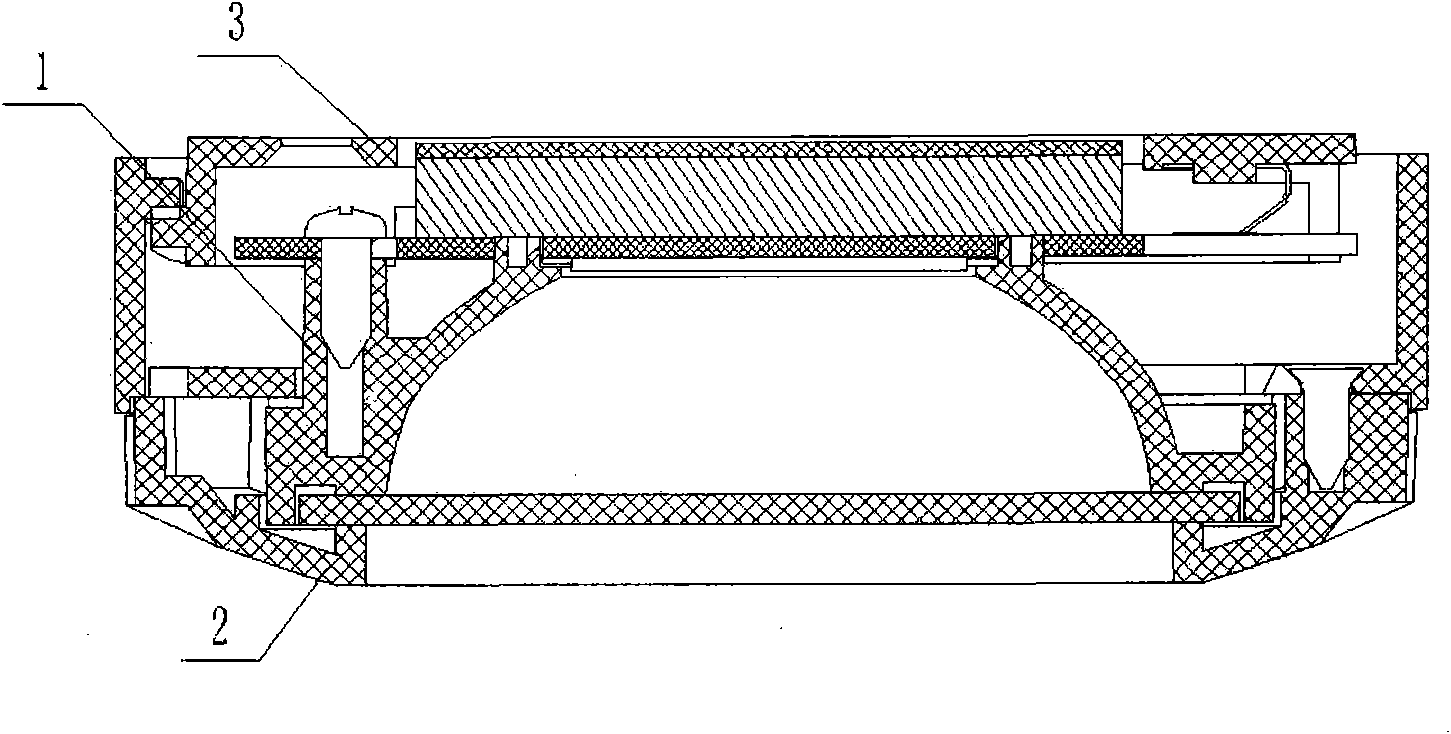

The invention provides a winch lifting point device for a shielding room and a using method thereof. The winch lifting point device comprises a guide wheel (1), a shielding case (2), a winch lifting point shielding case (3), a stopping block (5), a steel wire rope (10), a winch (12) and a sheep eye lifting hook (7). One end of the steel wire rope (10) is connected with the winch (12) arranged on a winch bracket through the guide wheel (1), and the other end of the steel wire rope (10) is connected with the sheep eye lifting hook (7). The steel wire rope (10) penetrates through the winch hoisting point shielding case (3), the shielding case (2) is arranged between the steel wire rope (10) and the winch hoisting point shielding case (3), the steel wire rope (10) is provided with the stopping block (5), and travel switches are respectively arranged above and below the stopping block (5). The problem of hoisting point positioning of the winch is solved. According to the winch lifting point shielding device, a shielding case shell is arranged at the position where the steel wire rope passes through, and an automatic limiting device is installed in the case shell.

Owner:李志珍 +1

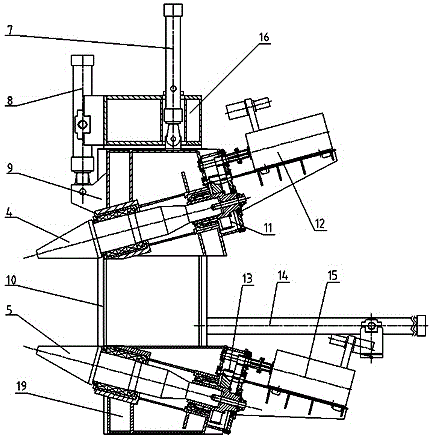

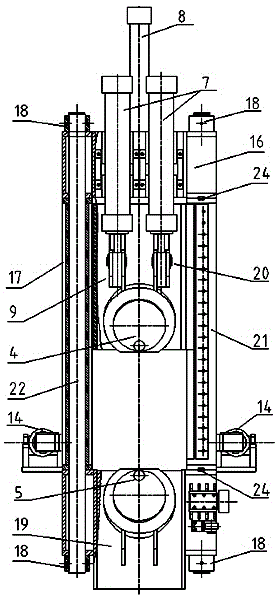

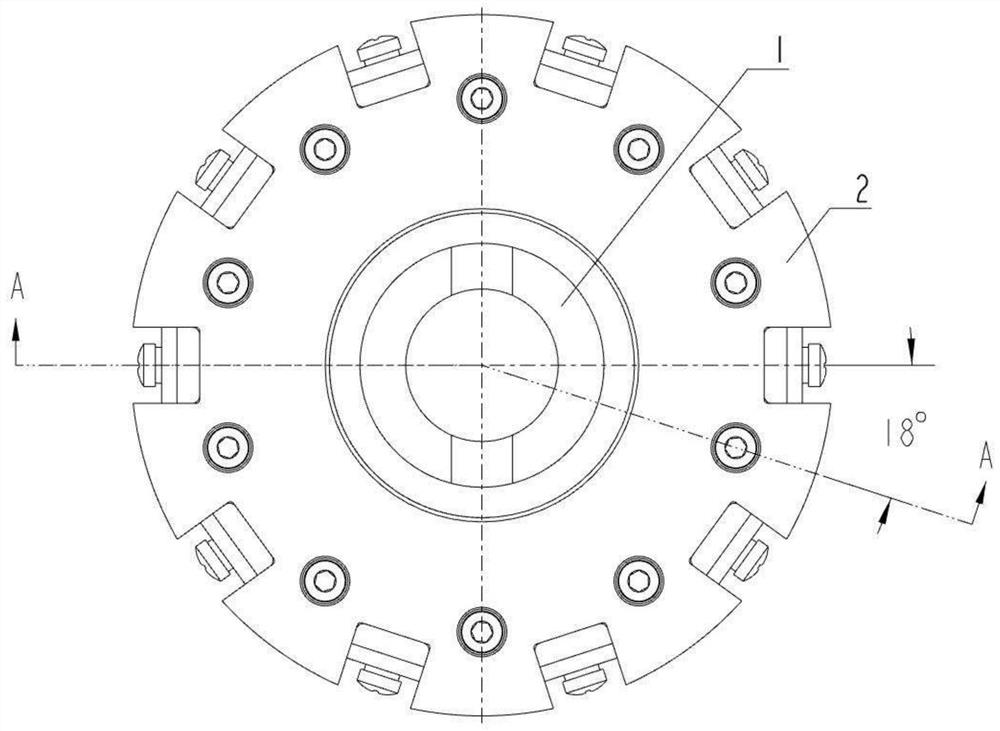

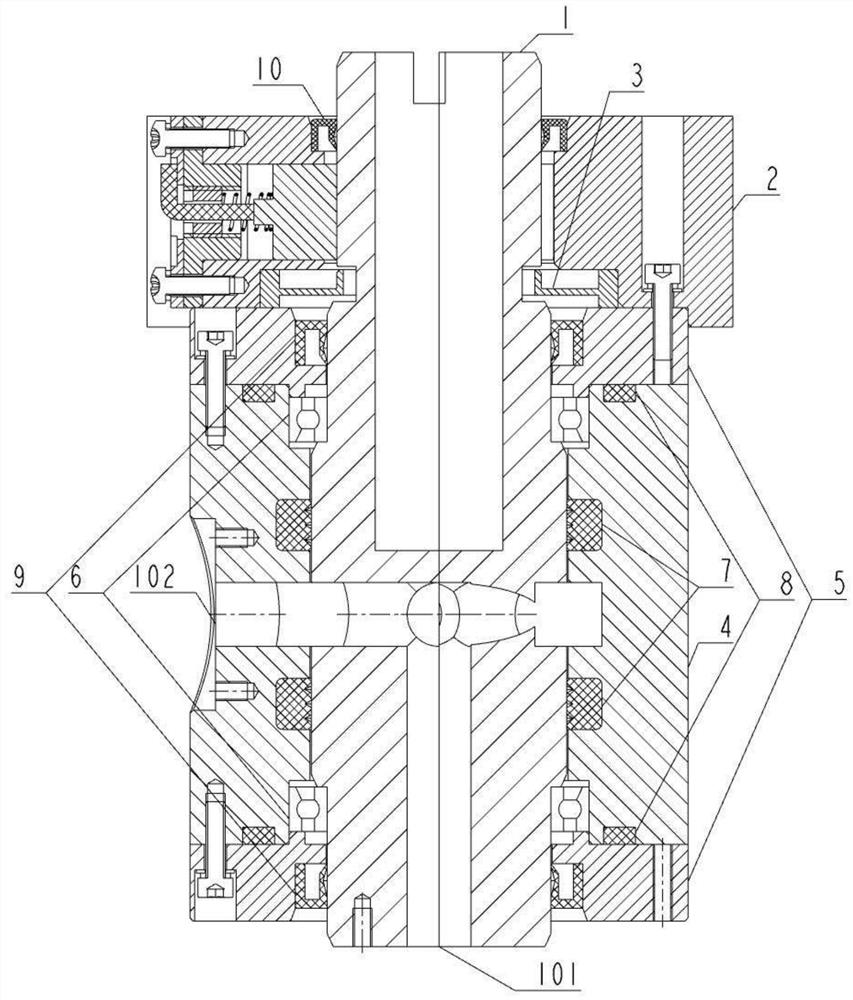

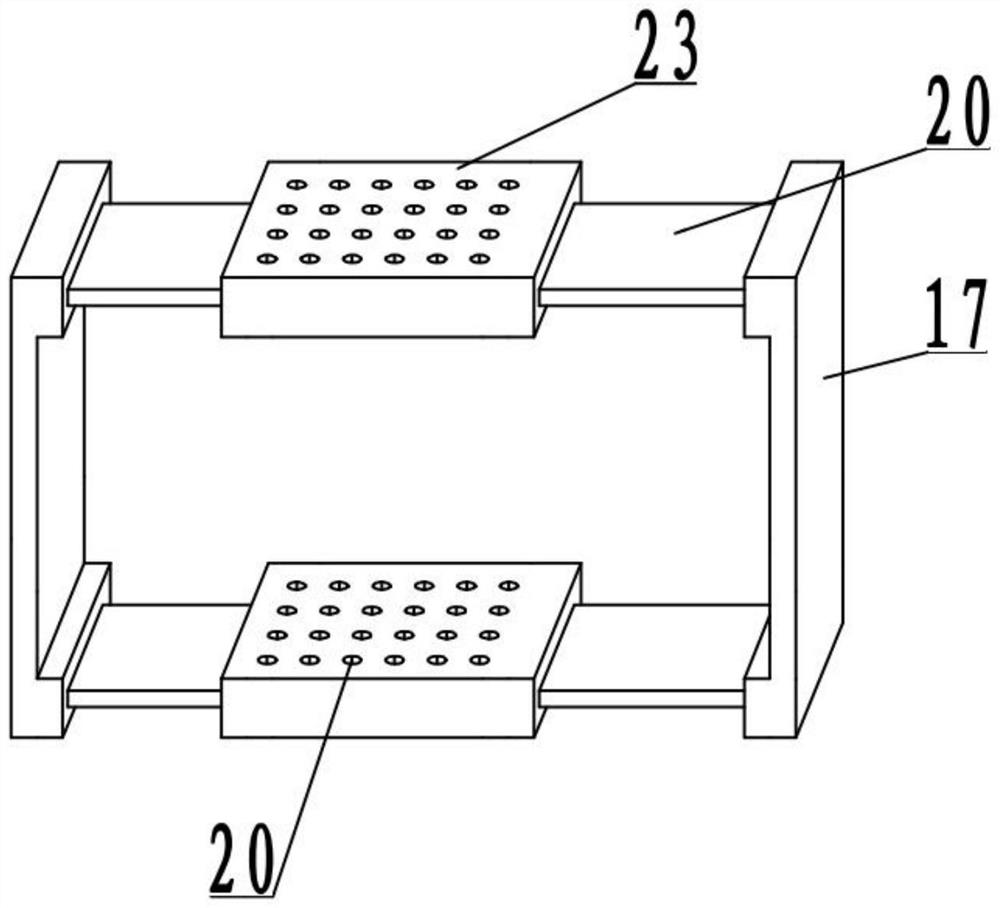

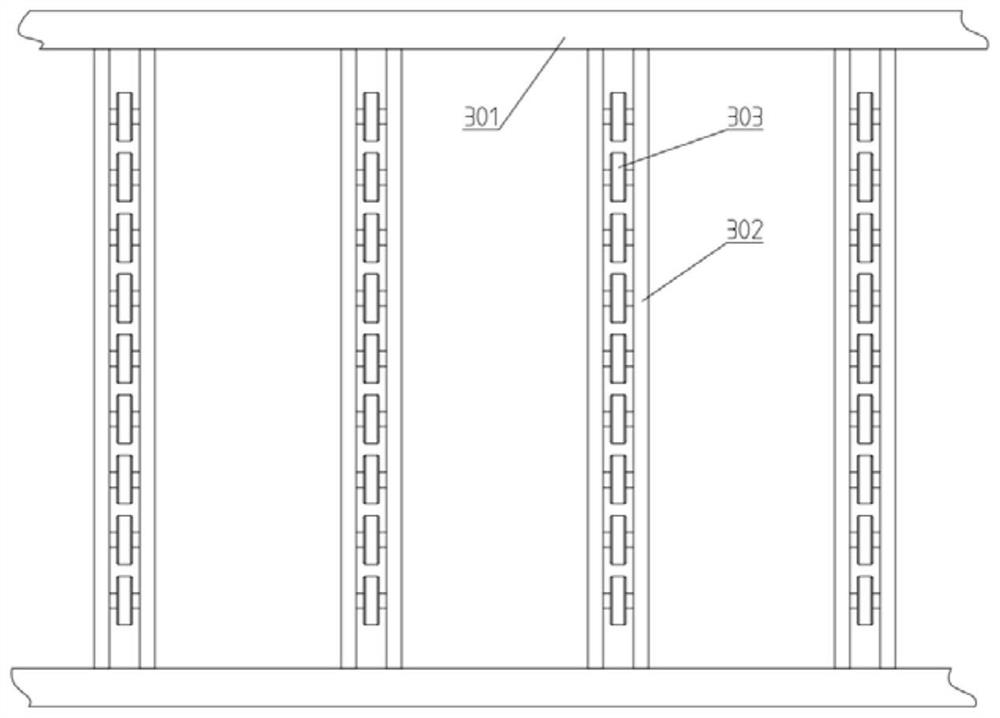

Frame of axial rolling device of ring rolling machine in four pull rod structure

The invention relates to a frame of an axial rolling device of a ring rolling machine in a four pull rod structure. The frame comprises a left side column and a right side column on a hypocone roller seat and an upper beam which connects the left and right side columns is arranged above the left and right side columns; threads are formed at two ends of two front pull rods and two back pull rods, the two front pull rods and two back pull rods penetrate through the hypocone roller seat, the left side column, the right side column and the upper beam and fastens the hypocone roller seat, the left side column, the right side column and the upper beam through column nuts at the upper and lower ends; flat keys are mounted on butt joint faces of the left side column and the upper beam and the hypocone roller seat respectively; flat keys are further mounted on butt joint faces of the right side column and the upper beam and the hypocone roller seat respectively; the flat keys are arranged in the middle parts of the butt joint faces along a front and back direction to play a role of positioning and bear a torsional force of a slide block rolled. The components can be respectively processed, the machining difficulty is greatly reduced, the precision is easy to ensure and the frame is convenient to assemble and maintain.

Owner:JINAN CASTING FORGING MACHINERY INST

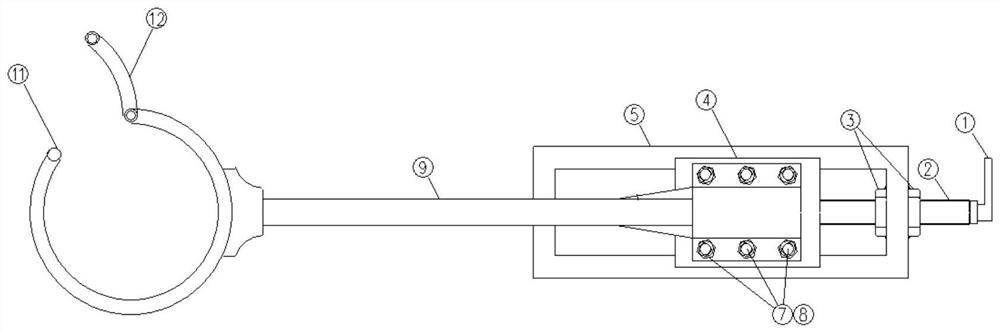

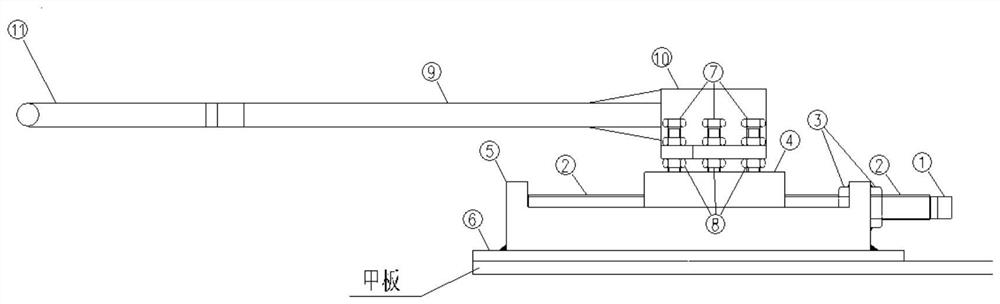

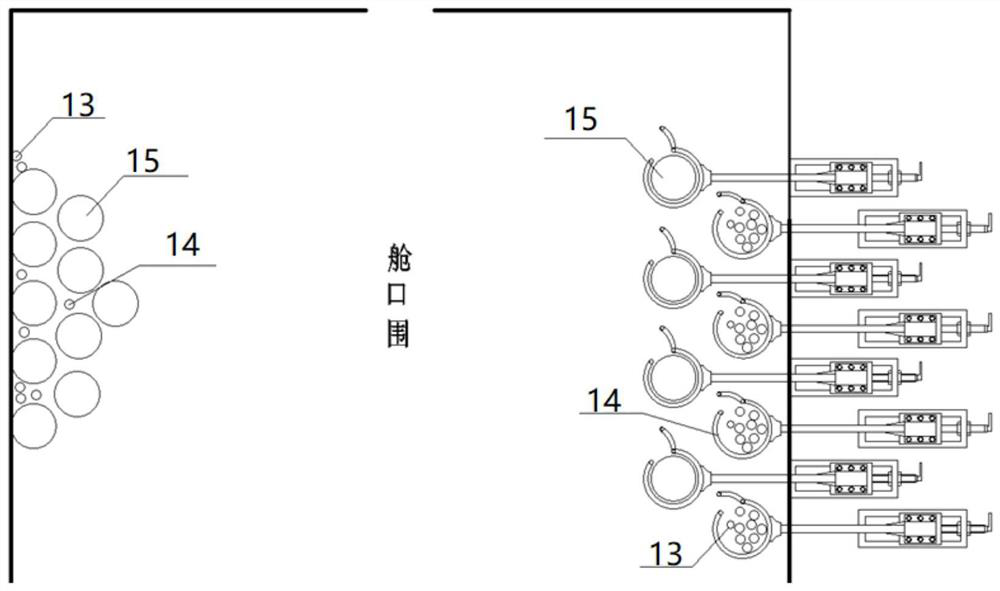

Ship hatch coaming wind pipe belt arrangement device and arrangement method

PendingCN113955043ASave spaceEasy maintenance and disassemblyWaterborne vesselsMarine engineeringWorking environment

The invention discloses a ship hatch coaming wind pipe belt arrangement device which comprises a base, an adjusting mechanism and a fixing mechanism, the adjusting mechanism is installed on the base, the fixing mechanism is installed on the adjusting mechanism, and the adjusting mechanism comprises a built-in guide rail type fixing frame, an adjusting screw rod, a sliding block and a guide nut. The built-in guide rail type fixing frame is installed on the base, a U-shaped groove is formed in the upper surface of the built-in guide rail type fixing frame, the guide nut is installed on one side of the U-shaped groove, one end of the adjusting screw rod penetrates through the guide nut and abuts against the other side of the U-shaped groove, the sliding block is installed in the U-shaped groove, a threaded hole is formed in the sliding block in a penetrating mode, the guide screw is in threaded connection with the threaded hole, and the fixing mechanism is installed on the sliding block. The device is simple in structure, can adapt to various working environments, facilitates pulling and arrangement of the air pipe belt on site, and is convenient to manage and arrange.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Sealing performance inspection unit for soft bag packaging system, and inspection method

PendingCN113447217AImprove work efficiencyEasy to installMeasurement of fluid loss/gain rateStructural engineeringVacuum pump

The invention discloses a sealing performance inspection unit for a soft bag packaging system, and an inspection method. The inspection unit comprises a detection groove, a vacuum pump, a top cover, a pressure sensor, a pressure gauge and an alarm system; the vacuum pump is arranged on one side of the detection groove, the top cover is arranged on the top of the detection groove, the pressure gauge is fixed on one side of the detection groove, the pressure gauge is connected with the pressure sensor, a mounting groove is formed in the inner wall of one side of the detection groove, the pressure sensor is mounted in the mounting groove, and a disassembly and assembly structure is arranged between the detection groove and the pressure sensor; an alarm system is additionally arranged in the sealing performance inspection unit for the soft bag packaging system, so that the alarm system can automatically start an alarm lamp after the sealing performance defect exists in the soft packaging bag during detection, an operator is reminded, and the operator does not need to repeatedly compare numerical values on the pressure gauge in the daily detection process, and judges whether the soft packaging bag has the sealing defect or not only by observing whether the alarm lamp is turned on or not.

Owner:西安乐析医疗科技有限公司

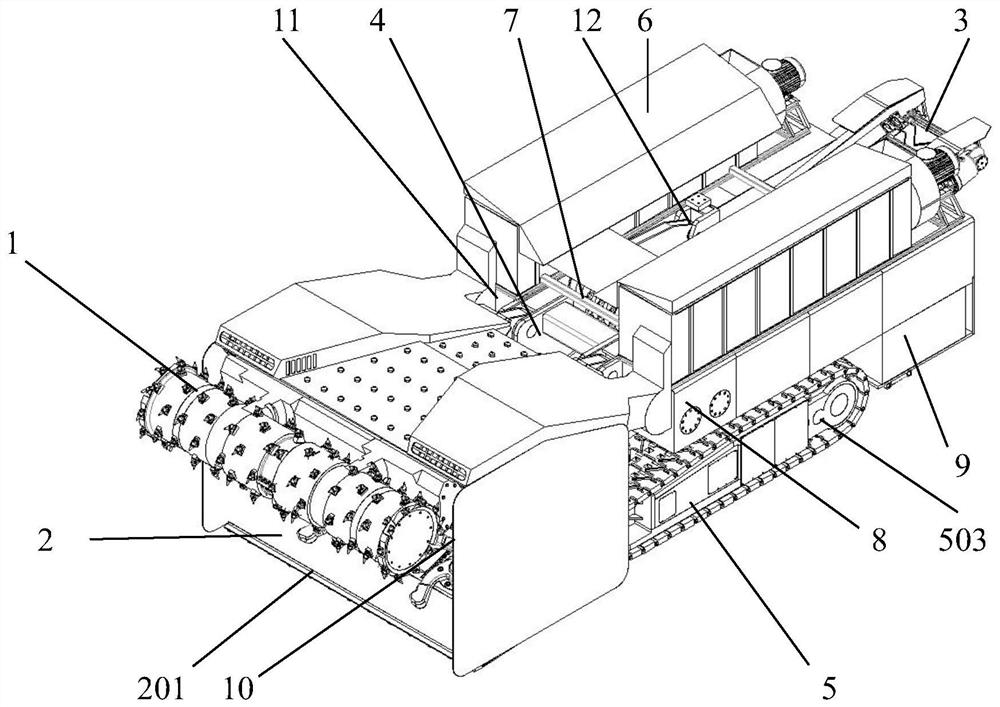

Intelligent continuous mining equipment for open-pit mine

PendingCN111810157ASimple structureQuick connectionOpen-pit miningFluid-pressure actuator componentsStructural engineeringMechanical engineering

Owner:SHANGHAI CHUANGLI GRP

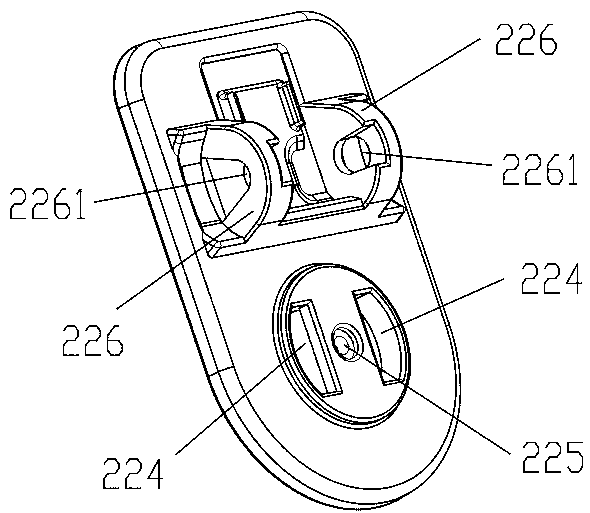

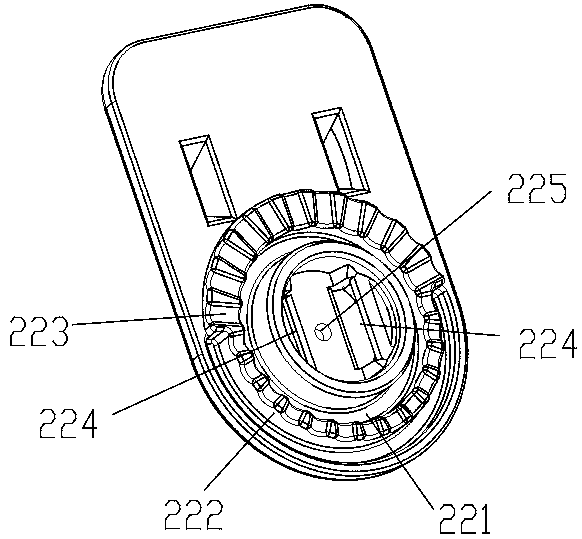

Rotary buckle for electronic product

InactiveCN109892770AFlexible adjustment of placement angleEasy maintenance and disassemblyPursesMoney bagsFault toleranceEngineering

The invention relates to a rotary buckle for an electronic product. The rotary buckle comprises a buckle body, a rotary component and a clamping component, the buckle body is elongated and comprises afront surface and a back surface which are reversely arranged, the rotary component is movably positioned on the buckle body, the clamping component is positioned on the back surface, one end of theclamping component is connected with the rotary component, the other end of the clamping component is abutted to the back surface, and the rotary component and the clamping component can synchronouslyrotate relative to the buckle body along the back surface. The buckle has the advantages that the placement angle of the electronic product can be flexibly adjusted, the buckle is convenient to maintain and disassemble after assembly, requirements for production lines and assemblers are low, the buckle can be disassembled and assembled at any time and has high fault tolerance and the like.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

Thermal-insulation insulating temperature measuring bolt

InactiveCN108006042ASimple structureEasy maintenance and disassemblyThermal insulationScrewsThermal insulationEngineering

The invention belongs to the field of fixing components, particularly relates to a bolt, and discloses a thermal-insulation insulating temperature measuring bolt which comprises a screw rod and a nut.The thermal-insulation insulating temperature measuring bolt is characterized in that the screw rod comprises a stainless steel screw rod and an insulating screw rod, the upper end of the insulatingscrew rod is provided with a straight tool hole and a square hole, a wireless temperature sensor is arranged inside the square hole, the lower portion of the insulating screw rod is connected with thestainless steel screw rod, and an air interlayer is arranged between the insulating screw rod and the stainless steel screw rod.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

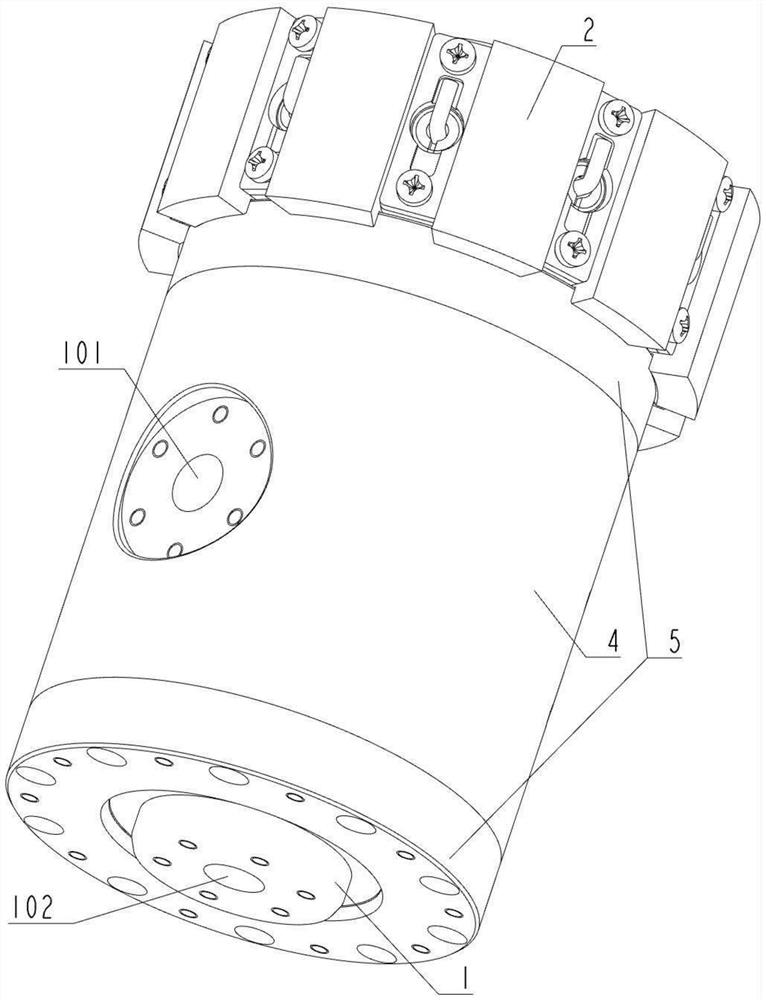

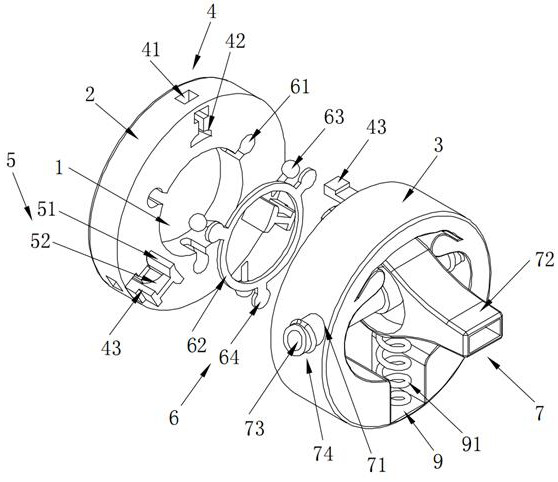

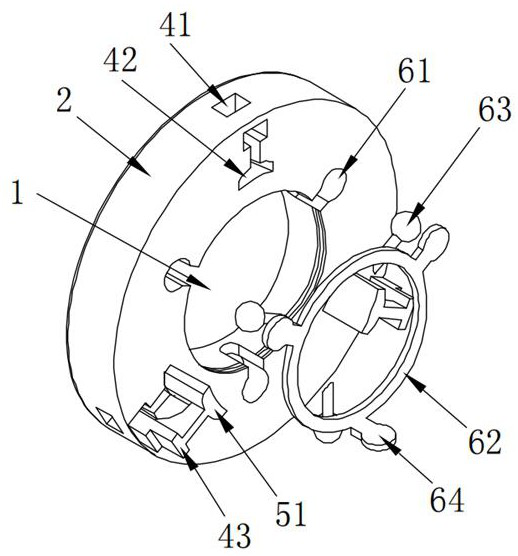

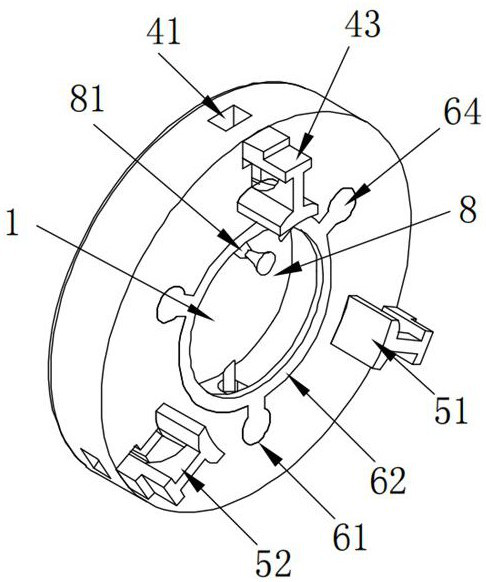

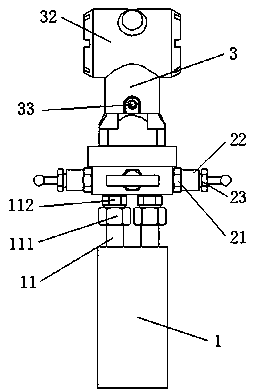

Electro-hydraulic co-rotating joint

ActiveCN113217728AReduce in quantityReduce volumeRotary current collectorAdjustable jointsBrushElectric signal

The invention discloses an electro-hydraulic co-rotating joint which comprises an inner ring and an outer ring arranged on the outer side face of the inner ring, and the inner ring and the outer ring can rotate relatively. The outer ring comprises an electric brush combination and a sealing shell; the electric brush combination and the sealing shell sleeve the inner ring, the electric brush combination is in contact connection with the inner ring through an electric brush, and the sealing shell is in contact connection with the inner ring; an outlet is formed in the sealing shell in the radial direction, an inlet is formed in the inner ring in the axial direction, an annular liquid flow channel is formed between the sealing shell and the inner ring, the outlet is communicated with the annular liquid flow channel, a plurality of connecting channels are formed in the inner ring in the radial direction, and two ends of each connecting channel are connected with the annular liquid flow channel and the inlet respectively; and the inlet, the connecting channel, the annular liquid flow channel and the outlet form a cooling liquid transmission channel. Under the condition of an extremely limited space, electro-hydraulic integrated design is carried out, the structure is compact, the same part can achieve rotary transmission of electric signals and rotary transmission of a cooling liquid, and meanwhile, the electric signals and the cooling liquid do not influence each other.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Dynamic three-dimensional display type dazzling jewelry

The invention belongs to the technical field of jewelry, and particularly relates to dynamic three-dimensional display type dazzling jewelry. The jewelry comprises a front cover and a rear cover which are used for installing a gemstone and fixedly connected into a whole through elastic clamping pieces. A through hole for mounting a gemstone is formed in the axis of the front cover, a fixed convex frame for preventing the gemstone from leaking is arranged at the edge, close to the outer end face, of the through hole, and the fixed convex frame is driven to be ejected out by a curve when the fixed convex frame is slidably inserted towards the outer end in the axis direction of the front cover through the elastic clamping piece. According to the dynamic three-dimensional display type dazzling jewelry, by arranging the elastic clamping pieces, the front cover and the rear cover can be inserted and fixed into a whole in the axis direction, on one hand, looseness is prevented, and on the other hand, gemstone installation and later maintenance and disassembly are facilitated; and by arranging the fixed convex frame, the effect of movably limiting the gemstone at the front end of the front cover can be achieved, meanwhile, the gemstone can be exposed to the outside to the maximum extent, and display is facilitated.

Owner:深圳市卡蒂珠宝有限公司

Rollover-prevention tire with spare steel rim

The invention discloses a rollover-prevention tire with a spare steel rim. The rollover-prevention tire comprises a tire body (1) and a steel rim (2). The rollover-prevention tire is characterized in that the spare steel rim (3) is installed in the wheel center of the tire. The rollover-prevention tire has the advantages of being simple in structure, low in use cost, safe and reliable. The spare steel rim is directly installed in the wheel center, the spare steel rim and a common tire rotate and stop at the same time, and tire screws and the wheel center are shared. The rollover-prevention tire can be widely popularized, and the safety of traffic participants comprising passengers in a car or other traffic participants is truly protected.

Owner:杨计

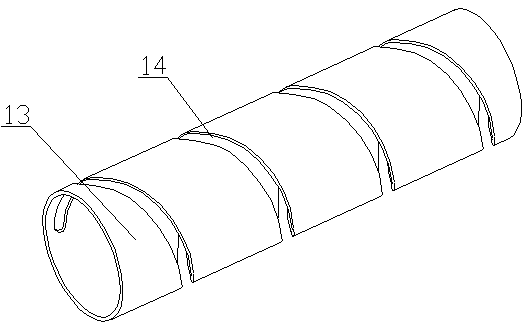

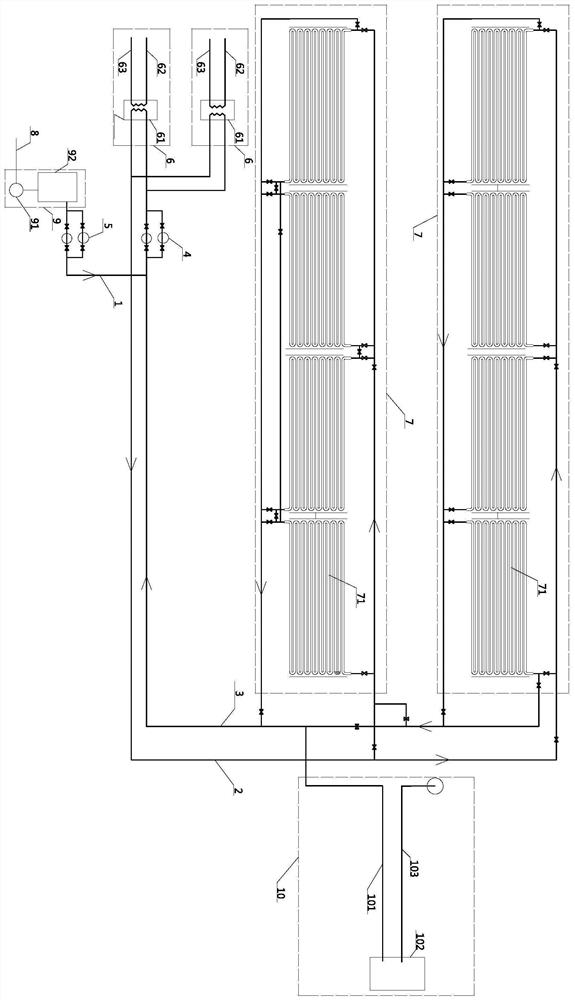

Kiln cylinder radiant heat heating system

InactiveCN113295014AIncrease temperatureTo achieve the effect of comprehensive utilizationEnergy efficient heating/coolingIncreasing energy efficiencyWater useRadiant heat

The invention discloses a kiln cylinder radiant heat heating system. The kiln cylinder radiant heat heating system comprises a water supplementing pipeline, a water inlet pipeline, a water return pipeline, a circulating water pump set, a water supplementing pump set, hot water output equipment and at least one heat collection device, wherein one end of the water supplementing pipeline communicates with a tap water pipe, the other end of the water supplementing pipeline communicates with the water return pipeline, and the water supplementing pump set is installed on the water supplementing pipeline. According to the kiln cylinder radiant heat heating system, the novel technology of waste heat utilization, environmental protection and no pollution is adopted, waste heat recovery can be achieved, heat radiation conduction is conducted through a kiln cylinder, the temperature of hot water is increased, heating and bathing can be better served, circulating water in the heat collection device is heated by collecting radiant heat energy of the rotary kiln cylinder, and the heat energy is collected, so that the comprehensive utilization effect of heating and supplying heat in winter and supplying bathing water to staff is achieved, heat collection units are split devices and are convenient to maintain, disassemble and assemble, and the heat collection units can be connected in parallel or in series, and the outlet water temperature can be adjusted at any time.

Owner:中城华安建设集团有限公司

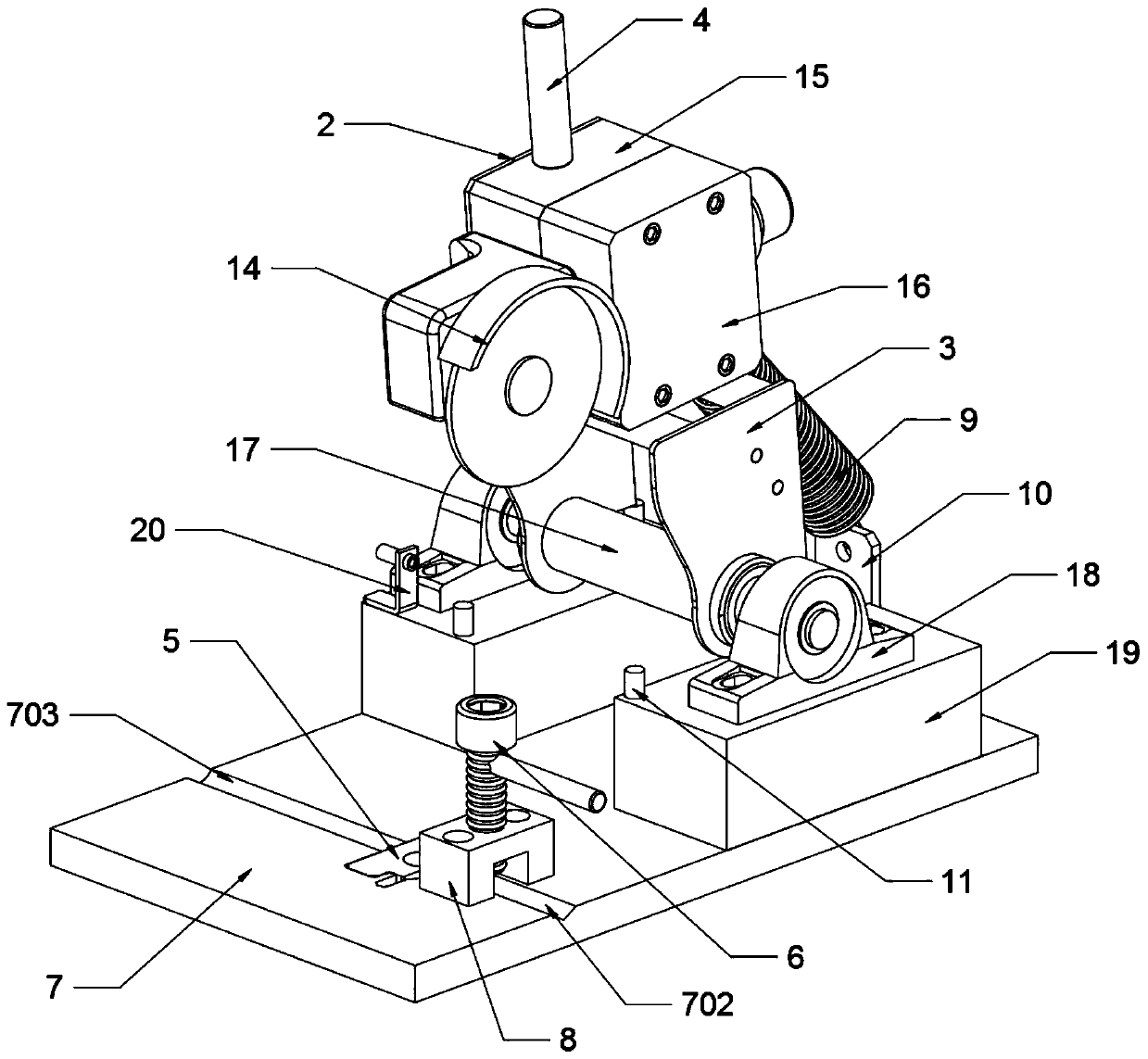

Special trimming machine for high-precision laser positioning die ejector rod

PendingCN110355652AGuaranteed grinding qualityGuaranteed stabilityGrinding machinesGrinding work supportsAngle grinderEngineering

The invention provides a special trimming machine for a high-precision laser positioning die ejector rod. The special trimming machine comprises an angle grinder, an angle grinder mounting block and an angle grinder dismounting block. Two main and auxiliary connecting rods are arranged, the left ends of the main and auxiliary connecting rods are connected to the inner wall of the right side of a cutting head main board, the right ends of the main and auxiliary connecting rods are connected to the inner wall of the left side of a cutting head auxiliary board, the bottoms of the cutting head main board and the cutting head auxiliary board are respectively sleeved and fixed on the outer end surfaces of the left side and the right side of a rotating shaft, the left end and the right end of therotating shaft are rotatably connected in two bearings correspondingly, and a pressing handle is mounted on the top end face of the angle grinder mounting block. Linear laser light is projected to agrinding groove part through a linear laser marker, the rotary trimming portion of the angle grinder is marked, so that personnel can adjust the position of the ejector rod inside a grinding groove according to the laser projection part of the linear laser marker, and the grinding precision of the ejector rod is guaranteed.

Owner:十堰天凯模具制造有限公司

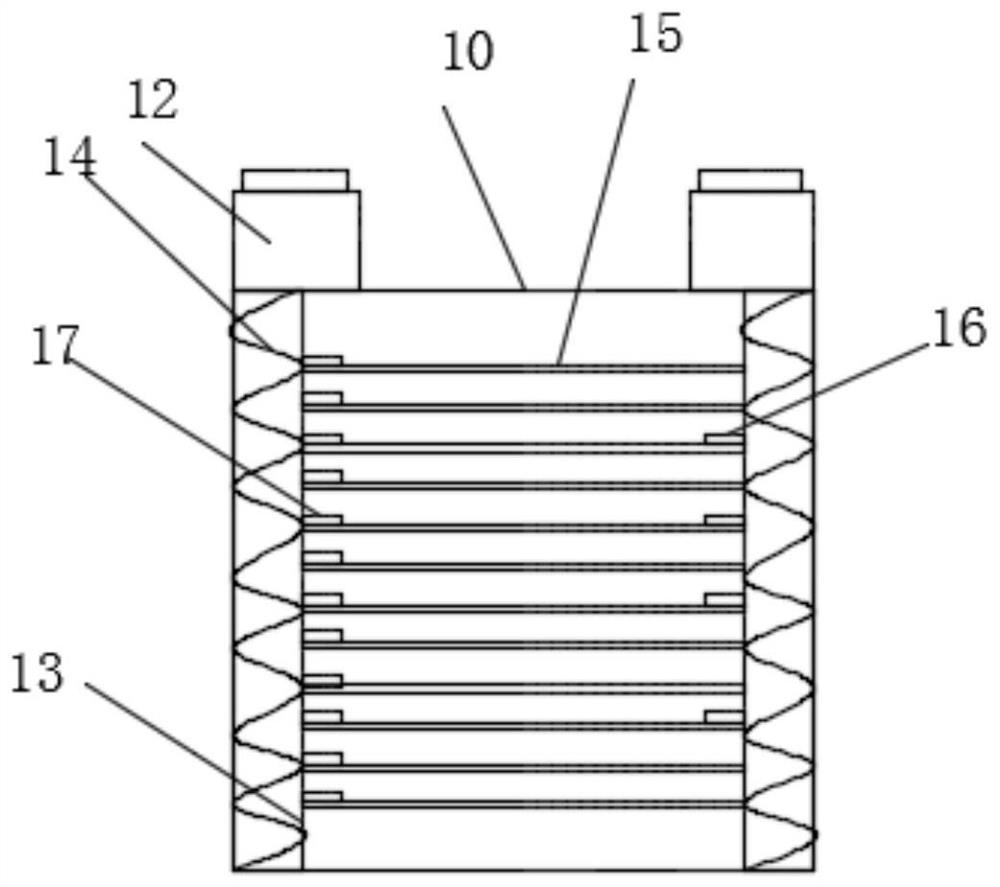

Lithium battery textile coating packaging structure

ActiveCN114464920AImprove protectionEasy maintenance and disassemblySecondary cellsCell component detailsPhysicsLithium battery

The invention discloses a lithium battery textile coating packaging structure, and relates to the technical field of lithium batteries, the lithium battery textile coating packaging structure comprises a bottom plate, mounting frames arranged on the two sides of the upper portion of the bottom plate, and surrounding plates arranged on one sides in the mounting frames in a sliding mode; the packaging mechanism arranged between the surrounding plates comprises a heat conduction shell arranged between the surrounding plates, the interior of the heat conduction shell is of a cavity structure, the top of the heat conduction shell is fixedly connected with a limiting plate, mounting grooves are formed in the two sides of the limiting plate, valve plates are slidably arranged in the mounting grooves, air guide holes are formed in the valve plates and the limiting plate, and one side of each valve plate is fixedly connected with the corresponding surrounding plate. A clamping assembly is arranged between the heat conduction shells and used for clamping and fixing a lithium battery, one side of an air guide pipe penetrates through a mounting frame, a pressure storage assembly is arranged at the end of the air guide pipe, backflow cooling pipes are arranged on the two sides of the pressure storage assembly, and under the action of the pressure storage assembly, hot air backflow cooling is achieved, a valve plate is driven to move, and rapid heat dissipation is achieved; and the transmission mechanism is arranged between the mounting frames and is used for converting the dismounting equipment.

Owner:河北金飒科技有限公司

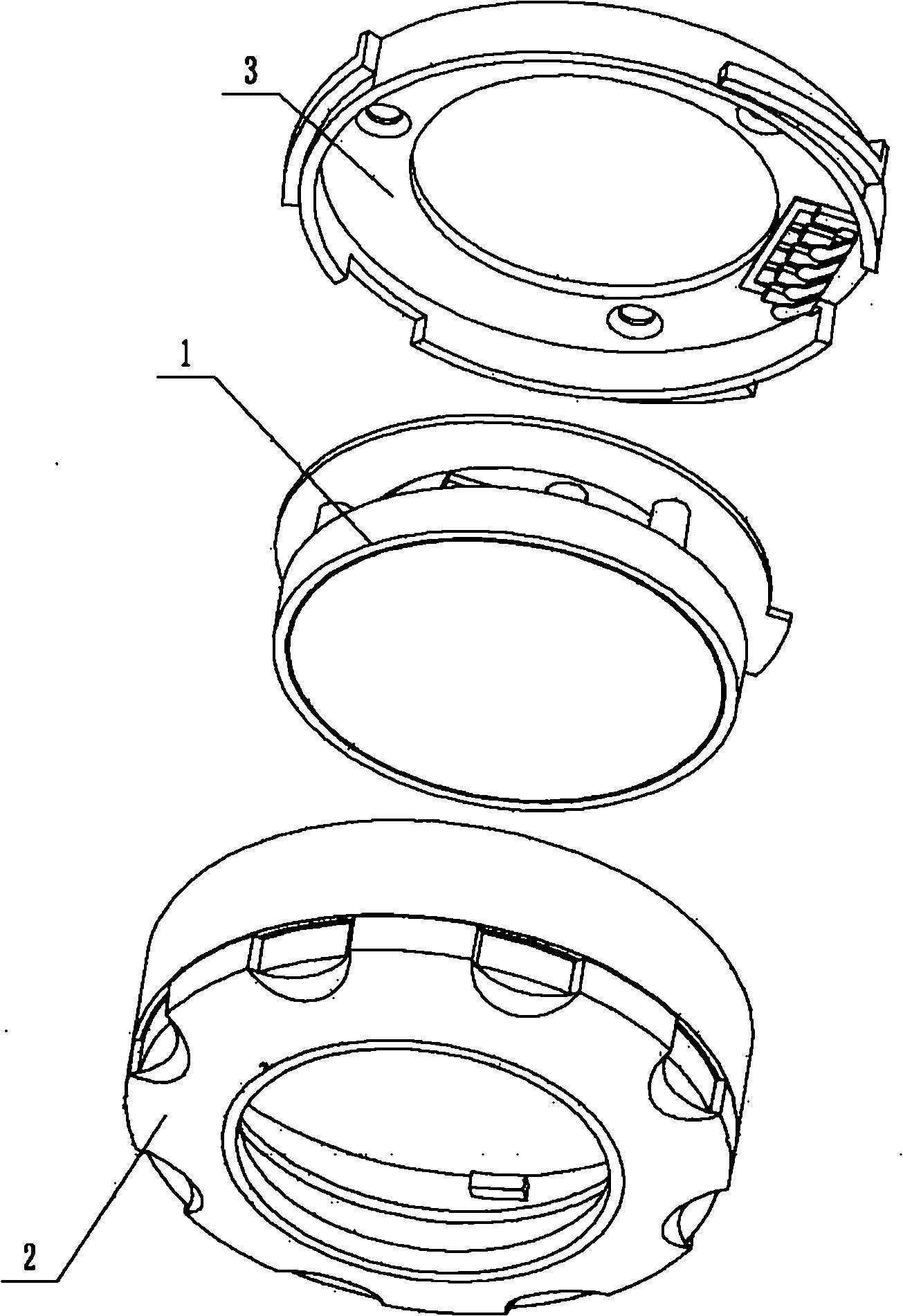

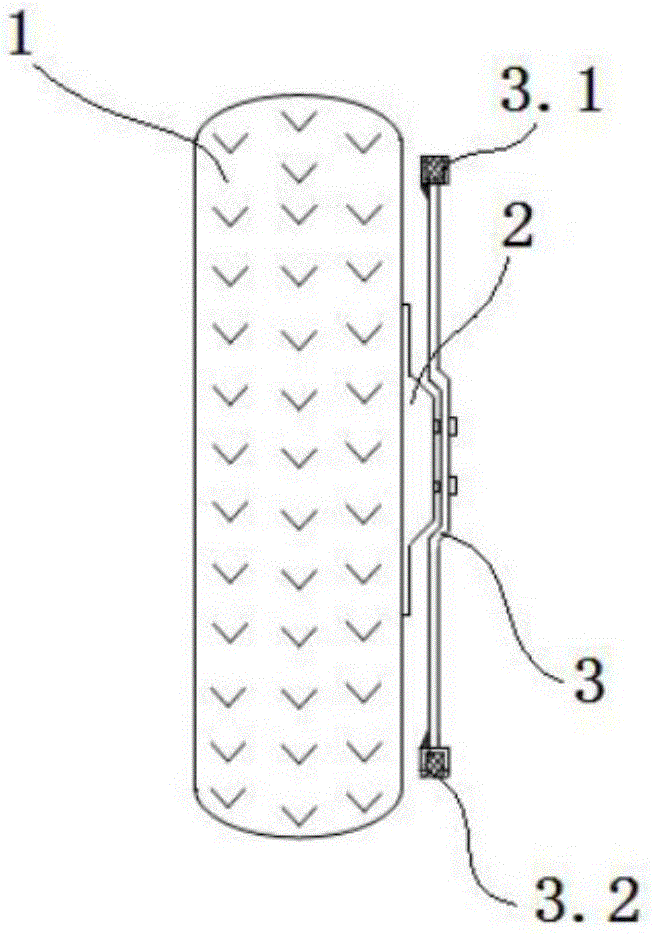

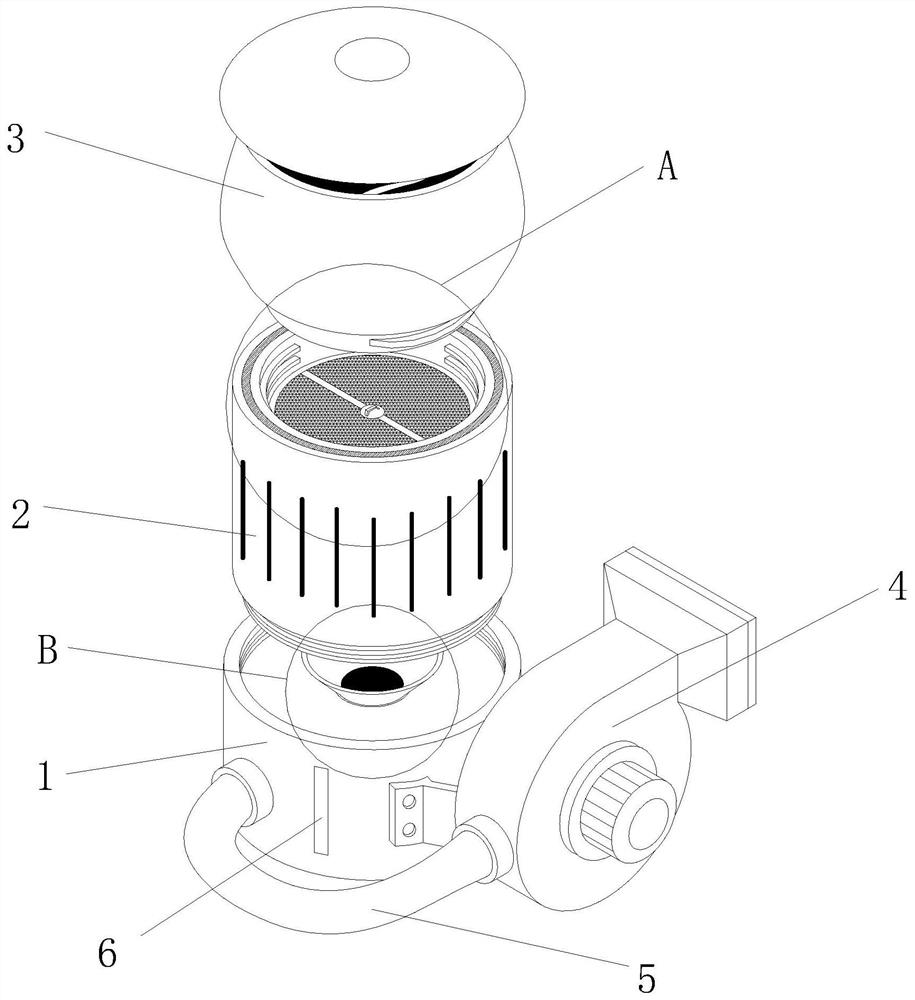

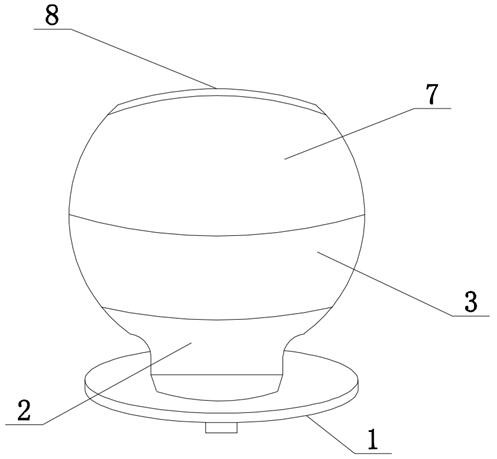

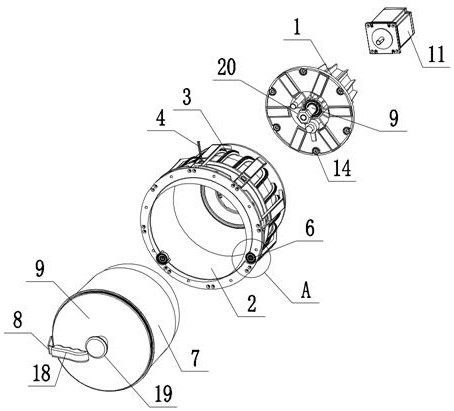

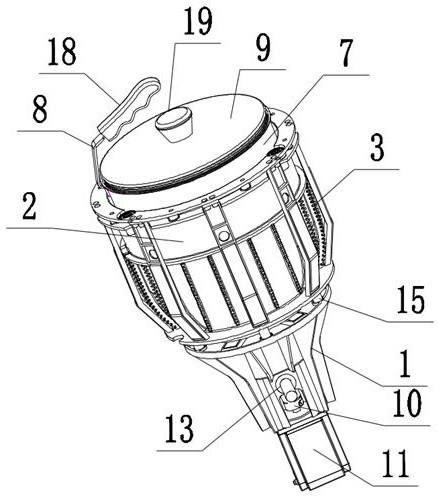

Cylindrical air purifier

PendingCN112325438AReduce dust accumulationQuality improvementMechanical apparatusLighting and heating apparatusAir purifiersWater filter

The invention provides a cylindrical air purifier, comprising a water filtering unit, a transferring unit and an air supply unit. The water filtering unit comprises a cylindrical box; the top of the cylindrical box is open; the transferring unit comprises an air collecting cylinder; the bottom of the air collecting cylinder is matched with and in threaded connection with the top of the cylindricalbox; the air supply unit comprises a sterilization cover; the upper and lower ends of the sterilization cover are both provided with circular openings; the lower end of the sterilization cover is provided with a convex ring part matched with the top of the air collecting cylinder; an annular ultraviolet lamp tube is installed on the sterilization cover along the periphery of the inner wall of thesterilization cover; a bearing frame is arranged at the upper end of the annular ultraviolet lamp tube; and an air outlet cap is rotatably arranged on the bearing frame. The cylindrical air purifieris convenient to maintain and detach, reduces the after-sales maintenance difficulty, reduces the later replacement cost waste caused by the utilization of a multi-layer filtering structure, and can achieve the uniform air supply effect while the air quality is fully improved.

Owner:JIUJIANG UNIVERSITY

Installation method of brilliance lamp irregular circuit board

InactiveCN106555991AEasy maintenance and disassemblyEasy to disassemble and maintainPrinted circuit detailsElectric circuit arrangementsElectrical and Electronics engineeringTower

The invention discloses an installation method of a brilliance lamp irregular circuit board. A brilliance lamp is a tower type brilliance lamp, circuit boards and support members are installed in space between adjacent layers of the brilliance lamp, the circuit boards are provided with gaps, and the support members pass through the gaps. The method has the following advantages: the limited internal space of the tower type brilliance lamp is utilized to a great extent, and maintenance dismounting of the brilliance lamp is facilitated.

Owner:SUZHOU ANCHORWILL TECH

Rotary circular spotlight

PendingCN113983380AEasy to adjustAccurate irradiationLighting support devicesLight fasteningsMechanical engineeringPhysics

The invention discloses a rotary circular spotlight. The spotlight comprises a base, a bottom box is fixedly installed at the upper end of the base, a lower lamp body is rotationally connected to the upper end of the bottom box, the bottom box and the lower lamp body are connected through a connecting assembly, a lamp cup is installed in the lower lamp body, a heat dissipation net is arranged on the upper surface of the lamp cup, the upper end of the lower lamp body is in threaded connection with an upper lamp body, and the upper end of the upper lamp body is in threaded connection with a shell. By means of a rotating disc in the connecting assembly, when the angle of the upper lamp body and the angle of the lower lamp body need to be adjusted, the upper lamp body and the lower lamp body are rotated to drive a second screw and the rotating disc to rotate, balls at the upper end of the rotating disc roll on clamping pieces, and therefore the lower lamp body and the bottom box rotate, and the angle of the upper lamp body and the angle of the lower lamp body can be adjusted conveniently; and when the spotlight is used, the irradiation angle can be adjusted at will, accurate irradiation to each position is facilitated, and the irradiation effect is greatly improved.

Owner:熊永志

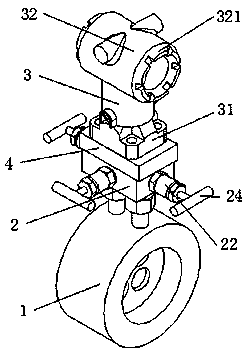

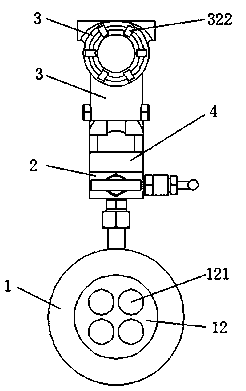

Differential pressure type adjustable flow meter special for natural gas

InactiveCN109443457AEasy maintenance and disassemblyReduce labor intensityVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a differential pressure type adjustable flow meter special for natural gas in the technical field of flow meters. The adjustable flow meter comprises a measuring steel pipe, adifferential pressure transmitter and a flow meter body, wherein a connecting plate is arranged at the upper end of the differential pressure transmitter, connecting pipes are arranged on the two sides of the upper end of the measuring steel pipe, and the upper ends of the outer sides of the connecting pipes are in threaded connection with first nuts; second nuts are installed on the upper sides of the first nuts, and a clamping head is installed at the top of the flow meter body; the left side and the right side of the clamping head are in threaded connection with clamping rings, and groovesare formed in the circumferences of the front surfaces of the clamping rings; bolts are arranged in the middle of the lower ends of the front and back sides of the flow meter body. The differential pressure type adjustable flow meter special for the natural gas is reasonable in structural design; the clamping head is additionally arranged, and the grooves in the clamping rings are used so that quick clamping and installing can be achieved, the flow meter can be conveniently repaired and detached by workers, the labor intensity of the workers is reduced, and the working efficiency of the workers is improved.

Owner:上海库科自动化科技有限公司

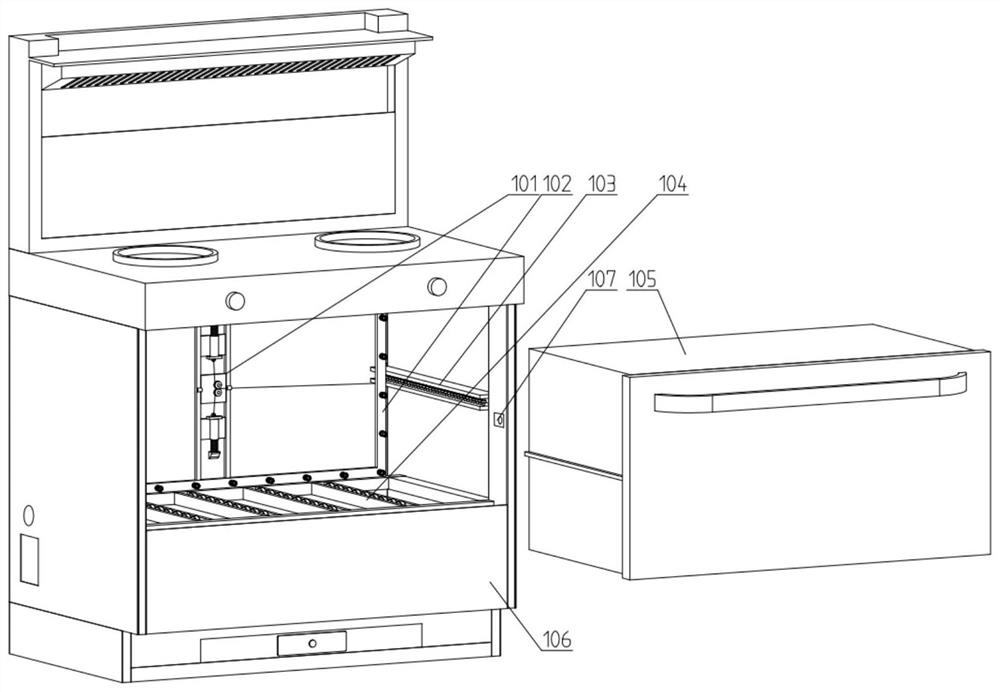

Locking mechanism of integrated cooker module

ActiveCN112503577AImprove installation efficiencyEasy maintenance and disassemblyStoves/ranges foundationsDomestic stoves or rangesCookerControl theory

The invention discloses a locking mechanism of an integrated cooker module, and belongs to the technical field of integrated cookers. The integrated cooker comprises an integrated cooker body, whereina containing space is formed in the integrated cooker body, and a module body is installed in the containing space in a matched mode. The locking mechanism is characterized in that a rear frame partis installed on the rear end face of the containing space, side limiting grooves are formed in the two side faces of the containing space, a bottom supporting mechanism is installed at the bottom of the containing space, the front end of the containing space is an open end, a mechanical locking mechanism is installed on the rear frame part, side protrusions matched with the side limiting grooves are installed on the side faces of the module body, and a clamping assembly matched with the mechanical locking mechanism is installed on the rear end face. By arranging the bottom supporting mechanism, the side limiting grooves, the rear frame part and the mechanical locking mechanism, a traditional connection mode is avoided, the influence of inexistance or existance of electricity is avoided, and mounting and dismounting can be achieved only by simply pushing and pulling the module body; and the operation is convenient and fast, physical strength is saved, and meanwhile the installation efficiency of installation personnel is improved.

Owner:嵊州市浙江工业大学创新研究院

Convenient pipeline connection inspection well

The invention relates to a convenient pipeline connection inspection well which is characterized by comprising an upper bell end and a lower bell end. Hasps which are peripherally uniformly distributed are arranged on the outer wall of an opening of the upper bell end, fasteners which correspond to the hasps are arranged on the outer wall of an opening of the lower bell end, and the hasps and the fasteners can be closed, so that the upper bell end and the lower bell end can be hermetically connected with each other. The convenient pipeline connection inspection well has the advantages that pipeline connection modes are simple in actual application, and the convenient pipeline connection inspection well is convenient to operate and brings convenience for follow-up maintenance and disassembly.

Owner:JIANGSU HIPPO PLASTICS

Novel cooker inner container structure

The invention discloses a novel cooker inner container structure which comprises a base, a pot bin is fixedly connected to the upper end of the base, a heating coil is arranged on the side wall of the pot bin, a dry burning sensor is arranged on the side wall of the pot bin, a round opening is formed in the lower end of the pot bin, rolling wheels are arranged at the upper end of the pot bin, a frying pot is placed in the pot bin, the side wall of the frying pan is connected with the rolling wheels in an attached mode, a side handle is fixedly connected to the upper end of the frying pan, a pan cover is clamped to the upper end of the frying pan, a transmission shaft is rotationally connected to the interior of the base, and a motor is fixedly connected to the lower end of the base. The pan bin and the frying pan are separately arranged, the frying pan is located in the pan bin, the frying pan can be taken out from the interior of the pan bin after dishes are fried, the fried dishes can be conveniently poured out, the frying pan can be conveniently cleaned after the dishes are fried, a dry burning sensor is arranged on the outer side of the pan bin, and the phenomenon that when the frying pan is not in the pan bin, a heating coil works is prevented, and the safety of the structure is improved.

Owner:深圳贝乐威科技有限公司

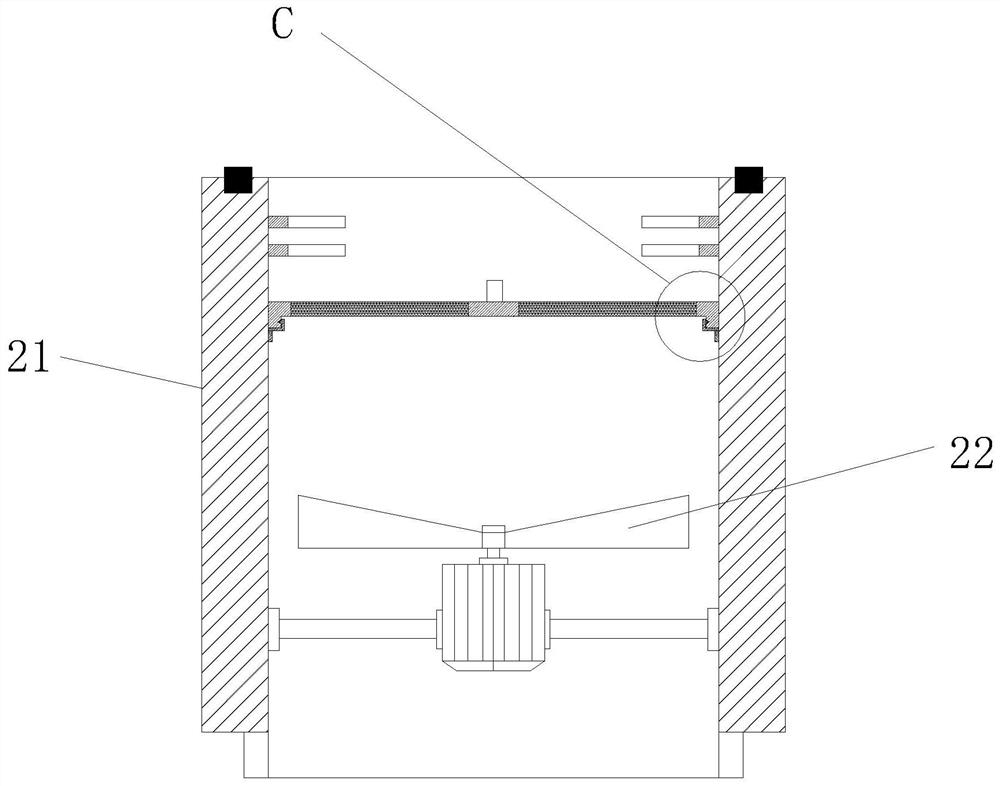

Drying device for paper product production

InactiveCN112482076AReduced area and weightEasy maintenance and disassemblyDryer sectionPaper sheetElectric heating

The invention discloses a drying device for paper product production. The device comprises an inner drying device shell; a first maintenance door, a second maintenance door and a third maintenance door are rotationally connected to the inner drying device shell through hinges correspondingly; and the first maintenance door, the second maintenance door and the third maintenance door are all fixedlyinstalled on the drying device shell through fastening bolts; ventilation plates are symmetrically arranged in the inner drying device shell, a clamping cavity is formed between each ventilation plate and the inner wall of the inner drying device shell, an electric heating wire is arranged in each clamping cavity, an air blower is arranged at the upper end of the inner drying device shell, an airoutlet of the air blower is communicated with the clamping cavities, and a plurality of containing tables are fixedly arranged between the two ventilation plates; a plurality of temperature sensors and humidity sensors are arranged on a plurality of shelving tables; and paper conveying devices are placed on the two sides of the inner drying device shell. The drying device can work continuously, is high in efficiency and can complete drying operation of paper on a large scale.

Owner:SHANGHAI ZHIQIN PRINTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com