Spray component

A technology of spray components and spray pipes, which is applied in spray devices, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve the problems of easy rust, water leakage, and leakage of galvanized water pipes, and achieve easy maintenance and disassembly , Improve the cleaning effect, the effect of high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

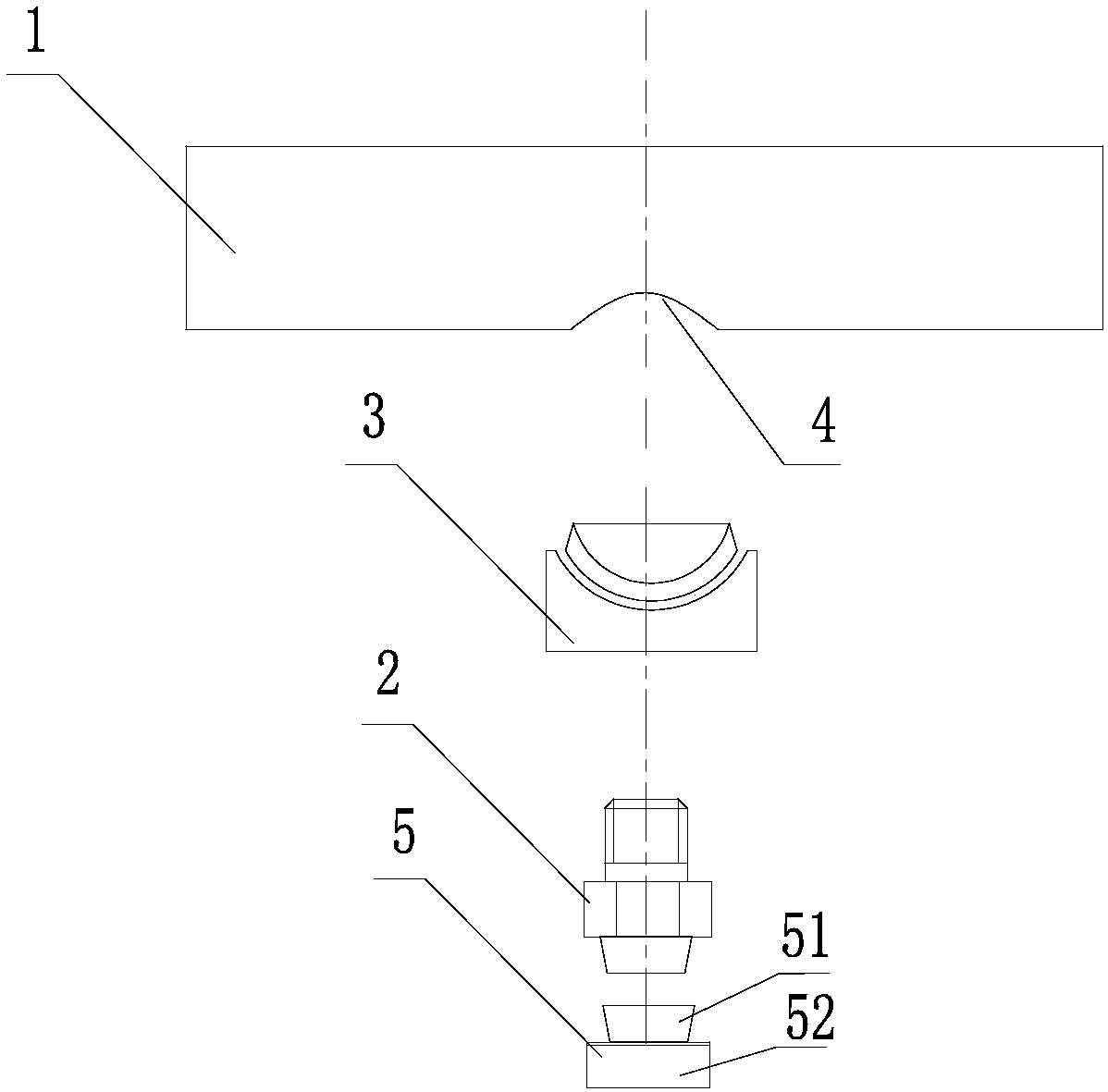

[0021] Embodiment 1: A spray assembly, including a spray pipe 1 and a spray head 2, the spray pipe and the spray head are connected 3 through a leak-proof connector; several water outlets 4 are provided on the spray pipe 1, and the The leak-proof connector 3 is installed on the water outlet 4 with an interference connection, and the nozzle 2 is also installed on the leak-proof connector 3 with an interference connection, and the cleaning water flows from the spray pipe 1 through the leak-proof connector 3 Nozzle 2, and then spray out through the nozzle 2 stabilized pressure.

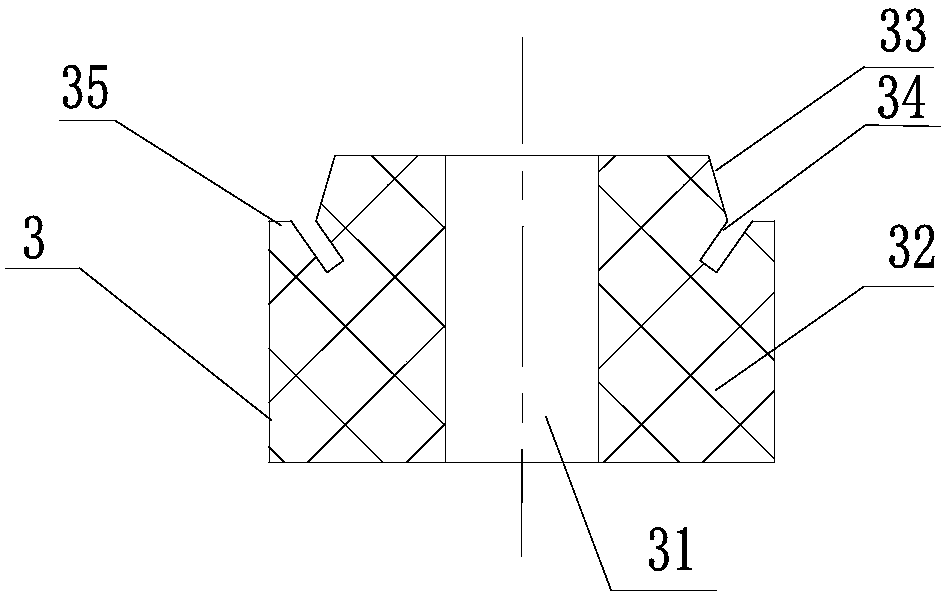

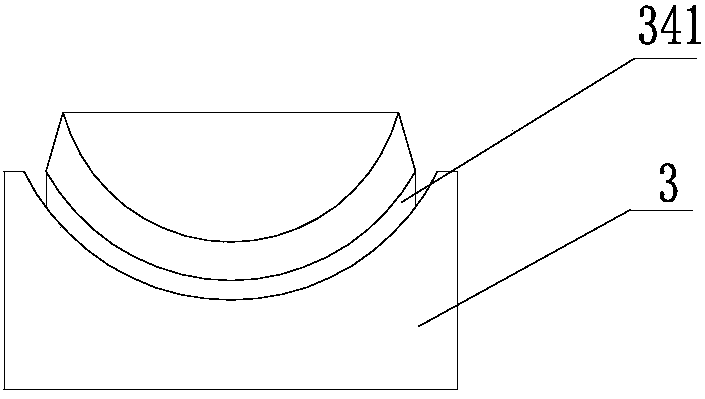

[0022] The leak-proof connector 3 is made of elastic material and is an integral part, including a connecting body, the center of which is provided with a water flow channel 31, and the connecting body is divided into a spray pipe built-in section 32 and a protruding connecting section 33, The transition between the built-in section 32 of the spray pipe and the protruding connecting section 33 is made by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com