Patents

Literature

42results about How to "Stable injection pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

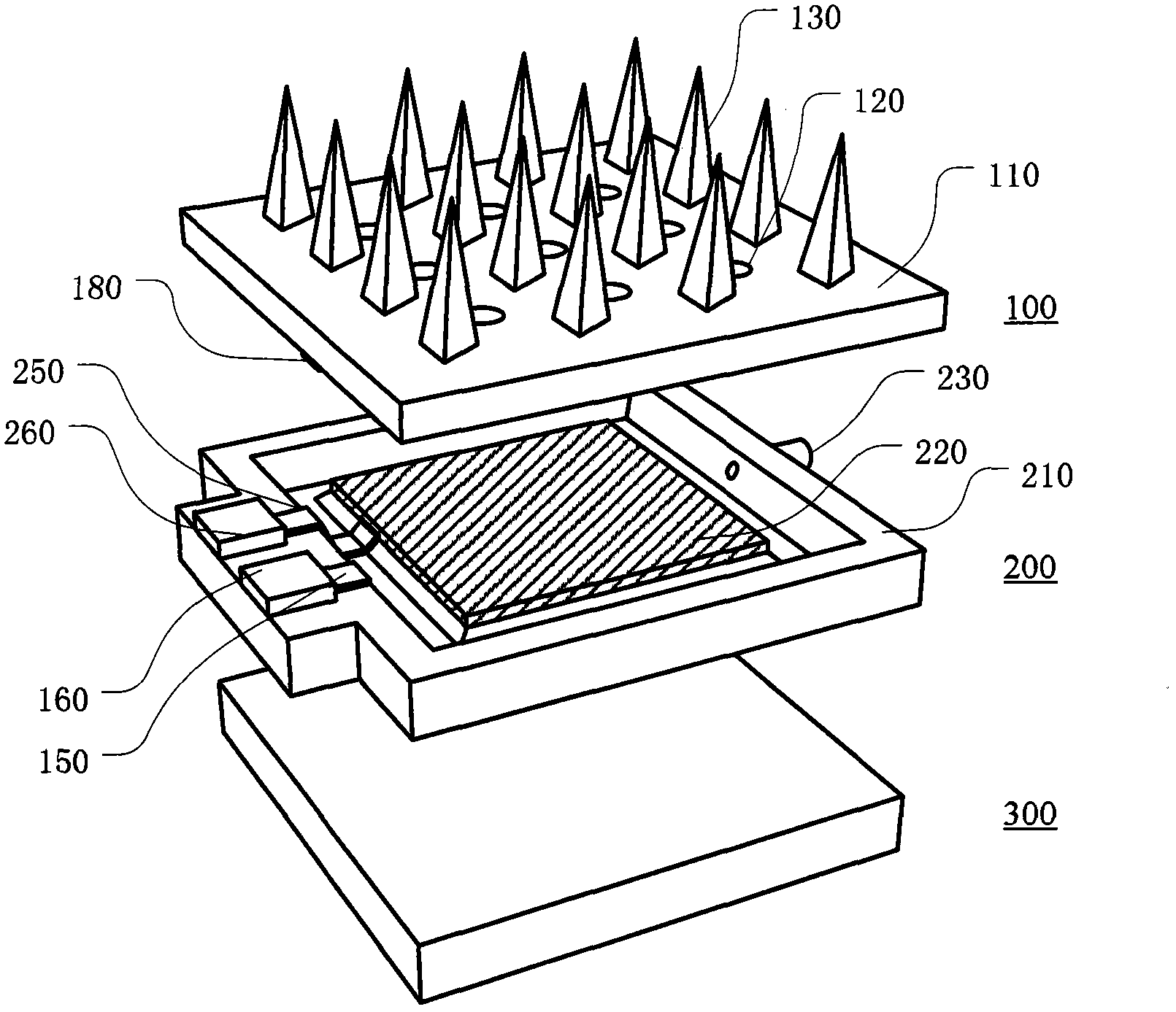

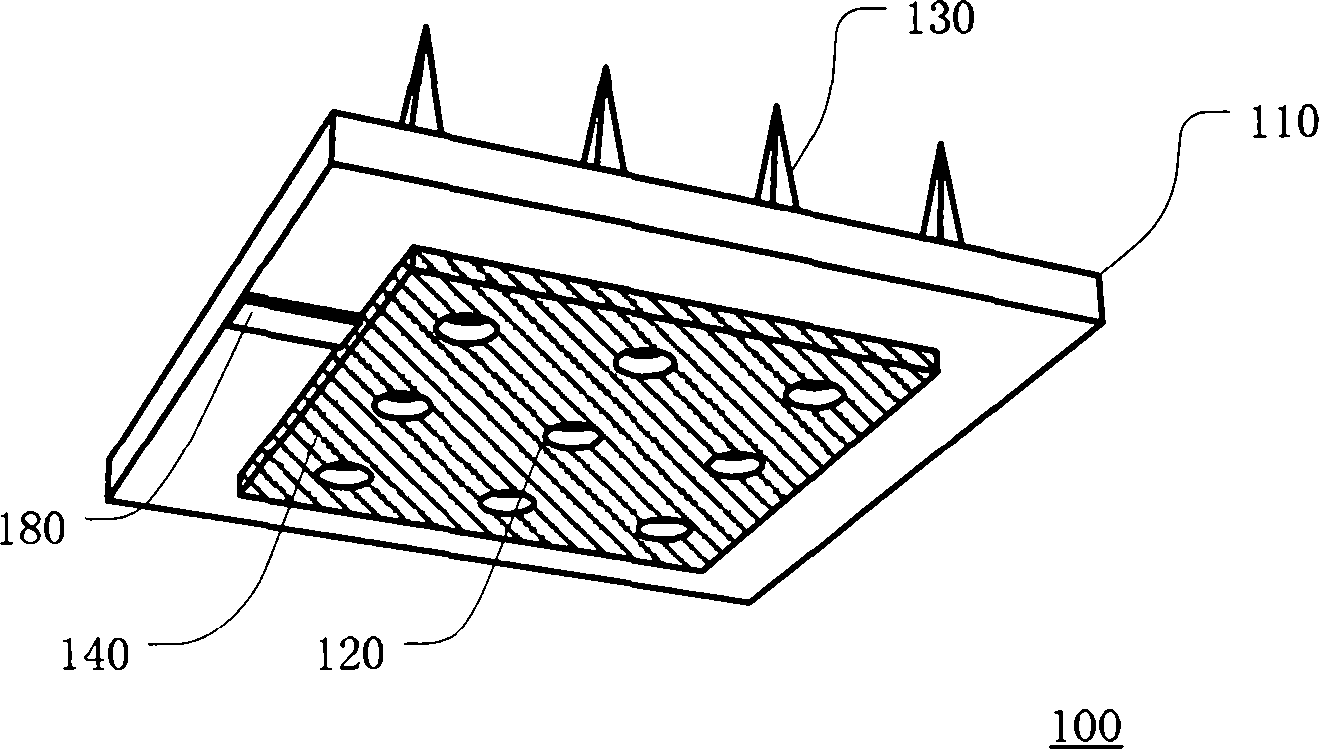

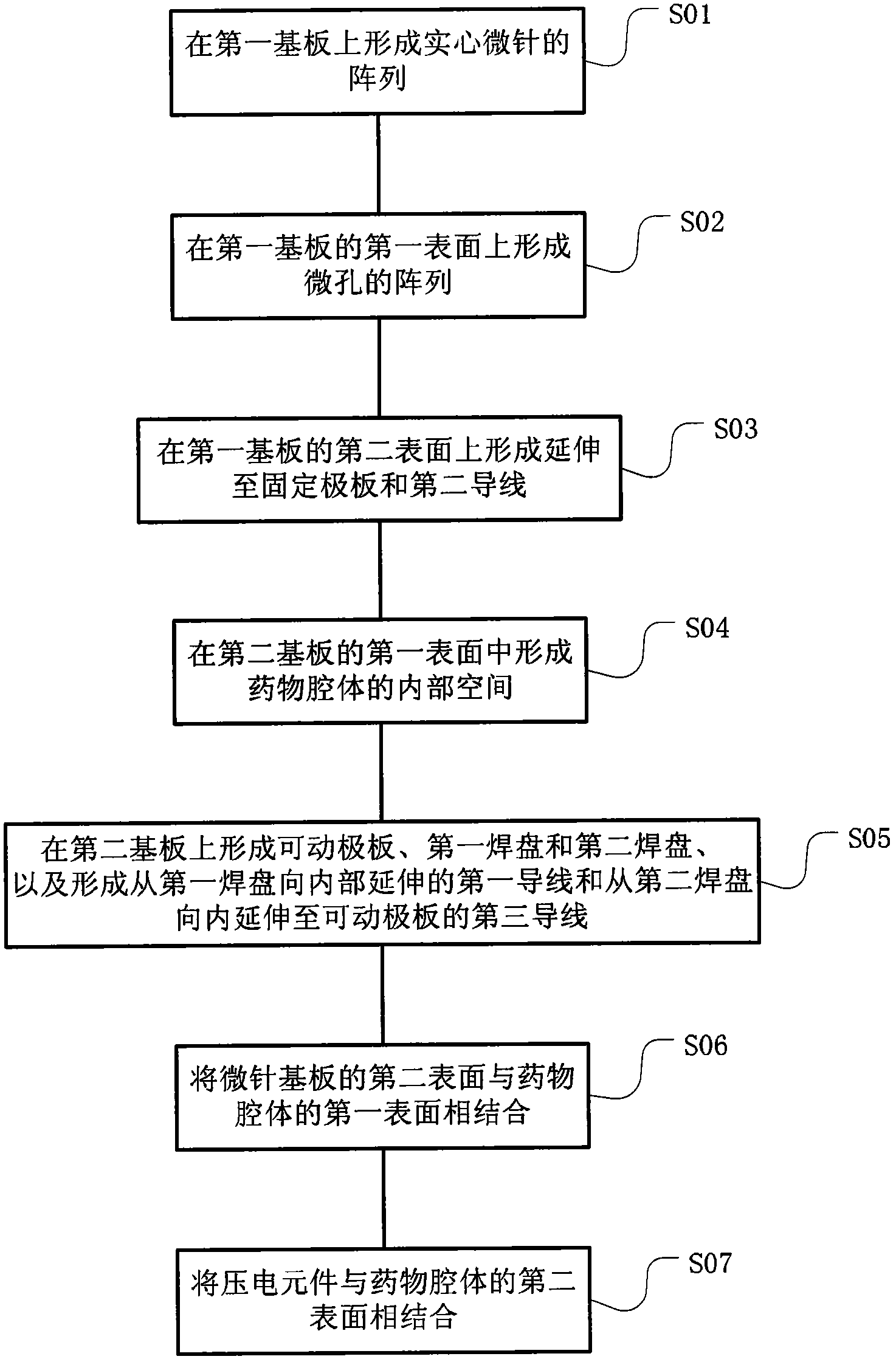

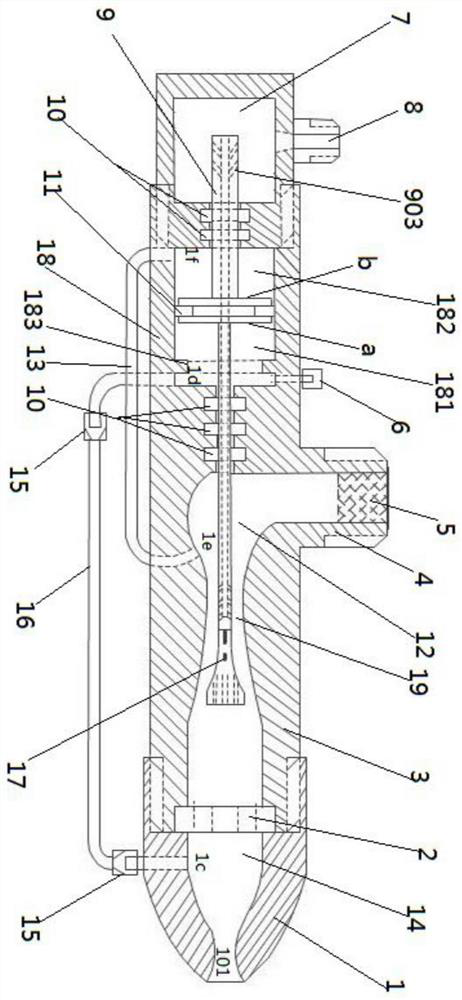

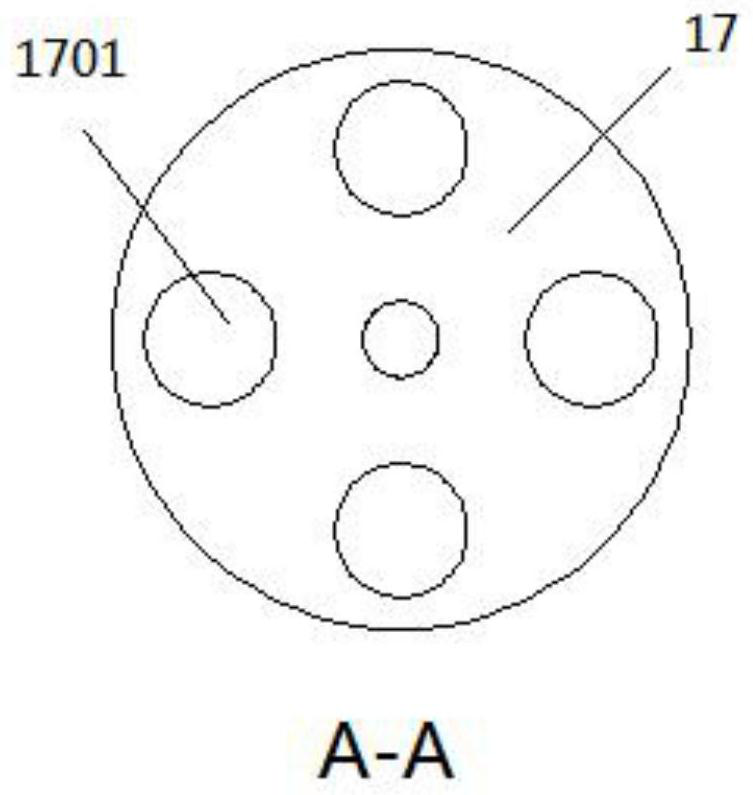

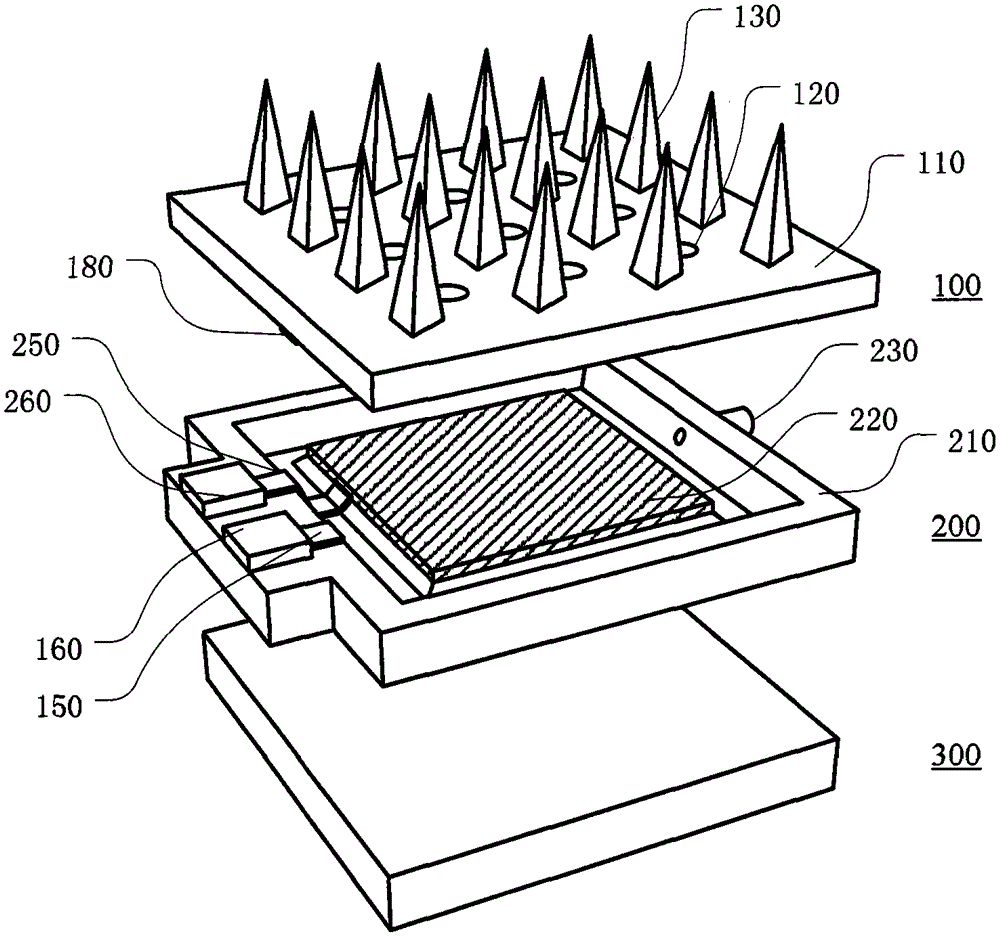

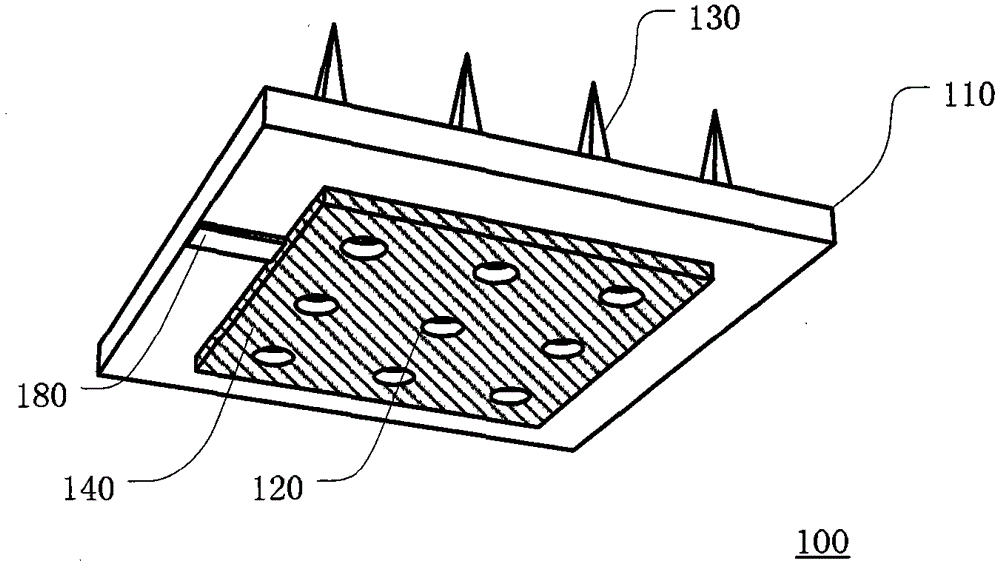

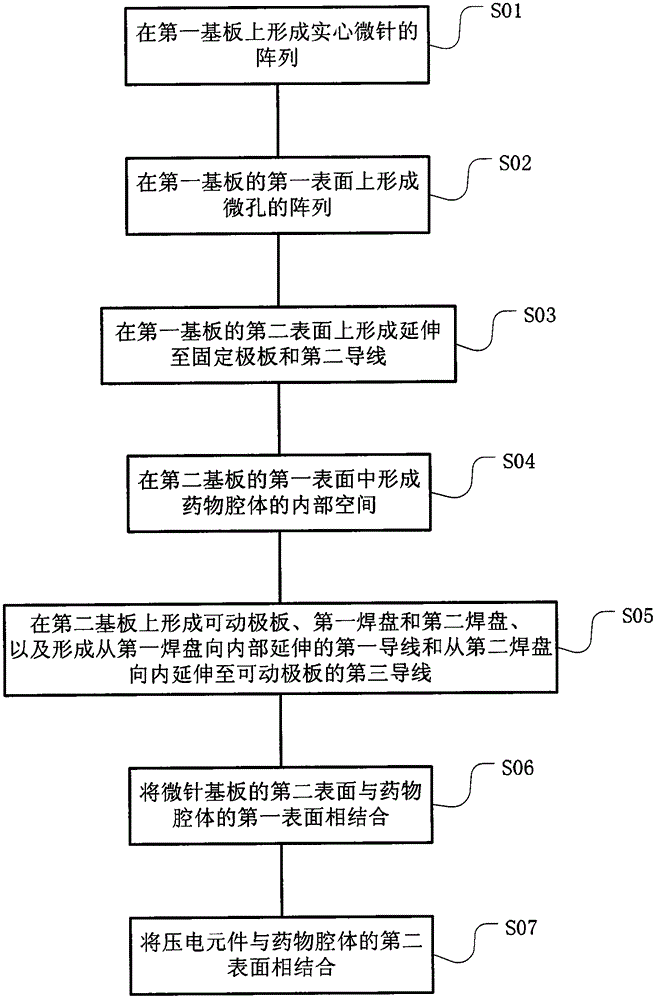

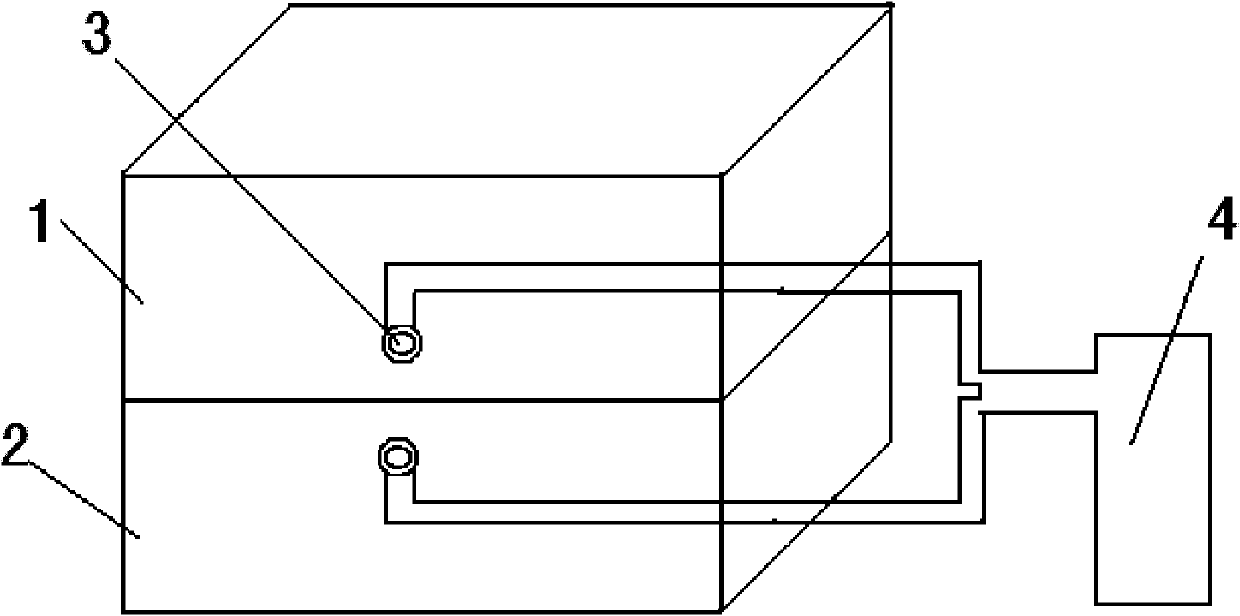

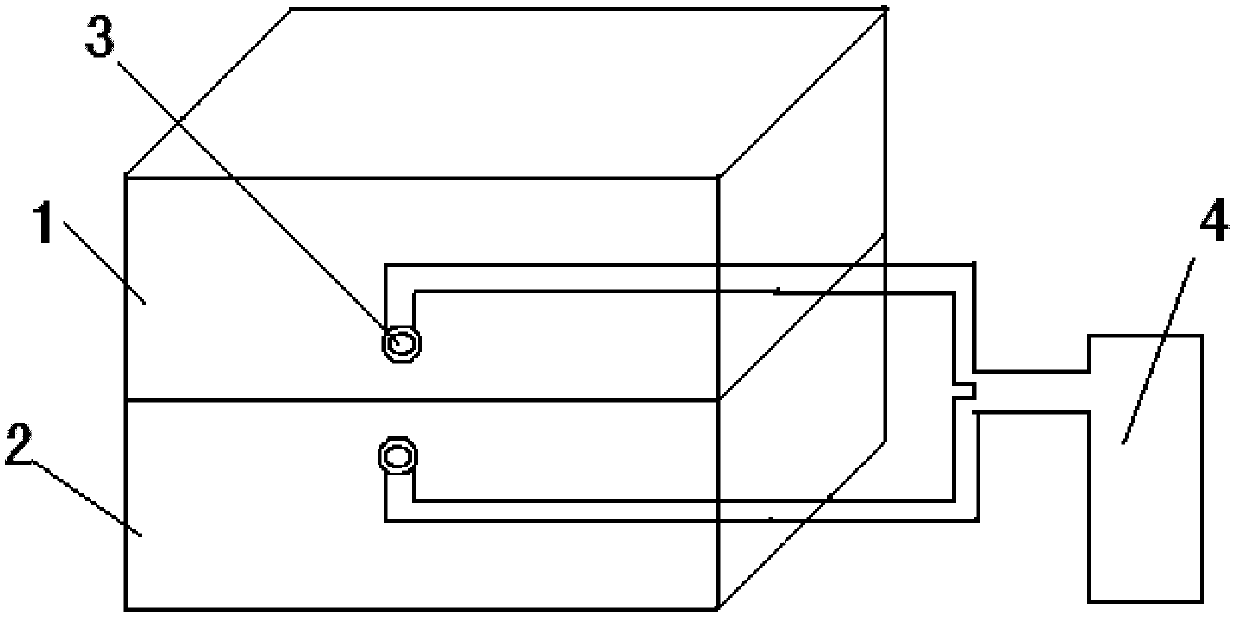

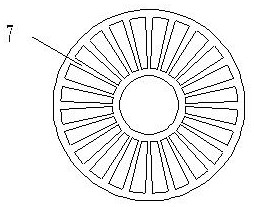

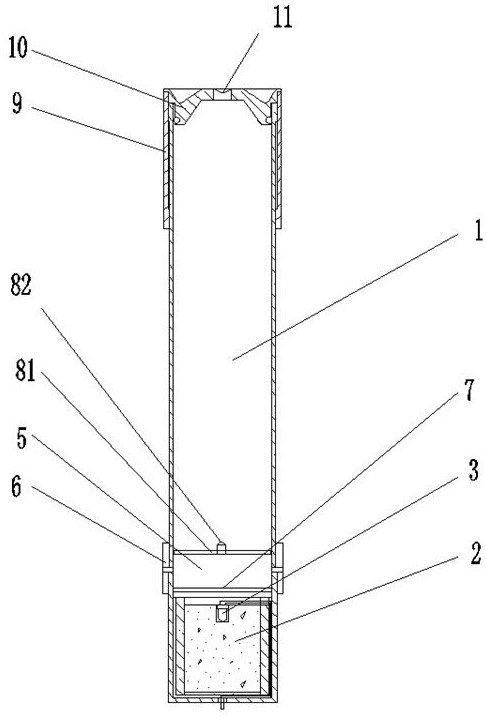

Microneedle doser and manufacturing method thereof

ActiveCN104307098AImprove transdermal effectImprove structural strengthMicroneedlesMedical devicesInterior spaceMems sensors

The invention discloses a microneedle doser and a manufacturing method thereof. The microneedle doser comprises a microneedle substrate, a medicine cavity and a piezoelectric element, wherein the microneedle substrate is provided with a first surface and a second surface, and comprises a solid microneedle array on the first surface and a micropore array which penetrates a first substrate and protrudes from the first surface to the second surface; the medicine cavity comprises an inner space exposed on the first surface and a second surface opposite to the bottom of the inner space, wherein the second surface of the microneedle substrate is combined with the first surface of the medicine cavity so as to enclose the inner space; the piezoelectric element is combined with the second surface of the medicine cavity, wherein the microneedle substrate and the medicine cavity are formed an MEMS (Micro-electromechanical Systems) sensor. According to the microneedle doser, the solid microneedle can be used for working continuously and efficiently, and the MEMS sensor can be used for realizing the precise and quantitative control.

Owner:唐晨

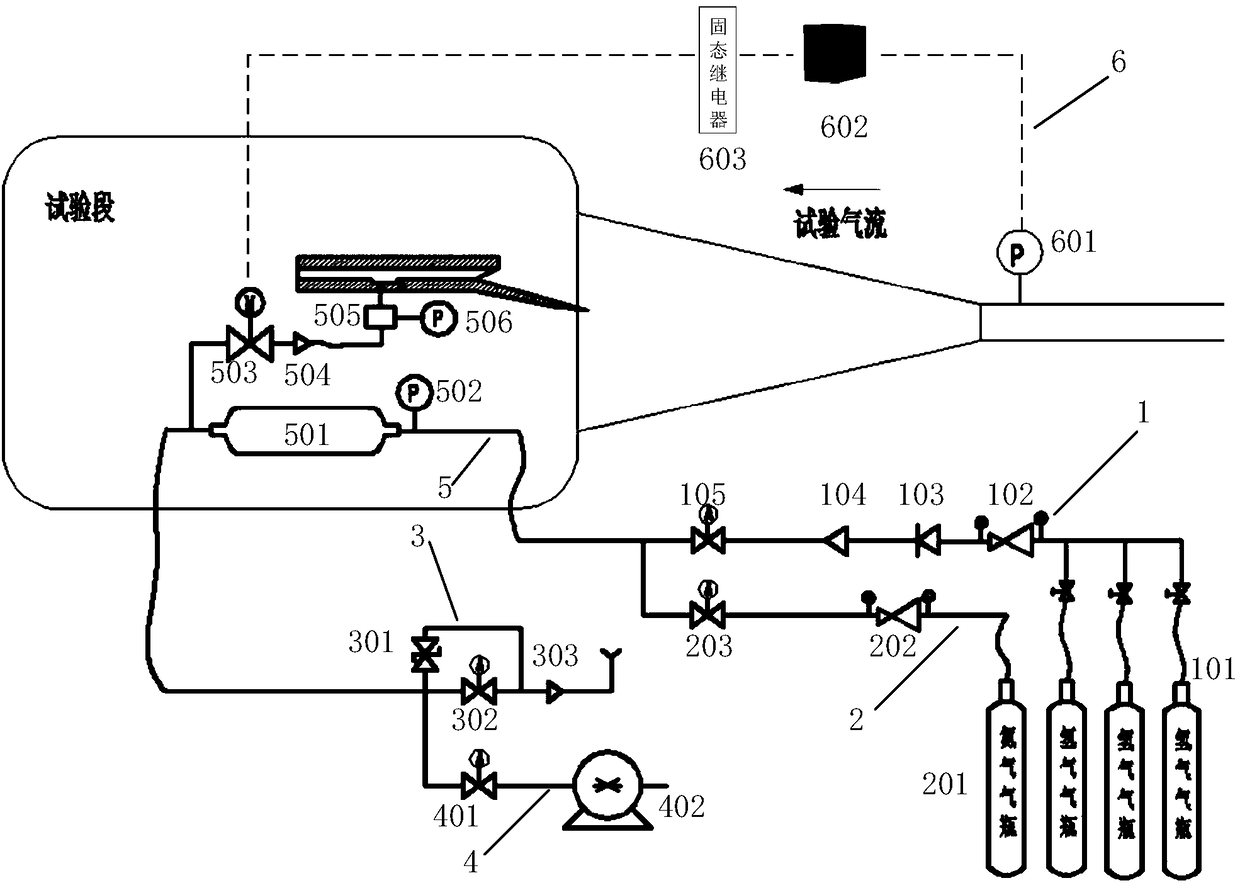

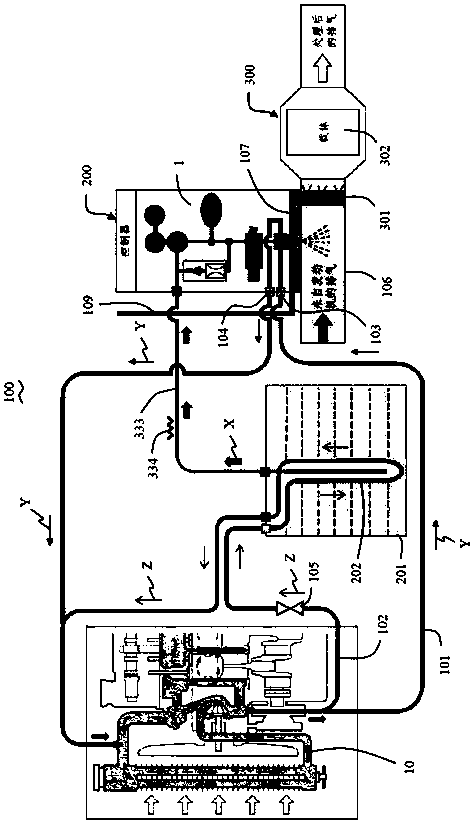

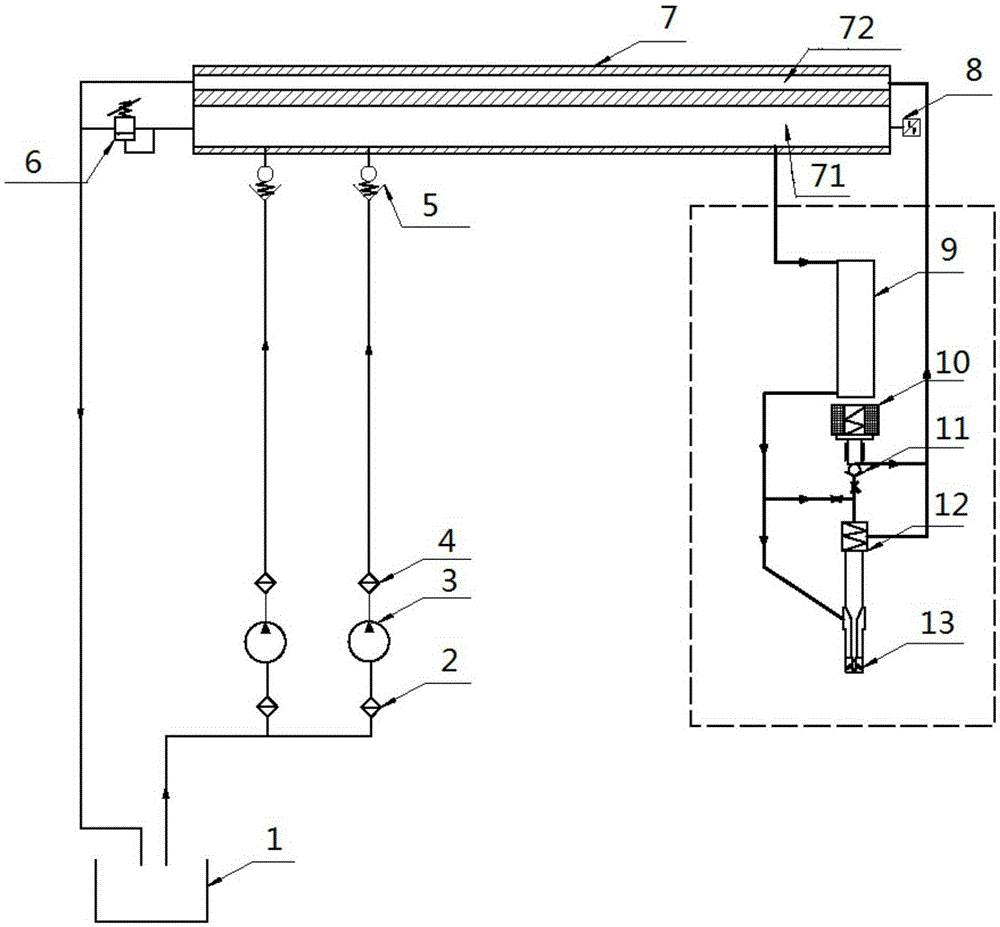

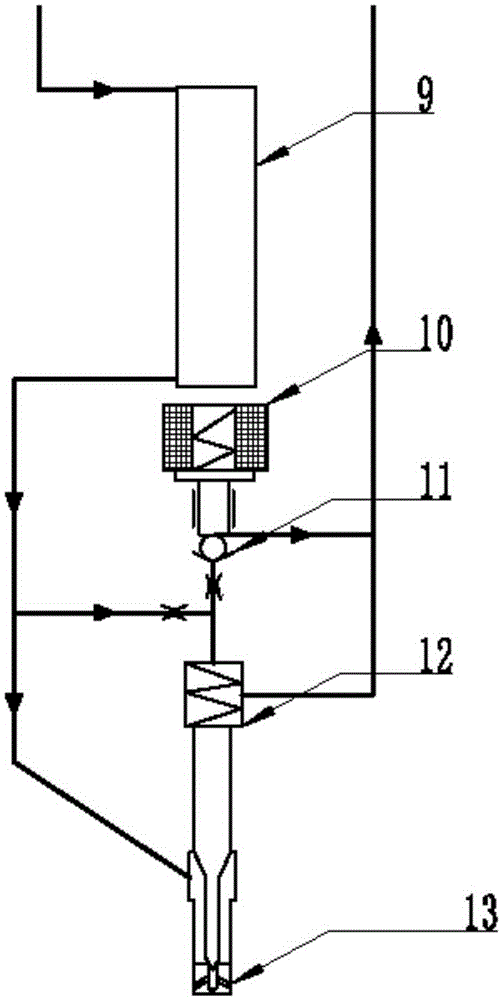

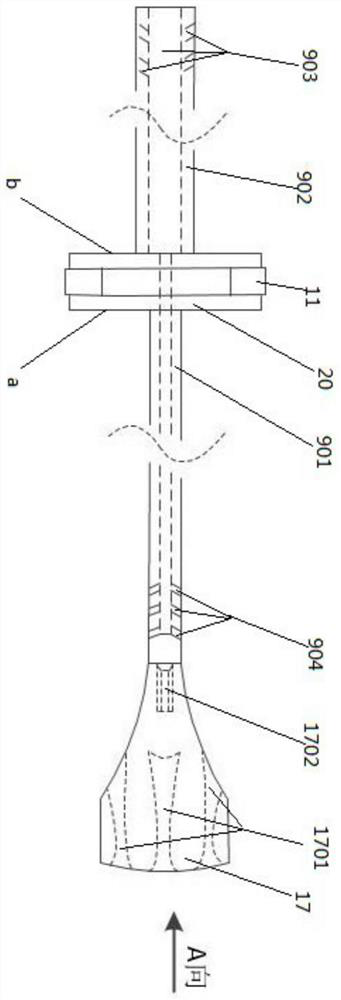

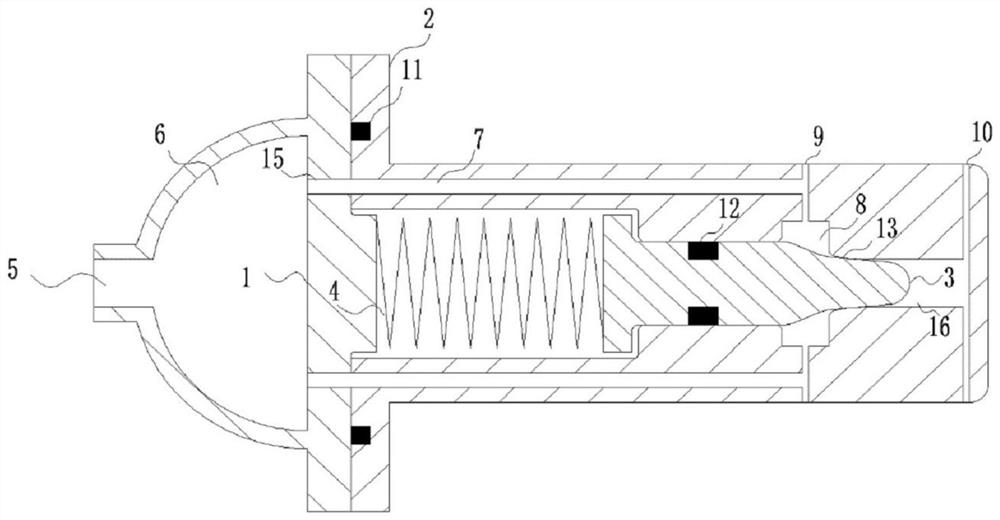

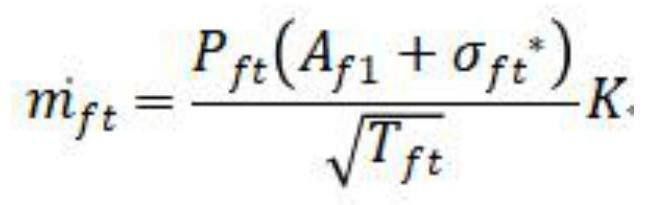

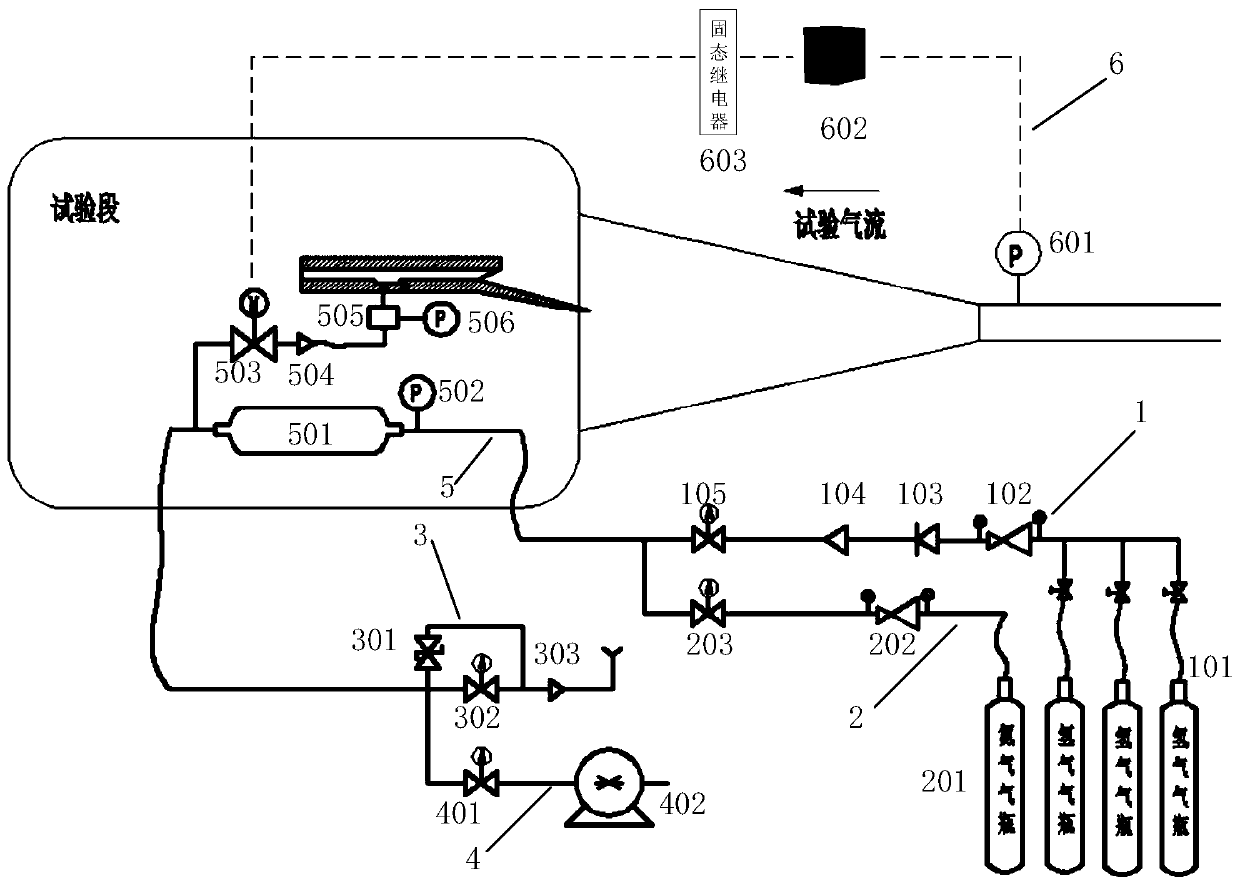

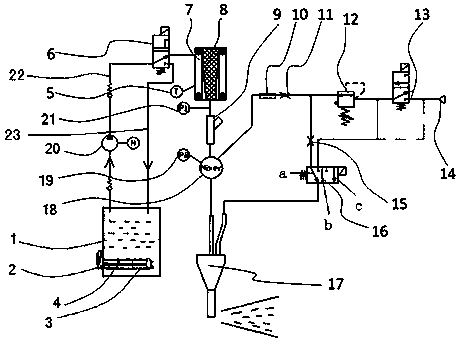

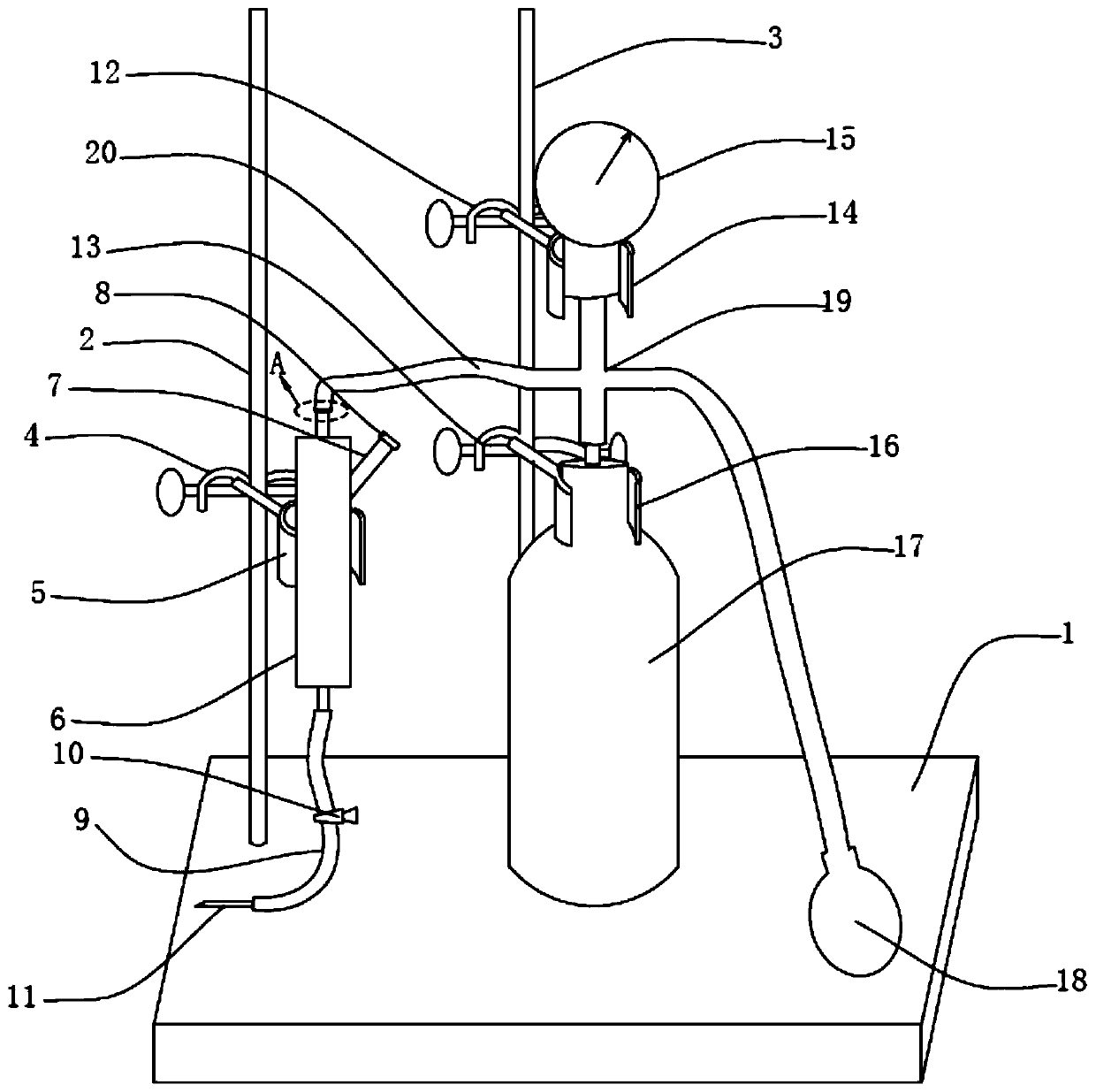

Fuel supply system and method for shock tunnel scramjet engine air intake test

ActiveCN108398272AStable fuel injection pressureSecurityGas-turbine engine testingAerodynamic testingInjection testControl system

The invention relates to a fuel supply system and method for a shock tunnel scramjet engine air intake test and belongs to the hypersonic velocity shock tunnel test technical field. According to the fuel supply system and method of the invention, with the reasonable matching of pipelines and the coordinated matching of a jet flow high-speed valve and the software and hardware of a control system adopted, a shock tunnel fuel supply and tunnel incoming flow time sequence control problem can be solved; a buffer tank and a pressure stabilizing chamber are built in a test section, and therefore, the linear loss of an air supply pipeline can be decreased, the injection pressure of fuel can be more stable; and the opening time of valves is set through the control system, and therefore, the amountof hydrogen of an injection test section can be strictly controlled, and the safety of the test can be ensured.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

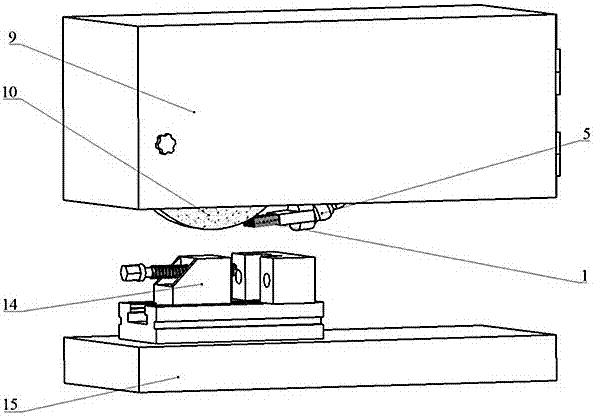

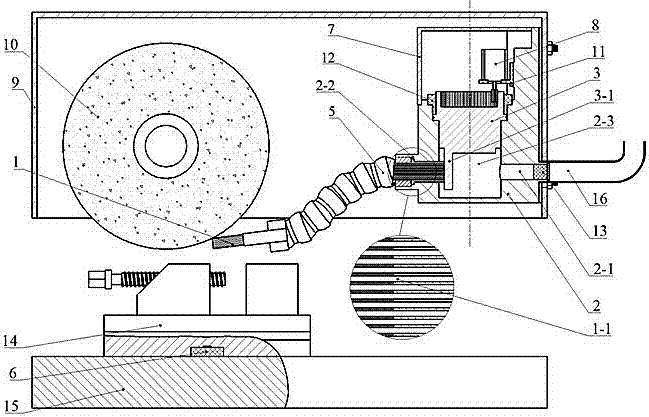

Brush-type nozzle capable of automatically adjusting flow of grinding fluid

InactiveCN107081680AReduce hindranceSolve the problem of difficult access to the grinding areaGrinding/polishing safety devicesFiber bundleEngineering

The invention discloses a brush nozzle capable of automatically adjusting the flow rate of grinding fluid, which comprises a brush nozzle and an automatic flow adjustment system. The brush nozzle includes a universal bamboo tube and a hollow fiber bundle, and the universal bamboo tube wraps the hollow fiber bundle to form a brush nozzle. The end of the hollow fiber bundle is close to the working surface of the grinding wheel and can destroy the air barrier layer on the surface of the grinding wheel, so that The grinding fluid sprayed by the hollow fiber bundle can effectively enter the grinding area for lubrication and cooling; the automatic flow adjustment system includes a valve body, a valve core, a motor, a gear and a force sensor. When the grinding force changes, it is installed on the fixture The force sensor sends a feedback signal, and the motor adjusts the spool through the gear to turn over a suitable angle to control the number of fiber openings in the inner cavity of the valve, thereby controlling the flow of grinding fluid entering the grinding area and realizing automatic adjustment of the flow of grinding fluid. The invention has the advantages of increasing the utilization rate of the grinding fluid, reducing the grinding temperature, improving the grinding quality, protecting the environment, saving costs and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

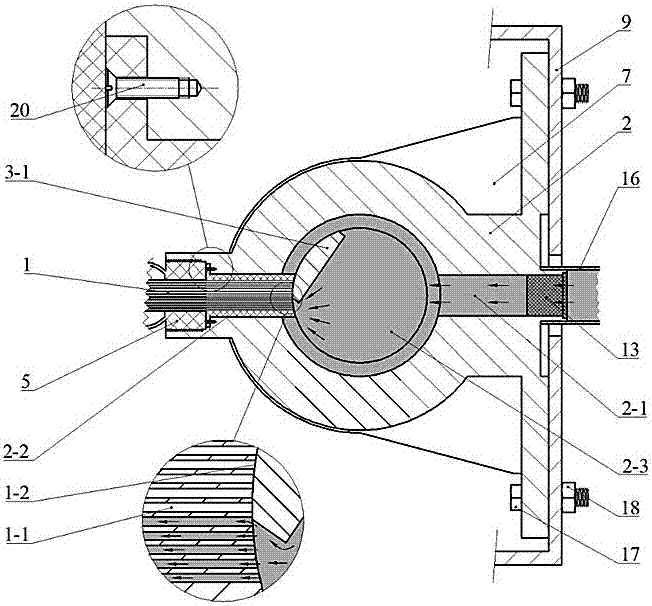

Adjustable-pressure type pressure-stabilizing nozzle

ActiveCN112170034AWith voltage stabilizing functionControl areaLiquid spraying apparatusJet flowEngineering

The invention discloses an adjustable-pressure type pressure-stabilizing nozzle, and relates to the technical field of nozzles. The adjustable-pressure type pressure-stabilizing nozzle comprises a shell, a liquid supply joint and a spraying head, wherein the liquid supply joint and the spraying head are formed by the shell; a rectifying chamber which communicates with the spraying head and a liquid inlet chamber which communicates with the liquid supply joint are also formed by the shell; a diameter-varied pipe section which has a structure of a contracted middle part and expanded front and rear parts and is formed by the shell is positioned between the liquid inlet chamber and the rectifying chamber which is arranged at the front end of the liquid inlet chamber; the shell is equipped witha separate pressure regulation chamber which is formed in the rear part of the liquid inlet chamber; the nozzle also comprises the shell which penetrates through the pressure regulation chamber and the liquid inlet chamber as well as between the pressure regulation chamber and the liquid inlet chamber, and a control rod which finally extends to the junction of the diameter-varied pipe section andthe liquid inlet chamber; and the control rod can be moved back and forth in the shell, and a pressure regulation process and a pressure stabilizing process of the nozzle can be realized through front and back movement of the control rod. The adjustable-pressure type pressure-stabilizing nozzle disclosed by the invention has a function of accurately regulating an ejection pressure ratio, and canensure that the pressure of flow filed in the nozzle is stable and can be regulated, so that the stability of the ejection flow of the nozzle is improved; and moreover, the nozzle also has an atomization enhancement function, and thus, the working quality of jet flow is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

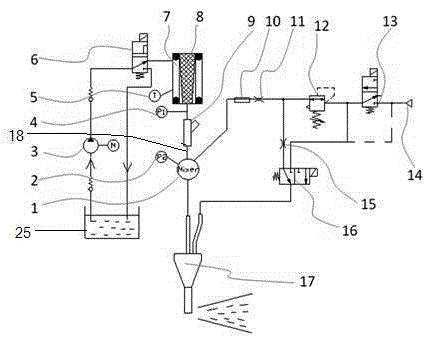

Ammonia injection system and control method thereof

ActiveCN108278144APrecision injectionAccurate measurementInternal combustion piston enginesExhaust apparatusInjection pressureAmmonia storage

The invention discloses an ammonia injection system and a control method thereof. The ammonia injection system comprises an ammonia storage tank, an ammonia supply module, an ammonia regulating valve,an ammonia metering valve, a pressure sensor, a valve seat, an ammonia nozzle and a controller, wherein the ammonia supply module communicates with the ammonia storage tank, and the ammonia supply module is connected with the ammonia regulating valve; ammonia in the ammonia storage tank enters the ammonia metering valve, and the stable ammonia injection pressure is guaranteed by the controller bycontrolling the opening and closing of the ammonia metering valve; and the controller is combined with the ammonia injection pressure to control the opening and closing duration of the ammonia metering valve so as to inject a proper amount of ammonia. According to the ammonia injection system, double valves including the ammonia regulating valve and the ammonia metering valve are controlled by anelectronic control unit (ECU), so that the stable ammonia injection pressure can be guaranteed, thereby realizing the accurate measurement of ammonia and satisfying the CHINA VI emission requirements; the ammonia regulating valve is an electric control switching valve, the structure is simple, the process is mature, the cost is low, and compared with a mechanical pressure regulating valve, the ammonia regulating valve has obvious cost advantages and reliability advantages.

Owner:CHINA FIRST AUTOMOBILE

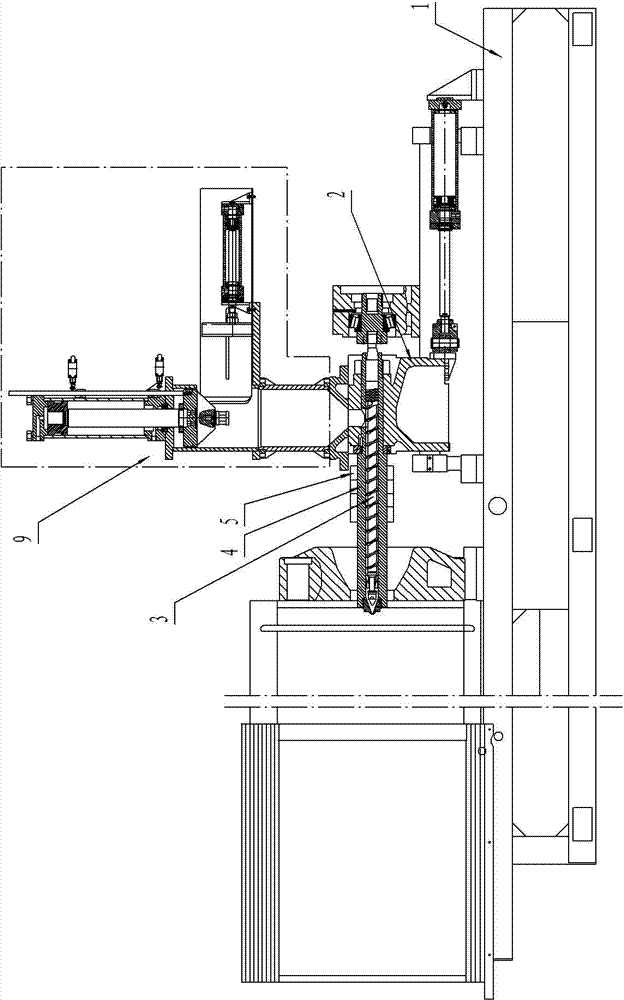

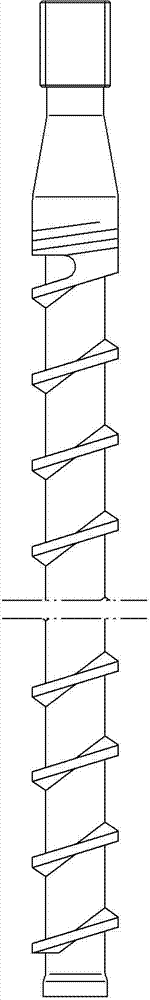

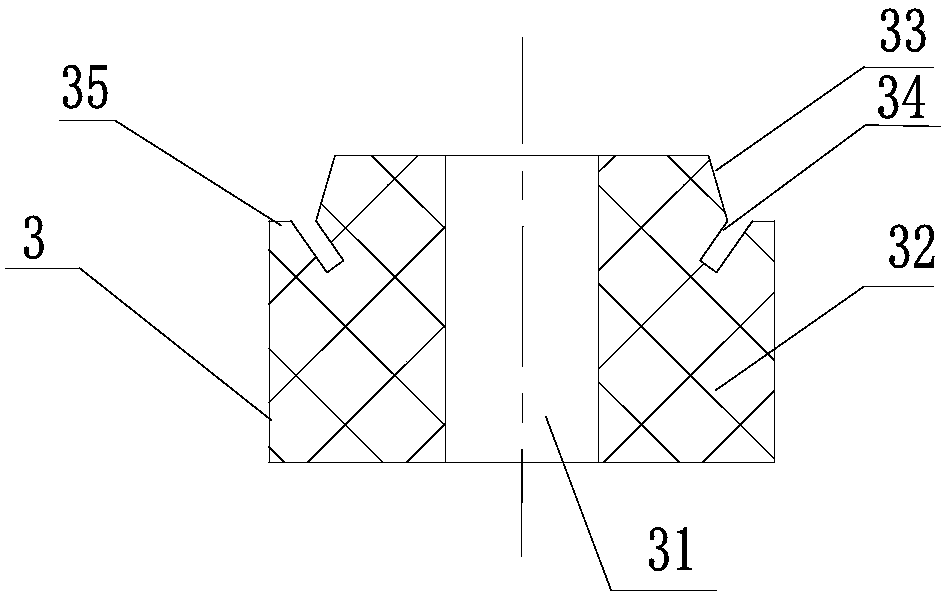

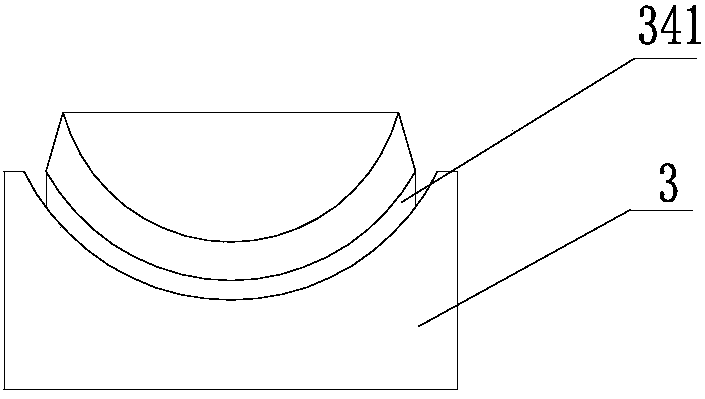

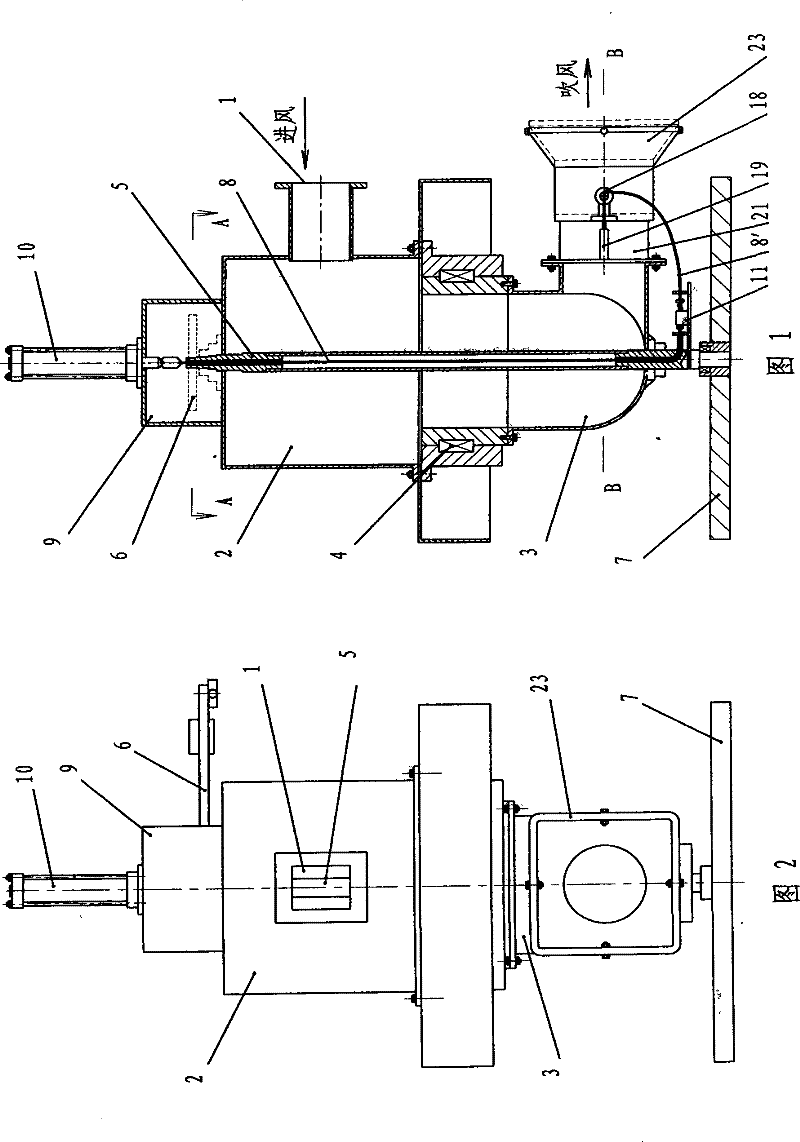

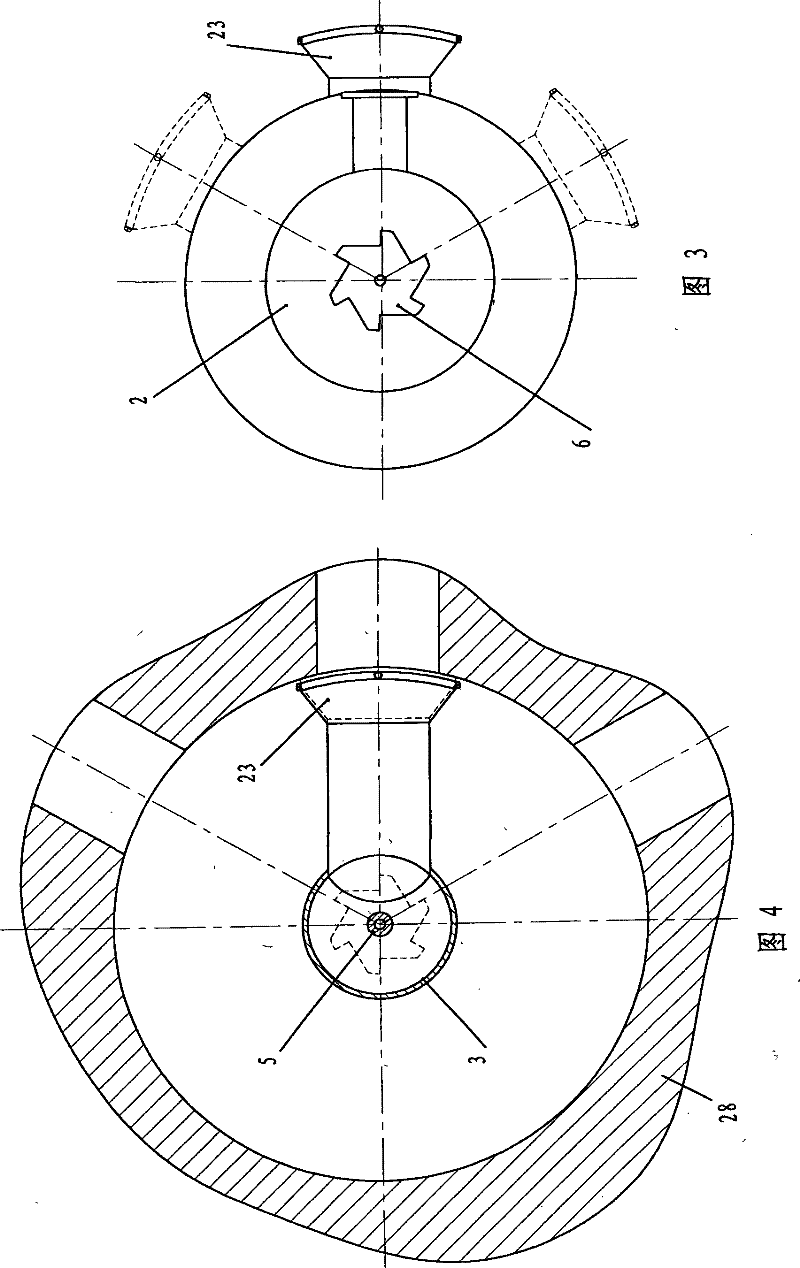

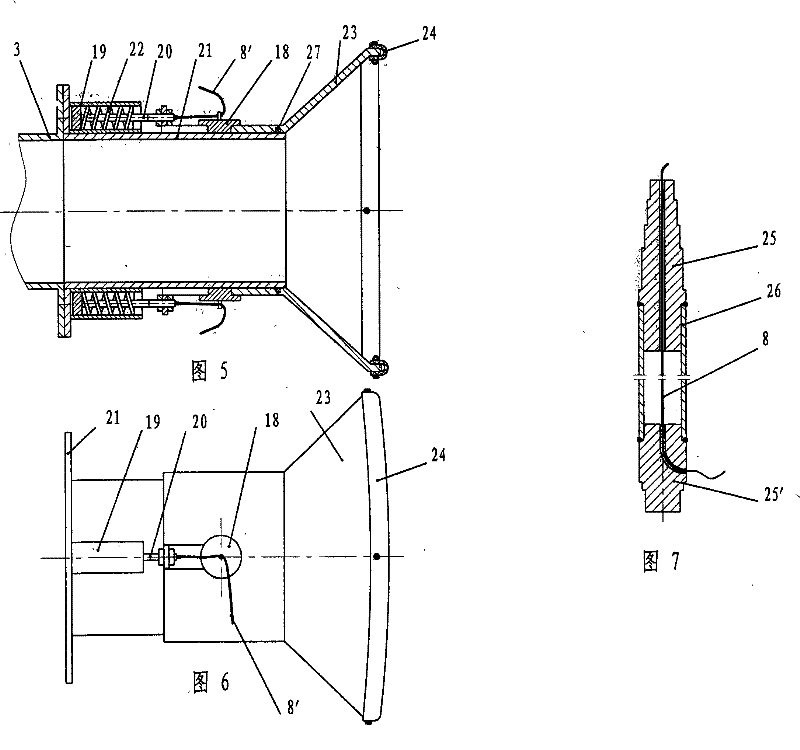

Injection molding machine for unsaturated polyester bulk molding compound

The invention discloses an injection molding machine for an unsaturated polyester bulk molding compound and belongs to the technical field of mechanical device manufacture. The injection molding machine comprises a machine frame, an injection seat, a screw, a machine barrel, a feeding device and a heater. The screw is connected with a screw head, the screw head is connected with the front end of a thrust rod, the back portion of the front end of the thrust rod is provided with a section of protruding baffle ring portion, a non-return ring is sleeved on the thrust rod, and an axial gap of 2-15mm is arranged on the non-return ring between the ring portion of the thrust rod and the screw head. The back end of the non-return ring is provided with a protruding ring portion, and the front end of the non-return ring is provided with a barrel provided with a plurality of gaps. The protruding ring portion is provided with a bonding face bonded with the baffle ring portion of the thrust rod, and the bonding face of the non-return ring is provided with a plurality of feeding through holes communicated to the outside of a barrel wall in front of the protruding ring portion. The injection molding machine for the unsaturated polyester bulk molding compound can solve the problem that plastic products are large in backflow amount, unstable in weight and poor in density degree and cannot be molded into products with high surface quality in the injection molding process.

Owner:钦州市钦南区金窝工业园管理委员会

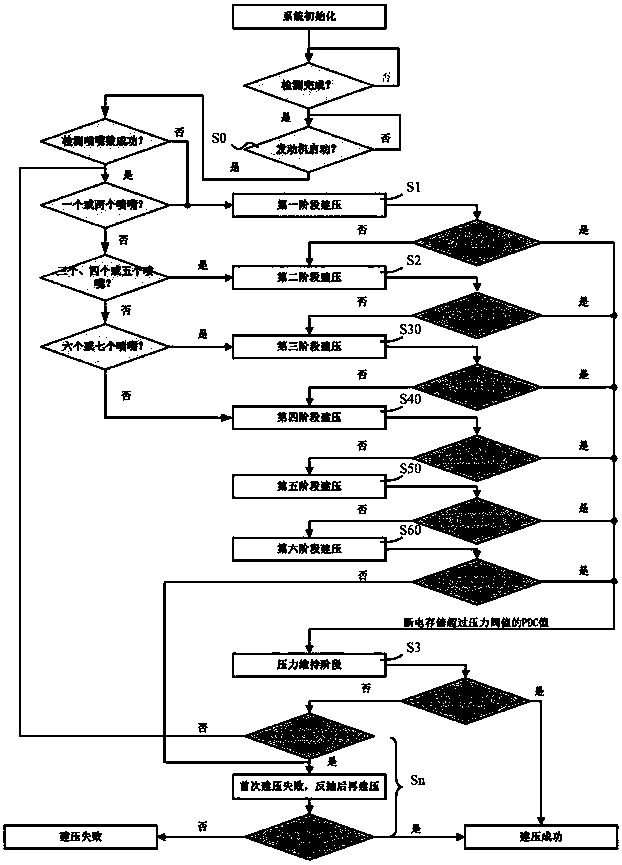

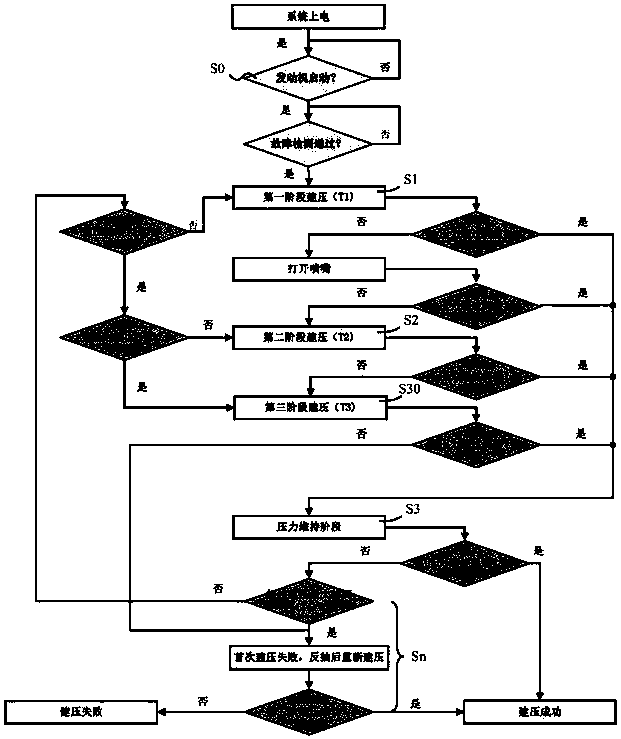

Segmented pressure buildup method for exhaust gas after-treatment system

ActiveCN108691623AImprove the success rate of pressure buildingImprove jetting accuracyGeometric CADInternal combustion piston enginesAfter treatmentTreatment system

The invention provides a segmented pressure buildup method for an exhaust gas after-treatment system. The segmented pressure buildup method at least comprises the following steps of: S 0. judging whether an engine is started, and if the engine is started, executing the step S1; S1. carrying out first-stage pressure buildup, to be specific, driving a pump component to operate at the first pump speed, checking whether the outlet pressure of the pump component exceeds a threshold value, if yes, executing the step S3, and if not, executing the step S2; S2. carrying out second-stage pressure buildup, to be specific, driving the pump component to operate at the second pump speed and checking whether the outlet pressure of the pump component exceeds the threshold value, if yes, executing the stepS3, and if not, executing the step Sn; S3. pressure maintaining stage, to be specific, judging whether the pressure maintaining is successful, if yes, the pressure buildup is successful, and if not,executing the step Sn; and Sn. if the first pressure buildup fails, driving the pump component to reversely pump, then carrying out secondary pressure buildup and judging whether the secondary pressure buildup is successful, if yes, the pressure buildup is successful, and if not, the pressure buildup fails.

Owner:TENNECO SUZHOU EMISSION SYST

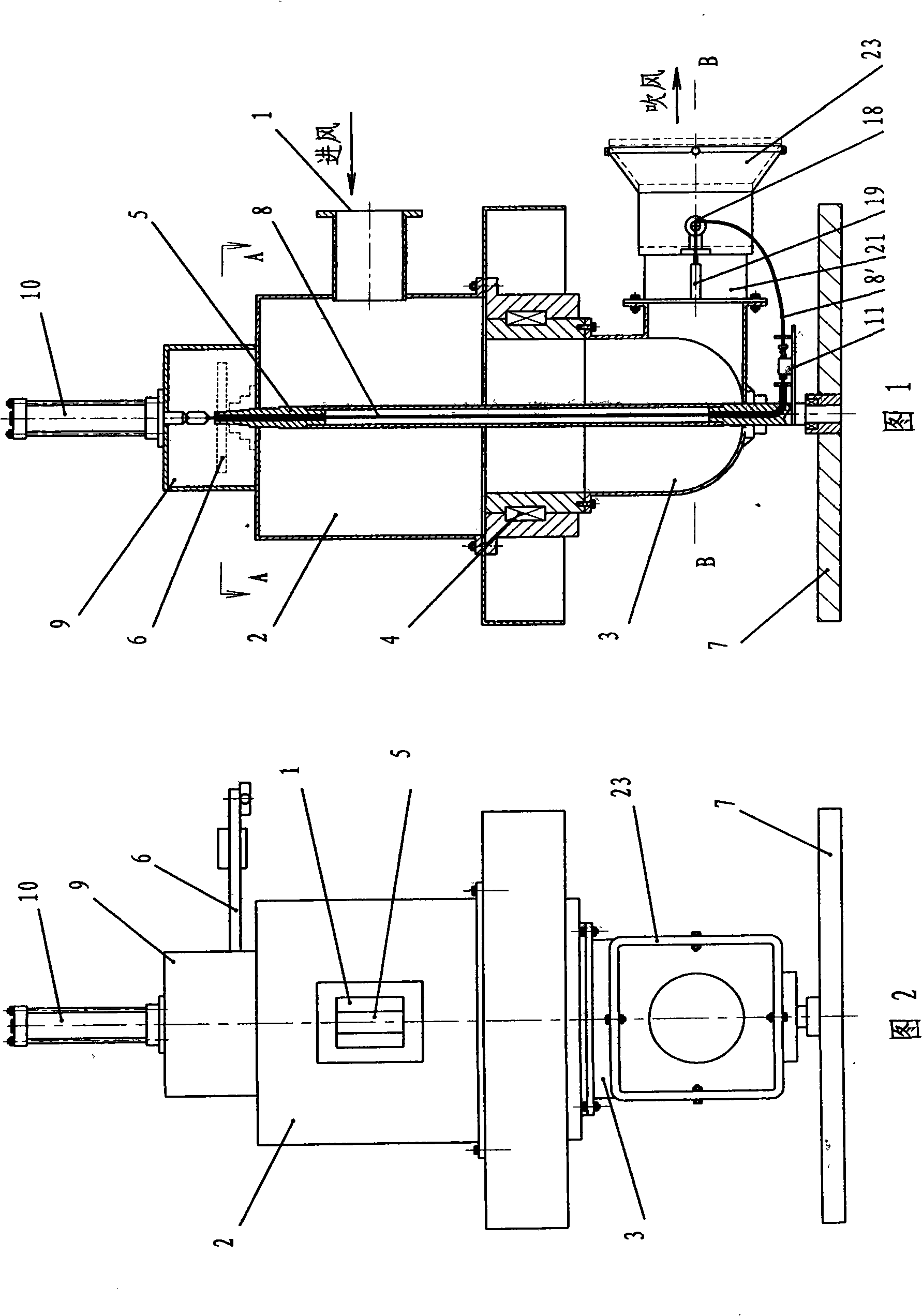

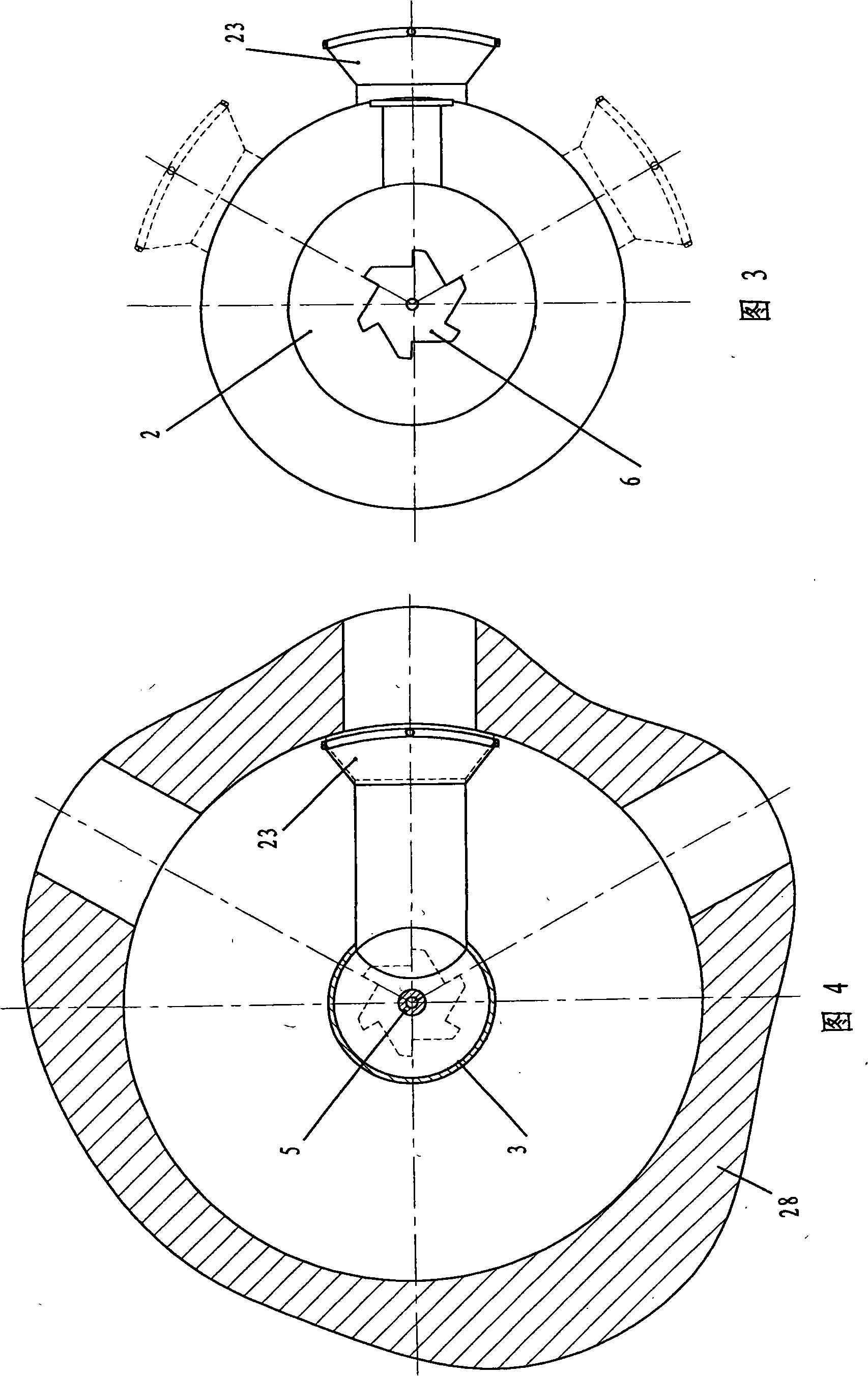

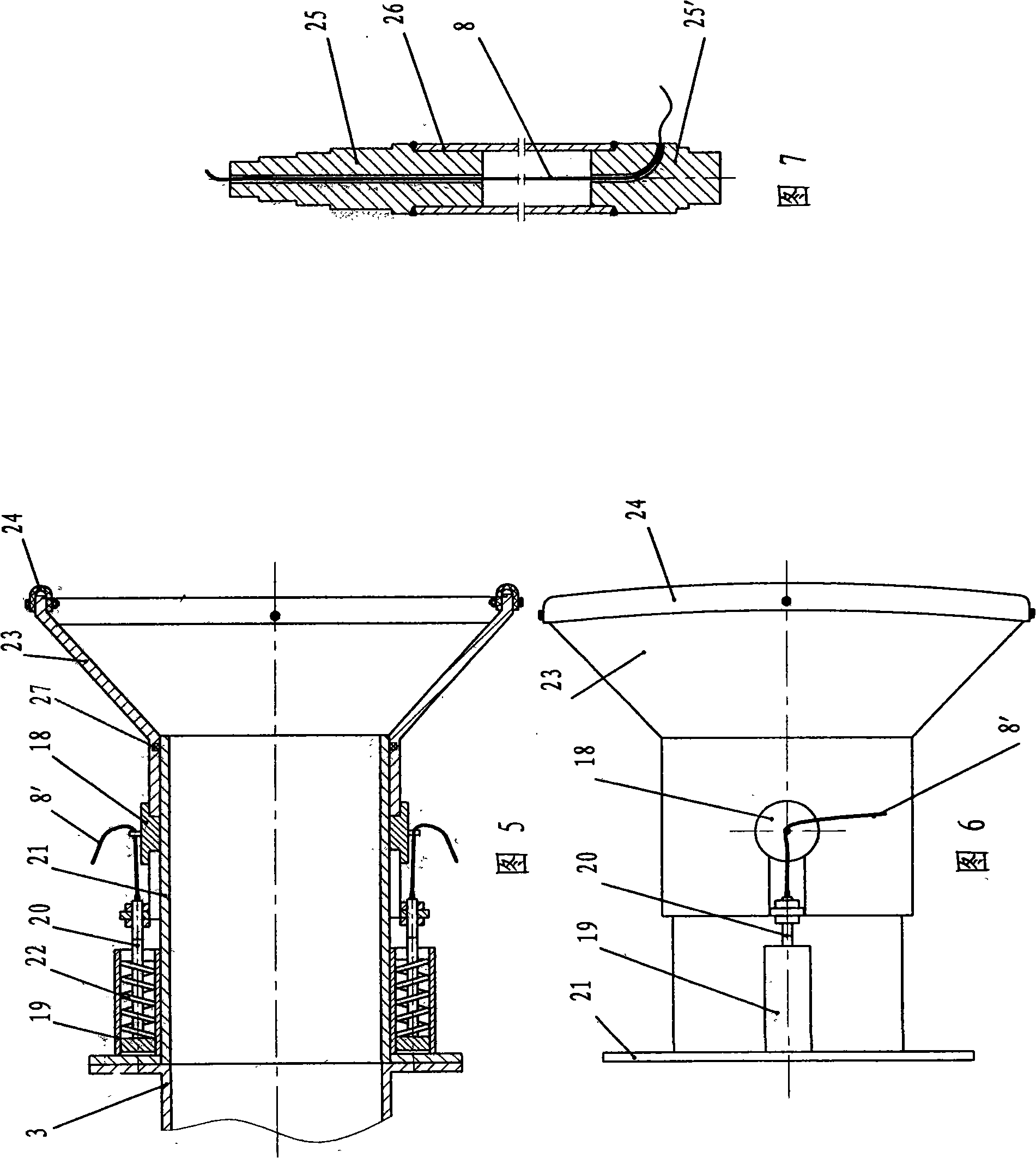

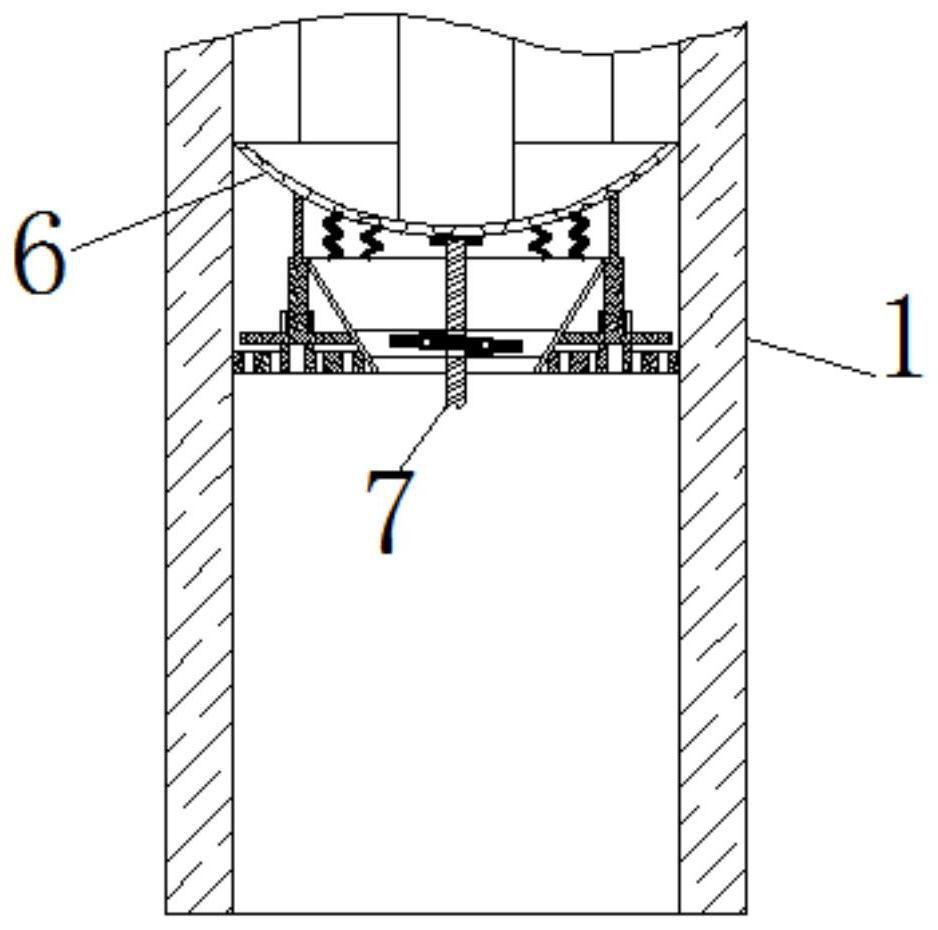

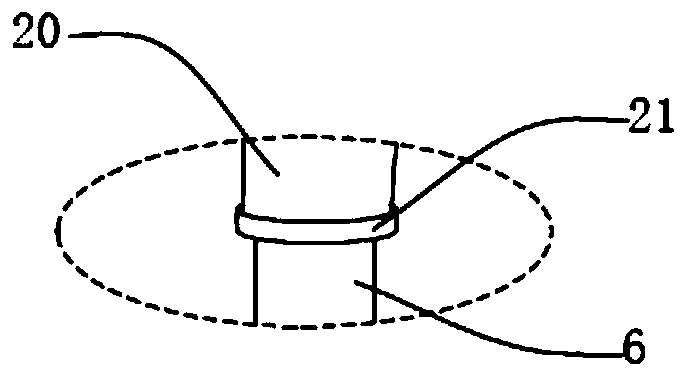

Air tightness rotating backblowing device for cloth bag dust remover

InactiveCN101279172AEnsure stabilityExtended service lifeDispersed particle filtrationButt jointAir tightness

The invention provides an air-impermeable reverse blowing device used in a bag-type dust collector, comprising a revolving shaft, a reverse blowing case body, a jetting pipe joint and a bracket, wherein, the structure of the revolving shaft is hollow and a stay cable is arranged in the revolving shaft; the upper end of the stay cable is fixedly connected with a piston rod of a cylinder which is arranged on the upper part of the reverse blowing case body and the lower end of the stay cable crosses horizontally from the lower part of the revolving shaft and is connected with a sliding rod on a base plate; the other end of the sliding rod is connected with an intermediate plate; two sides of the intermediate plate respectively get around a guidepost by the stay cable and are symmetrically and fixedly connected with stretching ends of spring shafts arranged in two spring sleeves; the two spring sleeves are respectively arranged and fixed symmetrically on the outer wall of a cylinder which is horizontally connected with the lower part of the jetting pipe joint; small springs are sheathed on the spring shaft and a butt-joint jetting muzzle with a horn mouth is movably sheathed outside the cylinder; the butt-joint jetting muzzle slides along the guidepost fixed on the cylinder and is fixedly connected with the stretching end of the spring shaft; the base plate is fixedly connected with the lower part of the revolving shaft. The device has the advantages of simple structure, flexible regulation, reliable sealing performance and low maintenance cost.

Owner:QINHUANGDAO QINGQING ENVIRONMENTAL PROTECTION EQUIP

Common rail type air cylinder oil injection lubricating system

InactiveCN105257362ASimple structureFlexible layoutMachines/enginesPressure lubricationInjection pressureLow speed

The invention discloses a common rail type air cylinder oil injection lubricating system. The common rail type injection principle is adopted, and only one oil product, namely, air cylinder lubricating oil is included. The common rail type air cylinder oil injection lubricating system comprises an air cylinder lubricating oil supply component, an air cylinder lubricating oil common rail pipe component, an oil injection gun component and a control component. The air cylinder lubricating oil supply component, the air cylinder lubricating oil common rail pipe component and the oil injection gun component are sequentially connected. The control component is connected with the air cylinder lubricating oil supply component, the air cylinder lubricating oil common rail pipe component and the oil injection gun component and controls the air cylinder lubricating oil common rail pipe component to adjust the lubricating oil supply pressure of the air cylinder lubricating oil supply component according to the requirements and controls the oil injection gun component to adjust the lubricating oil injection time and lubricating oil injection amount according to requirements. Flexible and soft control over the air cylinder oil injection amount, the oil injection pressure and the oil injection timing is achieved, the control precision and the control freedom degree are improved, the air cylinder lubricating condition is improved, the air cylinder oil injection efficiency is improved, and the air cylinder lubricating oil consumption is reduced. The common rail type air cylinder oil injection lubricating system has the beneficial effects of being compact in structure, stable in oil injection pressure and good in lubrication effect and is suitable for large-power ship diesel engines such as a low-speed two-stroke diesel engine.

Owner:CSSC POWER INST CO LTD +1

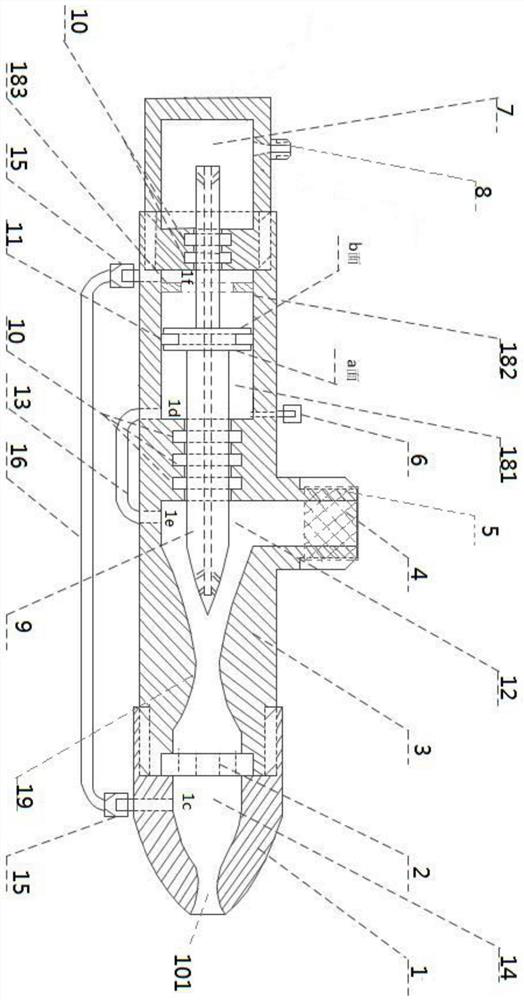

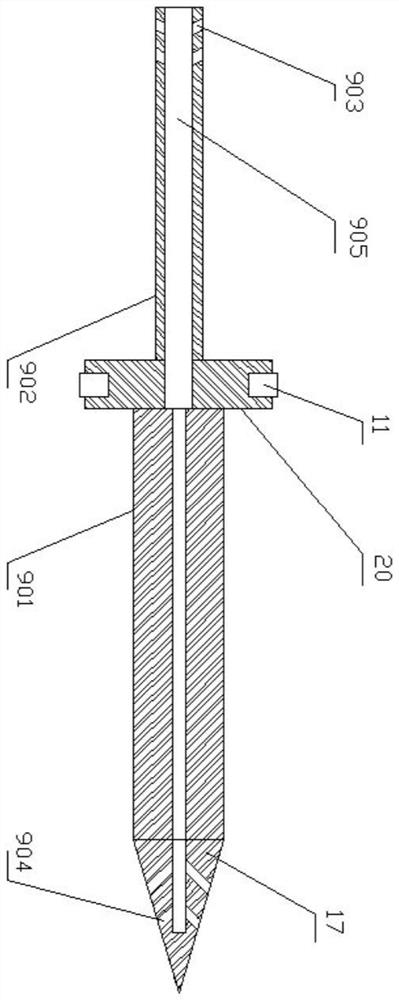

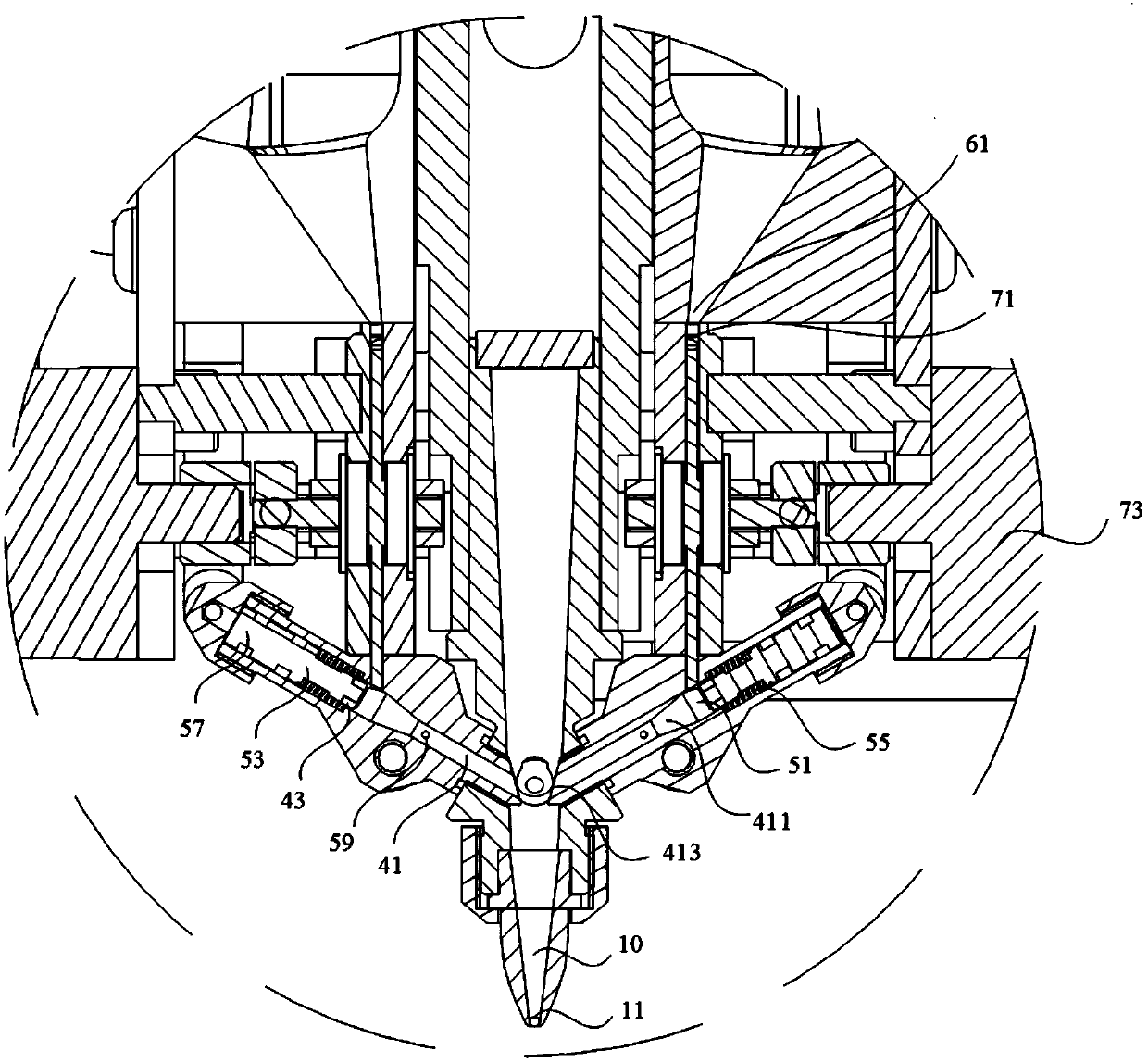

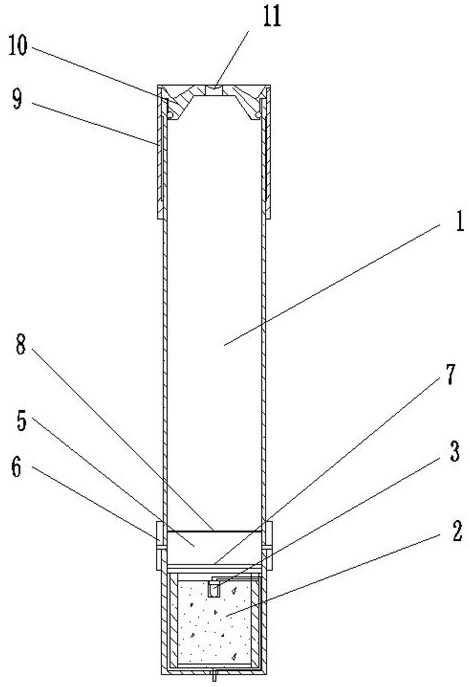

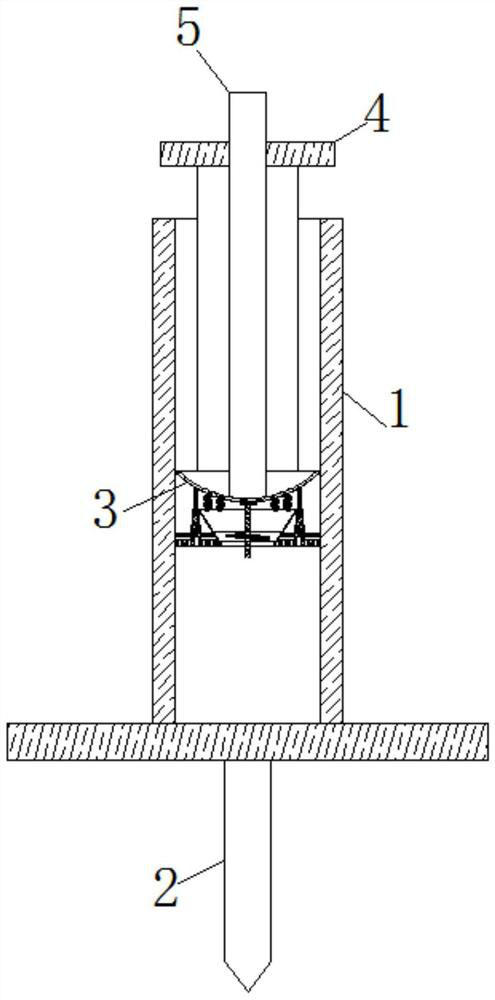

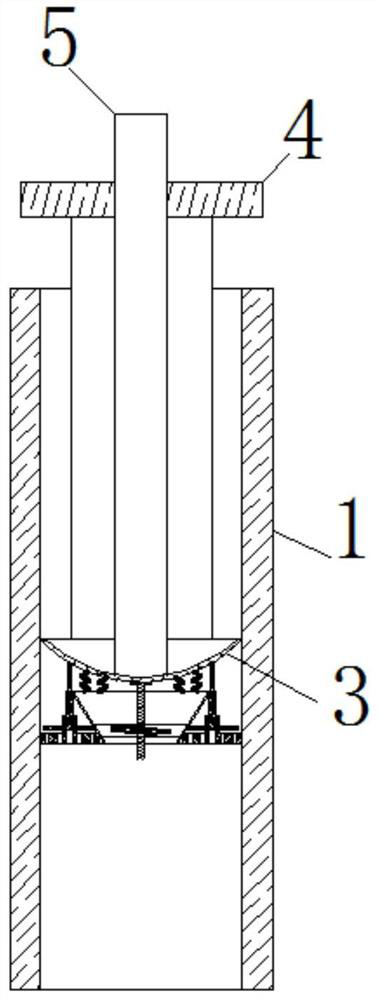

Medical-purpose advanced immunization apparatus for pseudorabies inpiglets in pseudorabies-positive pig farms

ActiveCN110811906ATo achieve the effect of sterile dilution of liquid medicineStable injection pressureInfusion syringesMedical devicesPig farmsRabies

The invention relates to the technical field of immunization against pseudorabies in pigs, and discloses a medical-purpose advanced immunization apparatus for pseudorabies inpiglets in pseudorabies-positive pig farms. The medical-purpose advanced immunization apparatus for pseudorabies inthe piglets in the pseudorabies-positive pig farms comprises a shell; a needle is fixedly connected with a surface of the shell; a piston block is movably connected with the interior of the shell; a pull rod is fixedly connected with a surface of the piston block; a dilution rod is in sliding connection with the interior of the pull rod; a negative-pressure film is fixedly connected with the interior of the piston block; and a rotating shaft is movablyconnected with the bottom of the negative-pressure film. When a compression spring loses tension so as to pull the negative-pressure film back to an original state and allowthe rotating shaft to reversely rotate, a steering wheel moves towards a directionclose to the needle on a surface of the rotating shaft, and a return spring moves slowly down under the action of a rotating force of the steering wheel and elasticity of the return spring itself; and the needle, which is already inserted into the body of a piglet, also moves slowly down against the pressure so as to have diluted drug liquid in the shell injected into the body of the piglet. Therefore, the effect of stable injection pressure is achieved.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

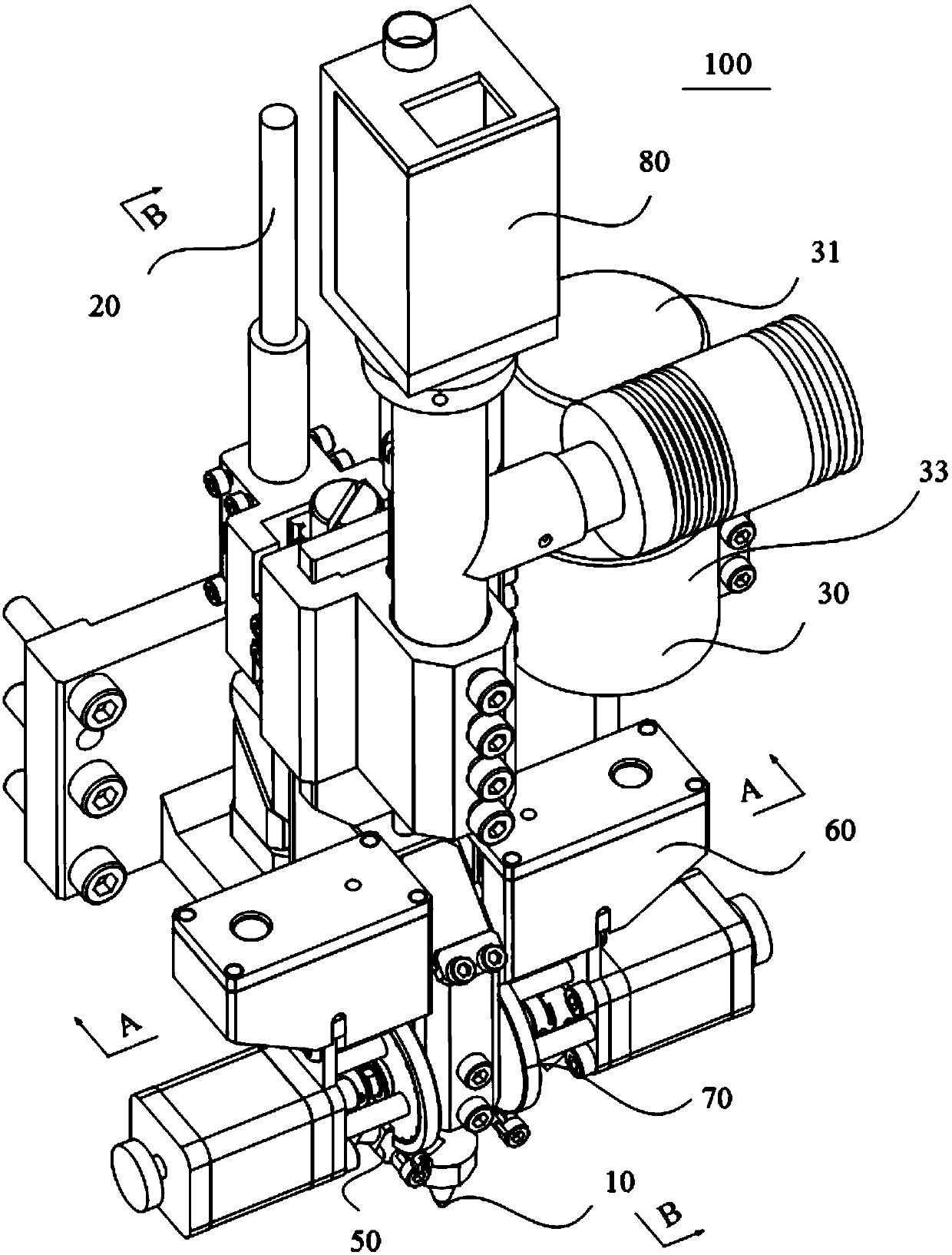

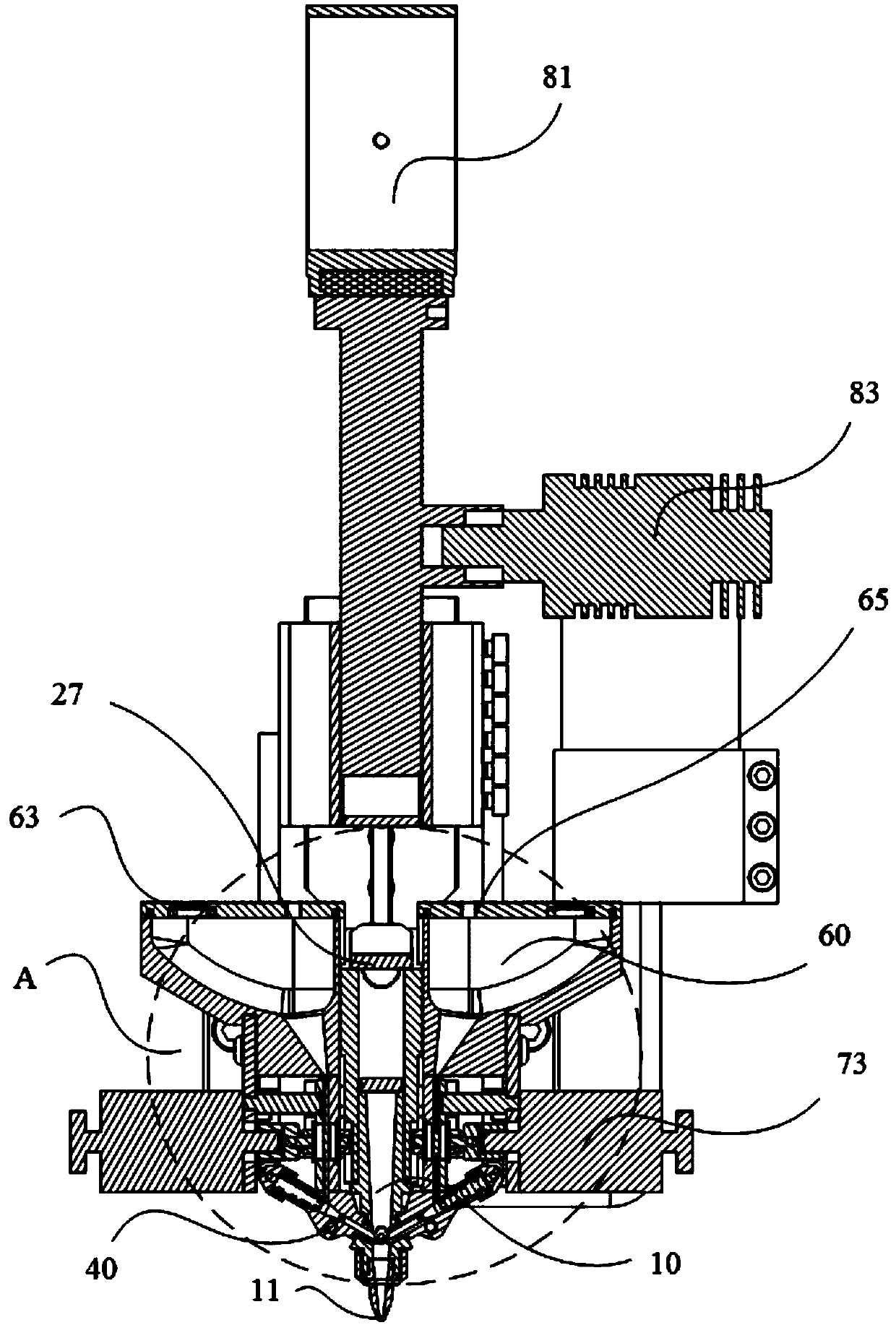

Welding equipment

PendingCN109590561AEasy to controlStable injection pressureMetal working apparatusSoldering auxillary devicesFixed positionTin

The invention discloses welding equipment for tin ball welding. The welding equipment comprises a spraying cavity, a laser module, a pneumatic module, a feeding module and a seal device. A tin ball fixing position is formed in the spraying cavity. A laser emitting port of the laser module is opposite to the tin ball fixing position and is used for heating a tin ball located at the tin ball fixingposition. An air outlet of the pneumatic module communicates with the spraying cavity and is used for spraying the machined tin ball. A conveying runner is formed in the feeding module and provided with a feeding port and a discharging port, and the discharging port communicates with the spraying cavity and is used for conveying the tin ball to the tin ball fixing position. The seal device is movably arranged on the feeding module so as to open or seal the feeding port. According to the purpose, the problems that in the laser tin welding process, spraying power control is poor, and the weldingprecision is influenced are solved.

Owner:SHENZHEN H TECH CO LTD

Pressure-adjustable type pressure-stabilizing nozzle

The invention discloses a pressure-adjustable type pressure-stabilizing nozzle, and relates to the technical field of nozzles. The pressure-adjustable type pressure-stabilizing nozzle comprises a shell, a liquid supply joint and a nozzle, wherein the liquid supply joint and the nozzle are formed by the shell; the shell also can form a rectifying cavity which communicates with the nozzle and a liquid feeding cavity which communicates with the liquid supply joint; a diameter-varied pipe section with a contracted middle part as well as expanded front and rear parts, which is formed by the shell,is arranged between the liquid feeding cavity and the rectifying cavity which is formed in the front end of the shell; the shell can form a separate pressure regulating cavity at the rear of the liquid feeding cavity; the nozzle also comprises a shell which penetrates through the pressure regulating cavity and the liquid feeding cavity and penetrates between the pressure regulating cavity and theliquid feeding cavity, and finally extends to a control rod which is positioned at an intercrossing part of the diameter-varied pipe section and the rectifying cavity; and the control rod can be movedback and forth in the shell, and a pressure regulation process and a pressure stabilizing process of the nozzle can be realized through back-and-forth movement of the control rod. The nozzle disclosed by the invention has a function of automatically and accurately regulating injection pressure ratio, and has the advantages that the stability and adjustability of the pressure of a flow field in the nozzle can be ensured, and the stability of injection flow of the nozzle is improved; and moreover, the pressure-adjustable type pressure-stabilizing nozzle also has an atomizing enhancement function, so that the quality of jet flow works is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

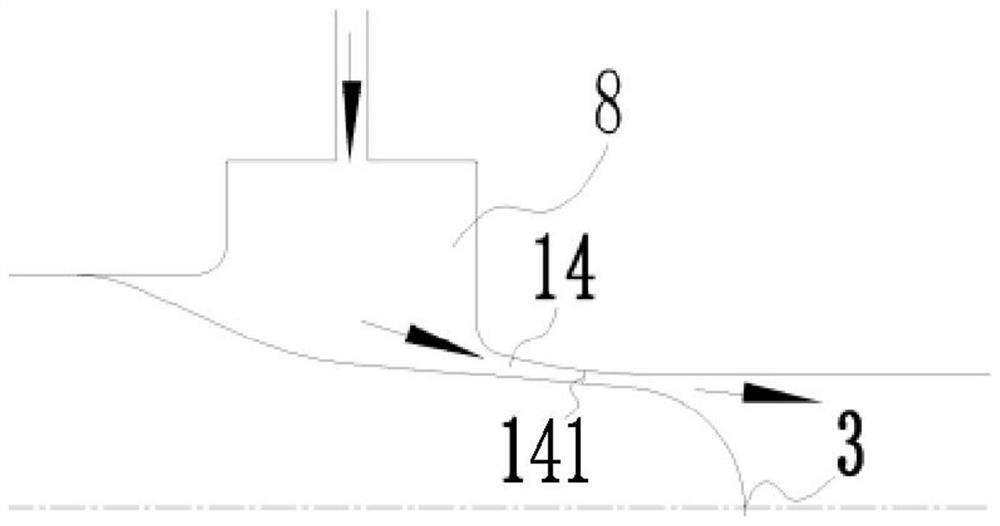

Active cooling engine fuel switching device and switching method

ActiveCN111980809AAdaptively adjust the cross-sectional area of the nozzle holeAdaptive adjustment of nozzle areaTurbine/propulsion engine coolingTurbine/propulsion fuel controlThermodynamicsActive cooling

The invention relates to the field of engine fuel injection, and provides an active cooling engine fuel switching device. According to the active cooling engine fuel switching device, when fuel entersa supercritical state or a gaseous state from a liquid state, the sectional area of a fuel injection hole is adaptively adjusted according to the fuel pressure change, the fuel injection pressure iskept stable, and thus stable combustion of an engine in the fuel switching process is ensured. The device comprises a shell with an opening in one end, an end face flange is installed on the opening side of the shell, a confluence cavity and a downstream cavity are sequentially formed in the side, away from the end face flange, of an inner cavity of the shell, a needle cone is inserted into the inner cavity of the shell, the head of the needle cone penetrates through the confluence cavity and extends into the downstream cavity, and an inner runner wall surface matched with the side wall of theneedle cone is arranged at the joint of the confluence cavity and the downstream cavity. The invention further provides an active cooling engine fuel switching method. The method is particularly suitable for stable fuel switching of the active cooling engine, and has high social use value and application prospect.

Owner:合肥中科重明科技有限公司 +1

Microneedle drug delivery device and method of making the same

ActiveCN104307098BEvenly distributedMeet injection needsMicroneedlesMedical devicesMems sensorsMicro-needle

The invention discloses a microneedle doser and a manufacturing method thereof. The microneedle doser comprises a microneedle substrate, a medicine cavity and a piezoelectric element, wherein the microneedle substrate is provided with a first surface and a second surface, and comprises a solid microneedle array on the first surface and a micropore array which penetrates a first substrate and protrudes from the first surface to the second surface; the medicine cavity comprises an inner space exposed on the first surface and a second surface opposite to the bottom of the inner space, wherein the second surface of the microneedle substrate is combined with the first surface of the medicine cavity so as to enclose the inner space; the piezoelectric element is combined with the second surface of the medicine cavity, wherein the microneedle substrate and the medicine cavity are formed an MEMS (Micro-electromechanical Systems) sensor. According to the microneedle doser, the solid microneedle can be used for working continuously and efficiently, and the MEMS sensor can be used for realizing the precise and quantitative control.

Owner:唐晨

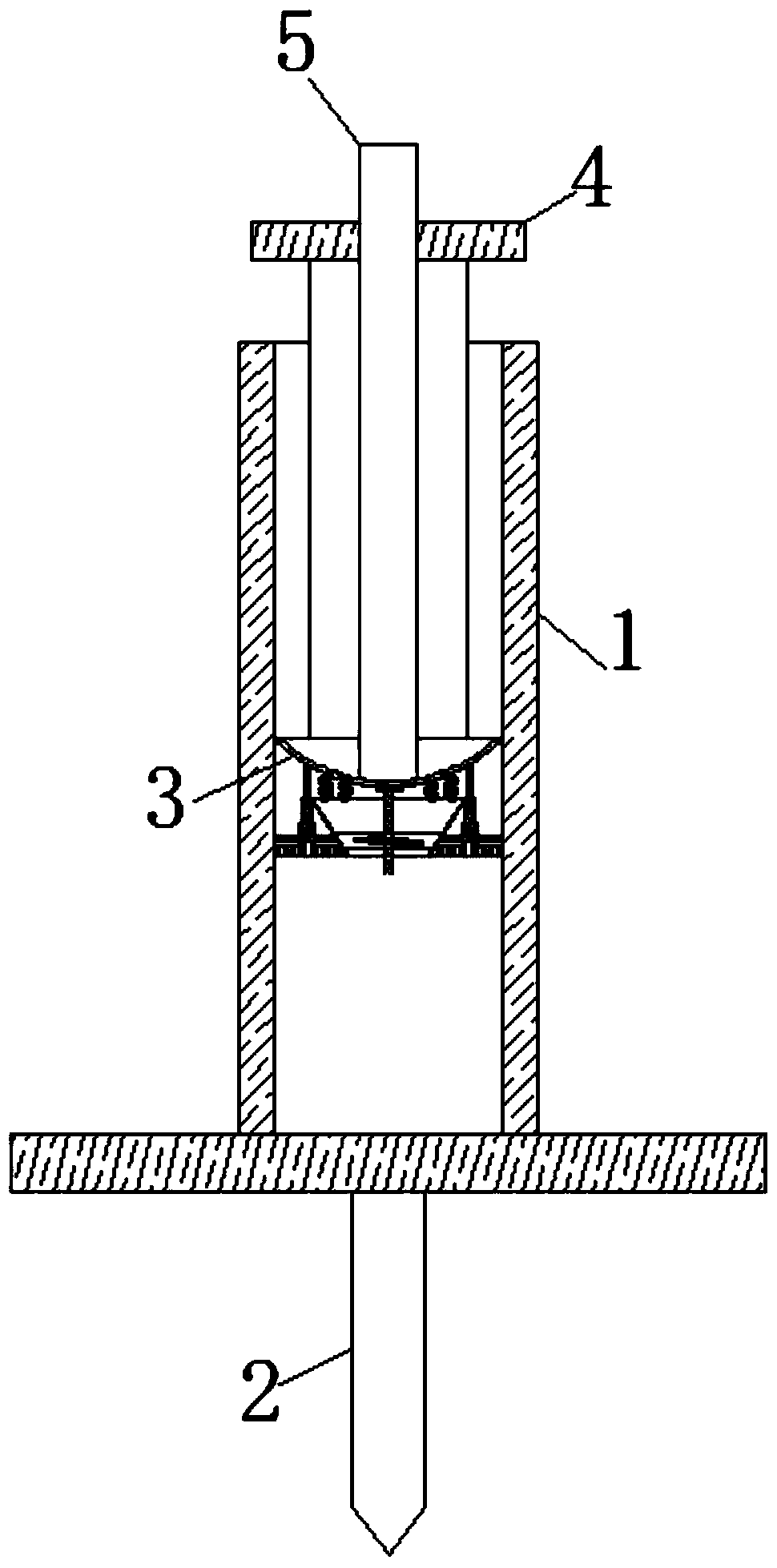

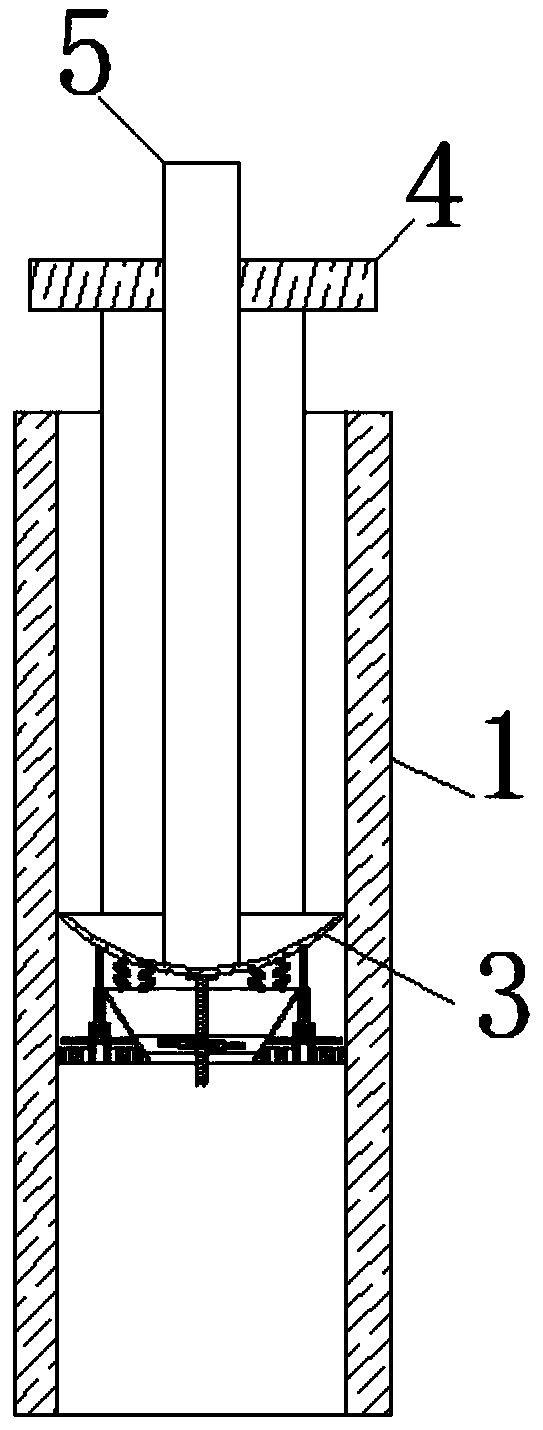

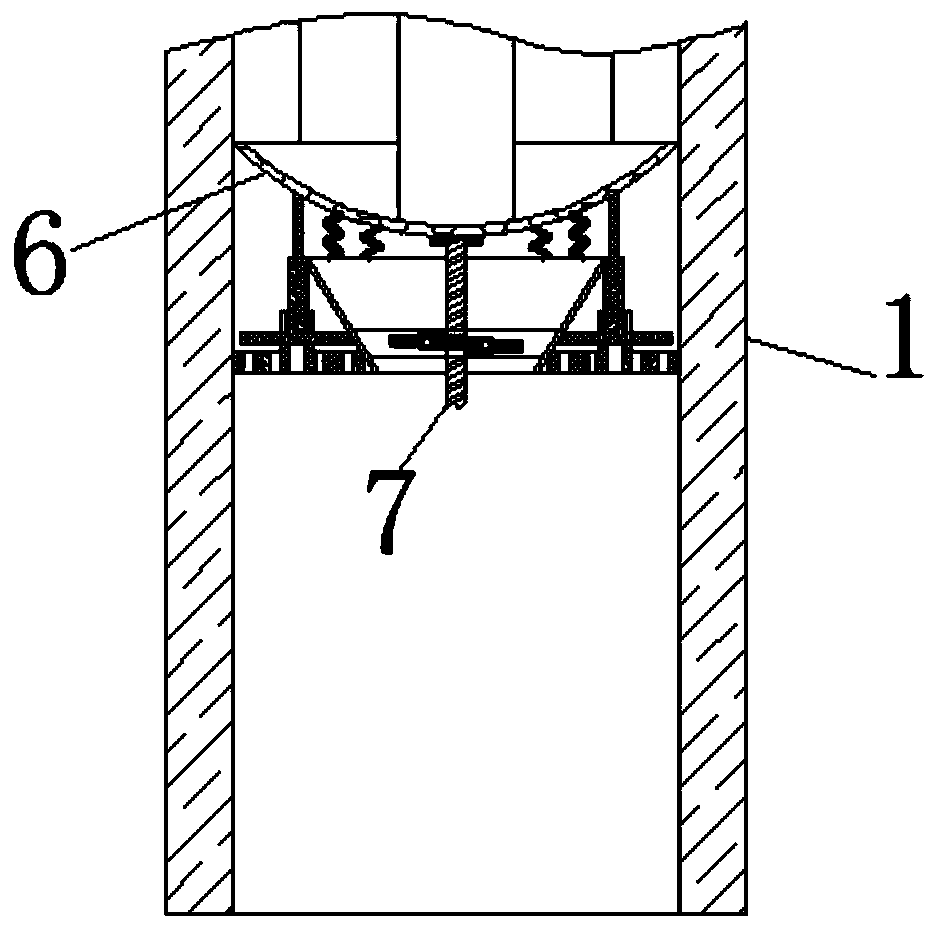

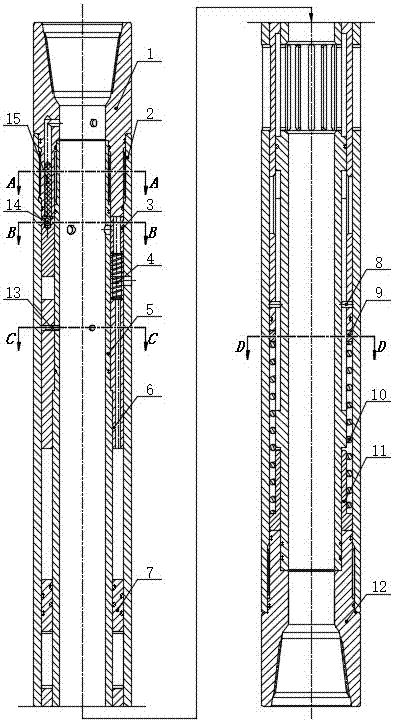

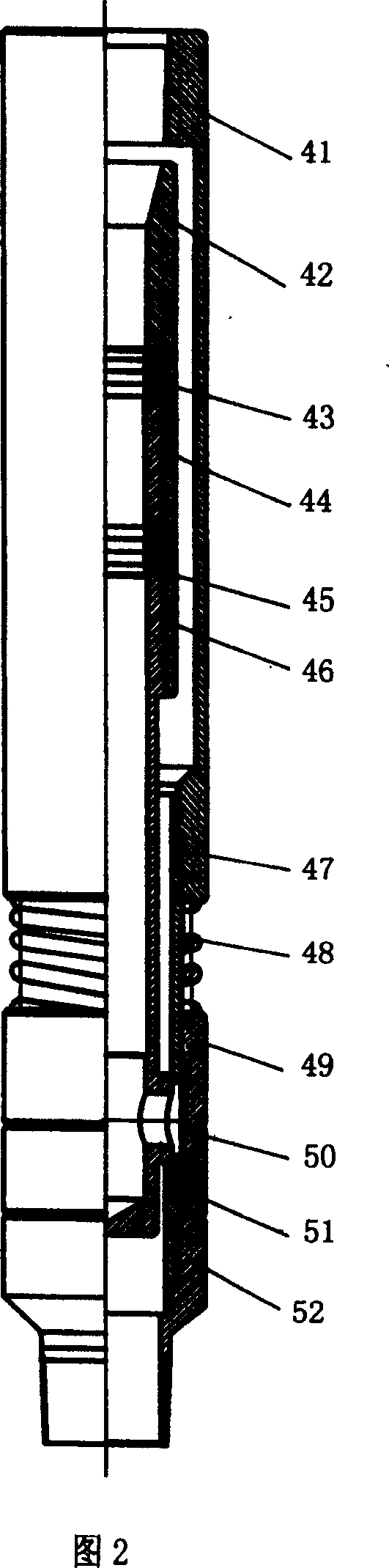

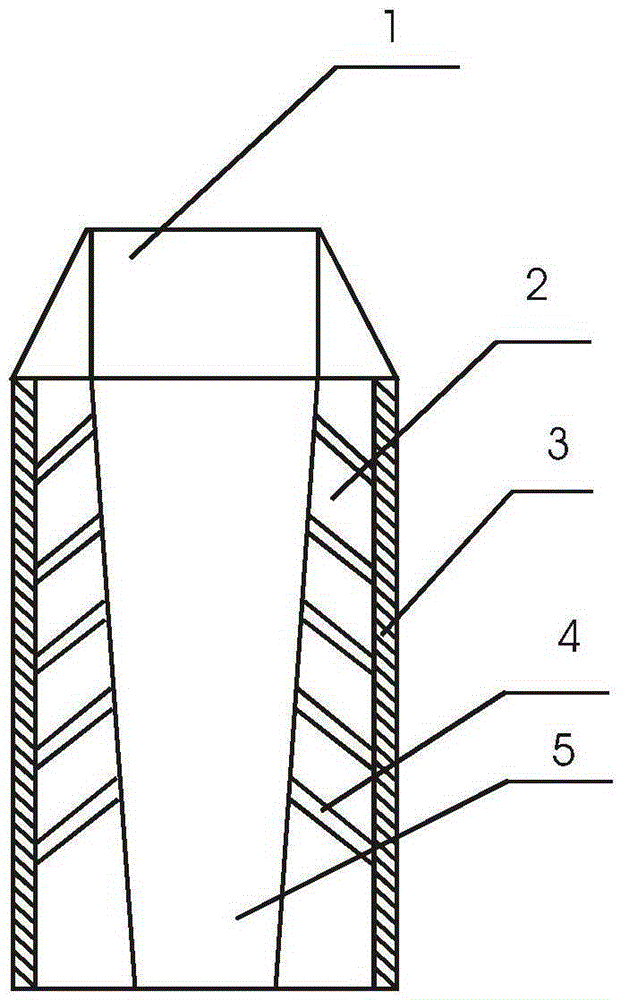

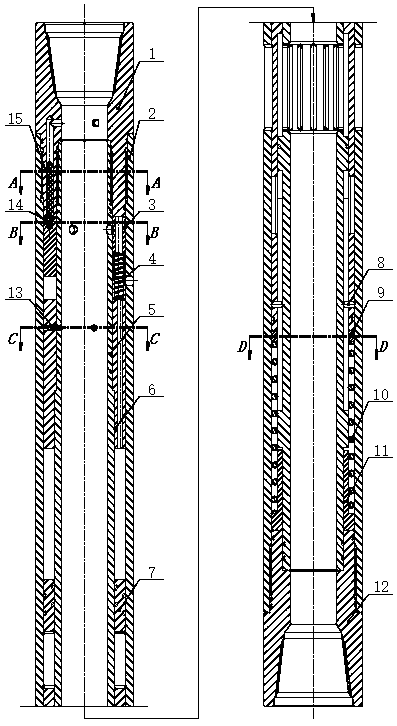

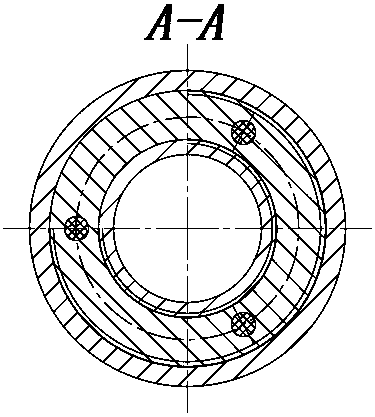

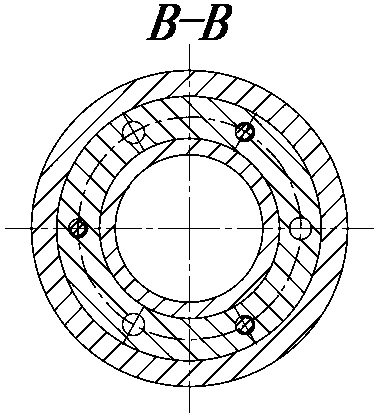

Novel sliding sleeve tool for achieving opening without ball throwing pressure control

ActiveCN107035341AStable injection pressureWell/borehole valve arrangementsSealing/packingPistonLiquid pressure

The invention discloses a downhole tool for achieving automatic opening and closing of a sliding sleeve by using liquid pressure and the tool is applied in the fields of petroleum development and the like. The technical scheme is as follows: an upper connector, an outer shell and a lower connector are connected through threads in sequence, the upper end of a central pipe is in threaded connection with the upper connector, the lower end of the central pipe is pressed tightly by the lower connector, a starting piston connector is located between the central pipe and the outer shell and connected with the central pipe through a positioning bolt, axial-direction positioning and circumference-direction positioning of the starting piston connector are achieved, a switch piston is located between the starting piston connector and a spring retainer ring and connected with the central pipe through a track pin A, positioning of the switch piston is achieved, a positioning spring achieves positioning through a spring clamping base and the spring retainer ring, the spring clamping base is located between the lower connector and the positioning spring, and axial-direction positioning of the spring clamping base is achieved through the lower connector. The tool can be used for well washing, water injection and fracturing in the oil drilling process.

Owner:YANGZHOU CHUANGQUN NETWORK TECH CO LTD

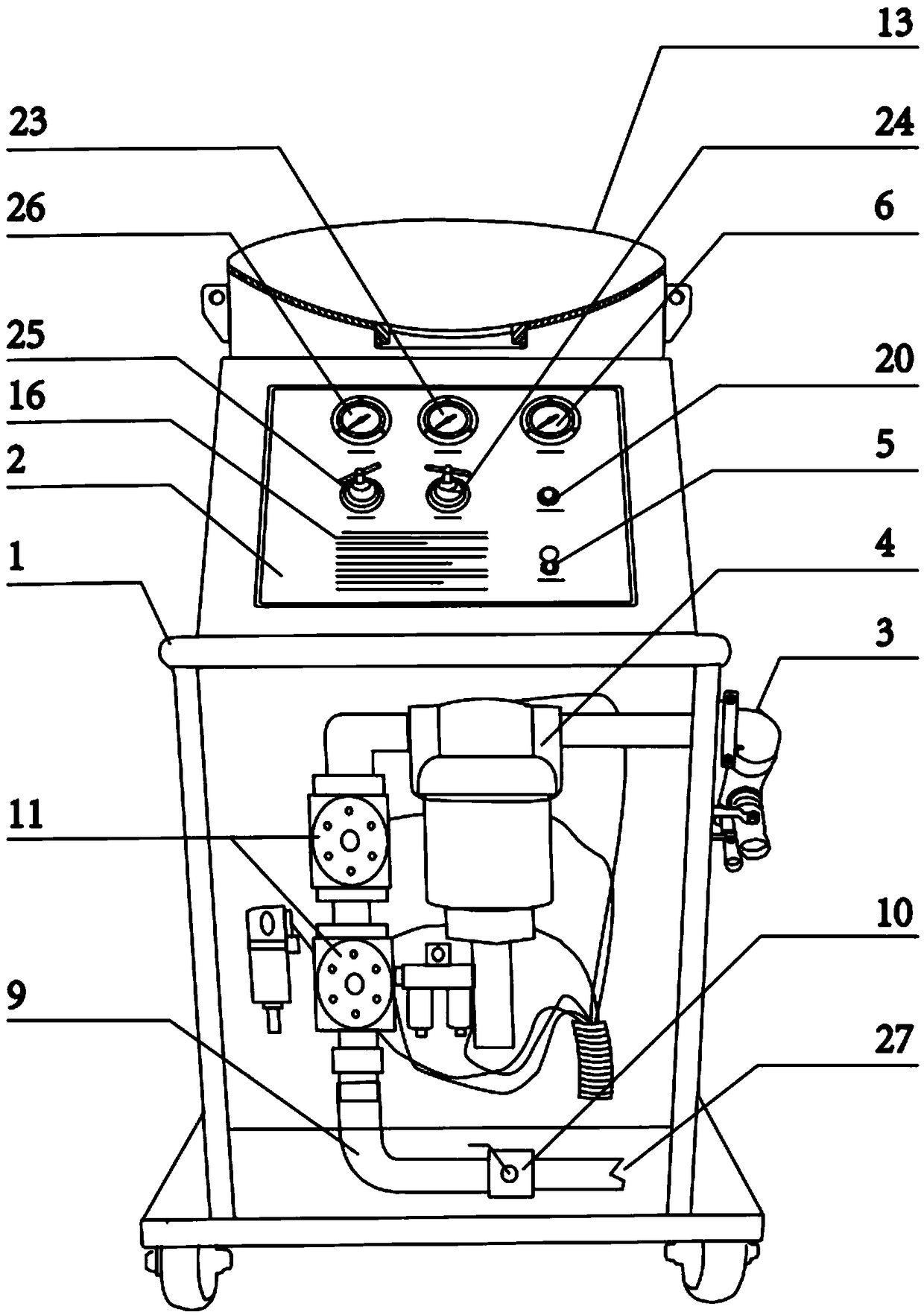

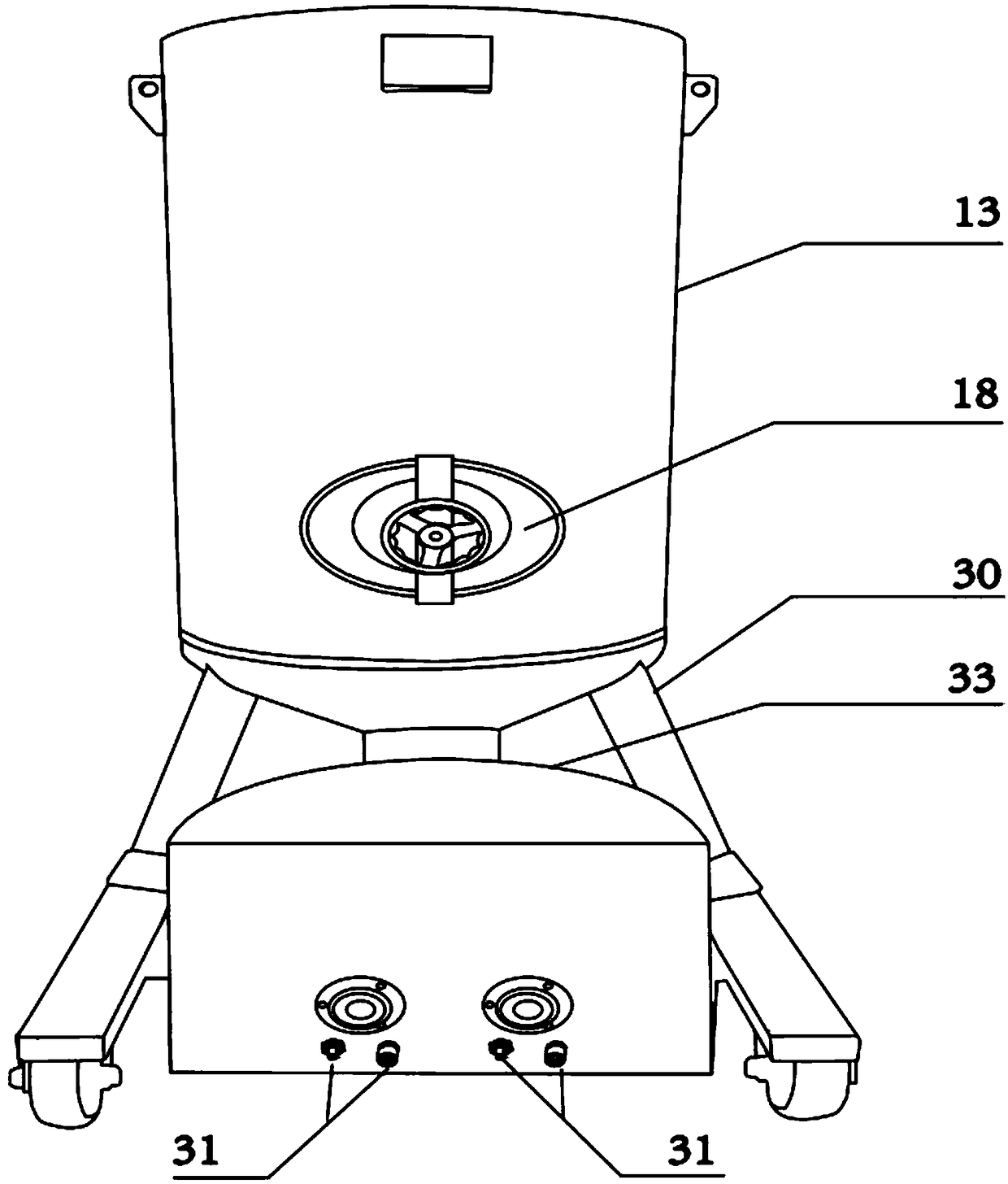

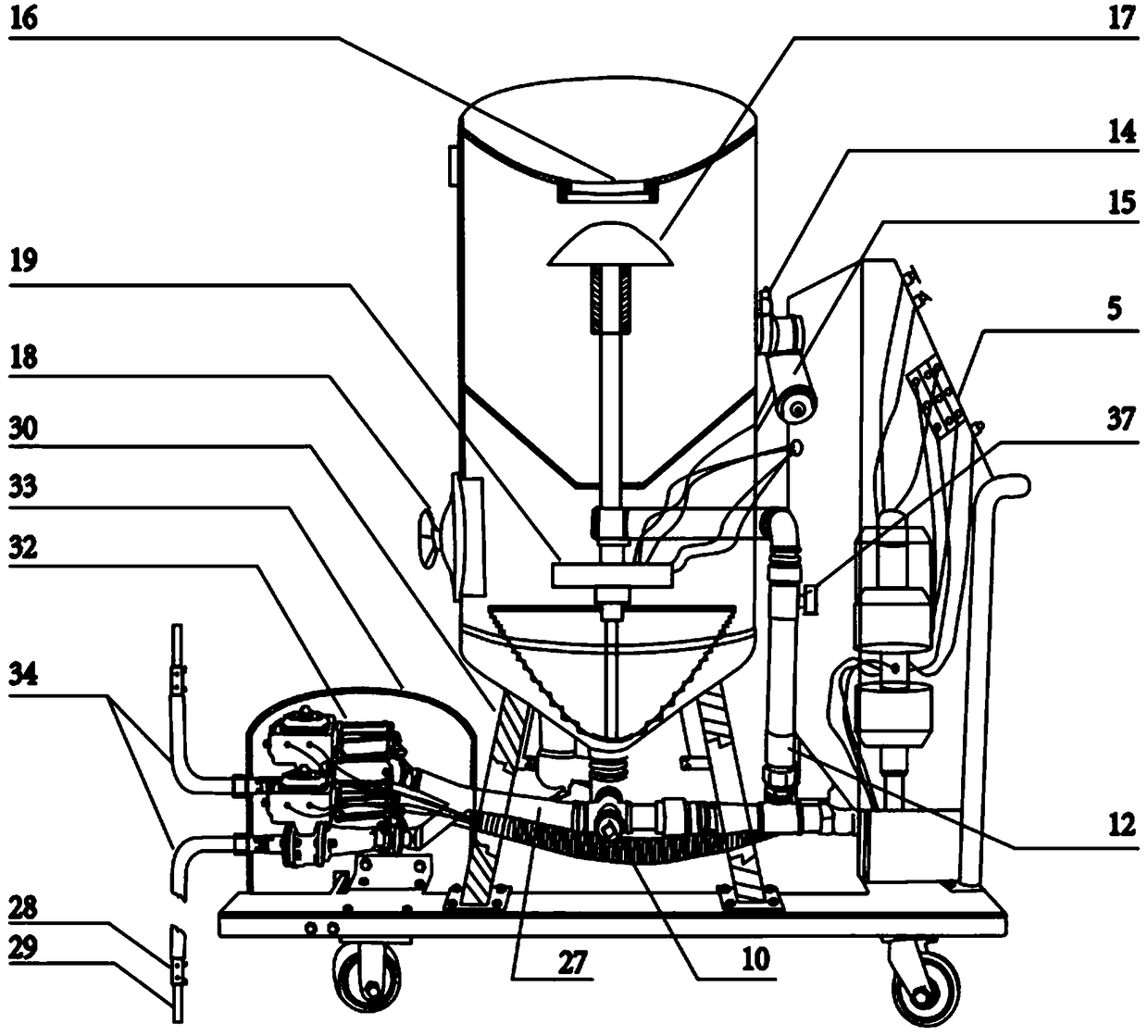

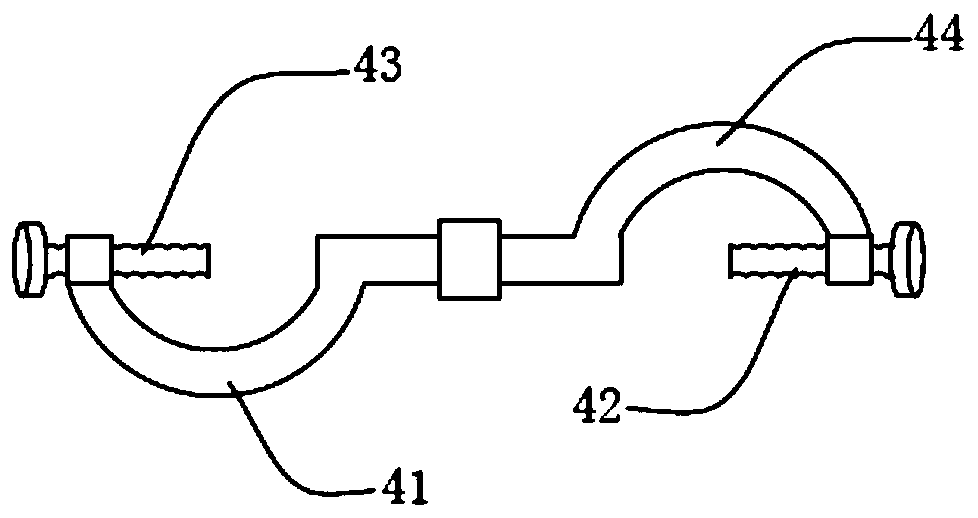

All-pneumatic sand blasting machine with multiple sand blasting guns

PendingCN108789169AReduce generationPromote generationBlast gunsAbrasive feedersSand blastingAir filter

The invention discloses an all-pneumatic sand blasting machine with multiple sand blasting guns, and relates to the field of surface processing. The all-pneumatic sand blasting machine with the multiple sand blasting guns comprises a machine body and an equipment operation table; the machine body is provided with a gas source external connector which is connected with an air filter; the air filteris connected with an equipment pressure main meter, a pneumatic valve, a jet pressure controller, a reducing valve, a pneumatic valve and a pipeline; a sand cylinder is arranged in front of the machine body; a feeder is arranged at the bottom of the sand cylinder and connected with a multi-sand-blasting-gun adjusting linkage device through a sand output pipeline; a sand distribution device of themulti-sand-blasting-gun adjusting linkage device is connected with a sand outlet; and the sand outlet is connected with the multiple sand blasting gun. A gas path which is designed and optimized by using polymeric sponge abrasive materials as blast rust removing materials is used and matched with the multi-sand-blasting-gun adjusting linkage device, the effect that the sand blasting machine is used synchronously and asynchronously, and the sand blasting guns are independent is achieved, use is convenient and efficient, the mechanical potential of the sand blasting machine can be greatly improved, the mechanical cost is reduced, and the work efficiency is high.

Owner:万卓均

Spray component

ActiveCN107638979AEasy to cleanHelp boostWater resource protectionSpraying apparatusInjection pressureInterference fit

The invention discloses a spray component which comprises a spray pipe and a spray head. The spray pipe and the spray head are connected through a leak-proof connector therebetween, and water flow channel communicated with the spray pipe and the spray head is arranged in the leak-proof connector; a plurality of water outlets are formed in the spray pipe, the leak-proof connector is mounted on thewater outlets in interference fit connection, the spray head is mounted on the leak-proof connector in interference fit connection, and cleaning water flows into the spray head from the spray pipe viathe lead-proof connector and is then sprayed out via the spray head. The non-metallic, elastic and easy-assembling leak-proof connector is additionally arranged between the spray pipe and the spray head which are of stainless steel metal materials, the spray pipe and the spray head are connected in a interference and sealing manner, and the problem about water leakage is effectively avoided; whenproblems like plugging of a spray system occur, maintenance and dismounting are facilitated, leakproofness is still good when the spray system is mounted once more, stable injection pressure of the cleaning water is guaranteed, and cleaning effect of cleaning targets is improved.

Owner:江苏欧倍力洗碗设备制造有限公司

Mold applied to production process of automotive interior parts

InactiveCN102431132ASmooth dischargeGuaranteed Design PerformancePulp and paper industryAtmospheric pressure

The invention discloses a mold applied to a production process of automotive interior parts. An exhaust hole is arranged on the mold, the exhaust hole is connected with an exhaust pipeline, and the pressure in the exhaust pipeline is smaller than the atmospheric pressure; and the exhaust pipeline is connected with a vacuum pump. The mold disclosed by the invention further has the characteristics of low manufacturing cost, obvious exhaust effect, long service life and the like. After the exhaust structure uses the vacuum pump to exhaust, the blockage phenomenon of an exhaust slot is further relieved, the injection molding pressure can be relatively smooth, an important role is played in stabilizing the quality of injection-molded products and reducing the scrappage of the products and the cost is further reduced.

Owner:芜湖跃兴汽车饰件有限公司

A kind of fuel supply system and method used in shock tunnel super-combustion engine inlet test

ActiveCN108398272BSolve the problem of incoming flow timing controlStable injection pressureGas-turbine engine testingAerodynamic testingSequence controlShock wave

The invention relates to a fuel supply system and method for a shock tunnel scramjet engine air intake test and belongs to the hypersonic velocity shock tunnel test technical field. According to the fuel supply system and method of the invention, with the reasonable matching of pipelines and the coordinated matching of a jet flow high-speed valve and the software and hardware of a control system adopted, a shock tunnel fuel supply and tunnel incoming flow time sequence control problem can be solved; a buffer tank and a pressure stabilizing chamber are built in a test section, and therefore, the linear loss of an air supply pipeline can be decreased, the injection pressure of fuel can be more stable; and the opening time of valves is set through the control system, and therefore, the amountof hydrogen of an injection test section can be strictly controlled, and the safety of the test can be ensured.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

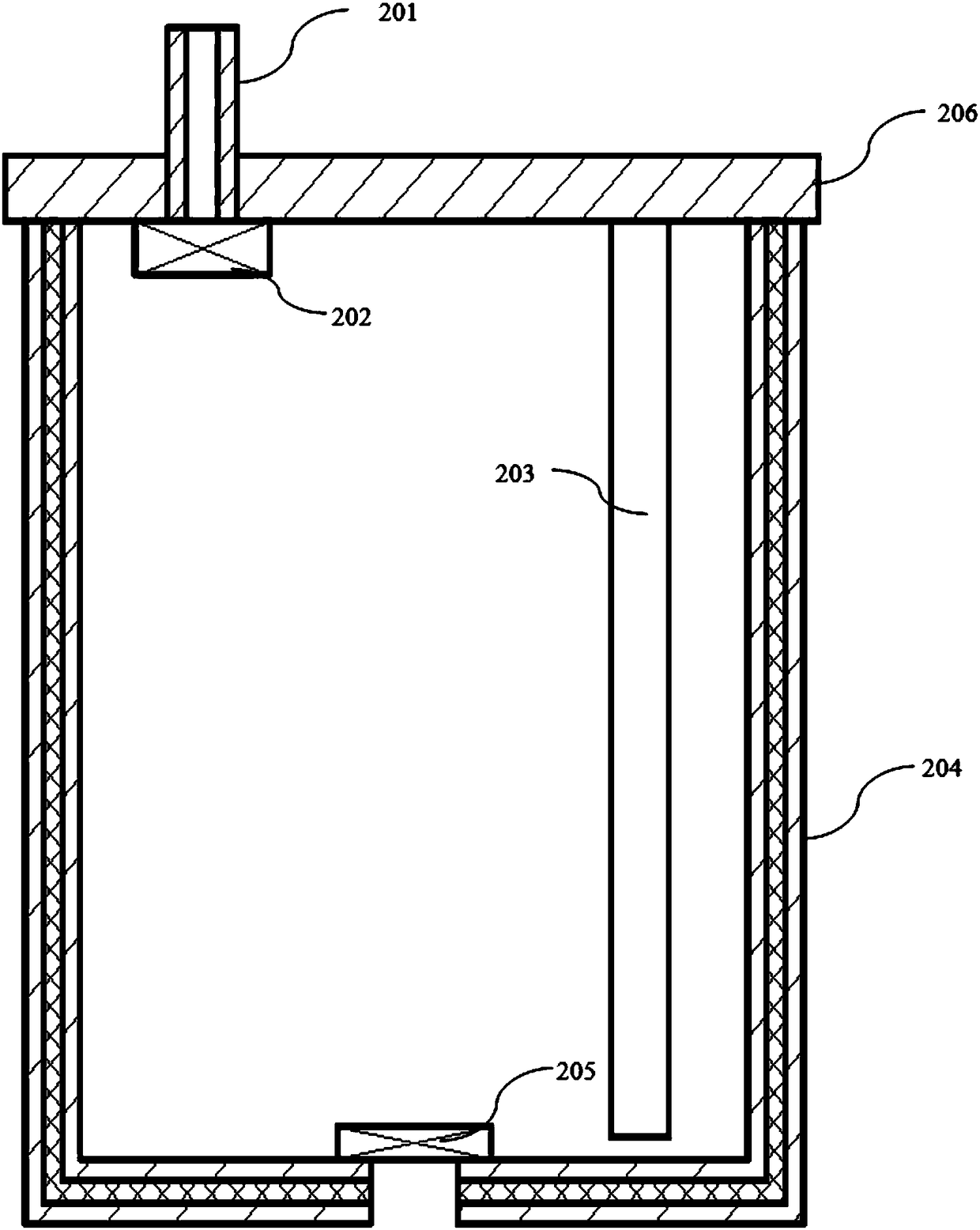

A water-system air-push fire extinguishing method and device

ActiveCN110368617BLong storage timeStable injection pressureFire rescueChemical storageProcess engineering

The invention discloses a water-based gas-push fire extinguishing method and device, which belong to the field of fire-fighting technology. The specific technical solution is to encapsulate the water-based fire extinguishing agent in a chemical storage chamber and isolate it from the gas-generating chamber filled with the gas-generating agent. The medicament storage chamber is at the gas outlet end of the gas generating chamber. After the gas generating agent is ignited, it gathers in the buffer chamber. The high-pressure airflow enters the chemical storage chamber to heat up part of the water-based fire extinguishing agent to vaporize and spontaneously pressurize. At the same time, the high-pressure airflow generated by the gas-generating agent acts as the power source of the fire extinguishing agent to push the fire extinguishing agent to spray outwards, and spray the fire to the fire site. The fire extinguishing method and device of the present invention are safe in use, simple in structure, convenient to carry and transport, have high fire extinguishing efficiency, and have little environmental pollution.

Owner:西安尚泰安全技术有限责任公司

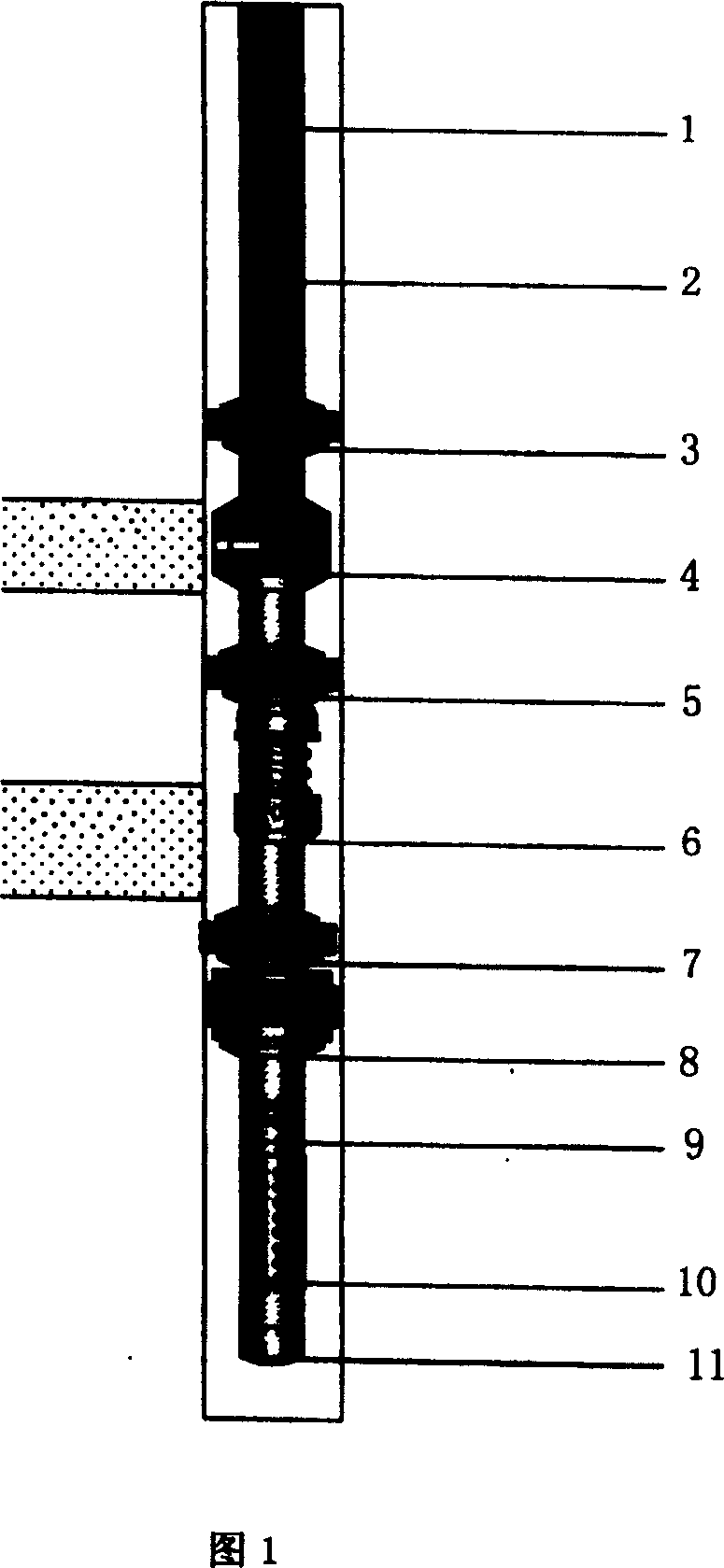

Separate layer gas injection tube pile

InactiveCN100343480CEffective stratified gas injectionAccurate Layered Gas InjectionFluid removalWater floodingCheck valve

The invention discloses a layered air injection tubular column, comprising outer tube, inner tube, channeled packer, balancing packer, safety injection valve, well washing packer, supporting fastening tile, circulating valve, sieve tube, and thread stopper, and also comprising a flow dividing check valve connected between the channeled packer and balancing packer, where the outer tube is connected to the channeled packer, the inner tube passes through the channeled packer and arranged in the flow dividing check valve, the balancing packer, and the bottom of the balancing packer is in sequence connected with the safety injection valve, well washing packer, supporting fastening tile, circulating valve, sieve tube and thread stopper. The invention has effective and accurate layered injection function, corrosion-sustaining agent injection function, less operating load, and low cost, applied to air injection or water flooding process of petroleum recovery.

Owner:OIL EXTRACTION TECH INST OF SINOPEC SHENGLI OILFIELD

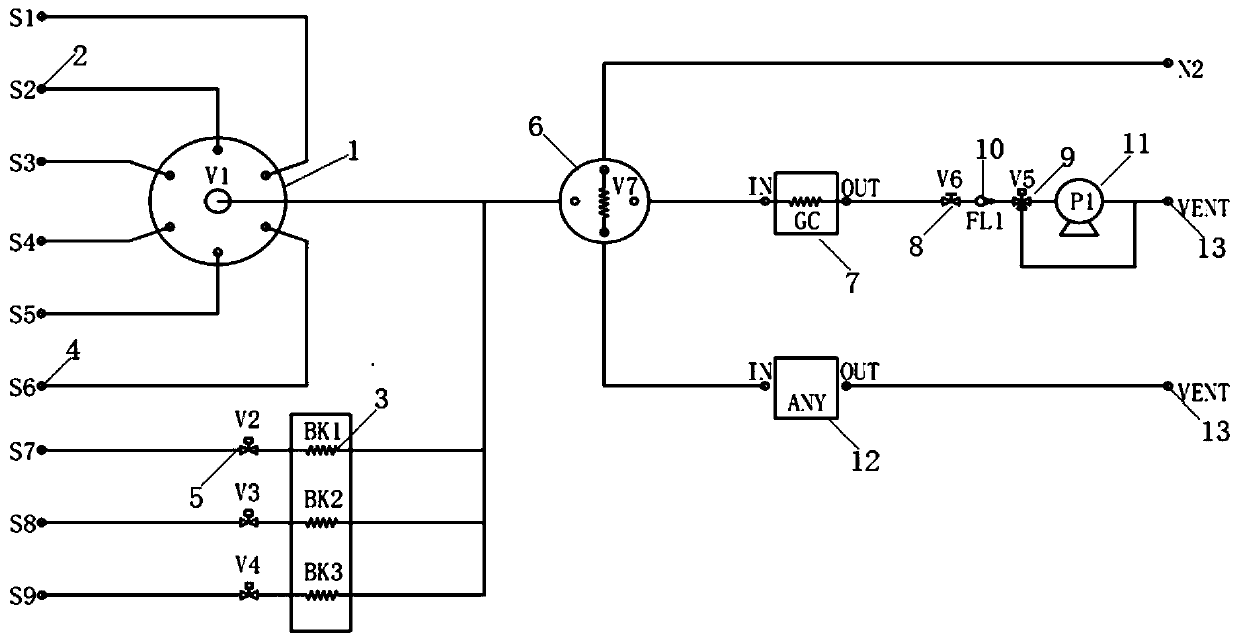

Polymorphic sample injection device

PendingCN110967423ASimple structureReduce the possibility of leaksComponent separationPhysicsElectromagnetic valve

The invention provides a polymorphic sample injection device. The polymorphic sample injection device comprises a six-way anti-adsorption sample injection valve, a plurality of channel capillary tubes, a quantitative switching valve, a chromatograph and an experimental analyzer, wherein six interfaces of the six-way anti-adsorption sample injection valve are communicated with six air bag sample injection port pagoda joints; the channel capillary tube is communicated with the steel cylinder sample inlet quick connector; a first interface of the quantitative switching valve is communicated withthe six-way anti-adsorption sample injection valve and the plurality of channel capillary tubes; the quantitative switching valve is connected with the chromatograph and the experimental analyzer. Thedevice is simple in structure, the three-way electromagnetic valve and the vacuum diaphragm pump are controlled by matching with the chromatograph, multi-channel gas bag full-automatic sample injection can be achieved, manual extrusion is not needed, and the leakage possibility during gas sample injection is reduced; 48 samples can be analyzed at most once in a full-automatic sample injection analysis process; by adopting constant-pressure constant-flow internal-drawing type sample injection, the leakage phenomenon in the sample injection process is completely eradicated, the stable sample injection pressure is ensured, and the accuracy and repeatability of analysis data are improved.

Owner:广州顺斡仪表科技有限公司

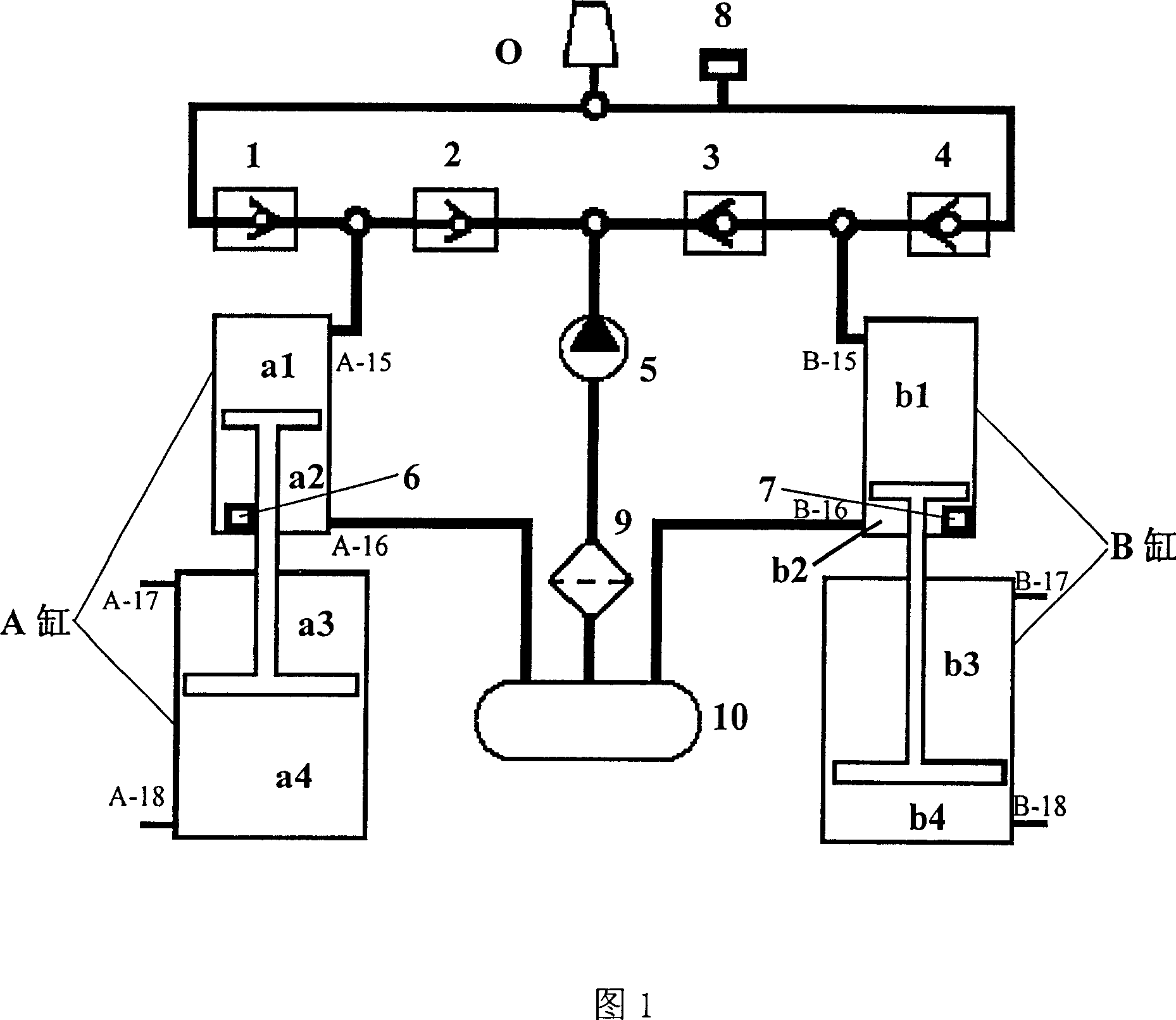

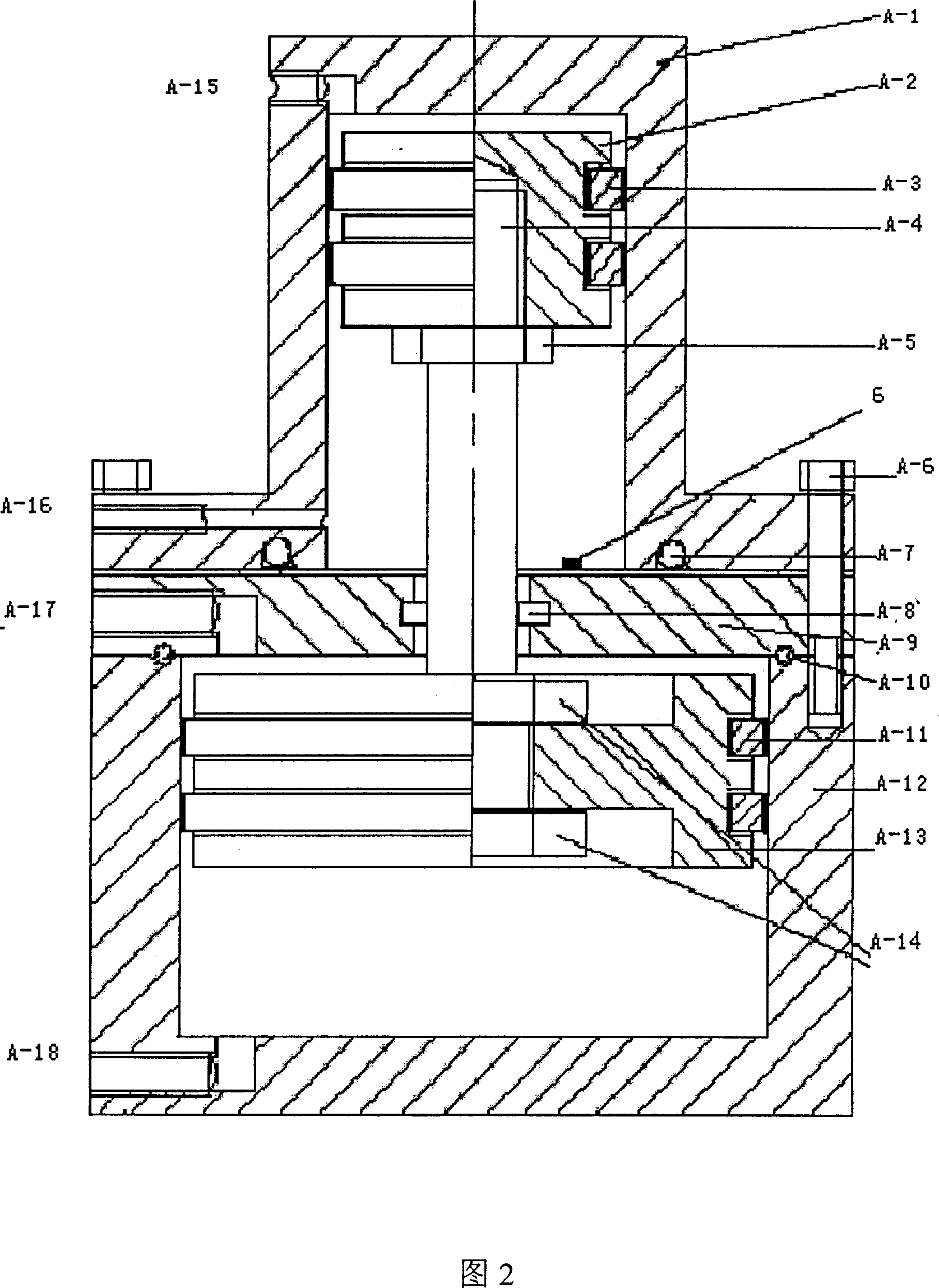

Fuel high pressure generator for oil supply system with direct jetting of liquefied petroleum gas/petrol in cylinder

InactiveCN100344868CEasy to achieve high pressure boostImprove reliabilityMachines/enginesLiquid fuel feedersGasoline direct injectionFuel tank

The high fuel pressure generator for oil supply system of directly jetting liquefied petroleum gas / petrol in cylinder includes fuel tank, fuel filter, fuel conveying pump, the first non-return valve, the second non-return valve, pressure sensor, the third non-return valve, the fourth non-return valve, and fuel pressure unit with cylinder A and cylinder B possessing fuel compressing cylinder position sensors. The present invention can realize high pressure of fuel easily, has no high speed moving part and raised system reliability and is suitable for pressurizing various kinds of liquid and gas fuel. It has two fuel compressing cylinders operating alternately to ensure stable fuel oil pressure without needing pressure accumulator.

Owner:ZHEJIANG UNIV

A kind of advanced immunization device for piglet pseudorabies in positive pig farm for medical use

ActiveCN110811906BTo achieve the effect of sterile dilution of liquid medicineStable injection pressureInfusion syringesMedical devicesPig farmsAnimal science

The invention relates to the technical field of porcine pseudorabies immunization, and discloses a device for advanced immunization against piglet pseudorabies in positive pig farms for medical use. Piston block, the surface of the piston block is fixedly connected with a pull rod, the inside of the pull rod is slidingly connected with a dilution rod, the inside of the piston block is fixedly connected with a negative pressure film, the bottom of the negative pressure film is movably connected with a rotating shaft, and the compression spring loses tension to pull the negative pressure film. The pressure film returns to its original state, and the rotating shaft rotates in the opposite direction, that is, the steering wheel moves on the surface of the rotating shaft toward the direction close to the needle. It penetrates into the piglet's body, but under the resistance of the pressure, it slowly moves downward, and injects the diluted medicinal liquid inside the shell into the piglet's body, thereby achieving the effect of stabilizing the injection pressure.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

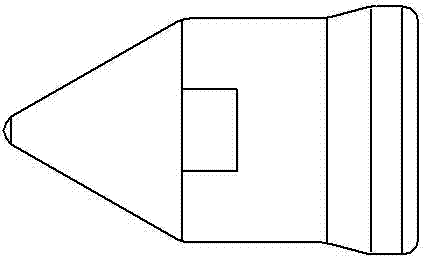

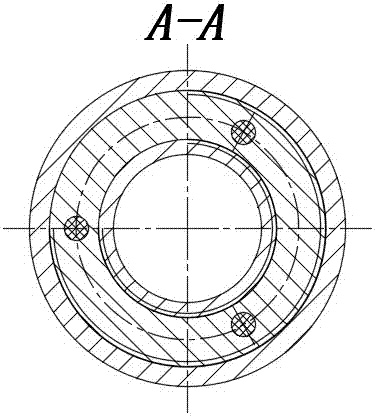

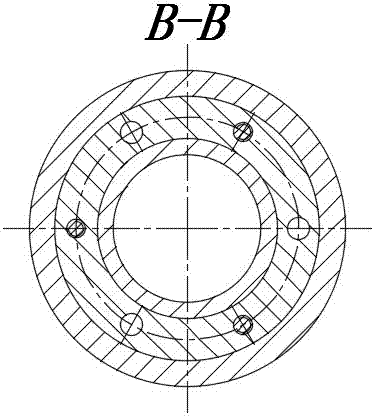

Multi-channel injection molding nozzle for fully plastic thread protector

The invention discloses a multi-channel injection molding nozzle for a fully plastic thread protector. The molding nozzle is used for an injection molding device for processing a thread protector of a steel pipe head. The molding nozzle comprises an ejector and an injection nozzle at the end of the ejector. The middles of the ejector and the injection nozzle form a through injection chamber. A material cavity is arranged between the injection chamber of the ejector and the outer wall of the ejector. A number of channels passing through the injection chamber are arranged in the material cavity. Through use of the channels, molten plastic enters the injection chamber through the channels so that the nozzle injection speed is uniform and injection molding pressure is stable.

Owner:天津市津英达塑料制品有限责任公司

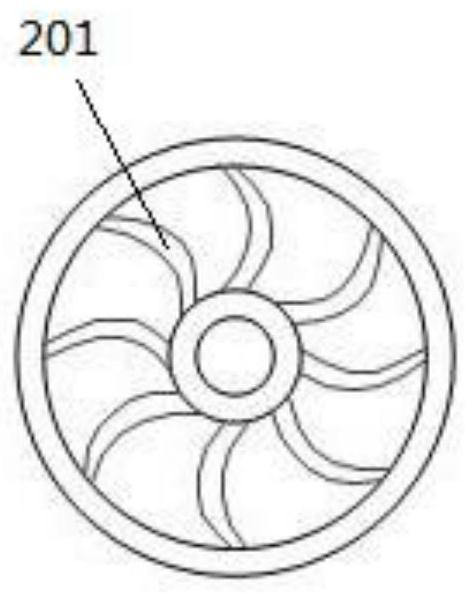

Differential pressure urea pump for aftertreatment of scr exhaust gas

ActiveCN105626205BAvoid cloggingImprove jetting accuracyInternal combustion piston enginesExhaust apparatusAfter treatmentDifferential pressure

A differential pressure type urea pump for SCR exhaust gas after-treatment comprises a urea box, a premixer and an air inlet and is characterized in that a heating unit is arranged in the urea box and heats reducing agents in the urea box, the urea box is connected to a liquid return solenoid valve through a liquid suction pipeline and a liquid return pipeline, the liquid return solenoid valve is connected to a pressure stabilizer, a filter core is arranged outside the pressure stabilizer, the pressure stabilizer is connected to a metering valve, the metering valve is connected to the premixer, the premixer is connected to a solenoid drive check valve, the solenoid drive check valve is connected to an air pressure adjuster, the rear part of the air pressure adjuster is connected to an air valve, the air valve is connected to a second hydraulic port of a strong-blowing solenoid valve through a pipeline, the rear part of the air valve is connected to the air inlet, and the strong-blowing solenoid valve and the premixer are connected to a nozzle simultaneously.

Owner:山东艾泰克环保科技股份有限公司

Anti-blockage device for air way of measurement unit of SCR system

ActiveCN105626210AControl congestionStable injection pressureExhaust apparatusSilencing apparatusDiaphragm pumpSolenoid valve

An anti-blockage device for an air way of a measurement unit of an SCR system comprises a urea box, a liquid inlet pipeline of the urea box is connected to a diaphragm pump, a liquid return pipeline of the urea box is connected to a liquid return solenoid valve, the liquid return solenoid valve is connected to a pressure stabilizer, the pressure stabilizer is connected to a measurement unit air valve, the measurement unit air valve is connected to a premixer, one end of the premixer is connected to a nozzle, the other end of the premixer is connected to a solenoid drive check valve, the solenoid drive check valve is connected to an air pressure adjuster, the air pressure adjuster is connected to an air valve, the air valve is connected to an air inlet, the air valve and the air pressure adjuster are connected to a strong-blowing solenoid valve, the strong-blowing solenoid valve is connected to the nozzle, an anti-blockage device body is connected between the measurement unit air valve and the premixer and is connected to a check valve piston for the premixer, a spring is arranged at the upper part of the check valve piston, a static iron core is arranged at the lower part of the check valve piston, solenoid coils are arranged outside the static iron core, and a fast mixing base body is arranged around the premixer and the check valve piston.

Owner:山东艾泰克环保科技股份有限公司

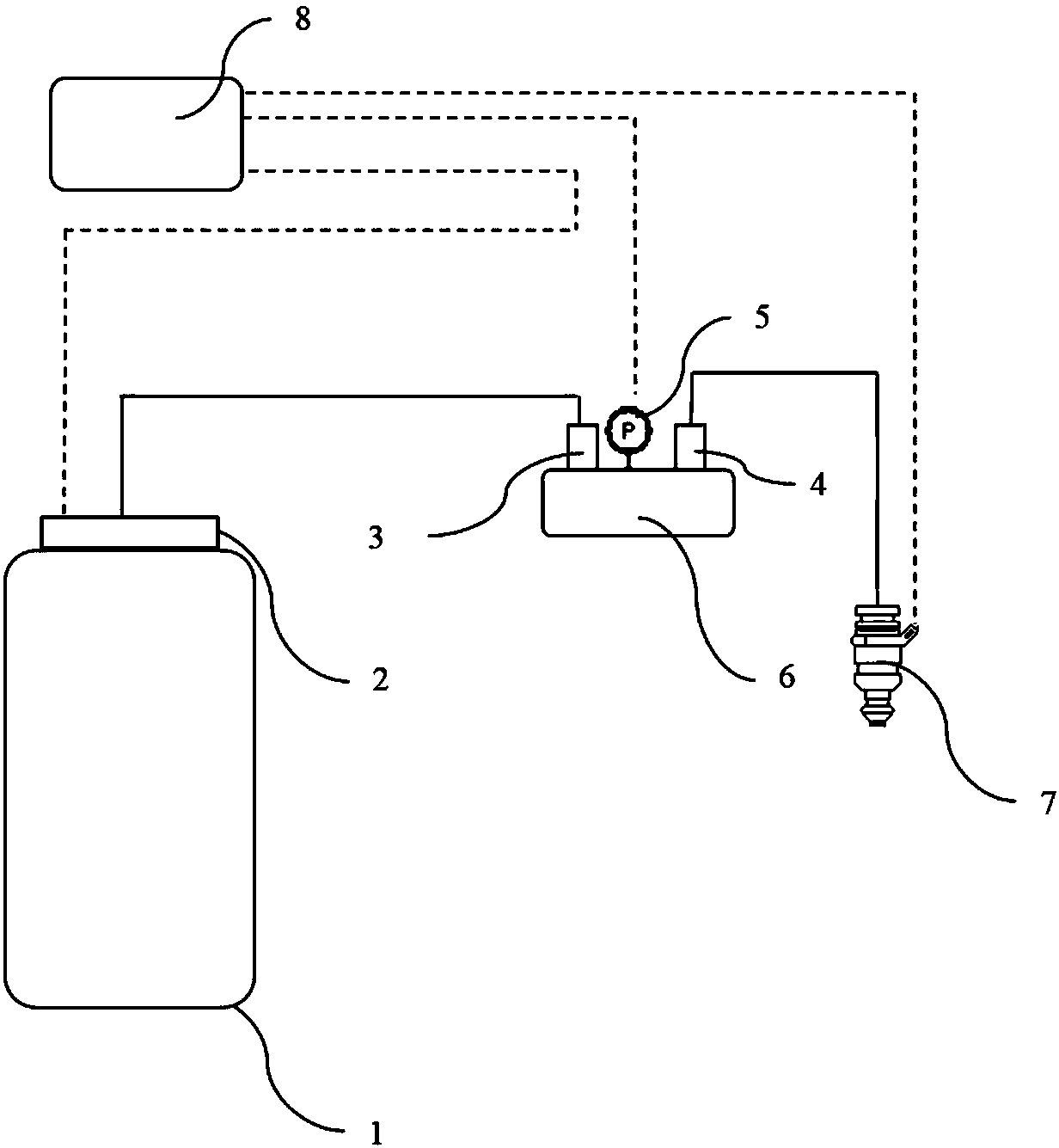

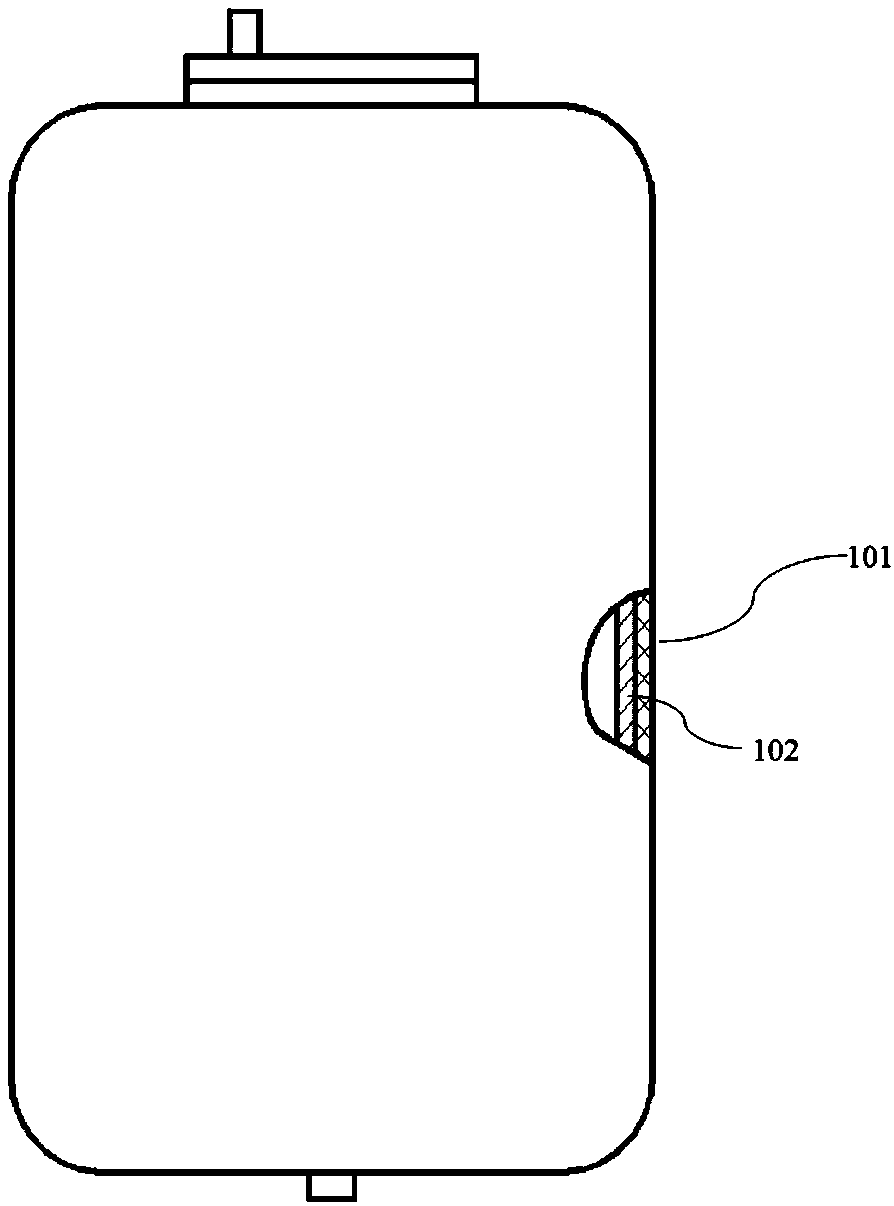

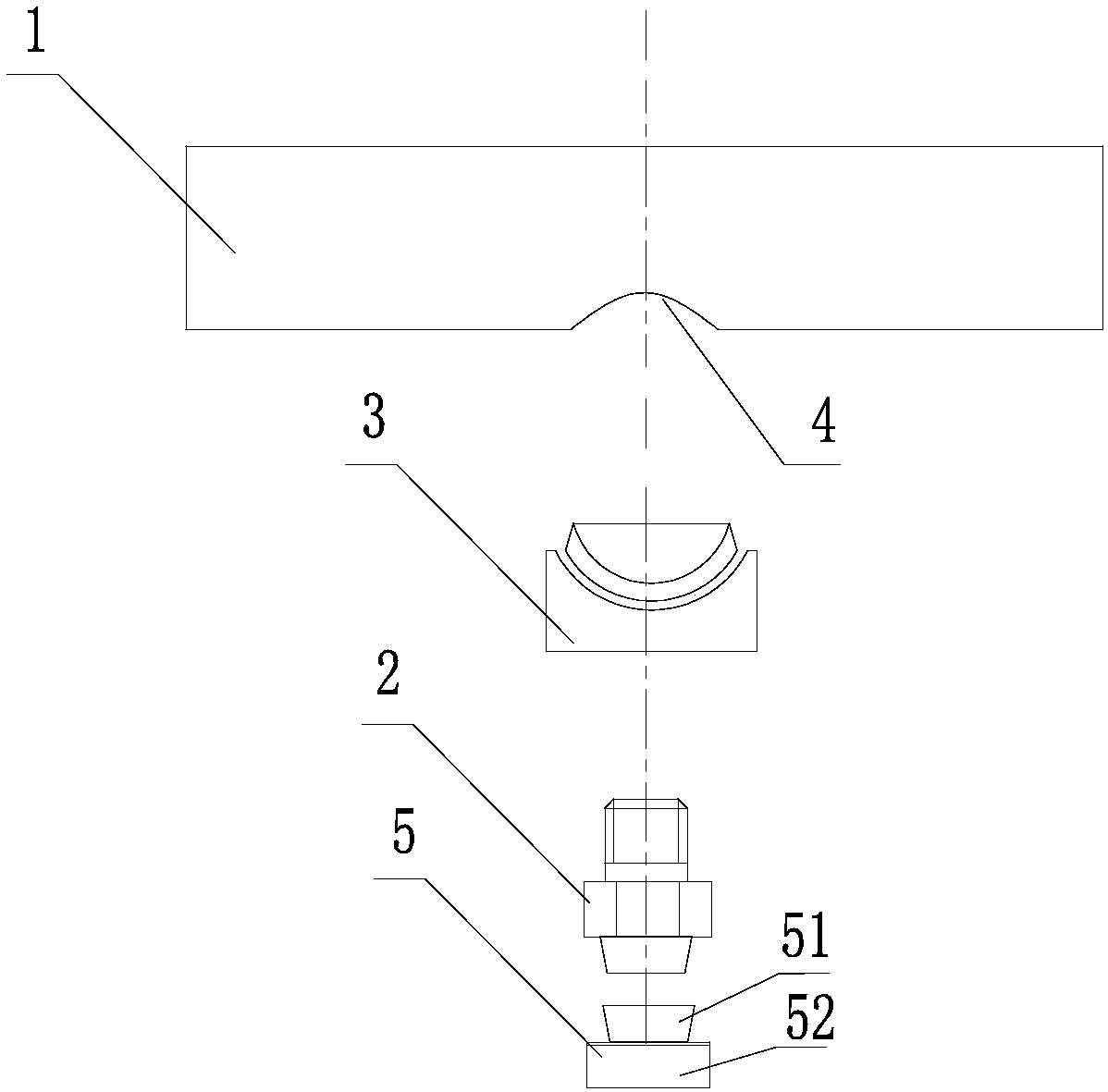

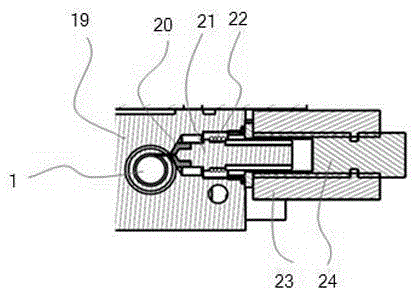

Angiography liquid, injection device and application of angiography liquid

PendingCN110031278AShort curing timeSpeed up the experiment processPreparing sample for investigationSmall branchBarium sulfate

The invention belongs to the technical field of angiography and relates to angiography liquid, an injection device and application of the angiography liquid. According to a weight ratio, the angiography liquid comprises liquid silica gel: dilute silicone oil: superfine barium sulfate powder: toner: curing agent: benzoic acid=2-6: 2-6: 1-3: 0.1-0.3: 0.05-0.1: 0.1-0.3. The injection device comprisesa base, wherein a connection pipe, an injection pipe, a pressure gage, a buffer gas cylinder and a pressurization device are connected with the base in sequence. The angiography liquid provided by the invention and blood are similar in viscosity. Curing time is reduced. Use is safe. An environment is not polluted. Health of a researcher is not damaged. When injection is carried out, small branches of a blood vessel are displayed clearly. The injection device provided by the invention is simple in structure and low in cost and is convenient for use. Pressure when the injection is carried out can be controlled precisely. After the injection is carried out, a blood vessel trunk and the small branches are guaranteed to be displayed clearly. Analysis and induction of blood vessel distributionare facilitated in a later period.

Owner:于大志

Air tightness rotating backblowing device for cloth bag dust remover

InactiveCN101279172BImprove cleanlinessExtended service lifeDispersed particle filtrationBaghouseButt joint

Owner:QINHUANGDAO QINGQING ENVIRONMENTAL PROTECTION EQUIP

Sliding tool for opening without pitching pressure control

ActiveCN107035341BStable injection pressureWell/borehole valve arrangementsSealing/packingOil drillingScrew thread

The invention discloses a downhole tool for achieving automatic opening and closing of a sliding sleeve by using liquid pressure and the tool is applied in the fields of petroleum development and the like. The technical scheme is as follows: an upper connector, an outer shell and a lower connector are connected through threads in sequence, the upper end of a central pipe is in threaded connection with the upper connector, the lower end of the central pipe is pressed tightly by the lower connector, a starting piston connector is located between the central pipe and the outer shell and connected with the central pipe through a positioning bolt, axial-direction positioning and circumference-direction positioning of the starting piston connector are achieved, a switch piston is located between the starting piston connector and a spring retainer ring and connected with the central pipe through a track pin A, positioning of the switch piston is achieved, a positioning spring achieves positioning through a spring clamping base and the spring retainer ring, the spring clamping base is located between the lower connector and the positioning spring, and axial-direction positioning of the spring clamping base is achieved through the lower connector. The tool can be used for well washing, water injection and fracturing in the oil drilling process.

Owner:扬州微声电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com