Anti-blockage device for air way of measurement unit of SCR system

A technology of SCR system and metering unit, which is applied in the direction of exhaust device, muffler device, engine components, etc., can solve the problems of low power of metering valve, blockage of air path, blockage of reducing agent, etc., and achieve stable injection pressure, high injection accuracy, Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

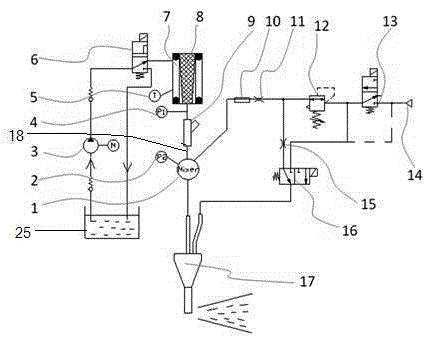

[0015] Embodiment 1, with reference to figure 1 , figure 2 , the anti-clogging device of the air circuit of the SCR system metering unit, including a urea tank 25, the liquid inlet line of the urea tank 25 is connected to the diaphragm pump 3, the liquid return line is connected to the liquid return solenoid valve 6, and the liquid return solenoid valve 6 is connected to A voltage stabilizer 8, the outside of which is provided with a filter element 7, the voltage stabilizer 8 is connected to the metering unit air valve 9, the metering unit air valve 9 is connected to the pre-mixer 1, and one end of the pre-mixer 1 is connected to There is a nozzle 17, and the other end of the mixer 1 is connected with an electromagnetically driven one-way valve 10, and the electromagnetically driven one-way valve 10 is connected with an air pressure regulator 12, and the air pressure regulator 12 is connected with an air valve 13, and the air The valve 13 is connected to the air inlet 14, an...

Embodiment 2

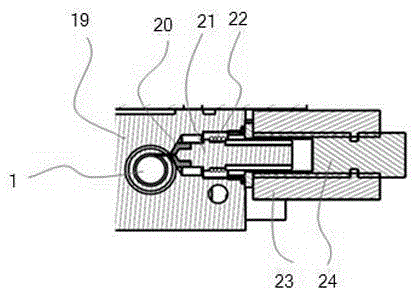

[0016] Embodiment 2, in the anti-clogging device of the air passage of the metering unit of the SCR system described in Embodiment 1: a sealing rubber 20 for sealing is provided between the pre-mixer and the piston 21 of the one-way valve.

Embodiment 3

[0017] Embodiment 3, in the anti-clogging device for the air passage of the metering unit of the SCR system described in Embodiment 1 or 2: the pre-mixer 1 is provided with a pressure sensor 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com