Patents

Literature

58results about How to "Improve jetting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

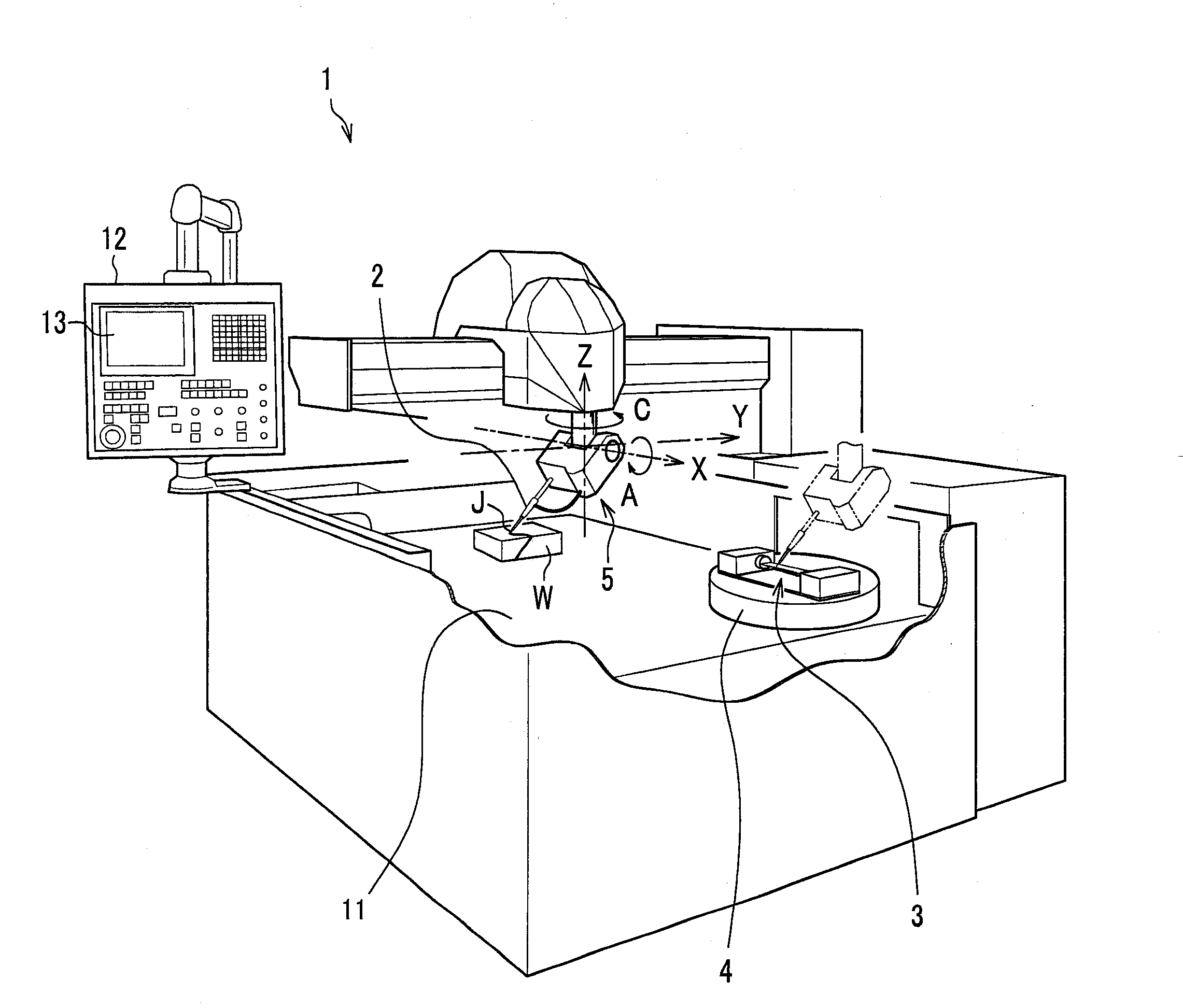

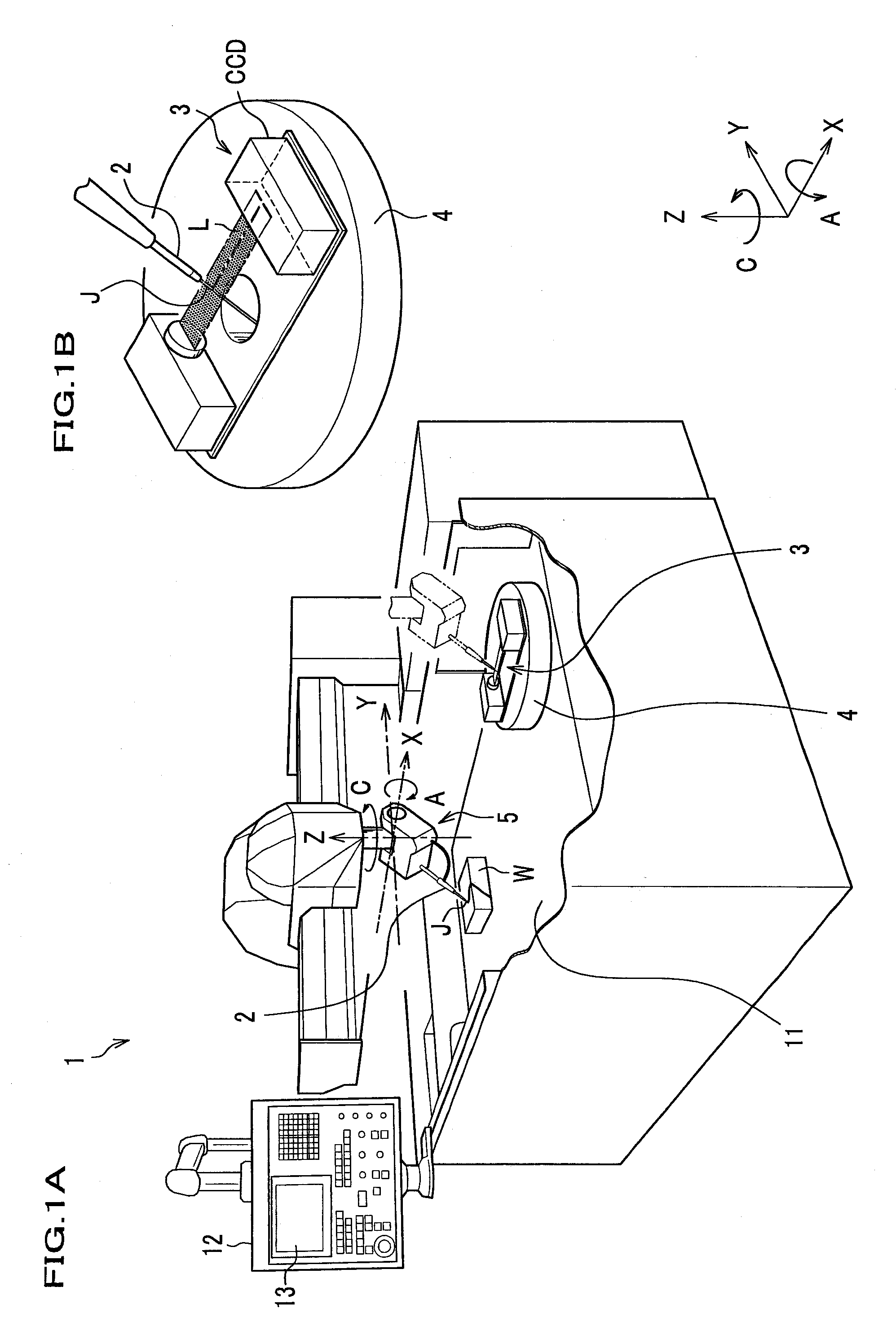

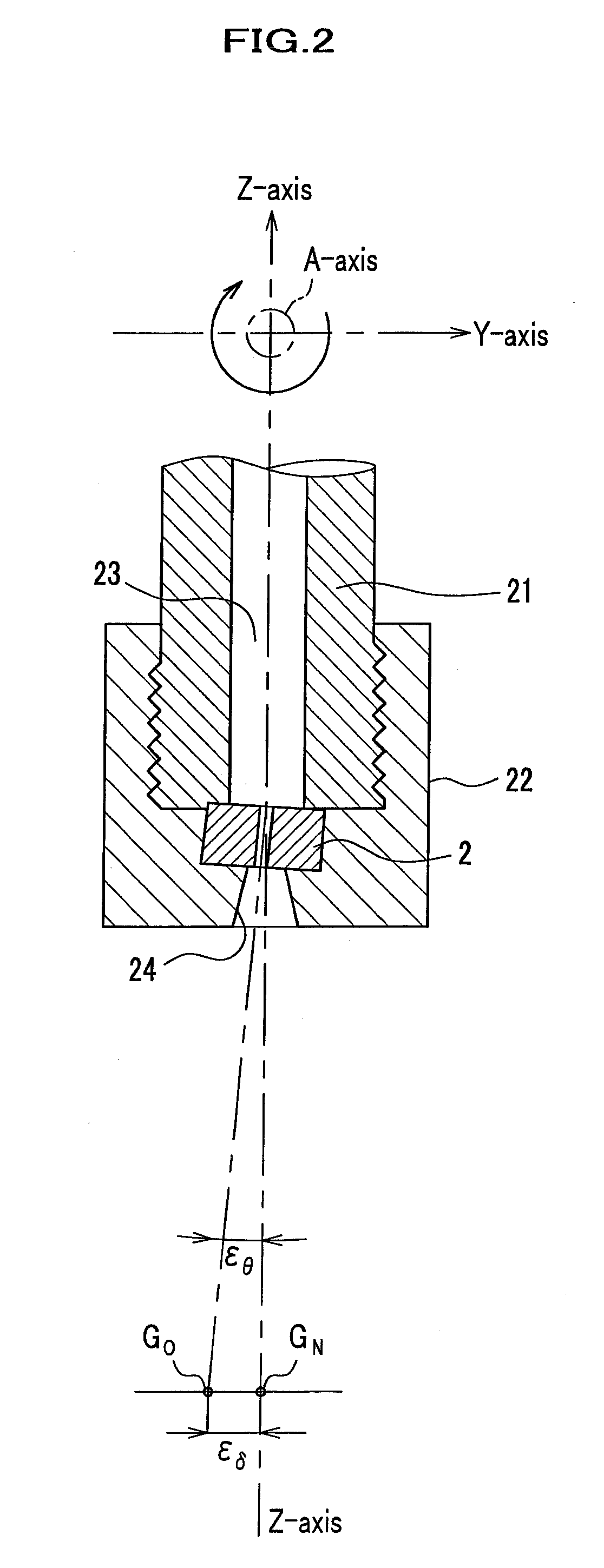

Jetting apparatus and origin correction method therefor

InactiveUS20090084235A1Improve jetting accuracyExclude influenceProgramme controlAutomatic control devicesHigh pressureComputer science

An origin correction method of matching a set processing top point with a machine top point of a high pressure jet in a jetting apparatus having a two-axis angle control for controlling tilt and -pivot angles other than a three-axis control consisting of X, Y, Z-axes includes: a jet radial-runout measurement process of measuring a position of the jet passing through an XY-plane; a jet radial-runout correction process of calculating an error at the processing top point and correcting radial runout of the jet; a jet top-point variation measurement process of changing the tilt angle and measuring two positions, where the jet passes through the XY-plane; and a jet top-point variation correction process of calculating an error at the processing top point from position data of the two positions and correcting a deviation of the processing top point.

Owner:SUGINO MACHINE

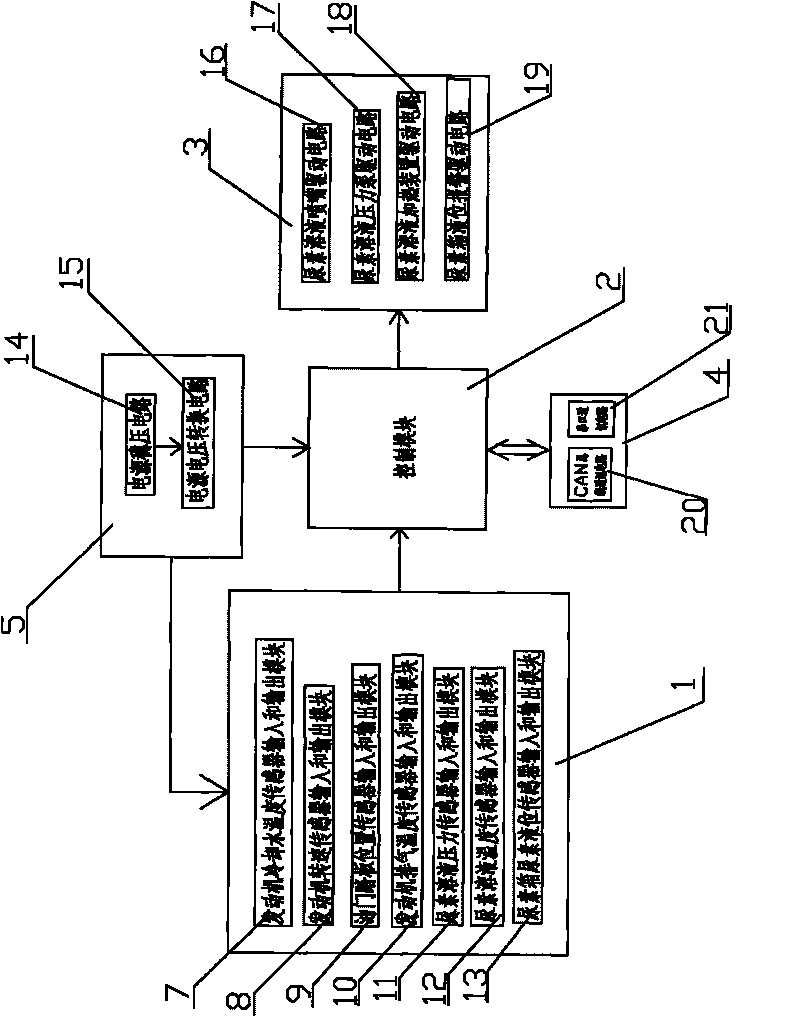

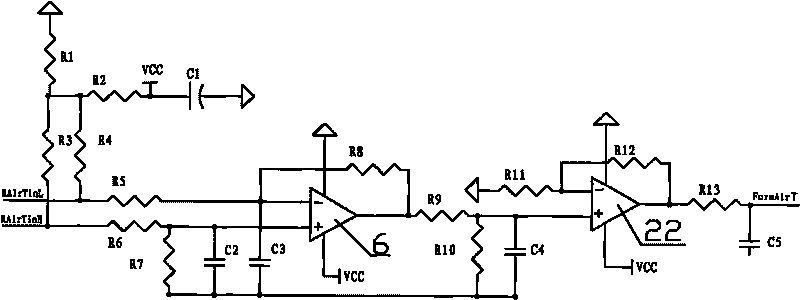

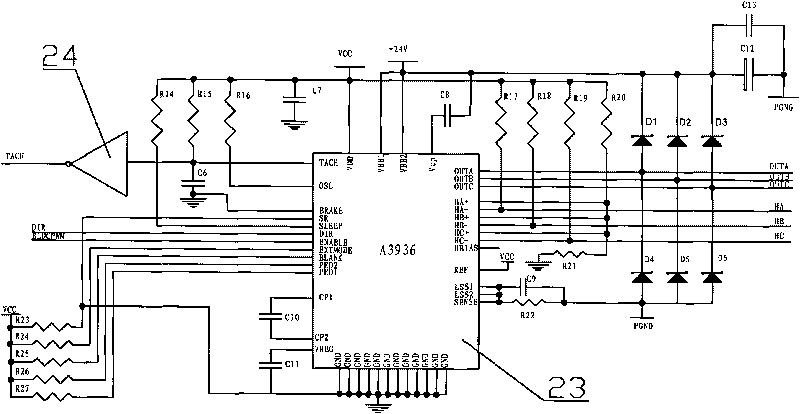

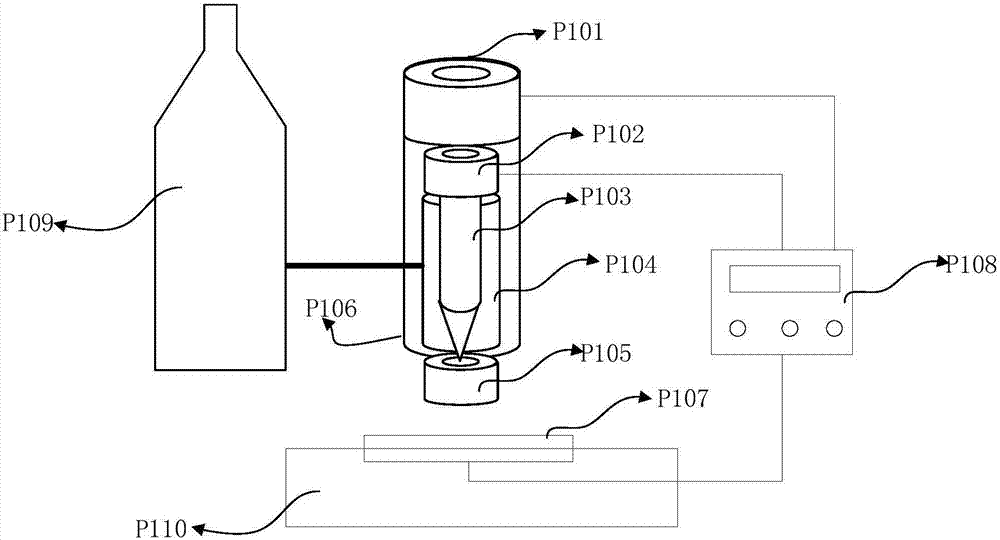

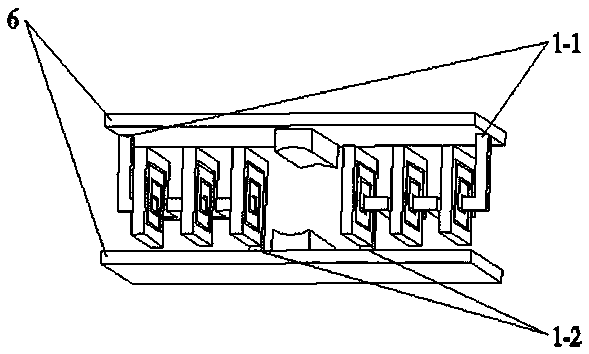

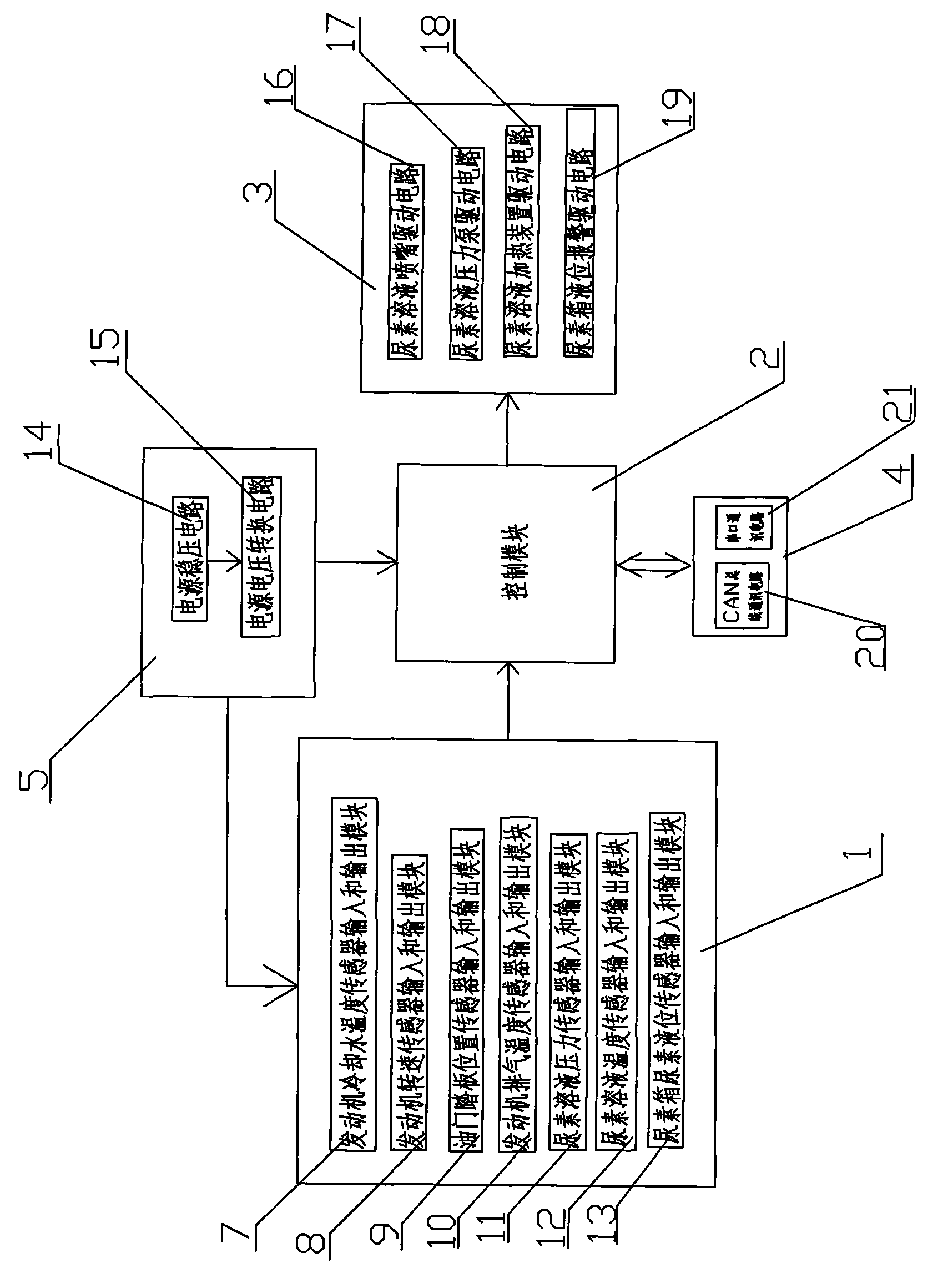

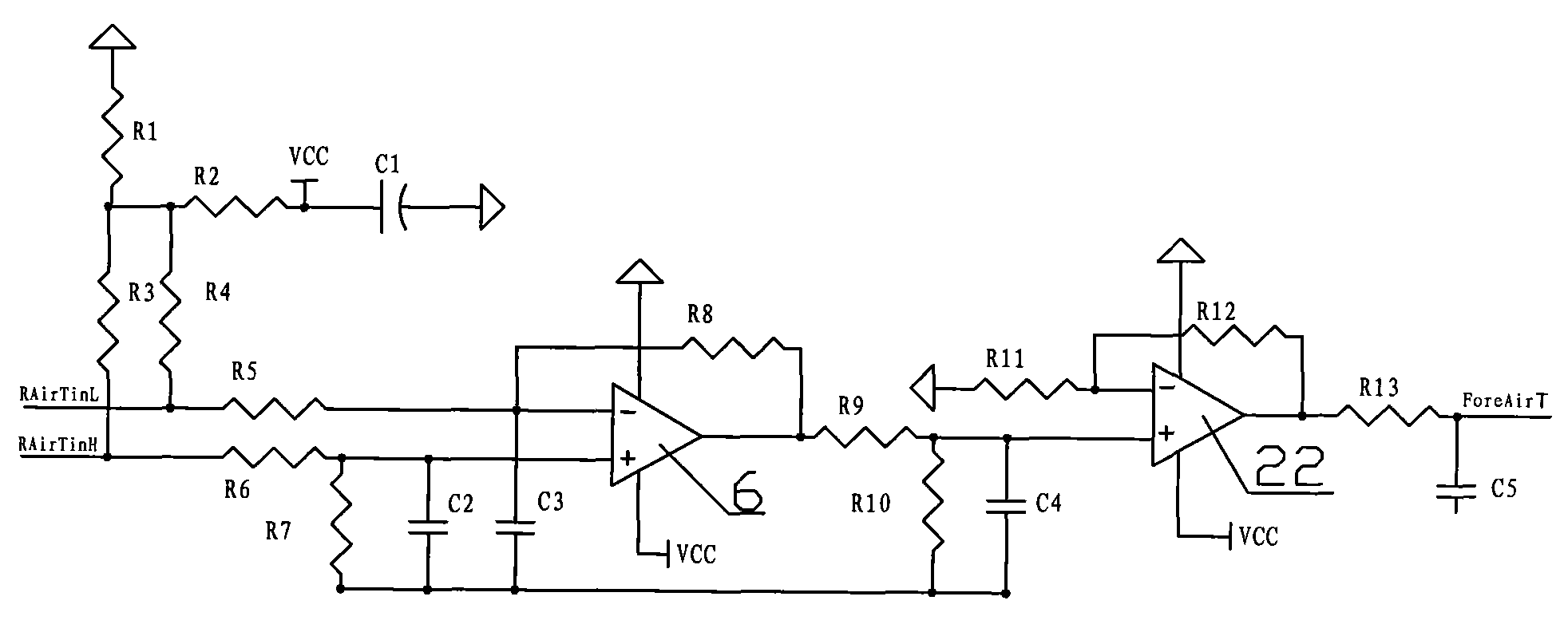

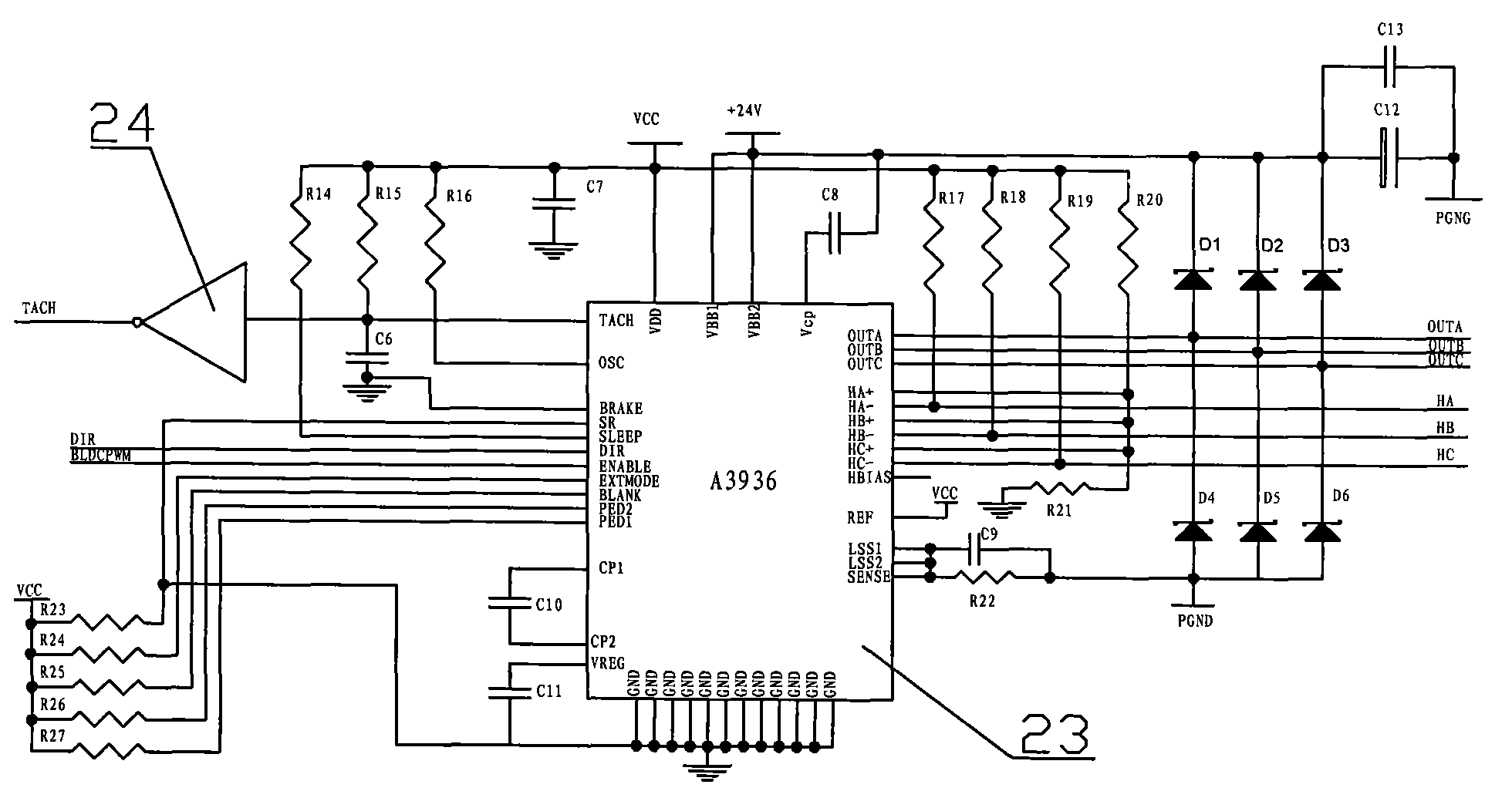

Urea solution spray electronic controller of selectively catalytic reduction system

ActiveCN101696649AImprove jetting accuracyStable pressureInternal combustion piston enginesExhaust apparatusDriver circuitElectronic controller

The invention relates to a controller, in particular to a urea solution spray electronic controller of a selectively catalytic reduction system. According to the technical scheme provided by the invention, the urea solution spray electronic controller of the selectively catalytic reduction system comprises a sensor module, a control module, an actuator drive module, a communication module and a power supply module, wherein the output end of the sensor module is connected with the input end of the control module; the output end of the control module is connected with the input ends of a urea solution nozzle driving circuit, a urea solution hydraulic pump driving circuit, a urea solution heating device and a urea tank liquid level alarm driving circuit in the actuator driving module; the output end of the power supply module is connected with the power supply ends of the control module and the sensor modules respectively; and the control module and the communication module are mutually connected. The controller can accurately control the spray amount of urea and has high spray accuracy and high adaptability.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

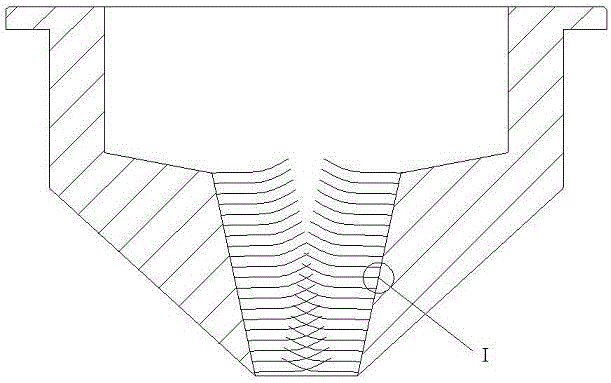

Low-pressure oil duct fuel injection valve

ActiveCN106762290AOptimizing the low pressure oil circuit systemImprove cooling effectFuel injection apparatusMachines/enginesVena contracta diameterCommon rail

The invention relates to a fuel injection valve which is particularly used for injecting high-pressure fuel from a high-pressure accumulation cavity into a diesel engine cylinder in a high-pressure common rail injection system of a diesel engine, and belongs to the technical field of engine fuel injection. The fuel injection valve comprises a control valve assembly, an electromagnet assembly, an electromagnet pressing cap, an electromagnet spring, a throttling orifice plate, a fuel injector body, a control piston and an ejector pin, wherein the throttling orifice plate is arranged in a throttling orifice plate chamber of the fuel injector body; the throttling orifice plate is located at the bottom of a control valve seat; a fuel injector body fuel return channel and a main fuel return hole which are staggered from each other are formed in the fuel injector body; and the upper end of the main fuel return hole is connected with the throttling orifice plate chamber. According to the fuel injection valve, a low-pressure fuel path system of the fuel injection valve is optimized; by a method of introducing static returned fuel with relatively low temperature to an electromagnetic actuator, the electromagnet assembly is effectively cooled; and meanwhile, by flowing of the returned fuel, a large quantity of harmful bubbles accumulated in an electromagnet and armature chamber can be brought out of the fuel injector body.

Owner:CHINA FIRST AUTOMOBILE

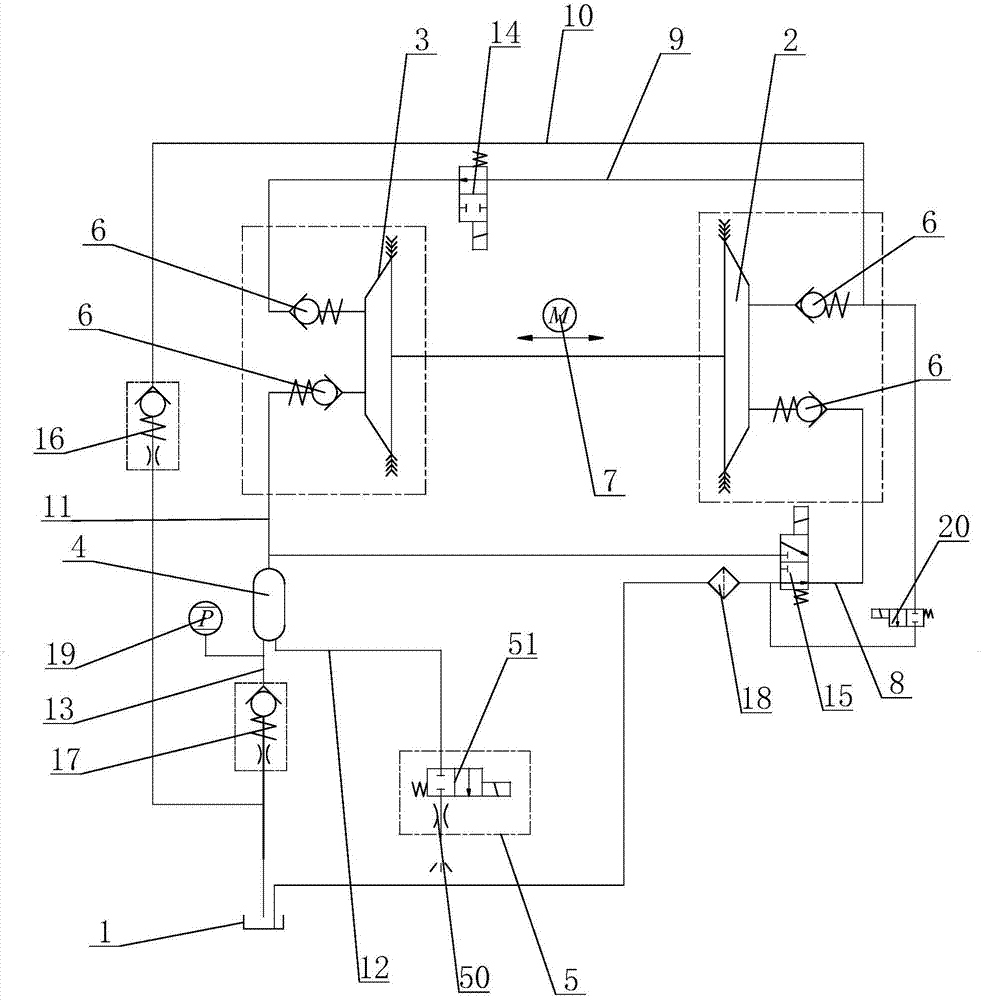

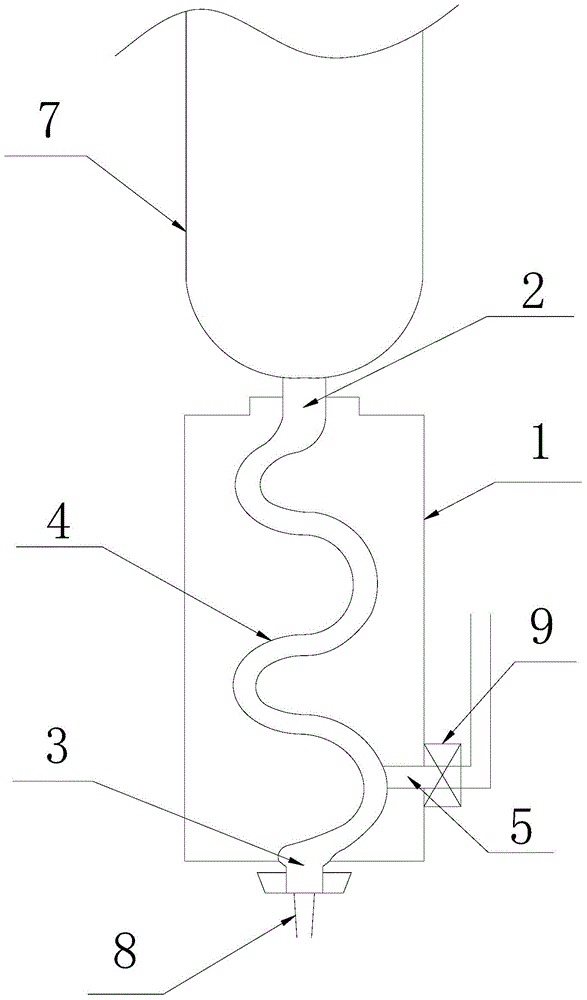

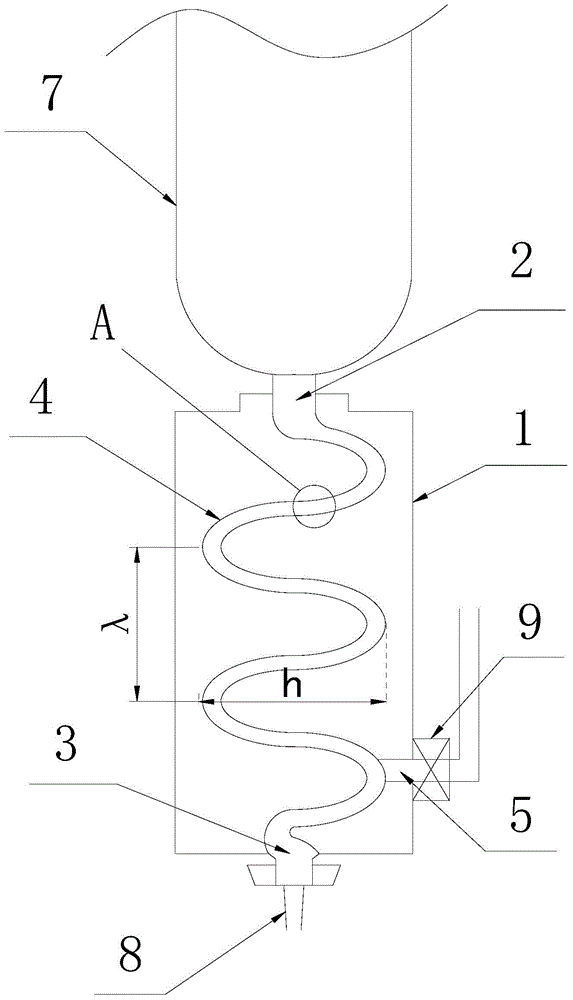

Urea solution supply system

ActiveCN107476860AImprove efficiencyEfficient use ofExhaust apparatusSilencing apparatusDiaphragm pumpEngineering

The invention discloses a urea solution supply system. The urea solution supply system comprises a urea box, a first diaphragm pump, a second diaphragm pump, an energy storage device and a nozzle module which are connected through pipelines, wherein the first diaphragm pump communicates with the urea box through a liquid inlet pipeline; the liquid outlet end of the liquid inlet pipeline is divided into two pipelines, one pipeline is connected with the liquid inlet end of the second diaphragm pump through a connecting pipeline, and the other pipeline communicates with the urea box through a backflow pipeline; the second diaphragm pump is connected with the liquid inlet end of the energy storage device through a first liquid outlet pipeline, the liquid outlet end of the energy storage device is divided into two pipelines, one pipeline is connected with the nozzle module, and the other pipeline communicates with the urea box through a third liquid outlet pipeline; and a reversing valve is mounted on the connecting pipeline, a primary backflow module is mounted on the backflow pipeline, and a second backflow module is mounted on the third liquid outlet pipeline. The urea solution supply system not only can prevent urea from crystallizing and blocking the pipelines, but also is stable in running and low in noise and improves jet precision.

Owner:HUST WUXI RES INST +1

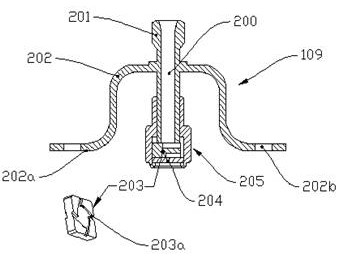

Swirl nozzle for treatment after exhaust of engine

ActiveCN105332768AGood atomization qualitySimple system structureExhaust apparatusSilencing apparatusNozzleMechanics

A swirl nozzle for treatment after exhaust of an engine comprises a nozzle body, a swirl chamber located in the nozzle body and a spraying hole located in the center of the swirl chamber, further comprises at least one tangential flow way, and is characterized in that the flow area of the tangential flow way is smaller than or equal to the flow area of the spraying hole. According to the nozzle, the nozzle is not prone to being blocked, reliable and stable in work, good in atomization quality, high in spraying precision, and more even in distribution of sprayed liquid, and is used for an SCR system and a DPF system.

Owner:福爱电子(贵州)有限公司

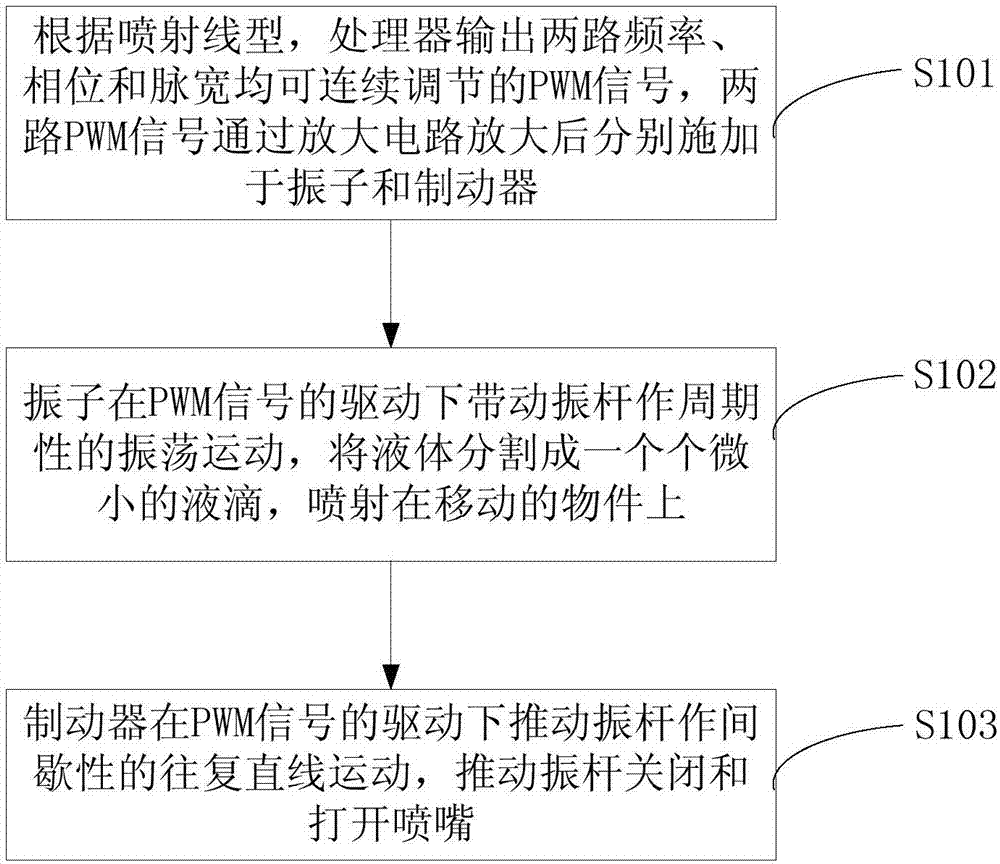

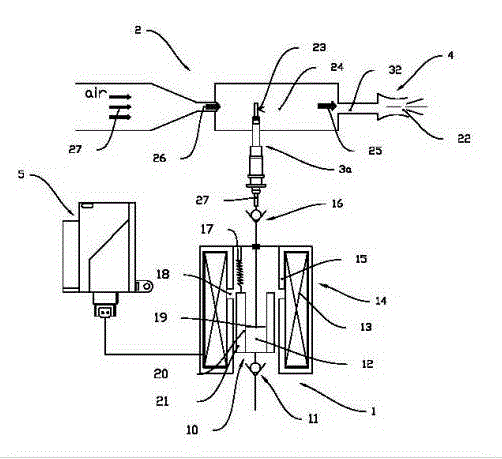

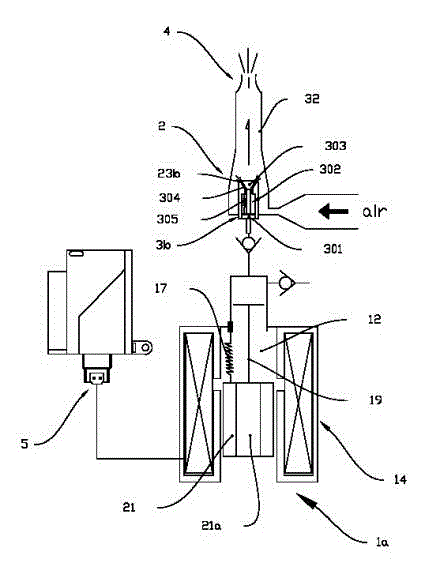

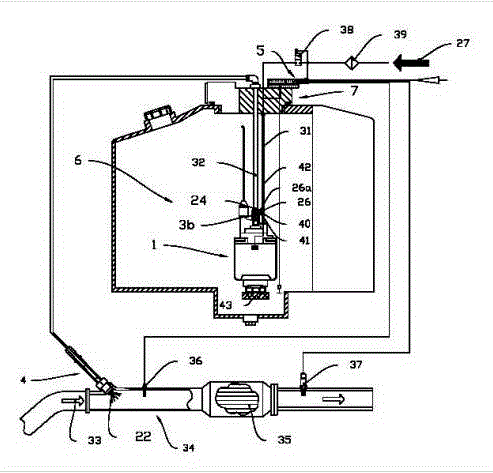

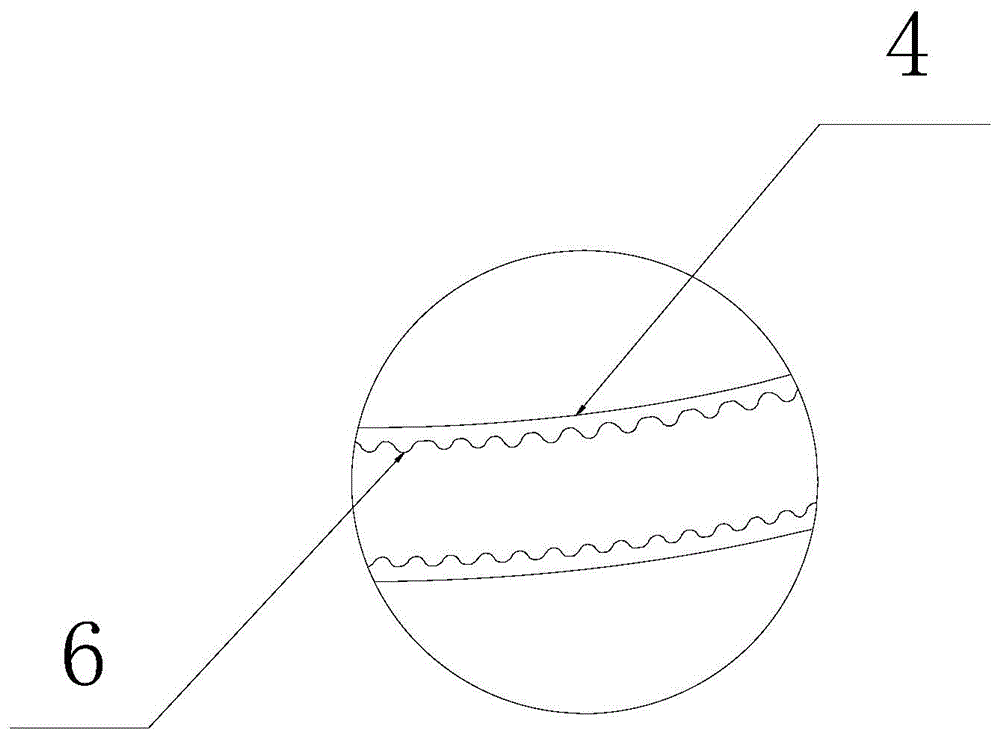

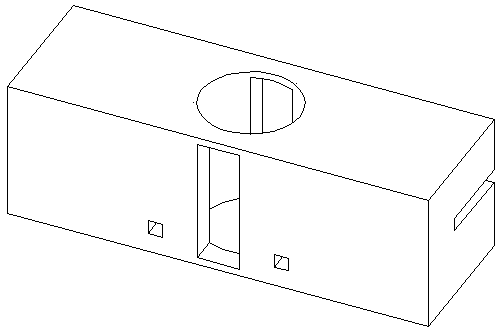

Micro drop jetting method and device

ActiveCN107138337APrevent sprayingSolve the problem of ejecting extra dropletsLiquid spraying apparatusEngineeringPwm signals

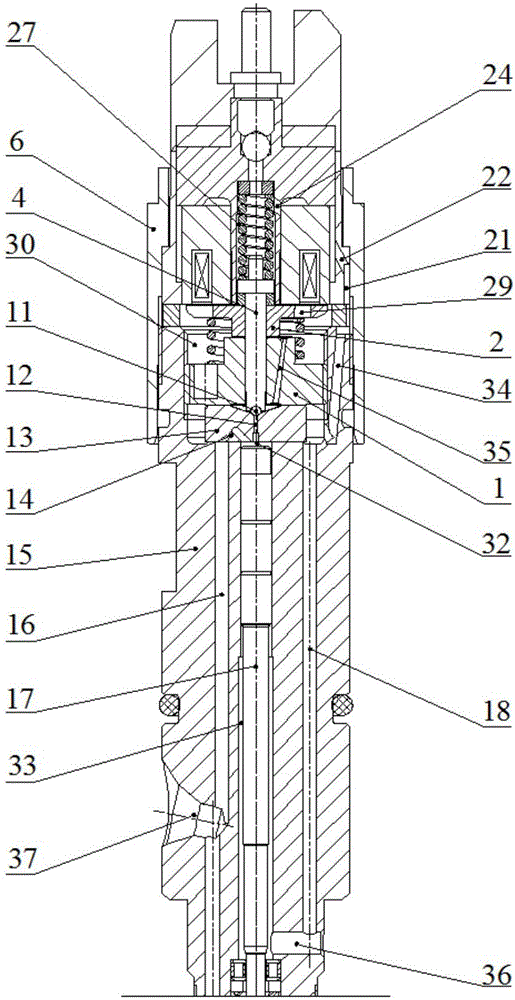

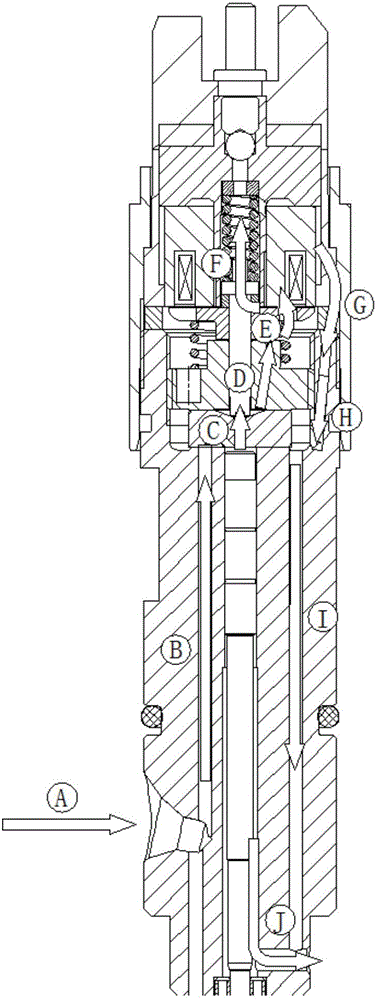

The invention discloses a micro drop jetting device which comprises a brake, a vibrator, a cavity, a vibration rod, a jet nozzle and a shell. The brake is located above the vibrator. The vibrator is connected with the vibration rod. The vibration rod is sleeved with the cavity. The jet nozzle is connected with the lower end of the cavity. The vibrator is connected with the upper end of the cavity. The brake, the vibrator, the cavity, the vibration rod and the jet nozzle are arranged inside the shell. The brake is driven by a PWM signal to push the vibration rod to do intermittent reciprocating linear movement so that the jet nozzle can be closed or opened. The vibrator is driven by the PWM signal to drive the vibration rod to do periodic oscillatory motion, and continuous liquid is divided into micro drops. According to the micro drop jetting device, compared with the prior art, through the periodic oscillatory motion of the vibration rod, the continuous liquid is divided into the micro drops, in addition, the jet nozzle can be closed by pushing the vibration rod, the liquid is prevented from overflowing, and accordingly the jetting precision is improved.

Owner:合肥铭传电子科技有限公司

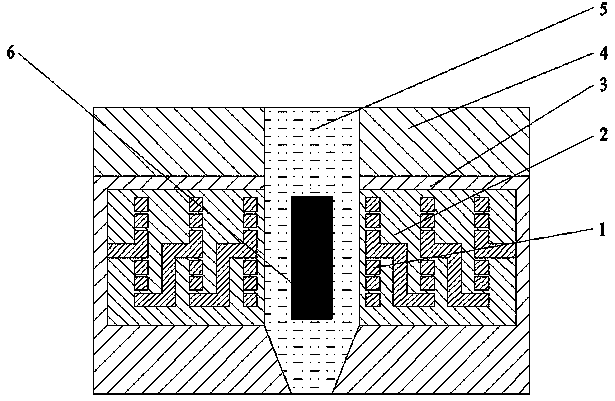

Gas-assisted atomized liquid metering jet apparatus

ActiveCN105822393AImprove jetting accuracyImprove atomization effectExhaust apparatusSilencing apparatusSpray nozzleExhaust pipe

A gas-assisted atomized liquid metering jet apparatus comprises a gas limiting hole, a jet hole, a liquid nozzle and a gas-liquid mixing cavity; the limiting hole is positioned at the upstream of the gas-liquid mixing cavity and connected with a compressed air source; and the jet hole is positioned at the downstream of the gas-liquid mixing cavity and communicated to an engine exhaust pipe. The gas-assisted atomized liquid metering jet apparatus is characterized in that the flow area rate of the limiting hole and the jet hole is less than 1, the gas reaches a critical state in the limiting hole, so that pressure in the mixing cavity remains stable relative to the engine exhaust pipe.

Owner:ZHEJIANG FAI ELECTRONICS

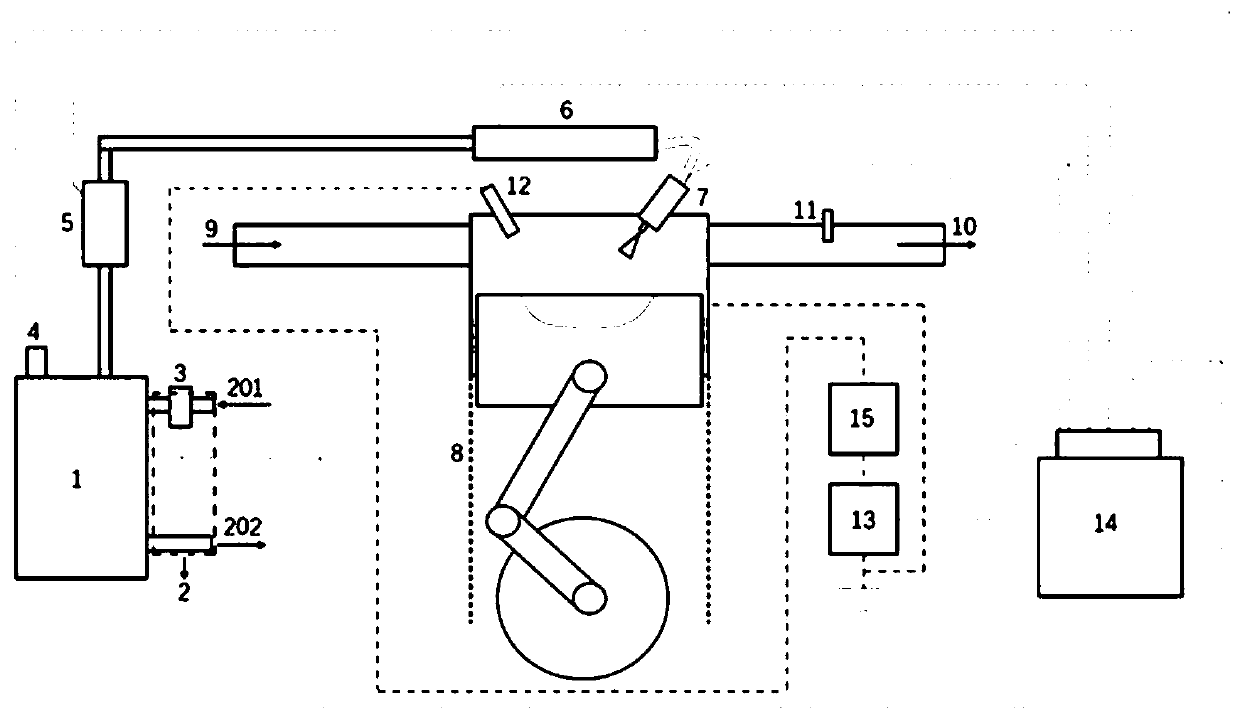

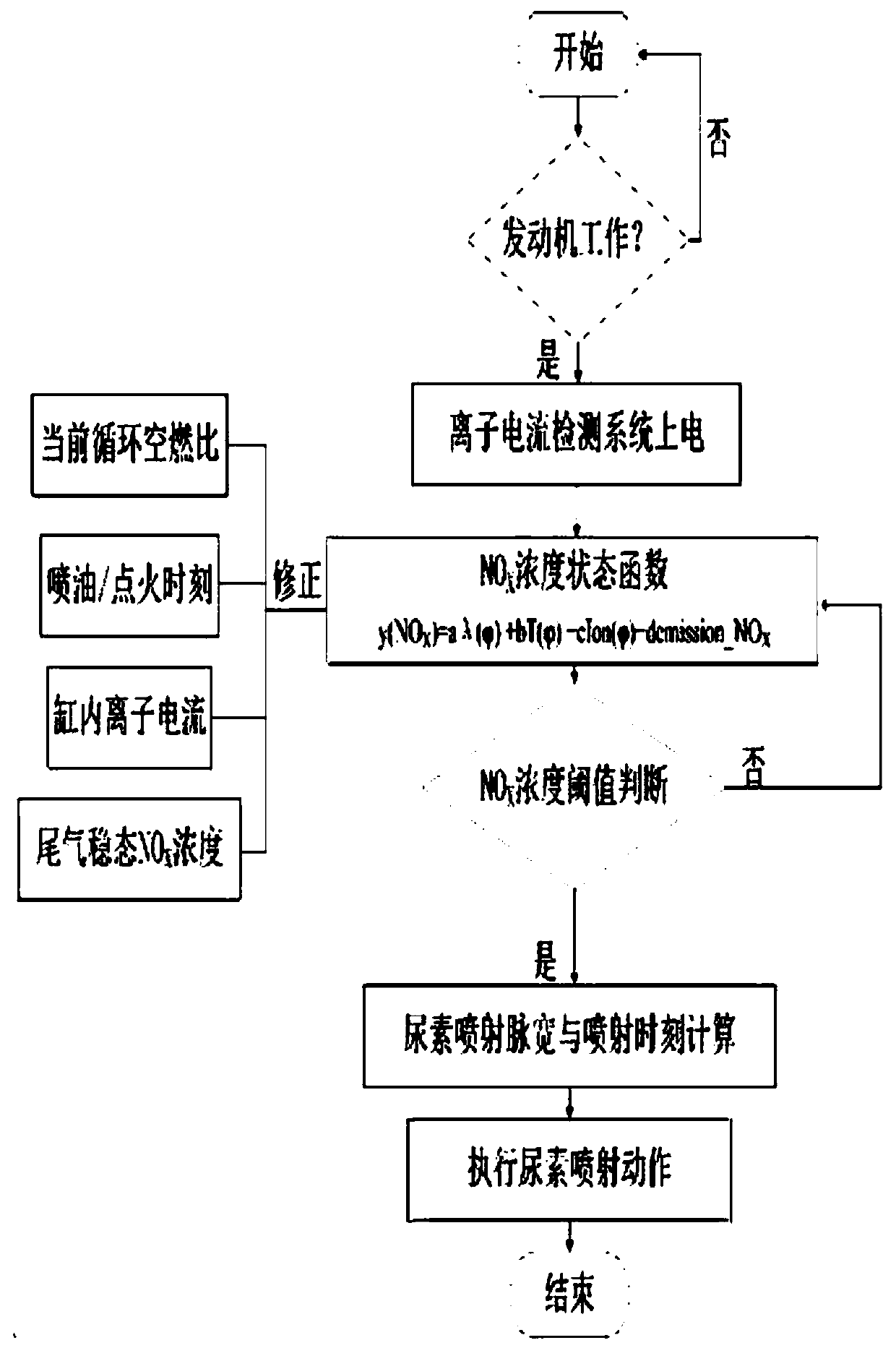

In-cylinder ion current and urea injection type closed-loop control system for nitrogen oxide emission of internal combustion engine

ActiveCN109882270ADirect injectionRealize high-precision optimal controlInternal combustion piston enginesExhaust apparatusLoop controlExternal combustion engine

Owner:CHONGQING UNIV

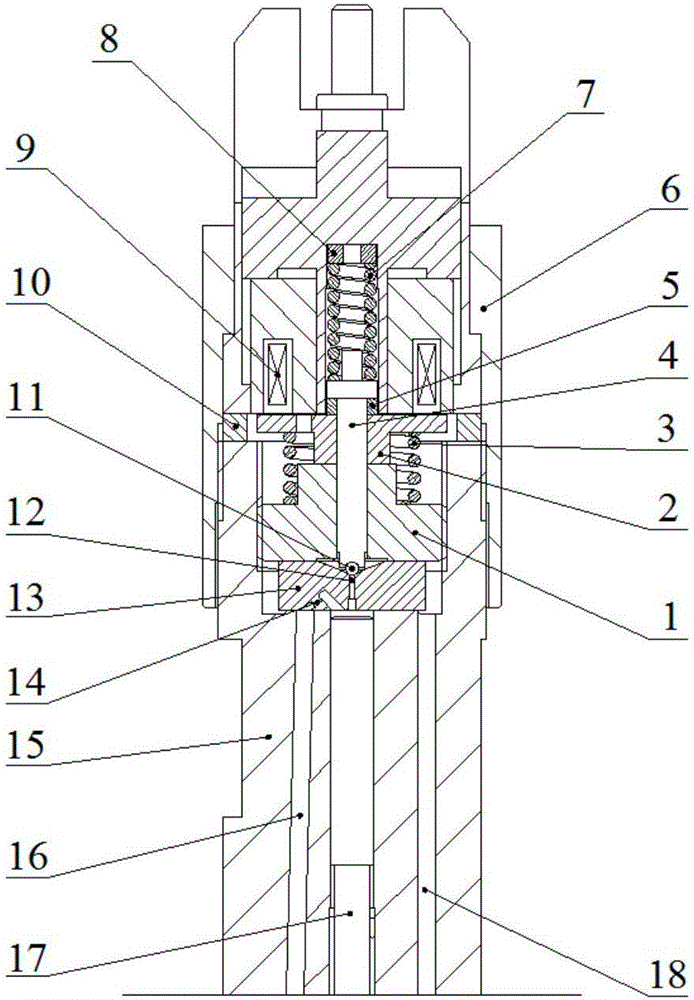

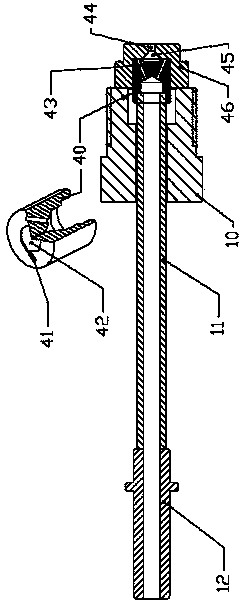

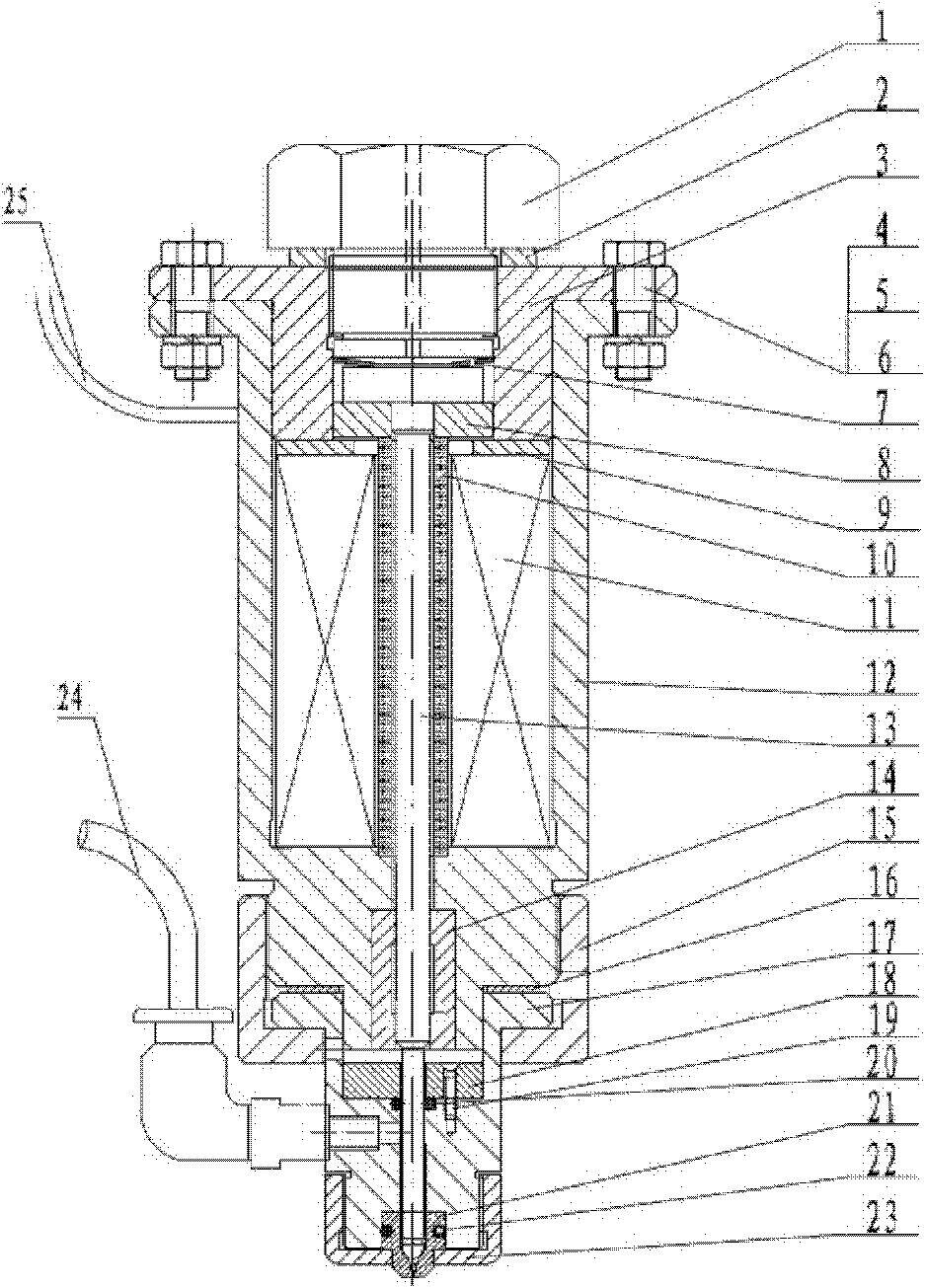

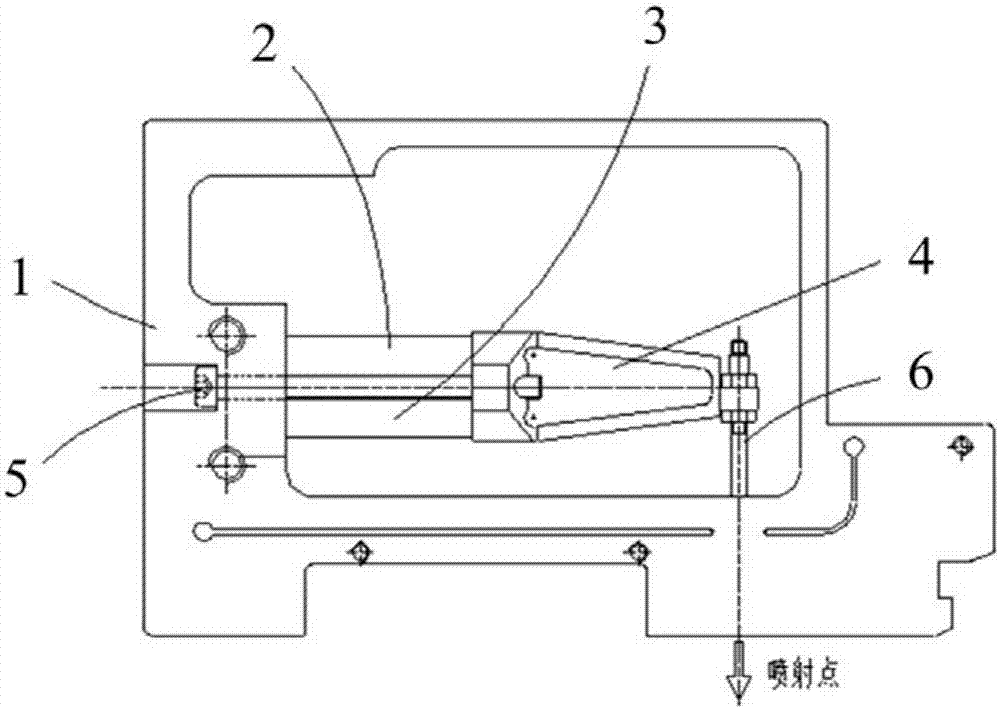

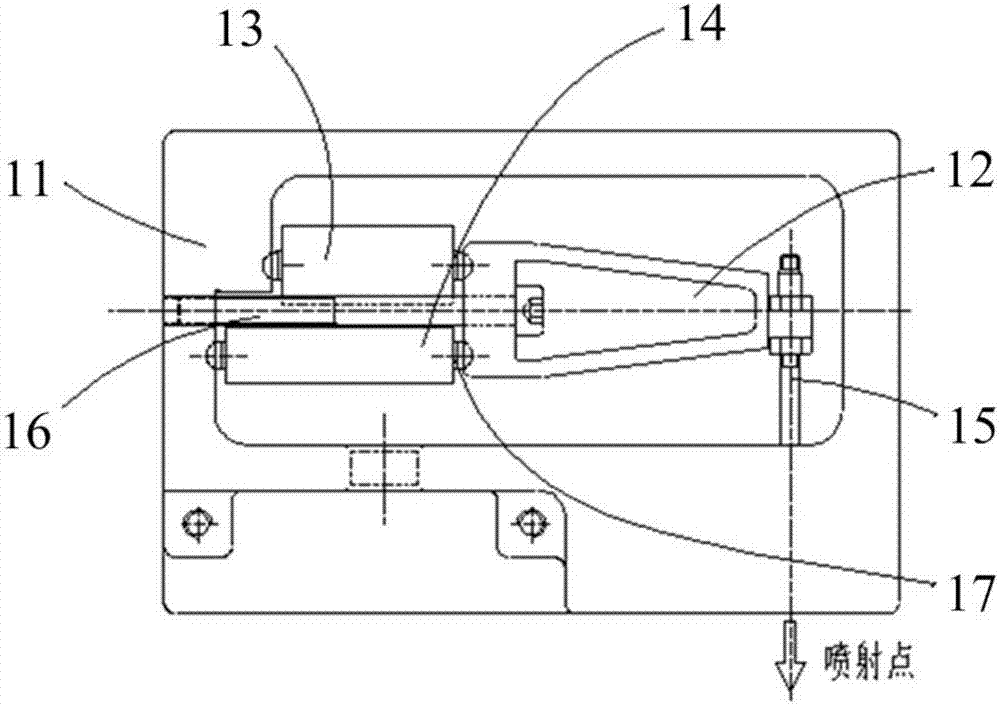

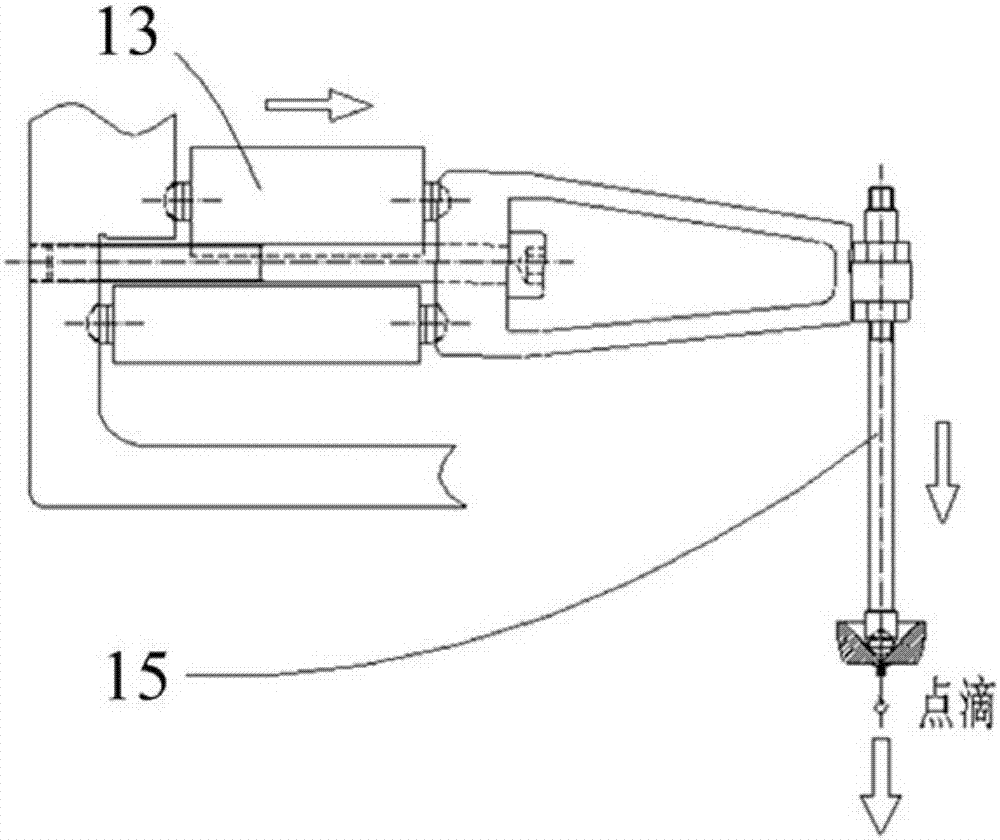

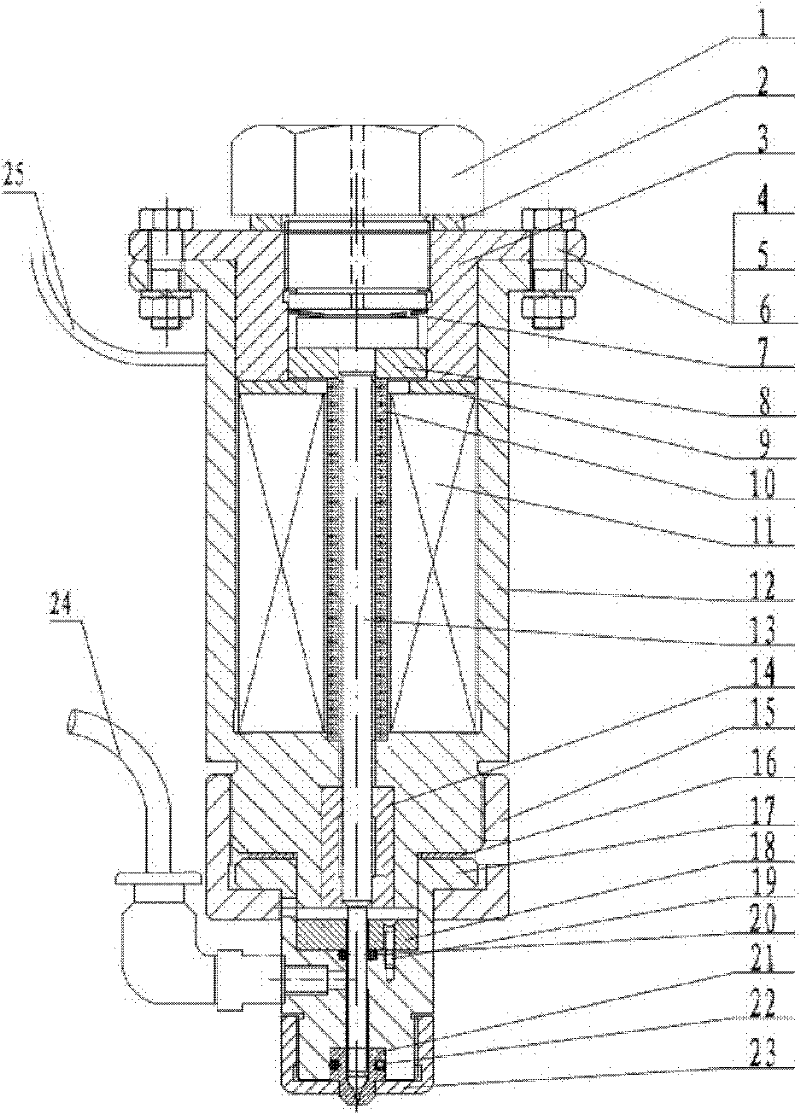

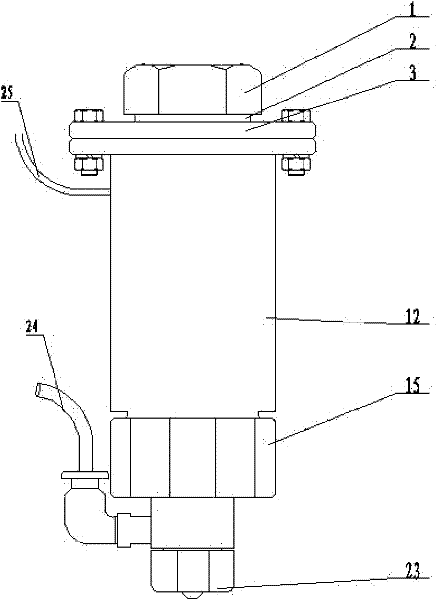

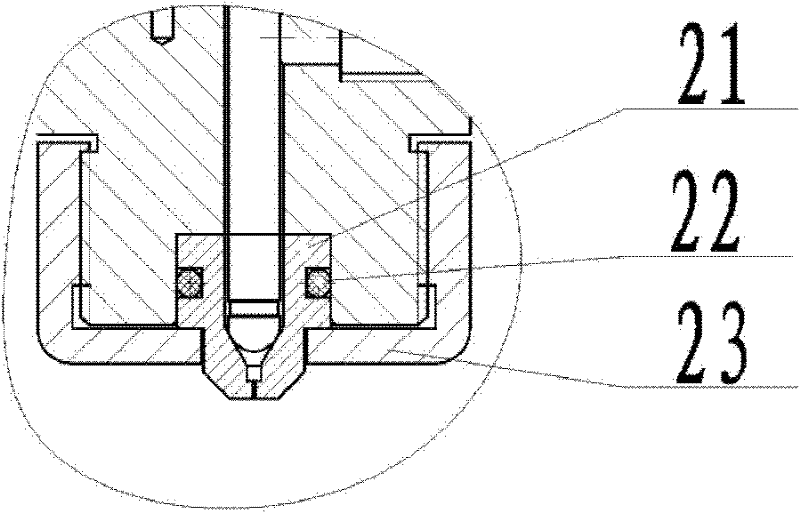

Spot gluing valve based on giant magnetostrictive rod drive

InactiveCN101786068AAvoid frequency doublingConsistent frequencyLiquid surface applicatorsCoatingsBiomedical engineeringExcitation coil

The invention discloses a spot gluing valve based on giant magnetostrictive rod drive, which comprises a spray needle (13) and a valve body. An end cover (3) is fixed on a shell (12), and an excitation coil (11) is fixed in the shell (12) through the end cover (3); an elastic pre-tightening device is arranged on the end cover (3); the upper end of the spray needle (13) is tightly pressed by the elastic pre-tightening device, and the lower end of the spray needle (13) enters the valve body through the shell (12); a giant magnetostrictive rod is arranged at the center of the excitation coil (11); one end of the giant magnetostrictive rod is tightly butted and fixed on the shell (12), and the other end of the giant magnetostrictive rod is butted on the spray needle (13) which is tightly pressed by the elastic pre-tightening device through a magnetic conduction sheet (8); the end cover (3), the magnetic conduction sheet (8) and the shell (12) are magnetic conduction materials; and the end cover (3), the magnetic conduction sheet (8), the shell (12) and the giant magnetostrictive rod form a closed magnetic circuit. In the invention, the spot gluing valve based on giant magnetostrictive rod drive has the advantages of simple structure, convenient use, high spraying frequency, high spraying accuracy and long service life.

Owner:CENT SOUTH UNIV

AB dispenser adhesive outlet mixing valve

The invention discloses an AB dispenser adhesive outlet mixing valve which comprises a valve body and a valve channel, wherein the valve body is provided with an upper valve port and a lower valve port, and the valve channel is formed in the valve body and connected with the upper valve port and the lower valve port. The valve body is further provided with an air inlet connecting the valve channel and an external air pump. The AB dispenser adhesive outlet mixing valve is characterized in that the valve channel is provided with one or more bent parts. Compared with a conventional adhesive outlet valve with a straight valve channel, due to the fact that the bent parts are arranged in the valve channel, certain bearing faces are provided for adhesives to resist gravity, and therefore the adhesive leakage phenomenon under the non-pressurized condition can be effectively prevented, and the adhesives and labor cleaning cost are saved; the bent valve channel and strong pressure interact with each other, the adhesives can be well stirred, the mixing effect of the adhesives in the valve channel is greatly improved, and the quality of dispensed products is further improved.

Owner:苏州光宝科技股份有限公司

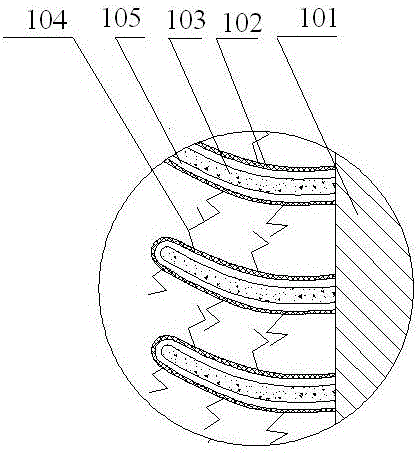

Bionic cilium type high-precision nanodrop nozzle device

ActiveCN106362899ANovel structureIncrease jet speedUltrasonic/sonic fibre treatmentMonocomponent synthetic polymer artificial filamentMagnetic powderContact type

The invention relates to a bionic cilium type high-precision nanodrop nozzle device, which belongs to a droplet nozzle device. A polyethylene glycol terephthalate nozzle is installed on the lower part of a bracket, a field coil is installed on the bracket and is located above the polyethylene glycol terephthalate nozzle, a focused ultrasound transducer is installed on the bracket and is located on the field coil, bionic cilia are arranged on the lower inner wall of a main body of the polyethylene glycol terephthalate nozzle, and a liquid storage chamber is arranged above the main body. The bionic cilium type high-precision nanodrop nozzle device has the advantage of novel structure; magnetic powder is controlled to swing by virtue of an alternating magnetic field, so that nanoscale movement of sprayed droplet materials is realized; droplet power is provided by non-contact type focused ultrasound, so that the spray speed is increased, and the droplet spray precision is greatly increased; and the sprayed droplet diameter is less than the diameter of the nozzle, so that the bionic cilium type high-precision nanodrop nozzle device can be used for spraying all low-viscosity droplet materials such as electrochemical electrolyte, cell suspension, low-viscosity photosensitive resin and the like.

Owner:JILIN UNIV

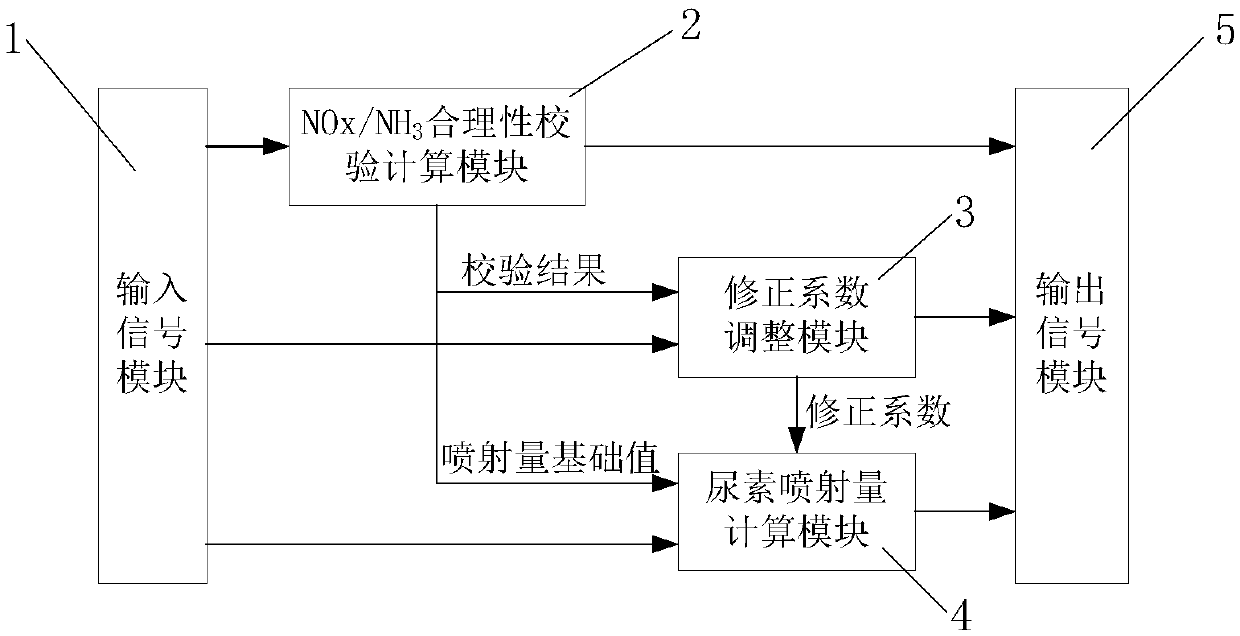

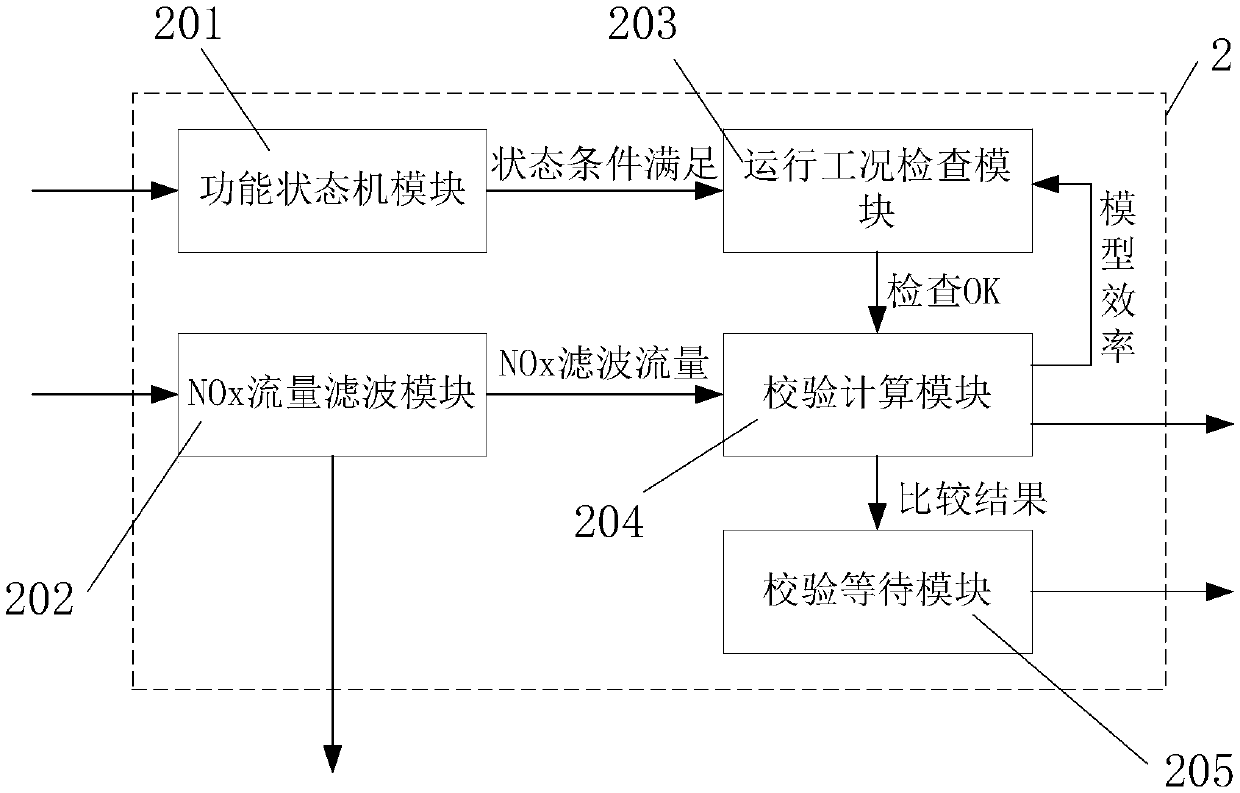

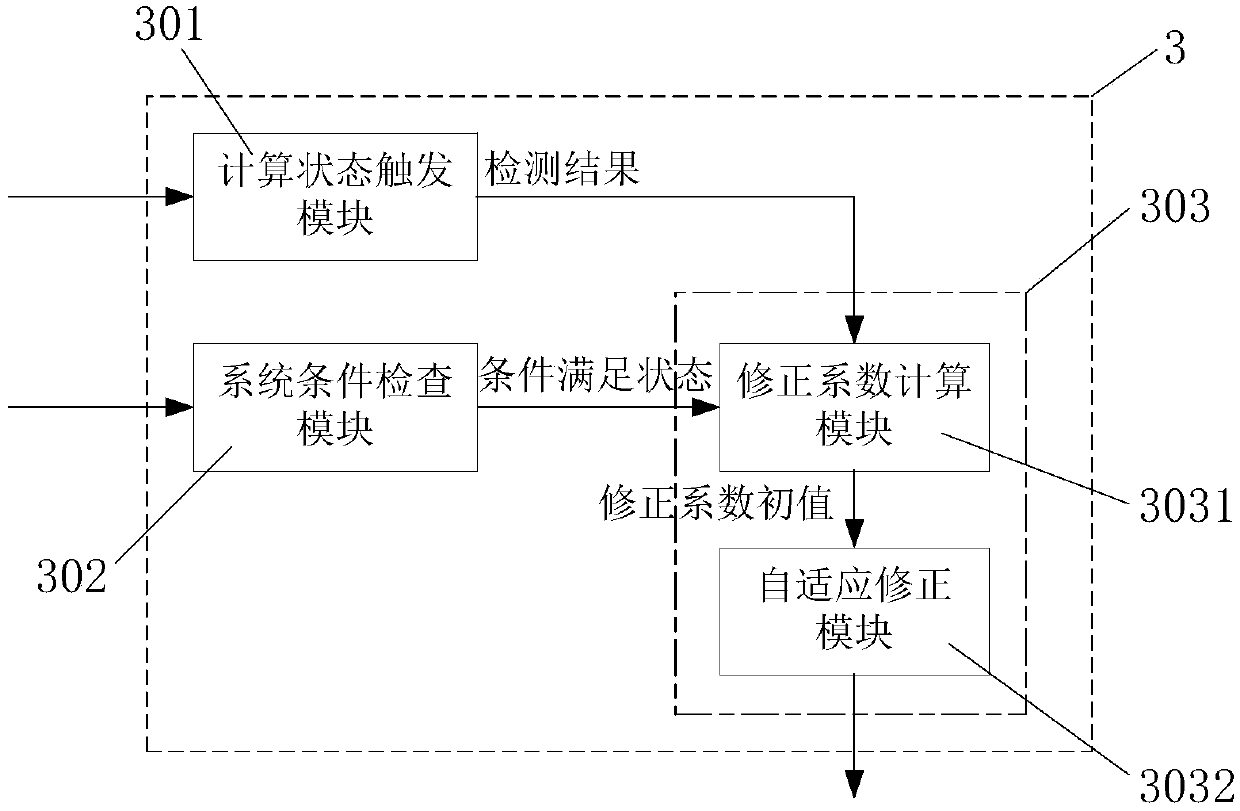

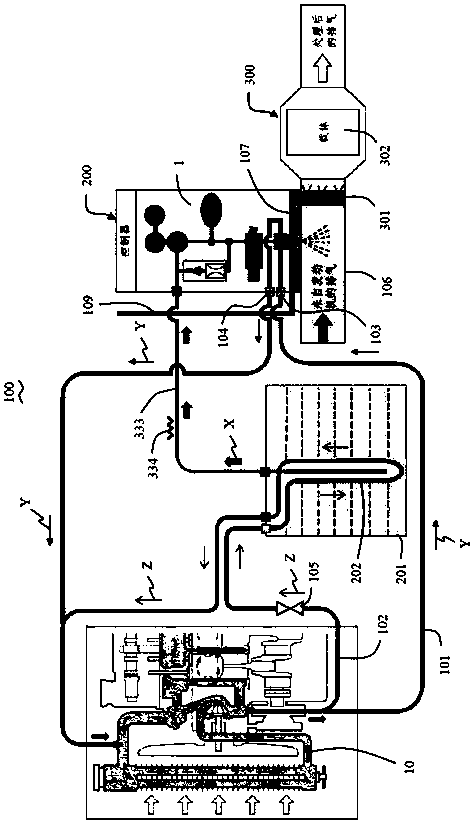

Control system for self-adaptive correction of urea injection on basis of NOx sensor

ActiveCN109681298APrecise control of injection volumeImprove jetting accuracyInternal combustion piston enginesExhaust apparatusControl systemClosed loop

The invention discloses a control system for self-adaptive correction of urea injection on the basis of a NOx sensor. The control system comprises an input signal module, the input signal module is connected with a NOx / NH3 rationality verification and calculation module, a correction coefficient adjustment module and a urea injection amount calculation module separately, the NOx / NH3 rationality verification and calculation module is connected with the correction coefficient adjustment module, the urea injection amount calculation module and an output signal module separately, the correction coefficient adjustment module is connected with the urea injection amount calculation module and the output signal module separately, and the urea injection amount calculation module is connected with the output signal module. Therefore, the urea injection amount can be precisely controlled according to the flow of NOx in a catalyst, and the robustness of an SCR closed-loop system can be enhanced.

Owner:JIANGSU UNIV

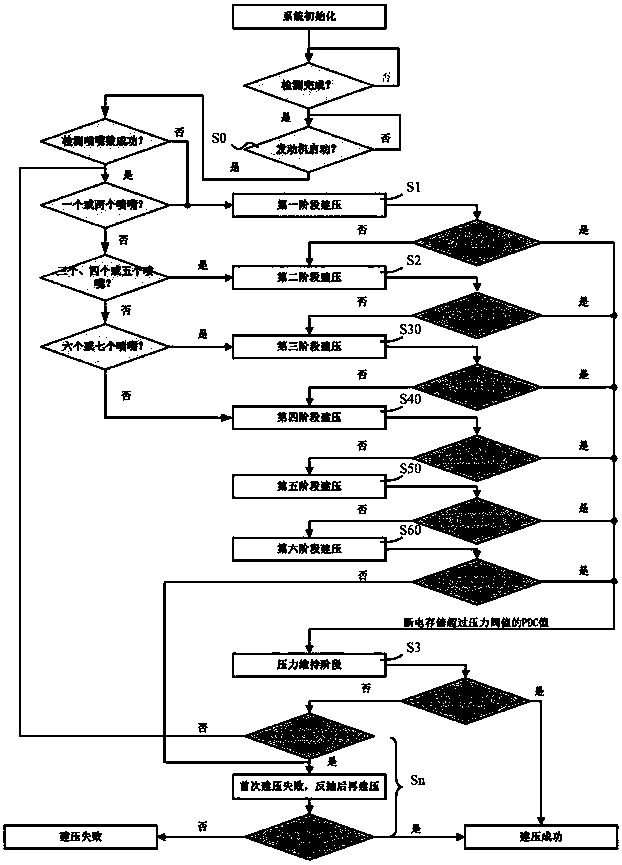

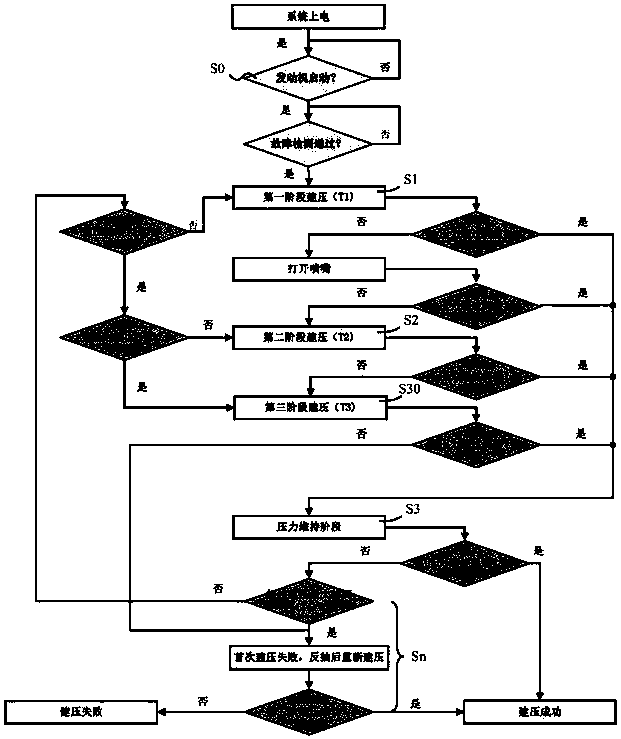

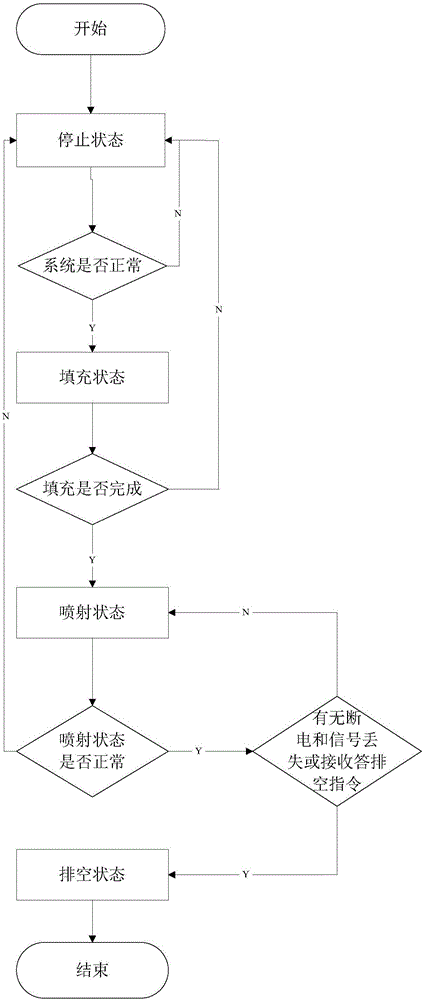

Segmented pressure buildup method for exhaust gas after-treatment system

ActiveCN108691623AImprove the success rate of pressure buildingImprove jetting accuracyGeometric CADInternal combustion piston enginesAfter treatmentTreatment system

The invention provides a segmented pressure buildup method for an exhaust gas after-treatment system. The segmented pressure buildup method at least comprises the following steps of: S 0. judging whether an engine is started, and if the engine is started, executing the step S1; S1. carrying out first-stage pressure buildup, to be specific, driving a pump component to operate at the first pump speed, checking whether the outlet pressure of the pump component exceeds a threshold value, if yes, executing the step S3, and if not, executing the step S2; S2. carrying out second-stage pressure buildup, to be specific, driving the pump component to operate at the second pump speed and checking whether the outlet pressure of the pump component exceeds the threshold value, if yes, executing the stepS3, and if not, executing the step Sn; S3. pressure maintaining stage, to be specific, judging whether the pressure maintaining is successful, if yes, the pressure buildup is successful, and if not,executing the step Sn; and Sn. if the first pressure buildup fails, driving the pump component to reversely pump, then carrying out secondary pressure buildup and judging whether the secondary pressure buildup is successful, if yes, the pressure buildup is successful, and if not, the pressure buildup fails.

Owner:TENNECO SUZHOU EMISSION SYST

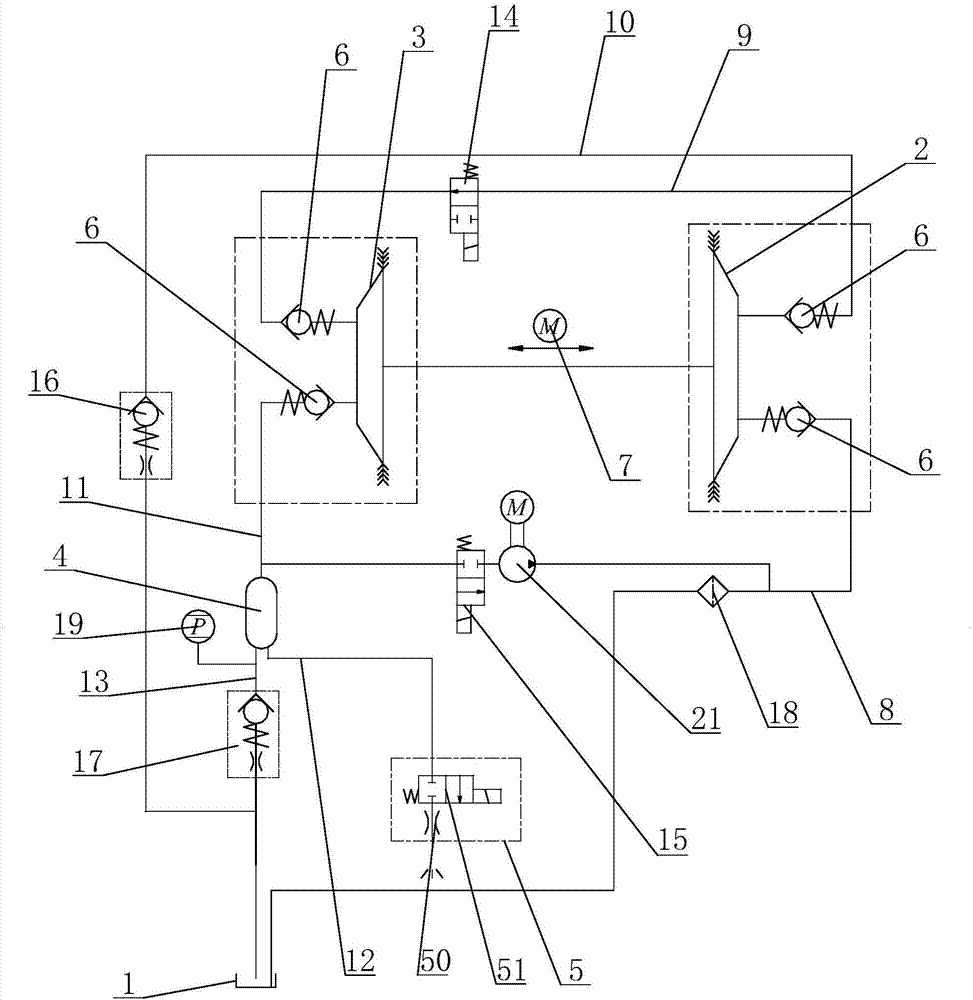

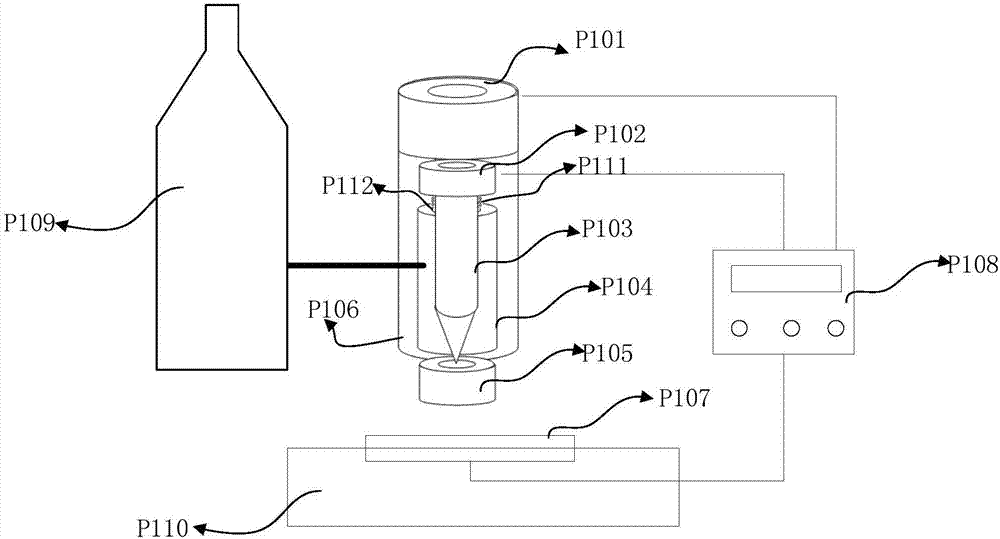

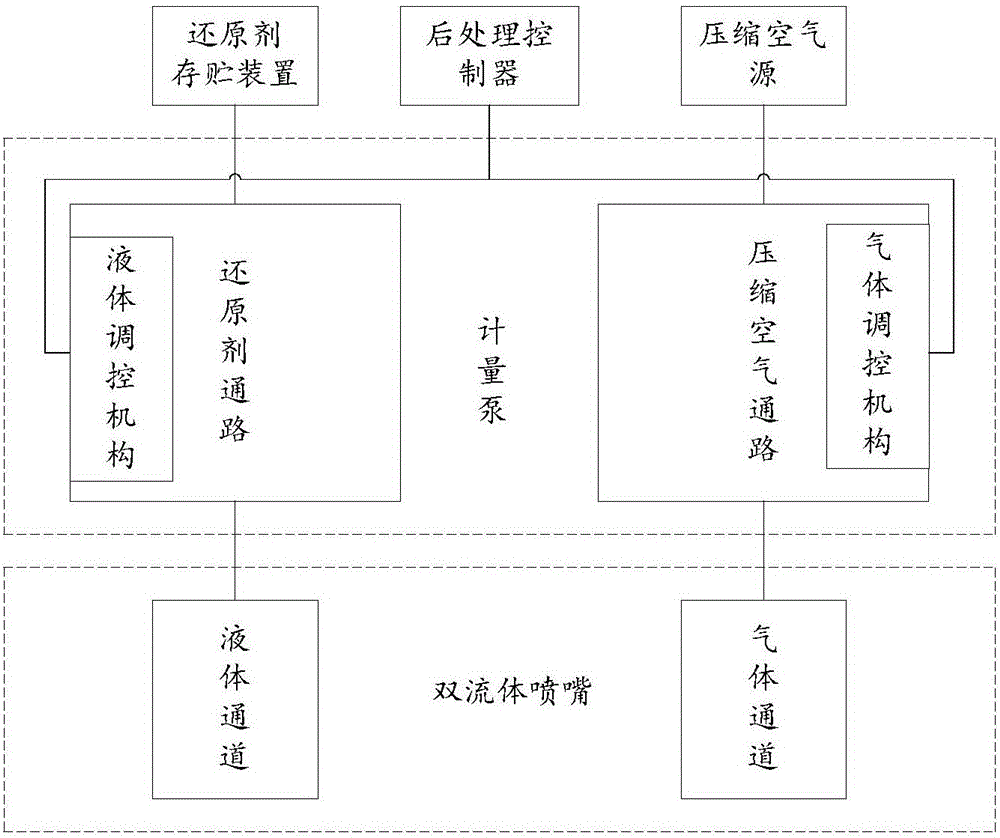

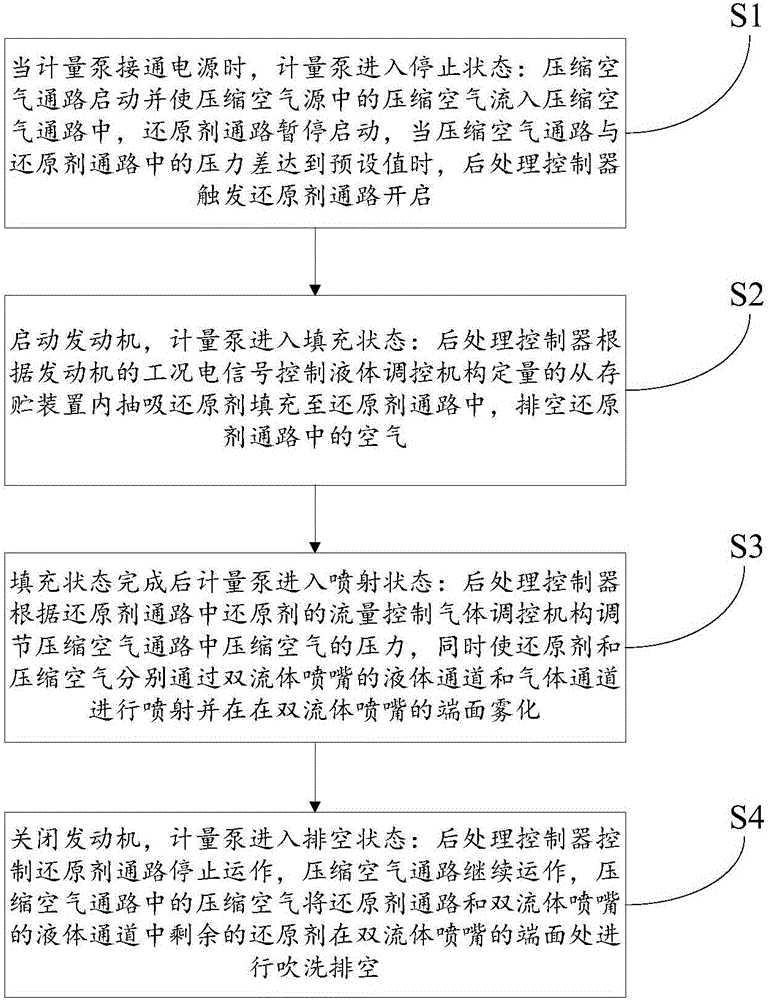

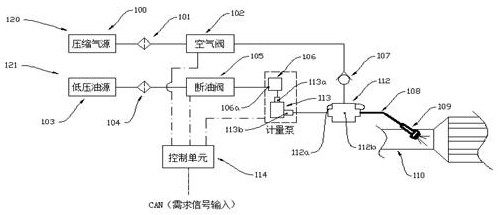

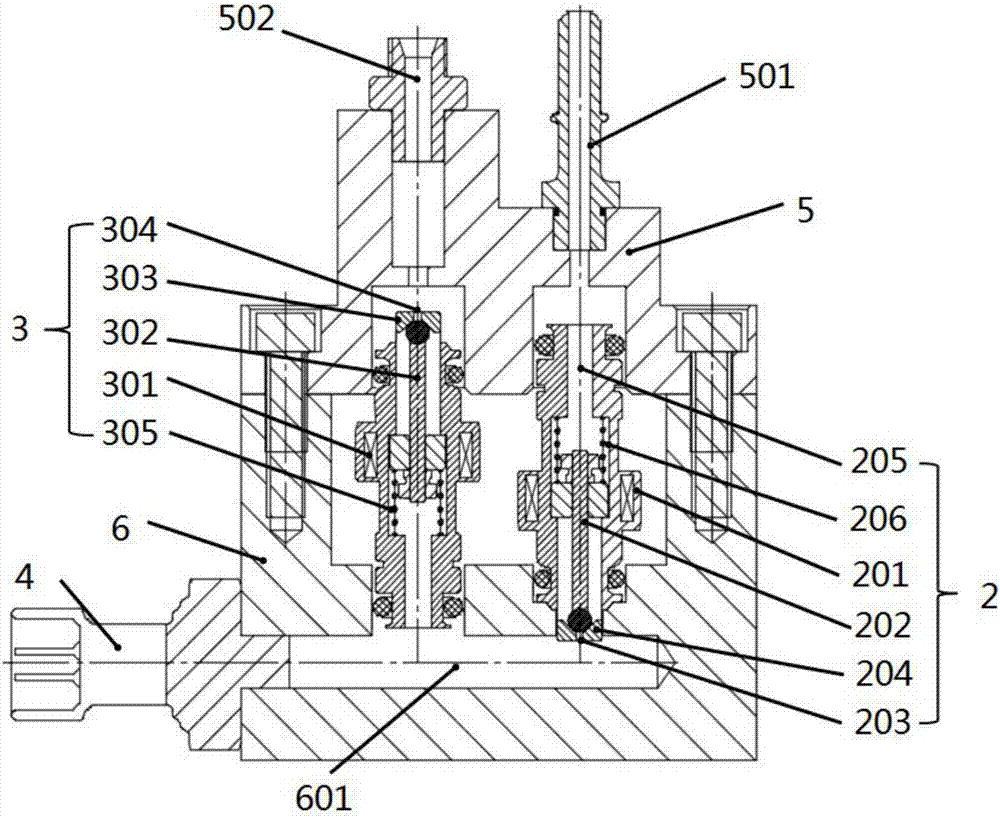

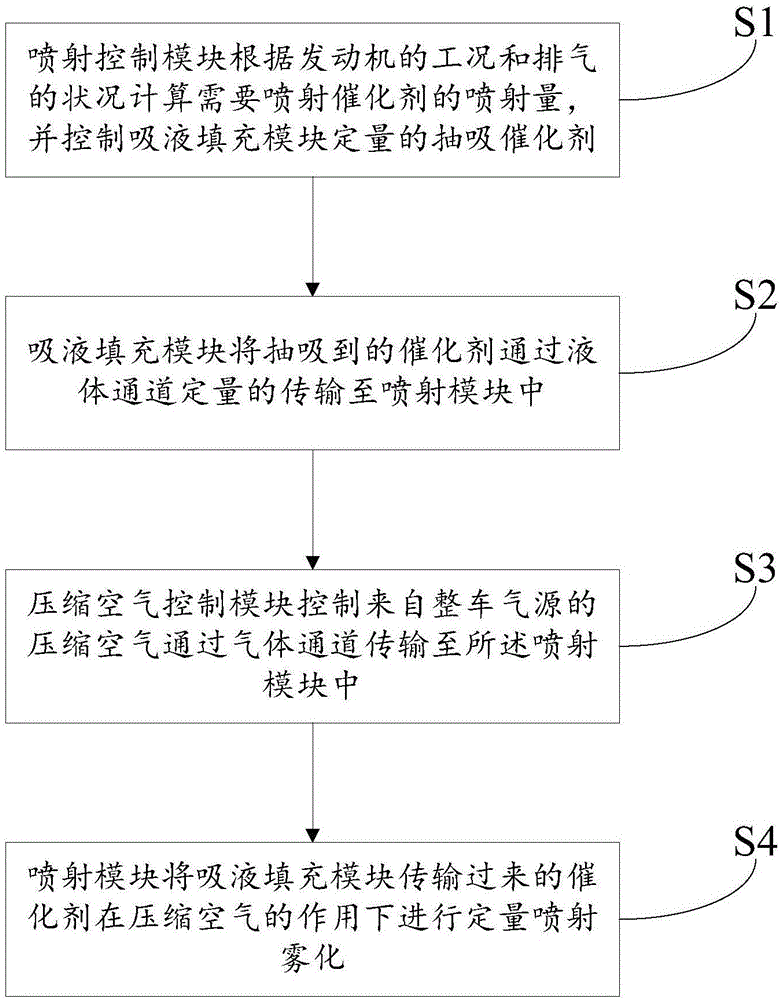

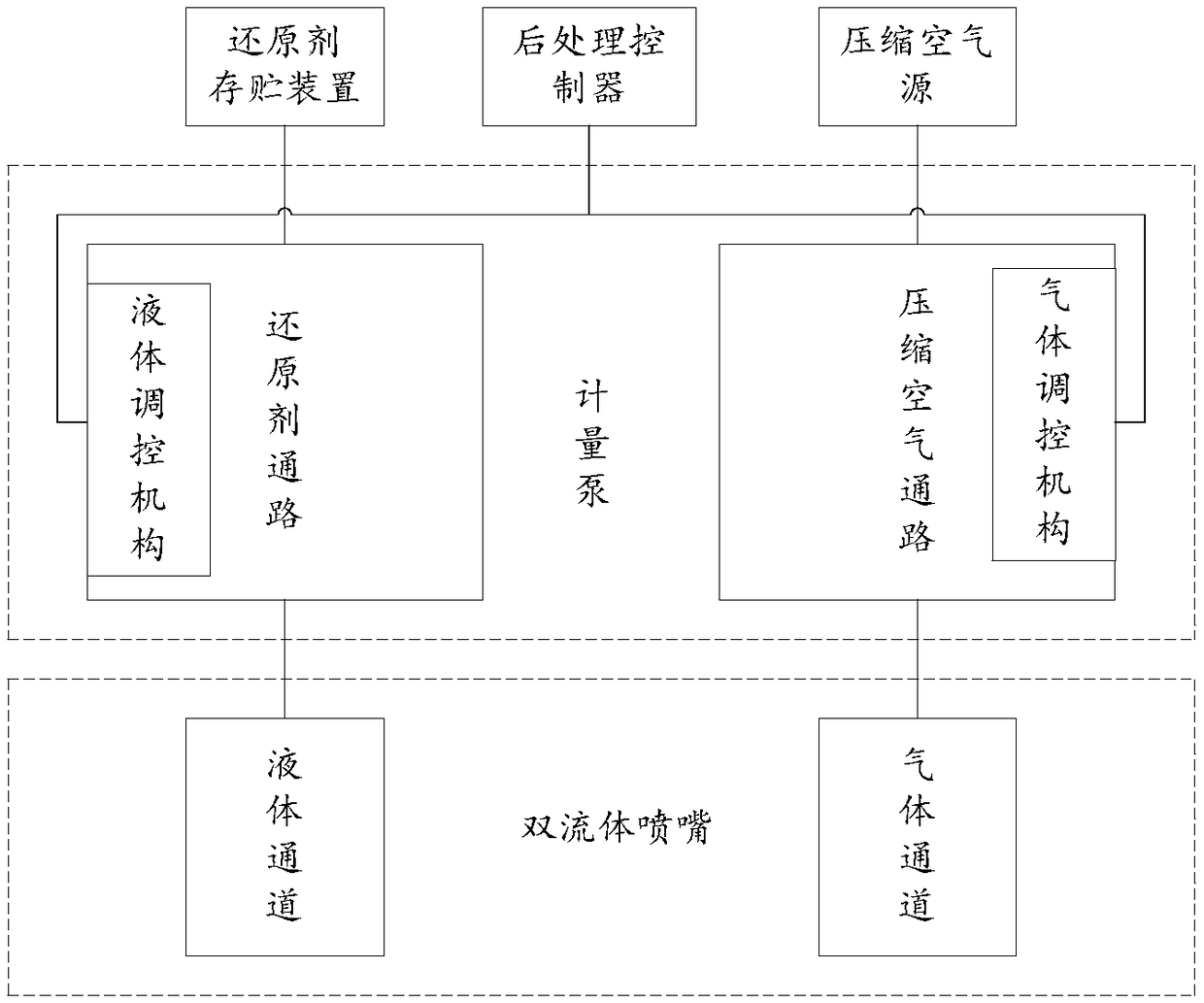

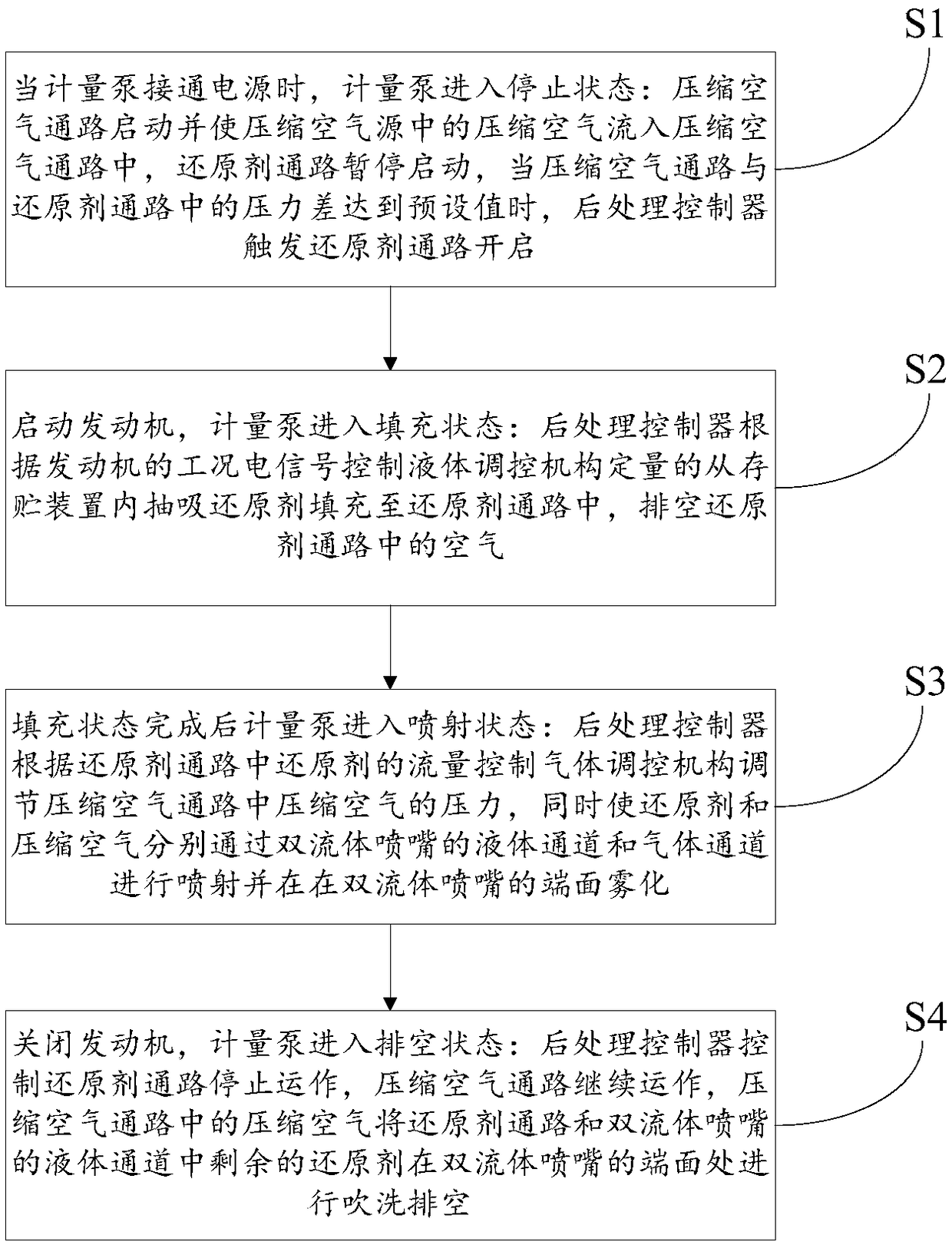

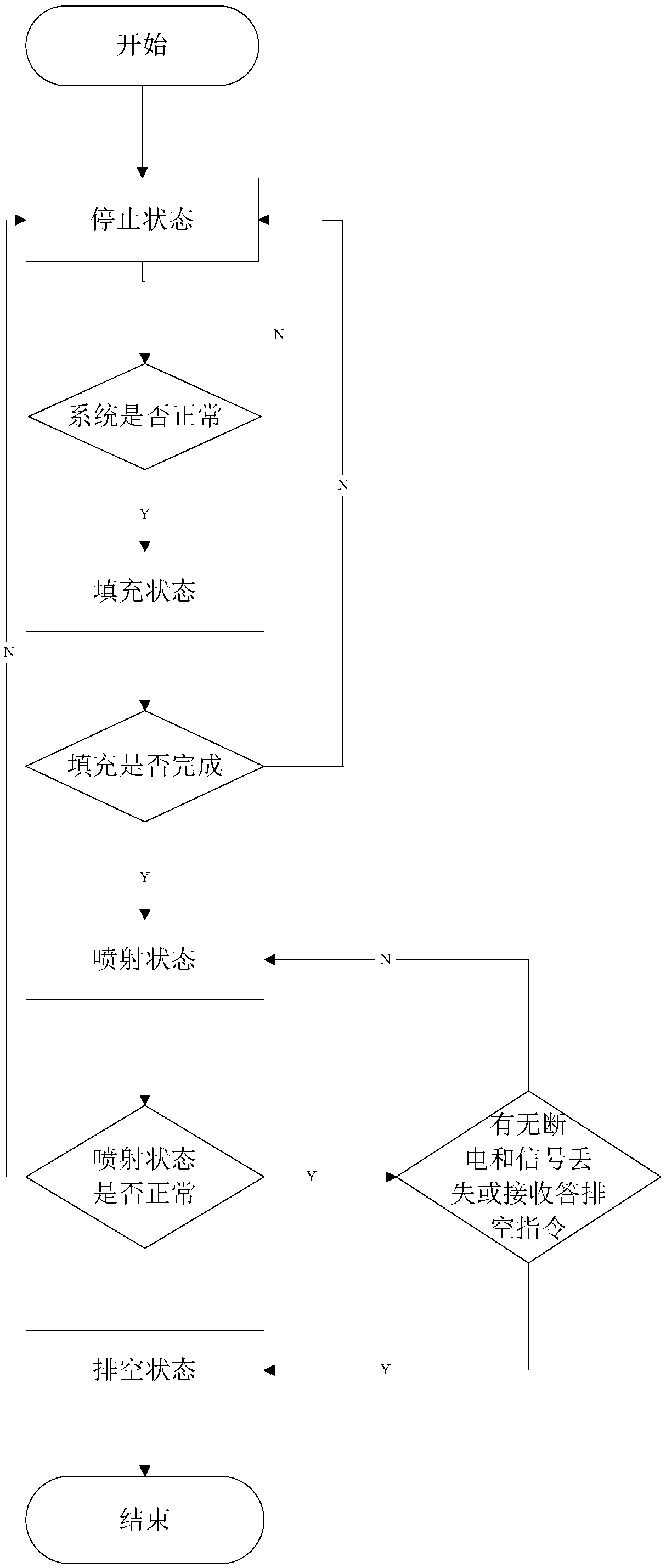

Gas-assisted type metered injection system and control method thereof

ActiveCN106762044APrevent crystallizationImproved effects and jetting precisionInternal combustion piston enginesExhaust apparatusProcess engineeringElectricity

The invention relates to a gas-assisted type metered injection system and a control method thereof. The system comprises a metering pump, a double-fluid nozzle, a reducing agent storage device, a compressed air source and an aftertreatment controller. A reducing agent passageway and a compressed air passageway which are independent from each other are arranged in the metering pump. An inlet of the reducing agent passageway is connected with the reducing agent storage device, an inlet of the compressed air passageway is connected with the compressed air source, and an outlet of the reducing agent passageway and an outlet of the compressed air passageway are correspondingly connected with a liquid channel and a gas channel of the double-fluid nozzle. A liquid regulating mechanism is arranged in the reducing agent passageway, and a gas regulating mechanism is arranged in the compressed air passageway. The liquid regulating mechanism and the gas regulating mechanism are electrically connected with the aftertreatment controller. A liquid and gas mixing cavity is not contained in the metering pump, the risk that a reducing agent is likely to be crystallized in a gas-liquid mixing state is greatly avoided, and the reducing agent injection atomization effect and the injection precision are improved.

Owner:烟台盈德精密机械有限公司

Engine exhaust hydrocarbon injection system and control strategy thereof

PendingCN113931721AImprove jetting accuracyImprove reliabilityInternal combustion piston enginesExhaust apparatusFuel oilMetering pump

The invention discloses an engine exhaust hydrocarbon injection system. The engine exhaust hydrocarbon injection system comprises an engine exhaust pipe, an air supply assembly, an oil supply assembly, a mixing chamber, an injection pipe, an HC nozzle and a control unit, the air supply assembly and the oil supply assembly are connected with the mixing chamber, the HC nozzle is located on the downstream of the mixing chamber and communicates with the mixing chamber, the air supply assembly comprises a compressed air source and an air valve, the oil supply assembly comprises a low-pressure oil source, an oil cut-off valve and a metering pump, and the metering pump is a solenoid pulse type metering injection unit and used for accurately metering the amount of fuel oil entering the mixing chamber. The hydrocarbon injection system is high in injection precision, good in atomization effect, high in system reliability and low in cost.

Owner:ZHEJIANG FAI ELECTRONICS

Electromagnetic nozzle based on MEMS process

ActiveCN105366625AReduce volumeHighly integratedTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLow noiseElectromagnetic field

The invention relates to an electromagnetic nozzle based on an MEMS process. The electromagnetic nozzle based on the MEMS process comprises a conducting coil, a soft magnetic material, a silicon material, a control chip, a conducting fluid and an electrode pair, wherein the conducting coil is arranged in the soft magnetic material, the silicon material coats the soft magnetic material, the positive electrode and the negative electrode of the conducting coil are respectively connected with the positive electrode and the negative electrode of the electrode pair, the control chip is arranged at the top of the silicon material, the conducting fluid flows out of the bottom of a spray hole penetrating through the control chip, the silicon material and the soft magnetic material, and the electrode pair is connected with the control chip at the top after penetrating through the soft magnetic material and the silicon material, thereby achieving micro-flowing control on the conducting fluid. After the micro electromagnetic nozzle manufactured based on the MEMS process is electrified, the conducting coil in series connection generates a magnetic field, the electrode pair generates an electric field, and an electromagnetic force formed by an electromagnetic field drives the conducting fluid in the nozzle to vertically flow downwards; the electromagnetic nozzle based on the MEMS process has the characteristics of simple structure, high precision and frequency, low noise, low heat and high reliability.

Owner:SHANGHAI UNIV

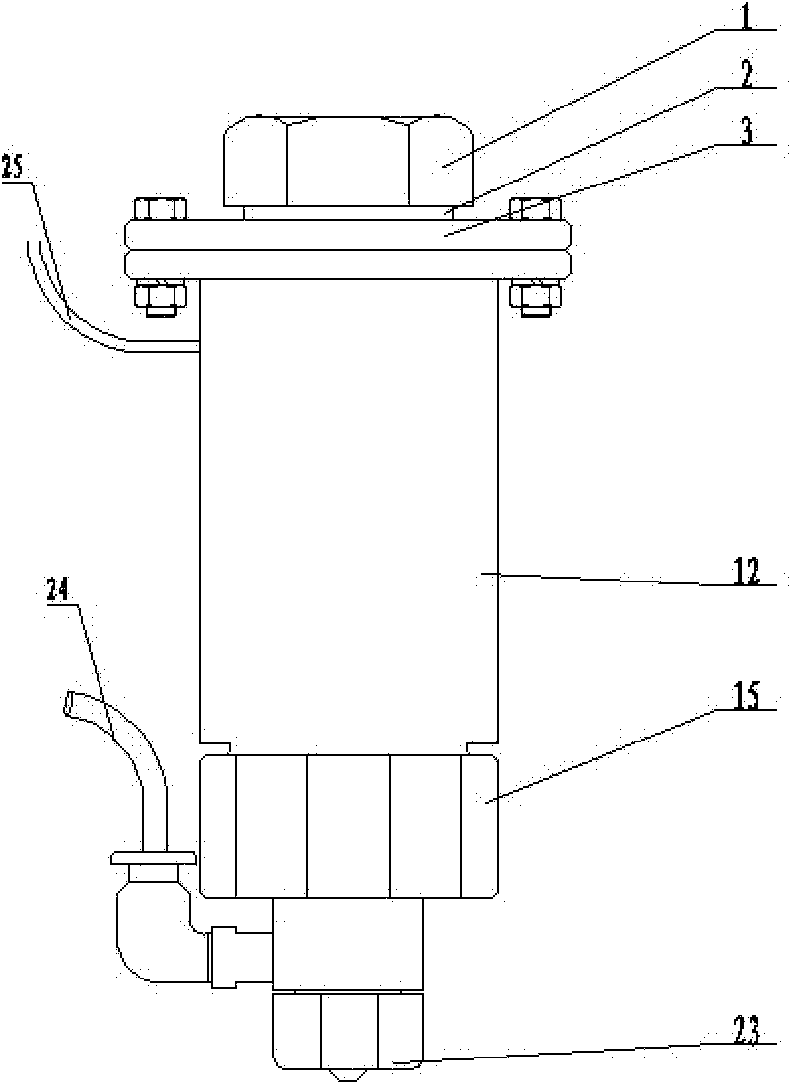

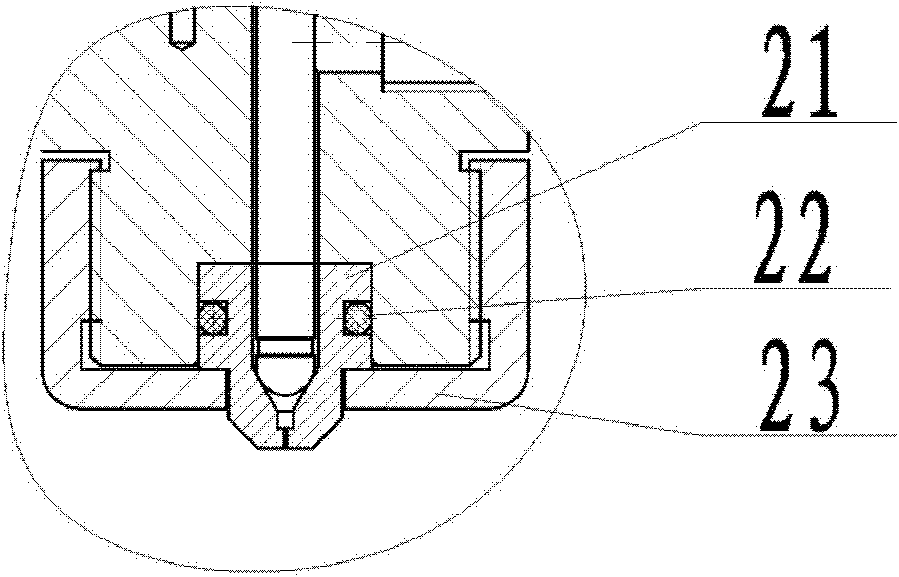

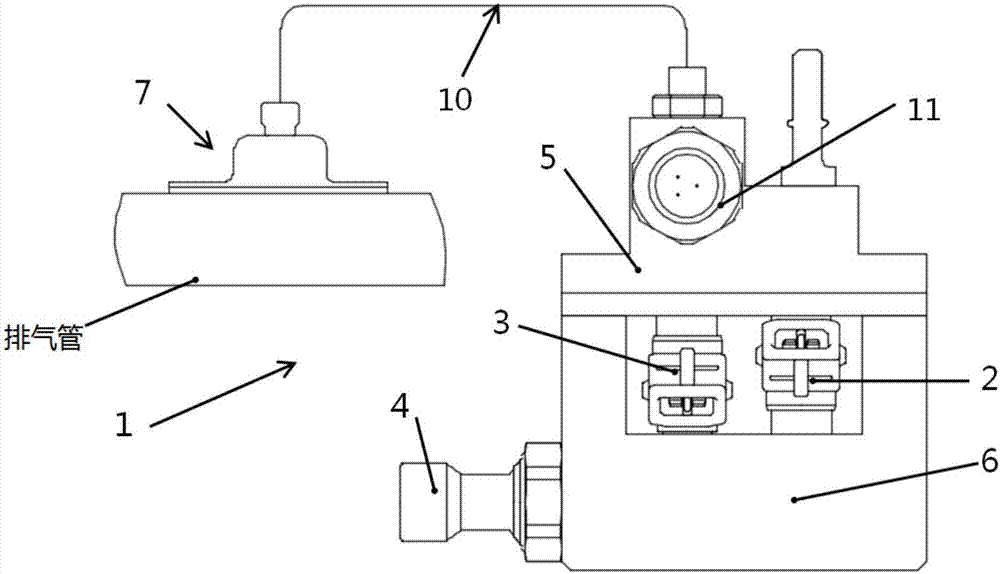

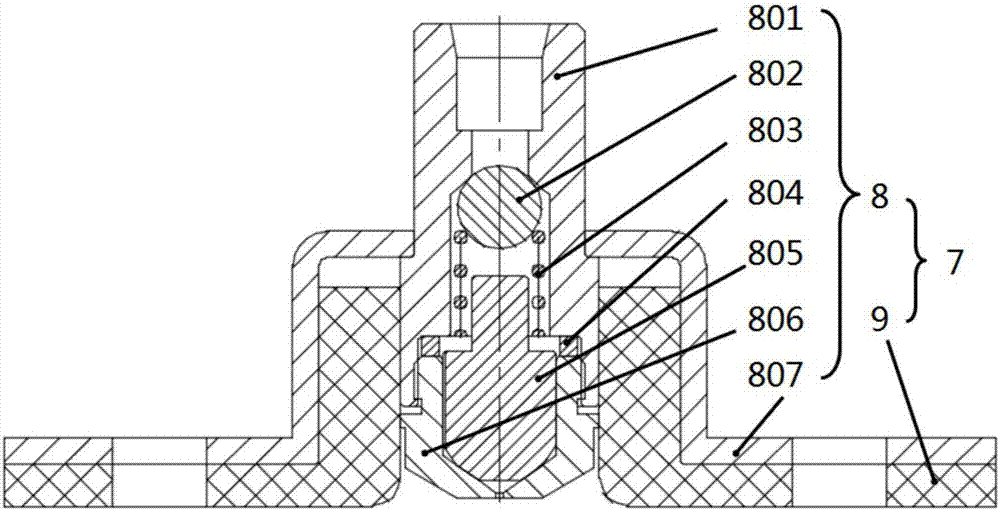

Injection system used for purifying smoke discharge soot particles and control method

ActiveCN107060954AImprove spray qualitySimple structureInternal combustion piston enginesExhaust apparatusSolenoid valveSpray nozzle

The invention belongs to the technical field of vehicles, and particularly discloses an injection system used for purifying smoke discharge soot particles and a control method. The injection system comprises a controller and an injector, wherein the controller is connected with an ECU; the injector is connected with a gas exhaust tube; the controller comprises a on-off solenoid valve, a metering valve, a first pressure sensor, a second pressure sensor, a controller upper housing and a controller housing; the on-off solenoid valve, the metering valve and the first pressure sensor are mounted on the controller housing; the controller upper housing is fastened onto the controller housing; the second pressure sensor is mounted on the controller upper housing; and the controller is connected with the injector through a fuel oil pipeline. The injection system can realize stabilization of pressure for injecting fuel oil through the controller; precise control on fuel oil injection can be realized through the metering valve; the coking risk of a spray nozzle can be avoided through the structural design of the spray nozzle of the injection system; and moreover, the invention discloses the injection system used for purifying smoke discharge soot particles and the control method, and the injection system is simple in structure and is low in manufacturing cost.

Owner:CHINA FIRST AUTOMOBILE

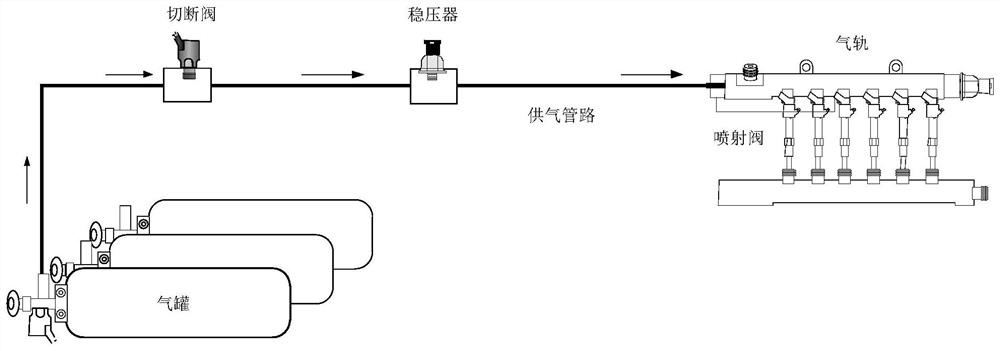

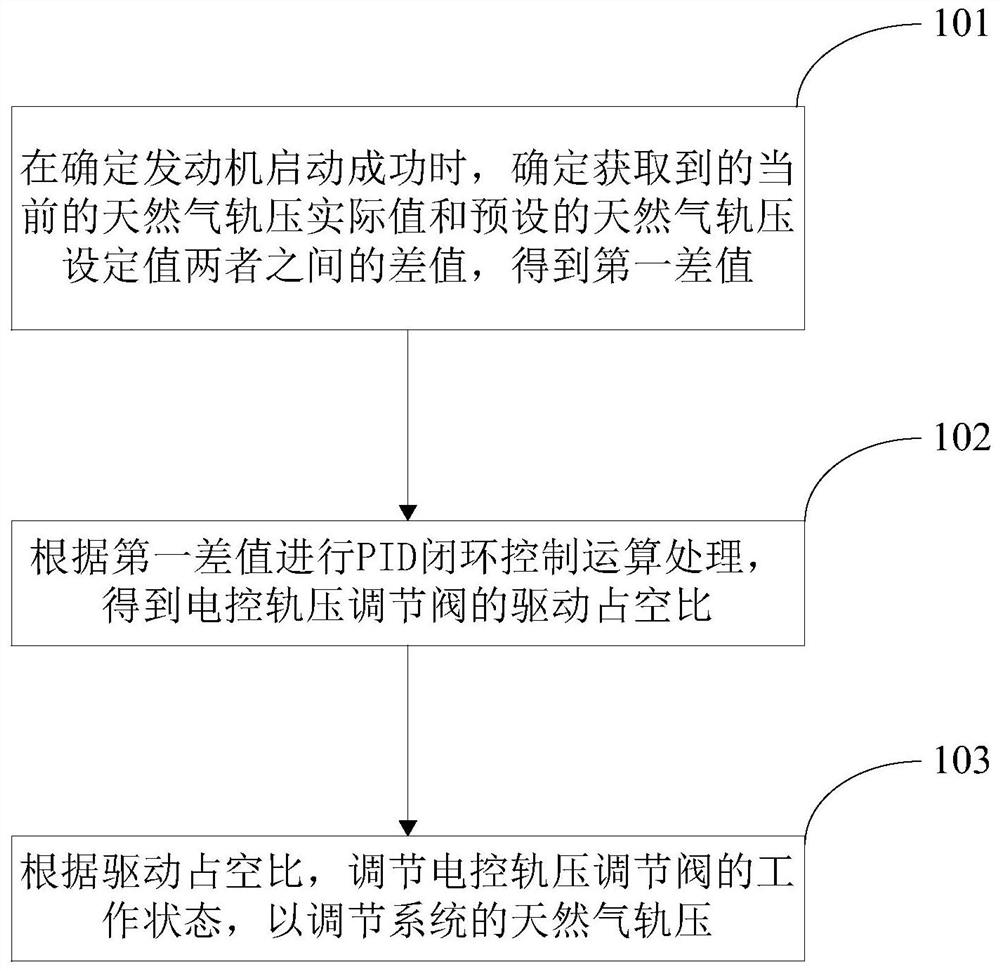

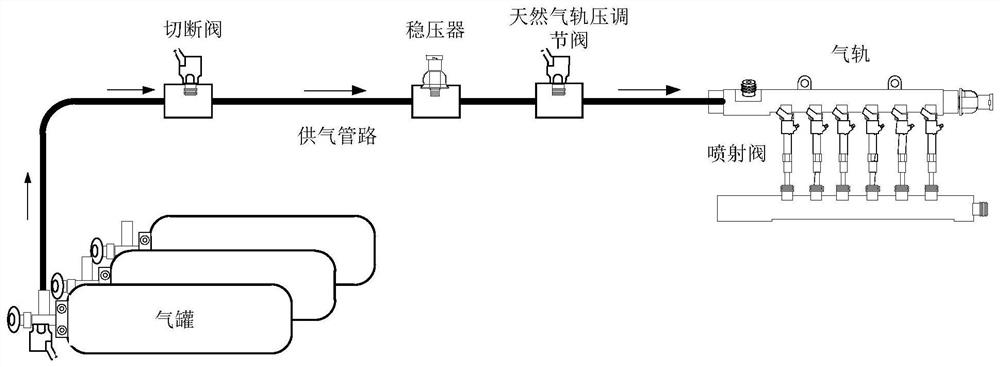

Ejection control method and equipment applied to natural gas engine gas supply system

ActiveCN111997765AImprove jetting accuracyMeet control needsElectrical controlMachines/enginesAutomotive engineeringRail pressure

The invention provides an ejection control method and equipment applied to a natural gas engine gas supply system. The ejection control method comprises the following steps: when determining that an engine is successfully started, determining the difference value between the obtained current natural gas rail pressure actual value and a preset natural gas rail pressure set value to obtain a first difference value; according to the first difference value, carrying out PID closed-loop control operation treatment to obtain the driving duty ratio of an electric control rail pressure adjusting valve; and according to the driving duty ratio, adjusting the working state of the electric control rail pressure adjusting valve to adjust the natural gas rail pressure of the natural gas engine gas supply system. With adoption of the ejection control method, the natural gas ejection precision is improved and stable control over the natural gas rail pressure is realized to improve the engine stability.

Owner:WEICHAI POWER CO LTD

Piezoelectric ejection printing head and printing device provided with same

The invention discloses a piezoelectric ejection printing head and a printing device provided with the same and belongs to the field of piezoelectric ejection. The piezoelectric ejection printing head comprises a valve body, a displacement amplifying mechanism, an upper piezoelectric ceramic, a lower piezoelectric ceramic and an impact bar, wherein the displacement amplifying mechanism is arranged in the valve body through a fixed rod; the upper piezoelectric ceramic and the lower piezoelectric ceramic are separately arranged on and under the fixed rod; one sides of the upper piezoelectric ceramic and the lower piezoelectric ceramic are connected to the inner wall of the valve body through ceramic bulges while the other sides of the upper piezoelectric ceramic and the lower piezoelectric ceramic are connected to two sides of the back end of the displacement amplifying mechanism through ceramic bulges; and the front end of the displacement amplifying mechanism is connected to the impact bar. Compared with the prior art, the piezoelectric ejection printing head disclosed by the invention has the advantages of being high in ejection precision, capable of preventing ceramic edges and corners from being extruded and damaged and low in cost.

Owner:北京派和智能装备技术有限公司

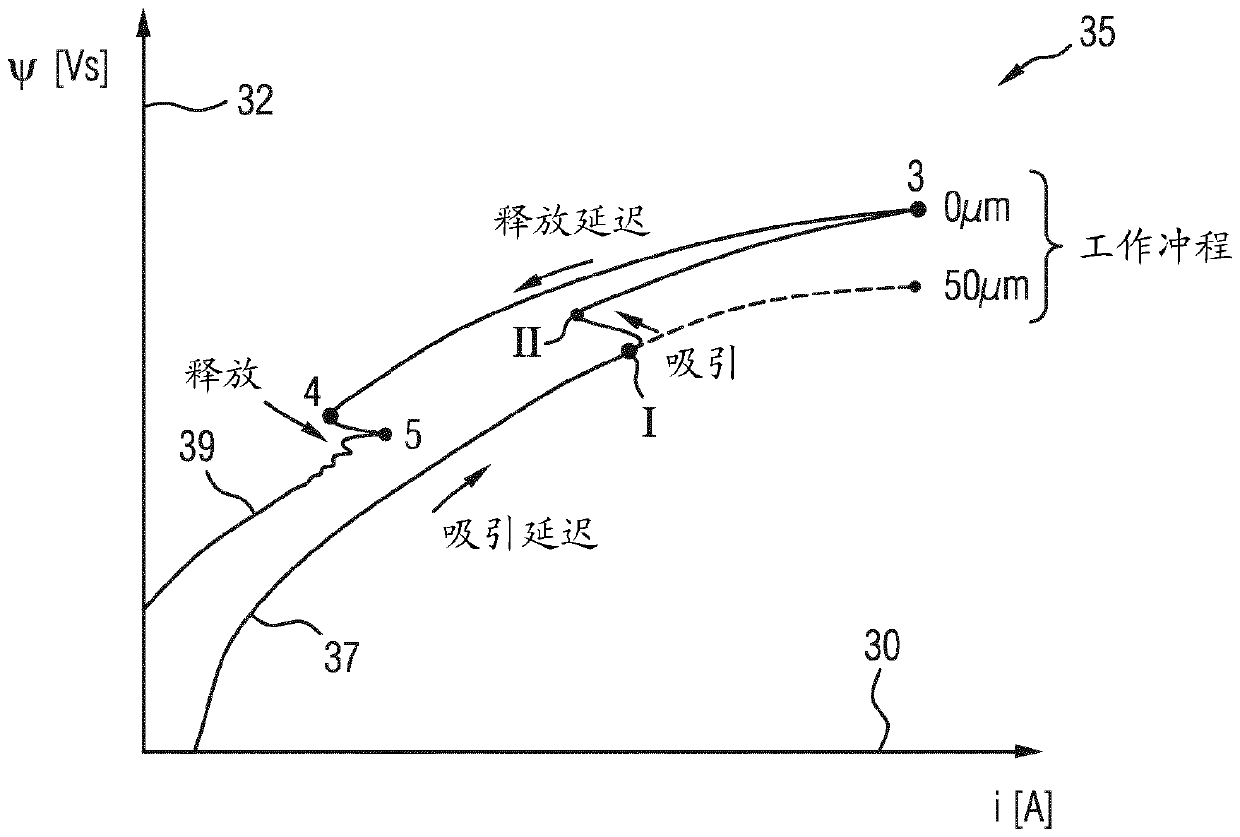

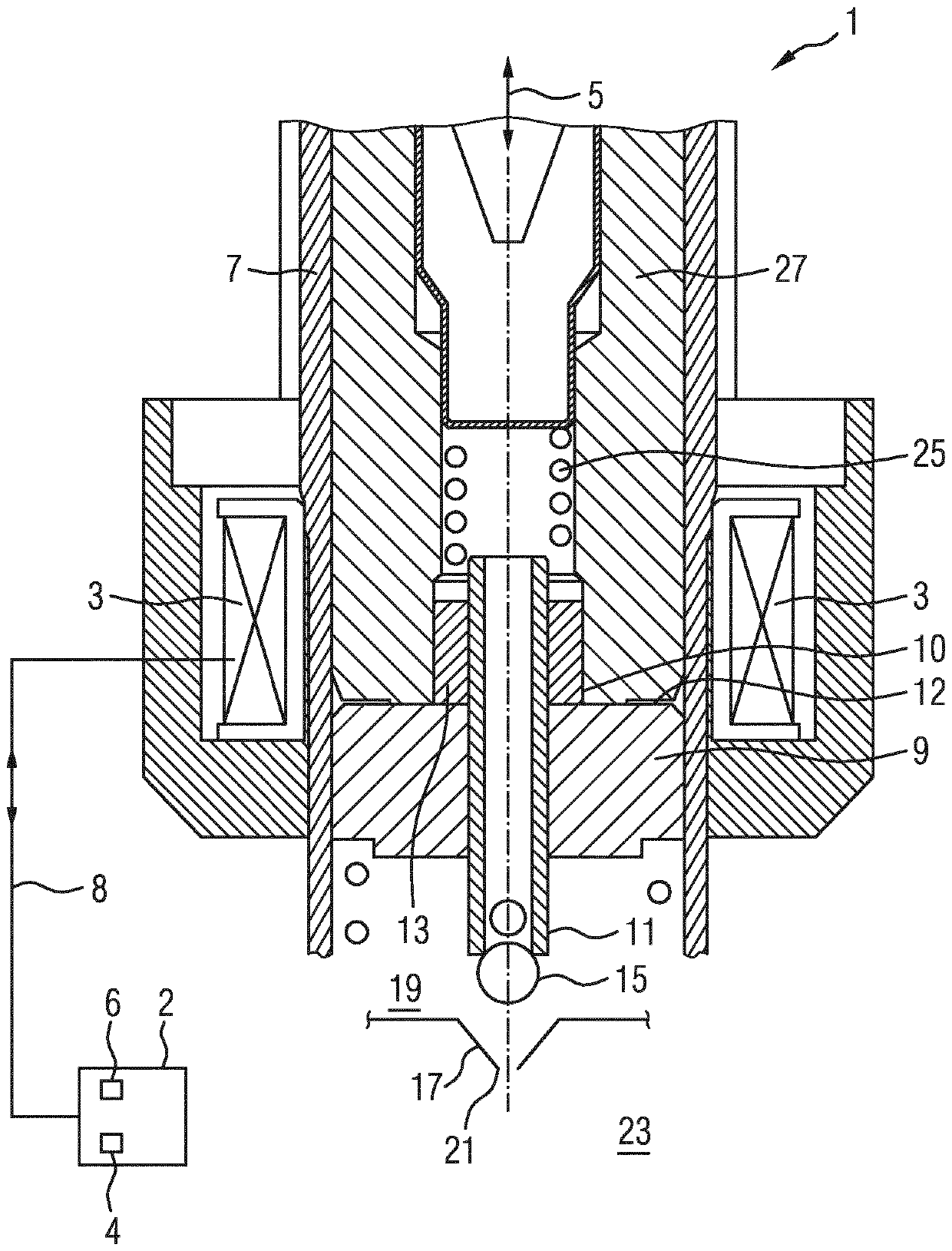

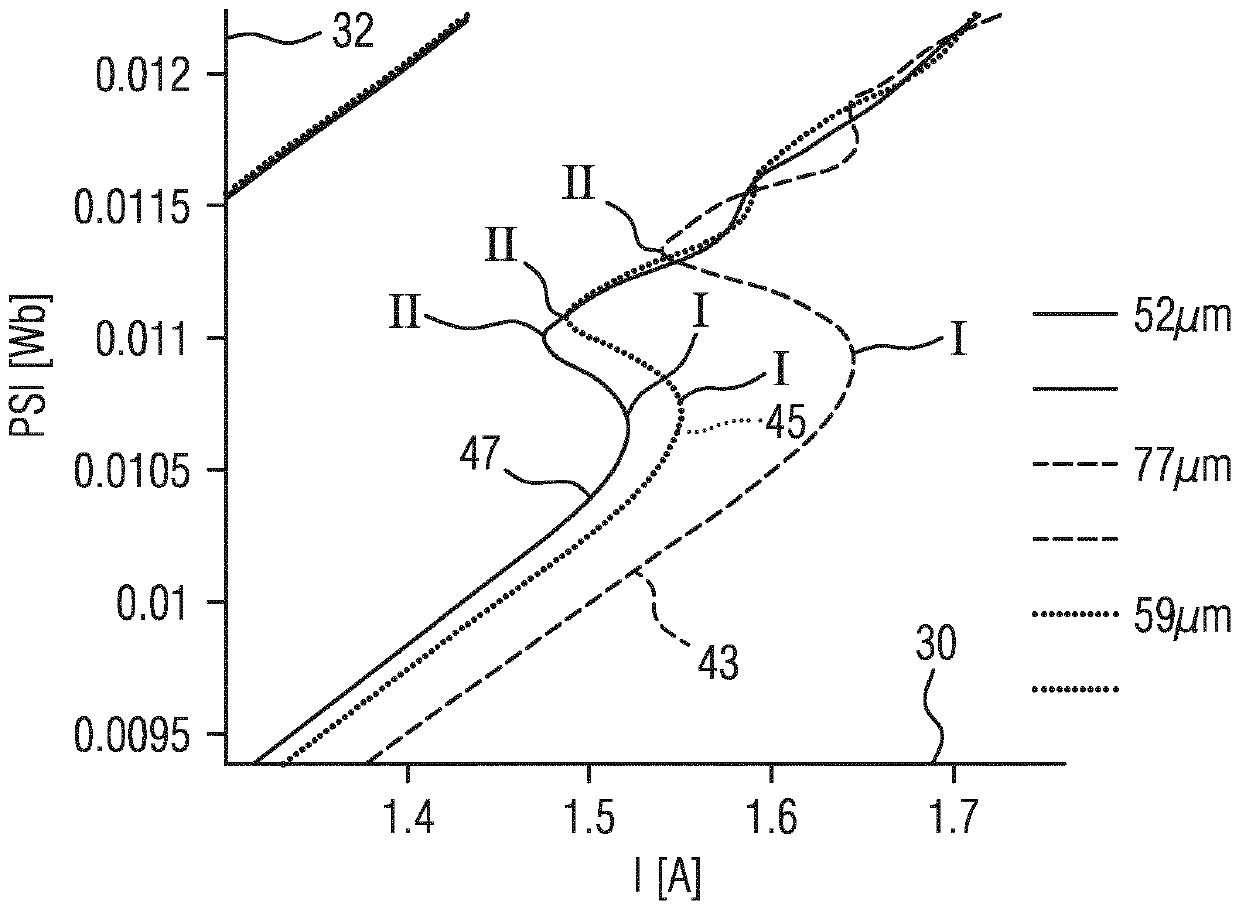

Pressure determination in a fuel injection valve

ActiveCN107567537AAccurate pressureImprove jetting accuracyElectrical controlMachines/enginesCombustion chamberSolenoid valve

The invention provides a device and a method for determining a pressure of a fuel (19) which is provided for being injected by way of a controllable closure element (11) of a solenoid valve (1) into acombustion chamber (23), wherein the method has: generating an electrical current flow (i) through a coil (3) of the solenoid valve (1) in order to generate a magnetic field in order to generate a magnetic force on an armature (9), which magnetic force displaces the armature (9) in a direction for opening the closure element (11); determining a magnitude of a magnetic flux ([psi]) of the magneticfield before or when a first state (I) is attained in which the armature begins to displace the closure element; and determining the magnitude of the pressure on the basis of the determined magnitudeof the magnetic flux.

Owner:VTESCO TECH GMBH

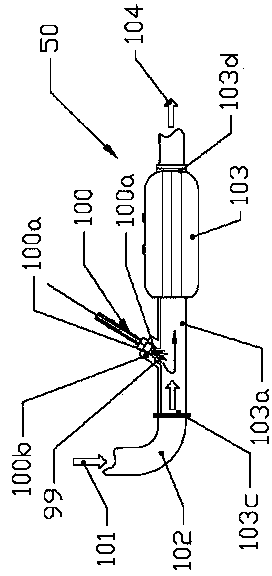

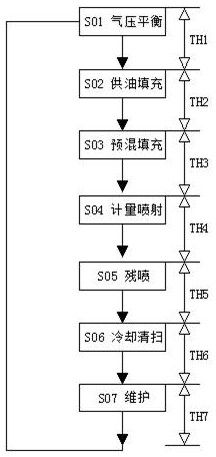

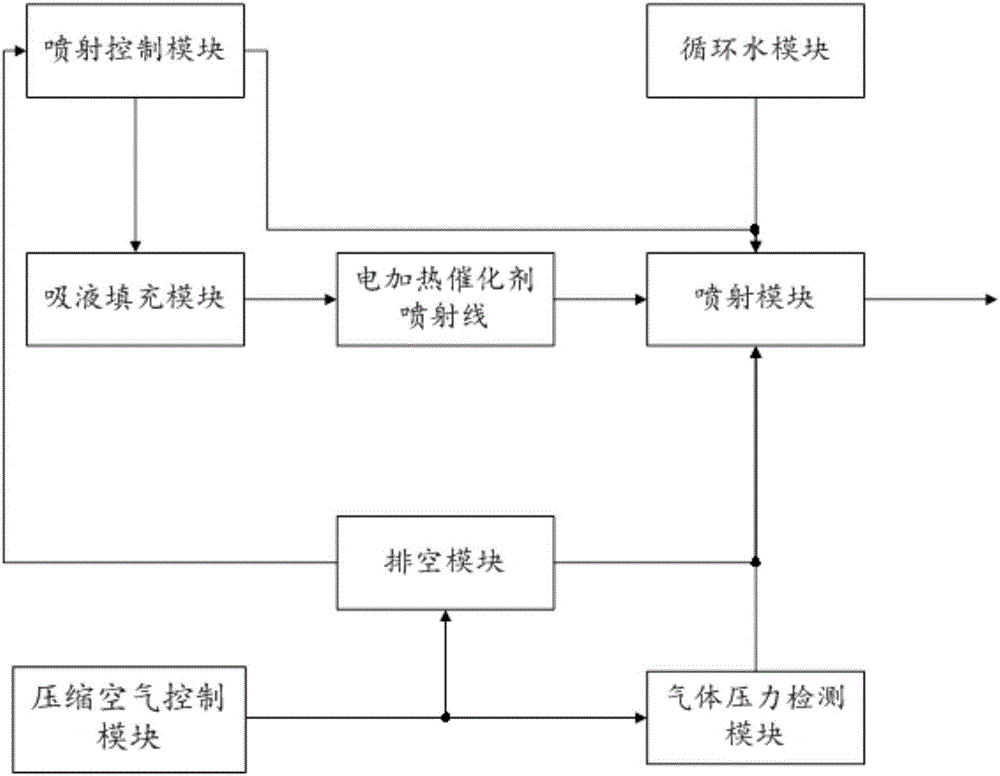

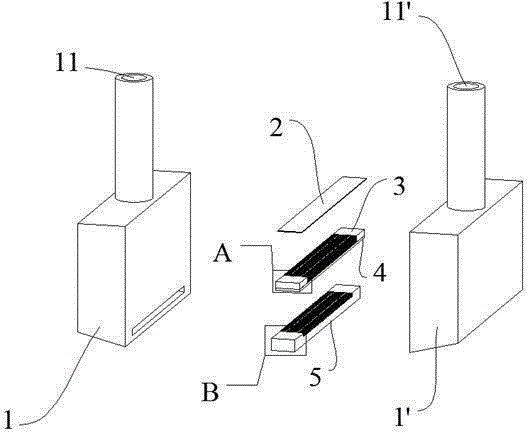

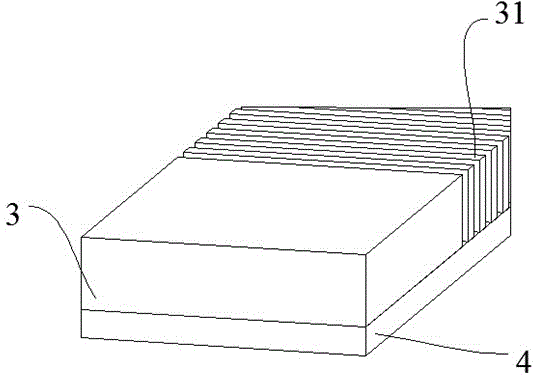

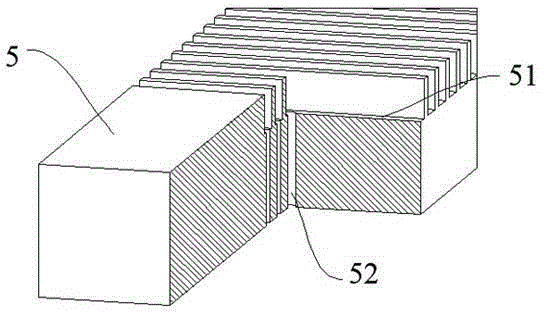

Catalyst spraying device and method in SCR system

InactiveCN106523093ASimplify the installation processImprove jetting accuracyInternal combustion piston enginesExhaust apparatusSpray atomizationCompressed air

The invention relates to a catalyst spraying device and method in an SCR system. The catalyst spraying device comprises a spraying controlling module, a liquid absorbing and filling module, a compressed air controlling module and a spraying module. The spraying controlling module, the liquid absorbing and filling module, the compressed air controlling module and the spraying module are integrated; the spraying controlling module is used for calculating the spraying quantity of catalyst required to be sprayed in accordance with the working condition of an engine and the condition of air exhausting and controls the liquid absorbing and filling module to quantificationally suck the catalyst; the liquid absorbing and filling module is used for quantificationally transferring the sucked catalyst into the spraying module through a liquid channel; the compressed air controlling module is used for controlling compressed air from a vehicle air source to transfer the compressed air into the spraying module through an air channel; and the spraying module is used for quantitative spraying atomization of the catalyst transferred by the liquid absorbing and filling module under the effect of the compressed air. According to the catalyst spraying device and method in the SCR system, the installation process is simplified, and spraying accuracy can be improved.

Owner:凯德斯环保科技(烟台)有限公司

Inkjet print head and inkjet printer

ActiveCN103496257BBraking structure is simpleLarge amount of deformationInking apparatusComputer printingInk printer

The invention discloses an inkjet printing head, which comprises at least one ejection unit, a cover film matched with the ejection unit, a piezoelectric ceramic actuator and a cover plate, a fluid inflow pipeline, a fluid outflow pipeline and a driving circuit device ; The piezoelectric ceramic brake and the cover plate are connected to form a number of independent piezoelectric ceramic units that are not connected to each other; the cover plate is connected to the injection unit, and the connection contact surface is provided with a number of fluid grooves on one side of the injection unit. The position of the unit corresponds to the position of the groove of the fluid tank; the fluid channel and the cover plate form a fluid channel, and each fluid channel is correspondingly equipped with at least one nozzle leading to the outside, so that the inkjet print head forms side or end surface spraying. Correspondingly, the invention also discloses an inkjet printer. With the present invention, on the premise of increasing the deformation of the piezoelectric ceramic brake and realizing the effective ejection action of the large-diameter ink, adjacent nozzles can operate simultaneously so that all nozzles can work simultaneously, thereby improving work efficiency.

Owner:JIN GANG NEW MATERIALS +2

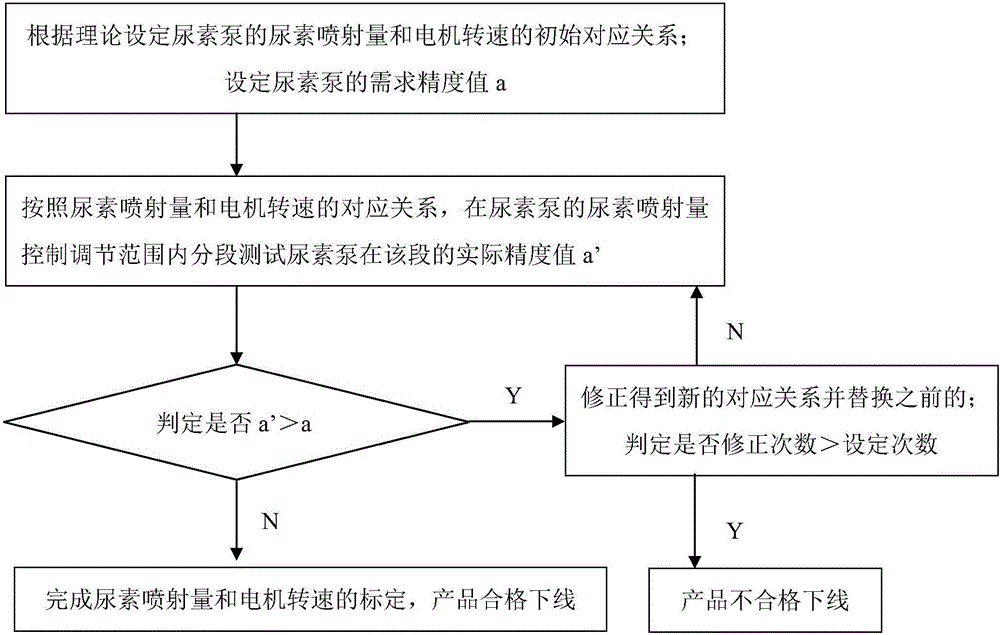

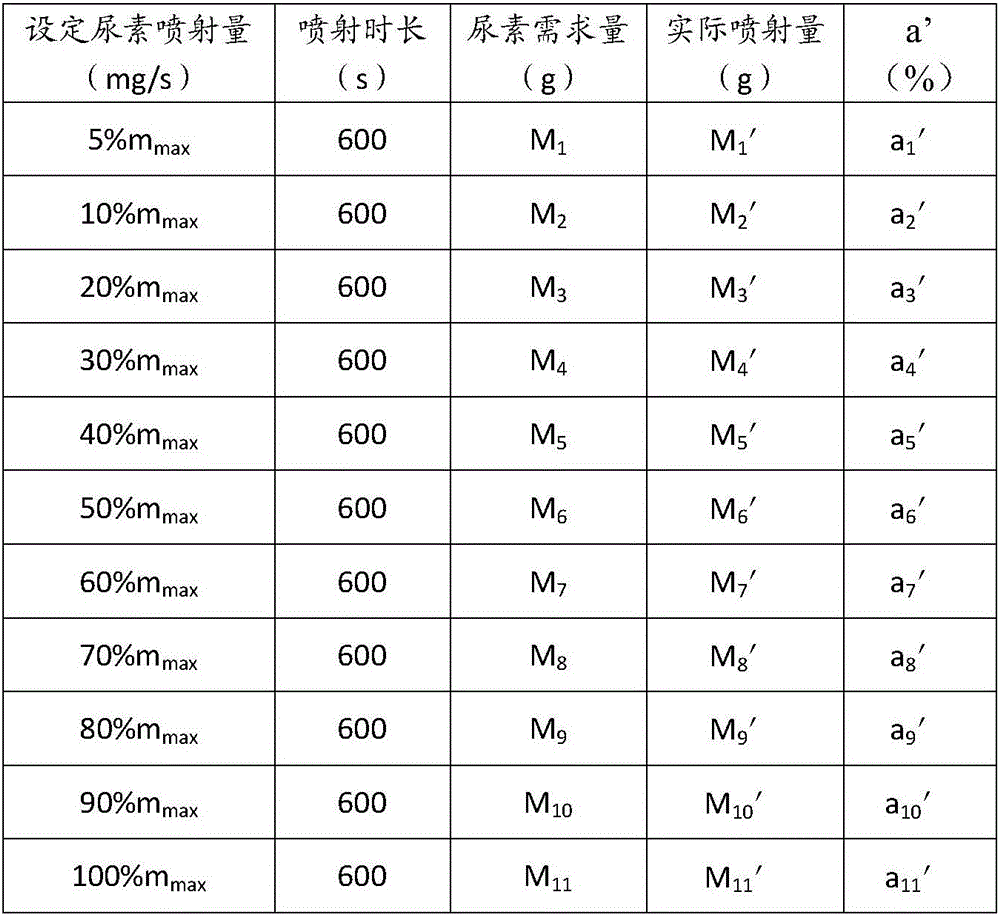

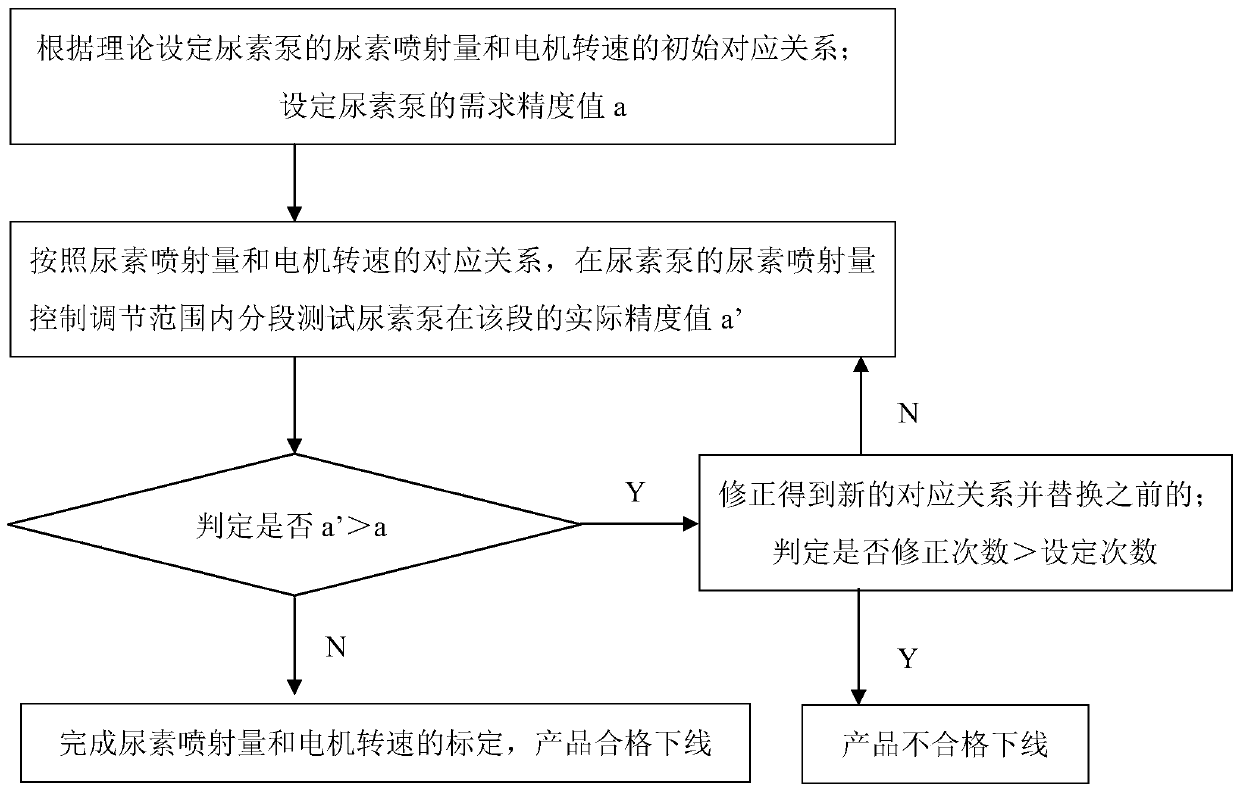

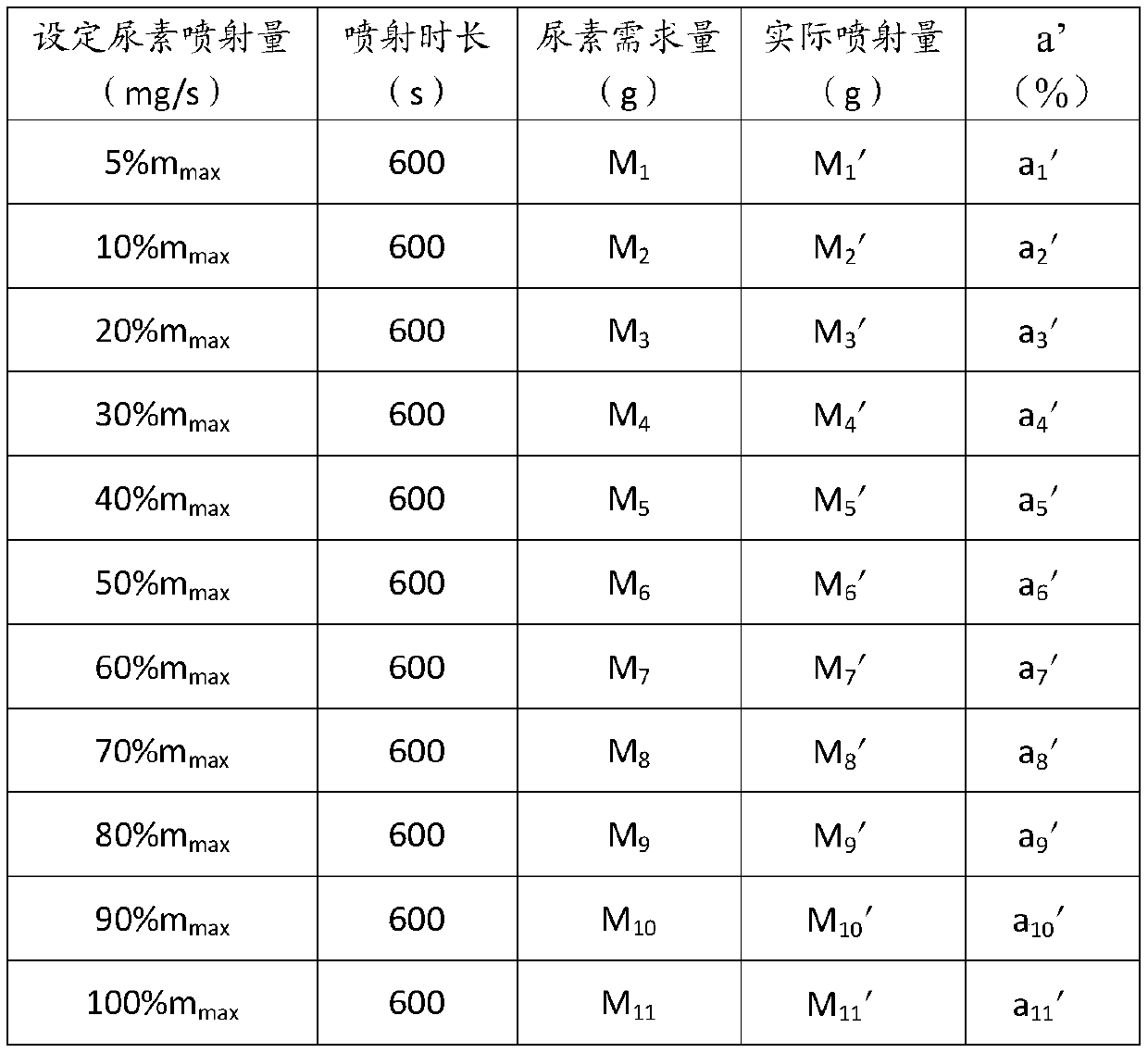

Control method for improving precision of urea pump

ActiveCN106545392AImprove jetting accuracyReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusClosed loopEngineering

The invention provides a control method capable of improving injection precision of a urea pump obviously, and particularly relates to the urea pump used for metering based on the stepping motor principle. The injection amount and the rotating speed of a motor are in positive correlation, namely the higher the rotating speed of the motor the larger the injection amount of urea. According to the method, the corresponding relation is adopted, the closed-loop control method is utilized, control precision of the urea pump can be improved by means of primary calibration, measurement, fine calibration and repeated measurement, and therefore the precision of the actual urea injection amount and required urea injection amount is realized.

Owner:WEICHAI POWER CO LTD +1

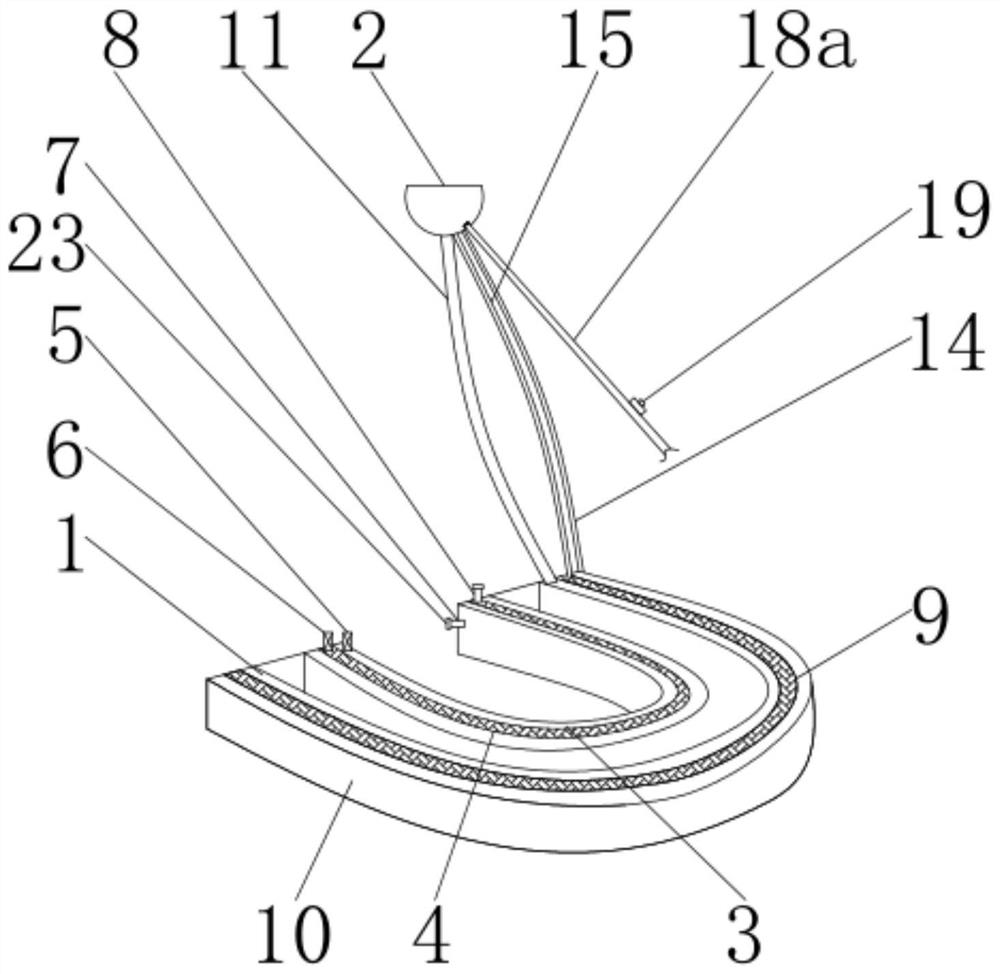

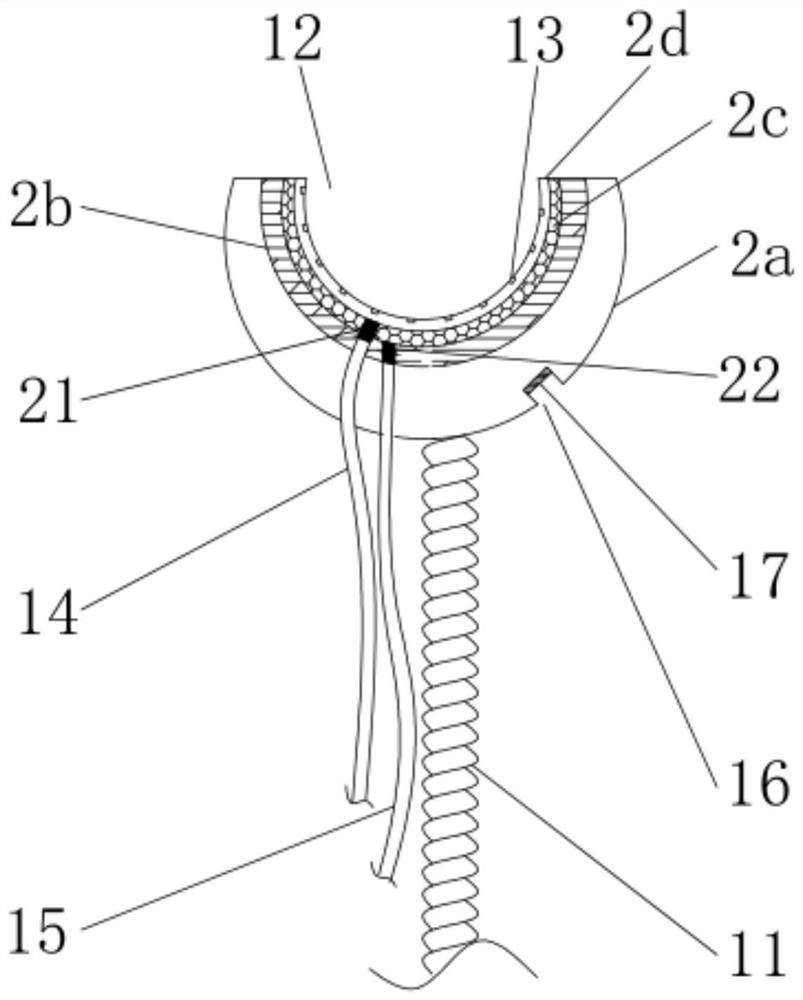

A self-service oral medication device

ActiveCN109125897BReduce workloadIndirect control of dosing timeMedical devicesOral medicineBite force quotient

The invention discloses a self-service oral medicine feeding device, which comprises a tooth cover and a medicine feeding device. The tooth cover is an arc-shaped structure with an opening upward and adapted to the upper teeth and lower teeth in the oral cavity, and is located inside the tooth cover and is composed of The medicine feeding airbag 1 and the inflatable airbag 1 are respectively arranged from the inside to the outside; the medicine feeding device includes a fixed seat with an upward semi-spherical structure, a support plate, a support airbag and a medicine spraying airbag, and the right side of the bottom end of the fixed seat There is groove 2, and the bottom end of groove 2 is provided with a permanent magnet, and a positioning mechanism is arranged in said groove 2. The self-service oral medication device provided by the present invention is not only very comfortable, but also easy to operate , In the process of applying medicine, it will not affect activities such as drinking water, spitting, and walking. It can also complete positioning spraying through self-perception to improve spraying accuracy and spraying efficiency. At the same time, it can also control the bite force of teeth The size indirectly controls the time of drug application.

Owner:张宪英

A gas-assisted metering injection system and its control method

ActiveCN106762044BAvoid the risk of easy crystallizationGood effectInternal combustion piston enginesExhaust apparatusElectricitySpray nozzle

Owner:YANTAI YINGDE PRECISION MASCH CO LTD +1

Urea solution spray electronic controller of selectively catalytic reduction system

ActiveCN101696649BImprove jetting accuracyStable pressureInternal combustion piston enginesExhaust apparatusDriver circuitElectronic controller

The invention relates to a controller, in particular to a urea solution spray electronic controller of a selectively catalytic reduction system. According to the technical scheme provided by the invention, the urea solution spray electronic controller of the selectively catalytic reduction system comprises a sensor module, a control module, an actuator drive module, a communication module and a power supply module, wherein the output end of the sensor module is connected with the input end of the control module; the output end of the control module is connected with the input ends of a urea solution nozzle driving circuit, a urea solution hydraulic pump driving circuit, a urea solution heating device and a urea tank liquid level alarm driving circuit in the actuator driving module; the output end of the power supply module is connected with the power supply ends of the control module and the sensor modules respectively; and the control module and the communication module are mutually connected. The controller can accurately control the spray amount of urea and has high spray accuracy and high adaptability.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

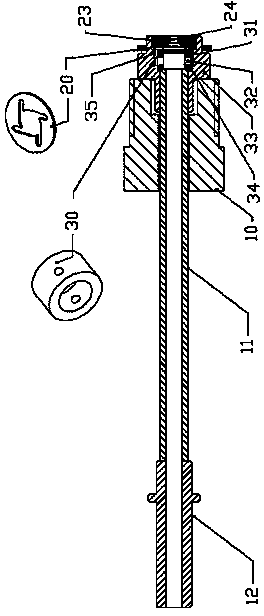

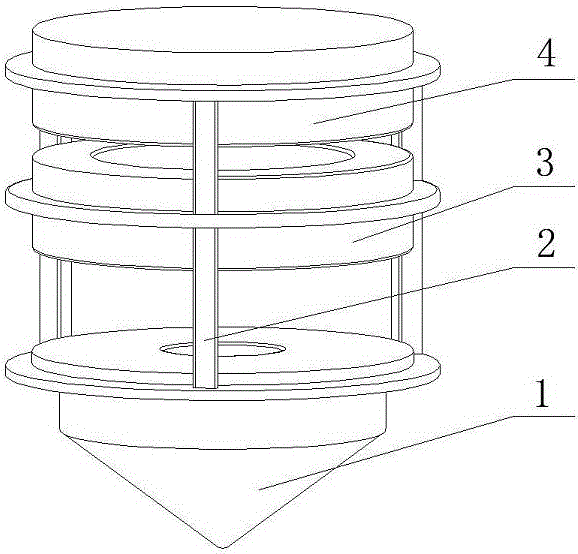

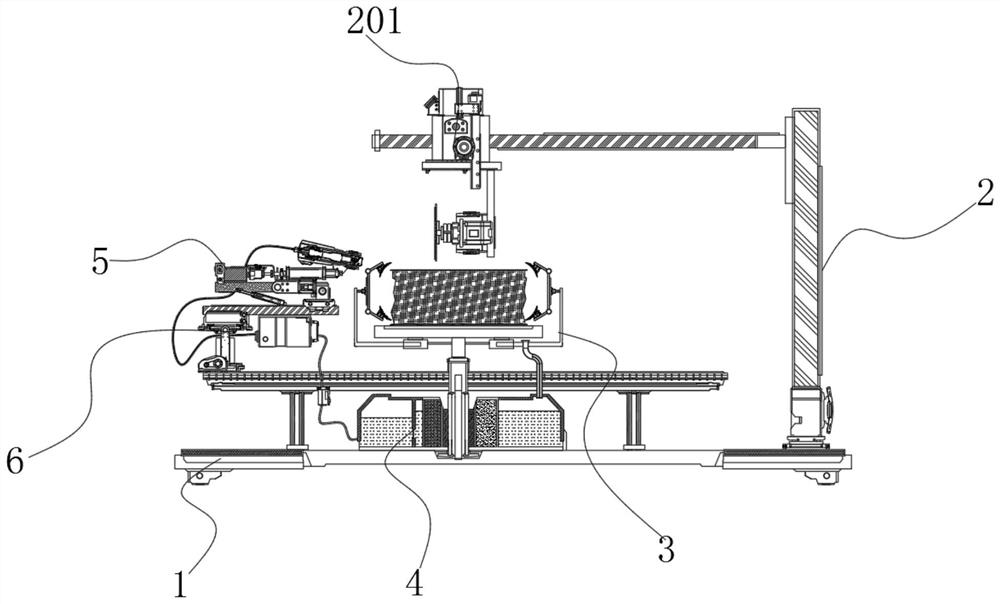

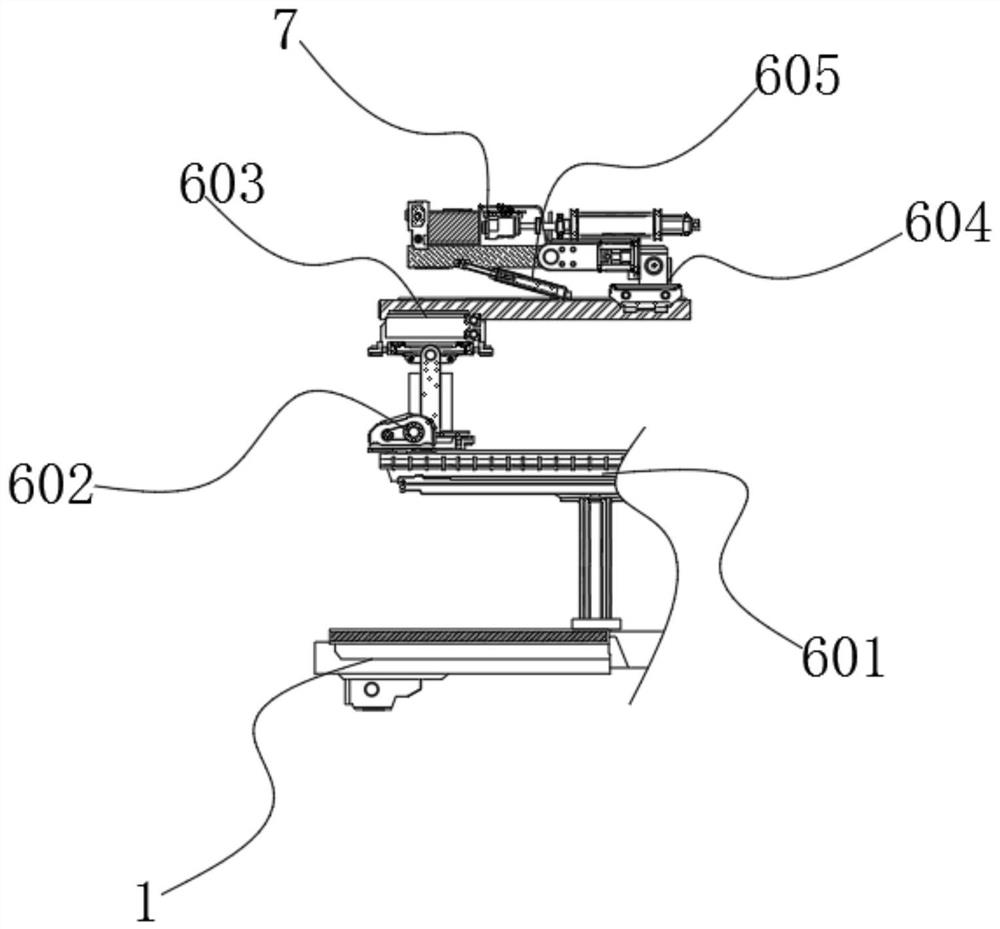

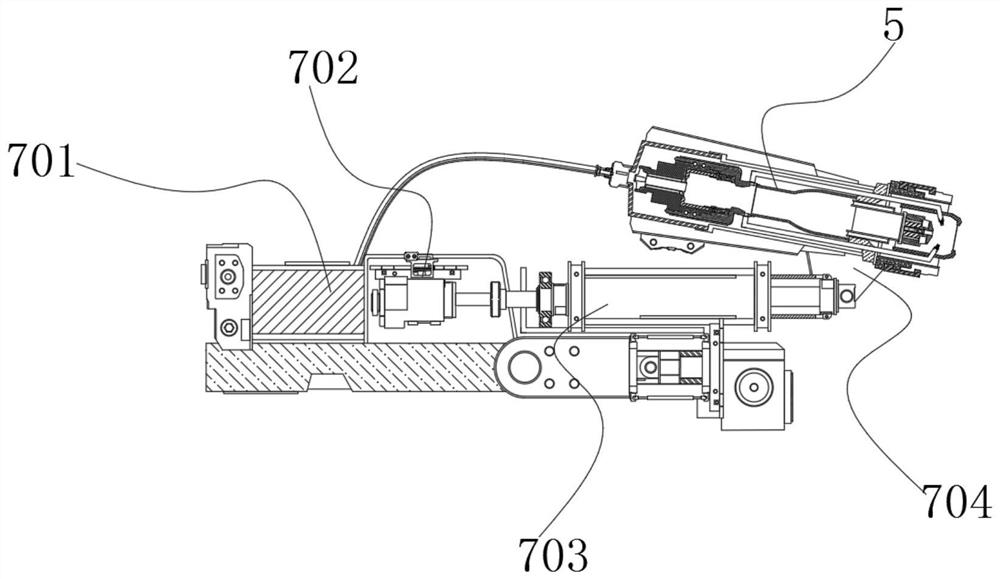

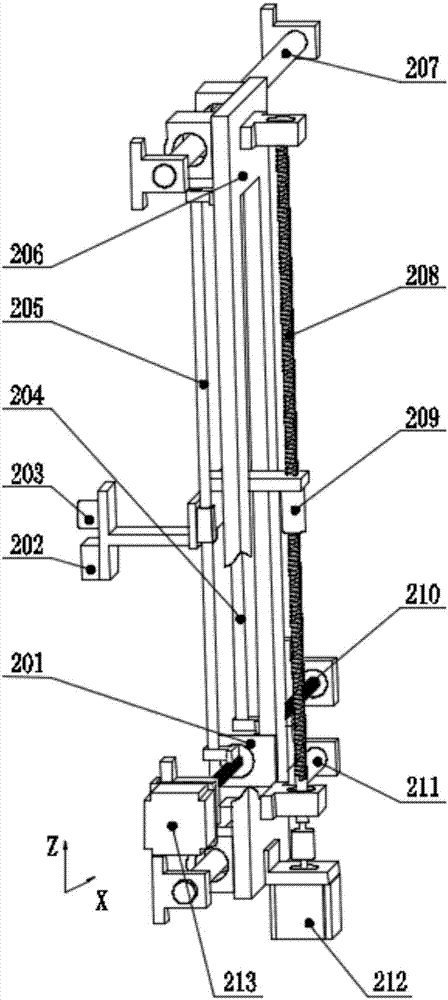

A jet mechanism of single crystal carbide material processing equipment

ActiveCN112899742BGuaranteed performanceTo achieve the purpose of multi-angle directional sprayElectrolysis componentsElectrolytic agentJet flow

The invention discloses a jet mechanism of single crystal carbonized material processing equipment, which comprises a support base, a fixing frame, a processing device, a bearing disc seat, a jet component, a main adjustment frame body and a filter purification component; the upper end surface of the support base One side is vertically fixed with a fixed frame, and a processing device is installed on the fixed frame; the center position of the upper end surface of the support base is supported and fixed with a bearing plate seat through a support column; the jet assembly is centered on the center of the bearing plate seat It can perform circular rotation around the bearing disc seat; the main adjustment frame can locally adjust the jet angle of the jet assembly on the horizontal plane, and the main adjustment frame can also make the jet assembly spray in a certain circle range through internal rotation. flow. The invention can realize accurate positioning spraying, large-area spraying and recycling electrolyte, which not only facilitates processing but also saves processing cost, improves processing efficiency and guarantees the performance of processed parts.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

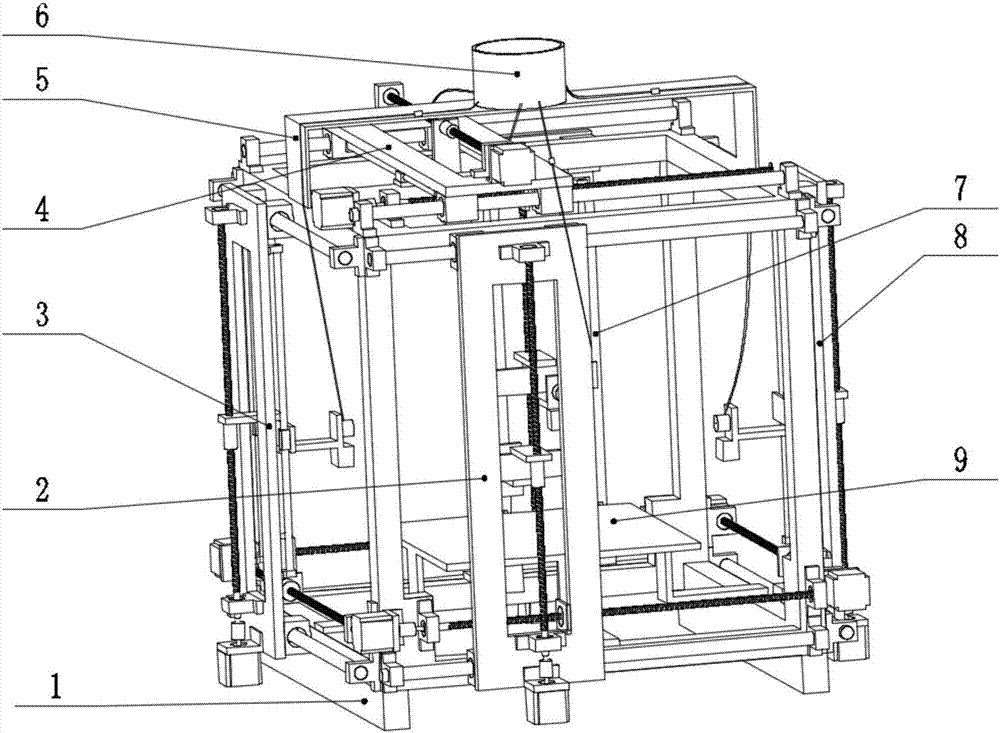

Device and method for multi-directional ultrasonic droplet jetting light-curing additive manufacturing

ActiveCN106113509BAvoid cloggingImprove mechanical propertiesAdditive manufacturing apparatus3D object support structuresAfter treatmentTransducer

The invention relates to a multi-directional ultrasonic micro-droplet jetting and photocuring additive manufacturing device and method and belongs to the field of additive manufacturing. Five identical two-axis movement assemblies are separately fixed to four side surfaces and one top surface of a rack, a material supply system bracket is fixed to the upper surface of a bracket, a material supply system is fixed to the material supply system bracket, and a base plate is fixed to the rack. Focused ultrasonic transducers are used as jetting driving force, the movement of the transducers on the five two-axis movement assemblies is controlled, and materials are continuously supplied to the focused ultrasonic transducers by a liquid storing tank. The multi-directional ultrasonic micro-droplet jetting and photocuring additive manufacturing device has the advantages that micro-droplets are jet by adopting a focused ultrasonic technology, jetting precision is high, jetting speed is high, the sizes of liquid drops are not limited by a nozzle, and the blockage of a sprayer is avoided; by adopting the focused ultrasonic transducers to simultaneously work in five directions, three-dimensional additive manufacture can be realized, the mechanical properties of molded components are controllable in all directions, an auxiliary support structure does not need to be additionally arranged for molding, a complicated after-treatment technology is avoided, and manufacture cost is reduced.

Owner:JILIN UNIV

A dispensing valve driven by giant magnetostrictive rods

InactiveCN101786068BAvoid frequency doublingConsistent frequencyLiquid surface applicatorsCoatingsMagnetostrictive actuatorConductive materials

Owner:CENT SOUTH UNIV

A control method for improving the precision of urea pump

ActiveCN106545392BImprove jetting accuracyReduced risk of crystallizationInternal combustion piston enginesExhaust apparatusClosed loopUrea

The invention provides a control method capable of improving injection precision of a urea pump obviously, and particularly relates to the urea pump used for metering based on the stepping motor principle. The injection amount and the rotating speed of a motor are in positive correlation, namely the higher the rotating speed of the motor the larger the injection amount of urea. According to the method, the corresponding relation is adopted, the closed-loop control method is utilized, control precision of the urea pump can be improved by means of primary calibration, measurement, fine calibration and repeated measurement, and therefore the precision of the actual urea injection amount and required urea injection amount is realized.

Owner:WEICHAI POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com