Patents

Literature

117results about How to "Precise control of injection volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

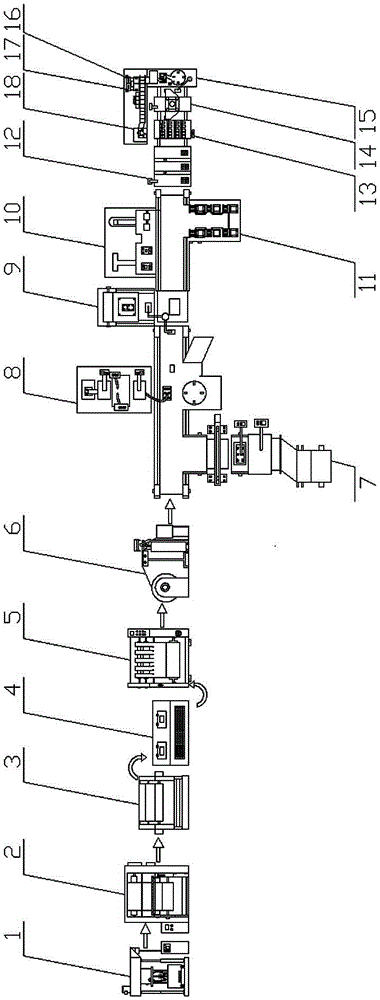

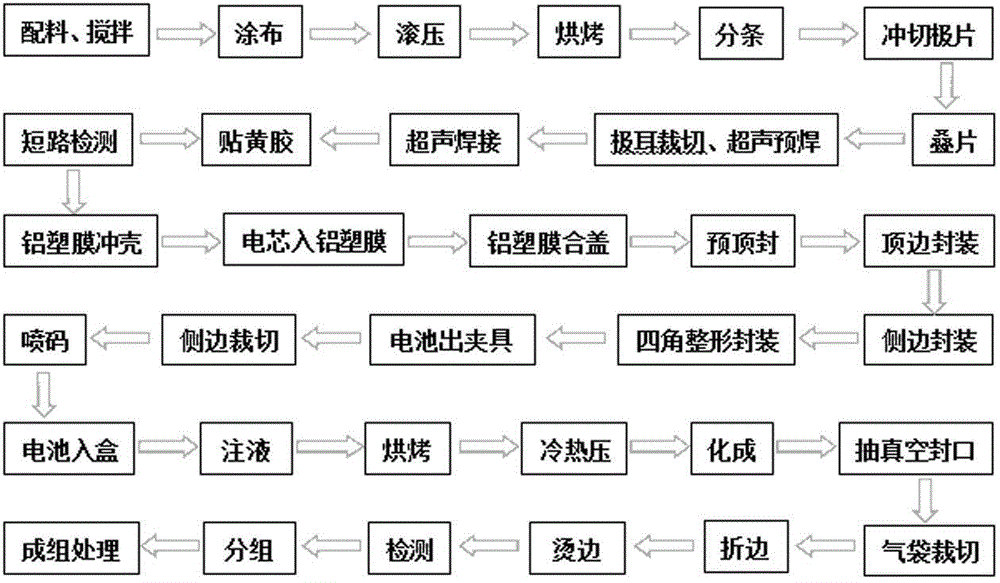

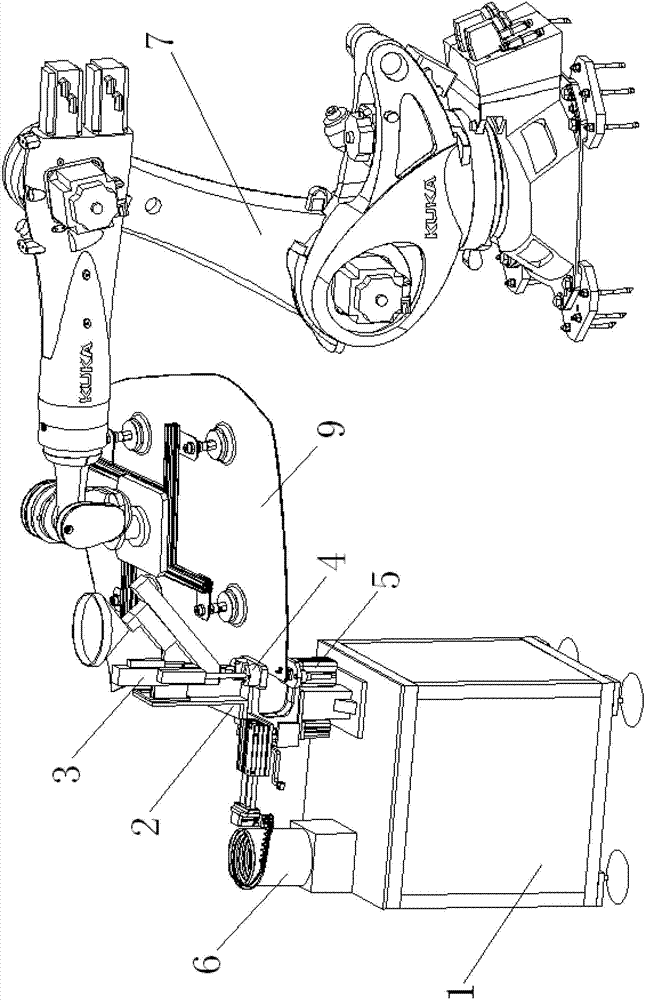

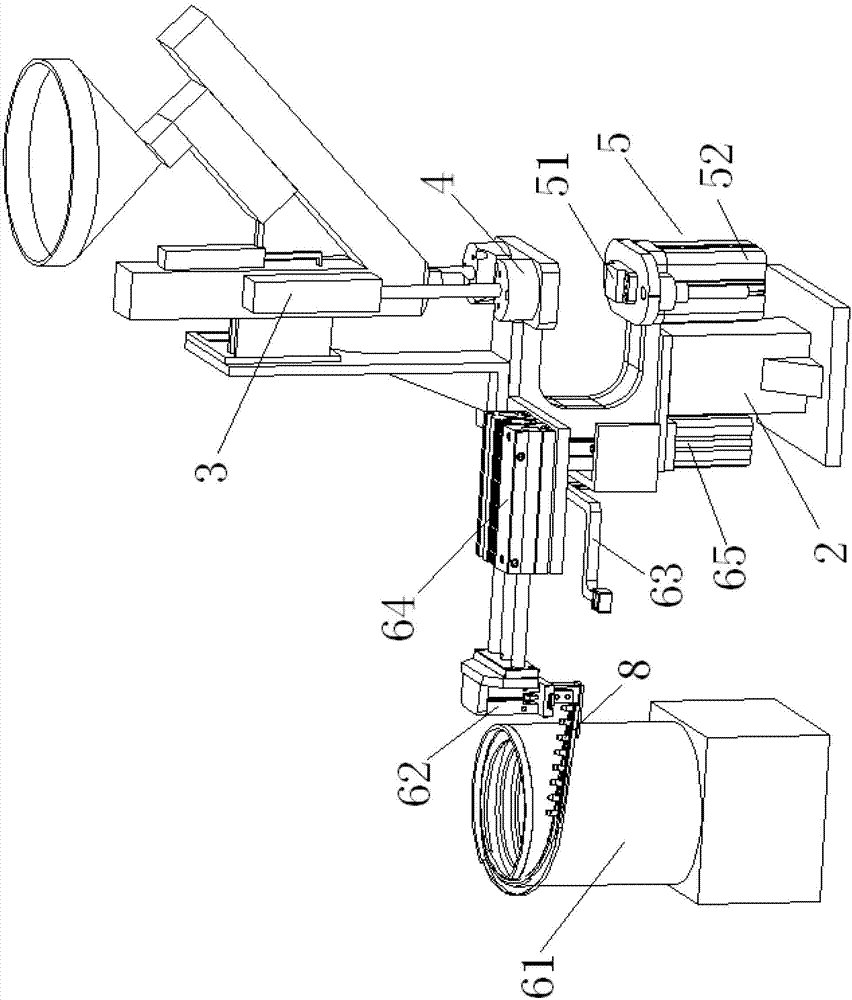

Power type lithium battery full-automatic production line and production technology thereof

ActiveCN105280957AStorableAchieve readFinal product manufactureElectrolyte accumulators manufactureProduction lineControl system

The invention relates to a power type lithium battery full-automatic production line and a production technology thereof. The power type lithium battery full-automatic production line mainly consists of a pole piece manufacturing unit, a battery assembling unit, a battery liquid injecting unit and a factory processing unit; each unit key equipment electrical control system is composed of a PLC, an industrial personal computer, a hydraulic and pneumatic component; the PLC controls each mechanism of the equipment to act in a coordinated manner; and the industrial personal computer collects data to realize the function that the data of the whole line can be stored, read and the like. The main effects lie in that mutual matching of production efficiency of each unit is realized through key debugging for production parameters, a conveyor is adopted in an intermediate link, and full automation of production process is finally realized; the production line is compatible with multi-standard battery production requirements, the production when the product is remodeled can be realized just by adjusting the equipment parameters and replacing partial work fixtures, and order form-based production requirement of the product is met; key equipment and technology on the line are independently researched and developed, the operation is reliable and stable, and the production line has higher cost performance.

Owner:东营黄蓝知识产权运营管理有限公司

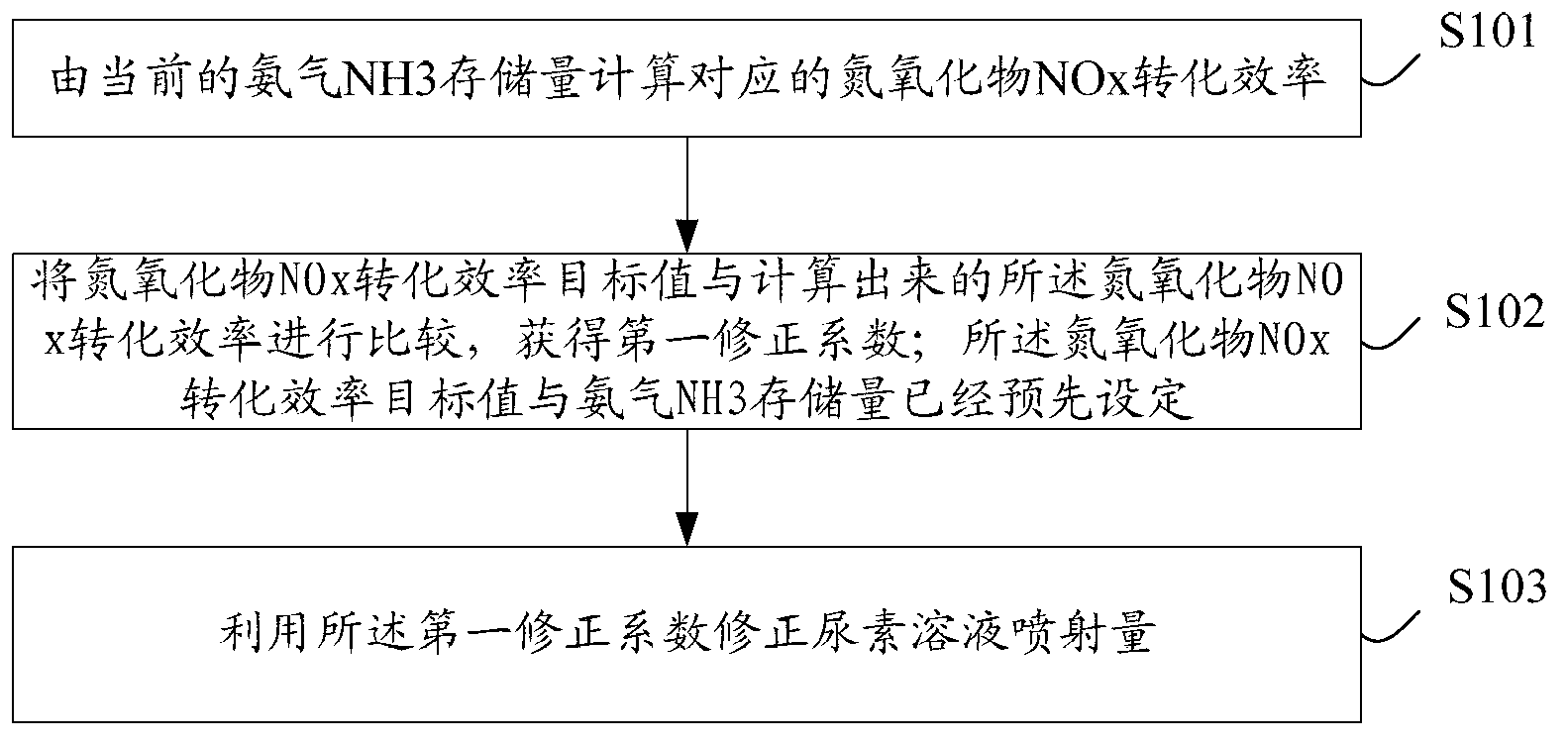

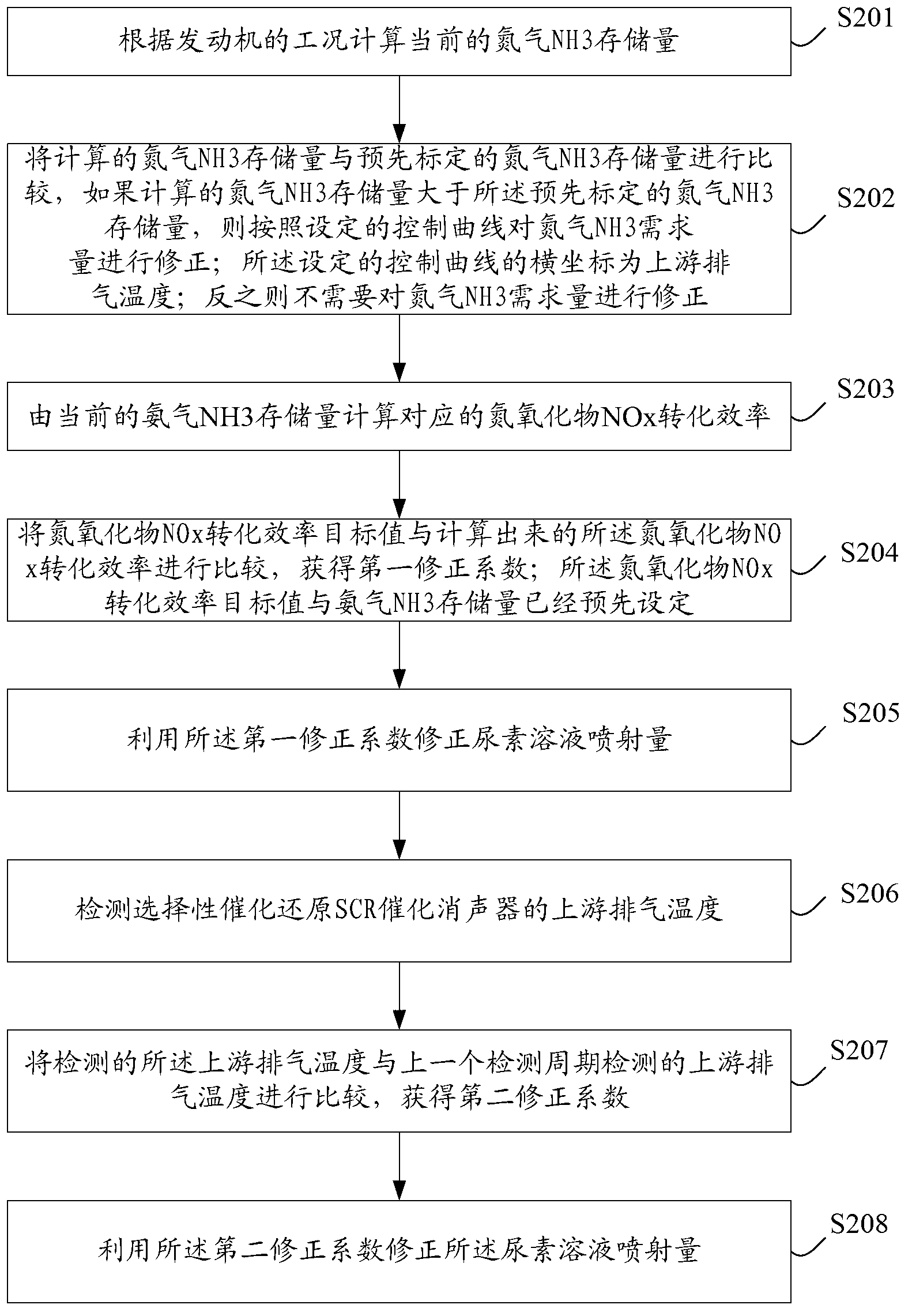

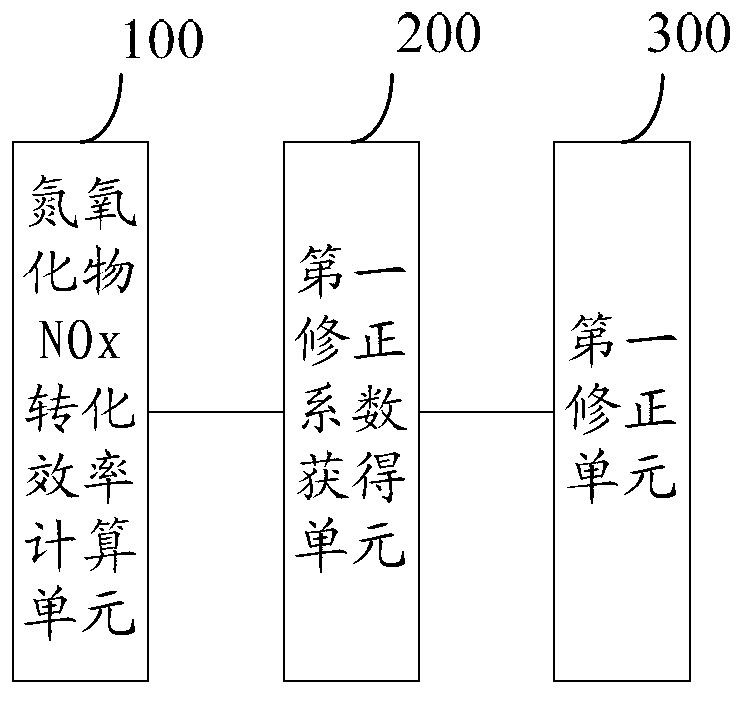

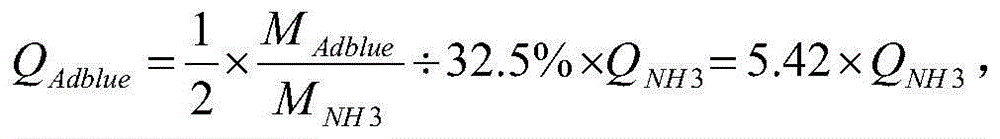

Method and system for controlling emitted dose of urea solution by SCR (Selective Catalytic reduction)

ActiveCN103016112APrecise control of injection volumeReduce injection volumeInternal combustion piston enginesExhaust apparatusReaction temperatureClosed loop

The invention provides a method and a system for controlling the emitted dose of a urea solution by SCR (Selective Catalytic Reduction) by taking three parameters, namely NH3 storage amount, NOx conversion efficiency and exhaust gas temperature into account. When the working condition of en engine instantaneously changes, the exhaust gas temperature can possibly and suddenly raise to cause increase of exhaust gas flow, and excessive NH3 escape is caused in the prior art; or when the working condition of the engine changes, the emitted dose of the urea solution is lower to cause insufficiency of the NOx conversion efficiency. Under the conditions that the requirements on the catalyst amount and the NH3 escape amount are definite, the maximum NOx conversion efficiency depends on the catalyst reaction temperature and the exhaust gas flow. According to the control method provided by the invention, a target value of the NOx conversion efficiency and the available NOx conversion efficiency based on the NH3 storage amount are added as closed-loop amendments, so that the emitted dose of the urea solution can be accurately controlled, the NOx conversion efficiency is furthest improved and the NH3 escape amount is reduced.

Owner:WEICHAI POWER CO LTD +1

Medical quantitative infusion device

The invention discloses a medical quantitative infusion device which comprises a shell and an injector, wherein a controller, a guide rod, a screw rod, a slide block and a servo motor or a stepping motor are arranged in the shell; the screw rod and the guide rod are arranged at one side in the shell in parallel; a driven shaft of the motor is connected with the screw rod; the slide block is movably sleeved on the guide rod, and the screw rod passes through a screw hole in the slide block; the controller is used for controlling the motor; a long hole which is parallel to the guide rod is formed on the shell, so that the slide block passes through the long hole and then extends out of the shell; an injection cylinder of the injector is installed and fixed on the shell through a movable positioning piece arranged on the shell; the tail end of a piston push rod of the injector is connected and positioned on the slide block through the movable positioning piece; and a key for controlling drug absorption and injection, a digital input key and a display screen for displaying data, which are connected with the controller, are also arranged on the shell. The infusion device is accurate in quantitation and convenient to use, and the injector is easy to replace.

Owner:肖俊涛

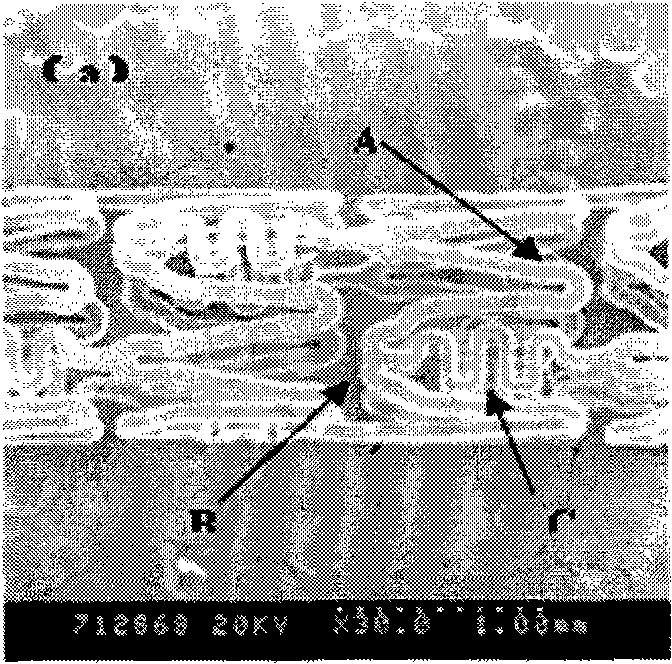

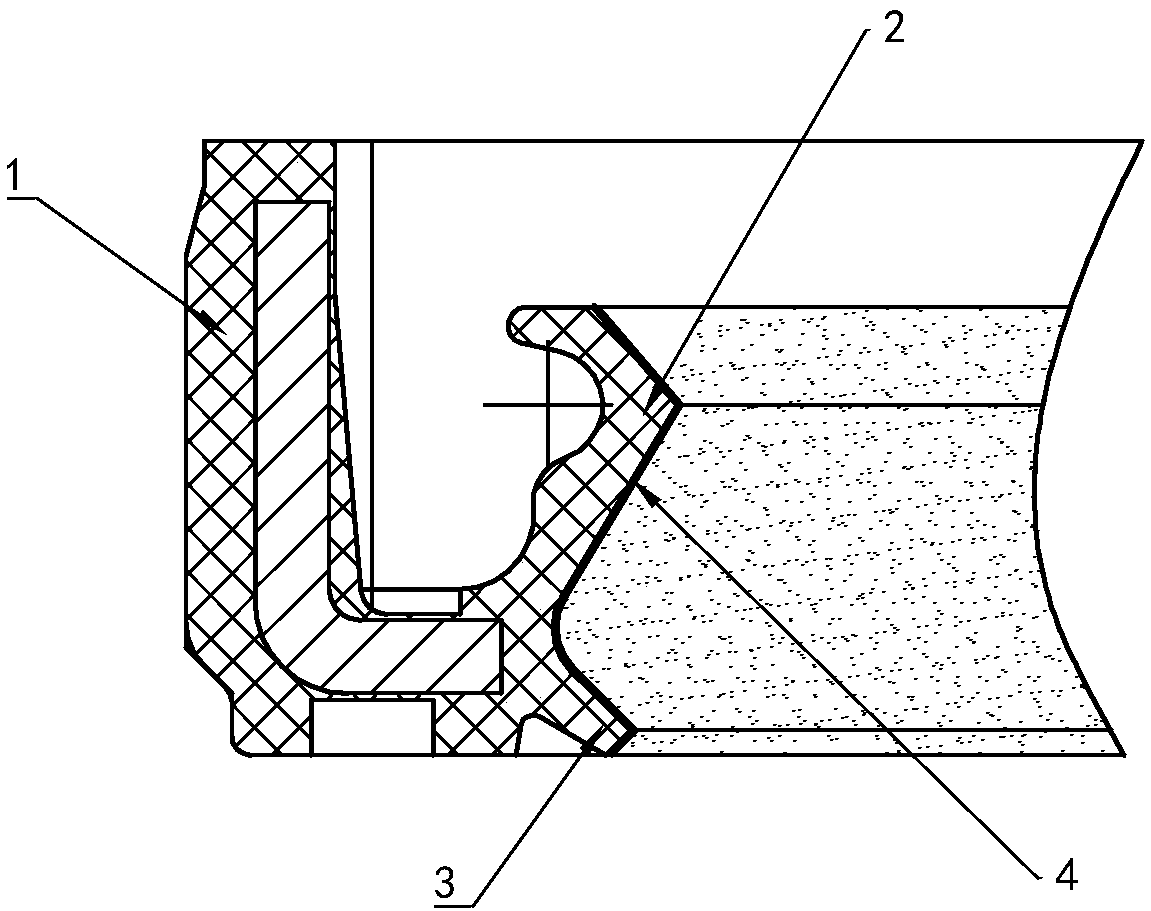

Method for preparing blood vessel stent with polyester medicament eluting coating

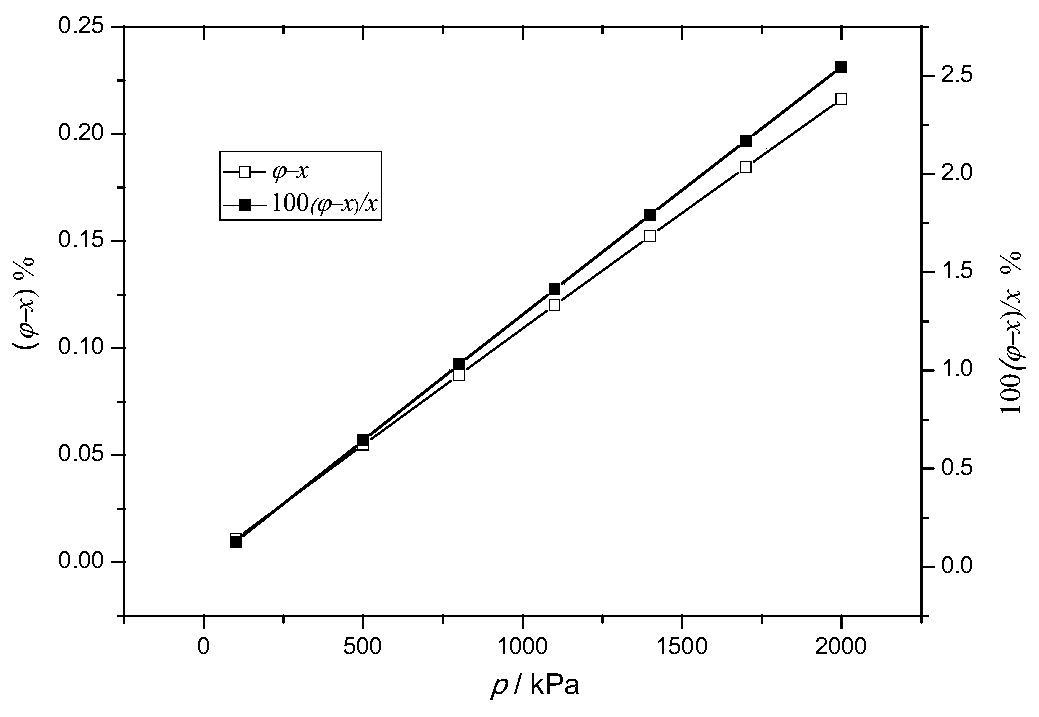

ActiveCN101279111AReduce the occurrence of restenosisReduce the occurrence of subacute thrombosis and hemangiomaStentsSurgeryCarbon dioxidePercent Diameter Stenosis

The invention provides a preparation method of polyester drug-eluting coating intravascular stent. The method comprises the steps of the cleaning of the intravascular stent, the preparation of a coating solution, the coating of drug-eluting coating, the drying and disinfecting processes of drug-eluting coating, etc. The preparation method selects the polyester, which can be degraded into carbon dioxide and water in the human body in 3 to 6 months, metabolized by the human body and finally excreted out, as a polymer drug carrier. By adopting the polymer drug carrier, the stent with the coating can not only reduce the occurrence of restenosis, but also effectively reduce the occurrence of subacute thrombosis and hemangioma afterstent implantation, and guarantee the long-term clinic safety and efficiency after stent implantation. The polymer carrier with antiproliferative drugs is coated on the outer surface of the stent to achieve the function of reducing the intimal hyperplasia at one side of blood vessels and tissues. Meanwhile, fewer drugs are carried at the side facing to the blood vessel cavity to facilitate the curing of endothelium.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

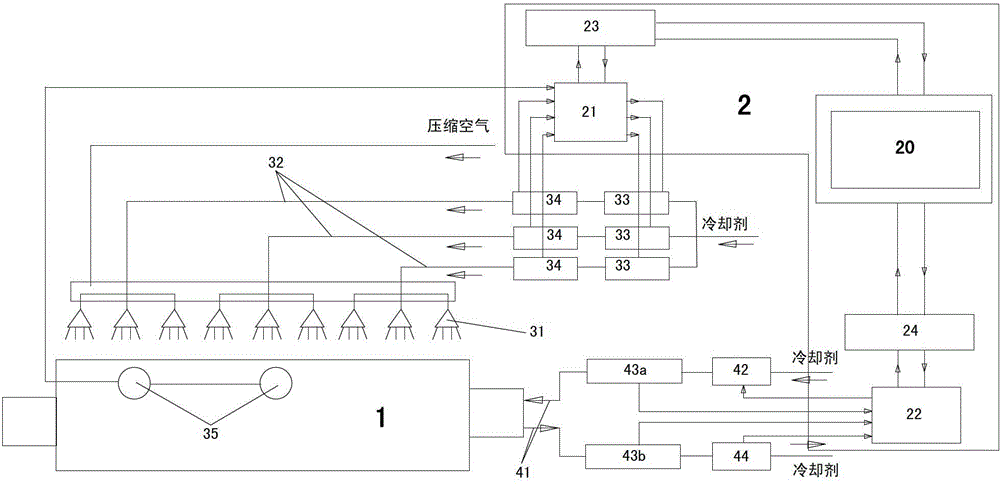

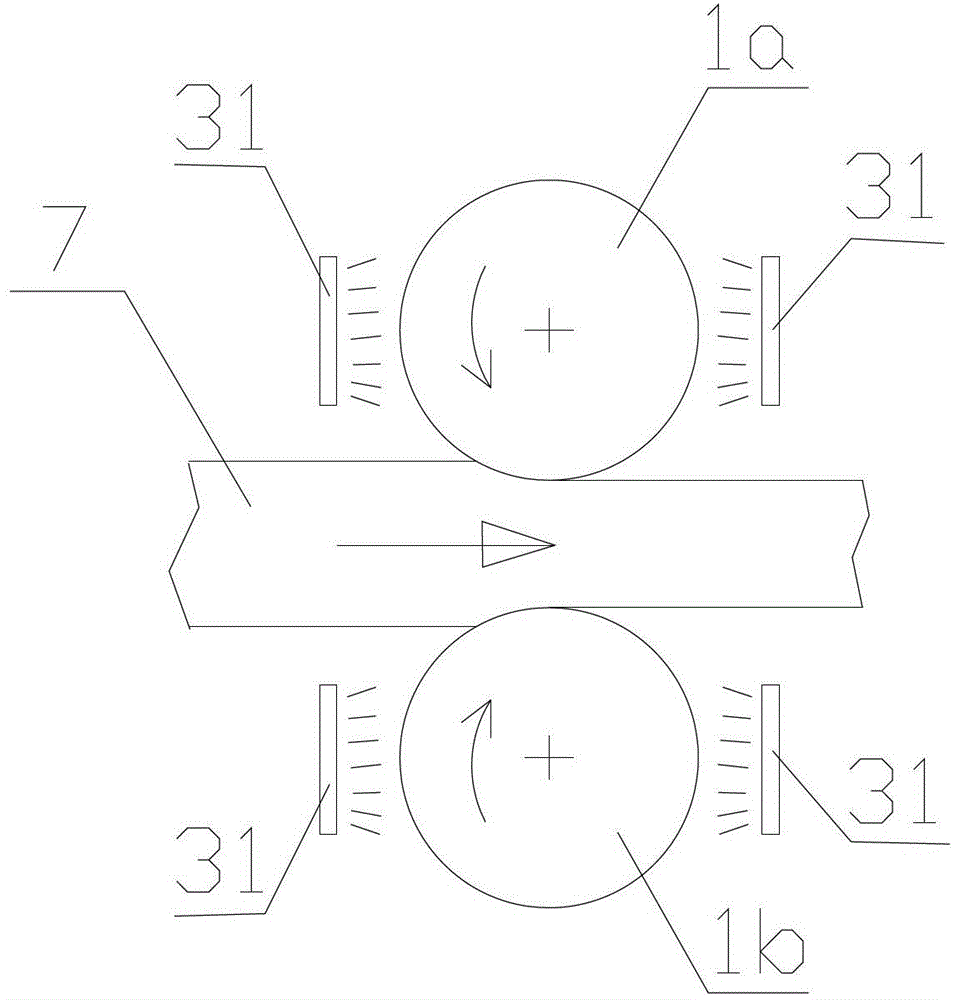

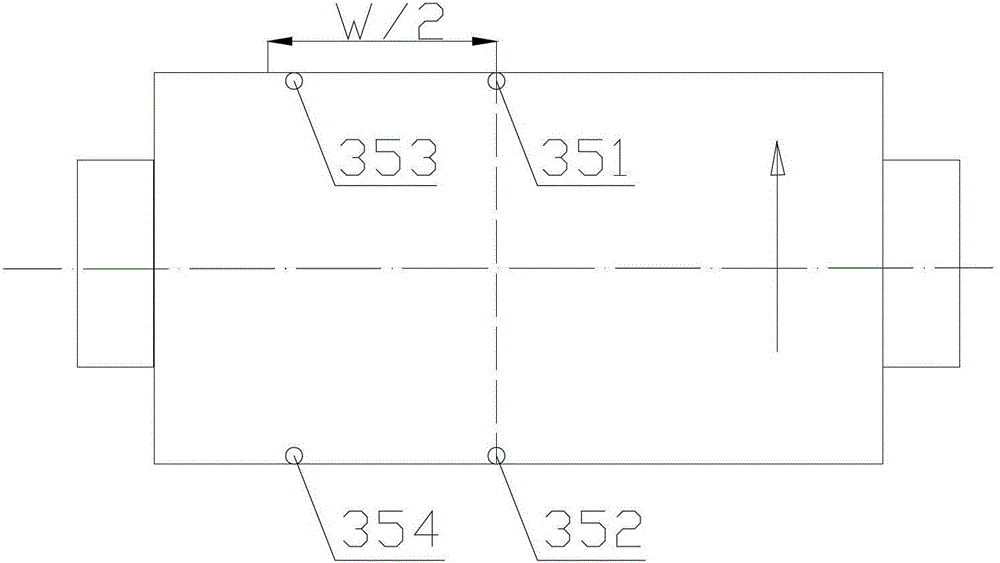

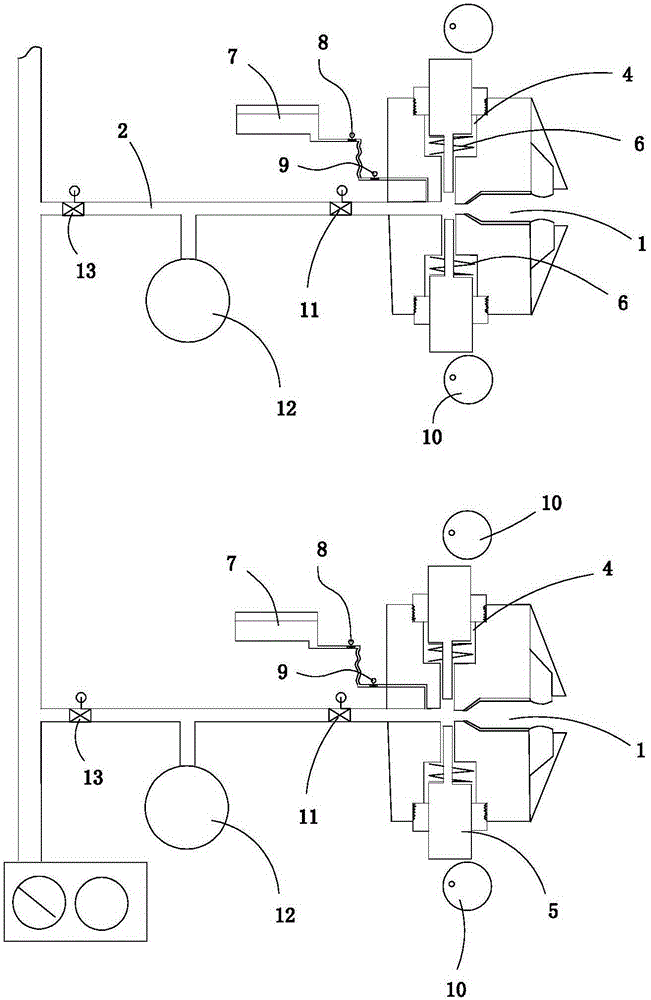

Roller cooling system and cooling control method thereof

ActiveCN103143570AReal-time detection of temperatureTemperature calculationTemperature control deviceRollsControl systemClosed loop

The invention discloses a roller cooling system and a cooling control method thereof. The roller cooling system adopts a system combined with exterior cooling and interior cooling, and the roller cooling control method is realized through a feedback-control loop consisting of a series of instrument equipment and a closed loop control system consisting of roller cooling control models. With the use of the method, the roller surface temperature and the roller interior temperature can be detected, fed back and calculated, moreover, each area of the roller surface is controlled alone through the closed loop control system; the heat convexities in the radial direction of the roller and in the peripheral and axial directions of the roller surface can be effectively controlled; the heat shock is reduced; and the service life of the roller is effectively prolonged by more than one time according to the field application statistics. The control models are simple and convenient to set and adjust, can precisely control the roller surface aerosol cooling injection amount, and guarantees no affection of rolling mill coolant on the surface quality of a continuous casting billet in the rolling mill position.

Owner:BERIS ENG & RES CORP +1

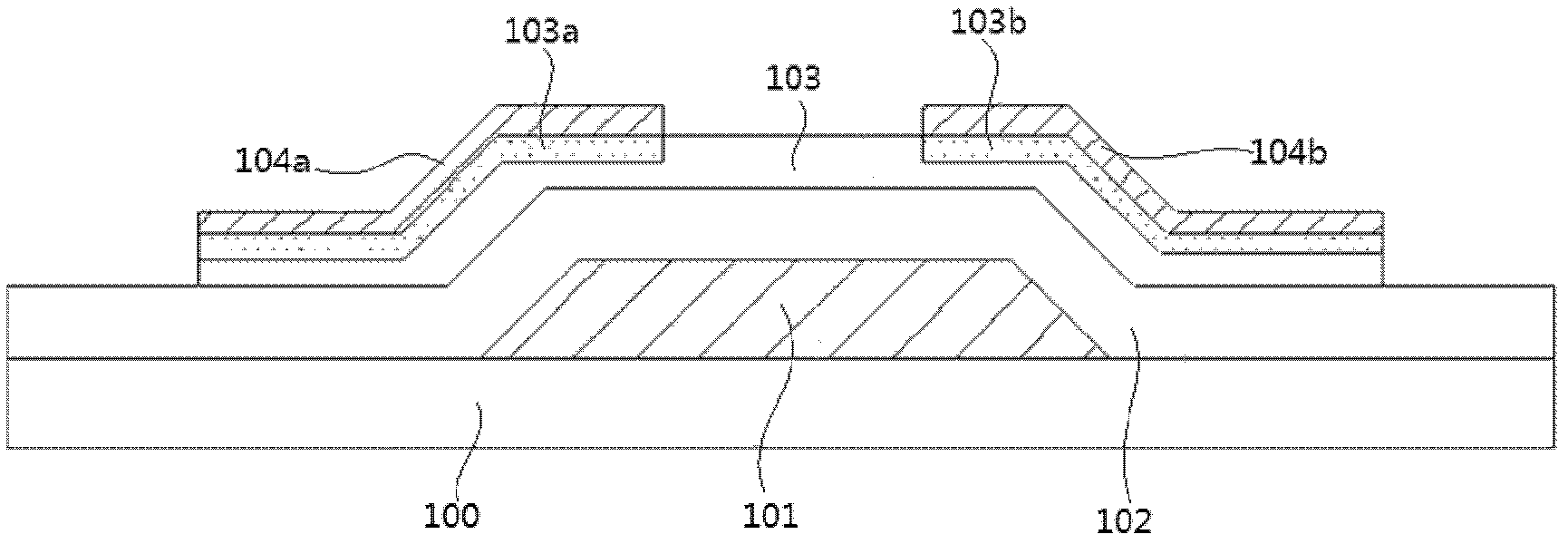

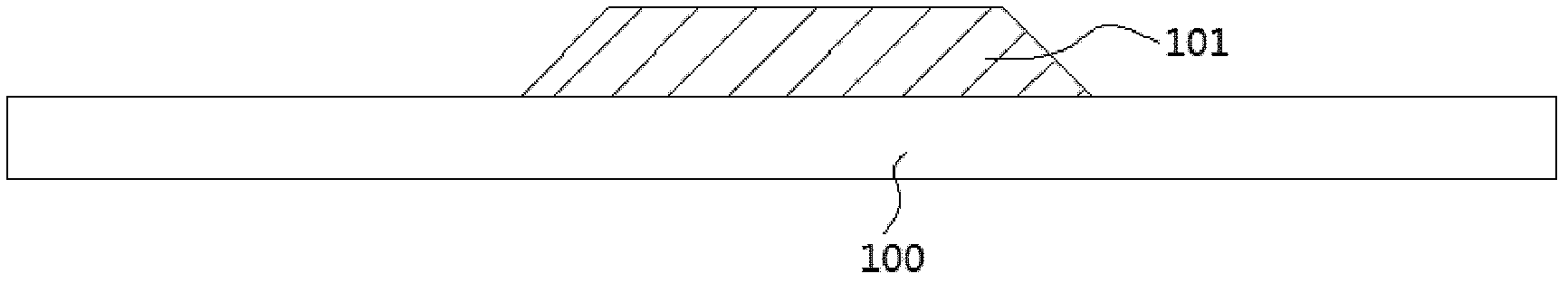

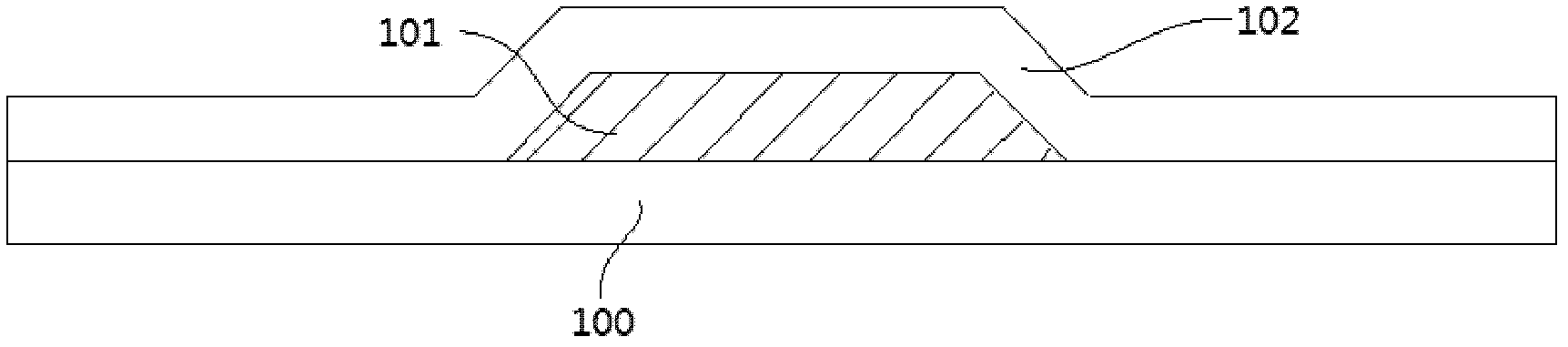

TFT (thin film transistor) and manufacturing method thereof

InactiveCN102646715ALow resistivityImprove stabilityTransistorSemiconductor/solid-state device manufacturingSemiconductorOxide semiconductor

The invention provides a TFT (thin film transistor), comprising a substrate, a gate electrode layer, a gate electrode insulating layer, an oxide semiconductor layer, a source electrode layer and a drain electrode layer, wherein the gate electrode insulating layer is arranged on the gate electrode layer; the oxide semiconductor layer is arranged on the gate electrode insulating layer and comprises a first transition area, a second transition area and a channel area, the first transition area and the second transition are not mutually adjacent and the channel area is arranged between the first transition area and the second transition area; and the source electrode layer and the drain electrode layer are arranged on the first transition area and the second transition area, the resistivity of the first transition area and the second transition area is lower than the resistivity of the channel area, the first transition area and the source electrode layer form ohm contact, and the second transition area and the drain electrode layer also form the ohm contact. The invention further provides a manufacturing method of the TFT. Through the technical scheme of the invention, the stability and the on-state current of the TFT are improved.

Owner:BOE TECH GRP CO LTD

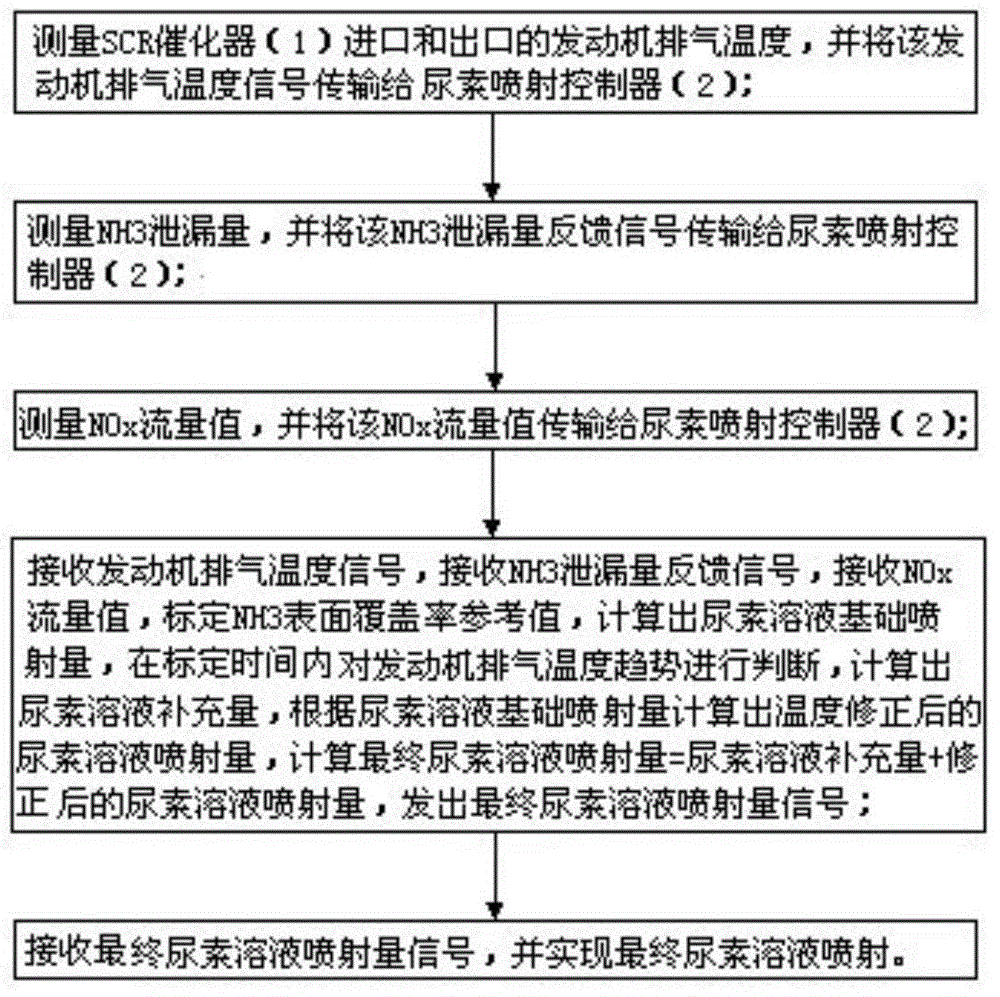

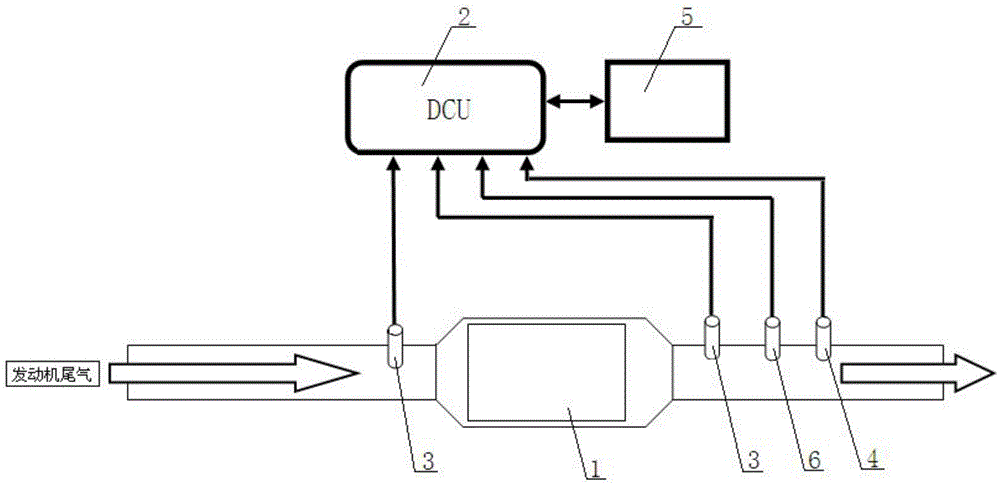

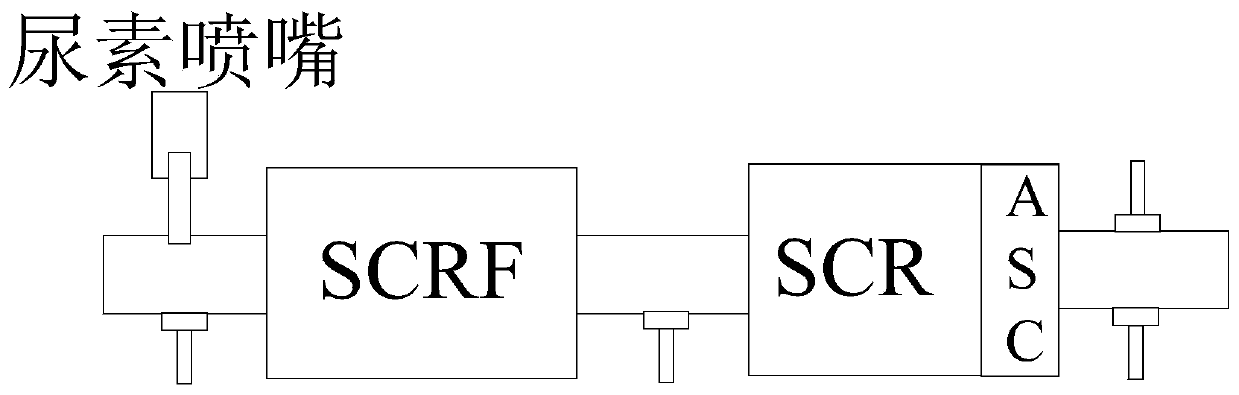

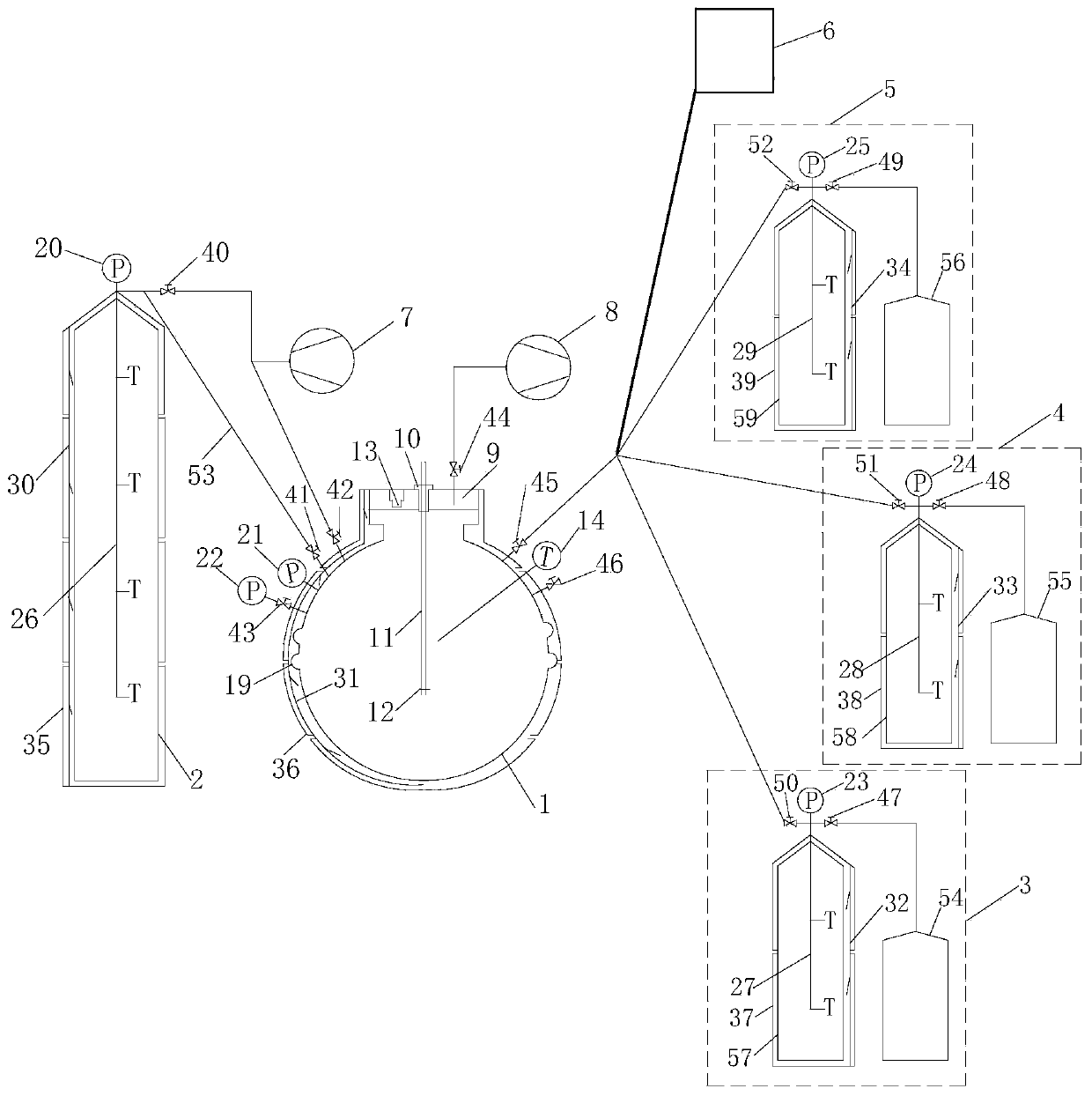

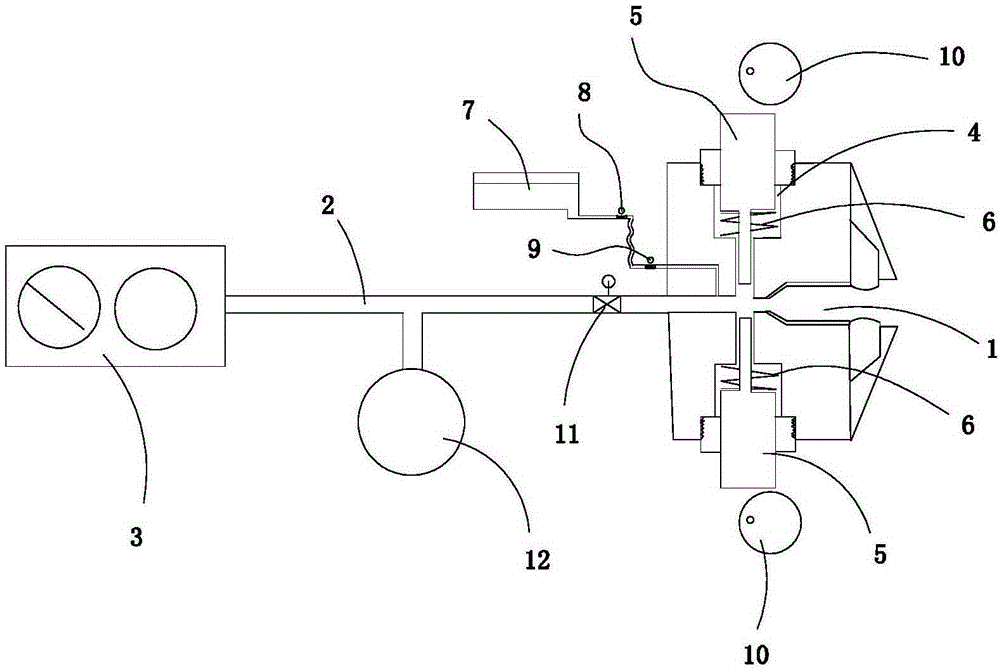

Method and system for controlling urea solution spraying amount in closed loop mode through SCR system

ActiveCN104612791APrecise control of injection volumeReduce leakageInternal combustion piston enginesExhaust apparatusElectricityClosed loop

The invention provides a method and system for controlling the urea solution spraying amount in a closed loop mode through an SCR system. The method for controlling the urea solution spraying amount includes the steps of measuring and transmitting SCR catalyst converter temperature signals, measuring and transmitting NH3 leakage rate feedback signals, measuring and transmitting NOx flow values, and calculating and sending out the final urea solution spraying amount. The system for controlling the urea solution spraying amount comprises an SCR catalyst converter (1), a urea spraying controller (2), an exhaust air temperature sensor (3), an NH3 sensor (4), a urea spraying metering pump (5) and an NOx sensor (6). The exhaust air temperature sensor (3), the NH3 sensor (4), the urea spraying metering pump (5) and the NOx sensor (6) are electrically connected with the urea spraying controller (2). The urea solution spraying amount can be more accurately controlled on the premise that two different SCR catalyst converter temperature conditions are distinguished.

Owner:DONGFENG COMML VEHICLE CO LTD

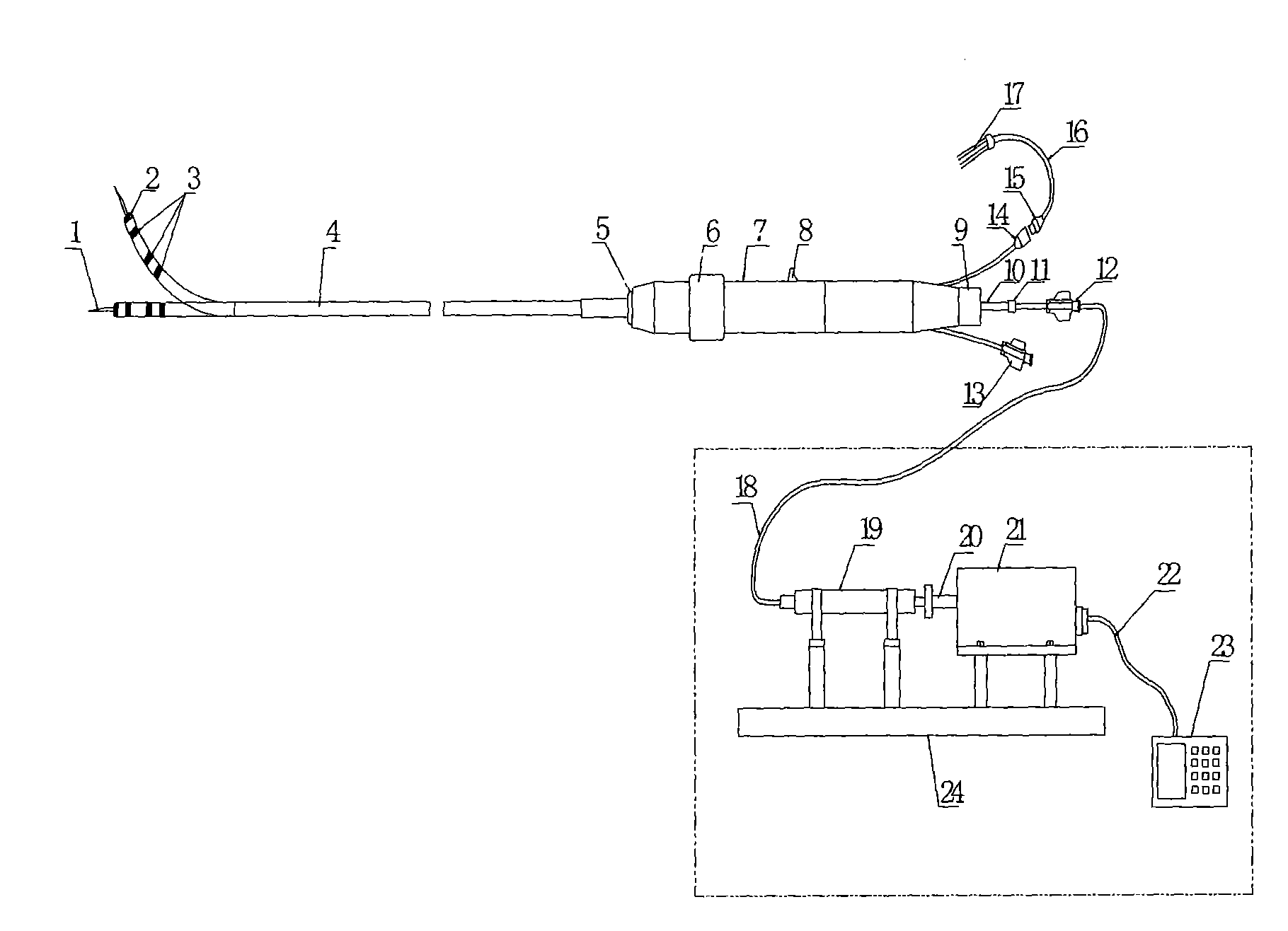

Device and system for locally delivering therapeutic agents

The invention discloses a device for locally delivering therapeutic agents, which comprises a main body catheter, an injection catheter and an operating handle, wherein a head electrode and a plurality of ring electrodes are arranged on a bendable section of the main body catheter; the head electrode is connected with the ring electrodes through a lead; the other end of the lead is connected witha connecting tail line jack on the operating handle; and a magnetic field sensor is fixed on the head electrode and is connected with the connecting tail line jack on the operating handle through a lead thereon. The invention also discloses a system. The head electrode and the ring electrodes are arranged on the bendable section for collecting electric signals, and a doctor distinguishes a pathological area of a patient according to the signals. Due to the arrangement, the device is compatible with magnetic positioning equipment and electrical positioning equipment, a three-dimensional geometrical model and a three-dimensional potential model are established, and a therapeutic part is accurately determined. According to a bending control piece on the operating handle, bidirectional bending is realized, and the therapeutic part is convenient and accurate to select.

Owner:MICROPORT SINICA CO LTD

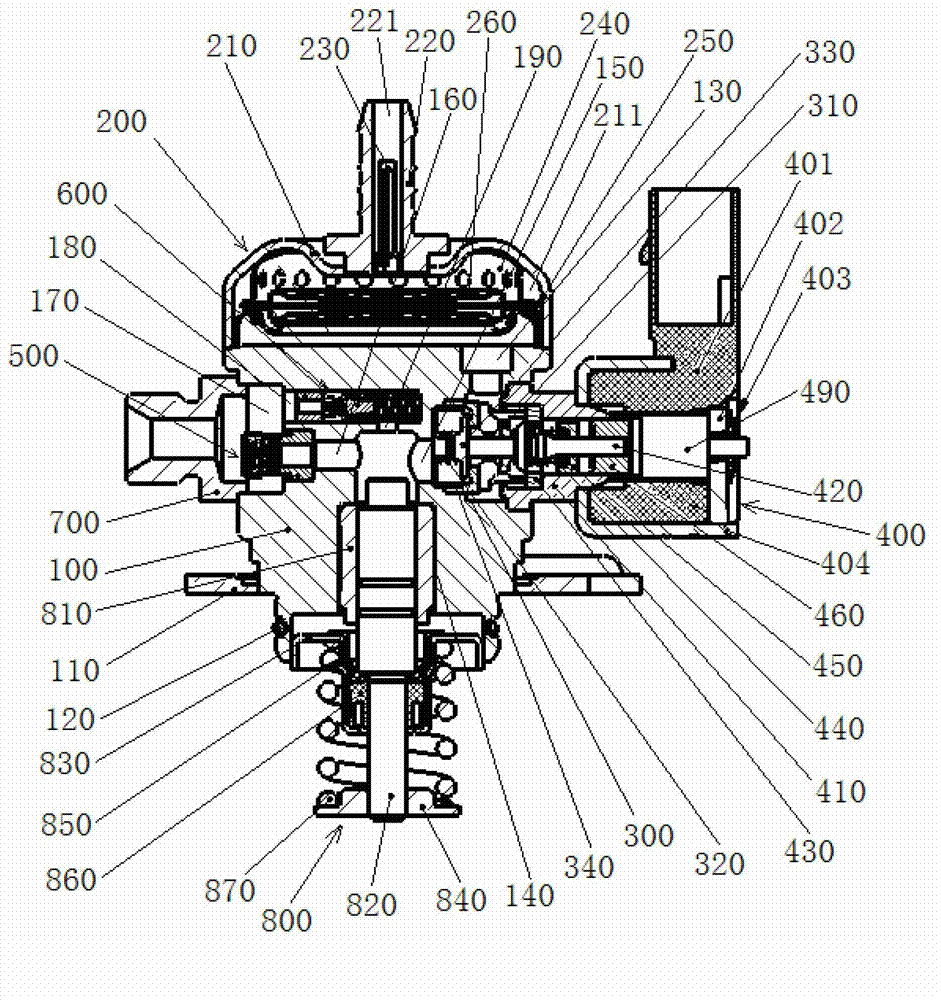

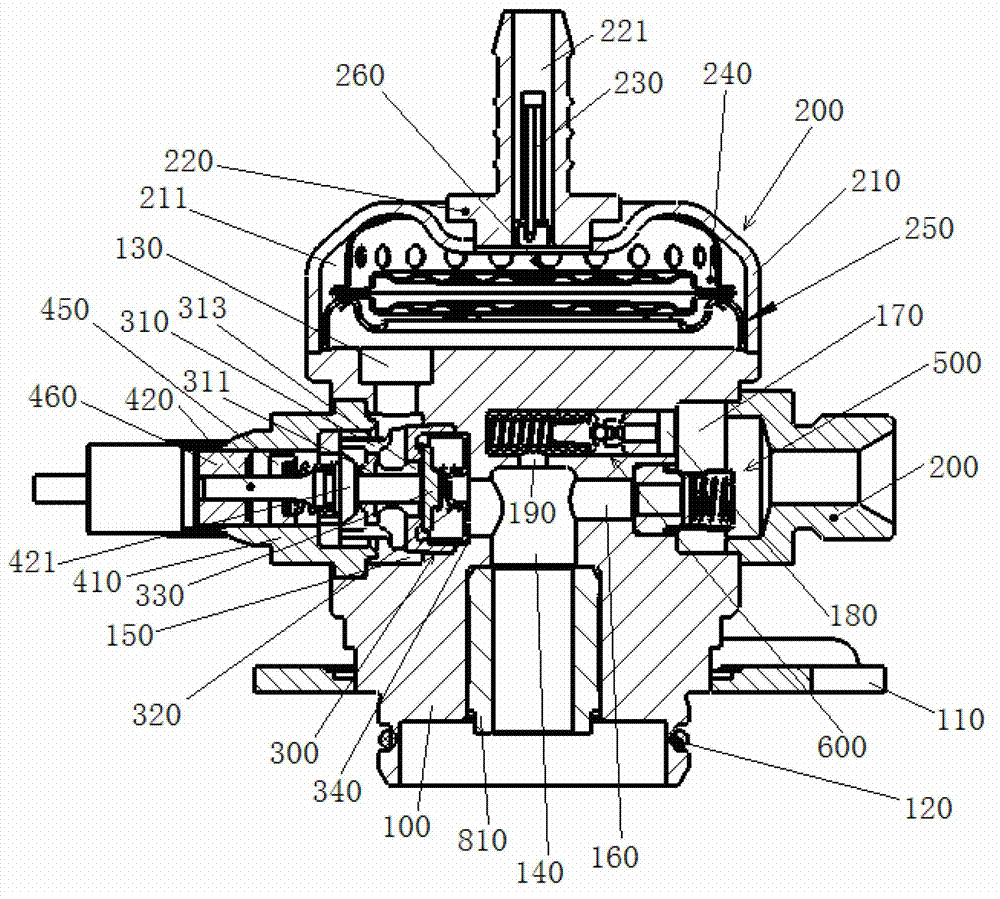

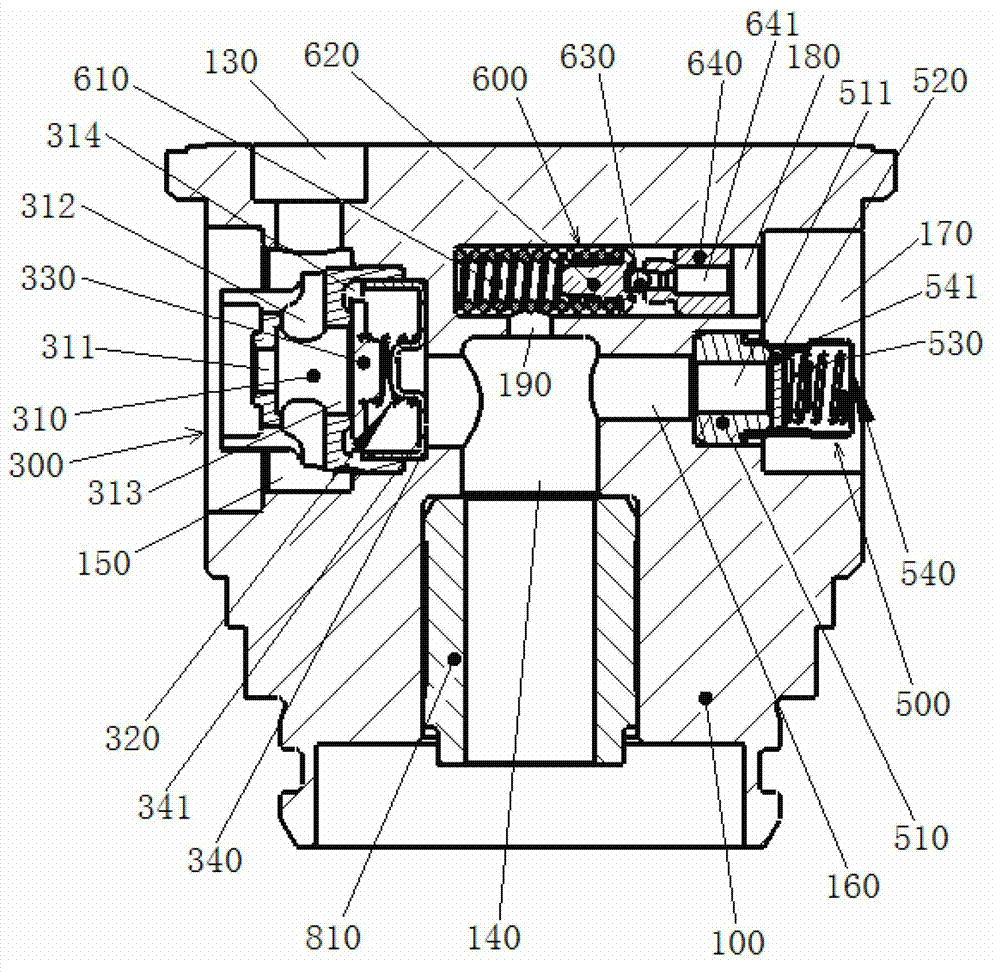

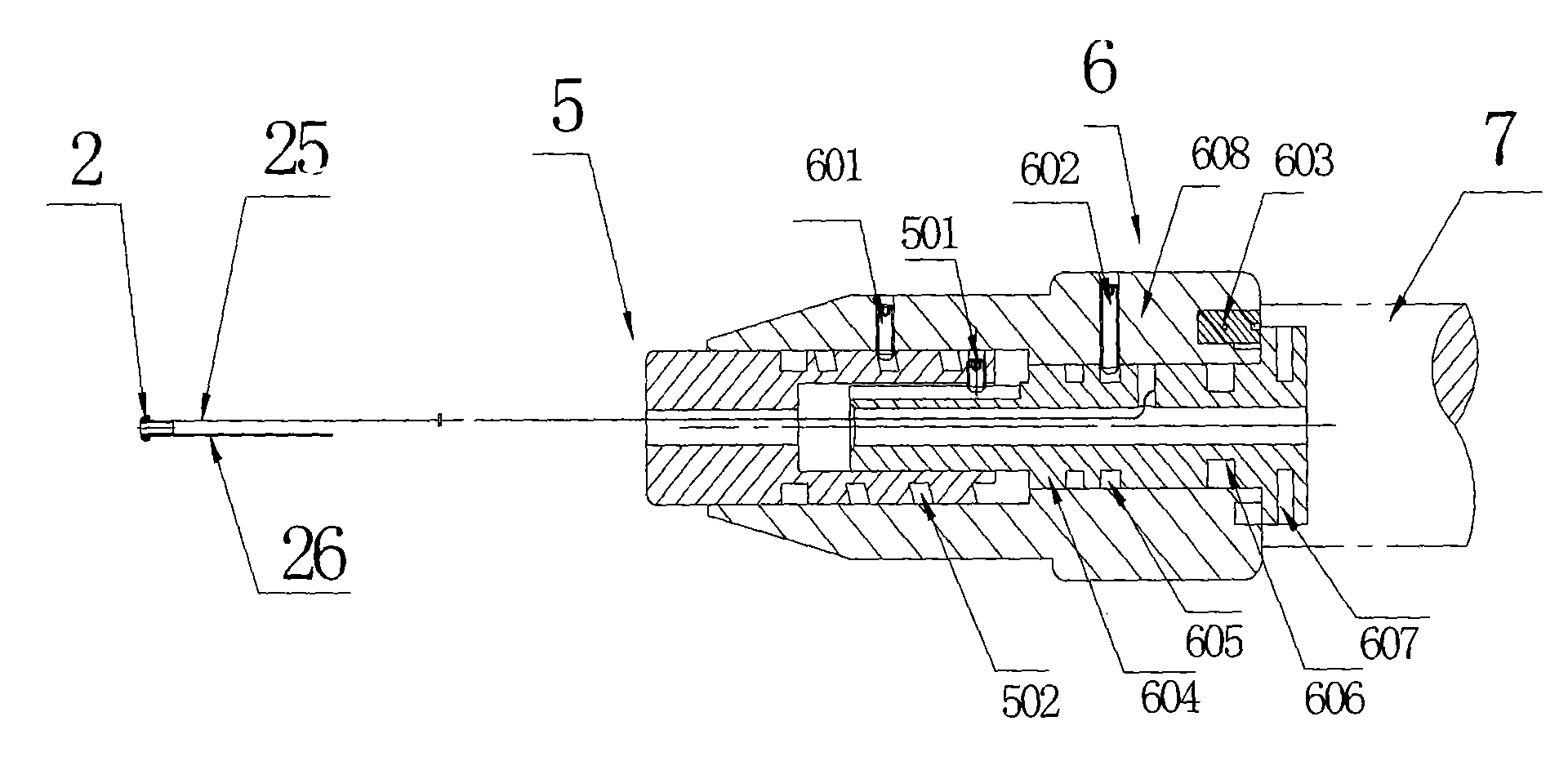

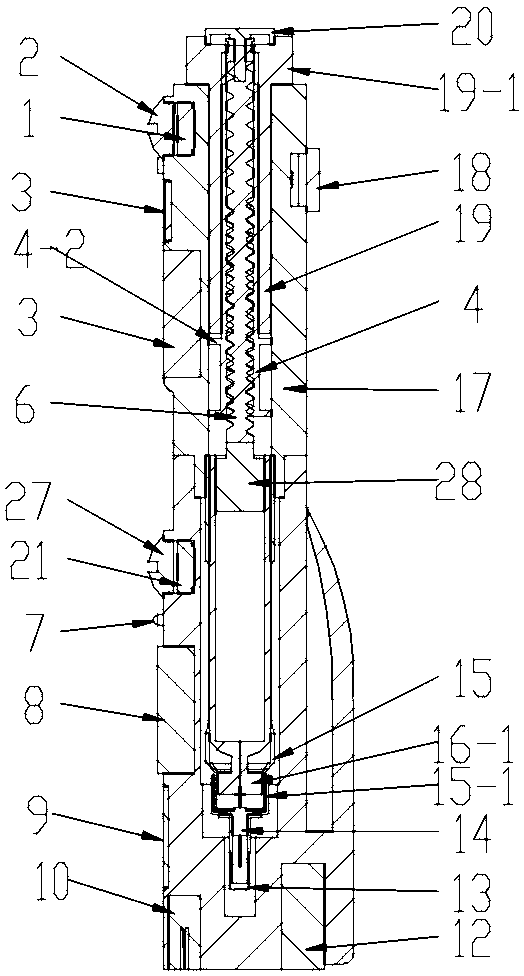

Gasoline direct injection fuel injection pump

ActiveCN102817756AQuiet operationPrecise control of injection volumeMachines/enginesFuel injecting pumpsCombustion chamberInlet valve

The invention discloses a gasoline direct injection fuel injection pump. The gasoline direct injection fuel injection pump is directly installed on an engine cylinder head and comprises a pump body, a pressure stabilizing component, a fuel inlet valve component, an electromagnetic driving component, a plunger valve component, a fuel outlet valve component, a fuel drain valve component and a fuel outlet connecting sleeve, wherein the pressure stabilizing component is installed on the pump body, and the fuel outlet connecting sleeve is hollow inside and is connected with a high-pressure fuel supply rail. According to the gasoline direct injection fuel injection pump, an air inlet camshaft is used for driving a plunger in the plunger valve component, thus, compared with outside jet engines, the pump has the advantages that the friction force and the chain force are reduced, an engine can operate quietly, and fuel is saved. The fuel injection pump provides the fuel which is stored in the high-pressure rail, the fuel is transferred to a fuel injector through the high-pressure rail, and fuel injection quantity parameters of the fuel injector are used for accurately controlling the injection quantity of the fuel of the fuel injection pump through sending of electric signals by an electronic control unit (ECU). The fuel injector controls the injection quantity of the fuel accurately through electrons according to the air intake volume, the fuel and the air are fully atomized and mixed, a combustion chamber is uniformly filled with gas mixtures which conform to a theoretical air-fuel ratio, and every drop of fuel is used fully.

Owner:NANYUE FUEL INJECTION SYST CO LTD

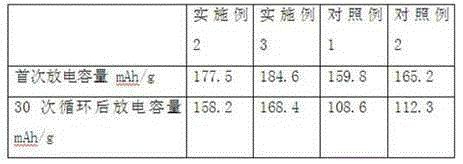

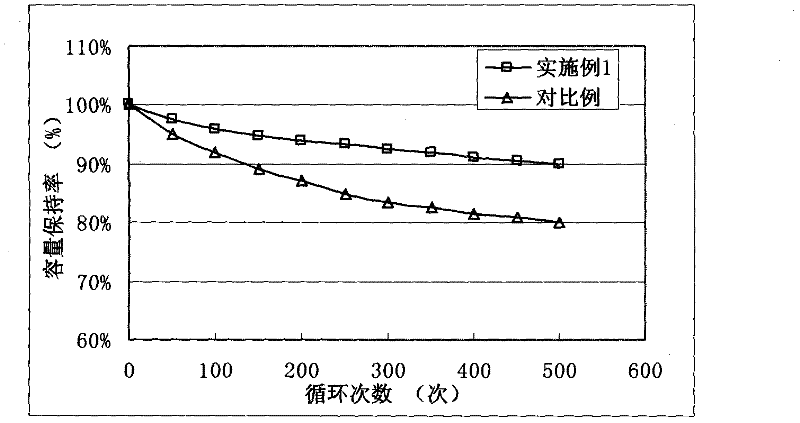

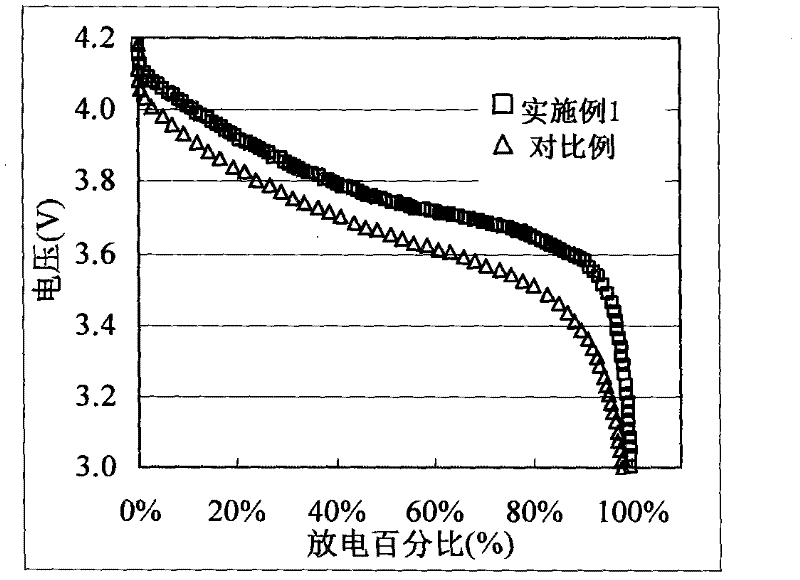

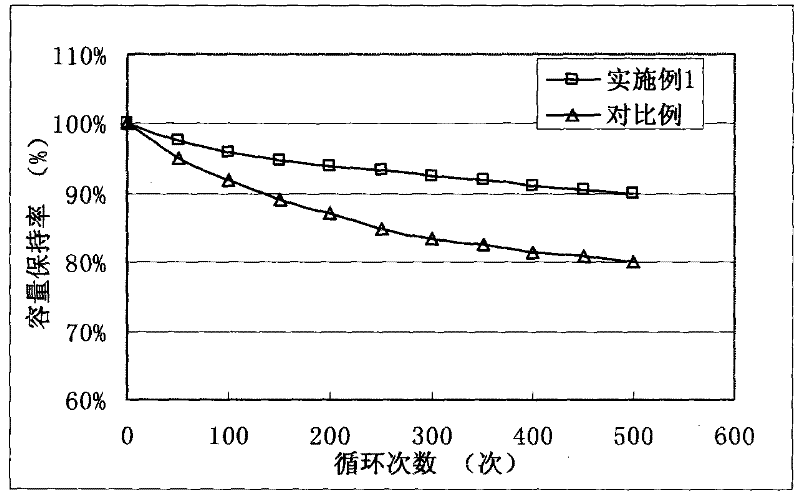

Manufacturing method for lithium ion battery pole piece

The invention relates to the technical field of a lithium ion battery, and particularly relates to a manufacturing method for a lithium ion battery pole piece by using a foam metal as a current collector. The invention adopts a slurry pouring or powder forming method to settle the difficulty of a traditional coating process in coating slurry on a surface of a foam current collector and to acquire the lithium ion battery having high energy density and excellent electrical property. The foam current collector has large porosity and slurry can be filled in pores, thereby greatly reducing the space occupied by the current collector inside a battery, being capable of efficiently reducing the layer number of the battery and obviously promoting the energy density of the battery.

Owner:DONGGUAN AMPEREX TECH +1

Method and device for bonding stud onto glass

The invention relates to the technical field of glass accessory bonding, in particular to a method and a device for bonding a stud onto glass. The method comprises the following steps of: respectively coating a base coat on the surfaces of the stud and the glass to be bonded; turning on an injection molding machine, setting injection molding parameters, and fixedly embedding the stud in a groove of an injection mold; compressing the surface of the glass to be bonded on the bottom of the injection mold so as to form a closed cavity; starting the injection molding by the injection molding machine, and injecting a plasticized soft resin into the injection mold so that the soft resin is coated on a base of the stud and is firmly bonded by the base coat; and finally removing a pouring gate remained in the stud after de-molding. The invention further provides a bonding device used for carrying out the method. According to the method and the device for bonding a stud onto glass, the injection molding process is simple so that the automatic production can be realized, the production is fast so that the production efficiency can be increased, the bonding strength is high due to the dual function of base coat bonding and PVC (polyvinyl chloride) coating, the development costs of a bonding material and a mold are low so that the production cost is lowered.

Owner:FUZHOU FUYAO MOLD TECH

Oil seal coating agent, spraying method thereof and oil seal prepared therefrom

InactiveCN108587404APrecise control of injection volumeReduce coefficient of frictionEngine sealsPretreated surfacesGraphiteFriction force

The invention relates to an oil seal coating agent, a spraying method thereof and an oil seal prepared therefrom. The oil seal coating agent is composed of a component A, a component B and a componentC according to a mass proportion of 100:7-8:100, wherein the component A is composed of graphite powder, molybdenum disulfide and polytef, the component B is waterborne curing agent and is composed of homopolymer of polyethylene glycol monomethyl ether terminated 1, 6-diisocyanate hexane and 1, 6-diisocyanyl hexane, and the component C is composed of polyacrylate salt and waterborne epoxy resin.The coating agent is used for being coated in oil seal main lip and dustproof lip areas, and coating thickness is about 30um. When the oil seal works, part of the coating agent is transferred from theoil seal to the surface of a shaft, a coating film is promoted to closely cover the surface of the shaft under action of contact force between an oil seal lip opening and the shaft at the same time to enable the shaft to be smoother so as to play a role in lowering friction coefficient, and low and stable friction force and friction torque are provided in the whole life cycle of the oil seal.

Owner:广东天诚密封件股份有限公司

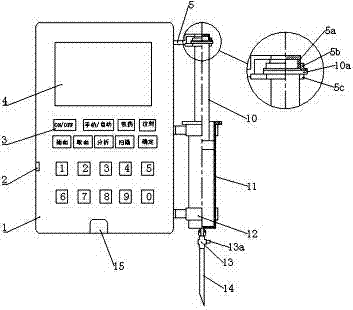

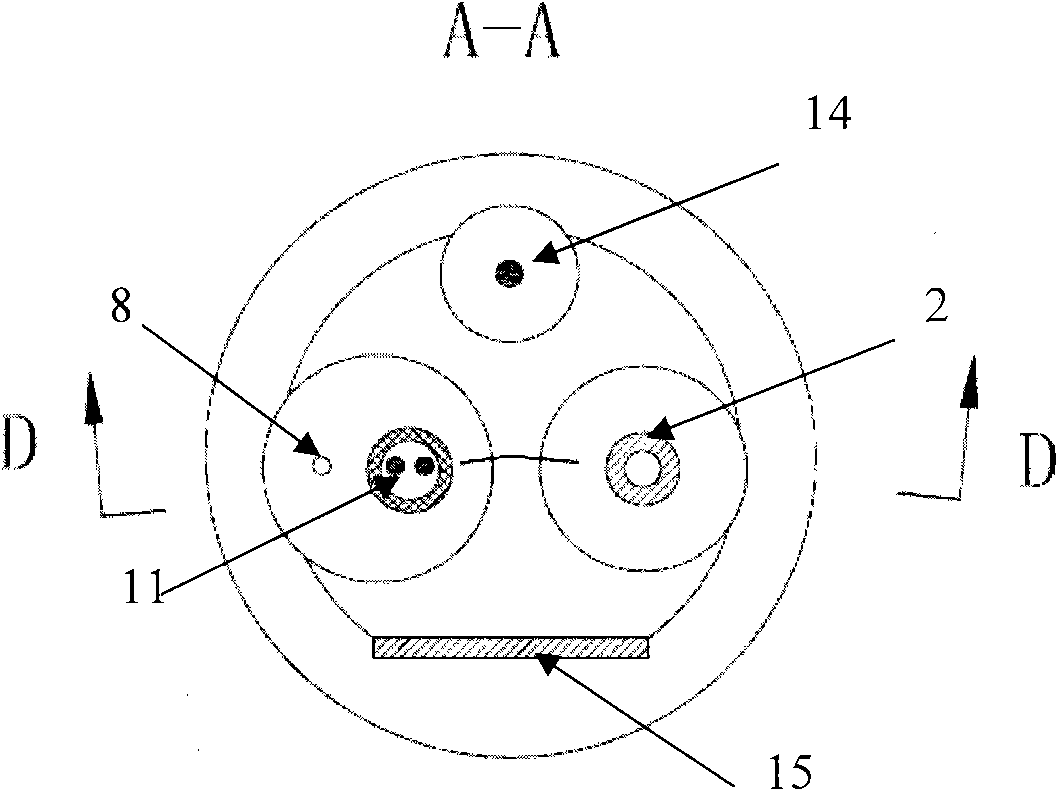

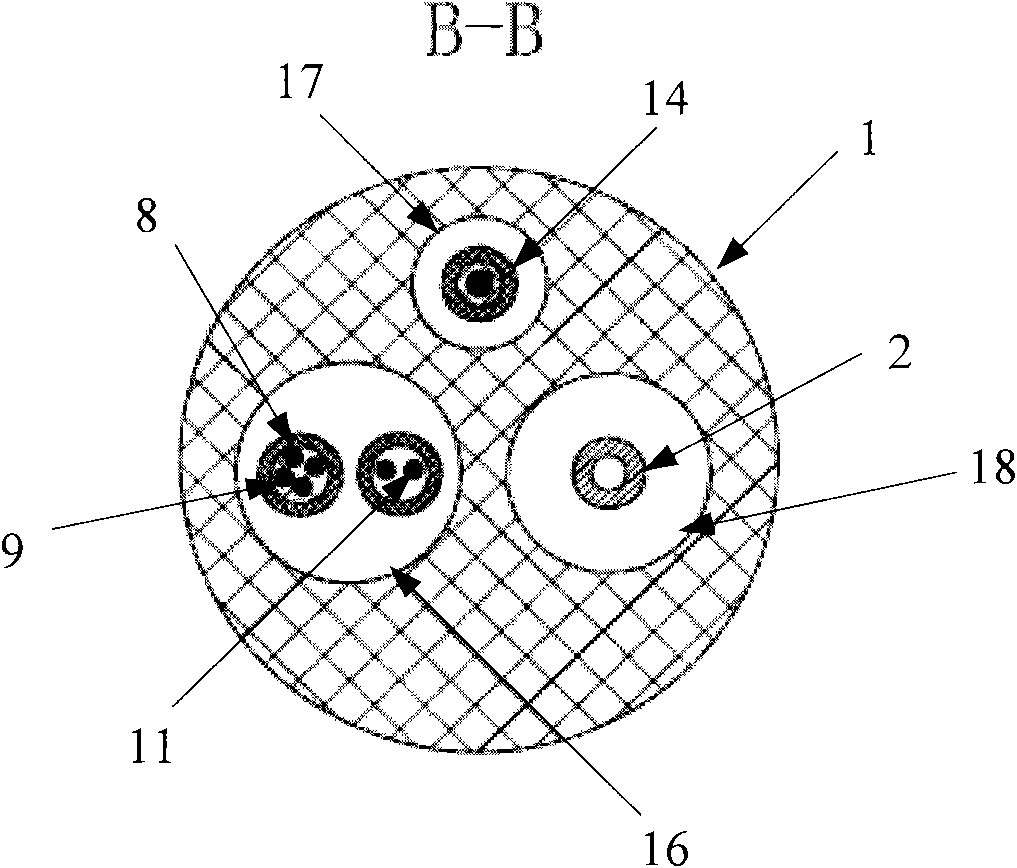

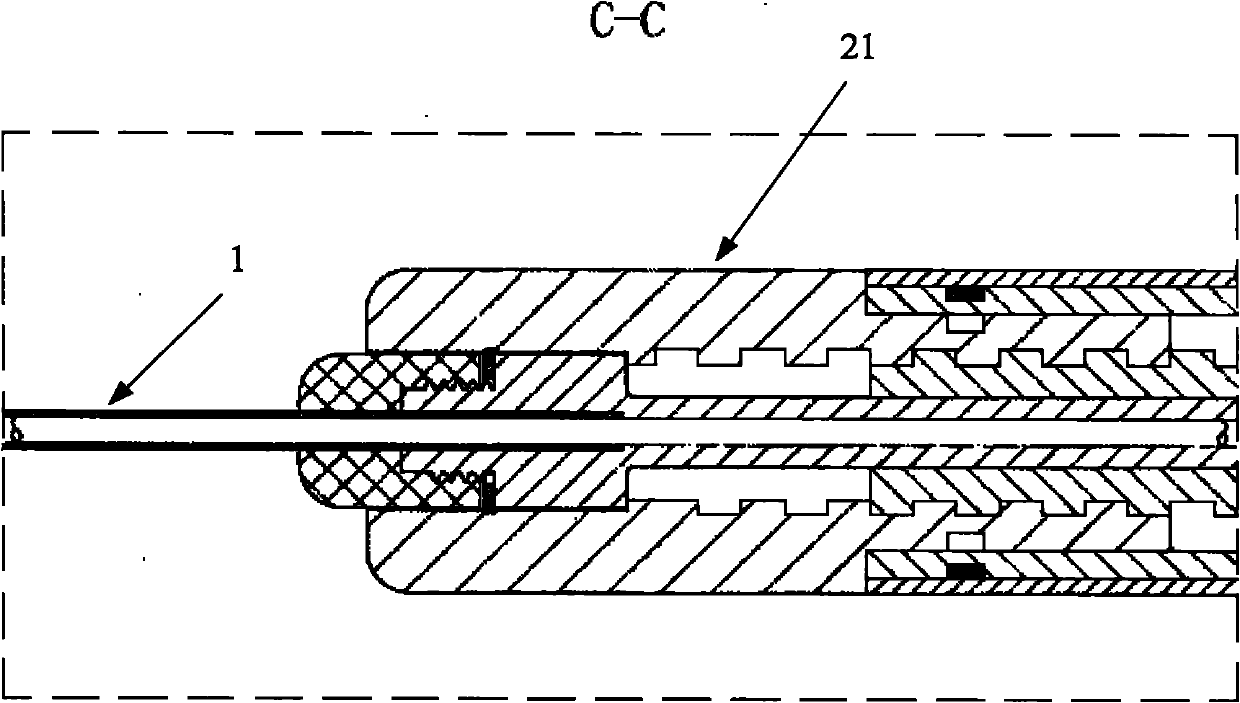

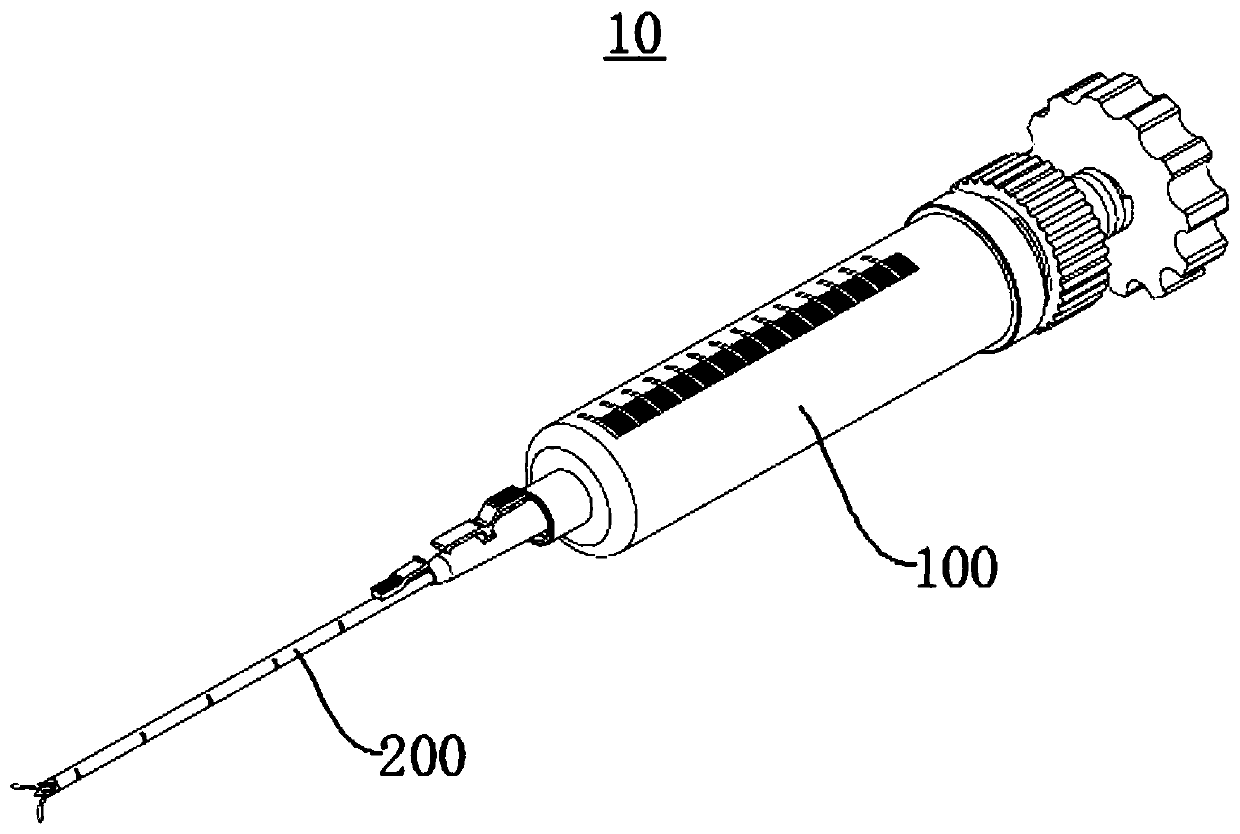

Injection system

ActiveCN101536902ASimple and quick injectionMeasure the electrical signalMedical devicesIntravenous devicesInjections needleBiomedical engineering

The invention discloses an injection system. The injection system comprises an injection device and an electric signal detection device. The injection system is characterized in that the electric signal detection device comprises at least one electrode; and the electrode is arranged at the injection end of the injection device. The injection system can accurately position a target injection region so as to accurately inject medicine to a target region of the inner wall of a body cavity. The injection device can be better realized by mounting a bending compensation mechanism for the length of an injection needle, an injection needle locking mechanism, a quantitative automatic injection mechanism and the like.

Owner:MICROPORT SINICA CO LTD

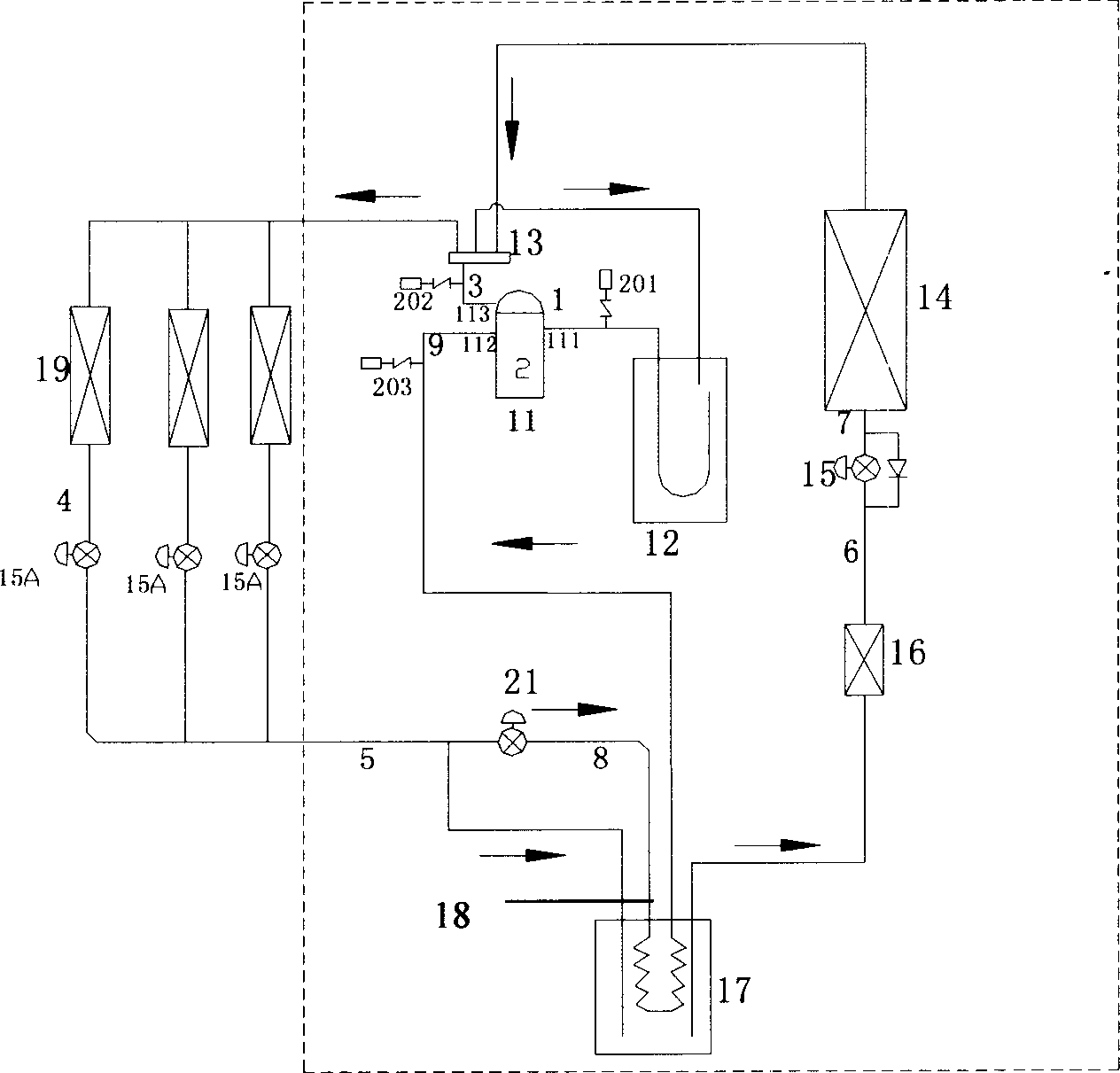

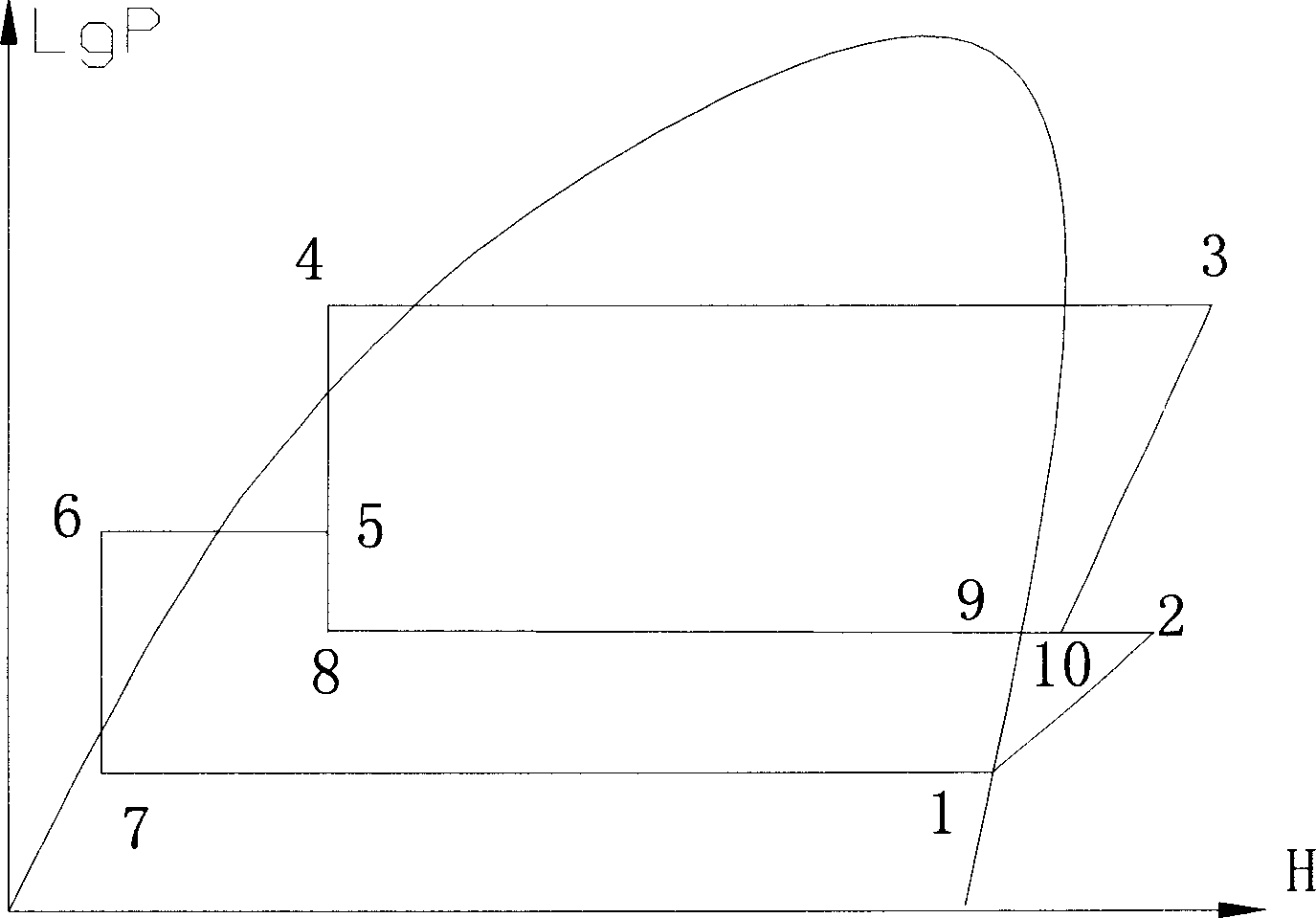

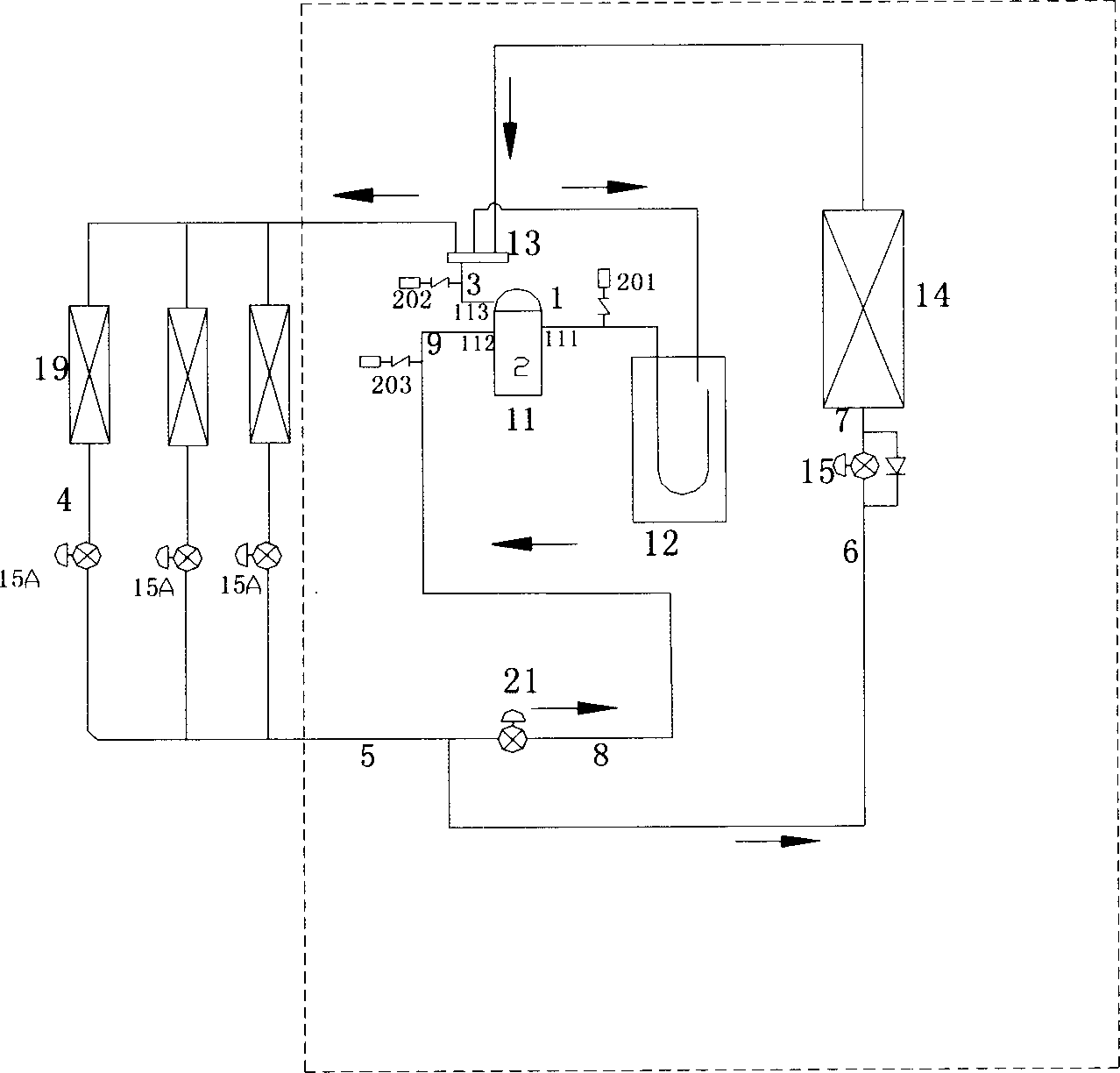

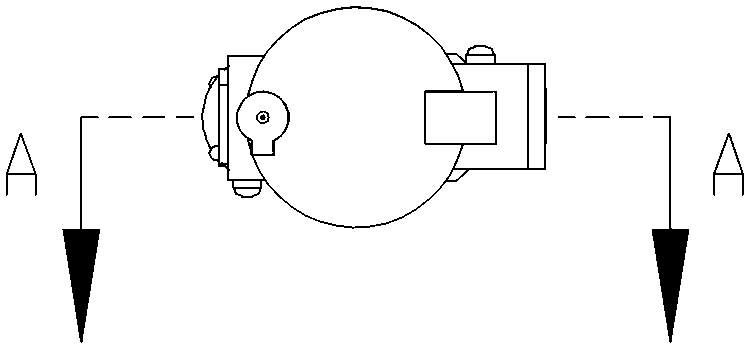

Heat pump air conditioner system and its steam jet control device and method

ActiveCN1828186AGood heating effectIncrease heating capacityHeat pumpsCompression machines with non-reversible cycleFour-way valveBusiness efficiency

The invention relates to a heat pump air conditioner with better heating effect in low-temperature, which comprises a compressor, a four-way valve, indoor and outdoor heat exchangers, and main throat device, which are connected via tubes. Wherein, said compressor has a outlet and two inlets; a bypass tube is arranged at the front and back of main throat device to connect the second inlet of compressor. The invention comprises a steam ejection controller, which at least includes three sensors and one electric expansion valve, while the sensors are at the outlet and two inlets of compressor, and the electric expansion valve is on the by-pass tube. The invention detects the ejector pressure of compressor to control the ejected amount of refrigeration accurately, improve the heating effect and energy / efficiency ratio in lower temperature. it can accurately control the open degree of electric expansion valve, to reduce the vibration of indoor temperature.

Owner:GREE ELECTRIC APPLIANCES INC

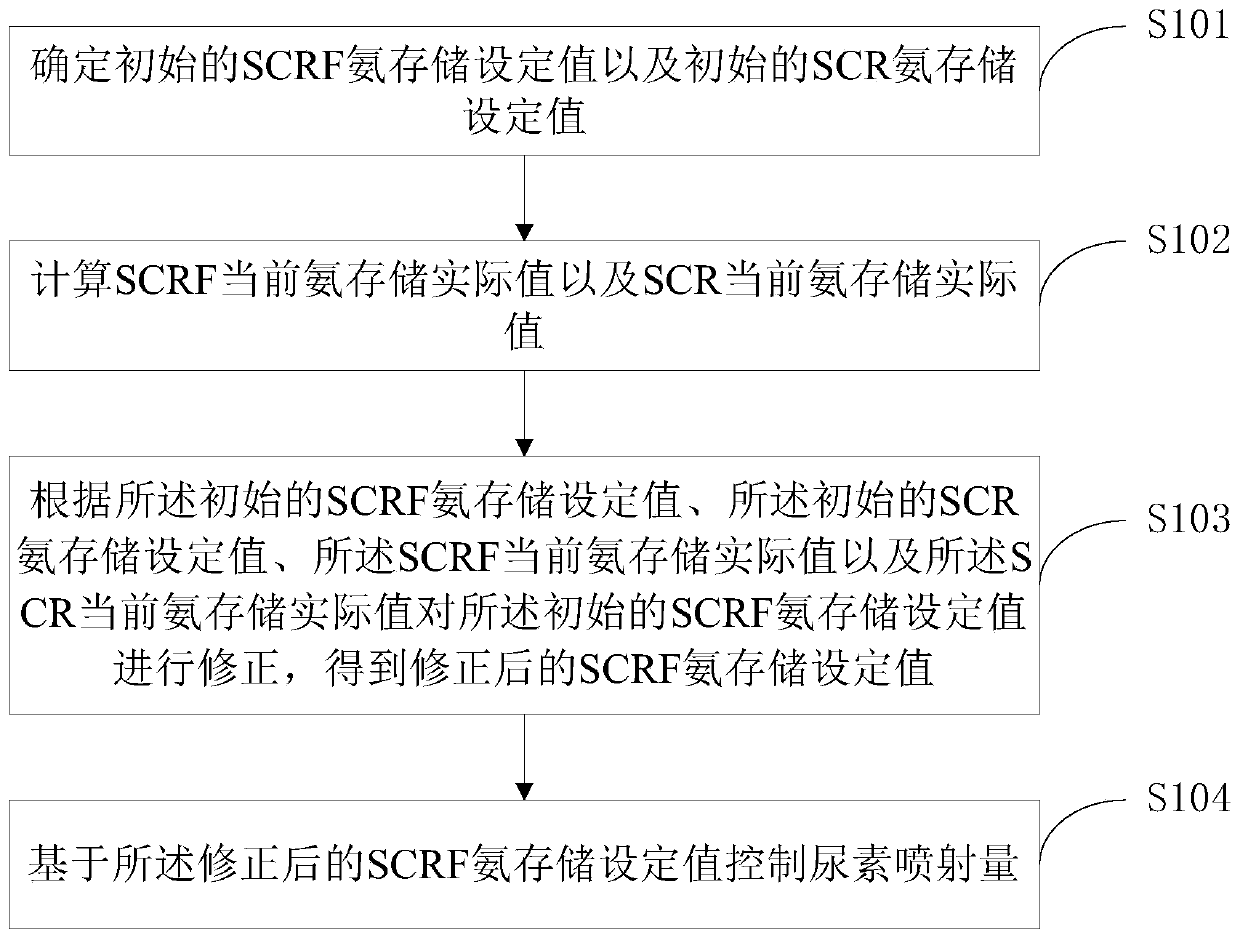

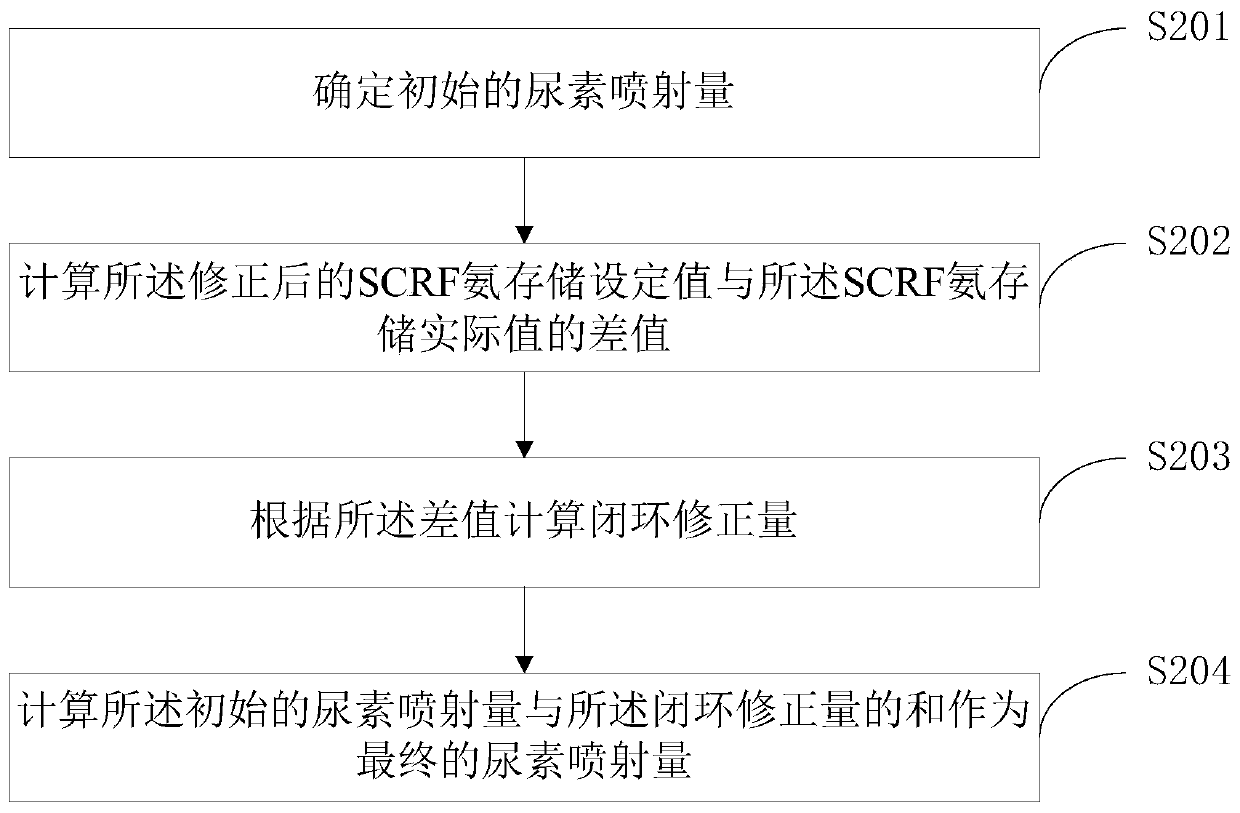

Urea injection quantity control method and device

ActiveCN110185523AControl injection volumeInjection Quantity ControlInternal combustion piston enginesExhaust apparatusAmmonia storageComputer science

The application discloses a urea injection quantity control method and device. The urea injection quantity control method comprises the steps of determining an initial SCRF ammonia storage set value and an initial SCR ammonia storage set value; calculating an SCRF current ammonia storage actual value and an SCR current ammonia storage actual value; correcting the initial SCRF ammonia storage set value according to the initial SCRF ammonia storage set value, the initial SCR ammonia storage set value, the SCRF current ammonia storage actual value and the SCR current ammonia storage actual valueto obtain a corrected SCRF ammonia storage set value; and controlling the urea injection quantity based on the corrected SCRF ammonia storage set value. Through the above process, accurate control ofthe urea injection quantity can be realized.

Owner:WEICHAI POWER CO LTD

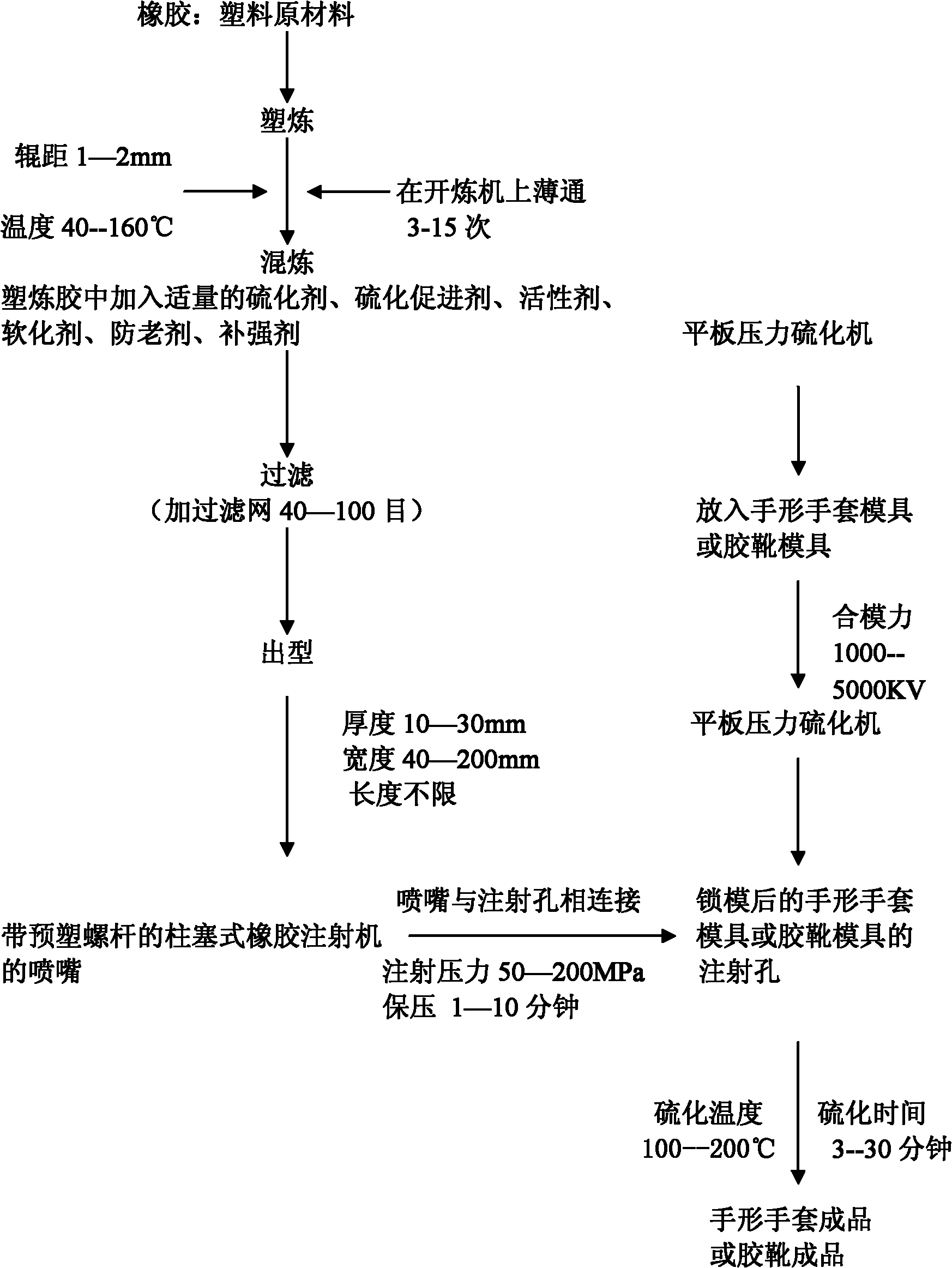

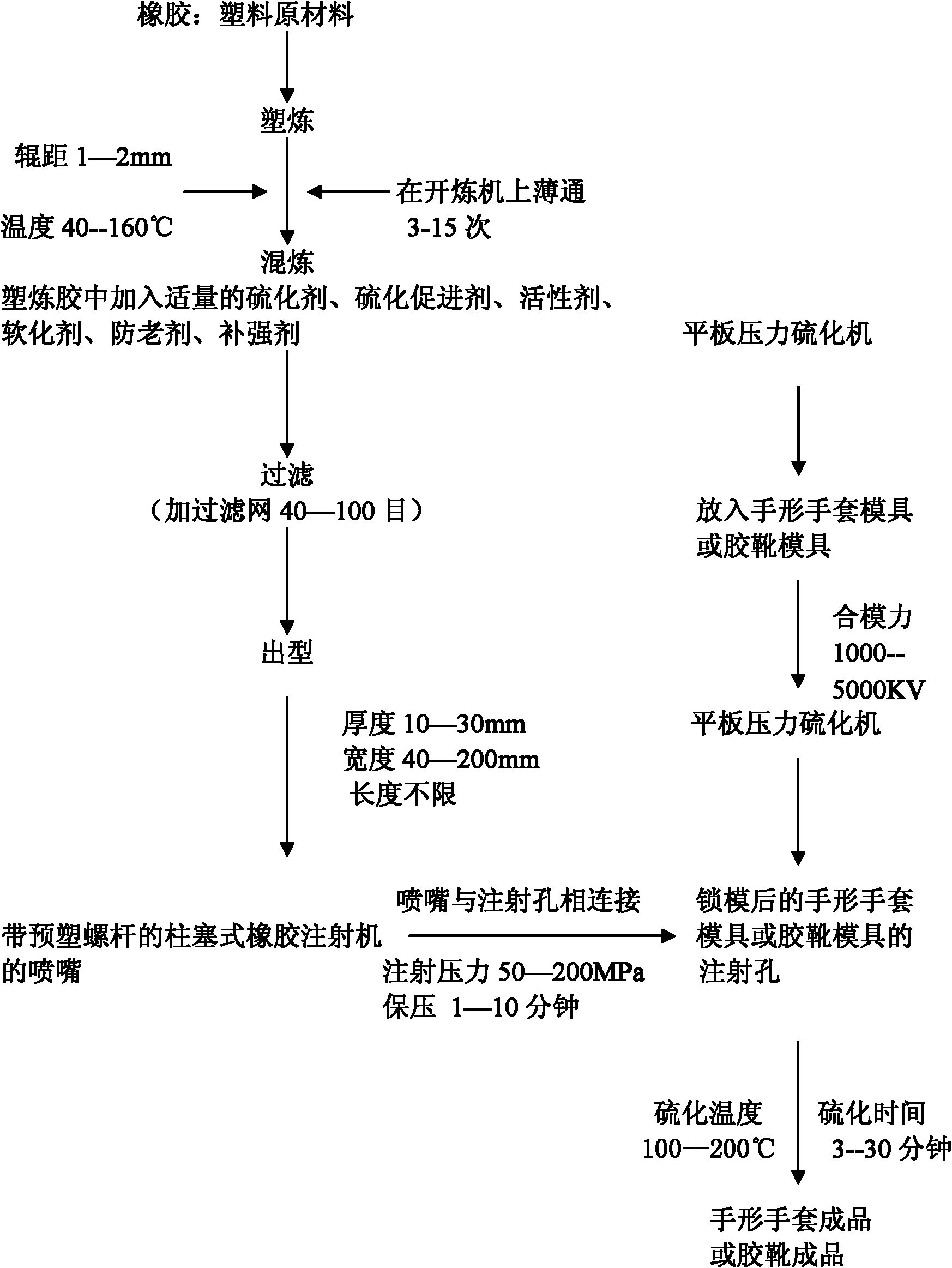

Injection moulding method of rubber and plastic electric insulation hand gloves and rubber boots

InactiveCN101913226AHigh densityHigh electrical insulationDomestic footwearPlate pressureVolumetric Mass Density

The invention relates to an injection moulding method of rubber and plastic electric insulation hand gloves and rubber boots, belonging to the technical filed of rubber and plastic moulding. The injection moulding method of the rubber and plastic electric insulation hand gloves and the rubber boots comprises the following steps: (1) taking rubber as a raw material; (2) plastication: thinly passing 3-15 times when the roller space on an open mill is 1-2mm; (3) mixing: mixing in the open mill or a banbury mixer; (4) filtering by a filter; (5) shaping to prepare rubber sheets the thickness of which is 10-30mm and the width is 40-200mm; (6) plasticizing: adding the rubber sheets to a plunger type rubber injection machine provided with a pre-plasticized screw rod to plasticize; (7) injection and sulfuration: connecting the nozzle of a movable plunger type rubber injection moulding machine provided with the performing screw rod with the injection hole of the mould locked in a flat-plate pressure vulcanizer, injecting size into a hand glove mould or a rubber boot mould for moulding, maintaining pressure and vulcanizing; and (8) demoulding products. The method of the invention has the advantages of simple process, accurate control, small equipment investment, low cost, high production efficiency, high product density, good comprehensive performance, high electric insulation degree and the like.

Owner:天津市腾盛橡塑制品厂(普通合伙)

Gasoline direct injection fuel injection pump

ActiveCN102817756BQuiet operationPrecise control of injection volumeMachines/enginesFuel injecting pumpsCombustion chamberInlet valve

The invention discloses a gasoline direct injection fuel injection pump. The gasoline direct injection fuel injection pump is directly installed on an engine cylinder head and comprises a pump body, a pressure stabilizing component, a fuel inlet valve component, an electromagnetic driving component, a plunger valve component, a fuel outlet valve component, a fuel drain valve component and a fuel outlet connecting sleeve, wherein the pressure stabilizing component is installed on the pump body, and the fuel outlet connecting sleeve is hollow inside and is connected with a high-pressure fuel supply rail. According to the gasoline direct injection fuel injection pump, an air inlet camshaft is used for driving a plunger in the plunger valve component, thus, compared with outside jet engines, the pump has the advantages that the friction force and the chain force are reduced, an engine can operate quietly, and fuel is saved. The fuel injection pump provides the fuel which is stored in the high-pressure rail, the fuel is transferred to a fuel injector through the high-pressure rail, and fuel injection quantity parameters of the fuel injector are used for accurately controlling the injection quantity of the fuel of the fuel injection pump through sending of electric signals by an electronic control unit (ECU). The fuel injector controls the injection quantity of the fuel accurately through electrons according to the air intake volume, the fuel and the air are fully atomized and mixed, a combustion chamber is uniformly filled with gas mixtures which conform to a theoretical air-fuel ratio, and every drop of fuel is used fully.

Owner:NANYUE FUEL INJECTION SYST CO LTD

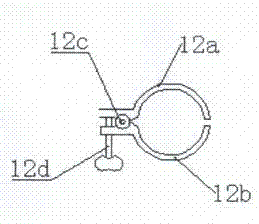

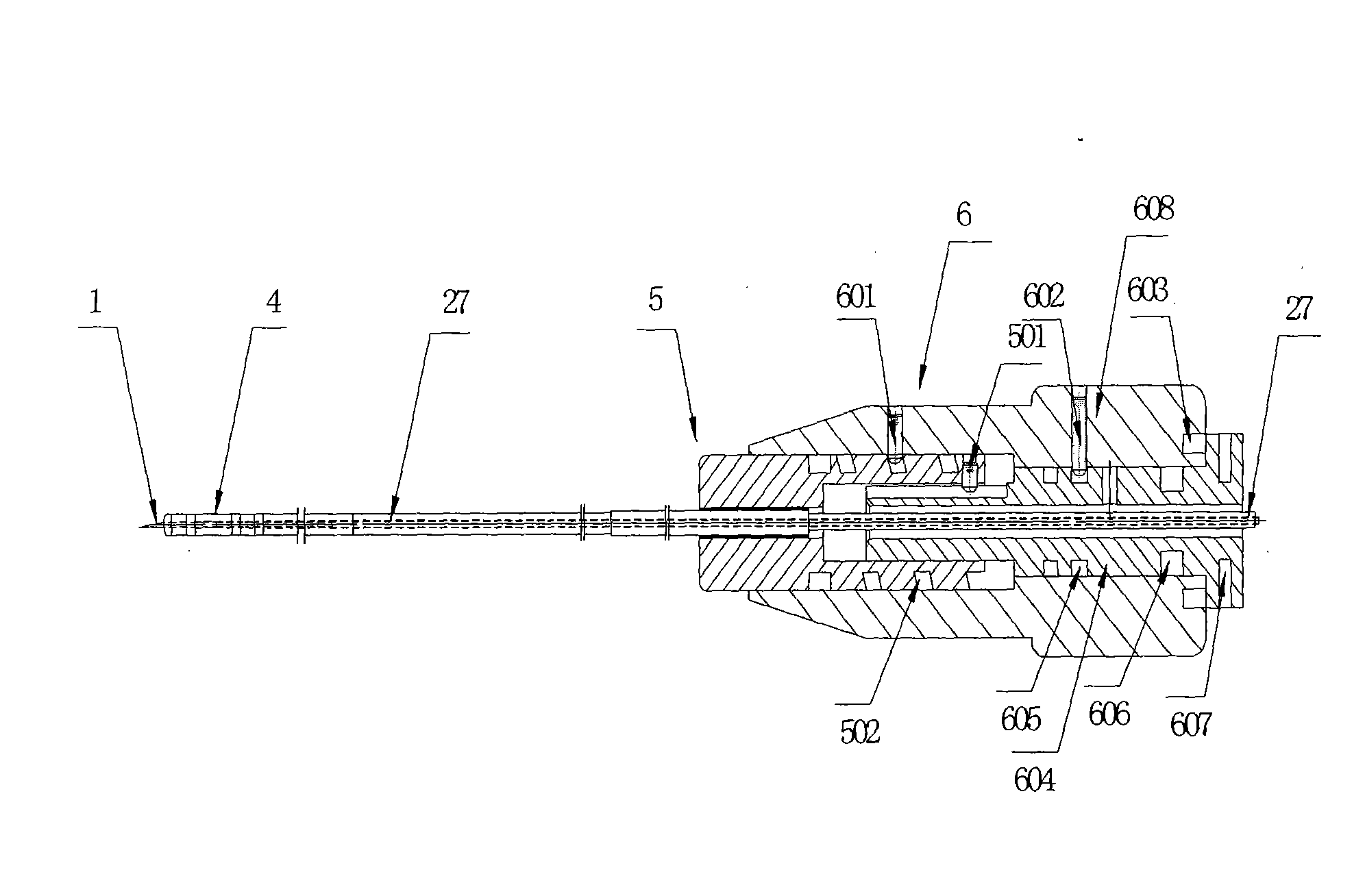

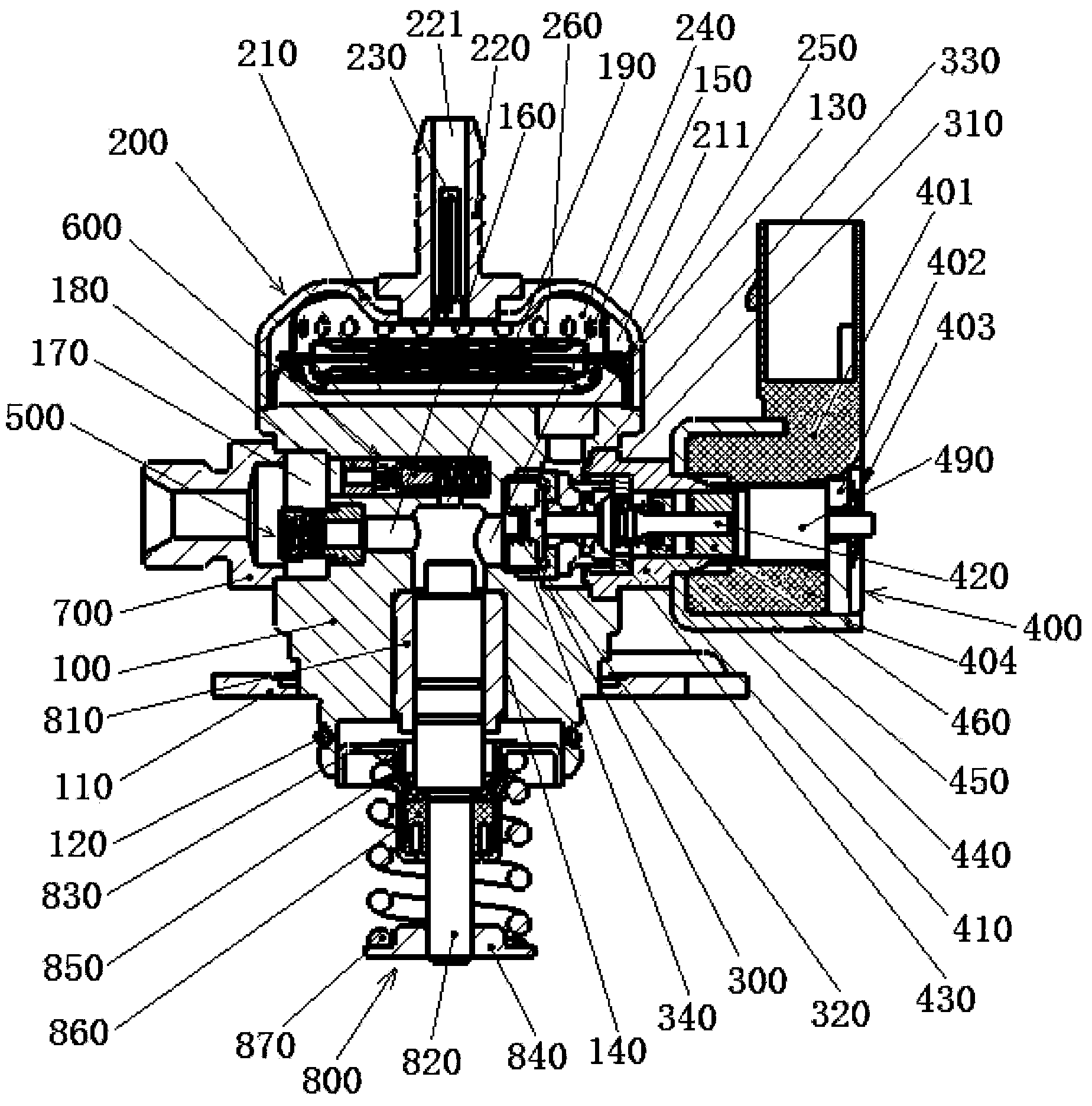

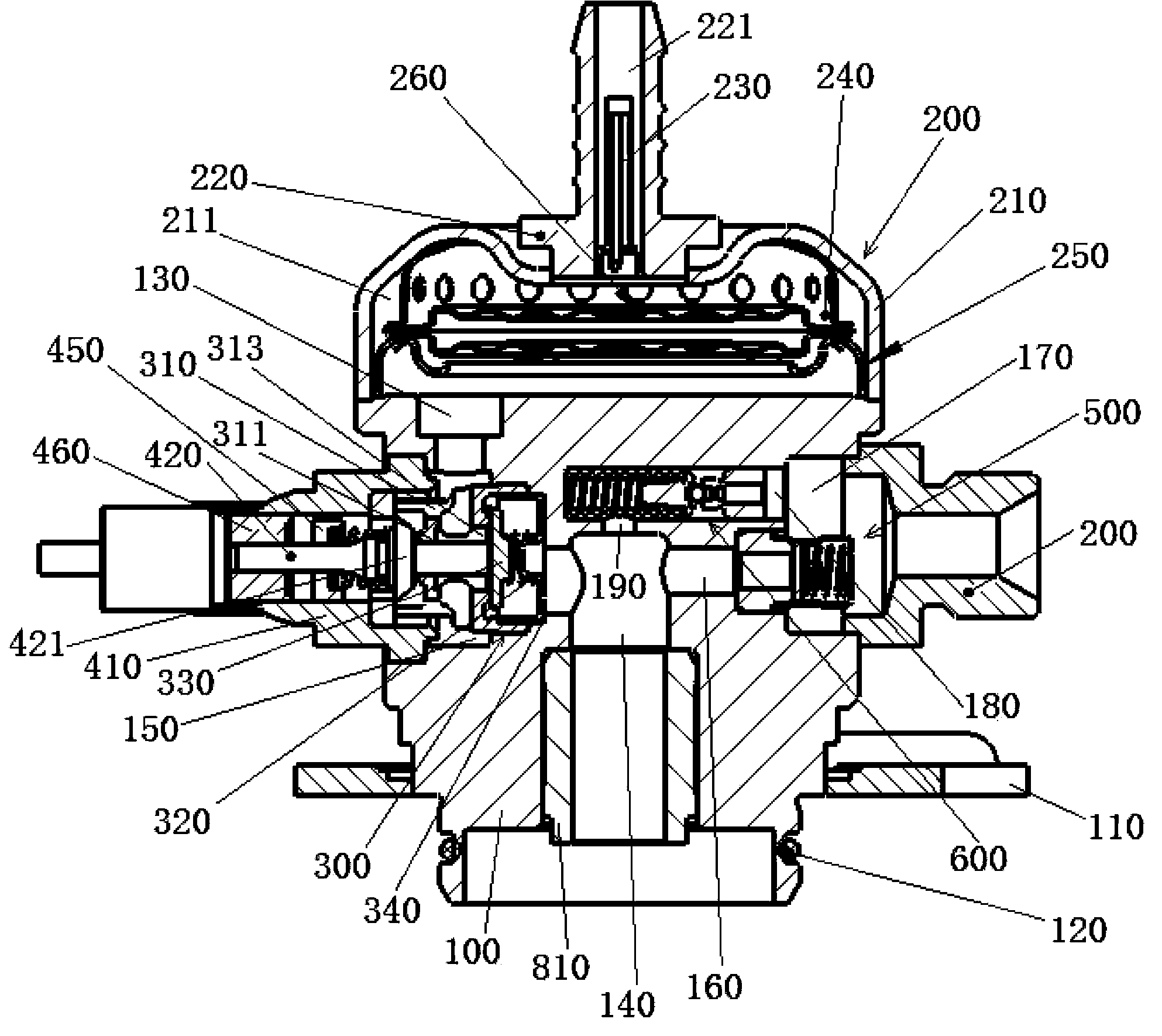

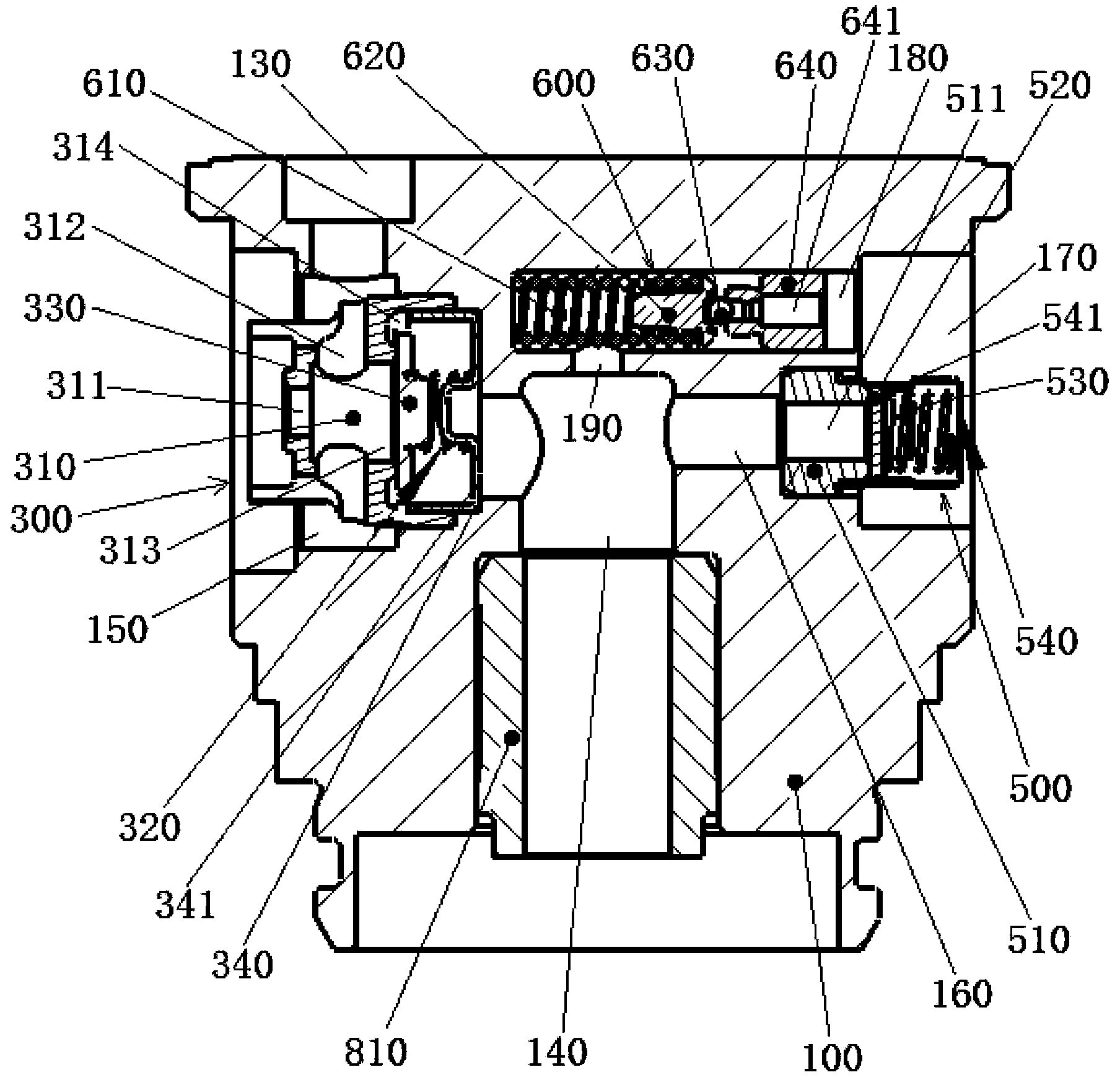

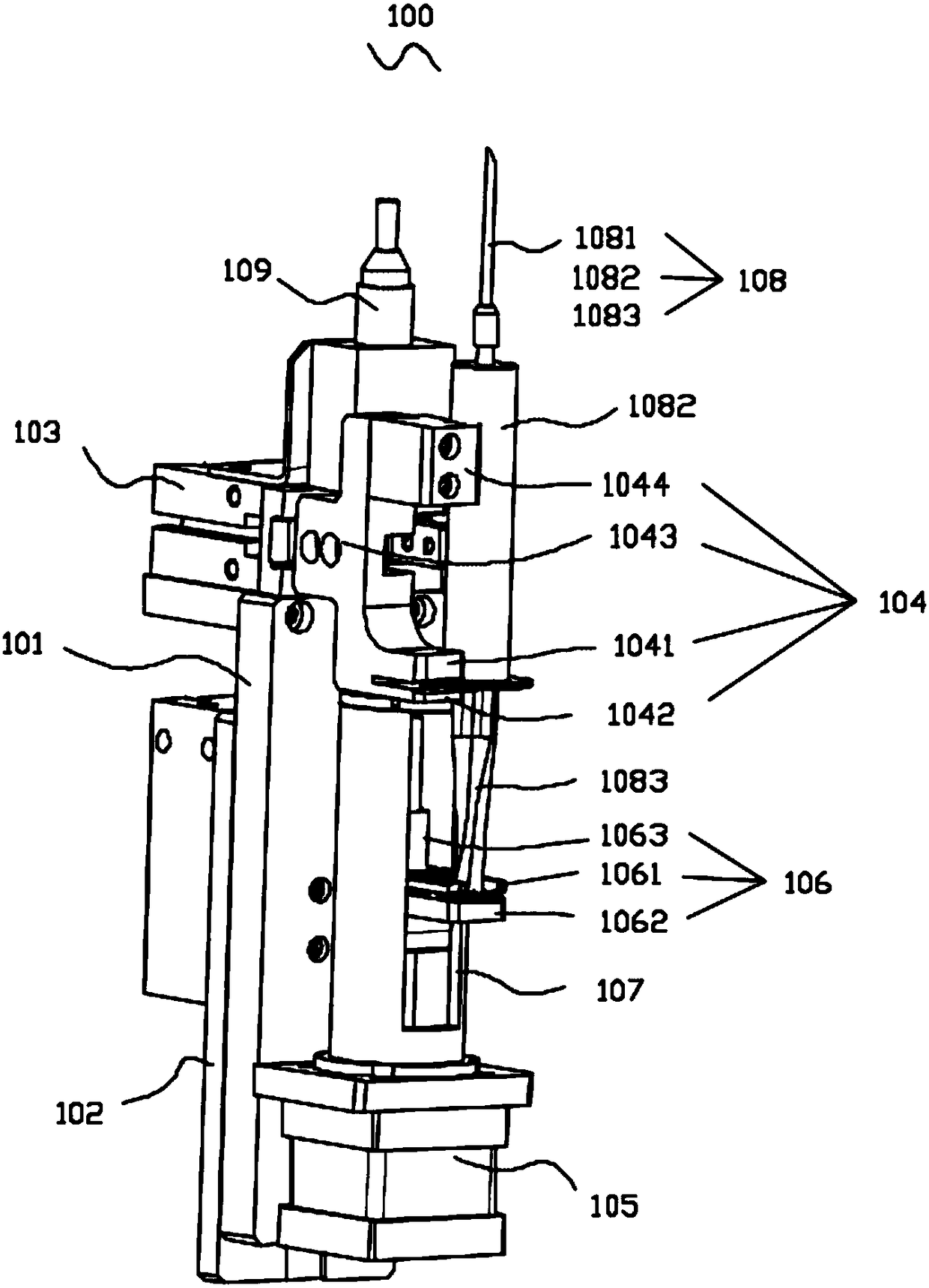

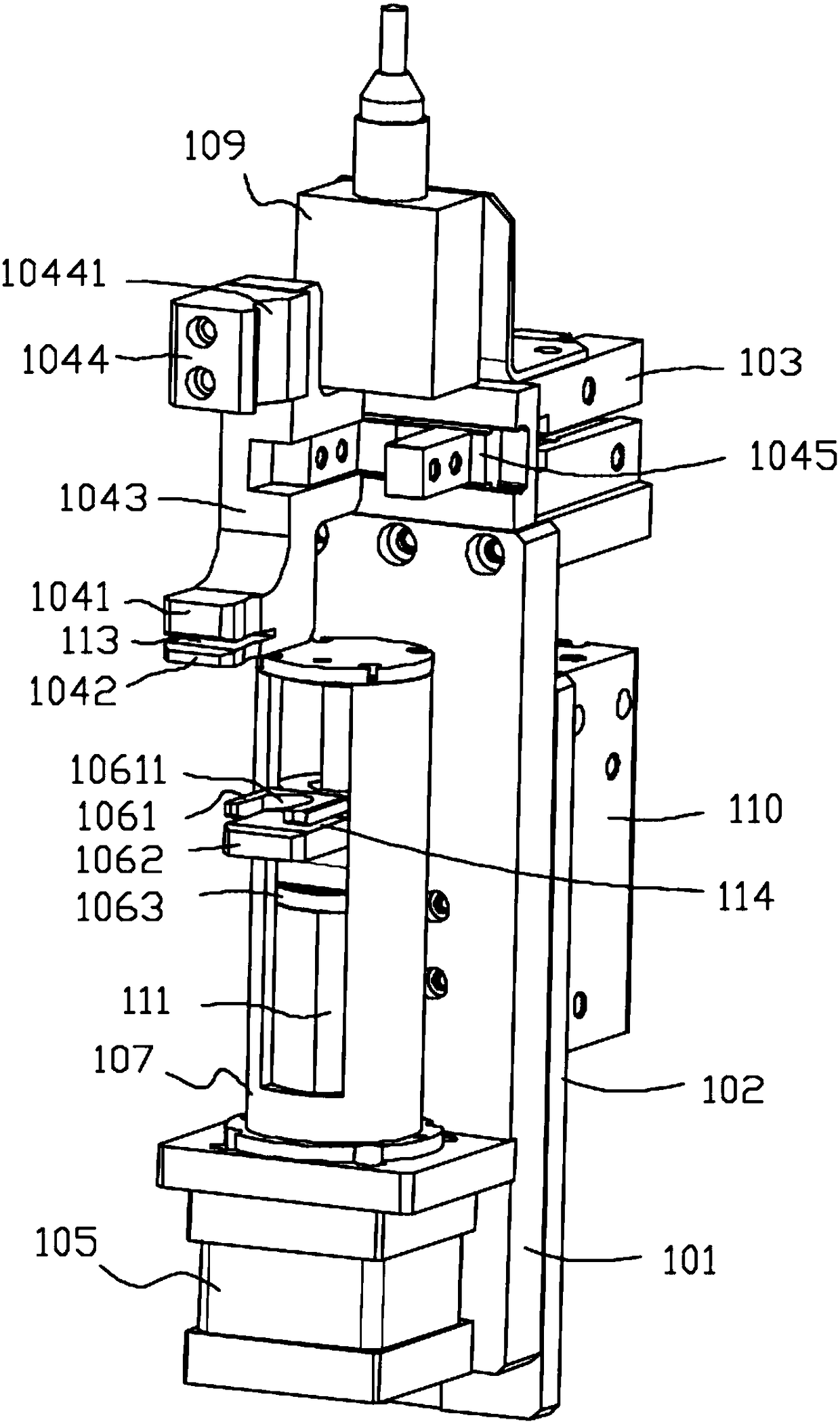

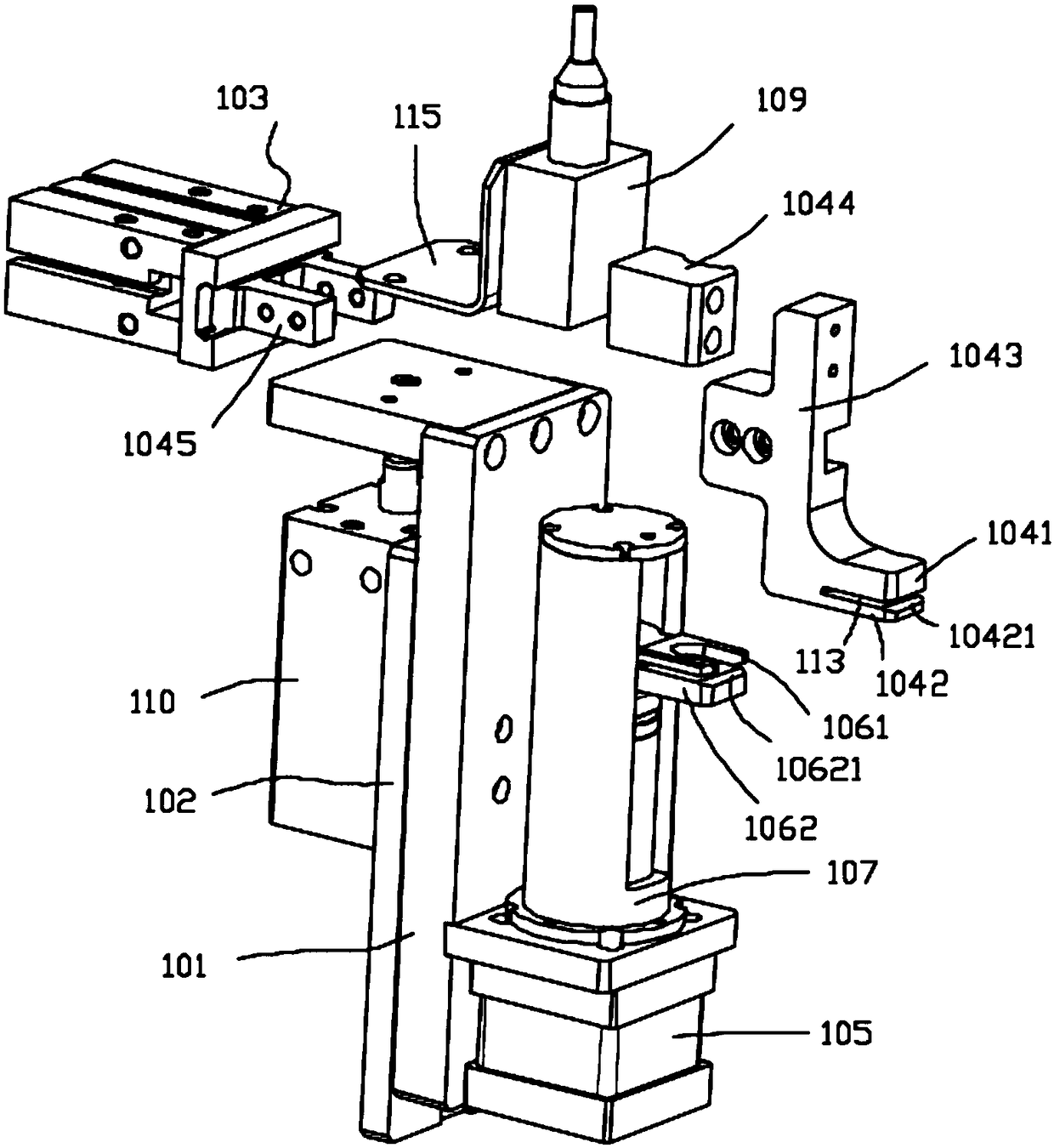

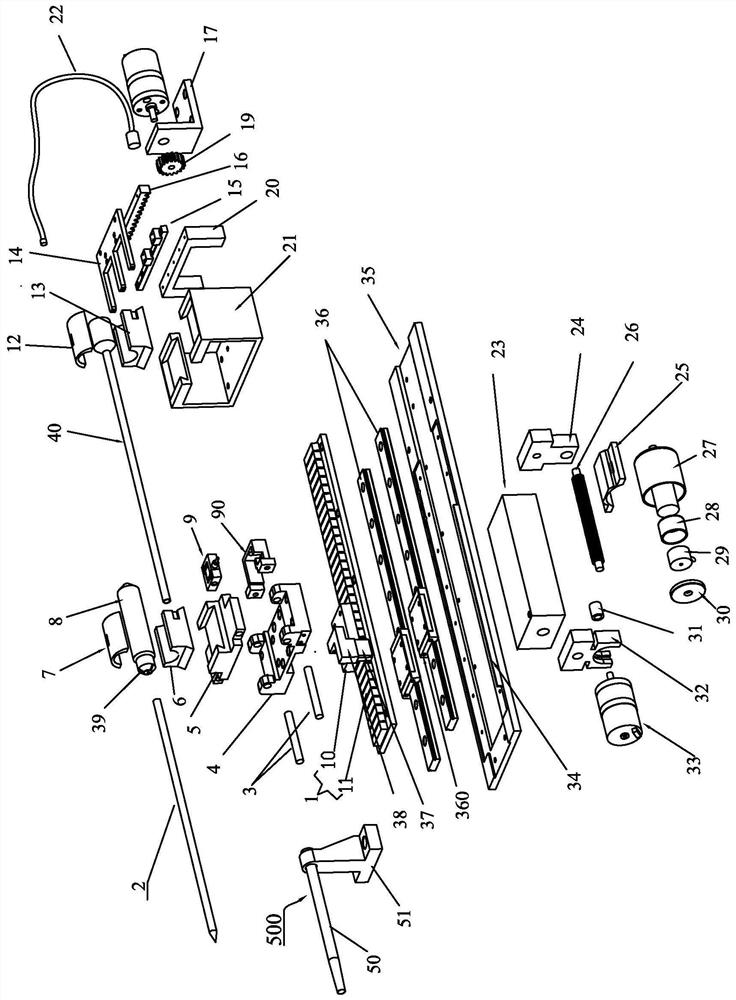

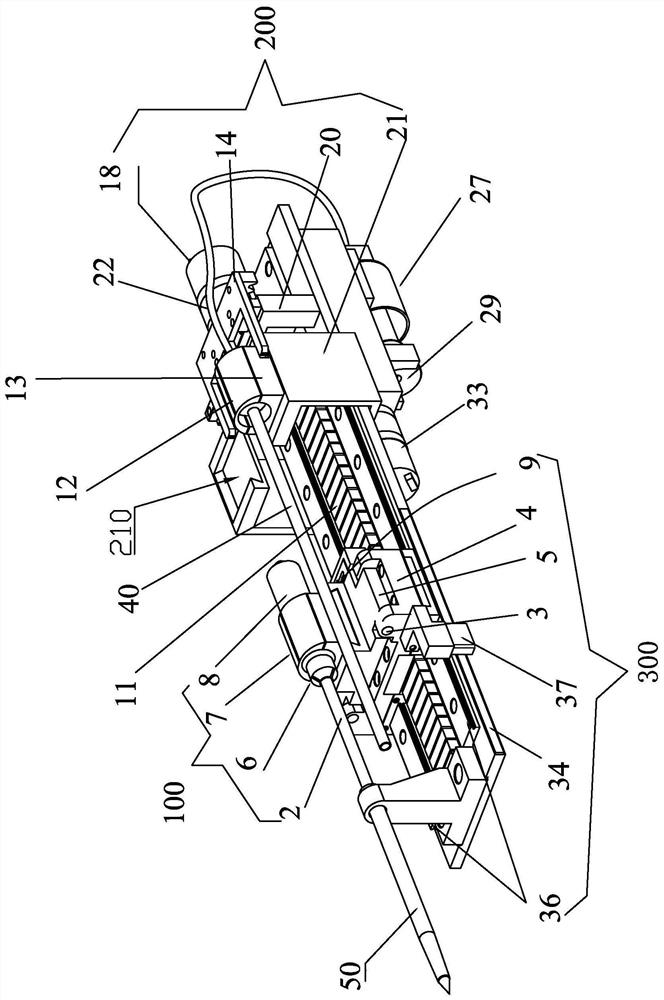

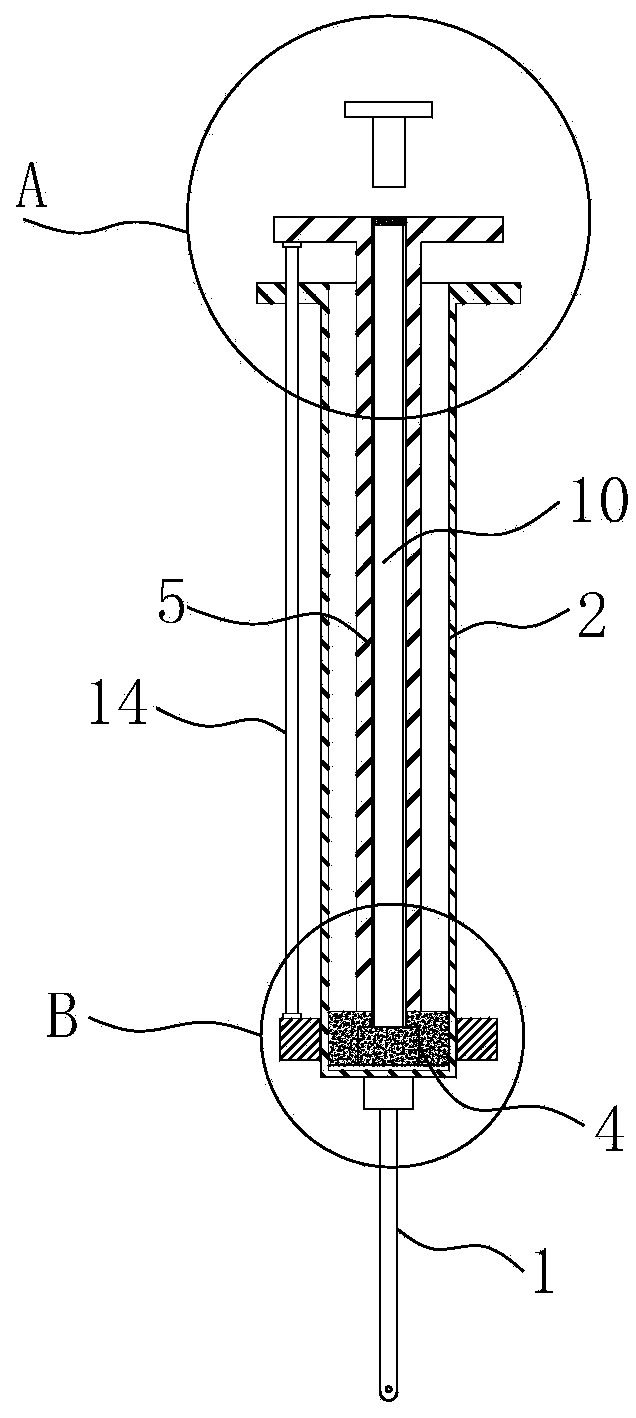

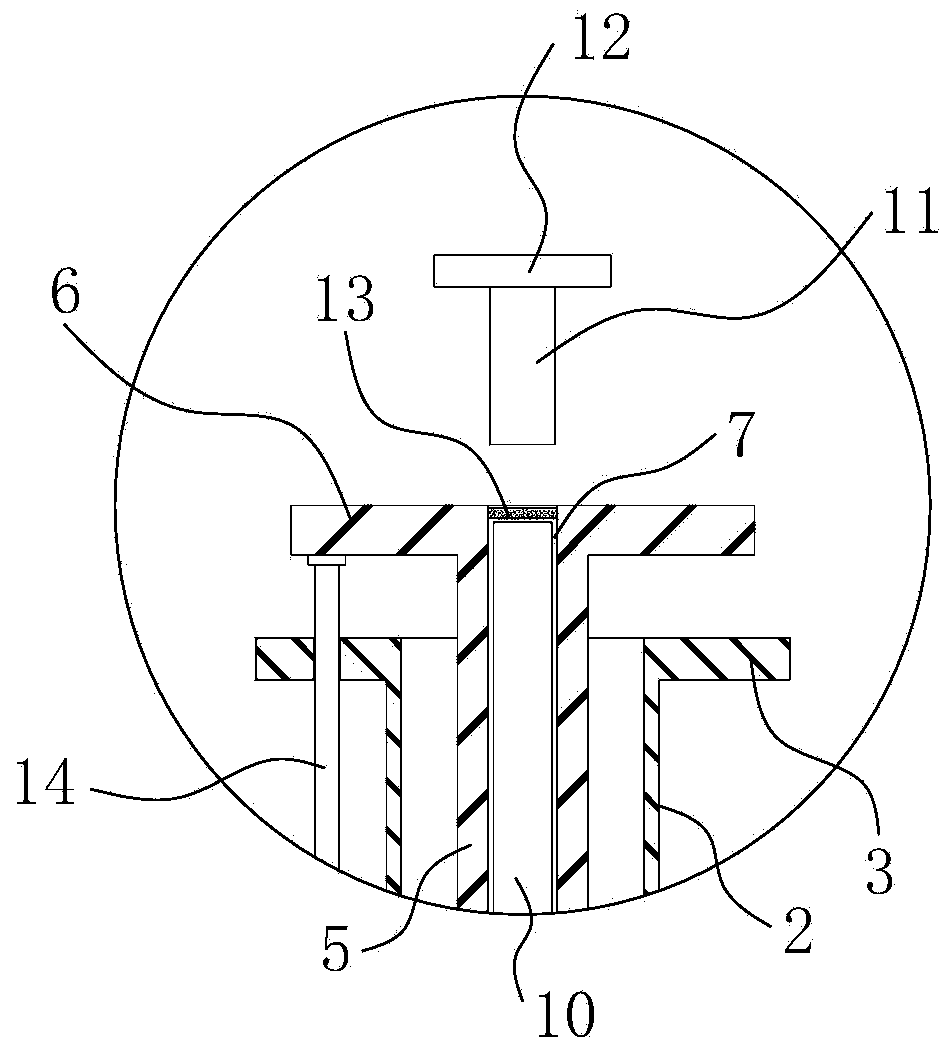

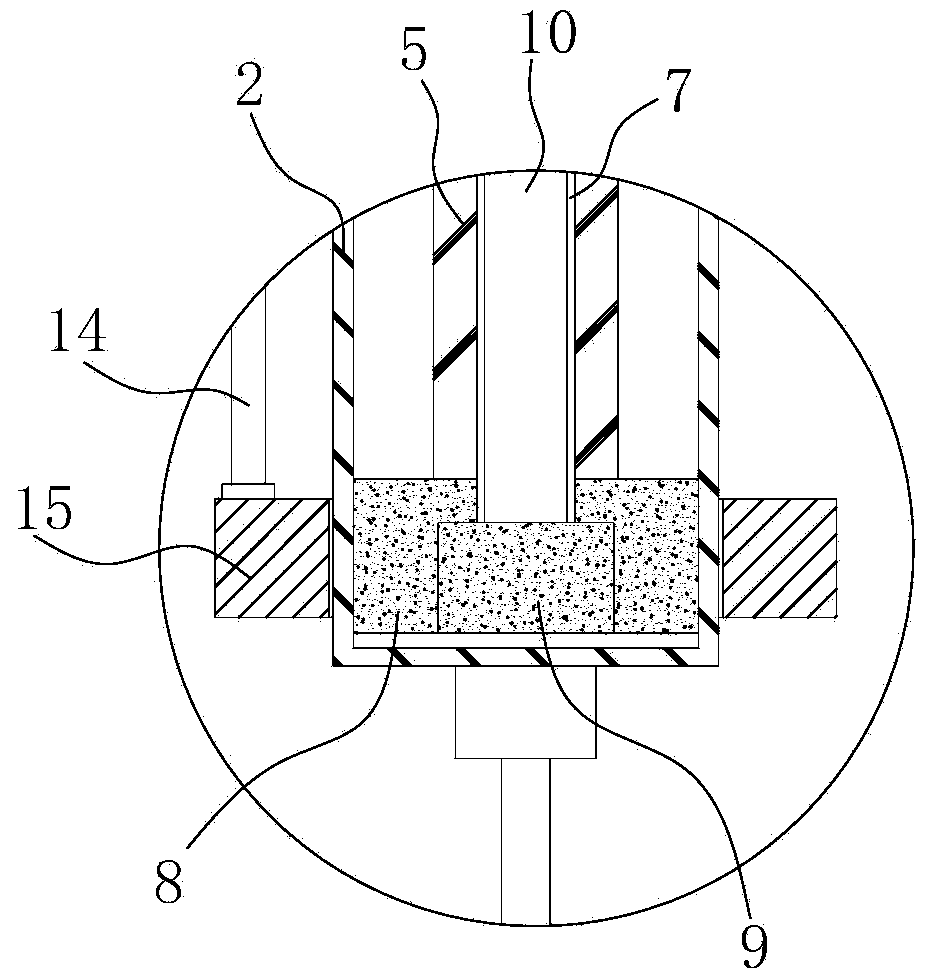

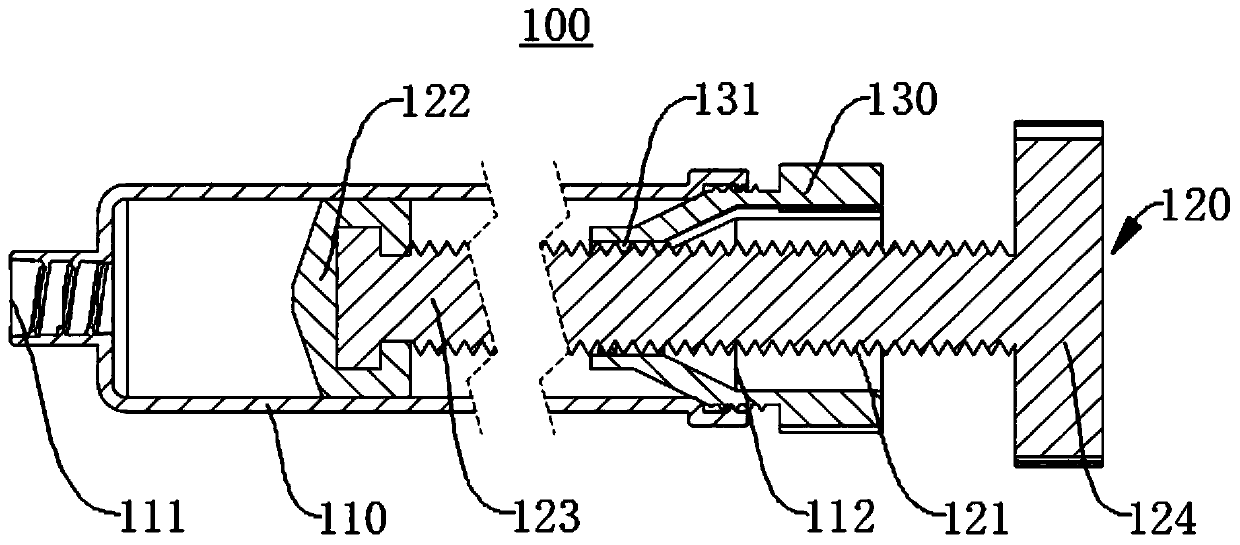

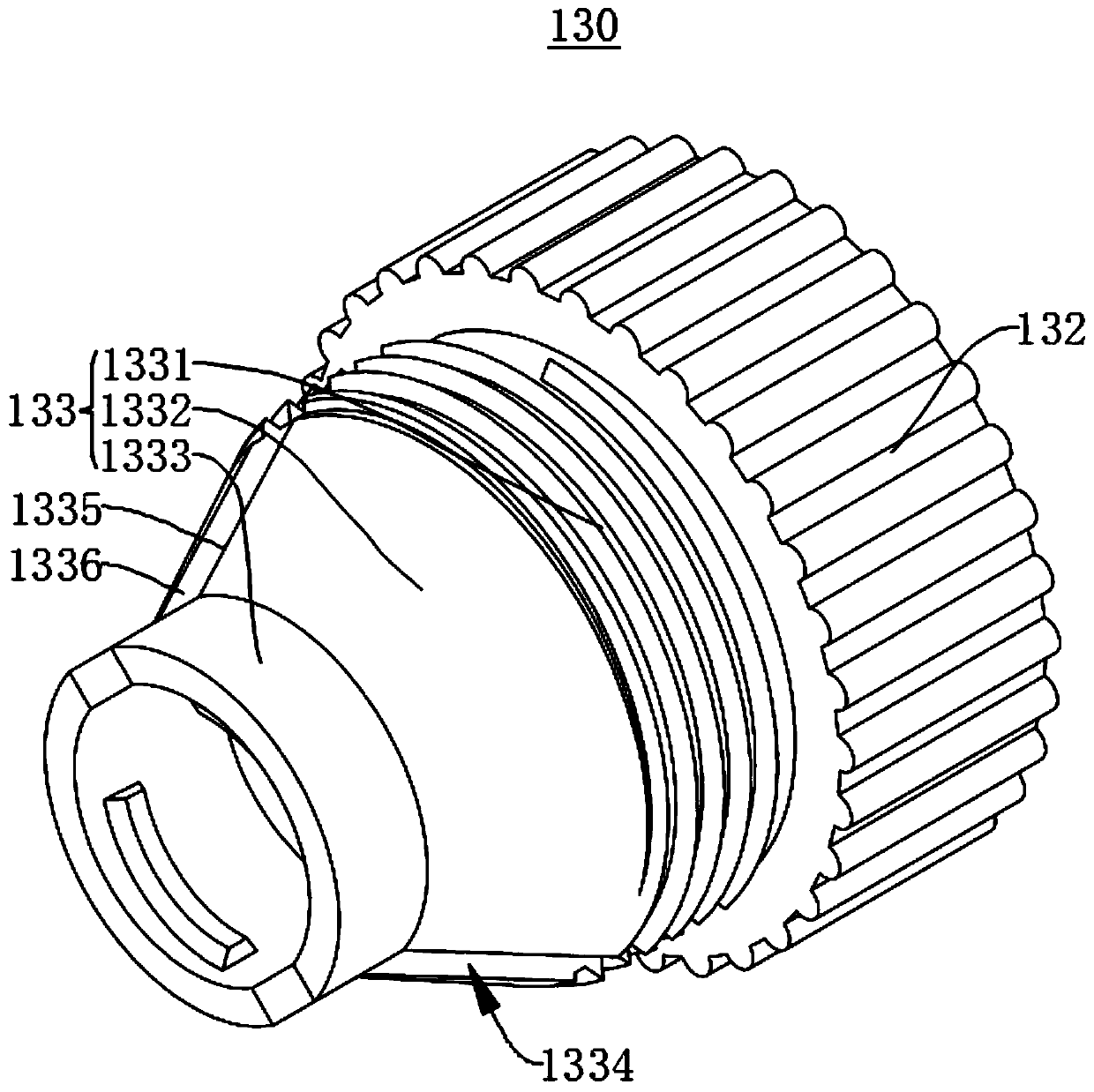

Module for controlling syringe

InactiveCN108273159APrecise control of extraction volumePrecise control of injection volumeInfusion syringesPharmaceutical containersSyringeEngineering

The invention provides a module for controlling a syringe. The module comprises a first mounting base and a plunger operation assembly; the plunger operation assembly is provided with a first fixed part and a first movable maintenance part, the first fixed part is fixed to the first mounting base, and the first movable maintenance part is movably arranged on the first fixed part and used for keeping a plunger of the syringe and driving the plunger to move. The module is simple in structure and can operate the syringe instead of medical workers, and the workload of the medical workers is reduced. By quantitatively controlling the movement distance of the first movable maintenance part, the movement amount of the plunger can be controlled, the extraction amount or injection amount of the syringe is precisely controlled accordingly, and compared with poor precision of quantitative control of manual operation, precise extraction or injection can be conducted for a long time.

Owner:深圳市阿瑟医疗机器人有限公司

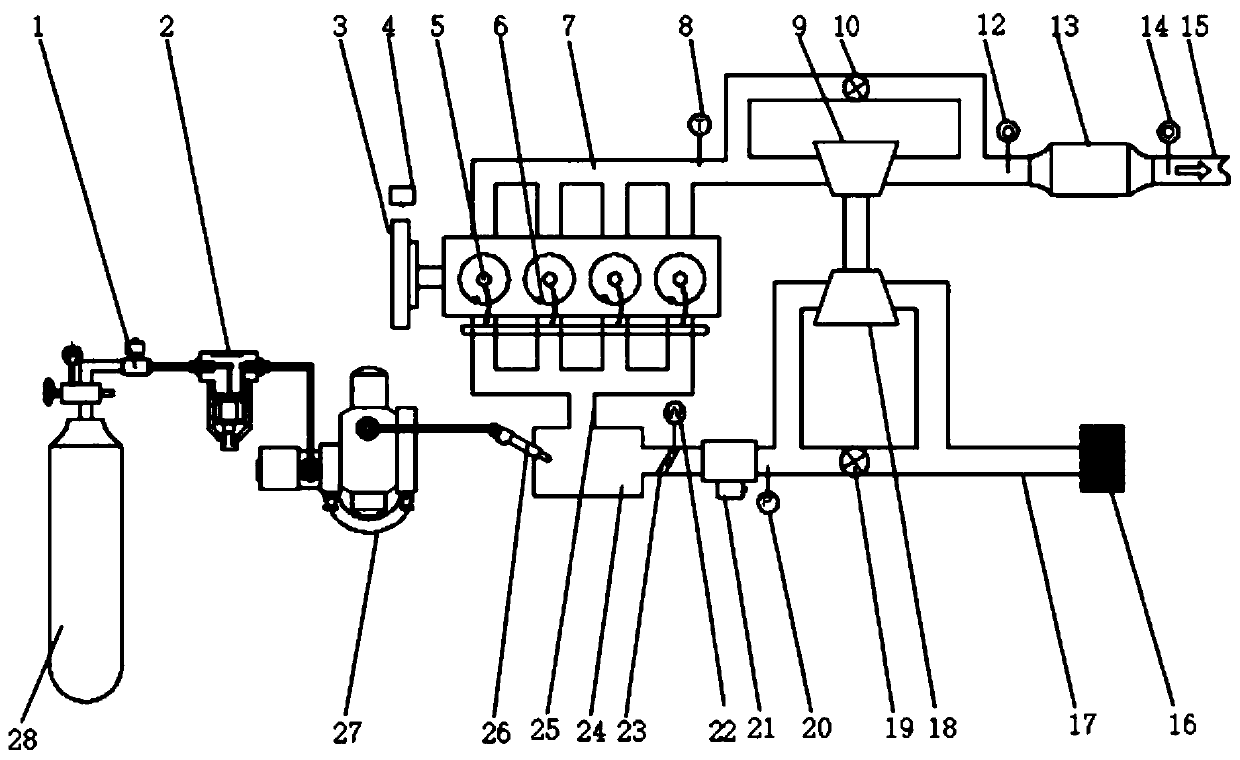

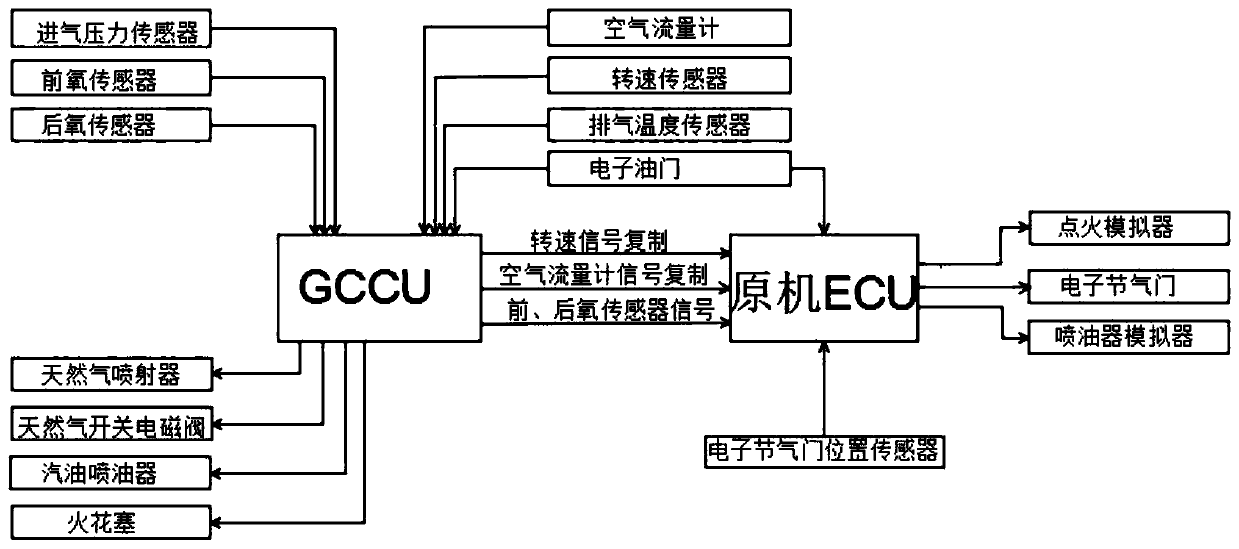

Direct injection gasoline-natural gas dual-fuel engine control system and control method

InactiveCN110778404AGuaranteed cooling effectGuaranteed lubrication effectElectrical controlMachines/enginesElectronic throttleControl system

The invention relates to the technical field of automobiles, in particular to a direct injection gasoline-natural gas dual-fuel engine control system and control method. The direct injection gasoline-natural gas dual-fuel engine control system comprises a natural gas supply system, an original direct injection gasoline engine electronic control system and further an electronic control unit (ECU),wherein the electronic control unit is correspondingly connected with the natural gas supply system and the original direct injection gasoline engine electronic control system. According to the directinjection gasoline-natural gas dual-fuel engine control system and control method, an original engine electric control system and the electronic control unit are adopted to jointly control the working process of a natural gas-gasoline double-fuel engine, the ECU of the engine can normally work, and meanwhile control of the electronic throttle valve is realized; and in addition, parameters such asignition energy, the natural gas injection amount, the gasoline injection amount of the dual-fuel engine can be accurately controlled through the electronic control unit, the cost is saved while theperformance requirement is met, and the maintenance difficulty is reduced.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Full-function insulin syringe

ActiveCN110960758APrecise control of injection volumeEnsure safetyInfusion syringesMedical devicesInsulin injectionBlood glucose meters

The invention discloses a full-function insulin syringe which comprises an insulin injection pen and a blood glucose collecting part. The injection amount of insulin is accurately controlled by utilizing the structures of a spiral propelling rod and a spiral propelling sleeve. Through time setting, light flickering and sound making, a patient is reminded of injection regularly. The situation thatinjection is forgotten or excessive injection occurs is avoided. A guarantee is provided for safety of the patient. A chip can be connected with a mobile phone APP to detect the injection dosage and the blood sugar value at regular time. A mobile phone stores data to form a data set of the patient, and the data set is taken to doctors regularly to form health evaluation. A glucometer is provided with the sound device, and blood glucose data are directly read out. A range is set in advance in the chip. If the blood glucose is within the range, the sound prompt can turn on and flicker a green light, on the contrary, the prompt does not turn on or flicker a red light. The life health of the old people is better protected through the design.

Owner:NANTONG UNIVERSITY +1

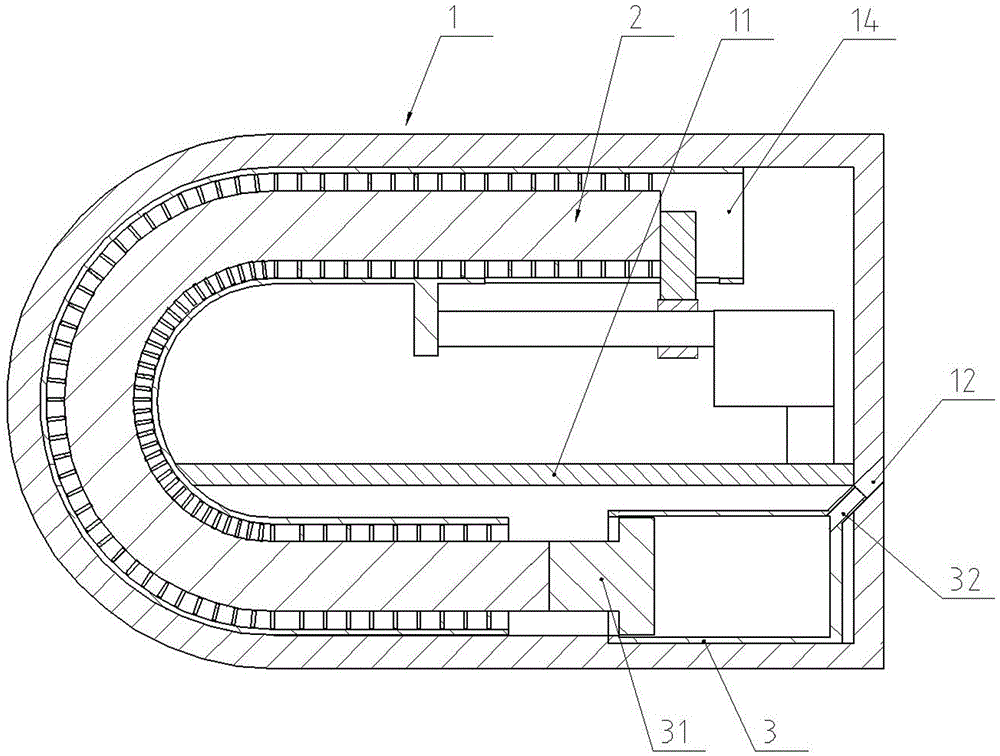

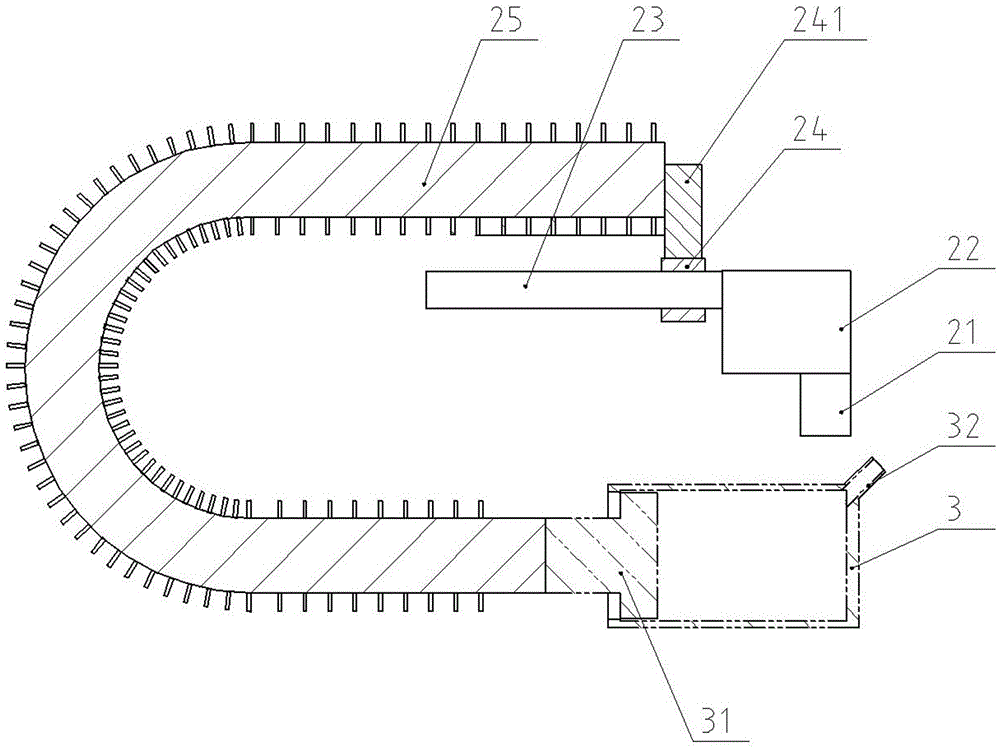

Intelligent insulin attaching pump

ActiveCN105664290AAvoid hypoglycemic reactionsImprove securityPressure infusionElectric machineryPower component

The invention discloses an intelligent insulin attaching pump. The intelligent insulin attaching pump comprises a shell, an insulin pumping device and a medicine box provided with a piston, wherein the insulin pumping device and the medicine box are packaged in an inner cavity of the shell, and the insulin pumping device comprises a power component and a transmission component which are connected in sequence; preferably, the power component comprises a micro motor and a gear reducer, and the transmission component comprises a transmission lead screw and a transmission nut; the rotating speed of the micro motor is reduced through the gear reducer, then the transmission lead screw is made to rotate at a low speed, motion is transmitted through the transmission nut so as to make the piston move along the inner wall of the medicine box to extrude and pump an insulin preparation out to be injected into the body of a patient through a subcutaneous remaining needle, the amount of residual liquid is small, hypoglycemia reaction possibly caused by the large length of a connecting pipeline in the prior art can be avoided, and waste of liquid medicine can be avoided so that expenses can be reduced. An output pipe tilting up by 45 degrees is arranged on the upper side of the outer end of the medicine box, an oblique hole inclining by 45 degrees is also formed in the corresponding position of the shell to allow the remaining needle to be inserted therein, and it is guaranteed that the remaining needle is inserted into subskin at 45 degrees too.

Owner:江苏耑叶医疗科技有限公司

High pressure explosion limit measuring device and molar fraction gas distribution method based on the device

ActiveCN110082392AExact mole fractionSolve problems that cannot be accurately and quantitatively characterizedMaterial exposibilityMeasurement deviceTemperature measurement

The invention discloses a high pressure explosion limit measuring device and a molar fraction gas distribution method based on the device. The device comprises an explosion container, a compressed airstorage tank, and one or more combustible gas distribution assemblies, wherein the explosion container and the compressed air storage tank are connected via a compressed air inlet, the respective combustible gas distribution assemblies are connected to the explosion container, and the explosion container and the compressed air storage tank are both provided with temperature measuring components,temperature control components and pressure sensors. The high pressure explosion limit measuring device and the molar fraction gas distribution method based on the device provided by the invention canaccurately obtain the accurate mole fraction of combustibles in the mixture with air, and solve the problem that the explosion limit experimental research cannot be accurately quantitatively characterized since the beginning. For flammable gas, the molar fraction of the mixture can also be accurately determined by establishing its precise dedicated equation of state, especially the Helmholtz equation of state.

Owner:XI AN JIAOTONG UNIV

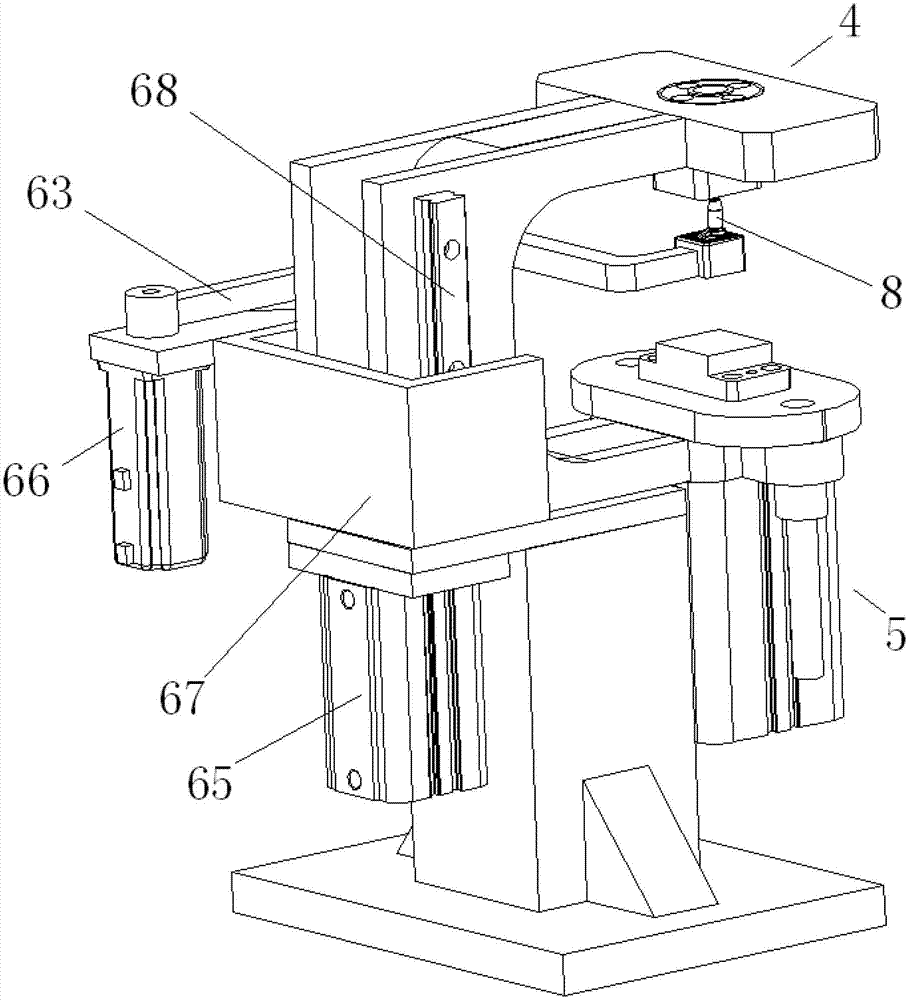

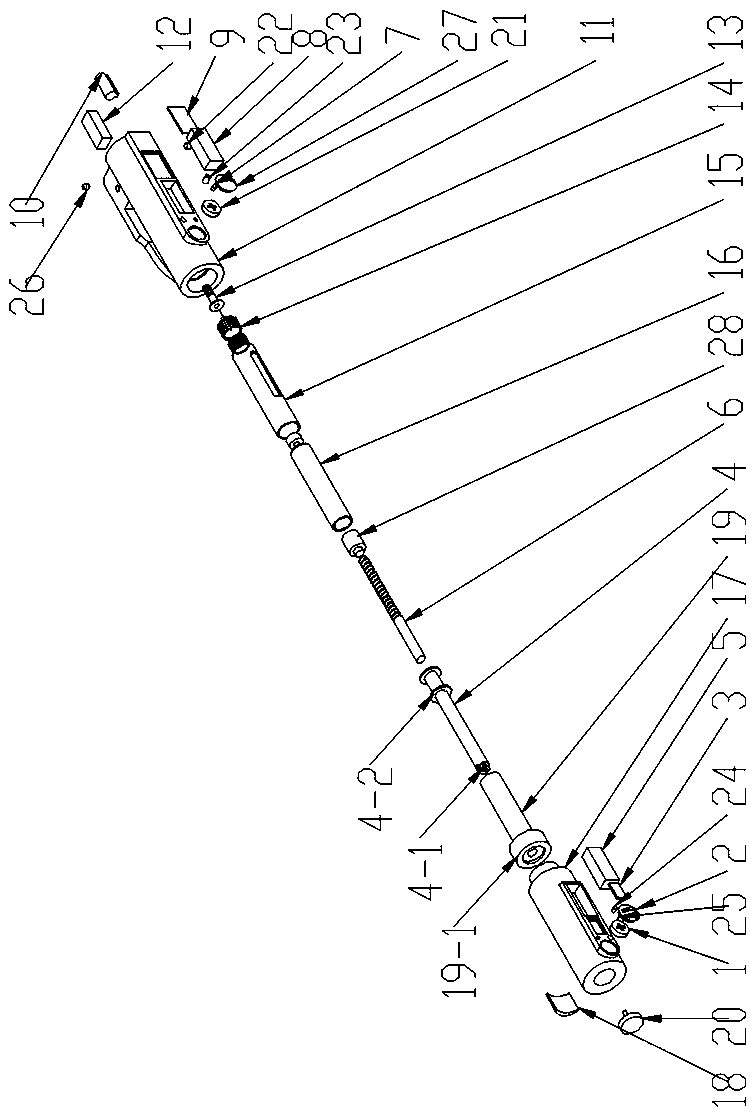

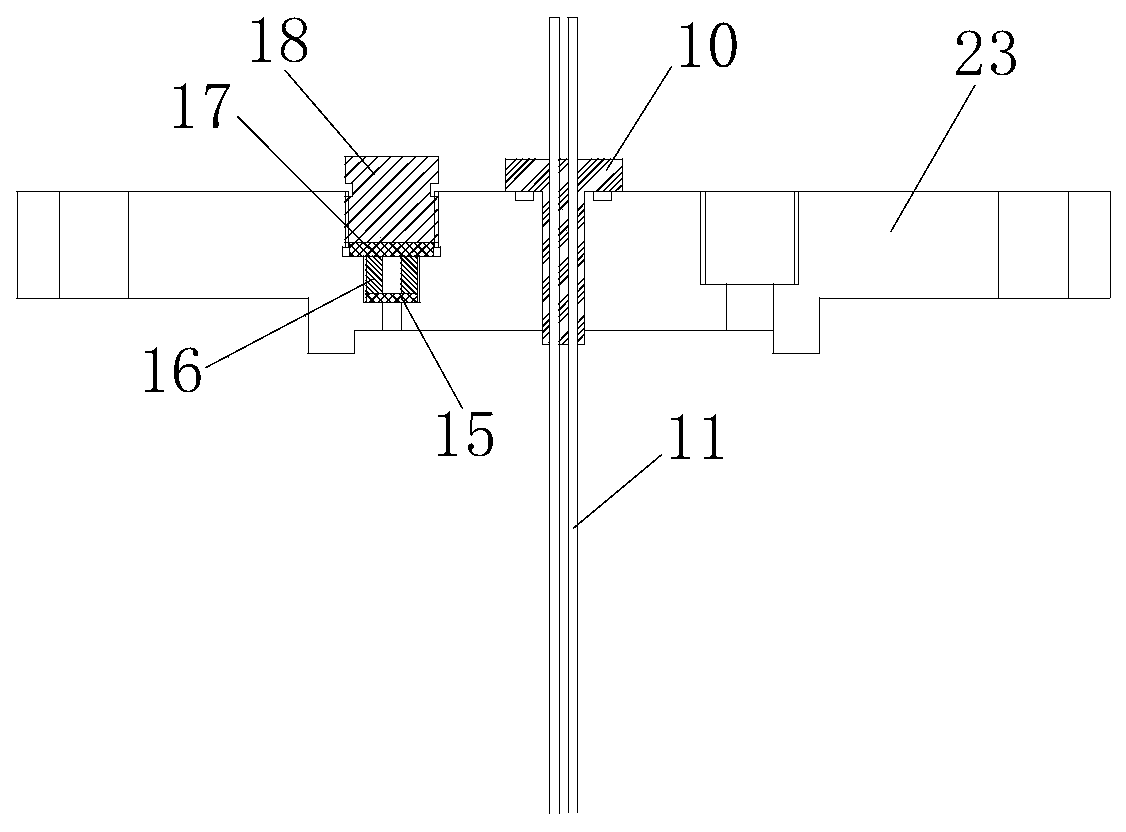

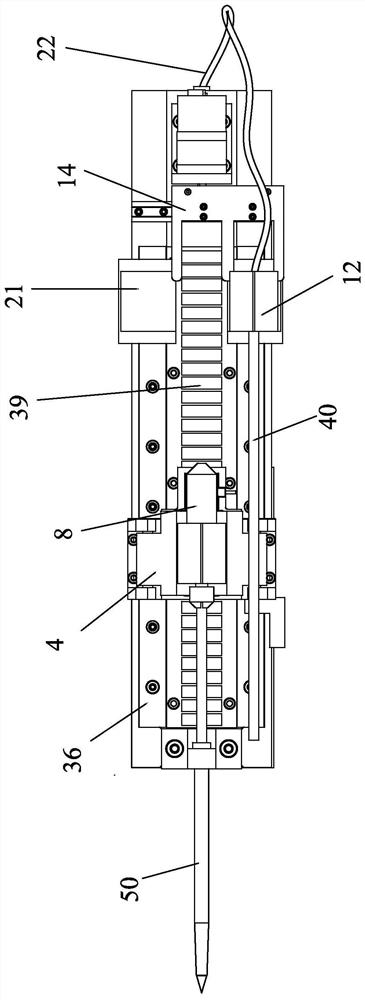

Automatic vertebral body puncture forming device and orthopedic surgery robot system

PendingCN113425414ARealize fully automatic operationReduce labor intensitySurgical needlesSurgical manipulatorsOrthopedics surgeryPuncture procedure

The invention discloses an automatic vertebral body puncture forming device and an orthopedic surgery robot system. The automatic vertebral body puncture forming device comprises a bottom plate, a puncture unit and a bone cement filling unit, wherein the puncture unit and the bone cement filling unit are arranged on the bottom plate; the automatic vertebral body puncture forming device further comprises a linear feeding unit and a tool replacement unit which are installed on the bottom plate; the linear feeding unit carries the puncture unit or the bone cement filling unit to move forwards to conduct puncture operation or injection molding operation of bone cement or moves backwards to return to the tool replacement unit; and the puncture unit or the bone cement filling unit conducts position replacement on the tool replacement unit so as to leave or enter the linear feeding unit. The automatic vertebral body puncture forming device is used in cooperation with an orthopedic surgery robot, and intelligent automatic orthopedic surgery puncture and bone cement injection are achieved.

Owner:SHENZHEN XINJUNTE SMART MEDICAL EQUIP CO LTD

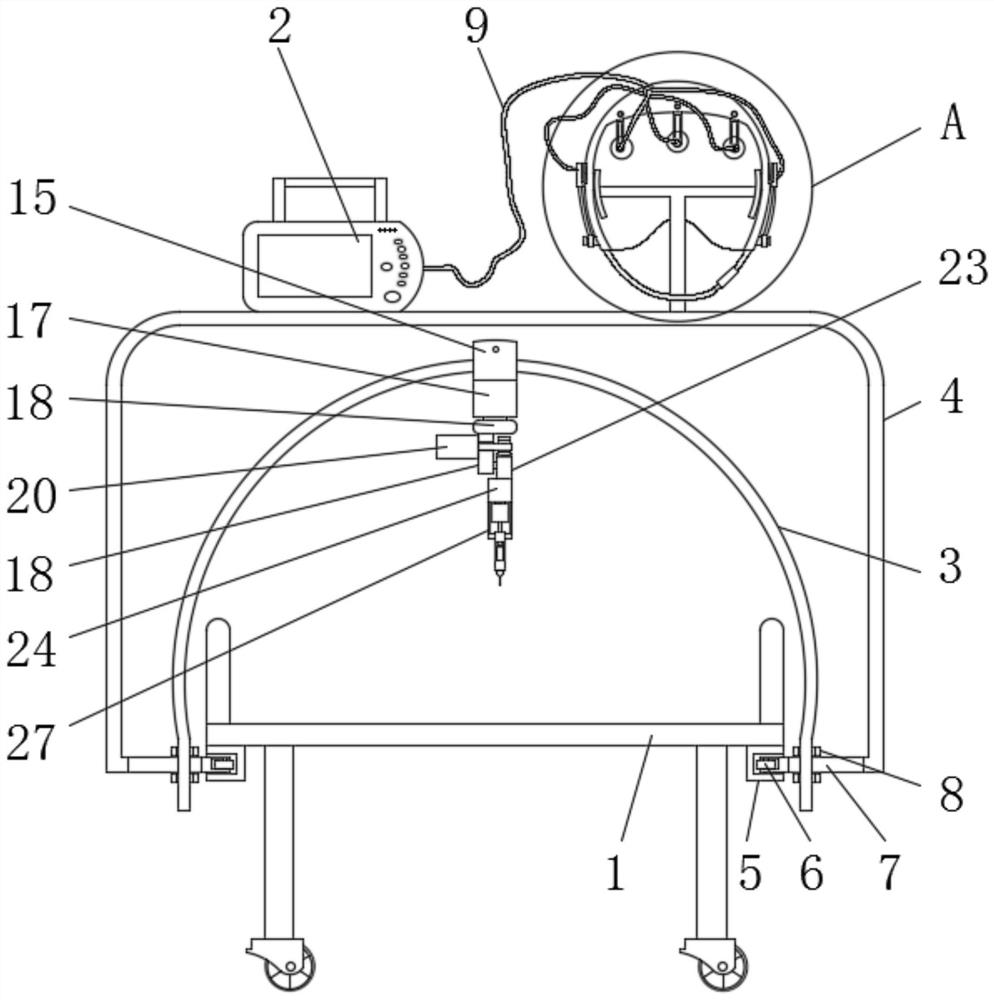

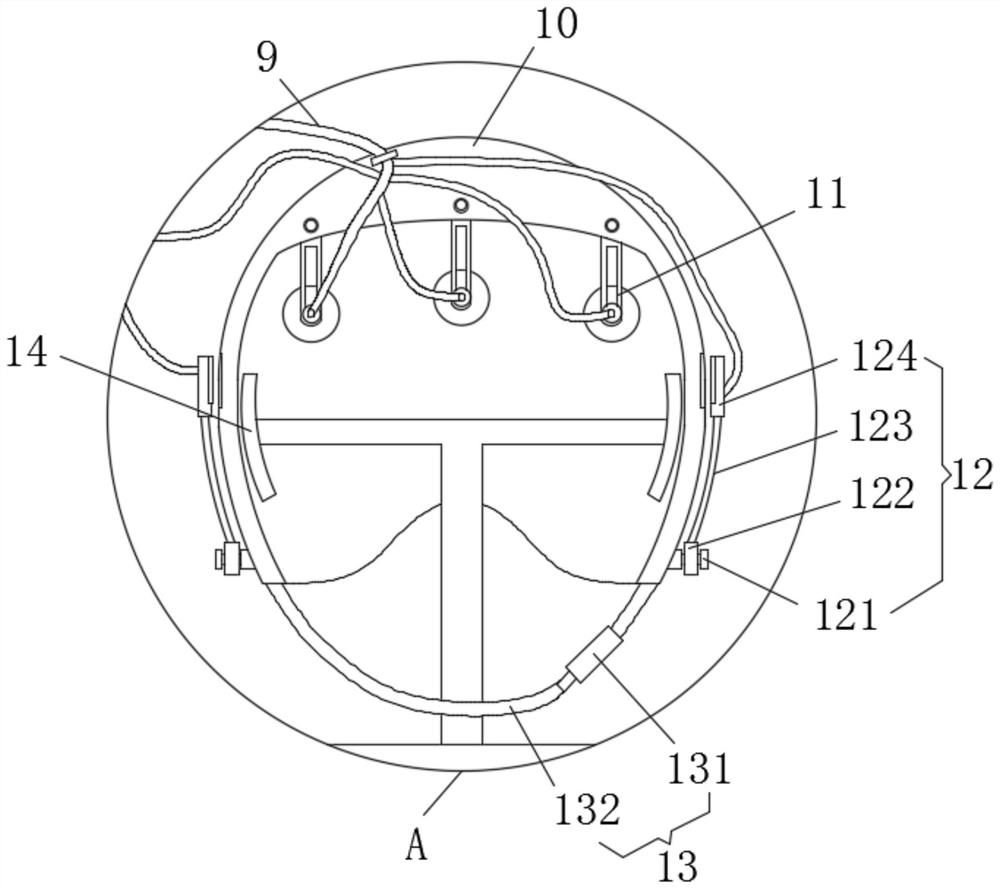

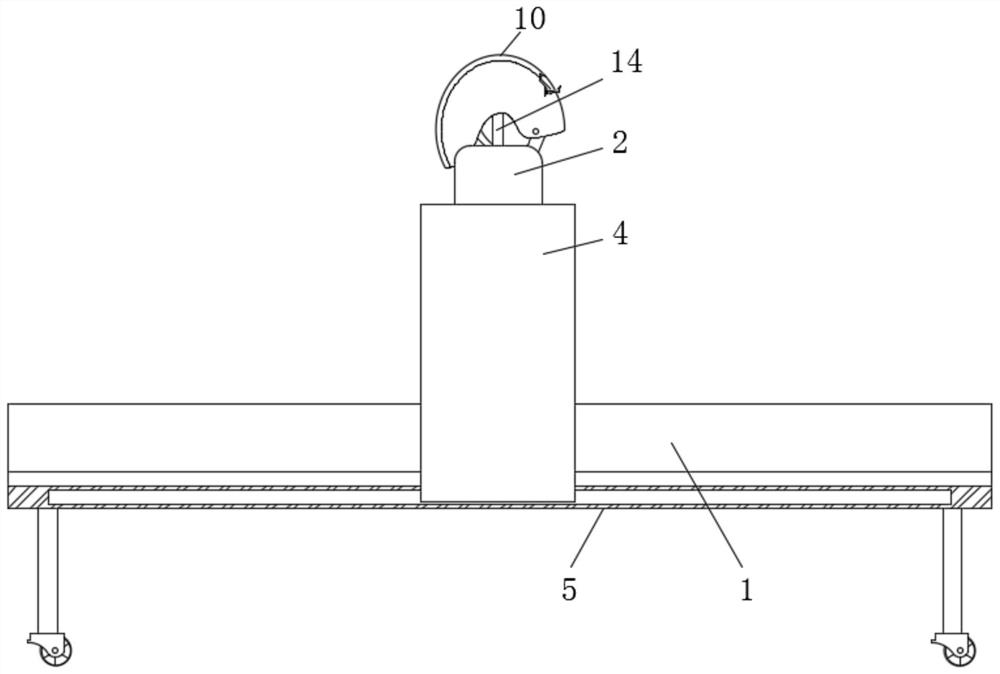

Device applied to anesthesia depth monitoring and anesthetic injection

InactiveCN113144344APrecise control of injection volumeImprove convenienceElectrocardiographyAutomatic syringesAnesthetic AgentHuman body

The invention discloses a device applied to anesthesia depth monitoring and anesthetic injection and relates to the technical field of medical equipment. The device specifically comprises an operating table, a monitor, an arc-shaped plate and a moving frame, wherein guiding grooves are formed in bottoms of the two sides of the operating table, rollers are in rolling connection with interior of the guiding grooves, single ends, far away from the guiding grooves, of the rollers are fixedly connected with the end face of the moving frame, and shifting chutes are formed in bottoms of internal walls of the moving frame. Through arranging the monitor, an injection unit and a motor B, the effect of accurately controlling an anesthetic injection amount is achieved, and the problem that anesthetic injection is hardly controlled relatively accurately due to the fact that anesthetic injection for a human body is achieved through manually operating an anesthetic injection unit, the amount of an anesthetic is difficult to control due to injection by this method, the anesthetic stresses of different people are different, the amount of the anesthetic is required to be adjusted through uninterruptedly observing an anesthesia depth monitor, and the error range of manual regulation on the amount of the anesthetic is relatively large is solved.

Owner:民勤县人民医院

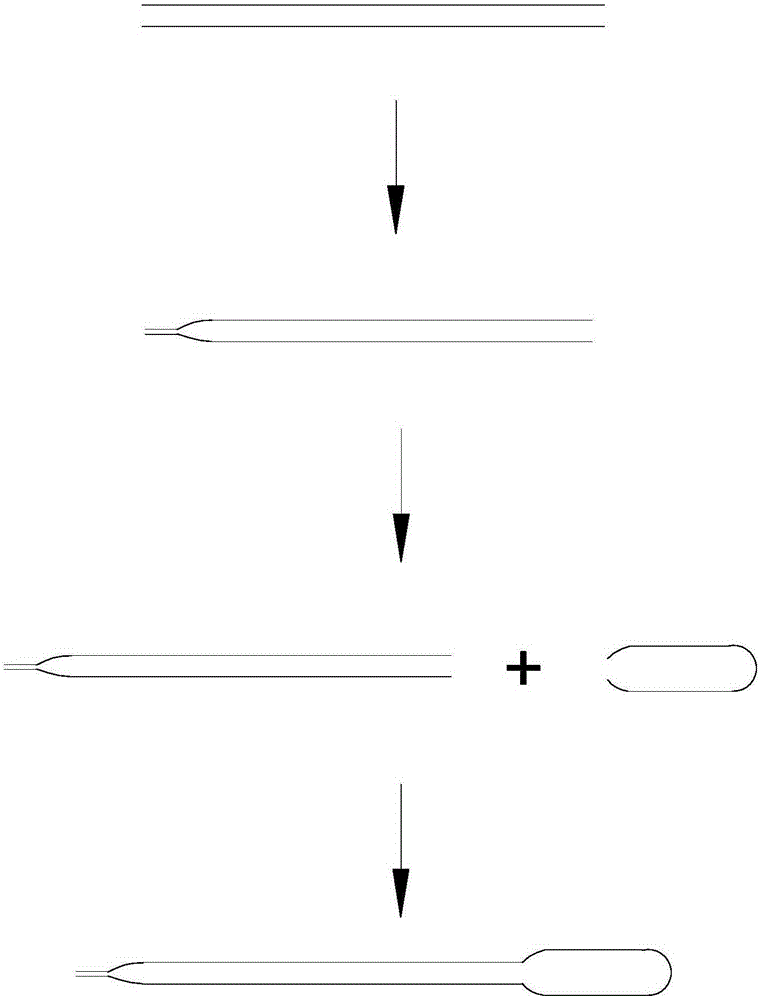

Method for extracting and injecting adipose-derived stem cells

InactiveCN110241078AIncrease acquisition rateImprove survival rateCell dissociation methodsInfusion syringesMedicineAcquisition rate

The present invention relates to the technical field of cosmetics and aims to provide a method for extracting and injecting adipose-derived stem cells. The method can improve extraction amount and survival rate of adipose and can achieve precise injection during an injection phase. A used technical scheme is as follows: cultured autologous adipose-derived stem cells are filled in an adipose precision syringe, and then injection is conducted in recipient areas in a first rough injection and then fine injection manner; a rough injection amount is obtained by reducing 5% based on an estimated injection amount and a fine injection amount is obtained by slow push of the syringe by cosmetic doctors after completion of the rough injection according to obtained actual effects based on the actual injection amount; and the estimated injection amount is obtained according to expected cosmetic effects. The method can improve acquisition rate and backfilling survival rate of the autologous adipose-derived stem cells, conveniently controls the injection amount of the autologous adipose and facilitates the precise injection.

Owner:成都天府新区可纳儿医疗美容门诊部有限公司

Medium and trace element composition for water-soluble fertilizer, water-soluble fertilizer and preparations and application thereof

InactiveCN106673803AImprove the mixing effectImprove stabilityCalcareous fertilisersMagnesium fertilisersTrace element compositionNutrient content

The invention relates to the field of agricultural fertilizers, in particular to a medium and trace element composition for a water-soluble fertilizer, the water-soluble fertilizer and preparations and application thereof. The medium and trace element composition comprises a medium and trace element, a thickening substance and an anti-frosting substance, wherein the medium and trace element comprises at least one of calcium, magnesium, iron, manganese, molybdenum, copper, zinc and boron; the thickening substance comprises at least one of polysaccharide thickeners and inorganic polymeric thickeners; the anti-frosting substance comprises at least one of alcohols and inorganic salts. The thickening substance contained in the medium and trace element composition can improve the blending performance and the stability of a finished product; the contained anti-frosting substance can improve the frosting resistance of a suspended water-soluble fertilizer as the finished product, so that the suspended water-soluble fertilizer does not separate out salt in the case of -20 DEG C. Through application of the formula of the medium and trace element composition, a pertinent customized fertilizer formula with different nutrient contents can be formed, so that different needs of different crops in different regions are met, and soil testing for formulated fertilization is achieved.

Owner:北京天辰云农场有限公司

Injection device

PendingCN111529826AQuick suctionPrecise control of injection volumeInfusion syringesPharmaceutical containersApparatus instrumentsSurgery

The invention discloses an injection device, and relates to the technical field of medical instruments. The injection device includes an injector; a pressing and loosening mechanism is installed on anouter sleeve; a plunger rod passes through the pressing and loosening mechanism, and extends into the outer sleeve; the plunger rod can move relative to the outer sleeve so as to inward draw or outward inject a liquid medicine; the pressing and loosening mechanism is provided internal threads; a circumferential surface of the plunger rod is provided with external threads; the pressing and loosening mechanism can be pressed outside the plunger rod so as to make the internal threads engaged with the external threads; and the pressing and loosening mechanism can also loosen the plunger rod so asto make the internal threads separated from the external threads. Compared with the prior art, due to the fact that the pressing and loosening mechanism installed on the outer sleeve and the plungerrod in screw-thread fit with the pressing and loosening mechanism are employed, the injection device provided by the invention can rapidly draw the liquid medicine when drawing the liquid medicine, and can accurately control the injection dose when the liquid medicine is injected, and is convenient and practical.

Owner:CANYON MEDICAL INC

Normal-temperature vacuum exhaust machining equipment of gravity heat pipe

ActiveCN105222626APrecise control of injection volumePromote rapid formationIndirect heat exchangersHeat exchange apparatusHeat conductingEngineering

The invention discloses normal-temperature vacuum exhaust machining equipment of a gravity heat pipe. The equipment comprises a sealing joint, a quantitative conveying device and a seal pressing device, wherein the sealing joint is connected with a vacuum pump through an air extracting pipeline; a first electromagnetic valve is arranged on the air extracting pipeline; the quantitative conveying device is used for conveying a quantitative heat conducting medium into a metal pipe, and a liquid conveying pipeline thereof is connected with a position, near the sealing joint, of the air extracting pipeline; and the seal pressing device is suitable for closing an opening end of the metal pipe after the injection of the heat conducting medium in the metal pipe, and is near the sealing joint. When the machining equipment is used for machining the gravity heat pipe, the machining can be performed under normal temperature, so that the heating or refrigerating treatment is not needed after the injection of the heat conducting medium, and the energy consumption in the machining process is effectively reduced; and meanwhile, the quantitative conveying device is arranged for precisely controlling the medium injection quantity in the injection of the heat conducting medium in the metal pipe, and guarantees the medium injection quantity to be equal in the same batch of products, so that the product pass percent and the consistency of the products in the same batch are guaranteed.

Owner:浙江省太阳能产品质量检验中心

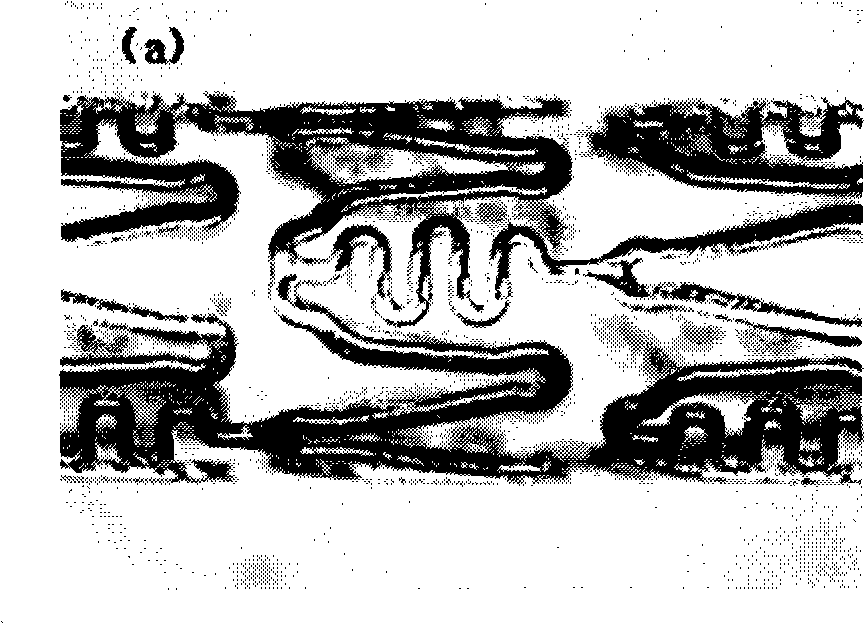

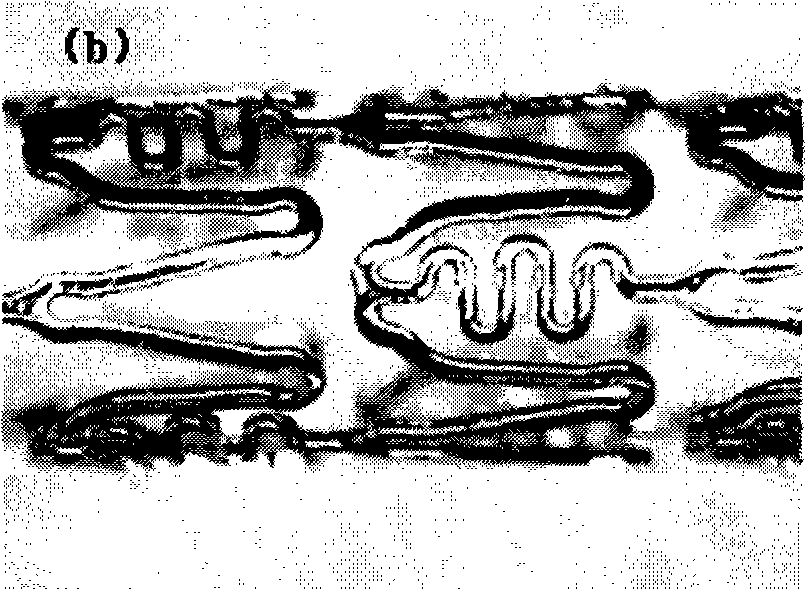

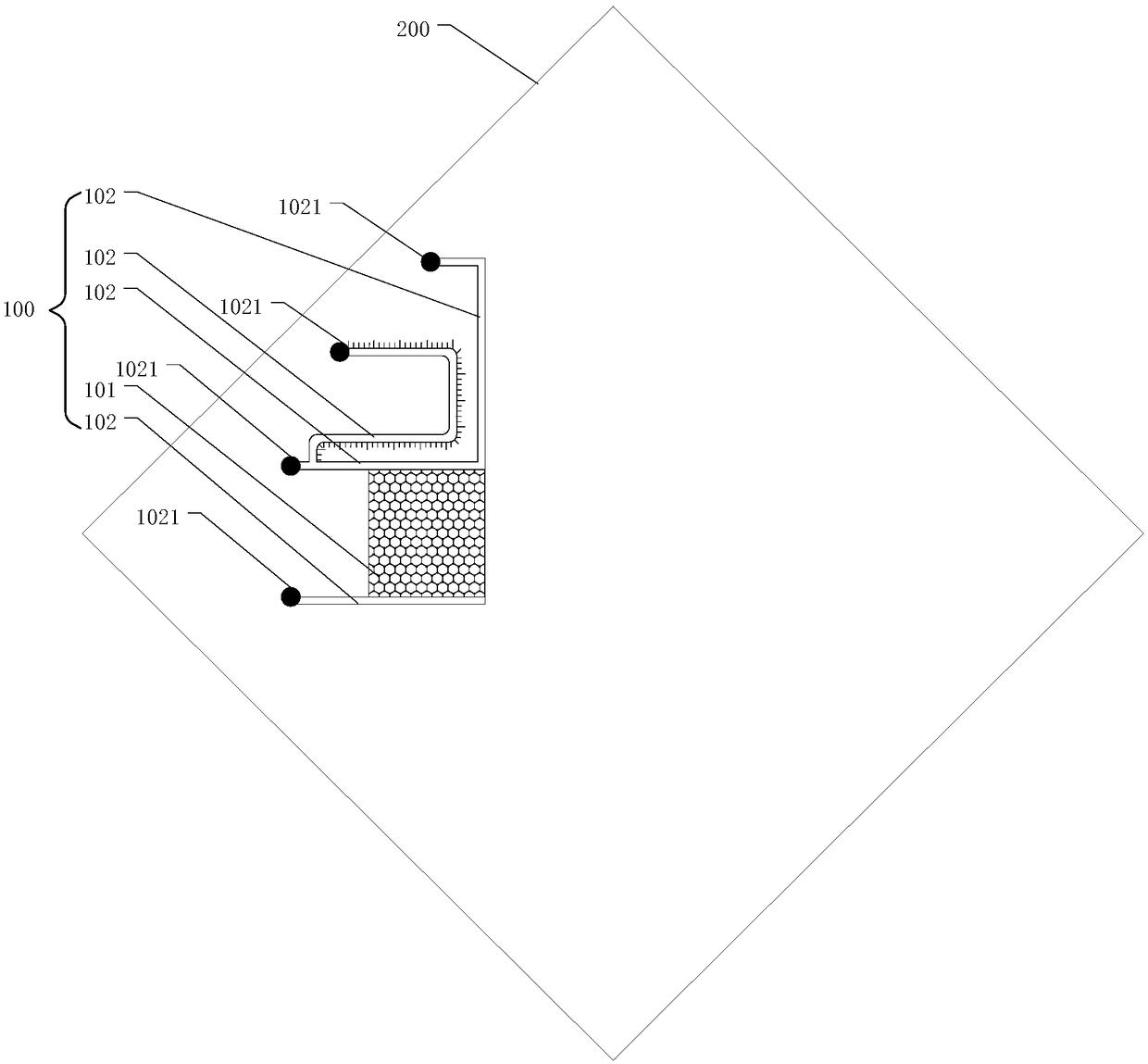

Microscopic oil displacement chip with displacement fluid injection volume marking scale in flow-guiding flow passage

ActiveCN108246371APrecise control of injection volumeSolve the problem that the injection volume of displacement fluid cannot be precisely controlledLaboratory glasswaresInjection volumeEngineering

The invention provides a microscopic oil displacement chip with a displacement fluid injection volume marking scale in a flow-guiding flow passage. The microscopic oil displacement chip comprises an oil displacement model arranged on a chip substrate, wherein the oil displacement model comprises an oil displacement area and 4 flow passages; the 4 flow passages are an oil outlet flow passage, a water / oil injection flow passage, a displacement fluid flow-guiding flow passage and an oil washing flow passage respectively; one ends of the flow passages are communicated with the oil displacement area; the other ends of the flow passages are communicated with injection or extraction ports in the chip substrate; the displacement fluid flow-guiding flow passage is used for injecting a displacementfluid into the oil displacement area, and the displacement fluid injection volume marking scale is arranged therein. During an experiment, the scale can be used for intuitively making the injection volume of the displacement fluid; compared with an injection system such as a constant-flow pump, the microscopic oil displacement chip has the advantages as follows: an injection volume error caused byan error of the injection system itself, pipeline expansion, fluid compression and the like is avoided and precise control of the injection volume of the displacement fluid can be achieved through observation on the scale, so that the problem that the experimental repeatability is poor because the conventional chip cannot precisely control the injection volume of the displacement fluid is solved.

Owner:SOUTHWEST PETROLEUM UNIV

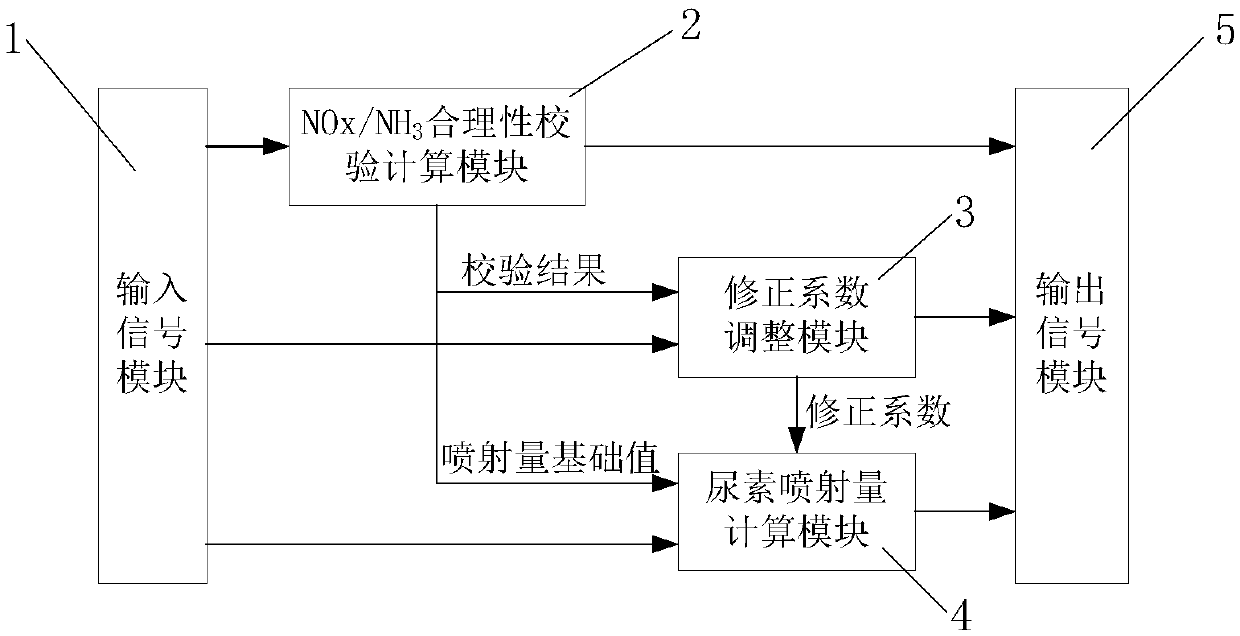

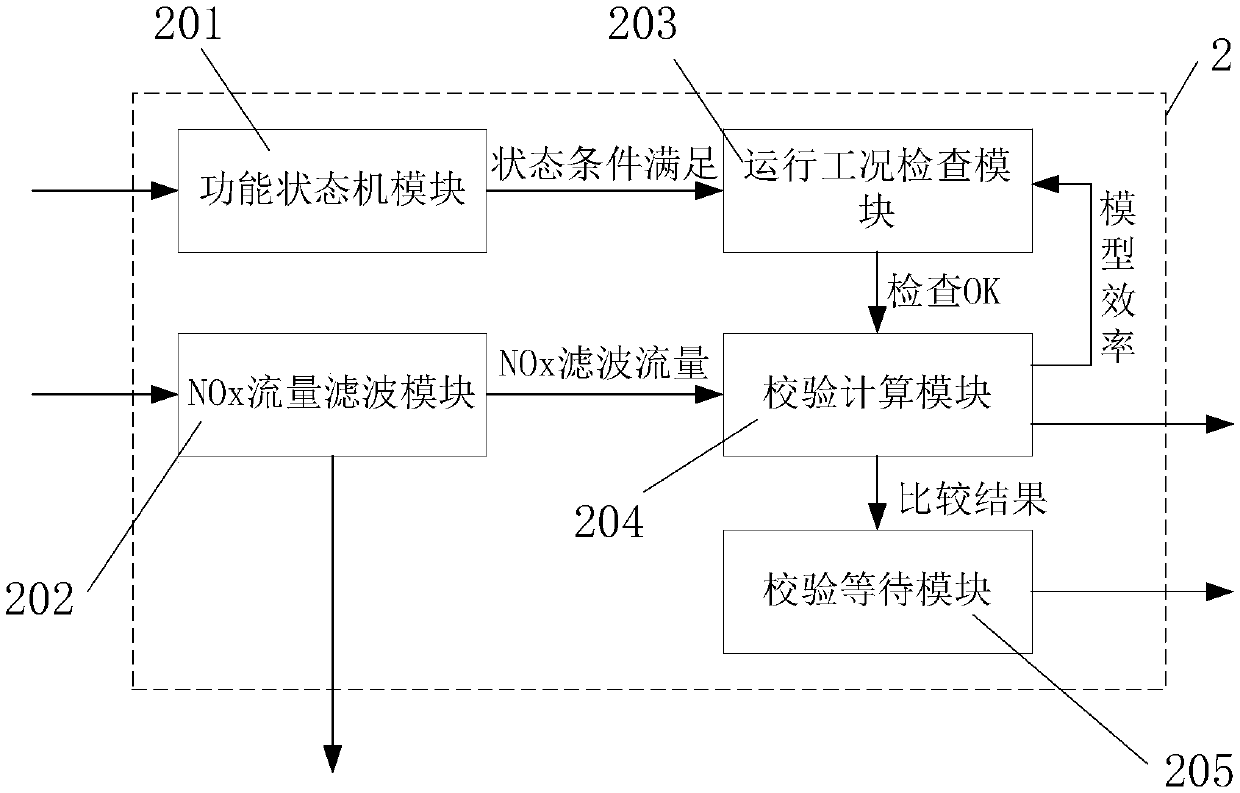

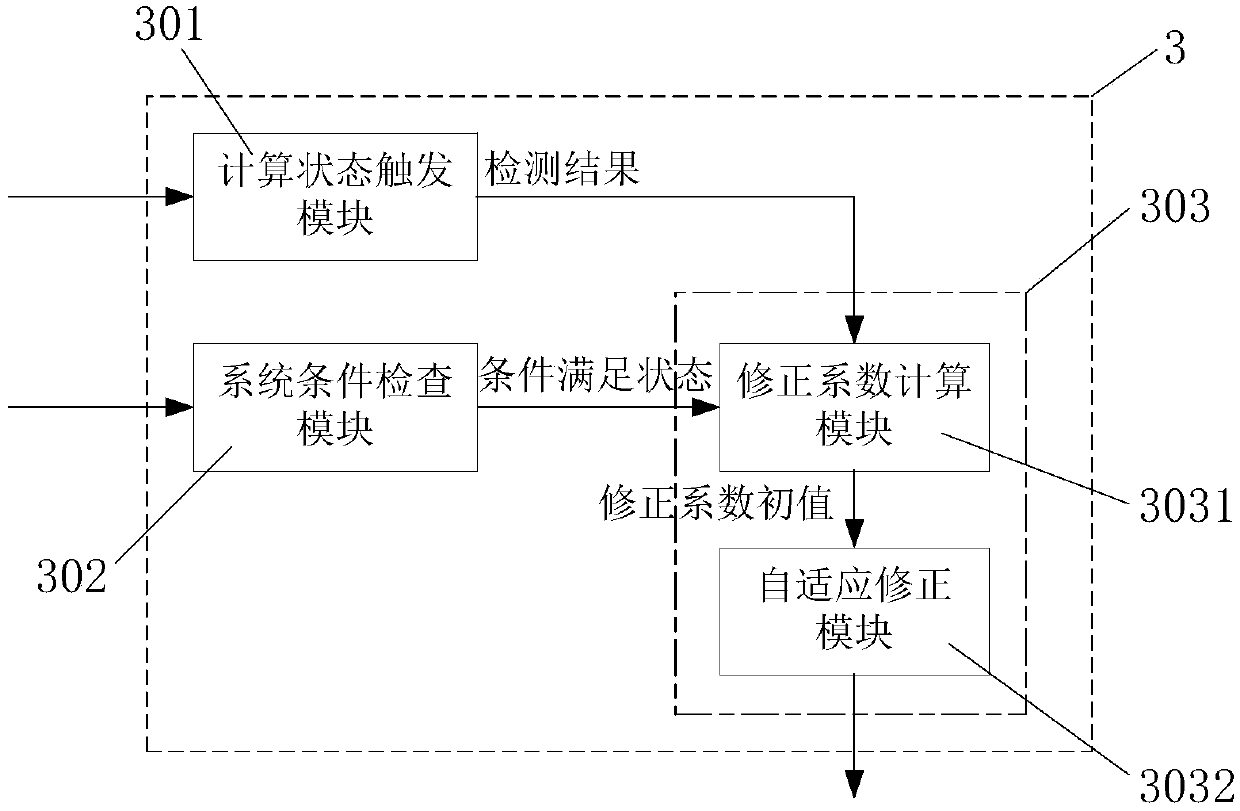

Control system for self-adaptive correction of urea injection on basis of NOx sensor

ActiveCN109681298APrecise control of injection volumeImprove jetting accuracyInternal combustion piston enginesExhaust apparatusControl systemClosed loop

The invention discloses a control system for self-adaptive correction of urea injection on the basis of a NOx sensor. The control system comprises an input signal module, the input signal module is connected with a NOx / NH3 rationality verification and calculation module, a correction coefficient adjustment module and a urea injection amount calculation module separately, the NOx / NH3 rationality verification and calculation module is connected with the correction coefficient adjustment module, the urea injection amount calculation module and an output signal module separately, the correction coefficient adjustment module is connected with the urea injection amount calculation module and the output signal module separately, and the urea injection amount calculation module is connected with the output signal module. Therefore, the urea injection amount can be precisely controlled according to the flow of NOx in a catalyst, and the robustness of an SCR closed-loop system can be enhanced.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com