Patents

Literature

157results about How to "Control injection volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

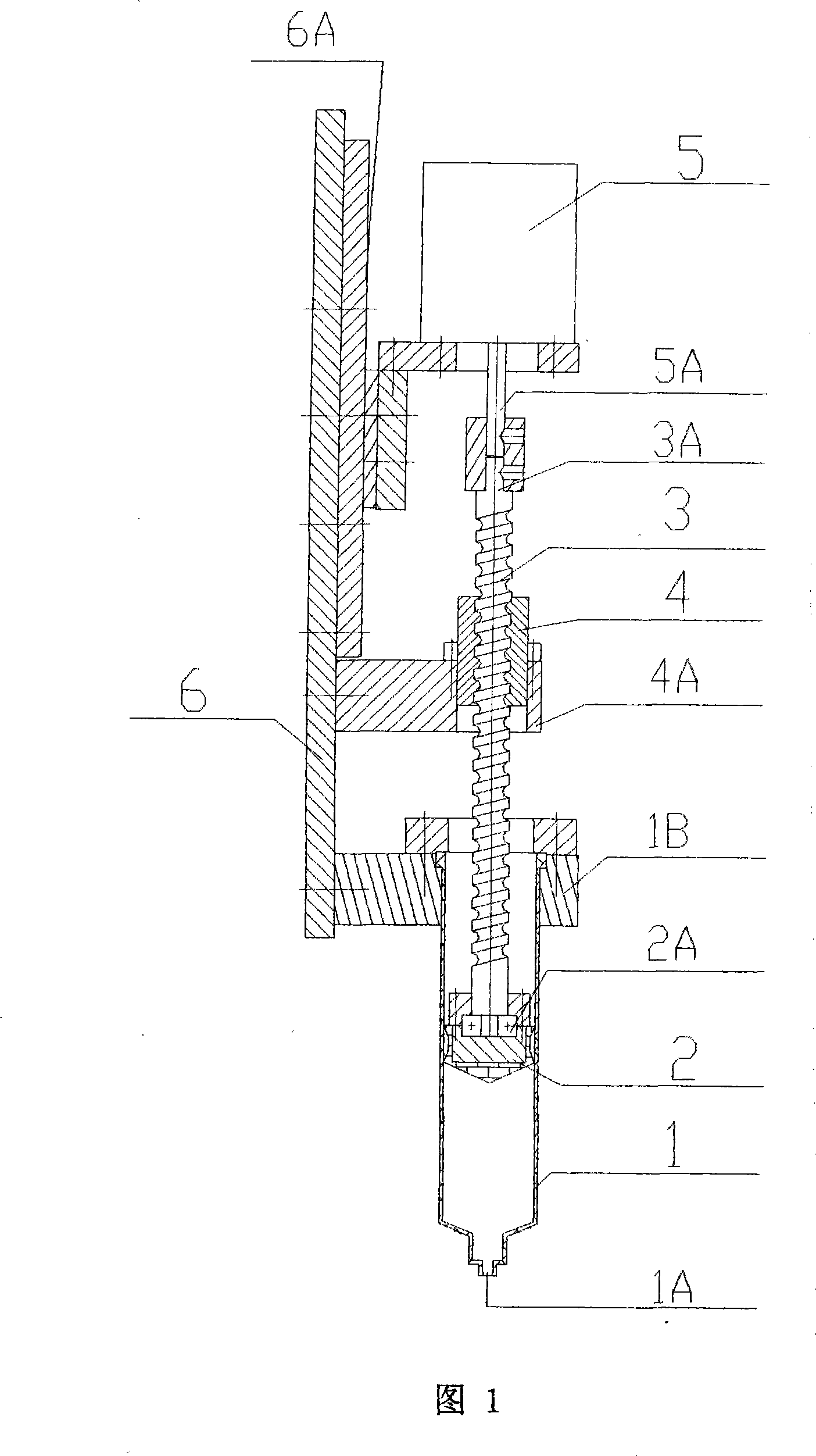

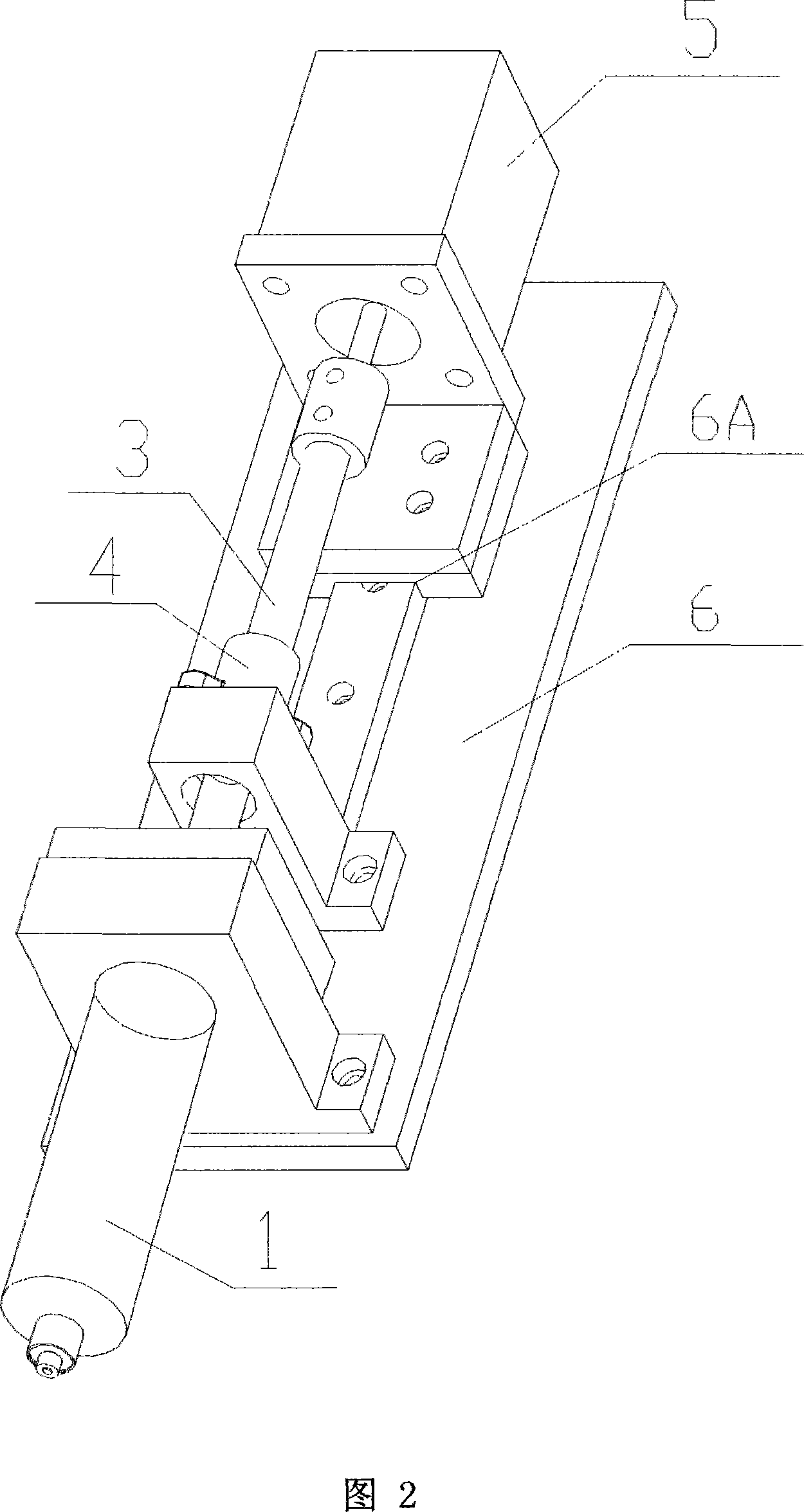

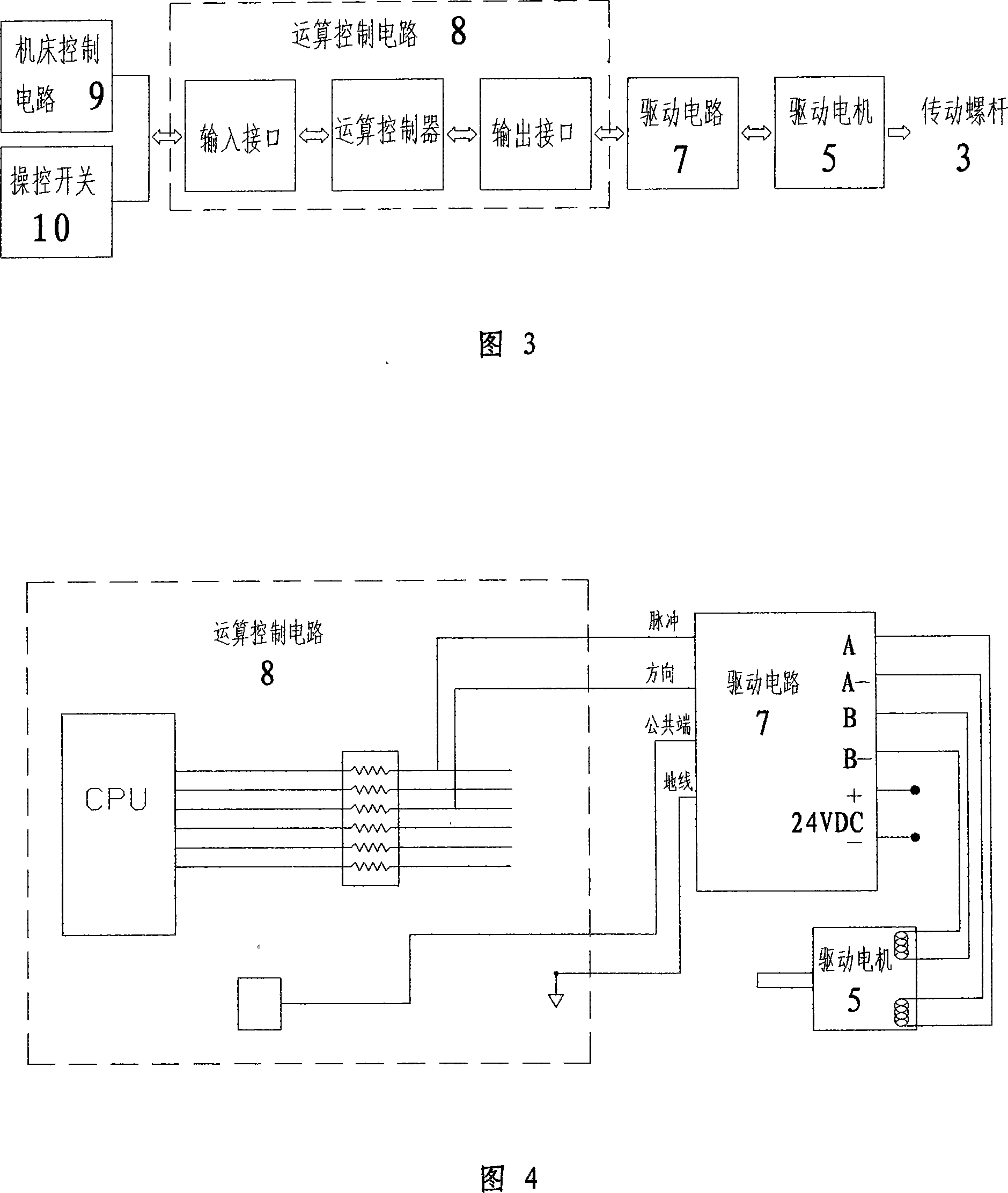

Electric point gum machine and working way thereof

InactiveCN101224454AIncrease forceFast injectionLiquid surface applicatorsCoatingsAxial displacementMotor drive

The invention discloses a motor adhesive injecting device and an operating mode thereof. The device comprises a shooting cylinder which is provided with an outlet at the bottom, a pressure ram arranged inside the shooting cylinder, a drive screw connected with the upper part of the pressure ram, a fixing screw used together with the drive screw and a drive motor arranged on top of the drive screw. The rotation of a motor drives the screw to make the spiral movement inside the nut and drives a piston to have the axial displacement to act on the liquid. The operating mode is that the rotating axle of the motor is controlled to continuously rotate, discontinuously rotate, impulse rotate or reverse the axle to drive the piston to move up and down or vibrate correspondingly to the cylinder. With excellent response, the motor can control the injection rate accurately by the controlling the rotating angle. The motor can satisfy the requirements for accurate and rapid adhesive injecting for the constant running speed and uniform flowing speed of the liquid.

Owner:PRECISION TECH DEV SHENZHEN

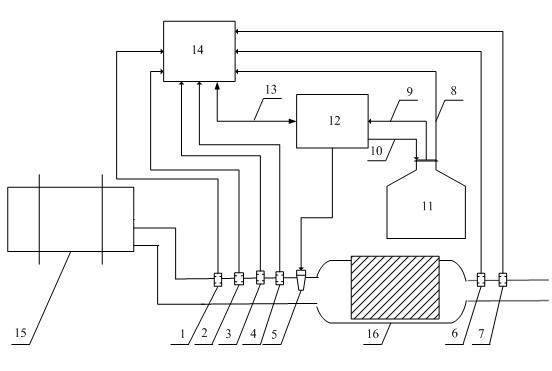

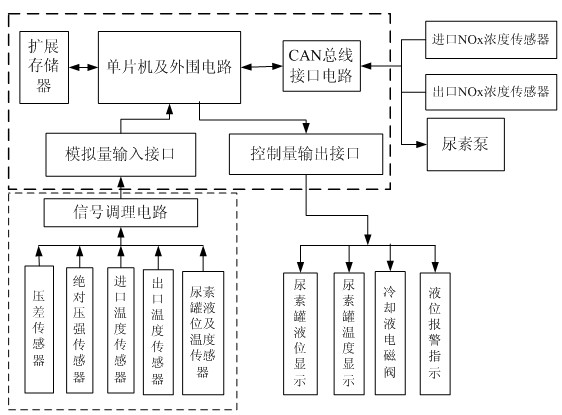

Independent SCR (semiconductor control rectifier) system control method and control device based on NOx (nitrogen oxide) sensor

InactiveCN102678239AEasy to obtain exhaust parametersControl injection volumeInternal combustion piston enginesExhaust apparatusInlet temperatureUrea

The invention discloses an independent SCR (semiconductor control rectifier) system control method and a control device based on a NOx sensor. A signal acquiring unit disclosed by the invention mainly comprises a differential pressure transducer, an inlet NOx sensor, an absolute pressure sensor, an inlet temperature sensor, an outlet temperature sensor and an outlet NOx sensor. The control device is provided with a CAN (controller area network) bus interface, and a singlechip is communicated with an urea pump through the CAN bus interface to control the spray of the amount of blue adding solution. The signal acquiring unit acquires the state of engine tail gas in real time, and the acquired state is transmitted to the singlechip for calculating the required spray amount of the blue adding solution. According to the independent SCR system control method and the control device, the design of a traditional engine control system is not changed, and only six sensors are installed on an exhaust pipeline to directly configure the independent SCR control device, and the SCR control device is completely independent from an engine electronic controller.

Owner:ZHEJIANG UNIV

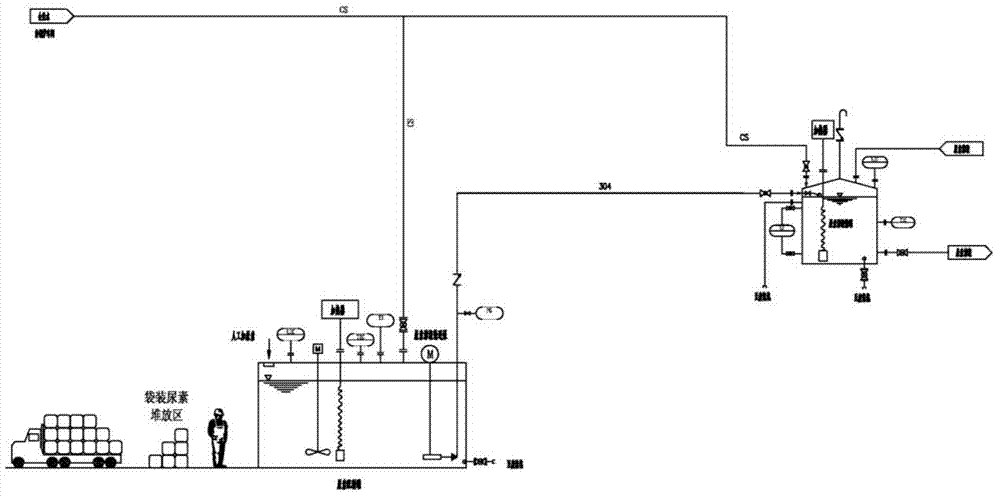

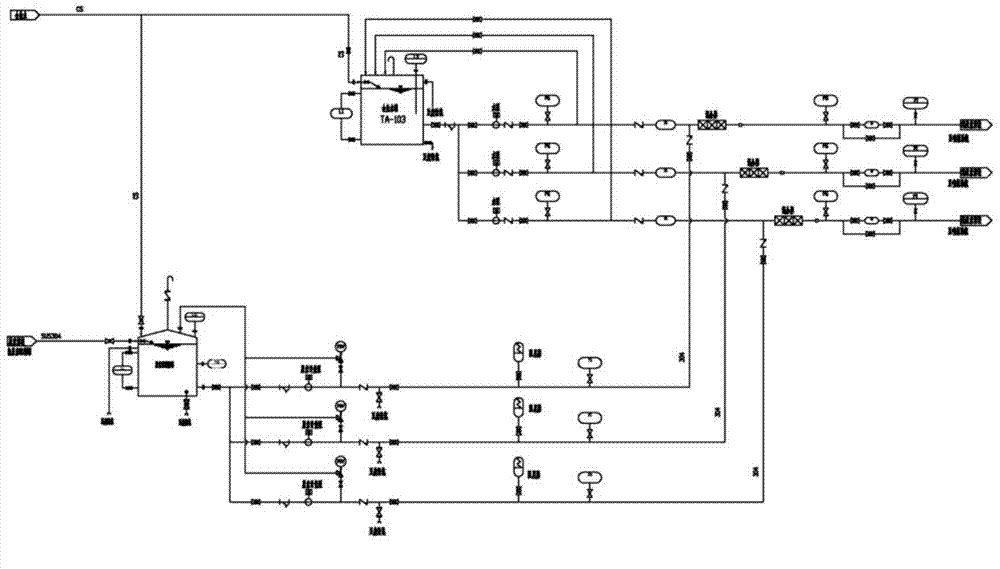

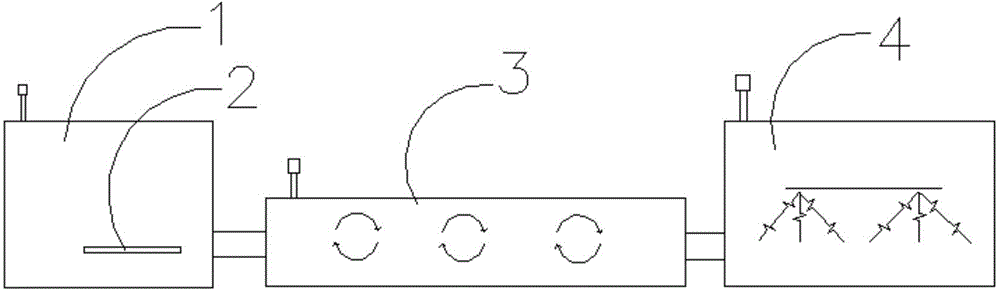

fully-automatic regulating SNCR (selective non-catalytic reduction) denitrification device

InactiveCN103657386AGuaranteed liquidityEasy to controlDispersed particle separationFlue gasEngineering

The invention relates to a flue gas denitrification device, and particularly relates to a fully-automatic regulating SNCR (selective non-catalytic reduction) denitrification device. The SNCR denitrification device is optimized further based on an original SNCR denitrification technique. The SNCR denitrification device for the fully-automatic regulating comprises a reducing agent (urea solution) preparation and storage module, a conveying and circulation module, an on-line metering and diluting module, and a distributing and jetting module arranged on the boiler wall based on CFD (computational fluid dynamics) simulation computation. The SNCR denitrification device for the fully-automatic regulating is characterized in that particle urea is conveyed to the storage module after being prepared into a urea solution; the conveying and circulation module and the metering and diluting module are arranged between a urea storage tank and the jetting module; the urea solution is quantitatively distributed in the jetting module after being metered and diluted, and a jet gun in the module is used for jetting; the storage module, the conveying and circulation module, the metering and diluting module, and the distributing and jetting module are controlled by a control module. According to the device, based on conventional SNCR, the technological process is optimized; an ammonia nitrogen reaction region at the rear end is controlled accurately; meanwhile, by adopting the multi-stage configuration of jetting guns, the full-automatic operation is realized completely according to the actual running situation of a boiler.

Owner:广东清华中邦热能科技有限公司

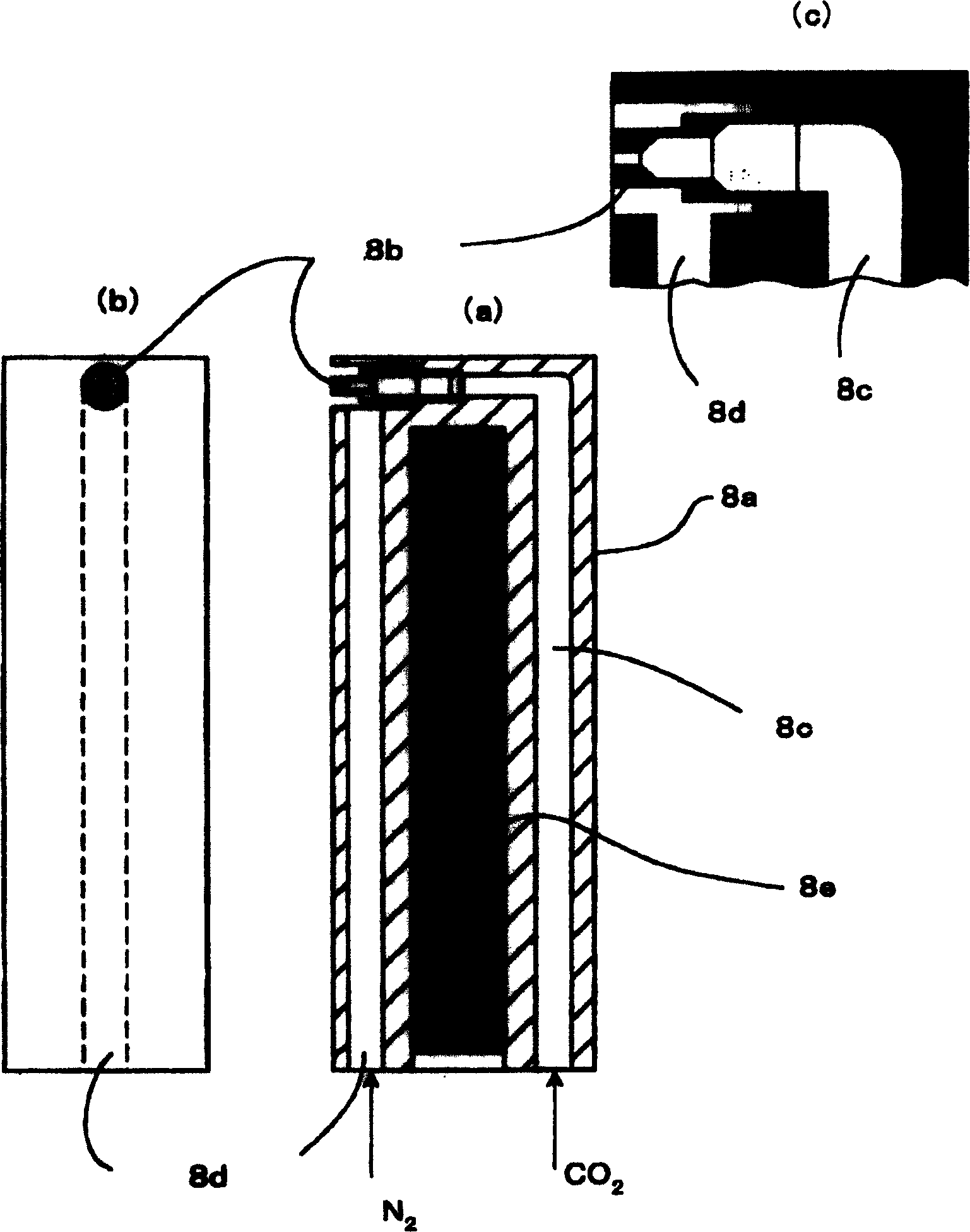

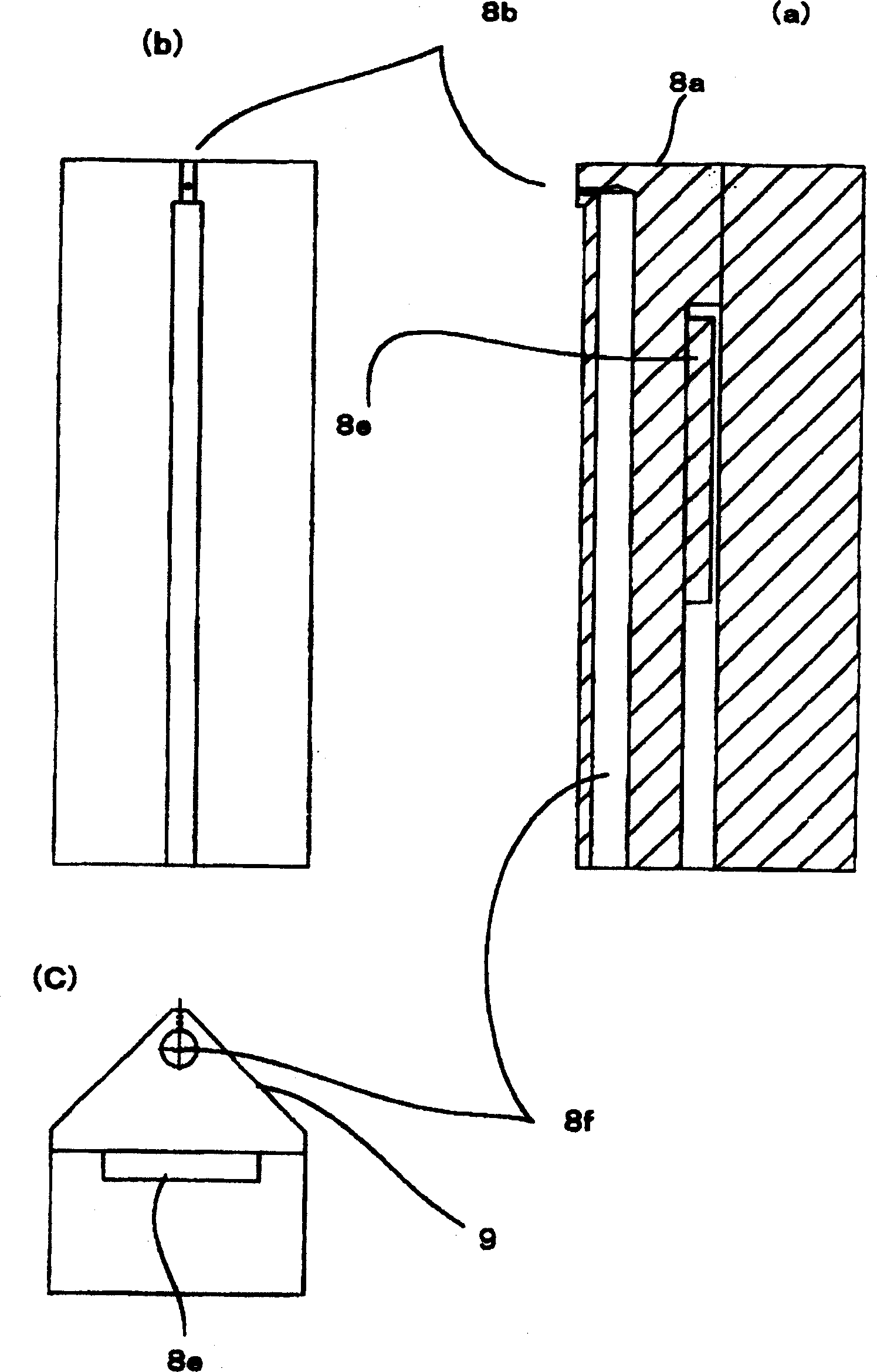

Production method of miniature alkali metal atom chamber unit

InactiveCN104891431AImprove consistencyNo need to worry about premature precipitation affecting bondingPrecision positioning equipmentSoldering apparatusDecompositionUltraviolet

A production method of a miniature alkali metal atom chamber unit belongs to the field of micro-electro-mechanical systems, and solves the problems of unable accurate injection of alkali metal elements into present miniature alkali metal atom chambers and interference of a lot of residues. The production method of the miniature alkali metal atom chamber unit comprises the following steps: photoetching a single chamber unit on a silicon chip, depositing a silicon dioxide layer and a silicon nitride layer, smearing a photoresist, carrying out photoetching treatment, opening a silicon chip window, producing an activated miniature chamber framework substrate, bonding the substrate with a glass flake, evaporating a cesium azide film in a silicon-glass half chamber by using a deposition device, bonding the upper surface of the silicon-glass half chamber with another glass flake, and irradiating and heating by using an ultraviolet lamp to vaporize simple substance cesium in order to obtain the miniature alkali metal atom chamber unit. A cesium azide decomposition technology is adopted in the invention, so no residual substances are generated, and accurate control of the injection amount of cesium azide can be realized.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

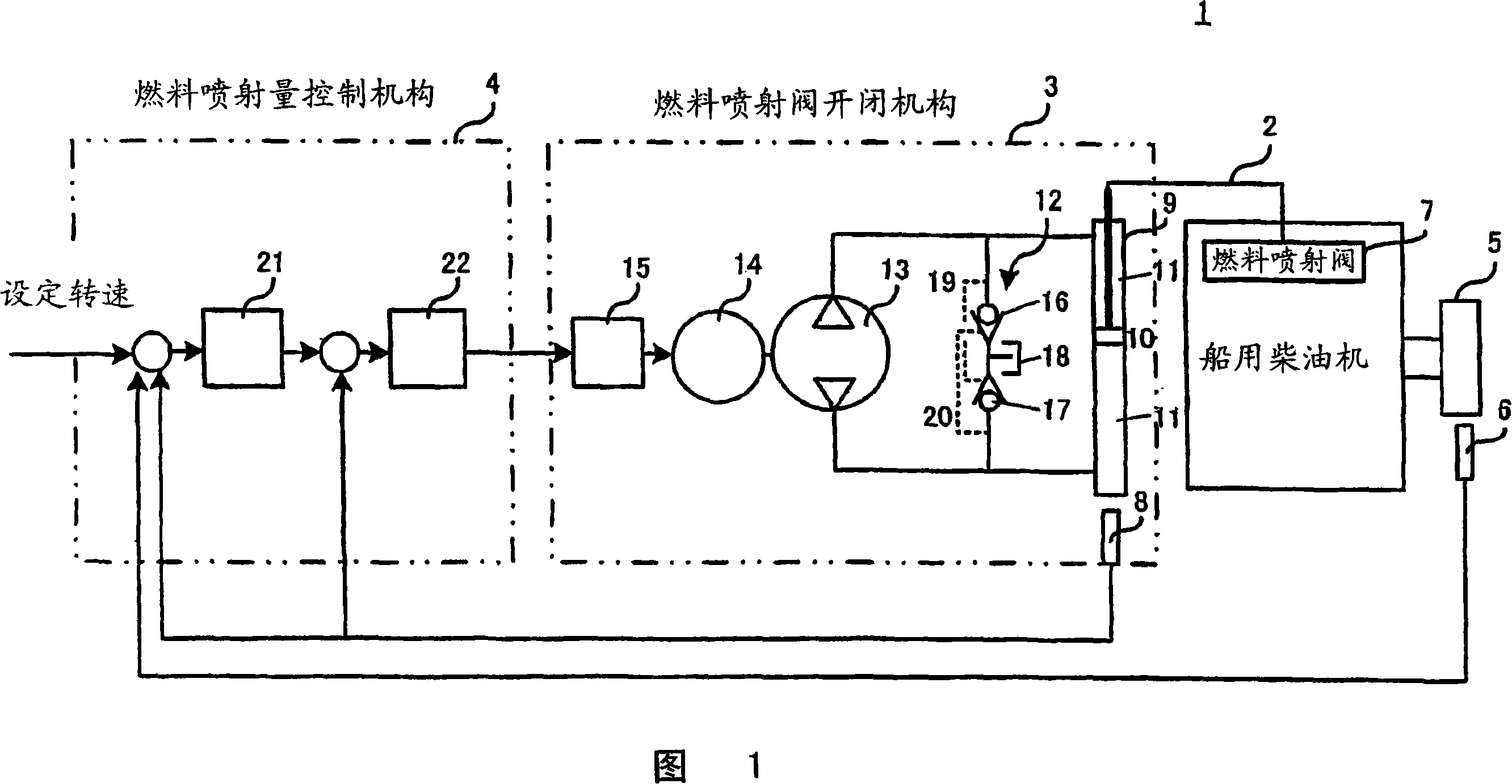

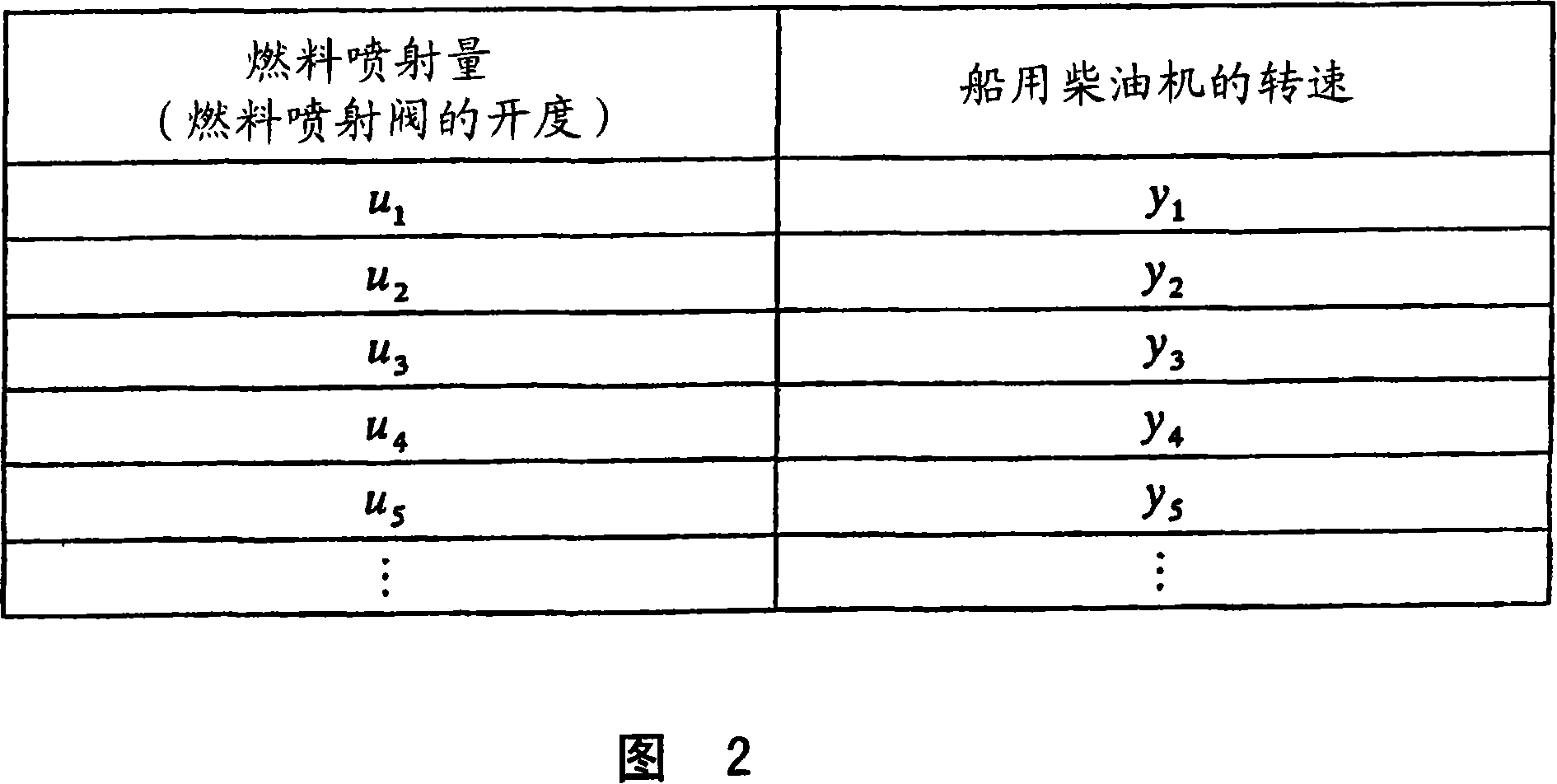

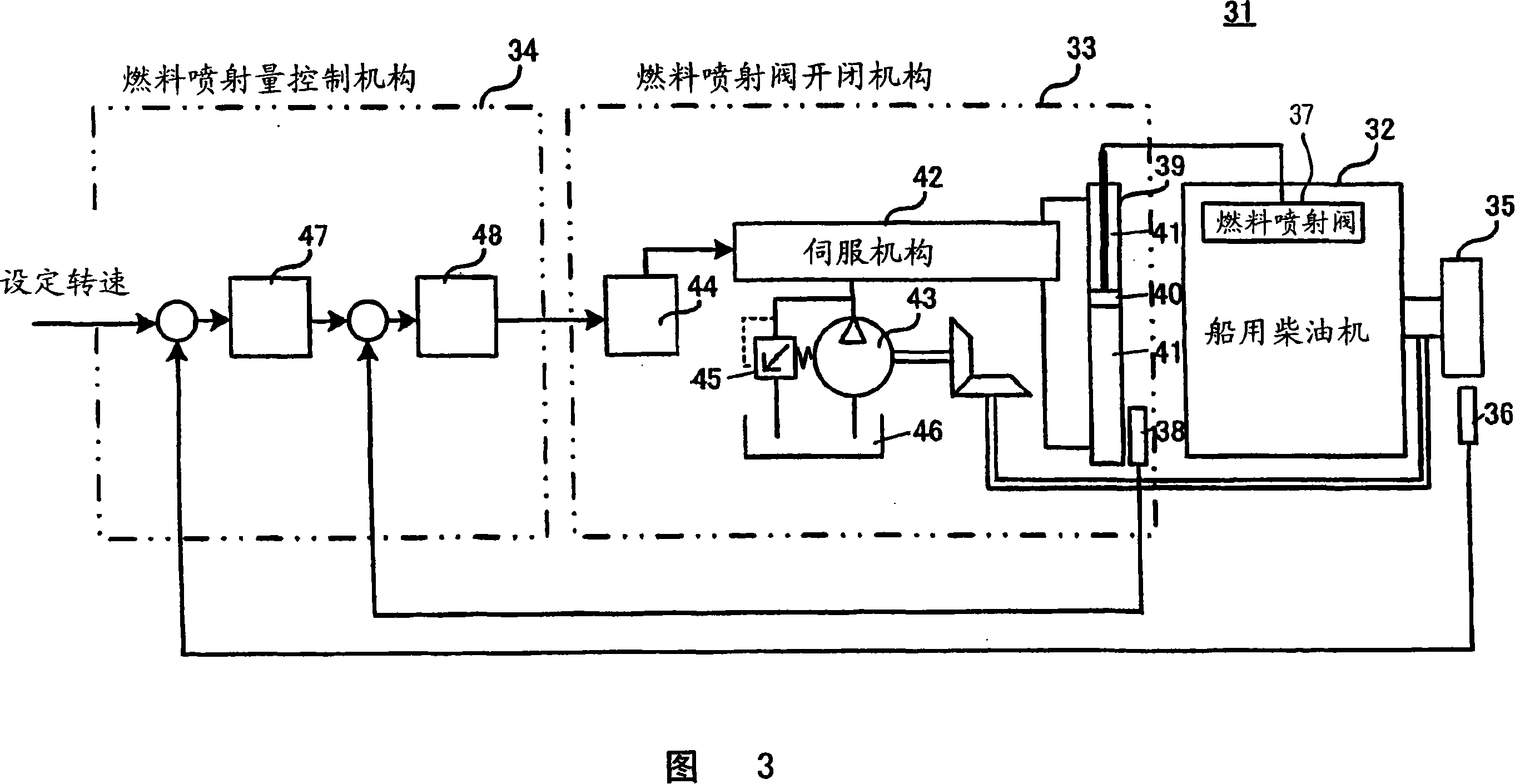

Method and device for controlling injection of fuel for marine diesel engine

InactiveCN101091046AReduce NO

<sub>X</sub>Optimum Injection QuantityElectrical controlCombustion enginesDiesel engineFuel injection

A method and a device for controlling fuel injection of a marine diesel engine wherein the control is exercised so as to match the loading condition at the time point of fuel injection are provided. The method comprises: a step of measuring the fuel injection amount and the rotational speed of the marine diesel engine a prescribed number of times at prescribed time intervals and inputting the measurements, a step of evaluating a relational expression satisfying the relation between the fuel injection amount and the rotational speed of the marine diesel engine, a step of calculating the fuel injection amount (u k ) that should be injected at present according to said relational expression when the rotational speed of the marine diesel engine is set to a target rotational speed, and a step of controlling the opening of the fuel injection valve of the marine diesel engine so as to match said calculated fuel injection amount at present.

Owner:TOKYO UNIV OF MANNE SCI & TECH

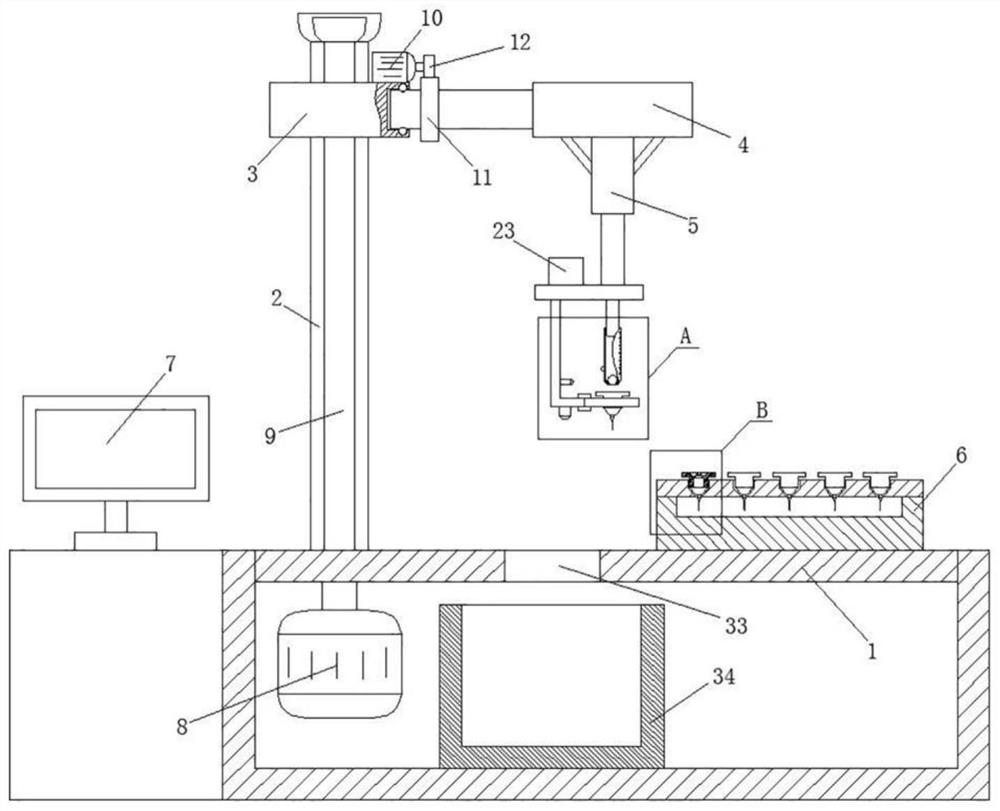

Automatic de-molding agent spraying system

InactiveCN103212658AControl injection volumeControl the degree of atomizationEngineeringHigh pressure

The invention relates to an automatic de-molding agent spraying system. The automatic de-molding agent spraying system comprises an agitation tank, a compressed air source and a spraying gun, wherein the agitation tank is communicated with the spraying gun through a de-molding agent conveying pipeline; the compressed air source is communicated with the spraying gun through a compressed air conveying pipeline; the de-molding agent conveying pipeline between the agitating tank and the spraying gun is sequentially provided with a tank body valve, a high-pressure pneumatic plunger pump and an oil amount adjusting valve; the compressed air conveying pipeline between the compressed air source and the spraying gun is sequentially provided with a decompression valve and an air quantity adjusting valve; a de-molding agent conveying pipeline between the high-pressure pneumatic plunger pump and a de-molding agent flow adjusting valve is provided with an energy accumulator; and a de-molding agent conveying pipeline between the energy accumulator and the de-molding agent flow adjusting valve is provided with a pressure sensor. According to the automatic de-molding agent spraying system disclosed by the invention, oriented and quantitative atomization and spraying on the surface of a mould can be realized so that a uniform sprayed film is formed on the surface of the mould and the surface of the mould is prevented from being damaged by being stuck with hot metal in a forging process.

Owner:韩丽华 +1

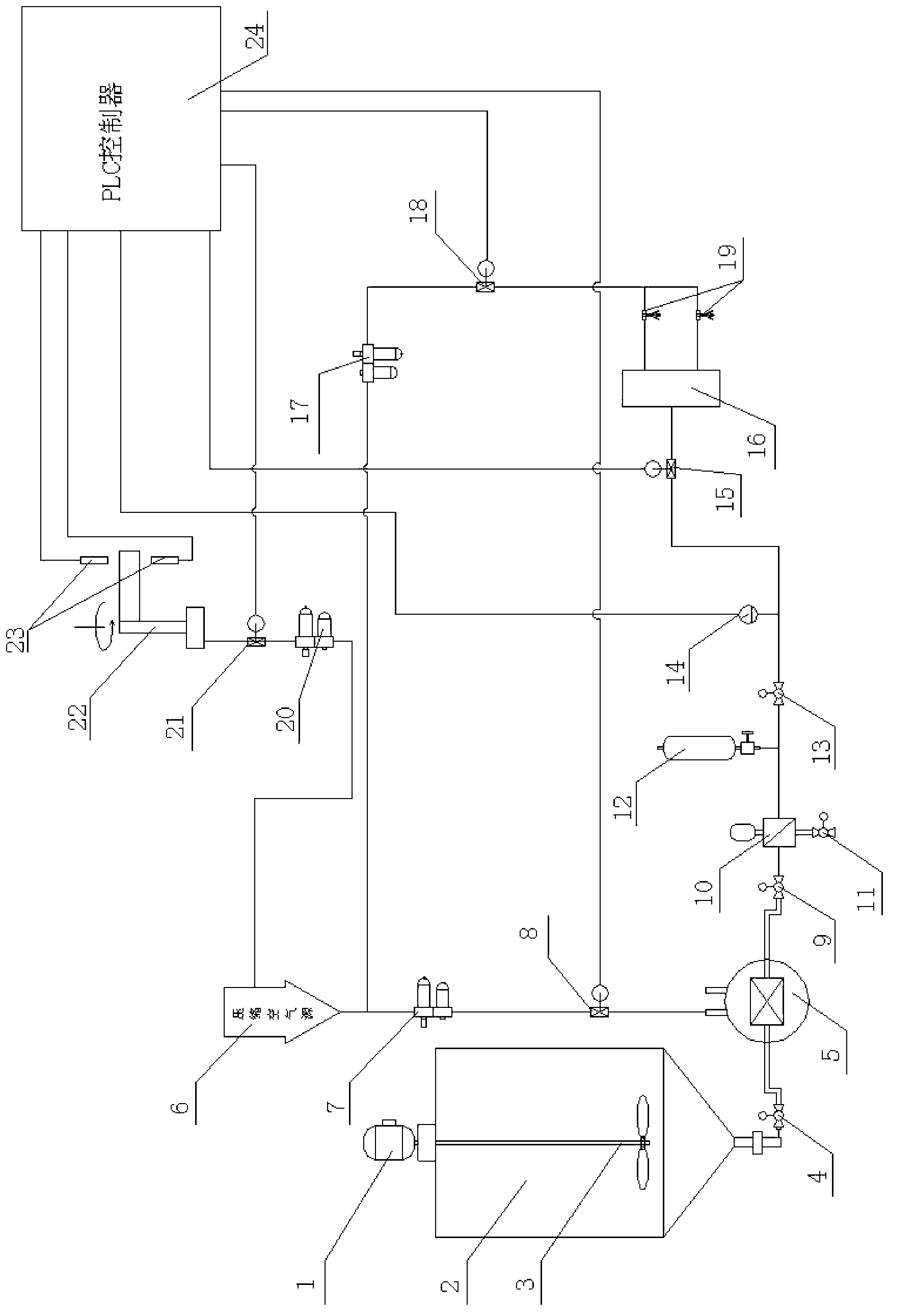

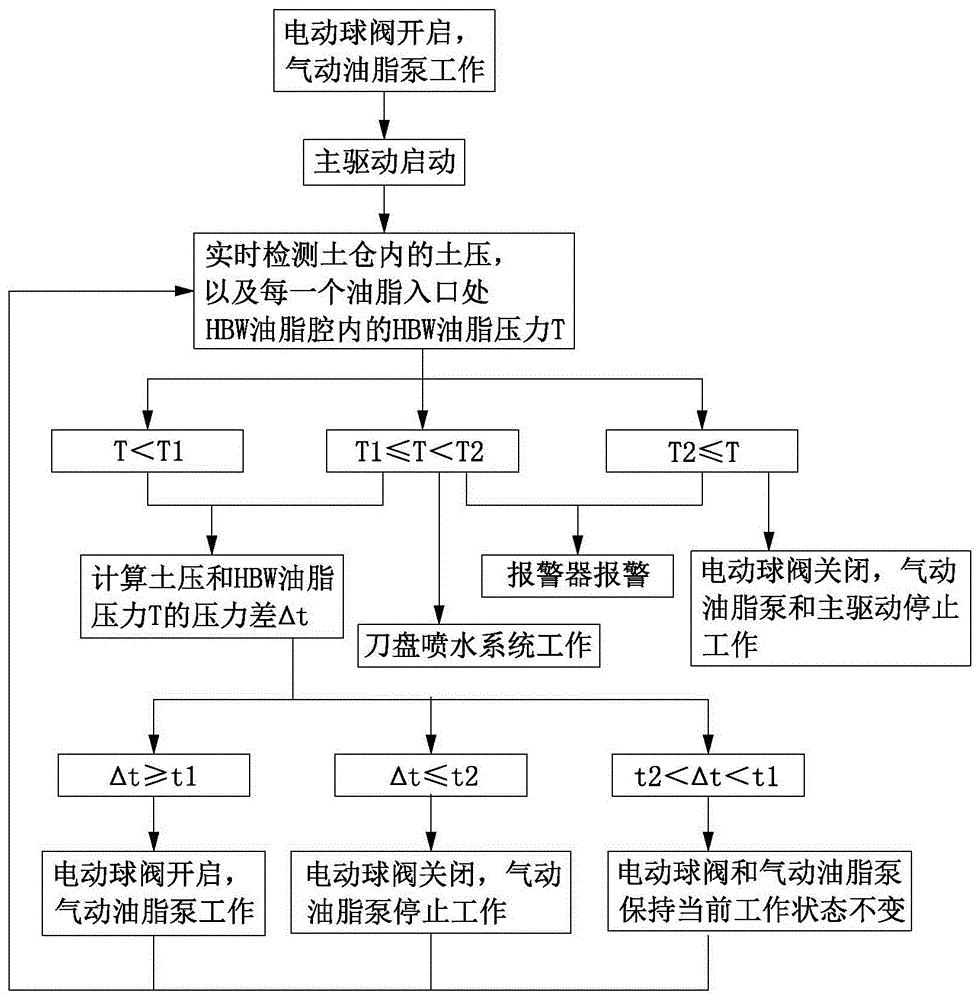

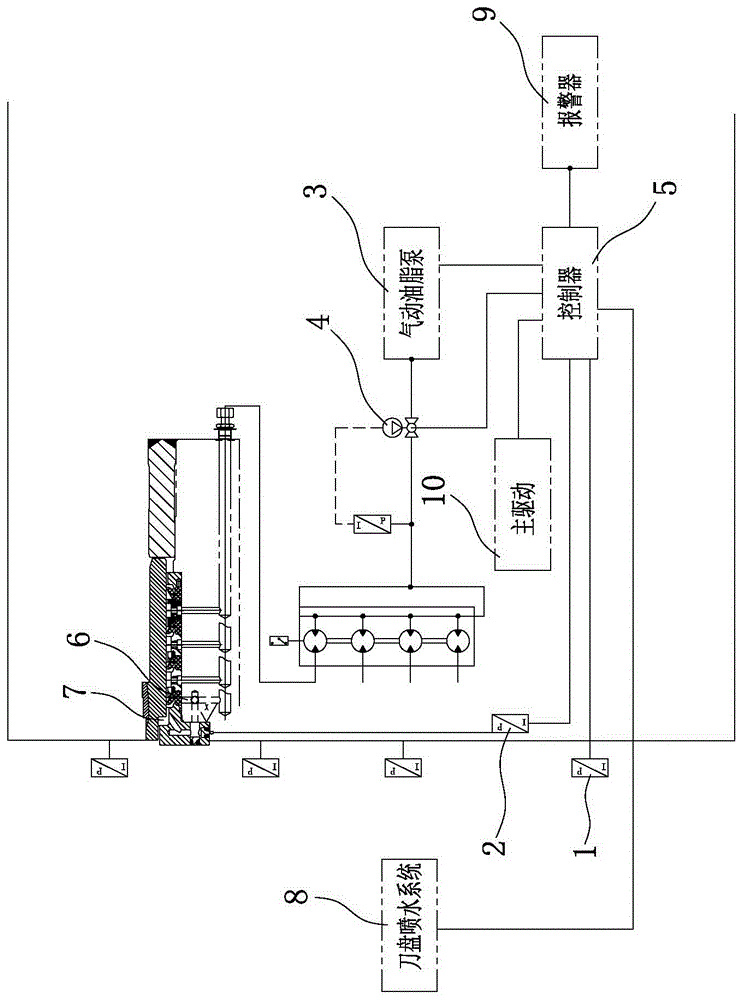

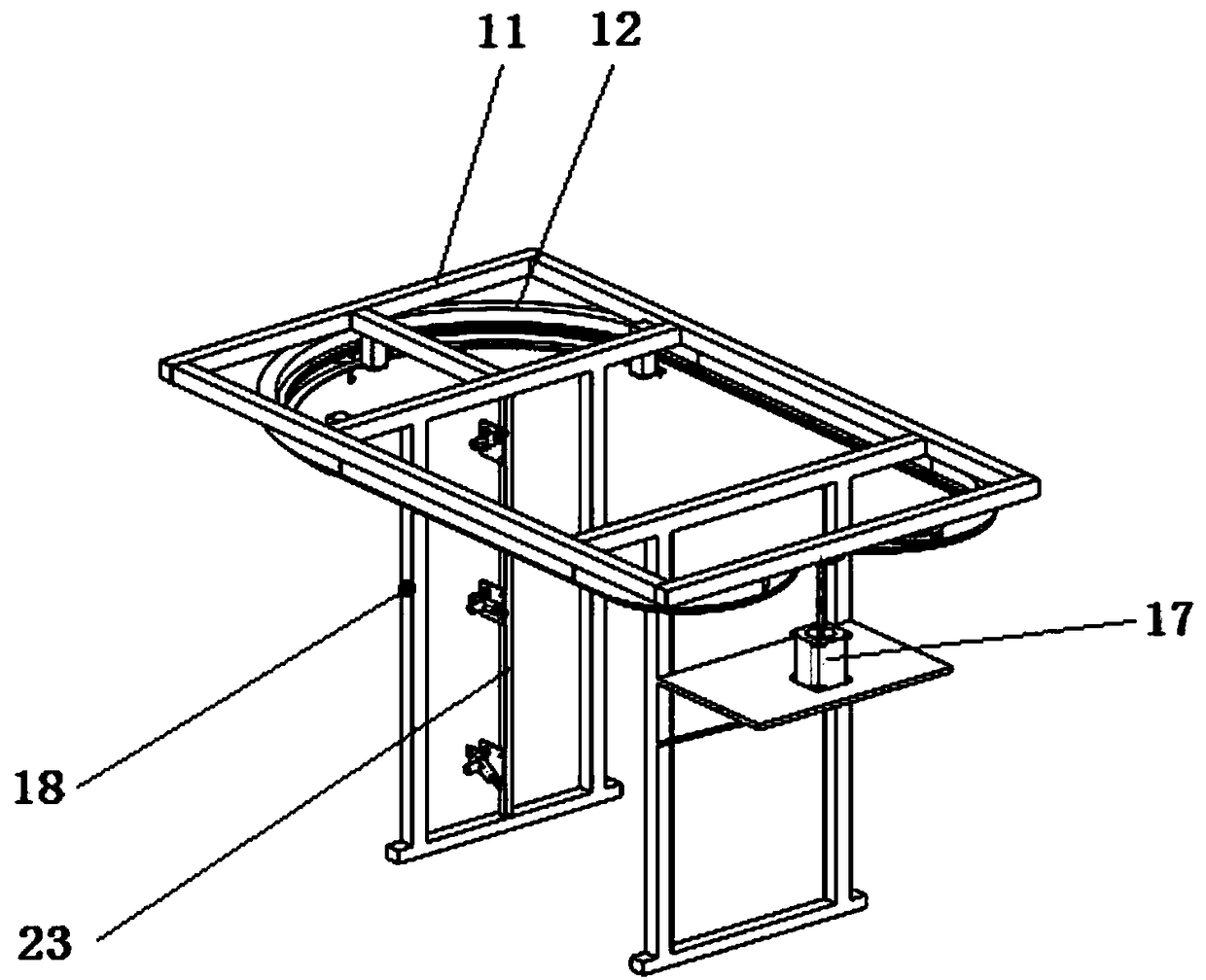

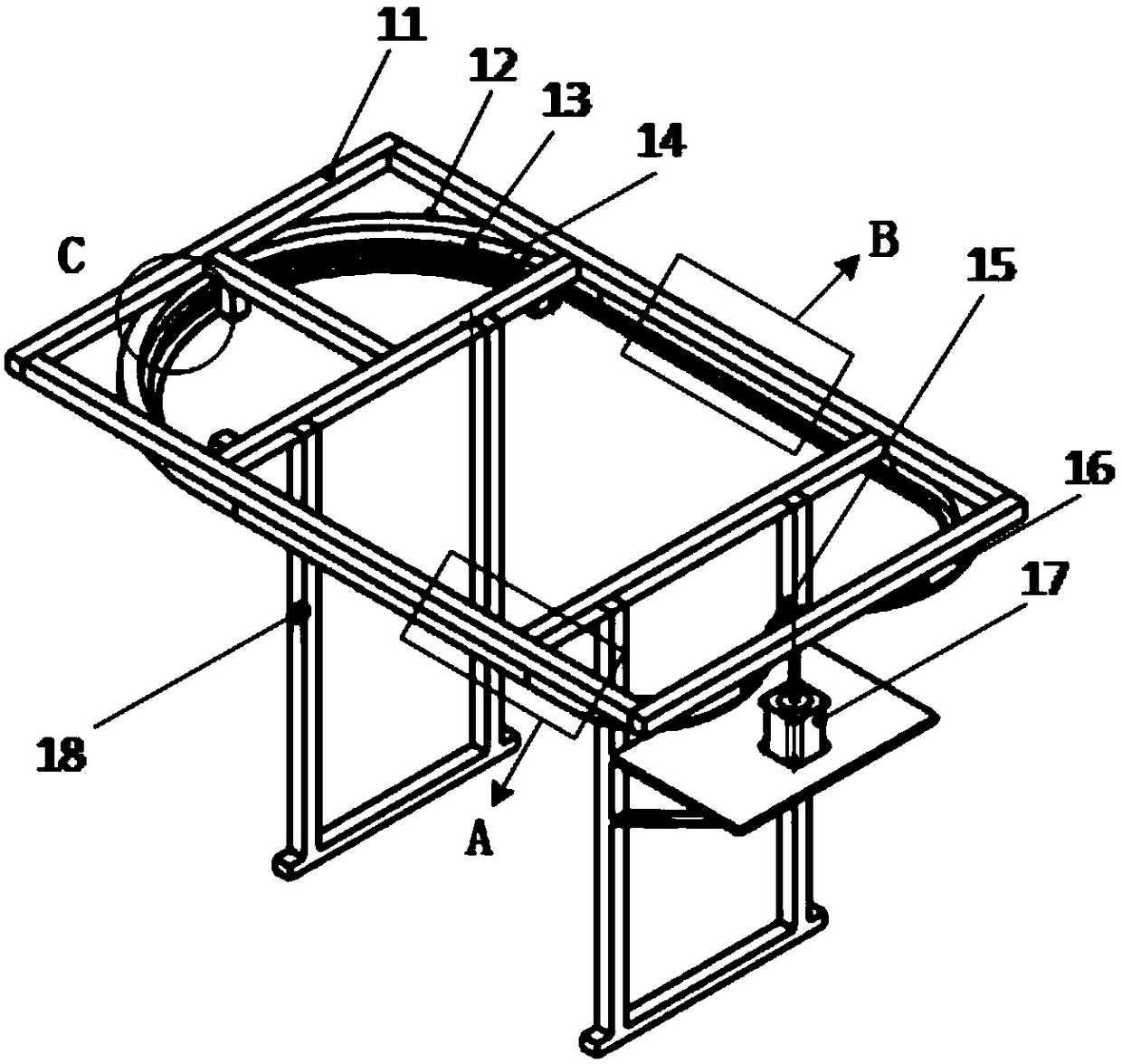

Improved shield master driving HBW grease injection device and control method thereof

ActiveCN106640100AReduce consumptionReduce construction costsEngine sealsMining devicesBall valveChamber pressure

The invention discloses an improved shield master driving HBW grease injection device and a control method thereof. The device comprises multiple soil chamber pressure sensors, multiple grease cavity pressure sensors, a pneumatic grease pump and an electric ball valve, wherein the soil chamber pressure sensors are evenly distributed in front of a shield shell and a main driving shell and used for detecting soil pressure in a soil chamber; the grease cavity pressure sensors are correspondingly arranged in HBW grease cavities in the positions of grease injection inlets respectively and used for detecting HBW grease pressure in the HBW grease cavities; the pneumatic grease pump is used for pumping HBW grease to each grease injection inlet; the electric ball valve is installed at an outlet of the pneumatic grease pump and used for controlling the on-off state of a grease channel in front of the pneumatic grease pump. When a controller detects that the difference value between the soil pressure and the HBW grease pressure is larger than or equal to the preset allowable maximum difference value, the electric ball valve is controlled to be opened and the pneumatic grease pump is controlled to pump the HBW grease. According to the pressure in the soil chamber, the injection pressure of the HBW grease is changed, so that the injection amount of the HBW grease is precisely controlled, consumption of the HBW grease is reduced, and the construction cost is reduced.

Owner:XIAMEN XIAGONG CHINA RAILWAY HEAVY MACHINERY CO LTD

Etching and cleaning device and method for OSP substrate

ActiveCN104599950AAvoid influenceAchieve the effect of etching and cleaningSemiconductor/solid-state device manufacturingSolventChemical agent

The invention discloses an etching and cleaning method for OSP substrate. The etching and cleaning method for OSP substrate comprises the following steps: step 1, mixing the H2SO4 solvent, H2O2 solvent, additive AGS2116, additive AGS2115 and pure water, adding the chemical agent prepared according to the ratio into the cavity of the etching and cleaning device; step 2, guiding the OSP substrate to the etching and spraying chamber and the cleaning and spraying chamber through the track of the etching and cleaning device; step 3, etching the OSP substrate in the etching and spraying chamber, cleaning the OSP substrate in the cleaning and spraying chamber; step 4, checking the etching effect, confirming whether the OSP layer and the oxide layer are etched from the bonding pad. An etching and cleaning device for OSP substrate is also provided, the etching effect of the chemical agent is good, and the etching effect is more even. The H2SO4, H2O2 and other chemical agent are separated via the etching device and prepared according to the scene production status and practical situation of the OSP substrate, and the etching value is controlled, the operation is convenient and the efficiency is high.

Owner:NANTONG FUJITSU MICROELECTRONICS

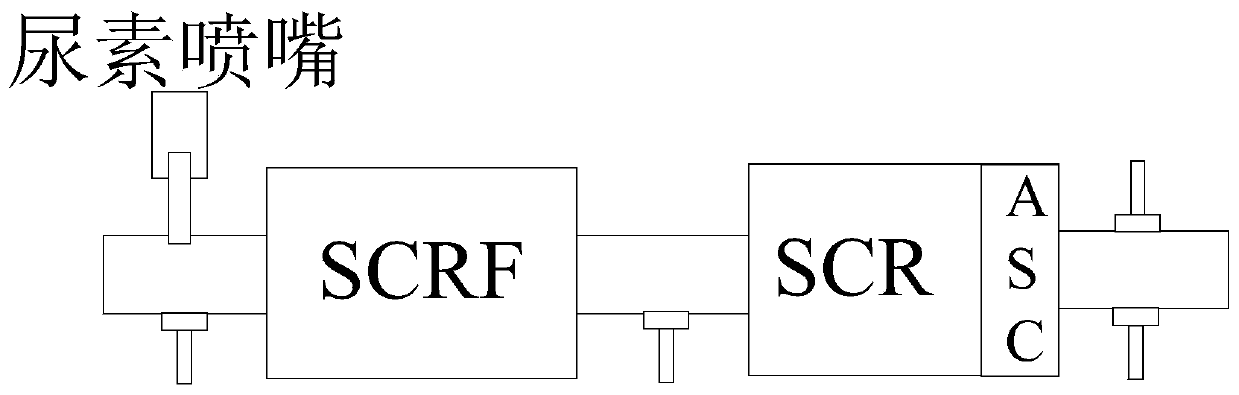

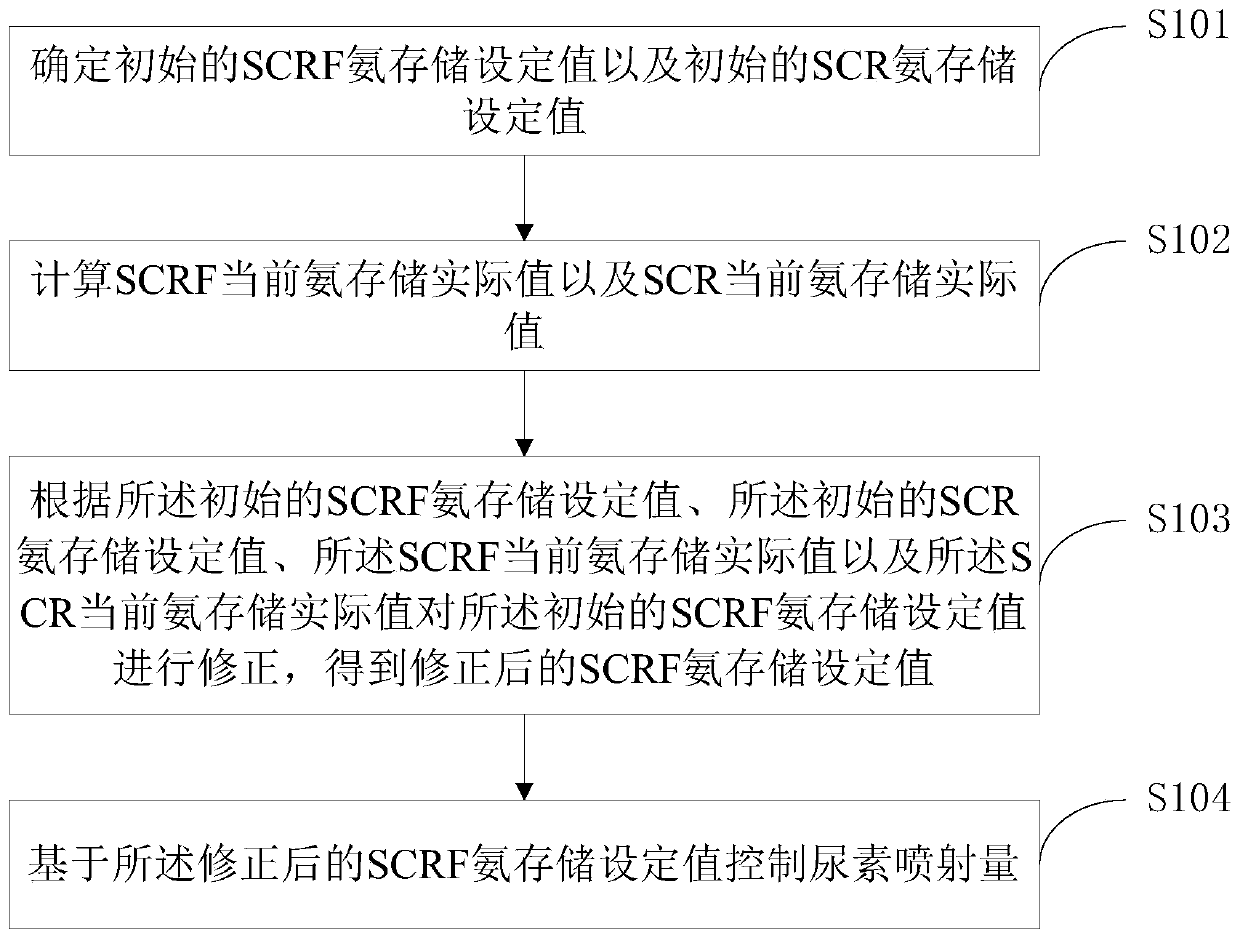

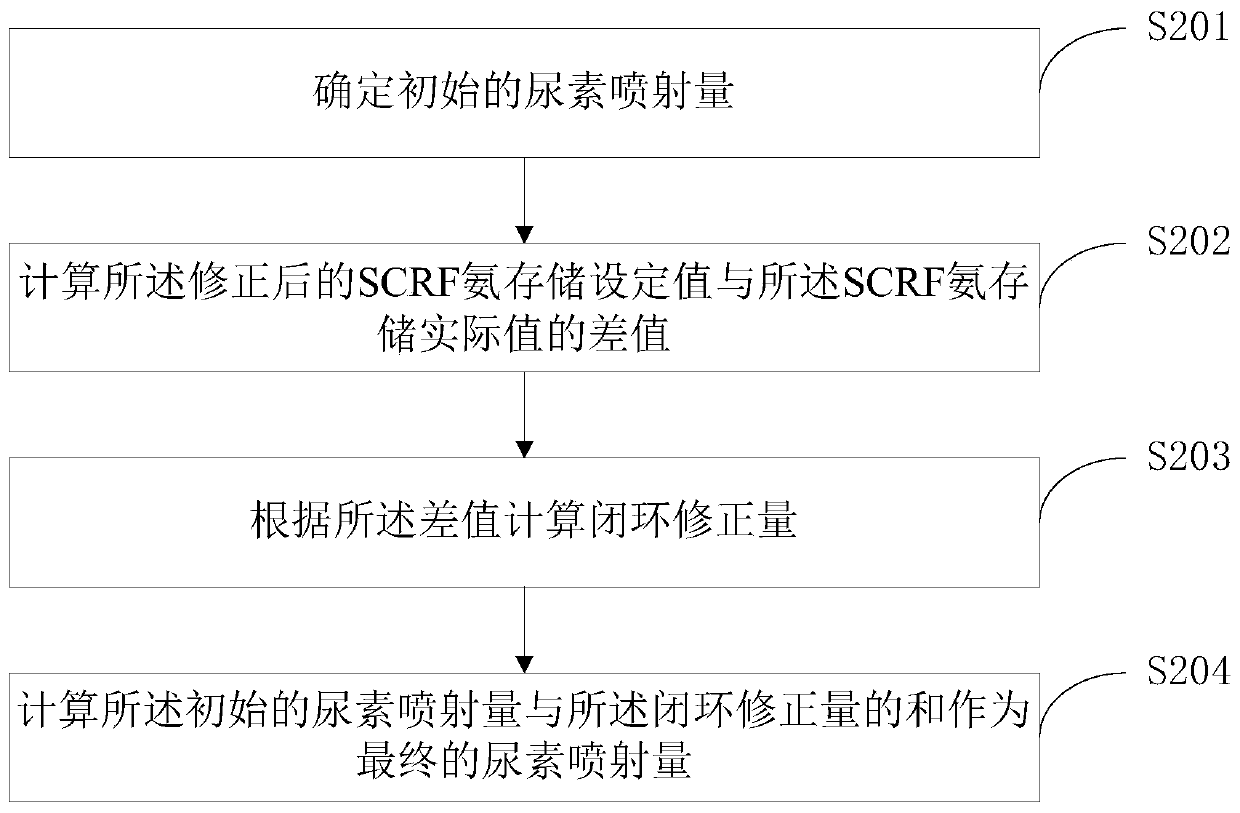

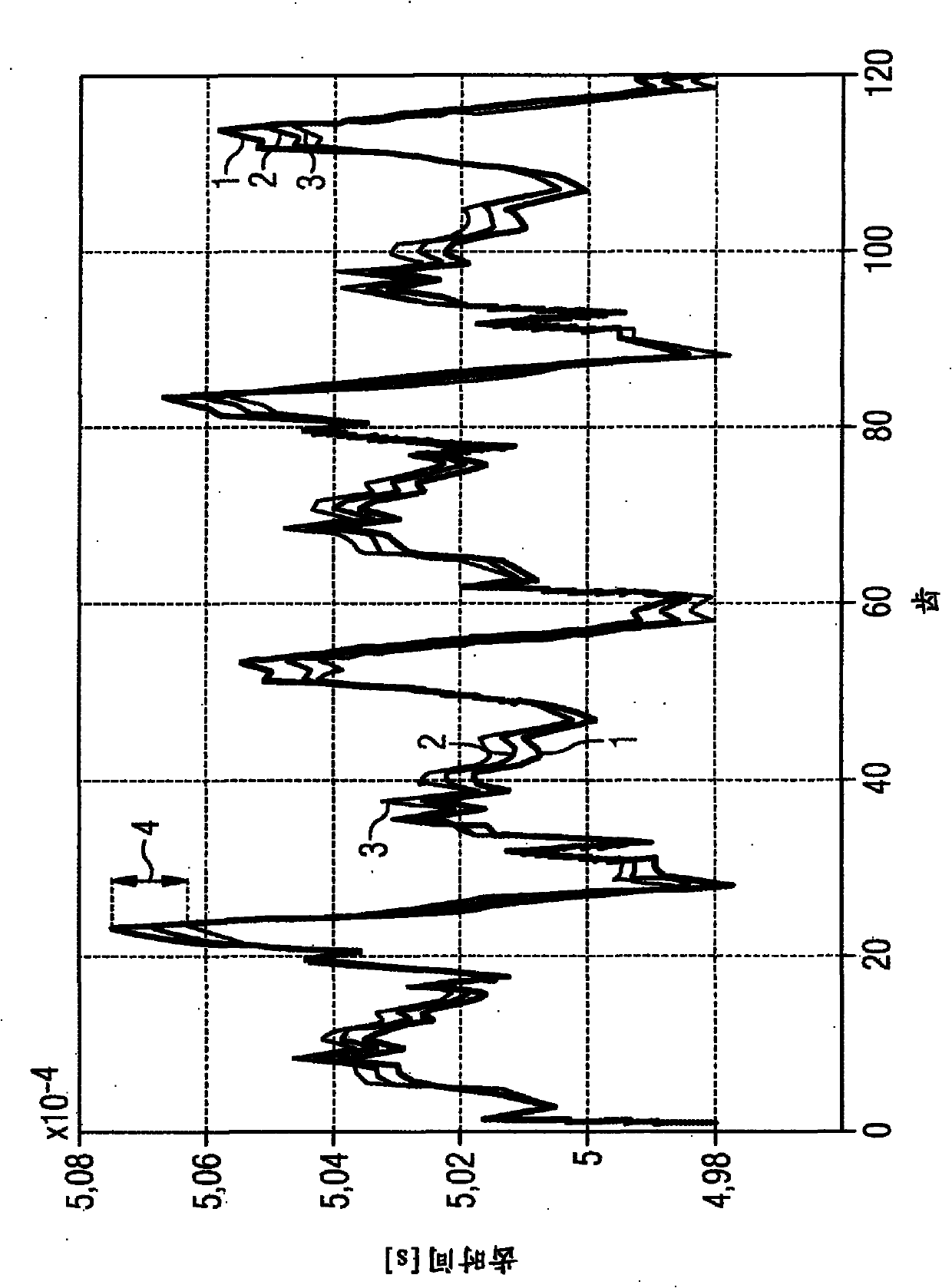

Urea injection quantity control method and device

ActiveCN110185523AControl injection volumeInjection Quantity ControlInternal combustion piston enginesExhaust apparatusAmmonia storageComputer science

The application discloses a urea injection quantity control method and device. The urea injection quantity control method comprises the steps of determining an initial SCRF ammonia storage set value and an initial SCR ammonia storage set value; calculating an SCRF current ammonia storage actual value and an SCR current ammonia storage actual value; correcting the initial SCRF ammonia storage set value according to the initial SCRF ammonia storage set value, the initial SCR ammonia storage set value, the SCRF current ammonia storage actual value and the SCR current ammonia storage actual valueto obtain a corrected SCRF ammonia storage set value; and controlling the urea injection quantity based on the corrected SCRF ammonia storage set value. Through the above process, accurate control ofthe urea injection quantity can be realized.

Owner:WEICHAI POWER CO LTD

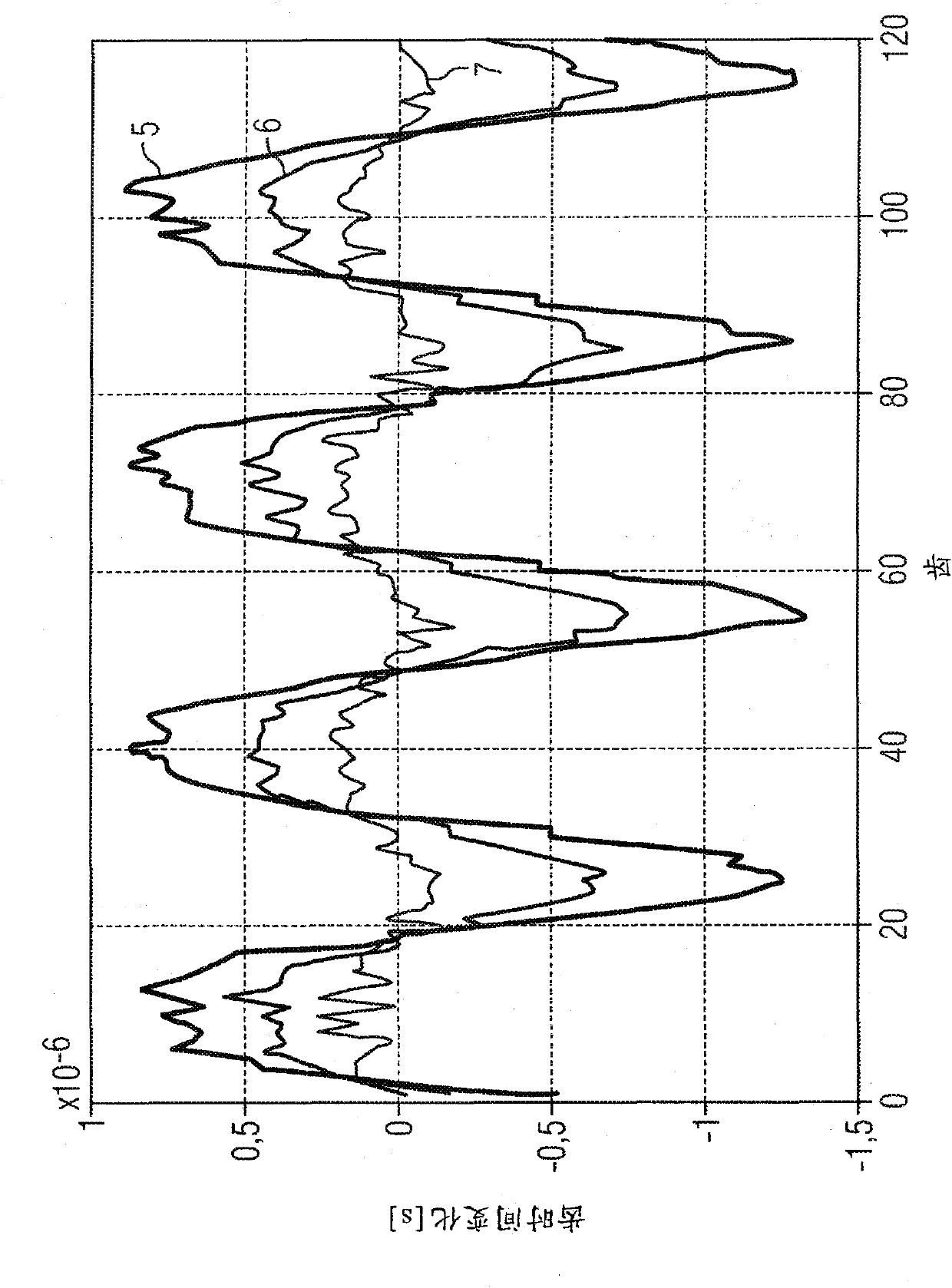

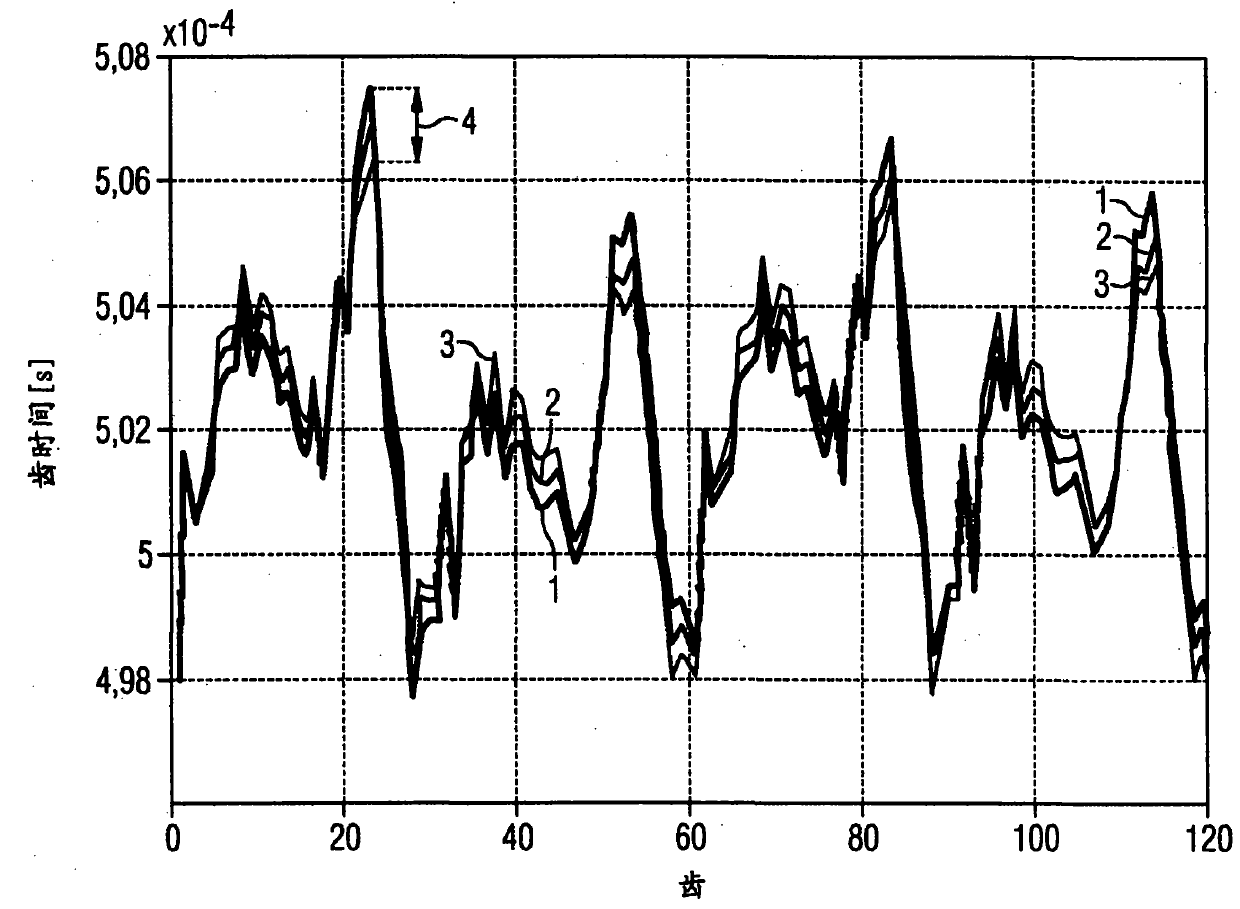

Method for determining the rail pressure in a common rail system, and common rail injection system

ActiveCN102016271AControl injection volumeElectrical controlMachines/enginesInjection volumeRail pressure

The present invention relates to a method for determining the rail pressure in a common rail system of an internal combustion engine, wherein at least one measurement variable is determined, which is a measure for the angular speed of a crankshaft movement of the internal combustion engine, and the rail pressure is derived from said measurement variable, or from a variable derived from the measurement variable. The invention further relates to methods that are based thereon for controlling an injection volume and for controlling a rail pressure, and to a corresponding common rail injection system.

Owner:VTESCO TECH GMBH

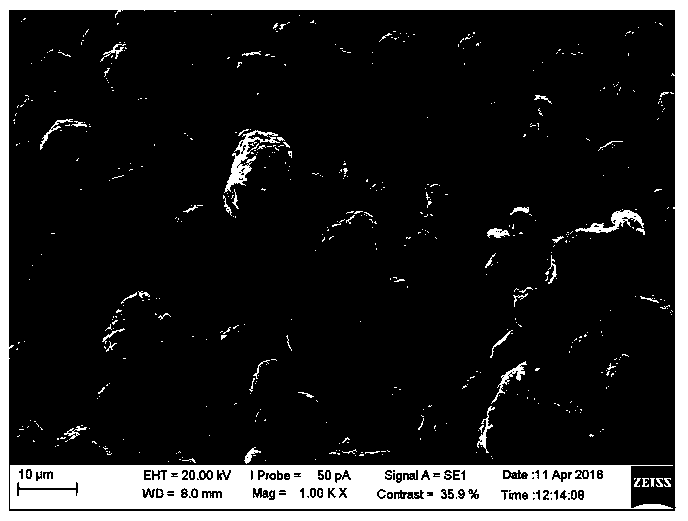

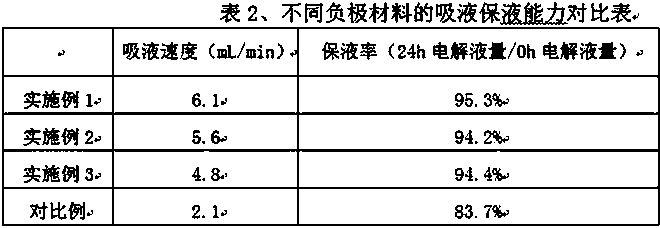

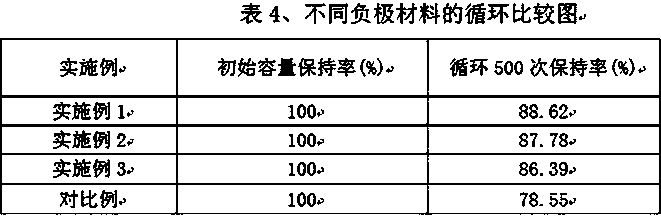

Sulfur/nitrogen/silicon co-doped graphite composite negative electrode material and preparation method thereof

ActiveCN109659546AImprove consistencyReduce bloatMaterial nanotechnologyCell electrodesAbsorption capacityCarbonization

The invention relates to a sulfur / nitrogen / silicon co-doped graphite composite negative electrode material and a preparation method thereof, and belongs to the technical field of the technical field of lithium ion battery material preparation. The technical solutions are as follows: (1) weighing 1 to 5 g of sulfur-containing organic compounds and 1 to 5 g of nitrogen-containing organic compounds,adding the compounds to 500 g of organic solvent, stirring evenly, adding 100 g of graphite into the solution, stirring evenly, filtering, then transferring the solution to a tube type furnace, raising the temperature to 200-500 DEG C under an inert atmosphere, then keeping the temperature for 1 to 6 h, and reducing the temperature to the room temperature in an inert atmosphere to obtain a graphite composite material A; (2) implanting the nano-silica in the surface layer of the graphite composite material A through high-speed particle beam bombardment and then carrying out carbonization to obtain the sulfur / nitrogen / silicon co-doped graphite composite anode material. According to the invention, the specific capacity of the graphite material is improved by doping sulfur in the graphite material, and nitrogen doping is carried out to improve the conductivity of the sulfur; the expansion of the material can be reduced; and the liquid absorption capacity of the material can be improved.

Owner:CHENGDU EMINENT NEW ENERGY TECH CO LTD

Fuel injection valve

ActiveCN104033300AIncrease electromagnetic forceQuick responseFuel injection apparatusMachines/enginesMagnetic coreNeedle valve

The invention discloses a fuel injection valve which comprises a magnetic valve, a coil, an armature, a magnetic ring, a damping spring, a damping block, a shell, a limiting core, a control spring, a spring seat, a needle valve, a sealing ball and a sealing ball seat. The coil is arranged in an annular coil groove of the magnetic core, the magnetic ring is fixedly arranged below the magnetic core, the armature is arranged on the upper portion of the inner circle of the magnetic ring and arranged on the lower end face of the magnetic core, the damping block is fixedly arranged below the armature in the inner circle of the magnetic ring, the damping spring is arranged between the armature and the damping block, the needle valve is arranged in the magnetic valve and inserted into the armature and the damping block in a sleeved manner, the upper portion of the needle valve is fixedly connected with the spring seat, and the upper portion of the spring seat is abutted on the limiting core inside the magnetic core while the lower portion of the same is abutted on the armature. By the structure, the fuel injection valve has the advantages of small magnetic flux leakage and high injection response speed, and bouncing when the fuel injection valve is closed can be reduced effectively, and multiple-time injection capability is improved.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

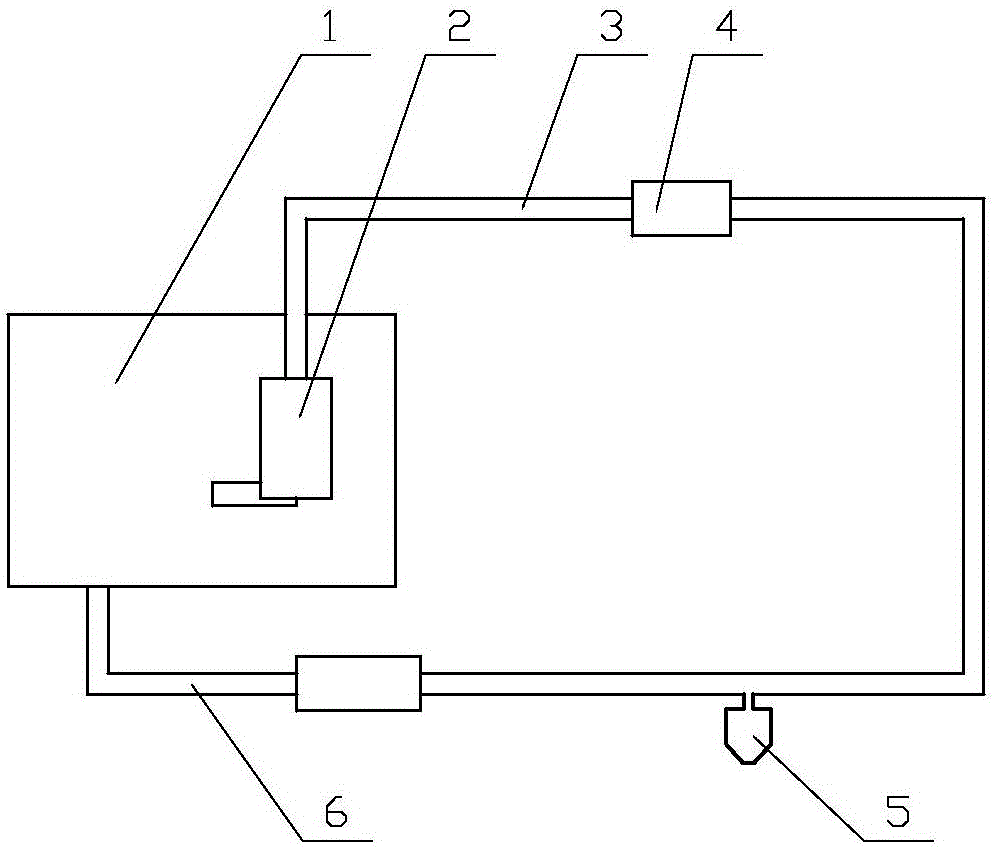

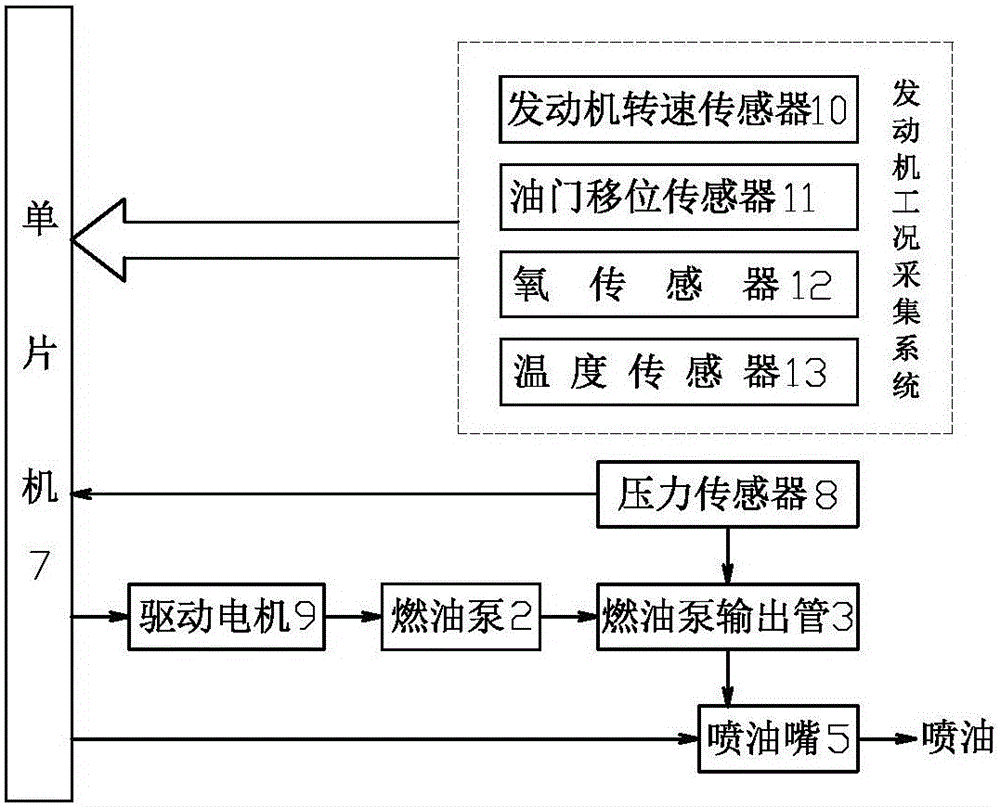

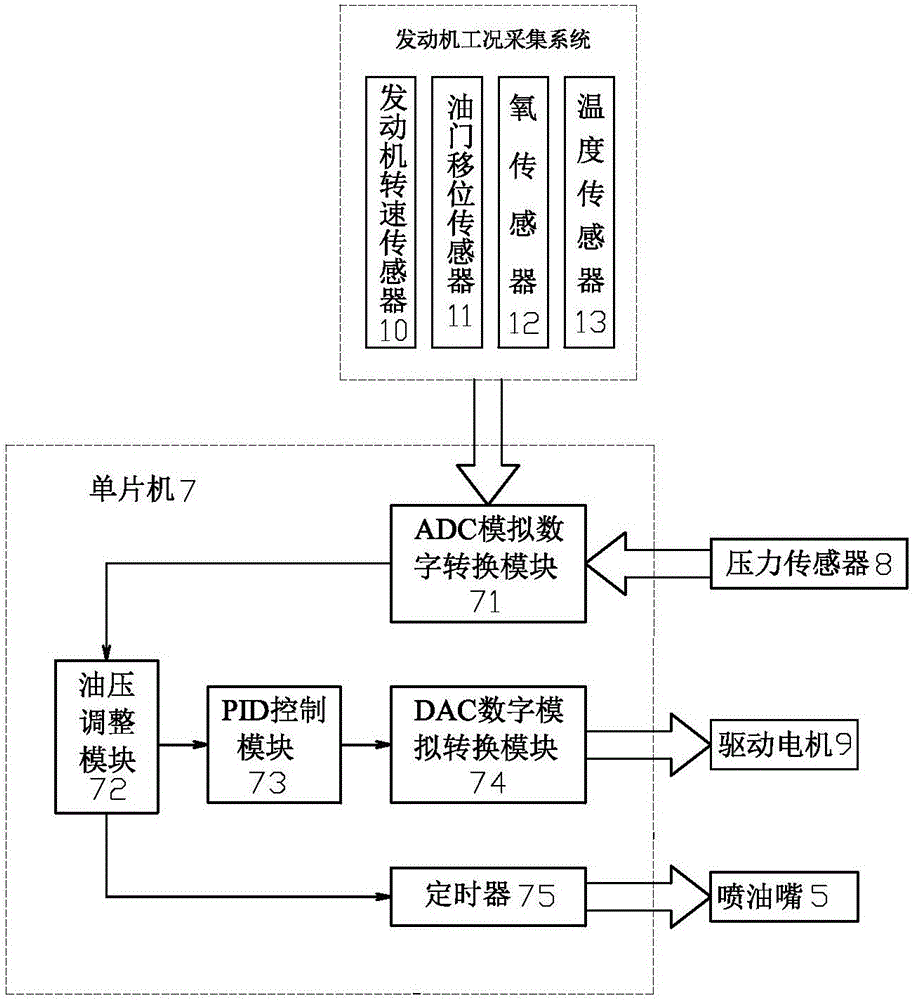

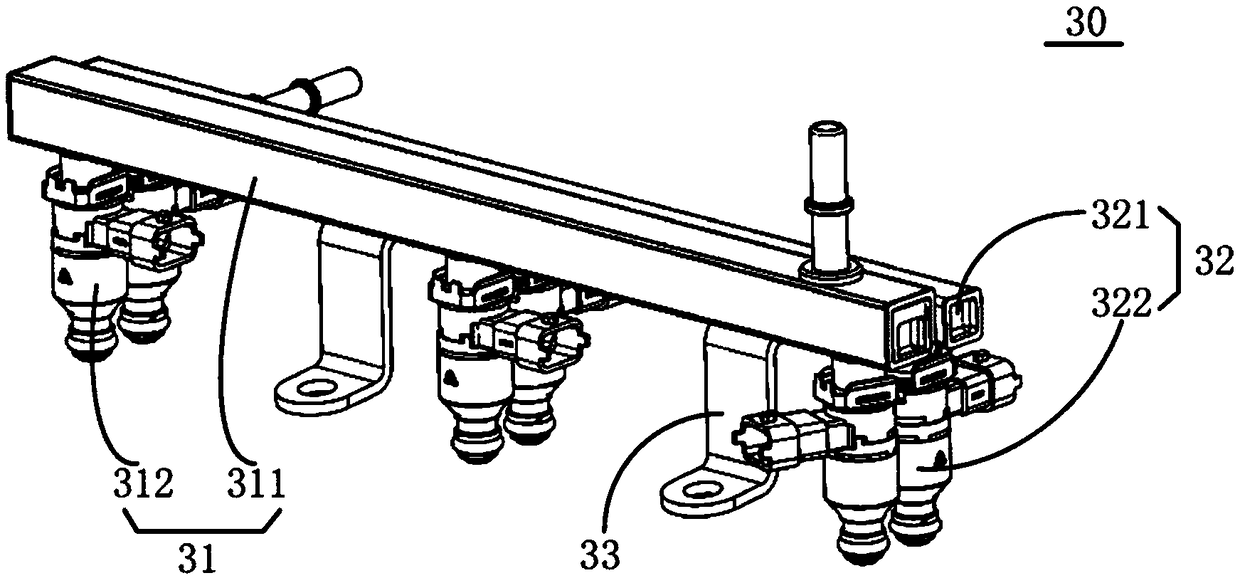

Electronically controlled common rail gasoline injection system of internal combustion engine and gasoline injection control method of electronically controlled common rail gasoline injection system

InactiveCN105971753AReduce energy consumptionExtended service lifeElectrical controlFuel injection apparatusMicrocontrollerBrushless motors

The invention discloses an electronically controlled common rail gasoline injection system of an internal combustion engine. The electronically controlled common rail gasoline injection system of the internal combustion engine comprises a singlechip, a pressure sensor, a driving motor, a fuel pump, a fuel pump output tube and a gasoline injection nozzle, wherein the driving motor is a direct-current brushless motor and drives the fuel pump in a connected manner; the fuel pump communicates with the gasoline injection nozzle by the fuel pump output tube; the pressure sensor is arranged on the fuel pump output tube and is connected with the singlechip; and the singlechip controls the driving motor and the gasoline injection nozzle in a connected manner. In addition, the invention also discloses a gasoline injection control method of the electrically controlled common rail gasoline injection system of the internal combustion engine. By the singlechip, fuel output pressure and starting time of the gasoline injection nozzle are adjusted in real time, and fuel injection is jointly controlled by the fuel output pressure and the starting time of the gasoline injection nozzle. The electronically controlled common rail gasoline injection system has the advantages of high adjustment precision, high adjustment speed, low energy consumption of the motor and long service life, so that fuel economization and emission reduction are realized effectively.

Owner:广州杰治文电子科技有限公司

Cleansing device

InactiveCN1572383AClean upControl injection volumeReconditioning/cleaning record carriersSuction cleanersEngineeringDew

This cleaning apparatus which cleans the object to be cleaned by injecting a solvent upon the object from a nozzle has a gas blowing means which blows a heated gas upon the surface of the object for preventing the occurrence of dew condensation on the surface of the object. This apparatus is constituted to move to the surface of the object at cleaning time and to retreat from the object at non-cleaning time. In addition, this apparatus is also constituted to blow the heated gas at a small flow rate at the non-cleaning time and at a large flow rate at the cleaning time.

Owner:FUJI ELECTRIC DEVICE TECH CO

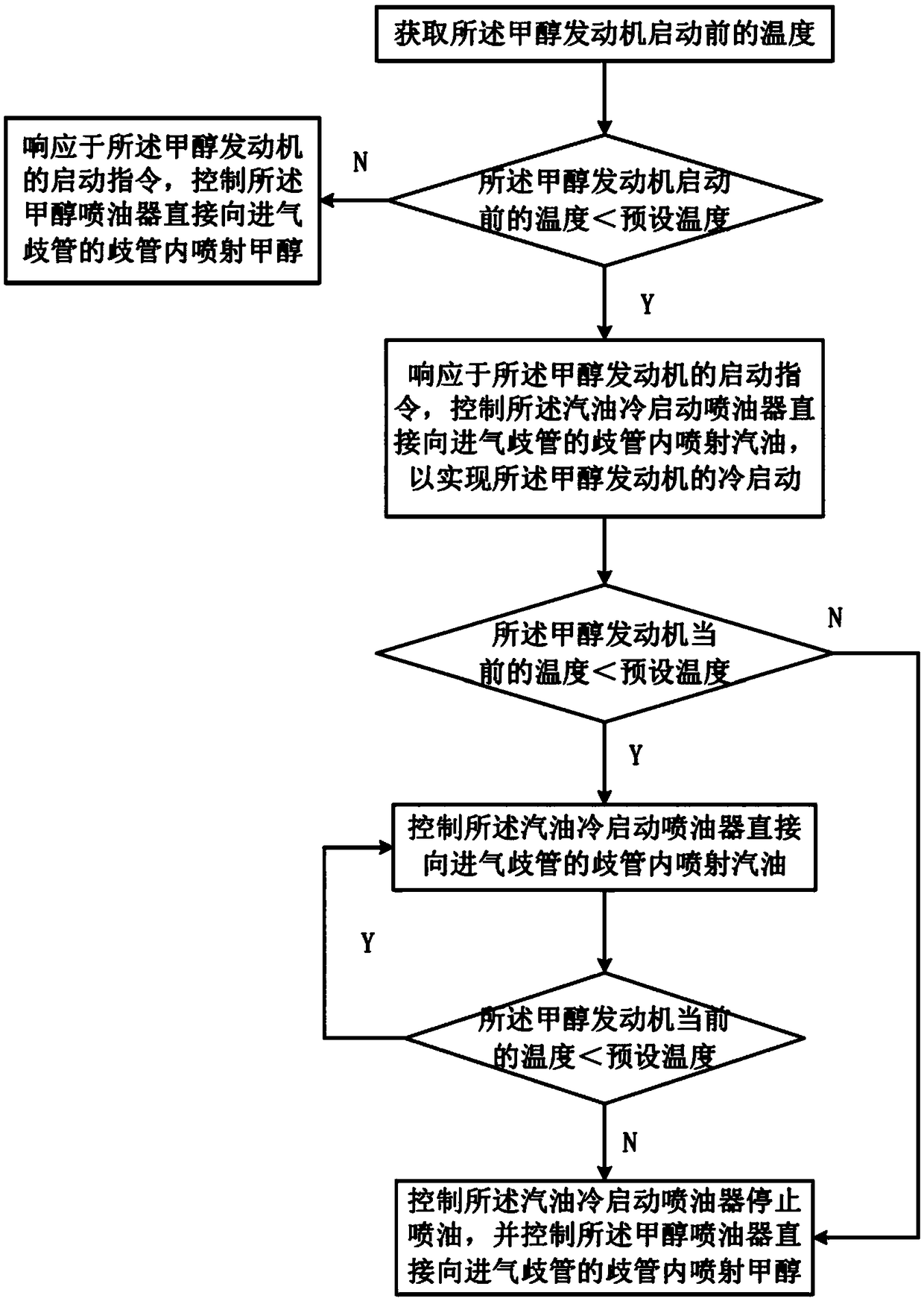

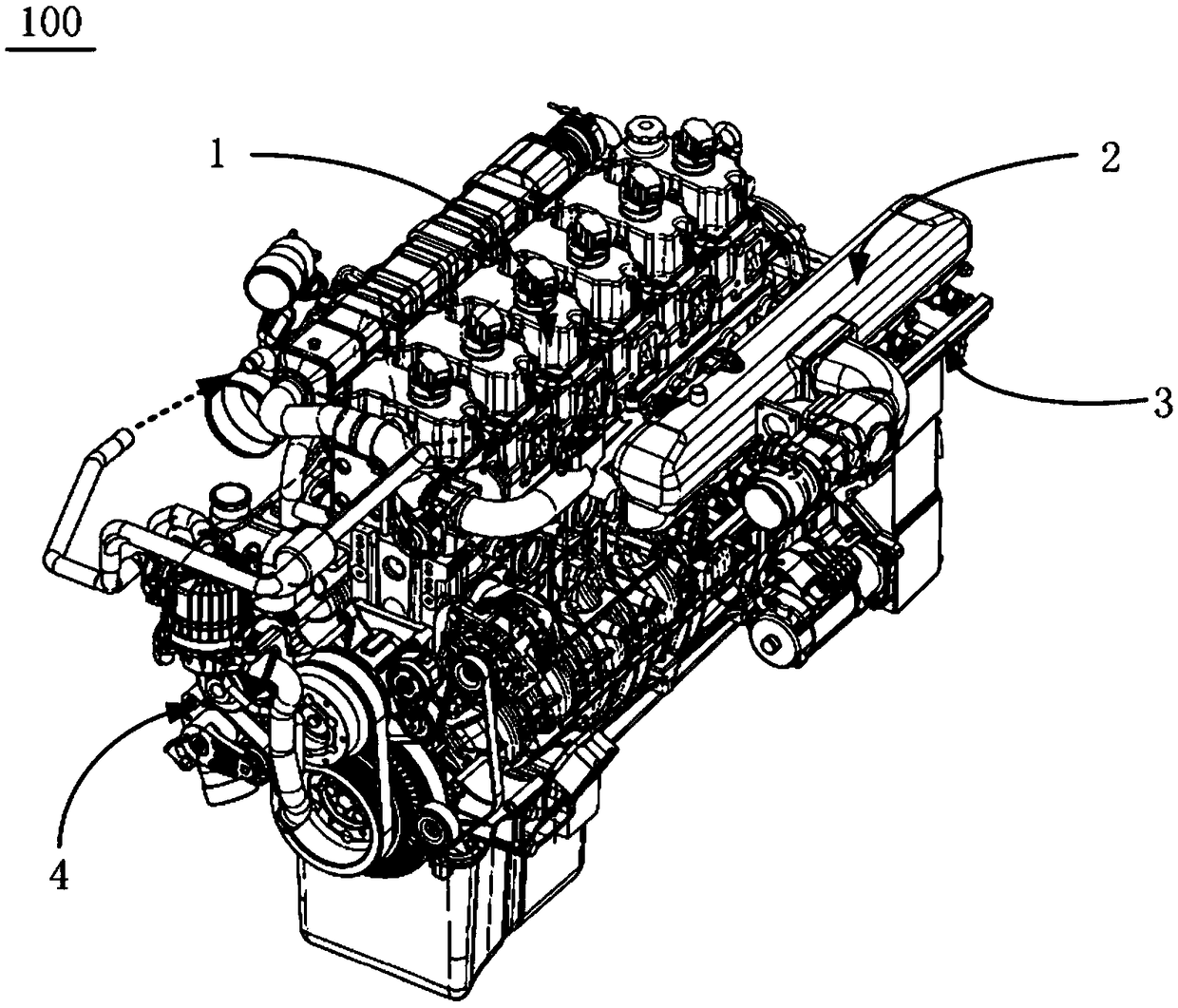

Starting method used for methanol engine and methanol engine

InactiveCN109057976ASolve the cold start problemAchieve cold startElectrical controlInternal combustion piston enginesGasolineEngineering

The invention provides a starting method used for a methanol engine and the methanol engine, and relates to the field of methanol engines. According to the starting method, before the methanol engineis started, the temperature of the engine is detected, and if the temperature before the methanol engine is started is lower than preset temperature, after a control unit receives a starting command,gasoline cold starting gasoline sprayers are controlled to spray gasoline into manifolds on an intake manifold so as to achieve cold starting of the methanol engine. In the method, the gasoline cold starting gasoline sprayers directly spray gasoline into the manifolds of the intake manifold to be mixed with air, the process that gasoline is directly sprayed into an intake pressure stabilization cavity of the intake manifold to be mixed with air and then distributed to the manifolds is avoided, and therefore the spray amount of gasoline can be effectively controlled, the problem of engine coldstarting failing caused by insufficient gasoline supply during cold starting of the methanol engine is avoided, and the problem that during cold starting of the methanol engine, too much gasoline is sprayed, and consequently discharging exceeds standards is avoided.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +3

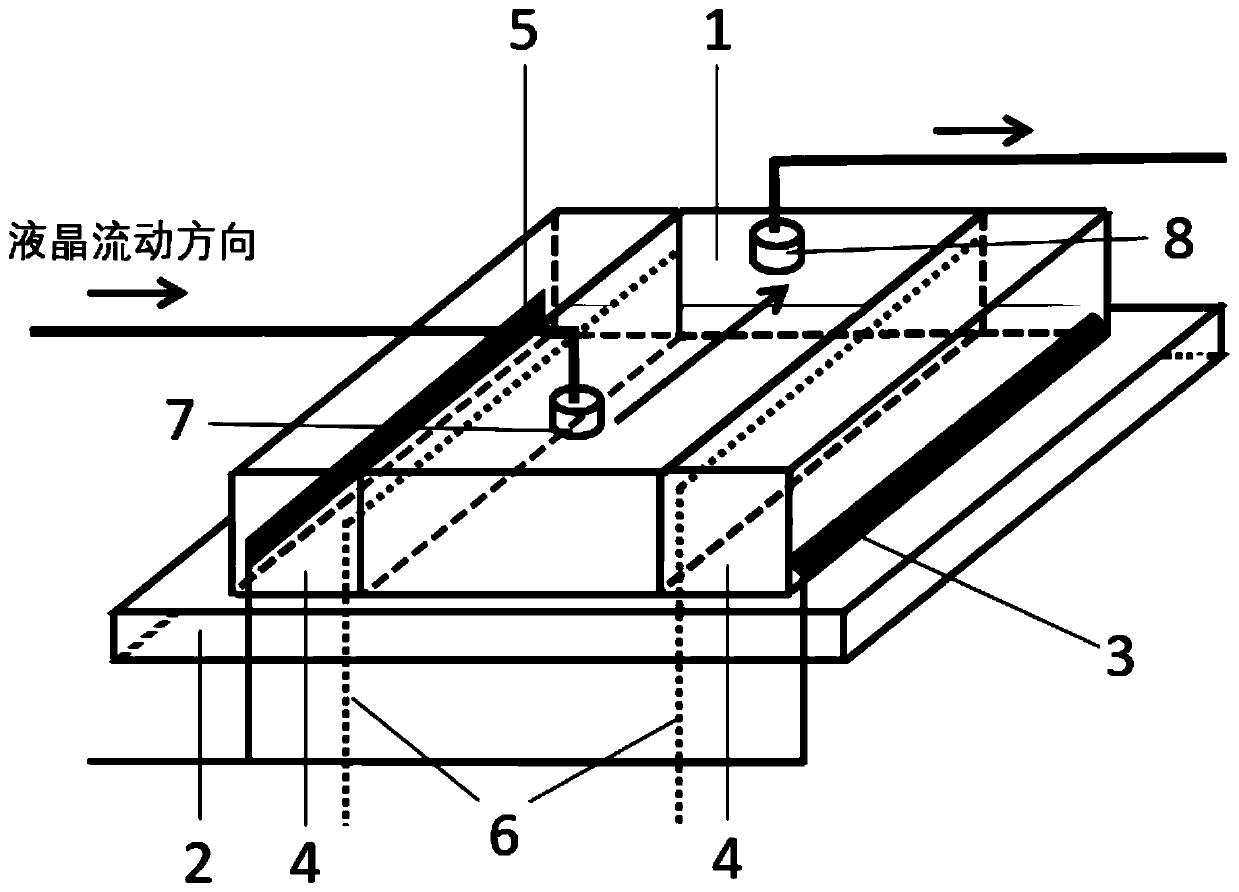

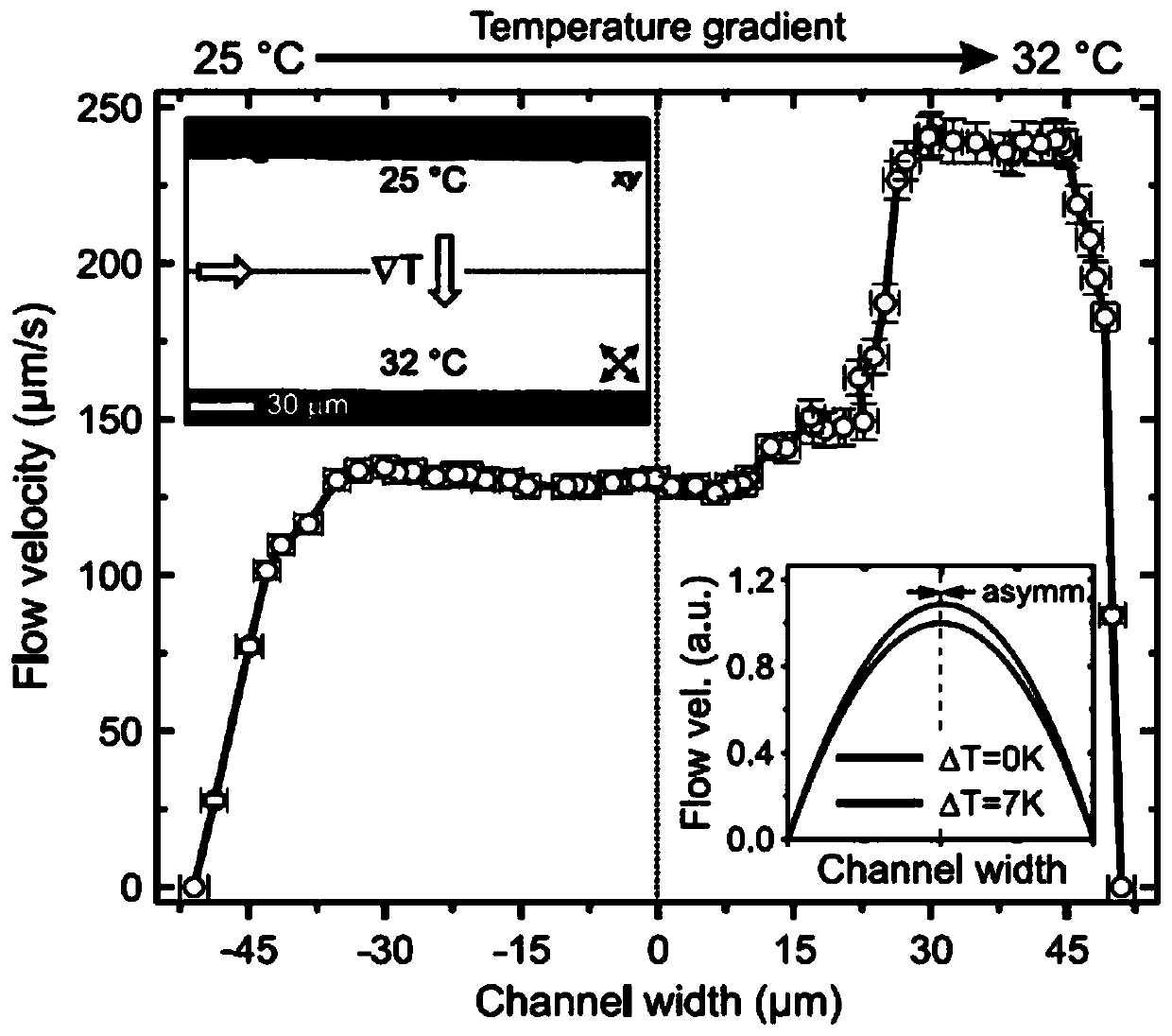

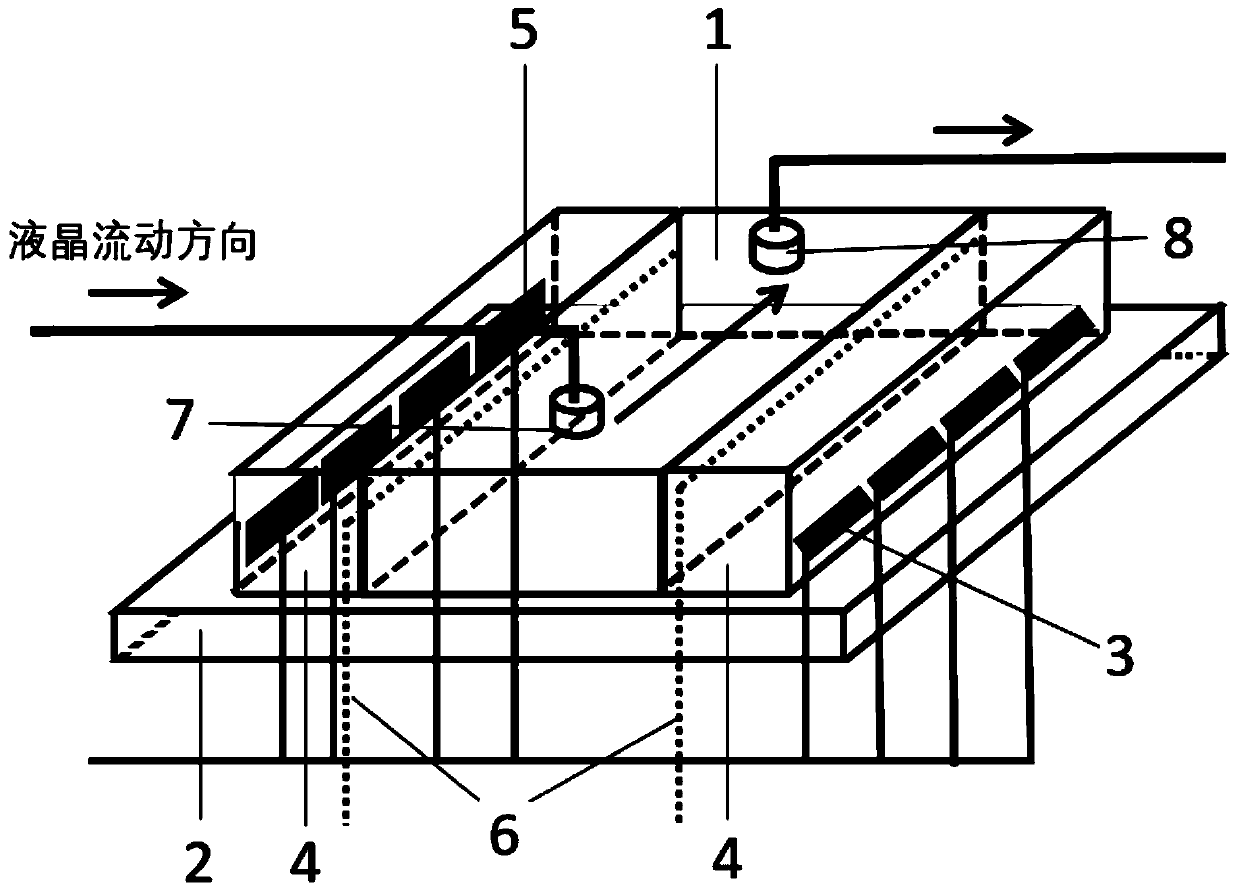

Temperature control micro-valve based on liquid crystal and single-stage and multi-stage control systems thereof

ActiveCN110605147AControl injection volumeIncrease contrastLaboratory glasswaresFluid controllersTemperature controlChemical reaction

The invention discloses a temperature control micro valve based on liquid crystal and single-stage and multi-stage control systems thereof, which are applied to the technical field of micro-fluidic chip micro valves; the temperature control micro valve comprises a micro-channel, a substrate, the liquid crystal and a temperature control element; wherein the micro-channel is arranged above the substrate; the liquid crystal is arranged in the micro-channel and can flow along the direction of the channel; the temperature control element is arranged on the micro-channel wall on any side vertical tothe liquid crystal flow direction; according to the invention, the runoff regulation of the sample is realized through the asymmetric flow characteristic of the liquid crystal under the non-uniform temperature field, so that the sample injection amount of different reactors or detectors is controlled, the comparison effect of chemical reaction or biological detection is remarkably enhanced, and the workload and related cost of experiments and detection are greatly reduced at the same time.

Owner:CHONGQING UNIV

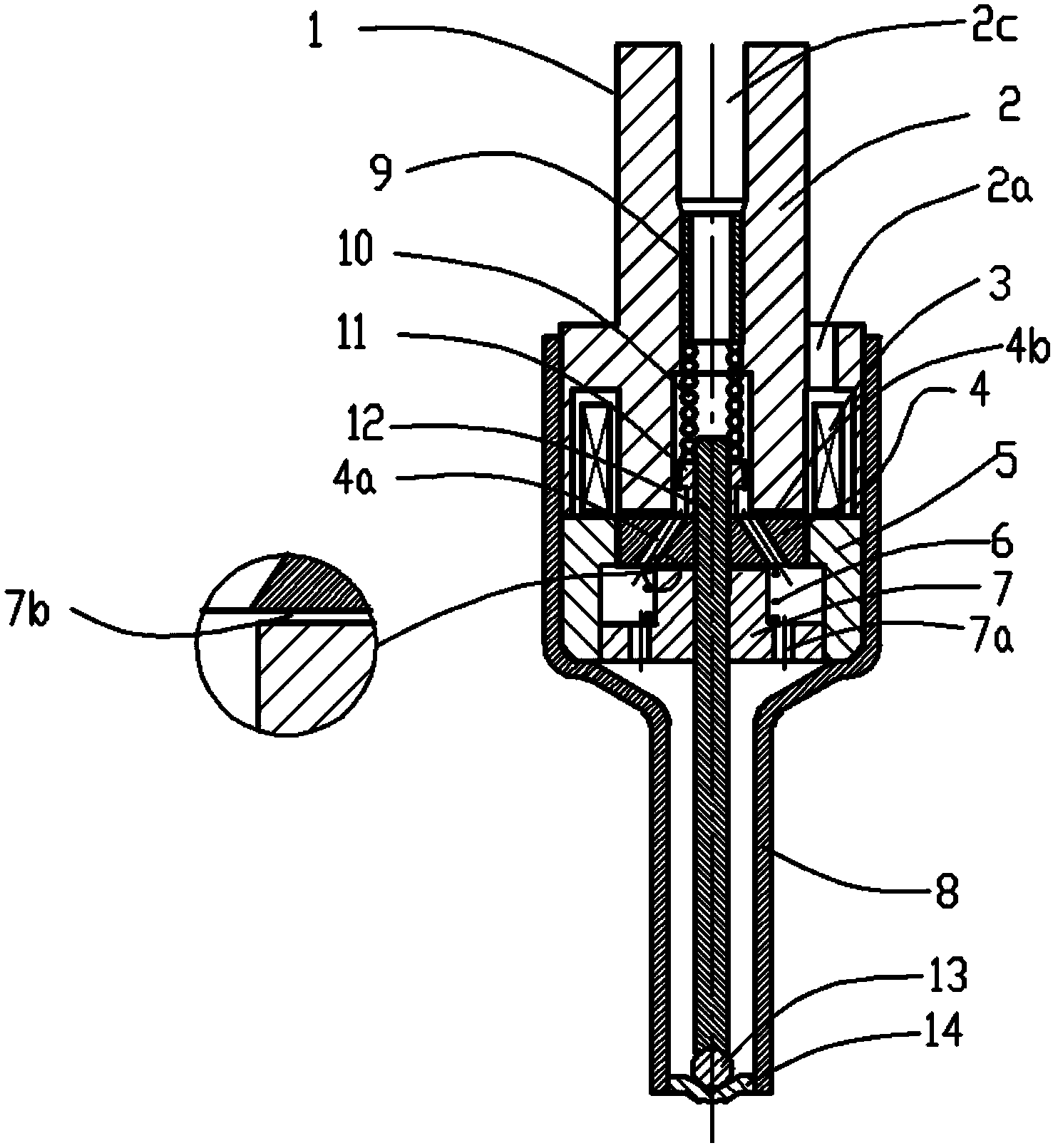

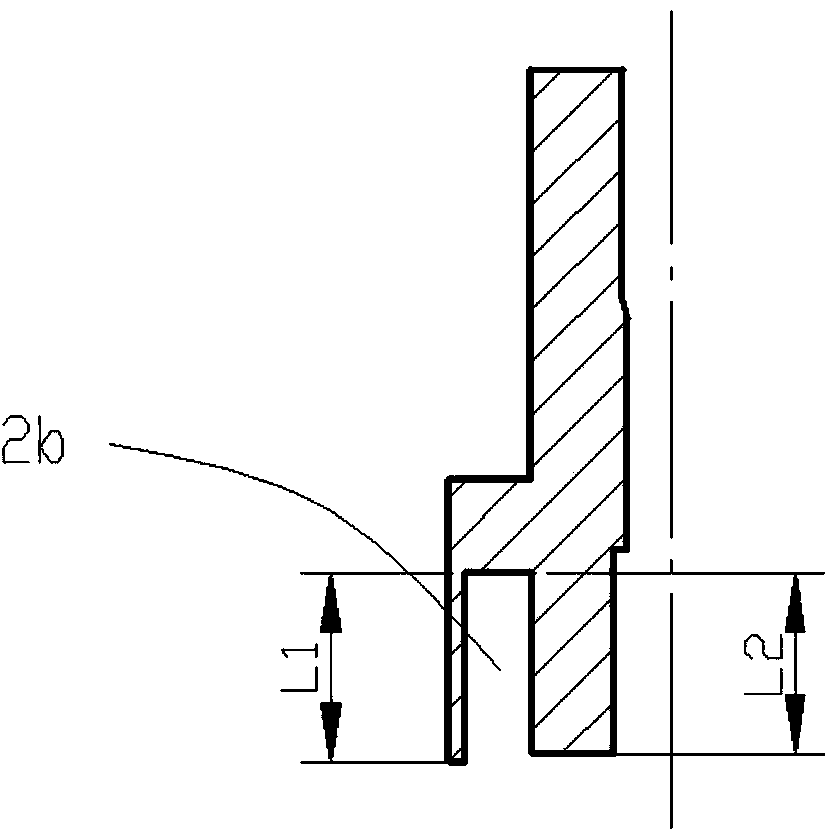

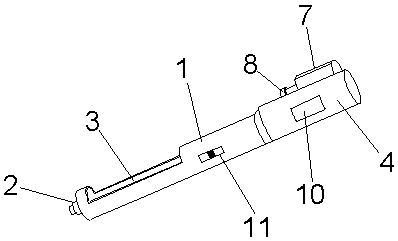

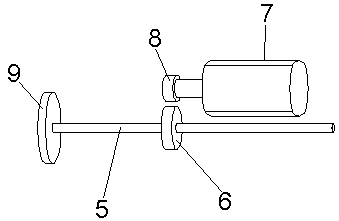

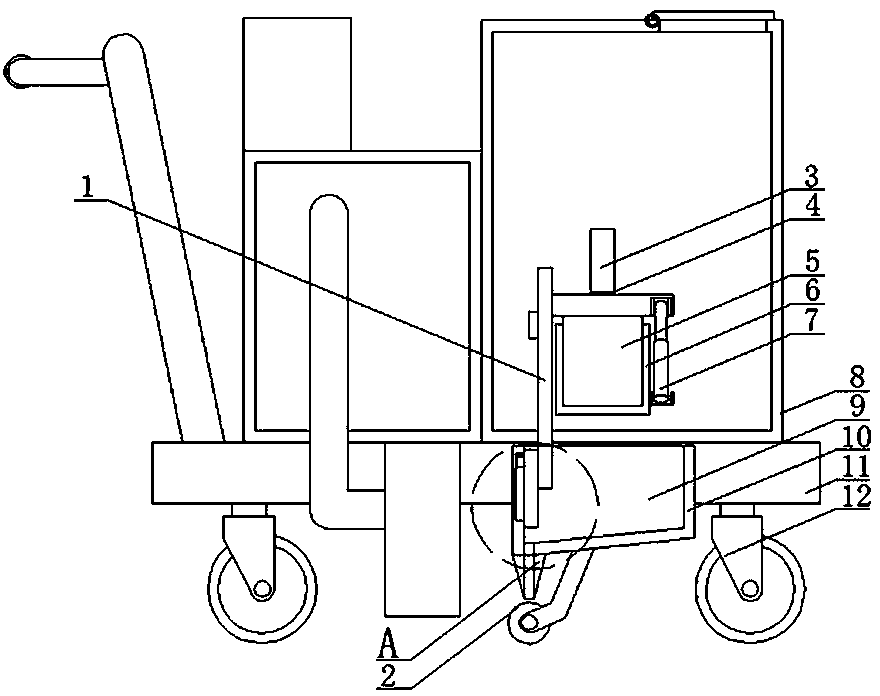

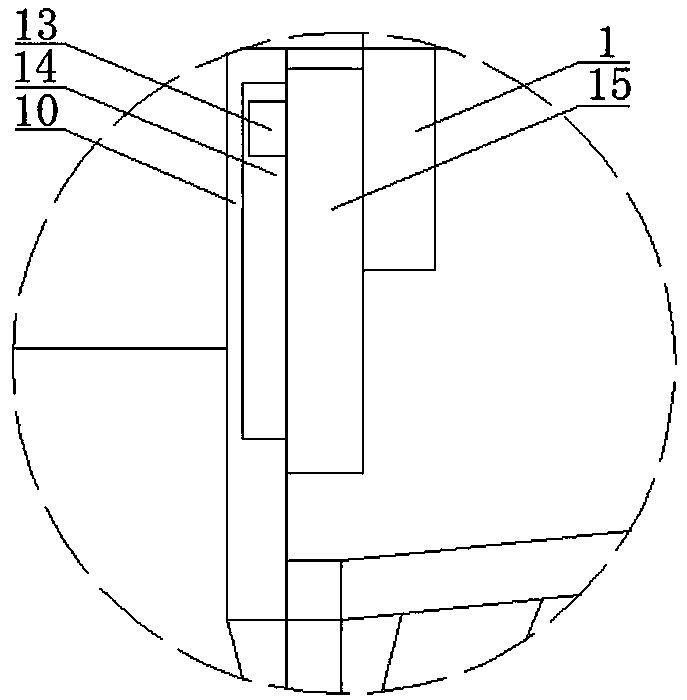

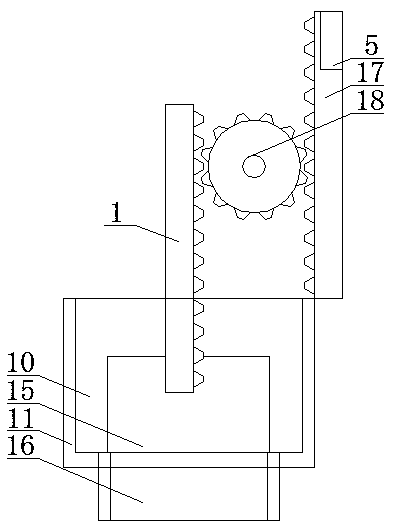

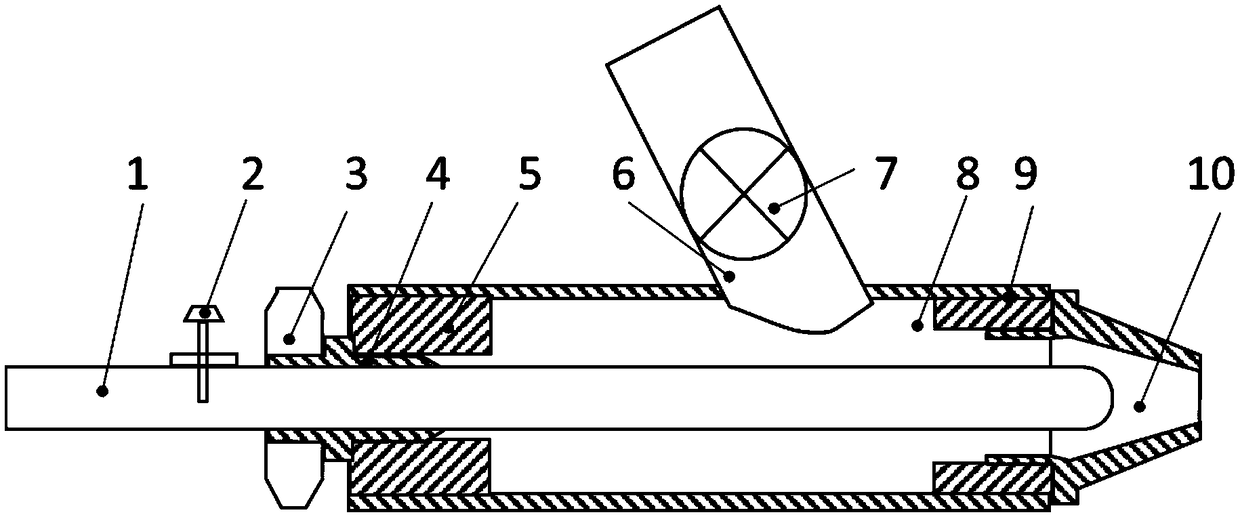

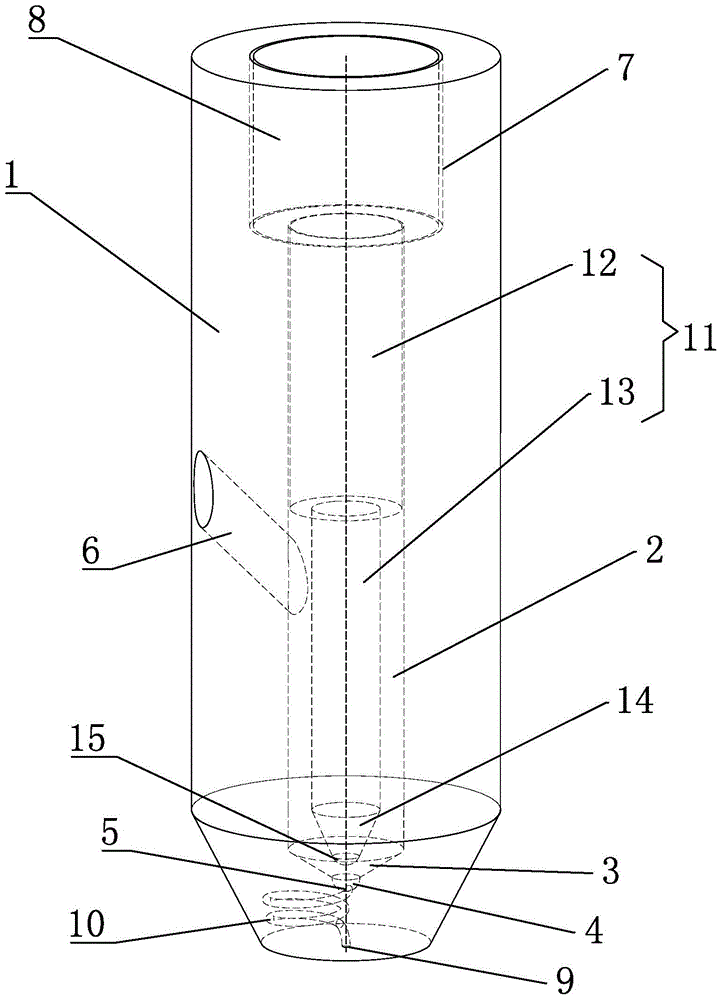

Syringe propelling device

PendingCN108525075AAvoid separationAvoid shakingAutomatic syringesIntravenous devicesGear wheelPropeller

The invention discloses a syringe propelling device which comprises a syringe sleeve (1). The front end of the syringe sleeve (1) is provided with a needle clamping groove, the syringe sleeve (1) is provided with a syringe placement groove (3), a propeller (4) is connected to the tail end of the syringe sleeve (1) and comprises an outer shell, a nut gear (6) is arranged on a propelling screw rod (5) which is arranged in the outer shell, and a transmission gear (8) meshed with the nut gear (6) is arranged on a rotating shaft of a motor (7) which is arranged on the outer shell. The syringe propelling device is convenient to use, injection operation of a syringe can be simplified, uniform injection speed is achieved, injection safety is improved, and separation of a syringe needle and a syringe tube in an injection process is avoided.

Owner:GUIYANG COLLEGE OF TRADITIONAL CHINESE MEDICINE

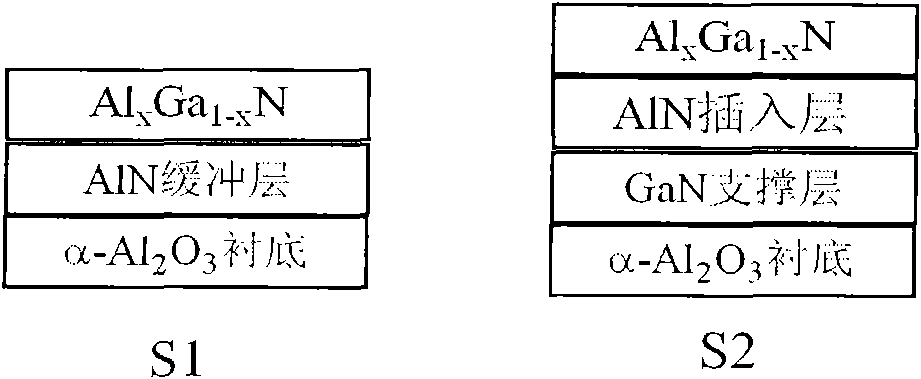

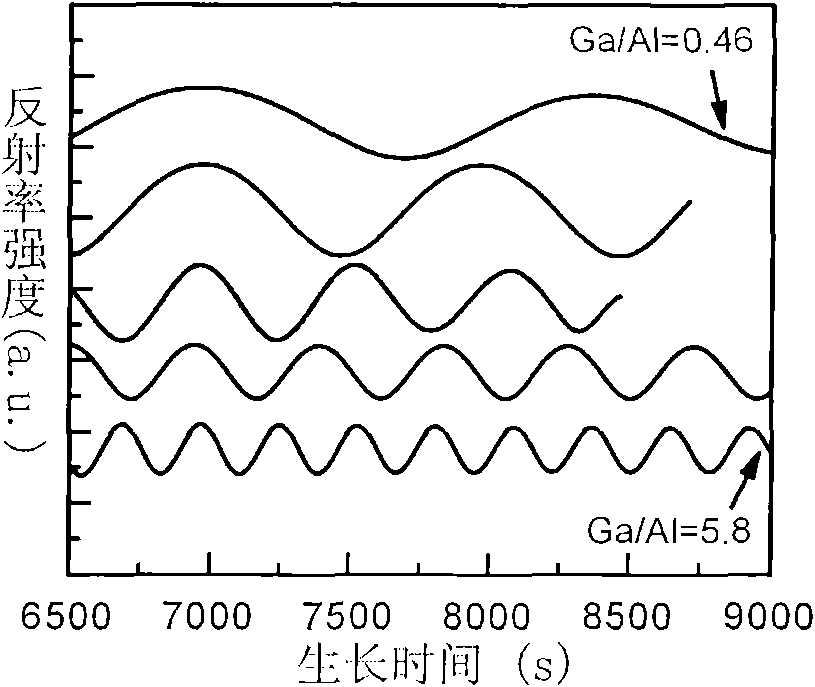

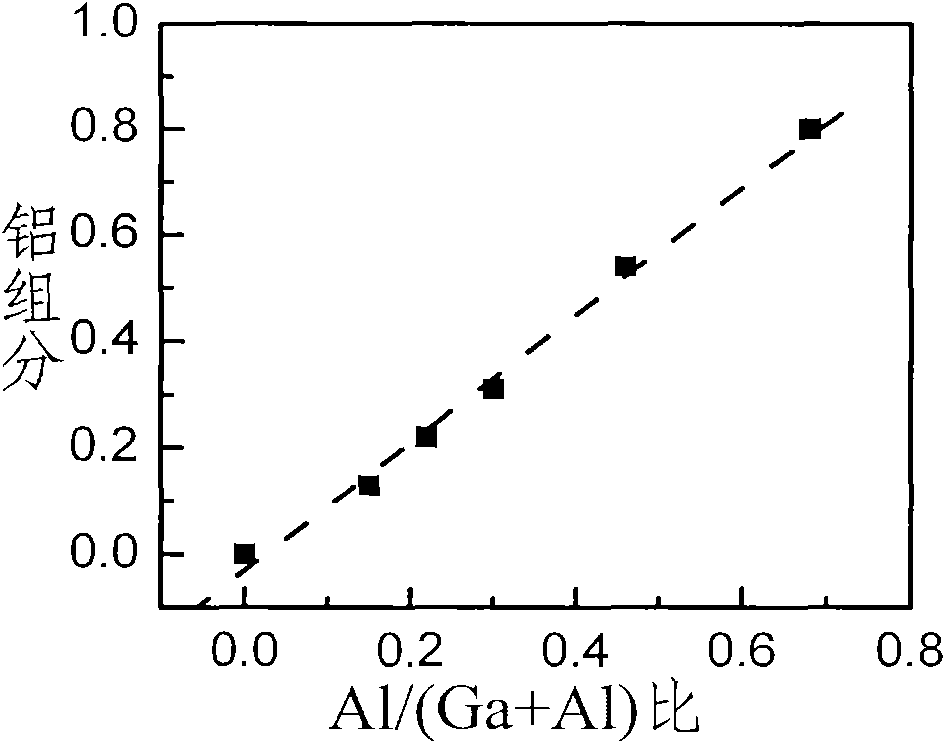

Growth method for obtaining high aluminium component Al-Ga-N alloys by improving aluminium doping efficiency

InactiveCN101777488AInhibit surface cracksGood qualitySemiconductor/solid-state device manufacturingSemiconductor devicesAluminiumCathodoluminescence

A growth method for obtaining high aluminium component Al-Ga-N alloys by improving aluminium doping efficiency is characterized by adopting MOCVD to epitaxially grow an AlxGa1-xN film alloy layer on the alpha-Al2O3 substrate, adopting an AlN buffer layer or insert layer to prevent crack on the film layer and realizing adjustment of the Al component in AlxGa1-xN by controlling the mole ratio of Al / Ga, wherein the number x of Al atoms is not less than 0 and not more than 0.8, and the control method of the Al component is as follows: keeping certain molar weight of the injected Al and reducing the mole ratio of Ga to Al from 5.8 to 0.46. The method has the following advantages: the AlxGa1-xN alloy can be obtained, the number x of Al atoms in the alloy is as high as 0.8, and the Al doping efficiency is improved by 9%; the Al-Ga-N film has excellent quality, the full-width at haft-maximum (FWHM) of the typical X-ray rocking curve of AlxGa1-xN (0002) is less than 300 seconds of arc; the luminescent property is excellent and the cathodoluminescence spectra show remarkably strong band-edge luminescence peaks; and the surface is smooth and flat and the typical roughness (RMS) is less than 0.8nm.

Owner:NANJING UNIV

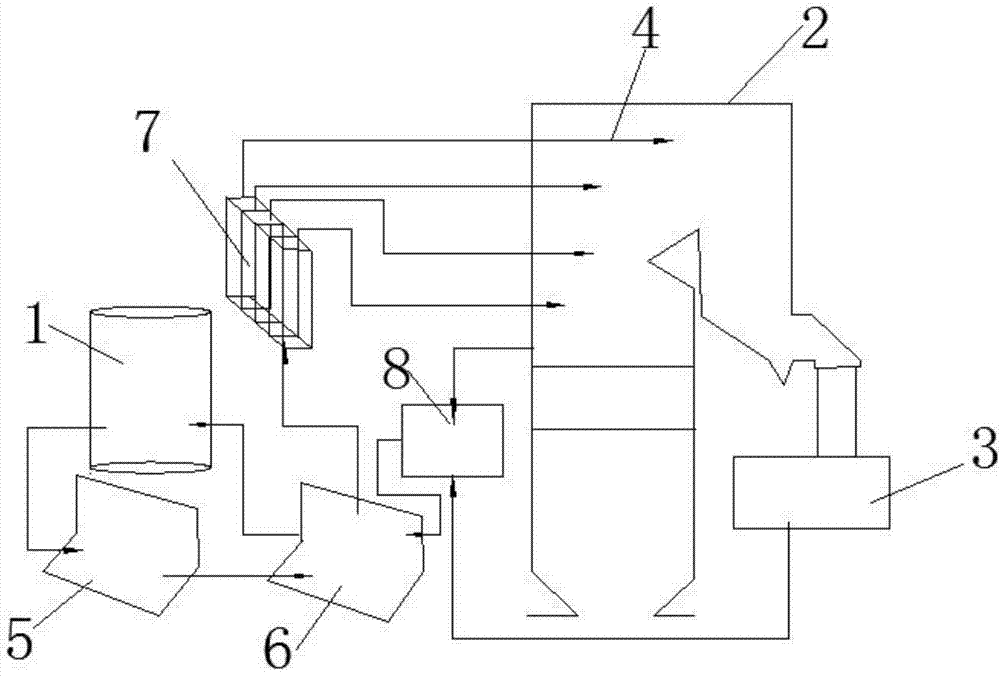

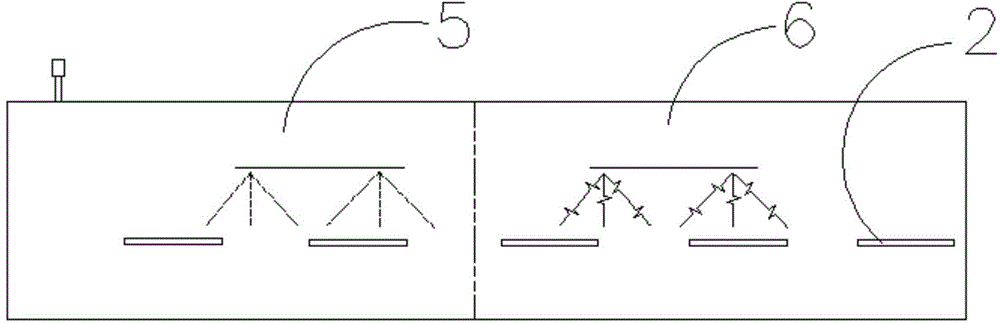

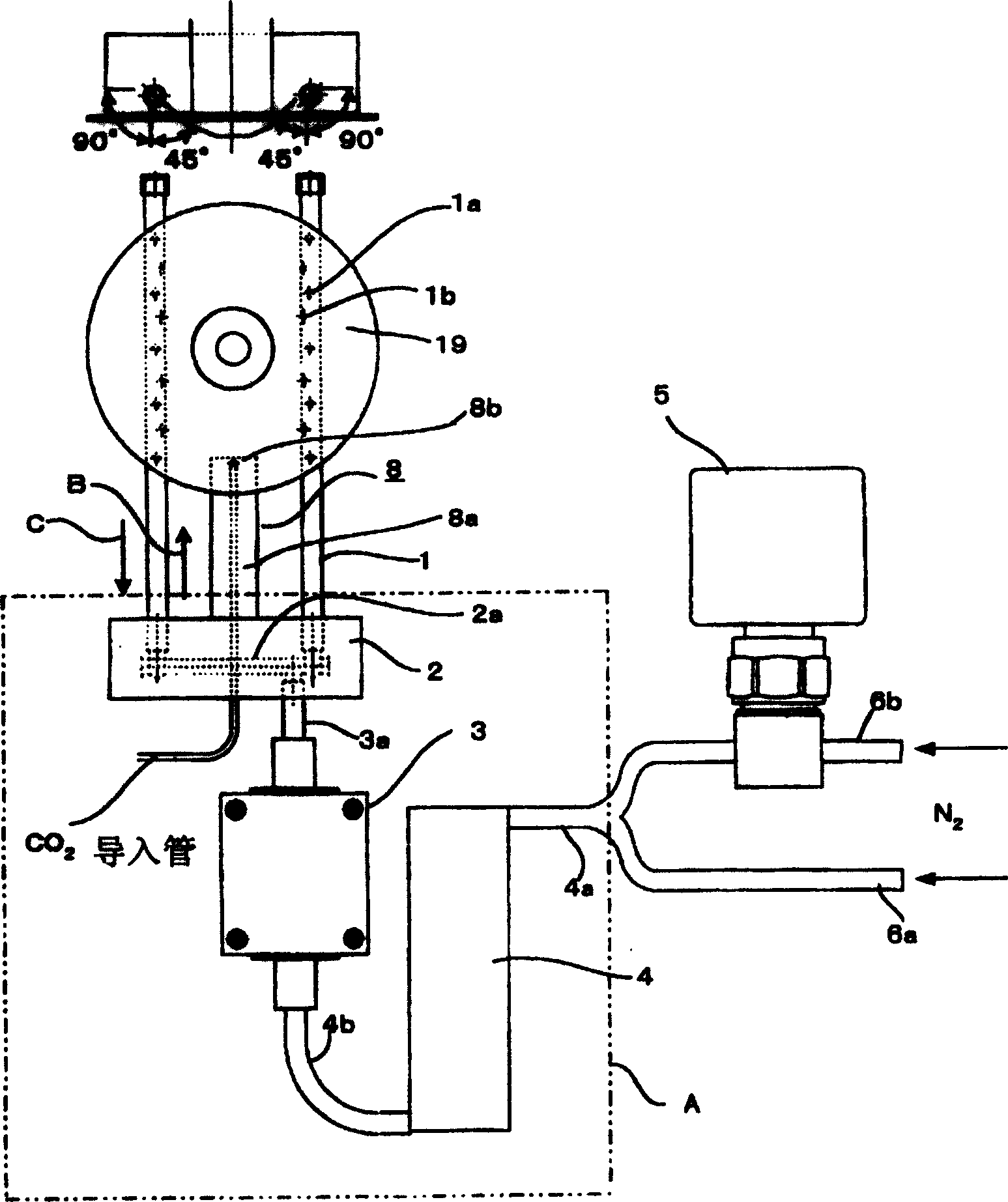

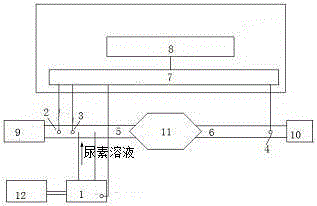

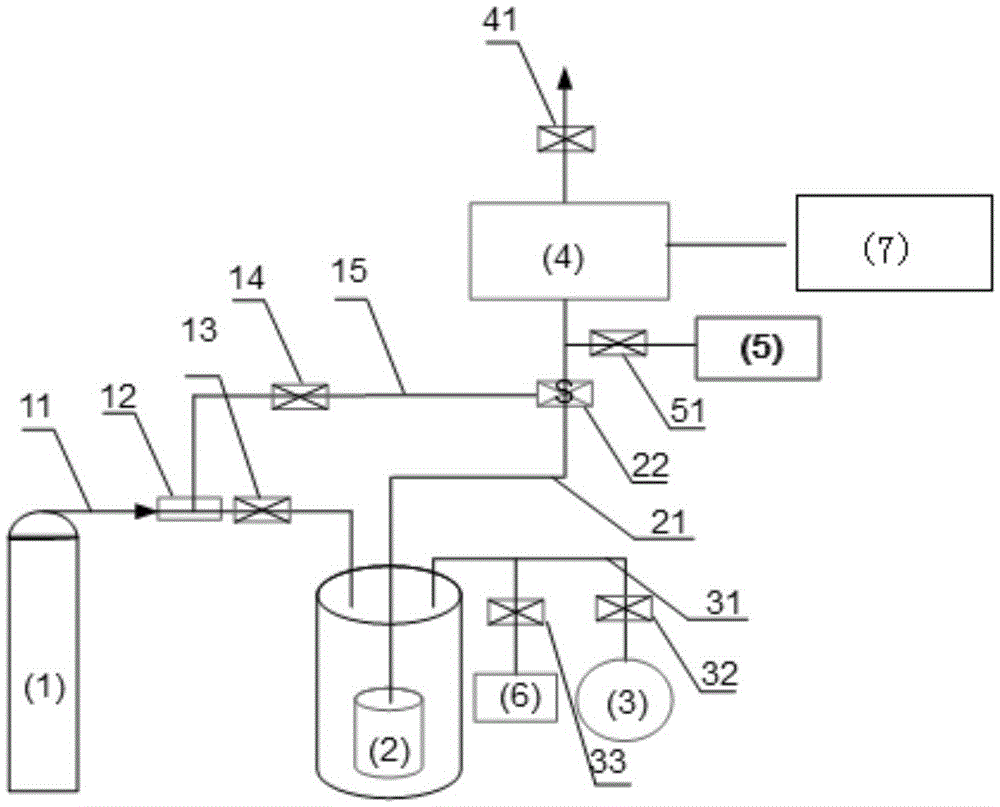

Marine SCR urea solution spraying system and control method

InactiveCN105179052AControl injection volumeInternal combustion piston enginesExhaust apparatusElectricityDifferential pressure

The invention relates to a marine SCR urea solution spraying system and a control method. An existing marine SCR urea solution spraying system cannot precisely control the amount of sprayed urea solutions. The marine SCR urea solution spraying system comprises a urea pump (1) and a flue divided into a front flue (5) and a rear flue (6), and the urea pump (1) sprays urea into the front flue (5); and the system is characterized in that a flowmeter differential pressure transmitter (2) and a first NOx sensor (3) are arranged in the front flue (5), and a second NOx sensor (4) is arranged in the rear flue (6); and the urea pump (1), the flowmeter differential pressure transmitter (2), the first NOx sensor (3) and the second NOx sensor (4) are all electrically connected with a data collecting module (7). The data collecting module is electrically connected with a central processing unit (8), and the control method is further provided. Through the provided control system and method, the sprayed amount of the urea solution can be precisely controlled.

Owner:NANTONG YATAI ENG TECH

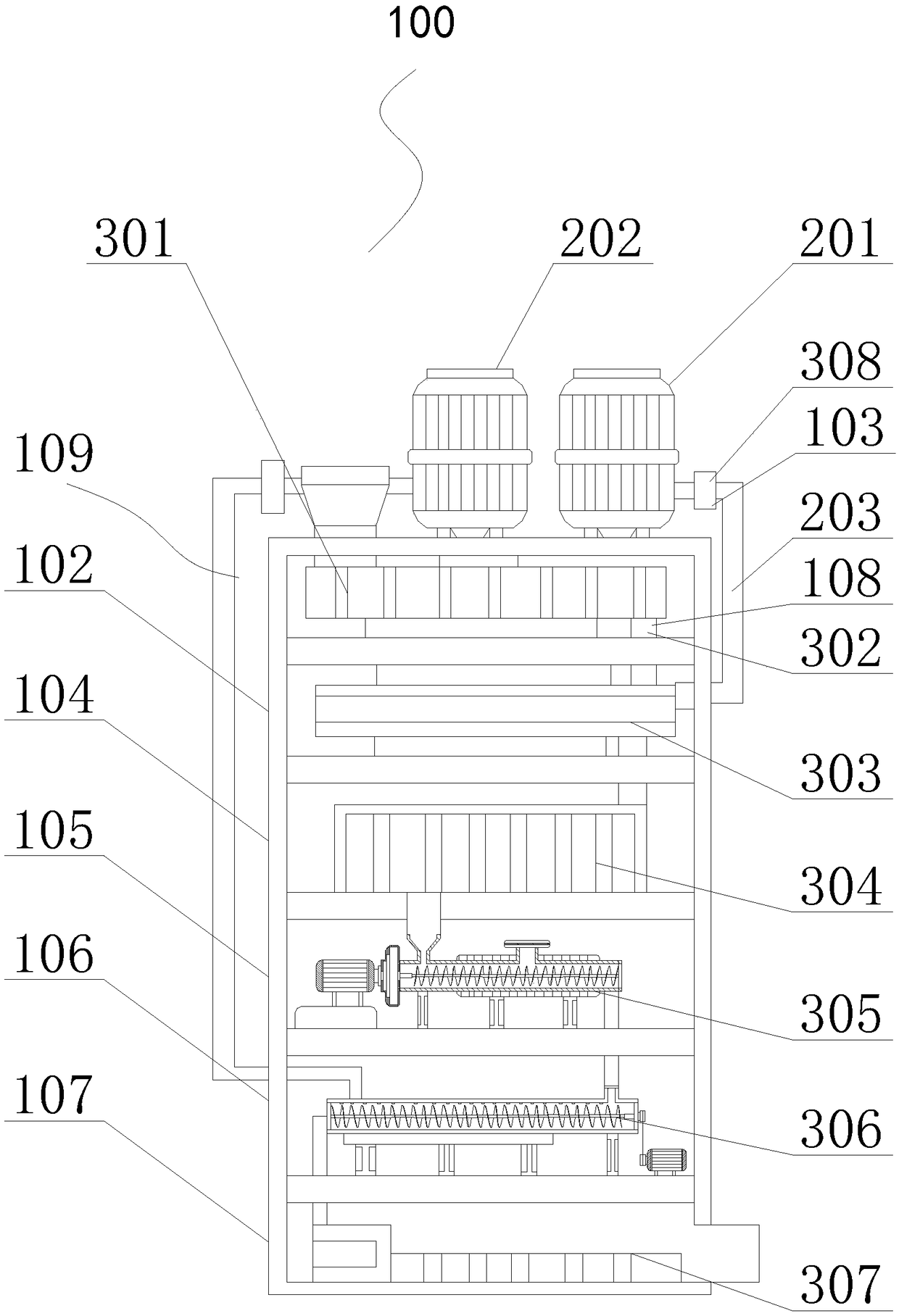

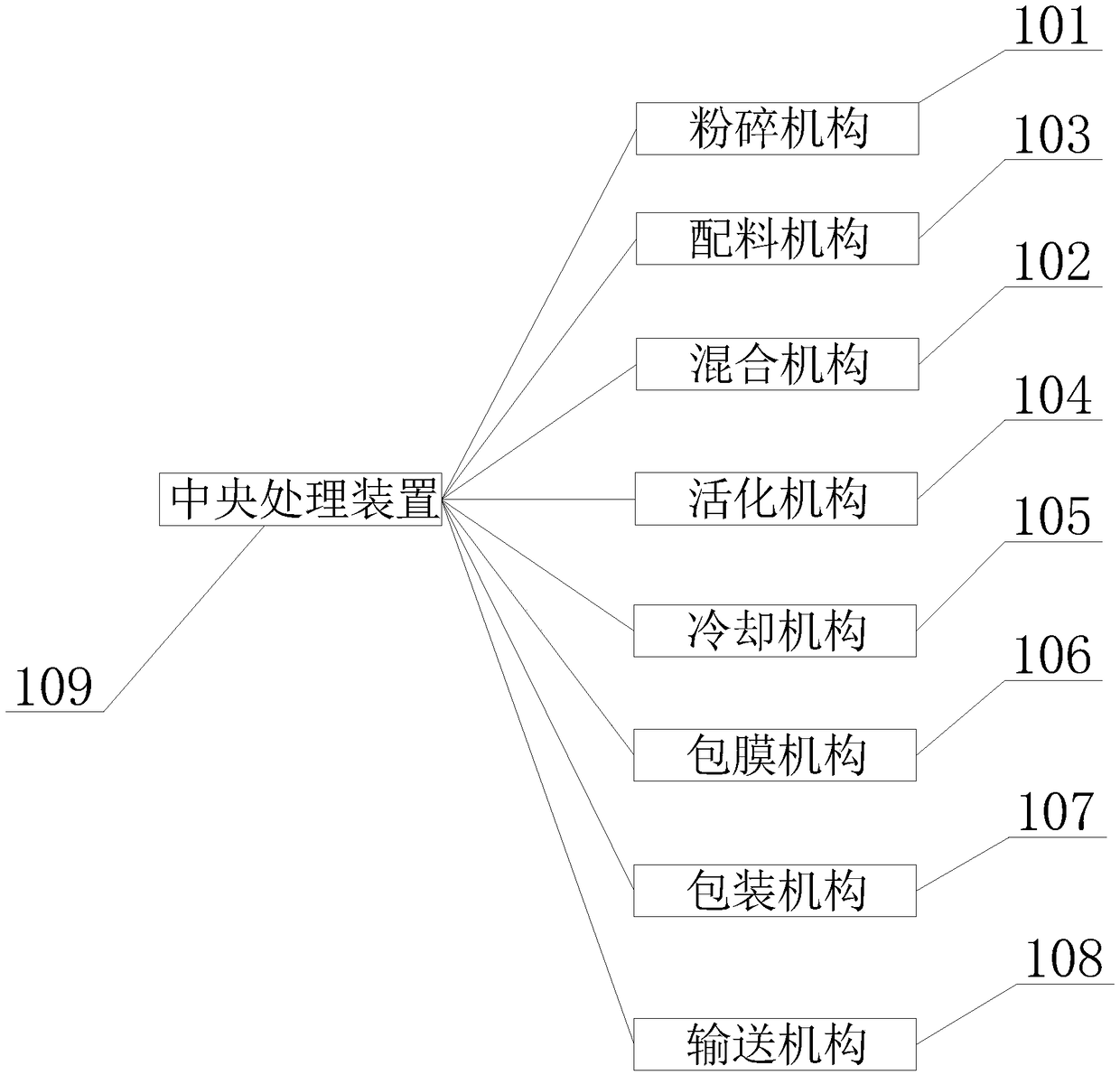

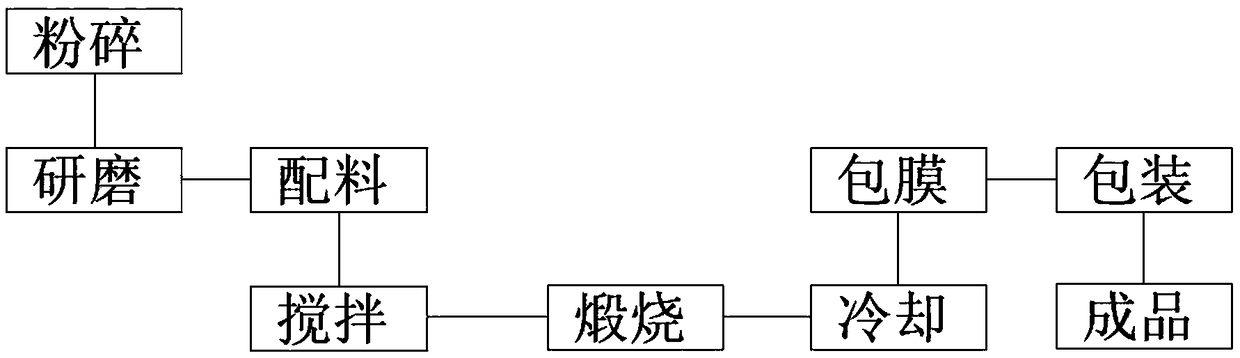

Preparation device system of soil conditioning powder

InactiveCN108822857AQuality improvementControl injection volumeTransportation and packagingMixer accessoriesEngineeringSoil conditioning

The invention provides a preparation device system of soil conditioning powder. The system comprises a central processing unit, a crushing mechanism, a mixing mechanism, a batching mechanism, an activation mechanism, a cooling mechanism, a coating mechanism, a packaging mechanism and a conveying mechanism. A metering valve accurately weighs crushed raw material powder and conveys the raw materialpowder to a stirrer, the metering valve accurately weighs the cooled raw materials and then conveys the raw materials to the coating mechanism, and a dosage controller controls the injection quantityof slow-release powder and auxiliary powder according to precise proportion. Compared with an existing preparation system of soil conditioning powder, the novel preparation system of the soil condition powder can know the content of the raw materials accurately when transferring the raw materials during preparation, so that the injection quantity of the auxiliary powder and the slow-release powderis controlled, errors are reduced, and the quality of the soil conditioning powder is greatly improved.

Owner:CHONGQING FUNONG MODERN BIOTECH CO LTD

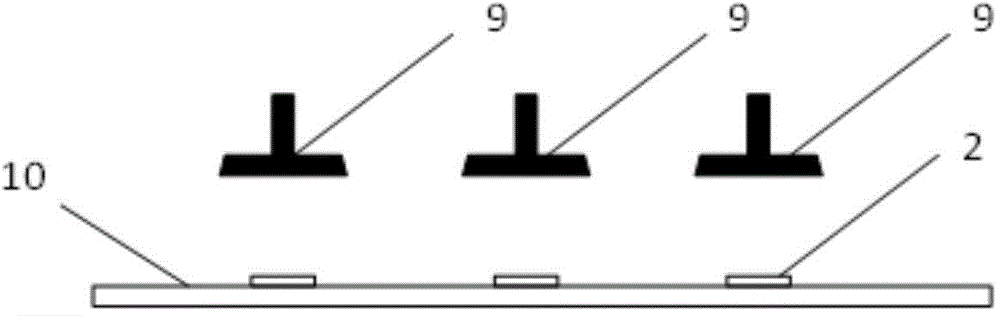

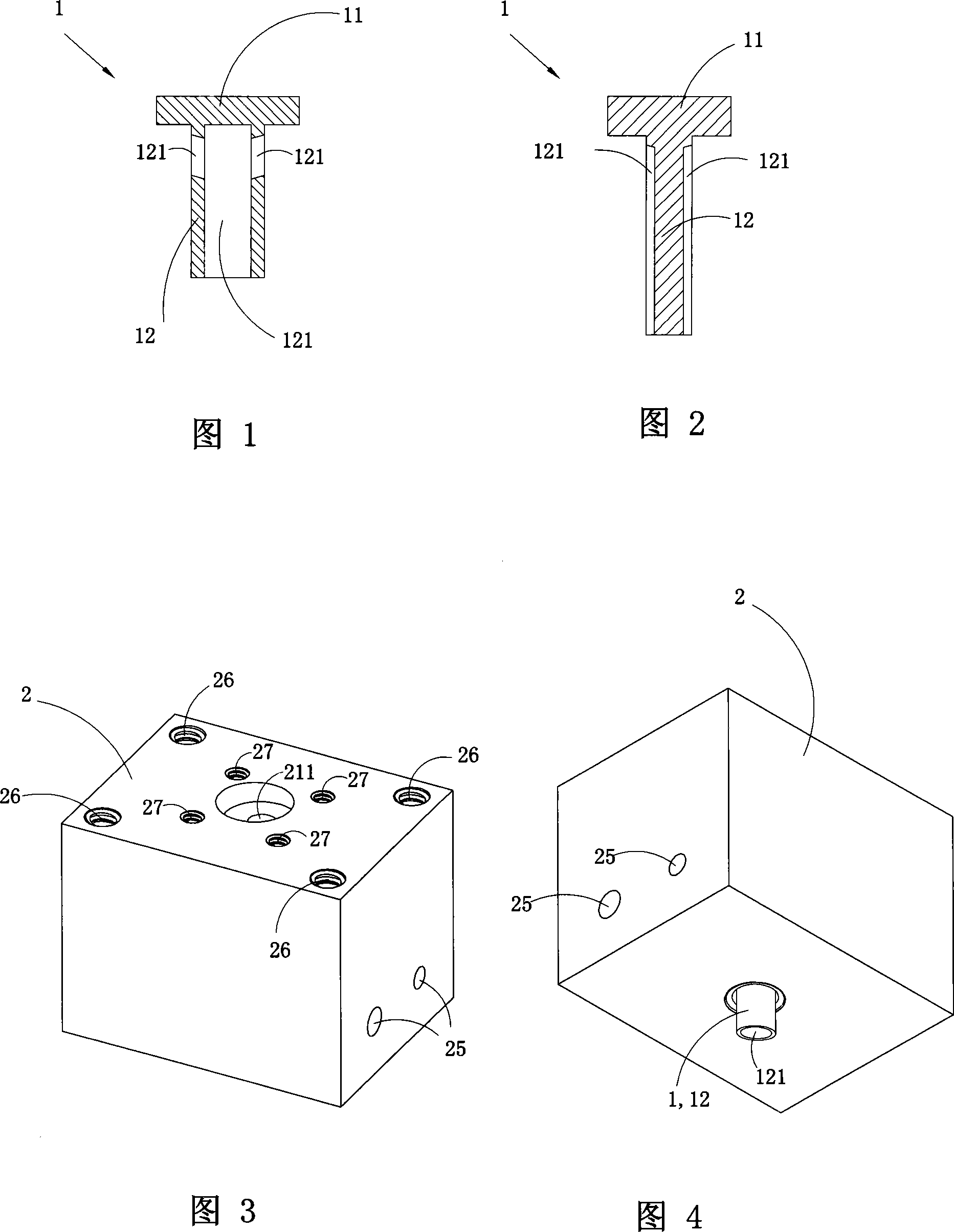

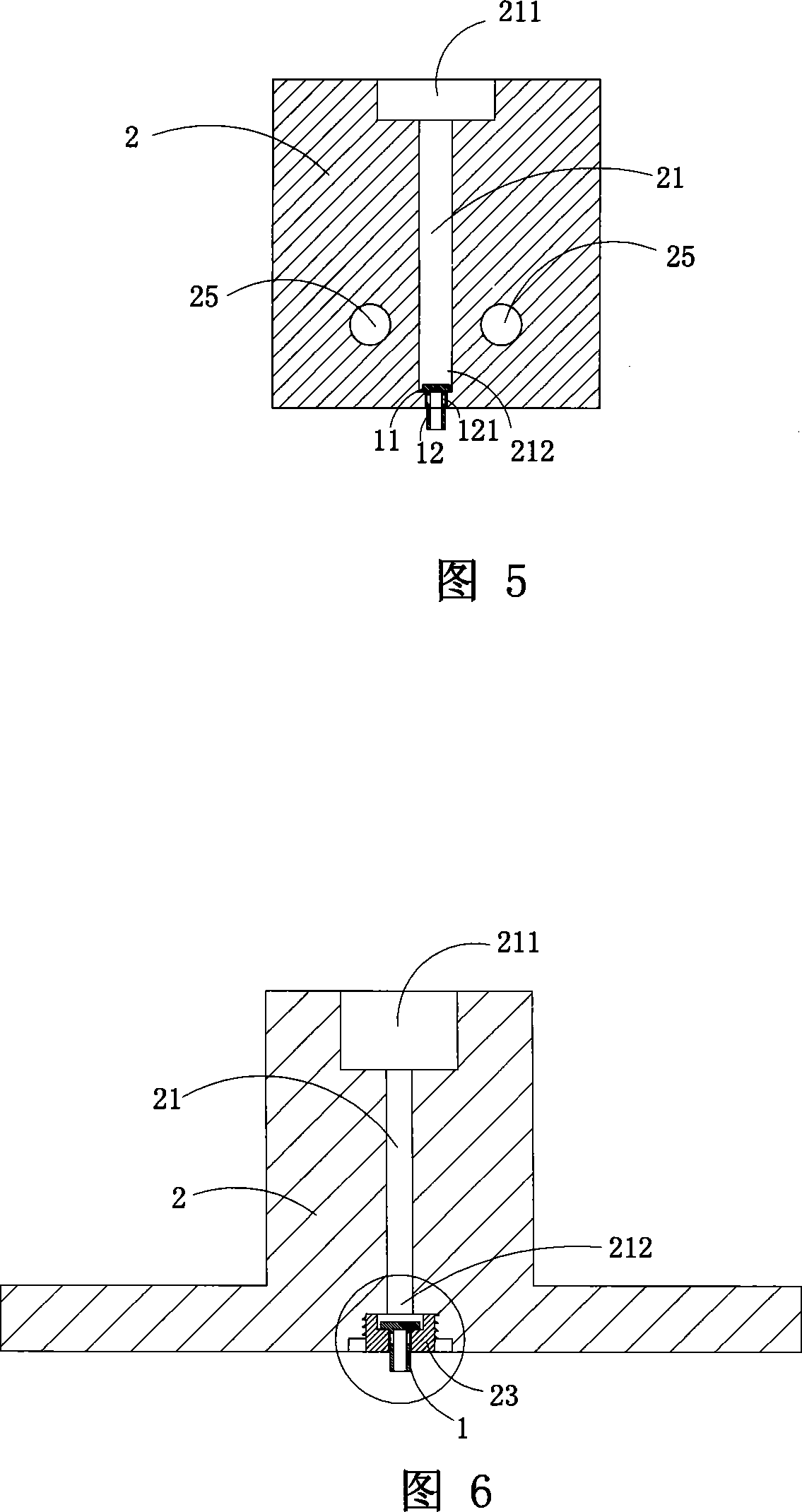

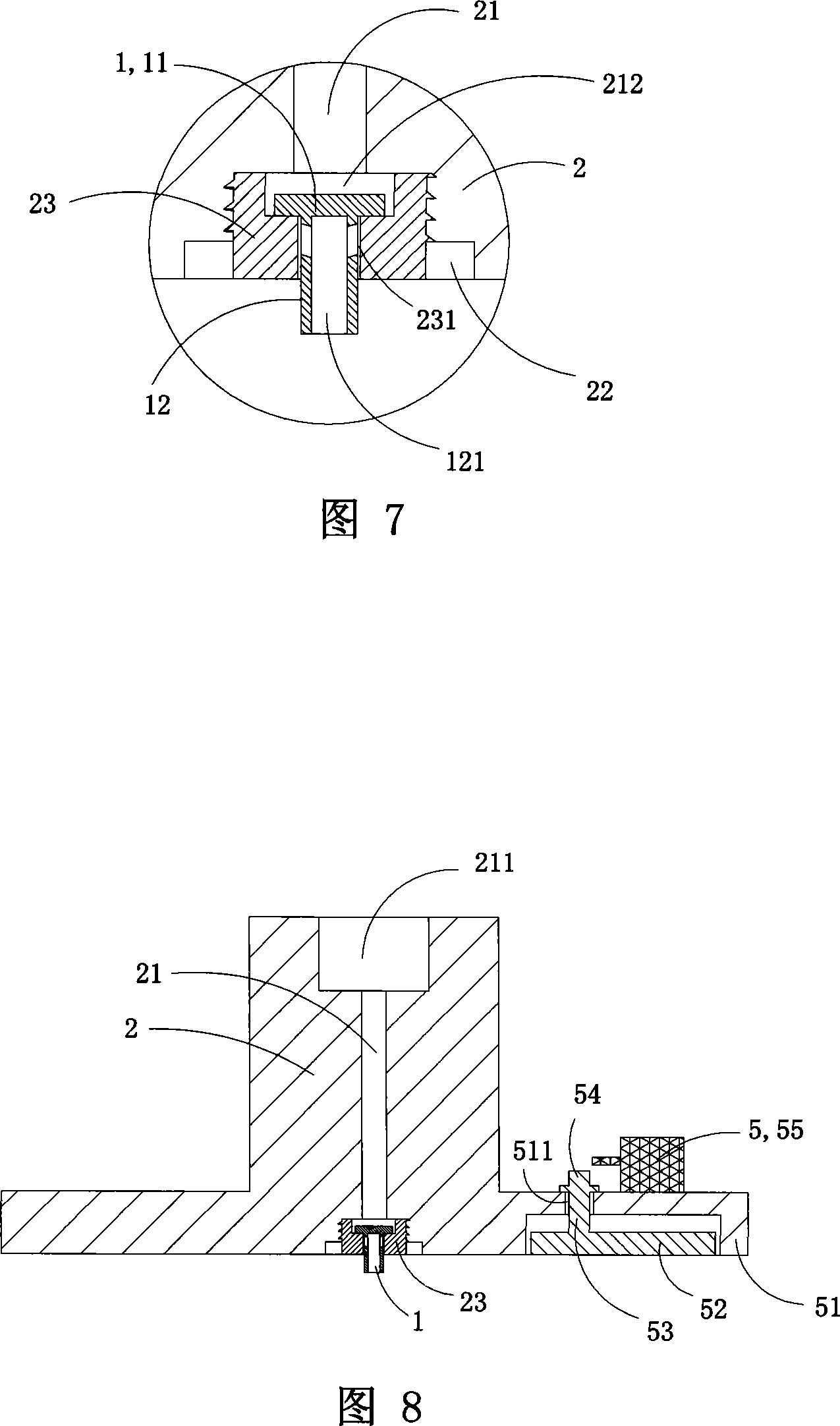

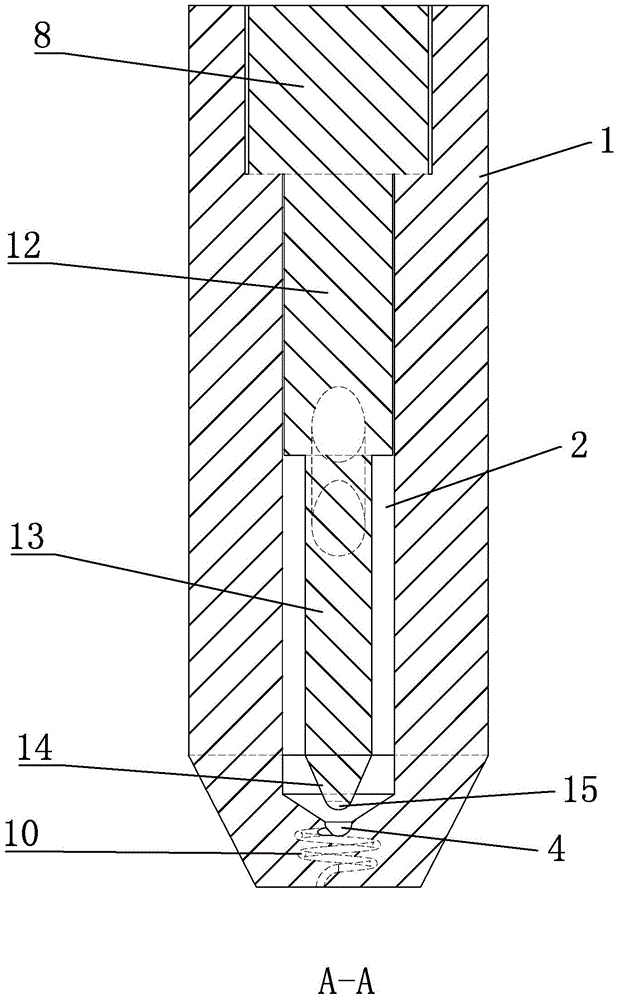

Injection mouth and vertical plastic injection forming machine injection head

The invention discloses an injection tooth and an injection head of an upright plastic injection molding machine with a said injection tooth. The injection tooth takes the shape of T, with the upper part being a sealing unit and the lower part being a discharge unit which is provided with a discharge channel. The body of the injection head is provided with an injection pore canal, a feeding port and an injection port for the injection pore canal; the injection tooth which can both inject materials and prevent the materials from leaking, is inserted into the feeding port; the injection tooth takes the shape of T, with the upper part being a sealing unit and the lower part being a discharge unit; the sealing unit can cover and seal up the feeding port; the discharge unit is provided with a discharge channel and the bottom of the discharge unit stretches out of the feeding port, that means, the bottom of the discharge unit is lower than the lower surface of the body of the injection head. The injection tooth and the injection head of the invention can prevent the materials from leaking from the injection head.

Owner:金孝禹

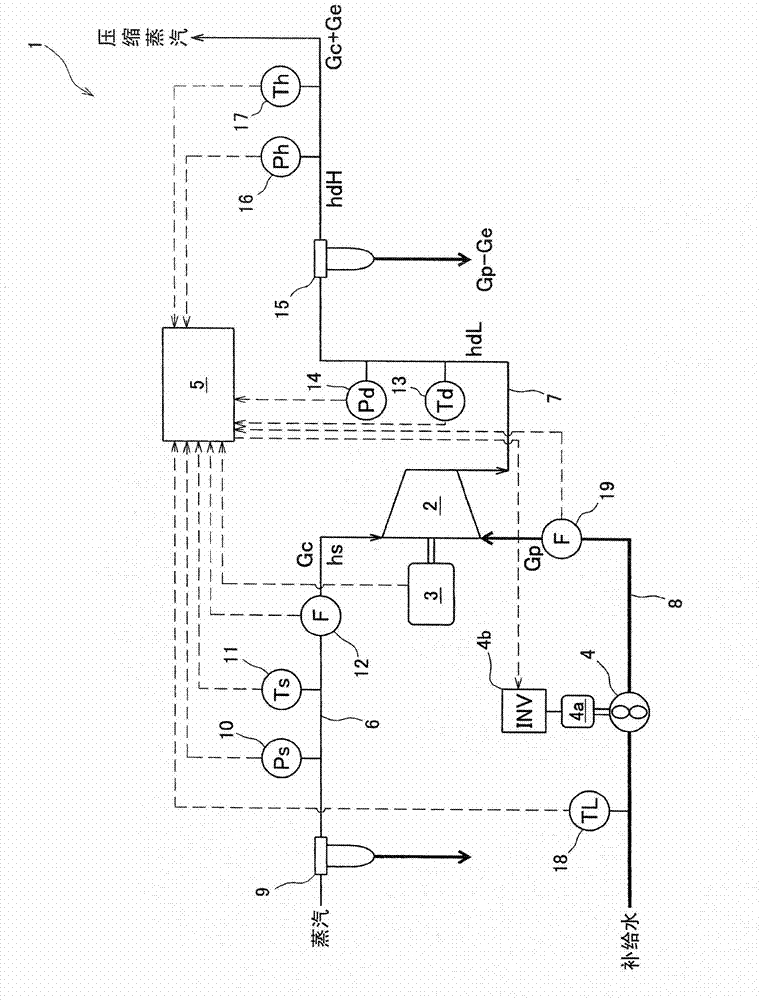

Water spray type steam compressor

ActiveCN102817849AIncrease volumeControl injection volumePositive displacement pump componentsEngine fuctionsInjection pressureEngineering

The present invention provides a water spray type steam compressor, which has a structure capable of accurately grasping the temperature of supply water and quantity state of the suction steam. The structure can help to prevent the sprayed steam from changing into superheated steam, and prevent the quantity of the sprayed steam from reducing. The water spray type steam compressor (1) is provided with a suction side drain water separator (9) arranged on a suction tube (6), a water injection pump (4) which sprays the supply water into the compression space inside a screw compressor (2), a supply water thermometer (18) for the detection of the temperature of the supply water, and a control part (5) used for controlling the injection quantity of the supply water. According to the specific enthalpy of the suction steam flowing in the suction tube (6) downstream side of the suction side drain water separator (9) and the specific enthalpy of the supply water calculated from the detection value of the supply water thermometer (18), the control part (5) controls the injection quantity of the supply water in a way of equaling the surplus output energy of the screw compressor (2) to the gasification heat of the supply water, wherein the surplus output energy equals that the total output energy minus the energy consumption of boosting the pressure of the suction steam up to prescribed injection pressure.

Owner:코벨코컴프레서가부시키가이샤

Rapid feeding equipment for road marking machine

InactiveCN108716181AEasy accessReduce labor intensityRoads maintainenceEngineeringUltimate tensile strength

The invention discloses rapid feeding equipment for a road marking machine. The rapid feeding equipment comprises a machine body, wherein a bearing block is fixed on one side of the machine body, a marking device is arranged at the lower end of the bearing block, a bearing slot is formed in the upper end of the bearing block, a sliding chute is formed in the side wall of one end in the bearing slot, a sliding block is mounted in the sliding slot, a baffle is fixed on one side of the sliding block, a first straight rack is fixed on one side of the baffle, and the upper end of the first straightrack penetrates through the bearing slot and extends to the upper end of the bearing block; and a coating bucket is fixed at the upper end of the machine body, a discharging device is arranged on thecoating bucket, and a second straight rack is fixed on one side of the discharging device. According to the rapid feeding equipment, the injection amount of a coating can be automatically controlled,so that the labor intensity of a worker is alleviated; the output amount can be effectively controlled, so that the overflowing of the coating is avoided, the wasting of the coating is avoided, the working efficiency is improved, and the marking quality is guaranteed; and the rapid feeding equipment is simple in structure and convenient to operate.

Owner:亚建科技有限公司

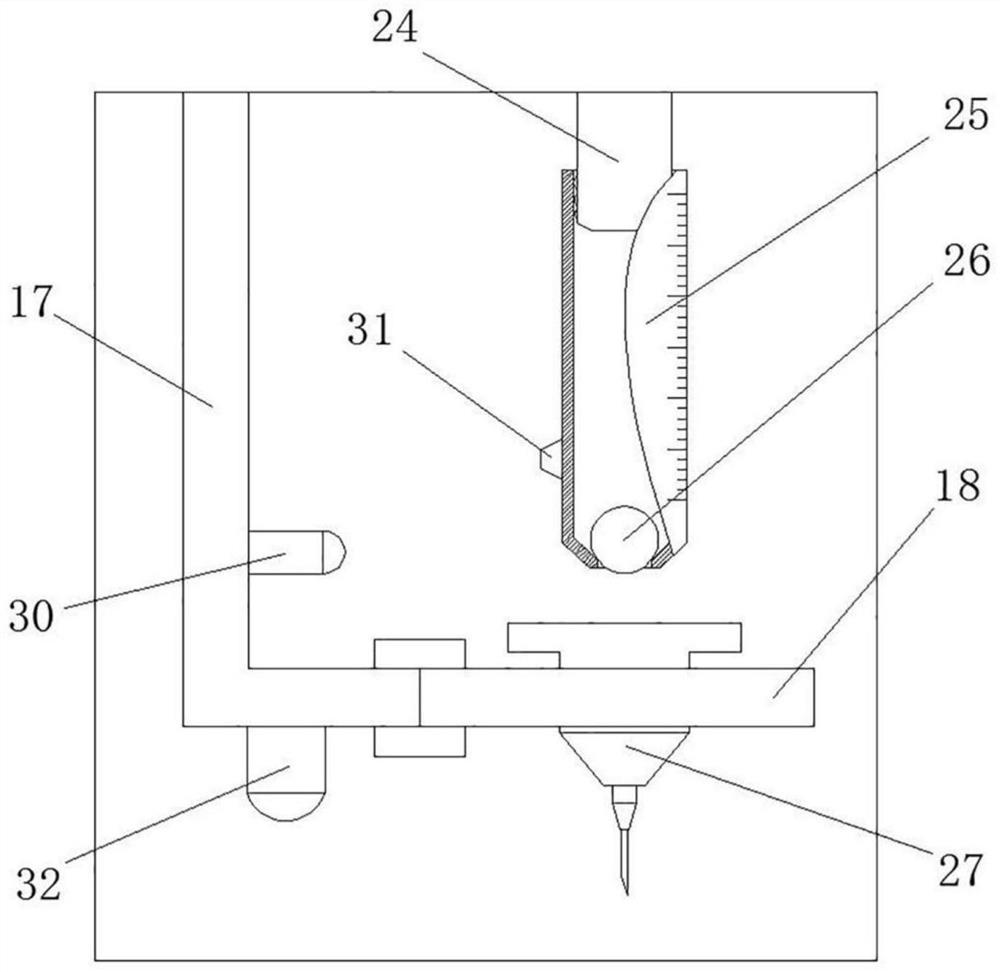

Adjustable meat salting device

ActiveCN108967512AVolume changeControl injection volumeClimate change adaptationMeat/fish preservation using solidsControl systemEngineering

The invention provides an adjustable meat salting device which comprises a conveying device, a salt spraying device and a control system. The salt spraying device comprises a sprayer bracket and at least one sprayer. The sprayer comprises an air inlet pipe, a sleeve, a feeding pipe, a feeding switch and a nozzle. The distance between the air outlet of the air inlet pipe and the orifice of the nozzle is adjustable, a flow adjusting valve is arranged on the air inlet pipe, the feeding switch is arranged on the feeding pipe, the conveying device comprises a conveying line assembly and a rotary lifting tool, the rotary lifting tool rotates passing through a salt spraying area, and the control system can adjust the spraying amount of the sprayer and the moving speed and the rotating speed of the rotary lifting tool, so that the salting amount and the salting uniformity are controlled. The adjustable meat salting device can alleviate labor, salts meat uniformly, and can judge whether the rotary lifting tool entering the salt spraying area has meat or not, so that salt is prevented from being sprayed when the rotary lifting tool is idle.

Owner:JIANGSU UNIV

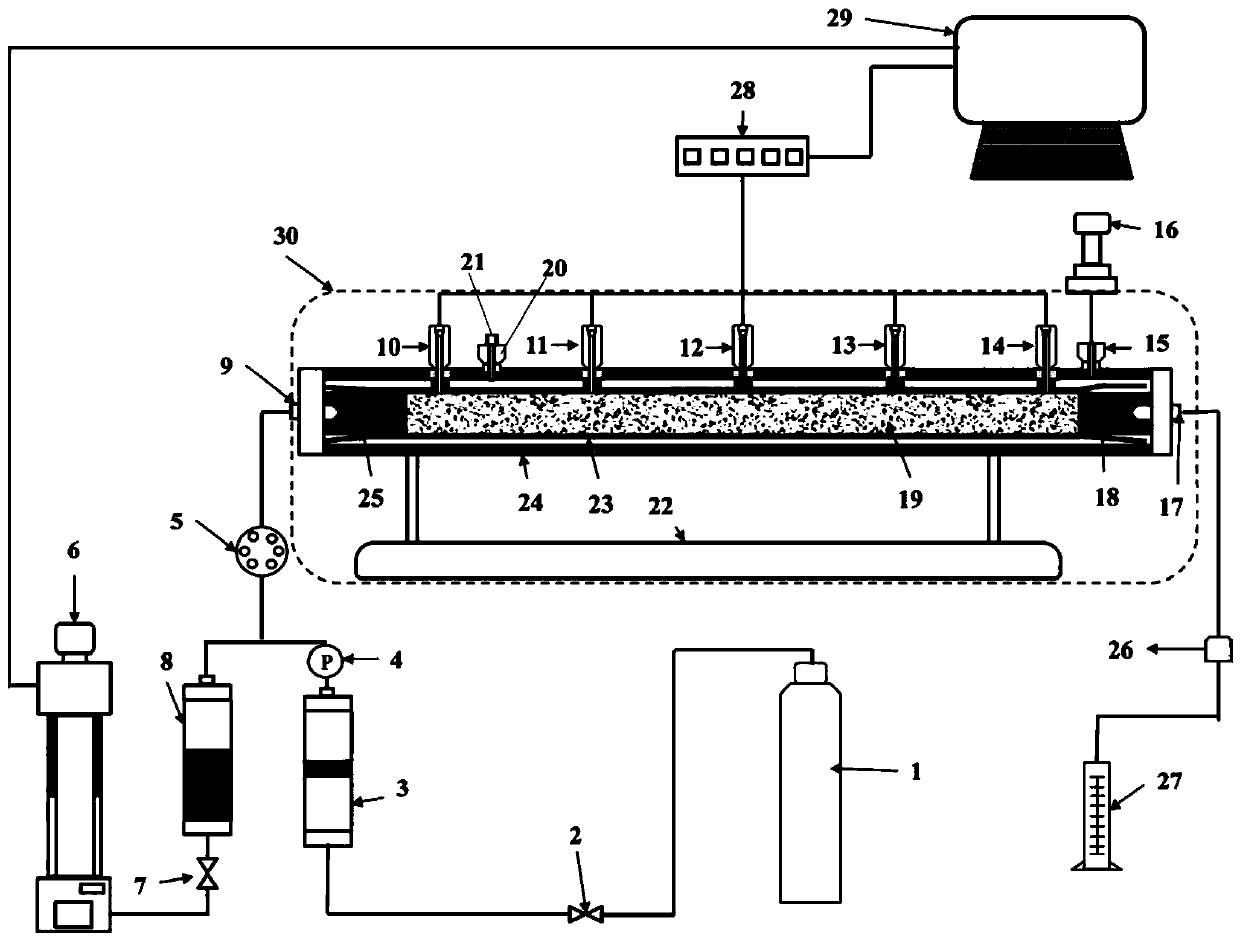

Multi-stage pressure-measuring water-gas alternating oil extraction experimental device and method for CT scanning

PendingCN110924907AFine experimental basisEasy to switchFluid removalCollection systemGeotechnical engineering

The invention discloses a multi-stage pressure-measuring water-gas alternating oil extraction experimental device and method for CT scanning. A core sample is arranged in an inner cavity of a seepagecavity, and a seepage cavity front-plug and a seepage cavity rear-plug are separately arranged at two ends of the core sample; the core sample, the seepage cavity front-plug and the seepage cavity rear-plug are covered with rock covering sleeves, and a seepage cavity injection opening and a seepage cavity liquid discharge outlet are separately formed in two ends of the seepage cavity; a confiningpressure valve and a confining pressure drain valve are arranged on the seepage cavity, and the condensing pressure valve is connected with a liquid injection pump; a water injection system and a gasinjection system are connected with the seepage cavity injection opening, and the seepage cavity liquid discharge outlet is connected with a metering system; and a pressure data collection system comprises a plurality of pressure sensors distributed in the length direction of the core sample, and the pressure sensors are used for detecting pressure at different positions of the core sample. The multi-stage pressure-measuring water-gas alternating oil extraction experimental device and method for CT scanning can be used for evaluating the pressure transmission law of fluid in the rock and the distribution characteristics of remaining oil under the action, and provide an important experimental basis for the design of the process parameters of oil extraction in a mine.

Owner:XI'AN PETROLEUM UNIVERSITY

Robot injection device

PendingCN112604085AWide range of injection anglesInject evenlyAutomatic syringesIntravenous devicesPhysical medicine and rehabilitationJoint injection

The invention relates to ruin rescue equipment, in particular to a robot injection device. The device comprises a pose adjusting mechanism and an injection mechanism; the pose adjusting mechanism comprises a telescopic joint and a coupling joint, and the injection mechanism comprises a pushing joint for controlling the depth of a needle inserted into a body and a dosing joint for controlling the injection amount of liquid medicine in the body. One end of the telescopic joint is installed on the robot, the other end of the telescopic joint is a telescopic end, one end of the coupling joint is connected with the telescopic end of the telescopic joint and driven by the telescopic joint to stretch out and draw back, and the other end of the coupling joint has pitching freedom degree or deflection freedom degree; the pushing joint is installed at the other end of the coupling joint, the output end of the pushing joint is connected with a medicine feeding joint, and the pushing joint and the medicine feeding joint are driven by the telescopic joint and the coupling joint to reach the set position and angle. The device has the characteristics of light weight and modularization of the structure, high injection precision, easiness in installation and replacement and accuracy in operation and control.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

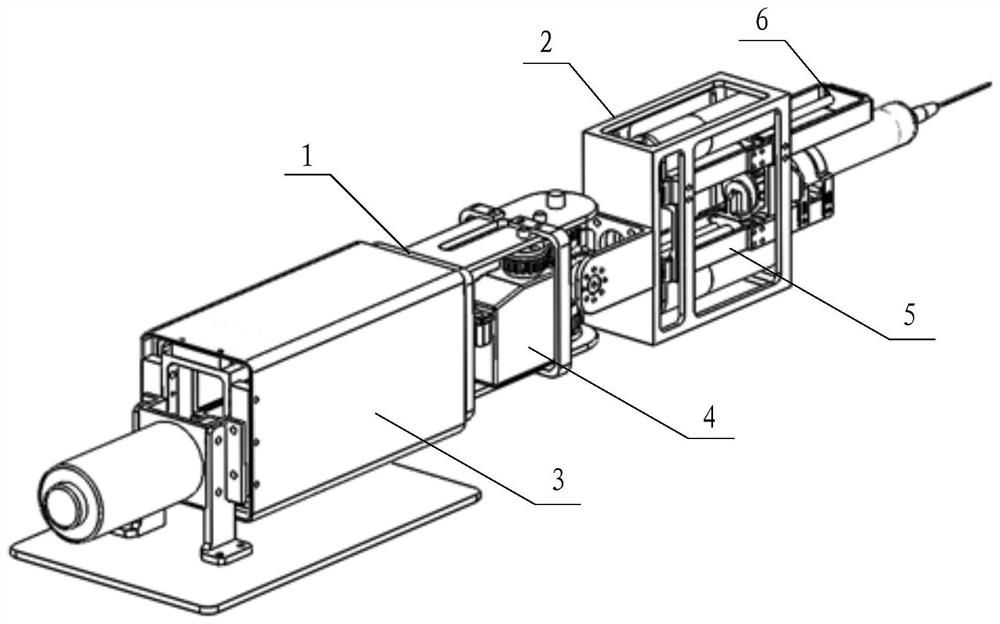

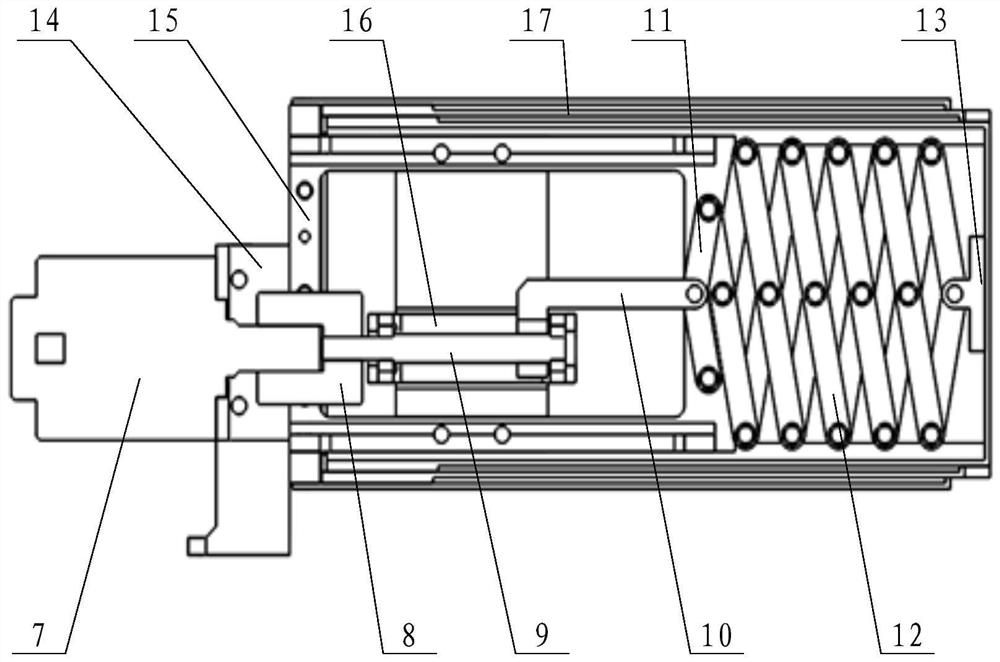

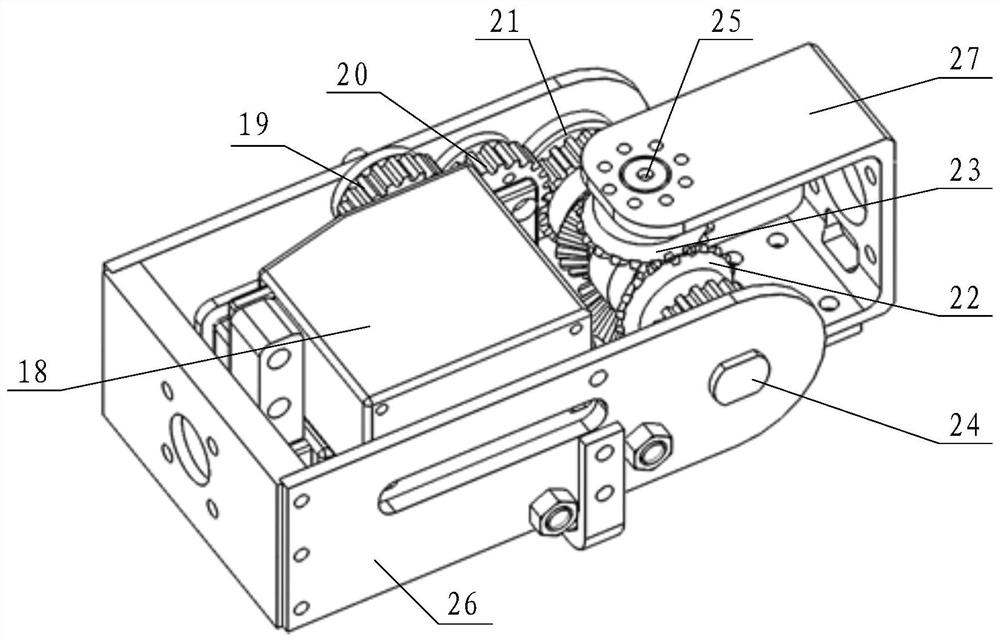

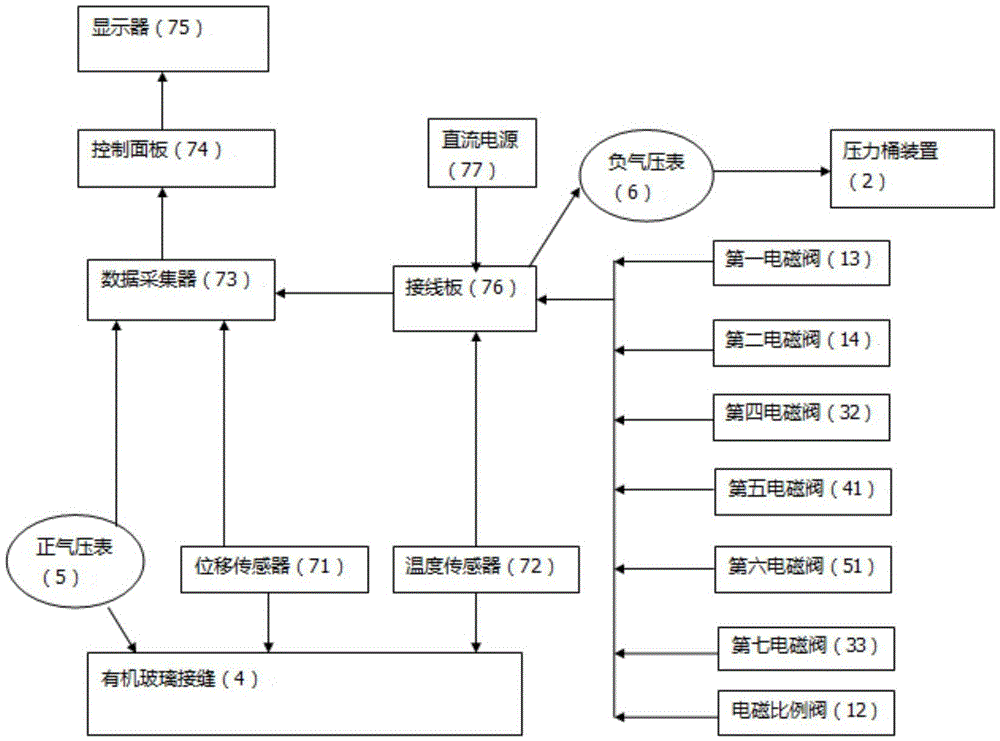

Organic glass seamless polymerization device and method

The invention discloses an organic glass seamless polymerization device and method. The polymerization device comprises a tool construction system, a glue injection system and a control system. The tool construction system comprises a tool clamp used for fixing two pieces of organic glass to be spliced, and a film arranged on the seam of the organic glass. The film is fixed to the surface of the organic glass through the tool clamp. The glue injection system is used for squeezing glue into the seam of the organic glass. The control system is used for controlling the glue injection system to be turned on or off. The tool clamp is adopted for fixing the spliced organic glass and the film, and therefore an environment with the good airtightness is provided for polymerization; a vacuum pump is used for pumping air in a polymerization glue device and a first pipeline, polymerization glue is squeezed out to the seam of the organic glass through inert gas, the automation degree is high, the quality is ensured, the efficiency is high, and the cost is saved.

Owner:SUN YAT SEN UNIV

Work method of navigation system capable of preventing pileup

InactiveCN105180948AAvoid getting lostPrecise positioningInstruments for road network navigationMachines/enginesRear-end collisionControl signal

The invention discloses a work method of a navigation system capable of preventing pileup. The navigation system comprises a navigation device and a plurality of camera devices arranged on the periphery of a vehicle, where the navigation device is installed. The navigation device comprises a processor module, which is connected to the vehicle controller of the vehicle. When the processor module finds out that brake lamp of a vehicle (A), which is in front of the vehicle (B) in the same lane, lights; the processor module sends a brake lamp control signal to the vehicle controller; the vehicle controller controls the brake lamp of the vehicle (B) to light so as to indicate a vehicle (C) behind the vehicle (B) to carry out effective action in time so as to keep a safe distance, thus the vehicle rear-end collision is avoided, so the pileup will not happen, and the traveling safety is guaranteed.

Owner:谢保全

Intelligent injection device

InactiveCN112237495AGuaranteed accuracyEasy to useAutomatic syringesMedical devicesControl engineeringControl theory

The invention discloses an intelligent injection device. The intelligent injection device comprises a base; a stand column is arranged on the base; a main sliding block is slidably connected to the stand column; a control device used for controlling the vertical position of the main sliding block is arranged on the base; a first telescopic rod is arranged on the main sliding block, and one end ofthe first telescopic rod is rotatably connected with a first sliding block; a second telescopic rod is vertically arranged at the other end of the first telescopic rod; a sterilization box for placinga needle head is fixedly arranged on the base; an injection assembly is arranged at the end, away from the first telescopic rod, of the second telescopic rod and comprises a clamping assembly used for clamping the needle head and a driving assembly used for controlling injection; the injection device further comprises a controller used for controlling all the power elements; and an operation screen electrically connected with the controller is arranged on the base. According to the scheme, through the arrangement of the stand column, the main sliding block, the first telescopic rod and the second telescopic rod, the position of the injection assembly can be adjusted in all directions, injection accuracy is guaranteed, the using effect is improved, and practicability is high.

Owner:湖南谨航科技开发有限公司

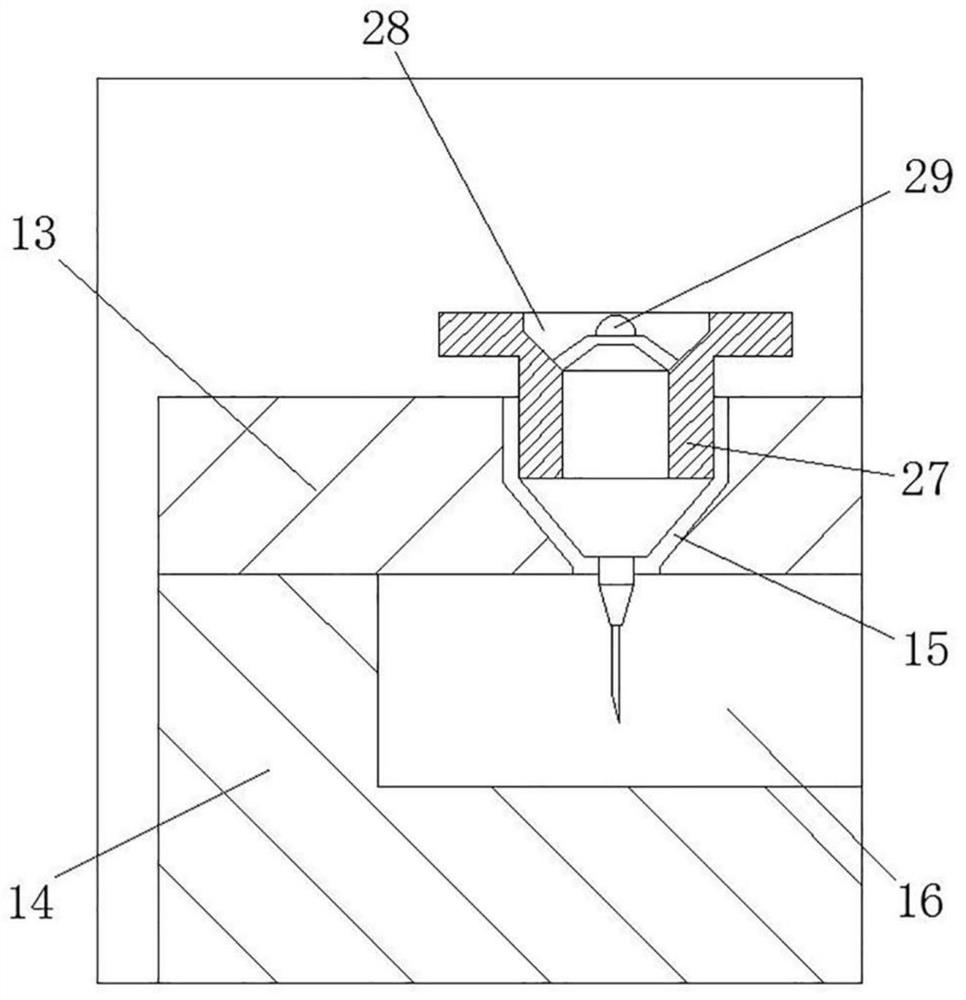

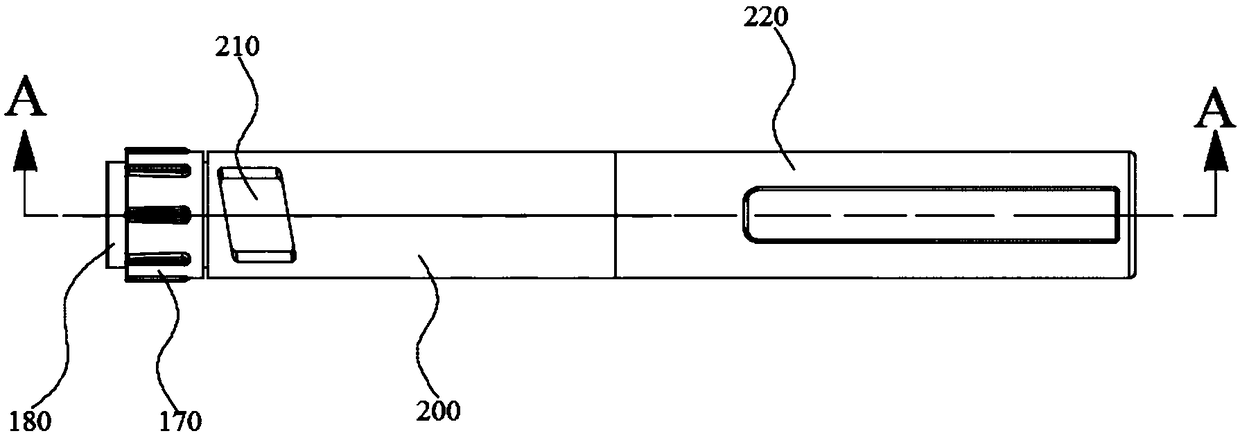

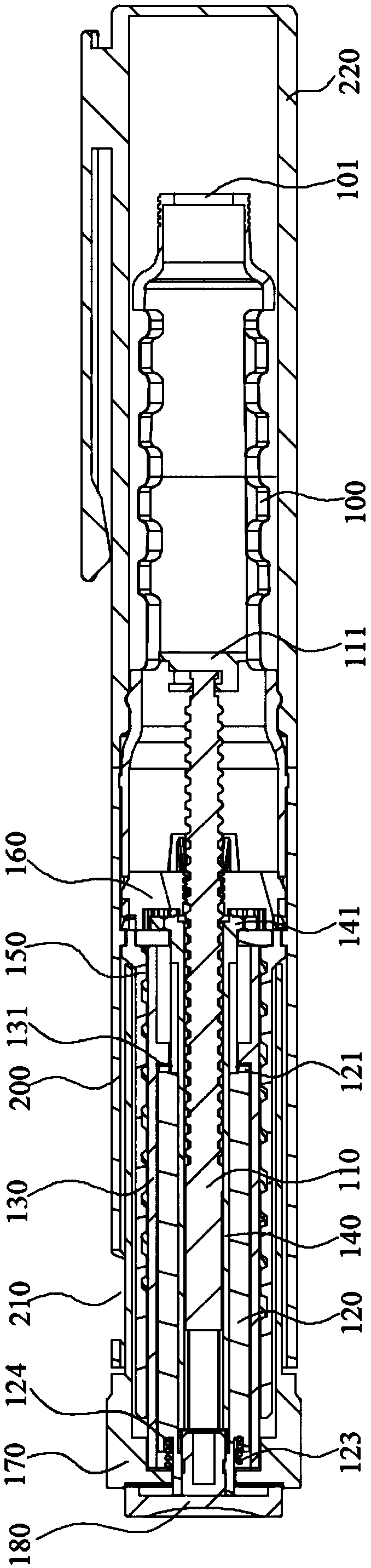

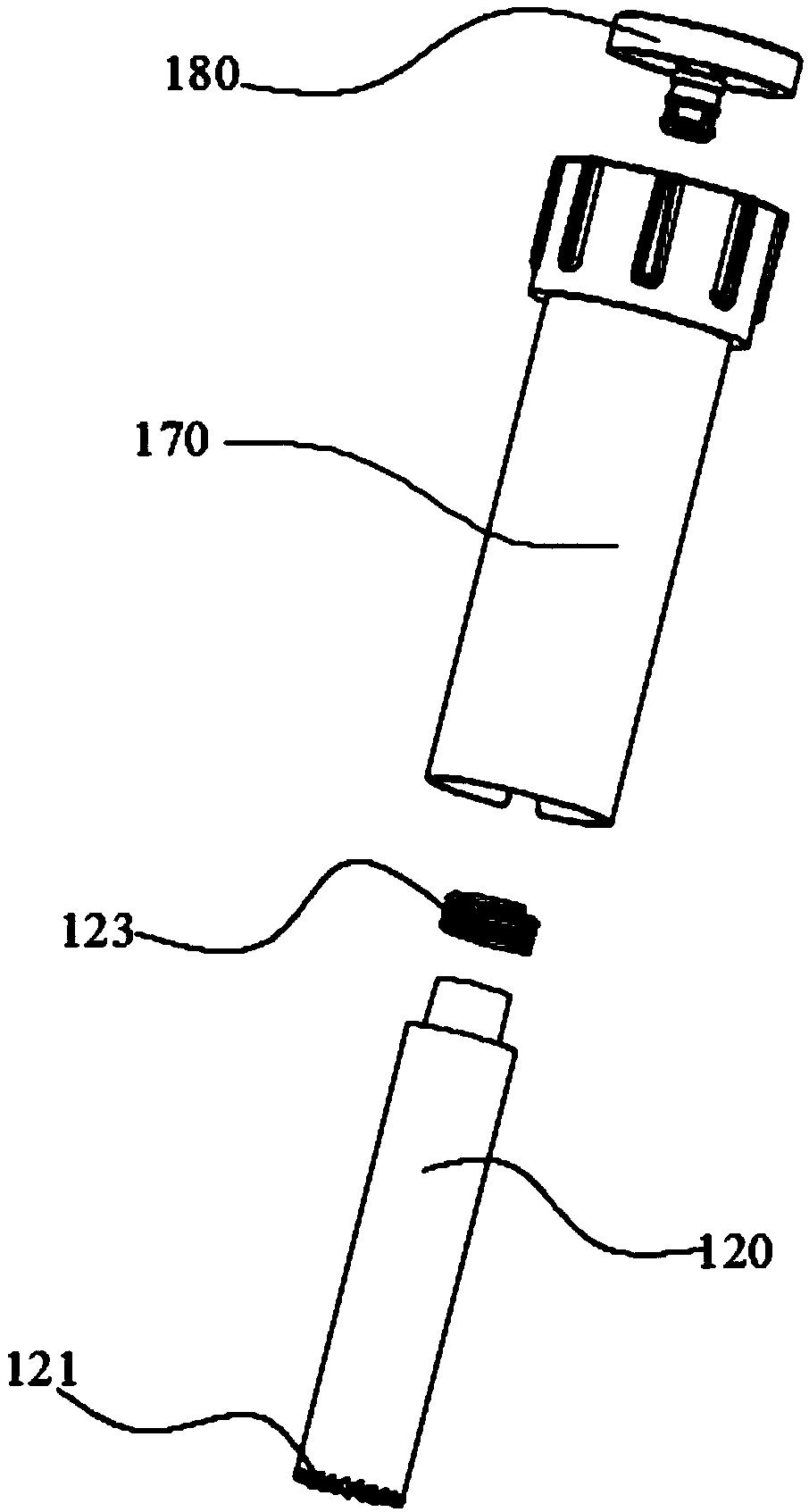

Injection device and injection device assembly

PendingCN109395205AControl injection volumeMeet the needs of useInfusion syringesIntravenous devicesEngineeringInjection device

The invention relates to an injection device and an injection device assembly, and belongs to the field of injection devices. The injection device comprises a loading bin, a screw, a push rod rotatingbarrel and a push barrel, wherein the loading bin is provided with at least one discharging outlet, the push rod rotating barrel can move in the direction close to or away from the loading bin, and the push barrel is provided with a linkage pulling ring. The screw is configured to move in the straight line direction so as to discharge materials in the loading bin from the discharging outlets, thepush barrel is configured to drive the linkage pulling ring to rotate in the first direction when the push rod rotating barrel moves towards the direction close to the loading bin, and the linkage pulling ring is configured to drive the screw to move in the straight line direction when rotating in the first direction. The injection device can precisely control the injection amount of the materials to meet the needs of use. The invention further provides the injection device assembly comprising the injection device.

Owner:JIANGSU WANHAI MEDICAL INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com