Electric point gum machine and working way thereof

A technology of dispensing device and working method, which is applied to the device and coating of surface coating liquid, which can solve the problems of unstable working pressure of compressed air, fluctuation of fluid injection speed, difficulty in increasing injection speed, etc., and achieve mobile The effect of constant speed, increased injection speed, and stable rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

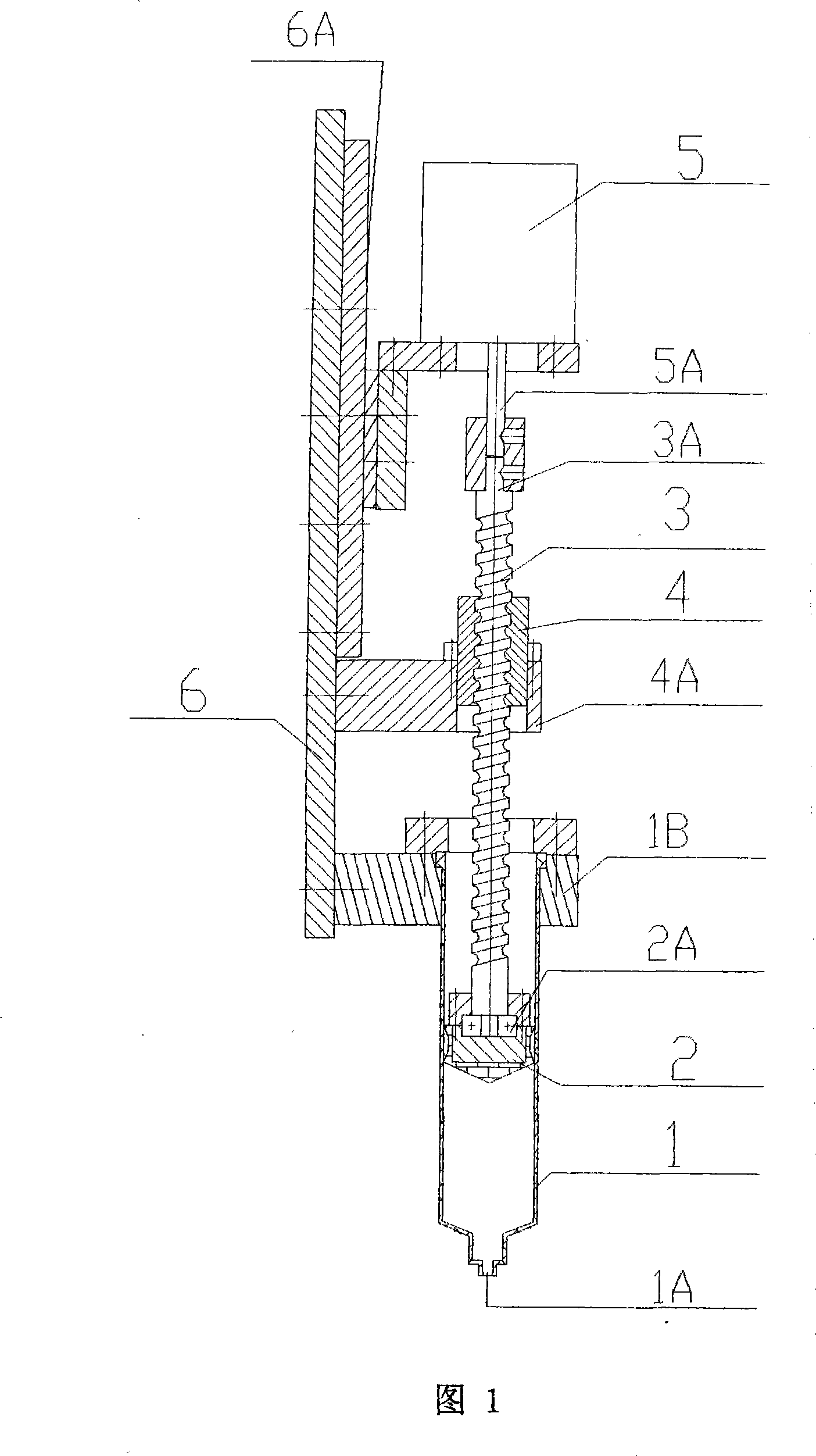

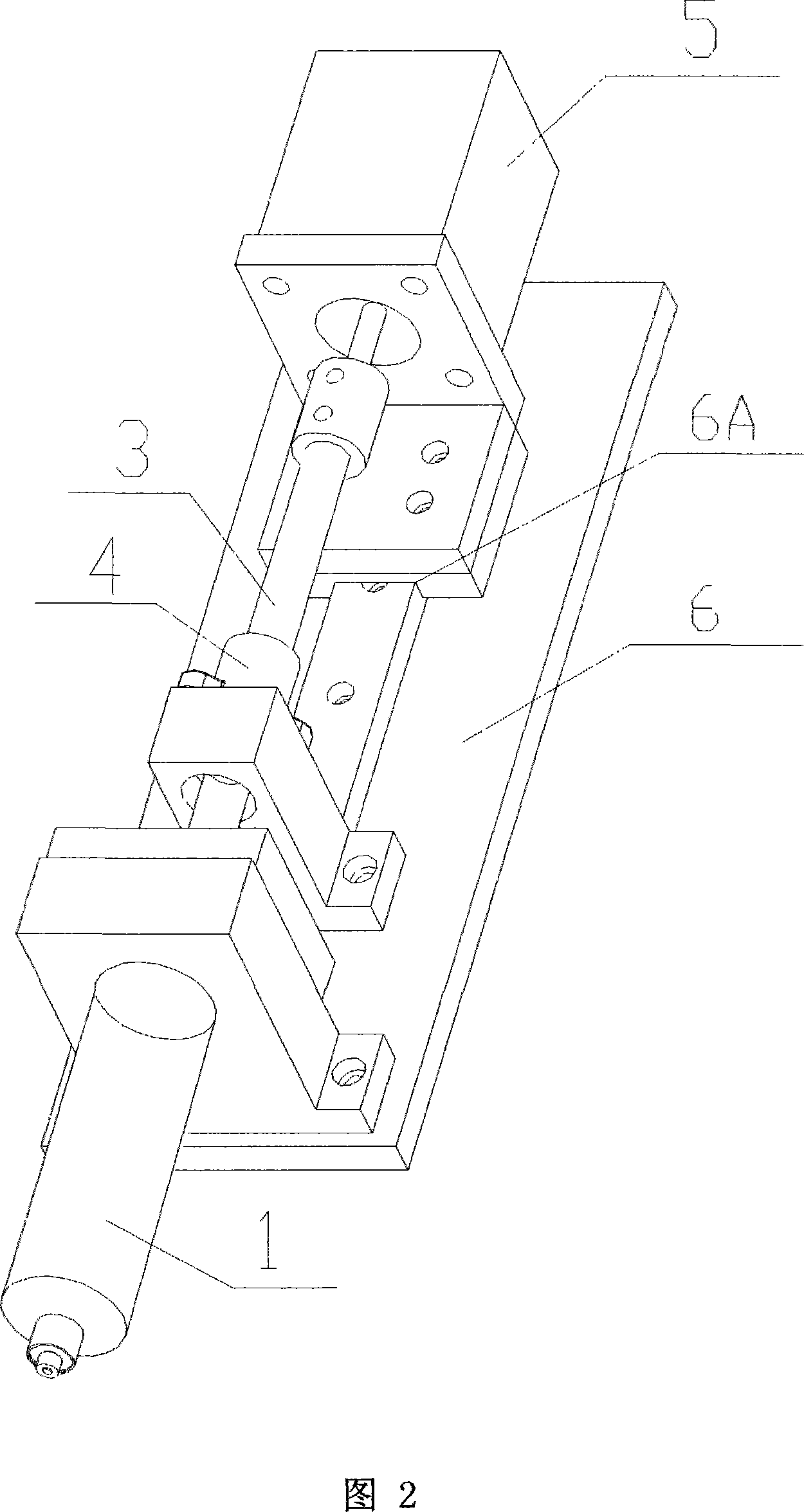

[0030] Figure 1 and Figure 2 are a front view and a perspective view of Embodiment 1 of an electric dispensing device, respectively.

[0031] It can be seen from the above figure that the injection barrel 1 for storing liquid has a discharge port 1A in the center of the bottom end of the barrel, and the barrel 1 is fixed on the lower part of the connection base 6 through the mounting plate 1B. The injection barrel 1 is provided with a pusher piston 2, and the piston 2 can slide up and down in the barrel 1 to squeeze the liquid in the barrel 1 or suck the liquid outside the barrel 1. A bearing 2A is installed inside the pushing piston 2, and the piston 2 is connected to the lower end of the transmission screw 3 through the bearing 2A, and the screw 3 can rotate relative to the piston 2. The fixed nut 4 used in conjunction with the screw rod 3 is installed on the middle and lower part of the base 6 through the connecting plate 4A, the position of the nut 4 relative to the barrel...

Embodiment 2

[0047] Fig. 5 is a front view of Embodiment 2 of the electric dispensing device.

[0048]As can be seen from the figure, its main difference with Embodiment 1 is: the structure of the pushing piston 2 is different, and it has been changed into a plunger type. The connection between the piston 2 and the transmission screw rod 3 is also different. The top of the piston 2 has an external thread and is screwed into the bottom of the bearing seat 2B. The piston 2 is connected to the lower end of the screw rod 3 by the bearing 2A in the bearing seat 2B.

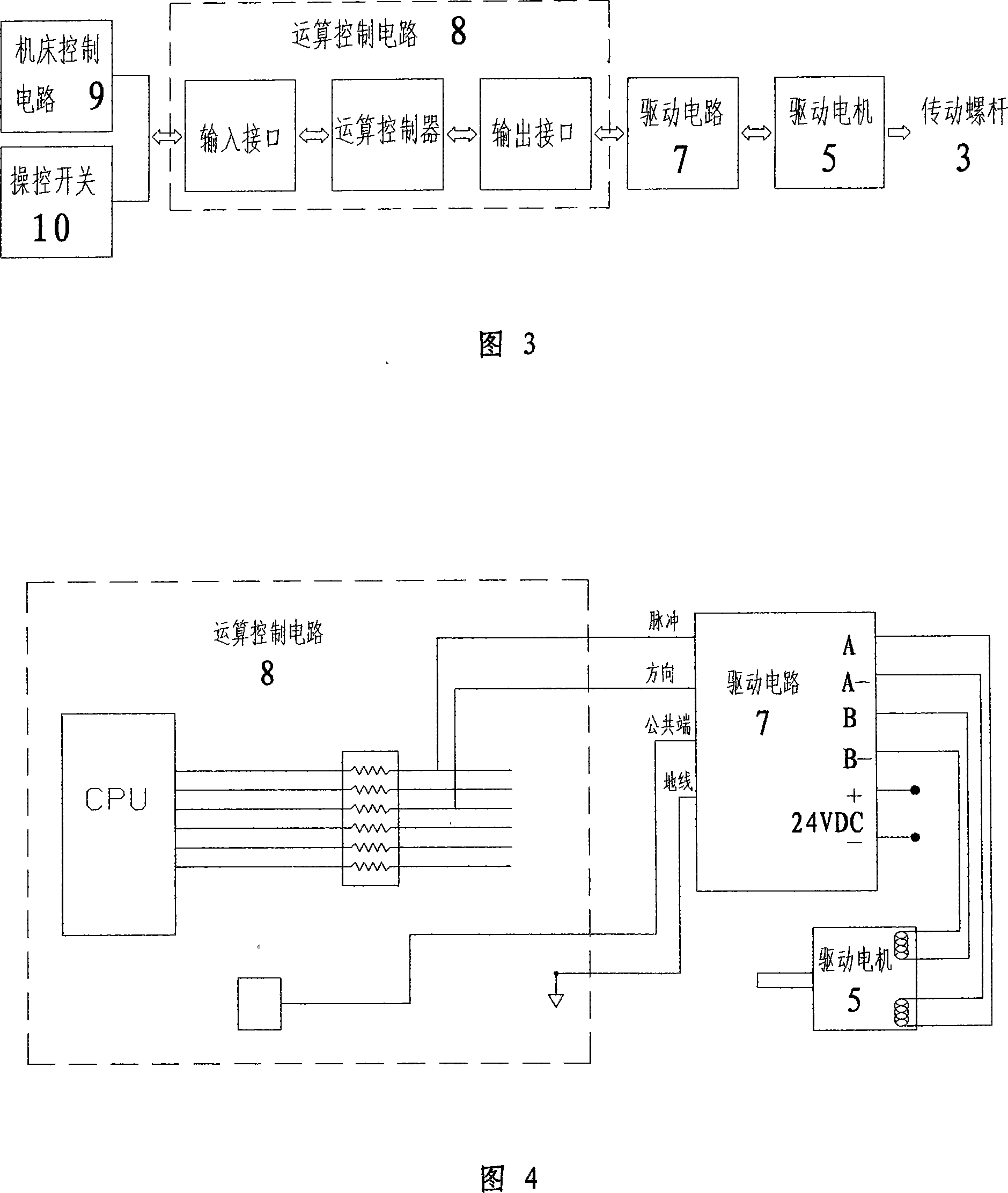

[0049] The electric dispensing device of the present invention can be realized by manipulating the switch 10,

[0050] 1. Burst:

[0051] Press the button to start the injection, and the injection will not end until the button is released.

[0052] Press the button to start the injection, and the injection will not end until the preset cycle time.

[0053] 2. Continuous shooting:

[0054] Injection starts when a start signal is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com