Injection mouth and vertical plastic injection forming machine injection head

An injection molding machine and injection head technology, applied in the field of plastic injection molding machinery design, can solve the problems of material leakage, economic loss of the owner, leakage of fluid materials, etc., and achieve the effect of preventing material leakage and facilitating the injection volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Example 1, injection nozzle)

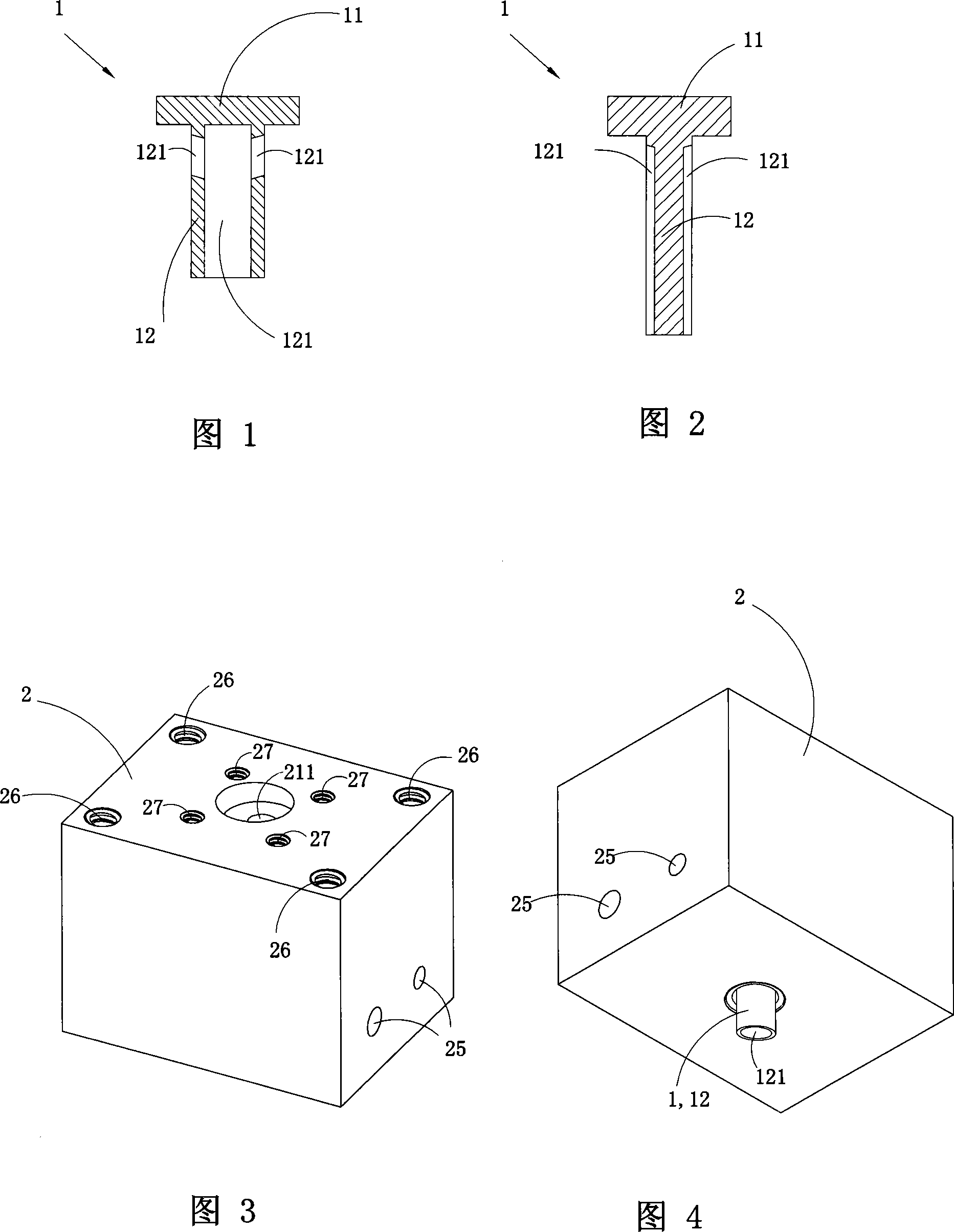

[0031] Fig. 1 is a cross-sectional schematic view of the first structure of the injection nozzle of the present invention, showing the first embodiment of the injection nozzle of the present invention.

[0032] See Fig. 1, the basic shape of this kind of injection nozzle is a T shape with a large top and a small bottom, the upper part is a sealing part 11, and the lower part is a discharge part 12; the discharge part 12 is provided with a discharge channel 121. The discharge channel 121 in the injection nozzle 1 is a Y-shaped channel arranged vertically on the discharge part 12, and the vertical part of the lower part of the Y-shaped channel is arranged at the center of the discharge part 12. In the round hole, the two branches on the upper part of the Y-shaped channel pass through the discharge part 12 .

Embodiment 2

[0033] (Example 2, injection nozzle)

[0034] Fig. 2 is a schematic cross-sectional view of the second structure of the injection nozzle of the present invention, showing the second embodiment of the injection nozzle of the present invention.

[0035] See Fig. 2, this embodiment is basically the same as Embodiment 1, the difference is: the shape and position of the discharge passage 121 of the discharge part 12 are different, and the discharge passage 121 of the present embodiment is arranged along the vertical direction Grooves on the outer surface of the discharge part 12.

Embodiment 3

[0036] (Embodiment 3, injection head)

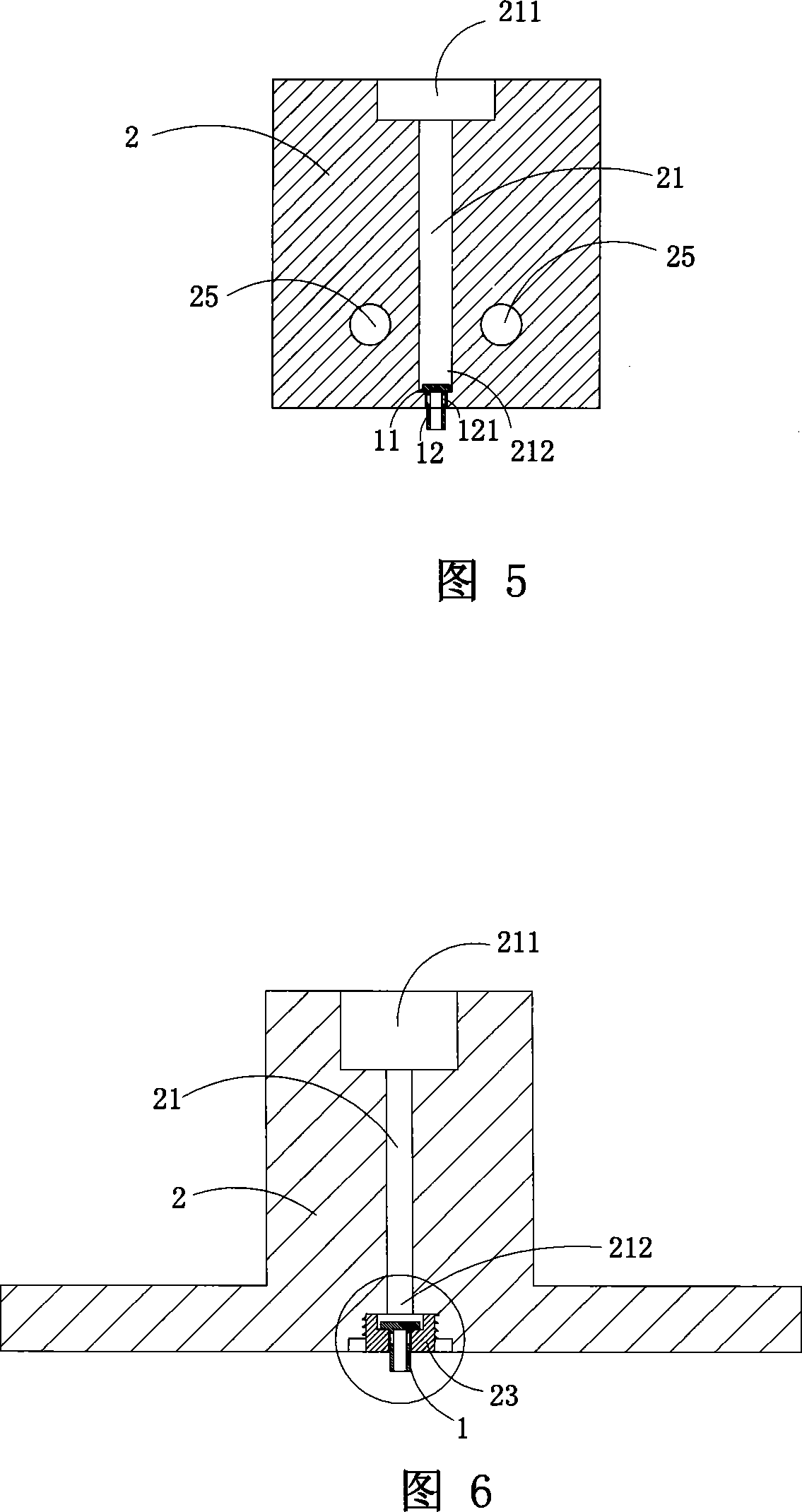

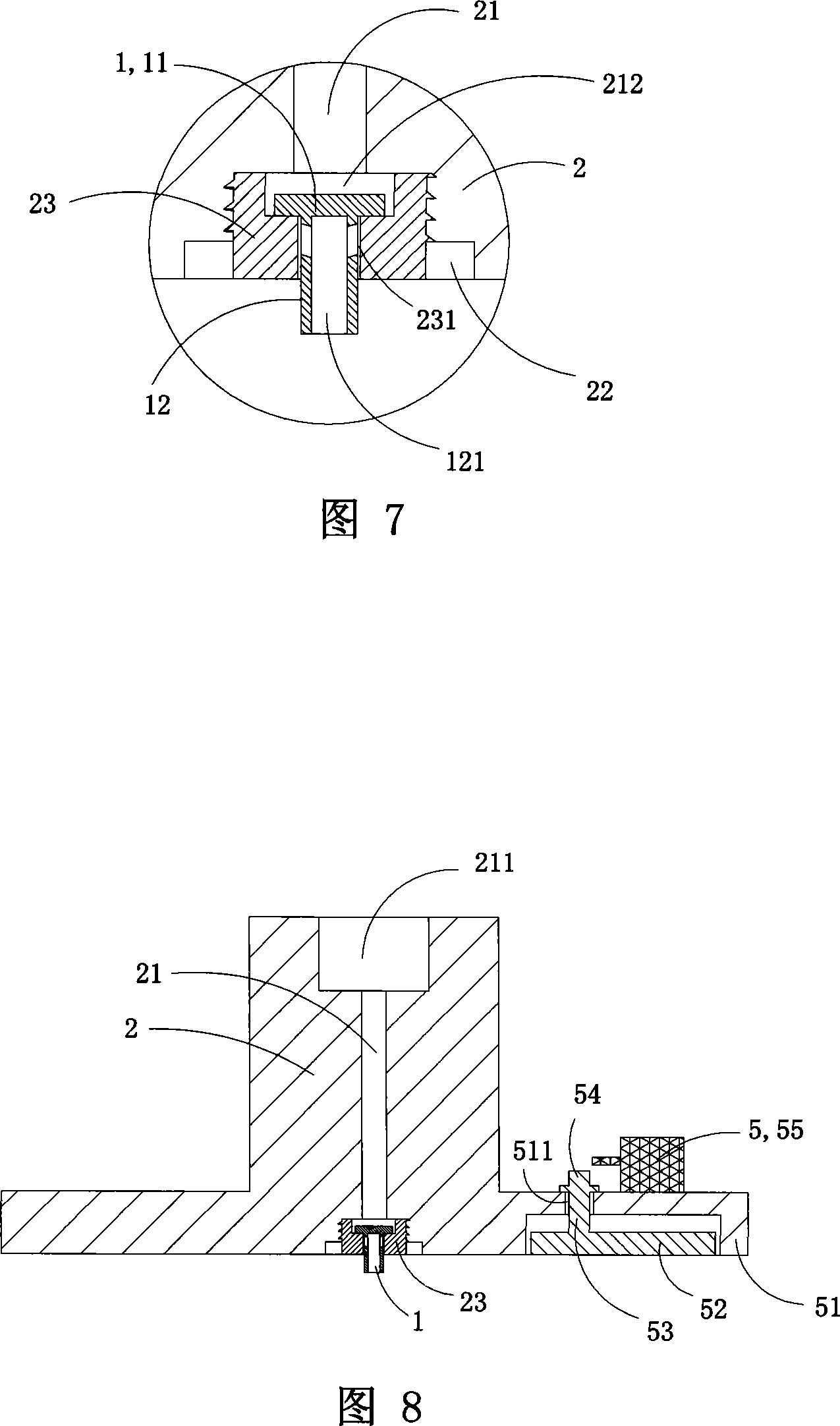

[0037] Figures 3 to 5 show the first embodiment of the injection head of the present invention, wherein Figure 3 is a schematic perspective view of the first structure of the injection head of the present invention. Fig. 4 is a schematic perspective view of the three-dimensional structure of the injection head shown in Fig. 3 viewed from another angle. Fig. 5 is a cross-sectional view of the injection head shown in Fig. 3 .

[0038] This embodiment is an injection head for a vertical plastic injection molding machine, the injection head body 2 is provided with a material injection channel 21, the material inlet 211 and the material injection port 212 of the injection channel 21; The feed port 211 of the injection head body is located at the top of the injection head body 2 , and the material injection port 212 is located at the bottom end of the injection head body 2 .

[0039] The injection nozzle 1 that can inject material and preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com