Patents

Literature

355results about How to "Volume change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

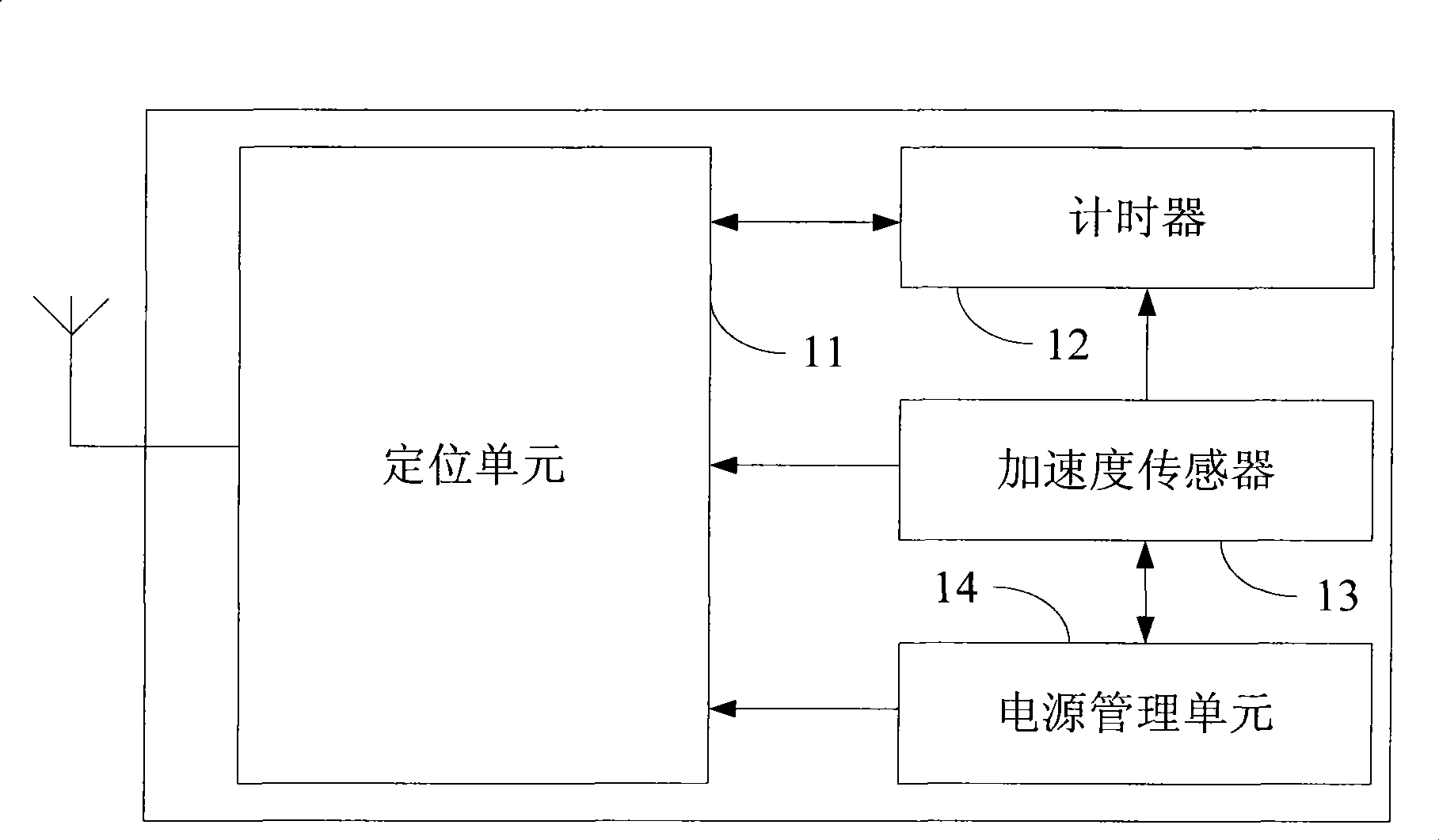

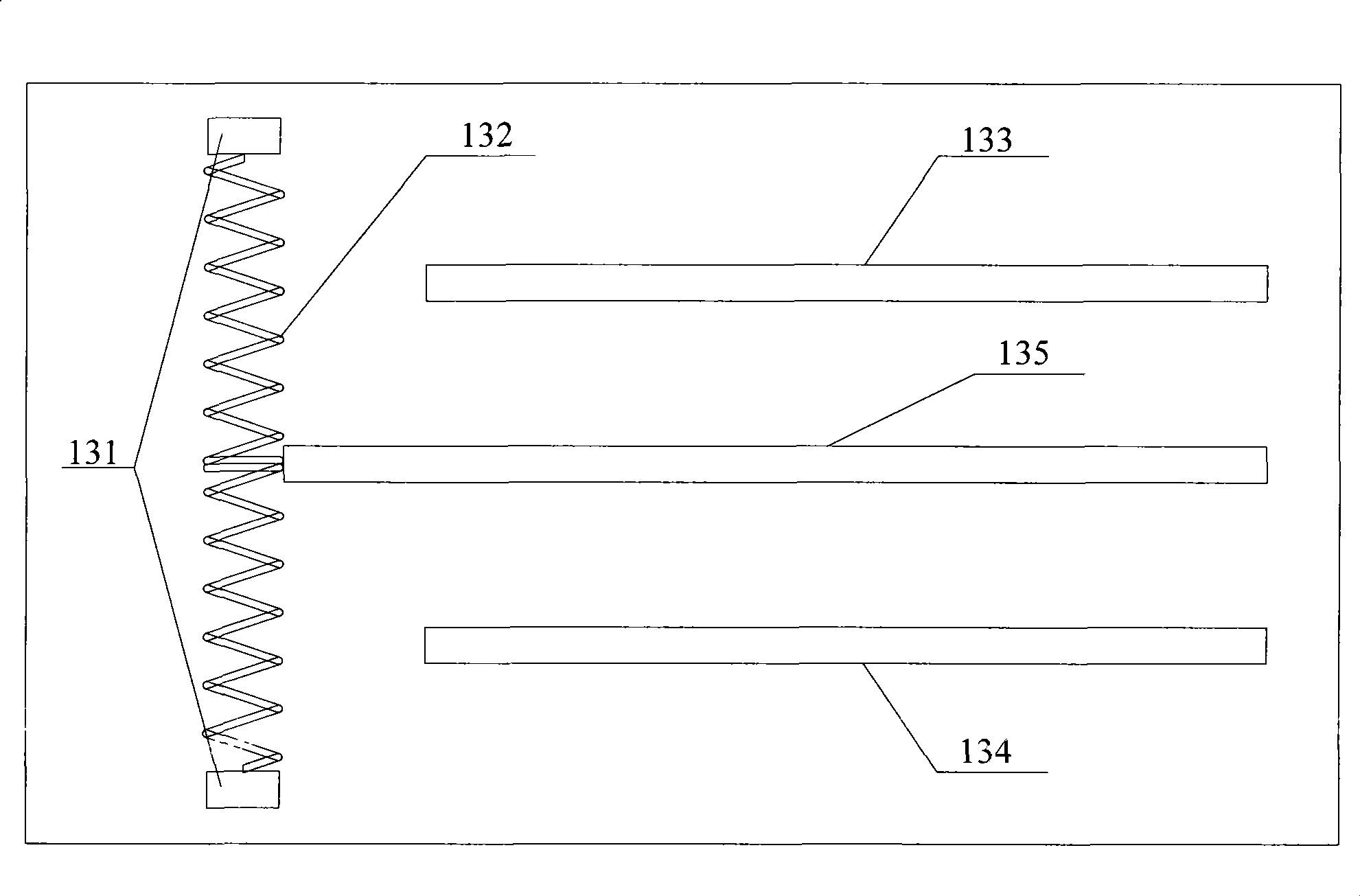

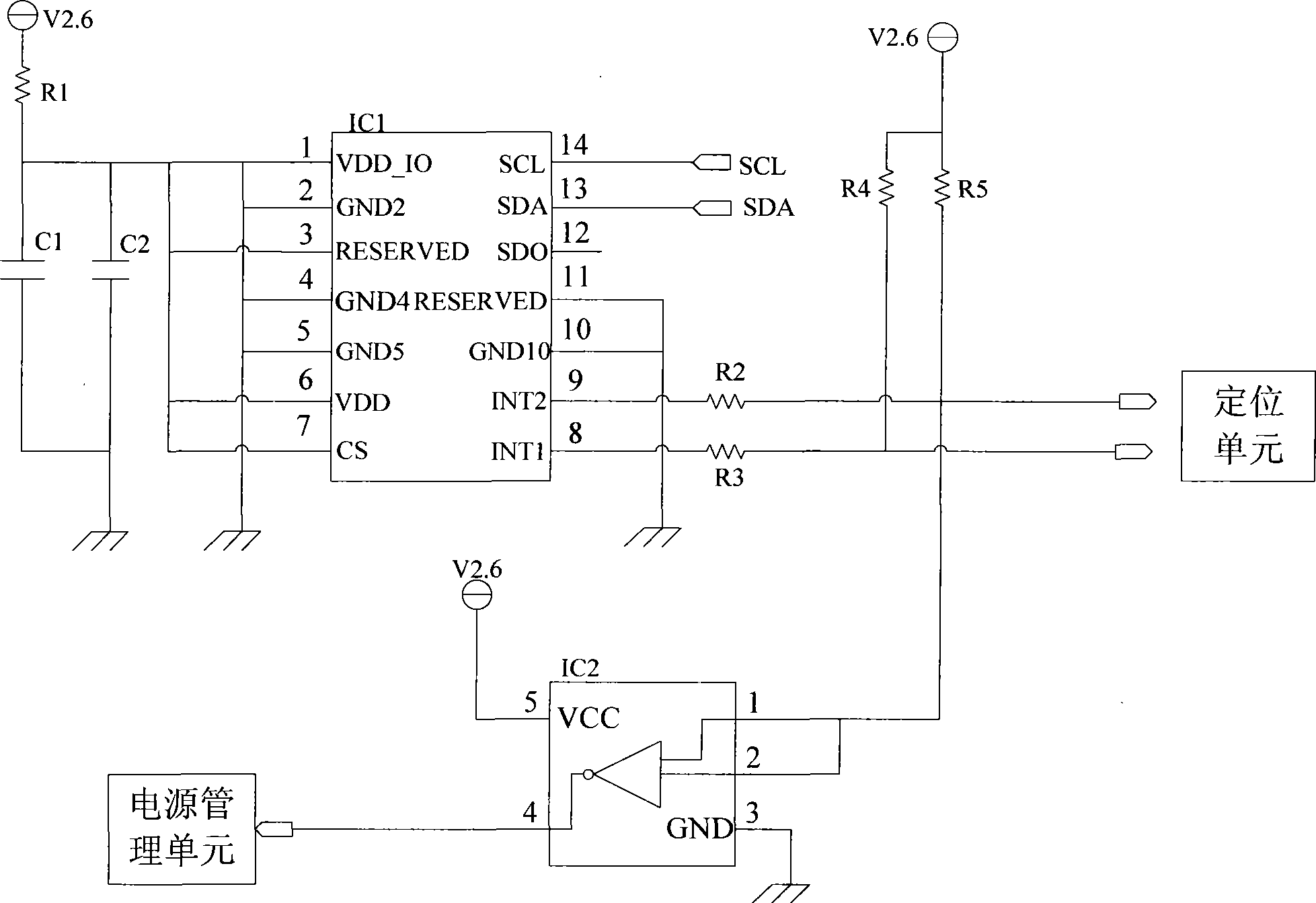

Energy consumption control method for positioning terminal and positioning terminal applying the method

InactiveCN101365197AReduce energy consumptionExtend standby timeCurrent supply arrangementsRadio/inductive link selection arrangementsWork periodSleep state

The invention discloses a method for controlling the power consumption of a positioning terminal. The method comprises the following steps: a. determining whether the position change of the positioning terminal occurs in a preset time, if yes, resetting the timer, and if not, carrying out step b; b. entering a sleeping state of the positioning terminal. Due to the definition of the actual working time to the positioning terminal in the invention, when the position of the positioning terminal is not changed, stopping the positioning operation so as to reduce the power consumption; and when the position of the positioning terminal is changed again, triggering the terminal to return to the working state so as to greatly reduce the power consumption on the premise that the positioning operation is not delayed, thereby greatly prolonging the stand-by time. The invention also discloses a positioning terminal.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

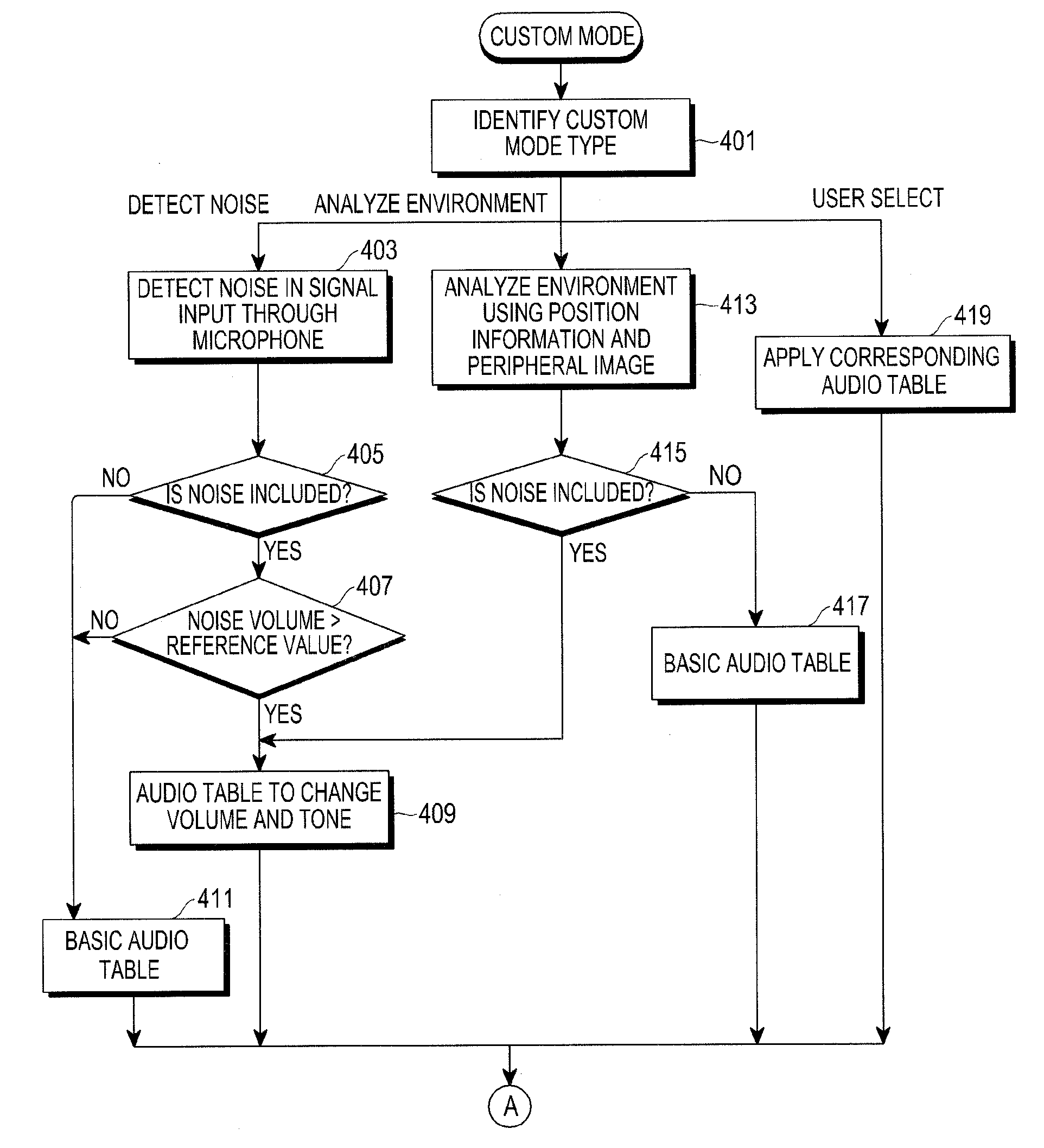

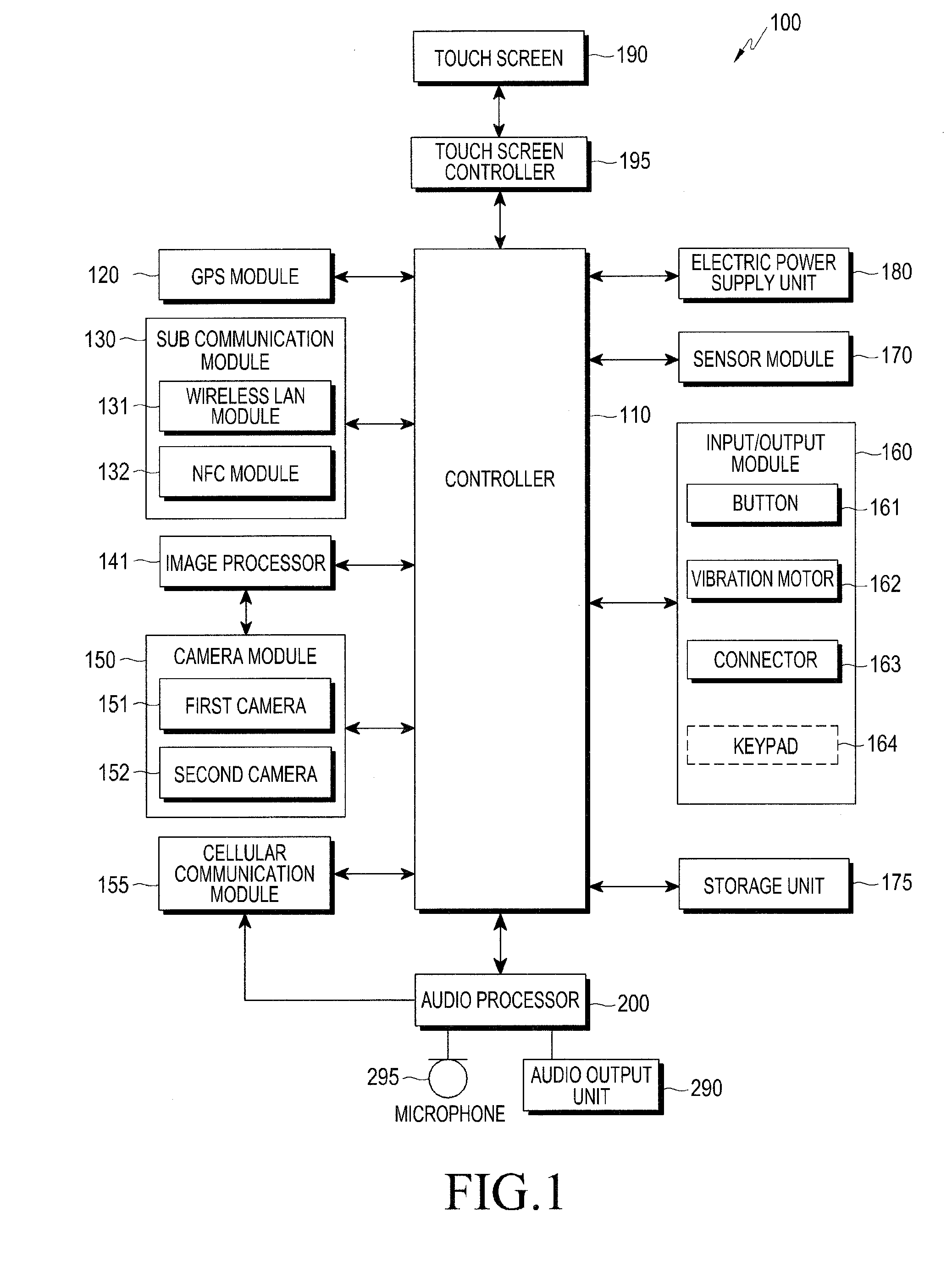

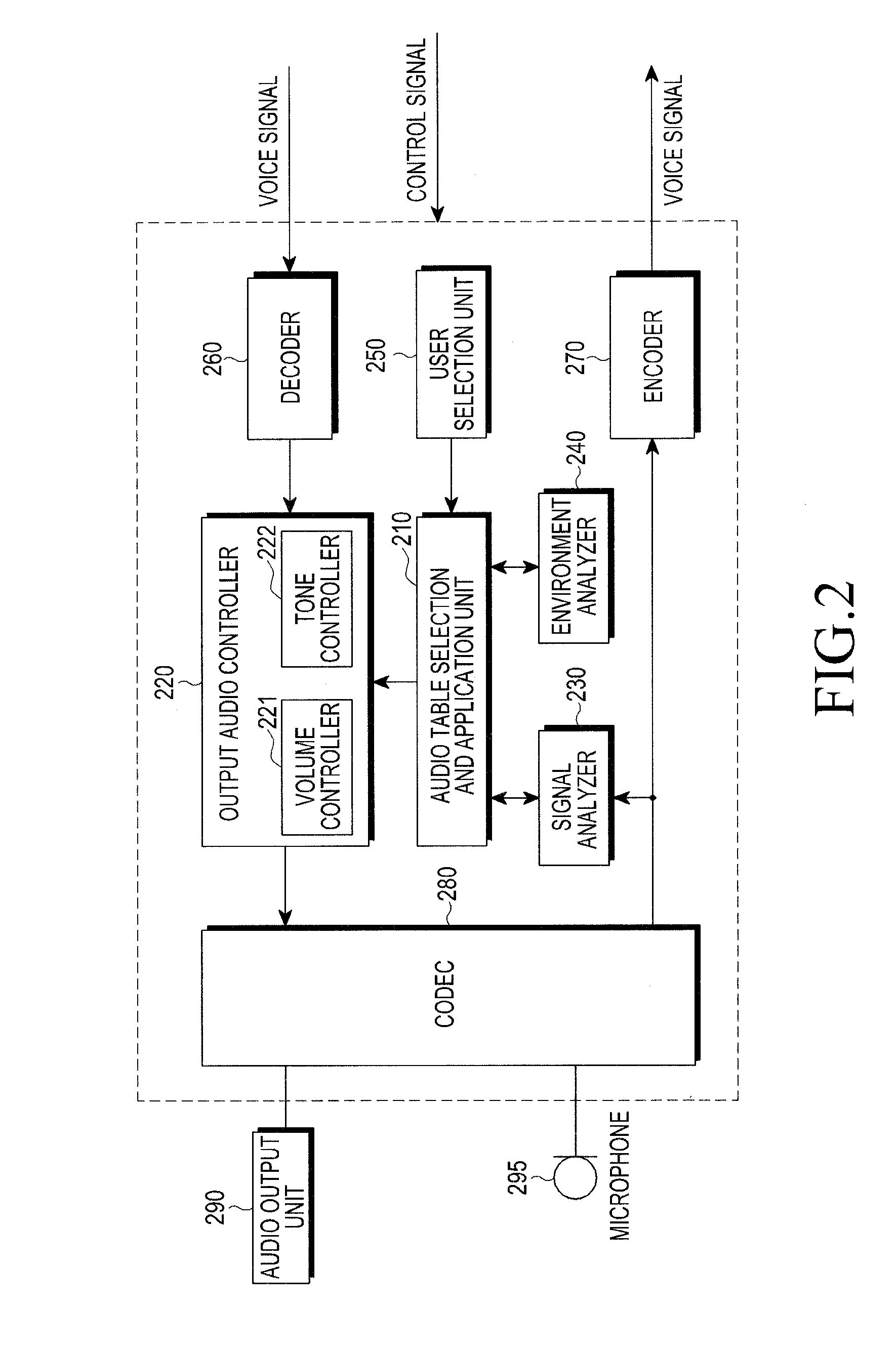

Apparatus and method for outputting audio

ActiveUS20130287215A1Volume changeManually-operated gain controlSubstation equipmentAudio frequencySpeech sound

An apparatus and method for outputting audio signals of a portable communication device are provided. The apparatus includes a plurality of audio tables including different volume control values or tone control values, and allows a user to selectively set audio tables corresponding to each of audio paths equipped with the portable communication device. Further, the apparatus analyzes a surrounding environment during a voice call, determines the absence or presence of noise, and suitably controls a volume or a tone of audio signals based on the result of the determination before outputting the audio signals. Accordingly, the apparatus can provide an improved calling condition in various calling environments.

Owner:SAMSUNG ELECTRONICS CO LTD

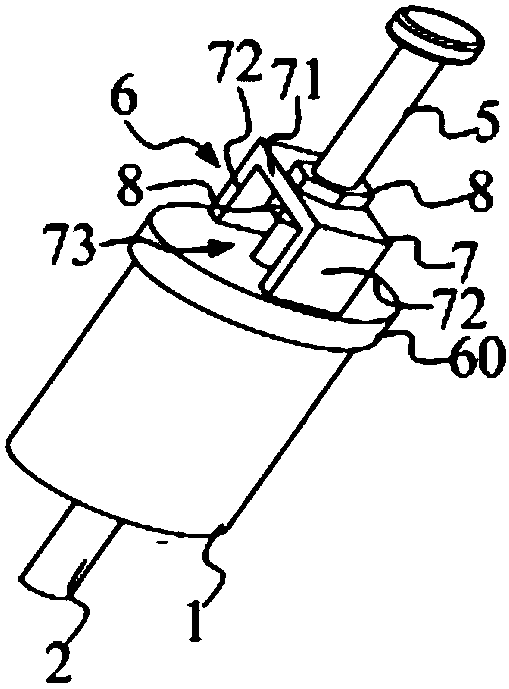

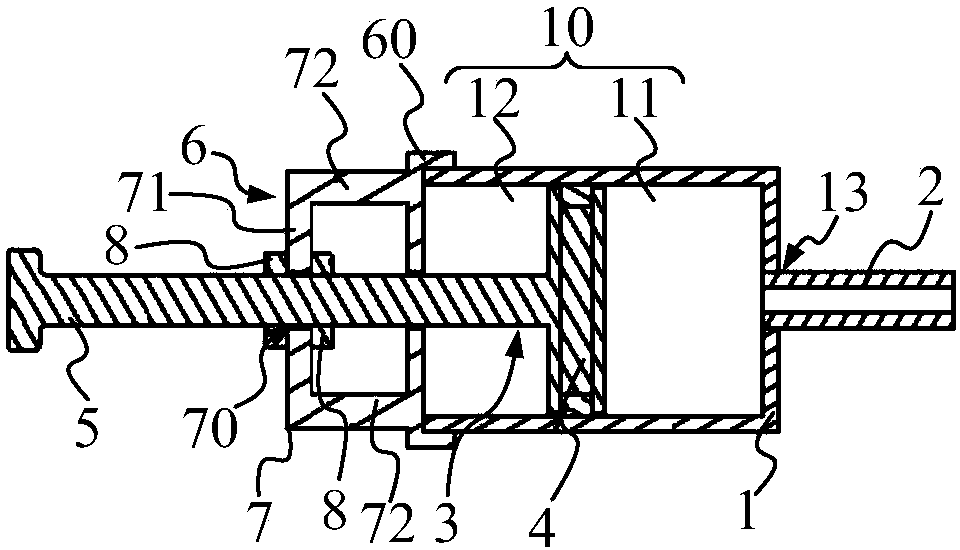

Helmholtz silencer for automobile air inflow and exhaust debugging

The invention relates to a helmholtz silencer for automobile air inflow and exhaust debugging. The helmholtz silencer comprises a shell with a silencing cavity and a connecting pipe located outside the silencing cavity and communicating with the silencing cavity; the helmholtz silencer further comprises an adjusting part, wherein the adjusting part is provided with a plurality of adjusting positions, and the silencing cavity has different volumes correspond to the multiple adjusting positions; and / or, the shell is detachably connected with the connecting pipe so as to replace the connecting pipes with different lengths and / or different inner diameters. According to the technical scheme, frequency of the silencing cavity can be changed according to needs by utilizing a helmholtz silencer, aplurality of helmholtz silencer samples do not need to be manufactured, and optimal noise eliminating frequency is locked, therefore, manufacturing cost can be saved, the development time period canbe shortened, and cost for air inflow and exhaust debugging can be reduced.

Owner:SAIC MOTOR

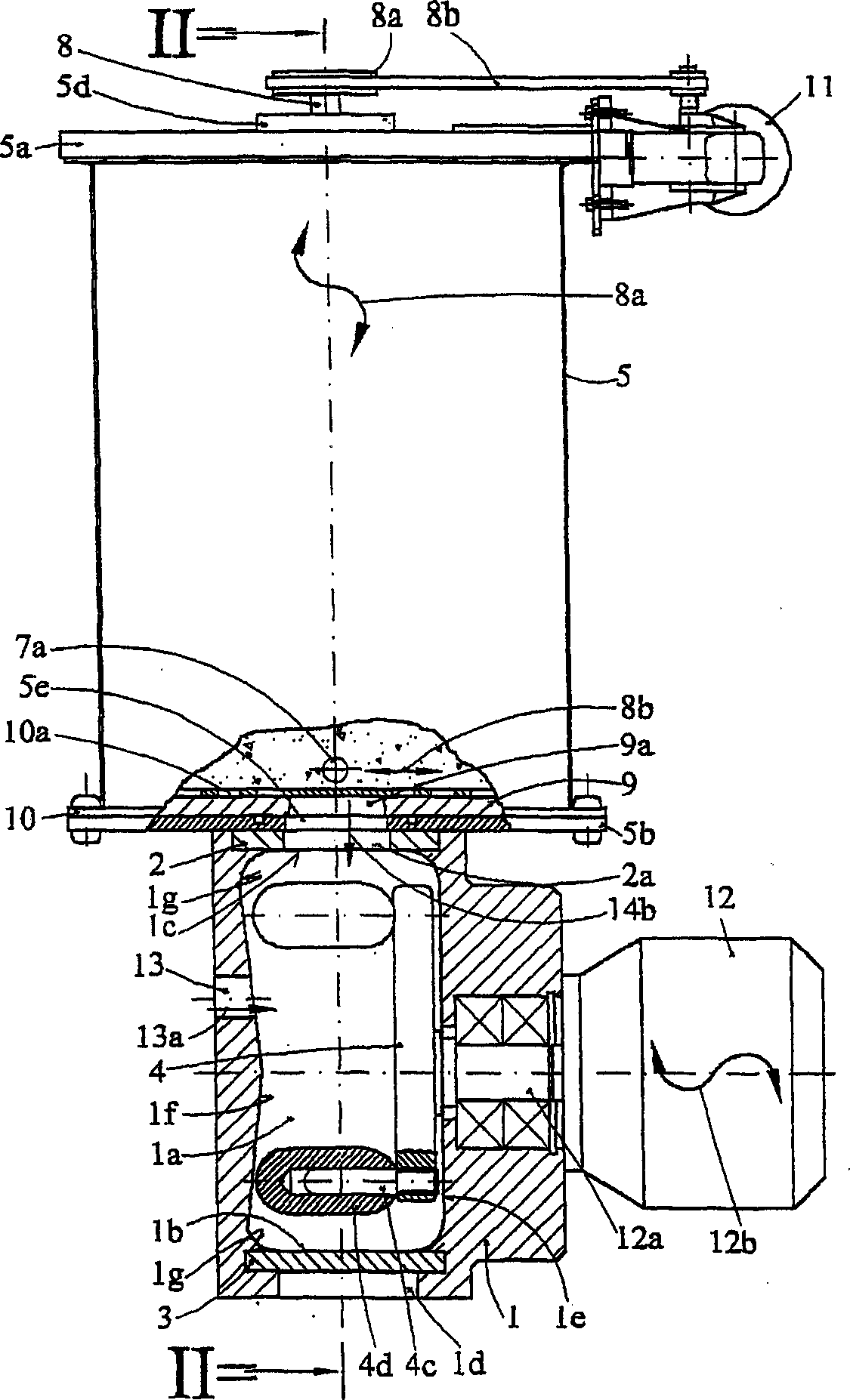

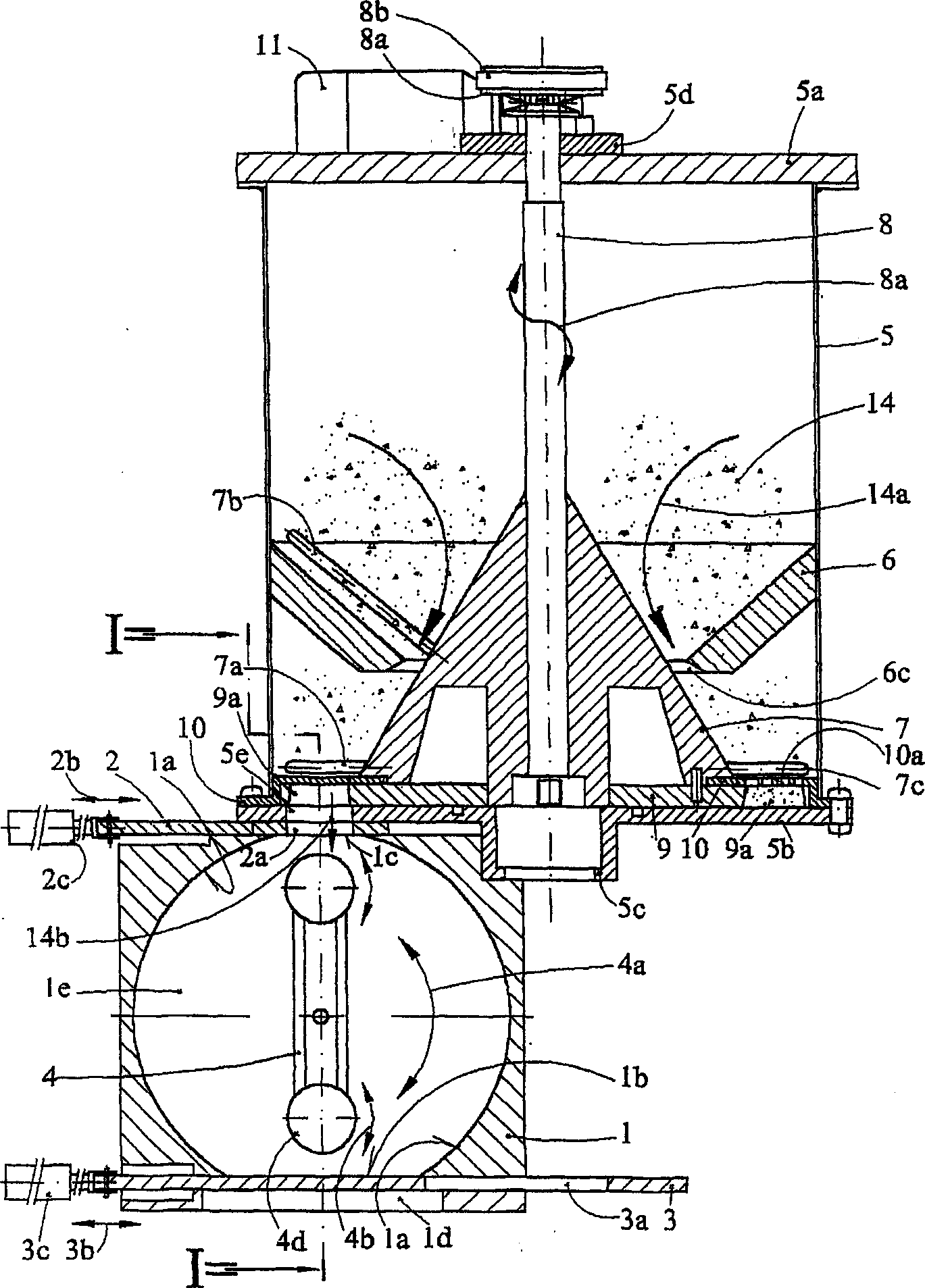

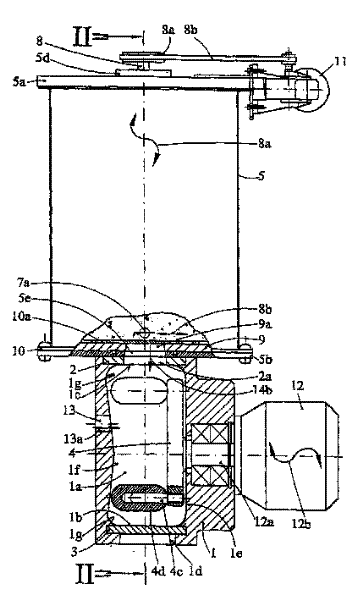

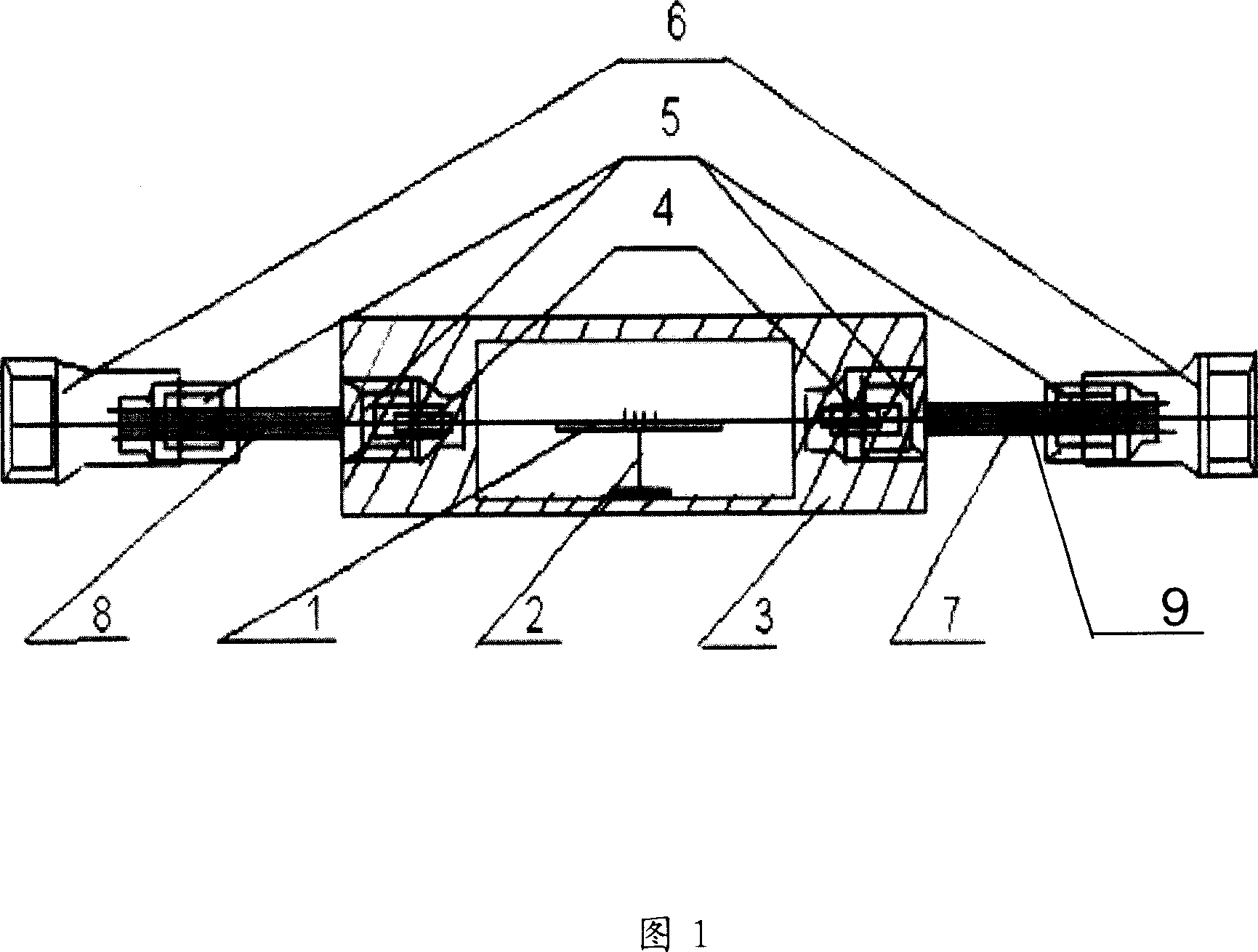

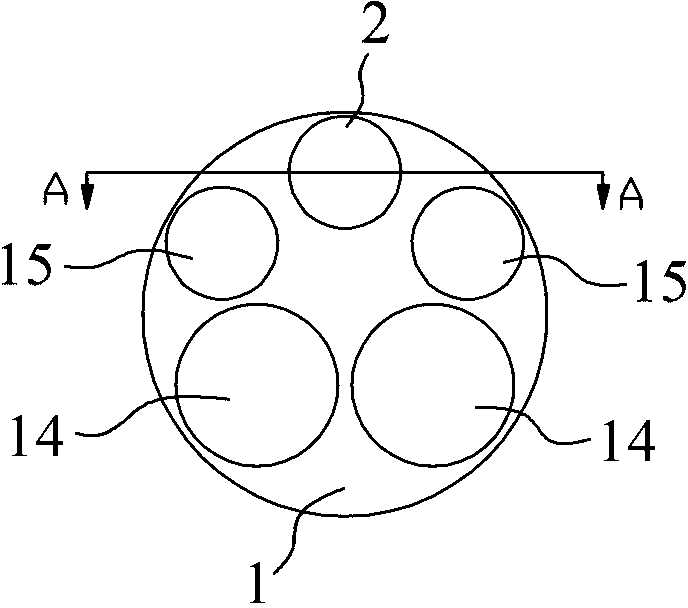

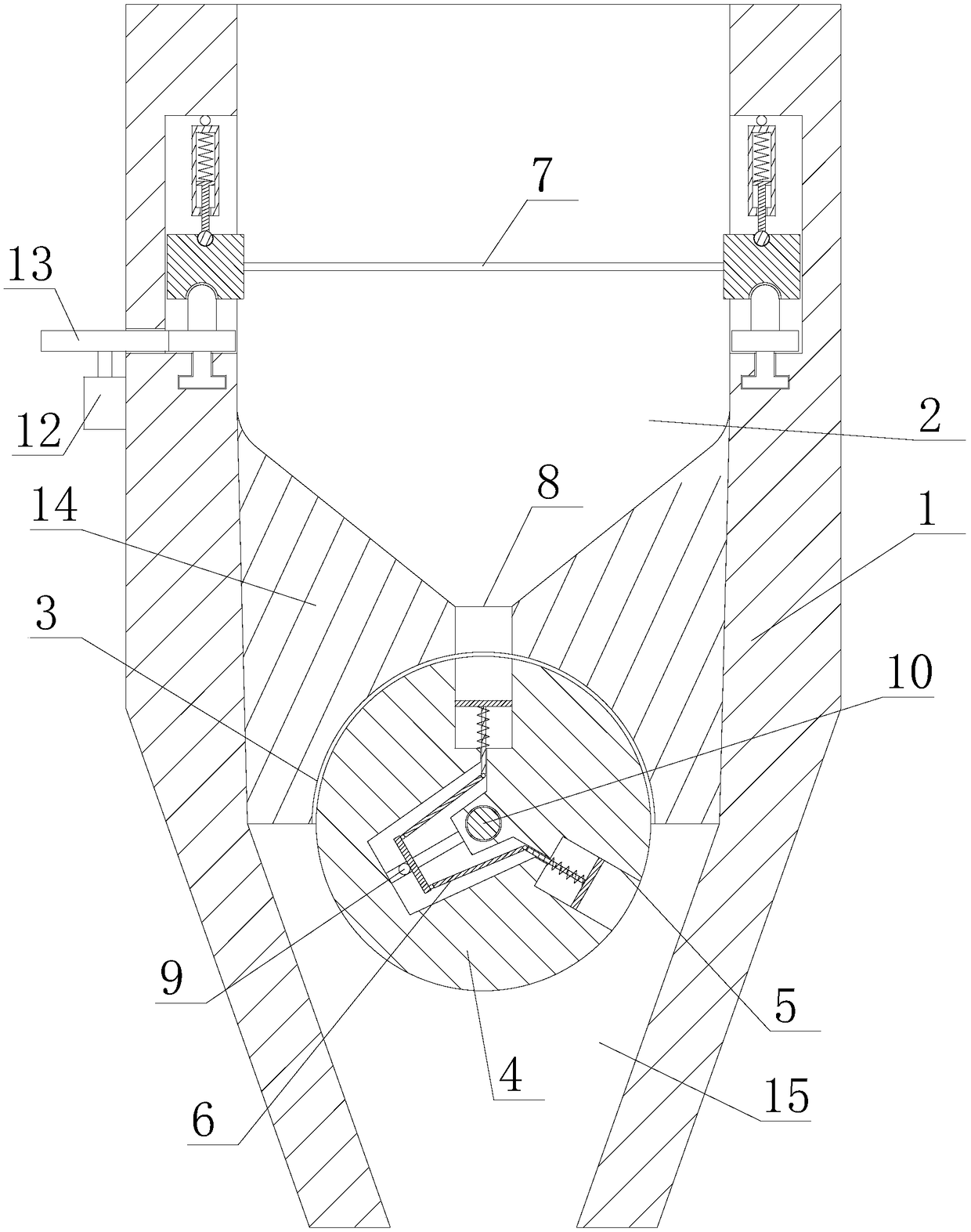

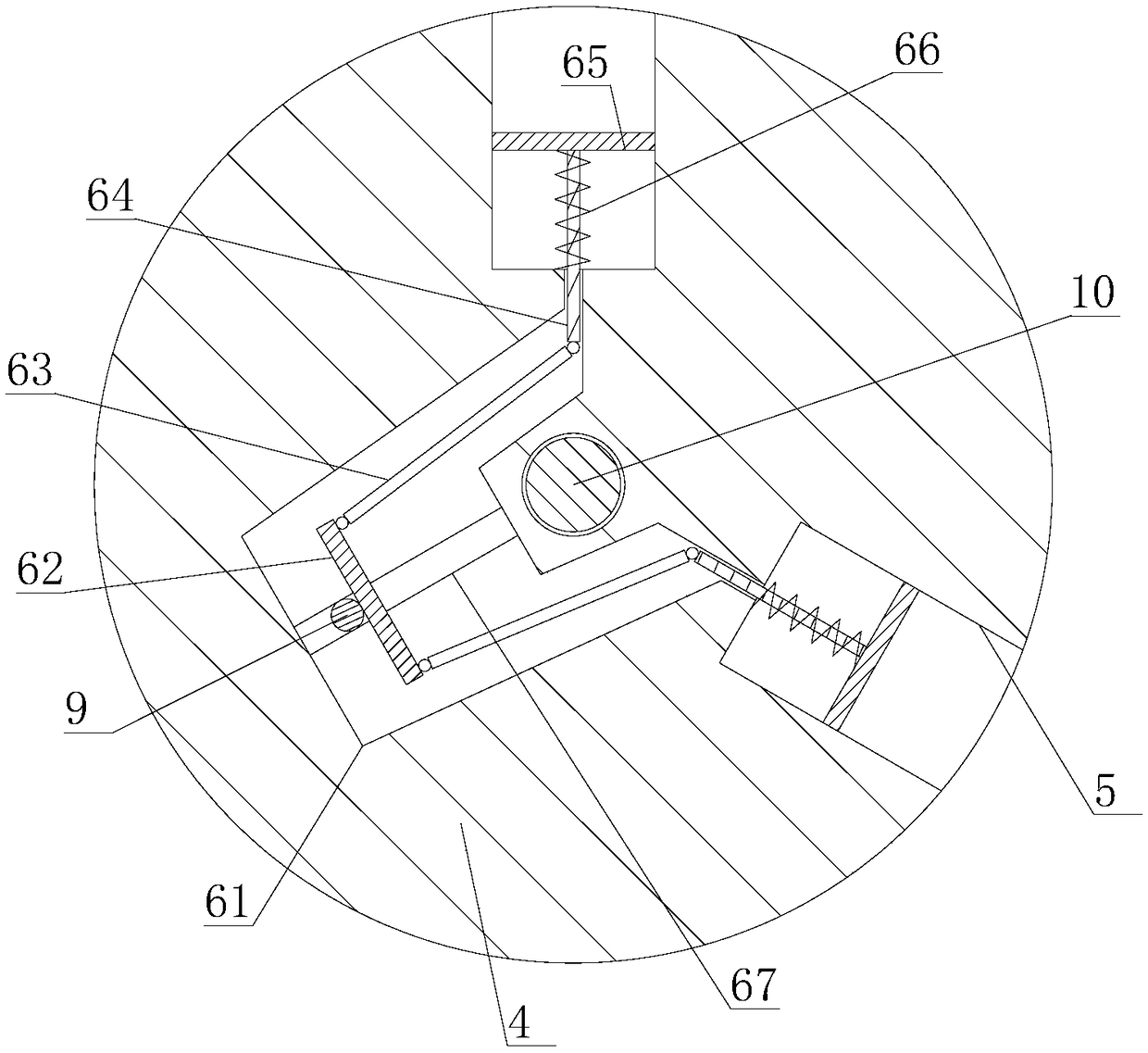

Kneading machine with dosing device

InactiveCN1372489AAbsorb evenlyMix completelyMixing/kneading structural elementsRotary stirring mixersRotational axisVertical plane

A dough or pastry mixer assembly has a main mixing chamber (5) discharging into a high speed single portion lower kneading chamber (1). In one horizontal plane the kneading chamber has essentially ring-shaped sidewalls with mixer paddles rotating through the vertical plane. At right angles to the first horizontal plane, the chamber has two circular facing sidewalls, one slightly conical and the other flat. The top and bottom of the kneading chamber are slightly flattened. The top has an inlet aperture which is kept free of food particles by a slide closure. The chamber bottom has a slide closure for discharge of the kneaded mixture. The slightly conical chamber sidewall terminates in a rounded tip parallel to the axis of mixer paddle rotation.

Owner:ARTOS SA

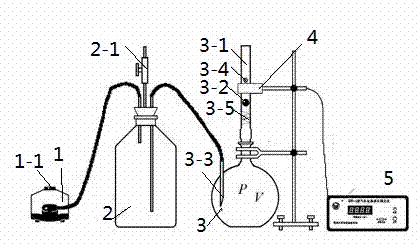

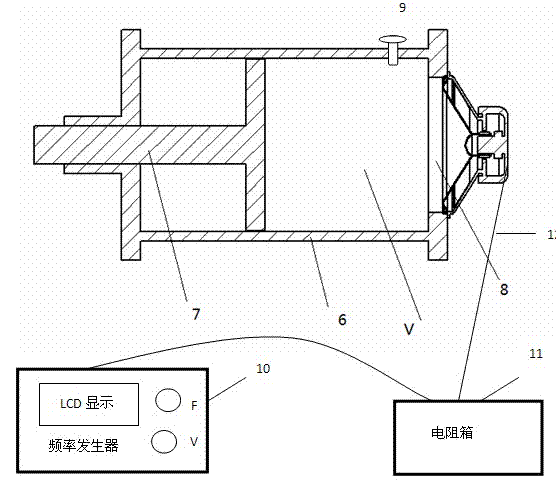

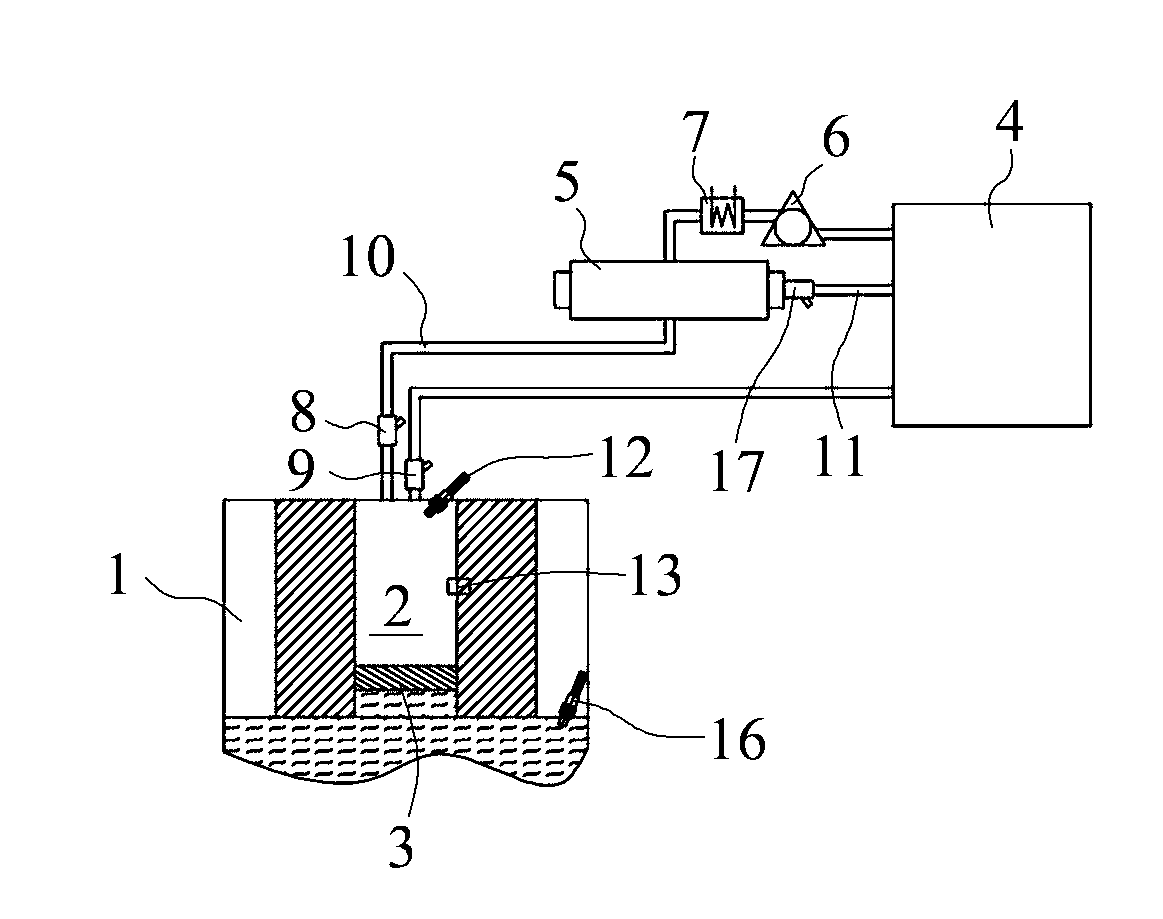

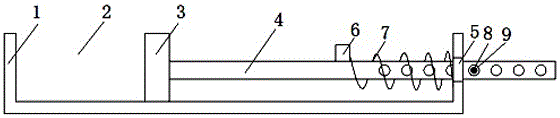

Device for measuring ratio of specific heat capacity of gas

The invention discloses a device for measuring a ratio of the specific heat capacity of gas, which comprises a signal generator, an AC (Alternate Current) voltage meter, a resistance box, a speaker and a cylindrical container. After being connected in series with the resistance box, the output end of the signal generator is connected in series with a voice coil of the speaker; the AC voltage meter is connected with the voice coil and is used for measuring a terminal voltage of the voice coil; a piston capable of being pushed and pulled back and forth is arranged at one end of the cylindrical container; the other end of the cylindrical container is connected with a paper cone of the speaker; an enclosed space which is used for placing the gas to be measured and has an adjustable capacity is formed between both the ends of the cylindrical container; and an air vent is also arranged on the side wall of the cylindrical container. The device has simple structure and is convenient to operate; the volume of the container can be changed; the specific heat capacities at a constant voltage under different volumes are measured; and the measurement error is small.

Owner:南京千韵电子科技有限公司

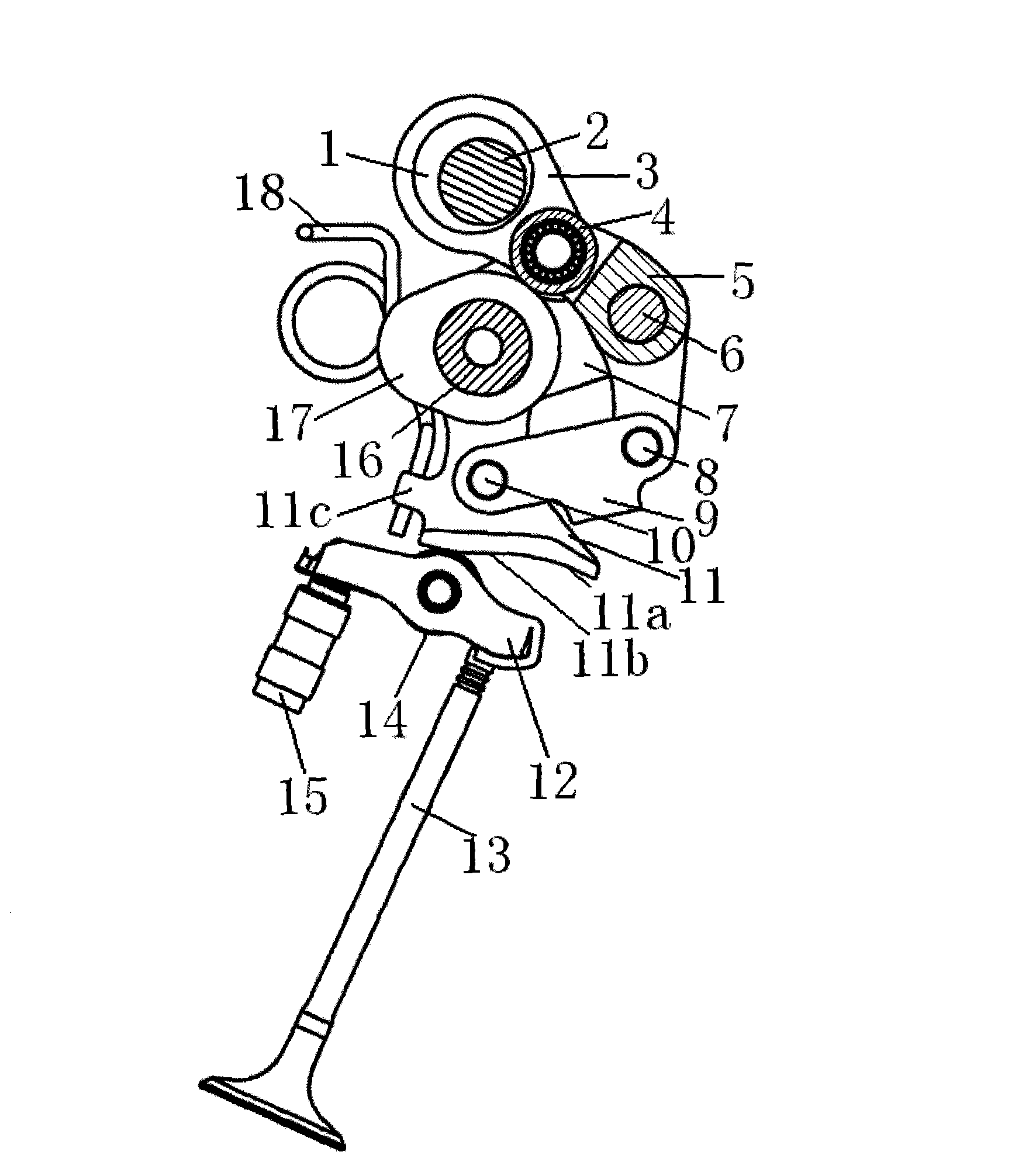

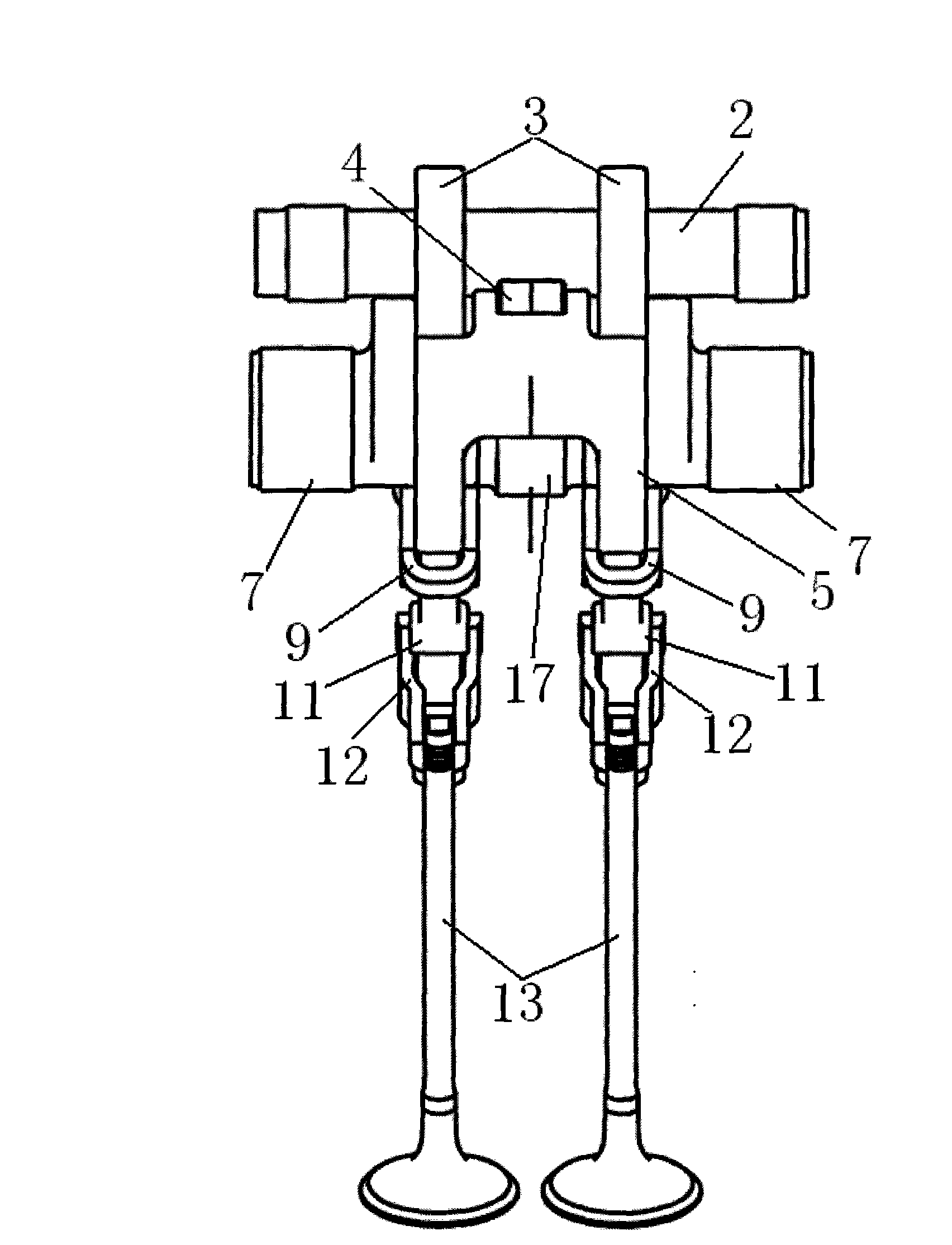

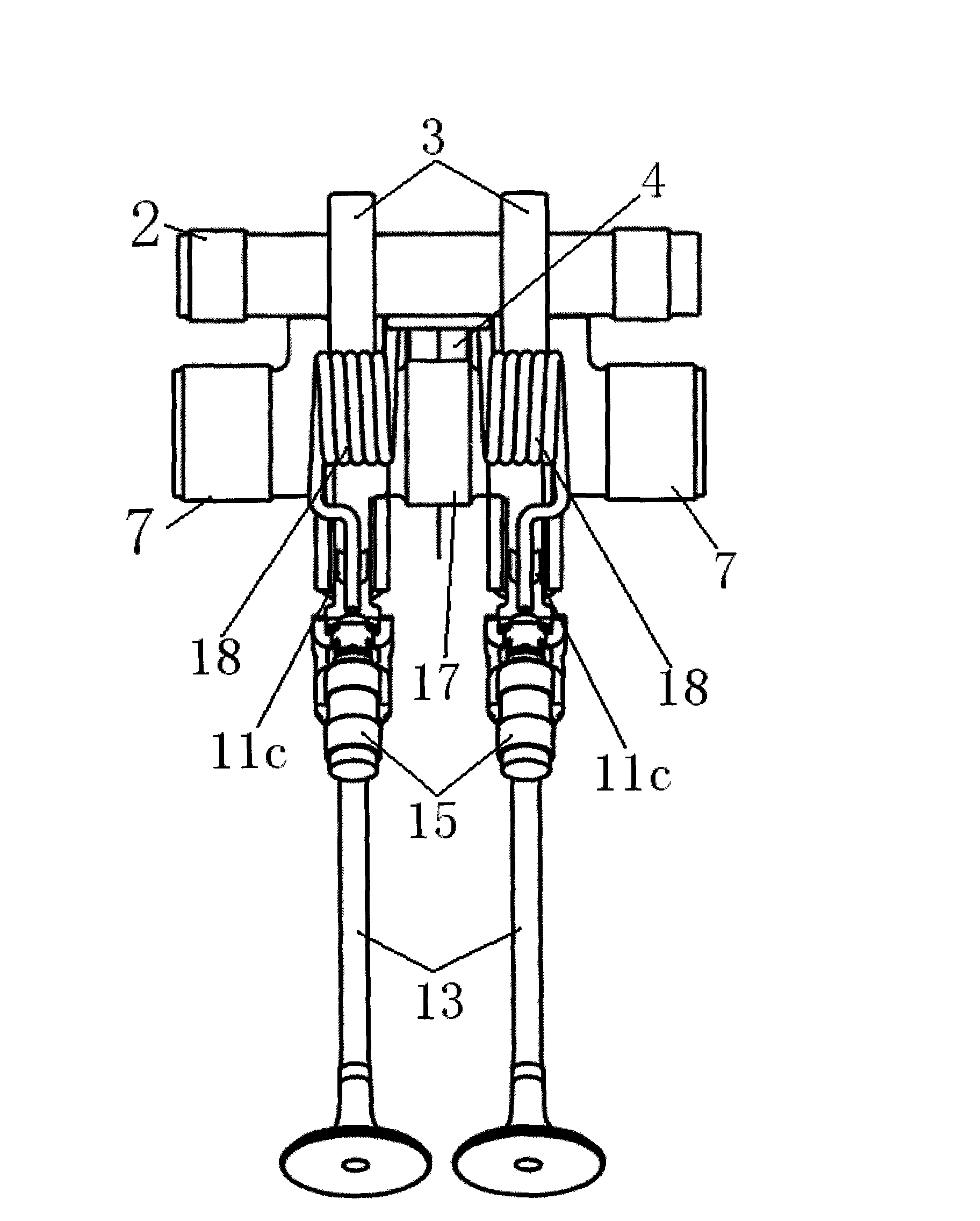

Novel stepless variable valve lift mechanism

ActiveCN101539041AQuick responseMatch the needs of different load conditionsValve arrangementsMachines/enginesCombustionControl arm

The invention provides a novel stepless variable valve lift mechanism applied to automotive internal combustion engines. A control shaft (2) is provided with one or a plurality of eccentric wheels (1) thereon. A first-level control arm (3) is sheathed on the eccentric wheel (1) and connected with a second-level control arm (7) at the other end. The second-level control arm (7) is arranged on a camshaft (16) which is connected with a first-level rocker arm (5). One end of a connecting arm (9) is connected with the first-level rocker arm and the other end thereof is connected with a second-level rocker arm (11) which joints with a third-level rocker arm (12) through a third-level rocker arm roller (14). The stepless variable valve lift mechanism is practical and feasible, can quickly respond and adjusts the load of an engine by controlling the valve lift amount, thus better meeting the requirements of different load working conditions and being capable of reducing the pumping loss of the engine and improving the properties of the engine.

Owner:CHERY COMML VEHICLE ANHUI

Package structure of optical fiber grating temperature sensor

The invention relates to a capsulation structure of fibre-optical grating temperature sensor that comprises protecting tube, hollow tube, optical fibre connector, the protecting tube is tight coupled with one end of the hollow tube via tube valve element, the other end of the hollow tube is also tight coupled with the optical fibre connector via tube valve element; a bare optical fibre grating carriage is mounted in the protecting tube, it is plastered or welded to the inwall of the protecting tube via its base, the bare optical fibre grating is plastered or welded to the bare optical fibre grating carriage by glue, the transmission optical fibre is connected with the optical fibre connector via the hollow tube, other parts of the bare optical fibre grating carriage except the base are not contacted with the protecting tube, so the optical fibre grating is only under the effect of temperature, the effect of stress to the optical fibre grating is basically eliminated. The fibre-optical grating temperature sensor capsulated in this invention has high stability and reliability; it is easy to be measured in distributed system, it is not sensitive to stress, and it is effective to avoid water logging and hydrogen logging, it is fit for the formidable environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

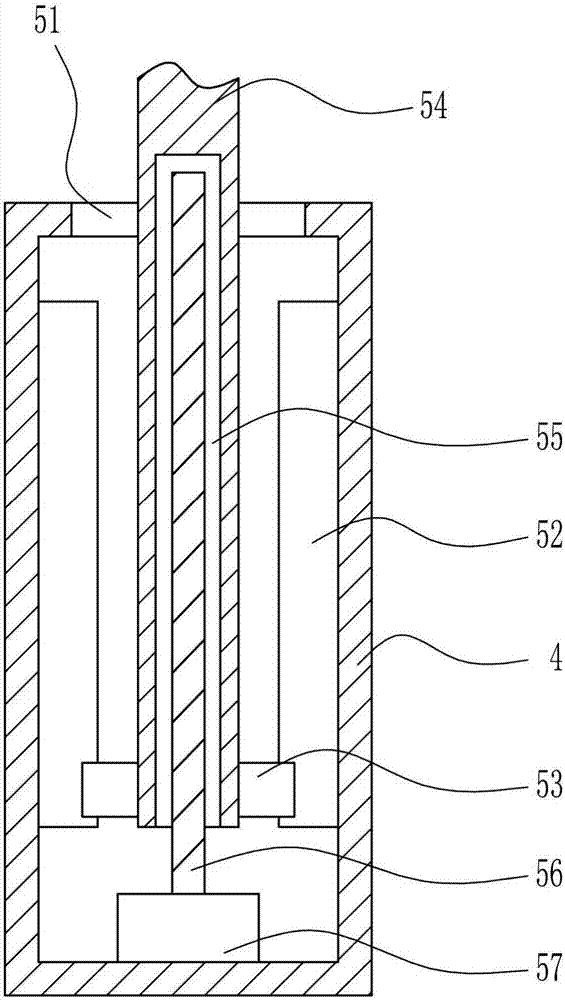

Variable-compression-ratio mechanism of engine

InactiveCN102937052AGuaranteed safe operationVolume changeEngine controllersMachines/enginesHydraulic cylinderCombustion chamber

The invention relates to an engine assembly, and in particular relates to a variable-compression-ratio mechanism of an engine. The variable-compression-ratio mechanism comprises a cylinder cover, wherein a hydraulic cylinder communicated with a combustion chamber of the cylinder is arranged on the cylinder cover; and a variable-pressure piston which can slide in the hydraulic cylinder under drive of a hydraulic device is arranged in the hydraulic cylinder. The variable-pressure piston is driven to move in the hydraulic cylinder through the hydraulic device, and the volume of a part at which the hydraulic cylinder is communicated with the combustion chamber can be changed, so that the total size of the combustion chamber is changed, the aim of changing the compression ratio of the engine is fulfilled, and the structures of a crankshaft and a connecting rod are not required to be changed.

Owner:GREAT WALL MOTOR CO LTD

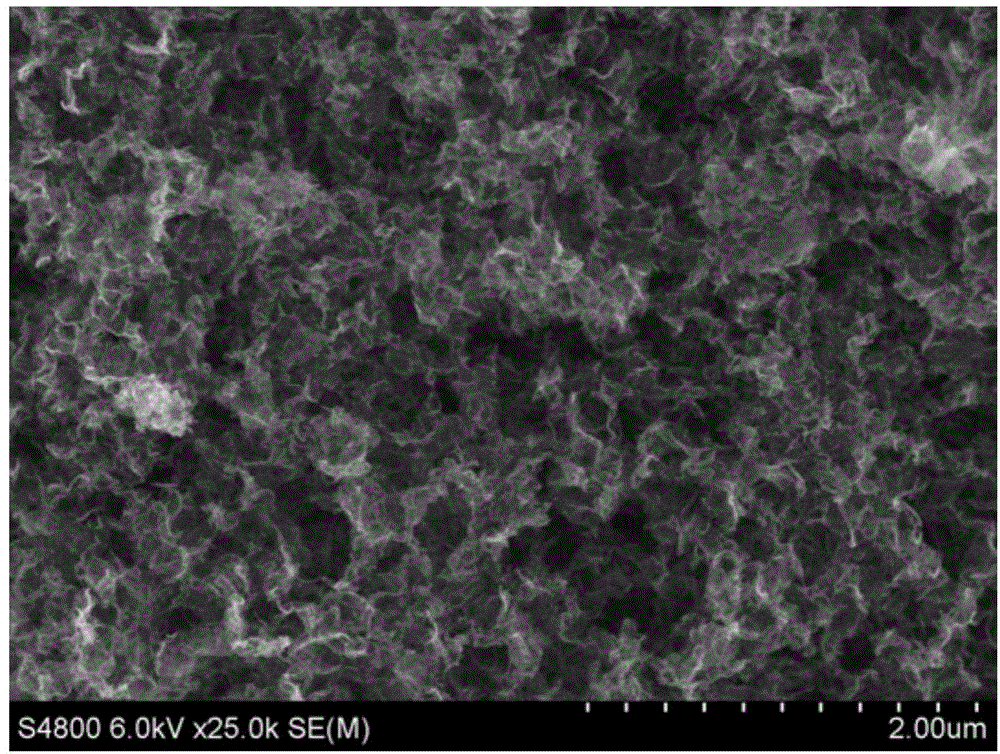

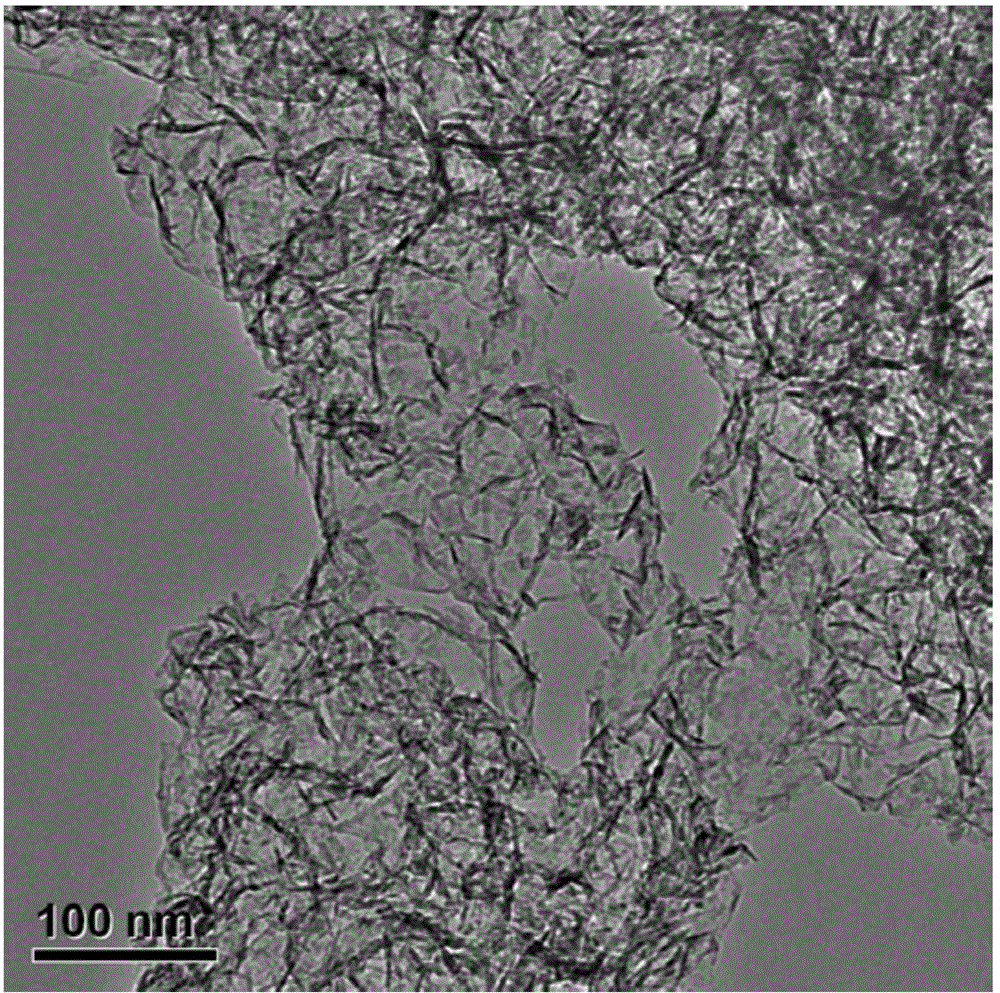

Aza-graphene and manganese dioxide hybrid aerogel, preparation method and application thereof

The present invention relates to an aza-graphene and manganese dioxide hybrid aerogel, a preparation method and an application thereof. The aerogel uses a three-dimensional network structure formed by two-dimensional aza-graphene sheets as a substrate, and manganese dioxide particles are loaded on the aza-graphene sheets. According to the preparation method, an aza-graphene hydrogel is soaked in a mixed solution of potassium permanganate and sodium sulfate, and the potassium permanganate and carbon in the aza-graphene act so as to obtain the aza-graphene and manganese dioxide hybrid aerogel. After action, the manganese dioxide is uniformly loaded onto the aza-graphene sheets. The preparation method is simple and convenient, and is applicable to large-scale production. The hybrid aerogel prepared by the preparation method has high specific surface area, a porous three-dimensional network structure, high specific capacity, and good circulation stability, thereby being applied to fields such as lithium ion batteries.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

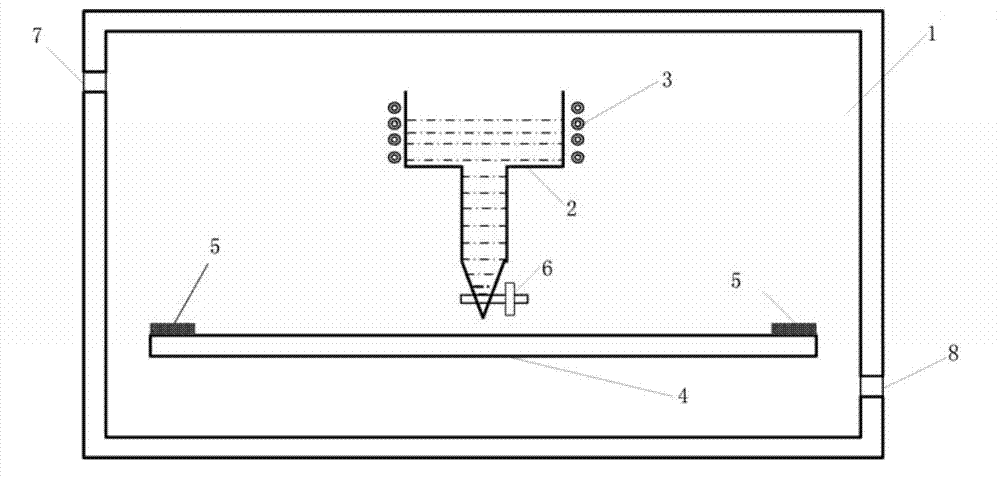

Device and method for preparing metal microballoons by using ultrasonic surface standing waves

The invention discloses a device and method for preparing metal microballoons by using ultrasonic surface standing waves, relates to a device and a method for preparing the metal microballoons, and aims to solve the problems that the conventional device for preparing the metal microballoons is complicated, and the size cannot be controlled flexibly. The device consists of an air storehouse and a titanium alloy casting die, a heating element, a base plate, two ultrasonic surface wave emission devices and a droplet flow control device which are positioned in the air storehouse. The method comprises the following steps of: 1, completely dissolving a metal material to obtain a metal solution, gradually dropping the metal solution on the surface of the base plate, and forming spherical metal droplets with the same size under the action of ultrasonic waves; and 2, cooling the metal microballoons by an air-cooling system until the metal microballoons are cooled to be solids, and thus obtaining the metal microballoons with the same size. By the device and the method, various metal microballoons with relatively small sizes can be prepared; the preparation process takes 1 to 2 minutes at one time, so that the production efficiency is greatly improved; and the device and the method are applied to the field of preparation of the metal microballoons.

Owner:HARBIN INST OF TECH

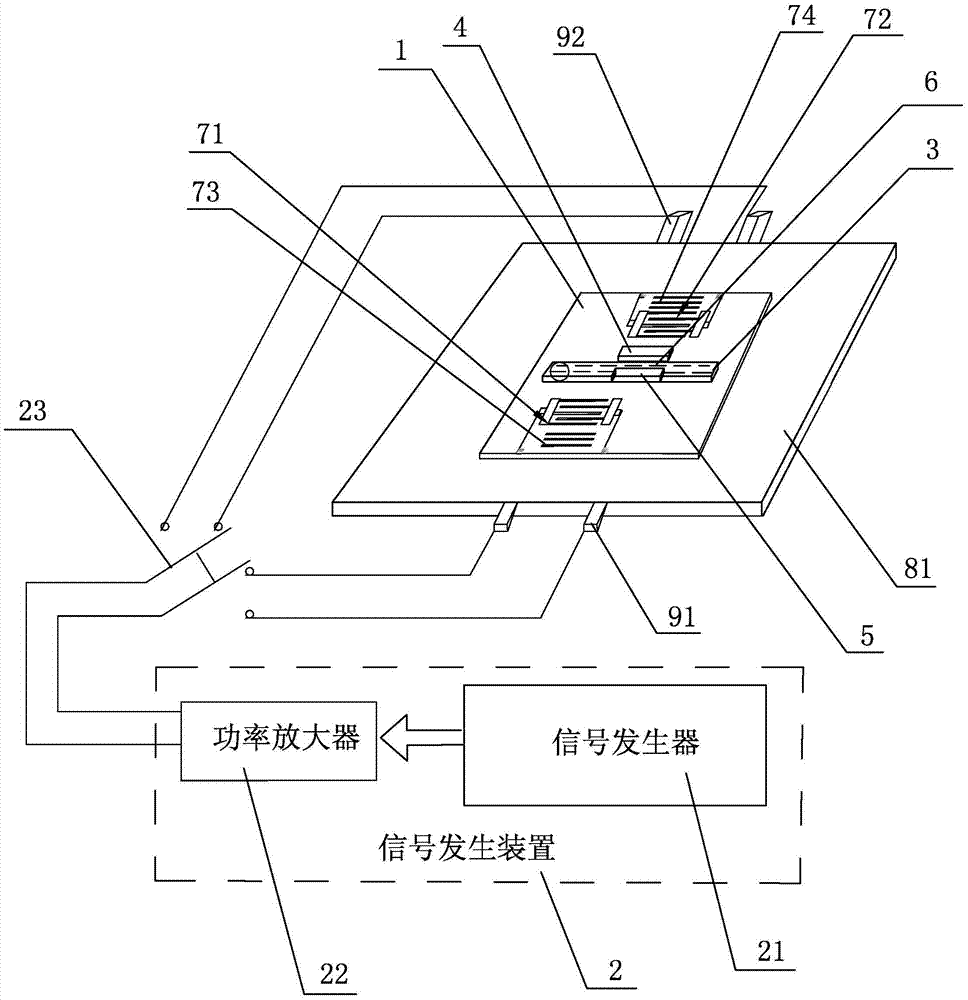

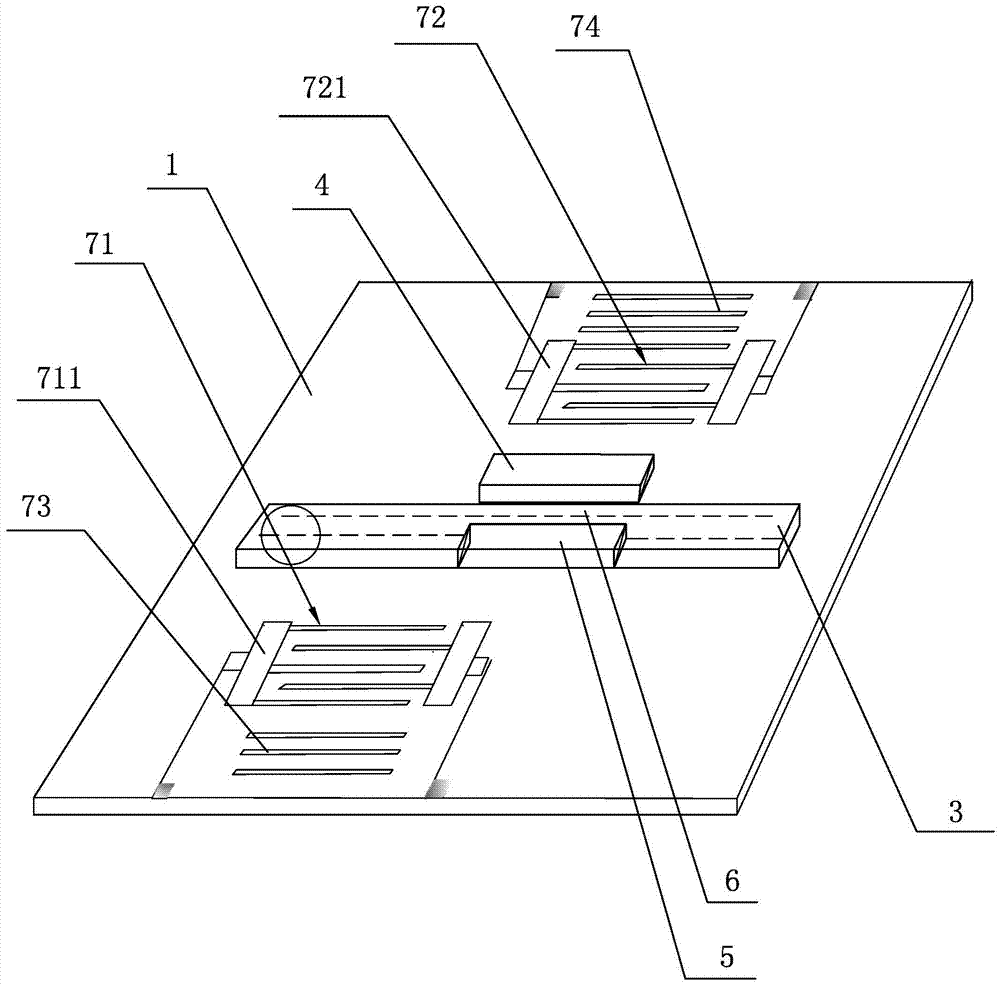

Apparatus and method for micro-droplet split in microchannel

The present invention discloses an apparatus and a method for micro-droplet split in a microchannel. The apparatus comprises a piezoelectric substrate and a signal generating apparatus. A microchannel, a sound-absorbing coating and two unweighted inter-digital transducers are arranged on the working surface of the piezoelectric substrate; a flow blocking strip is arranged in the microchannel; the first side surface of the flow blocking strip is tightly adhered to the first side wall of an inner cavity of the microchannel; a sub-channel is formed between the second side surface of the flow blocking strip and the second side wall of the inner cavity of the microchannel; surface acoustic waves excited by the first unweighted inter-digital transducer are applied to micro-droplets transported in the front portion of the microchannel, and the micro-droplets move towards an inlet of the sub-channel under the effect of a continuous oil phase microfluid; most of surface acoustic waves excited by the second unweighted inter-digital transducer are absorbed by the sound-absorbing coating, and a small portion of the surface acoustic waves are applied to a part of the micro-droplets exposed outside of the outlet of the sub-channel to achieve split. The apparatus and the method have the advantages that the micro-droplet split can be achieved with relatively low electrical signal power, so that the piezoelectric substrate is effectively avoided from being broken.

Owner:CHANGZHOU INST OF TECH

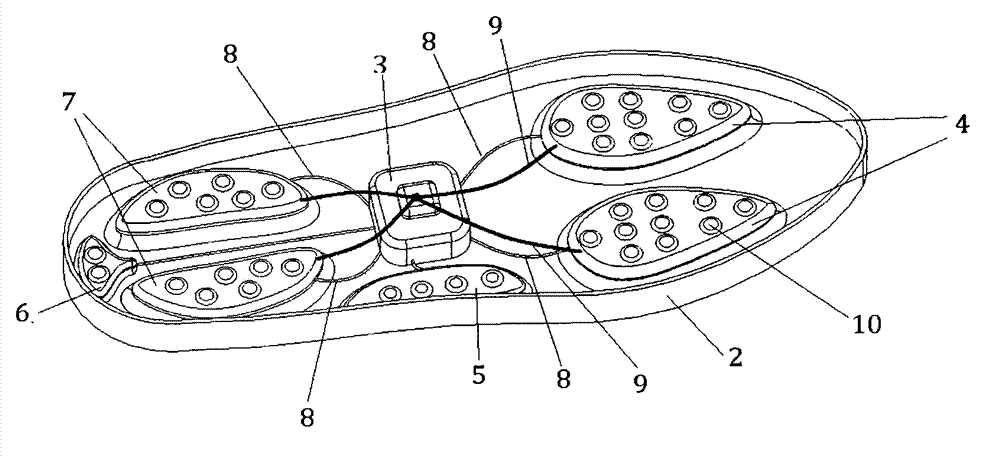

Recovery shoe

ActiveCN103110239AVolume changePrevent fallingDiagnostic recording/measuringSensorsPlastic bagEngineering

The invention relates to a recovery shoe which comprises a vamp, a shoe sole plate and a six-axis inertial sensor which is arranged on a waist portion of the human body and is used for generating an accelerated speed signal and an angular speed signal. The shoe sole plate is provided with a rubber plastic bag control box and a rubber plastic bag. The rubber plastic bag control box is provided with a raw material device, a guide flexible pipe, an electric machine, a motor which is connected with the electric machine through a coupler, and a control system which is provided with a multi-direction reversing valve and is connected with the motor. The guide flexible pipe is connected with the rubber plastic bag through a hollow pipeline of the multi-direction reversing valve. A pressure sensor used for detecting a human body foot bottom pressure signal is arranged on the surface of the rubber plastic bag. According to the recovery shoe, the position gesture of a sole can be adjusted in real time, and toppling of a human body can be prevented.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

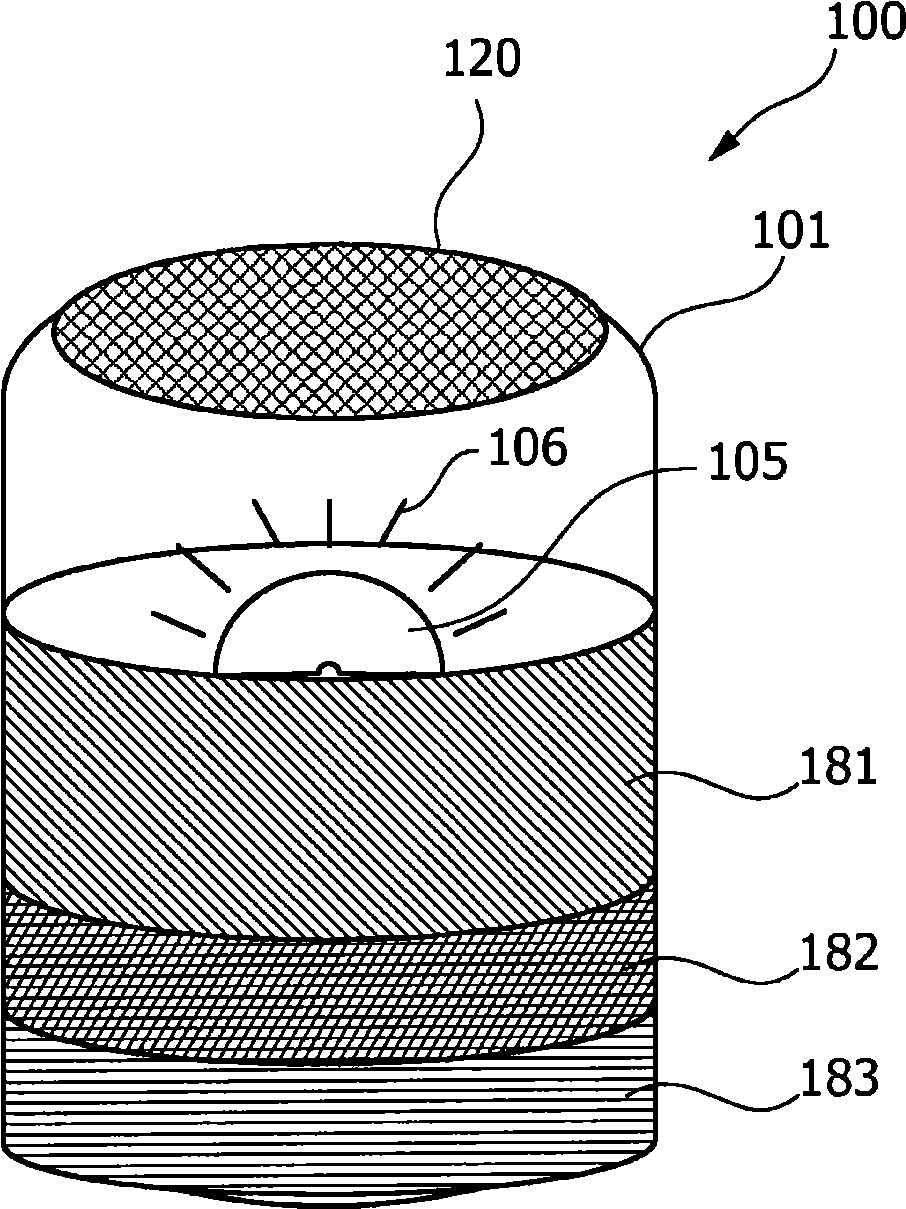

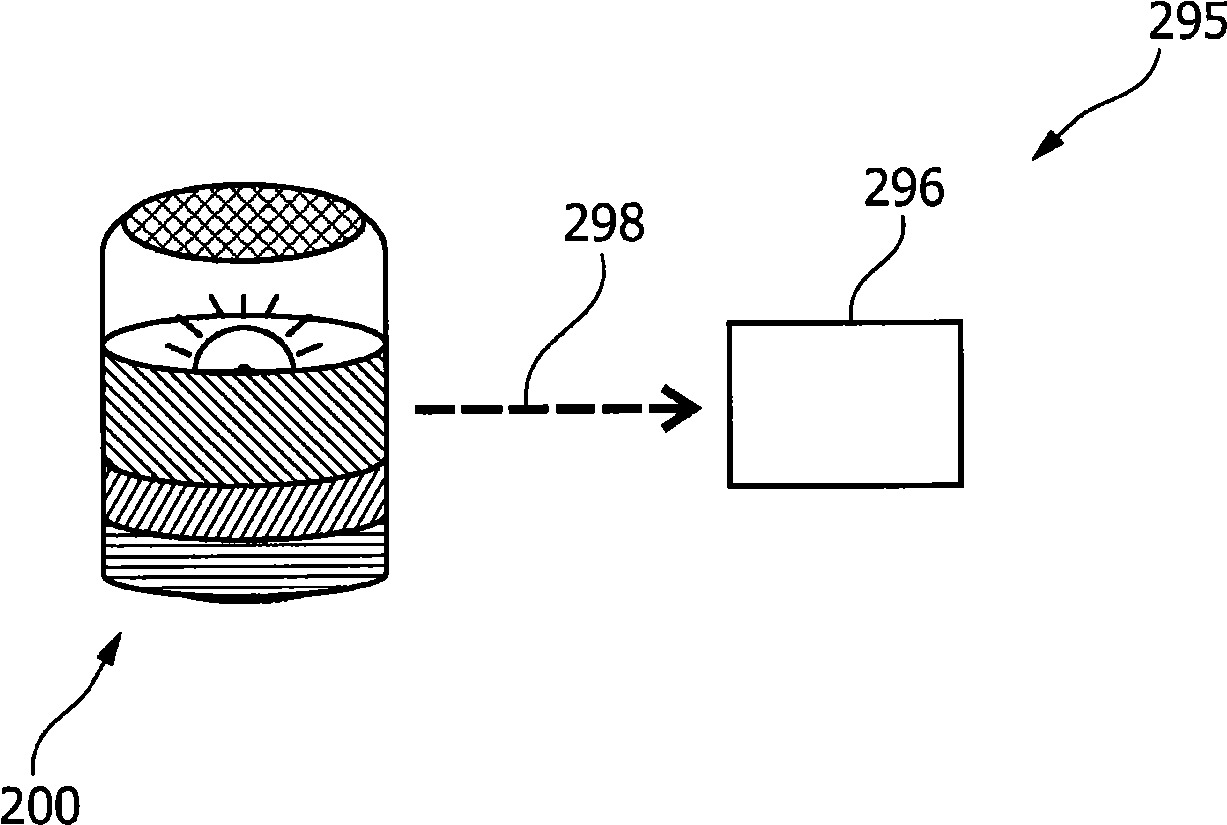

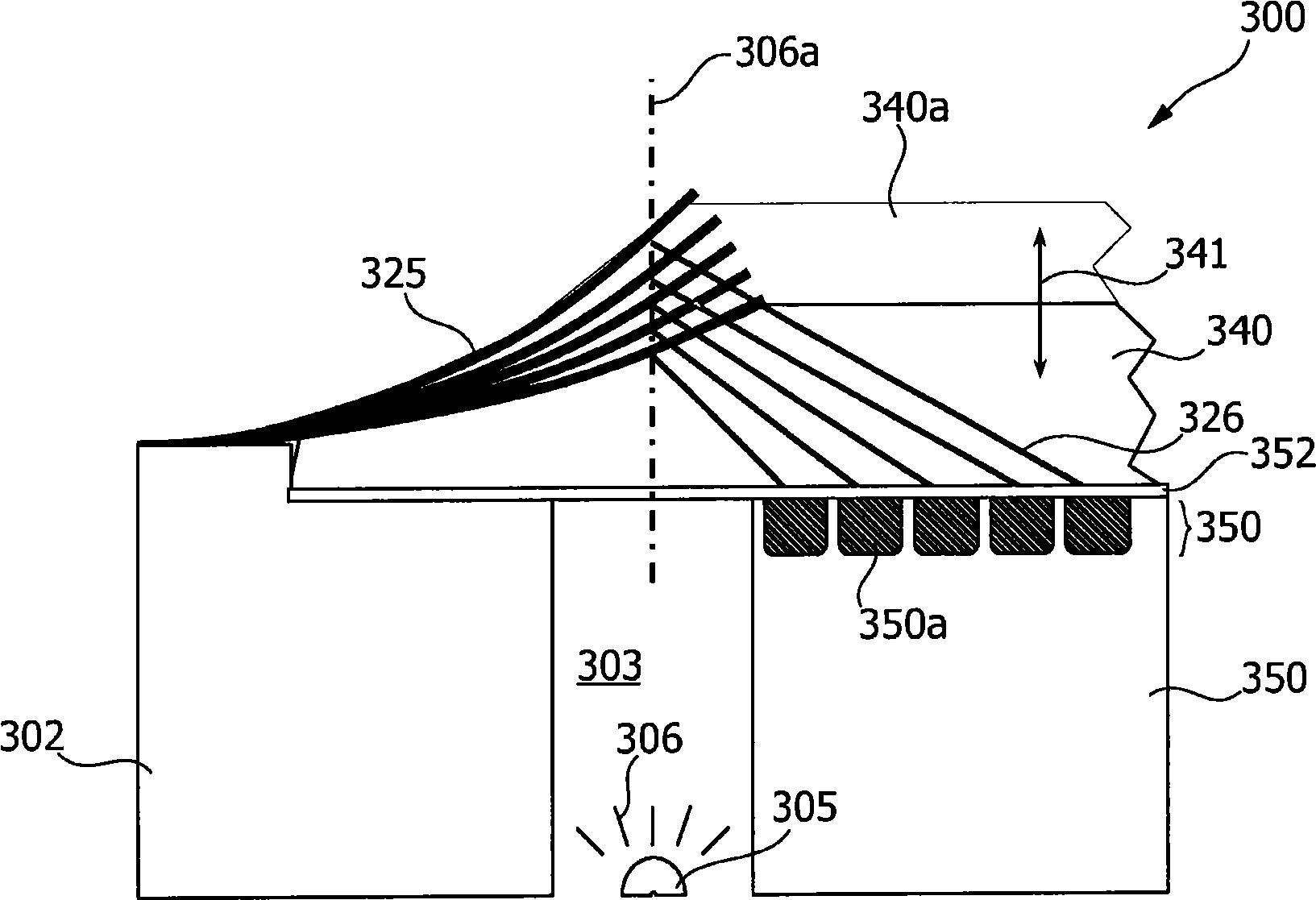

Environmental state detection with hydrogel based fully integrated transducer device

InactiveCN101523192AReduce noiseImprove life expectancyMaterial analysis by observing effect on chemical indicatorDiagnostics using fluorescence emissionTransducerElectromagnetic radiation

The invention describes a hydrogel based transducer device for detecting an environmental state, in particular for detecting an environmental state within a biological material. The transducer device (300) comprises a base element (302), a radiation source (305), which is formed at the base element (302) and which is adapted to emit electromagnetic radiation (306), an optical element (325), which is arranged at the base element (302) and which is adapted to interact with the electromagnetic radiation (306). The transducer device (300) further comprises a radiation detector (350), which is adapted to receive the electromagnetic radiation (326) having interacted with the optical element (325), and a hydrogel material (340), which is mechanically coupled to the optical element (325) and which is adapted to change its volume when getting into contact with an environmental material of the transducer device (300) such that the spatial position of the optical element (325) is changed. The base element (302), the radiation source (305) and the radiation detector (350) are formed integrally from an electronic substrate material.

Owner:KONINK PHILIPS ELECTRONICS NV

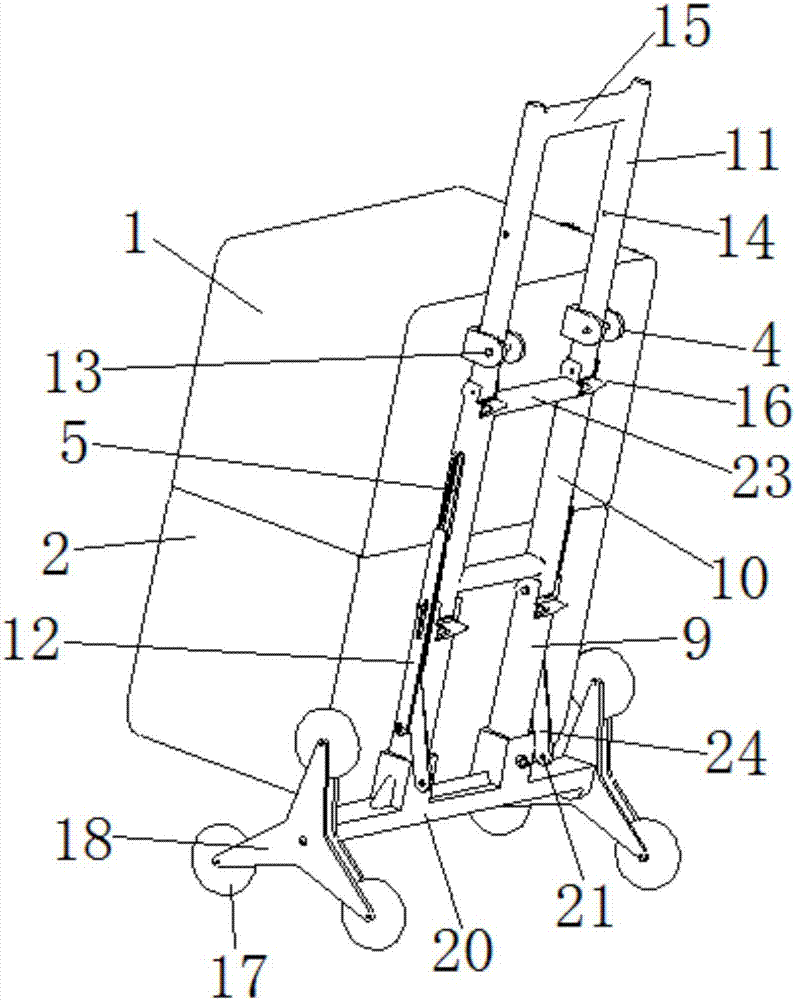

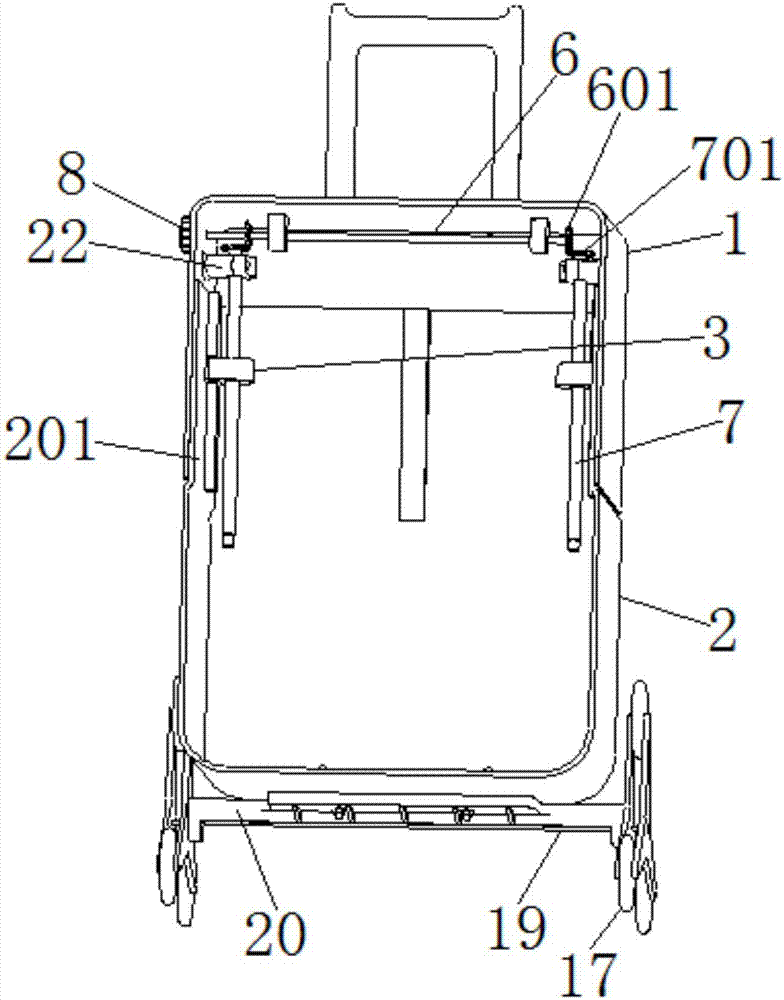

Seat type trolley luggage case with variable volume

InactiveCN107019310AIncreased comfort and flexibilityHumanized and convenient designLuggageEngineeringMechanical engineering

The invention relates to a seat-type trolley luggage case with variable volume. The trolley luggage case includes a lower case body with an upward opening and an upper case body with an opening downward and slidingly arranged on the lower case body. The bottom of the lower case body is provided with a lower case body. The box body is provided with a stair-climbing mechanism, a pull rod type seat mechanism is arranged on the outer side, and a volume control mechanism is arranged between the upper box body and the lower box body. Compared with the prior art, the present invention can change the volume of the trolley case and the state of the trolley seat mechanism according to different usage requirements, improve the comfort and flexibility of the trolley case, and make the design of the trolley case easier. It is more user-friendly and convenient, and has broad application prospects.

Owner:TONGJI UNIV

Powder spreading device capable of quantitatively dropping powder

InactiveCN109482878AForming surface is flatAvoid quality defectsSievingAdditive manufacturing apparatusMotor driveMetal powder

The invention discloses a powder spreading device capable of quantitatively dropping powder and relates to the technical field of 3D printing. The powder spreading device comprises a powder spreadingmain body, a rotating drum, an adjusting mechanism, a screening mechanism, a first motor and a second motor. A partition is arranged in the powder spreading main body. A powder storage cavity is formed above the partition. Two powder storage grooves are formed in the outer surface of the rotating drum. The first motor drives the rotating drum to rotate through a driving rotating shaft. The adjusting mechanism changes the powder storage amount of the powder storage grooves under the pushing of a pushing rod. The screening mechanism is driven to move through a driving wheel under the drive of the second motor. Before printing, firstly, the falling amount of powder is adjusted according to metal powder, and after the falling amount of powder is determined, the size of the powder storage grooves is changed through an adjusting mechanism, so that the purpose of changing the falling amount of powder is achieved; and during printing, the screening mechanism is operated, so that metal blocks bonded into blocks are blocked from falling above a screen mesh, the forming surface of the single-layer powder is smoother, and quality defects in parts are eliminated.

Owner:安徽恒利增材制造科技有限公司

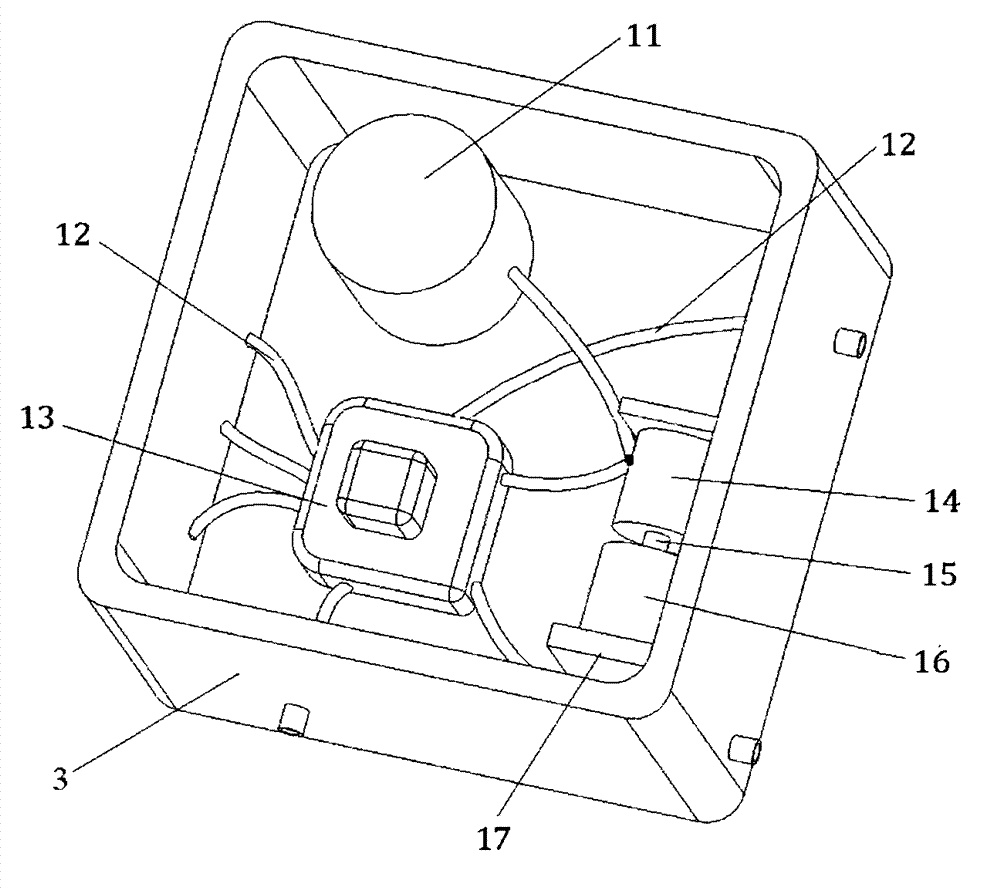

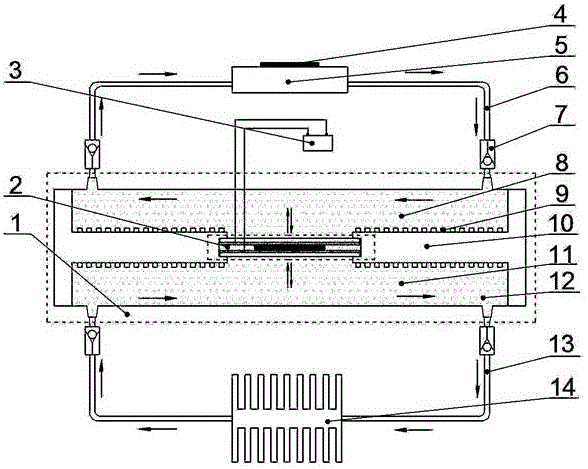

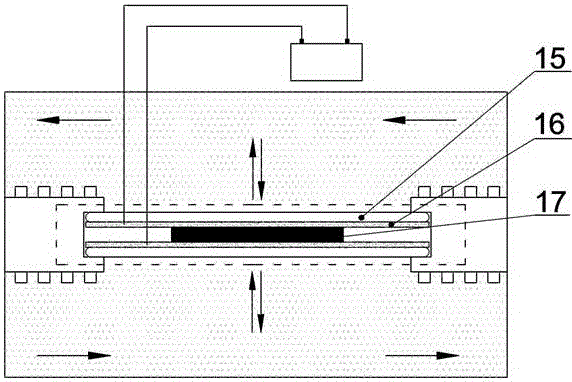

Heat transfer system driven by piezoelectricity and applied to self-priming liquid heat exchanger and heat transfer method thereof

ActiveCN106679471AVolume changeAchieve directional circulation flowIndirect heat exchangersElectricityEnhanced heat transfer

The invention discloses a heat transfer system driven by piezoelectricity and applied to a self-priming liquid heat exchanger and a heat transfer method of the heat transfer system driven by the piezoelectricity and applied to the self-priming liquid heat exchanger. The heat transfer system driven by the piezoelectricity and applied to the self-priming liquid heat exchanger comprises the self-priming liquid heat exchanger (1), an alternating-current power source (3), a heat source pipeline (6), one-way valves (7), a cold source pipeline (13) and a heat dissipation element (14). The self-priming liquid heat exchanger (1) comprises a piezoelectric vibration partition plate (2), a heat source heat exchange cavity (8), an enhanced heat transfer structure (9), a heat transfer partition plate (10) and a cold source heat exchange cavity (11). According to the heat transfer method of the heat transfer system driven by the piezoelectricity and applied to the self-priming liquid heat exchanger, the piezoelectric vibration partition plate (2) generates periodic vibration under the action of the alternative-current power source (3) to change the volumes of the heat source heat exchange cavity (8) and the cold source heat exchange cavity (11), and a working medium conducts directional circular flow to conduct heat exchange under the blockage function of the one-way valves (7) and the function of periodic vibration. By the adoption of the heat transfer system driven by the piezoelectricity and applied to the self-priming liquid heat exchanger, a liquid drive device in the heat transfer system is simplified, the heat exchange efficiency is improved, and the heat dissipation requirement of a tiny electronic element in a limited space is met.

Owner:SOUTH CHINA UNIV OF TECH

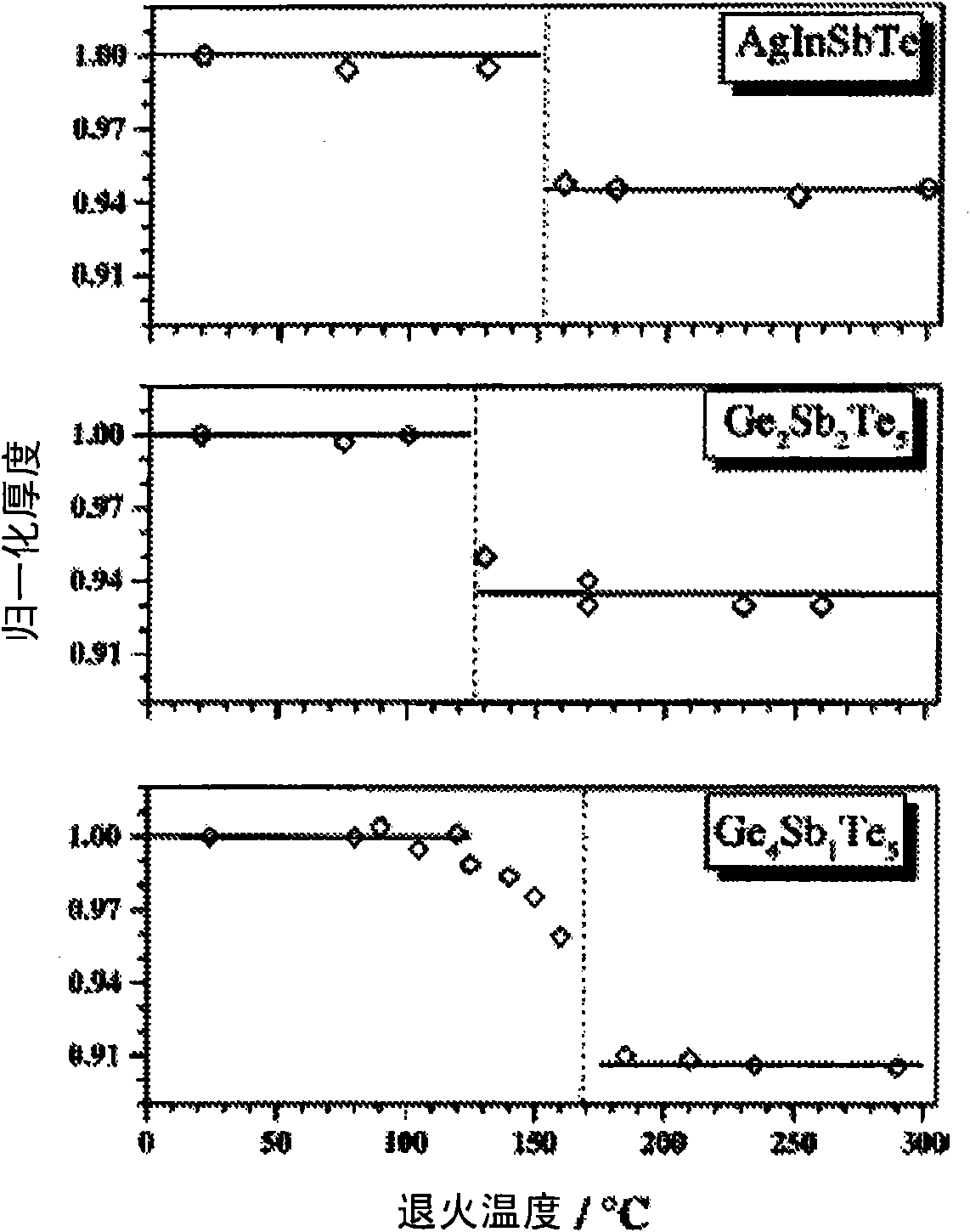

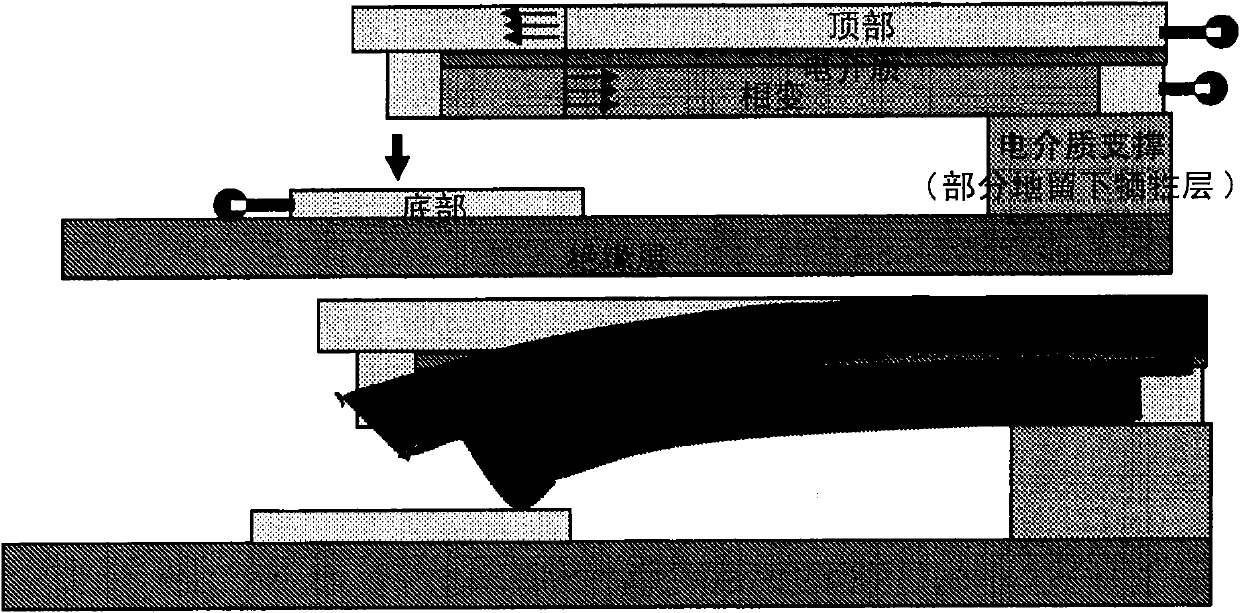

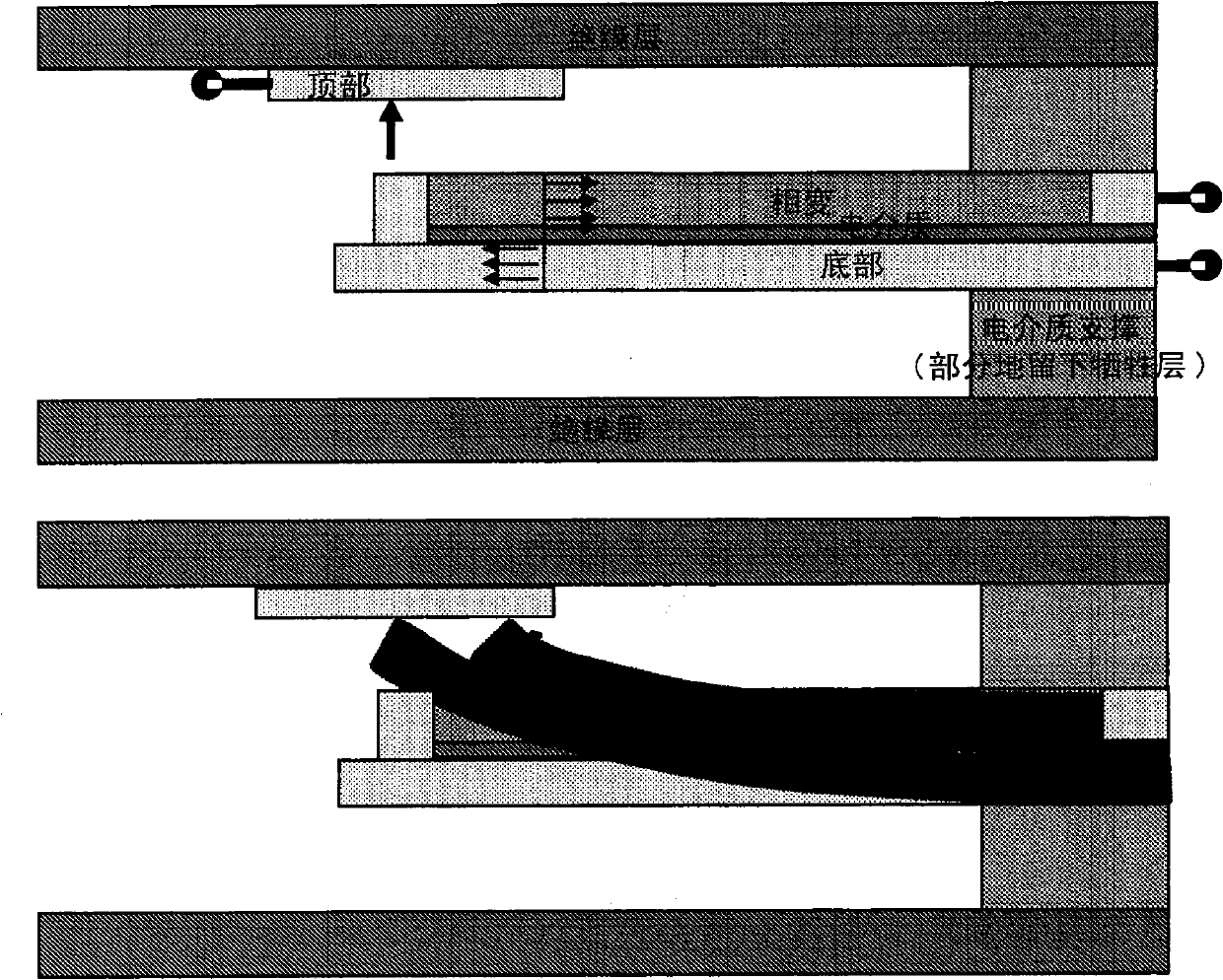

Tunable capacitor and switch using mems with phase change material

ActiveCN102007559AGood tunabilityGuaranteed steady stateElectrostatic/electro-adhesion relaysNanoelectromechanical switchesMultiplexerPhase change

The present invention relates to a MEMS, being developed for e.g. a mobile communication application, such as switch, tunable capacitor, tunable filter, phase shifter, multiplexer, voltage controlled oscillator, and tunable matching network. The volume change of phase-change layer is used for a bi-stable actuation of the MEMS device. The MEMS device comprises at least a bendable cantilever, a phase change layer, and electrodes. A process to implement this device and a method for using are given.

Owner:NXP BV

Diving device and method capable of realizing expanding and contracting through filling liquid

InactiveCN106314735ASeal does not breakIncrease in sizeNon-magnetic metal hullsUnderwater vesselsWater dischargeEngineering

The invention provides a diving device and method capable of realizing expanding and contracting through filling liquid. According to the diving device and method disclosed by the invention, the compression of water pressure to a housing of a submersible is counterbalanced with incompressibility of liquid, and value of buoyant force is adjusted by changing the volume of the submersible by utilizing intensity of pressure generated by the gasification of the liquid. The technical scheme adopted by the diving device lies in that the submersible is provided with a housing and an inner pocket; a space between the housing and the inner pocket of the diving device is filled with the liquid, so that the compression of external water pressure to the housing of the submersible is resisted; the liquid in the inner pocket is heated to be gasified, so that the inner pocket expands, and the housing is driven to expand; and therefore, water discharge capacity is improved to obtain great buoyant force.

Owner:侯方勇

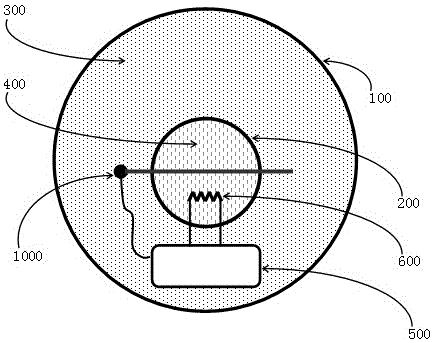

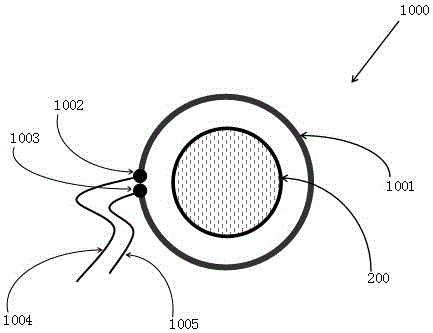

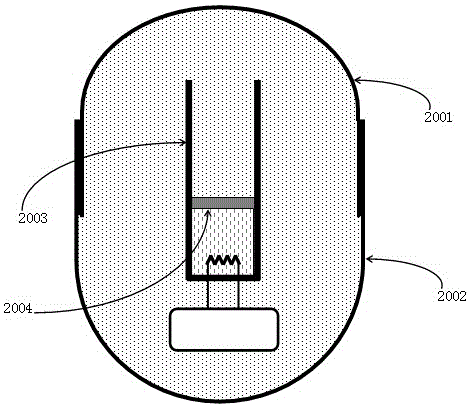

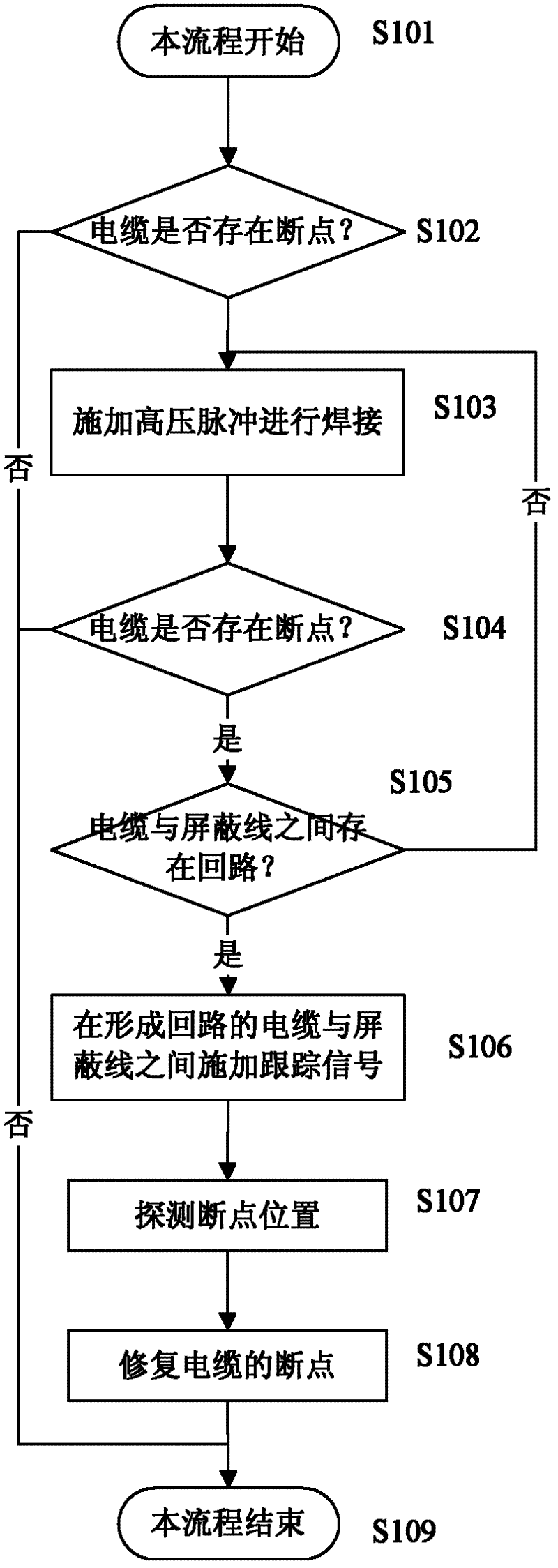

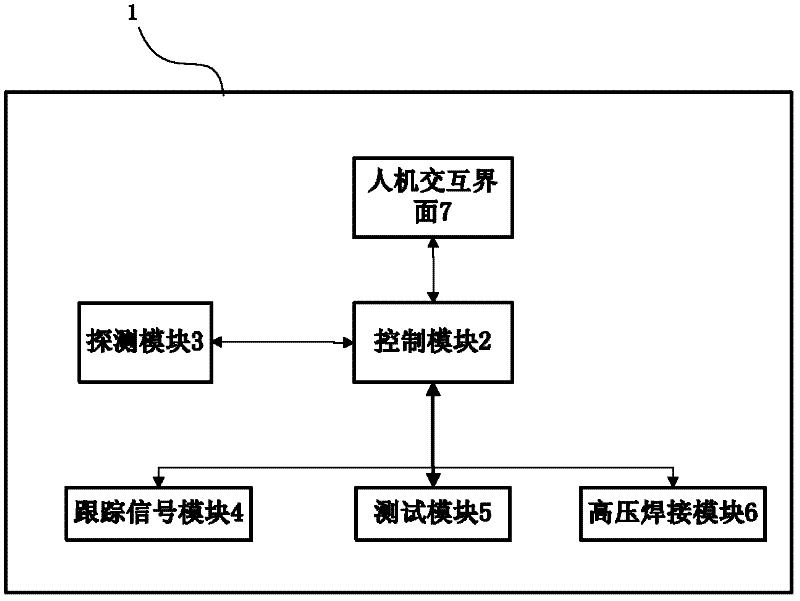

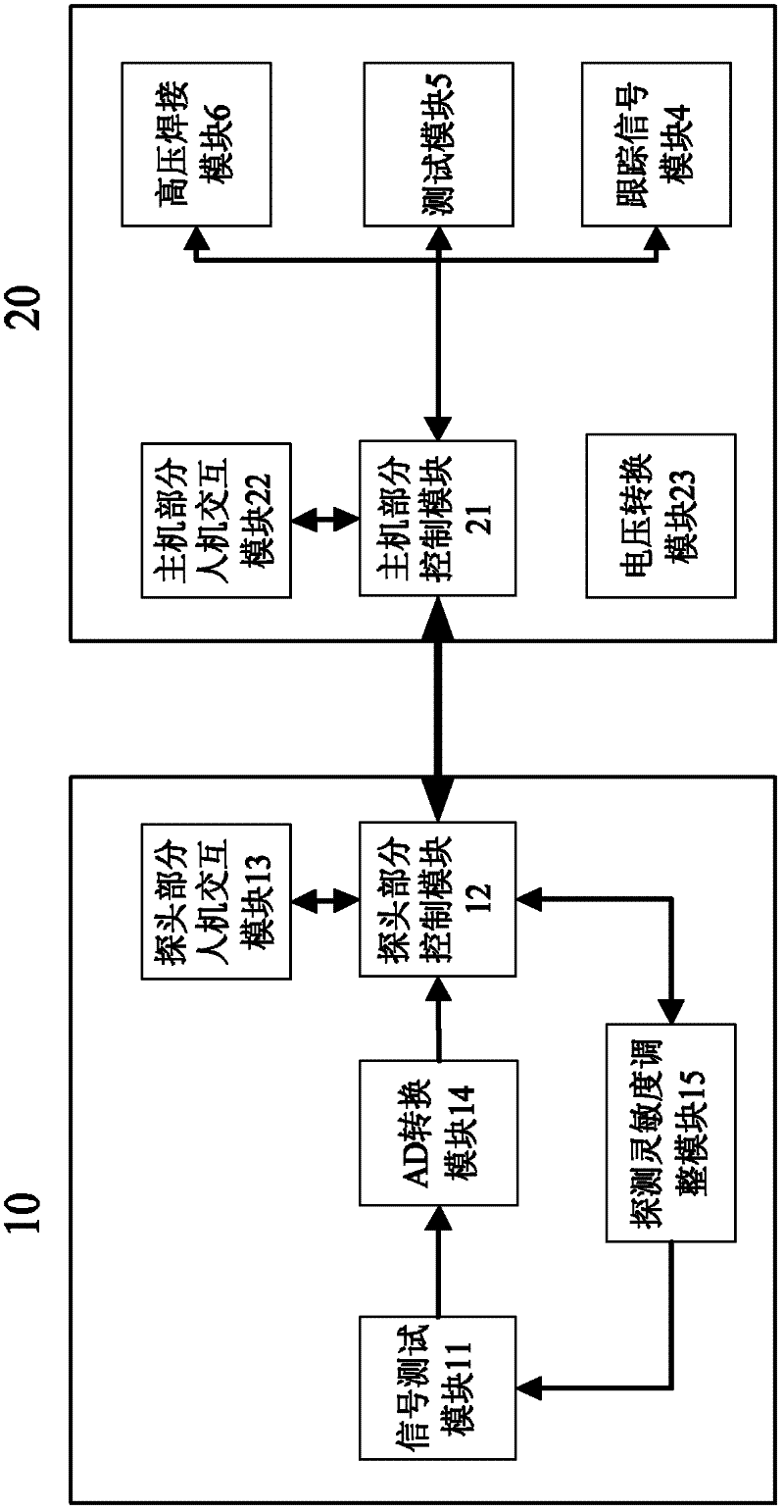

Fault point intellectualized diagnosis and repairing method for geothermal cable and device

ActiveCN102540011AAvoid damageImplement automatic breakpoint repairFault locationInformation technology support systemComputer moduleEngineering

The invention provides a fault point intellectualized diagnosis and repairing method for a geothermal cable and a device. The device comprises a control module, a detection module, a tracing signal module, a test module, a high pressure welding module and a man-machine interaction interface, wherein the detection module is used for detecting a magnetic filed signal near the geothermal cable, the tracing signal module is used for generating high frequency an alternating signal, and high frequency alternating signal input is exerted between the geothermal cable and a shielding line of the cable which form a loop, the test module is used for detecting whether a break point exists on the geothermal cable and whether the loop exists between the geothermal cable and the shielding line of the cable, the high pressure welding module is used for generating high pressure pulse and adding high pressure pulse at two ends of the geothermal cable having a break point to weld the break point, and the man-machine interaction interface is used for achieve interaction between an operator and the device. The device can automatically locate a fault point and can achieve automatic repair of the break point for the cable with a small break position. For the break pint which can not be automatically repaired, the device can enable the repair work to have smallest damage to the ground by accurately finding a the position of the break point.

Owner:狄诺瓦(北京)电子设备有限公司

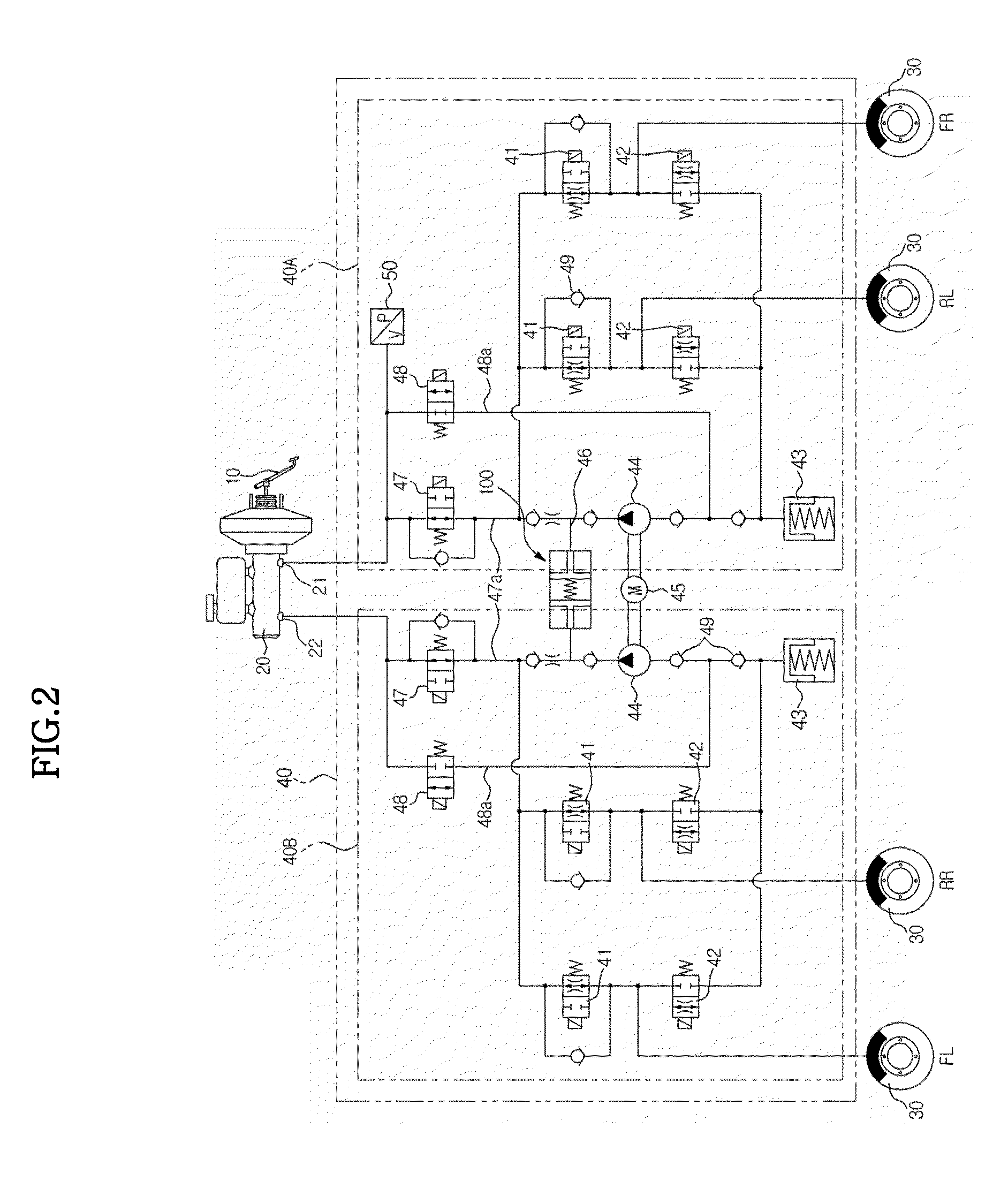

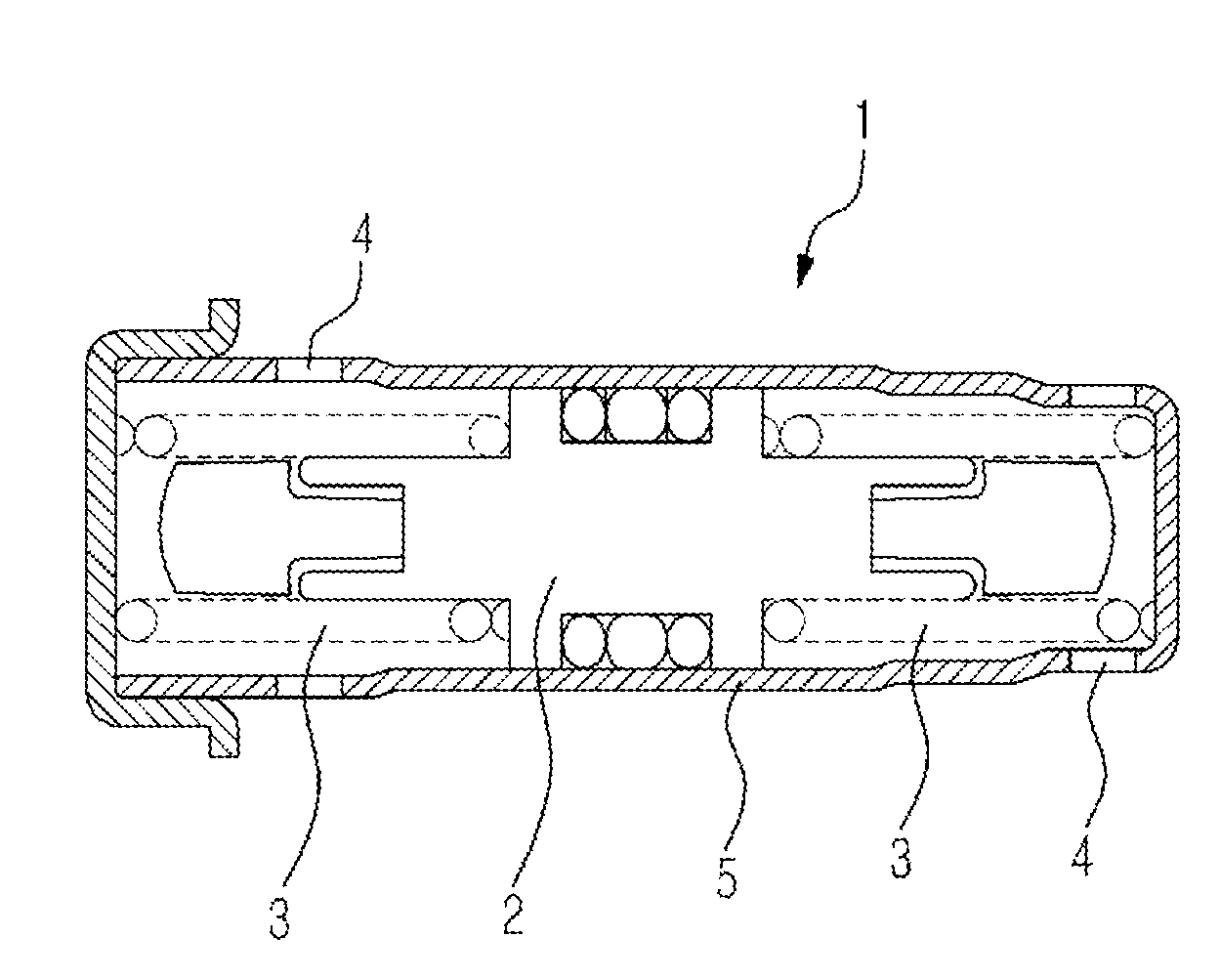

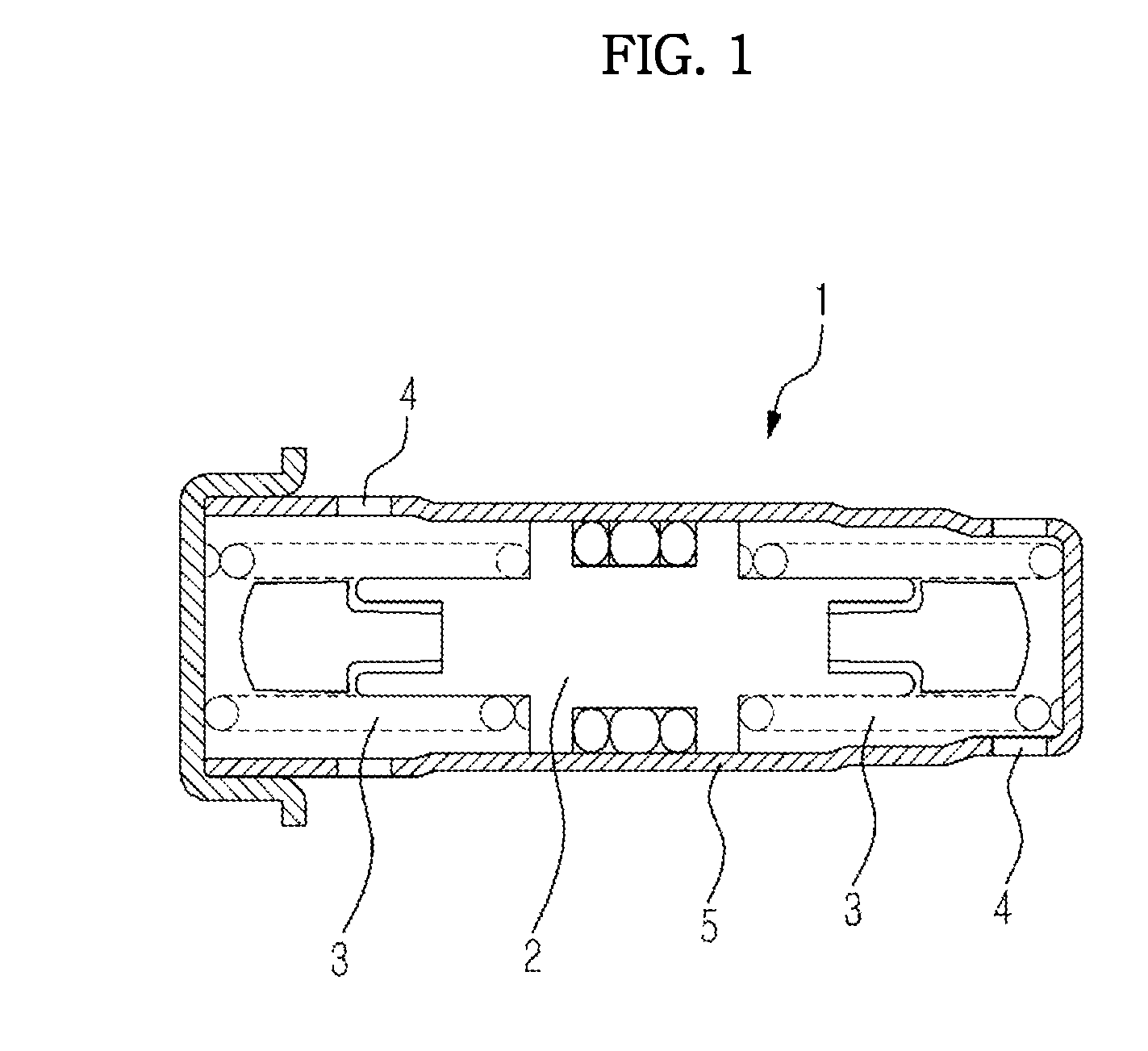

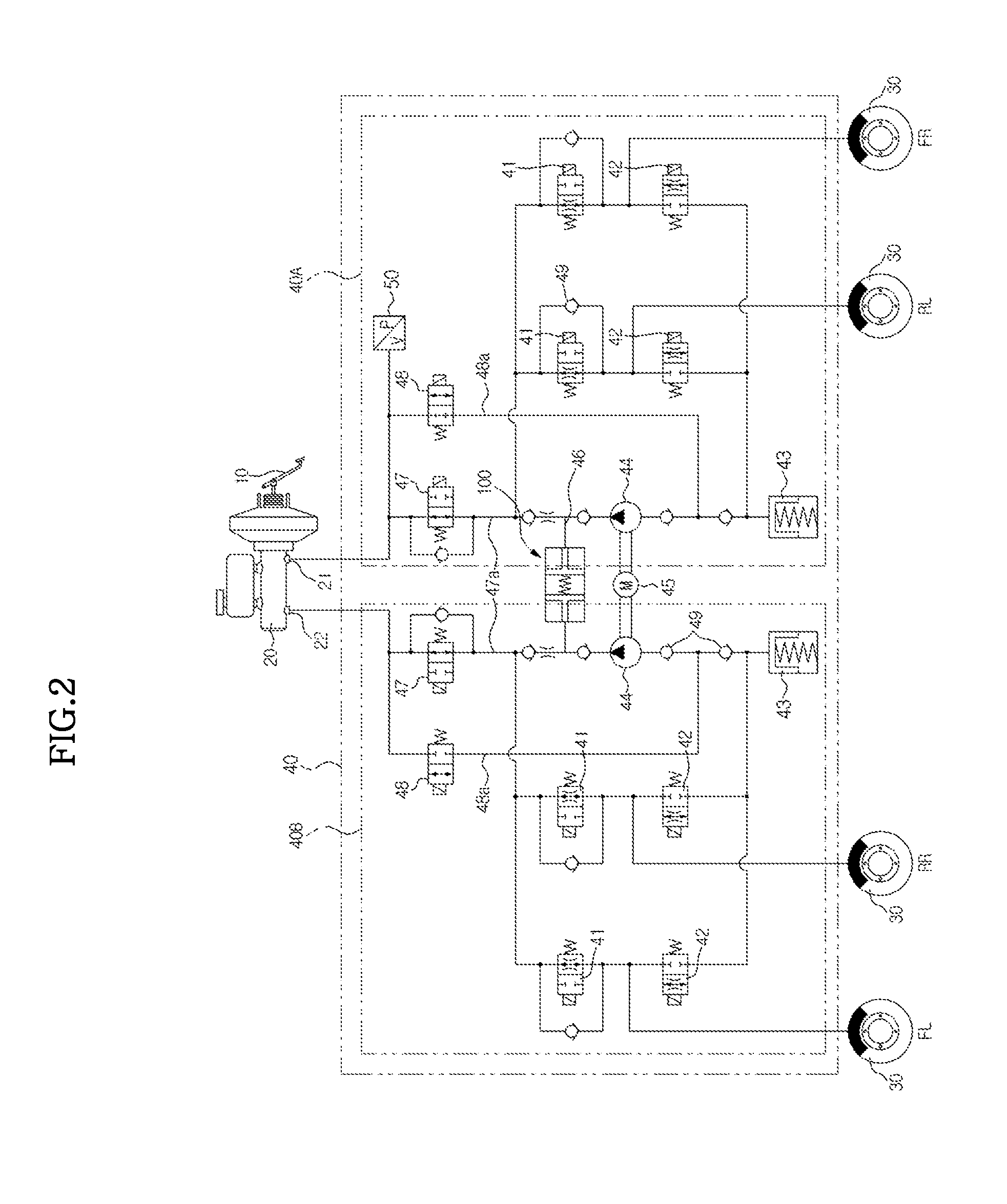

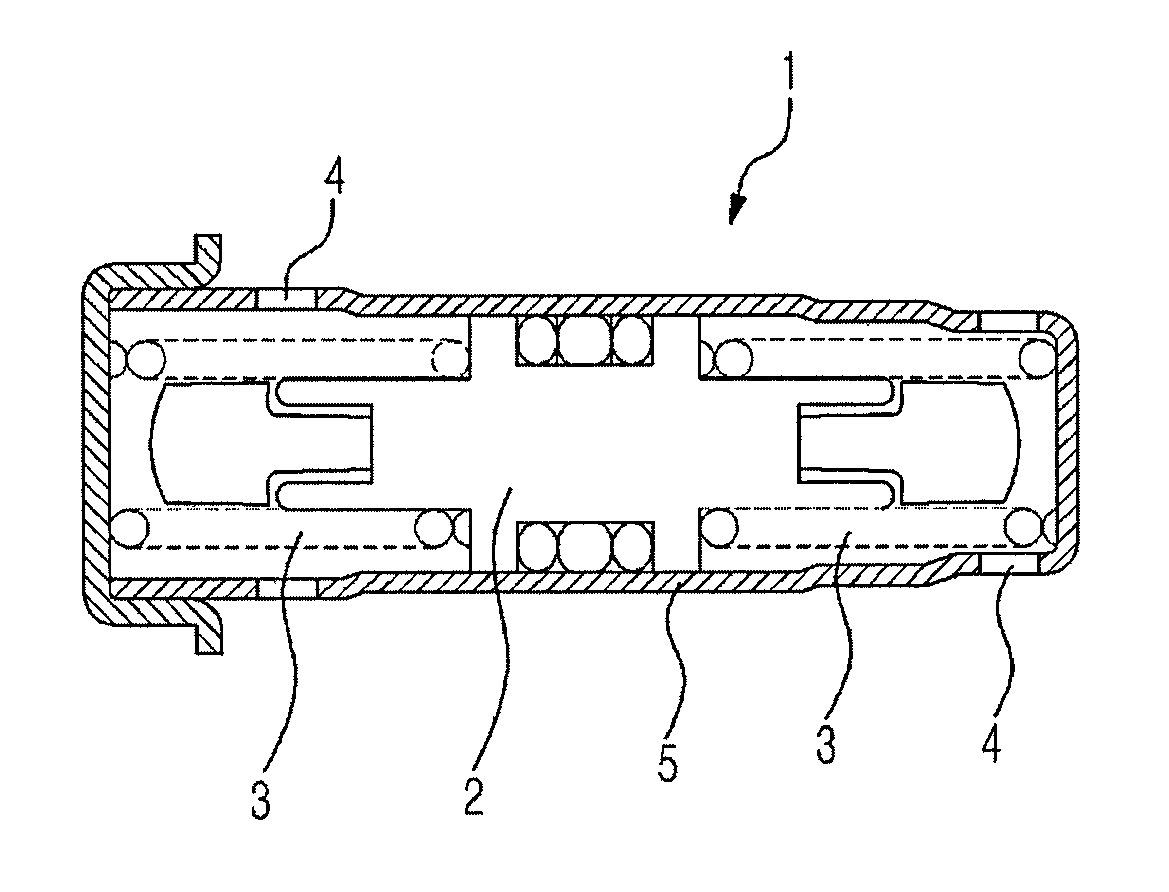

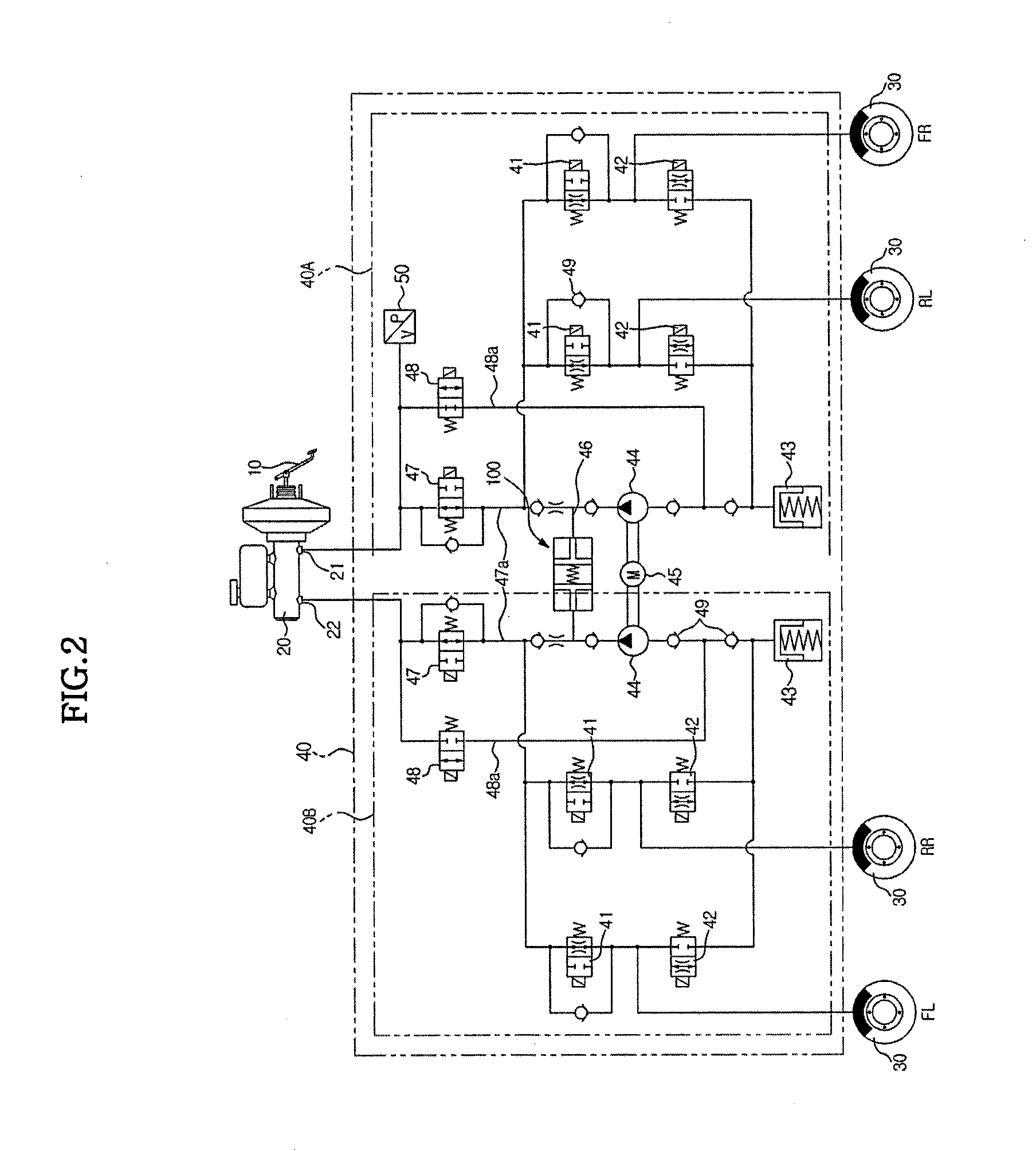

Pressure damping device for brake system

ActiveUS8875741B2Volume changeReduce pressure pulsationPipe elementsPiping arrangementsHydraulic circuitEngineering

There is provided a pressure damping device for a brake system. According to an embodiment of the present invention, an air damping space whose volume is changed in accordance with pressure is provided in an oil passage for connecting two hydraulic circuits, thereby reducing a pressure pulsation generated by a liquid pressure.

Owner:HL MANDO CORP

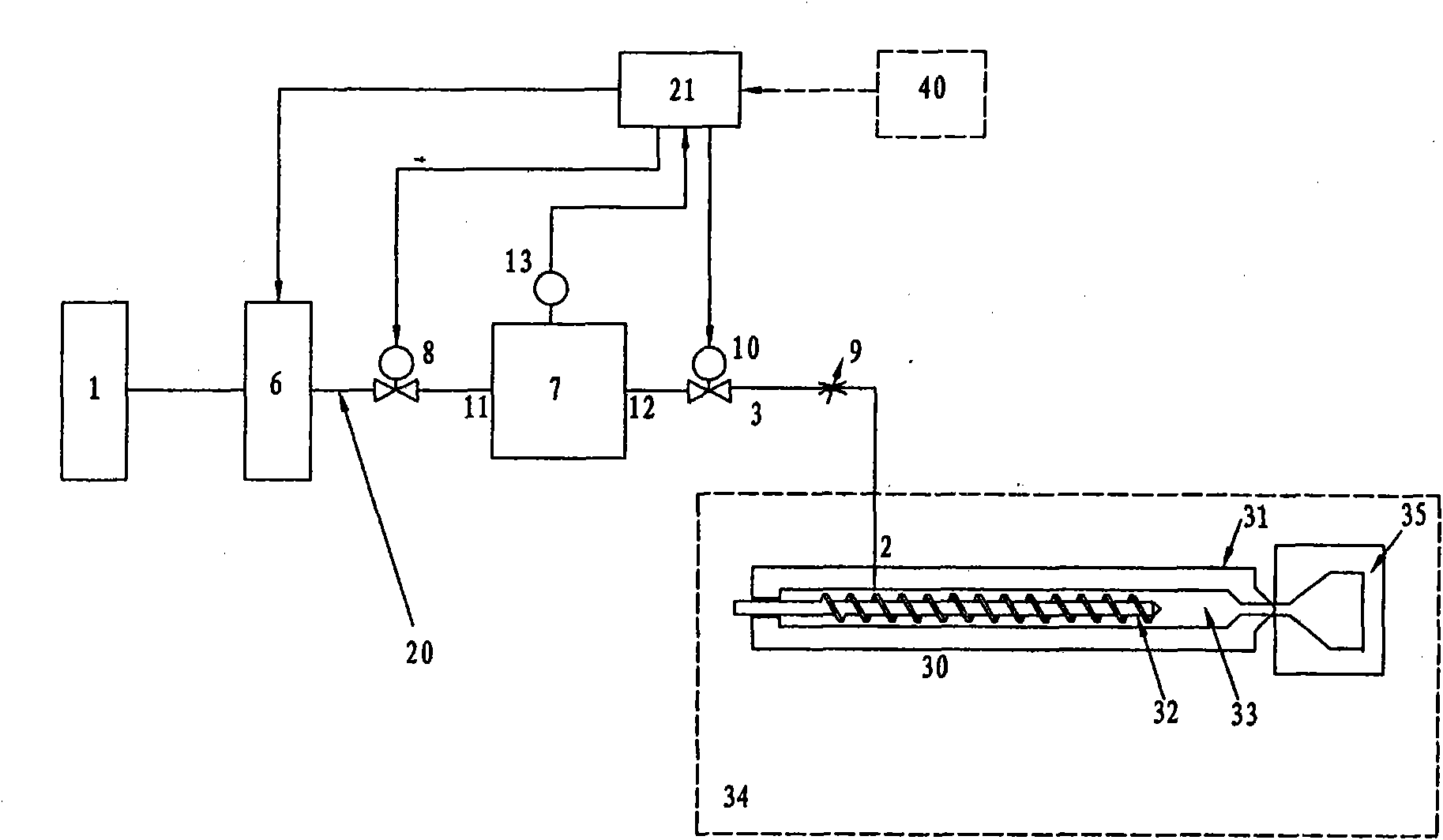

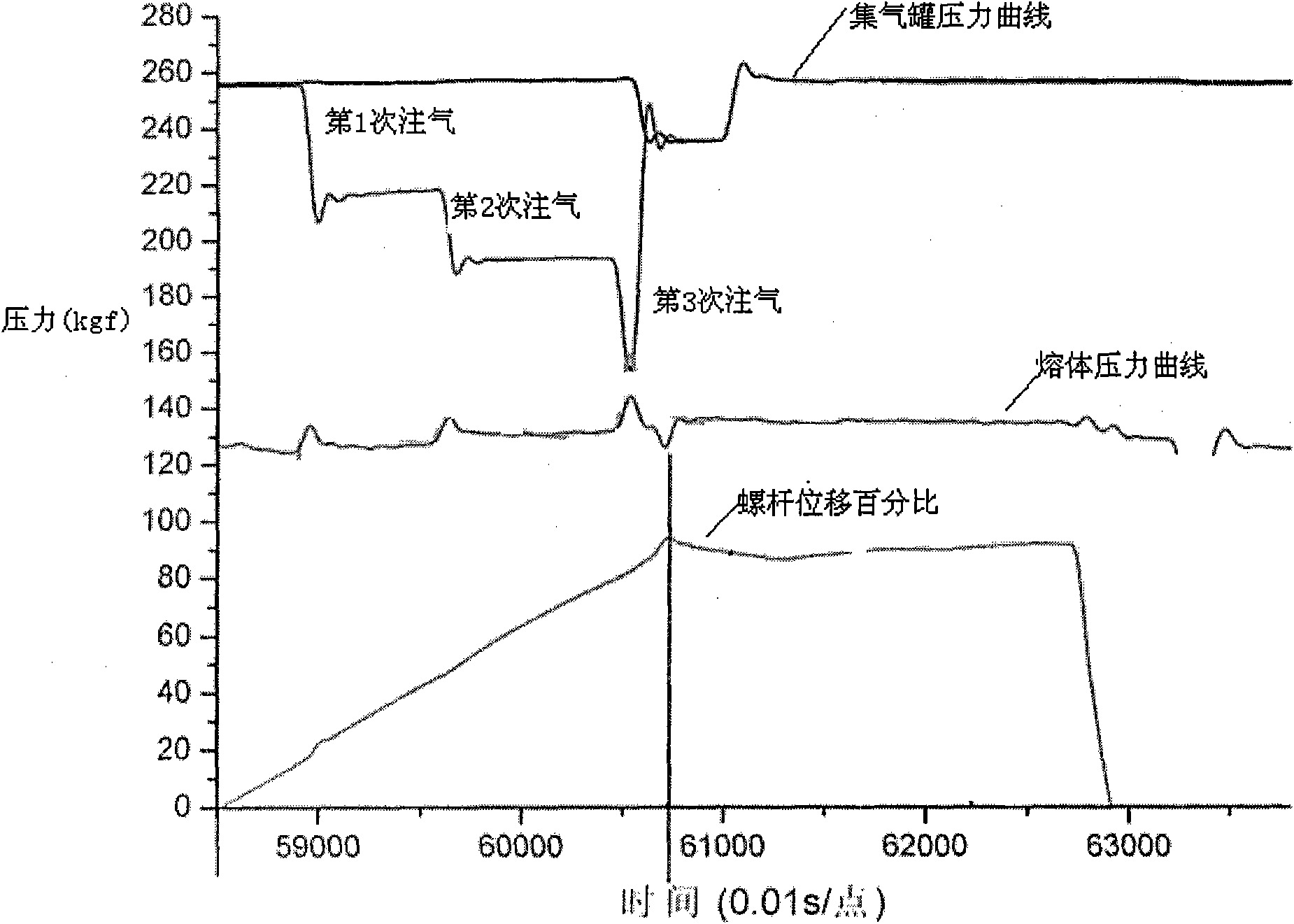

Discontinuous foaming agent control lead-in system and method

The invention relates to a discontinuous foaming agent control lead-in system and a method, which are used for introducing foaming agent to high polymer material in high polymer foamed plastic processing. The system comprises: an air source, a foaming agent filling opening and a pipeline system connected with the air source and the fluid phase of the foaming agent filling opening, wherein, the pipeline system is provided with a gas booster, an air collector and on-off valves respectively installed at an inlet and an outlet of the air collector. At least one current restrictor is installed between the on-off valve at the outlet of the air collector and the foaming agent filling opening. In addition, the system also comprises a control system which receives a signal from processing equipment of the high polymer material, calculates the pressure in the air collector, meanwhile controls the action of the gas booster to adapt to the high polymer material processing and outputs a signal to control the opening or closing of the on-off valves at the inlet and the outlet of the air collector, thus realizing the discontinuous filling of the foaming agent. The invention has simple structure, convenient operation, low cost and is convenient for realizing industrial production.

Owner:BEIJING UNIV OF CHEM TECH

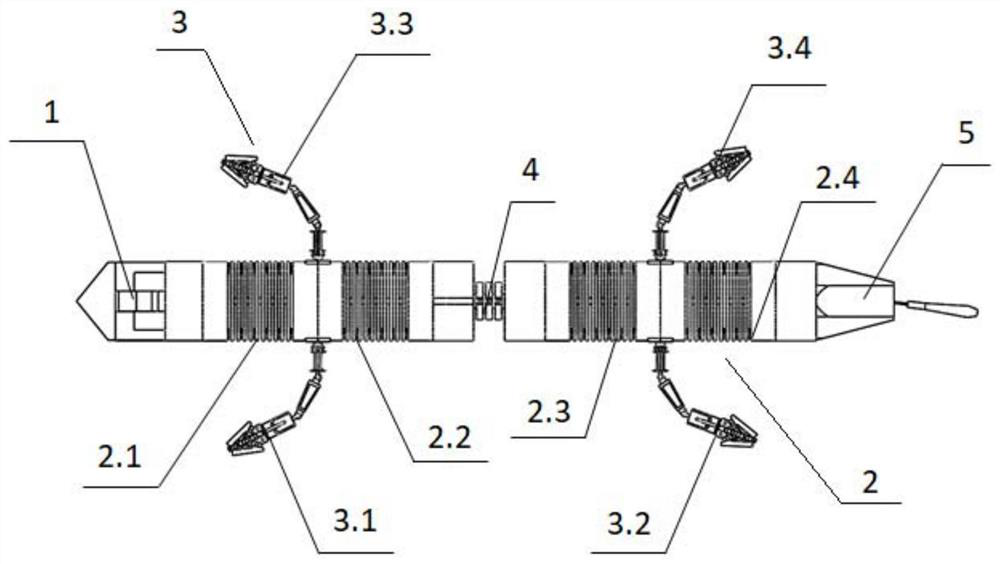

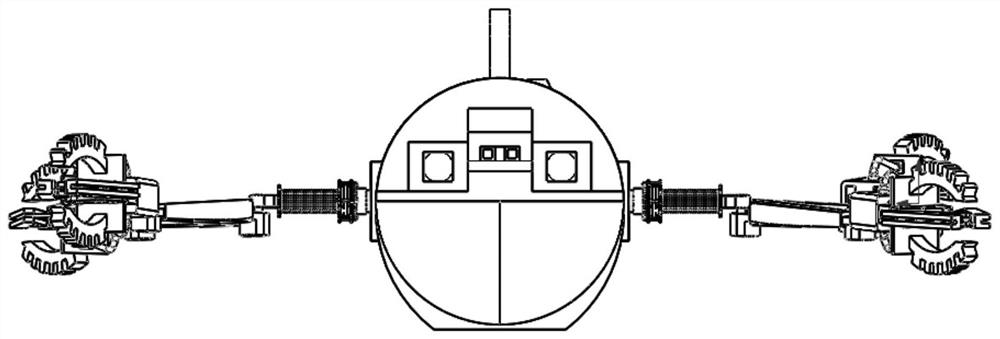

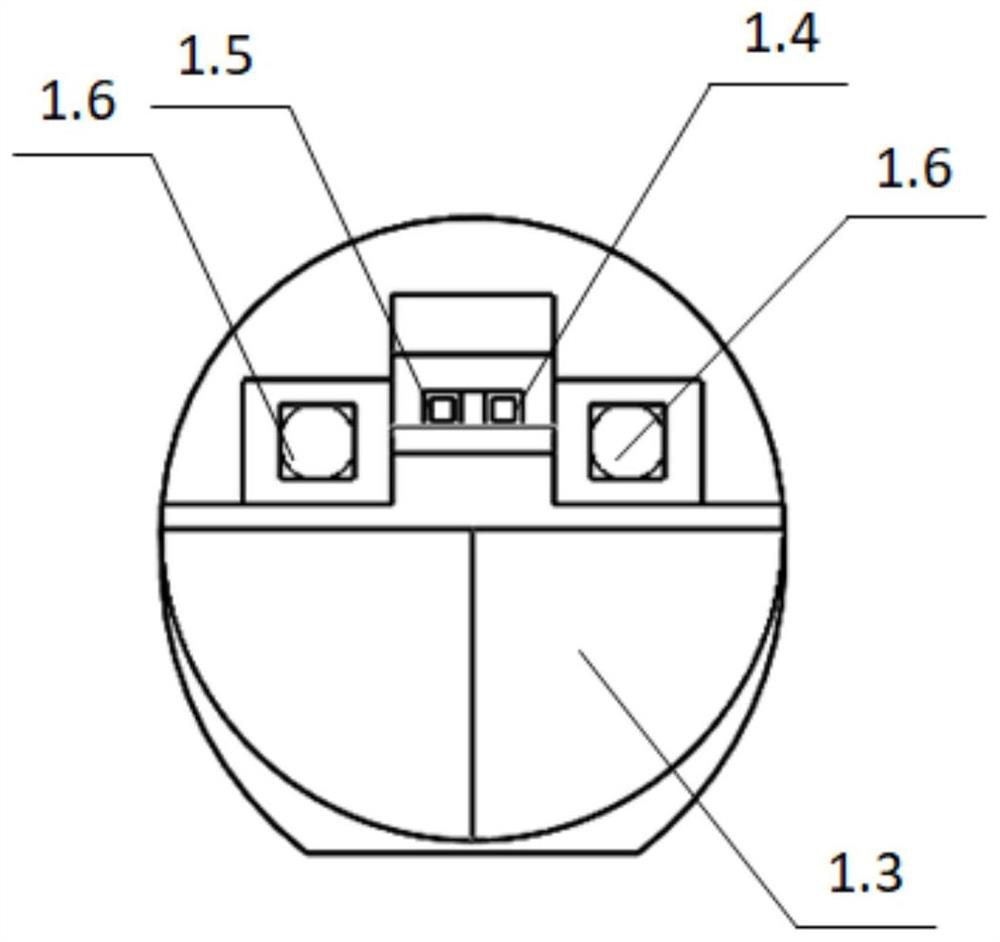

Soft bionic underwater detection robot

ActiveCN112091988AReduce resistanceFlexible swimmingJointsGripping headsControl engineeringElectric machinery

The invention discloses a soft bionic underwater detection robot. The soft bionic underwater detection robot comprises a head detection mechanism, movable base bodies, a mechanical arm module, a spherical hydraulic muscle joint, a tail swing mechanism, a control circuit board and a battery module. Mechanical arms based on a swing mechanism driven by shape memory alloy and a motor in a mixed manneris adopted, a spherical hydraulic muscle joint structure is adopted at the joint of the movable base bodies, the swing degrees of the mechanical arms are changed according to the deformation degree of the spherical joint, and the obstacle passing capacity of the robot is greatly improved. Composite grabbing structures are designed at the tail ends of the mechanical arms, soft hydraulic claws andrigid mechanical claws are combined, and therefore the grabbing capacity of the robot is improved. The tail swing mechanism is based on the electromagnetic principle, and two independently controlledcoils are adopted to attract or repel a magnet between the two coils, so that the swing function is achieved. An ultrasonic detection sensor, an infrared camera and other sensors are integrated in thehead detection mechanism, so that the robot has very high environmental adaptability and working capacity in an underwater natural environment.

Owner:NINGBO UNIV

Slide with thin bottom sample slot

Owner:芜湖市科源教学设备有限公司

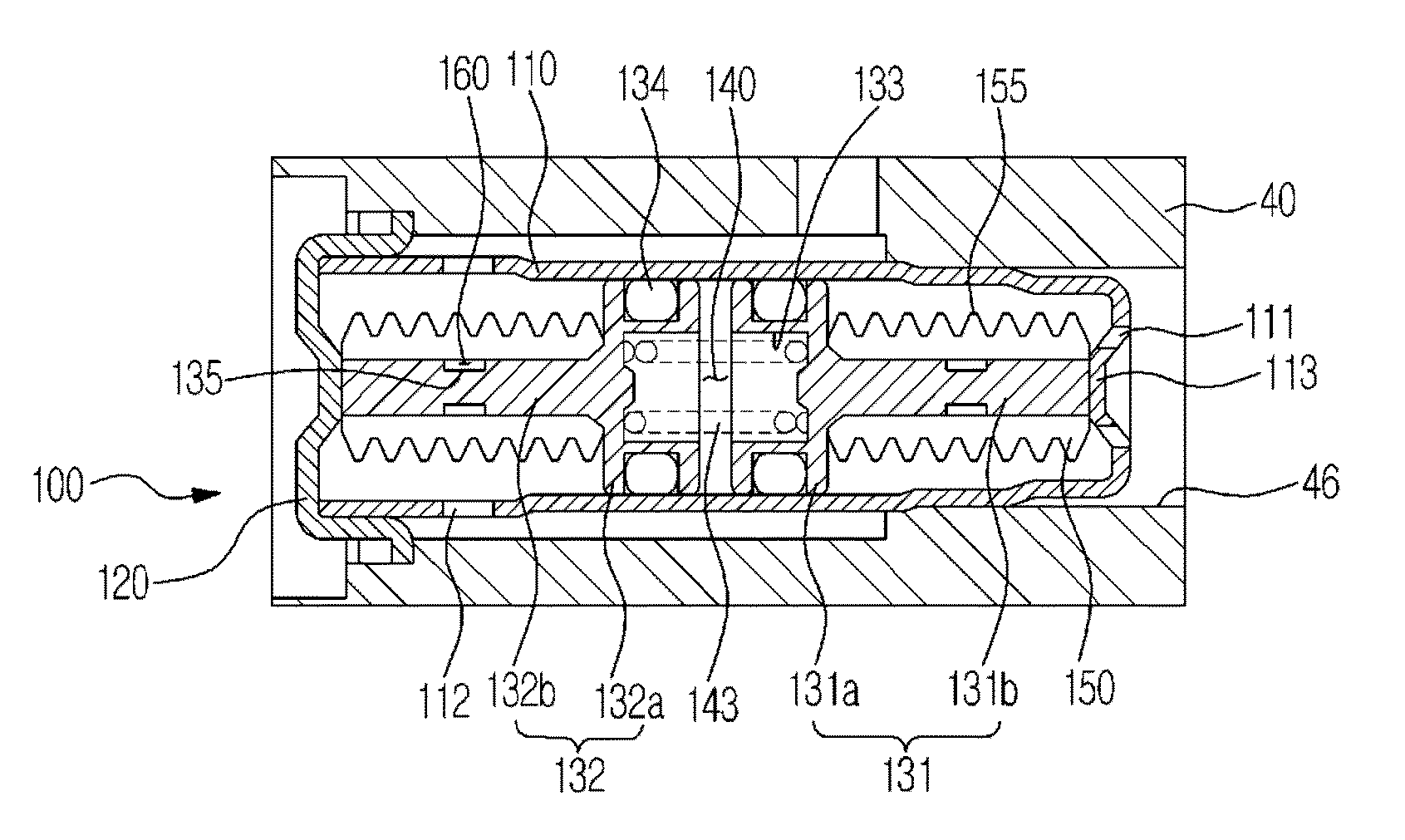

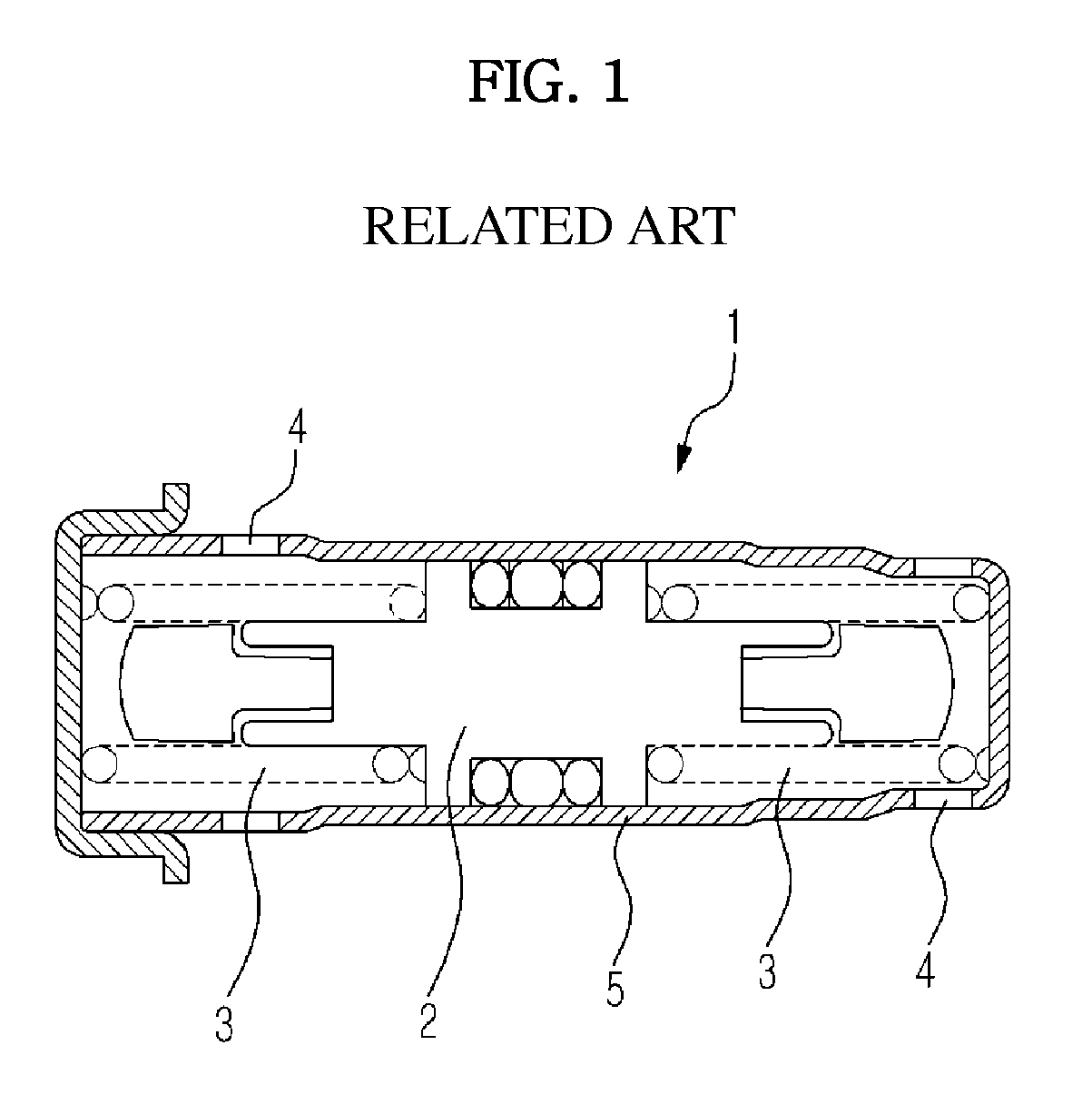

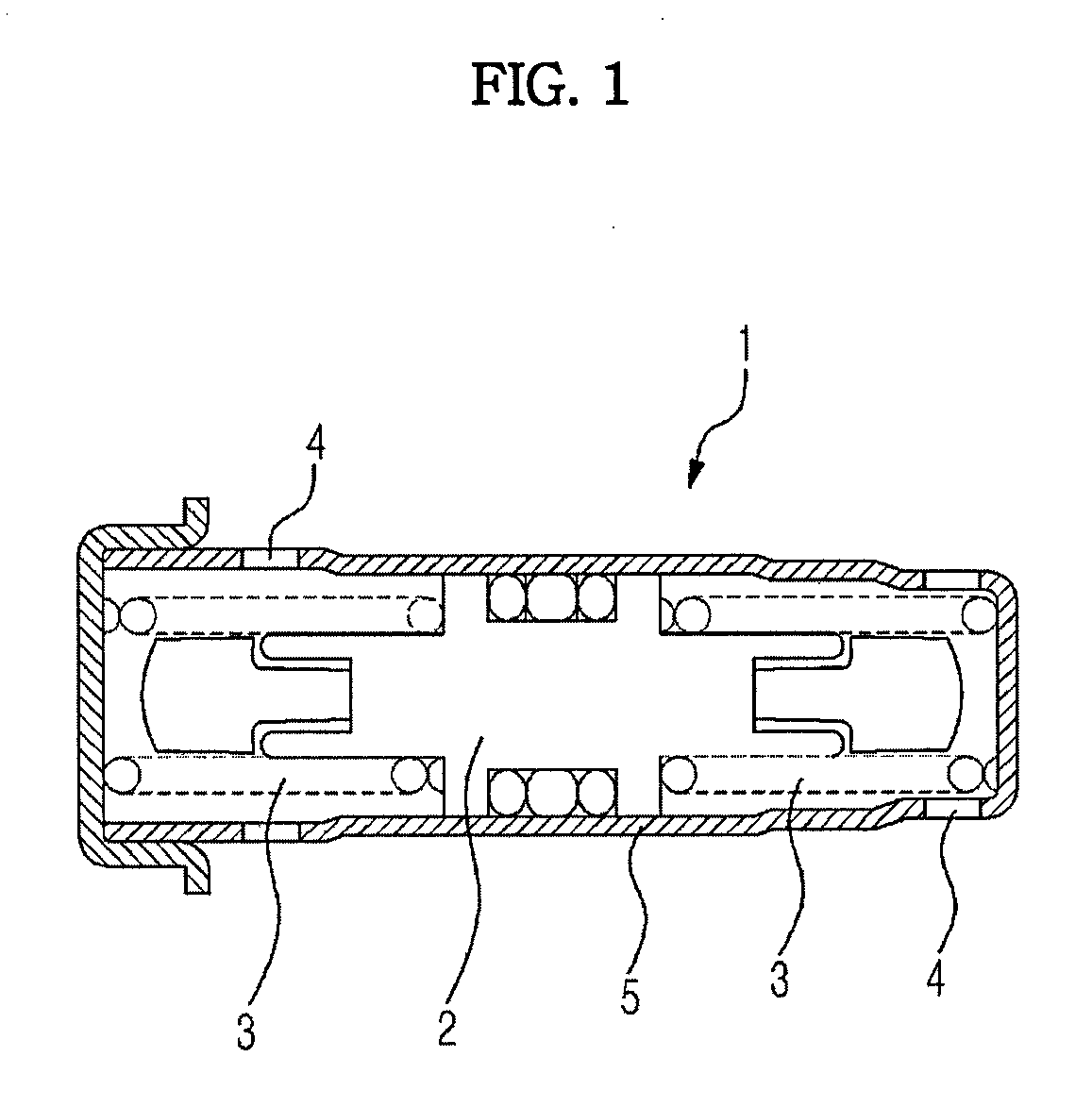

Pressure damping device for brake system

ActiveUS20130269815A1Reduce pressure pulsationVolume changePipe elementsPiping arrangementsHydraulic circuitEngineering

There is provided a pressure damping device for a brake system. According to an embodiment of the present invention, an air damping space whose volume is changed in accordance with pressure is provided in an oil passage for connecting two hydraulic circuits, thereby reducing a pressure pulsation generated by a liquid pressure.

Owner:HL MANDO CORP

Pressure damping device for brake system

ActiveUS20130269816A1Reduce pressure pulsationVolume changePipe elementsPiping arrangementsPistonLiquid pressure

There is provided a pressure damping device for a brake system. The damping device includes a cylindrical housing that is fixed to the oil passage, includes a first liquid pressure hole and a second liquid pressure hole respectively communicating with a main oil passage of the first and second hydraulic circuits, and is opened on one side thereof, a lid member that is coupled so as to close the opened one side of the housing, first and second pistons that are spaced apart from each other and move forward and backward within the housing, and a spring that is interposed between the first and second pistons to provide an elastic force to the first and second pistons. Here, a sealing member is provided on an outer circumferential surface of each piston so that a space between the first and second pistons is sealed, and an air damping space whose volume is changed in accordance with a pressure of a liquid pressure is provided between the first and second pistons.

Owner:HL MANDO CORP

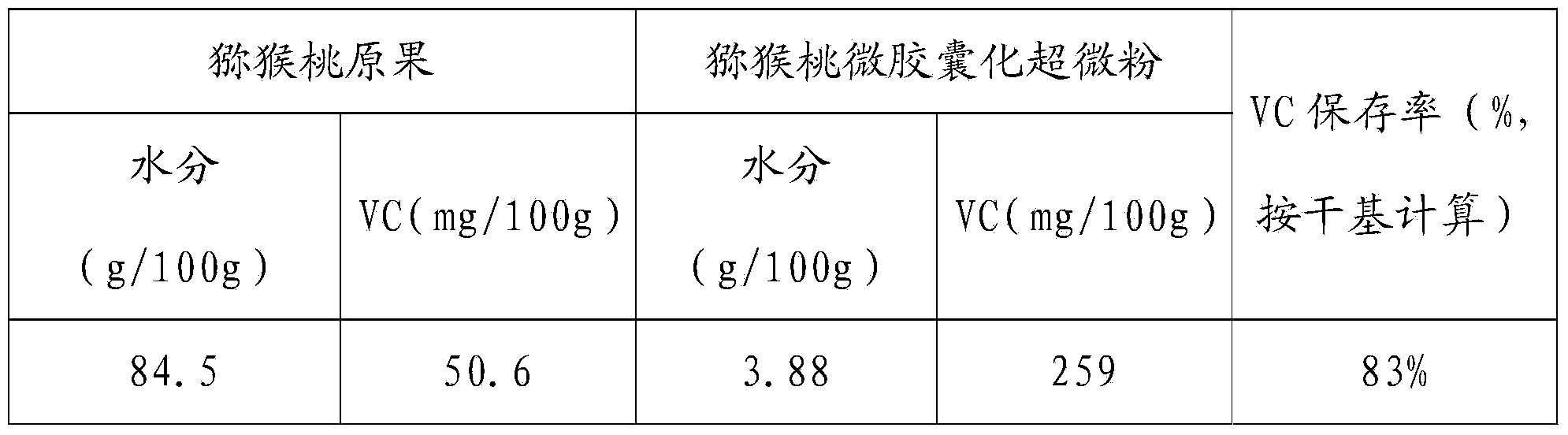

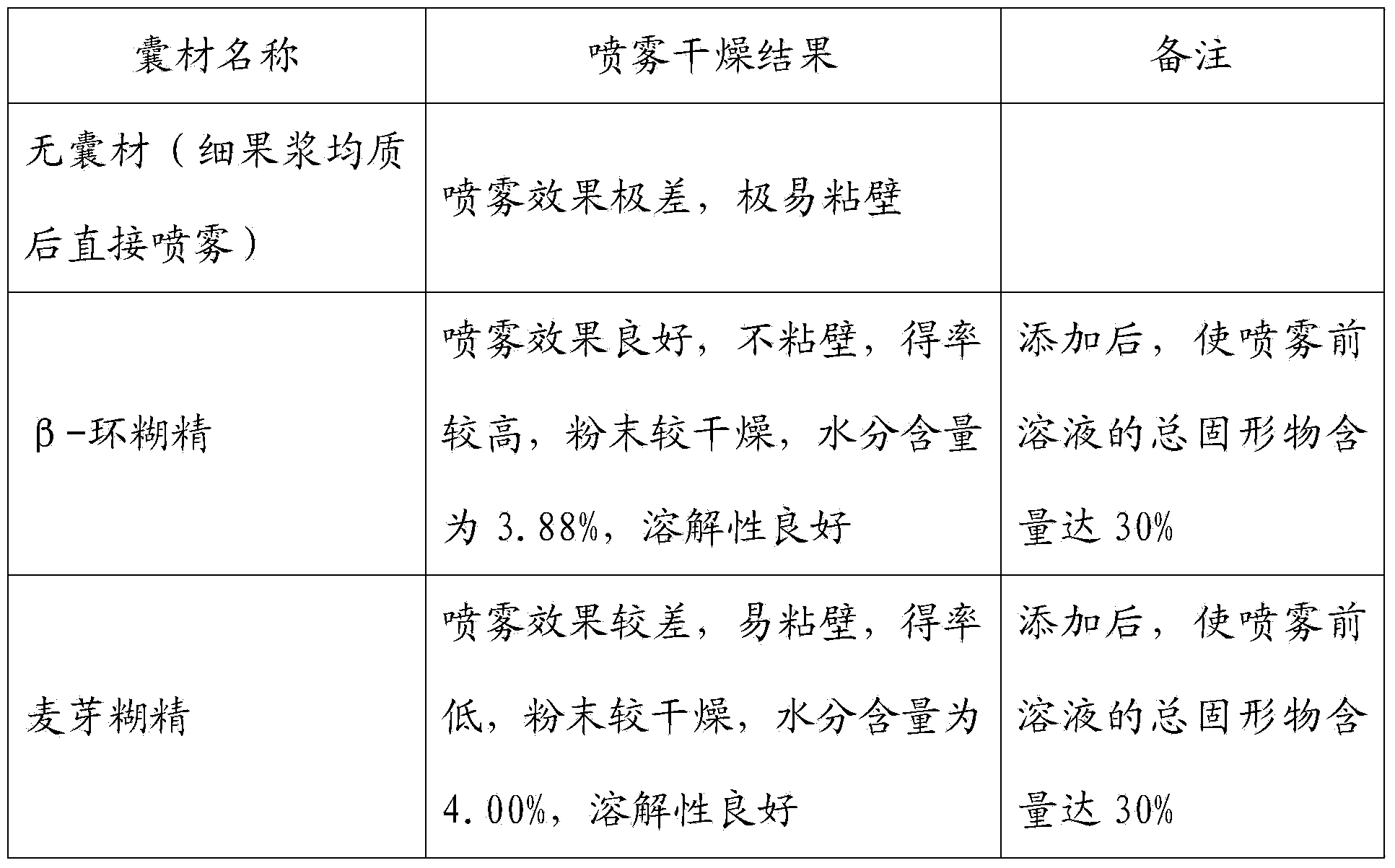

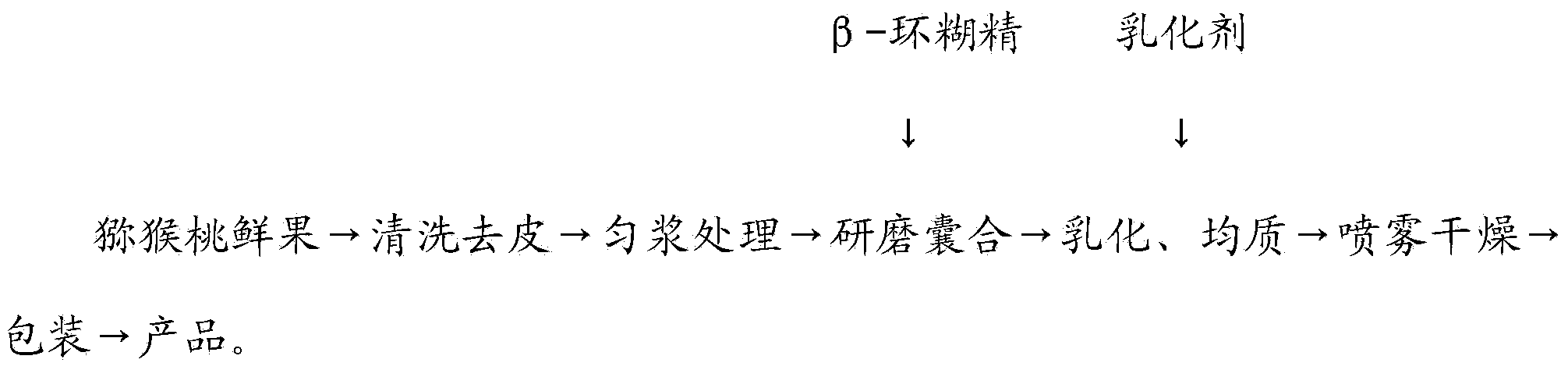

Microencapsulated kiwi fruit ultramicropowder and preparation method thereof

The invention relates to microencapsulated kiwi fruit ultramicropowder and a preparation method thereof. According to the method, kiwi fruit subjected to peel and seed removal is microencapsulated and superfinely grinded; microencapsulating and superfine grinding processes are fused into a preparation process; in the same processing process, the kiwi fruit can be microencapsulated, superfinely grinded and powdered (juice). The microencapsulated kiwi fruit ultramicropowder is uniform and stable in color, basically keeps the original flavor, is low in nutrition loss, long in storage time, convenient to transport and use, good in dispersity and easy to digest and absorb, can be widely used as various food ingredients, functional food ingredients, special nutritional food and the like, and is especially suitable for making foods for olds, foods for children, beauty foods, nutritional healthcare foods, baked foods and the like.

Owner:CHONGQING FOOD IND RES INST

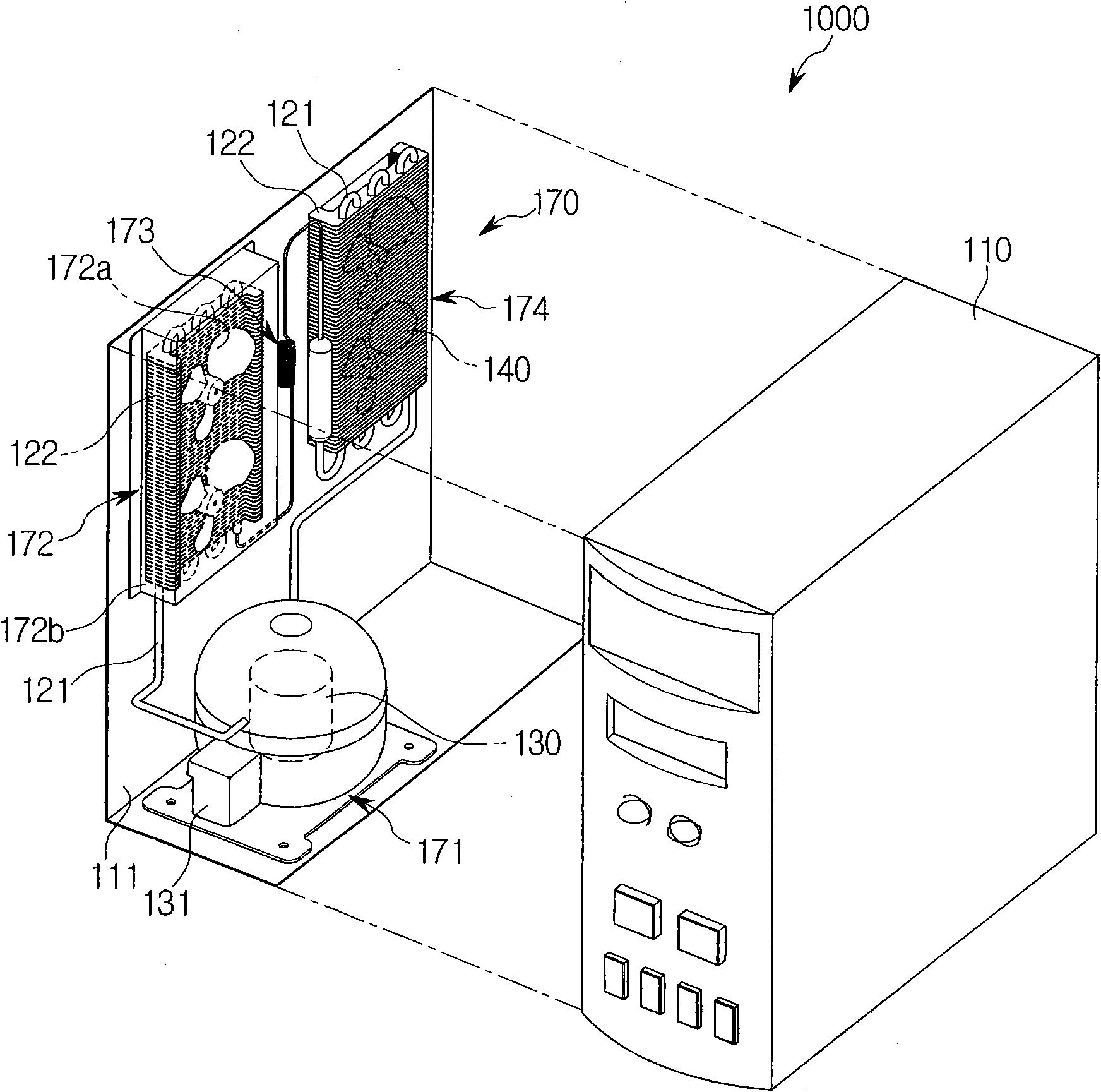

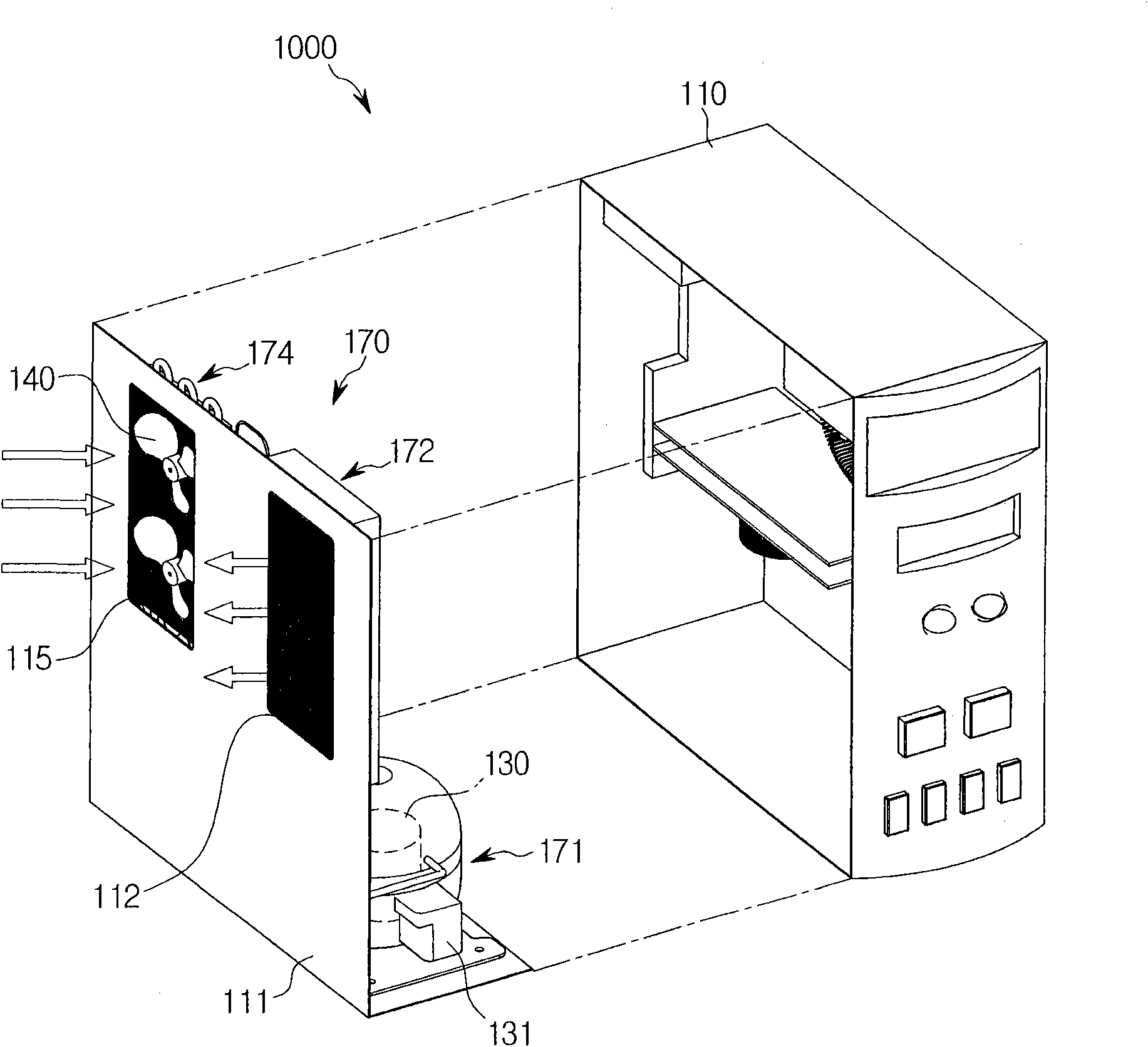

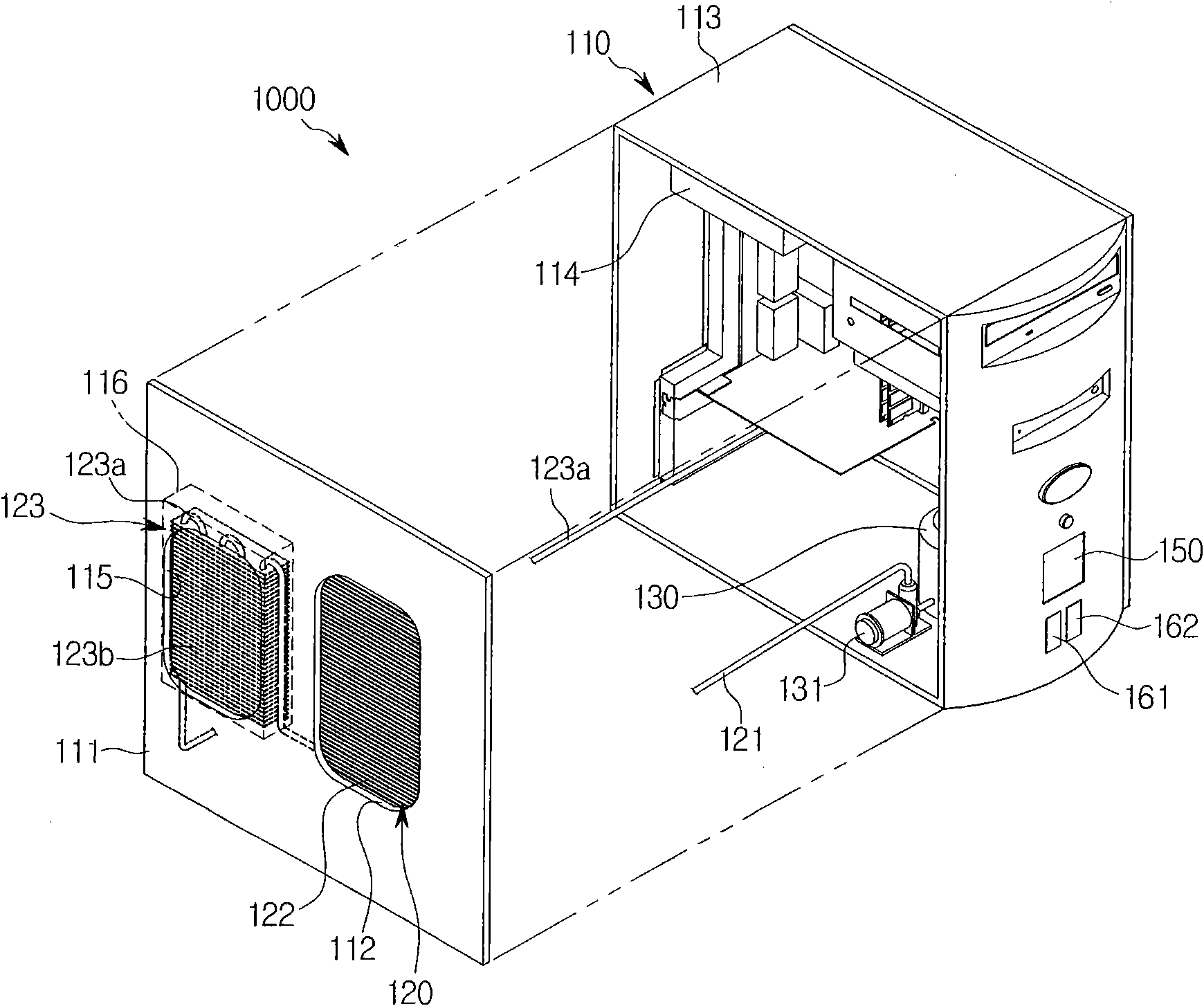

Apparatus for cooling computer body by introducing cooling air therein

InactiveCN102122200AGuaranteed uptimeImprove cooling efficiencyDigital data processing detailsEngineeringRefrigerant

Disclosed herein is an apparatus, which circulates a refrigerant in a computer body to produce cooling air and introduces the cooling air into the computer body, thus cooling the computer body. The apparatus includes an opening hole formed in either of side covers closing both side surfaces of the computer body to permit inflow of external air. A cooling hole is formed in the side cover in such a way as to be spaced apart from the opening hole. A cooling means is provided inside the side cover of the computer body, produces cooling air and cools a refrigerant by supplying, circulating and collecting the refrigerant stored in a refrigerant tank, thus cooling the interior of the computer body with the cooling air.

Owner:徐昌涣

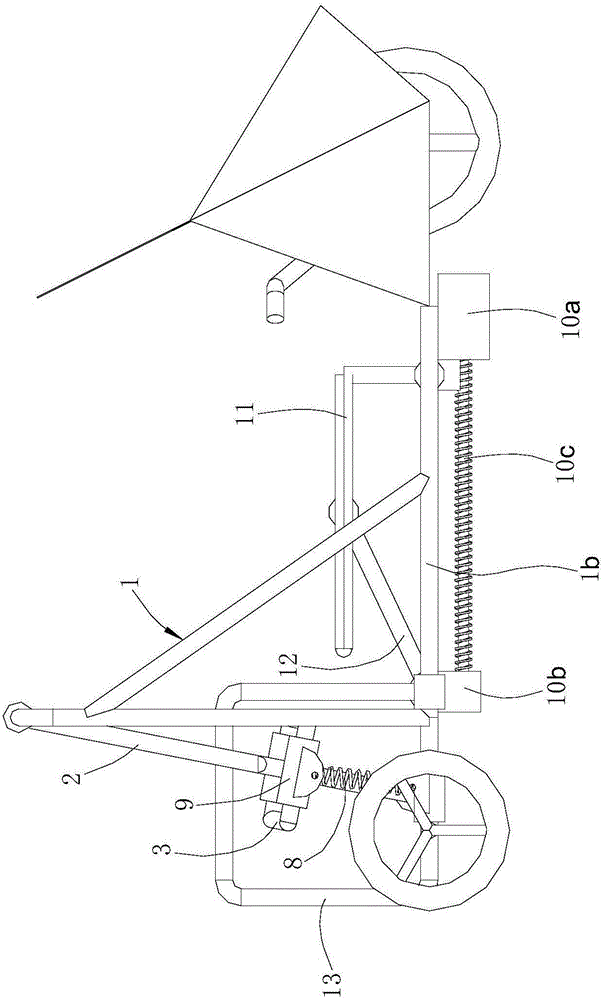

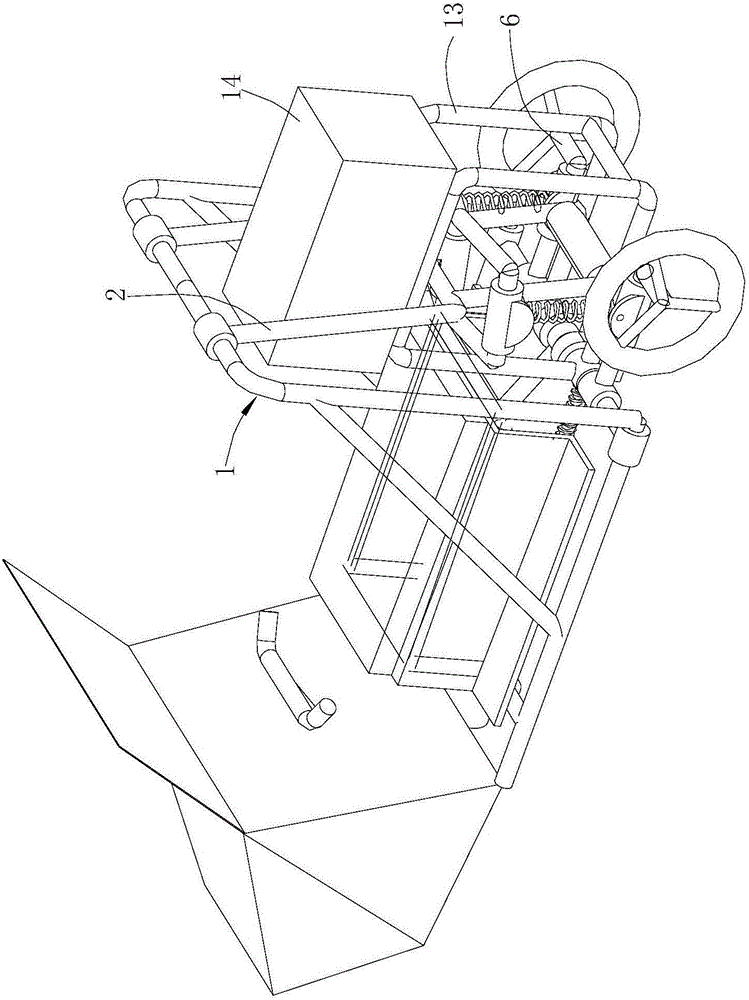

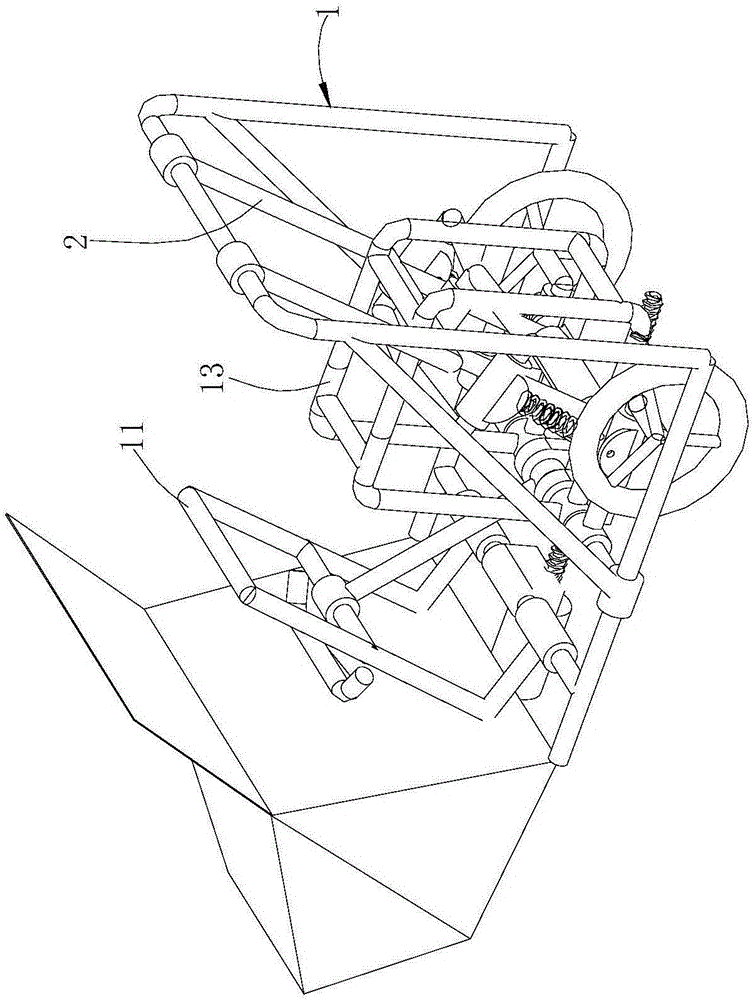

Stretchable trolley frame device and stretchable trolley

The invention provides a stretchable trolley frame device which comprises a frame, a swinging frame, a stretchable assembly and two axles. A containing cavity is formed in the rear portion of the frame. The upper end of the swinging frame and the upper end of the containing cavity are hinged. The stretchable assembly comprises a sliding rod and a sliding rail. The sliding rail is arranged on the side wall of the containing cavity. The sliding rod is matched with the sliding rail. The sliding rod and the swinging frame are connected through a first connecting rod. The two axles and the sliding rod are connected through a second connecting rod. The middle of a rocking frame and the swinging frame are hinged, and shock absorbers are arranged between the two sides of the rocking frame and the two axles. When the stretchable trolley frame device is in the retracted device, the sliding rod is operated to move towards the rear portion of the trolley, the swinging frame can be driven and drive the axles to be moved out of the containing cavity, and the internal space of the trolley frame is increased. The invention further provides the stretchable trolley which comprising the stretchable trolley frame device. The stretchable trolley has all the advantages of the stretchable trolley frame device.

Owner:陈卫

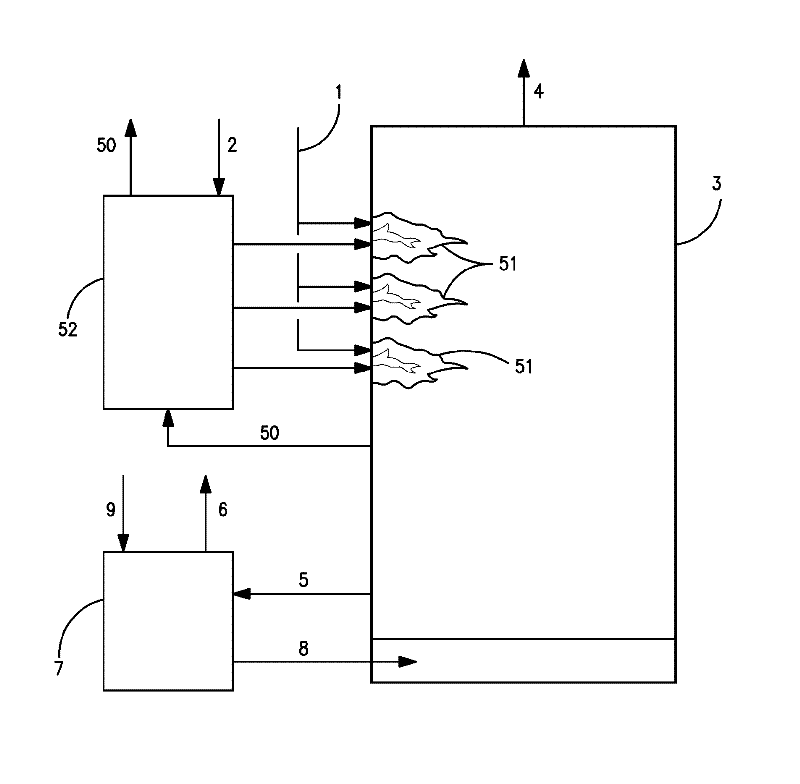

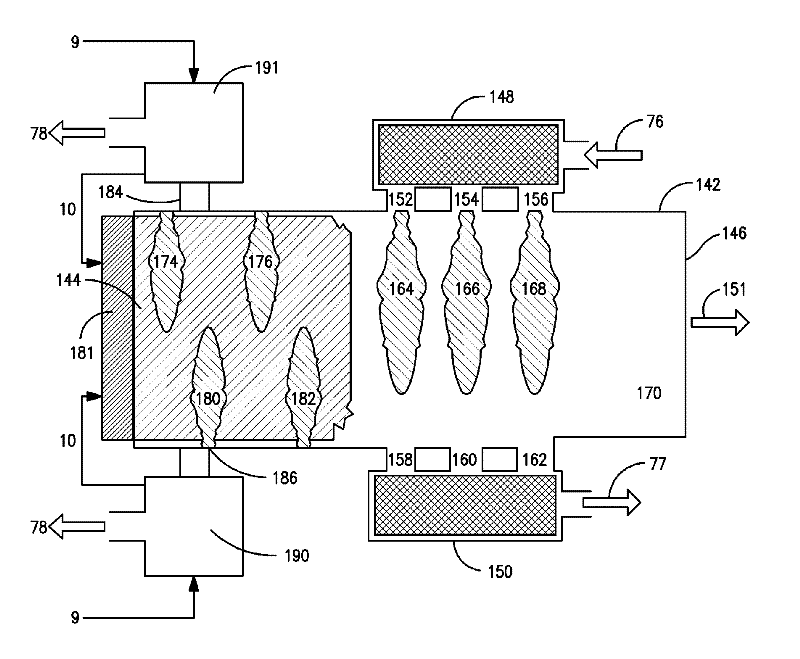

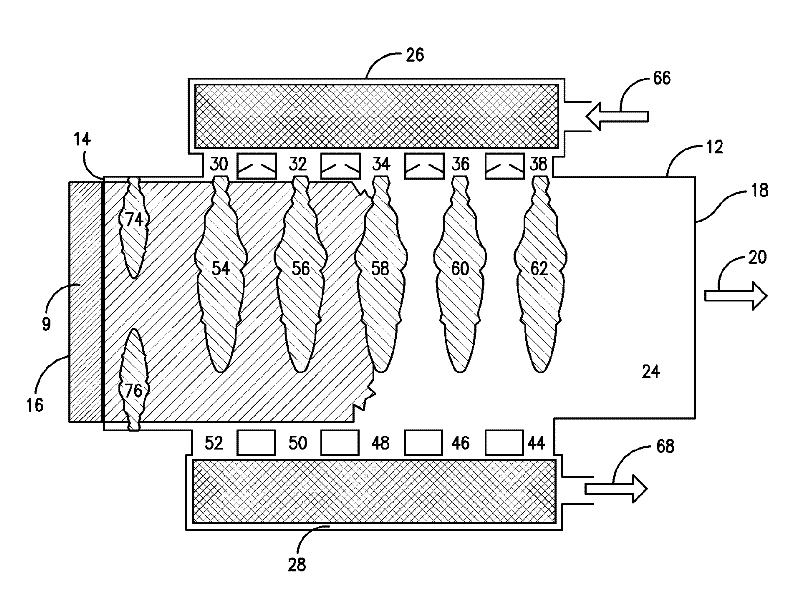

Furnace with multiple heat recovery systems

InactiveCN102227384AVolume changeCharging furnaceCombustion processProcess engineeringHeat capacity rate

Owner:PRAXAIR TECH INC

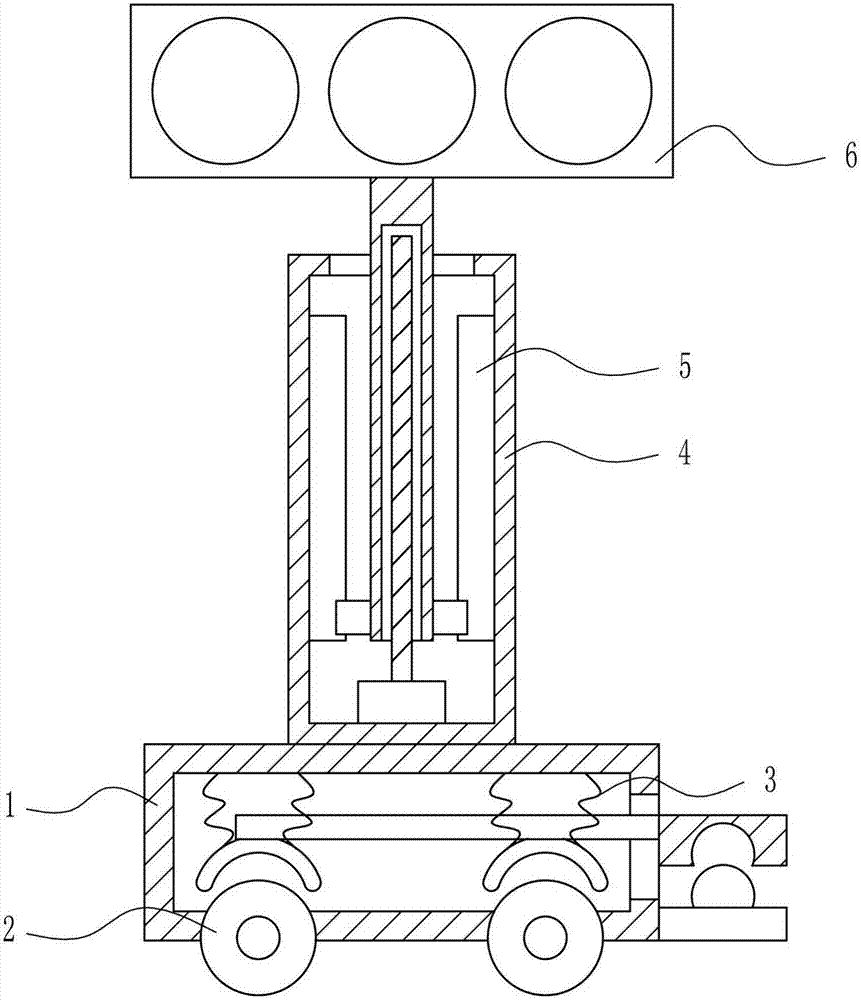

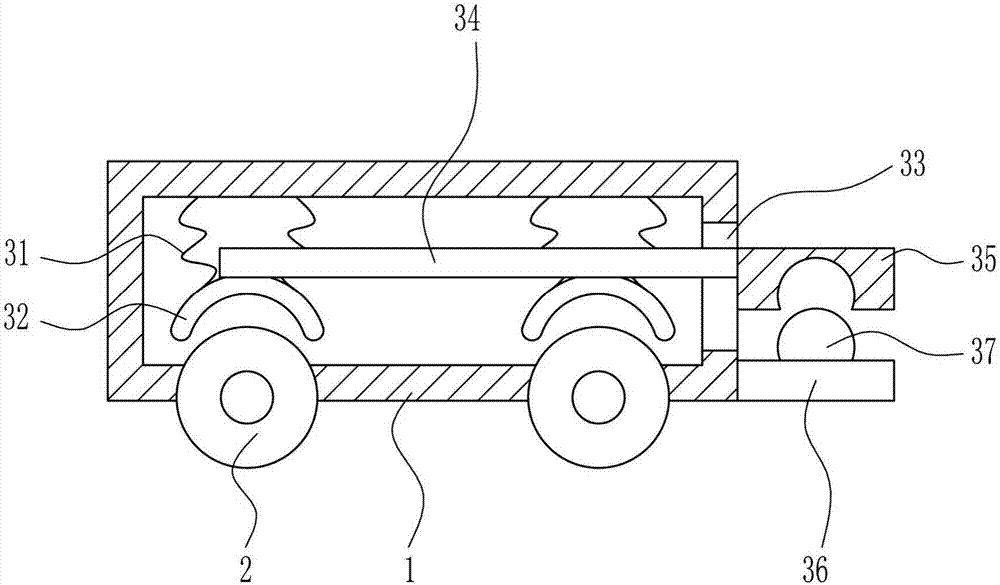

Portable traffic light equipment

InactiveCN107093325ATo achieve the effect of fixing the deviceVolume changeRoad vehicles traffic controlLight equipmentEngineering

The invention relates to traffic light equipment and especially relates to portable traffic light equipment. A technical problem is that the traffic light equipment which is liftable, and has a small volume and light weight is needed. In order to solve the above technical problem, the invention provides the portable traffic light equipment. The equipment comprises a pedestal and the like. Left and right sides of a bottom of the pedestal are symmetrically provided with wheels, and a middle-upper portion of the pedestal is provided with a fixing device. A center of a top of the pedestal is provided with an installation frame. A lifting device is arranged in the installation frame. A top of the lifting device is provided with a traffic light body. In the invention, through downwardly pedaling a concave pedal, the concave pedal gets stuck by an embossment so that a brake pad is contacted with wheel tops; and the wheels are fixed and an effect of fixing the equipment is achieved. Through controlling different direction rotation of a motor, the traffic light body can be risen to an appropriate height when the equipment is used so that an effect of convenient carrying is reached.

Owner:刘斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com