Microencapsulated kiwi fruit ultramicropowder and preparation method thereof

A technology of kiwifruit and ultrafine powder, which is applied in food preparation, application, food science, etc., can solve the problems that the particle size of the micropowder cannot meet the requirements of the ultrafine powder, easy loss of kiwifruit nutrients, and low utilization rate of raw materials, etc. To achieve the effect of short drying time, uniform product quality and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

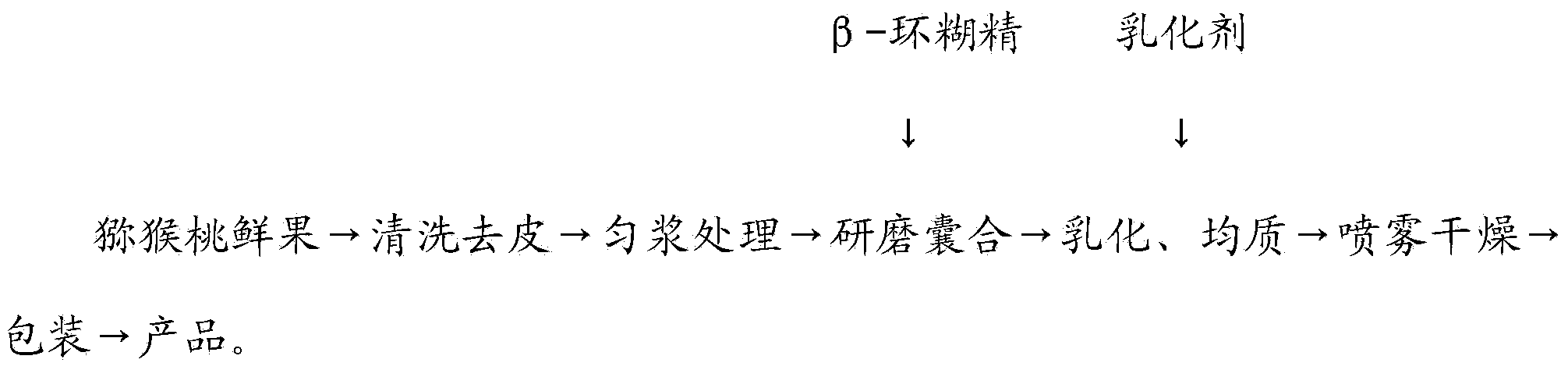

Method used

Image

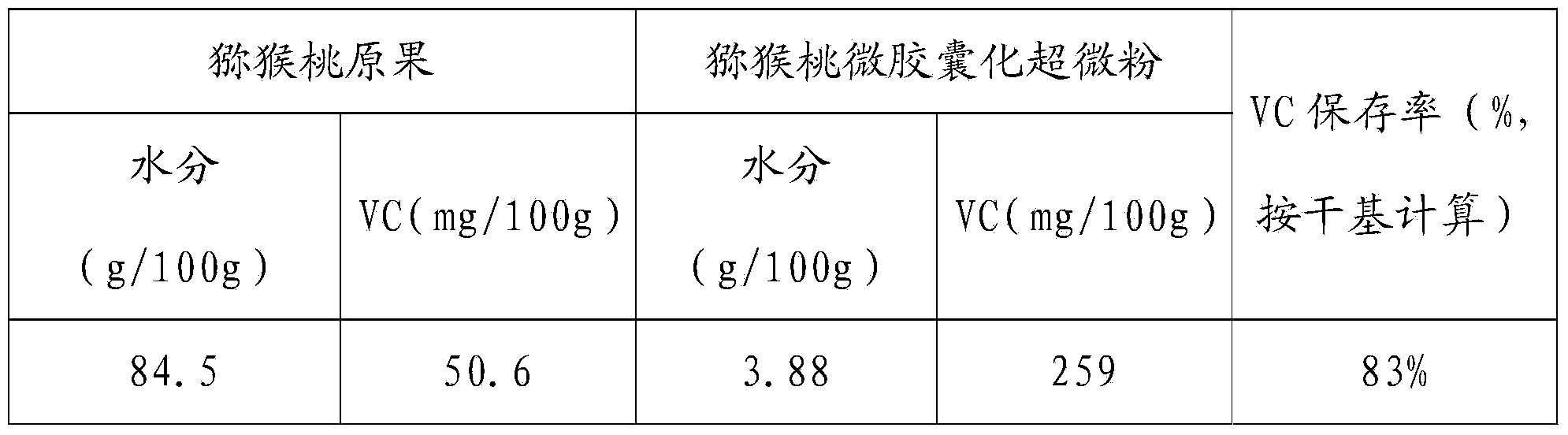

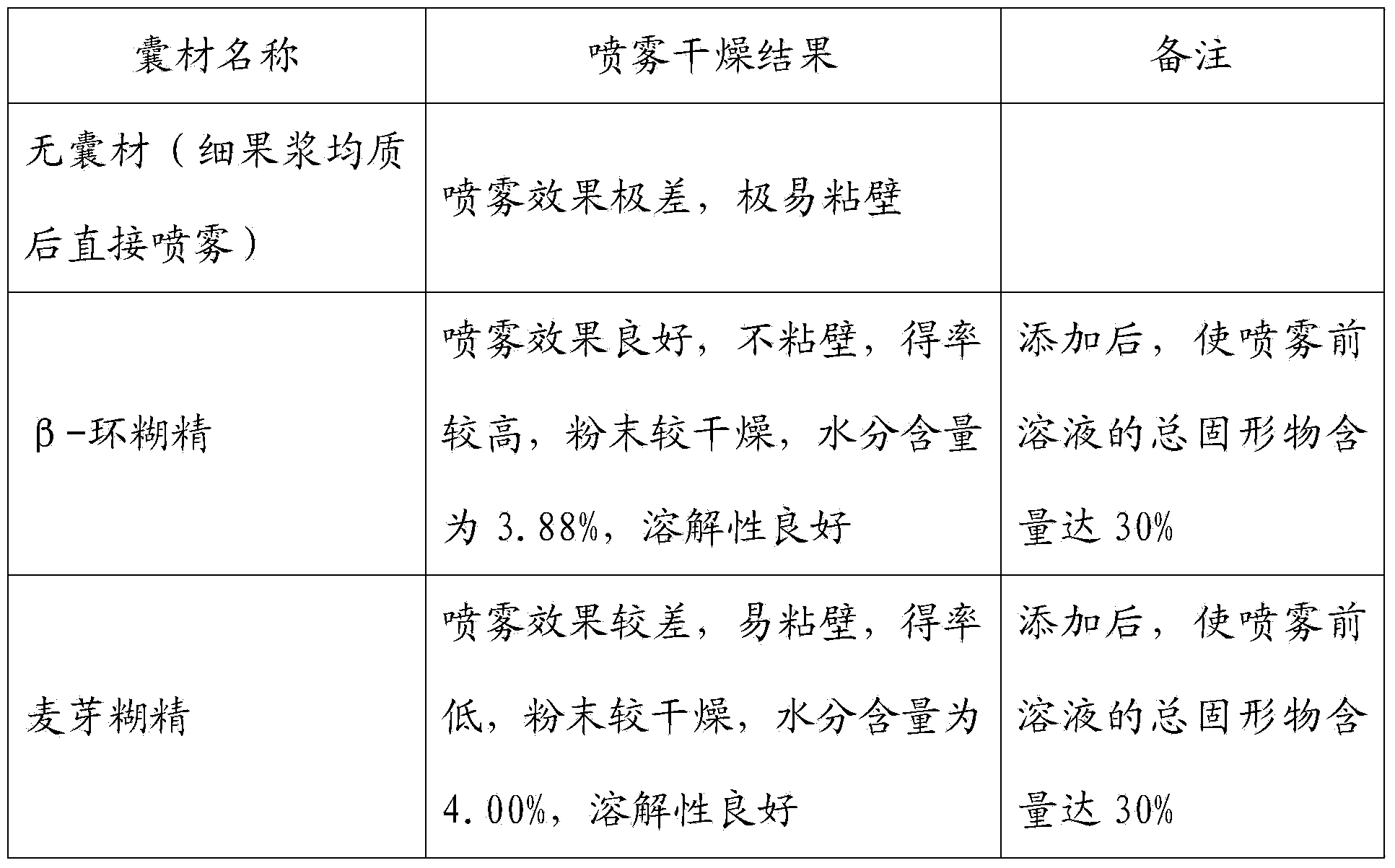

Examples

Embodiment 1

[0051] (1) Cleaning and peeling: 10kg of intact and ripe kiwifruit fresh fruit is cleaned with drinking water and drained, cut into pieces, placed in a beater and pulverized (mechanical peeling), and the coarse fruit pulp ( Contains pulp and juice) separated from the pomace and seeds.

[0052] (2) Homogenization treatment: the coarse pulp is homogenized with a biological homogenizer to obtain fine pulp with a uniform body.

[0053] (3) Grinding capsules: 0.8kg of β-cyclodextrin was evenly and slowly added to the fine fruit pulp under stirring, and stirred evenly; put into a colloid mill and grind twice to obtain a colloid grinding liquid.

[0054] (4) Emulsification and homogeneity: After dissolving 64g of monoglyceride fatty acid ester, slowly add it into the colloid grinding liquid under stirring, after mixing evenly, enter the homogenizer and process it twice under the pressure of 30MPa to obtain emulsification homogeneity liquid.

[0055] (5) Spray drying: pump the emuls...

Embodiment 2

[0058] (1) Cleaning and peeling: 10kg of intact and ripe kiwifruit fresh fruit is cleaned with drinking water and drained, cut into pieces, placed in a beater and pulverized (mechanical peeling), and the coarse fruit pulp ( Contains pulp and juice) separated from the pomace.

[0059] (2) Homogenization treatment: the coarse pulp is homogenized with a biological homogenizer to obtain fine pulp with a uniform body.

[0060] (3) Grinding and encapsulating: 1 kg of β-cyclodextrin was evenly and slowly added to the fine fruit pulp under stirring, and stirred evenly; it was put into a colloid mill and grinded 3 times to obtain a colloid grinding liquid.

[0061] (4) Emulsifying and homogenizing: After dissolving 40g of monoglycerin fatty acid ester and 30g of sucrose fatty acid ester, slowly add it to the colloid grinding liquid under stirring, enter the homogenizer and perform homogenization treatment twice under 40MPa pressure to obtain emulsification homogeneous liquid.

[0062...

Embodiment 3

[0065] (1) Cleaning and peeling: 10kg of intact and ripe kiwifruit fresh fruit is cleaned with drinking water and drained, cut into pieces, placed in a beater and pulverized (mechanical peeling), and the coarse fruit pulp ( Contains pulp and juice) separated from the pomace.

[0066] (2) Homogenization treatment: the coarse pulp is homogenized with a biological homogenizer to obtain fine pulp with a uniform body.

[0067] (3) Grinding capsules: 0.5 kg of β-cyclodextrin was evenly and slowly added to the fine pulp under stirring, and stirred evenly; it was put into a colloid mill and grinded twice to obtain a colloid grinding liquid.

[0068] (4) Emulsifying and homogenizing: After dissolving 40 g of sucrose fatty acid ester, slowly add it to the colloid grinding liquid under stirring, enter the homogenizer and perform homogenizing treatment twice under a pressure of 25 MPa to obtain an emulsified homogeneous liquid.

[0069] (5) Spray drying: the emulsified homogeneous liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com