Powder spreading device capable of quantitatively dropping powder

A powder spreading device and powder falling technology, which is applied in the field of 3D printing, can solve the problems of metal powder waste, part quality defects, and different amounts of metal powder, and achieve the effect of forming a smooth molding surface, eliminating quality defects, and changing the amount of powder falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Through the description of the embodiments below, the specific implementation of the present invention includes the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, the manufacturing process and the operation and use method of the various components involved. etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

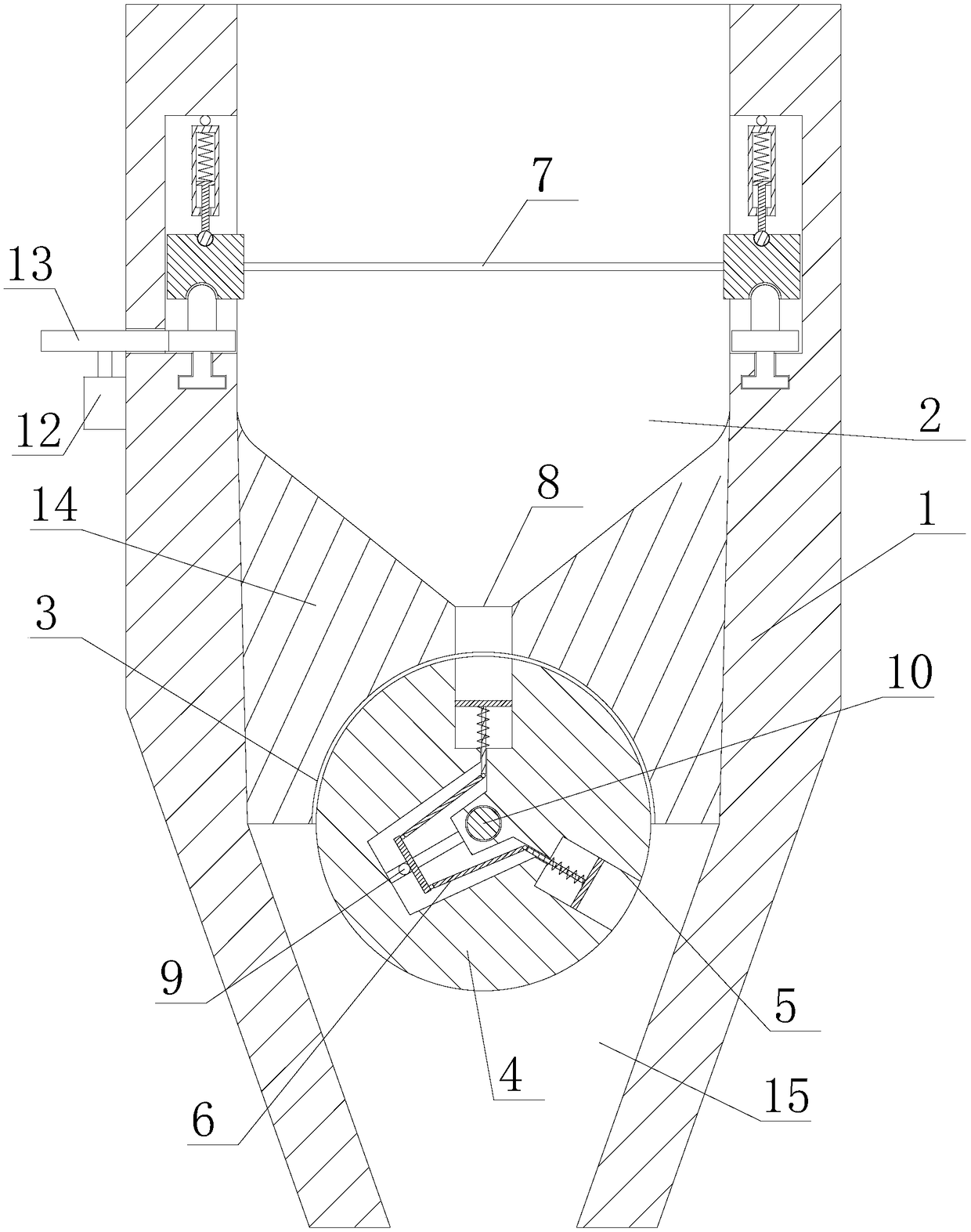

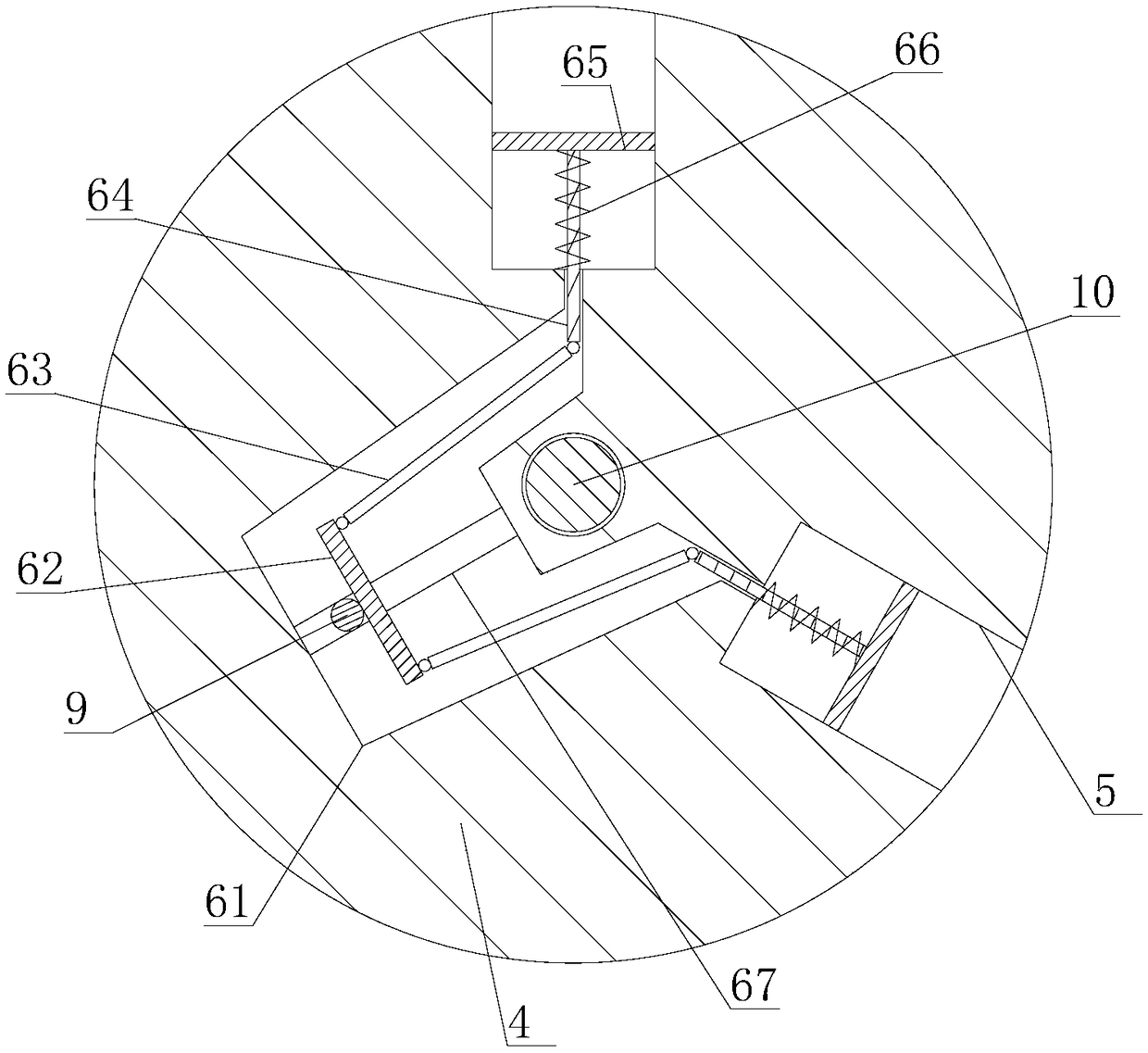

[0025] Based on the above purpose, as an embodiment of the present invention, a powder spreading device that can quantitatively drop powder, such as figure 1 and figure 2 As shown, it includes a powder spreading main body 1, a drum 4, an adjustment mechanism 6, a screening mechanism 7, a first motor 11 and a second motor 12, and the inside of the powder spreading main body 1 is provided with a partition 14, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com