Block injection molding equipment and injection molding method thereof

A technology of injection molding equipment and blocks, which is applied in the field of building material production, can solve the problems of energy consumption, uneven surface, low output, etc., and achieve the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

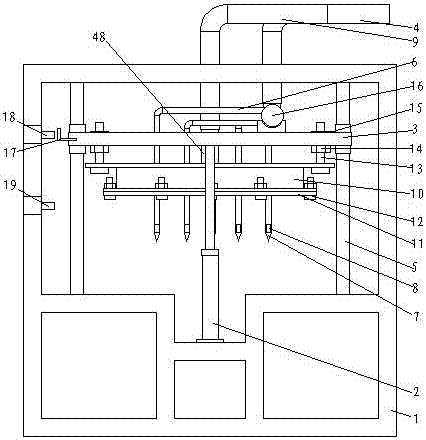

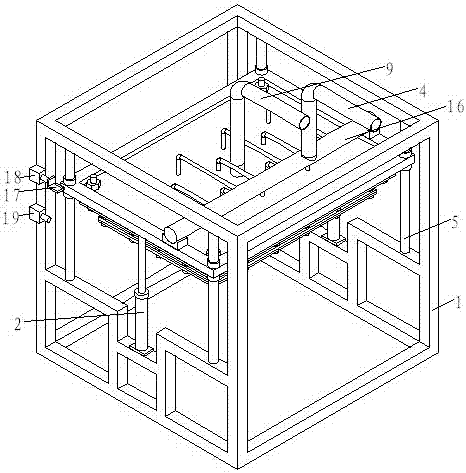

[0081] like Figure 8 As shown, the gas storage box 10 is driven by the power device A, the moving frame 3 is driven by the driving device B, the gas filling needle 7 can move up and down through the gas storage box 10, the power device A and the gas storage The box 10 is connected, and the power unit B is connected with the mobile frame 3. Both the power unit A and the power unit B can be hydraulic cylinders, cylinders or electric push rods. In this embodiment, the power unit A and the power unit B are cylinders 2, the mobile frame 3 and the gas storage box 10 move up and down along the guide column 5, the mobile frame 3 is fixedly connected with the gas storage pipe 16, and the gas filling needle 7 is connected to the storage tank through the rigid connection pipe 6. The trachea 16 is connected. When adding air, the air filling needle 7 and the air storage box 10 are driven up and down by the power unit A and the power unit B respectively.

specific Embodiment approach 3

[0083] like Figure 9 As shown, the gas storage box 10 and the mobile frame 3 are fixedly connected, the gas storage box 10 and the mobile frame 3 move up and down under the drive of the power device, the gas filling needle 7 penetrates the gas storage box, and the gas filling needle 7 7 does not communicate with the gas storage box 10, the gas storage box 10 communicates with the steam source through the rigid connecting pipe 48 and the flexible connecting pipe 9, the gas filling needle 7 is connected with the gas storage pipe 16 through the rigid connecting pipe 6, and the The gas storage pipe 16 is fixed on the mobile frame 3 , and the gas storage pipe 16 communicates with the steam source through the flexible connecting pipe 4 . When adding air, the power device makes the rubber plate 11 connected to the bottom of the air storage box 10 press on the block, and at the same time, the air-filling needle 7 is inserted into the polystyrene particles in the hole of the block, an...

specific Embodiment approach 4

[0085] like Figure 10As shown, the gas filling needle 7 communicates with the gas storage box 10 and is fixedly connected with the gas storage box 10. The gas storage box 10 can move up and down along the guide column 5 under the drive of the power device. The tank 10 is connected to a steam source through a rigid connection pipe 48 and a flexible connection pipe 9 . When adding gas, the rubber plate 11 connected to the bottom of the gas storage box 10 is pressed on the block, and the gas filling needle 7 is inserted into the inside of the polystyrene particles in the hole of the block, and the gas filling needle 7 and the gas storage box 10 are simultaneously injected into the block. Introduce high temperature steam. In this embodiment, the limit switch includes two upper and lower photoelectric sensors 18 and 19 fixed on the frame and a baffle I17 fixed on the gas storage box 10 and cooperating with the photoelectric sensors 18 and 19 to precisely control The upward and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com